Patents

Literature

151results about How to "Small backlash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

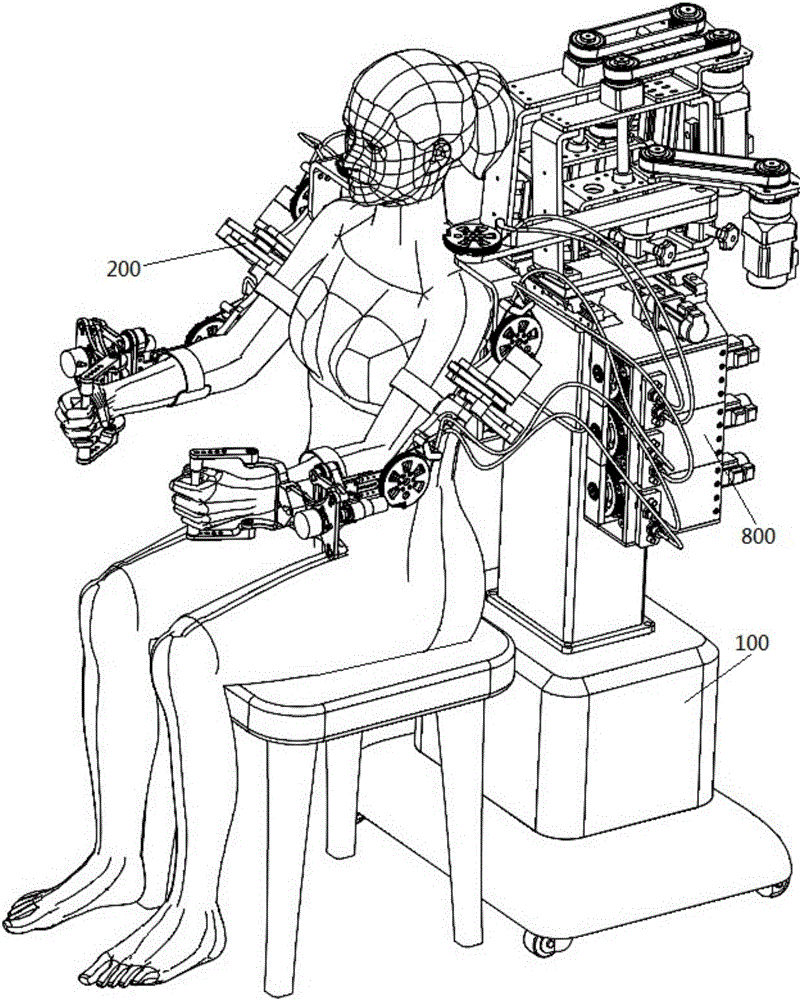

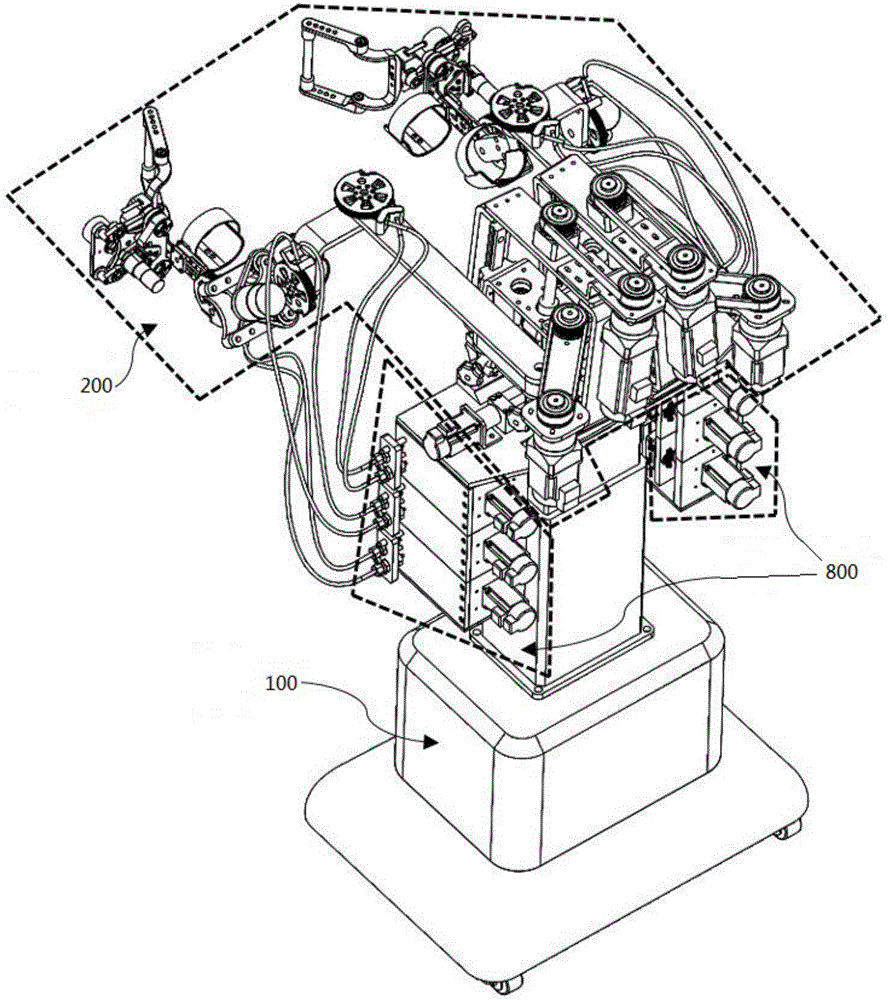

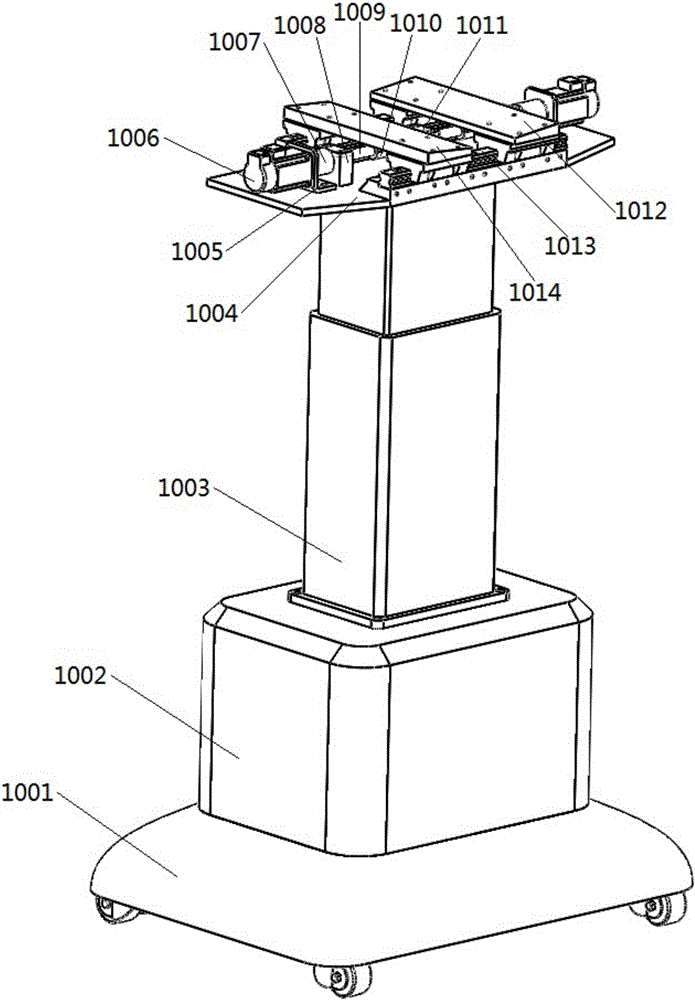

Exoskeletal rehabilitation robot for upper limbs

PendingCN105662782ASolving Mismatch ProblemsWon't hurtProgramme-controlled manipulatorChiropractic devicesEngineeringUpper limb rehabilitation

The invention discloses an exoskeletal rehabilitation robot for upper limbs. The exoskeletal rehabilitation robot comprises a base, two mechanical arm assemblies and six motor driving components, wherein the base comprises a moving base, an electrical cabinet, an electric lifting post, a base platform, a motor mounting corner bracket, a base rotating motor, a coupling, a base main bearing block, a base and ball screw nut assembly, a base nut seat, a base shared secondary bearing block, a right support, a base linear guide rail assembly and a left support; the mechanical arm assembly comprises a mechanical shoulder girdle assembly, a mechanical shoulder joint assembly, a mechanical elbow joint assembly, a mechanical front arm assembly, a mechanical wrist joint assembly and a mechanical hand part assembly; each motor driving assembly comprises a motor and speed reducing component, a torque sensor component and a driving component which are respectively arranged on the same motor driving base frame. The exoskeletal rehabilitation robot can be worn on the upper limbs of the human body and can be used for assisting the upper limbs of the human body in moving in a three-dimensional space and performing rehabilitation training.

Owner:SHANGHAI ZHUODAO MEDICAL TECH CO LTD

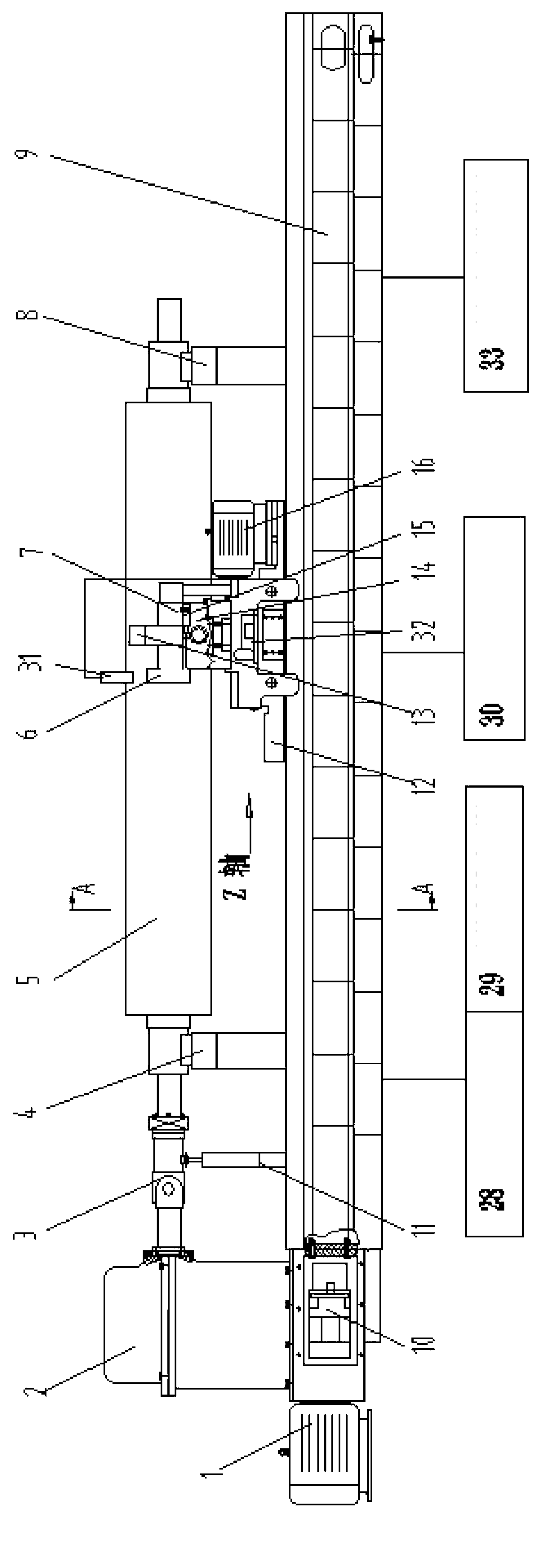

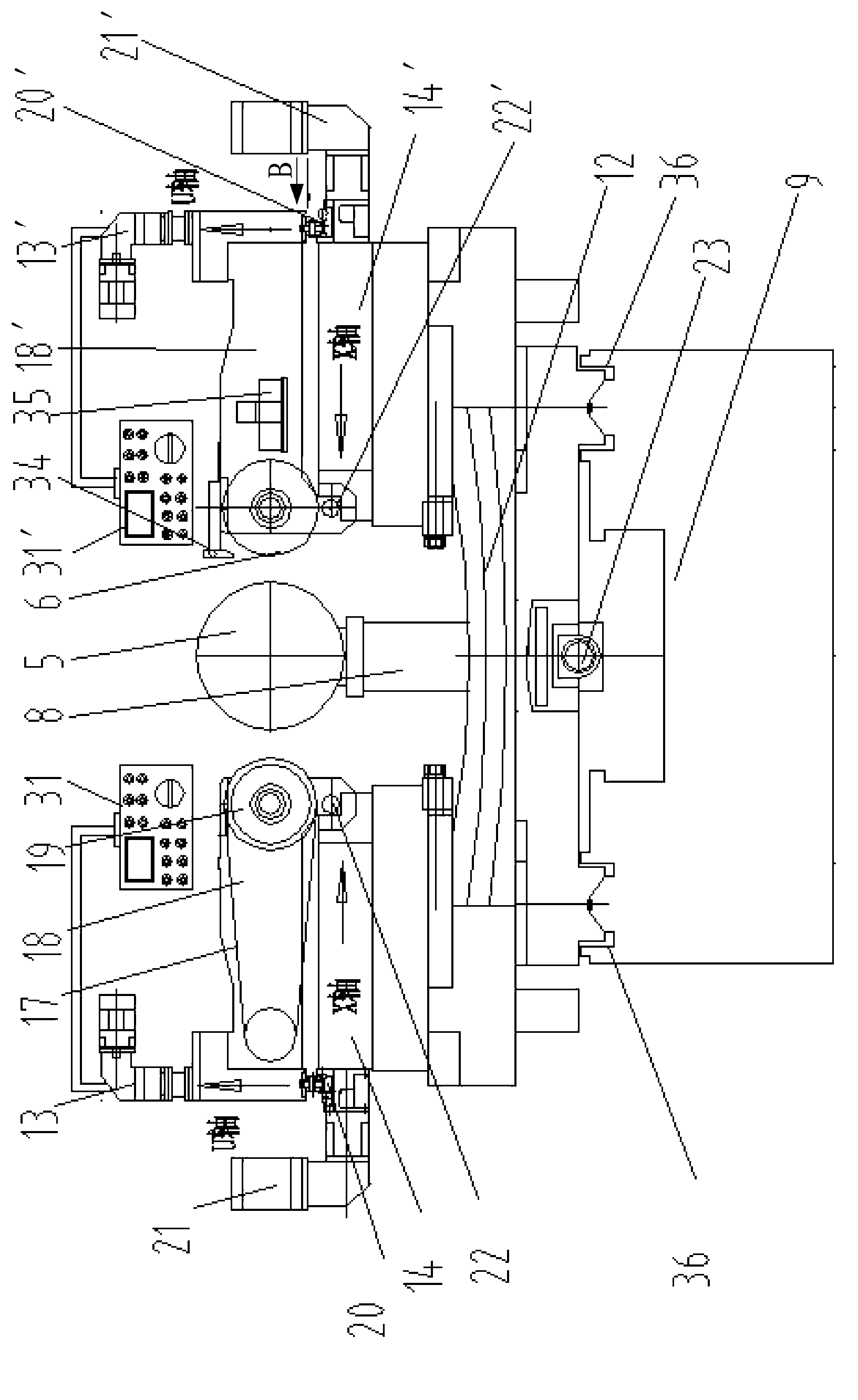

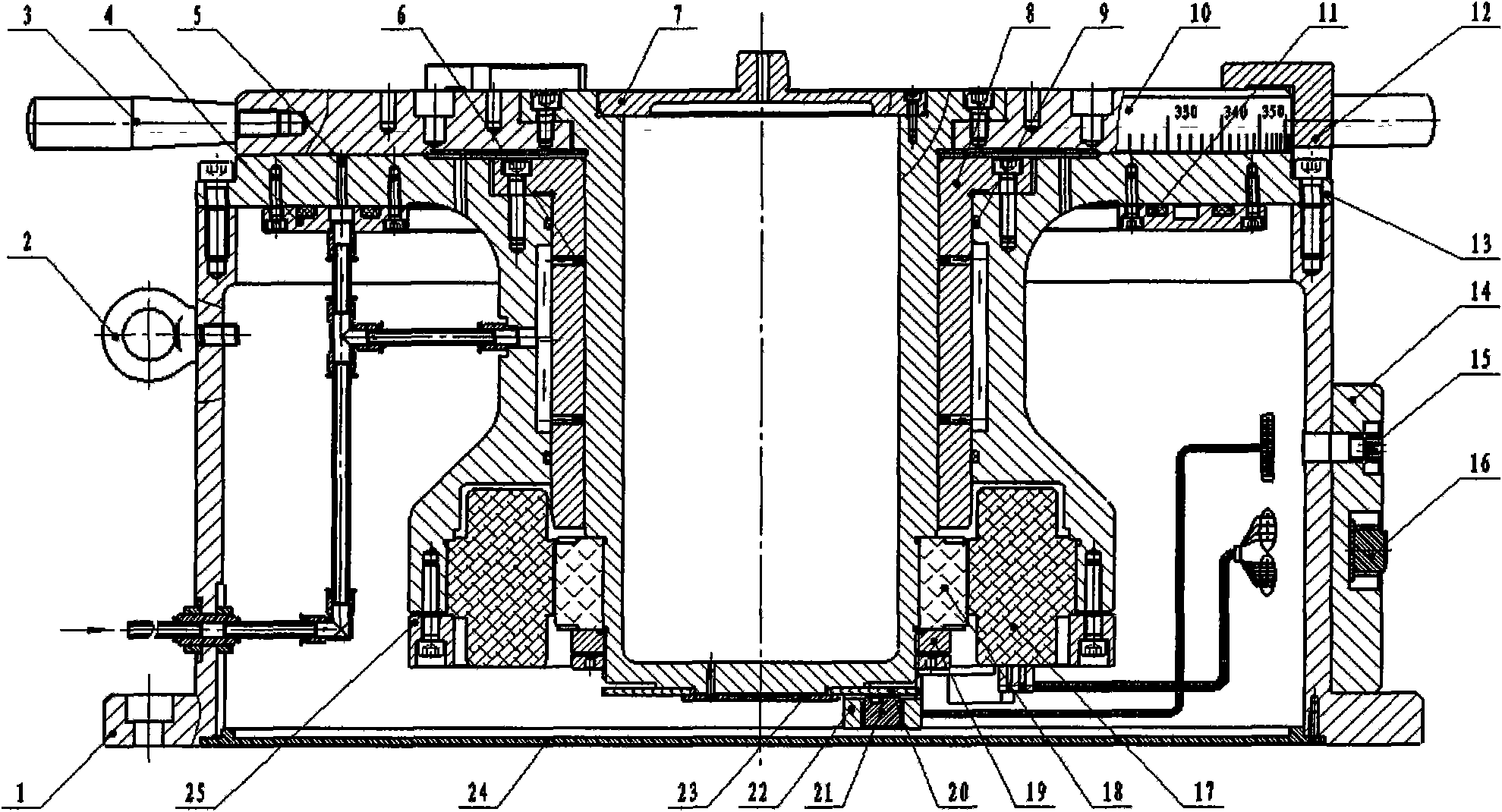

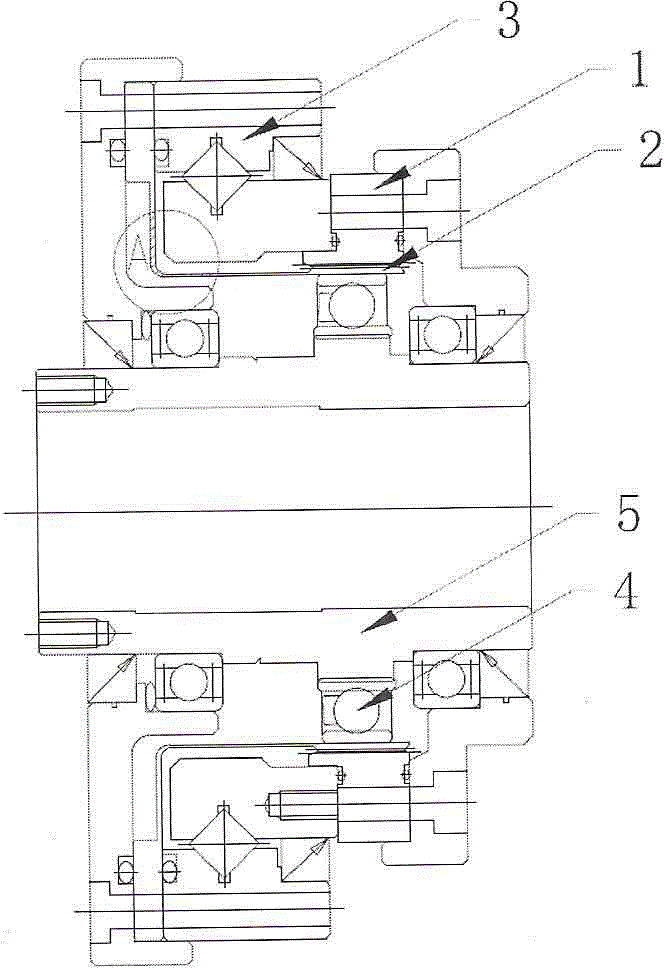

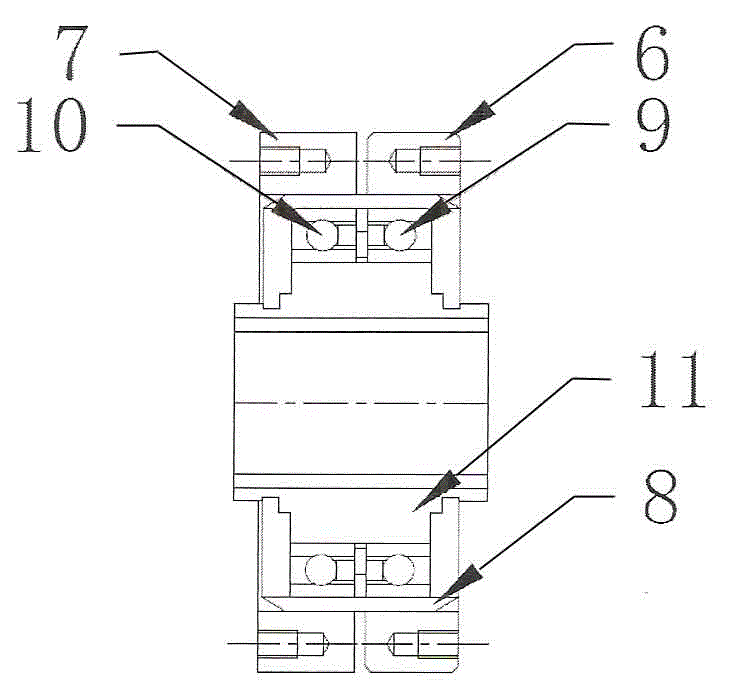

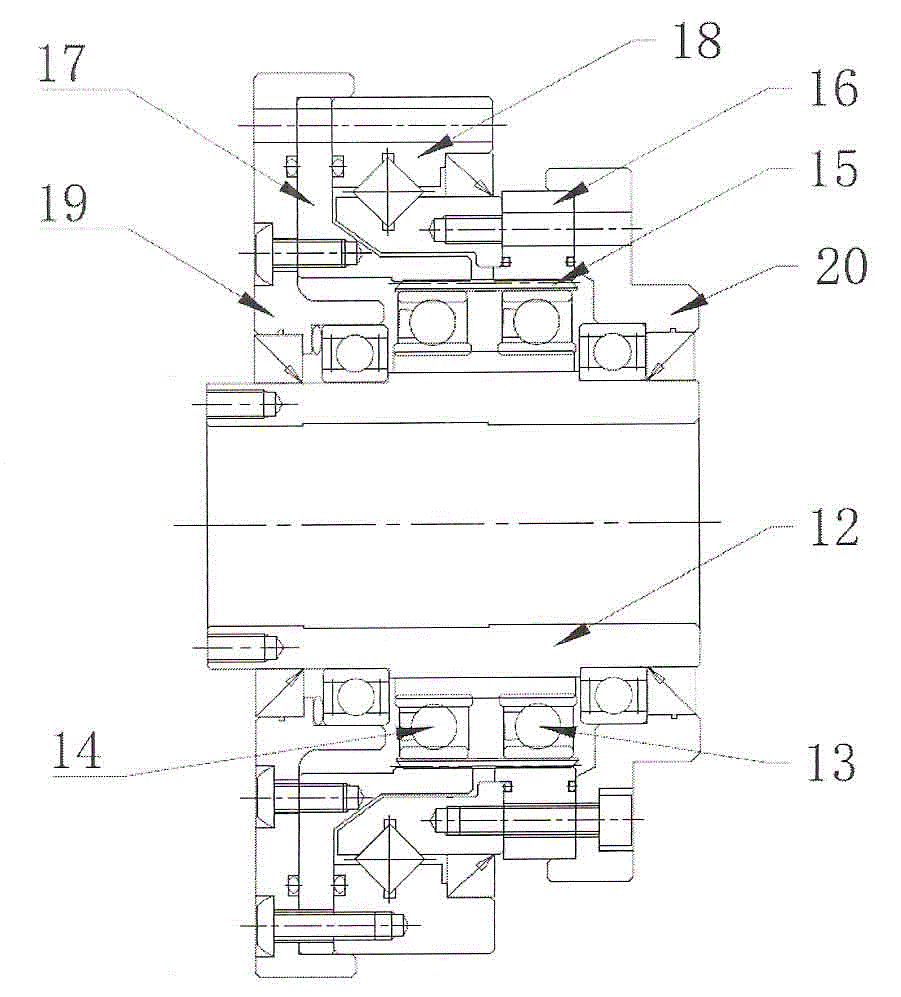

Two-wheeled numerical control roll grinder and numerical control method thereof

ActiveCN103009200ALow costSave energyRevolution surface grinding machinesBelt grinding machinesNumerical controlEngineering

The invention discloses a two-wheeled numerical control roll grinder and a numerical control method thereof. A small sliding frame of the double-wheeled numerical control roll grinder is provided with a U-axis micro-feeding mechanism, a main mechanical transmission case is lubricated by adopting an active lubricating loop, a cooling water purifying device is arranged on a grinder body, a large sliding frame guide rail is connected with a Z-axis guide rail hydraulic station through a lubricating oil tube, the Z-axis guide rail hydraulic station is subjected to dynamic pressure lubrication, a grinding wheel and an abrasive belt wheel are respectively connected with a shared mainshaft hydraulic station, a hybrid bearing and a capillary tube adjuster are respectively arranged at the front and the back of a main shaft of the grinding wheel and a main shaft of the abrasive belt wheel, and the mainshaft of the grinding wheel and the mainshaft of the abrasive belt wheel are subjected to dynamic and static pressure lubrication. According to the invention, due to adoption of a numerical-control setting manner, a roll curve is easy to change, ground workpieces are higher in quality and are easy to automatically control, the manual misoperation probability is lowered, a very excellent repeatable machining purpose is achieved and the quality of batch production can be ensured.

