Spiral hole milling device

A helical milling hole and screw technology, applied in the direction of feeding device, milling machine equipment, milling machine equipment details, etc., can solve the problems of large eccentricity adjustment error, difficult adjustment of radial offset device, poor rigidity of radial offset device, etc. , to achieve the effect of large friction force surface, good structure holding function and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

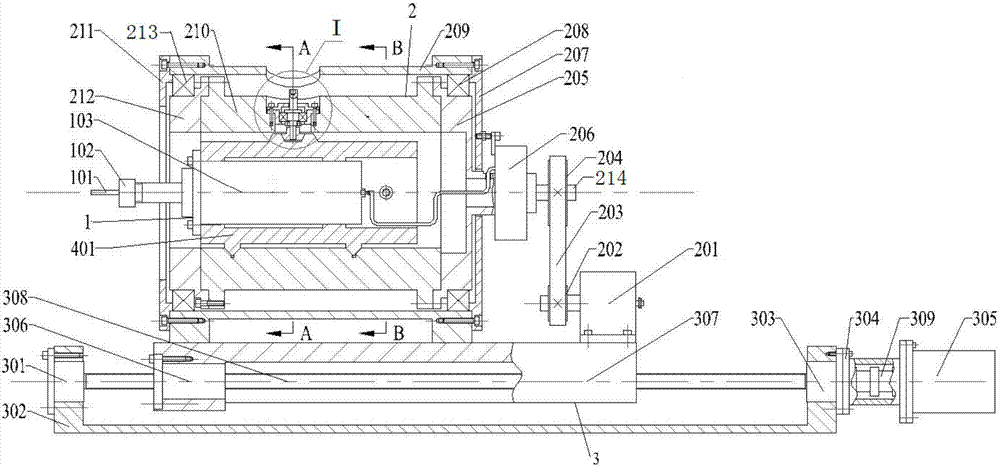

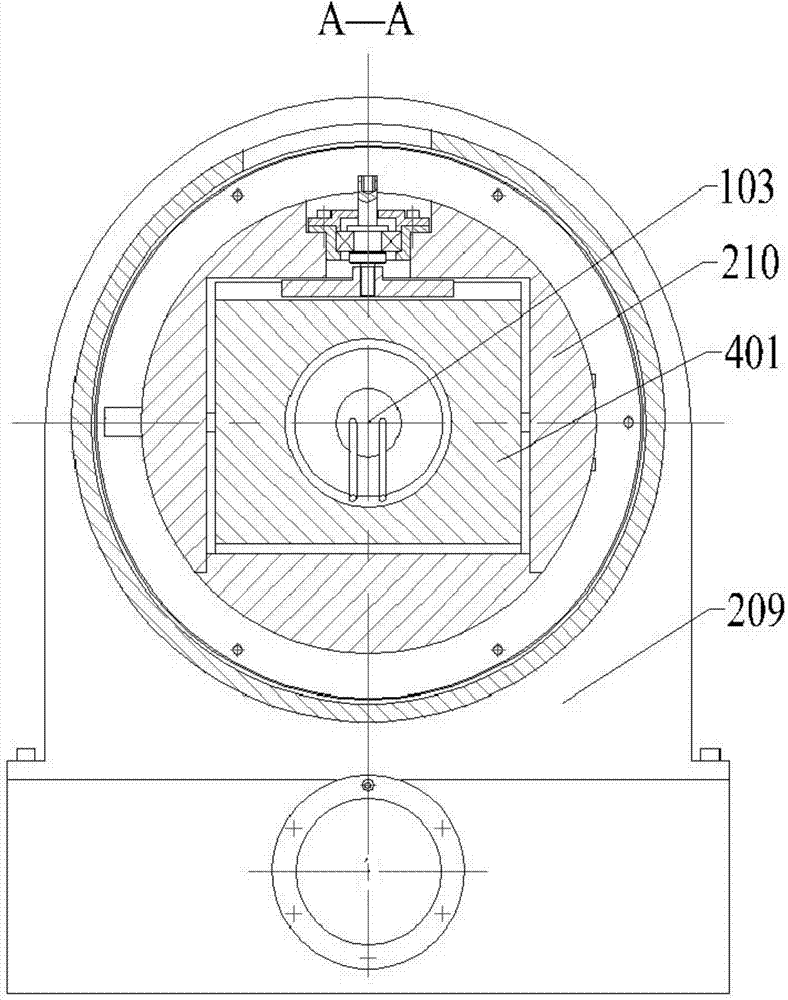

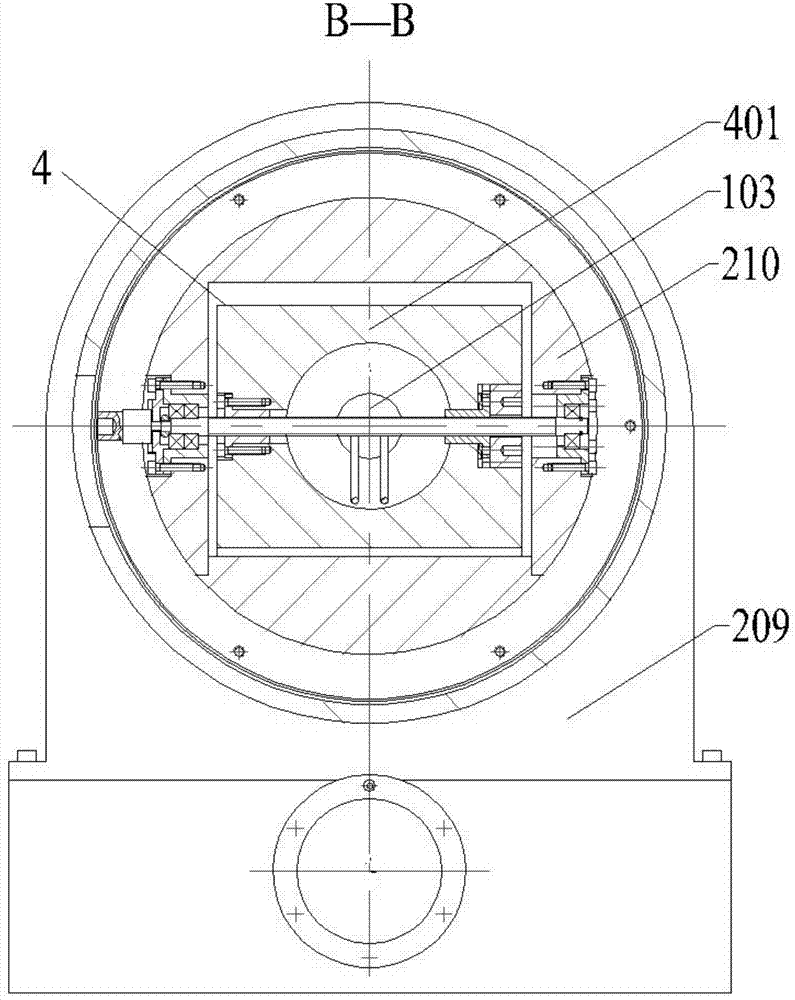

[0044] Such as Figure 1-Figure 5 As shown, a helical milling device includes an autorotation system 1, a revolution system 2, a feed system 3 and an eccentricity adjustment system 4 that drive the tool movement;

[0045] The autorotation system 1 is movably connected with the inner sleeve 210 through the offset slider 401, the autorotation system 1 includes a milling cutter 101, a collet 102 and an electric spindle 103, and the milling cutter 101 passes through the The collet 102 is fixedly connected to the output shaft of the electric spindle 103 .

[0046] The revolution system 2 includes a revolution motor 201, a small synchronous pulley 202, a synchronous belt 203, a large synchronous pulley 204, an inner sleeve rear end cover 205, a conductive slip ring 206, an outer sleeve rear end cover 207, and a radial bearing 208, outer sleeve 209, inner sleeve 210, outer sleeve front end cover 211 and inner sleeve front end cover 212, the outer sleeve 209 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com