Patents

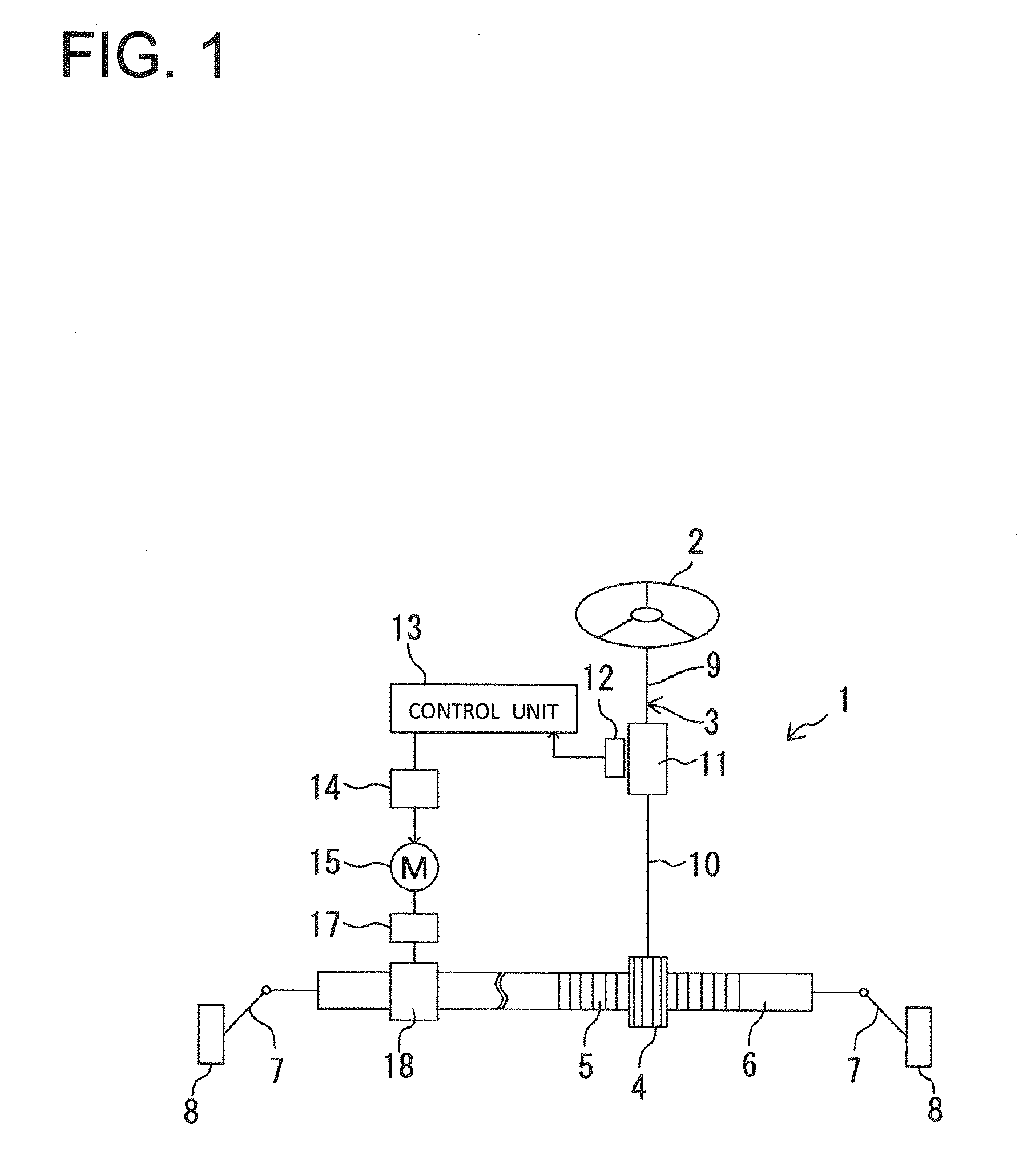

Literature

366results about How to "Fit evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

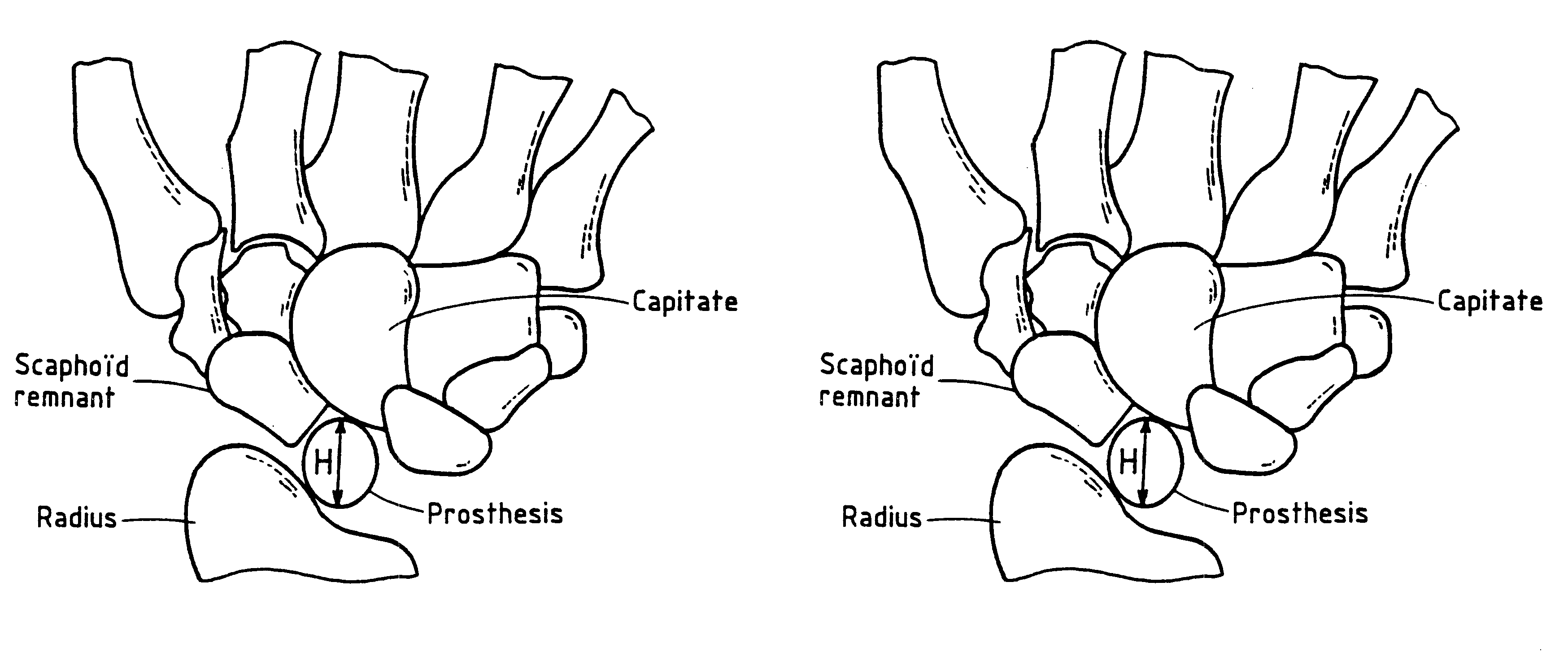

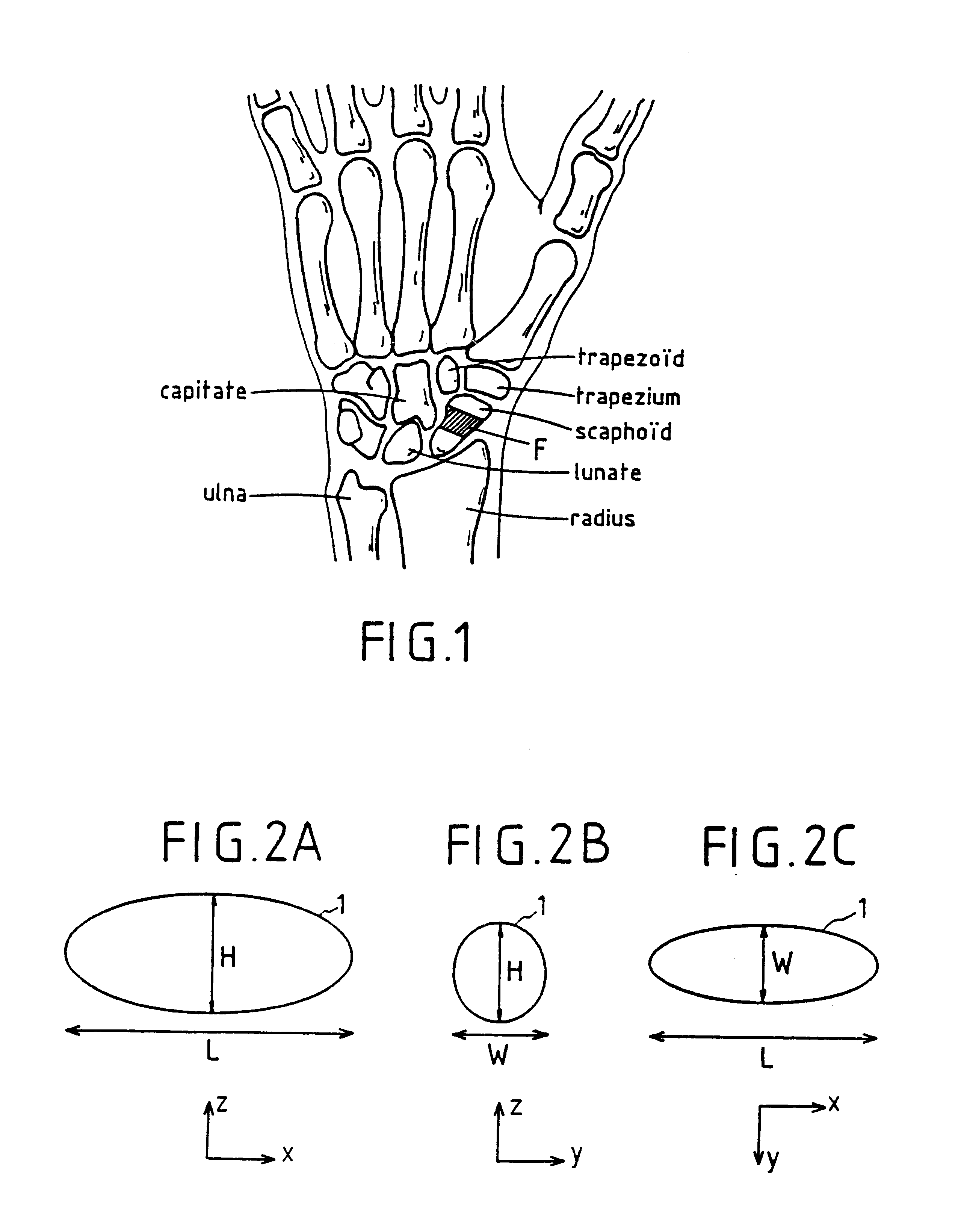

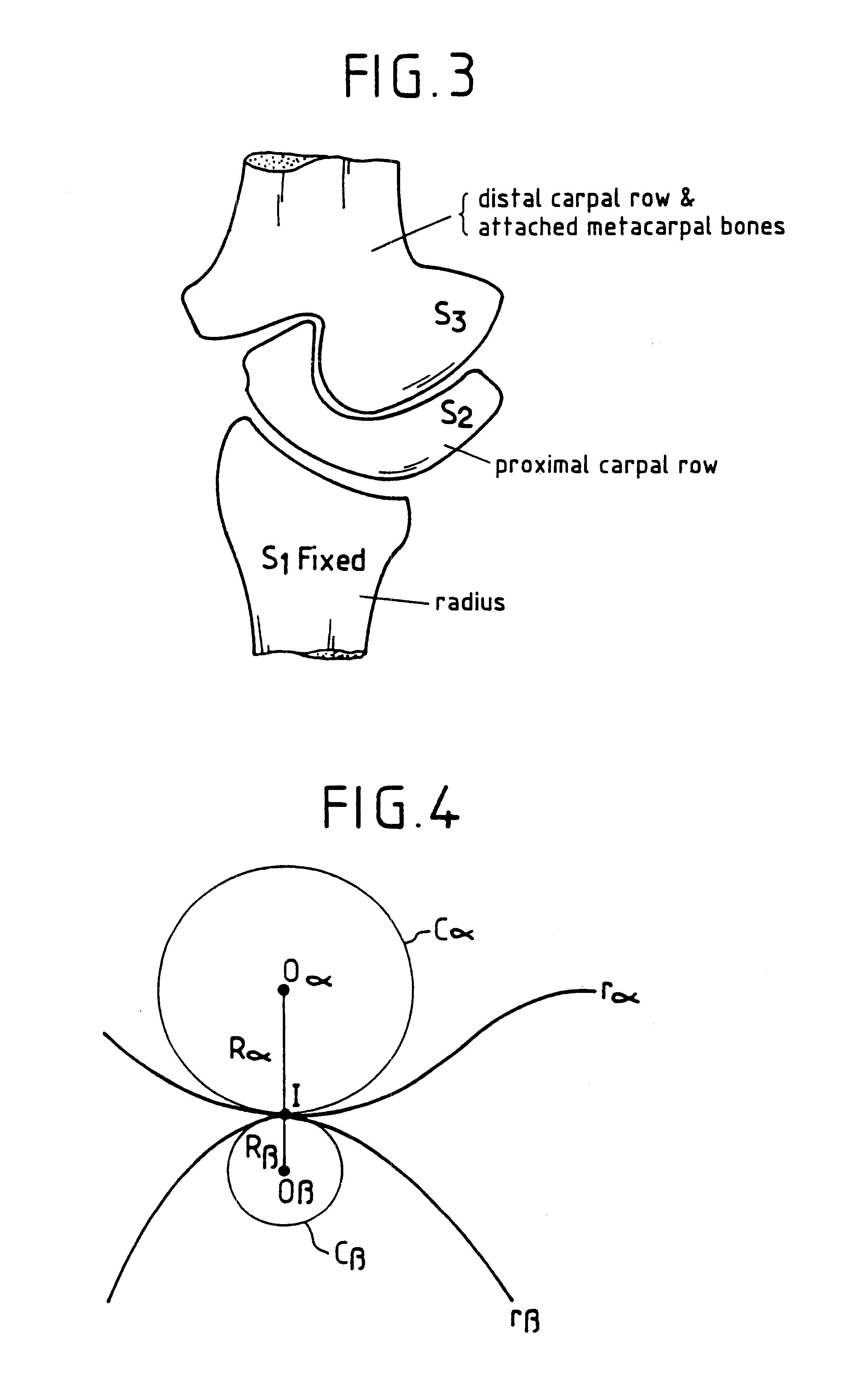

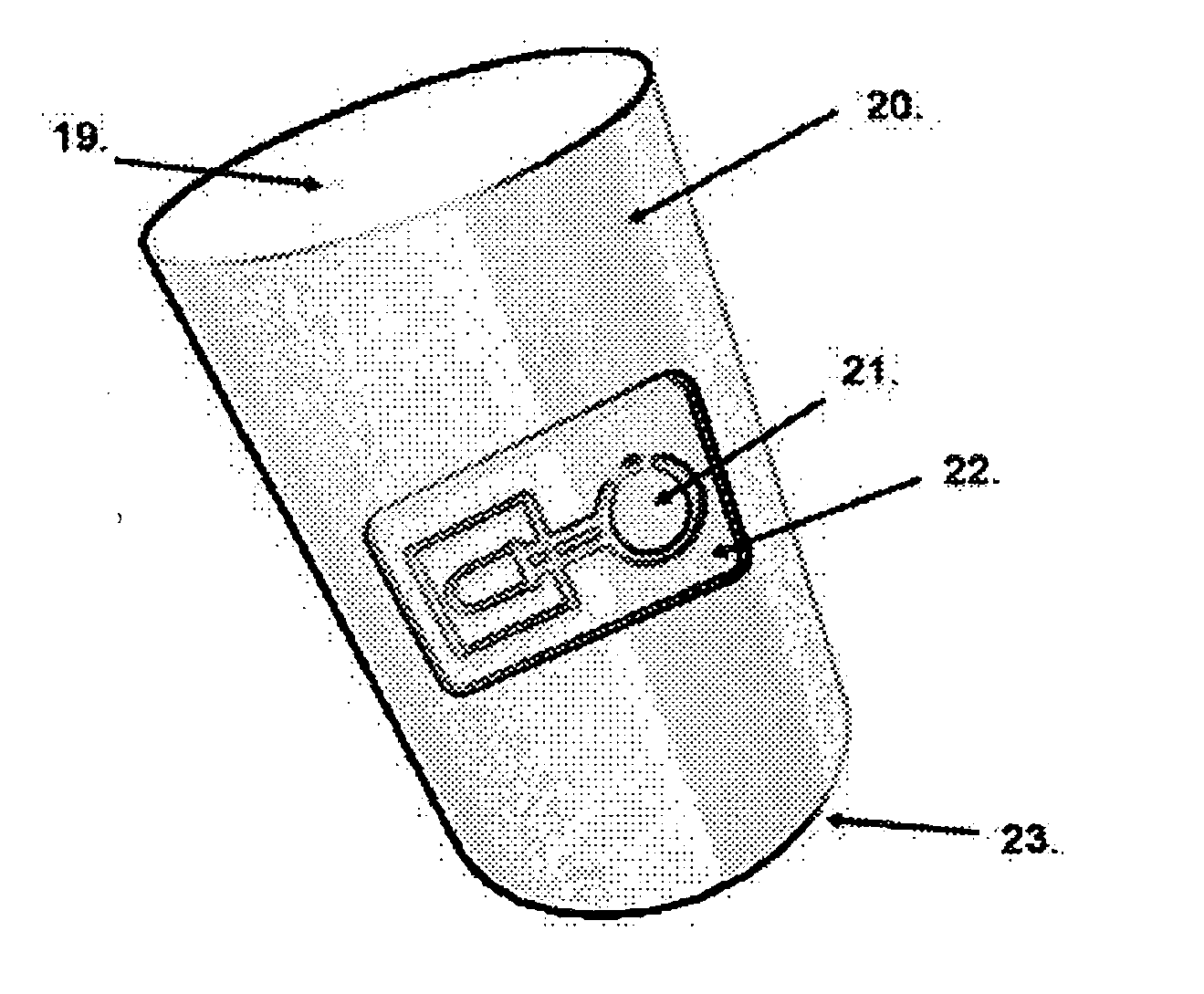

Implant for treating ailments of a joint or a bone

InactiveUS6436146B1Increase coefficient of frictionImprove stabilityFinger jointsWrist jointsDiseasePyrolytic carbon

The implant has at least one contact surface portion, made of pyrolytic carbon, designed to be in mobile contact with at least one bony surface when the implant is implanted in a patient. Furthermore, the implant is free from any attaching means, so that it remains free with respect to the at least one bony surface when implanted in the patient.

Owner:TORNIER SA SAINT ISMIER

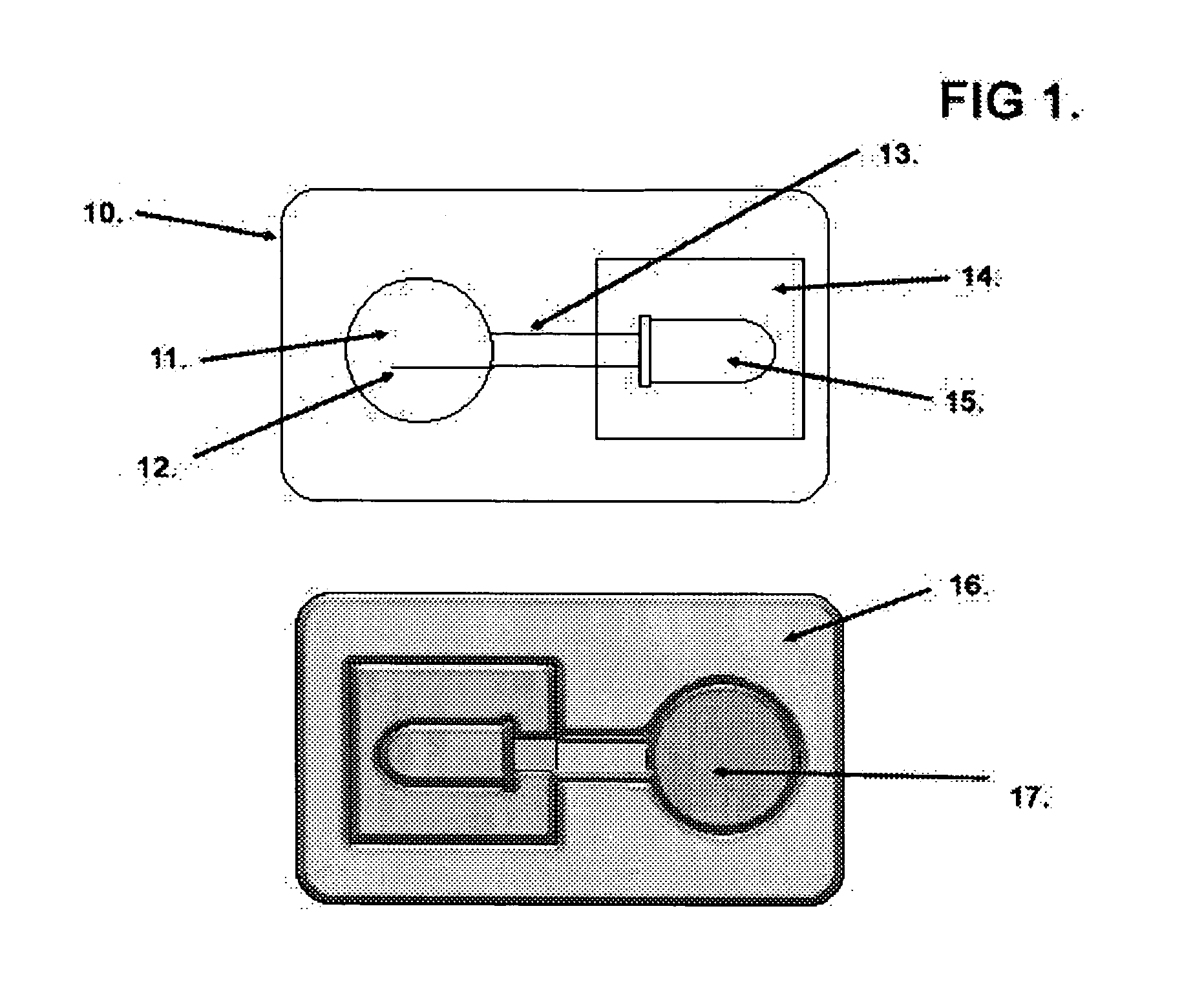

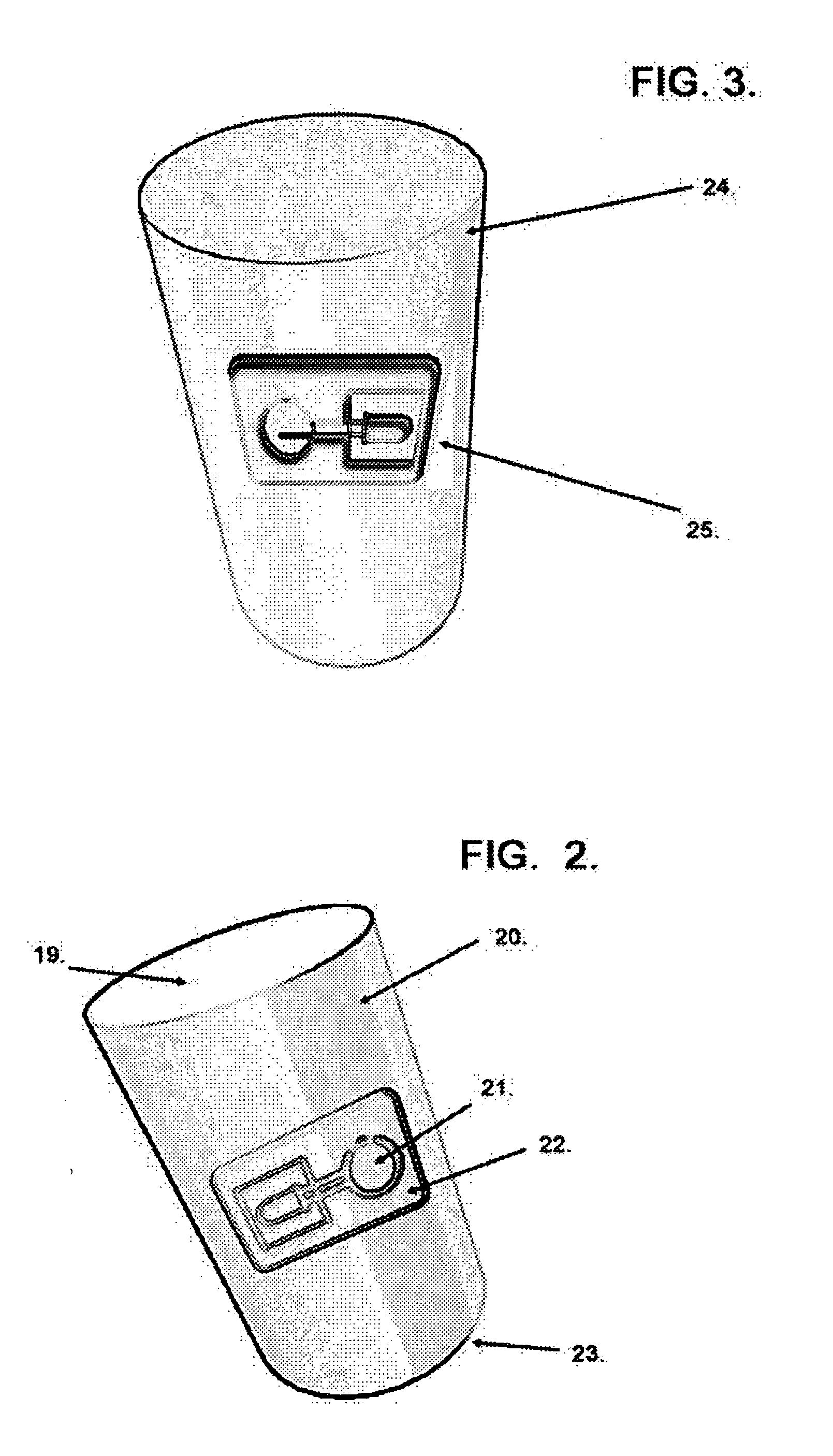

Container illumination

InactiveUS20050024858A1Be consistentFit evenlyContainer decorationsLevel indicationsEngineeringLight source

A container illumination assembly for use with a standard includes a selectively actuatable light source. A connection mechanism is adapted and constructed to secure the light source to the standard container. With the light source secured to the standard container with the connection mechanism, the contents of the standard container are selectively illuminated by the light source when the light source is actuated.

Owner:JOHNSON RICHARD

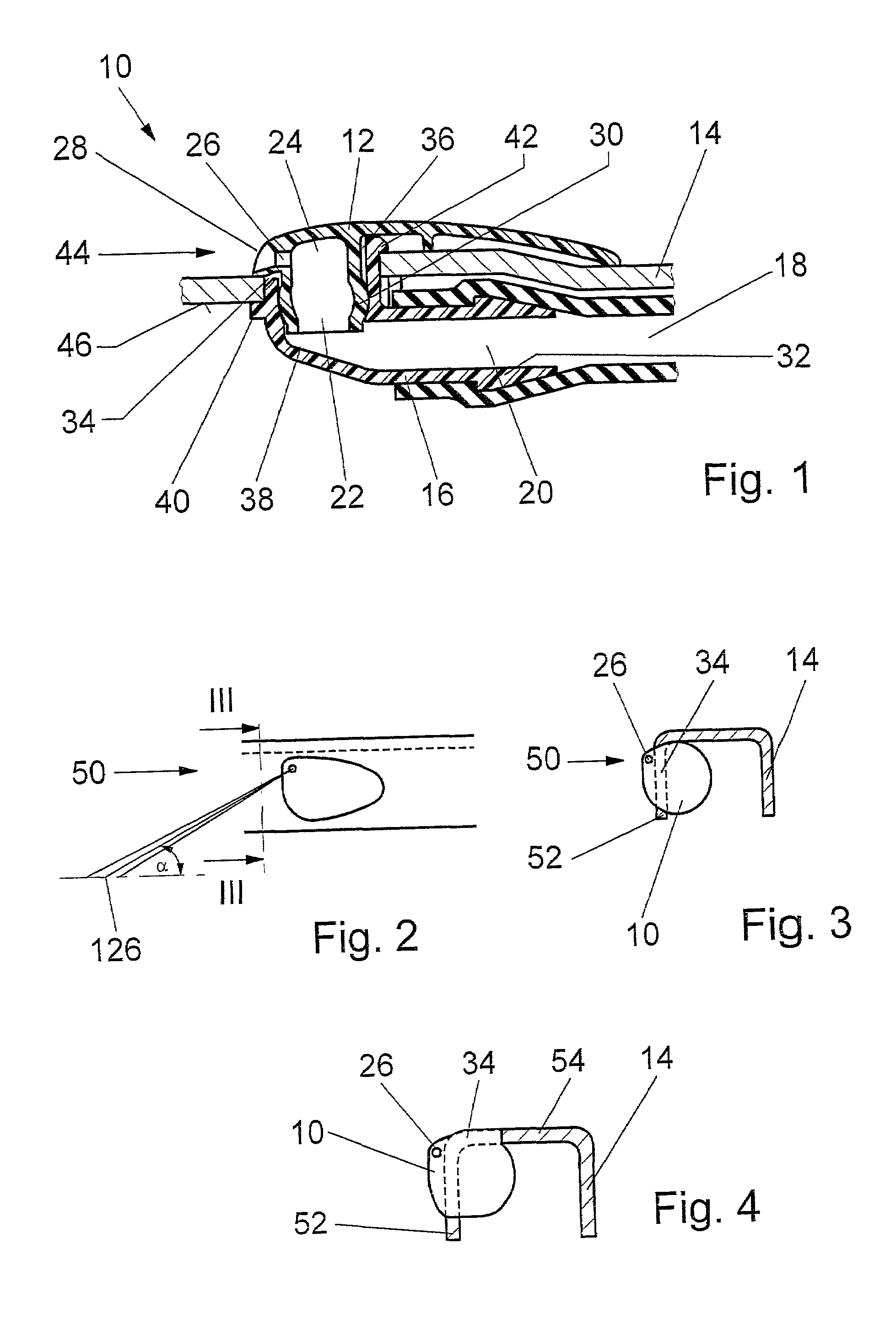

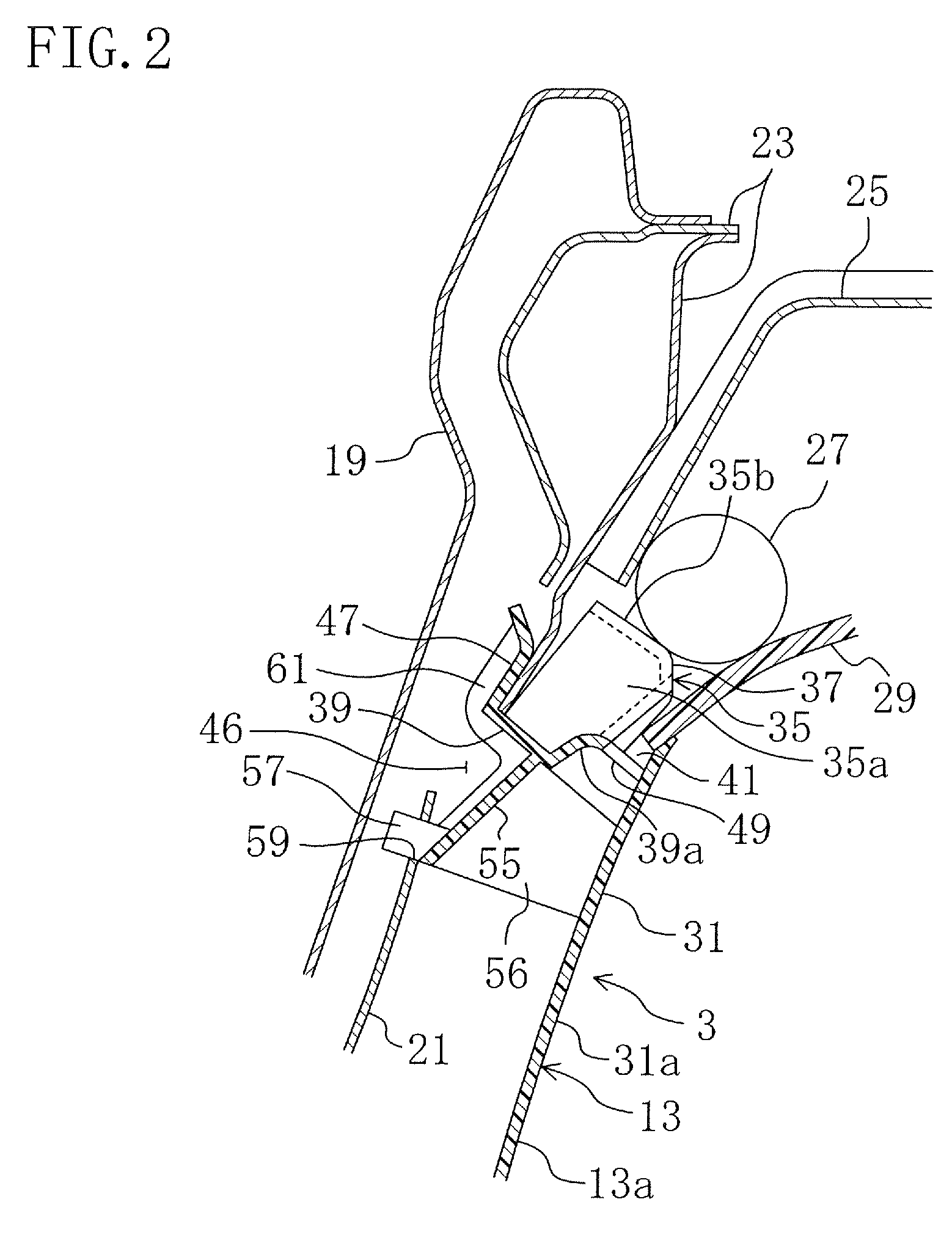

Windscreen wiper with spray nozzle

InactiveUS7093317B1Simple processReduce overall outer diameterSpray nozzlesWindow cleanersWindscreen wiperSpray nozzle

A windshield wiper includes a wiper arm, which is driven via a drive shaft and to which a wiper blade is pivotably connected, in which at least one spray nozzle (10) is disposed on a pivotable part (14), the spray nozzle being composed of a plurality of parts and its housing (16) communicating disconnectably via a water line (18) to a water pump (118). In the housing (16) or in a nozzle body (12) communicating with it, a continuous water conduit (20) connected to the water line (18) is provided, from which a connecting conduit (22) branches off that leads to a spray conduit (24) that is approximately parallel to the water conduit (20) and has a nozzle opening (26), the water conduit (20) being closed on its free end (38).

