Apparatus and method for hydroenhancing fabric

a technology of hydroentanglement and fabric, applied in the direction of lighting and heating apparatus, drying machines, drying machines, etc., can solve the problems of not developing apparatus and process line technology which achieves production line efficiency, fails to suggest or teach a hydroentanglement process that can be employed, and conventional processes have not proved entirely satisfactory in yielding uniform fabric enhancement. , to achieve the effect of uniform finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples i-xiii

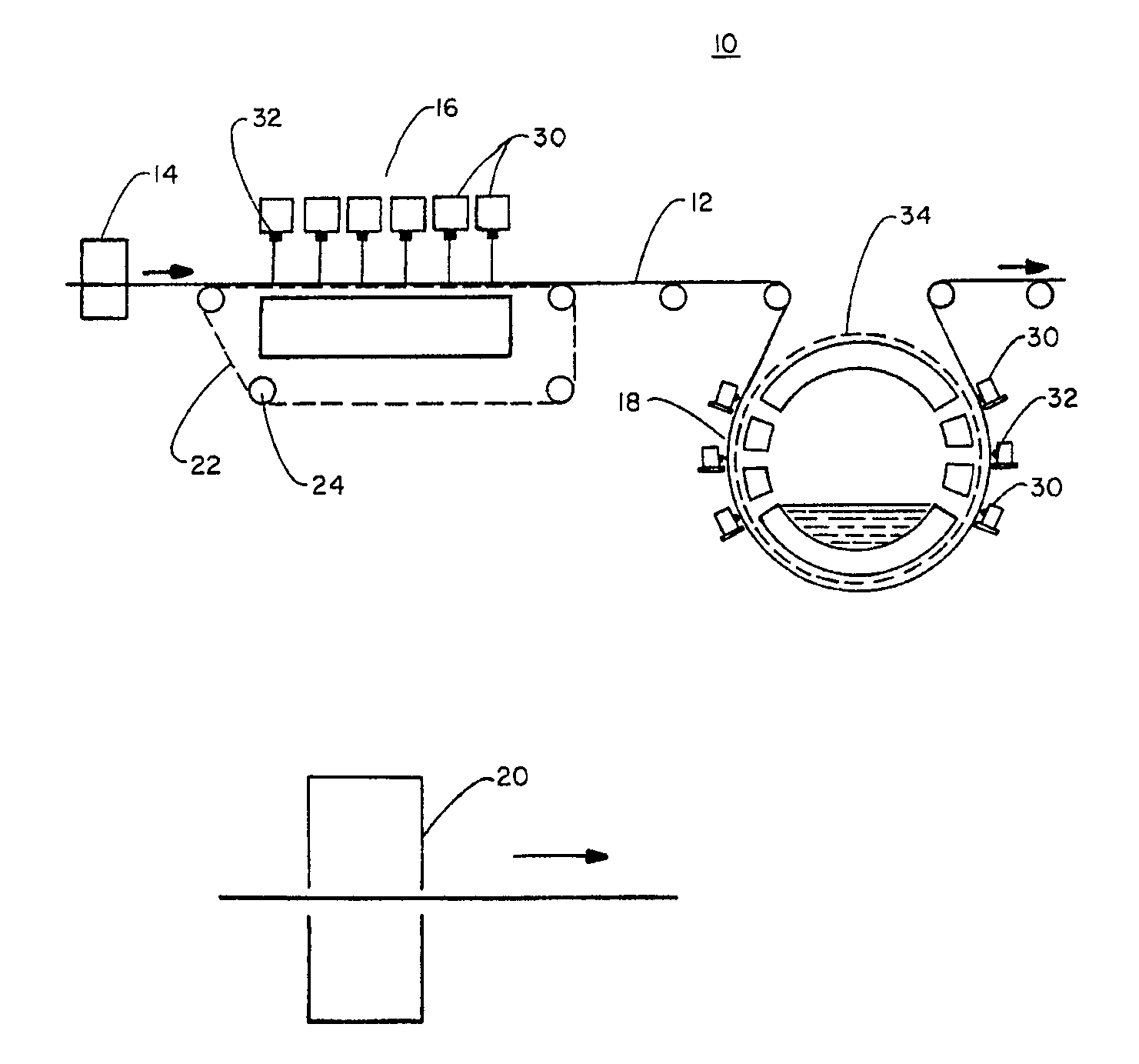

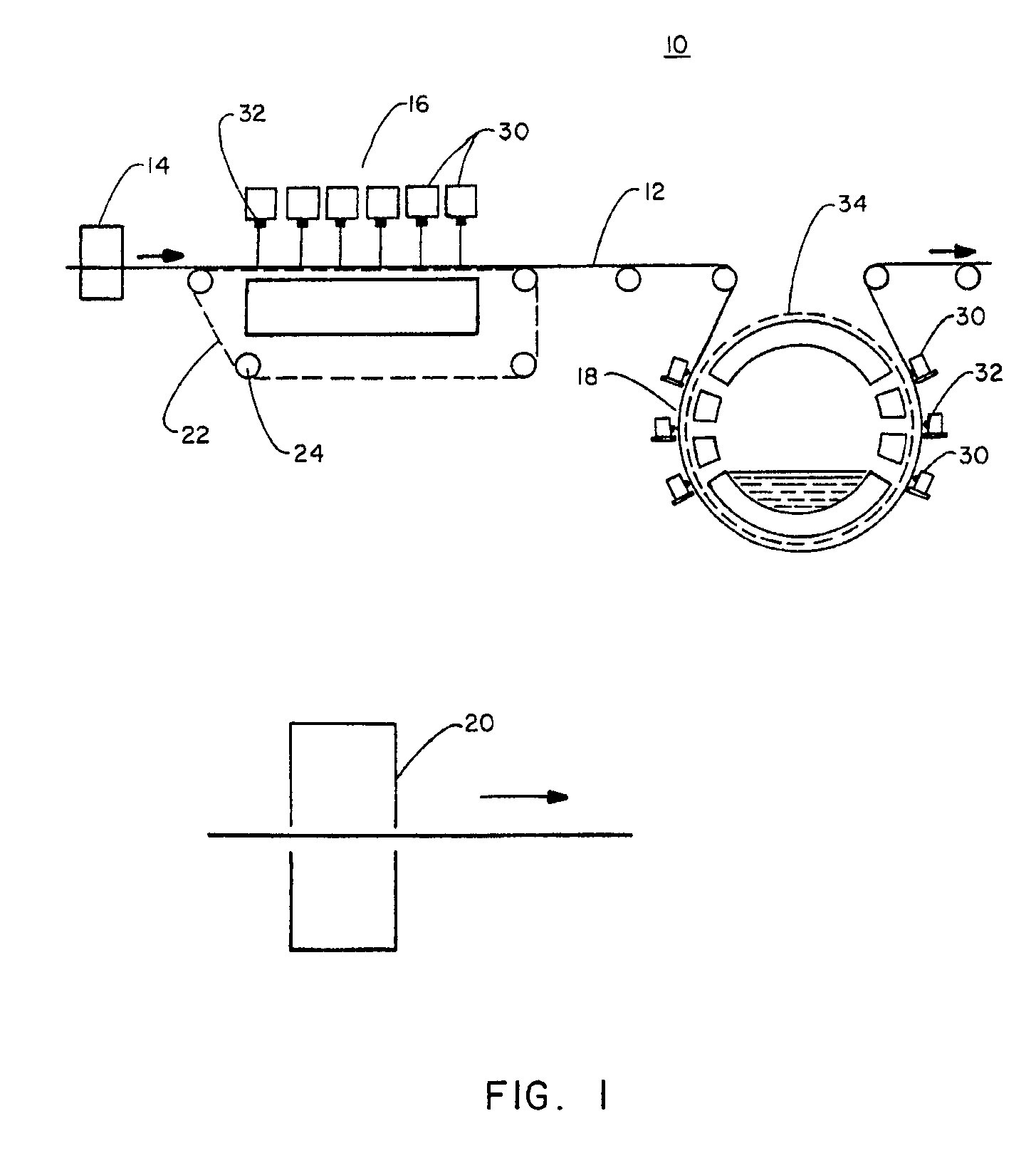

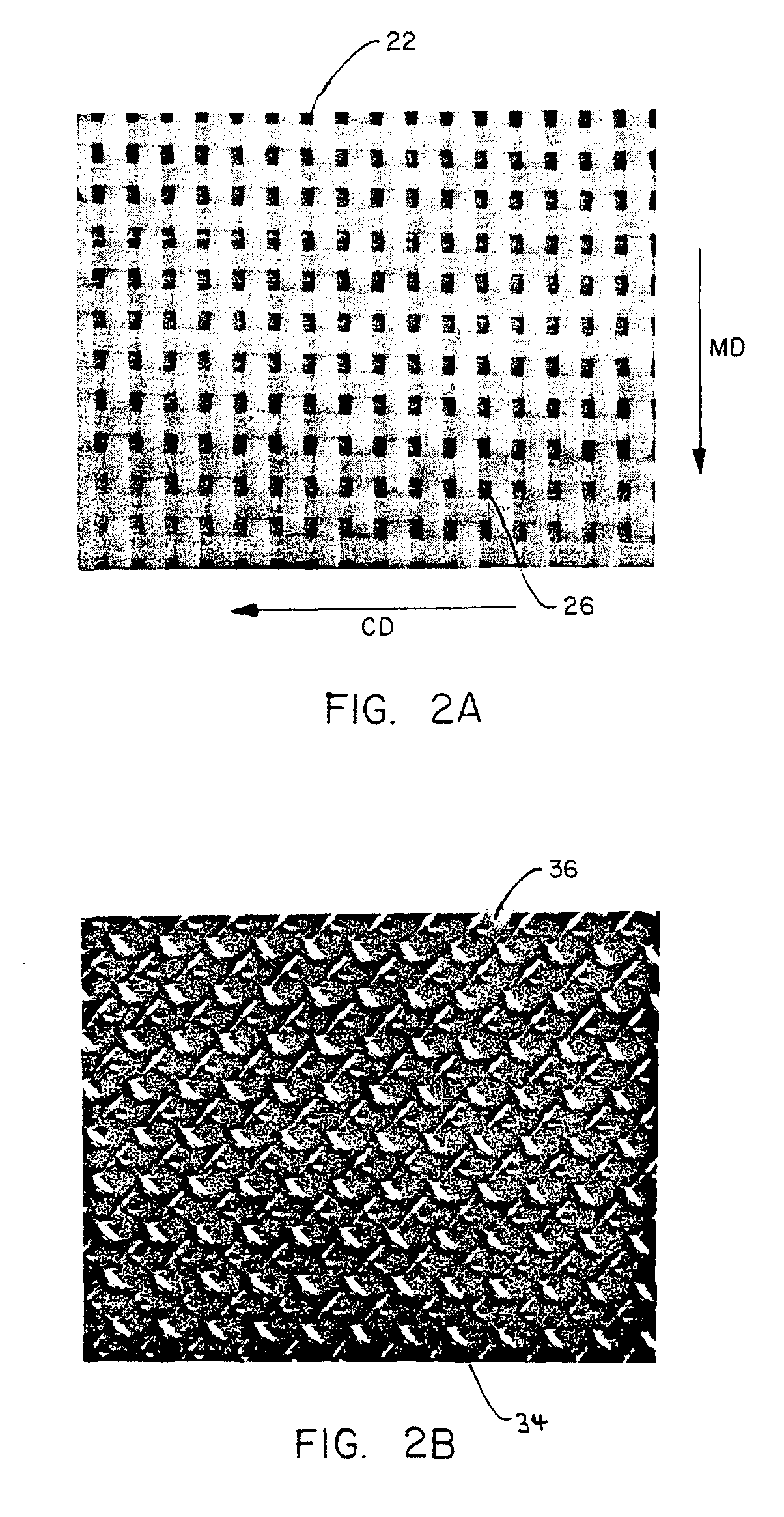

[0066]FIGS. 3-15 illustrate representative woven and knit fabrics enhanced in accordance with the method of the invention, employing test conditions which simulate the line of FIG. 1. Table II sets forth specifications for the fabrics illustrated in the drawings.

[0067]As in the FIG. 1 line, the test manifolds 30 were spaced approximately 8 inches apart in modules 16, 18, and provided with densely packed columnar jet orifices 32 of approximately 60 / inch. Orifices 32 each had a diameter of 0.005 inches and were spaced approximately 0.5 inches from the first and second support members 22, 34.