Owner:武汉宝德机电股份有限公司

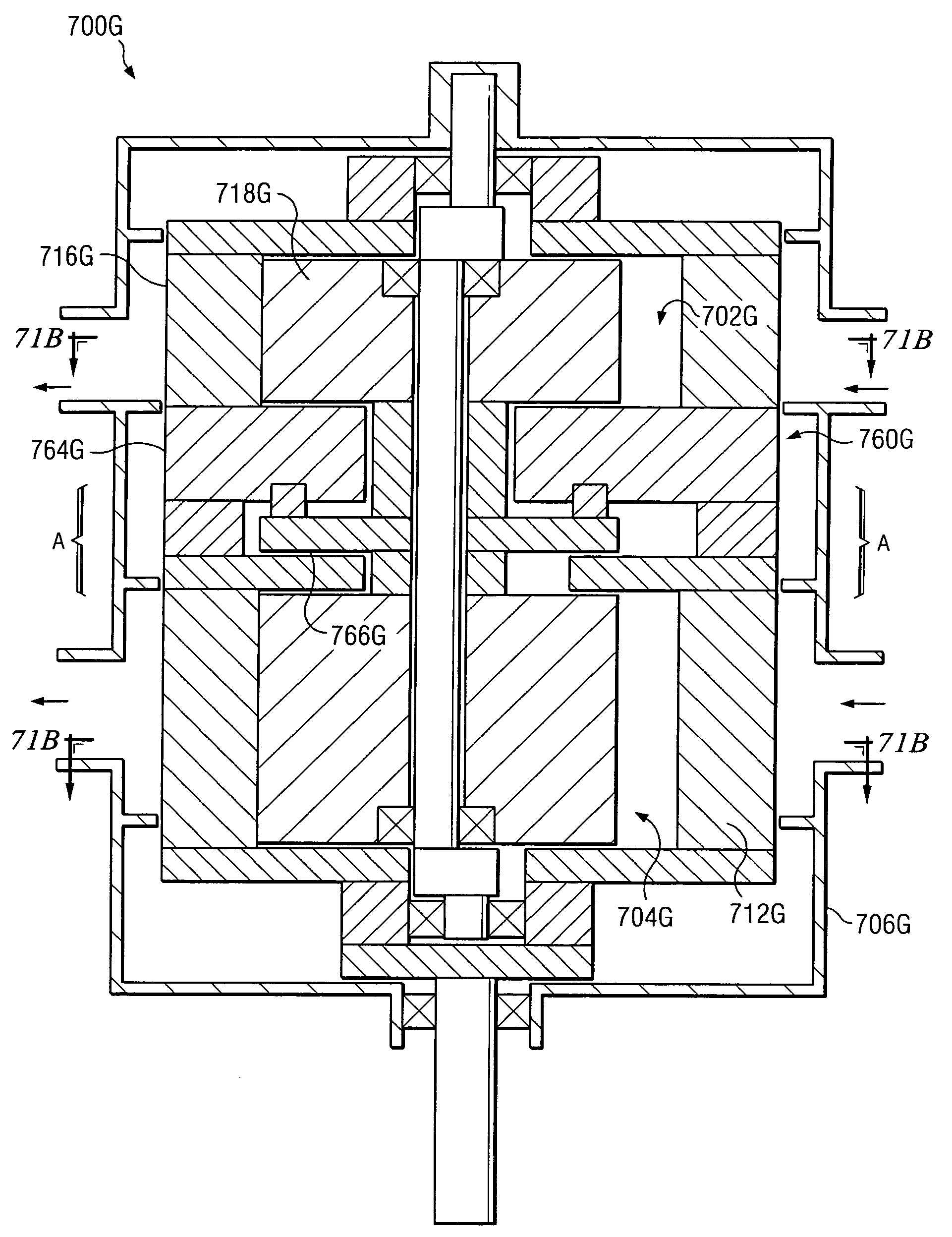

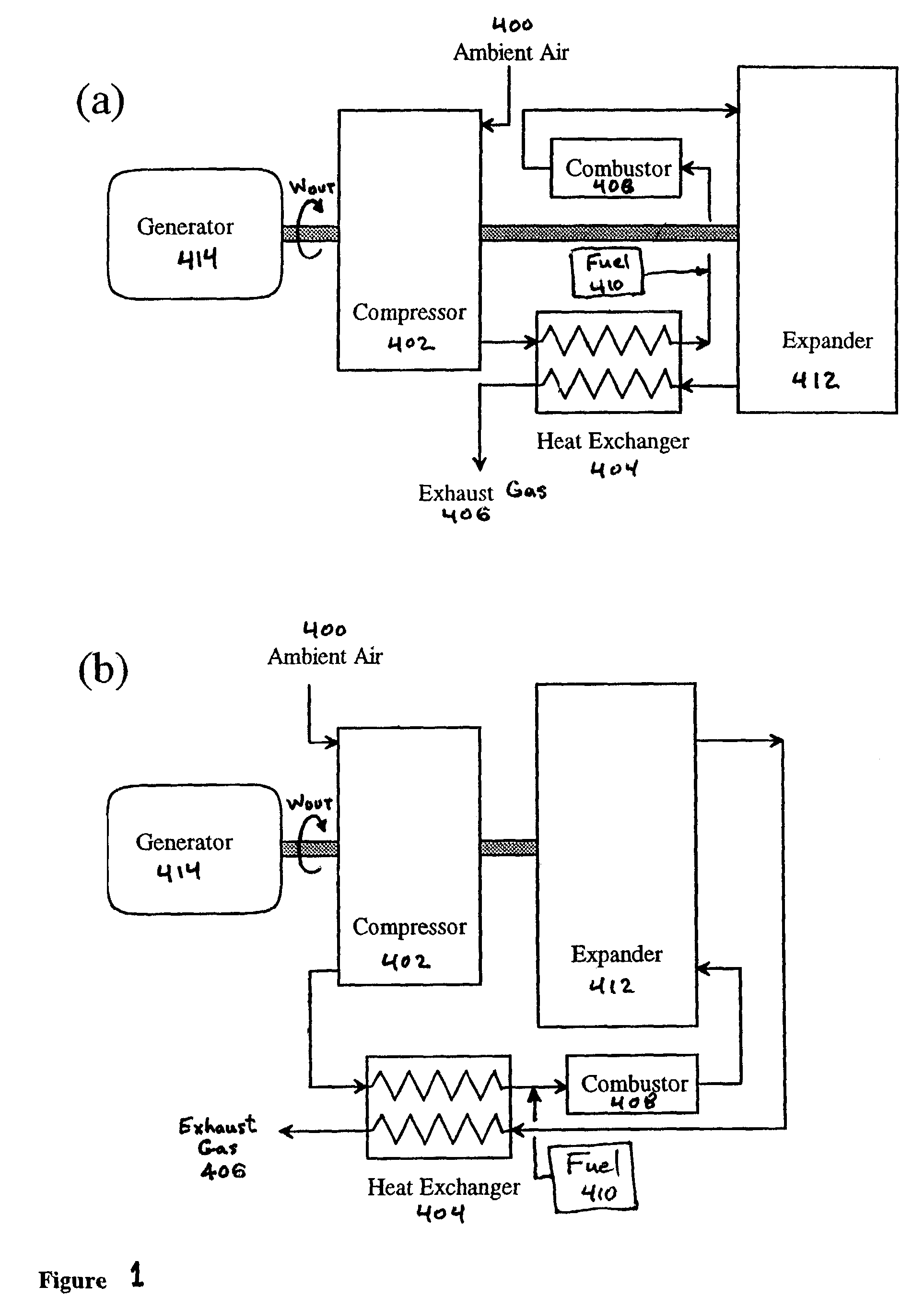

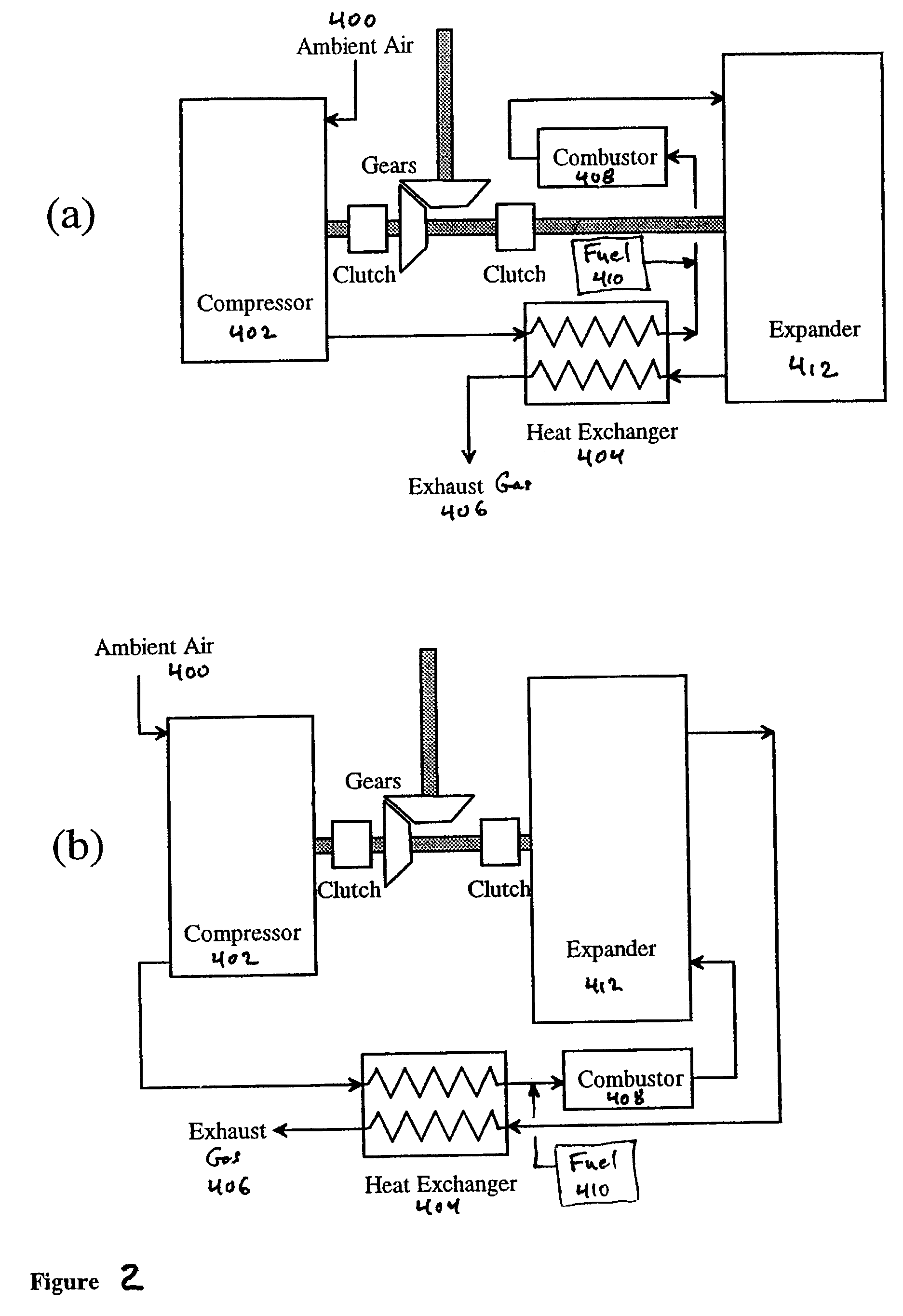

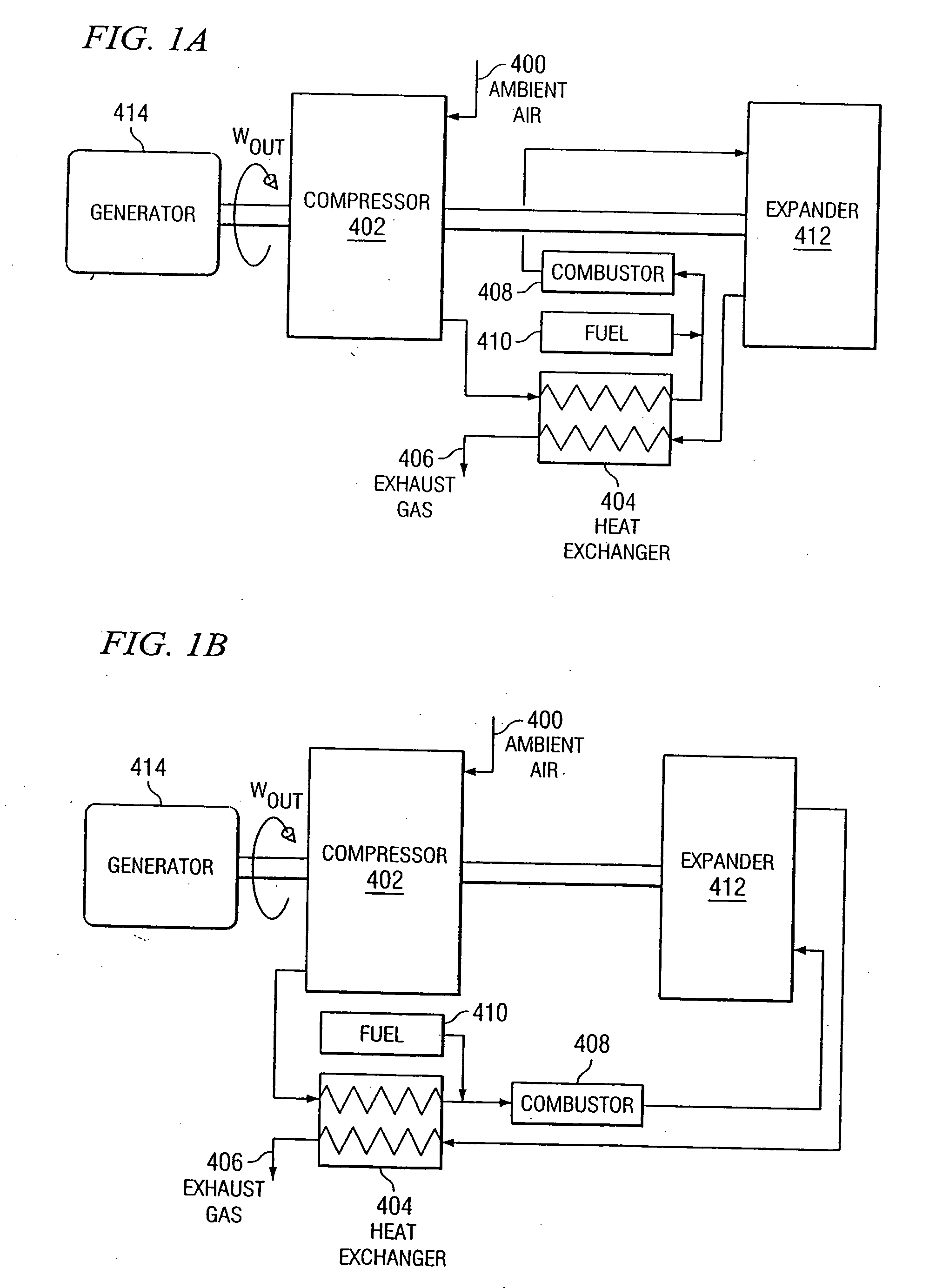

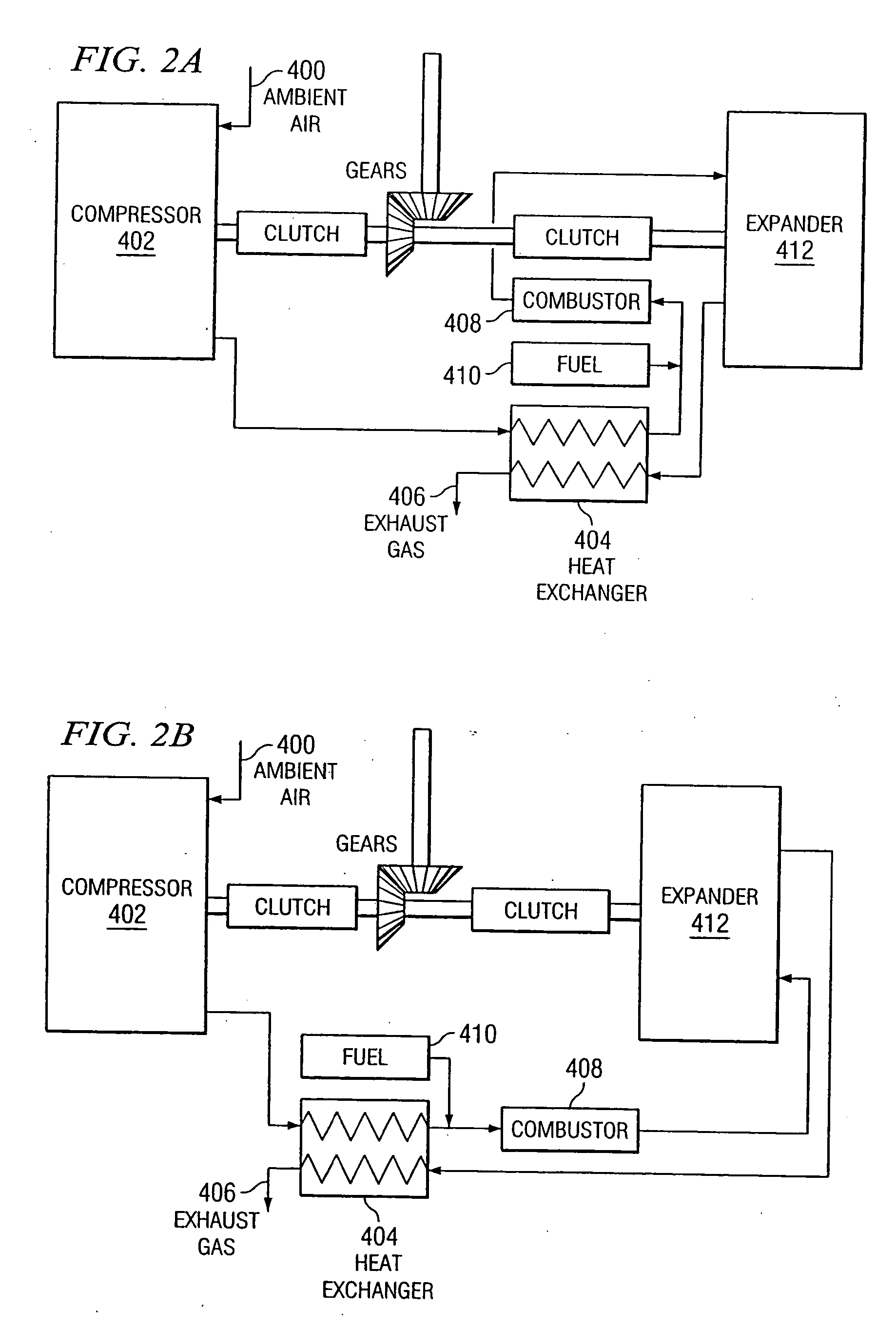

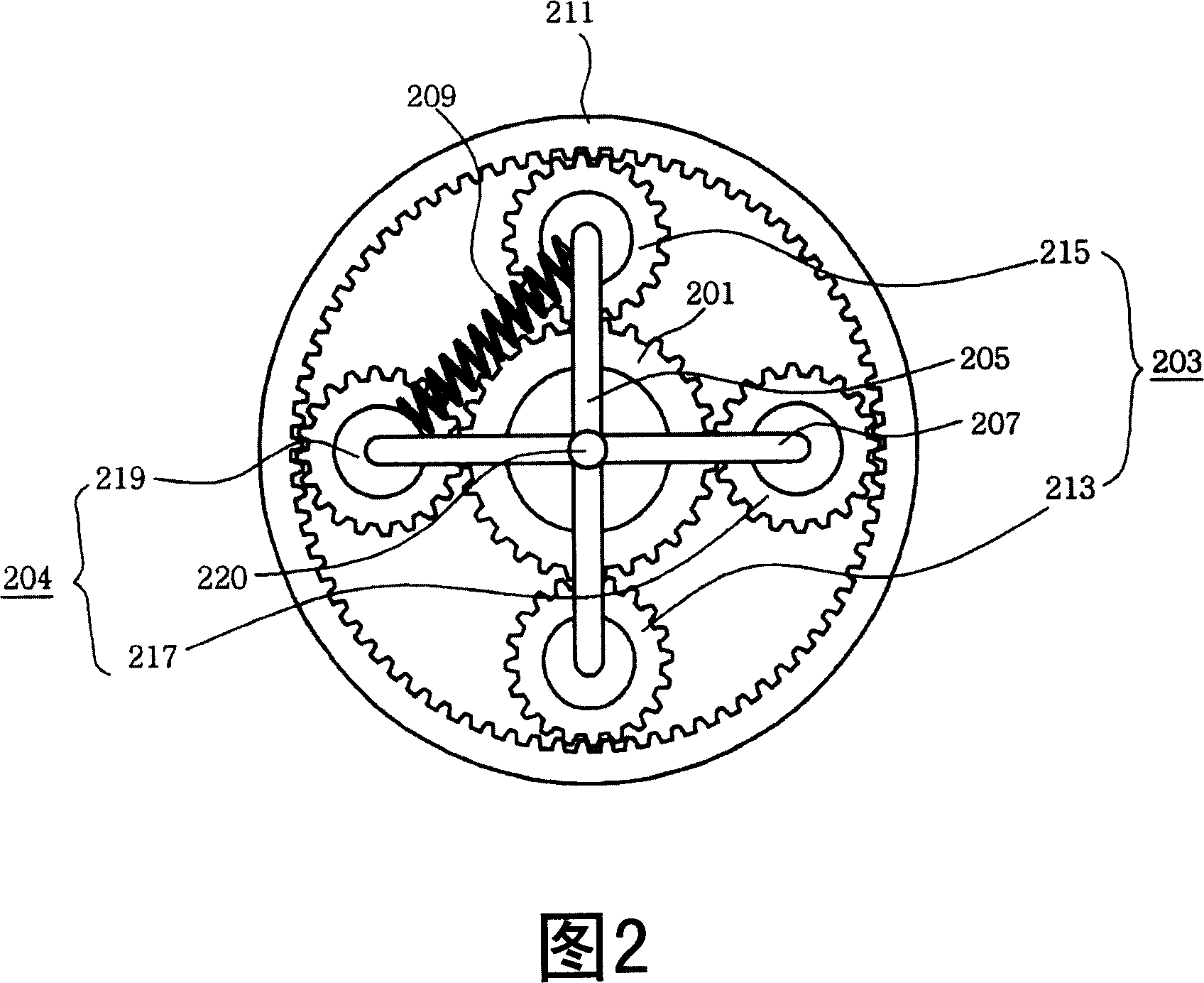

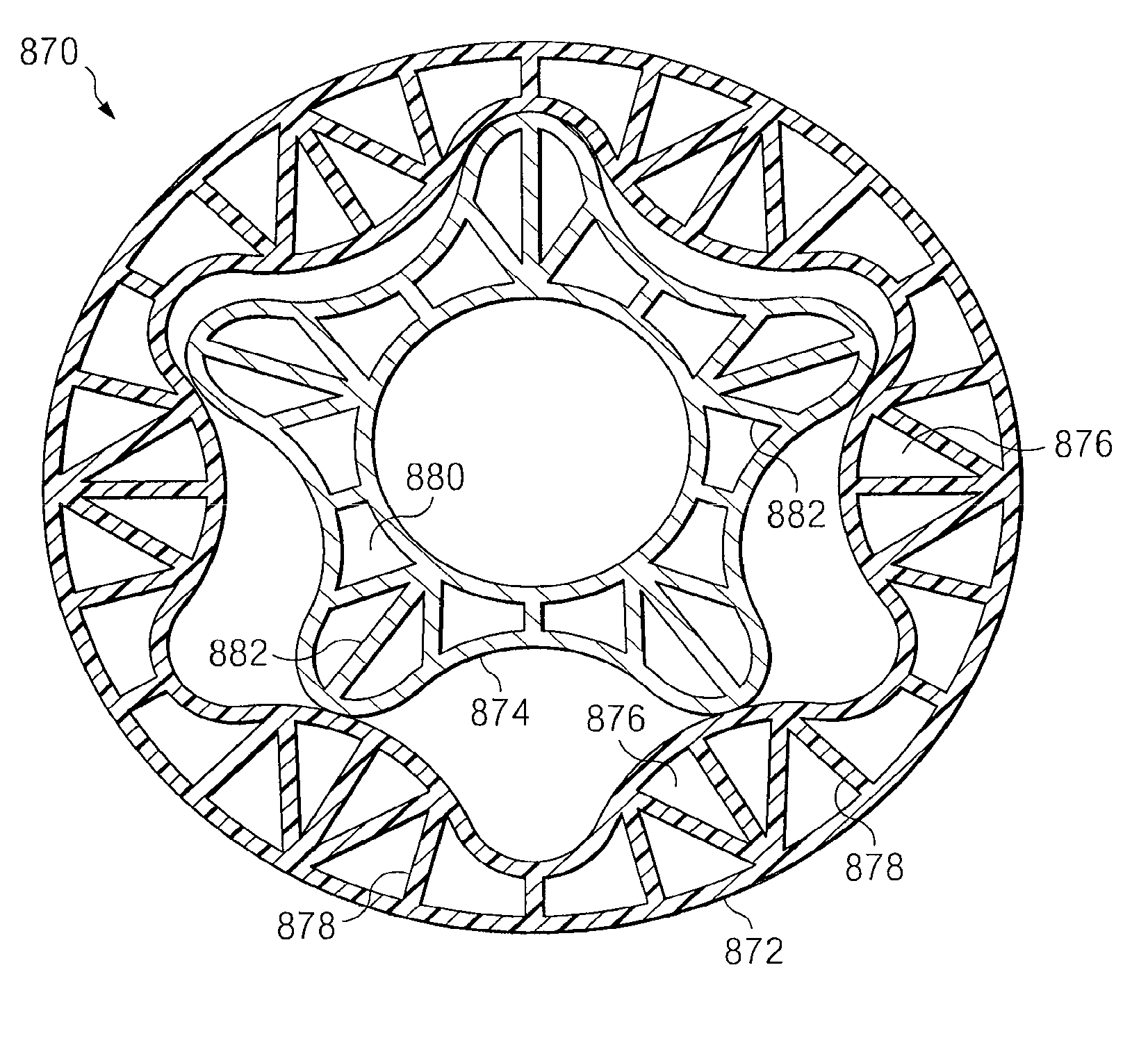

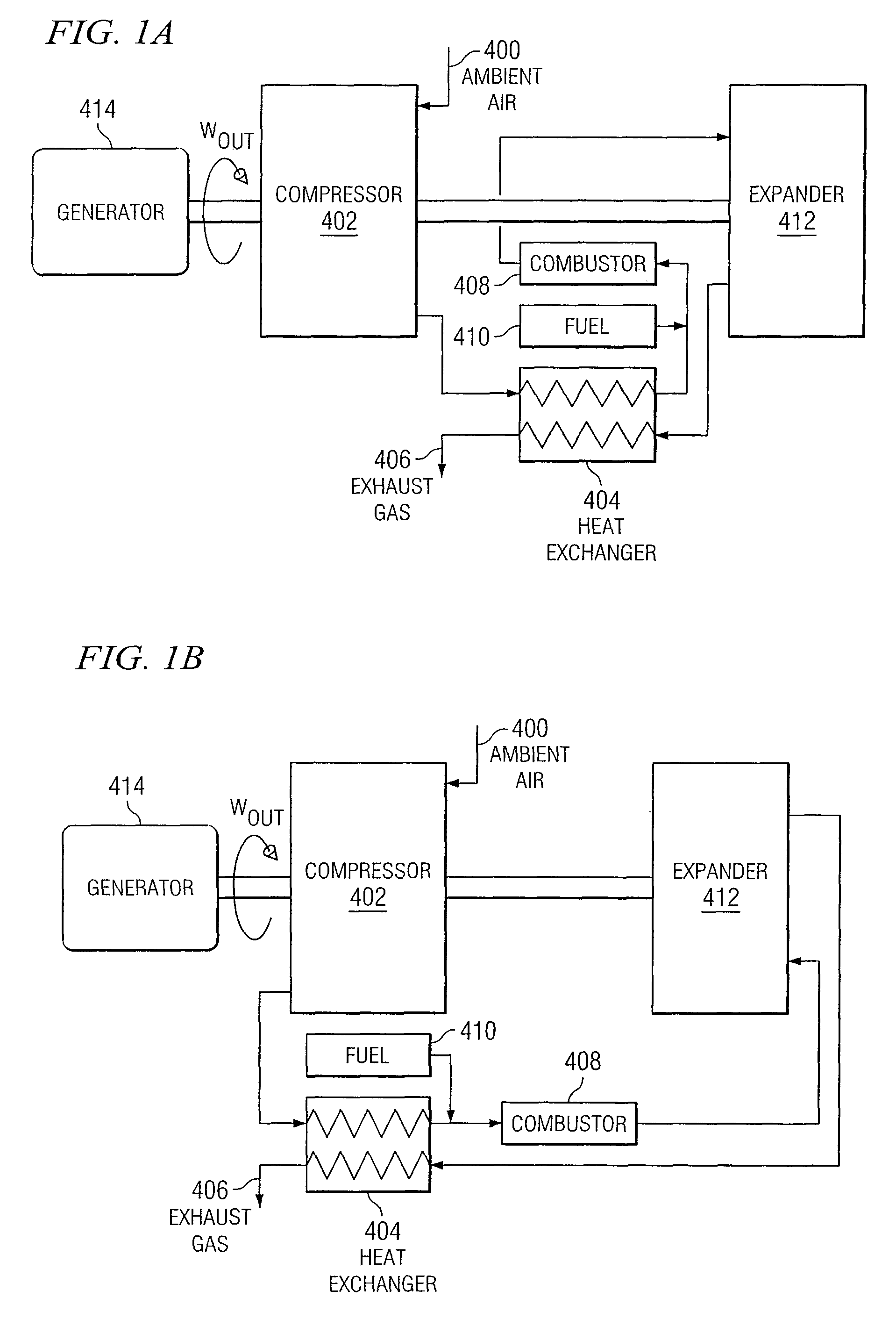

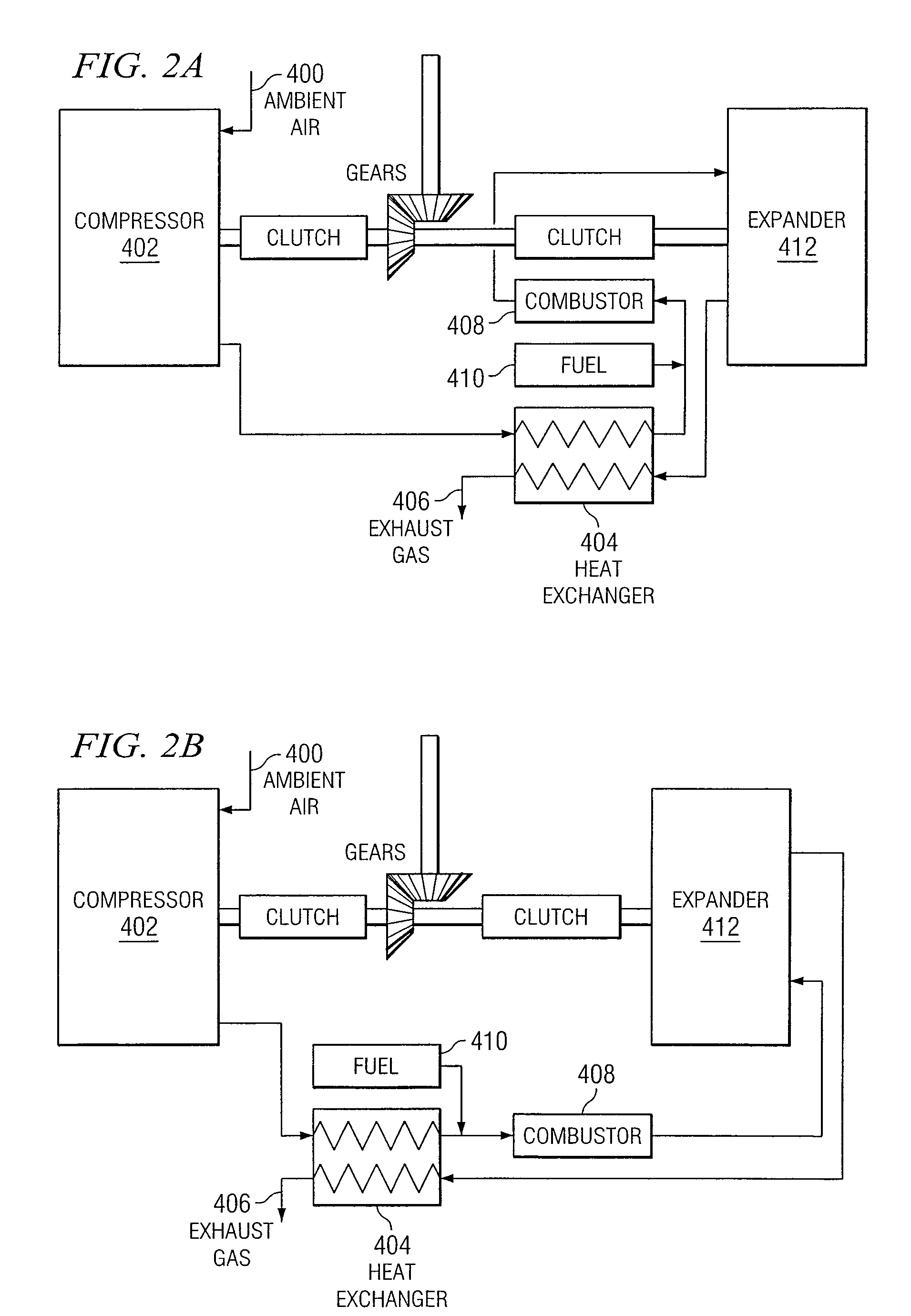

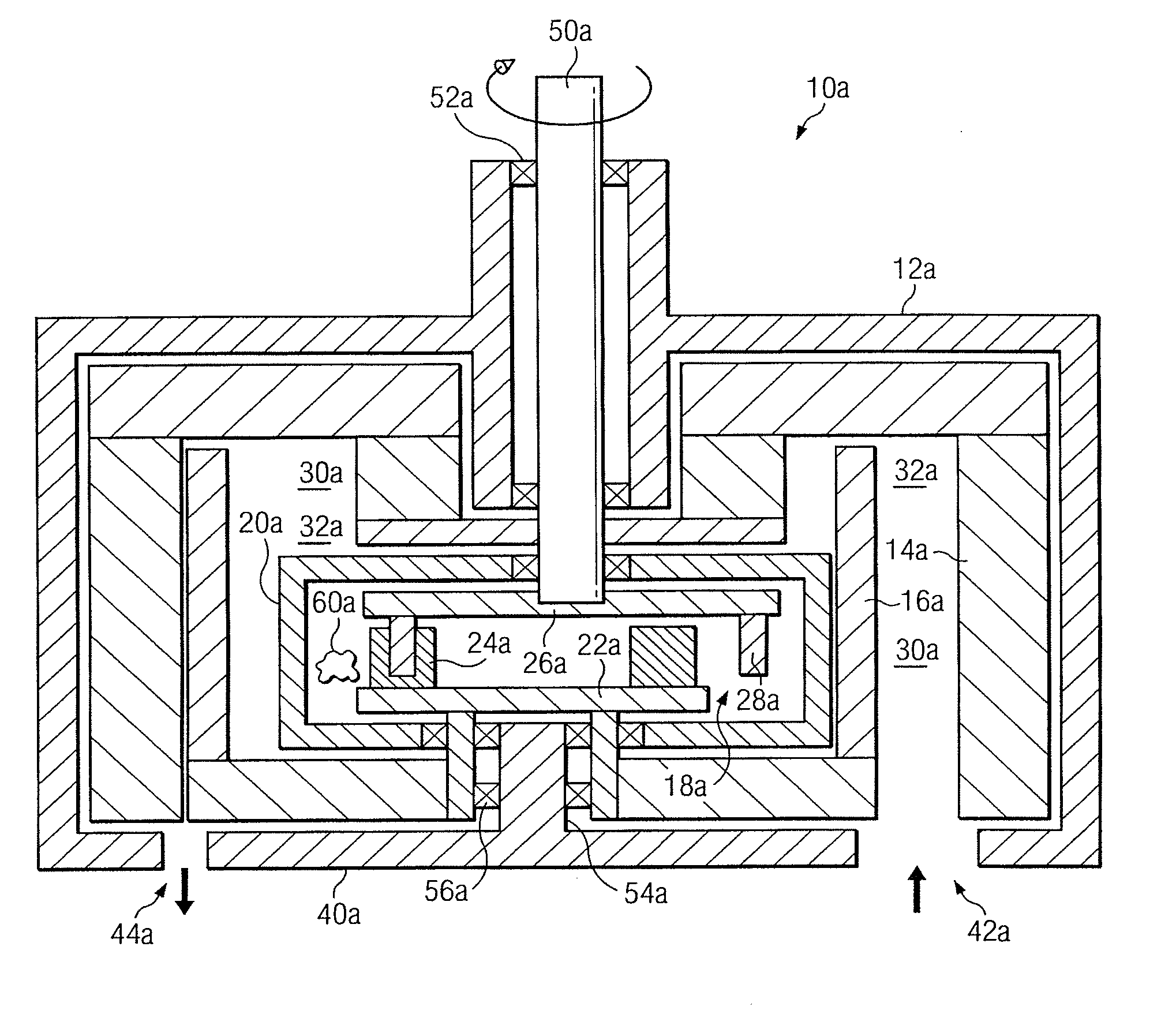

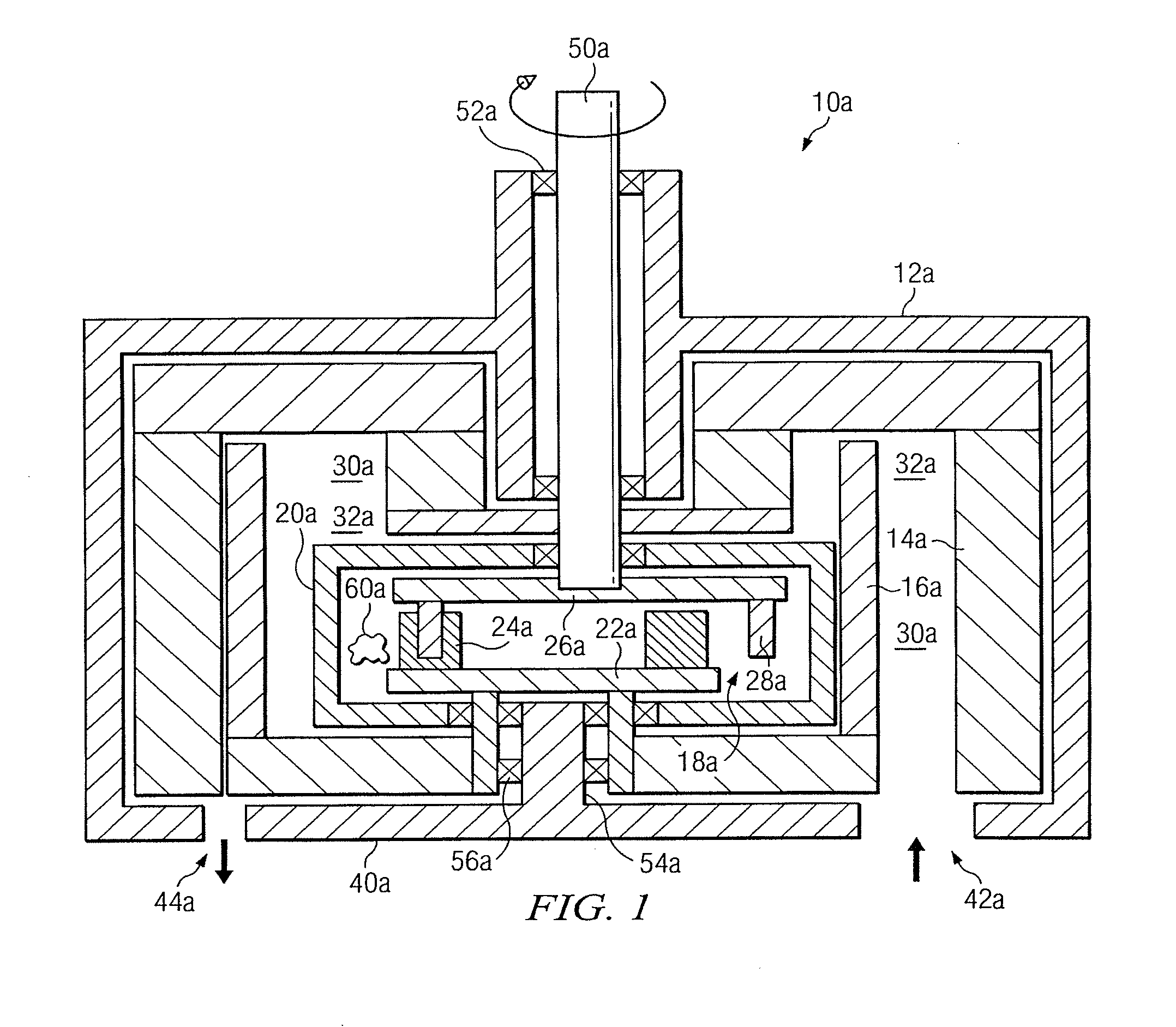

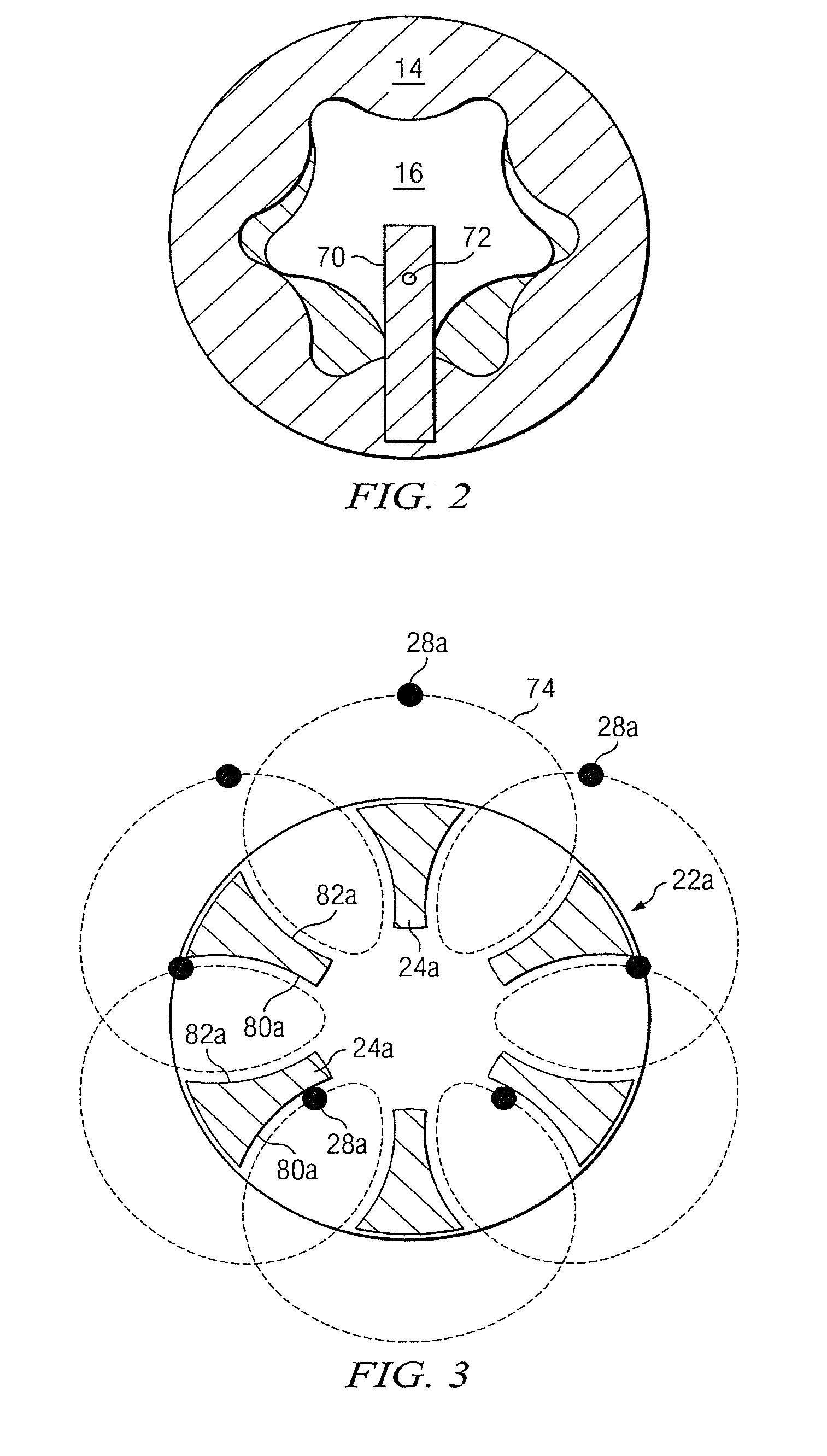

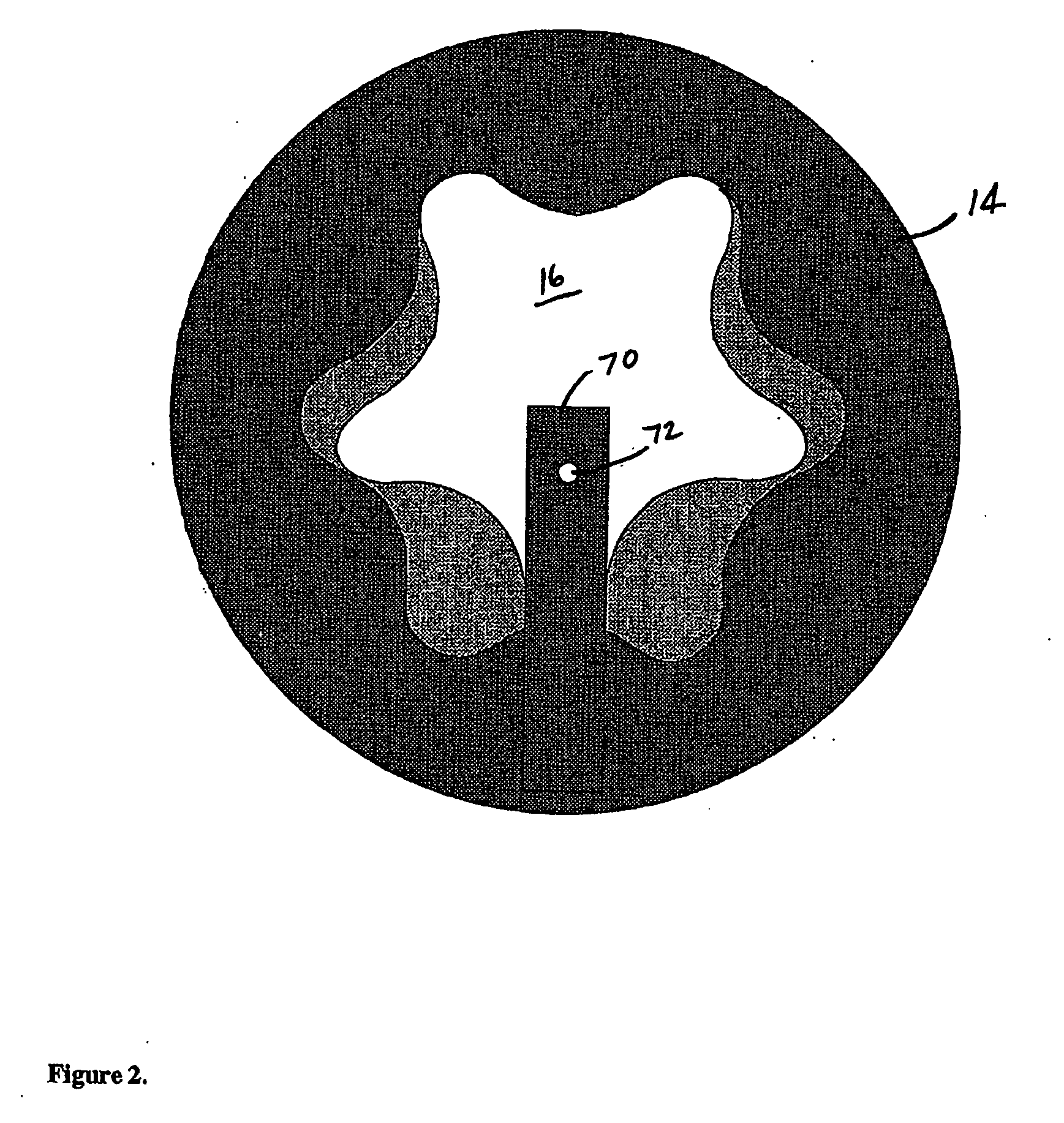

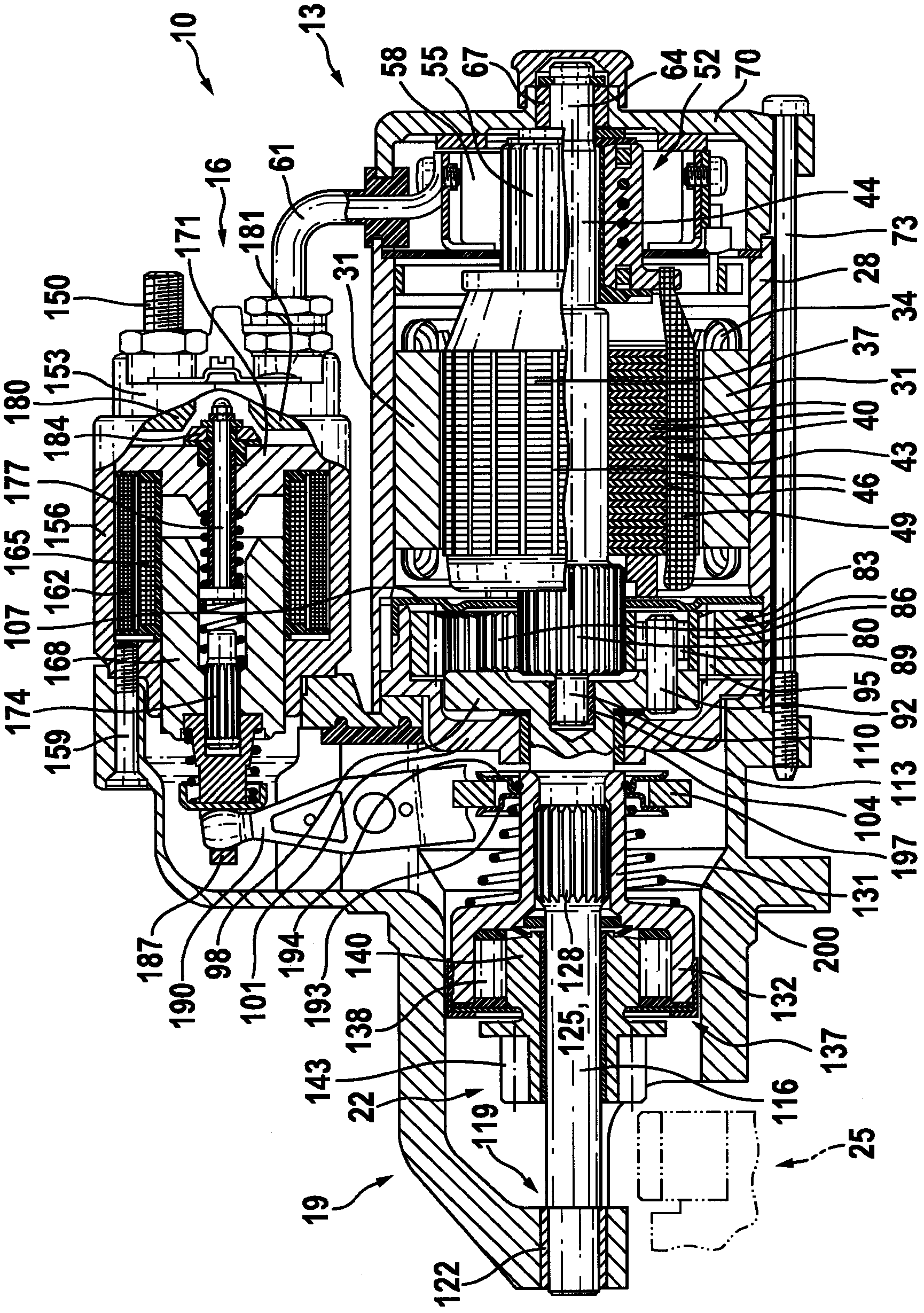

Gerotor apparatus for a quasi-isothermal brayton cycle engine