Owner:ROBERT BOSCH GMBH

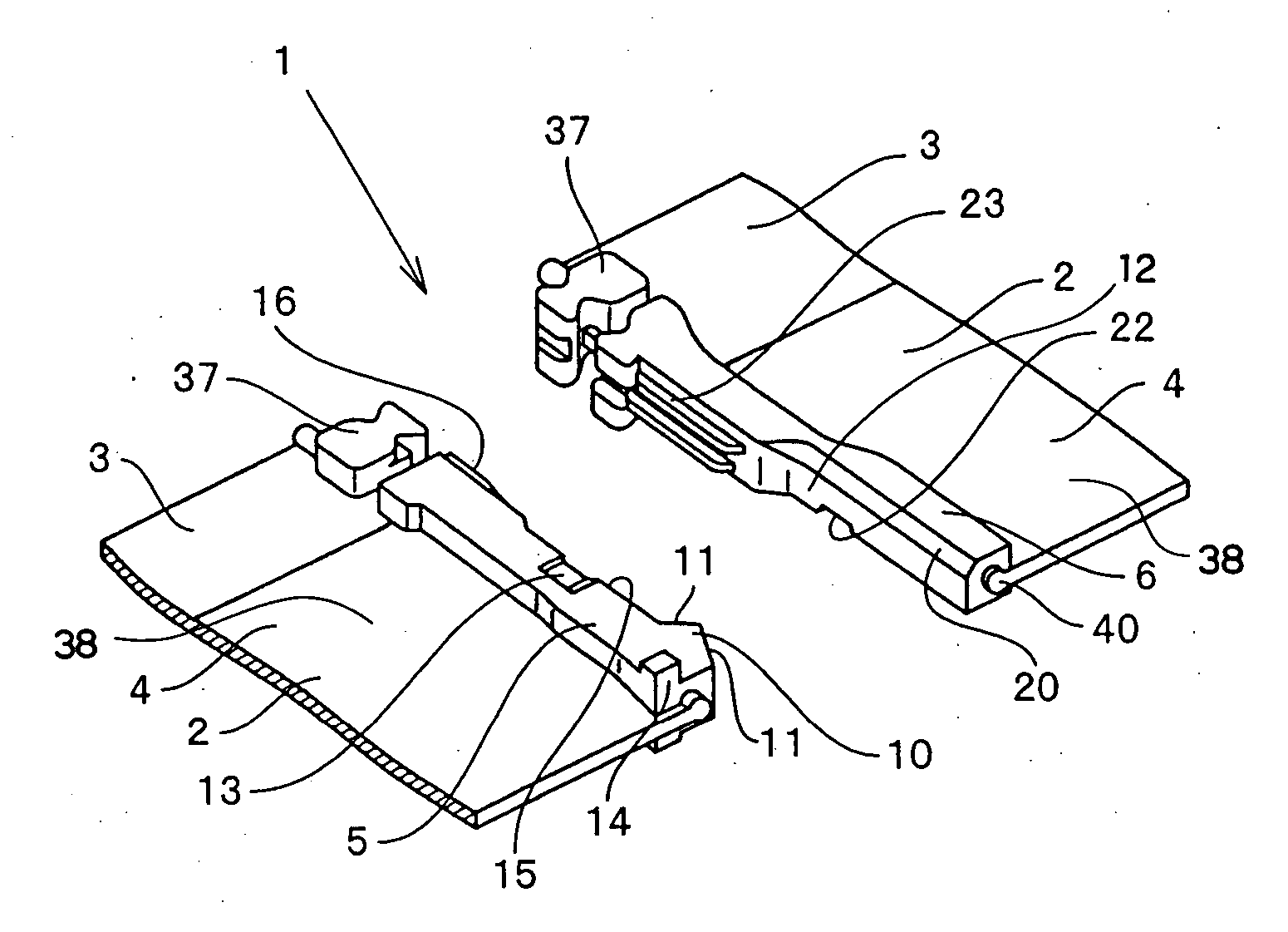

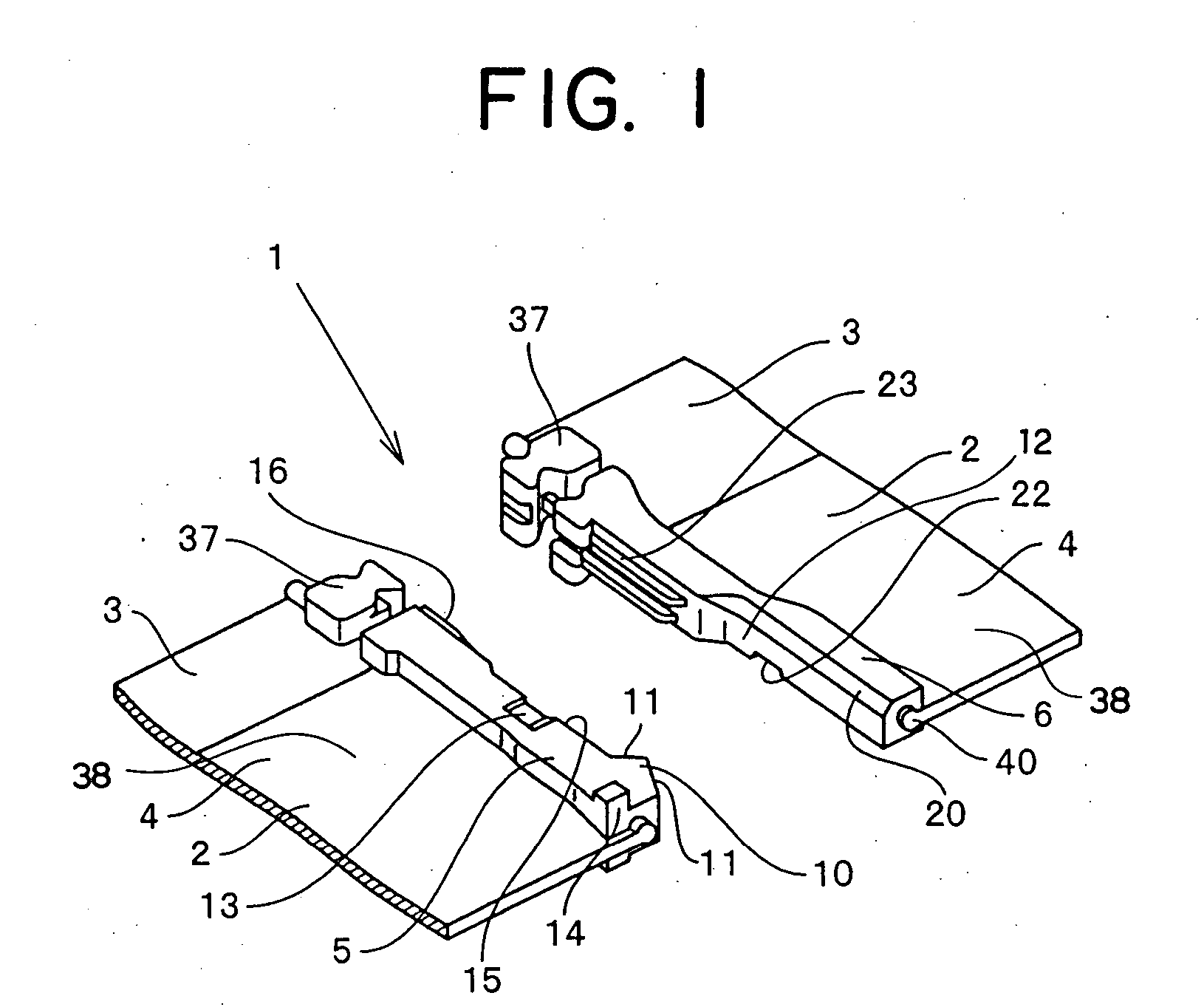

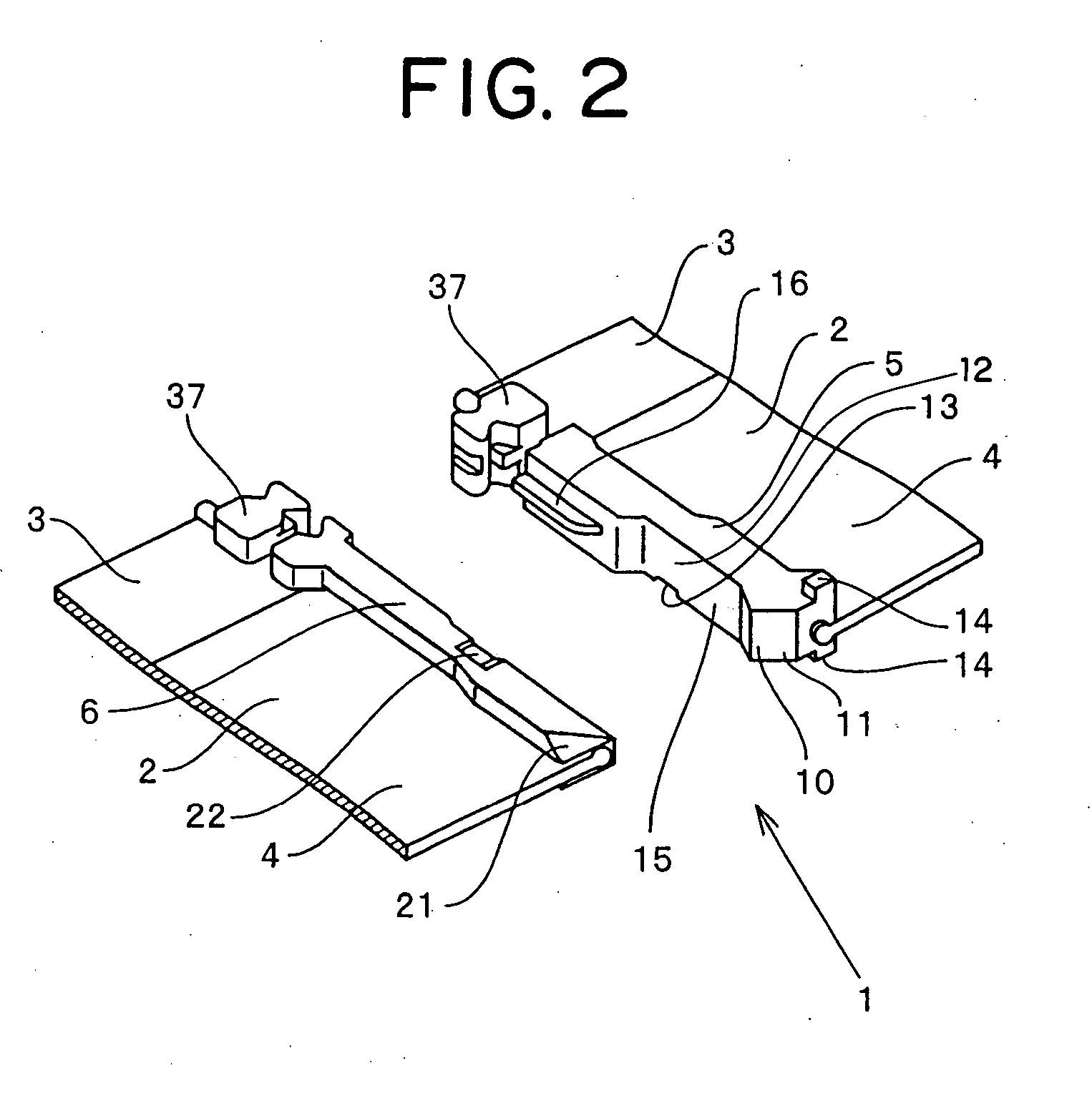

Slide fastener

A slide fastener, wherein in the fastener chain openable and closable from both ends thereof, a box pin and the insert pin, which can join with or separate from each other, are provided at least on an end of the fastener chain; and a protrusion facing the insert pin and projecting from an opposing face is provided at a front end of the box pin; the protrusion has slopes inclined in a direction of approaching the insert pin on upper and lower sides of the protrusion; and the lower side of the protrusion makes contact with a diamond of the reverse opening slider, while the upper side of the protrusion can guide the insert pin smoothly when the pin is inserted.

Owner:YKK CORP

Garments having a curable polymer thereon and a system and method for its manufacture

InactiveUS20090047481A1Improve tensile propertiesMinimize the possibilityTextile selvedgesDecorative surface effectsFiberEngineering

A method and system for garment manufacture fixes a curable polymer in either a continuous bead or in a non-continuous or segmented bead onto a cut fabric piece. The cut fabric piece, the continuous bead and the non-continuous, segmented bead have a wide array of configurations. If the cut fabric piece has a contoured edge region, a silicone bead proximate that edge has a conforming configuration. In the method, the cut fabric piece is placed in a coordinate space. The location of the cut fabric piece is sensed and that information is used to control the movement of a curable polymer dispenser. The dispenser applies a curable polymer from the curable polymer dispenser onto the cut fabric piece in the desired configuration after which the polymer is cured. If the fabric is cotton, the curable polymer is drawn into the cotton fibers prior to cure. The flow of curable polymer from the dispensing head can be started and stopped as the dispensing head moves relative to the fabric, allowing the curable polymer to be deposited on the fabric in any configuration.

Owner:CUPID FOUND

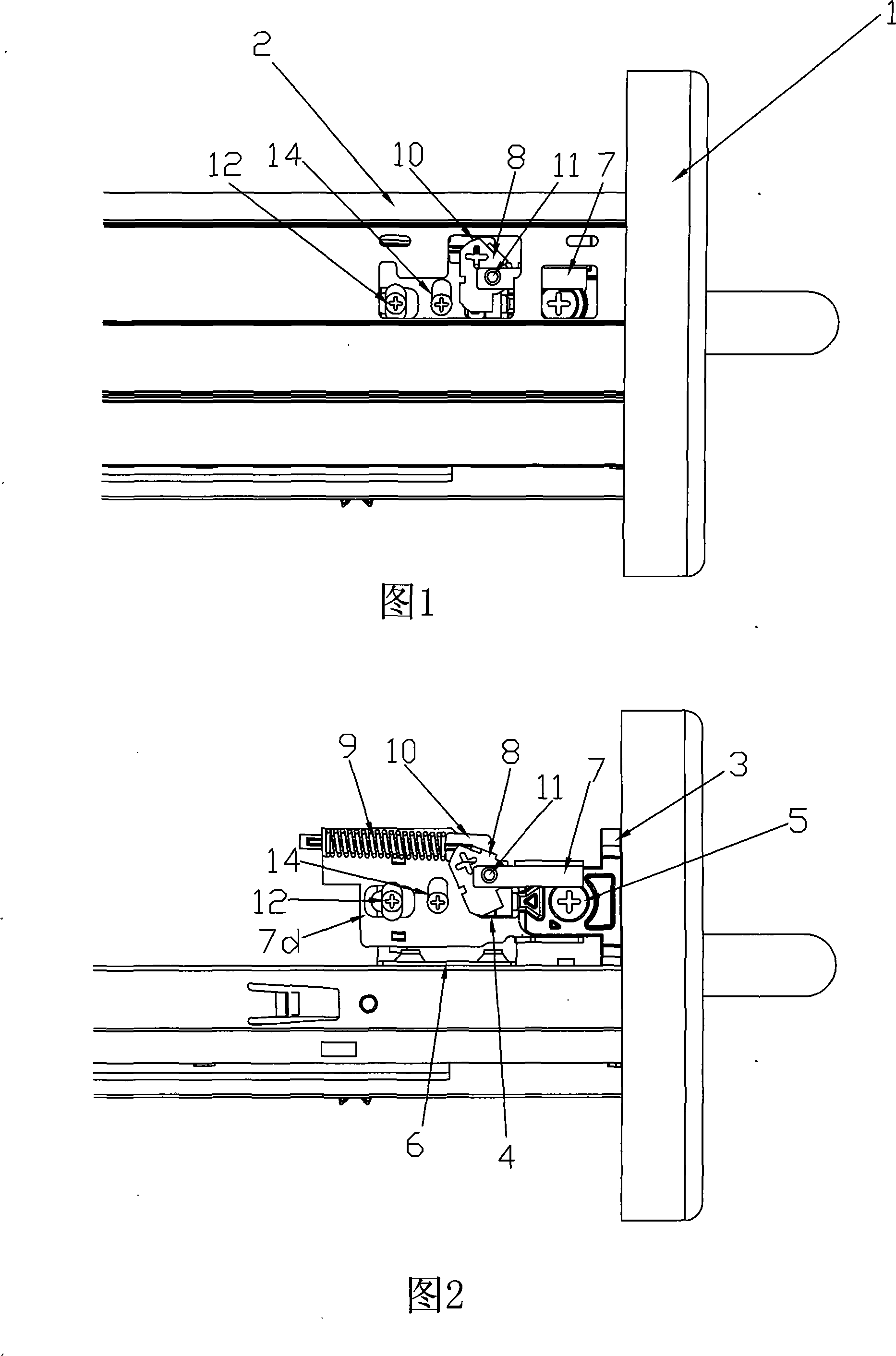

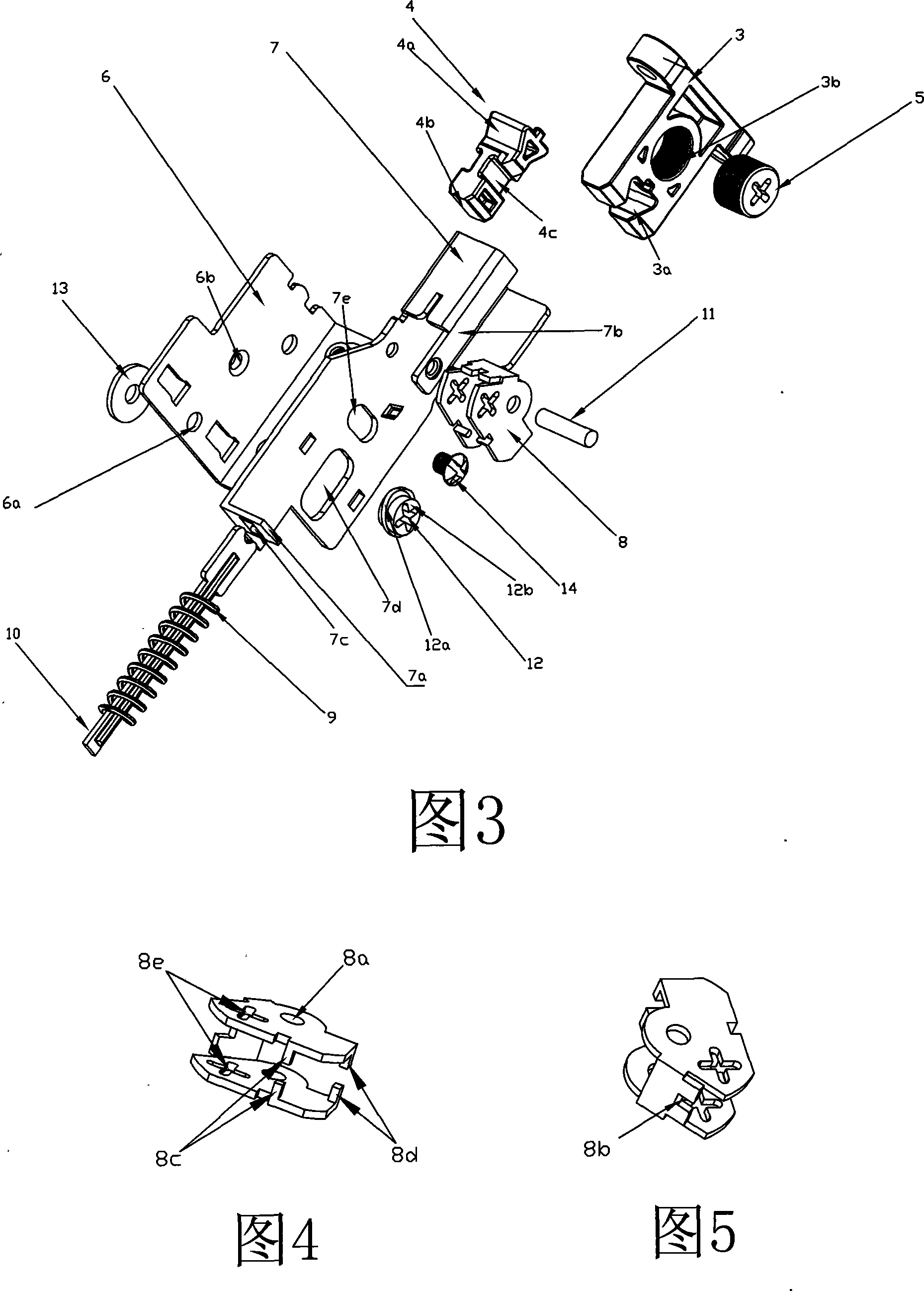

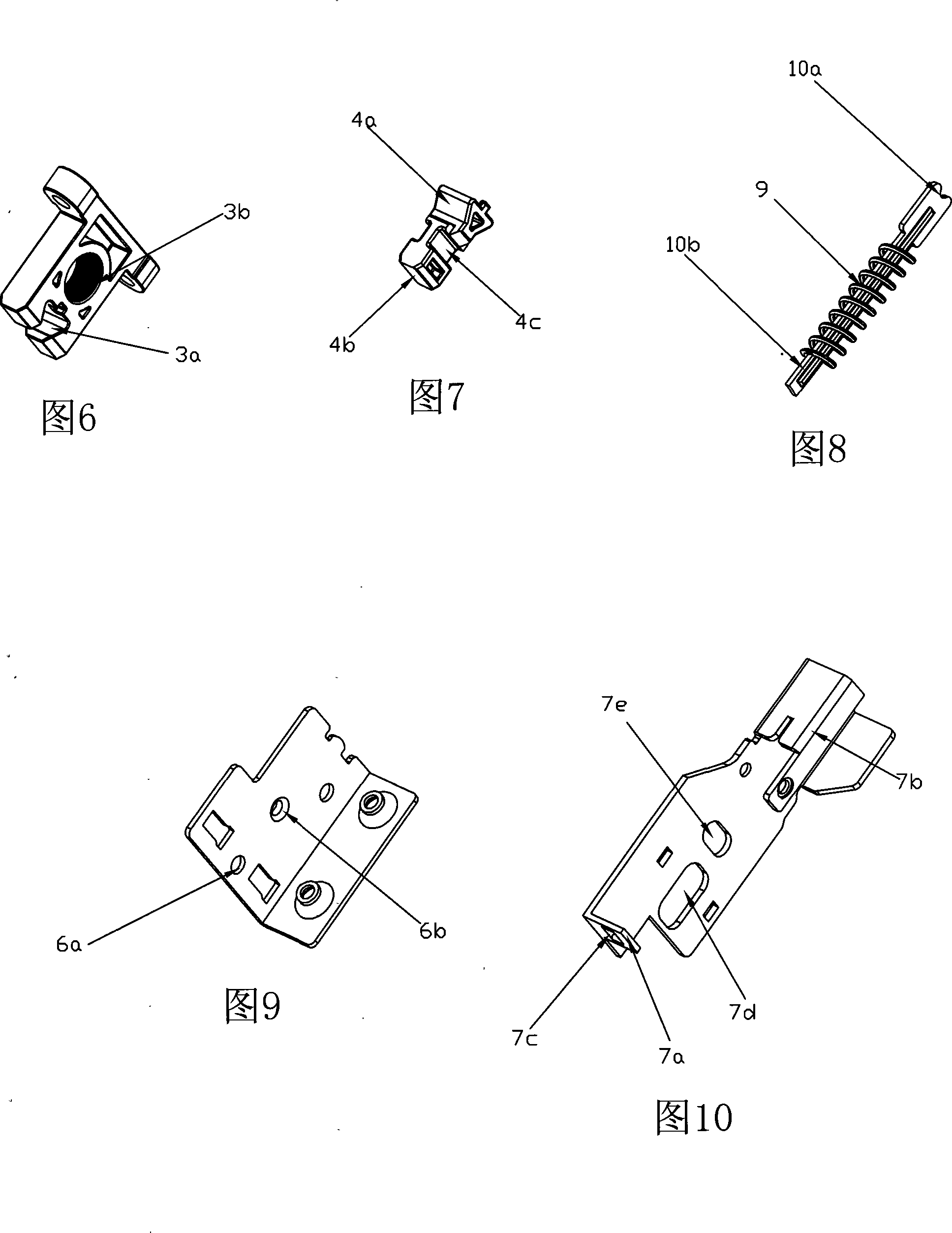

Connecting mechanism for drawer front faceplate and drawer side surface plate

InactiveCN101181116AImprove fastnessEasy left and right adjustmentDrawersFurniture joiningEngineeringSymmetric structure

The invention discloses a connecting device of a drawer front panel and a drawer side panel, which consists of a forward-aligned code fixedly arranged on the drawer front panel and a locking bracket fixedly arranged on the drawer side panel; the forward-aligned code is provided with a end face trigger and a locking groove which has the locking slot structure that has two-side symmetry; the locking groove comprises a bottom board, a main bracket, a rotary sliding block, a spring and a lever; the forward alignment code is inserted into the guiding groove of the main groove; the end face trigger of the forward-aligned code collides with the triggering baffle of the rotary sliding block, causing the rotary sliding block to rotate and the locking buckle of the rotary sliding block buckles the locking groove of the forward alignment code, locking the forward-aligned code and connecting the drawer front panel and the drawer side panel. The rotary sliding block of the invention adopts a fan-shaped sliding block of double-layer symmetric structure and the forward-aligned code is of double-faced symmetric locking groove structure and the double-layer rotary sliding block is provide with two symmetric locking buckles that are connected with the locking groove, thus ensuring the forward alignment code and the drawer front panel are stably to be fixed on the drawer side panel.

Owner:罗志明

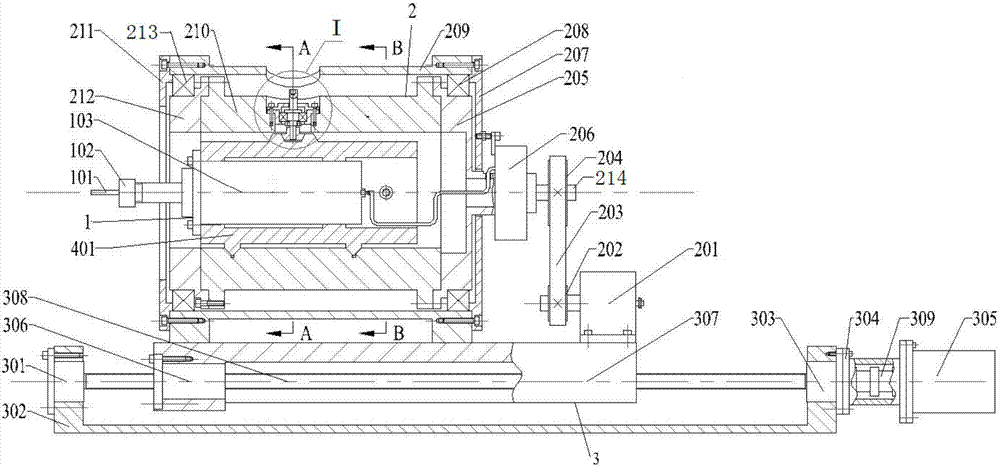

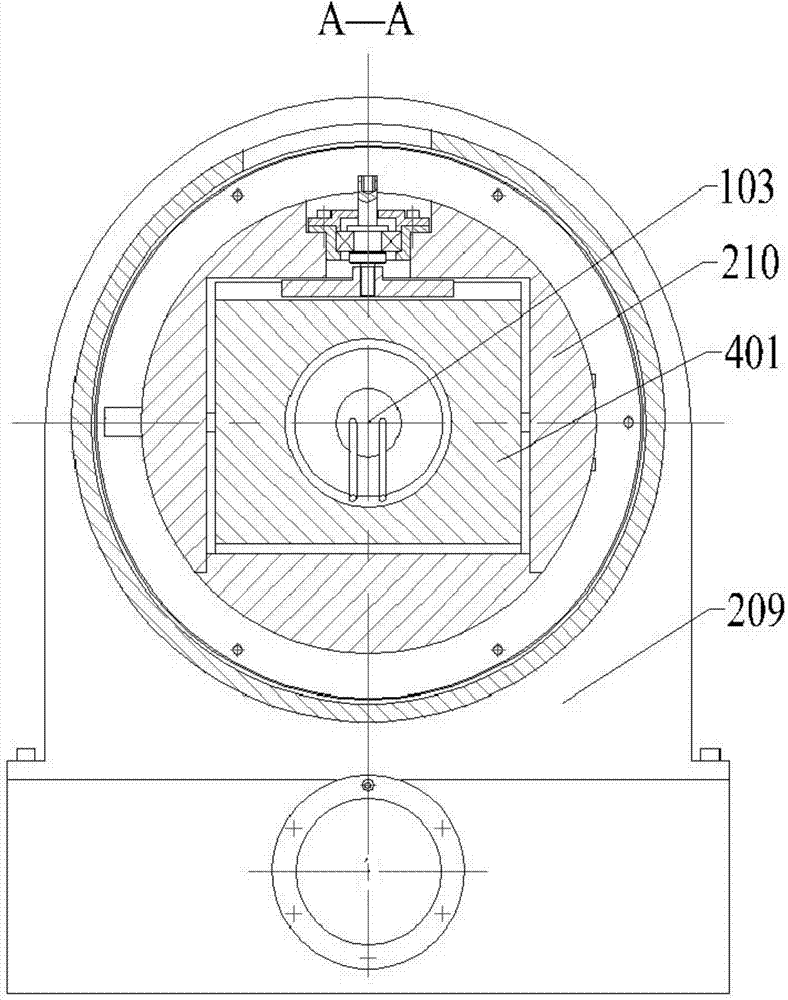

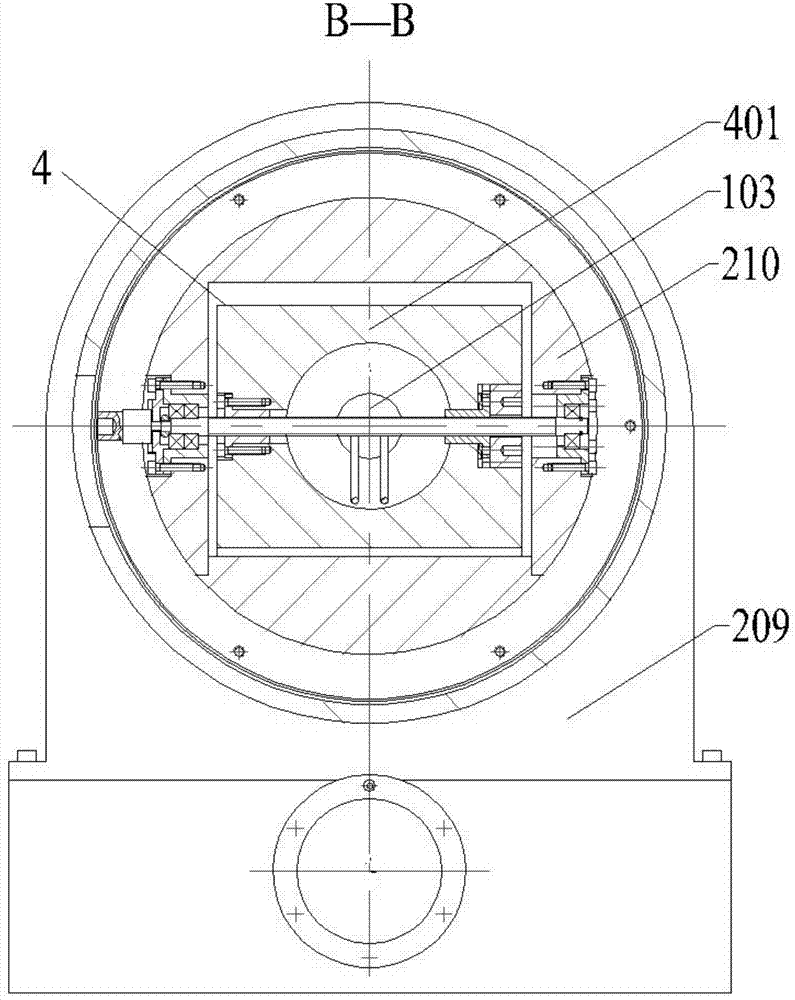

Spiral hole milling device

ActiveCN104117719AHigh adjustment accuracyIncrease adjustment errorFeeding apparatusMilling equipment detailsMilling cutterPulley

The invention discloses a spiral hole milling device. The spiral hole milling device comprises an rotationsystem, a revolution system, a feeding system and an eccentricity adjusting system. An electric main shaft in the rotation system drives a milling cutter to rotate through a spring collet arranged on an output shaft of the electric main shaft. A revolution motor in the revolution system drives an inner sleeve to perform revolution relative to the axis of an outer sleeve through a small synchronous pulley, a synchronous belt and a large synchronous pulley. A feeding motor in the feeding system drives a feeding lead screw to enable a feeding nut to move so as to achieve feeding. An eccentricity adjusting mechanism in the eccentricity adjusting system controls motion of a shifting sliding block, a fixed anti-backlash nut and a movable anti-backlash nut remove the backlash of the eccentricity adjusting system, and therefore high-precision adjustment of the eccentricity can be achieved. A holding mechanism arranged on the inner sleeve achieves the aim that the shifting sliding block is held on the inner sleeve after the eccentricity adjustment is completed. The spiral hole milling device can be applied to integral, high-quality and high-efficiency hole forming of difficultly-machined materials in the aerospace field.

Owner:DALIAN JIAOTONG UNIVERSITY

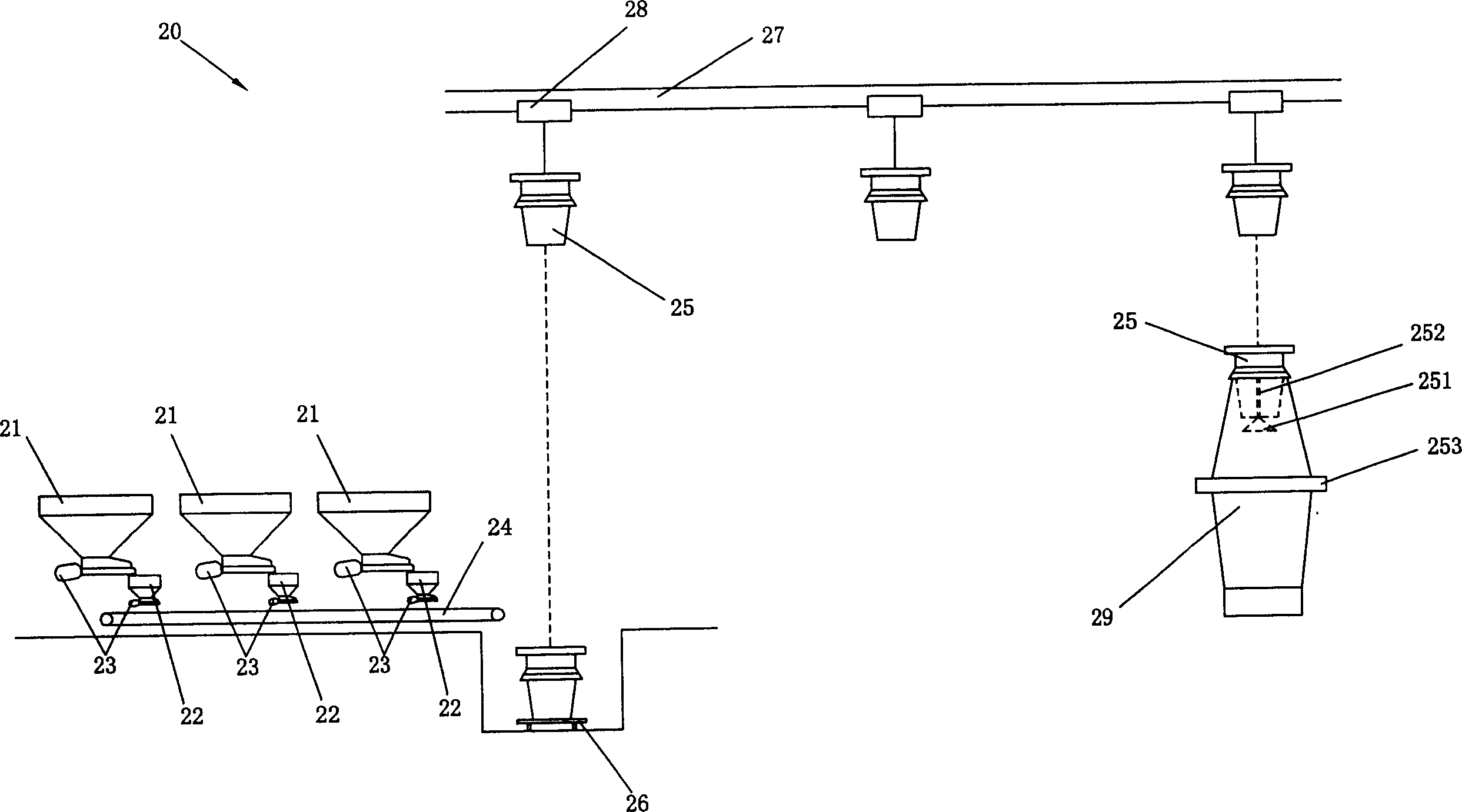

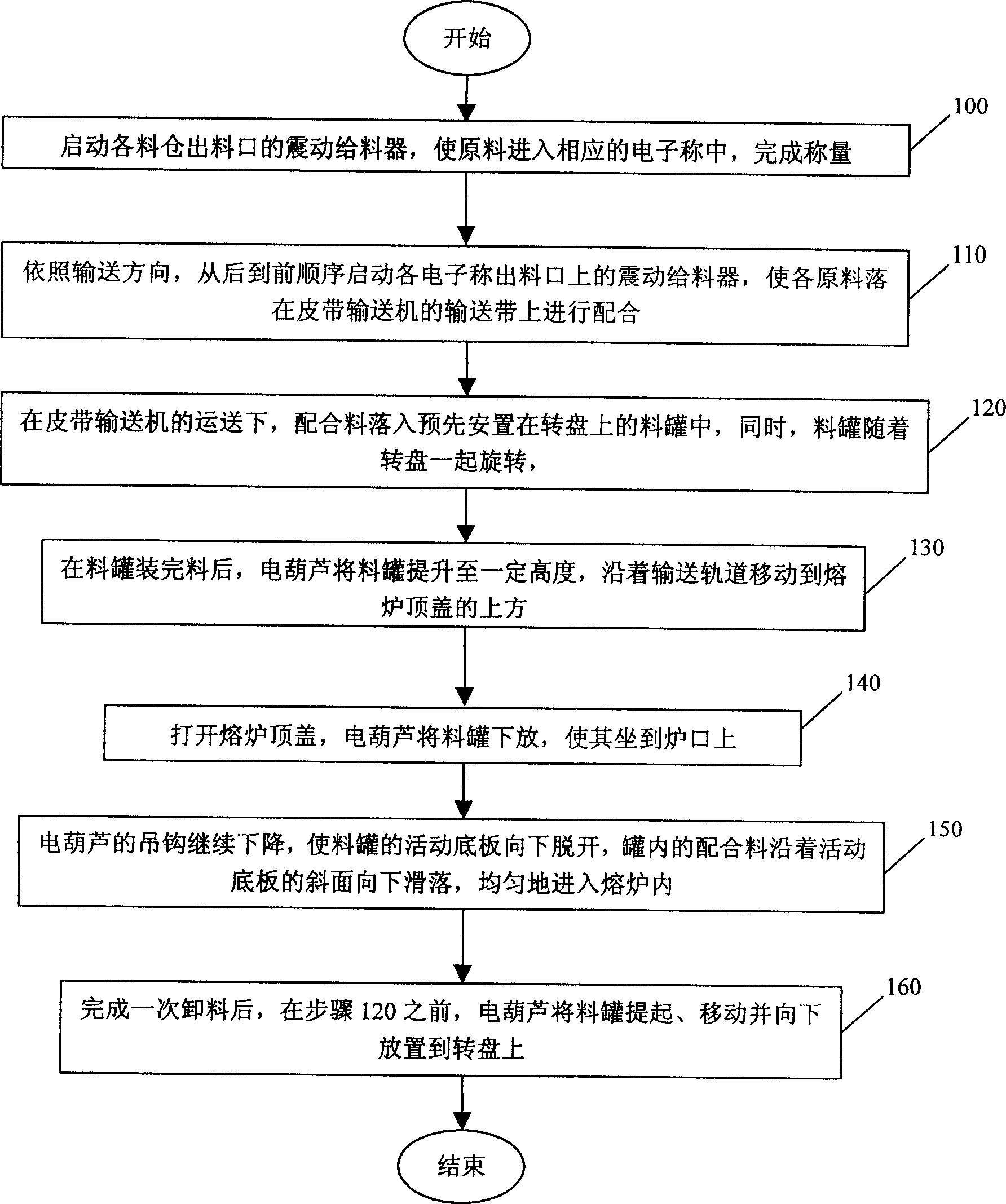

Charging method and system for industrial production

InactiveCN1651841AEvenly distributedFit evenlyCharging furnaceCharge manipulationIndustrial engineeringLeather belt

The present invention discloses a charging method for industrial production and its charging system. Said charging system includes the following portions: bunker, electronic-weighing system, belt conveyer, conveying guideway, bucket and smelting furnace. Said invention also provides the concrete steps of said charging method.

