Preparation process of a structured anti-corrosion layer for titanium alloy blades

A preparation process, titanium alloy technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of affecting the working efficiency and safe operation of steam turbines, poor bonding between cemented carbide sheets and blade base, and difficult to control. Beam cracks and other problems, to achieve the effect of low friction coefficient, combined with mild high, good anti-adhesive wear and friction wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

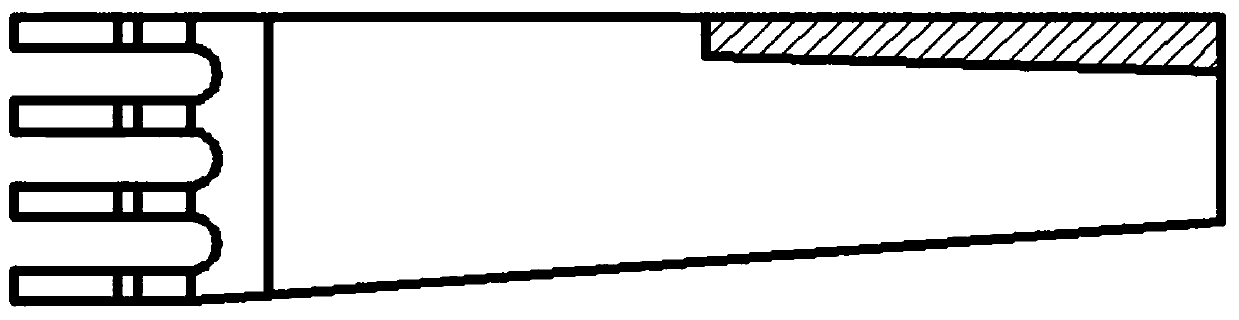

[0032] The preparation process of the structured anti-corrosion layer of the titanium alloy blade in this embodiment, the steps are as follows:

[0033] (1) Carburizing treatment: The embodiment of the present invention is a titanium alloy (TC4) blade. Before carburizing treatment, the entire blade needs to be cleaned with ethanol and then dried. After drying, it is put into a vacuum tube furnace for solid carburizing. The carburizing agent is mainly composed of two types of substances evenly mixed, one is coal powder that produces activated carbon atoms, accounting for about 90% of the total mass; the other is the infiltration agent sodium carbonate, accounting for about 90% of the total mass About 9%, and the other 1% of the mass is the rare earth element La. The carburizing temperature is 850°C, the gas in the vacuum tube furnace is argon, and the carburizing time is 8 hours; the blade after carburizing treatment needs to determine the contour line to be treated at the stea...

Embodiment 2

[0037] The preparation process of the structured anti-corrosion layer of the titanium alloy blade in this embodiment, the steps are as follows:

[0038] (1) Carburizing treatment: The embodiment of the present invention is a titanium alloy (TC4) blade. Before carburizing treatment, the entire blade needs to be cleaned with ethanol and then dried. After drying, it is put into a vacuum tube furnace for solid carburizing. The carburizing agent is mainly composed of two types of substances evenly mixed, one is coal powder that produces activated carbon atoms, accounting for 90% of the total mass; the other is the infiltration agent sodium carbonate, accounting for about 9% of the total mass , the other 1% by mass is La as a rare earth element. The carburizing temperature is 930°C, the gas in the vacuum tube furnace is argon, and the carburizing time is 8 hours; the blade after carburizing treatment needs to determine the contour line to be treated at the steam inlet side of the la...

Embodiment 3

[0042] The preparation process of the structured anti-corrosion layer of the titanium alloy blade in this embodiment, the steps are as follows:

[0043] (1) Carburizing treatment: The embodiment of the present invention is a titanium alloy (TC4) blade. Before carburizing treatment, the entire blade needs to be cleaned with ethanol and then dried. After drying, it is put into a vacuum tube furnace for solid carburizing. The carburizing agent is mainly composed of two types of substances evenly mixed, one is coal powder that produces activated carbon atoms, accounting for about 90% of the total mass; the other is the infiltration agent sodium carbonate, accounting for about 90% of the total mass About 9%, and the other 1% of the mass is the rare earth element La. The carburizing temperature is 1010°C, the gas in the vacuum tube furnace is argon, and the carburizing time is 8 hours; the blade after carburizing treatment needs to determine the contour line to be processed at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com