InactiveUS7008200B2Simpler gas flow pathLess loadRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesBrayton cycleEngineering

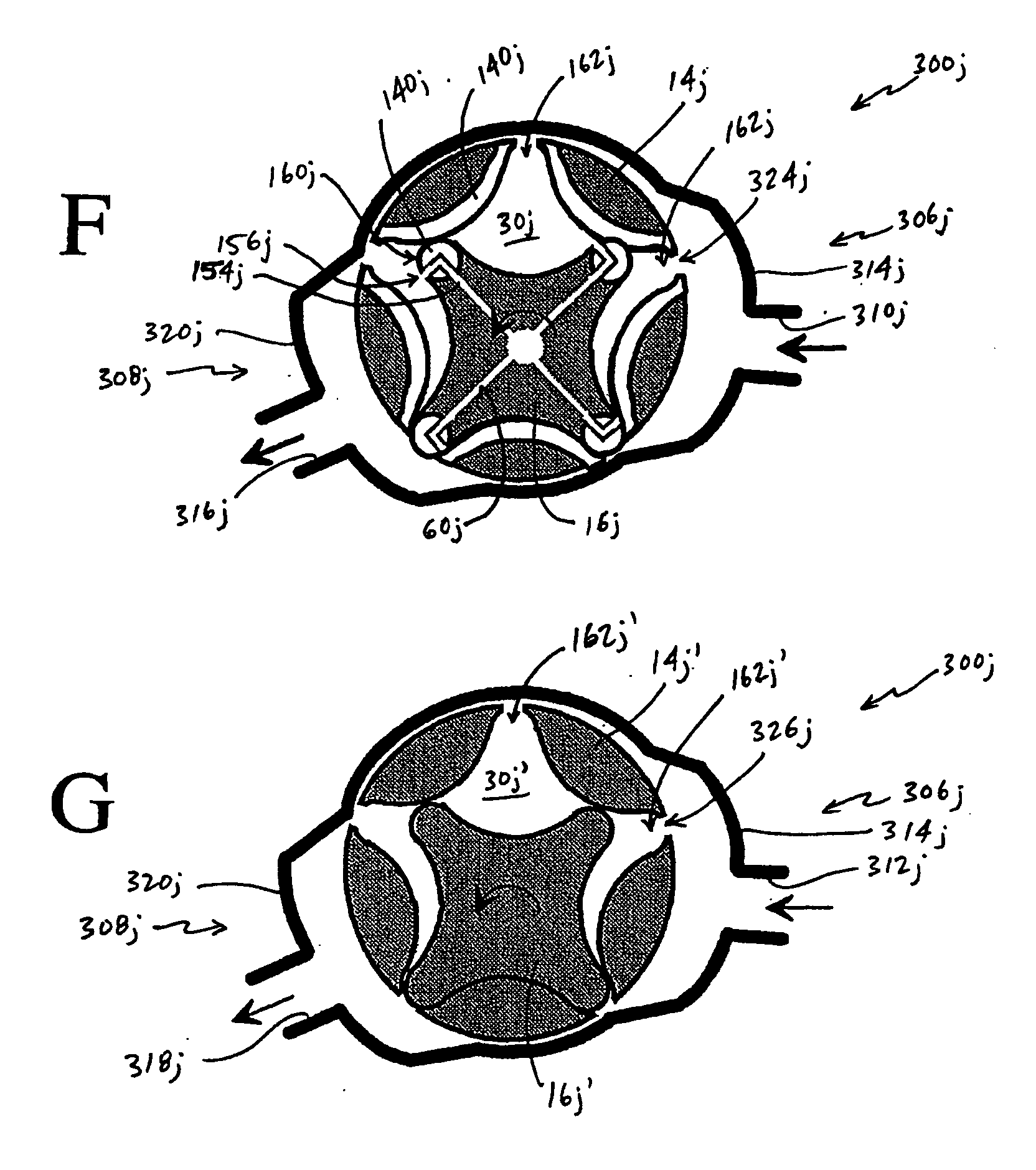

According to one embodiment of the invention, a gerotor apparatus includes an outer gerotor having an outer gerotor chamber, an inner gerotor, at least a portion of which is disposed within the outer gerotor chamber, and a synchronizing apparatus operable to control the rotation of the inner gerotor relative to the outer gerotor. The inner gerotor includes one or more entrance passages operable to communicate a lubricant into the outer gerotor chamber.