Owner:BEI JING NEW BUILDING MATERIALGRP

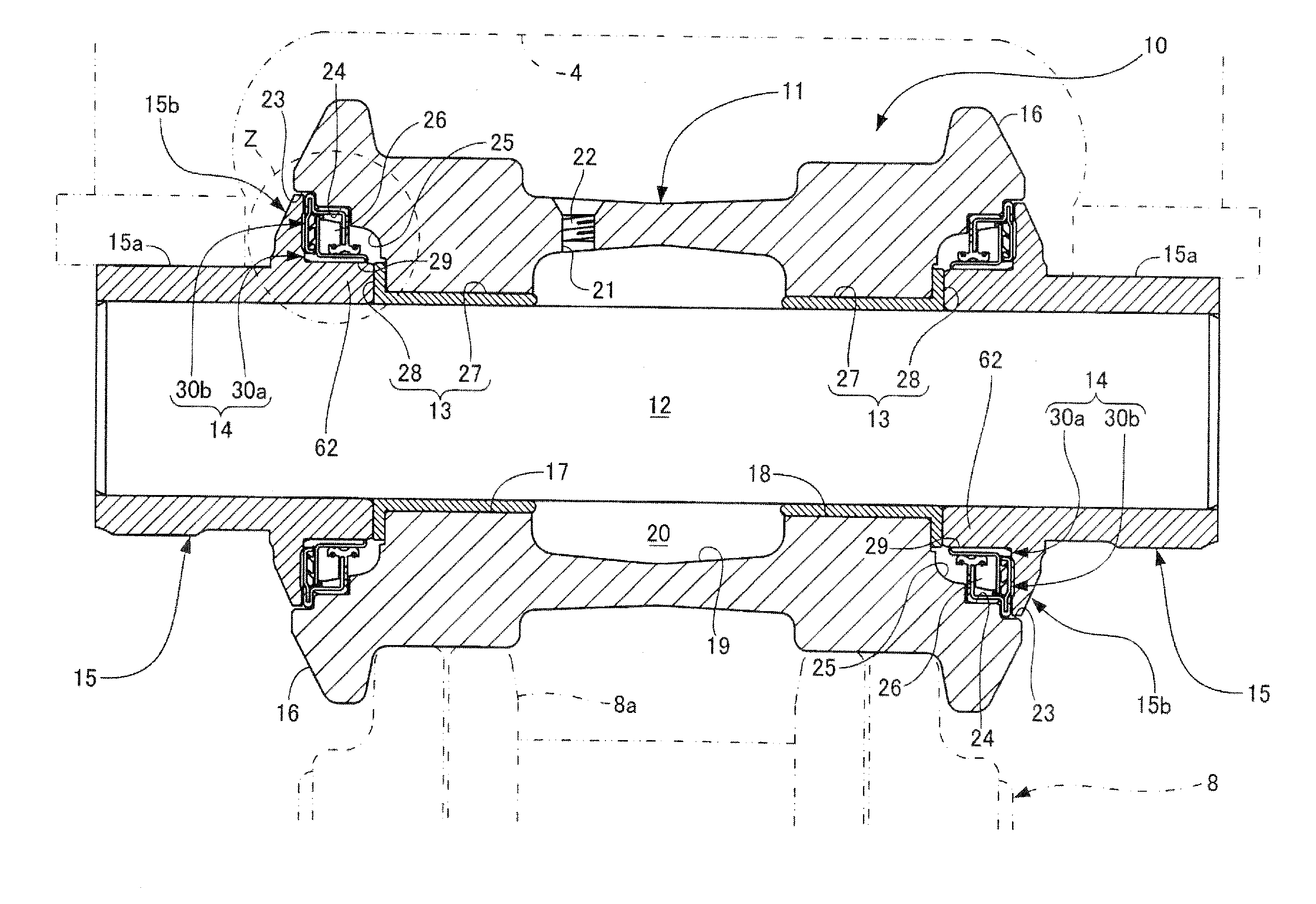

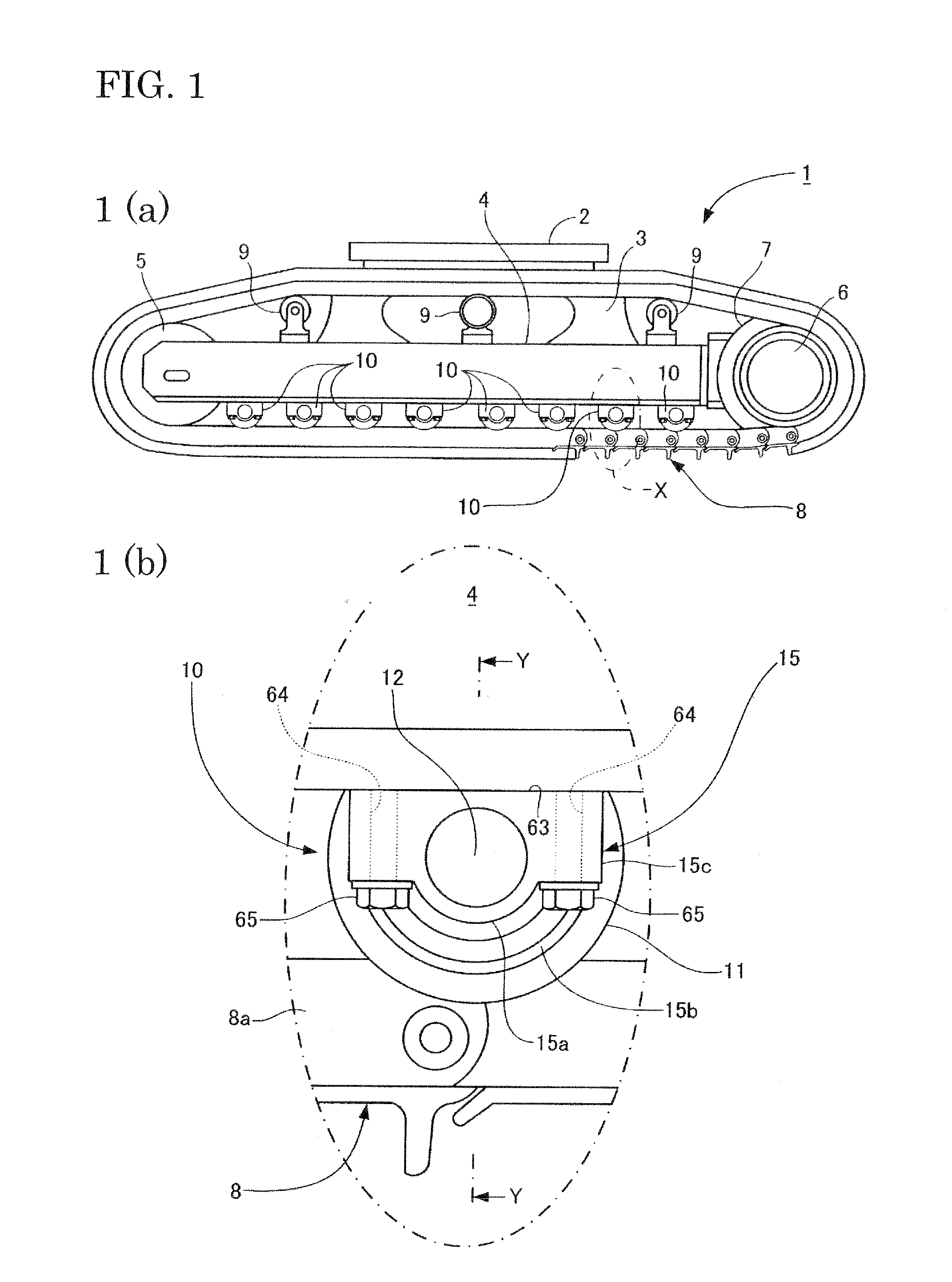

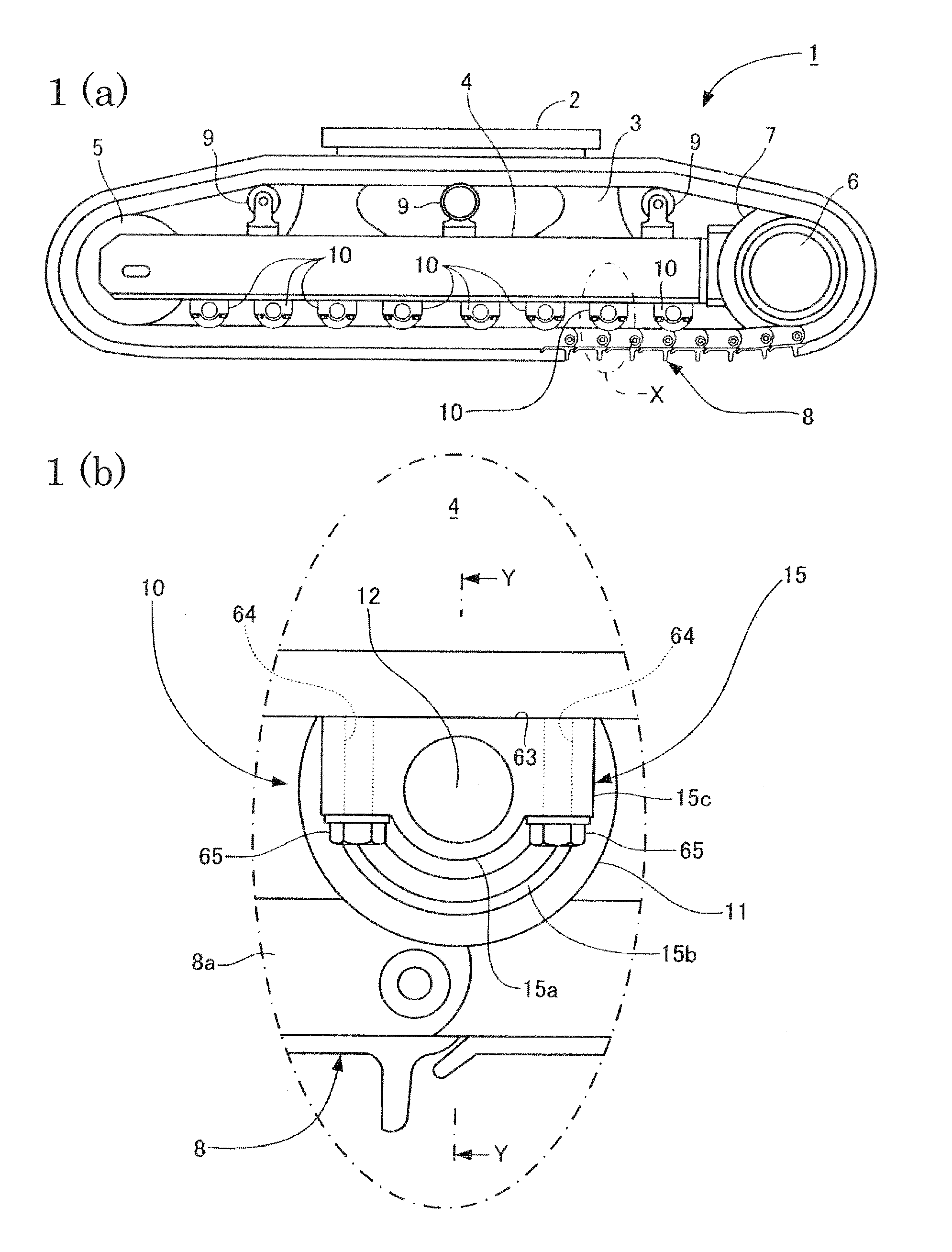

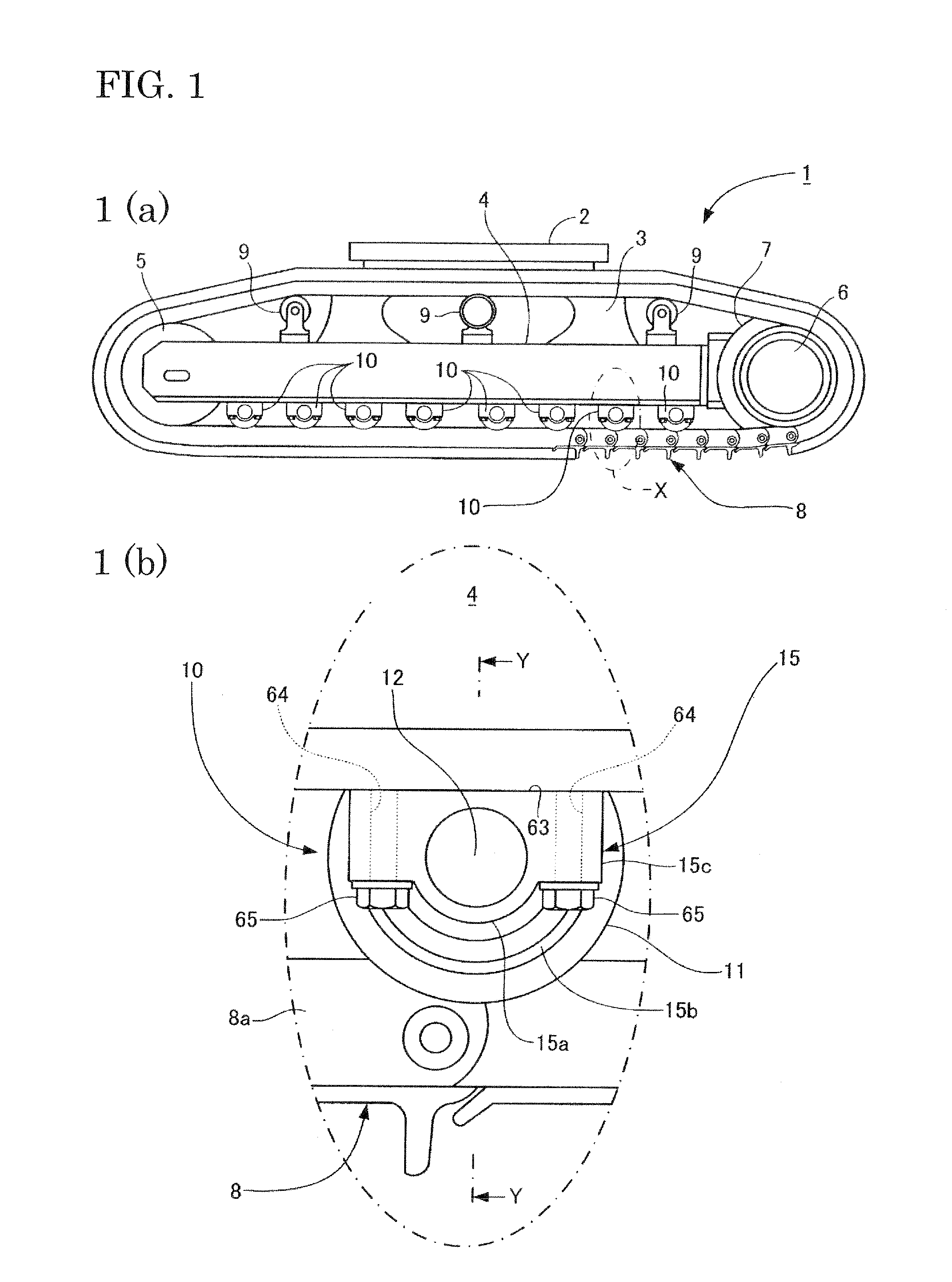

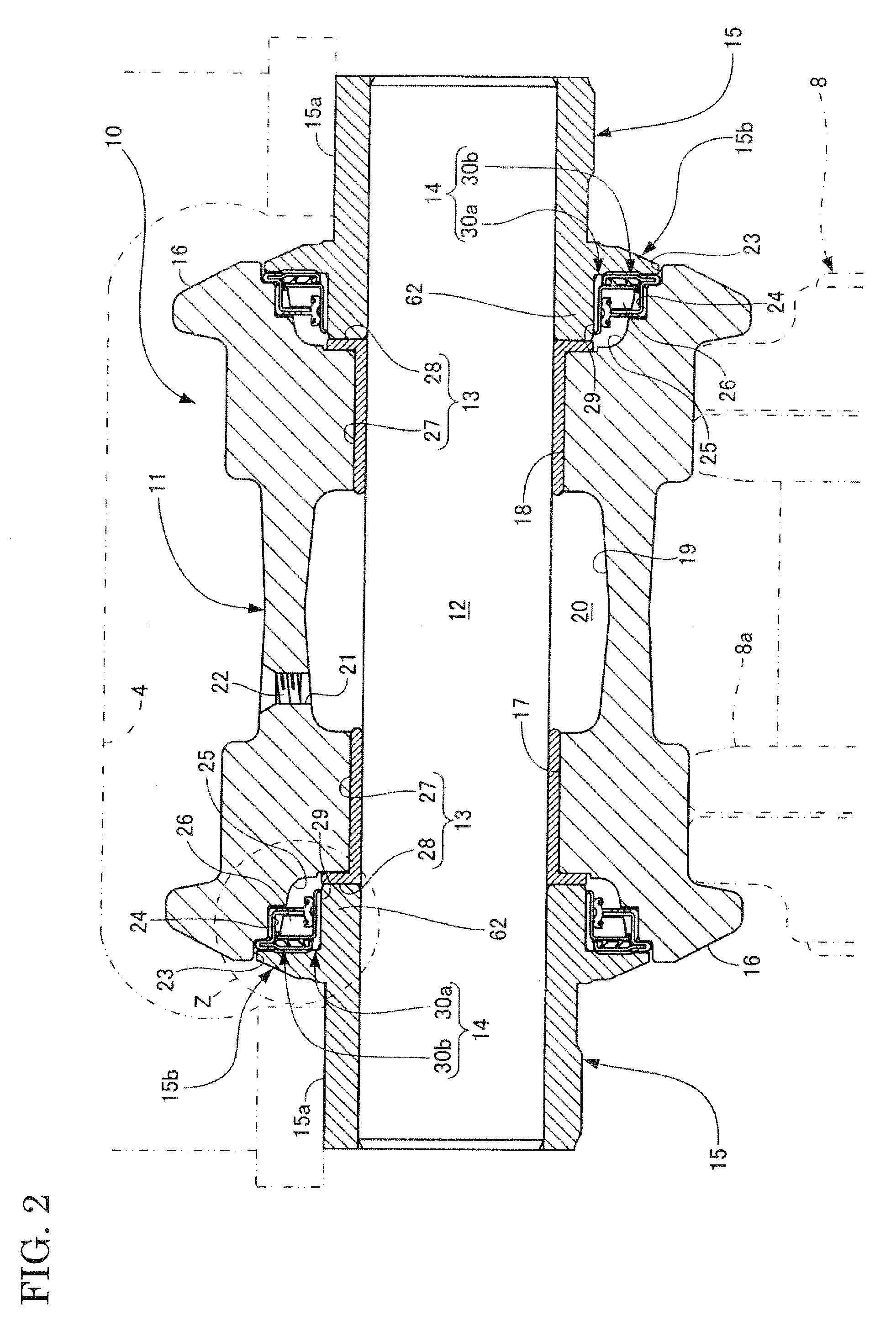

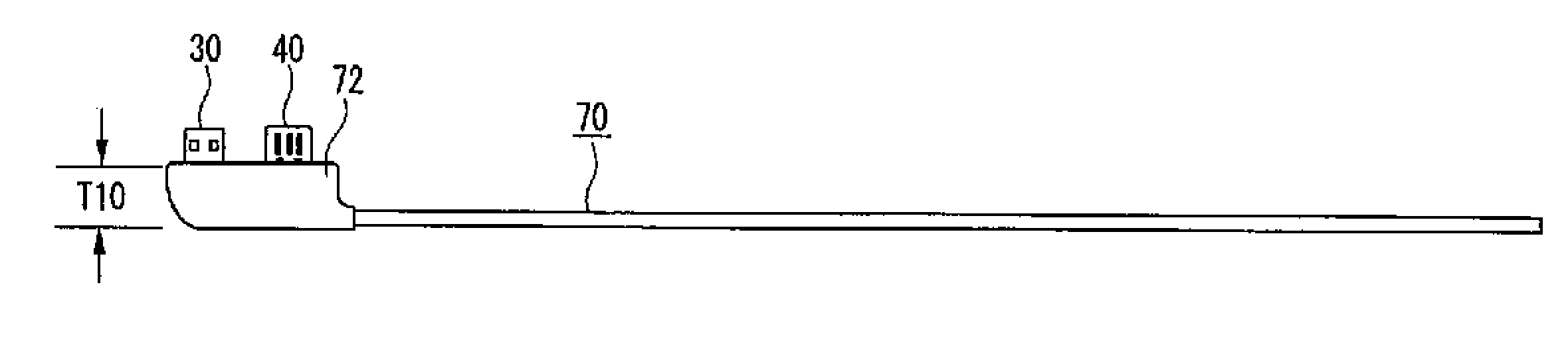

Roller unit

InactiveUS20120146397A1Extended service lifePrevent penetrationEngine sealsEngineering safety devicesFlange

[Subject] A roller unit is provided which is improved in the service life of the seal as well as in the ease of unit assemblability.[Means for Solving the Problem] A track roller unit 10 having a roller 11 configured to roll in contact with a crawler belt 8, a roller shaft 12 for rotatably supporting the roller 11, and a seal 14 fit in an annular space 26 defined between the roller 11 and the roller shaft 12; wherein the seal 14 is formed such that an inner circumference side sealing portion 30a located on an inner circumference side and an outer circumference side sealing portion 30b located on an outer circumference side are fit together so as to come into slidable contact with each other; which further comprises a collar 15 mounted to the roller shaft 12; and wherein the collar 15 has a boss portion 62 into which the seal 14 is pressed and a flange portion 15b in contact with an outer end face of the seal 14.

Owner:KOMATSU LTD

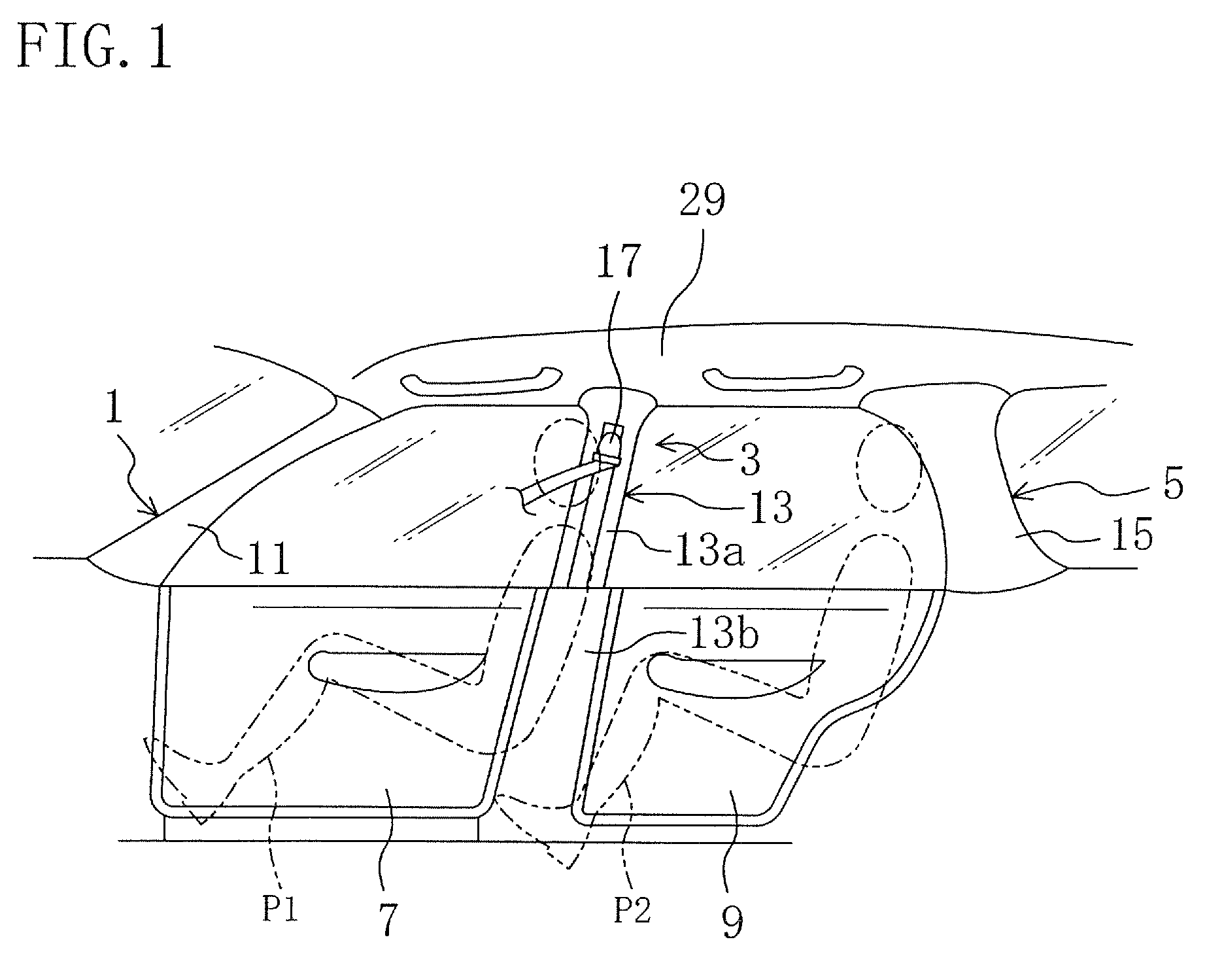

Pillar trim for motor vehicle

InactiveUS7963551B2Improve rigidityFit evenlyVehicle seatsPedestrian/occupant safety arrangementAirbagMotorized vehicle

A pillar trim on the vehicle-interior side of a pillar includes a pillar trim body located below an airbag and connected at its upper end part to the lower end of a top sealing member. A plurality of guide platforms are raised from the upper end part of the pillar trim body at spaced intervals in the vehicle front-to-rear direction to guide the inflation of the airbag towards the vehicle interior. The basal ends of each adjacent guide platforms are joined by a connecting part between the adjacent guide platforms. A groove for receiving the lower end of the top sealing member is formed between the vehicle-interior sides of the guide platforms and the pillar trim body. A through hole is vertically formed at least between the connecting part and the pillar trim body to open into the groove.

Owner:DAIKYONISHIKAWA CORP +1

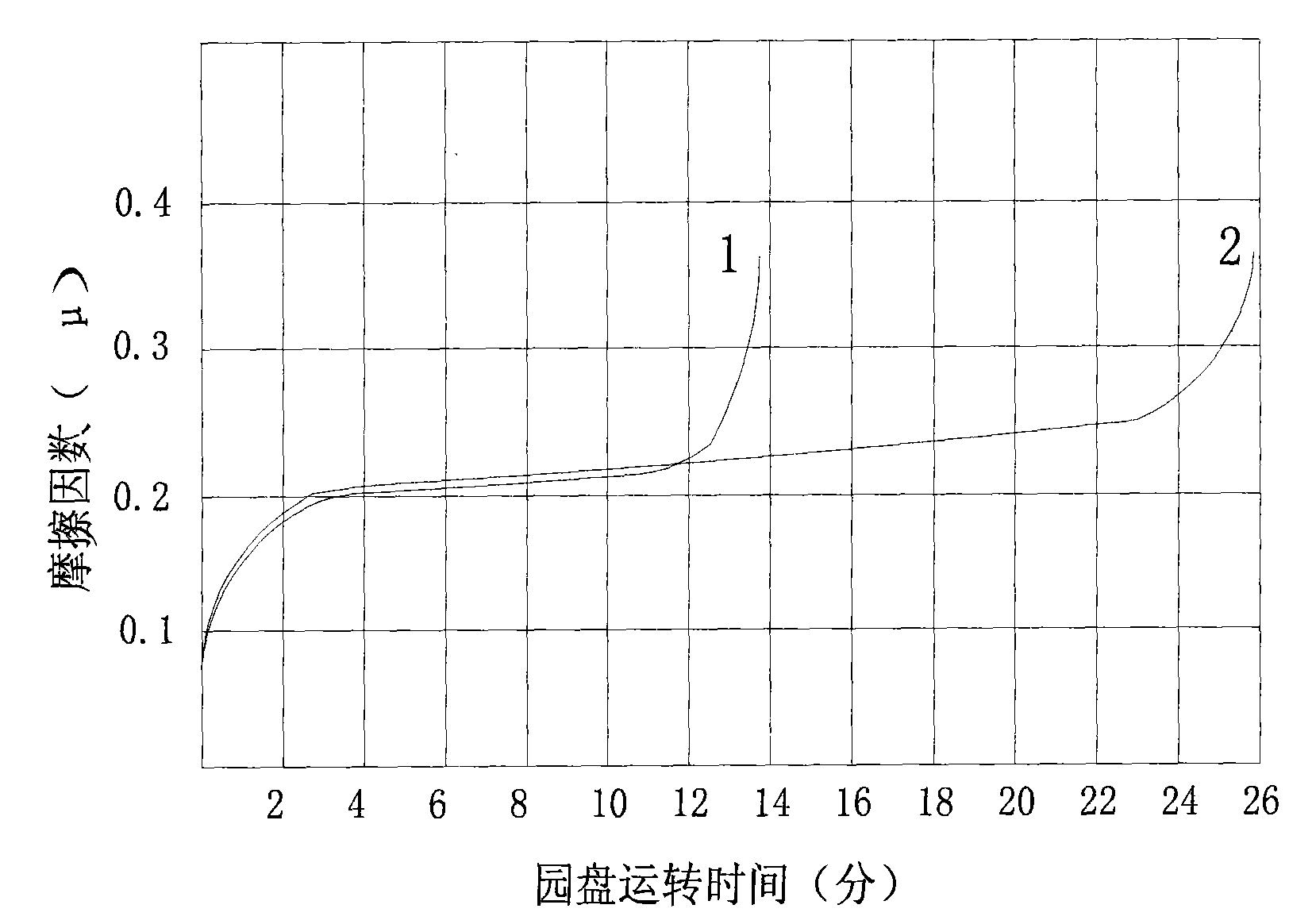

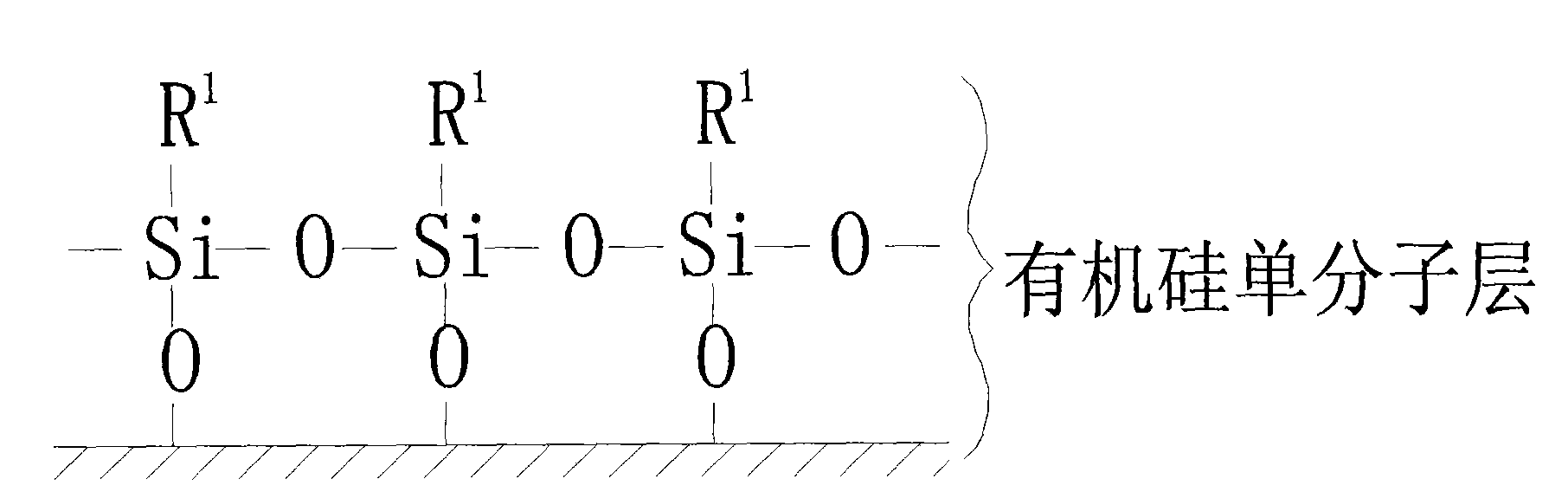

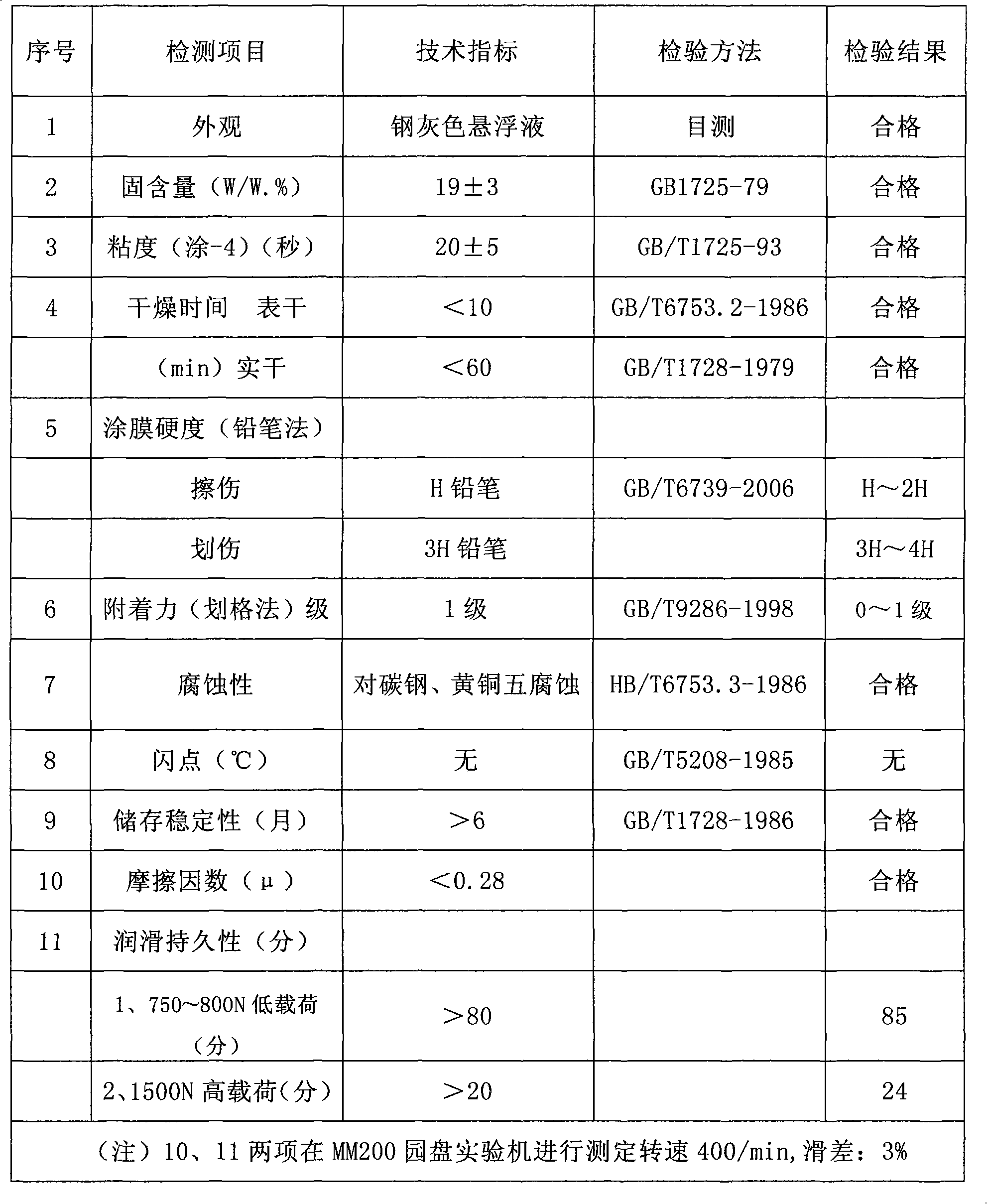

Large-load running rail dry-film lubricant

InactiveCN101586049AImprove extreme pressure performanceIncreased durabilityBase-materialsNano al2o3Room temperature

The invention discloses a large-load running rail dry-film lubricant, belonging to the single-constituent room-temperature solidification type dry-film lubricant, comprising the following constituents by weight parts: modified thermal plastic acrylic ester copolymer 30-40 parts, coupling agent 2-6 parts, nano Al2O3 0.5-4 parts, solid lubricant 55-70 parts, solvent 350-500 parts, additive 6-8 parts. The dry-film lubricant has features of good anti-friction and abrasion proofness; good extreme pressure property; no corrosion; safe use, construction and convey; accordance with environmental protection requirement; lower cost and wide application.