[0068]The process line of FIG. 1 includes enhancement modules 16, 18 which, respectively, are provided with six manifolds. In the Examples, modules 16, 18 were each fitted with two manifolds 34. To simulate line conditions, the fabrics were advanced through multiple runs on the line. Three processing runs in each two manifold module was deemed to be equivalent to a six manifold module.

[0069]Fabrics...

example xiv

[0097]A plain woven 100% polyester fabric comprised of friction spun yarn having the following specifications was processed in accordance with the inventive: count of 16×10 yarns / in2, weight of 8 ounces / yd2, an abrasion resistance of 500 grams (measured by 50 cycles of a CS17 abrasion test wheel) and an air permeability of 465 ft3 / ft2 / min.

[0098]The fabric was processed on a test line to simulate a speed of 300 ft / min. on process apparatus including four drums 42 and eighteen nozzles 16 at a pressure of approximately 1500 psi. Energy output to fabric at these process parameters was approximately 0.46 hp-hr / lb. Table XII sets forth control and processed characteristics of the fabric.

[0099]

TABLE XII100% Polyester Friction Spun FabricFabric CharacteristicControlProcessedCount (yarns / in.2)16 × 1017 × 10Weight (ounces / yd.2)88.2Abrasion resistance (cycles)5085Air permeability (ft3ft2 / min.)465181

examples xv

AND XVI

[0100]The process conditions of Example XIV were employed to process a plain woven cotton osnaburg and plain woven polyester ring spun fabrics yielding the results set forth in Tables XIV and XV.

[0101]

TABLE XVPlain Woven Cotton OsnaburgFabric CharacteristicControlProcessedCount (yarns / in.2)32 × 2632 × 32Abrasion resistance (cycles)140344Air permeability (ft3ft2 / min.)710120

[0102]

TABLE XIVFabric CharacteristicControlProcessedCount (yarns / in.2)44 × 2848 × 32Abrasion resistance (cycles)100225Air permeability (ft.3 / ft2 / min.)252 63

[0103]Fabrics processed in Examples XIV-XVI are characterized by a substantial reduction in air permeability and increase in abrasion resistance. Process energy levels in these Examples were approximately 0.46 hp-hr / lb. It has been discovered that there is a correlation between process energy and enhancement. Increased energy levels yield optimum enhancement effects.

[0104]The foregoing Examples illustrate applications of the hydroenhancing process of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com