Owner:STARROTOR CORPORATION +1

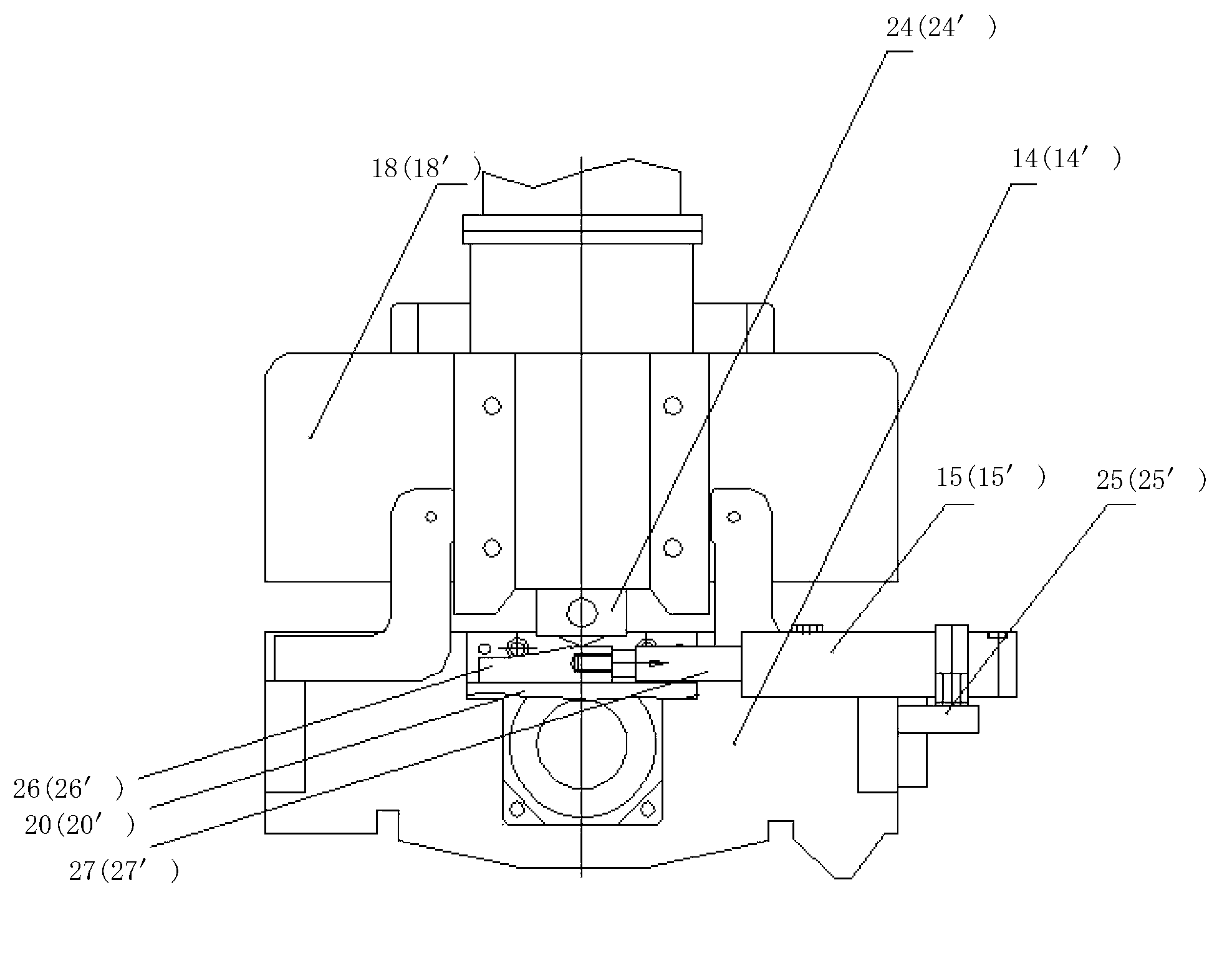

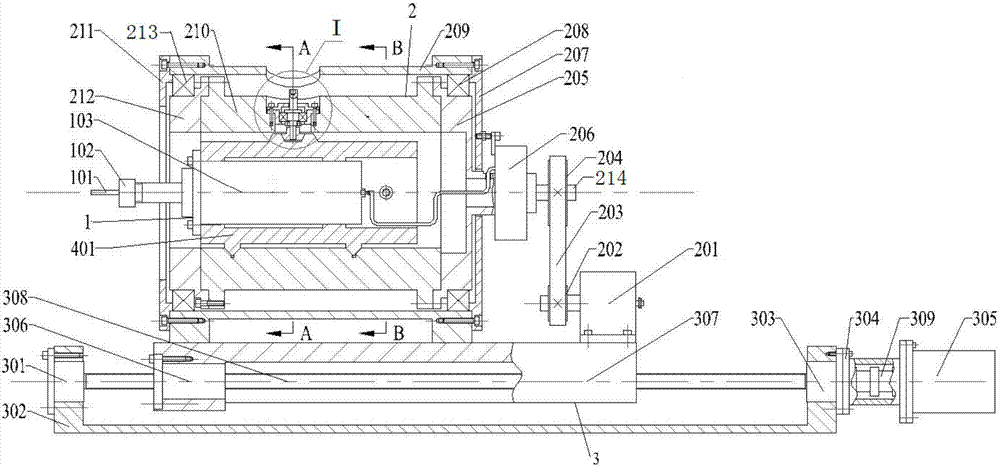

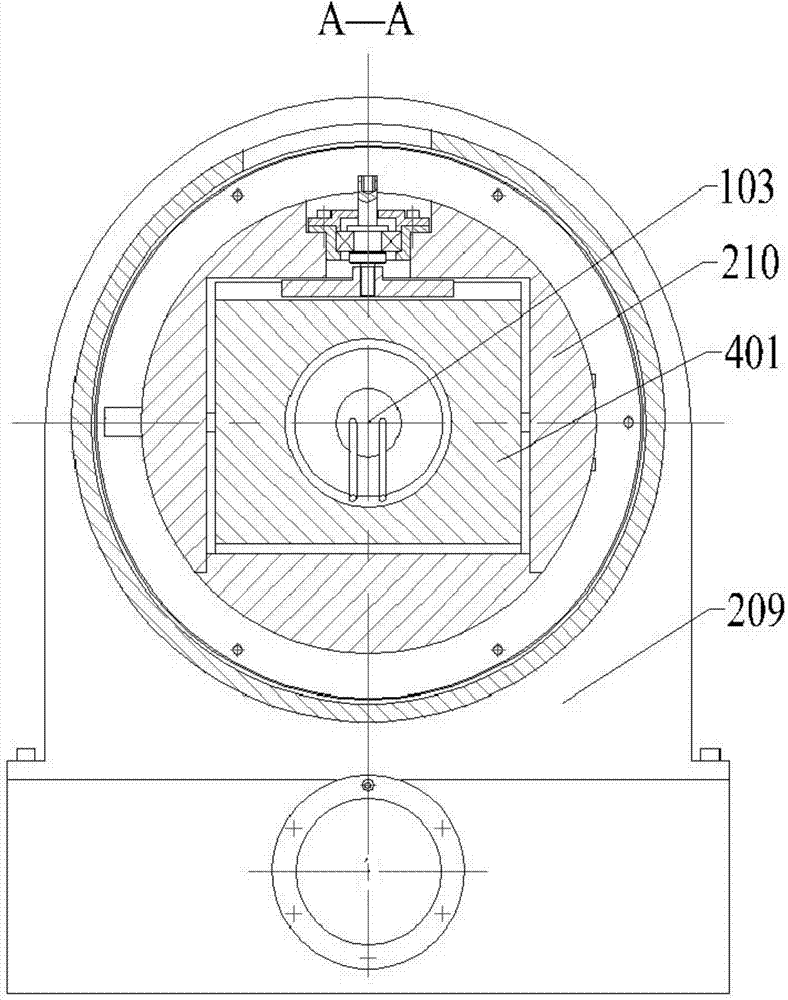

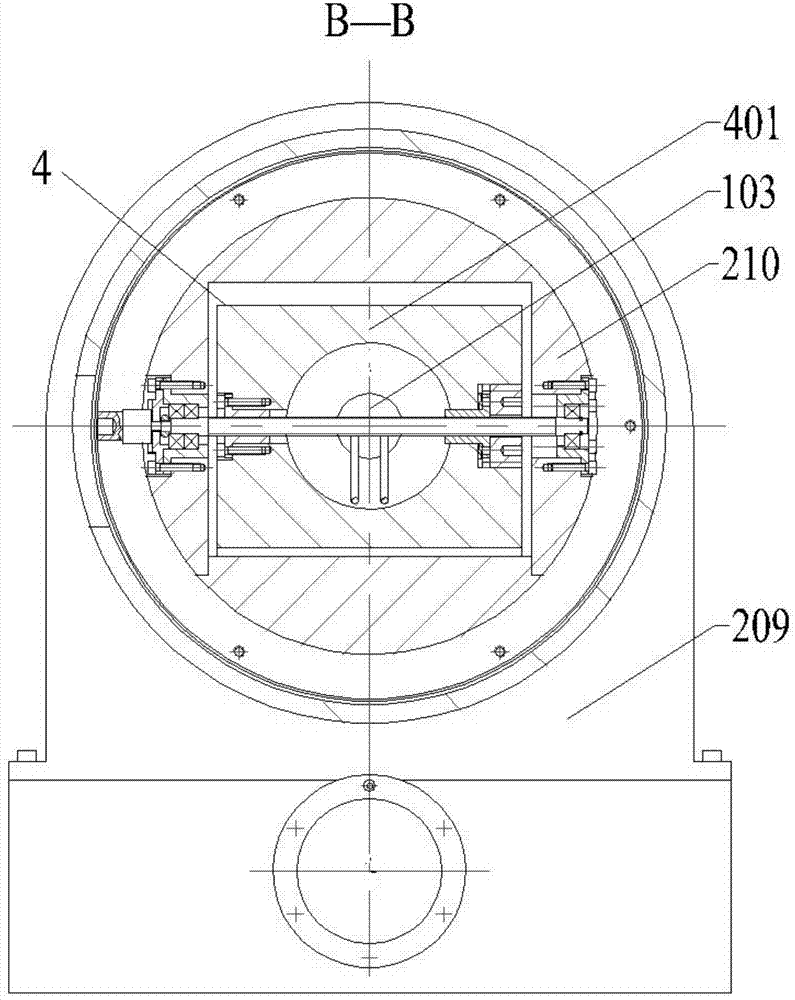

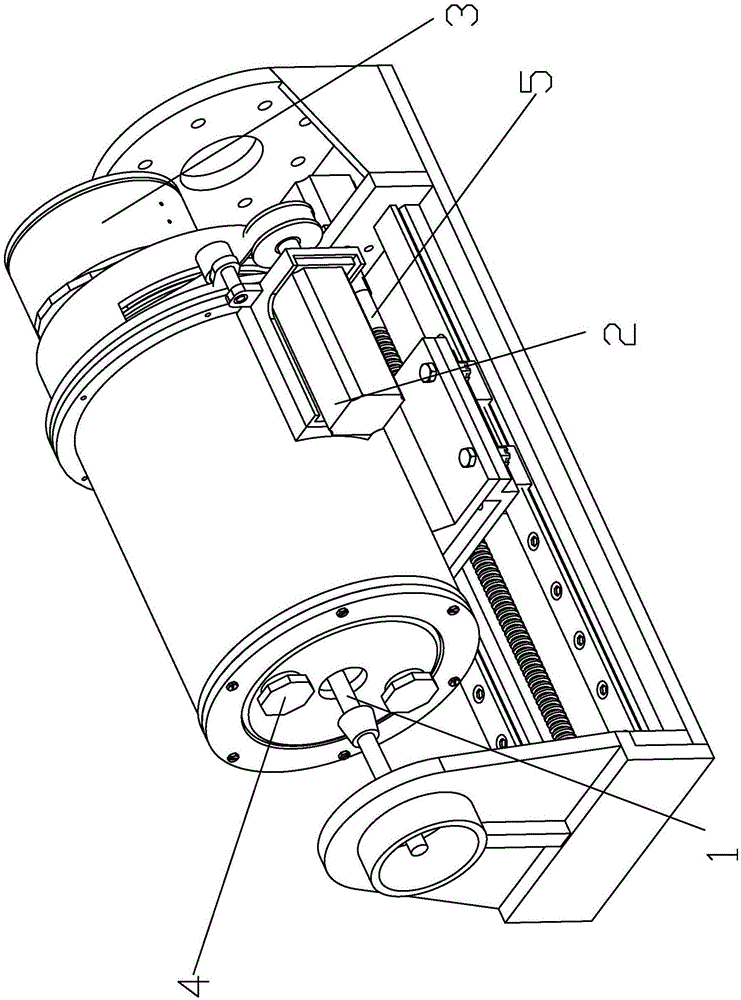

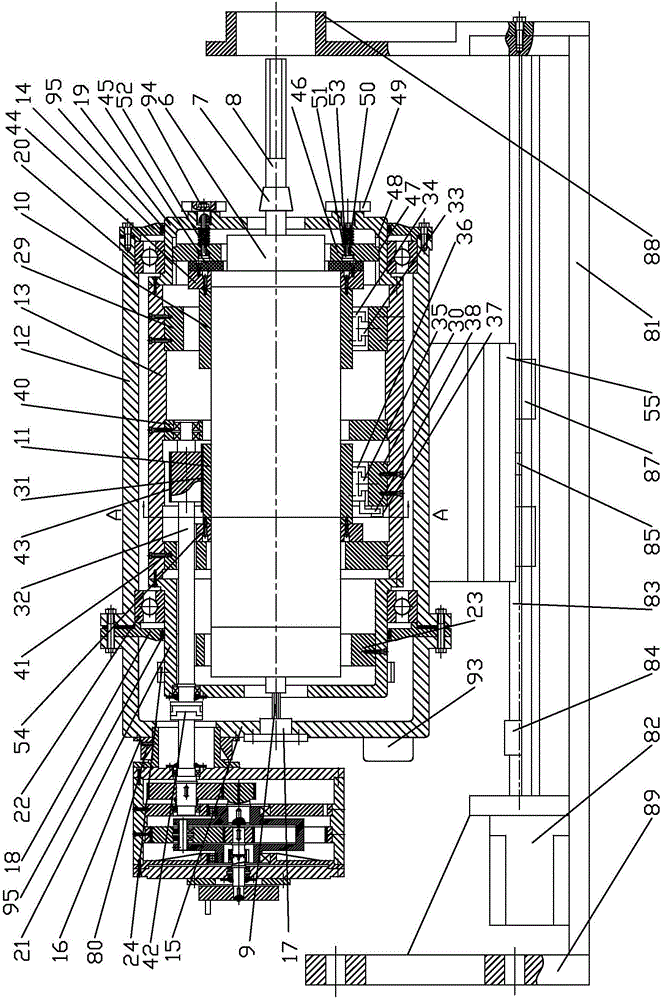

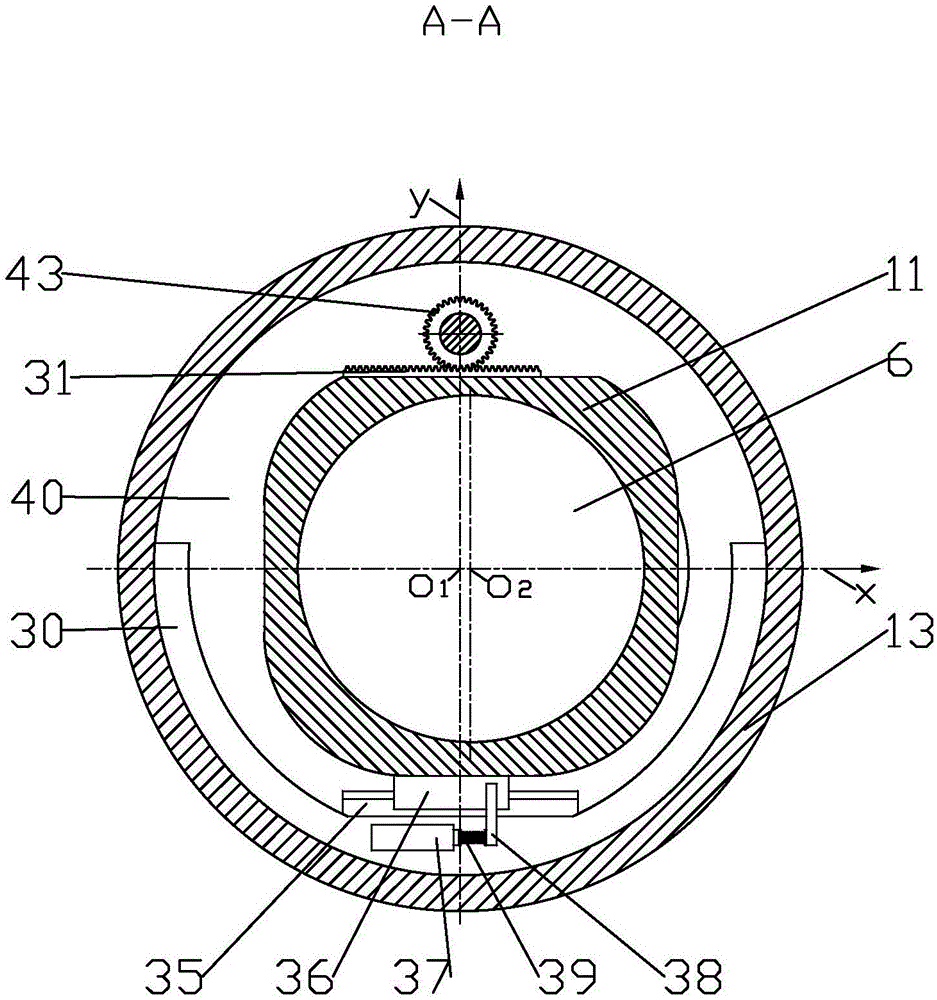

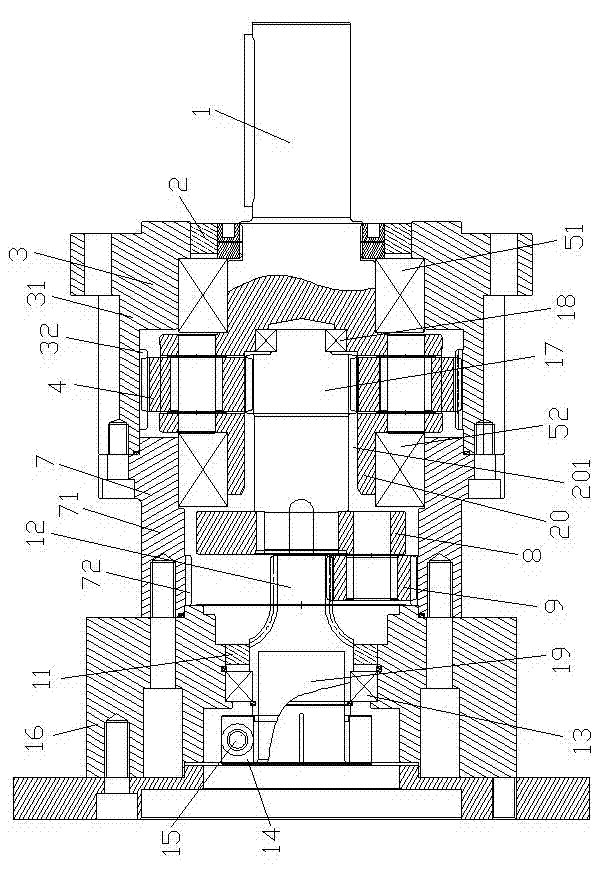

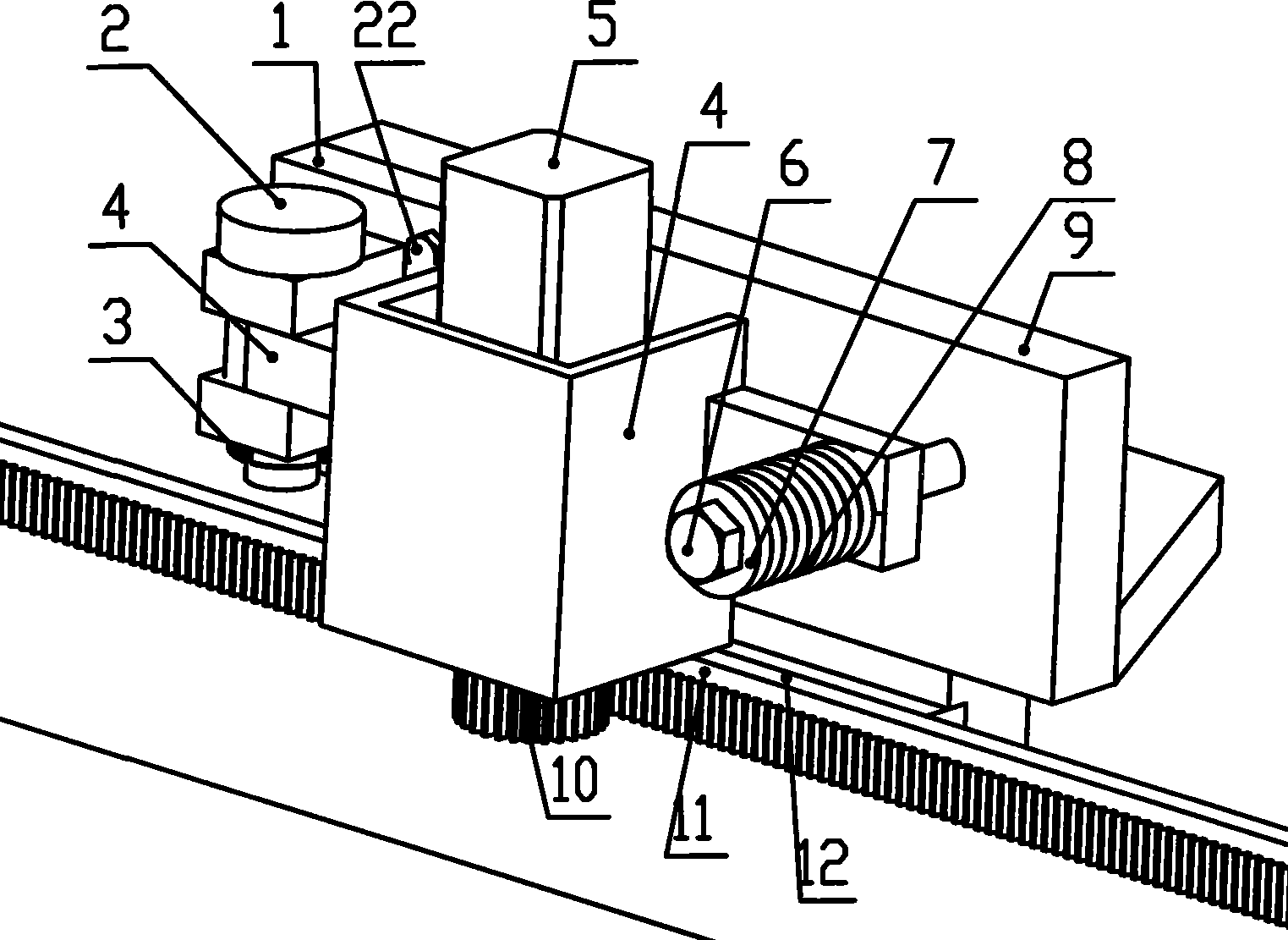

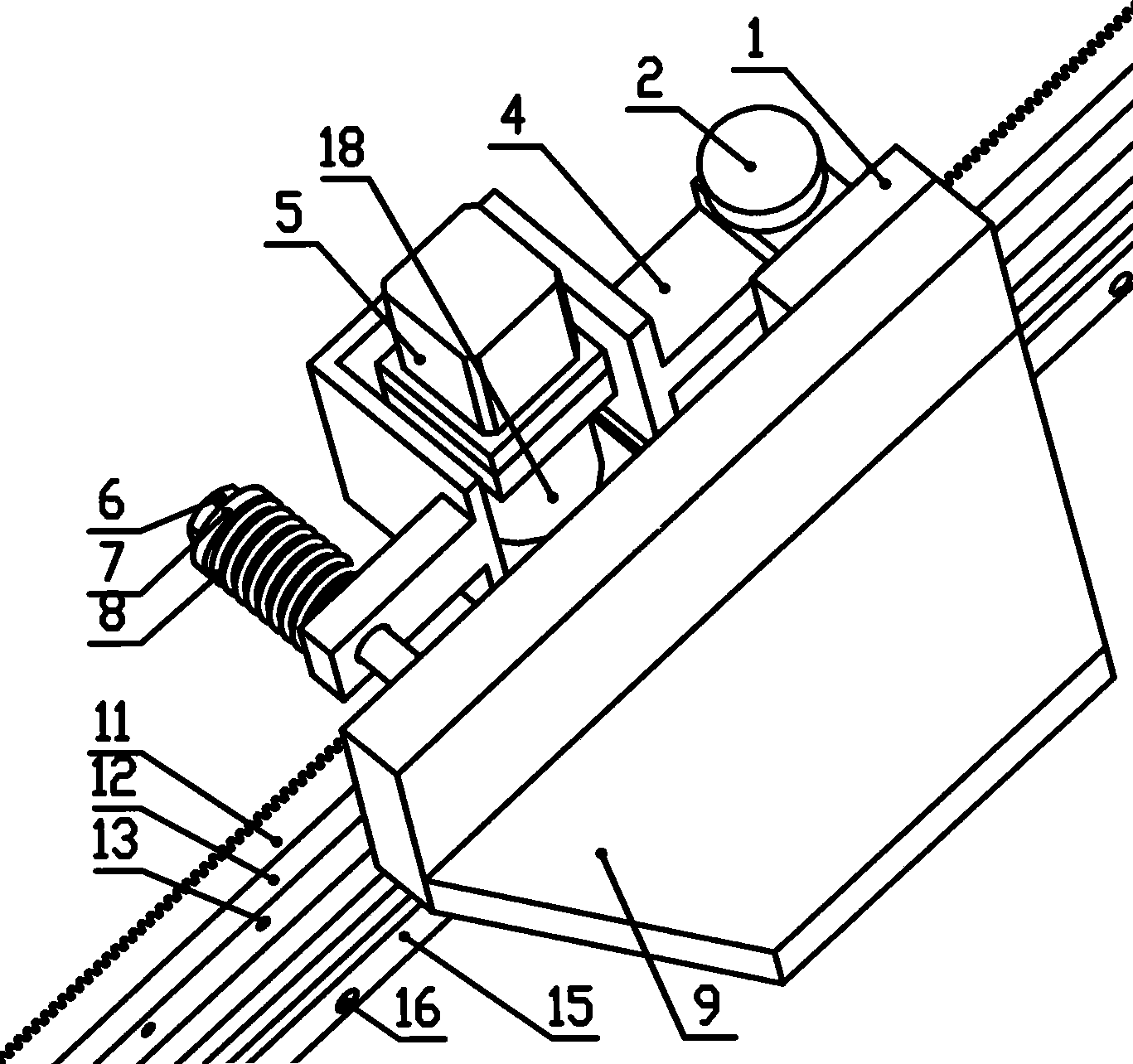

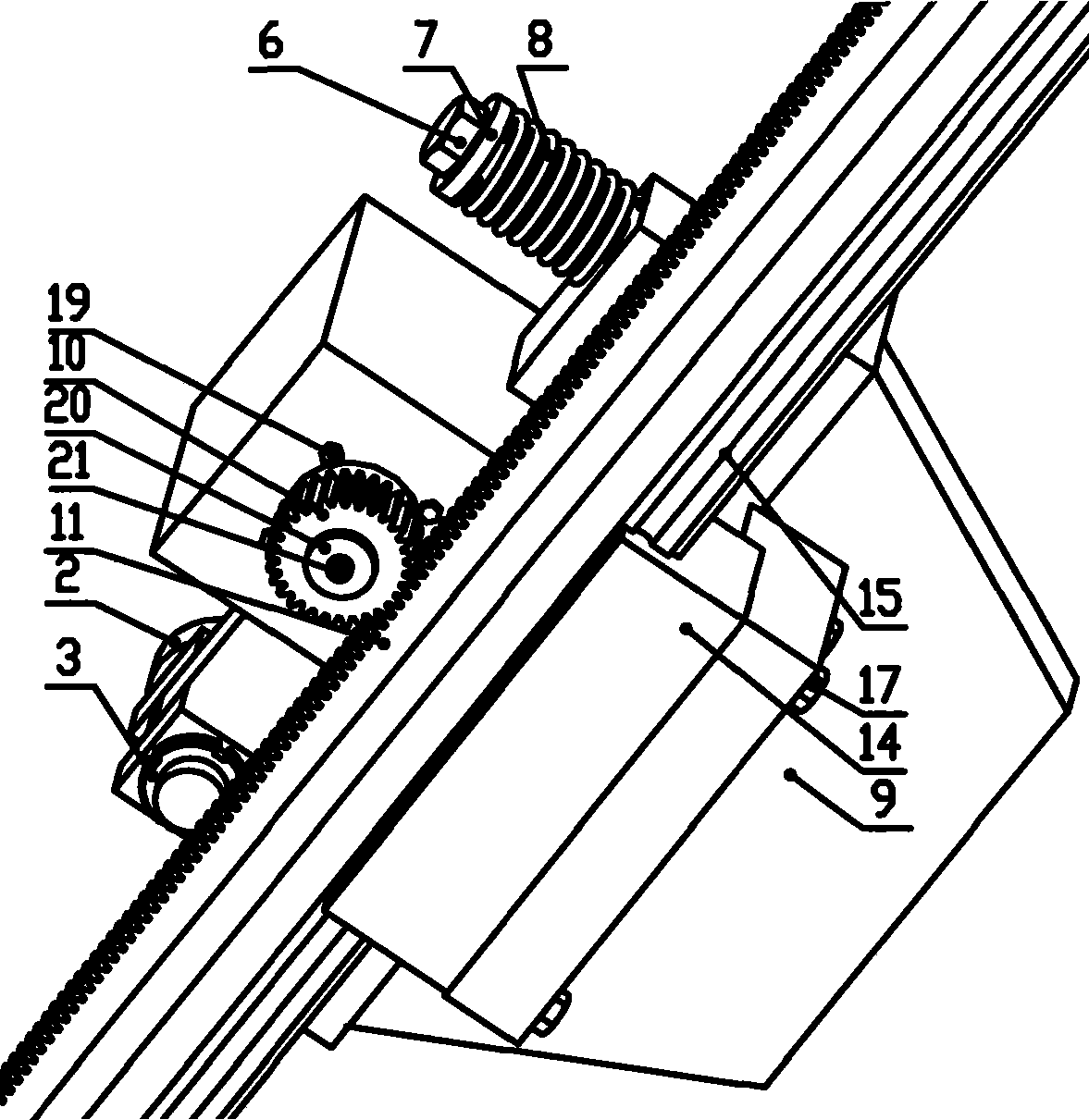

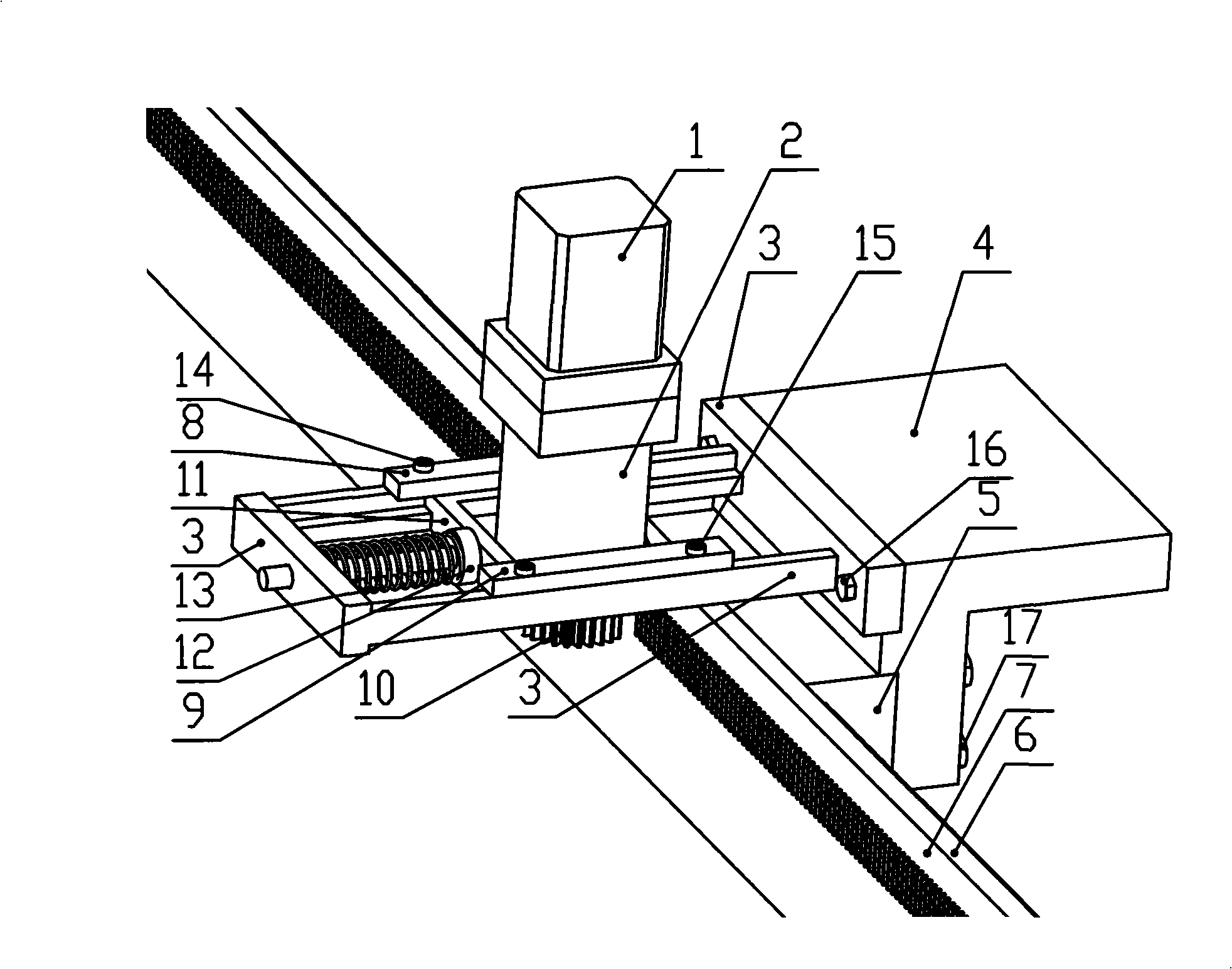

Spiral hole milling device

ActiveCN104117719AHigh adjustment accuracyIncrease adjustment errorFeeding apparatusMilling equipment detailsMilling cutterPulley

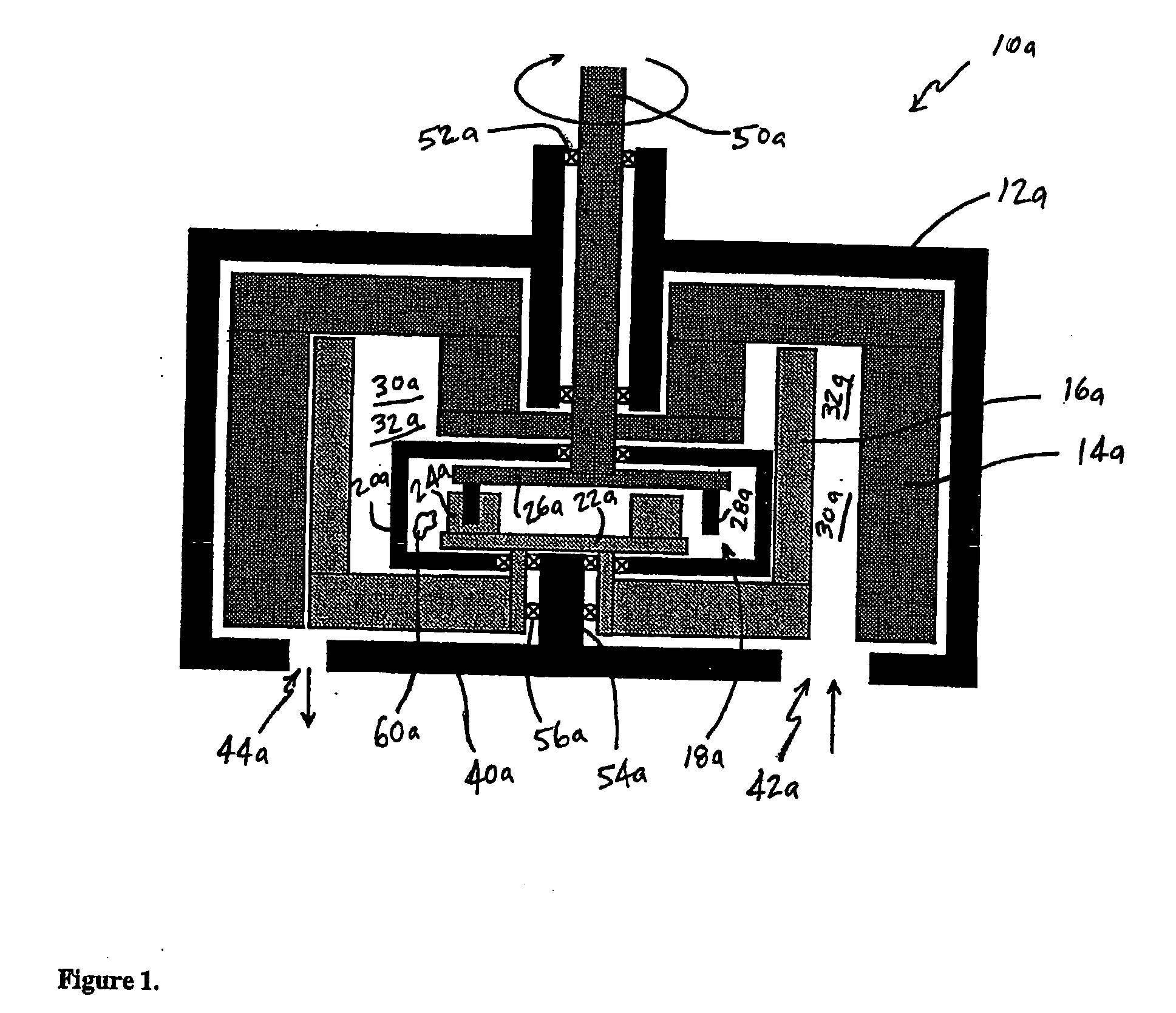

The invention discloses a spiral hole milling device. The spiral hole milling device comprises an rotationsystem, a revolution system, a feeding system and an eccentricity adjusting system. An electric main shaft in the rotation system drives a milling cutter to rotate through a spring collet arranged on an output shaft of the electric main shaft. A revolution motor in the revolution system drives an inner sleeve to perform revolution relative to the axis of an outer sleeve through a small synchronous pulley, a synchronous belt and a large synchronous pulley. A feeding motor in the feeding system drives a feeding lead screw to enable a feeding nut to move so as to achieve feeding. An eccentricity adjusting mechanism in the eccentricity adjusting system controls motion of a shifting sliding block, a fixed anti-backlash nut and a movable anti-backlash nut remove the backlash of the eccentricity adjusting system, and therefore high-precision adjustment of the eccentricity can be achieved. A holding mechanism arranged on the inner sleeve achieves the aim that the shifting sliding block is held on the inner sleeve after the eccentricity adjustment is completed. The spiral hole milling device can be applied to integral, high-quality and high-efficiency hole forming of difficultly-machined materials in the aerospace field.

Owner:DALIAN JIAOTONG UNIVERSITY

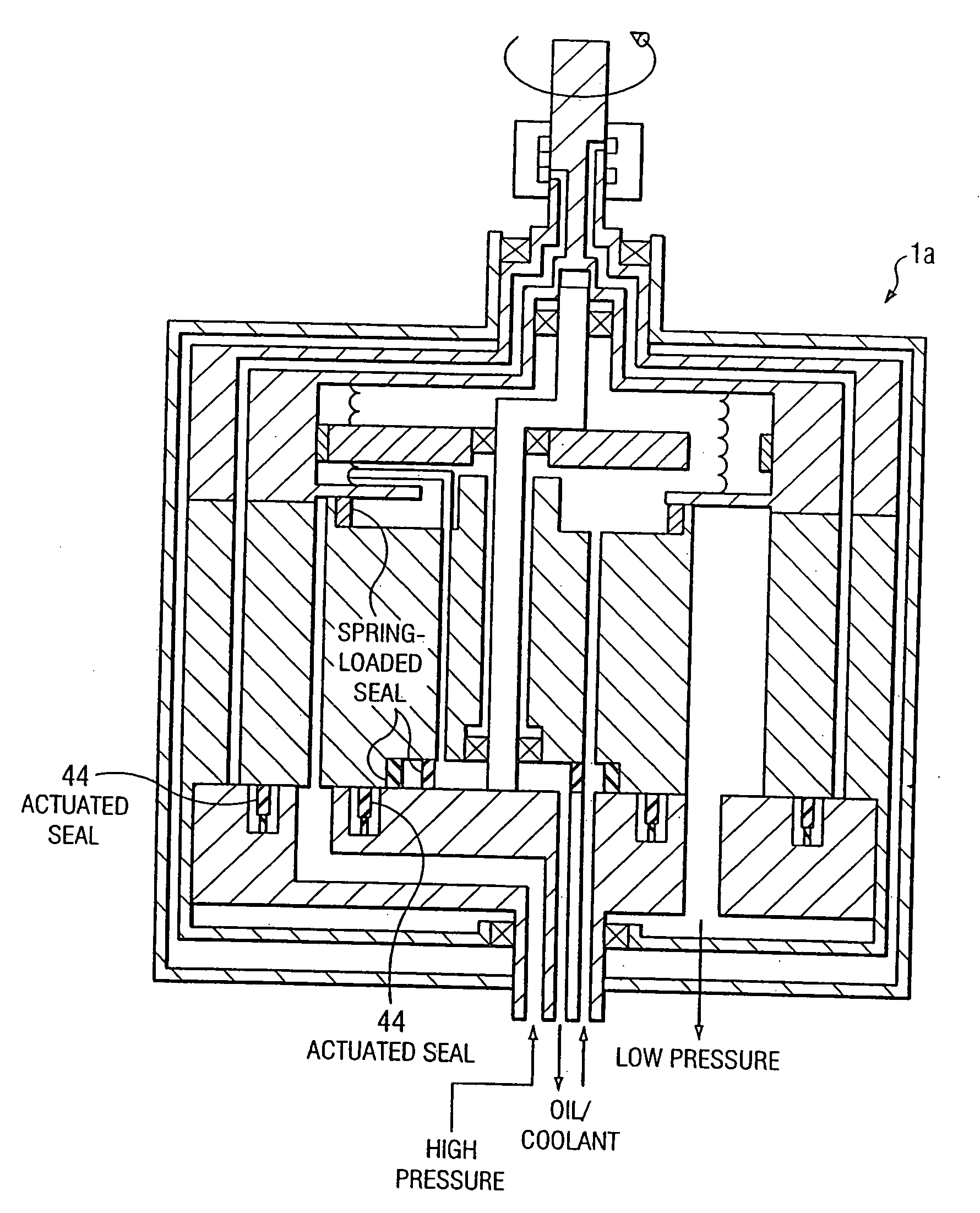

Gerotor apparatus for a quasi-isothermal Brayton cycle engine

InactiveUS20060239849A1Simple methodPrevent heat transferOscillating piston enginesSealing arrangement for pumpsBrayton cycleGerotor