Owner:麻城天安化工股份有限公司

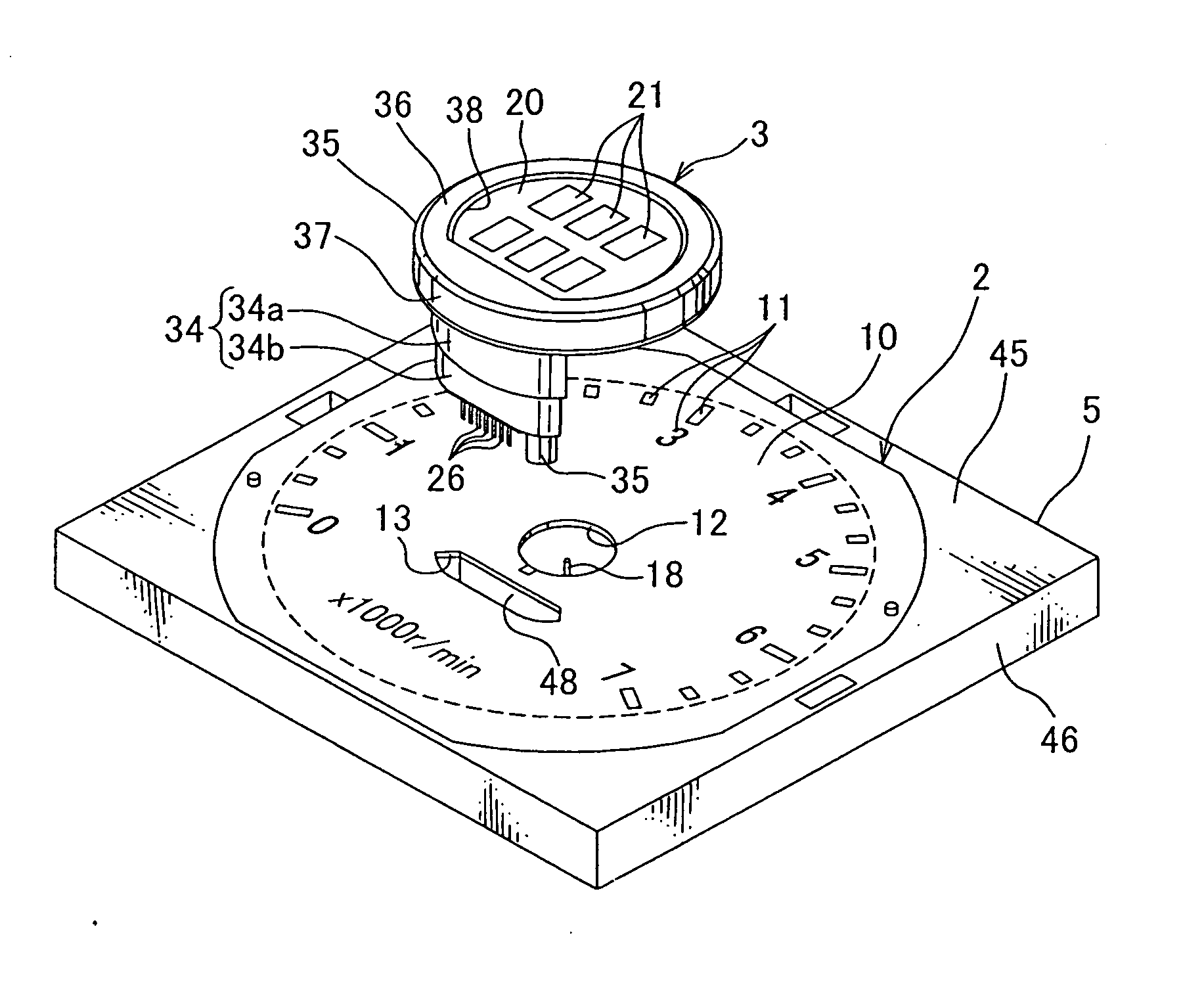

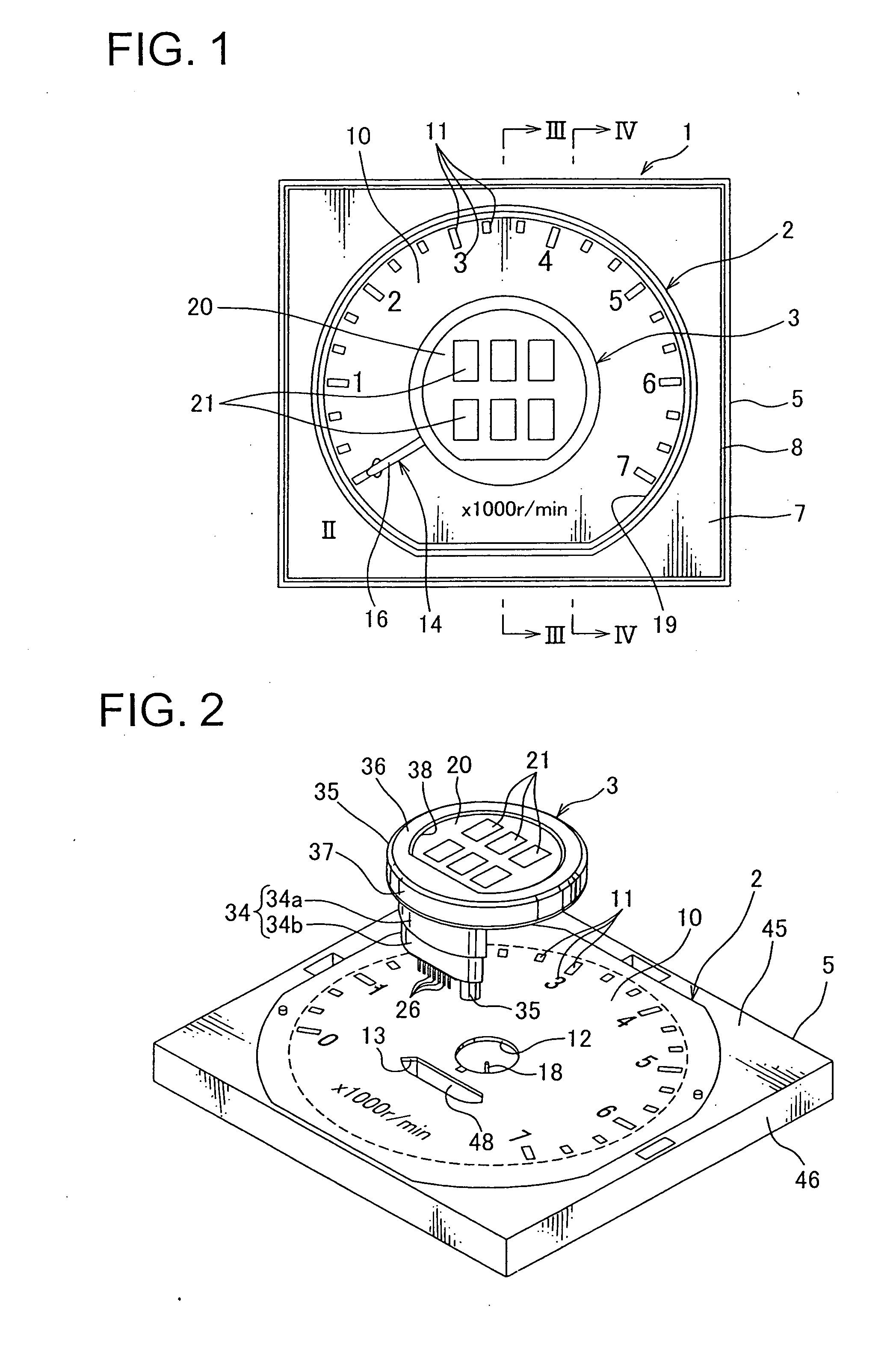

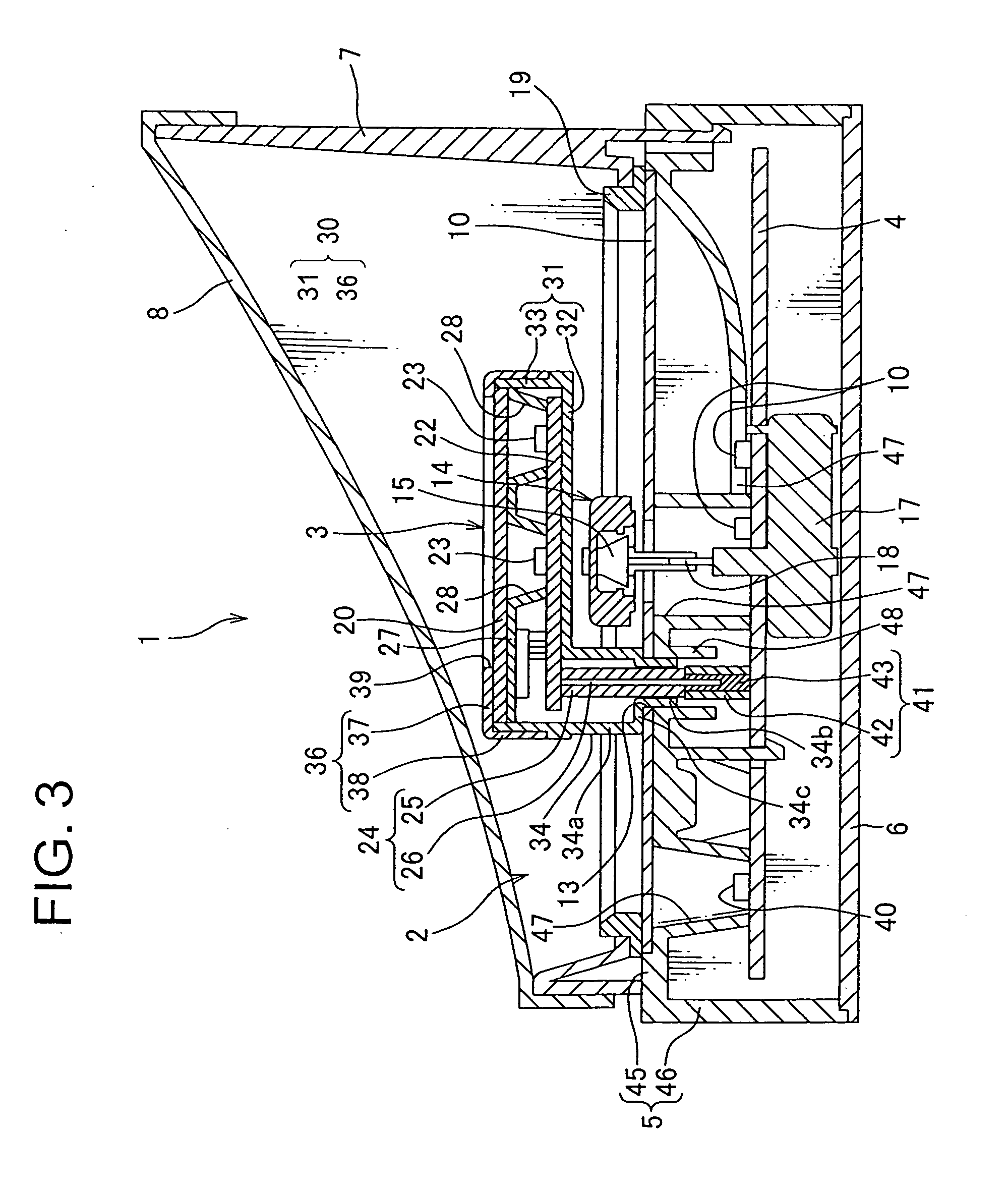

Instrument apparatus

ActiveUS20110154897A1Easy to operateFit evenlyStatus displaysInstrument arrangements/adaptationsEngineeringPrinted circuit board

An instrument apparatus, includes a tachometer having a chaptering plate provided at a front surface thereof; a display unit arranged at the front surface of the chaptering plate; a printed circuit board arranged at a rear surface of the chaptering plate and driving the display unit. The display unit includes a projecting portion projecting toward the chaptering plate and a male terminal provided at a top end of the projecting portion. The chaptering plate includes an insertion hole formed into a similar shape as an outline of the projecting portion, in which the projecting portion is inserted. The printed circuit board is arranged at a position, in which an insert direction of inserting the projecting portion through the insertion hole and the printed circuit board intersect, and includes a female terminal to be fitted and electrically connected with the male terminal.

Owner:YAZAKI CORP

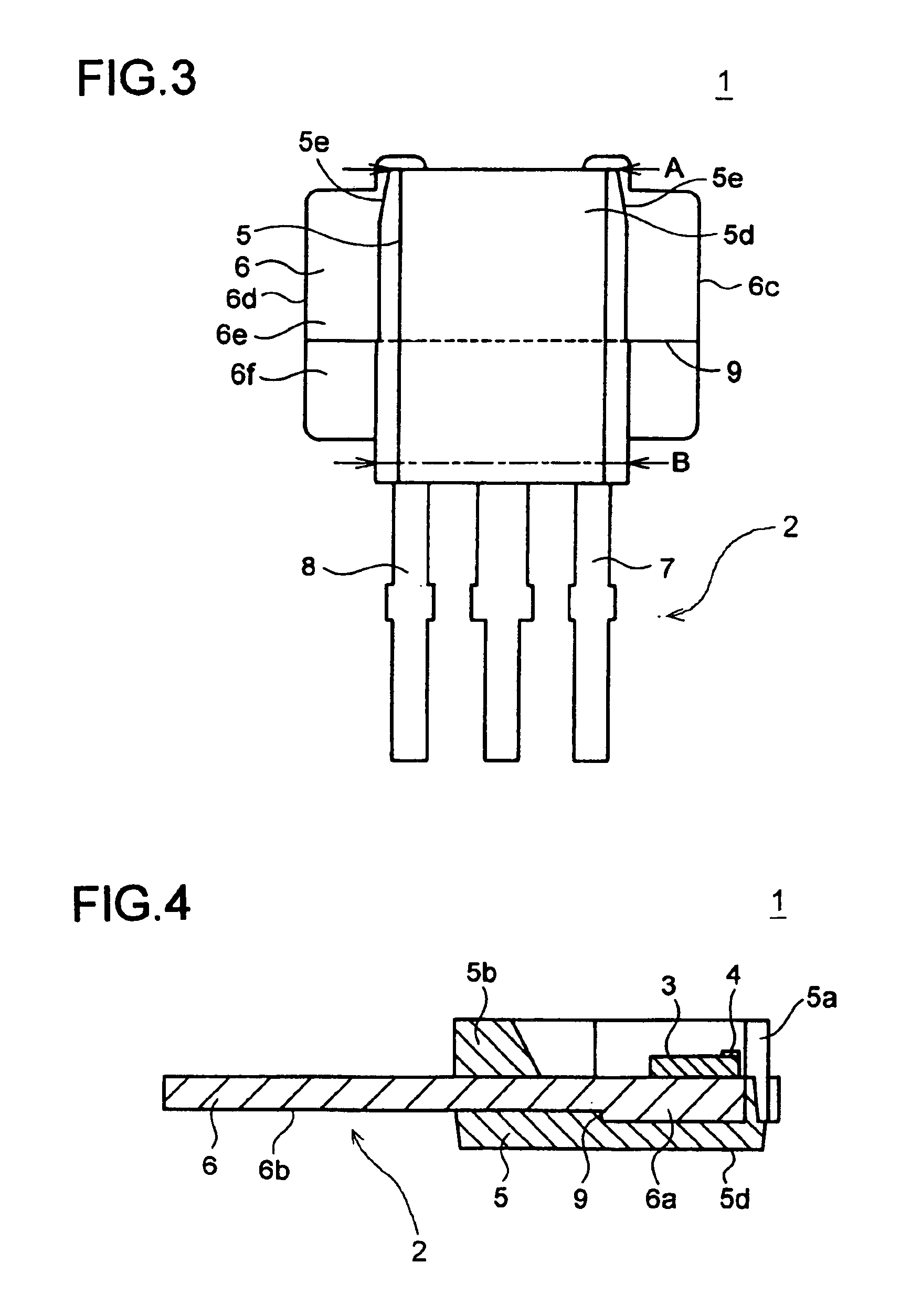

Semiconductor laser device

InactiveUS6885076B2Improve cooling effectHigh mechanical strengthLaser detailsSemiconductor/solid-state device detailsSemiconductorSemiconductor device

A semiconductor laser device includes a semiconductor laser element, a lead having an element disposing section where elements are disposed and a resin bonded to the lead. The lead has a thick portion and a thin portion with the thick portion being formed to extend at least in the direction of the width of the resin to cover a region having a length equal to or greater then the width of the resin. A semiconductor laser device has a semiconductor laser element, a lead having an element mount portion on which the semiconductor laser element is mounted and a resin maintained in intimate contact with the lead. The lead has a thicker portion and a thinner portion. The thicker portion is formed to extend in the direction of the width of the resin over a width equal to or greater than the width of the resin.

Owner:SANYO ELECTRIC CO LTD +1

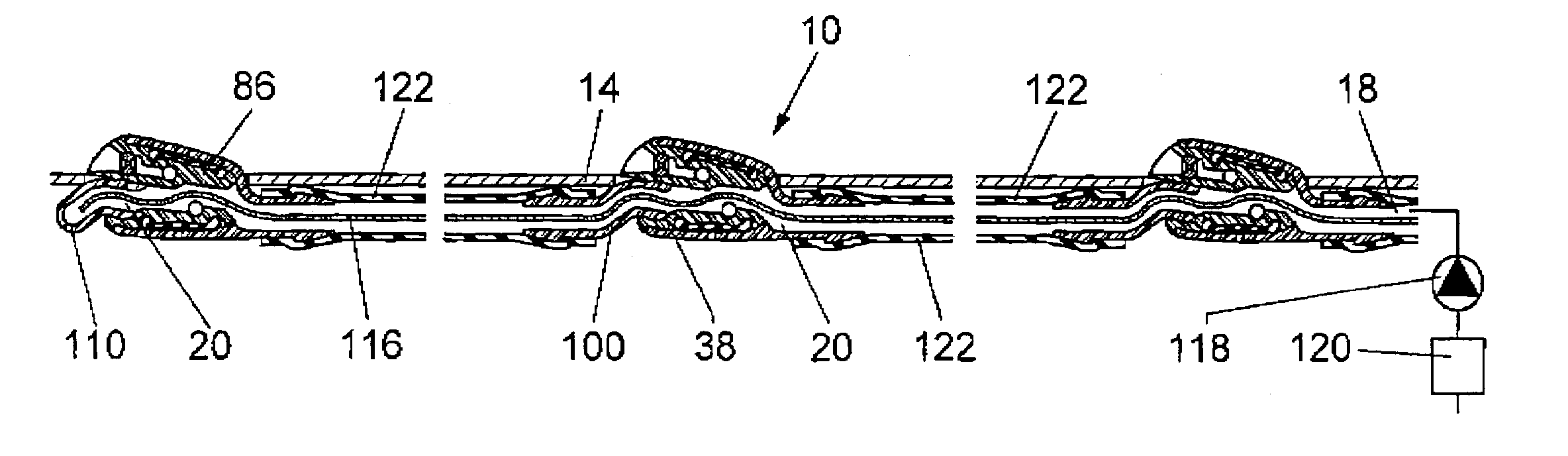

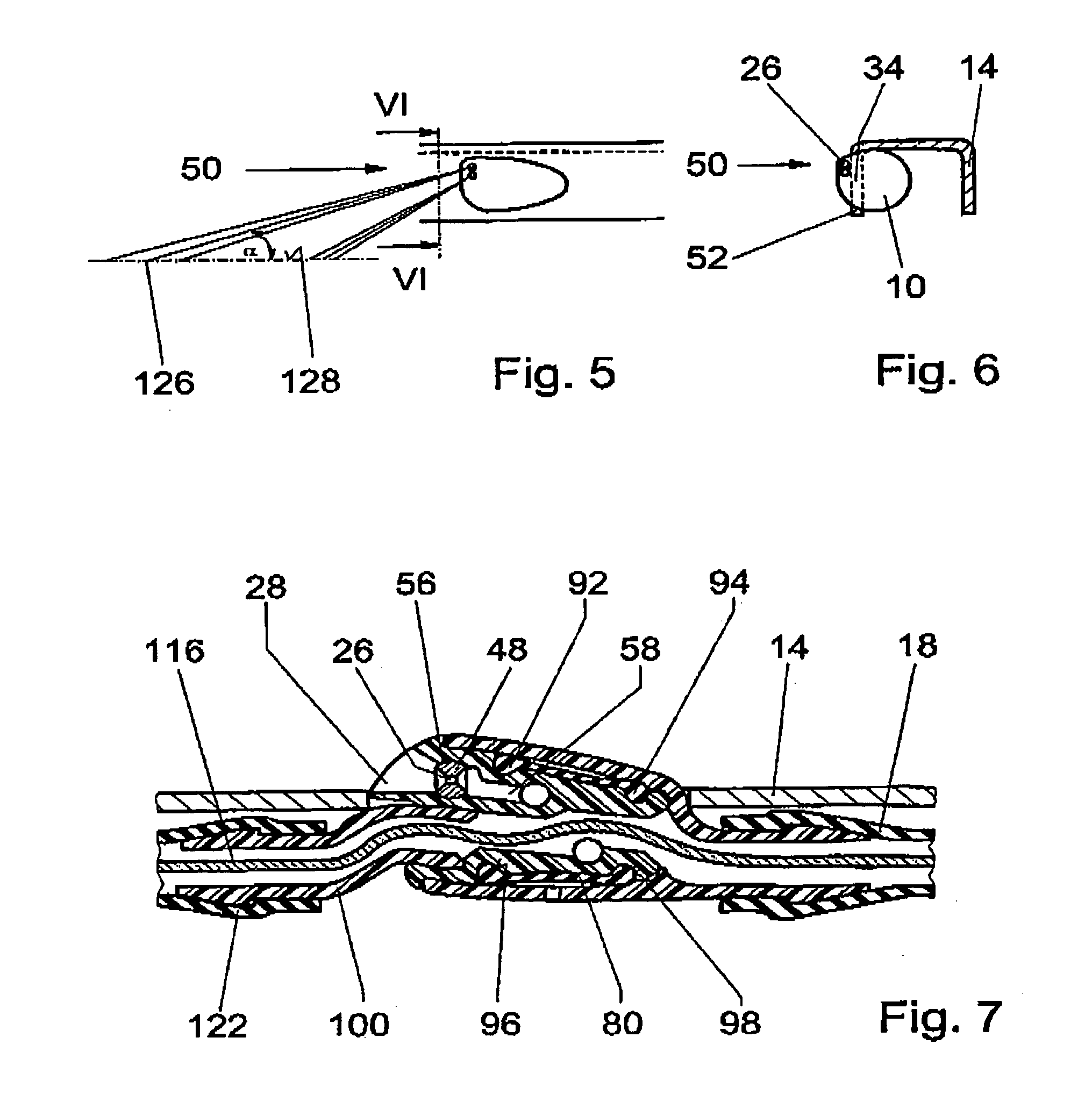

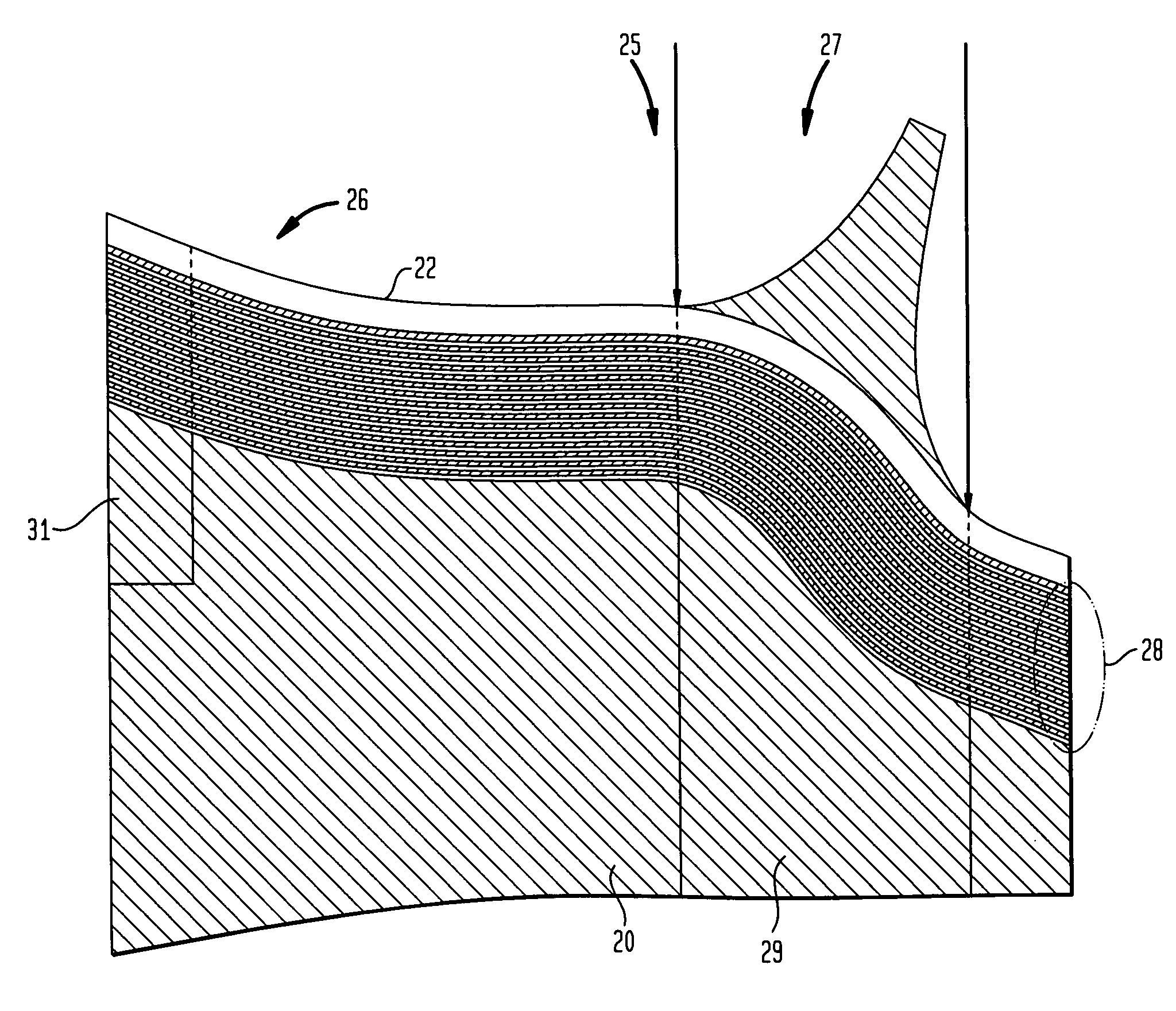

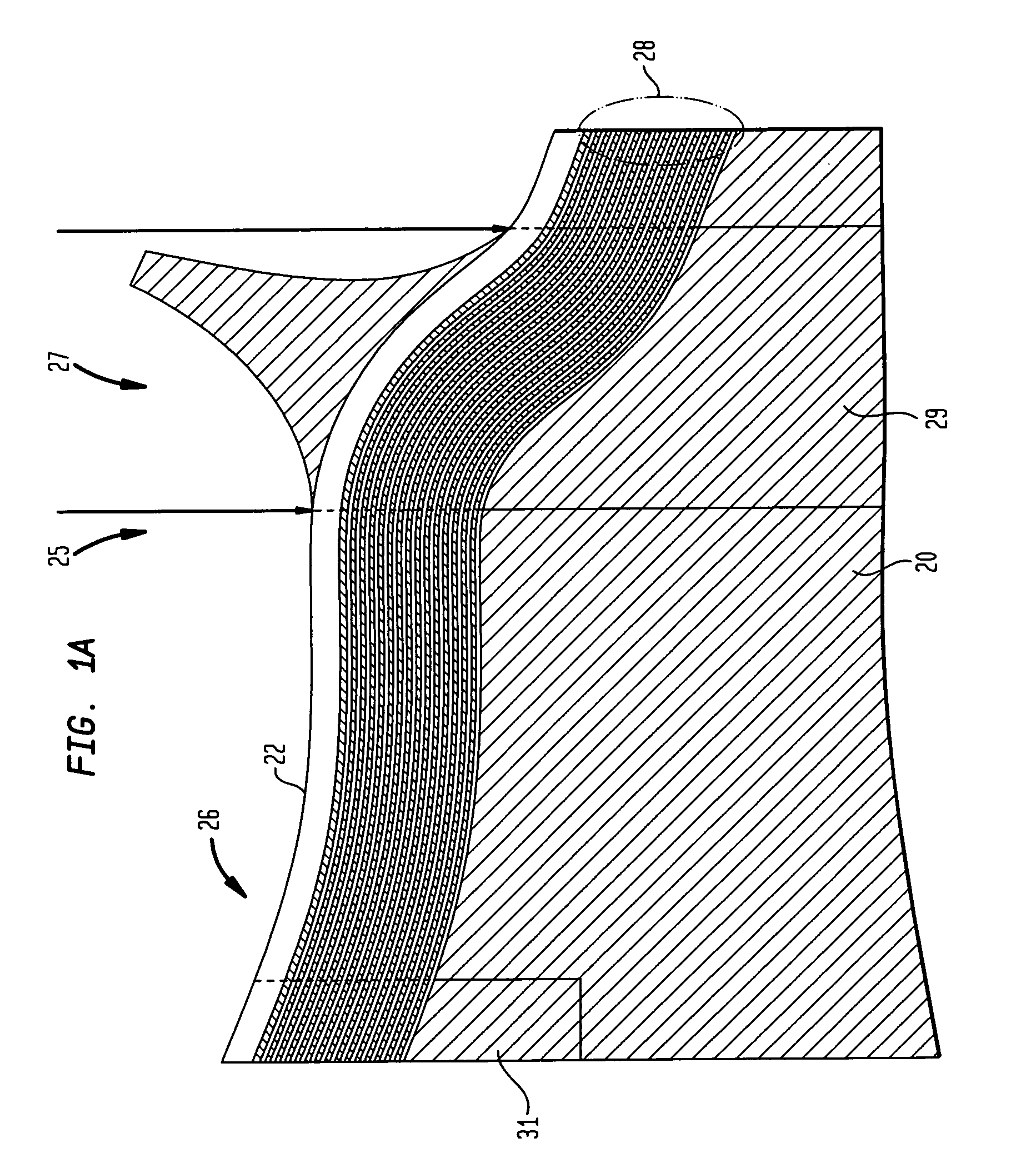

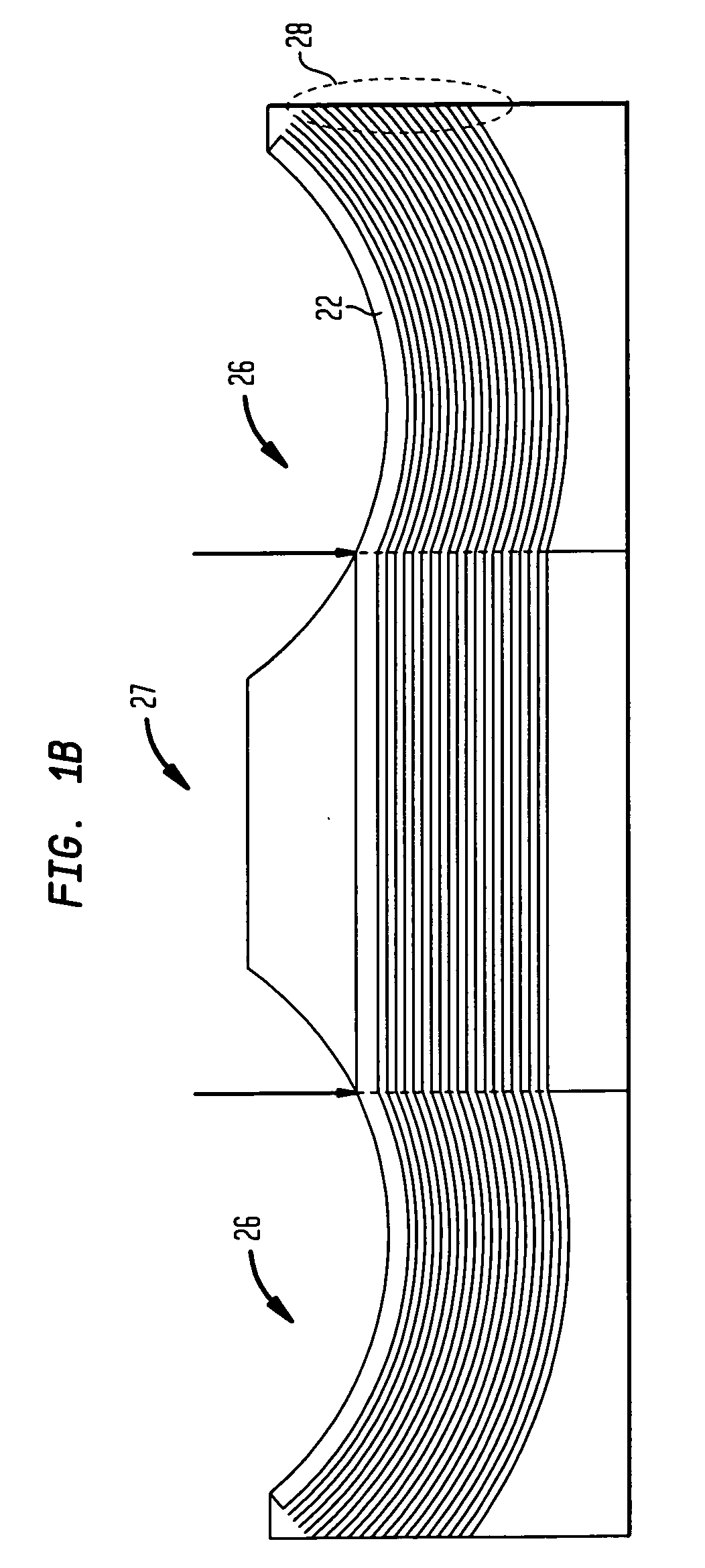

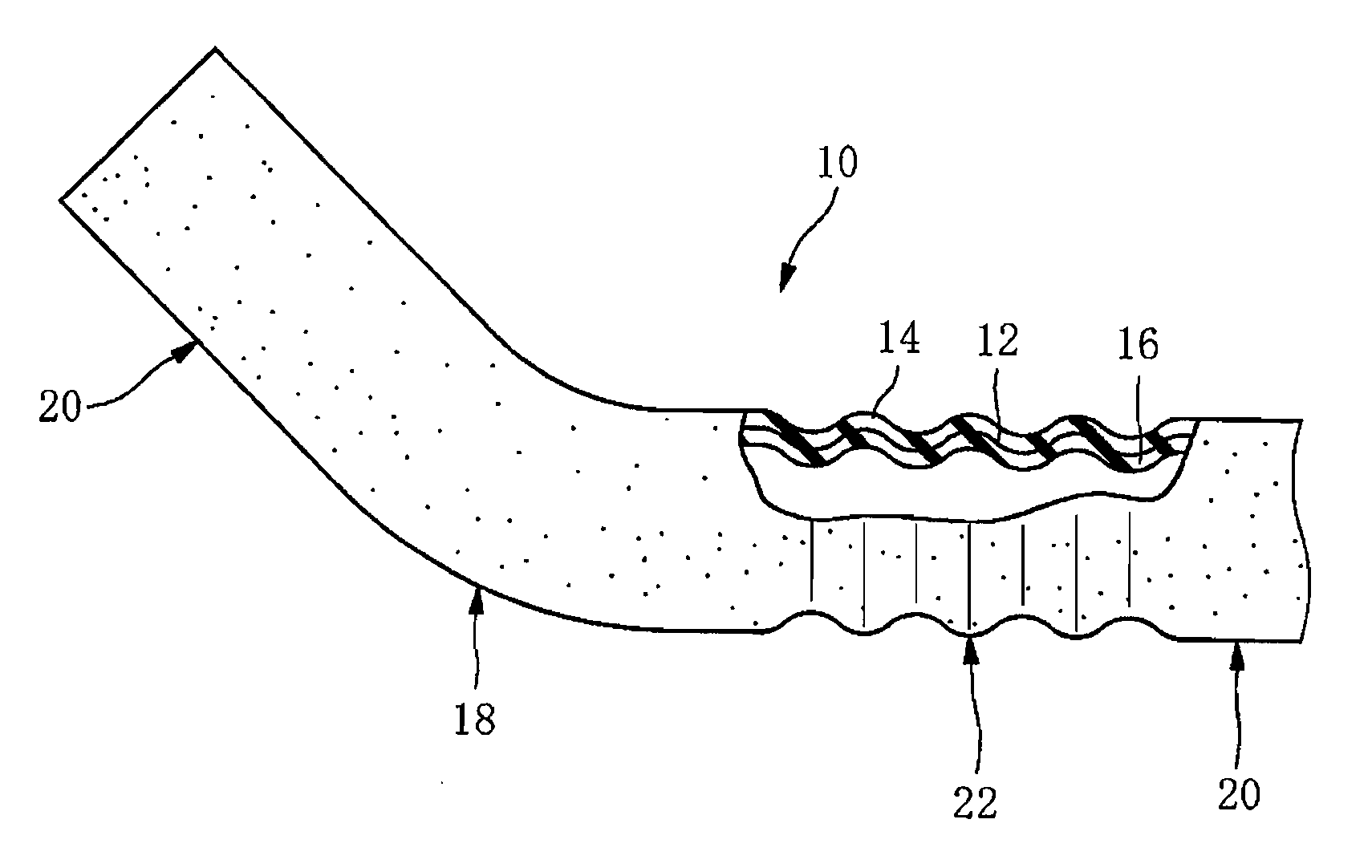

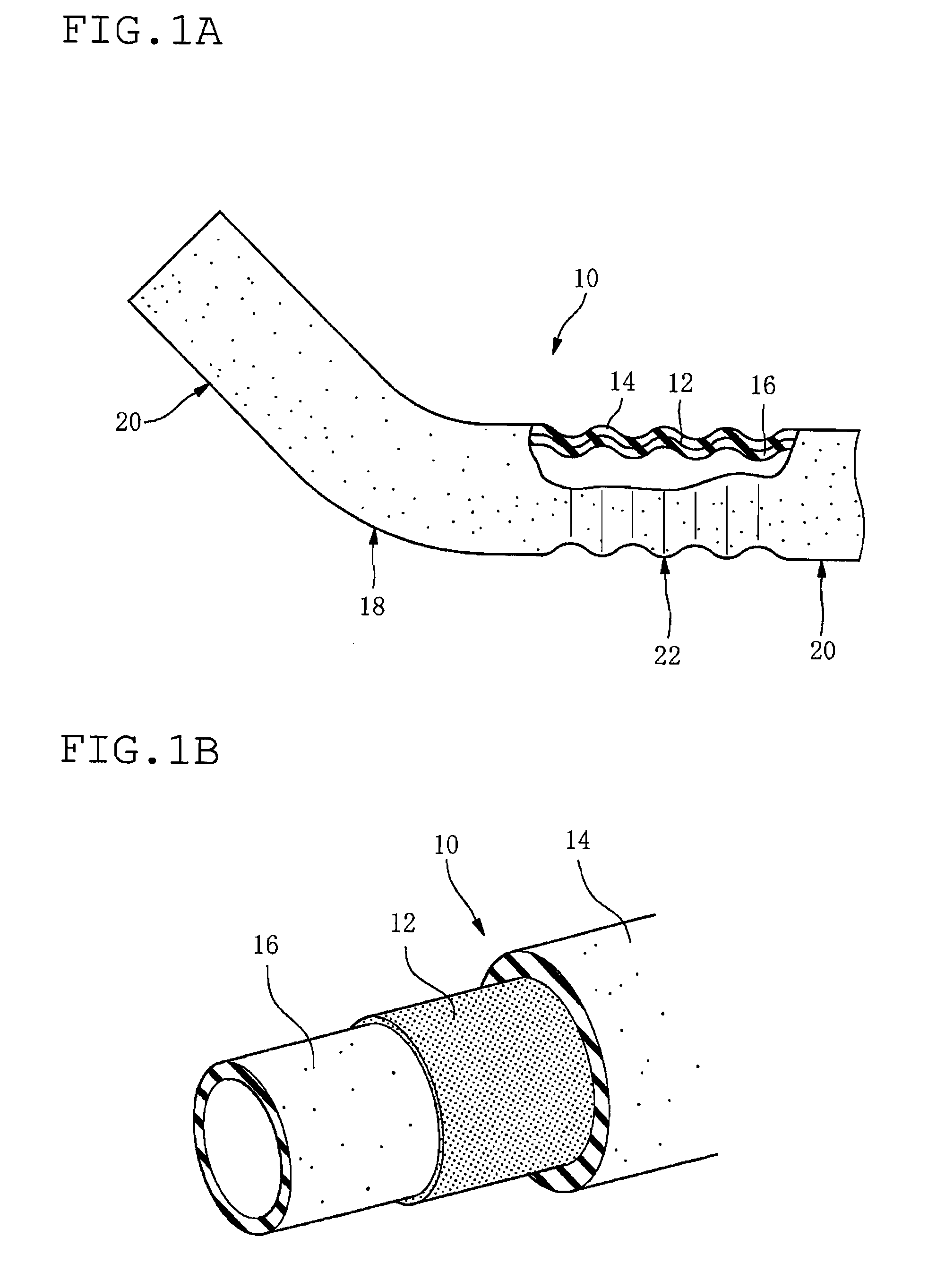

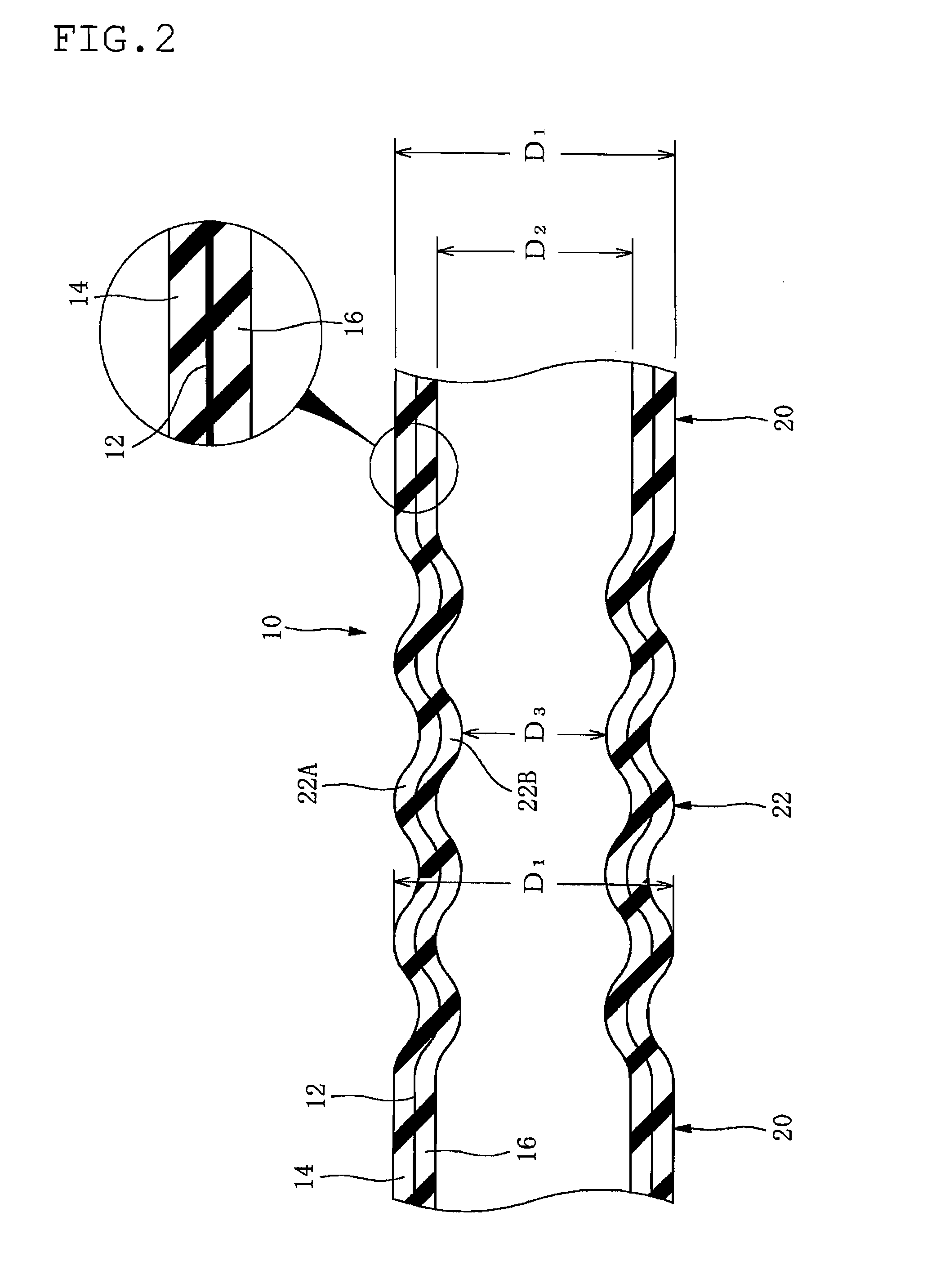

Corrugated Hose for Transporting Fluid and Method for Producing the Same

A corrugated hose for transporting a fluid has a multilayer construction including a resin layer as a barrier layer, an inner rubber layer and an outer rubber layer. The corrugated hose has a straight-walled portion, and a corrugated portion including corrugation valleys and corrugation hills, at least on one axial region of the corrugated hose. Each of the corrugation valleys has an inner diameter smaller than an inner diameter of the straight-walled portion, and each of the corrugation hills has an outer diameter equal to or smaller than an outer diameter of the straight-walled portion thereof.