Owner:TEXAS A&M UNIVERSITY

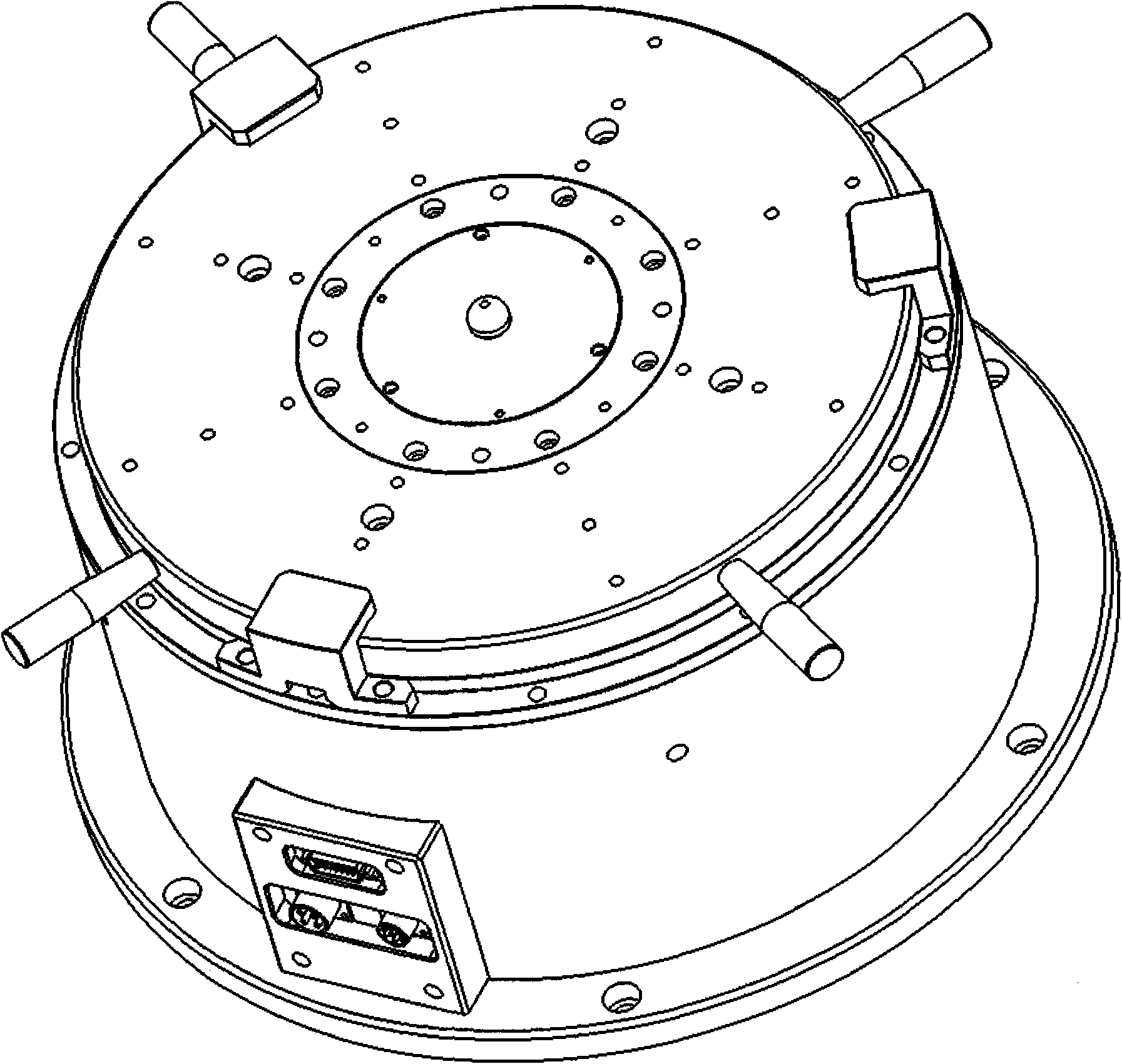

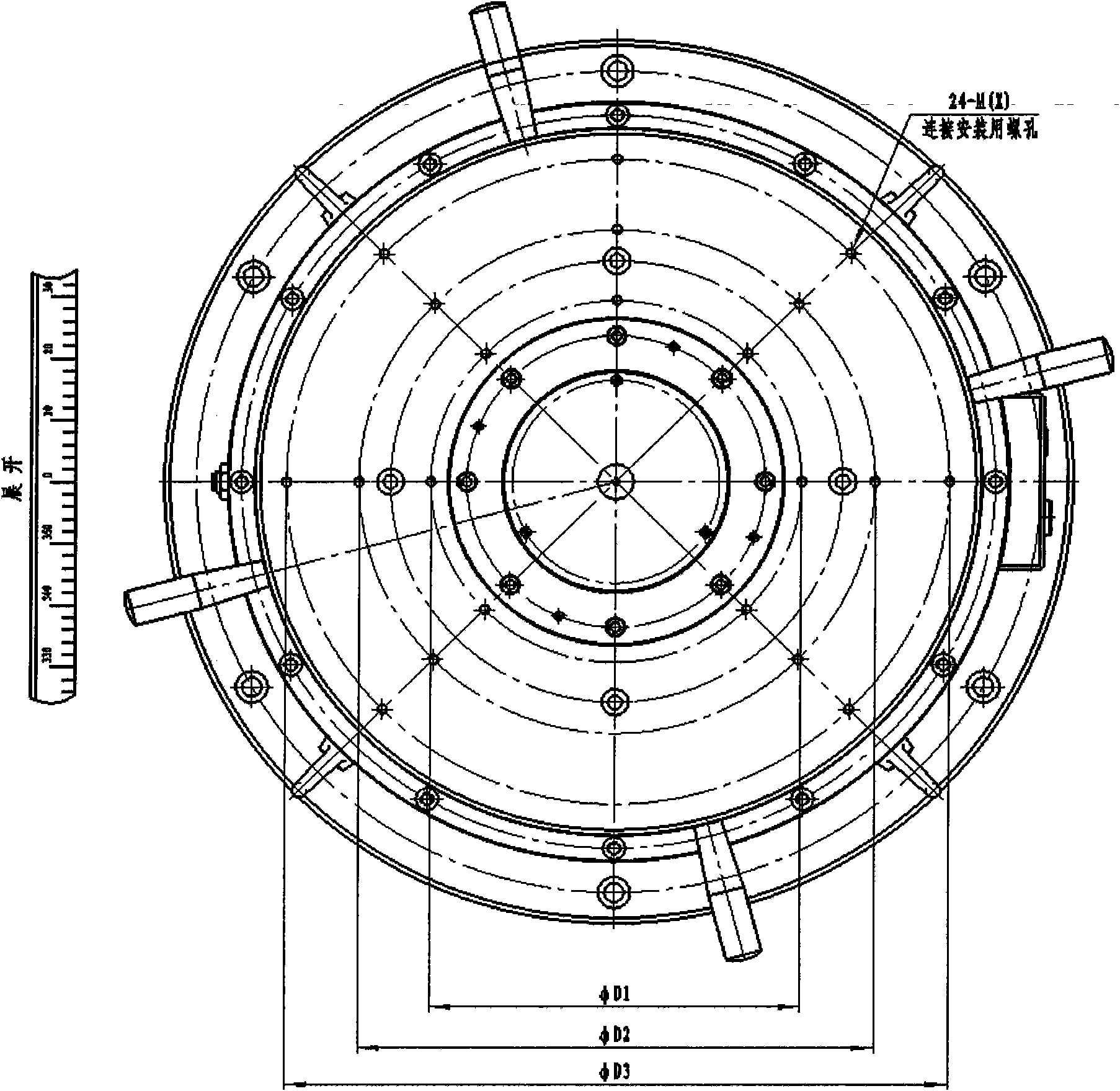

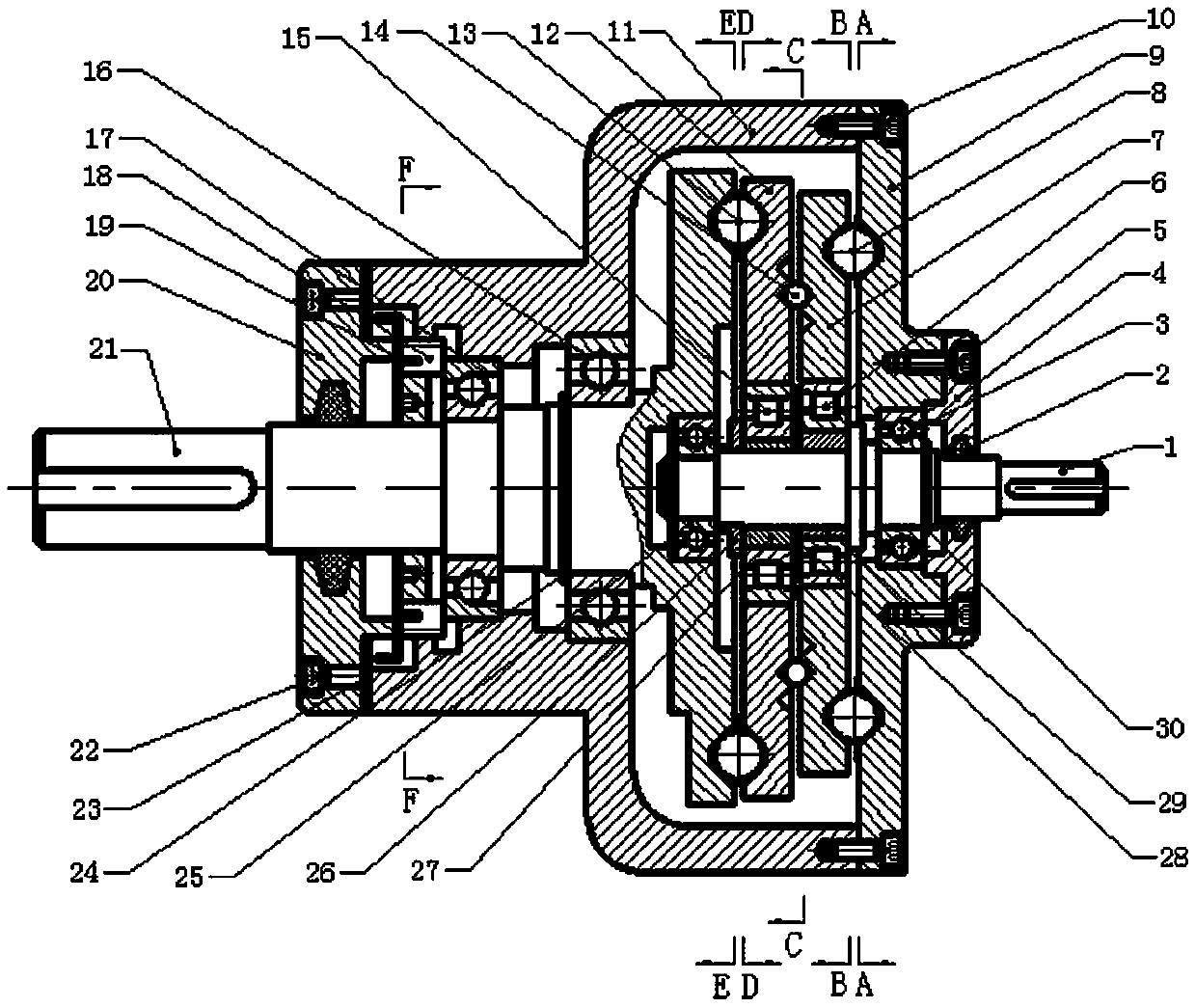

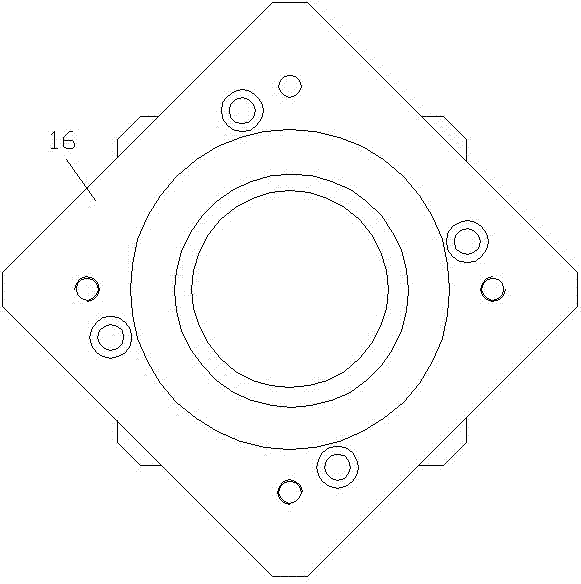

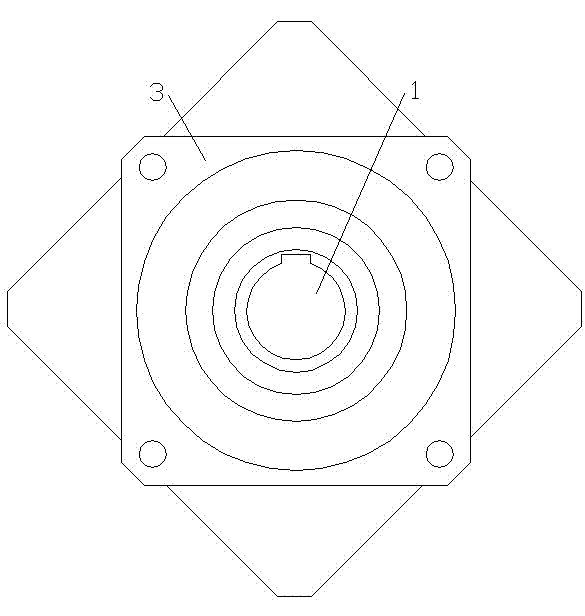

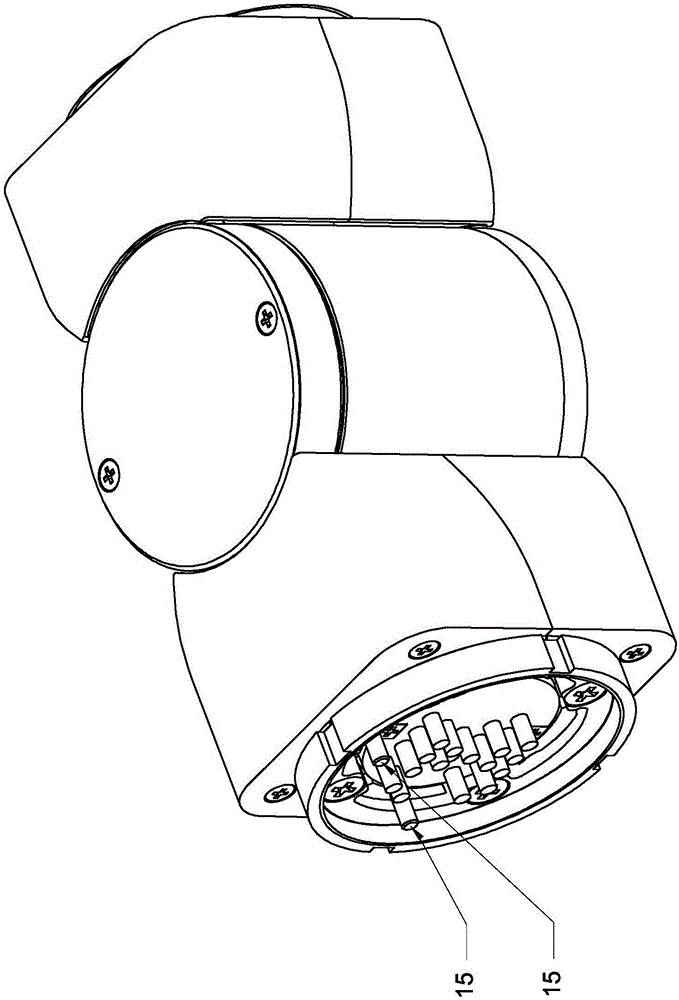

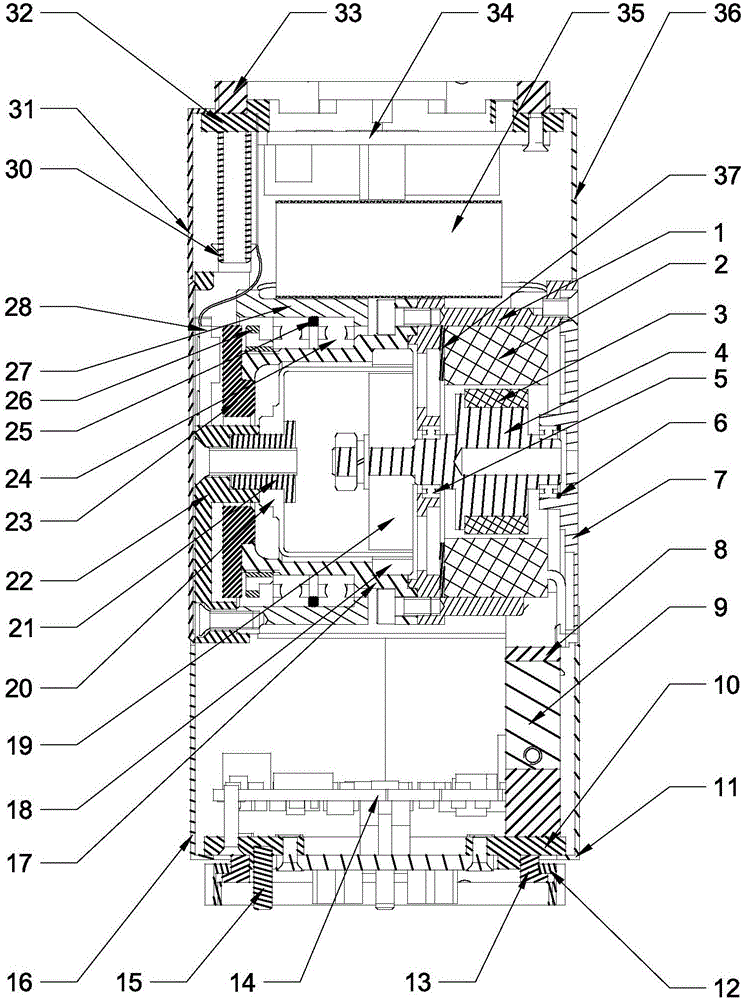

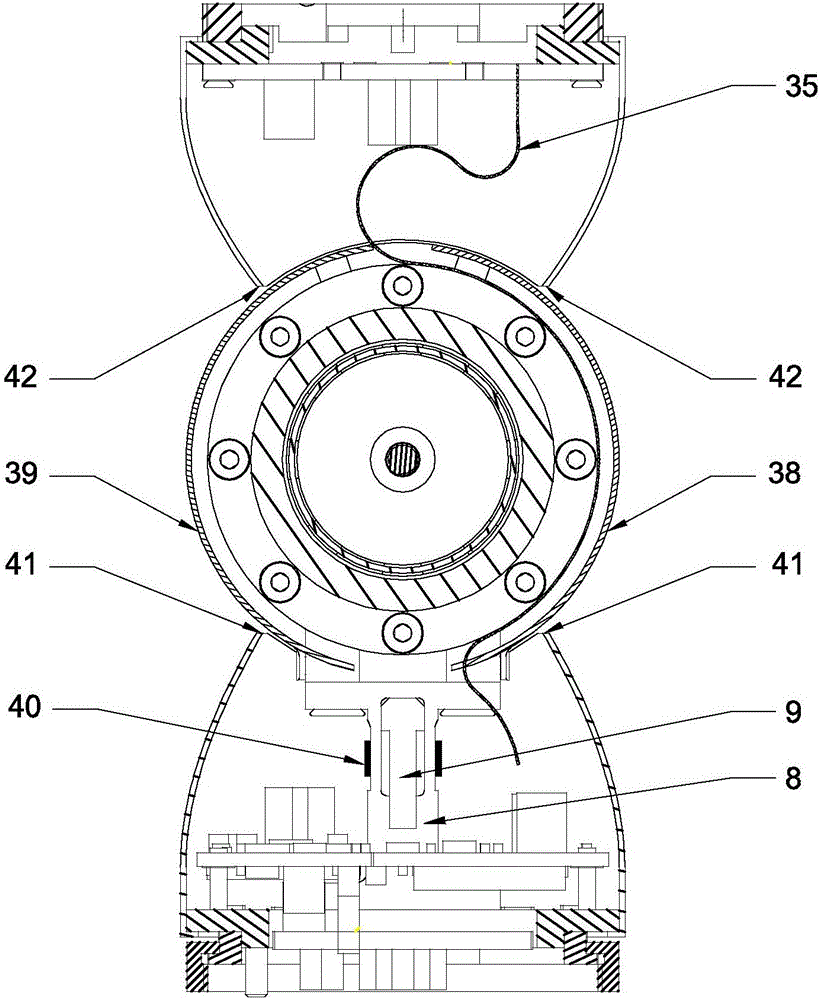

High-precision direct driven air flotation turntable

ActiveCN102011918AReduce intermediate transmission linksReduce the transmission linkStands/trestlesBearingsTorque motorEngineering

The invention discloses a high-precision direct driven air flotation turntable, which comprises a supporting seat (1), a hoisting ring screw (2), a handle (3), a sealing ring (4), an axial throttle (5), a radial throttle (6), a mounting pedestal (7), a radial bearing outer ring (8), an O-shaped rubber sealing ring I (9), an air flotation face assembly (10), an O-shaped rubber sealing ring II (11), a pressure block (12), a motor mounting seat (13), a socket (14), a plug I (15), a plug II (16), a torque motor stator (17), a torque motor rotator (18), a small pressure ring (19), a grating disc (20), a reading head (21), a reading head bracket (22), a gland (23), a sealing plate (24) and a large pressure ring (25). The turntable has high indexing precision and low end face run-out and radial run-out, and solves the precise indexing problem under the condition of high load.

Owner:BEIJING SATELLITE MFG FACTORY

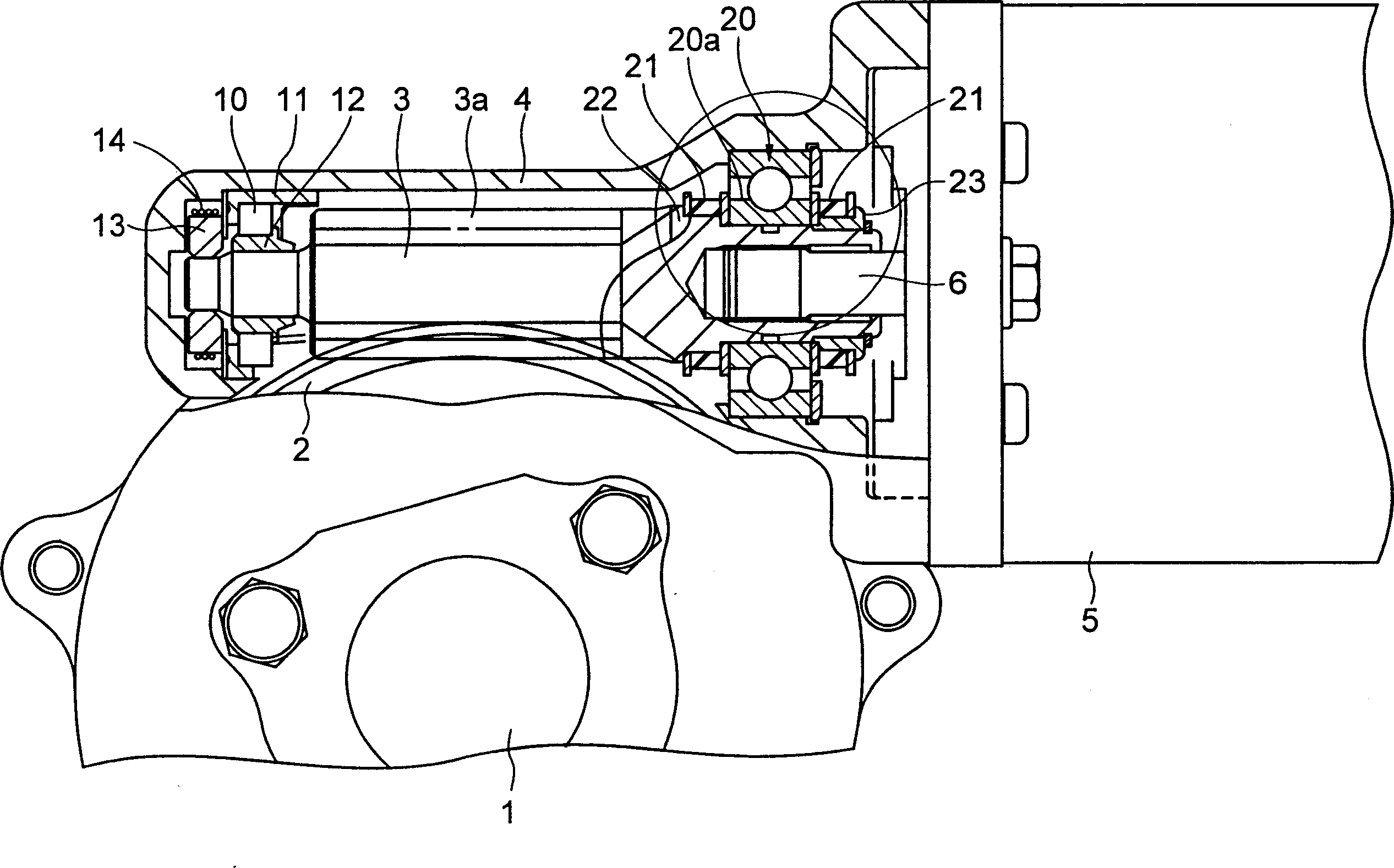

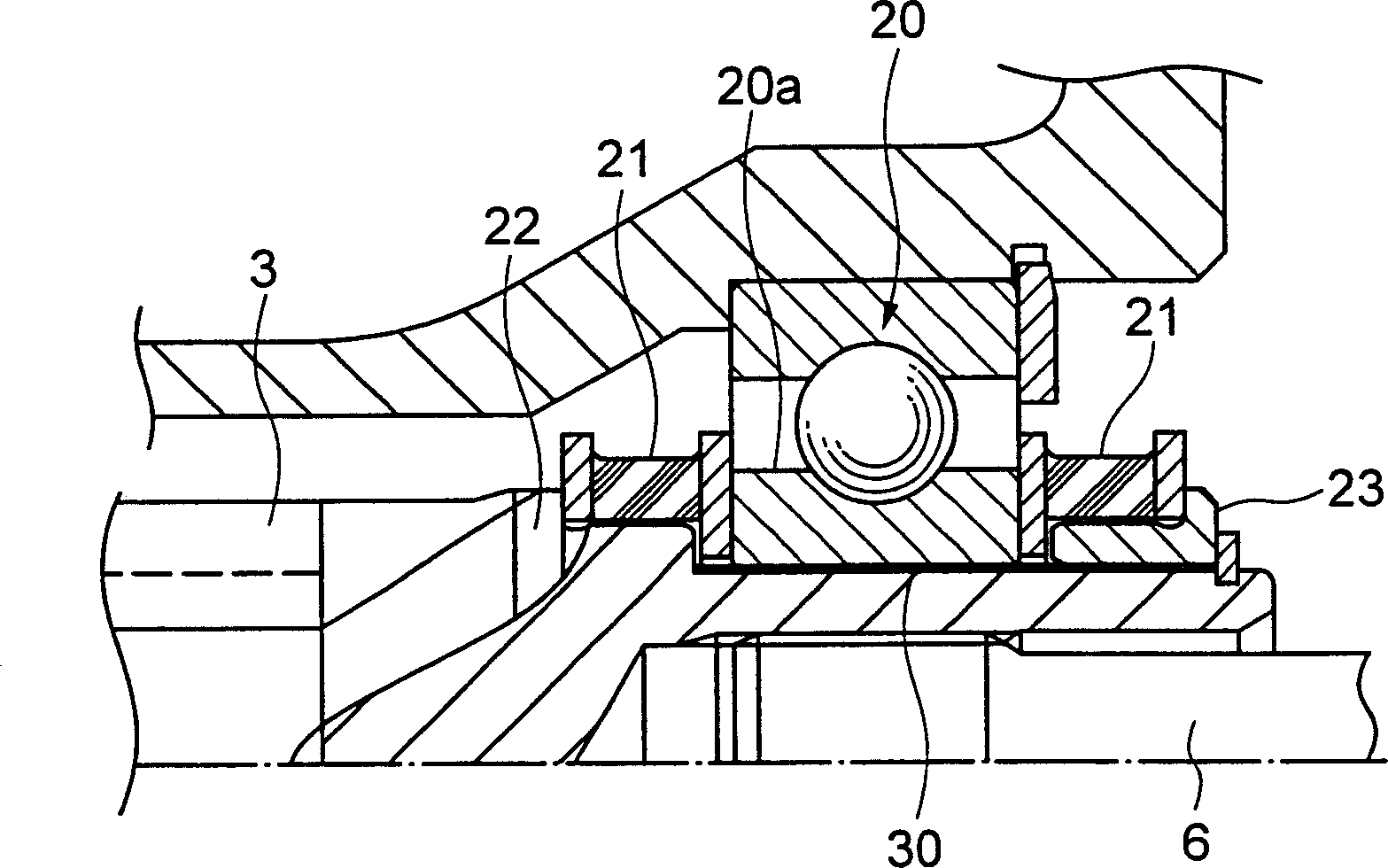

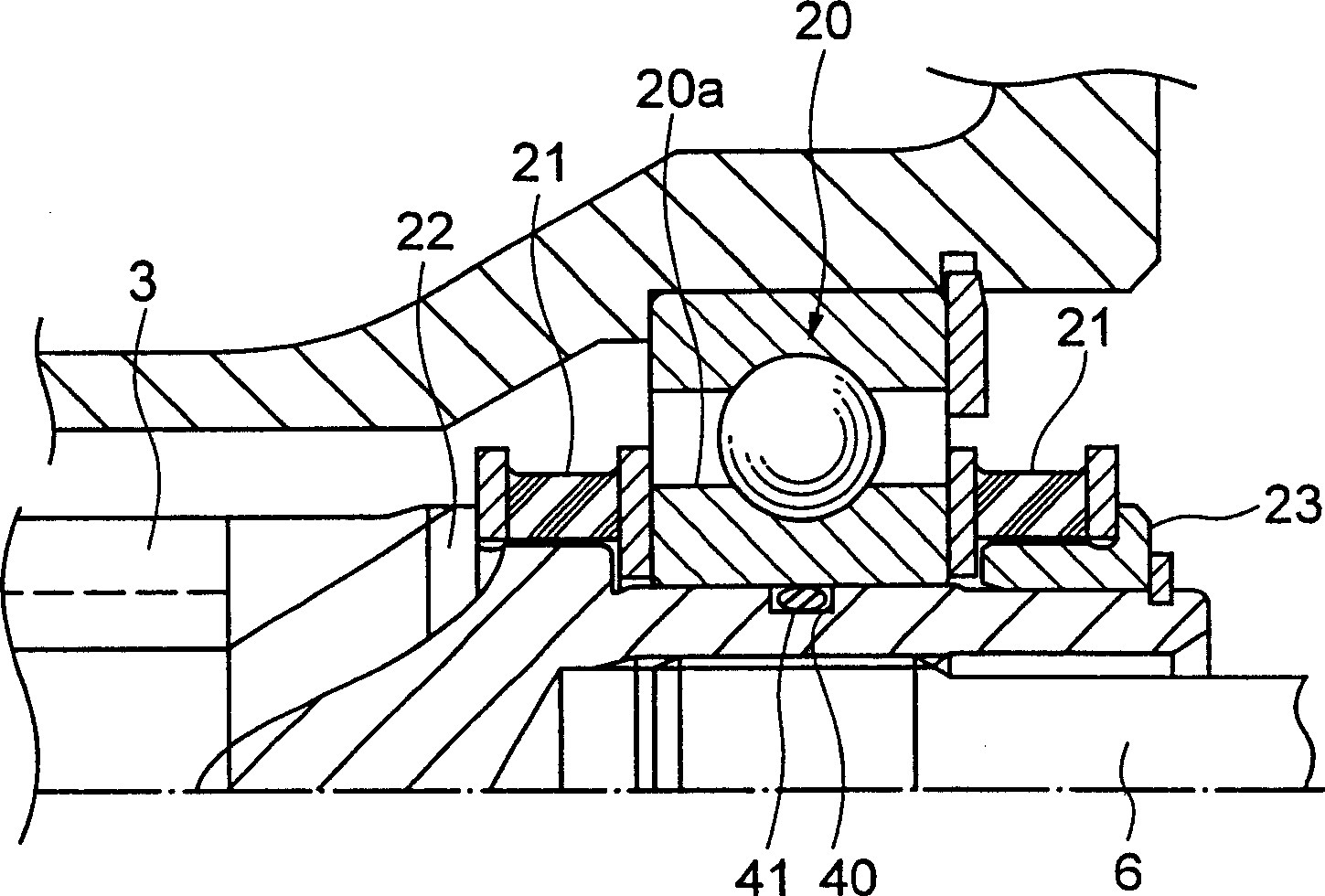

Electric power steering apparatus

InactiveCN1723146ASmall backlashGear vibration/noise dampingBall bearingsElectric power steeringEngineering

A small gap is formed between a worm shaft 3 and a second bearing 20, so that the worm shaft can be tilted relative to the inner ring 20a of the second bearing 20 without fail when preloaded by a torsion spring 14. An elastic member 41 is provided in at least portion of a circumferential groove 40 in the small gap. The worm shaft 3 and the inner ring 20a of the second bearing 20 are not in contact with each other, and their metallic clank in the small gap can be prevented. By providing a projecting portion(s) 3b on one side or both sides, with respect to the axial direction, of the circumferential groove 40, the small gap between the worm shaft 3 and the inner ring 20a of the second bearing 20 can be made large, and it is possible to enlarge the range over which the worm shaft 3 can swing.

Owner:NSK LTD

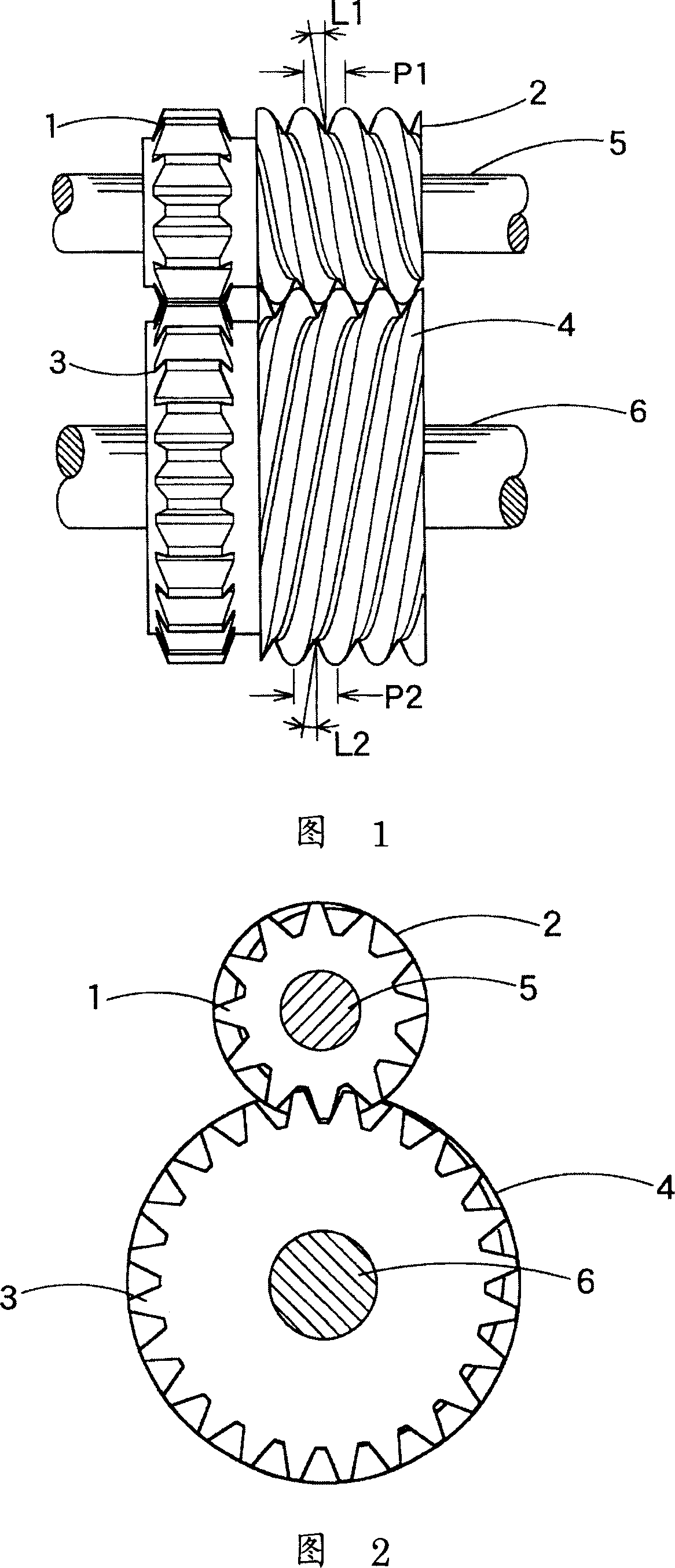

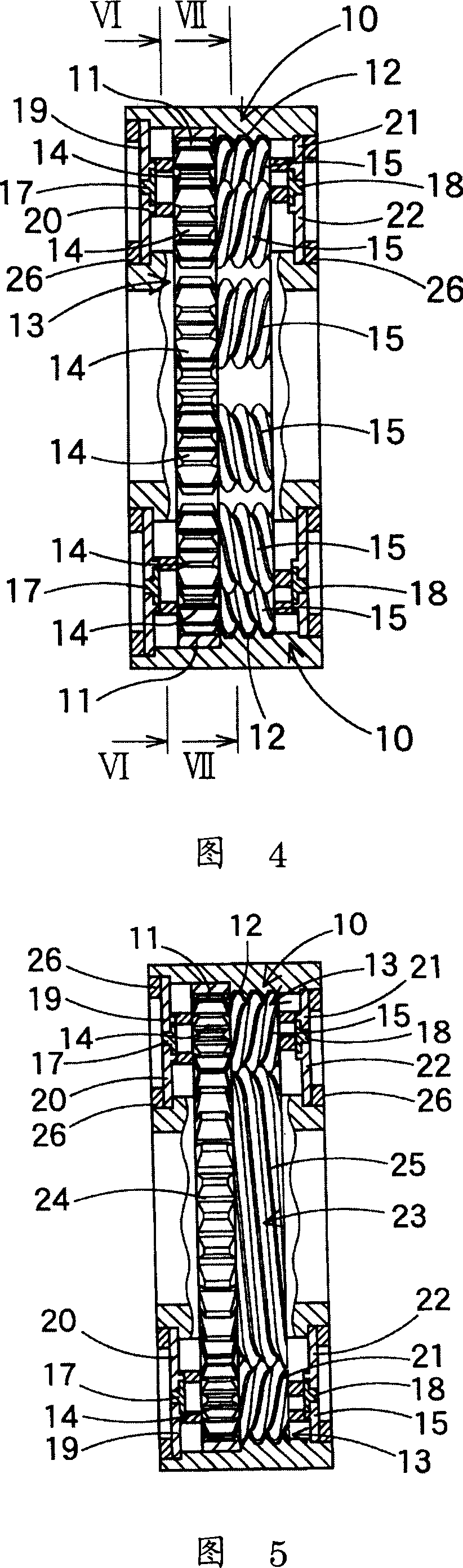

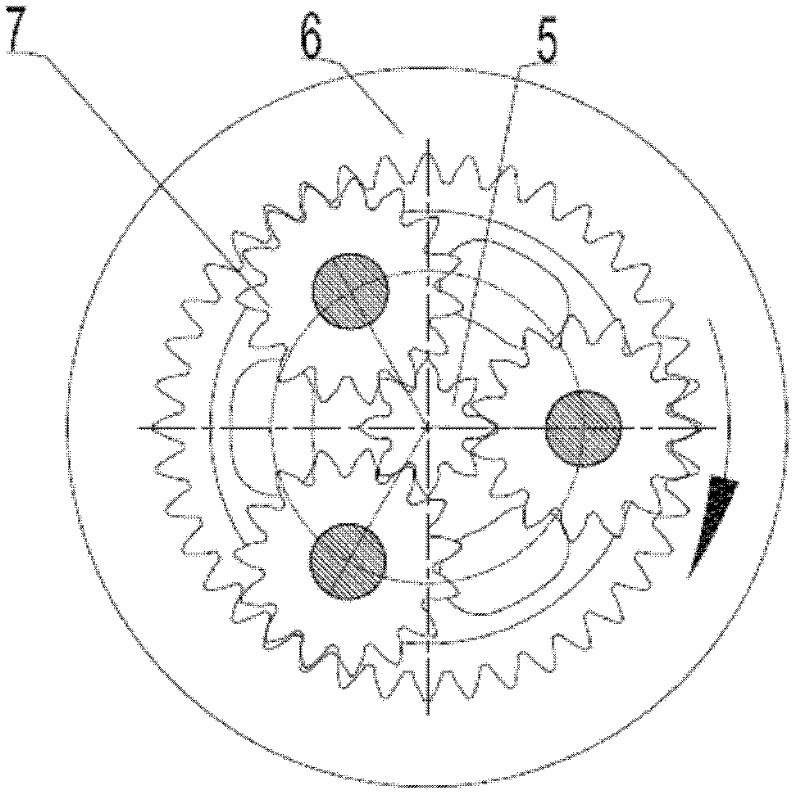

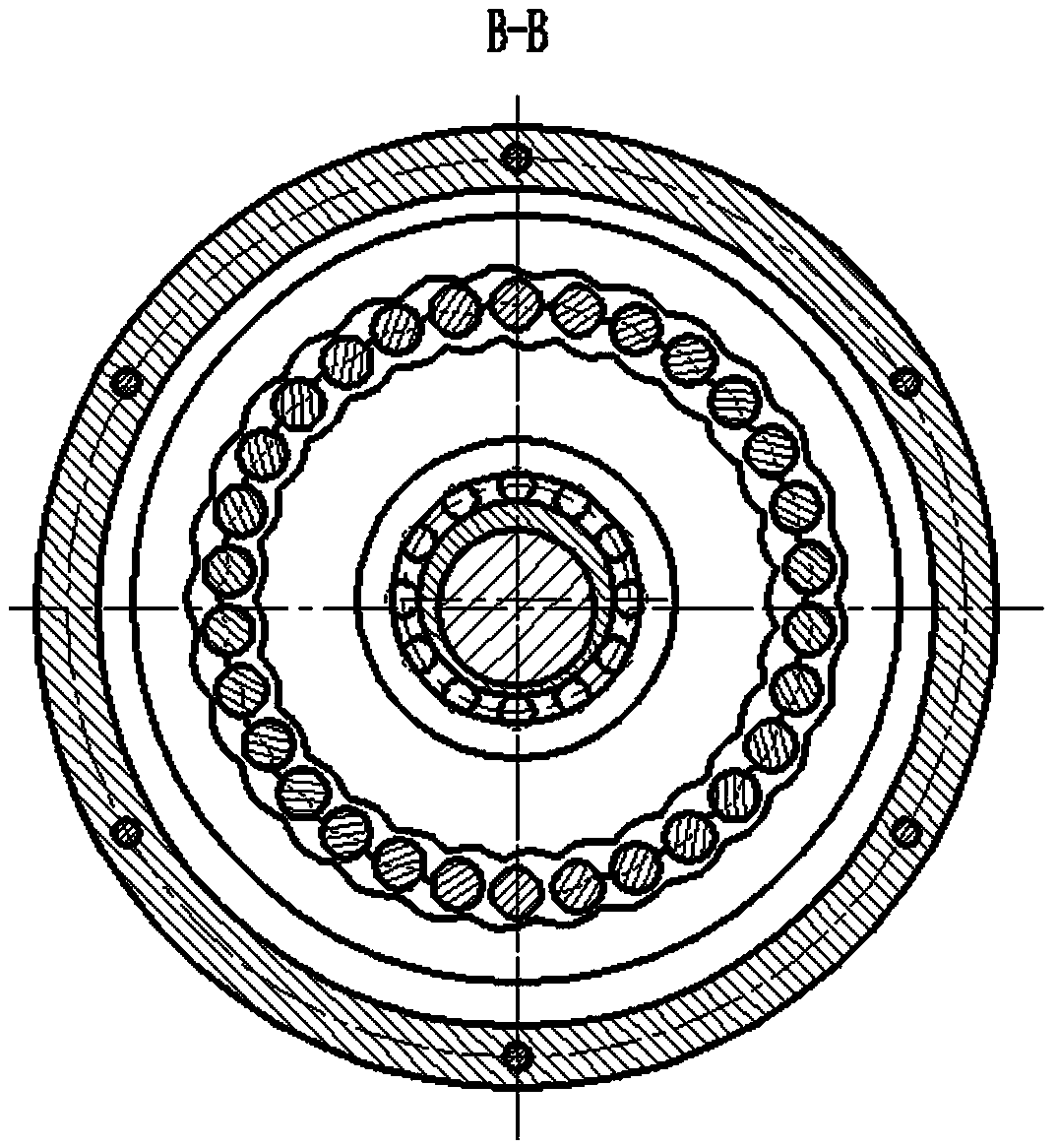

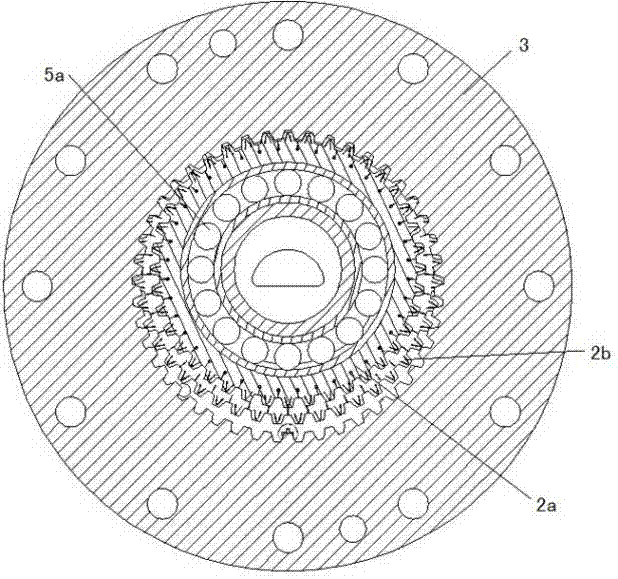

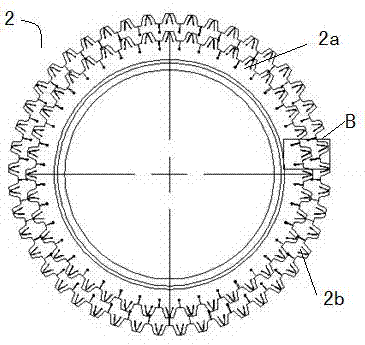

Gear mechanism, planetary gear device, rotating bearing device, and magical planetary gear speed reducer

InactiveCN1973149ASuppress crashSmall backlashRolling contact bearingsToothed gearingsGear wheelReducer

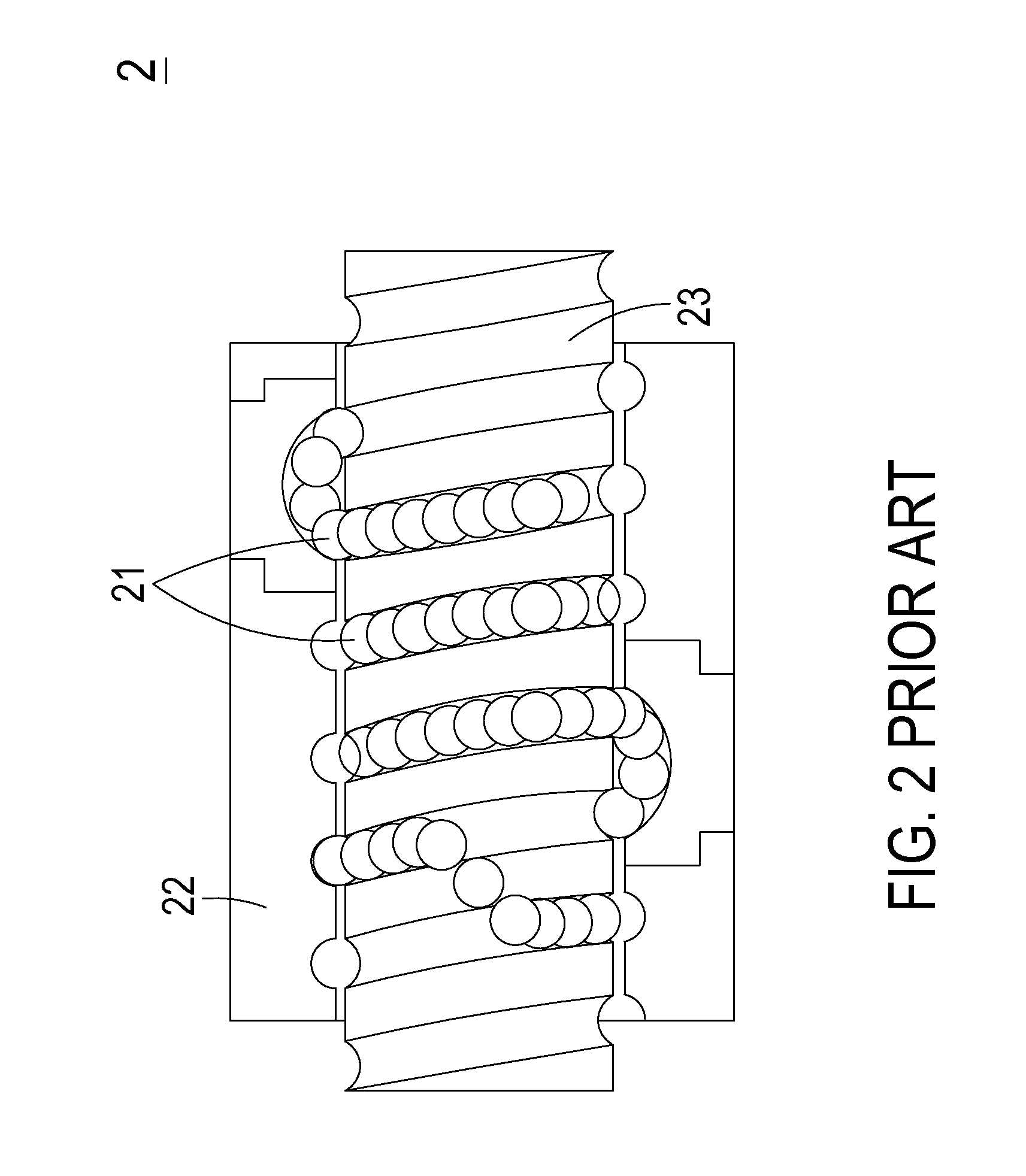

A gear mechanism having extremely less backlash, capable of suppressing the rattling noise of gears, having a large loading resistance in the thrust direction, and capable of transmitting high torque by using the gears transmitting a force by the meshing of the gears with each other in place of the transmission of the force by friction. The gear mechanism is formed by disposing the plurality of spur gears in the meshed state with each other. The screw-like gears (2) and (4) are disposed on the same axis as the spur gears (1) and (3) in the meshed state with each other. The screw-like gears (2) and (4) adjacent to each other are formed in screw shapes having lead angles extending in the reverse directions to each other and equal in angle to each other. The spur gear (1) and the screw-like gear (2) are rotated integrally with each other to transmit its rotation to the spur gear (3) and the screw-like gear (4) adjacent to each other.

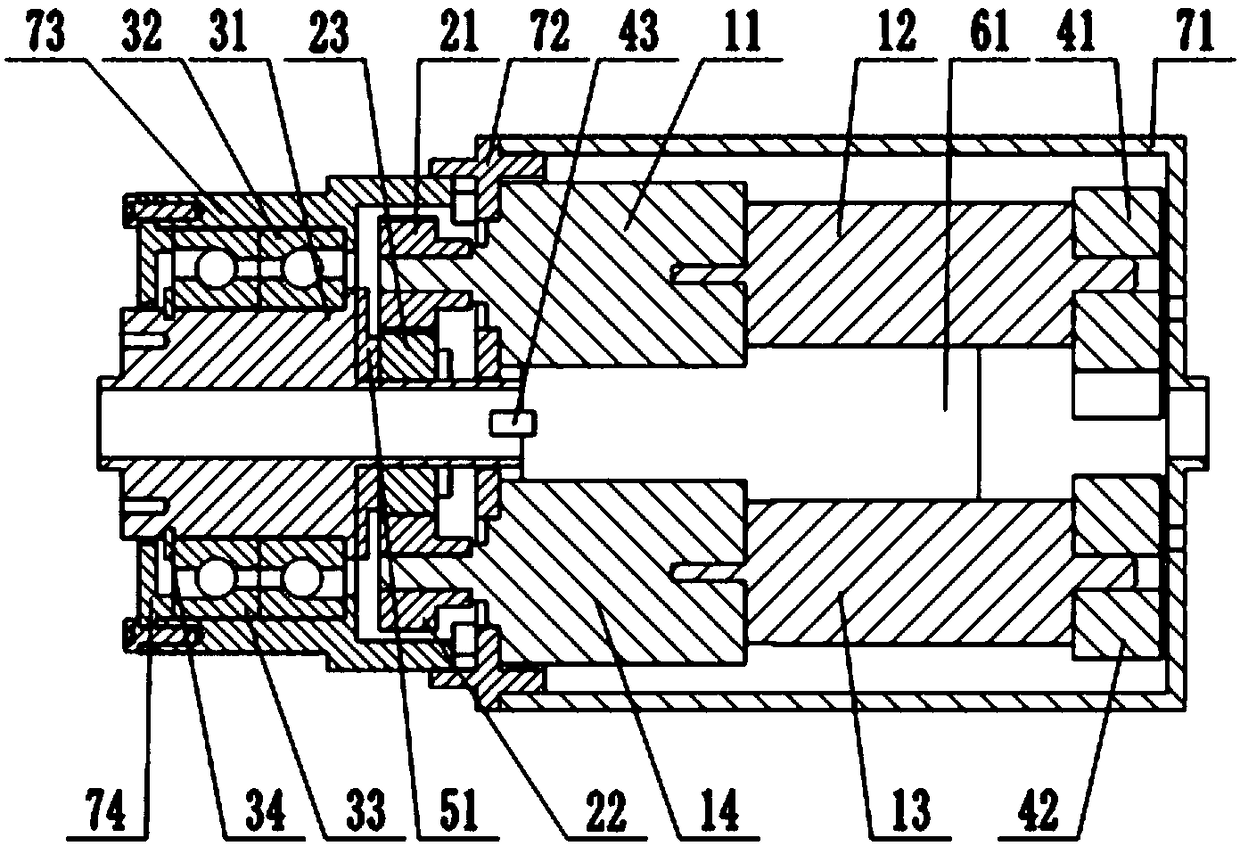

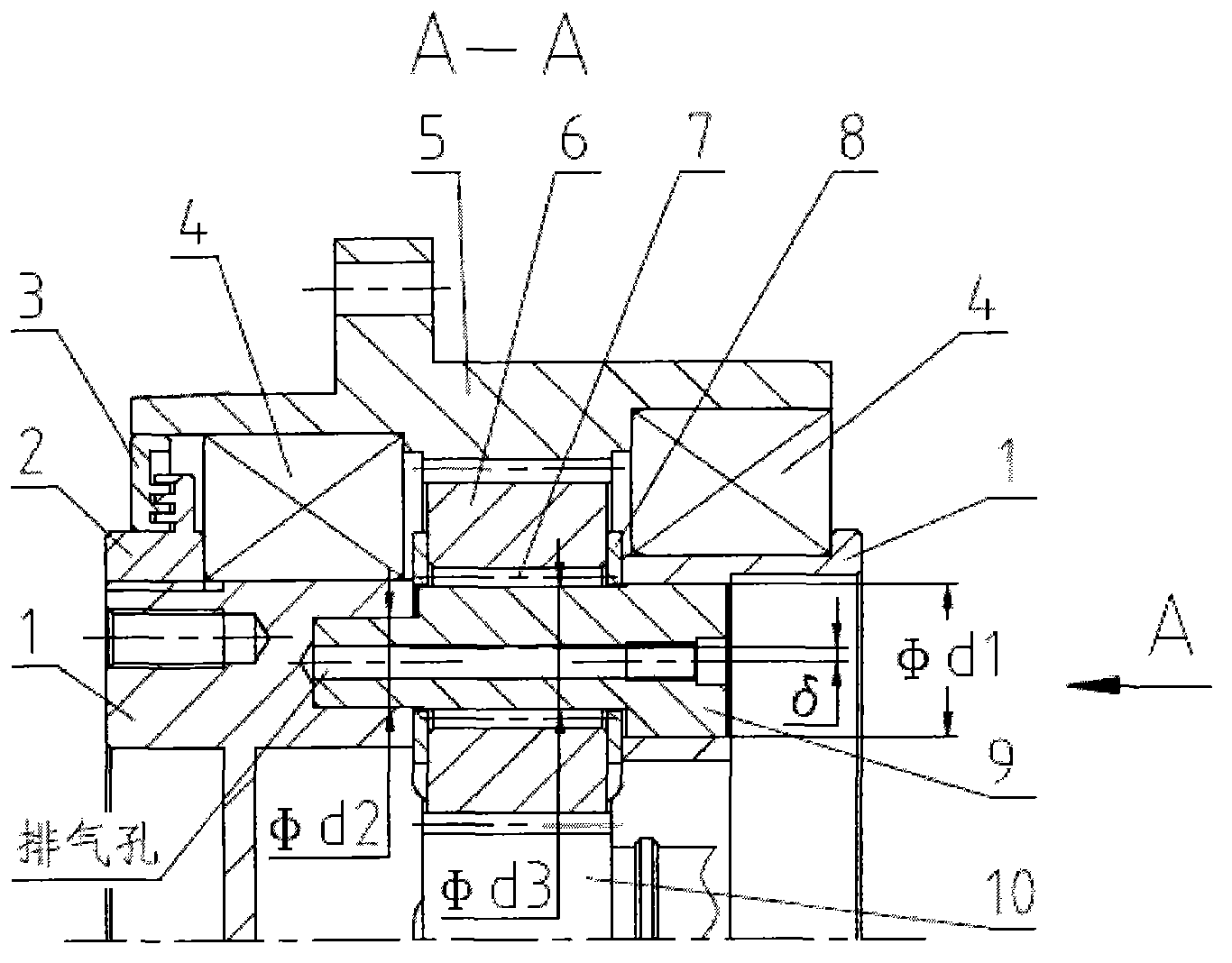

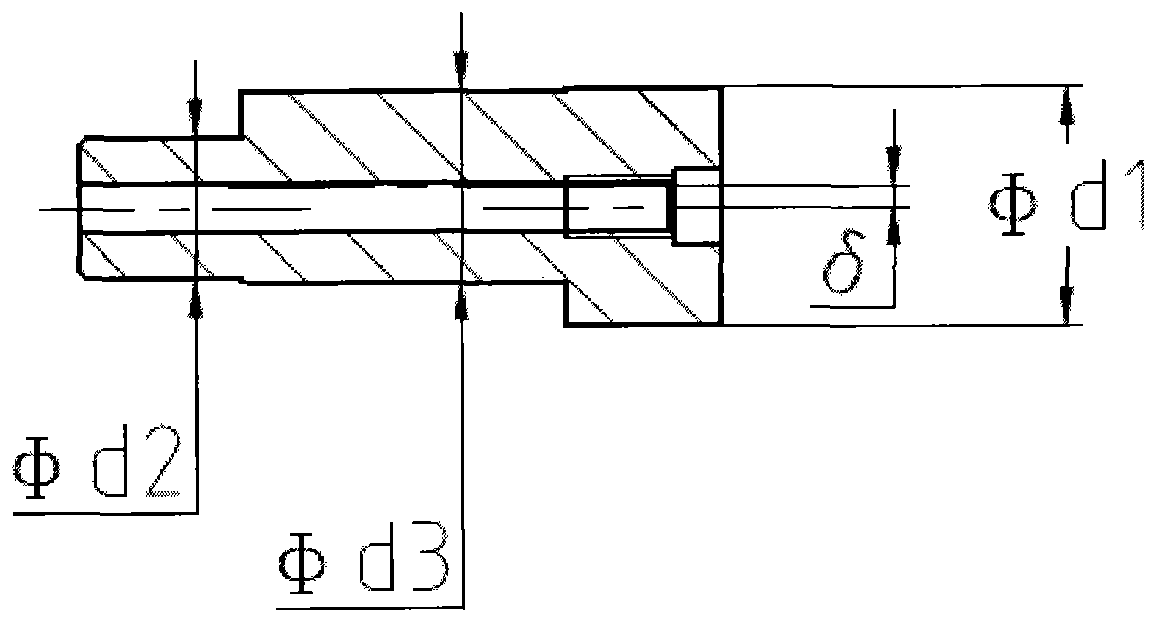

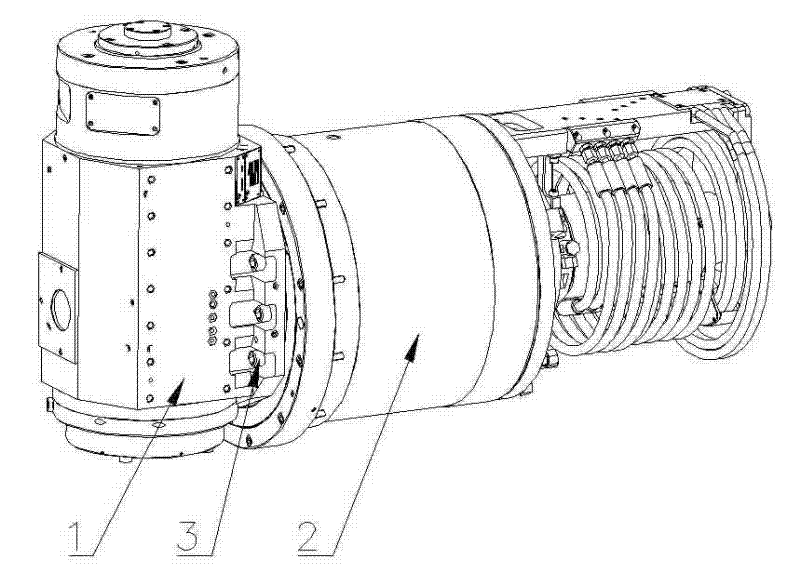

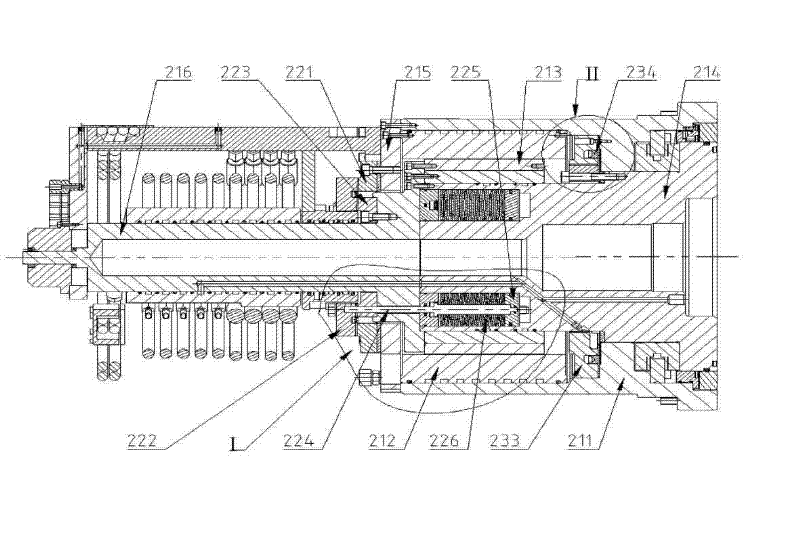

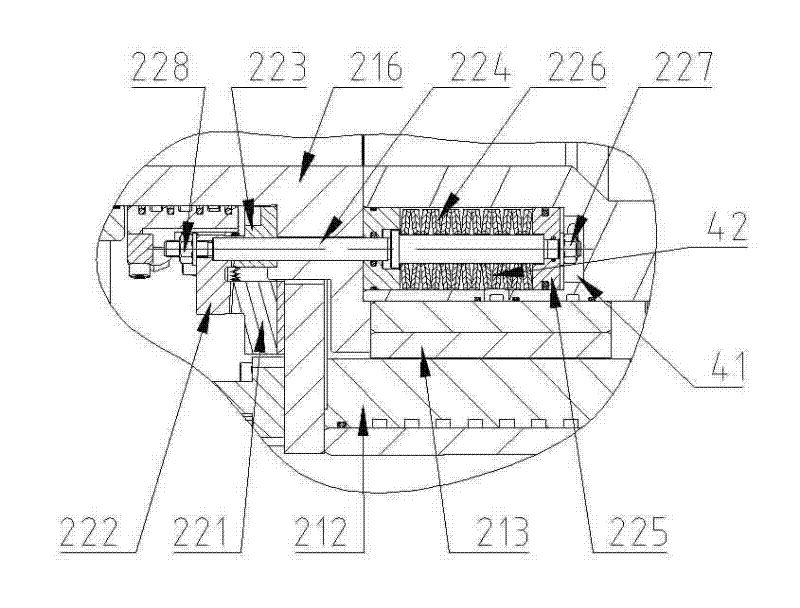

Planetary speed reduction type eccentricity-adjustable helical hole-milling device

ActiveCN106670553AReduce frictional resistanceReduce input powerFeeding apparatusLarge fixed membersSelf lockingEngineering

The invention discloses a planetary speed reduction type eccentricity-adjustable helical hole-milling device. The planetary speed reduction type eccentricity-adjustable helical hole-milling device is characterized by comprising a rotation system, a revolution system, a radial eccentricity adjusting system, a clamping braking system assembly and an axial feeding system. The radial eccentricity adjusting system can achieve precise trace linear eccentricity adjustment with high transmission ratio, and required input power is small. Compared with sliding block adjusting structures disclosed by existing patents, the radial eccentricity adjusting system can perform adjustment conveniently with less labor, and compared with a dual eccentric sleeve structure and an offset sliding block structure, the ratio of the size of the adjusting structure to the size of a rotation power source is greatly decreased, the occupied space is reduced, and the dead weight is reduced relatively in case of the identical material. Compared with an electromagnetic brake, the clamping braking system assembly can perform braking easily and conveniently; compared with a radial screw holding structure, the required pretightening force is small, and clamping is reliable; and compared with a worm and gear structure, self-locking never fails, and the working stability is high.

Owner:DALIAN JIAOTONG UNIVERSITY

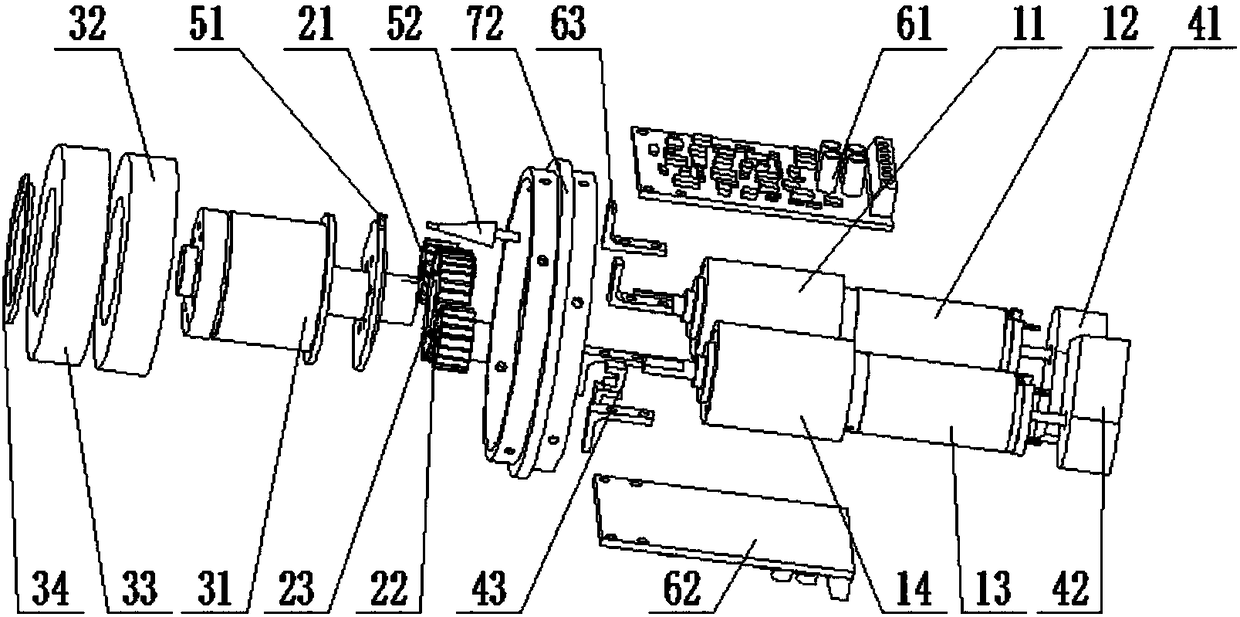

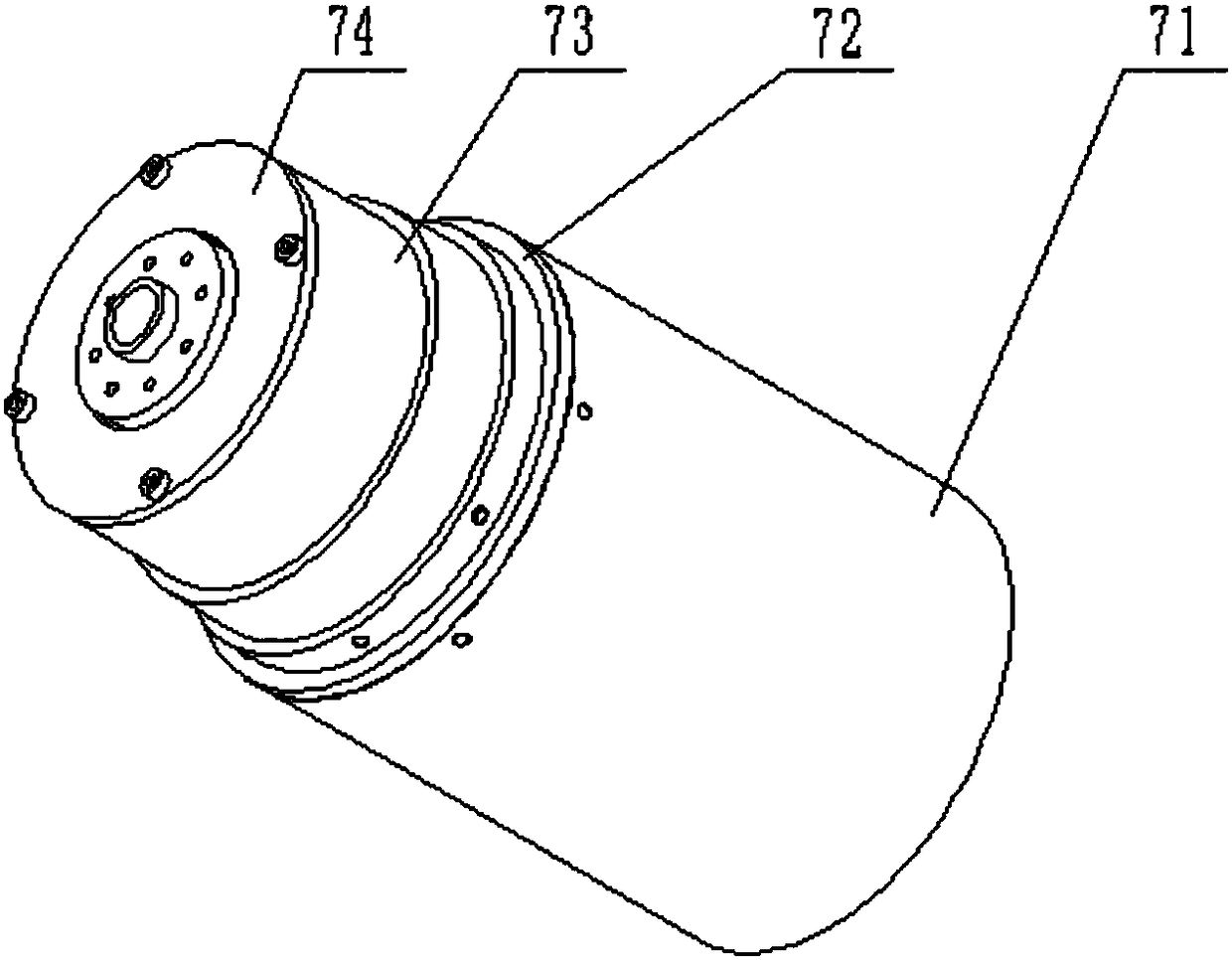

Two-motor drive modular joint and mechanical arm

ActiveCN108189073AEffective anti-backlashEasy to installProgramme-controlled manipulatorJointsMotor driveComputer module

The invention relates to a two-motor drive modular joint. According to the two-motor drive modular joint, an output shaft is rotationally connected with a shell and fixedly connected with an output gear; the output shaft comprises a through hole extending in the axial direction; the shell comprises a penetrating hole corresponding to the through hole, and the through hole and the penetrating holeare used for storing a line; the output shaft further comprises a radial channel which cooperates with a zero-bit detection module to determine the zero bit; a first gear and a second gear are engagedwith the output gear and are free of interference; a first servo motor is connected with the first gear and a first motor encoder; and a second servo motor is connected with the second gear and a second motor encoder. The two-motor drive modular joint can eliminate the gap between the output gear and a drive device, so that transmission is more precise, and the joint can still run in a gapless mode even when the gears are abraded. The zero-bit detection module is used for determining the zero bit of the output shaft. Through cooperation of the penetrating hole and the through hole, various cables can be arranged inside the joint, and thus the joint is simple and compact as a whole.

Owner:NORTHEASTERN UNIV

Variable gear ratio steering apparatus for an automobile

ActiveCN101007543ASmall backlashDevices with rotatable cameraToothed gearingsSteering wheelEngineering

Owner:HL MANDO CORP +1

Harmonic-wave speed reducer with improved structure

The invention discloses a harmonic-wave speed reducer with an improved structure of double rigid wheels. Two identical flexible bearings are mounted onto a wave generator. Flexible wheels are circular ring-shaped and mounted onto outer rings of the flexible bearings. The number of internal teeth of a first rigid wheel is greater than that of external teeth of each flexible wheel by two. The first rigid wheel, a rear end cover and an inner ring of a criss-cross roller bearing are connected together as a fixing end of the harmonic-wave speed reducer. The number of internal teeth of a second rigid wheel is the same as that of external teeth of each flexible wheel. The second rigid wheel, a front end cover and an outer ring of the criss-cross roller bearing are connected together as an output end of the harmonic-wave speed reducer.The harmonic-wave speed reducer with the improved structure has a reasonable structure and high load-carrying and impact-resisting capabilities.

Owner:上海鑫君传动科技有限公司

Electric lifting adjusting device for seat

The invention discloses an electric height adjusting device for a seat. The electric height adjusting device comprises a seat height adjusting toothed plate and an electric mechanism driving the seat height adjusting toothed plate to rotate. The electric mechanism comprises a reduction gearbox body, a motor, a worm, a bevel gear component, a flexible bearing, a flexible wheel, a rigid wheel body, a reduction gearbox cover and an output transmission piece. The direct-current motor is used as a power source of the electric mechanism, motor torque is transmitted to the worm and then transmitted to the bevel gear component through the worm, and first-level speed reduction of the electric mechanism is composed of the worm and the bevel gear component. After first-level speed reduction transmission is completed, power is output to the output transmission piece through a harmonic gear mechanism composed of the bevel gear component, the flexible bearing, the flexible wheel to be output. The electric height adjusting device for the seat has the advantages of being small in size, large in output torque, large in transmission ratio, high in transmission precision, small in return stroke clearance, high in bearing capacity and the like, adjustment handleability and the overall strength of the seat are increased, and the noise level is greatly lowered.