Owner:SUMITOMO RIKO CO LTD

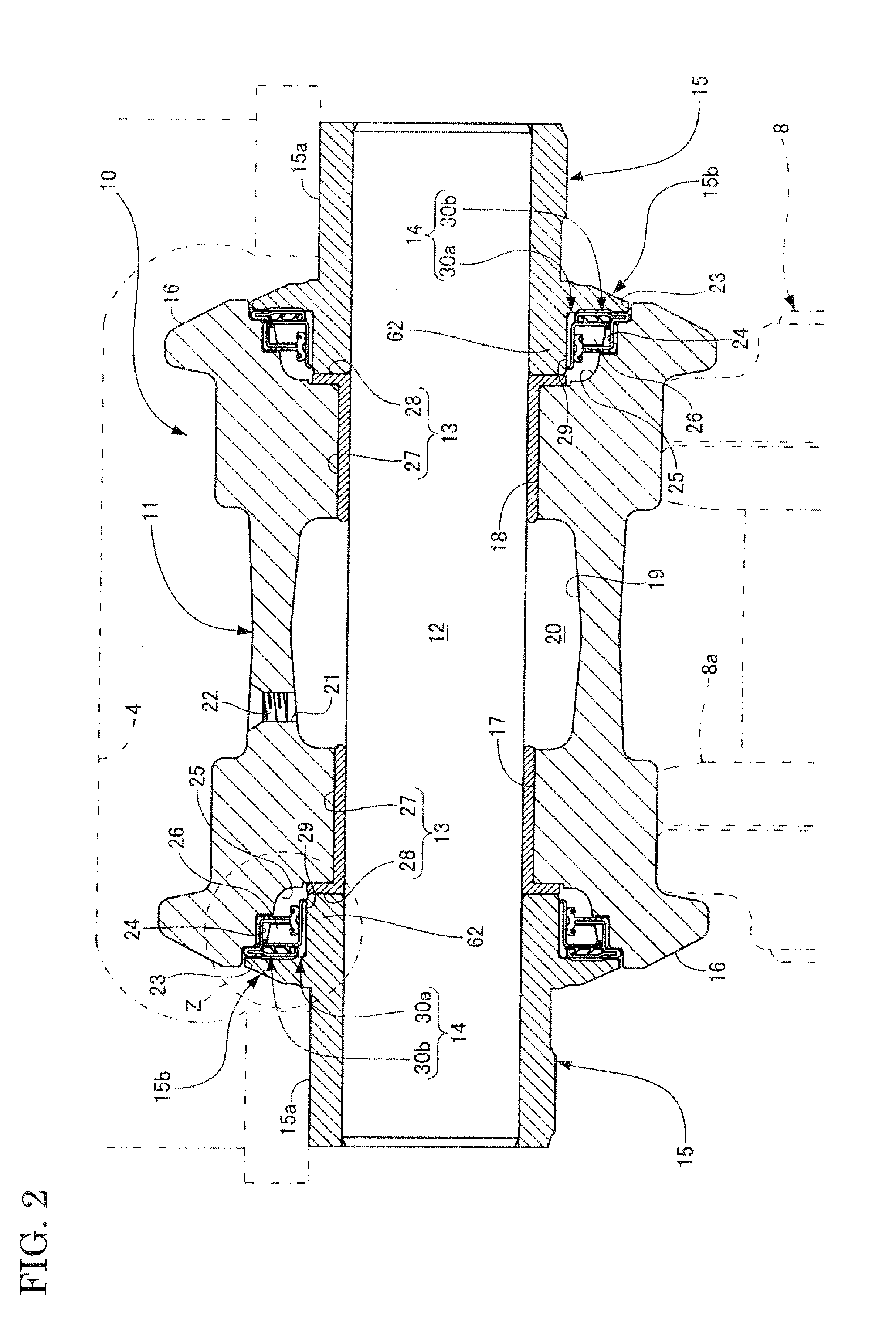

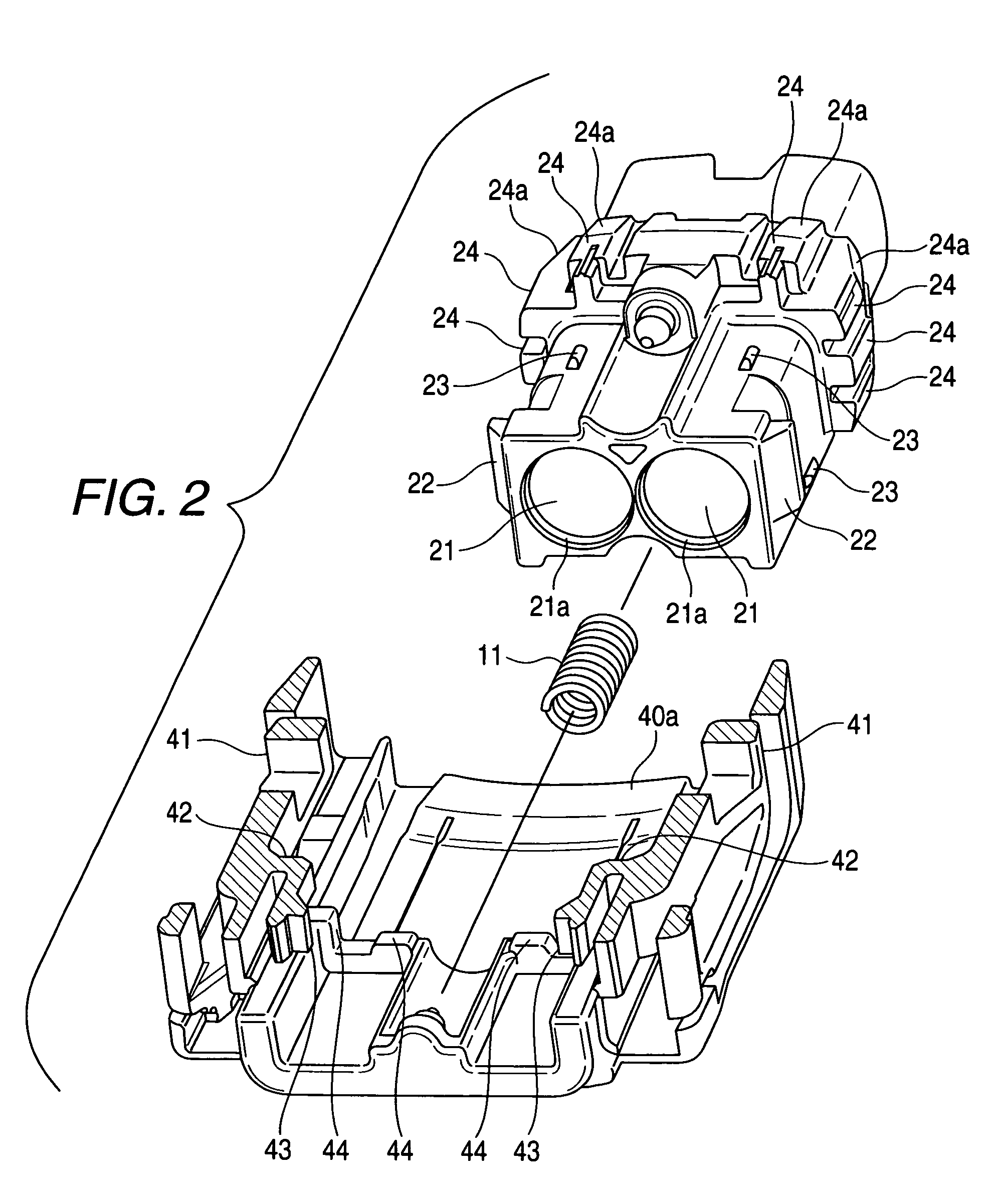

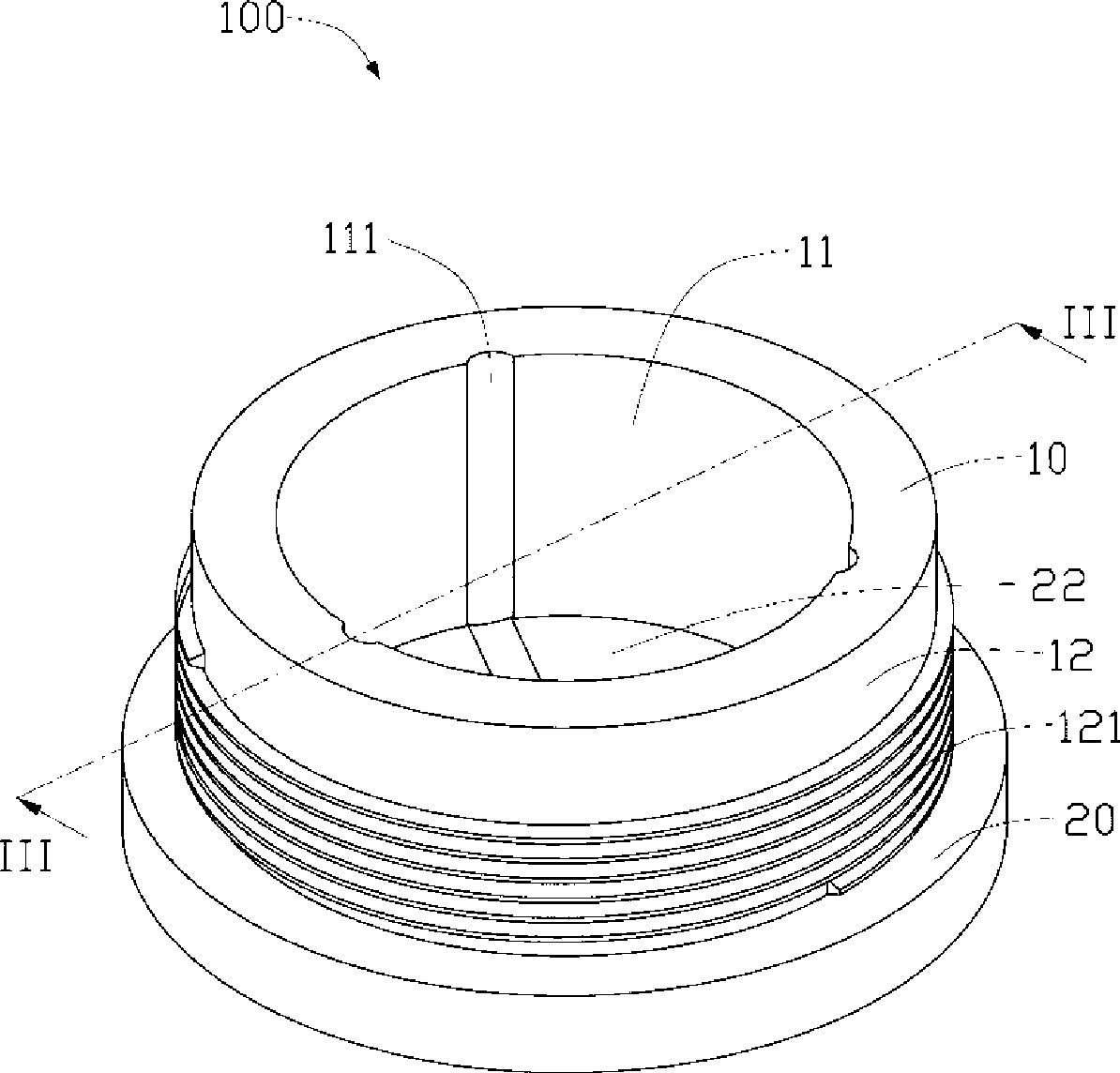

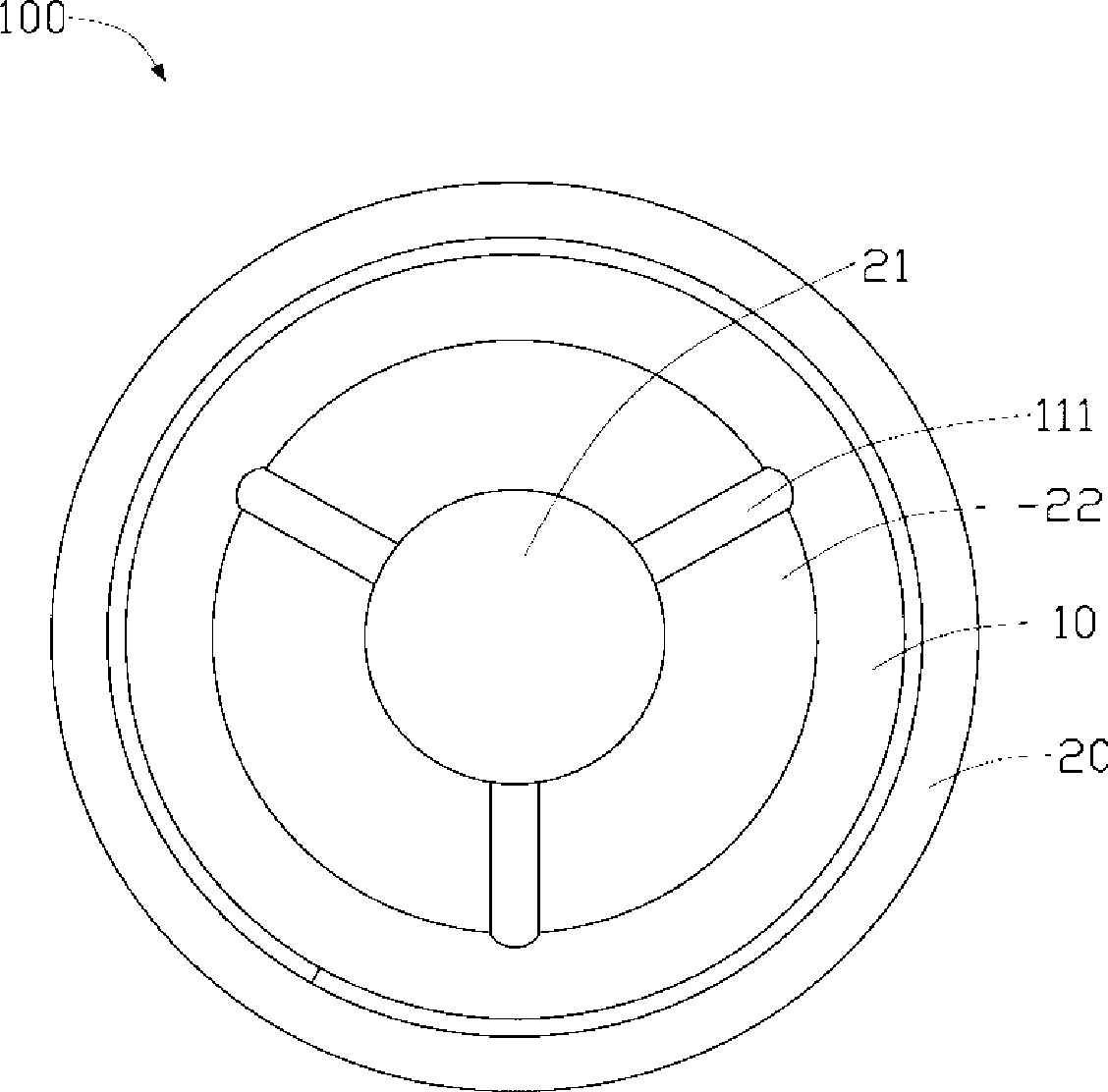

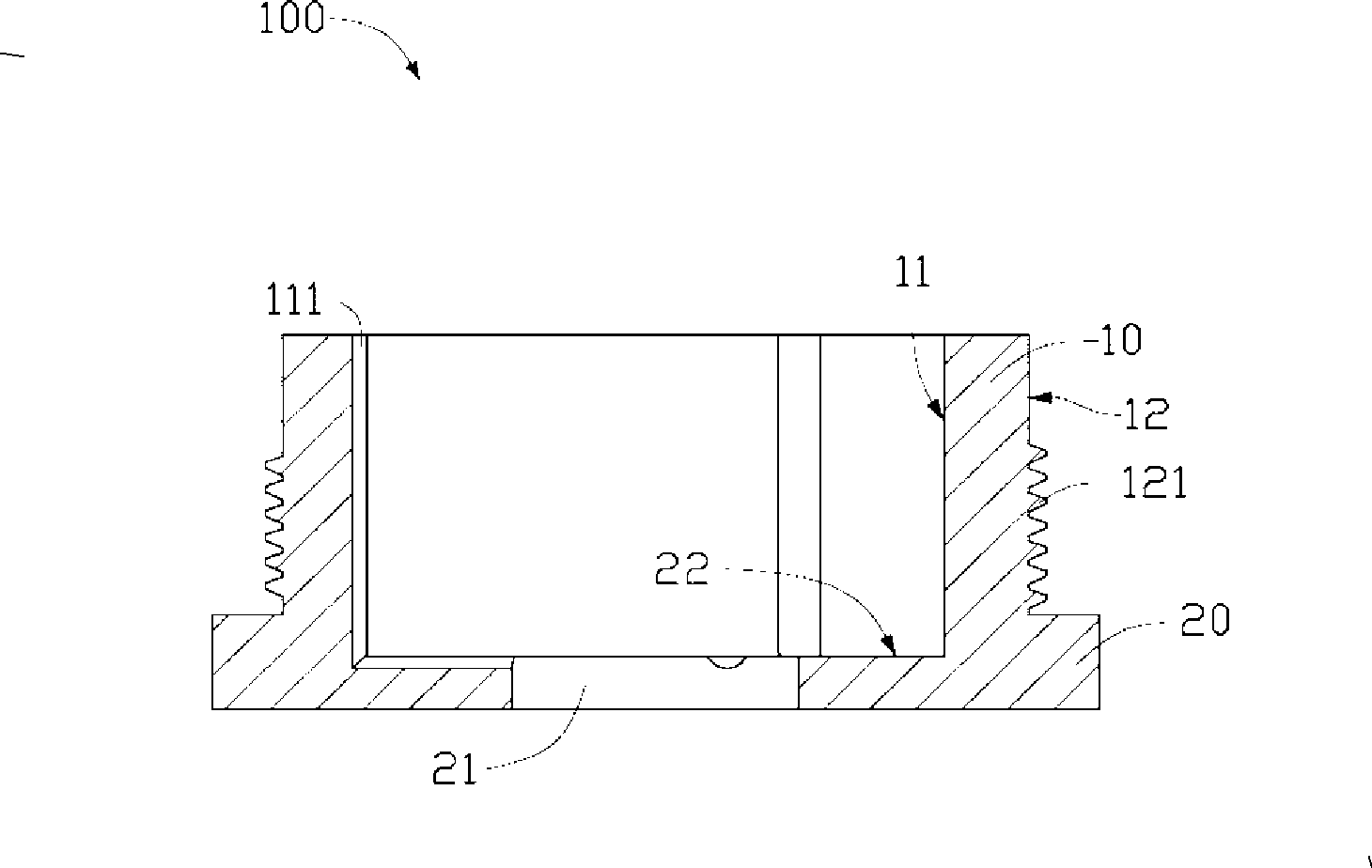

Roller unit

InactiveUS8979219B2Extended service lifePrevent penetrationControlling membersEngine sealsEngineeringFlange

A roller unit is provided which includes: (i) a roller configured to roll in contact with a crawler belt; (ii) a roller shaft for rotatably supporting the roller; (iii) a seal fit in an annular space defined between the roller and the roller shaft, wherein the seal is formed such that an inner circumference side sealing portion located on an inner circumference side and an outer circumference side sealing portion located on an outer circumference side and press-fit in the roller are fit together so as to come into slidable contact with each other; and (iv) a collar mounted to the roller shaft, wherein the collar has a boss portion onto which the inner circumference side sealing portion is pressed and a flange portion disposed on an atmosphere side of the inner circumference side sealing portion.A gap is formed between an end face of the outer circumference side sealing portion and the flange portion and the flange portion is provided with a circumferentially extending groove formed on a side opposed to the outer circumference side sealing portion. The outer circumference side sealing portion is disposed so as to enclose the inner circumference side sealing portion, and the flange portion is brought into contact with an end face of the inner circumference side sealing portion located on the atmosphere side of the inner circumference side sealing portion.