Owner:KEIPER SEATING MECHANISMS CO LTD

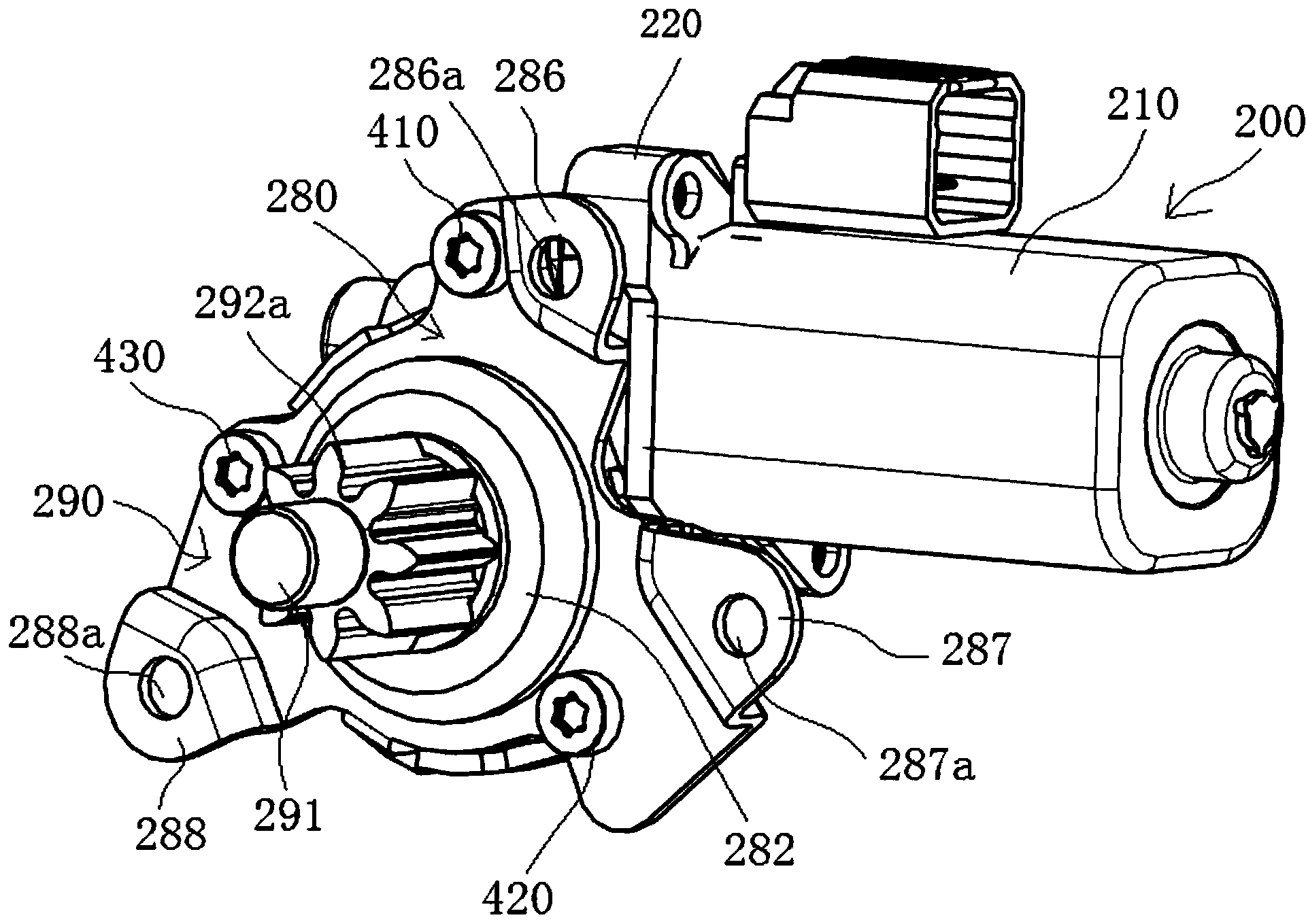

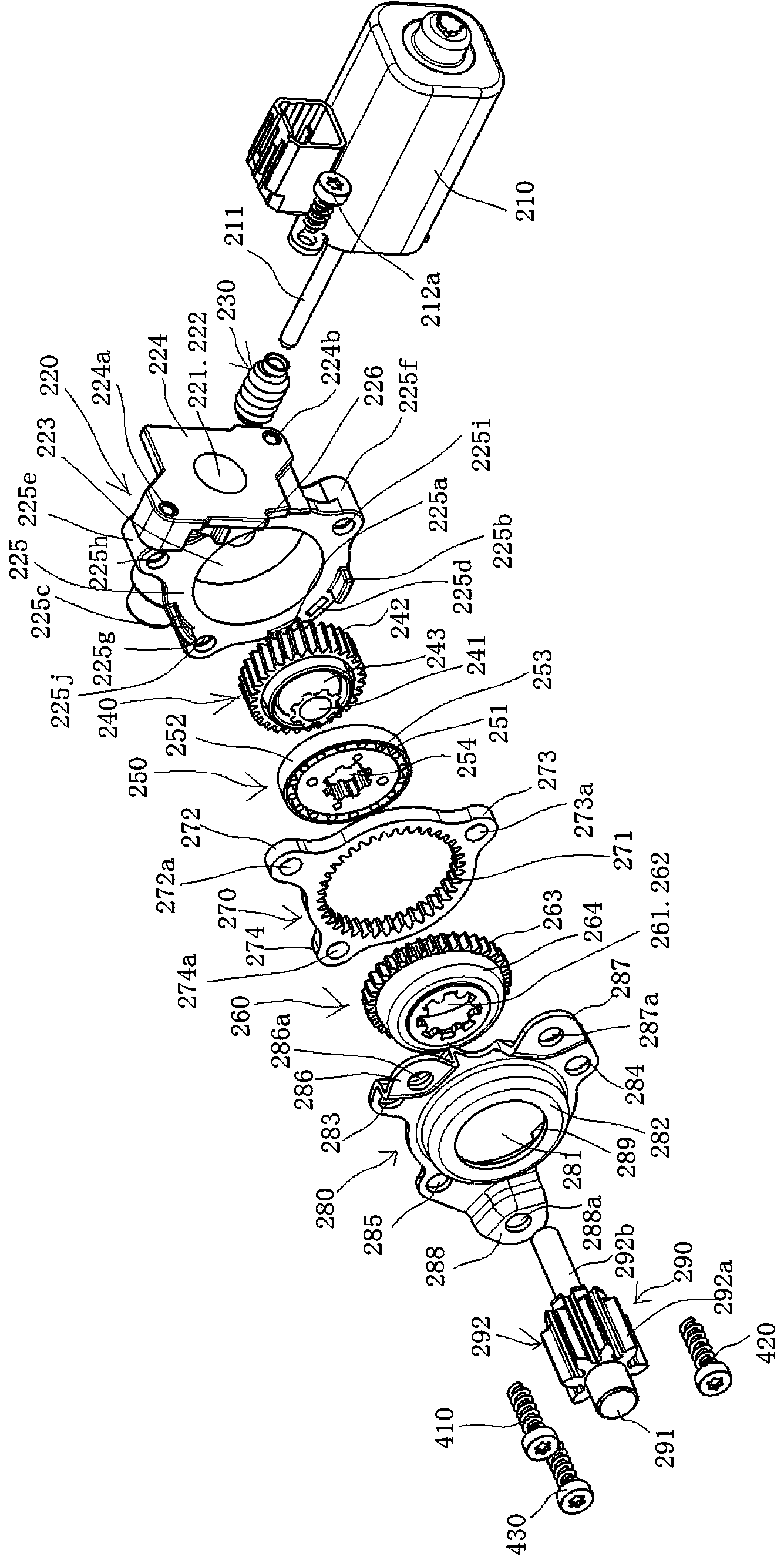

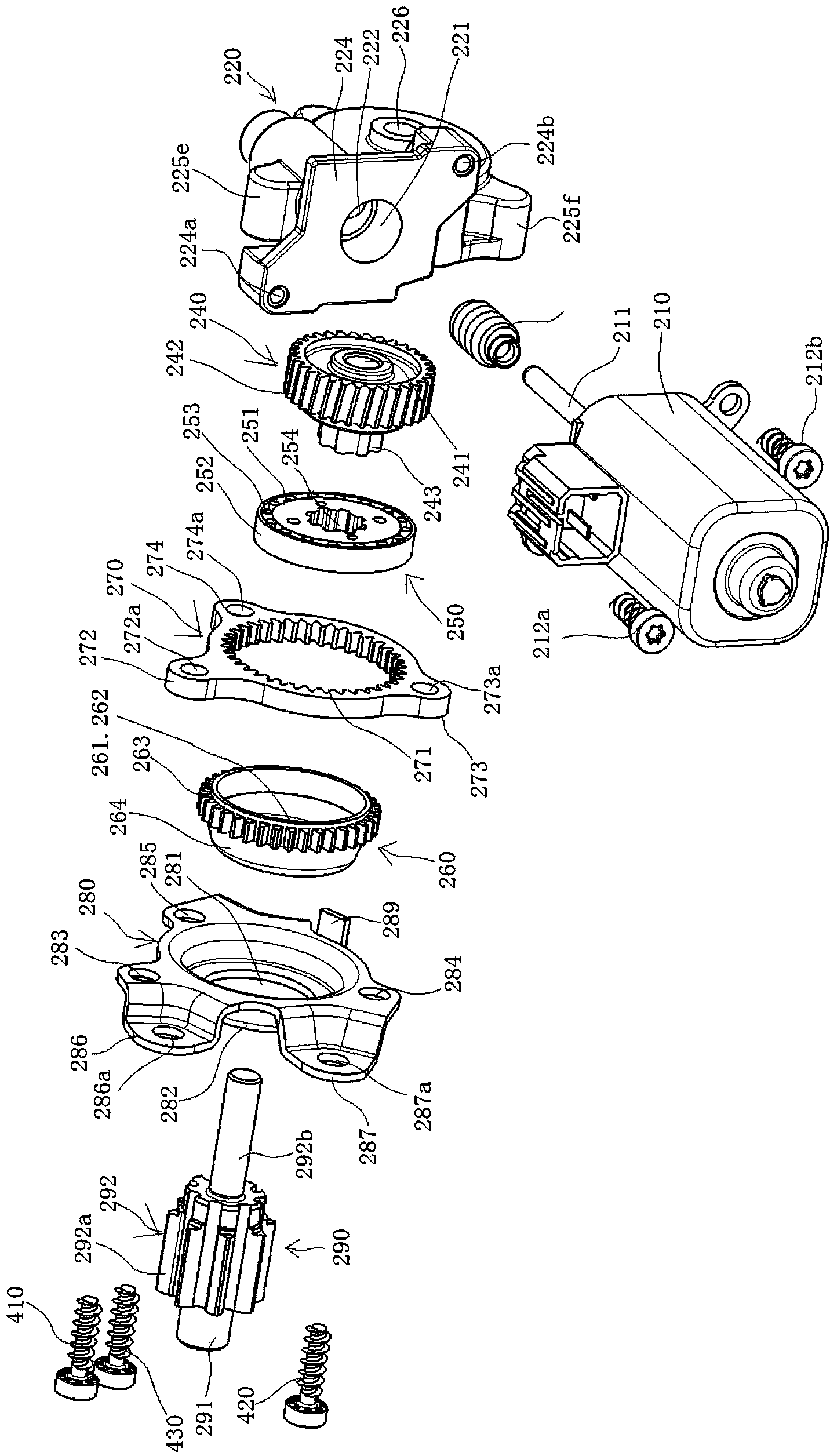

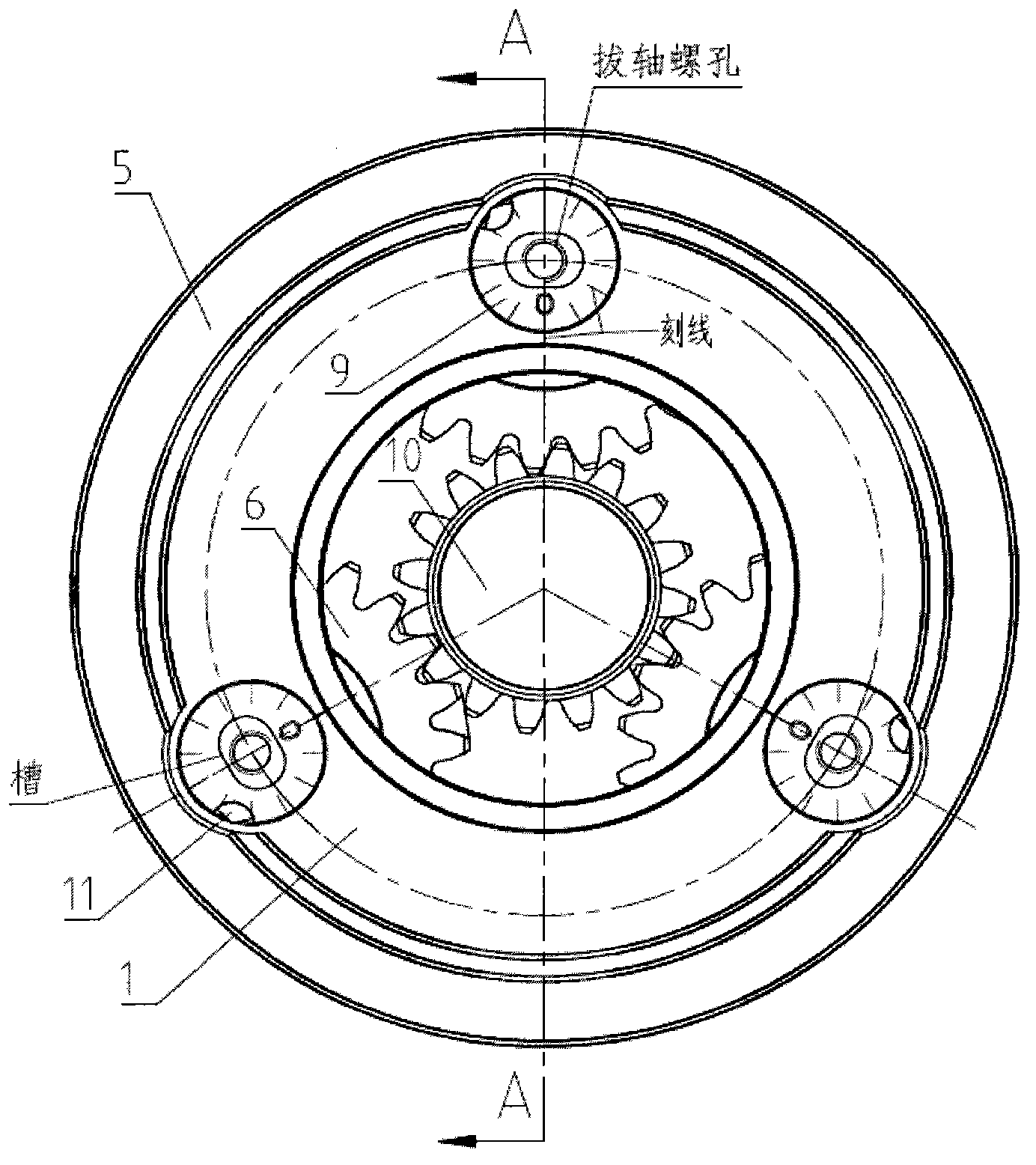

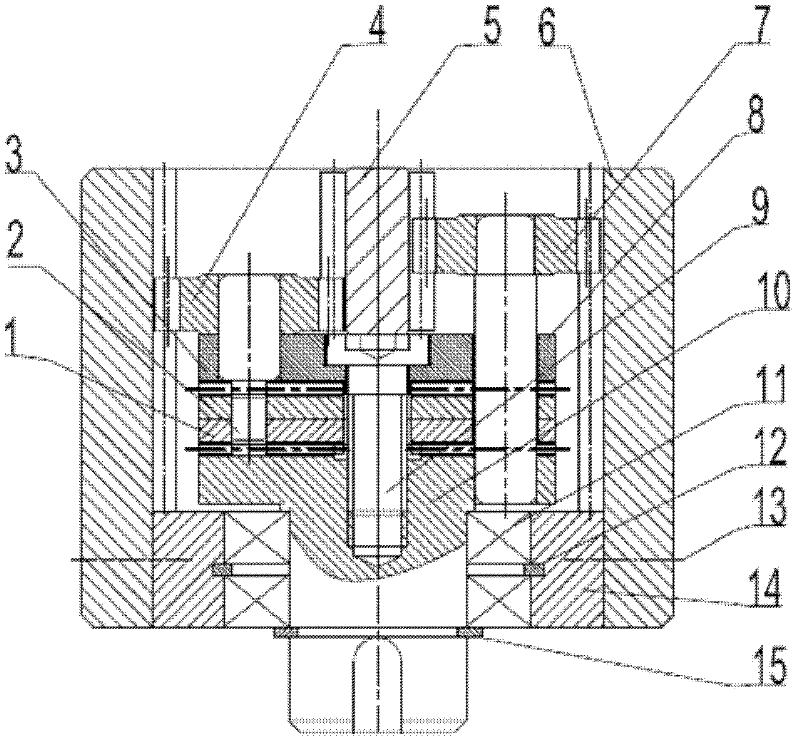

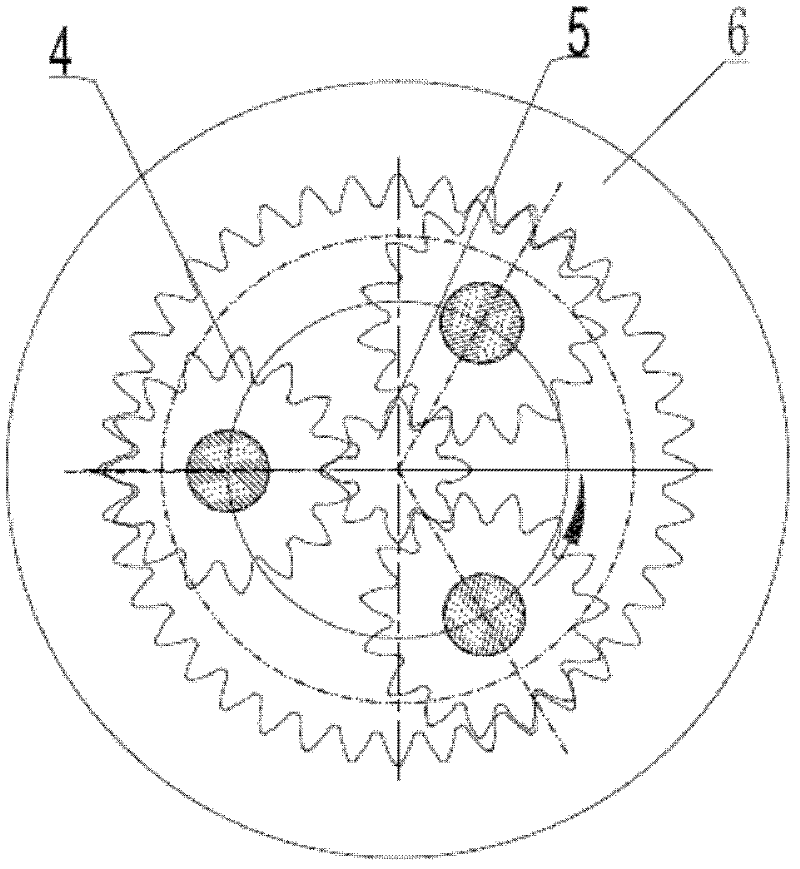

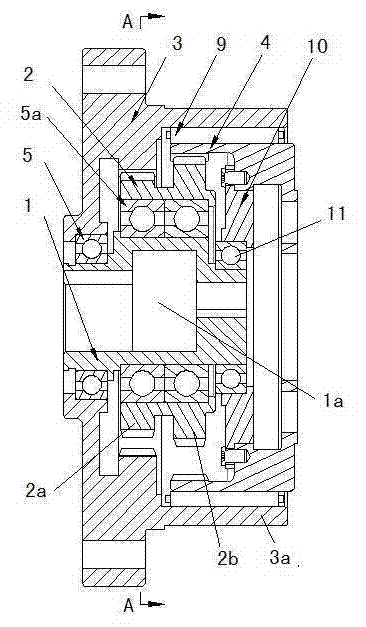

Planetary gear transmission device and assembly method thereof

The invention belongs to the technical field of planetary gear transmission, particularly relates to a precise planetary gear transmission device with small back clearance, low no-load torque and large rigidity and an assembly method thereof, and the planetary gear transmission device is widely used for actuating mechanisms of various servo drive systems. The planetary gear transmission device disclosed by the invention adopts an eccentric planetary gear shaft structure which does not rotate with planetary gears, and eccentric planetary gear shafts are rotated so that the planetary gears are close to an inner gear ring, therefore, the tooth gaps of the planetary gears and the inner gear ring are reduced. The assembly method of the planetary gear transmission device comprises the following steps of: consistently rotating the eccentric planetary gear shafts so that the planetary gears are close to the inner gear ring; after the gear backlashes of the inner gear ring and the planetary gears are regulated, measuring and calculating the appropriate tooth thickness of a sun gear by using a special tool; and then grinding an appropriate sun gear in a matching way. The integral planetary line gear can obtain the smallest backlashes, the low no-load torque and the large rigidity under the condition of no clamping or previous tightening through the measures.

Owner:CHINA NORTH VEHICLE RES INST

A planetary gear reducer with adjustable backlash

ActiveCN102297257AEliminate meshing backlashSmall backlashGearing detailsSurface toothReduction drive

The invention discloses a planetary gear reducer with an adjustable back lash; an inner gear ring in the reducer is fixed and cannot rotate; the teeth of the planetary gear are respectively meshed with the outer teeth of a sun gear and the inner teeth of the inner gear ring; the planetary gear reducer with the adjustable back lash is characterized in that: a first planetary gear group and a second planetary gear group are respectively arranged in a transmission level; and end surface teeth which are mutually occluded are respectively arranged on a contact surface between a first planetary gear frame component and a lower lock block and the contact surface between a second planetary gear frame component and an upper lock block. According to the invention, the back lash required by the reducer is obtained through differential gear adjustment by simultaneously eliminating gear side spacing as well as the spacing between a shaft and an inner hole of a planetary gear in a clockwise direction and a counterclockwise direction.

Owner:合肥波林新材料股份有限公司

Modularized B-axis turning and milling composite functional unit

InactiveCN102398154AHazard reduction issuesEnsure rigidityFeeding apparatusOther manufacturing equipments/toolsNumerical controlMotor drive

The invention relates to a turning and milling composite functional unit for a numerical control machine, in particular to a modularized B-axis turning and milling composite functional unit, which comprises a B-axis module and a turning and milling head module, wherein the B-axis module comprises a driving device, a three-fluted-disc indexing structure and a brake structure, the turning and milling head module comprises a motor driving device and a three-fluted-disc fixing device, the turning and milling head module id driven by a built-in motor, and is provided with a three-fluted-disc locking structure, during turning, three fluted discs are locked to ensure structure rigidity, during milling or drilling, the three fluted discs are loosened, and a main shaft rotates to drive a cutter to carry out processing. The B-axis module is driven by the built-in motor, during indexing processing, the three-fluted-disc locking structure is adopted to ensure the structure rigidity and the indexing accuracy; and during processing at any angle, the brake mechanism is adopted to ensure the processing rigidity. The B-axis module and the turning and milling head module are connected through screws, and according to processing requirements, different turning and milling heads are replaced so as to expand processing capability.

Owner:SHENYANG MACHINE TOOLGRP RES & DESIGN INST CO LTD SHANGHAI BRANCH

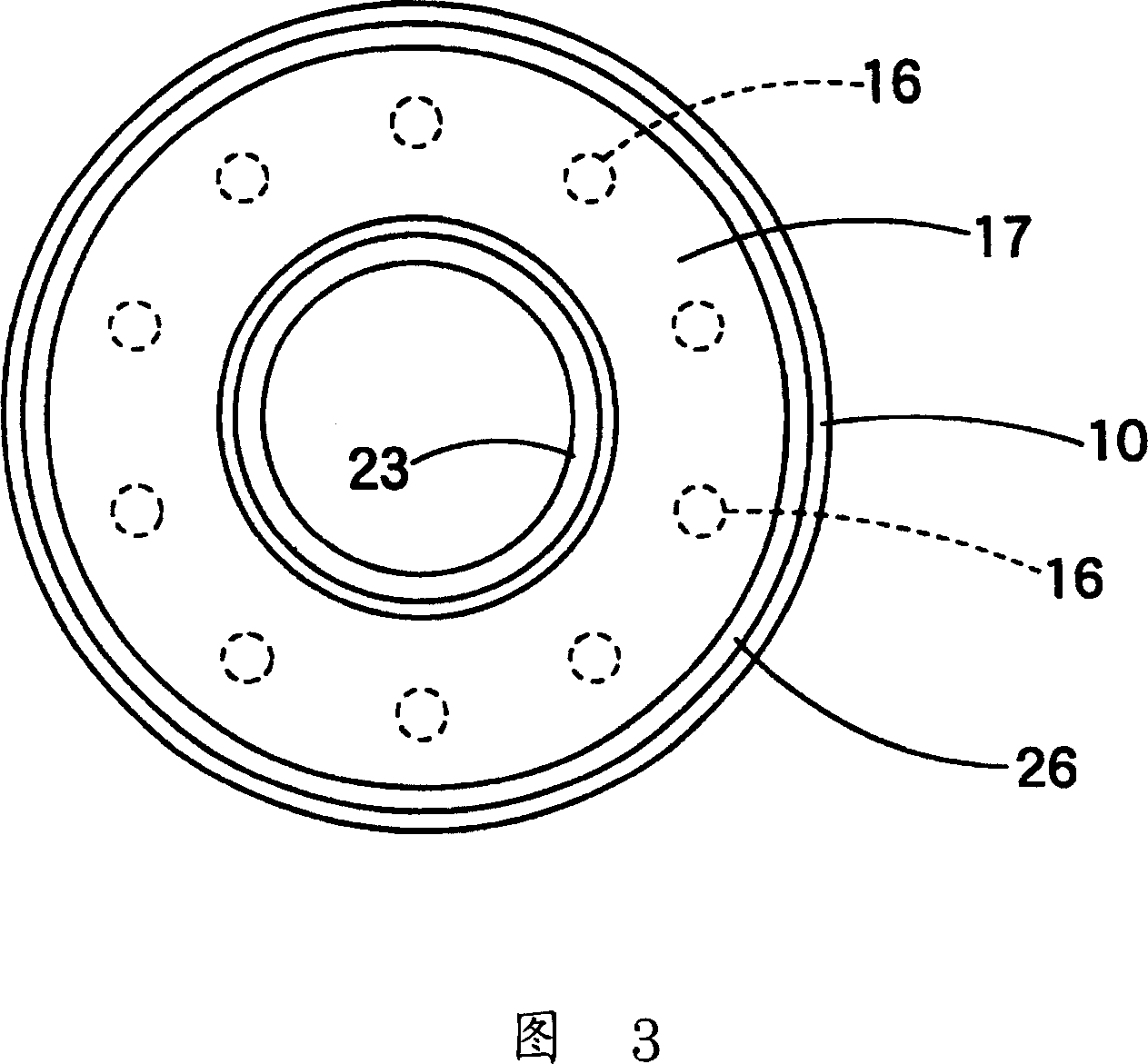

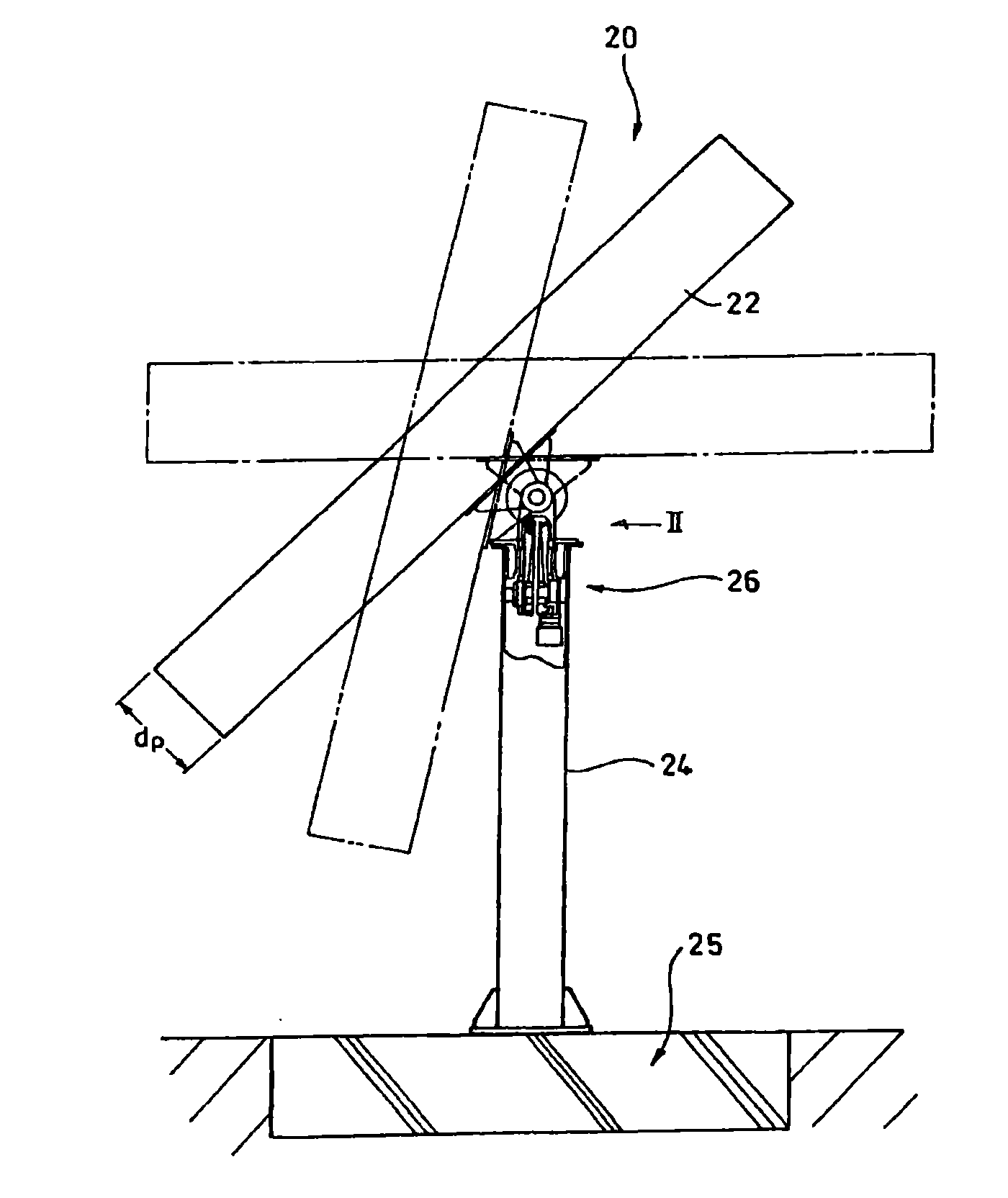

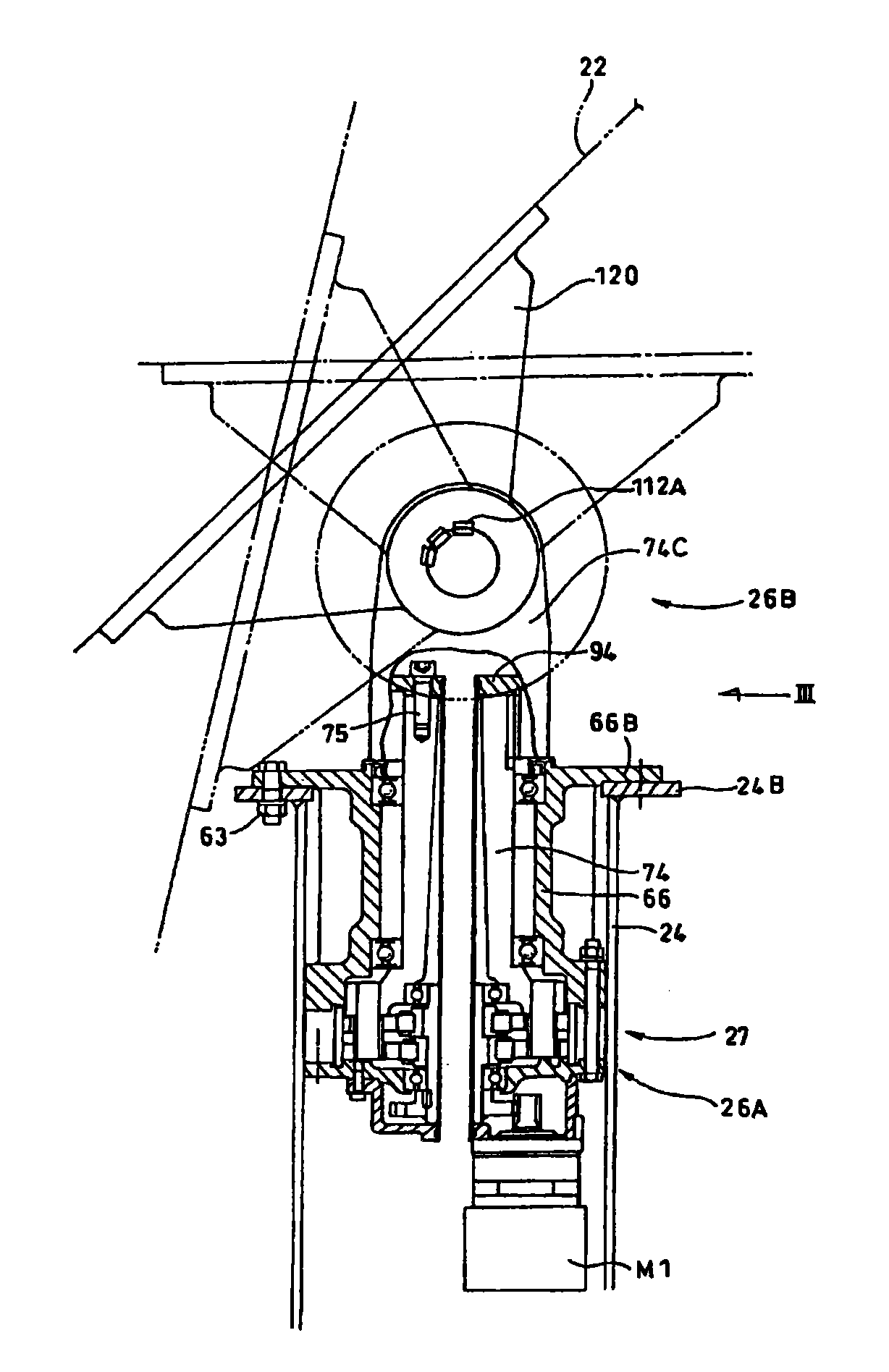

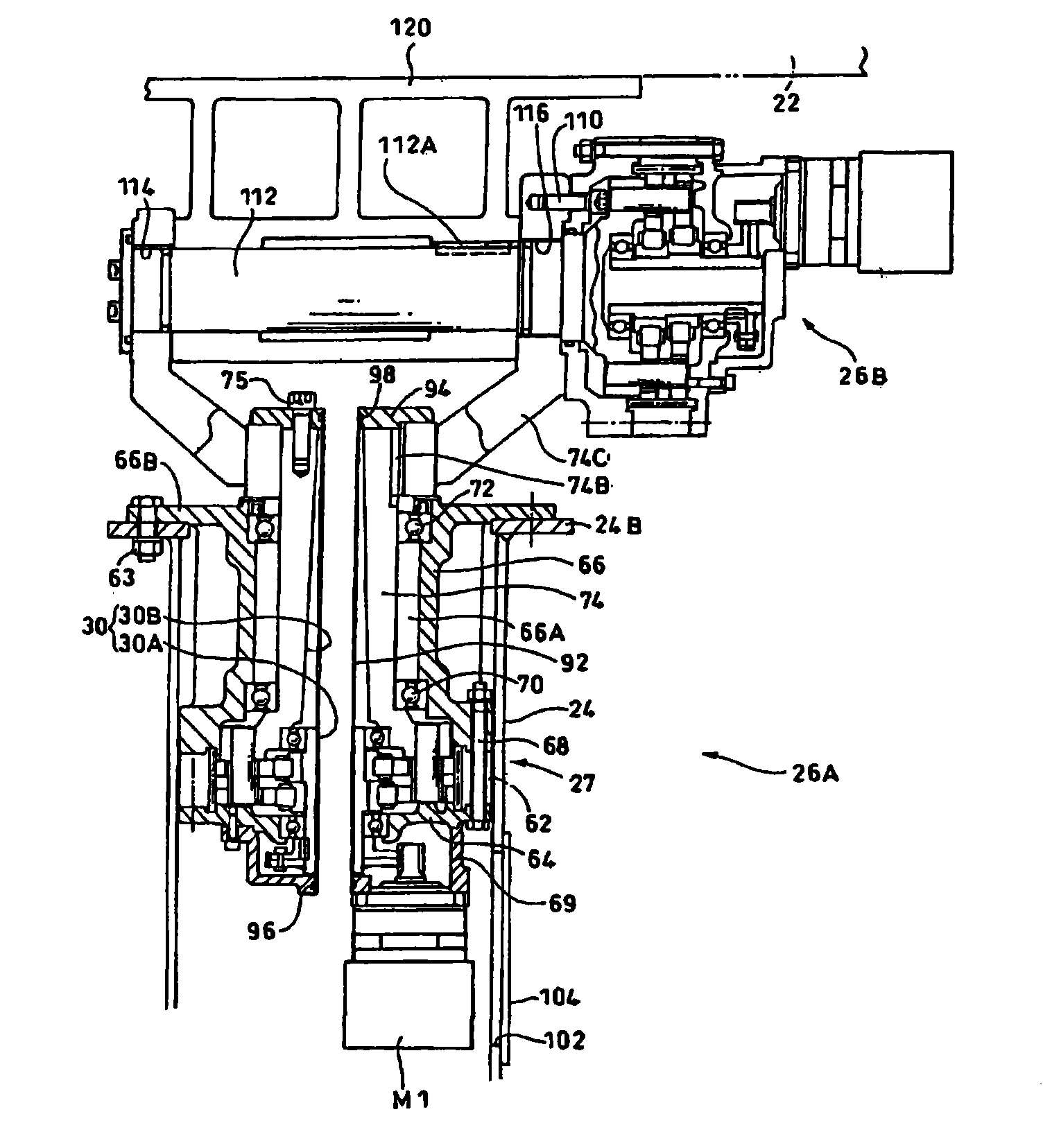

Power transmission device and method of producing the same

InactiveCN101606005AImprove operational efficiencyHigh positioning accuracyWind motor controlEngine fuctionsInterference fitGear wheel

A power transmission device having inherently high operation efficiency, having a highly effective reverse drive prevention function, and having very small backlash. The power transmission device has a reduction gear (power transmission device)(26A) having an internally meshing planetary gear mechanism that has an input shaft (44), an eccentric body (46) provided on the input shaft (44), an externally toothed gear (54) eccentrically rocking via the eccentric body (46), and internally toothed gear (60) with which the externally toothed gear (54) internally meshes. The externally toothed gear (54) is assembled to the internally toothed gear (60) in an interference fit.