Owner:KOMATSU LTD

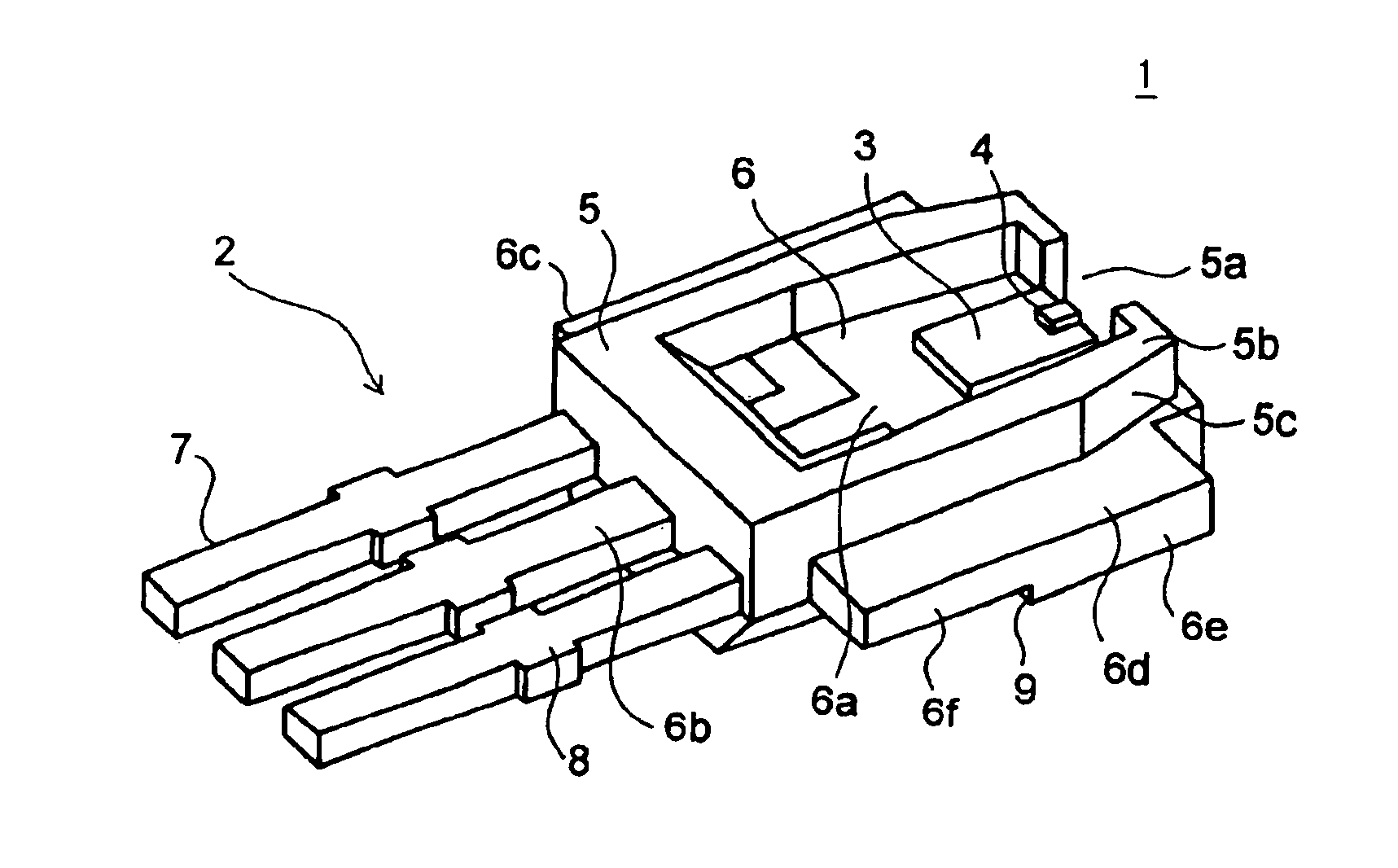

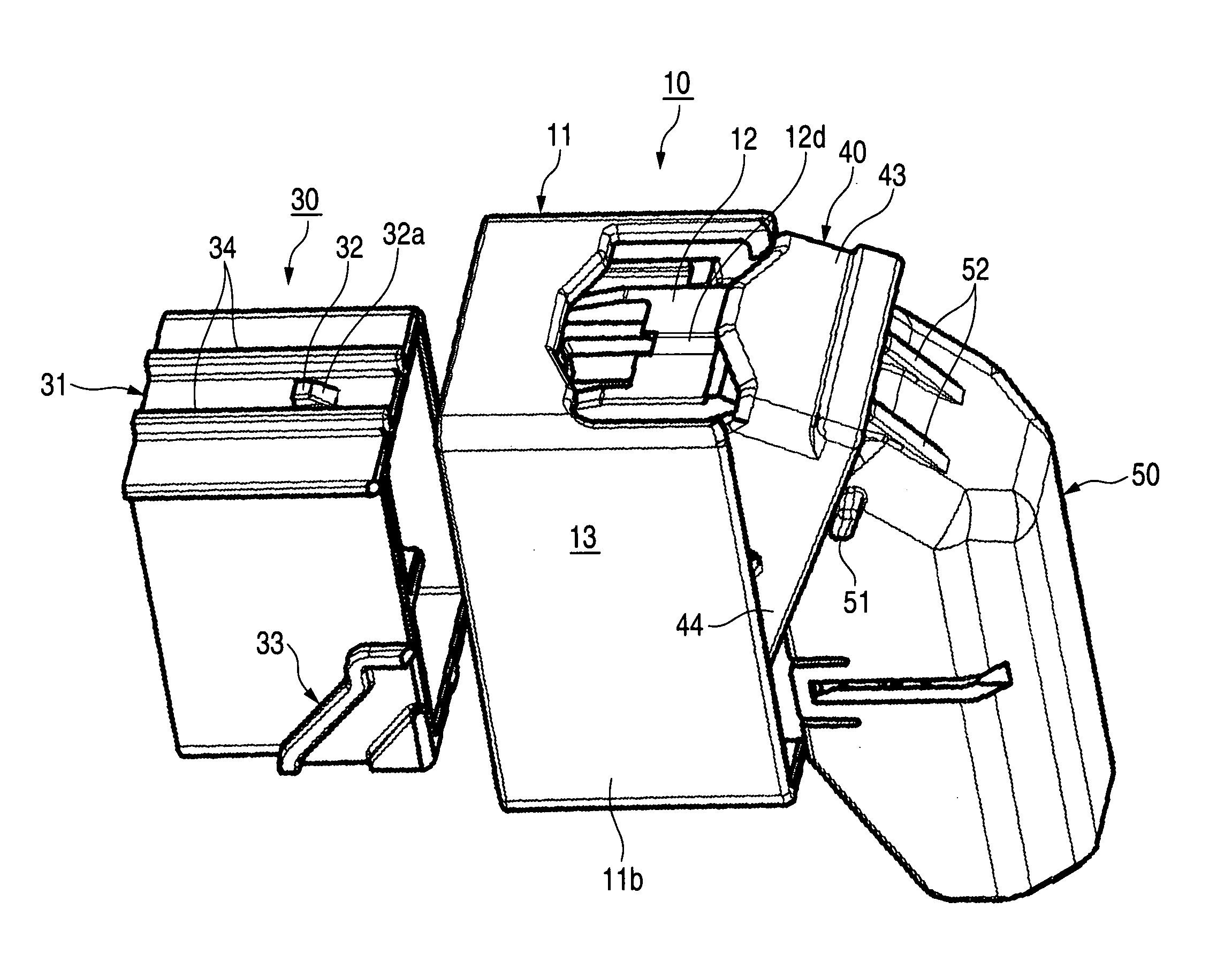

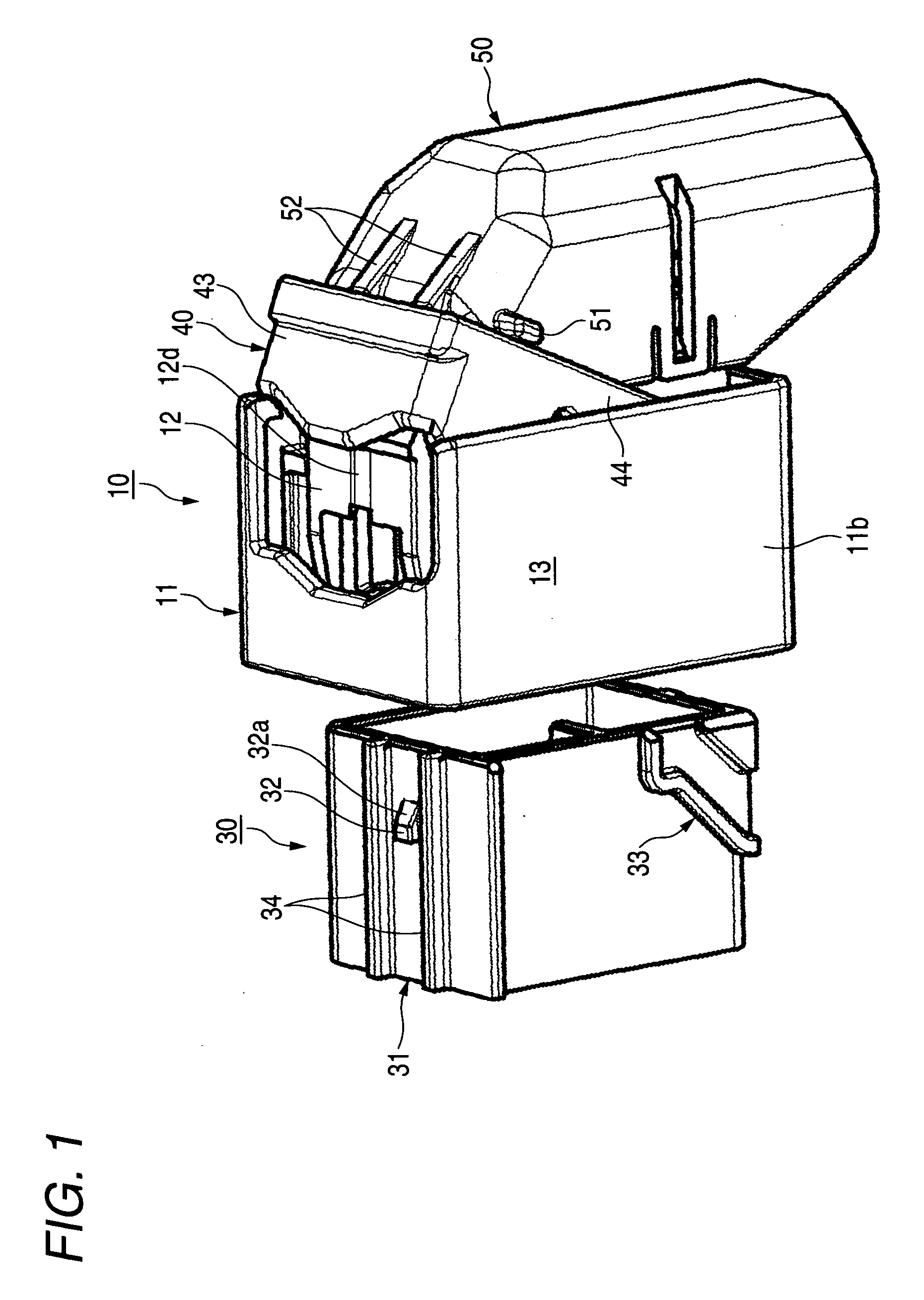

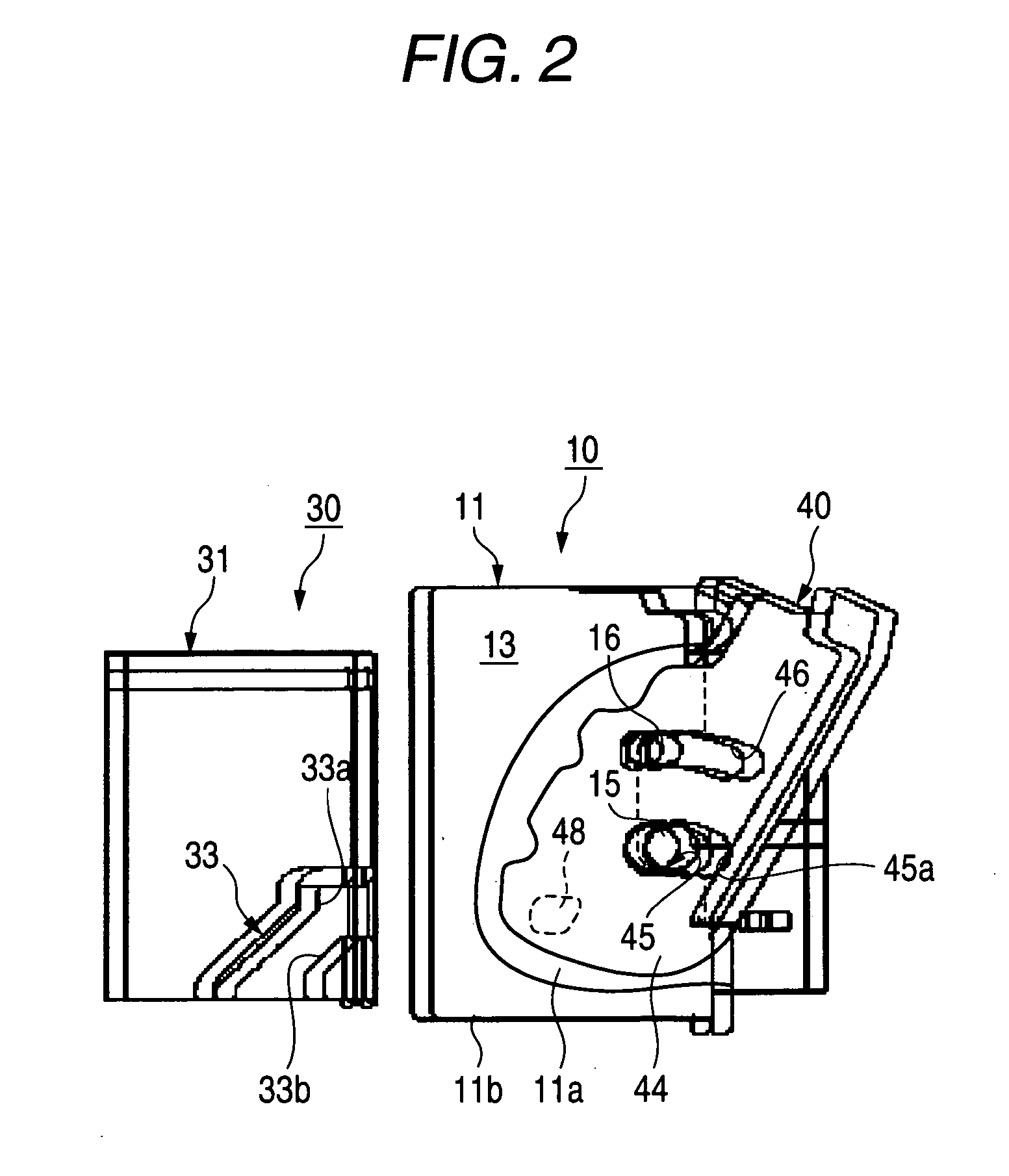

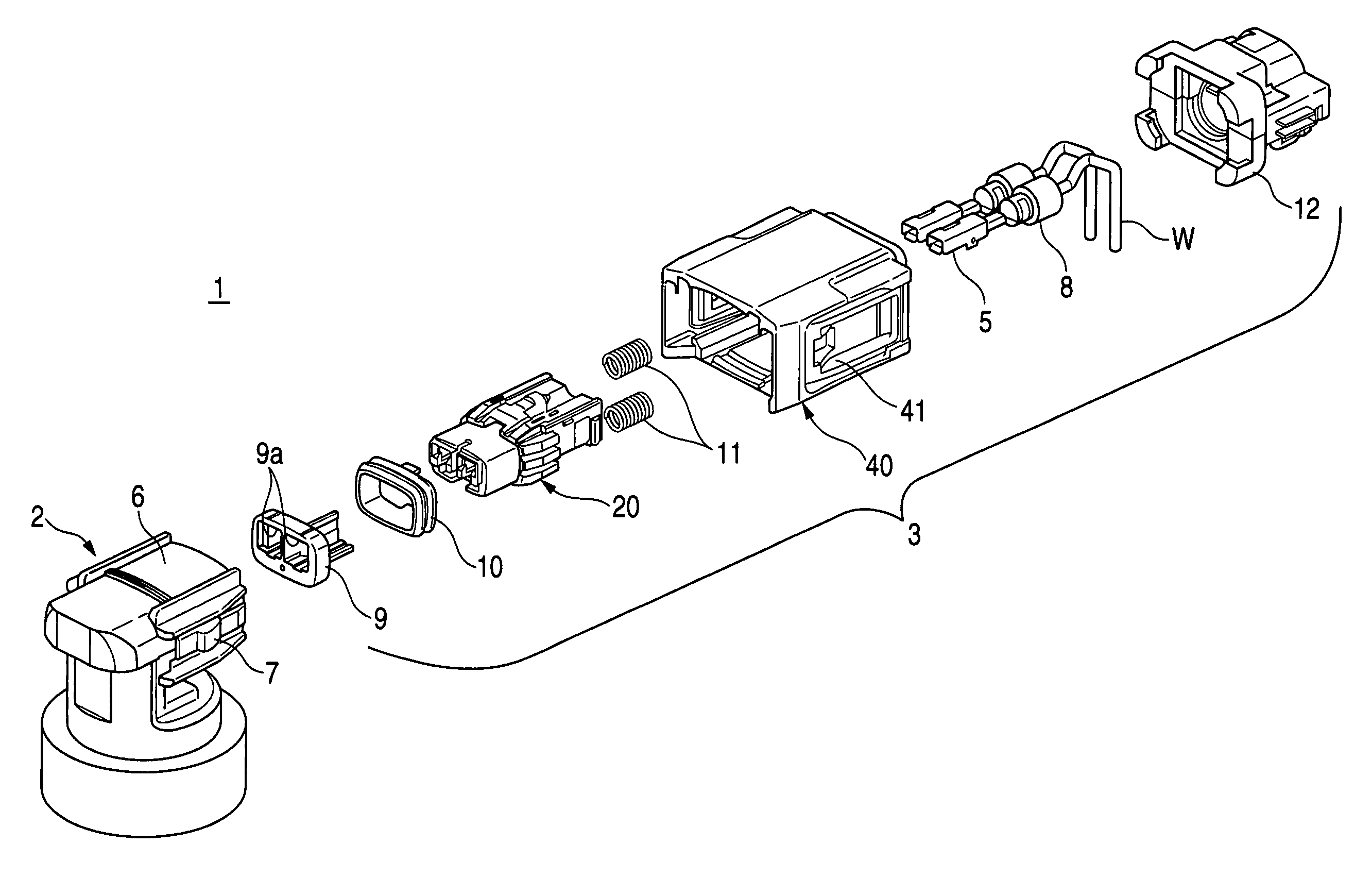

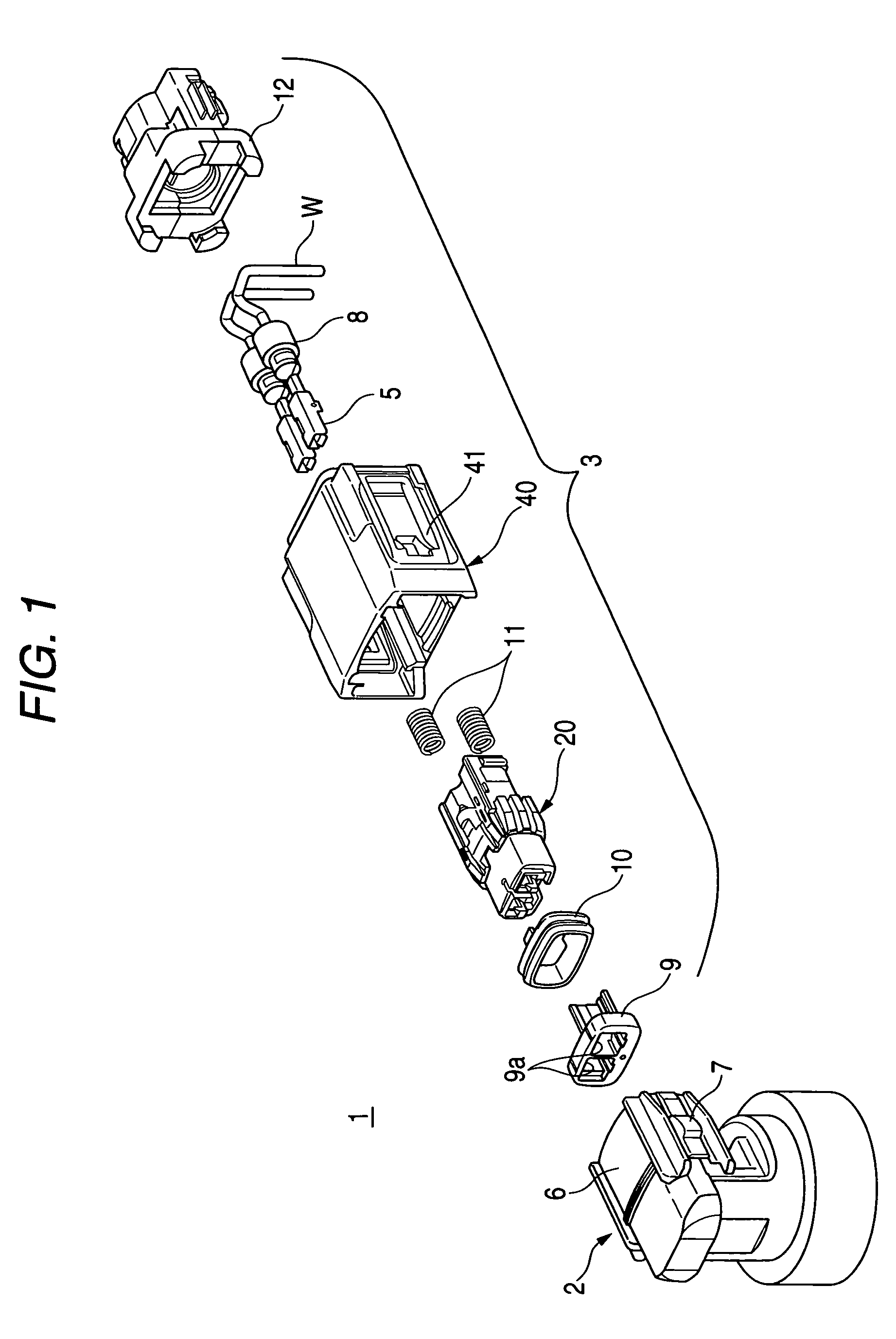

Connector fitting structure

ActiveUS20060270258A1Low costCompact designEngagement/disengagement of coupling partsClamped/spring connectionsEngineeringMechanical engineering

At a first stage of a pivotal movement of a lever, a housing-side boss slides in a fitting groove in the lever, and a fitting / disengagement projection is brought into abutting engagement with an engagement surface provided in a fitting / disengagement guide portion, and the boss is displaced to an abutment portion provided in the fitting groove. At a second stage of the pivotal movement, the lever is pivotally moved about the housing-side boss, and the fitting / disengagement projection is slid in and guided by the fitting / disengagement guide portion, so that a male connector can be completely fitted into a female connector.

Owner:YAZAKI CORP

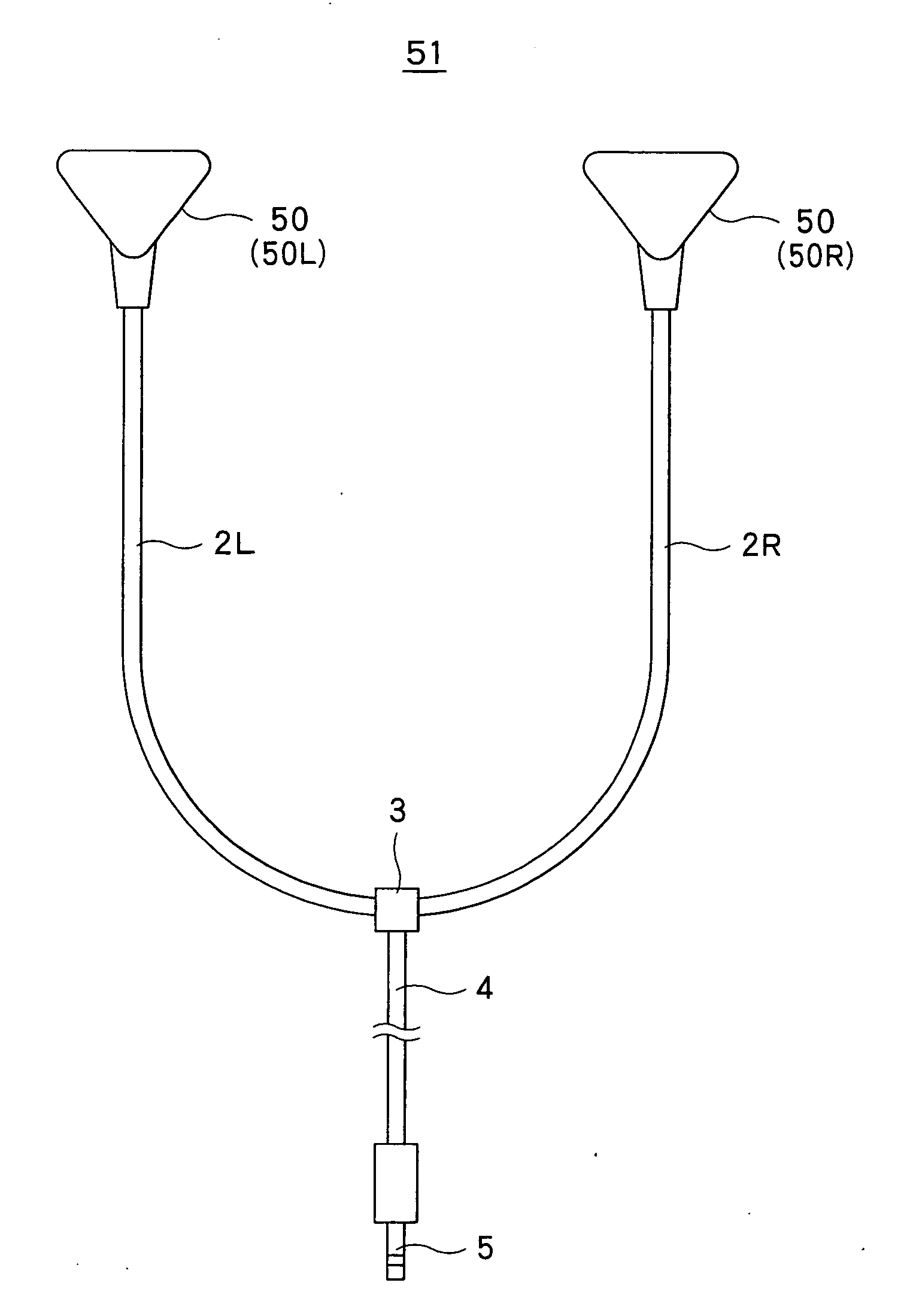

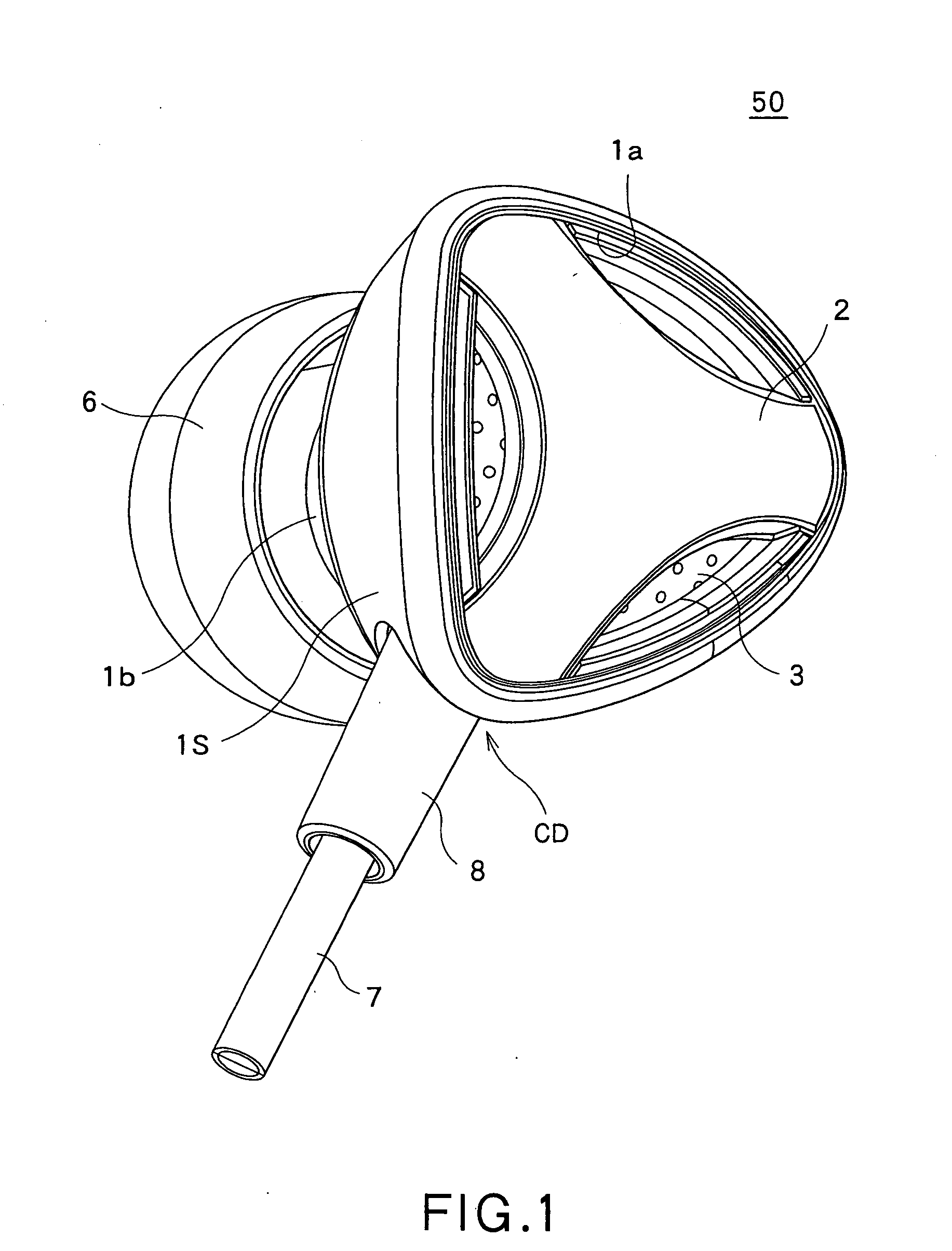

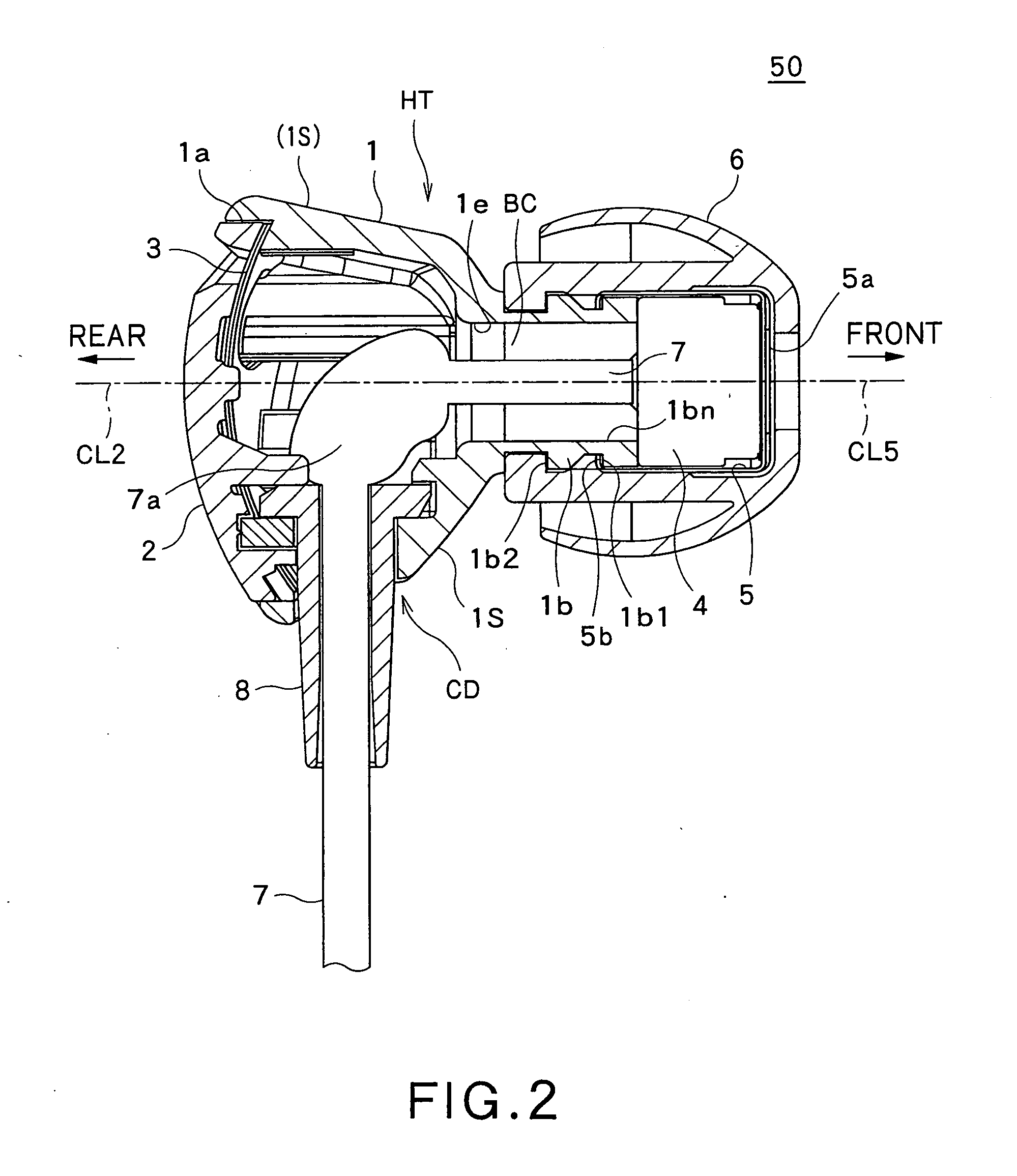

Headphone and stereo headphone

InactiveUS20110110543A1Fit evenlySupra/circum aural earpiecesLoudspeaker spatial/constructional arrangementsHeadphonesHorizontal and vertical

A headphone housing has a first and a second summit in cross section. A sound emitter protrudes from the housing in side section. In the cross section, the first summit protrudes as being away from a point of intersection of an axis line of the sound emitter, that is horizontal and vertical to the side and cross sections, respectively, and a first straight line going through a cord guide located in an outer edge of the cross section, in a first side with respect to the first line and in a second side far from the cord guide with respect to a second straight line going through the point and intersecting with the first line. The second summit protrudes as being away from the point in the second side and in a third side, the opposite of the first side with respect to the first line.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

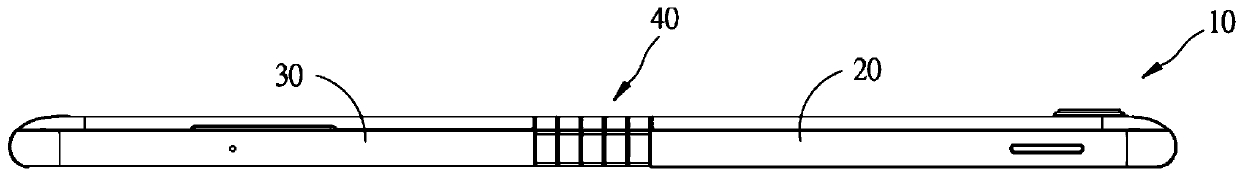

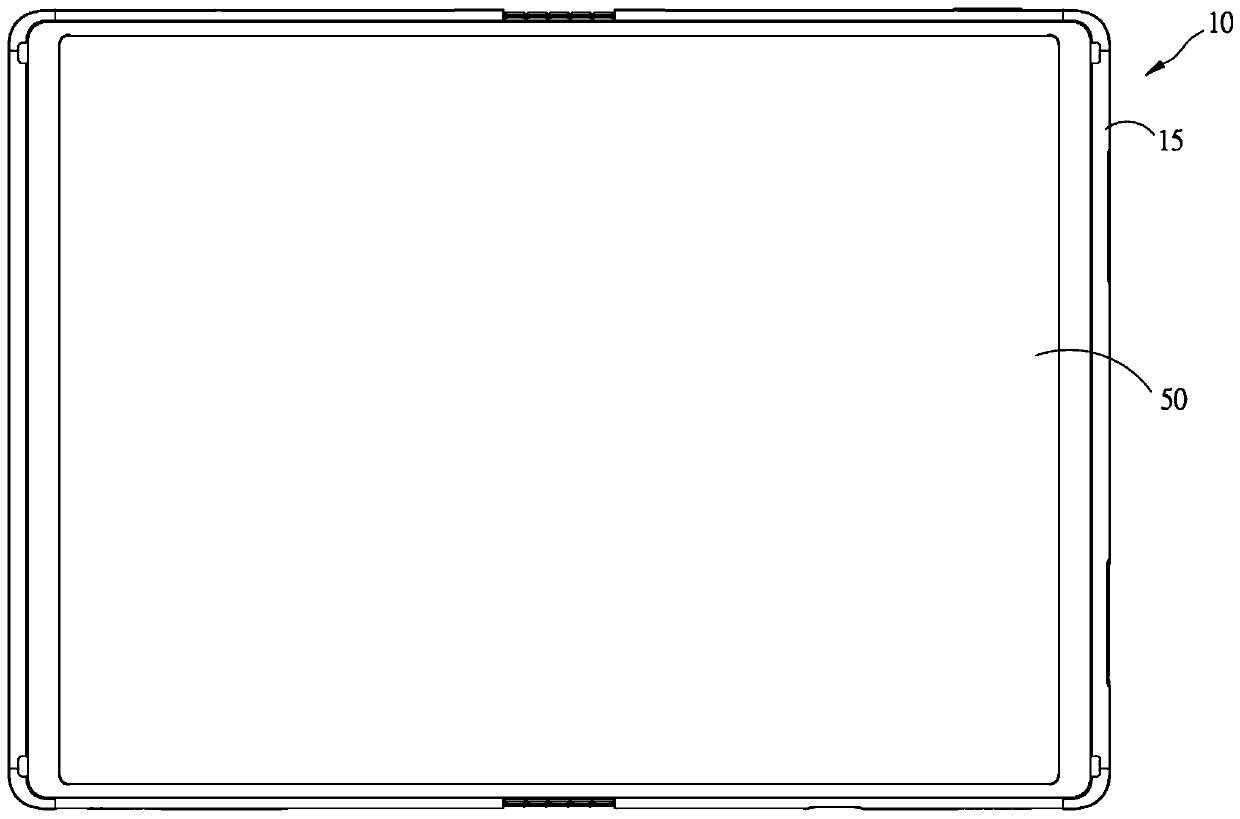

Foldable display device

ActiveCN109949707AReduce bending performance requirementsEasy to carryCasings with display/control unitsDetails for portable computersDisplay deviceLarge screen

The invention provides a foldable display device which comprises a machine body, a main display screen and an auxiliary display screen, wherein the main display screen and the auxiliary display screenare connected through a folding mechanism, and then folding and unfolding of the main display screen and the auxiliary display screen can be achieved; and after being unfolded, the main display screen and the auxiliary display screen are combined as a large screen.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

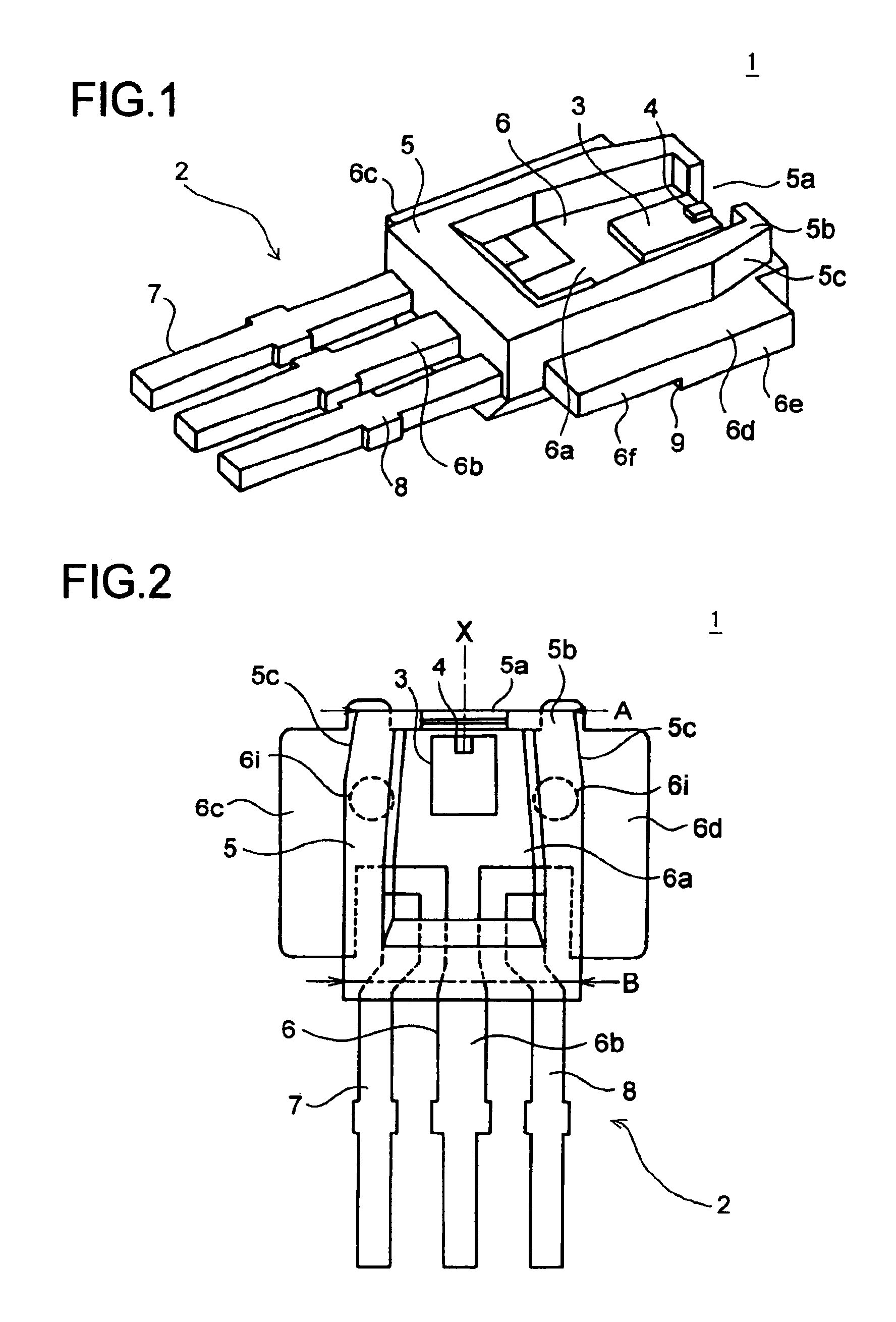

Connector

ActiveUS7572135B2Reduce wearReduce loadIncorrect coupling preventionEngineeringMechanical engineering

Owner:YAZAKI CORP

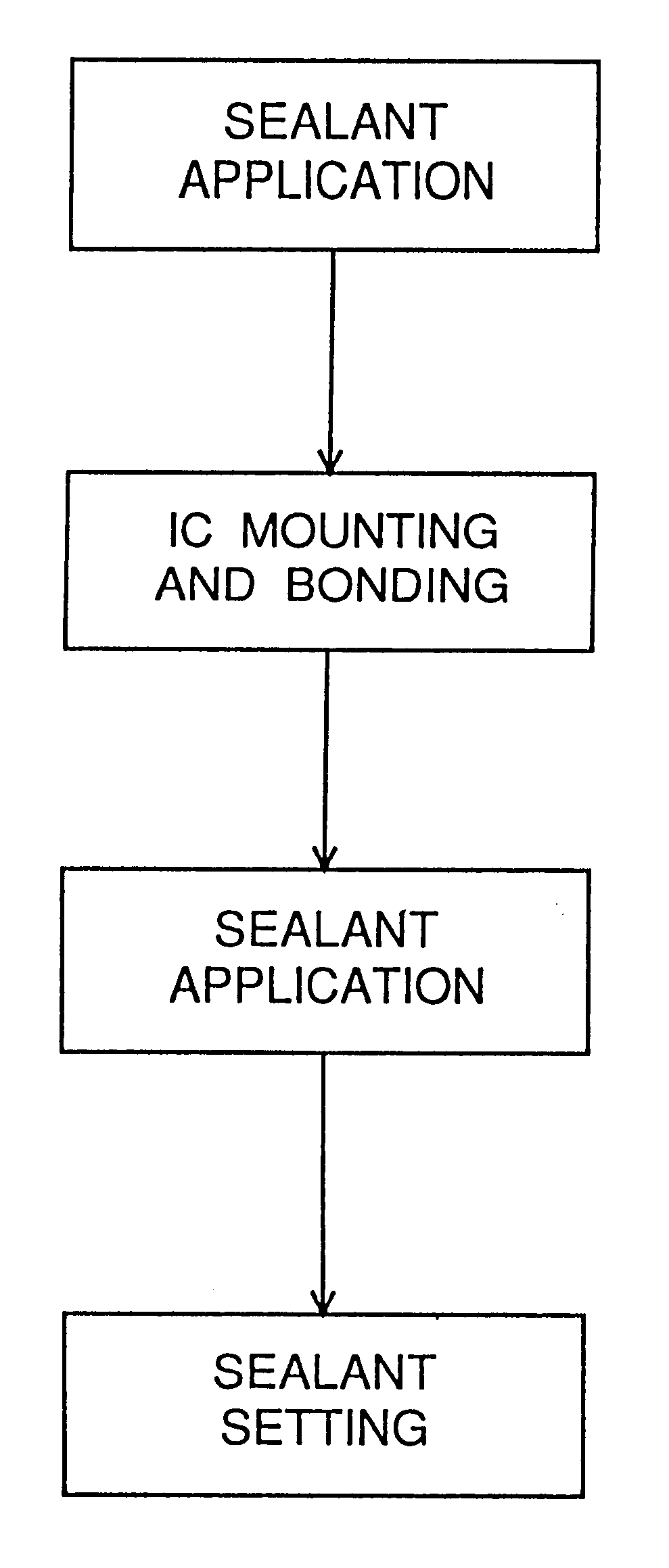

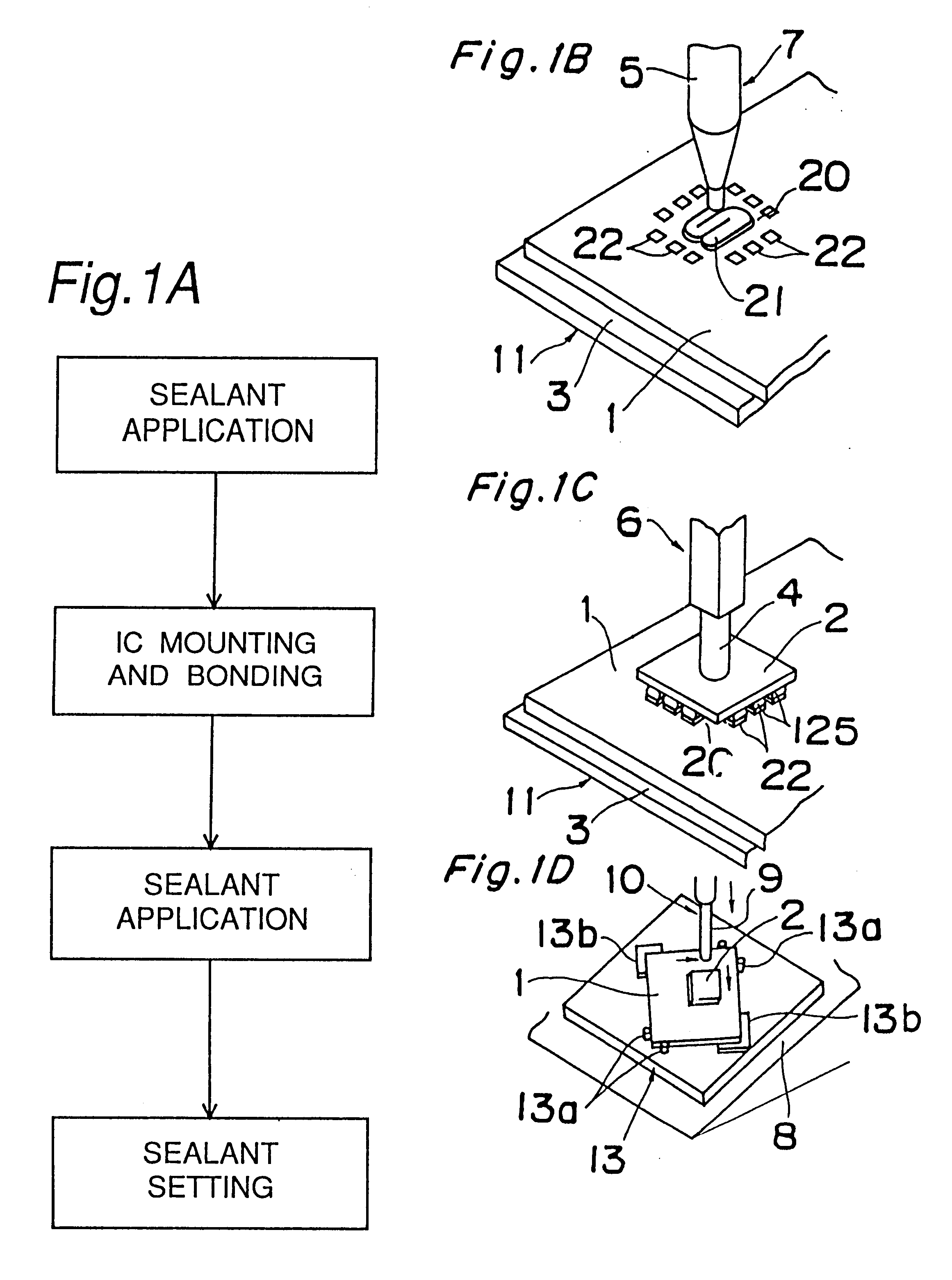

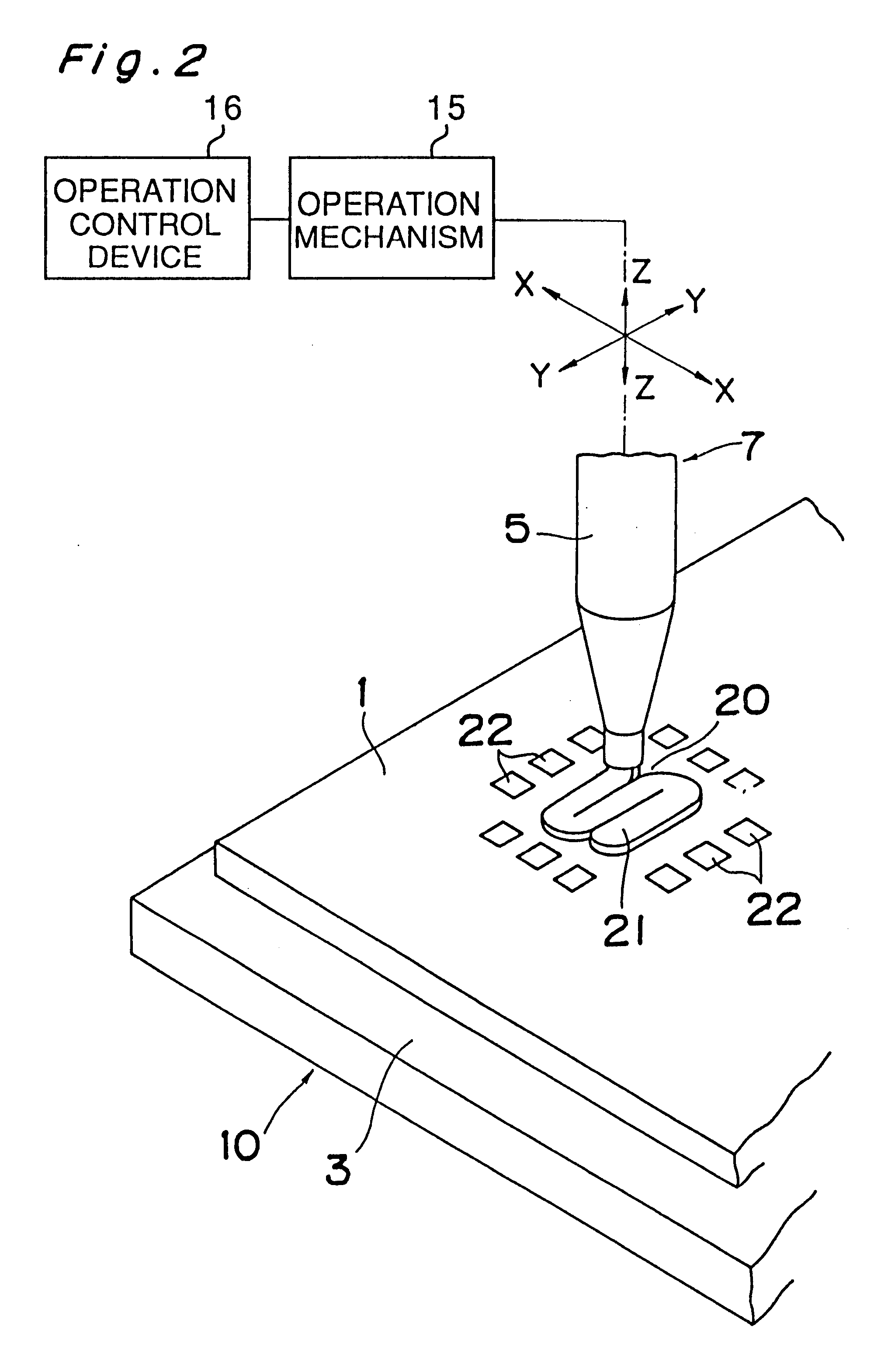

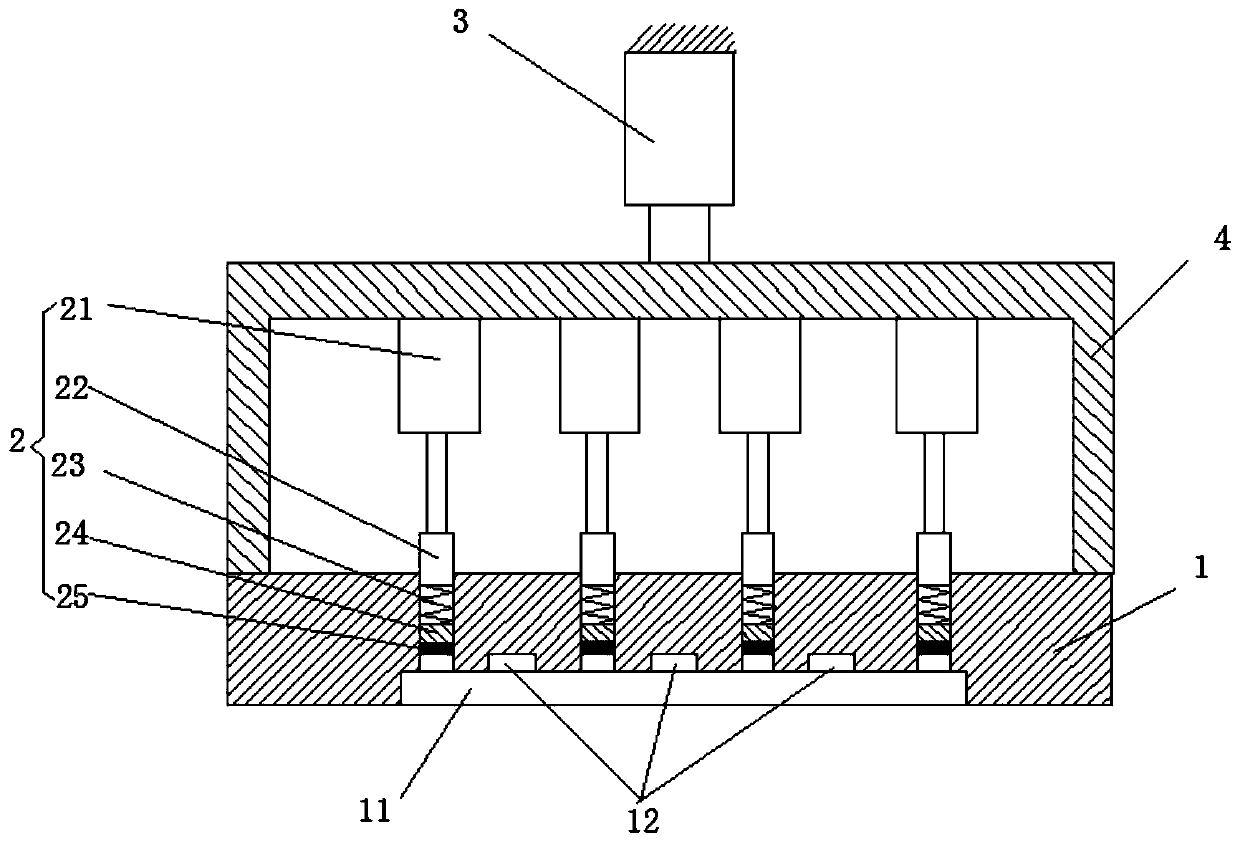

Apparatus for mounting an electronic component

InactiveUS6206066B1Quickly and sufficiently and forcibly appliedShorten production timeLiquid surface applicatorsManual label dispensersEngineeringElectronic component

A method of and apparatus for mounting an electronic component at a specified position of an object. The method includes applying a sealant in a first application process. The sealant is quickly, sufficiently and forcibly applied in the first application process simply by avoiding electrodes at the arrangement position, and tightly contacting the arranged electronic component and the object. Then the bonding of the electrodes is performed in the usual manner. A second application process is carried out by applying a sealant to the periphery of the electronic component in the same manner as in the convention method, which is sufficient to cause the sealant to flow to the sealant previously applied under the electronic component. The second application process can be accordingly conducted speedily and sufficiently. Air bubbles will not be trapped between the electronic component and the object, with the result that mounting failures due to breakage or corrosion of the electronic component can be reduced. Only a short period of time is required to apply the sealant even though it is applied twice, so that production time is shortened and production efficiency is improved.

Owner:PANASONIC CORP

Shoe sole positioning device

Owner:JIHUA LAB

Connector

ActiveUS20060240716A1Reduce wearReduce loadIncorrect coupling preventionCoupling device detailsEngineeringMechanical engineering

Owner:YAZAKI CORP

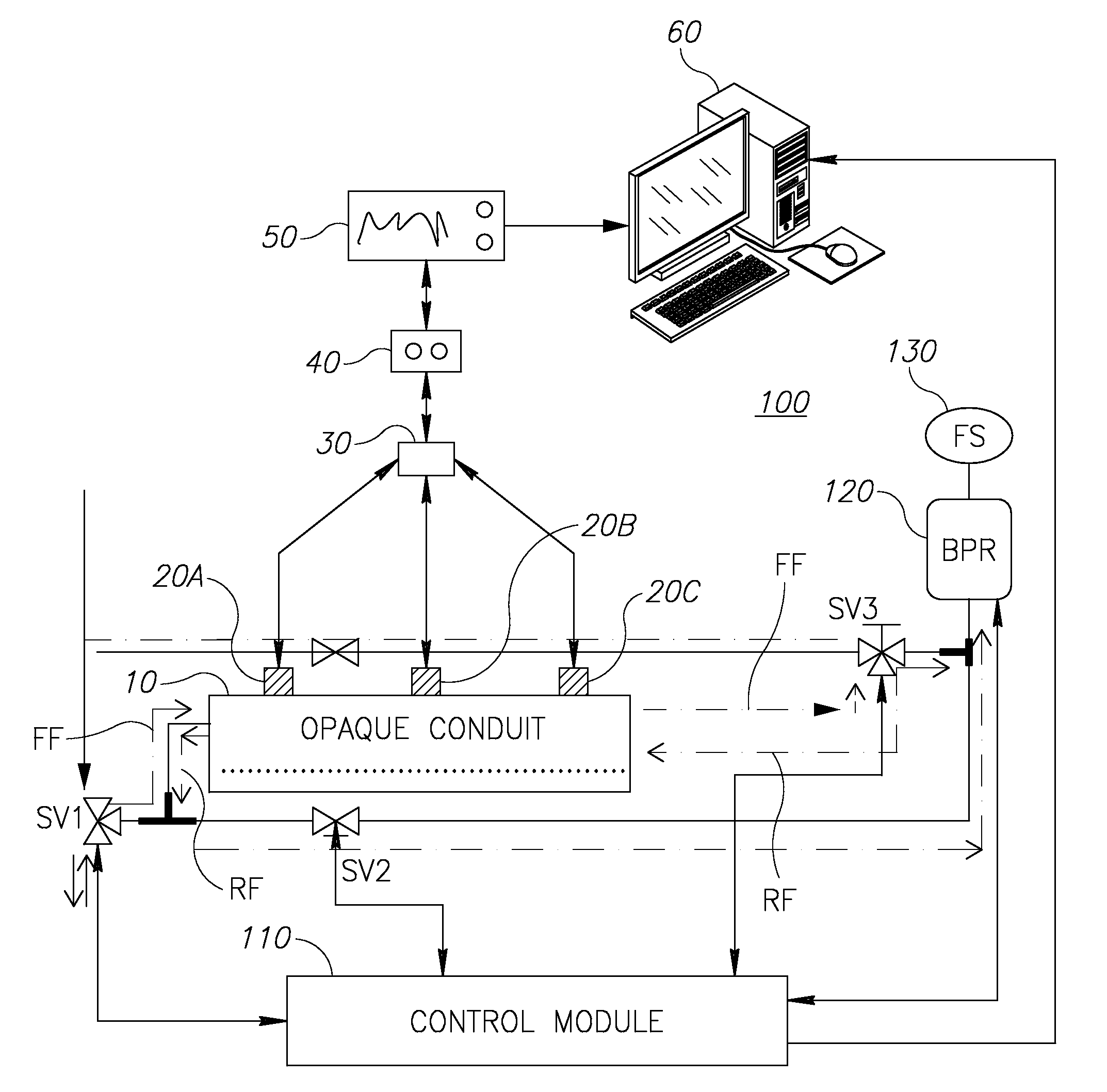

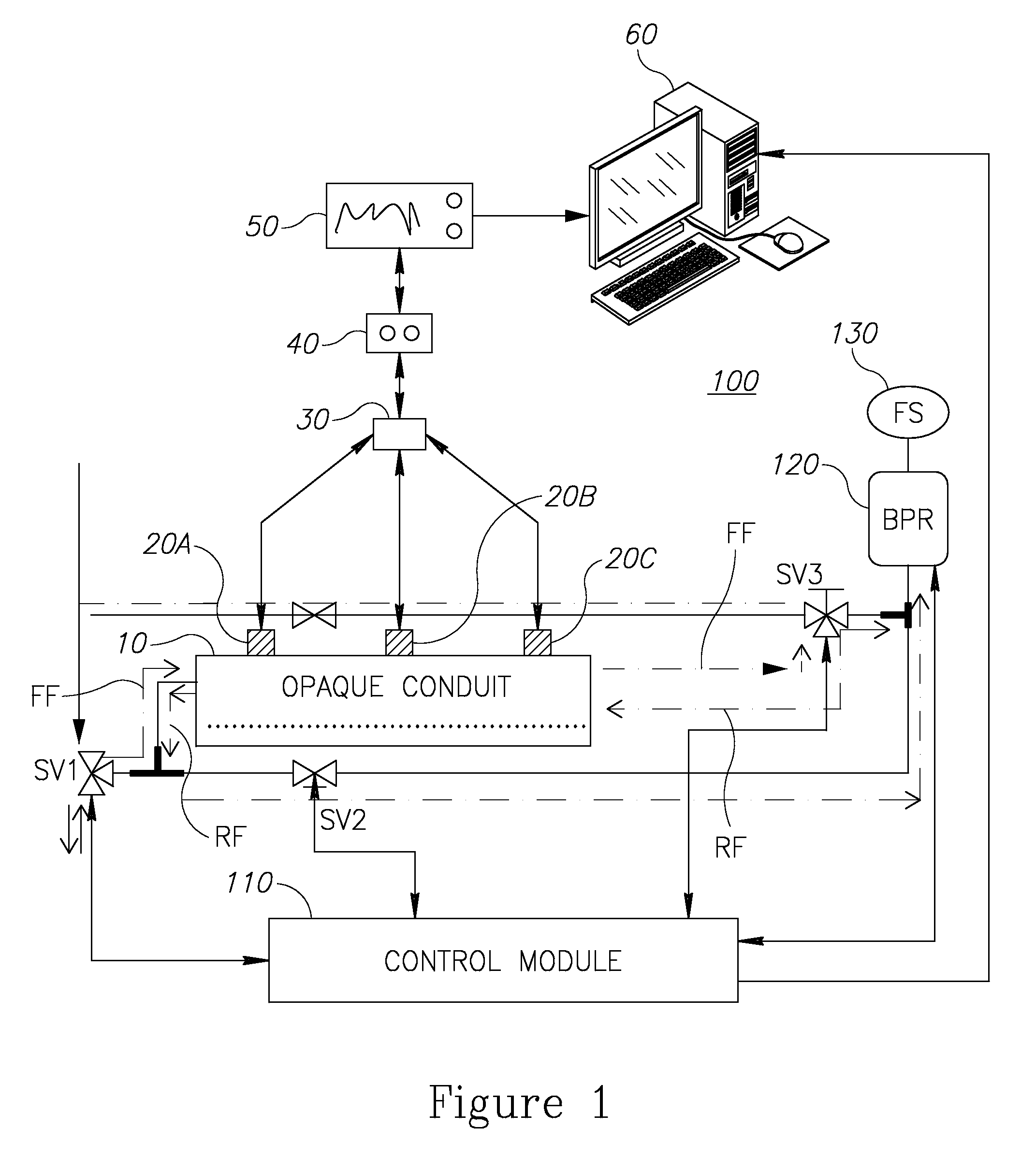

Analyzing ultrasonic signals using a dynamic window for an early detection of scaling in water processing equipment

ActiveUS20130238133A1Fit evenlySampled-variable control systemsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMoving averageEngineering

A method of early detection of scaling on internal surfaces of conduits of water processing equipment, is provided herein. The method includes: transmitting ultrasonic signals through the wall of the conduits; deriving data samples from received ultrasonic signals or reflections thereof; calculating a moving average of the scatter of the ultrasonic signals, over time, based on the data samples; applying a statistical operand to the moving average, to yield a statistical distribution metric; determining a dynamic window defined by: (i) an upper boundary being the moving average plus at least a fraction of the statistical distribution metric and (ii) a lower boundary being the moving average minus the at least a fraction of the statistical distribution metric; generating a trend line being a smooth fitting of the derived samples; and monitoring the trend line within the window to detect a crossover of the trend line at either of the boundaries.

Owner:UNIV OF COLORADO THE REGENTS OF +1

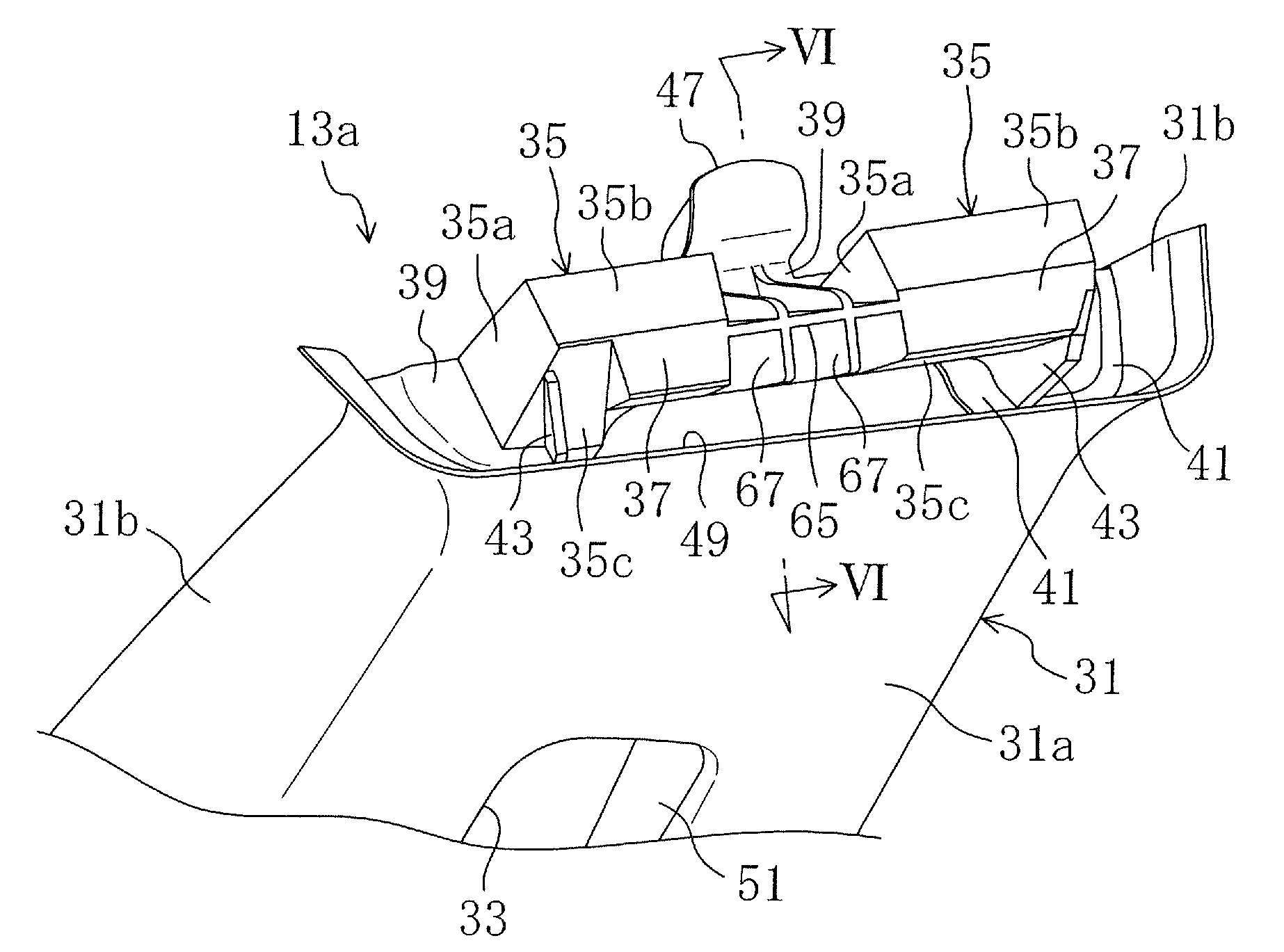

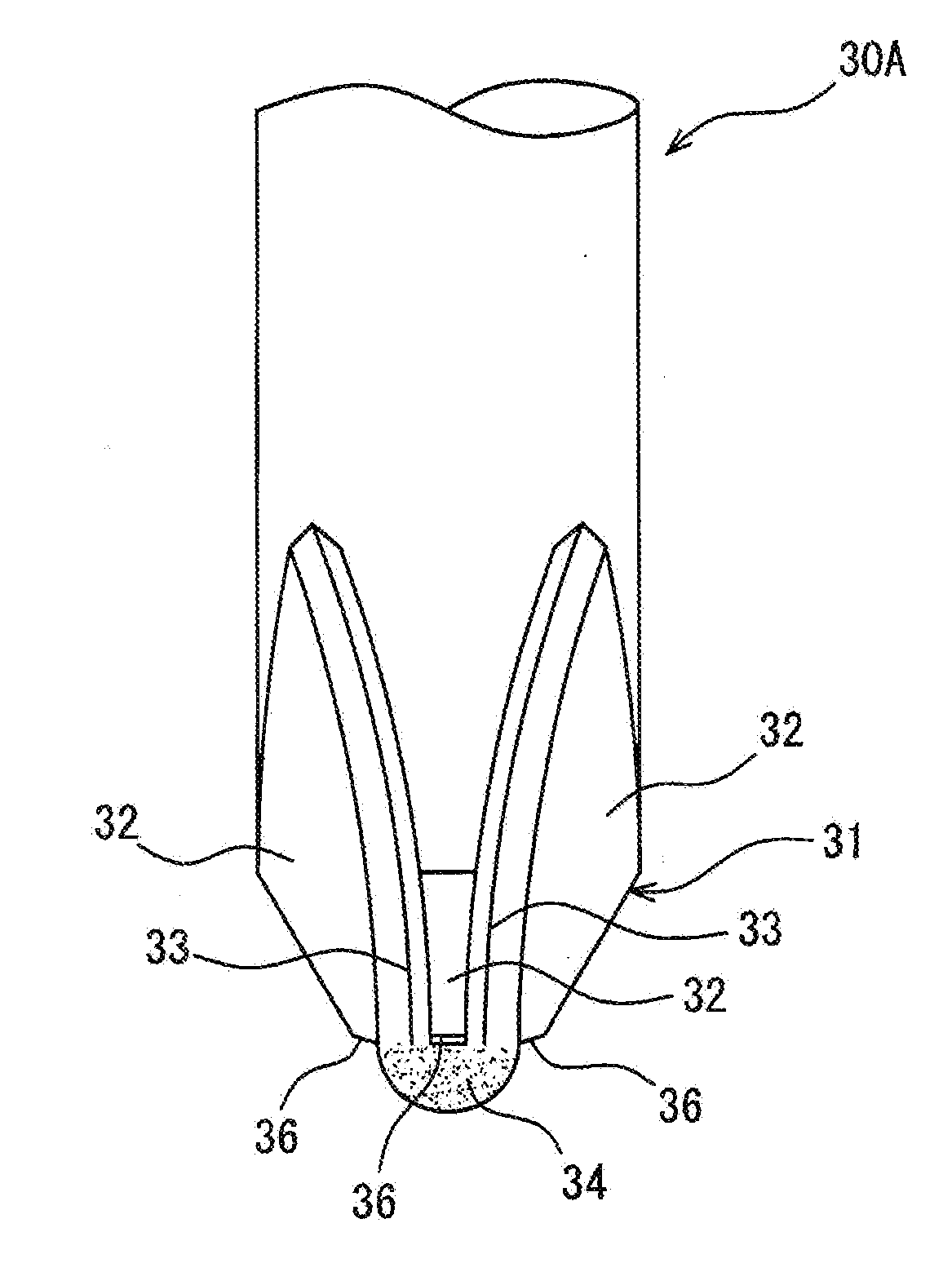

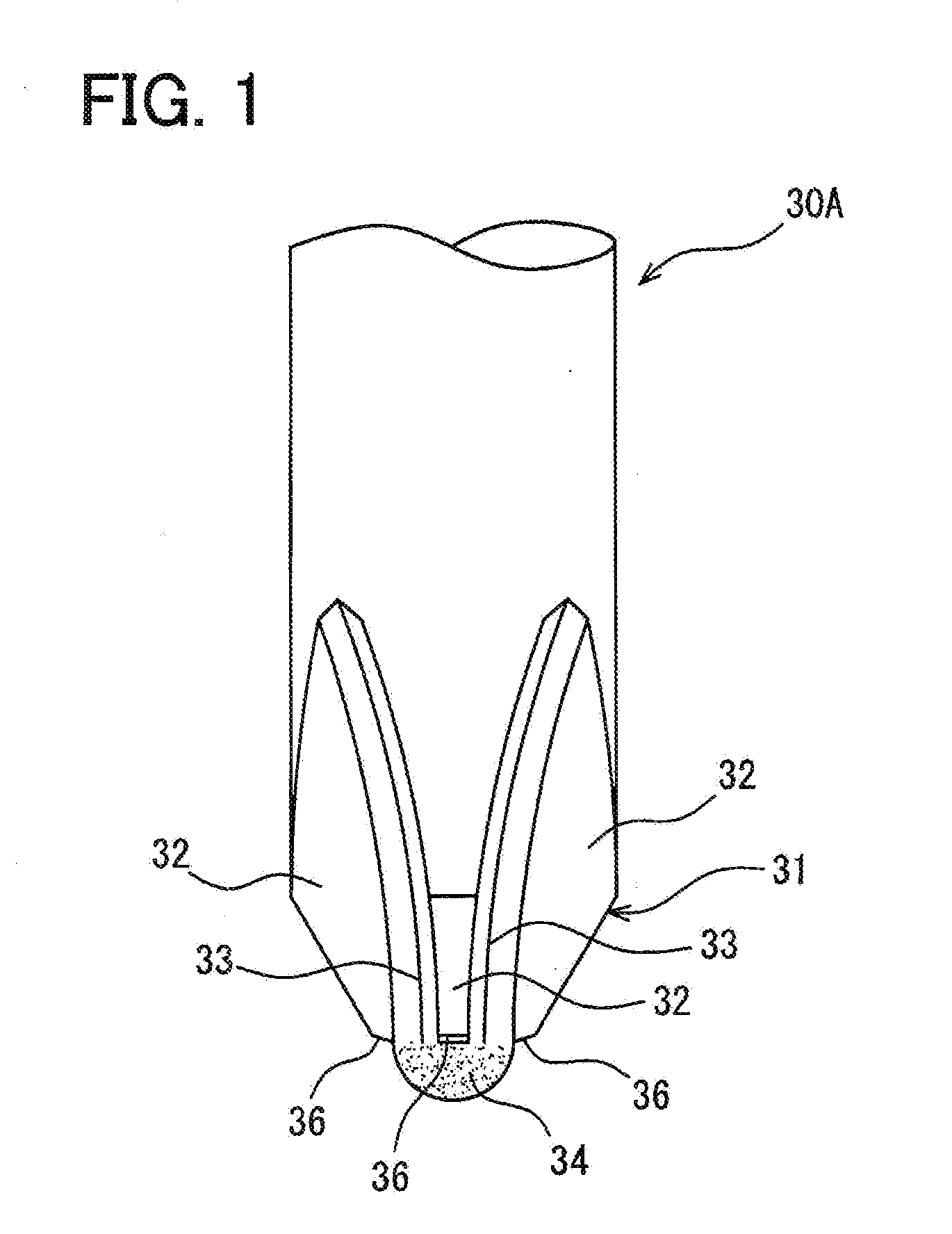

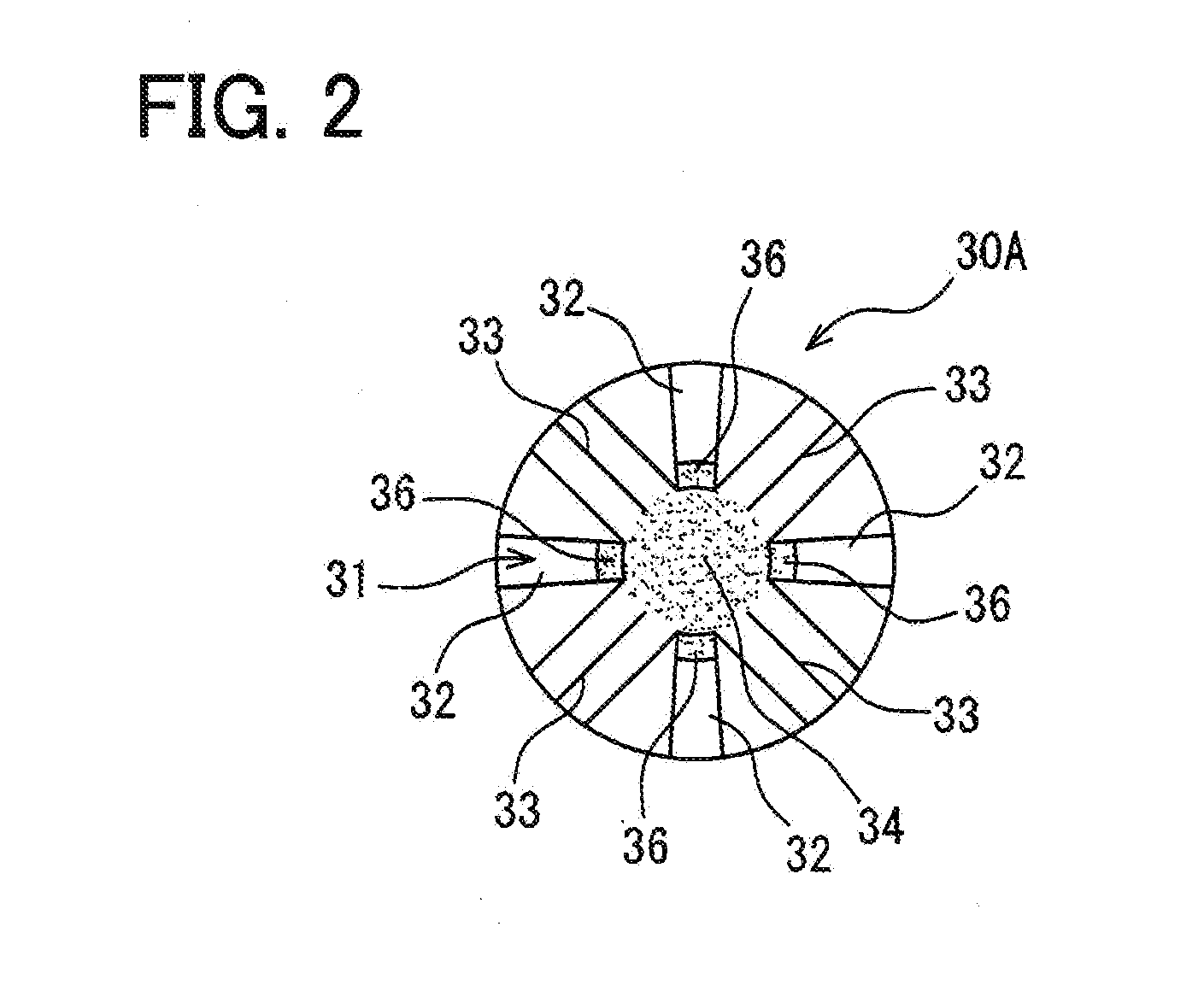

Screwdriver Bit

InactiveUS20120285301A1Promote efficiency and safetyPrevent occurrence of damageSpannersWrenchesDrill bitEngineering

A screwdriver bit configured in such a way that when the tip of the screwdriver bit is to be fitted into a bit fitting groove of a screw, said bit fitting groove being formed on the top surface of the head of the screw, then damage is prevented from occurring on the top surface of the head of the screw, and proper fitting of the tip of said bit into the bit fitting groove is promptly and smoothly accomplished, with the result that the efficiency and safety of screw tightening work are significantly enhanced. This driver bit (30) is provided with a cross-shaped tip edge which is to be fitted into the bit fitting groove provided on the top surface of the head of the screw, said bit fitting groove consisting of a cross-shaped groove. In this driver bit (30), the tip surface of said tip edge (31) is formed as a whole into a spherical surface shape (34) by means of planishing.

Owner:TOTSU KATSUYUKI

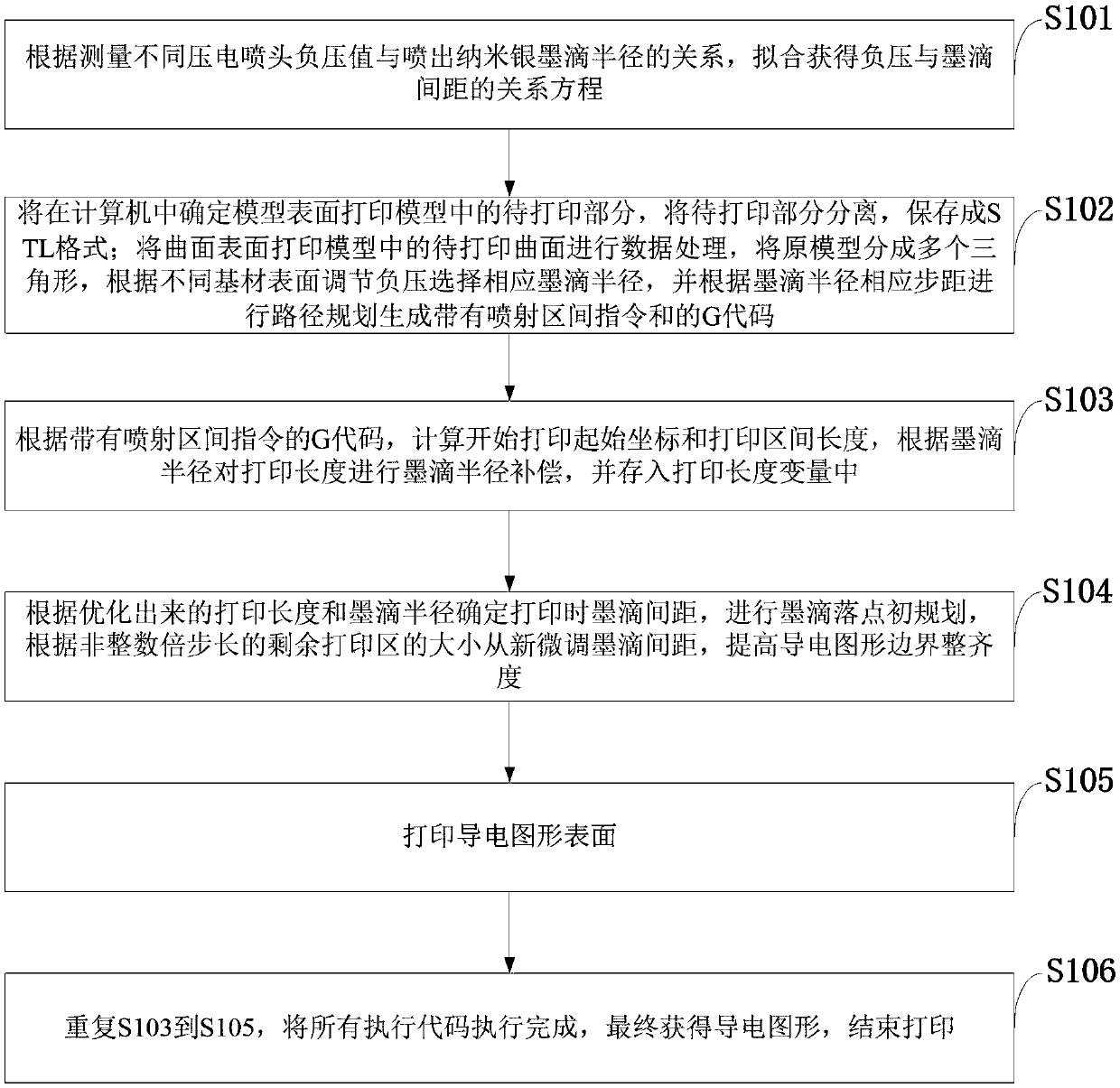

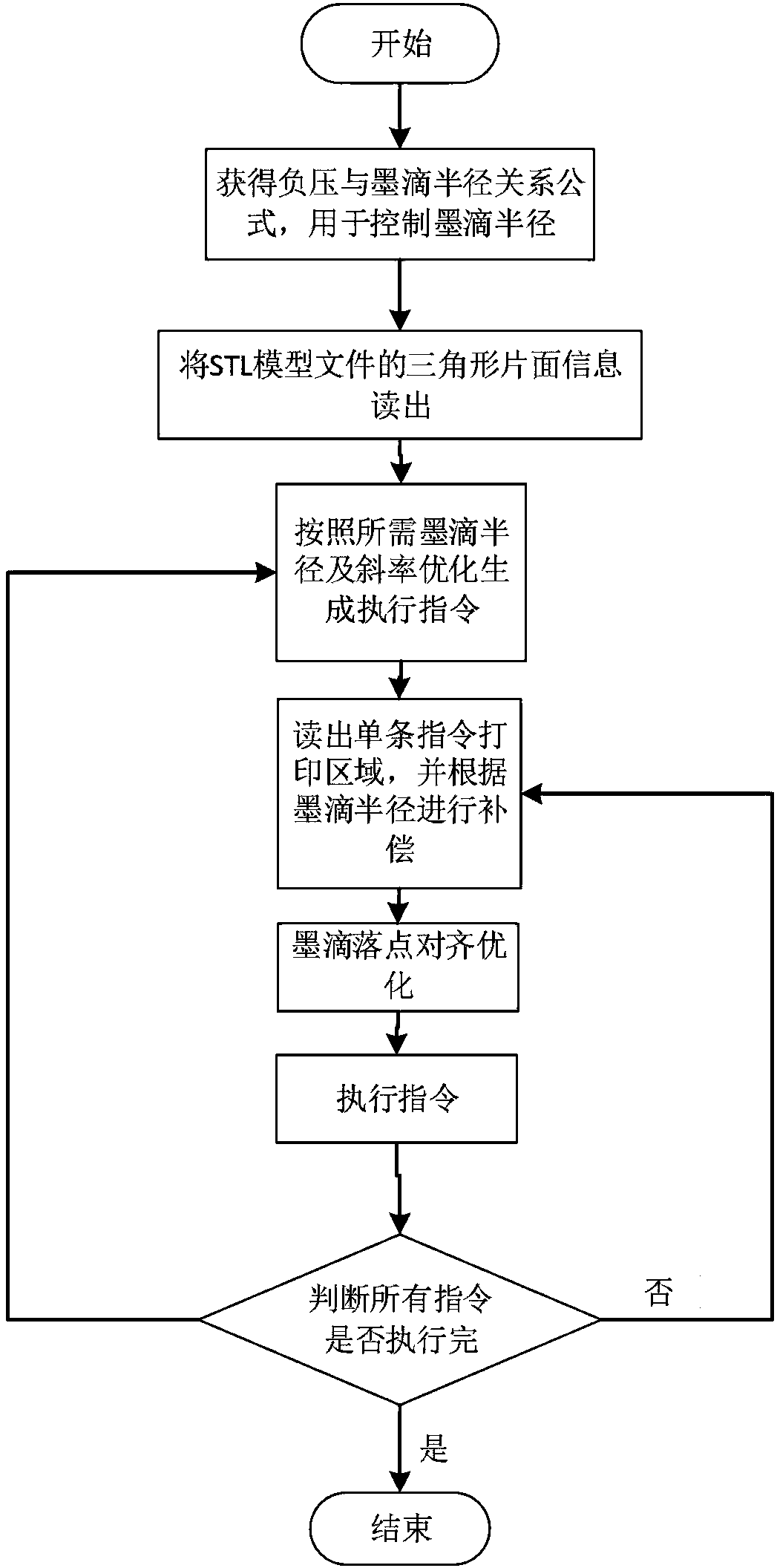

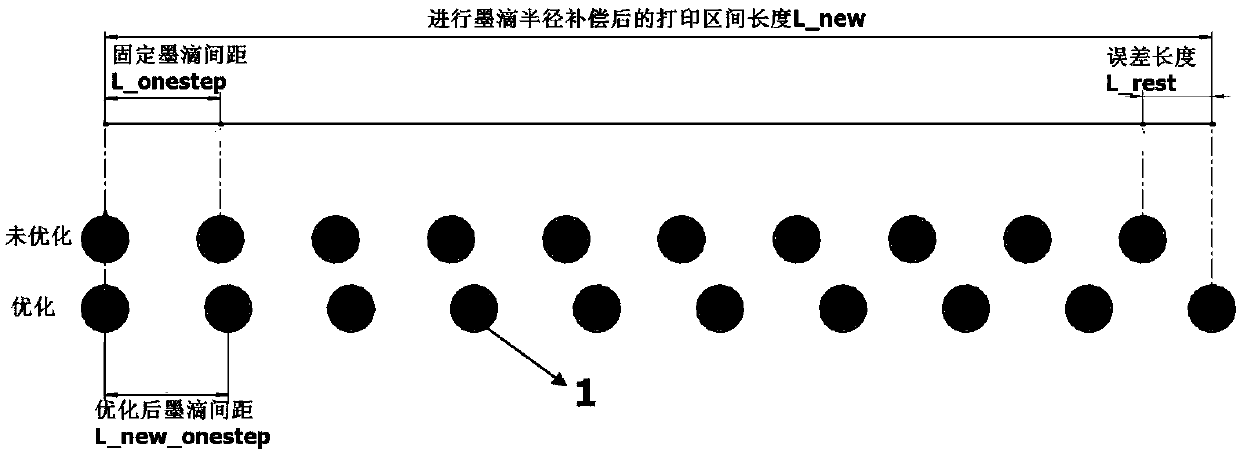

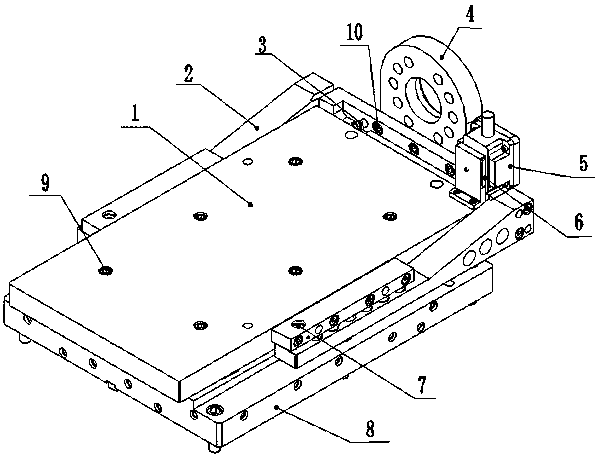

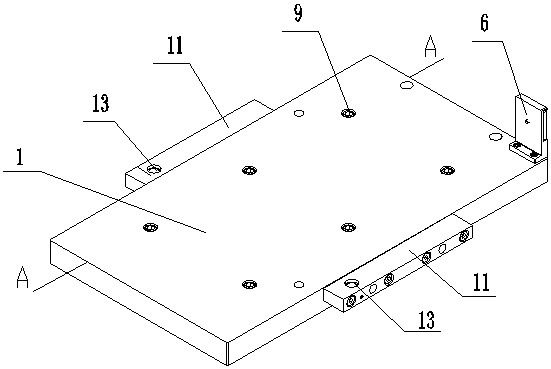

Ink droplet border aligning optimizing method for nano silver inkjet printing and printer

The invention belongs to the technical field of inkjet printing micro-manufacturing, and discloses an ink droplet border aligning optimizing method for nano silver inkjet printing and a printer. The ink droplet boarder aligning optimizing method includes the steps that a relationship equation of the negative pressure and the ink droplet distance is obtained by fitting according to measuring the relationship between negative pressure values of different piezoelectric nozzles and the radius of a jetted nano silver ink droplet; a to-be-printed part in a printing model of the model surface is determined in a computer, and the to-be-printed part is separated and stored in a STL format; a beginning printing start coordinate and the printing interval length are calculated according to a G code provided with a jet interval command, the ink droplet radius supplementation is conducted on the printing length according to the radius of the ink droplet, and the ink droplet radius is stored in printing length variable values; the ink droplet distance in the printing process is determined according to the optimized printing length and the ink droplet radius, and the ink droplet falling point initial planning is conducted; a conductive figure surface is printed; and execution of all execution codes is completed, and a conductive figure is obtained. According to different base materials, the negative pressure is adjusted so as to change the size of the ink droplet to adapt to the base materials, and thus the uniformity of the border of the conductive figure is improved effectively.

Owner:XIDIAN UNIV

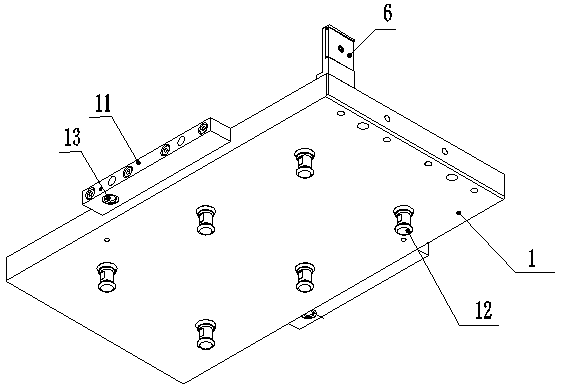

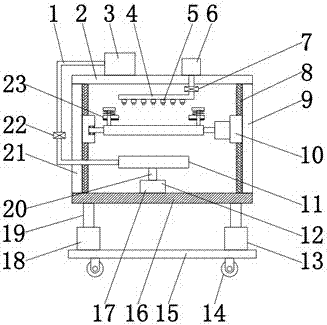

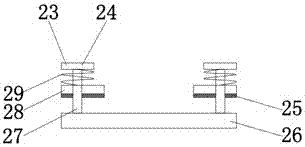

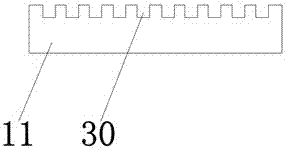

Feeding, discharging and positioning device suitable for robot feeding and discharging flexible production line

ActiveCN109366242ASolve the positioning errorWide range of useMetal working apparatusPosition sensorFlange

The invention discloses a feeding, discharging and positioning device suitable for a robot feeding and discharging flexible production line. A fork-shaped feeding and discharging device, a plurality of pull nails, an auxiliary workbench and a plurality of zero point positioning systems are included. The multiple pull nails are evenly arranged on a rapid replacement tray, two lug plates provided with positioning holes are arranged, and an RFID code is fixed to the corner. A robot flange assembly is fixed to the center of a transverse arm of a U-shaped fork-shaped assembly, a position sensor anda code reader are fixed to the two ends, and positioning pin installing holes for fixing positioning pins are formed in the two vertical walls. The zero point positioning systems are fixed to the positions, corresponding to the pull nails, of the auxiliary workbench. During work, the positioning holes of the rapid replacement tray are inserted and connected in the positioning pins of the fork-shaped assembly. The pull nails are arranged in pull nail zero point positioning holes of the zero point positioning systems, and inverted cone faces of the upper ends of the pull nails are clamped and connected in inverted cone holes of the zero point positioning systems. The feeding, discharging and positioning device is used in the robot feeding and discharging flexible production line, can adaptto diversity of workpieces and is high in recognition accuracy, good in grabbing reliability and high in zero point positioning precision.

Owner:BAODING XIANGYANG AVIATION PRECISION MACHINERY

Bamboo board bonding glue-spraying device with heating function

PendingCN107498660AImprove practicalityIncrease frictionWood veneer joiningGlue gunsBackplaneHeating effect

The invention discloses a bamboo board bonding glue-spraying device with a heating function. The bamboo board bonding glue-spraying device comprises first hydraulic telescopic rods, a motor, a cooling tank and a second hydraulic cylinder. The first hydraulic telescopic rods are used for adjusting the height of a bottom plate so that operators with different body heights can use the glue-spraying device. The cooling tank enlarges the cooling area of the top of a heating box, and thus the heating effect on a bamboo board which is fixedly placed at the top of the heating box is improved. The motor rotates to drive a mounting plate to rotate so as to enable a bamboo board fixedly placed on the mounting plate to right face the bamboo board fixedly placed at the top of the heating box. The second hydraulic cylinder is used for driving a second hydraulic rod to extend to push the heating box to be lifted, so that the bamboo board fixedly arranged at the top of the heating box and the bamboo board fixedly arranged on the mounting plate are attached, and thus bamboo board bonding is achieved. By heating the bamboo board fixedly arranged at the top of the heating box, the bamboo board bonding efficiency and effect are improved.

Owner:浙江凯欣食品有限公司

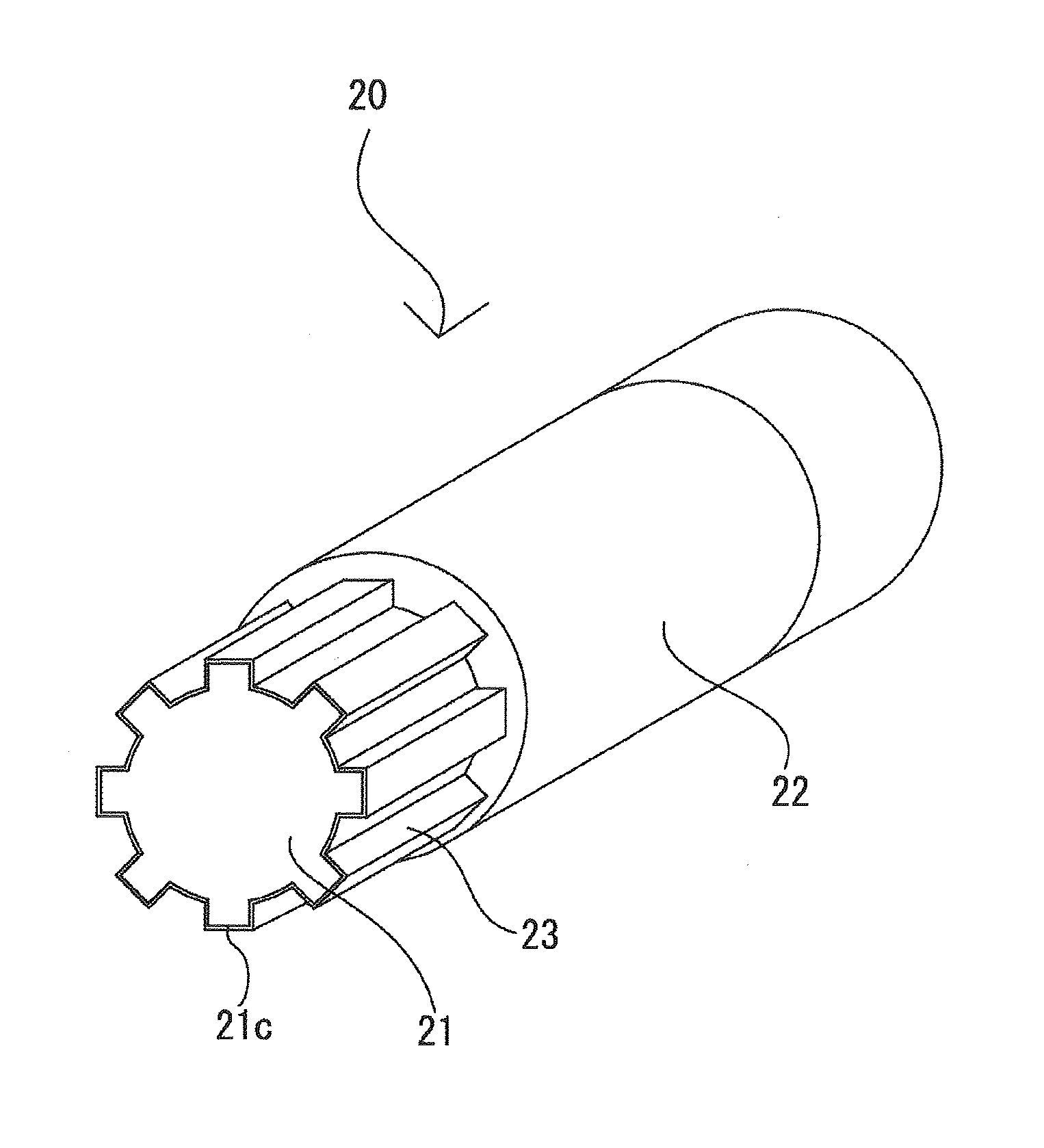

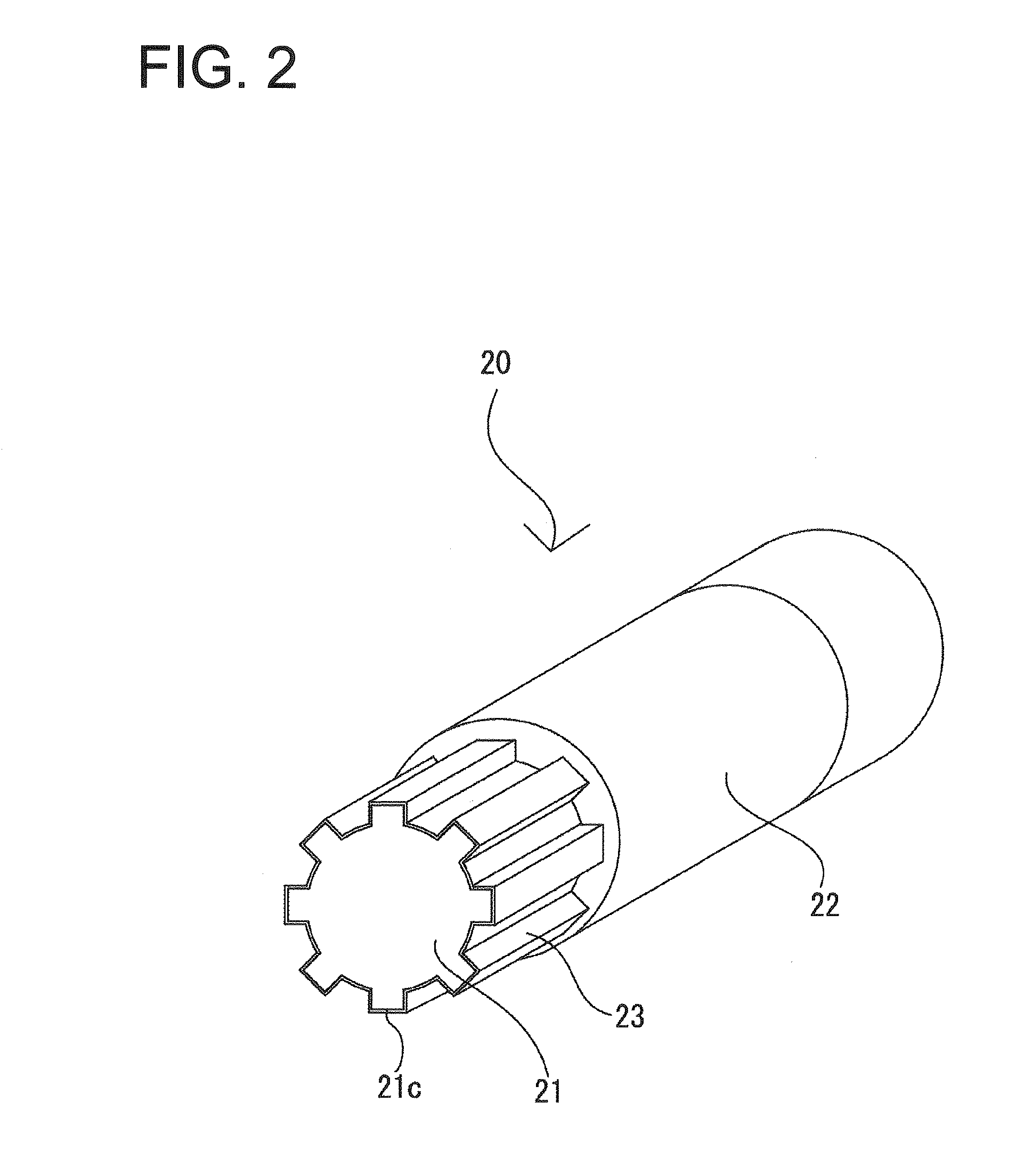

Structural body for shaft, male member, and female member

ActiveUS20150110551A1Reduced sliding resistanceReduce generationClutchesYielding couplingEngineeringPower transmission

A shaft structure installed in a shaft capable of making a power-transmission, the shaft structure including: a male component having a plurality of male splines formed on an outer peripheral part thereof; and a female component having a plurality of female splines formed on an inner peripheral part thereof, the inner peripheral part configured to allow the outer peripheral part of the male component to be engaged therein so that the male component and the female component can be slidably fitted with respect to each other in an axial direction thereby making up said shaft structure, wherein the outer peripheral part of the male component and the inner peripheral part of the female component have a fabric impregnated with rubber or resin interposed therebetween.

Owner:NITTA CORP

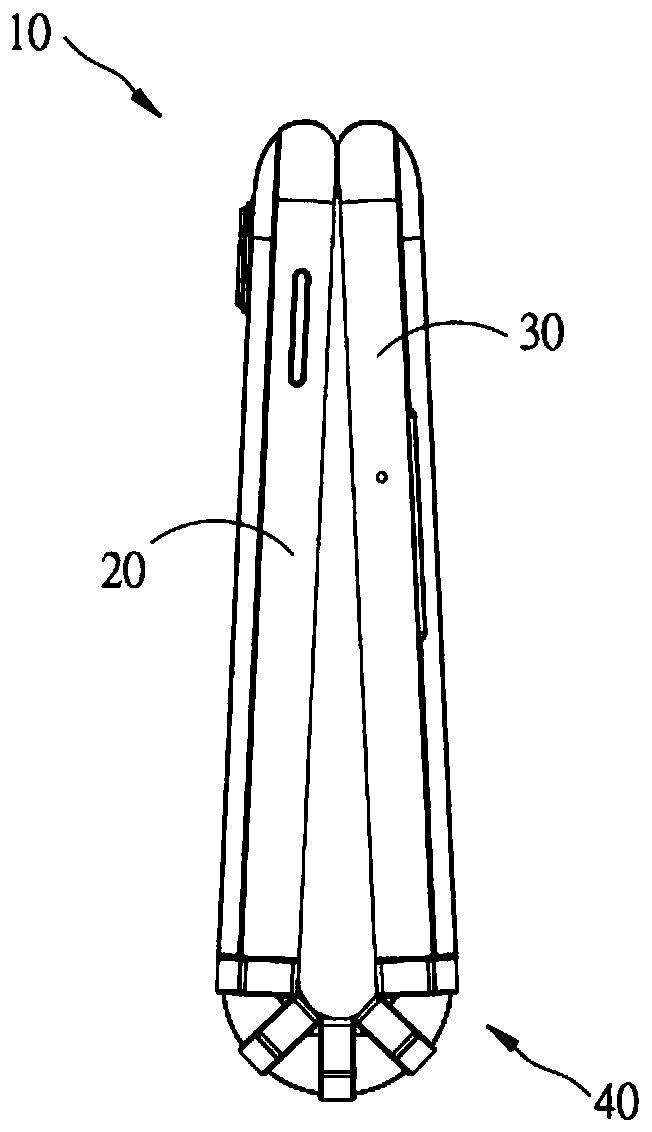

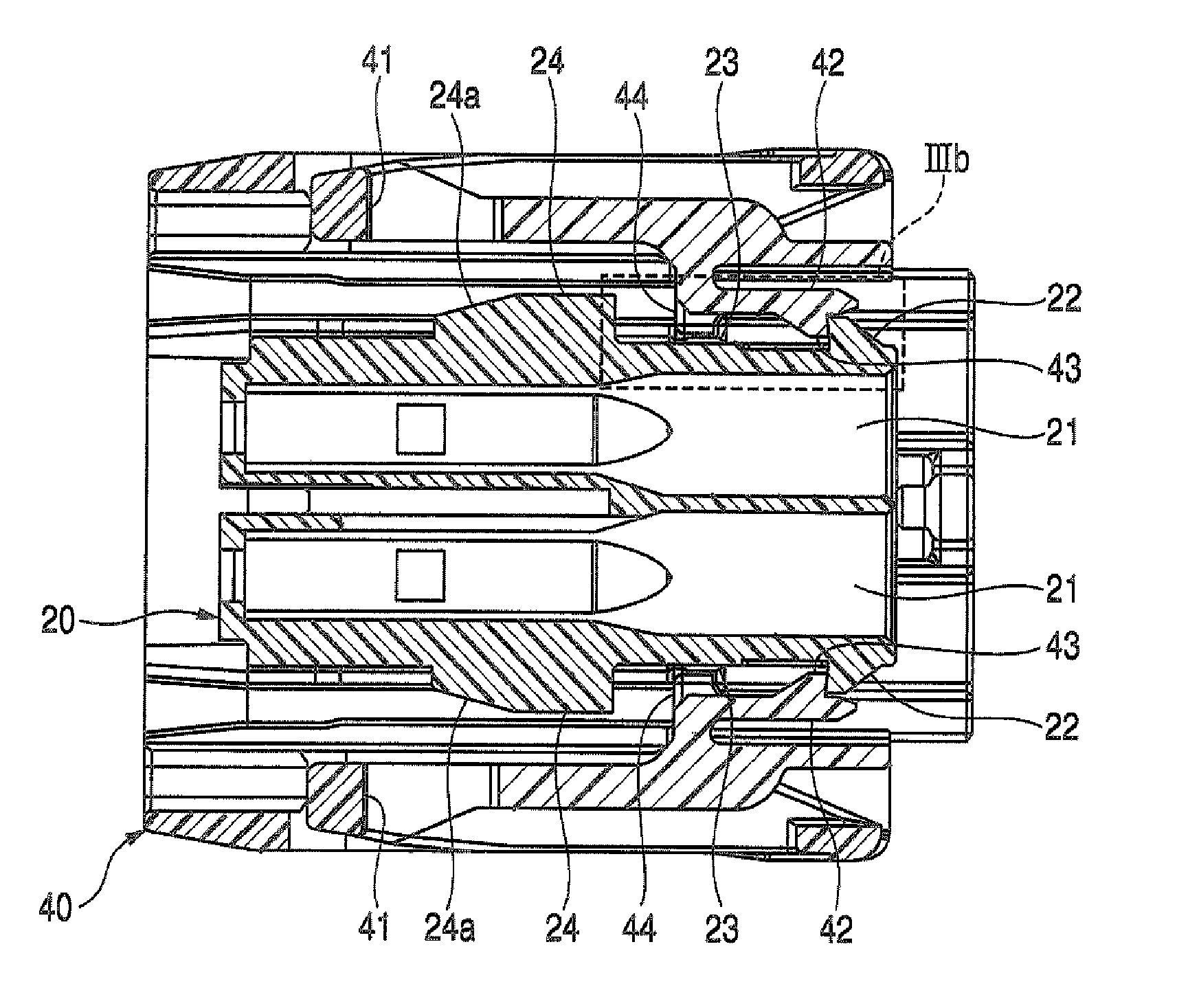

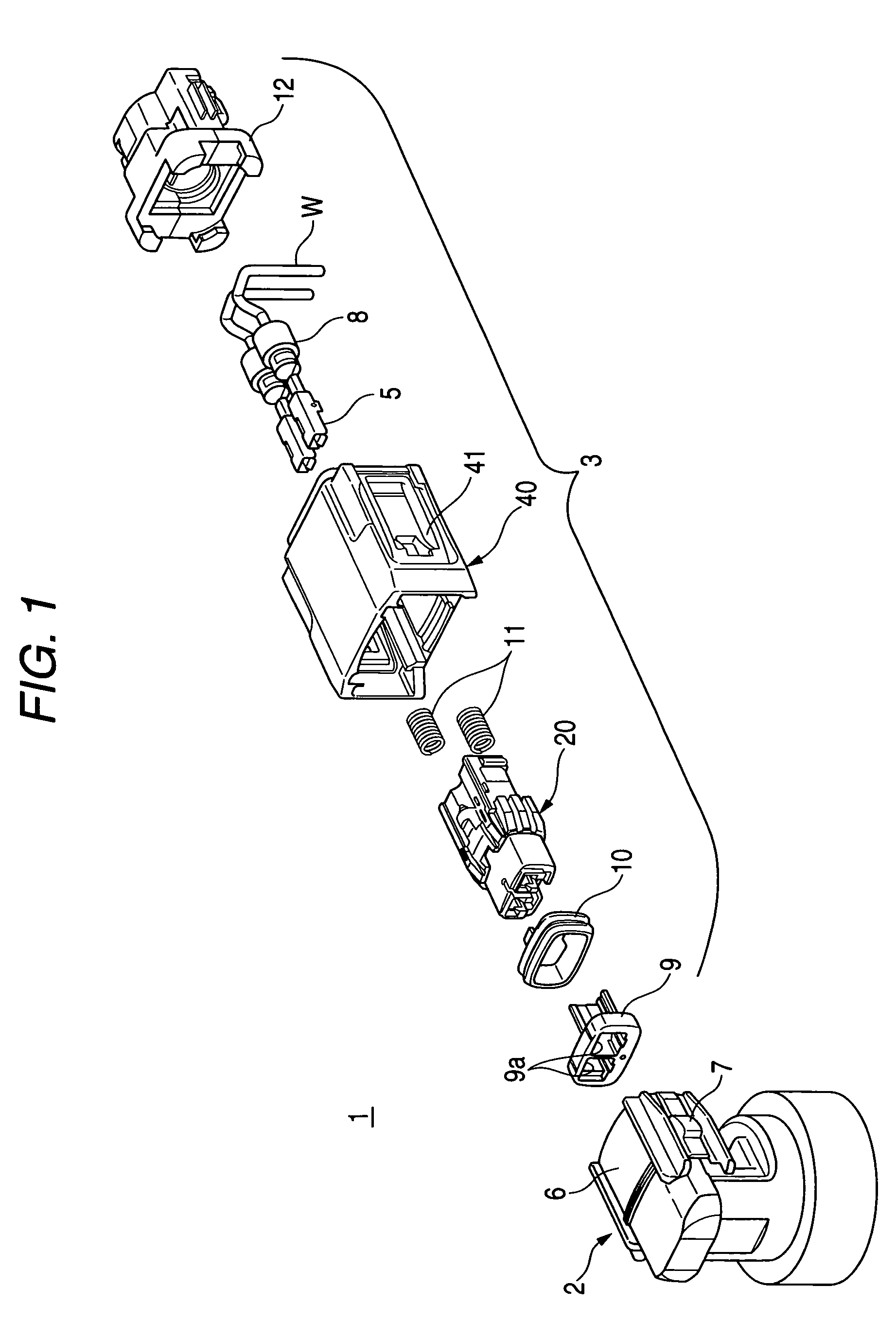

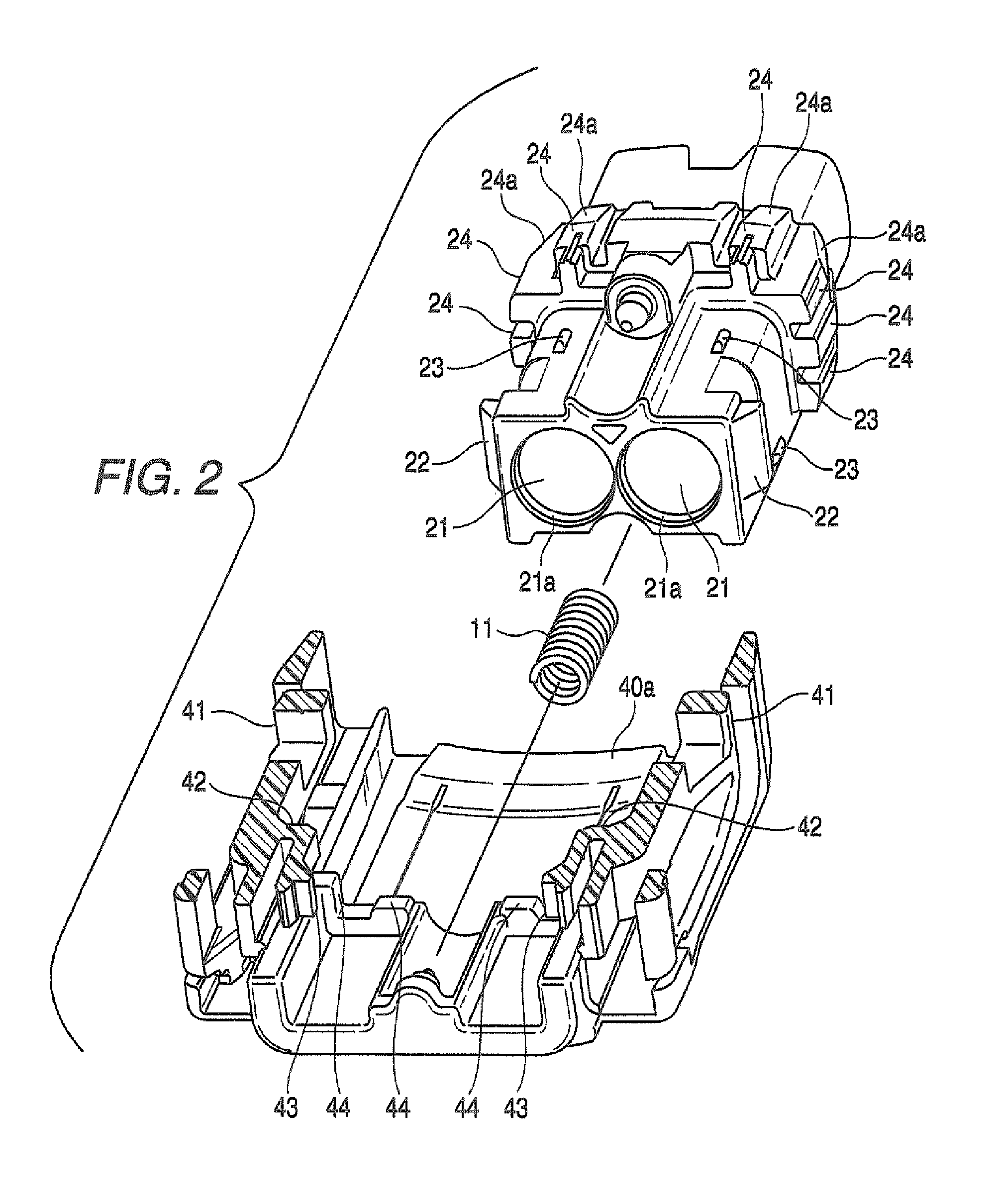

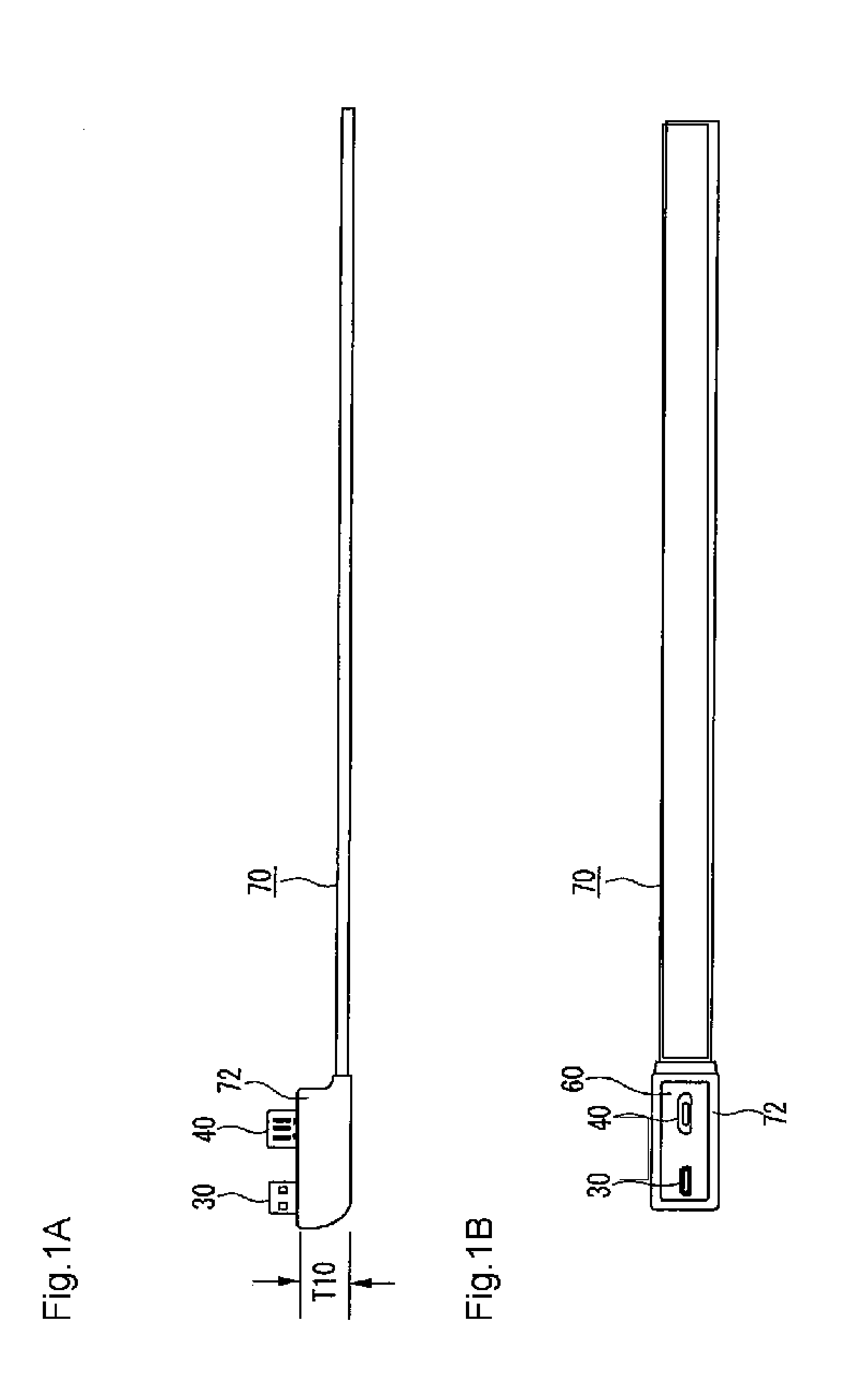

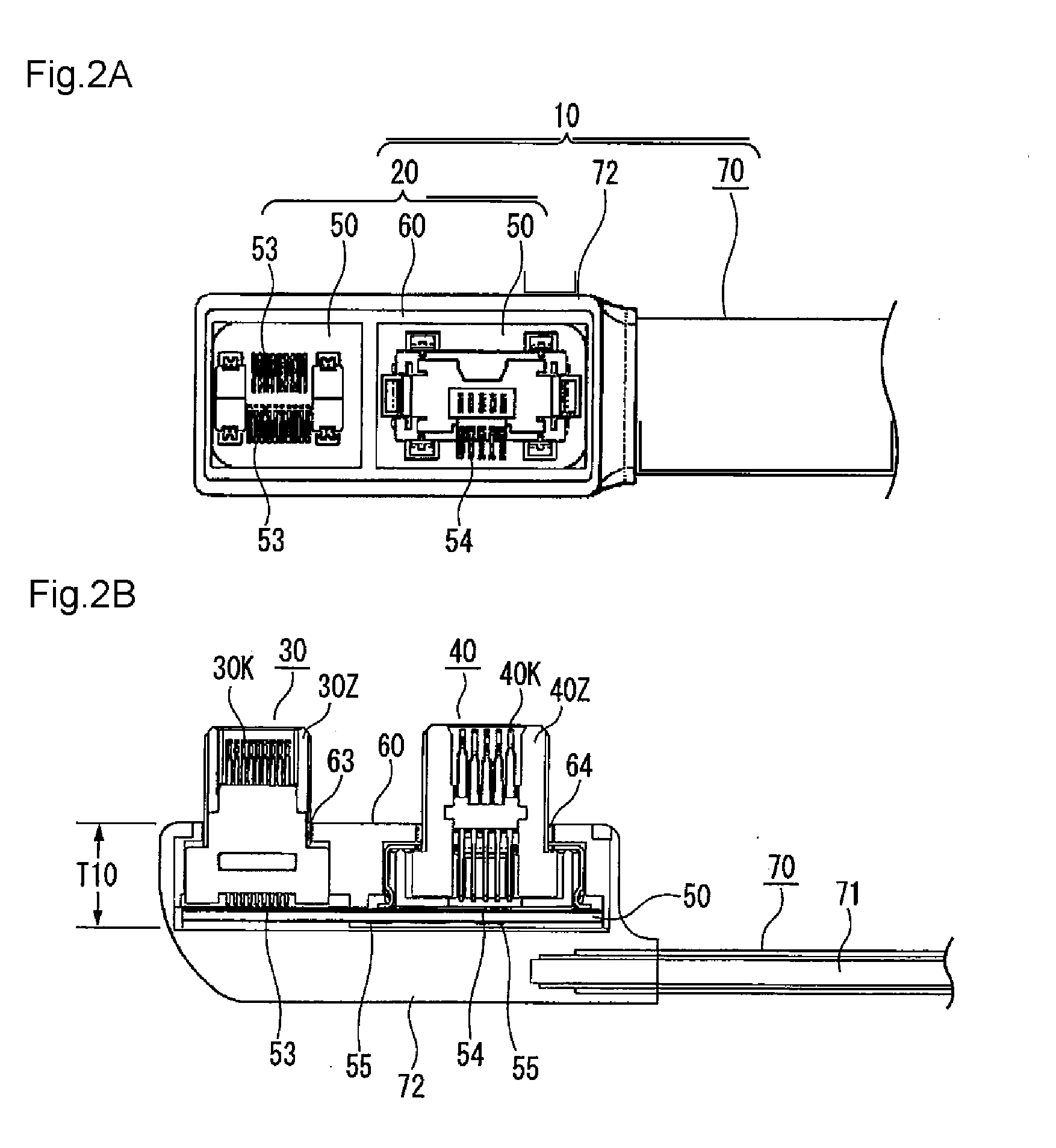

Multiple plug connector unit

InactiveUS20130295796A1Reduce depthFit evenlyElectric discharge tubesCoupling device detailsEngineeringMechanical engineering

Owner:KATO NOBUKAZU +2

Drawtube, lens module with the same, and lens module assembling method

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com