Owner:SUMITOMO HEAVY IND LTD

Gerotor apparatus for a quasi-isothermal Brayton cycle engine

InactiveUS7726959B2Simple methodPrevent heat transferOscillating piston enginesCombination enginesBrayton cycleEngineering

According to one embodiment of the invention, a gerotor apparatus includes an outer gerotor having an outer gerotor chamber, an inner gerotor, at least a portion of which is disposed within the outer gerotor chamber, and a synchronizing apparatus operable to control the rotation of the inner gerotor relative to the outer gerotor. The inner gerotor includes one or more entrance passages operable to communicate a lubricant into the outer gerotor chamber.

Owner:TEXAS A&M UNIVERSITY

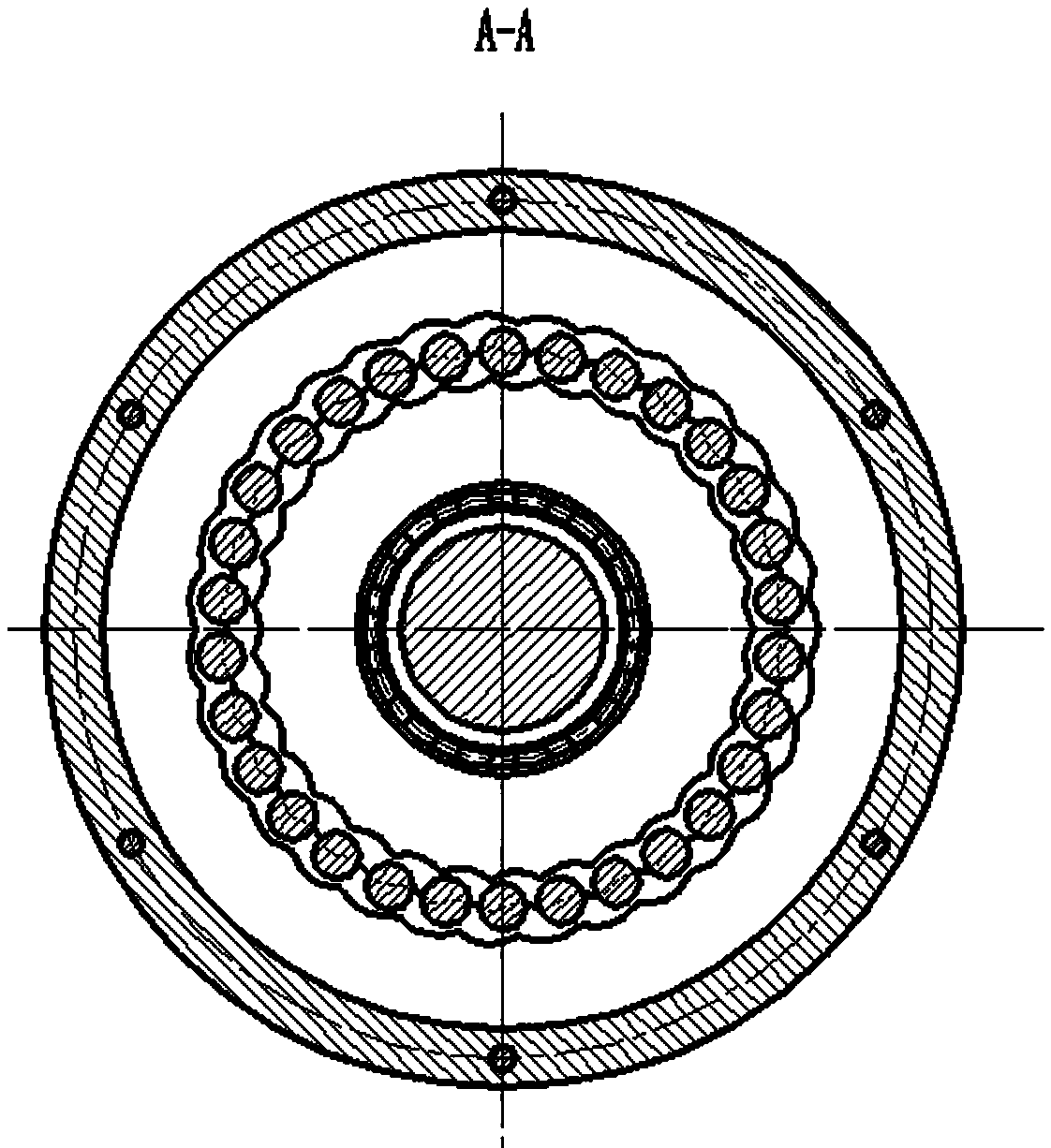

Two-stage-parallel cycloidal steel ball speed reducer

InactiveCN105508532AHigh transmission precisionSmall backlashGearing detailsFriction gearingsInertia forceEngineering

The invention provides a two-stage-parallel cycloidal steel ball speed reducer, belonging to the field of precise mechanical transmission. The two-stage-parallel cycloidal steel ball speed reducer comprises a shell, an input shaft, a planetary disk I, an eccentric sleeve I, a steel ball set, a planetary disk II, an eccentric sleeve II, a steel ball set, an end cover, an output shaft, a pretension nut, a support bearing and a bearing end cover. The speed reducer adopts the NN two-stage-parallel few-tooth-difference planetary transmission basic structure; by using the inner and outer cycloidal sealed grooves in the end surfaces of the end cover, planetary disk and output shaft as tooth profiles and using steel balls as a medium, meshing transmission is performed; and the four-point contact of the steel balls and cycloidal sealed grooves is utilized to eliminate the tooth space. The speed reducer has the advantages of simple structure, small size, high transmission ratio, zero tooth space, high transmission accuracy and low impact. Meanwhile, as distinguished from the common NN cycloidal steel ball transmission, the two planetary disks are installed on different eccentric shaft sections in a 180-degree symmetric mode, and connected through a steel ball ring groove constant speed unit, thereby achieving the balance between meshing force and inertia force. The speed reducer has the advantages of small inertia force during transmission operation, low load of the swing arm bearing, and long service life.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Method for producing simple planetary gear device and simple planetary gear device

ActiveCN101117996ABad situation where no space occursSmall backlashToothed gearingsPortable liftingGear wheelPower transmission

A method for producing simple planetary gear devices is provided in which minimum backlash is satisfactorily realized and maintained with a fewer number of parts without creating any space-related inconveniences. A dummy carrier pin is used which is provided with a rotation support section whose axis can be moved in the radial direction and can support a planetary gear around the rotation support section such that the planetary gear can rotate. The planetary gear is assembled, then, a sun gear is selected and assembled, and the positions of the dummy carrier pin are fixed. Thereafter, the dummy carrier pin is removed, and a carrier pin to be used in actual power transmission is press-fitted into the carrier at the position determined by the dummy carrier pin.

Owner:SUMITOMO HEAVY IND LTD

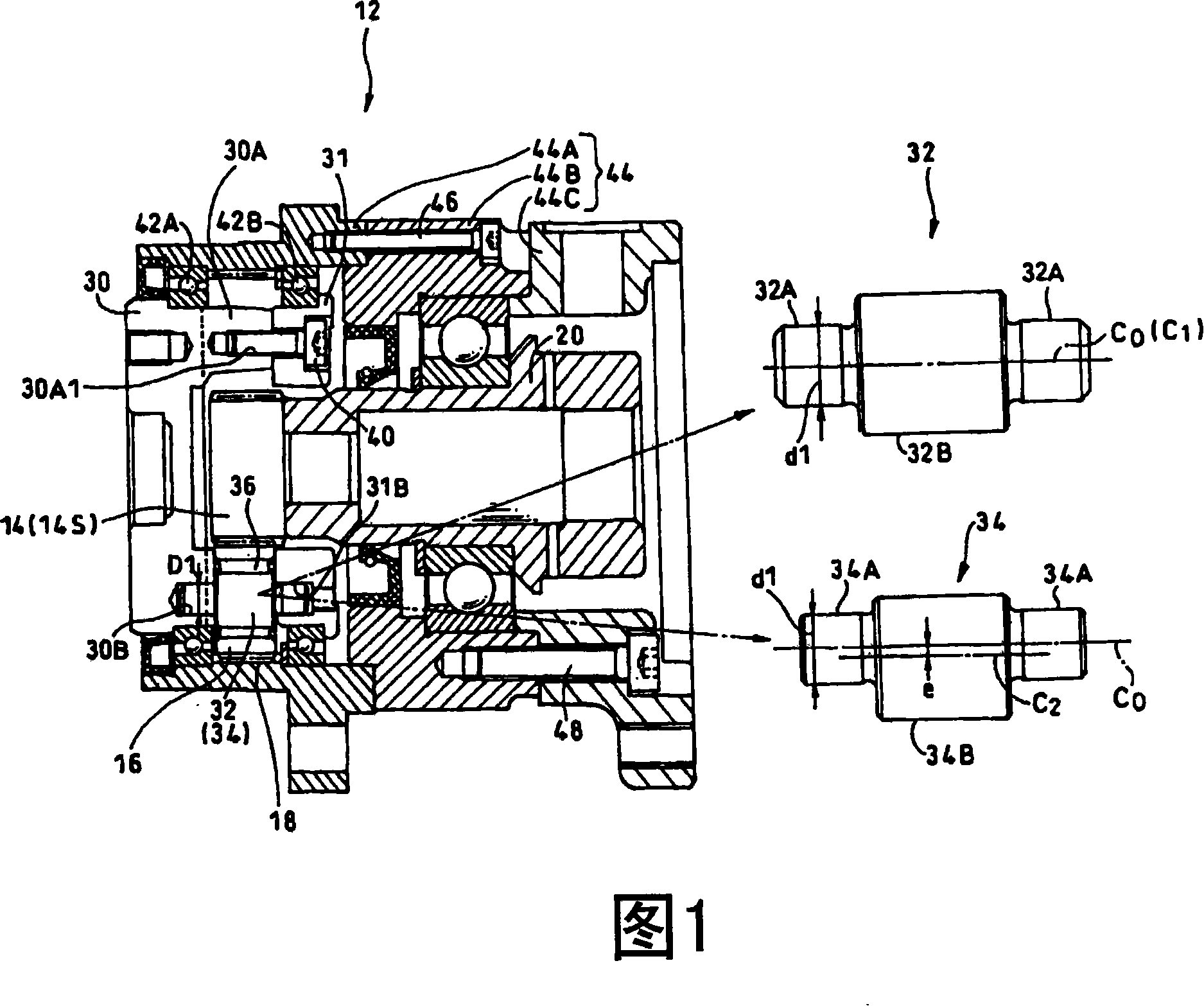

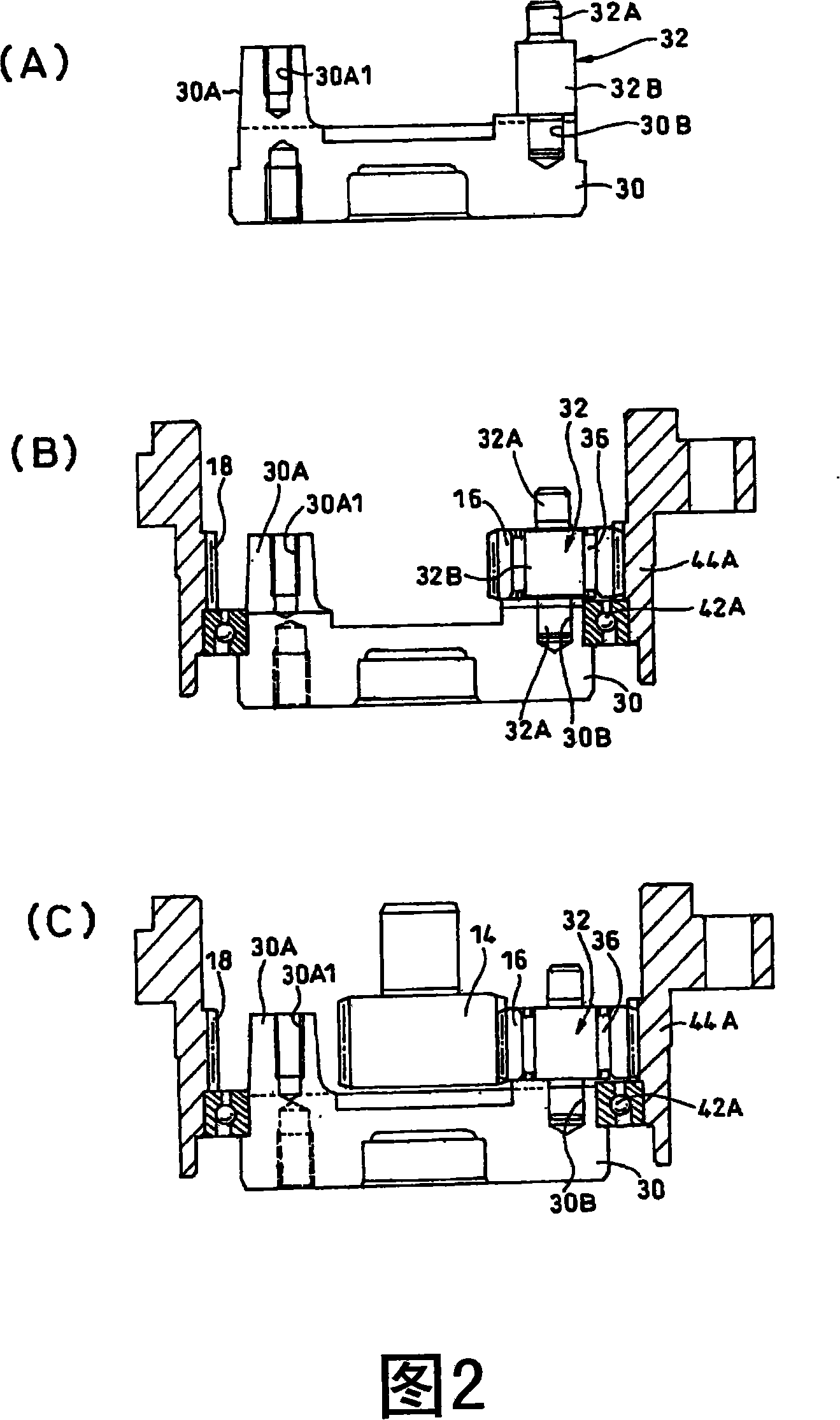

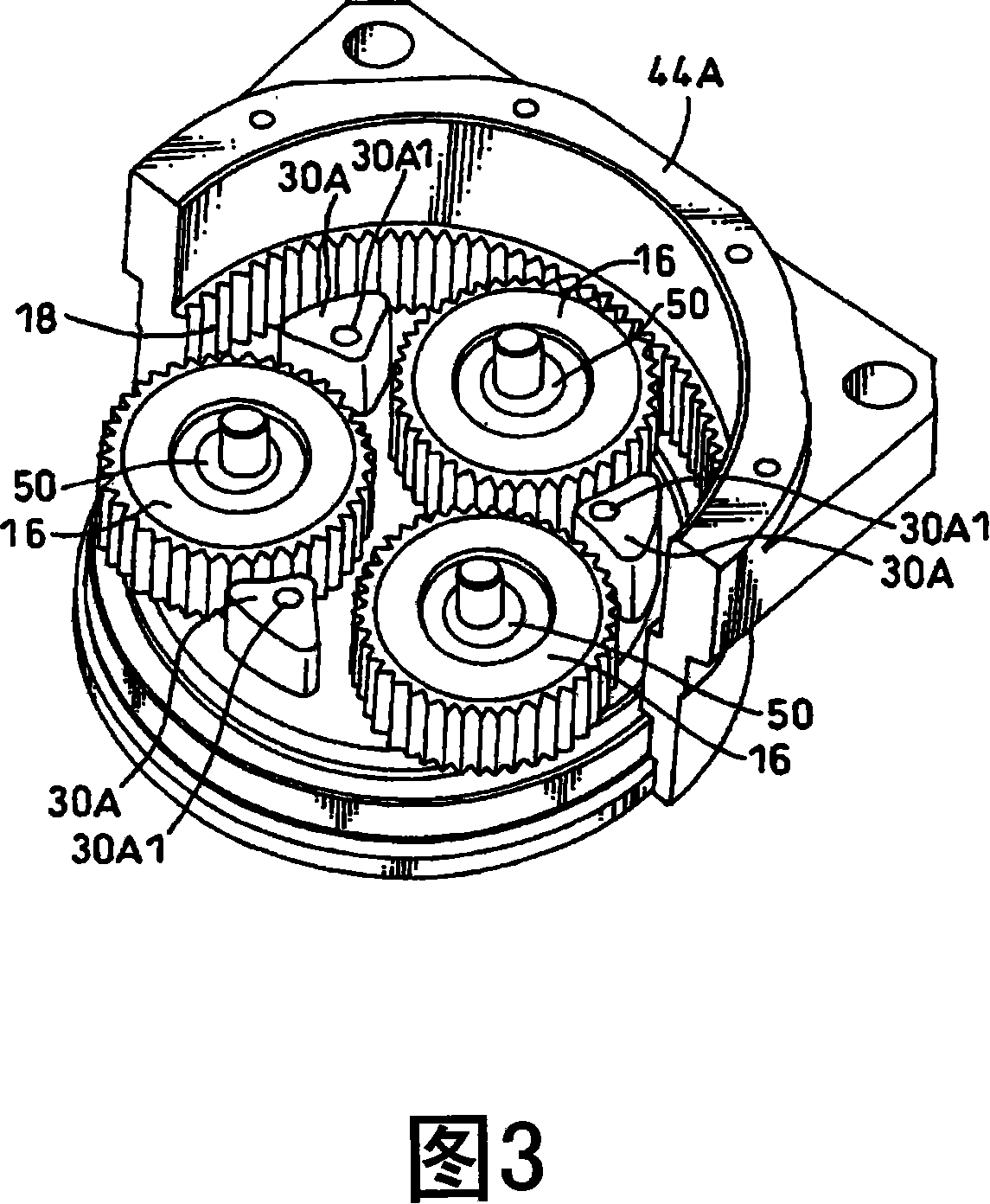

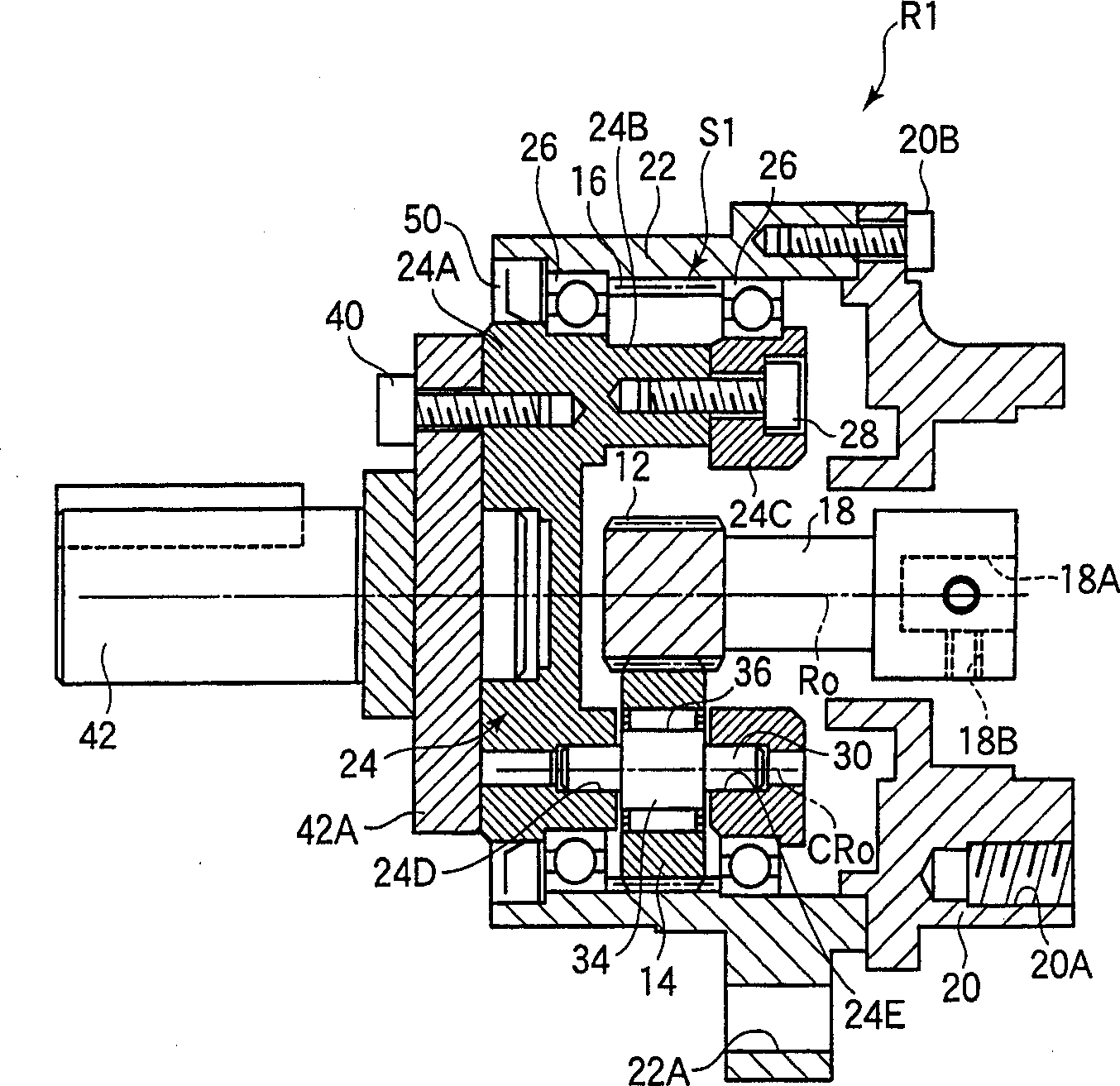

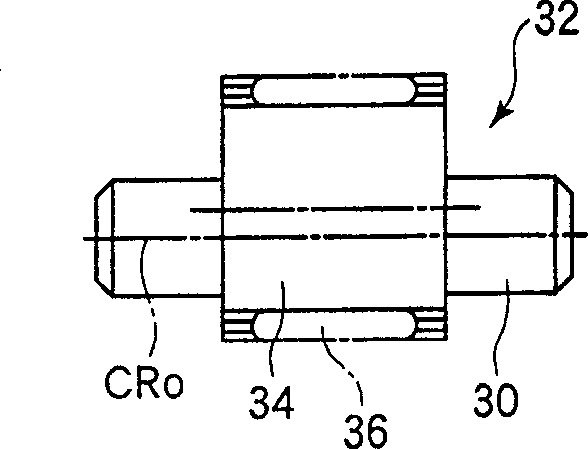

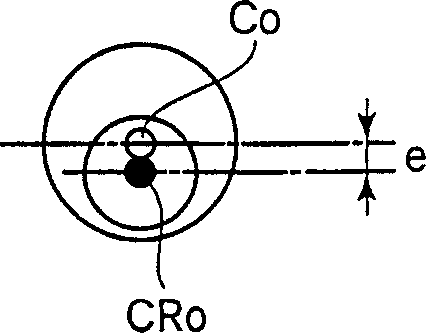

Planetary support structure in simple planetary gear mechanism and its manufacture

InactiveCN1370937ASmooth and smooth rotation effectSmall backlashToothed gearingsPortable liftingGear wheelEngineering

A simple planetary gear mechanism with an automatic centering function to support the planetary gears, thereby obtaining a reducer with reduced backlash through a simple method. The planetary gears (14) are supported by bracket pins (30) supported by the bracket. The bracket pin (30) includes a crank portion (32) which is eccentric "e" with respect to the axis of the bracket pin and whose eccentric angle α is variable. The planetary gear (14) is rotatably supported around the axis of the crank portion (32). As a result, by making the eccentric angle variable, the shaft centers of the planetary gears are automatically aligned in the radial direction when assembling each gear, so that the backlash can be adjusted to the minimum just by assembling a sun gear of an appropriate size.

Owner:SUMITOMO HEAVY IND LTD

Filtering reducer with high reliability and precision

The invention discloses a filtering reducer with high reliability and precision, which comprises an eccentric power input shaft, a duplicate gear, an internal fixing gear and an internal power output gear, wherein an eccentric section is arranged on the eccentric power input shaft; the duplicate gear comprises an external gear I and an external gear II, and rotationally matched with and mounted on the eccentric section in a sleeving manner; the internal fixing gear and the external gear I form a small tooth difference engagement pair I; the internal power output gear and the external gear II form a small tooth difference engagement pair II; and elastic grooving filtering structures are arranged in the small tooth difference engagement pair I and the small tooth difference engagement pair II, and comprise gear tooth grooves formed in gear teeth of the gears. Each gear tooth groove comprises two curved gear tooth grooves and a straight gear tooth groove, wherein the curved gear tooth grooves and tooth outlines of gear teeth form equidistant curves respectively; and each straight gear tooth groove is formed between a tooth crest of each gear tooth and a joint of every two curved gear tooth grooves; and / or, the elastic grooving filtering structures comprise gear grooves formed in tooth grooves of the gears; the gear grooves comprise straight gear grooves formed in the tooth grooves symmetrically; and the gear tooth grooves and the gear grooves are filled with elastomer.

Owner:SICHUAN UNIV

Gerotor apparatus for a quasi-isothermal brayton cycle engine

InactiveUS20110200476A1Simple methodImprove flowEngine of arcuate-engagement typeOscillating piston enginesBrayton cycleEngineering

According to one embodiment of the invention, a gerotor apparatus includes a first gerotor, a second gerotor, and a synchronizing system operable to synchronize a rotation of the first gerotor with a rotation of the second gerotor. The synchronizing system includes a earn plate coupled to the first gerotor, wherein the cam plate includes a plurality of cams, and an alignment plate coupled to the second gerotor. The alignment plate includes at least one alignment member, wherein the plurality of cams and the at least one alignment member interact to synchronize a rotation of the first gerotor with a rotation of the second gerotor.

Owner:TEXAS A&M UNIVERSITY +1

Double moduli high-accurate planet reducing mechanism

InactiveCN103089932AReasonable structural designSmooth runningToothed gearingsGearing detailsCouplingGear wheel

The invention relates to a double moduli high-accurate planet reducing mechanism. At present no high-accurate planet reducing mechanism is high in precision, compact in structure, small in meshing clearance and strong in bearing capability. The double moduli high-accurate planet reducing mechanism is characterized by comprising an output shaft, an output shaft oil sealing, a secondary gear ring shell body, a plurality of secondary planet gears, a primary gear ring shell body, an intermediate planet carrier, a plurality of primary planet gears, a primary sun gear, a coupling bearing, a simple-clamp type locking ring, a rear cover, a secondary sun gear, bearings, a coupling and a secondary planet carrier. The output shaft is installed inside a secondary gear case shell body through a front bearing, the secondary planet carrier is fixed at one end of the output shaft, the secondary planet gears are all installed on the secondary planet carrier, the secondary sun gear is installed in a secondary sun gear cavity of the secondary planet carrier, the primary planet gears are meshed with the primary gear ring, and the primary planet gears are all meshed with the primary sun gear. The double moduli high-accurate planet reducing mechanism is compact in structure, small in back lash, and high in concentric degree and repeated location.

Owner:浙江赛亚智能传动科技有限公司

Modular snake-like robot joint

ActiveCN107175682ACompact and reasonable structure designSmall footprintProgramme-controlled manipulatorJointsReduction driveHarmonic

The invention relates to a snake-like robot joint, in particular to a modular snake-like robot joint. The problems that due to combination of a servo driving mode and a gear transmission mode, an existing snake-like joint is large in reverse backlash, long in control period, low in precision and poor in positioning capacity are solved. The modular snake-like robot joint comprises a joint input part, a joint output part, an intermediate shaft section, a motor assembly and a harmonic reducer, wherein the joint input part and the joint output part are arranged at the two ends of the intermediate shaft section correspondingly; the motor assembly and the harmonic reducer are arranged inside the intermediate shaft section side by side; the output end of the motor assembly is connected with the harmonic reducer and drives the harmonic reducer to rotate; and the harmonic reducer drives the joint output part to make swinging motion with the intermediate shaft section as an axis. Through arrangement of a torque sensor and a joint output end position sensor for measuring force-position information of the snake-like robot joint, the perceptive function of a robot is improved, and the robot can be controlled conveniently. The modular snake-like robot joint is applicable to snake-like robots.

Owner:HARBIN INST OF TECH

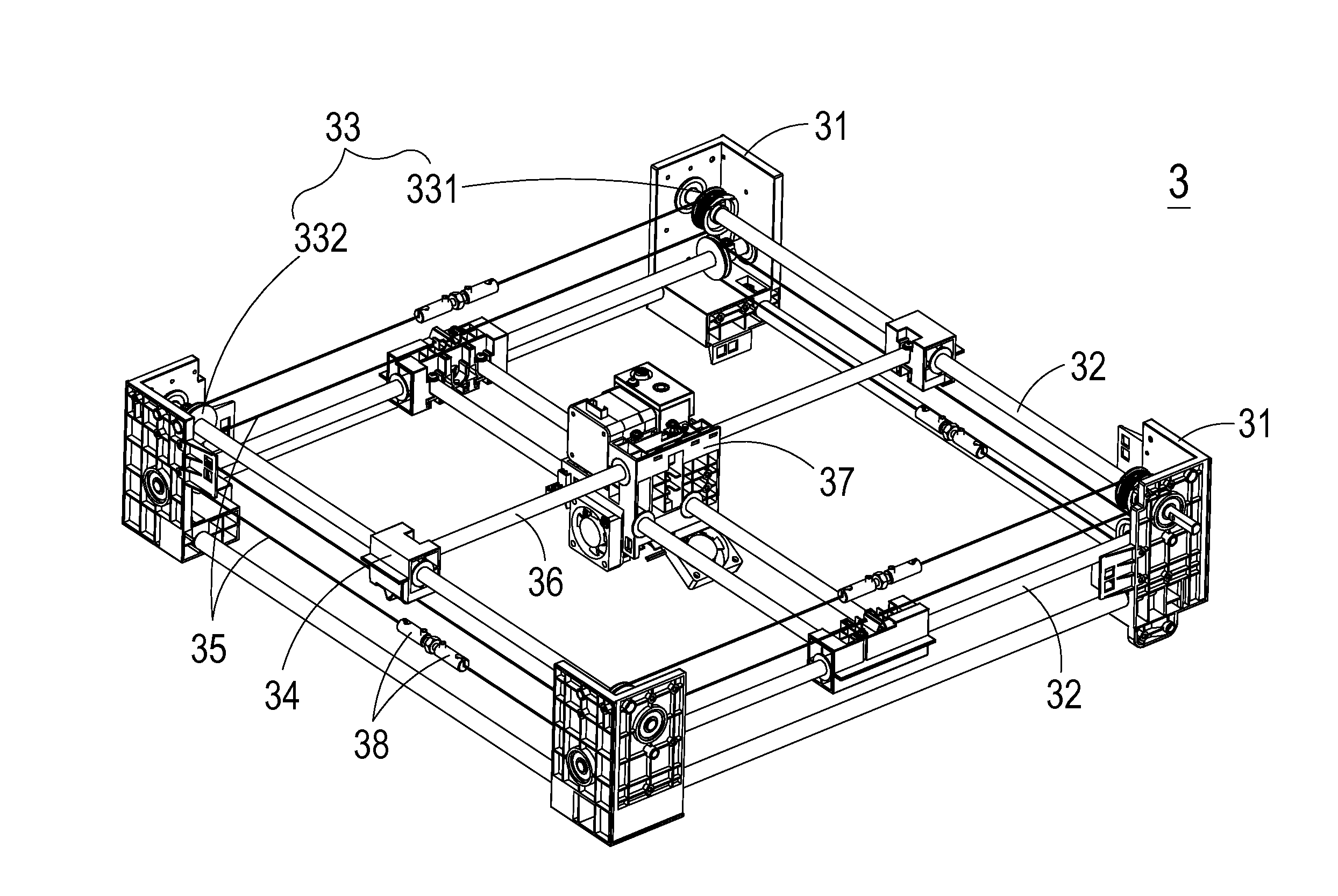

Steel wire transmission system for three-dimensional printer and adjusting mechanism thereof

ActiveUS20160368216A1Drawback can be solvedSmall backlashAdditive manufacturing apparatusRopes and cables for vehicles/pulleyTransmission systemEngineering

A steel wire transmission system includes plural slide rail seats, plural slide rails, plural wheel sets corresponding to the plural slide rails, plural slide blocks, plural steel wires, plural guide rods and a printhead module. The plural slide rails are disposed on the corresponding slide rail seats. Each wheel set includes a driving wheel and a driven wheel corresponding to the driving wheel. The driving wheel and the driven wheel of each wheel set are fixed at two ends of the corresponding slide rail. Each slide block is sheathed around the corresponding slide rail and movable between the corresponding driving wheel and the corresponding driven wheel. The plural steel wires are wound around the corresponding wheel sets. Each guide rod is connected with two corresponding slide blocks. The printhead module is connected with the plural guide rods.

Owner:TECO IMAGE SYST

Gerotor apparatus for a quasi-isothermal brayton cycle engine

InactiveUS20100003152A1Simple methodImprove flowEngine of arcuate-engagement typeOscillating piston enginesBrayton cycleGear wheel

According to one embodiment of the invention, a gerotor apparatus includes a first gerotor, a second gerotor, and a synchronizing system operable to synchronize a rotation of the first gerotor with a rotation of the second gerotor. The synchronizing system includes a cam plate coupled to the first gerotor, wherein the cam plate includes a plurality of cams, and an alignment plate coupled to the second gerotor. The alignment plate includes at least one alignment member, wherein the plurality of cams and the at least one alignment member interact to synchronize a rotation of the first gerotor with a rotation of the second gerotor.

Owner:STARROTOR CORPORATION +1

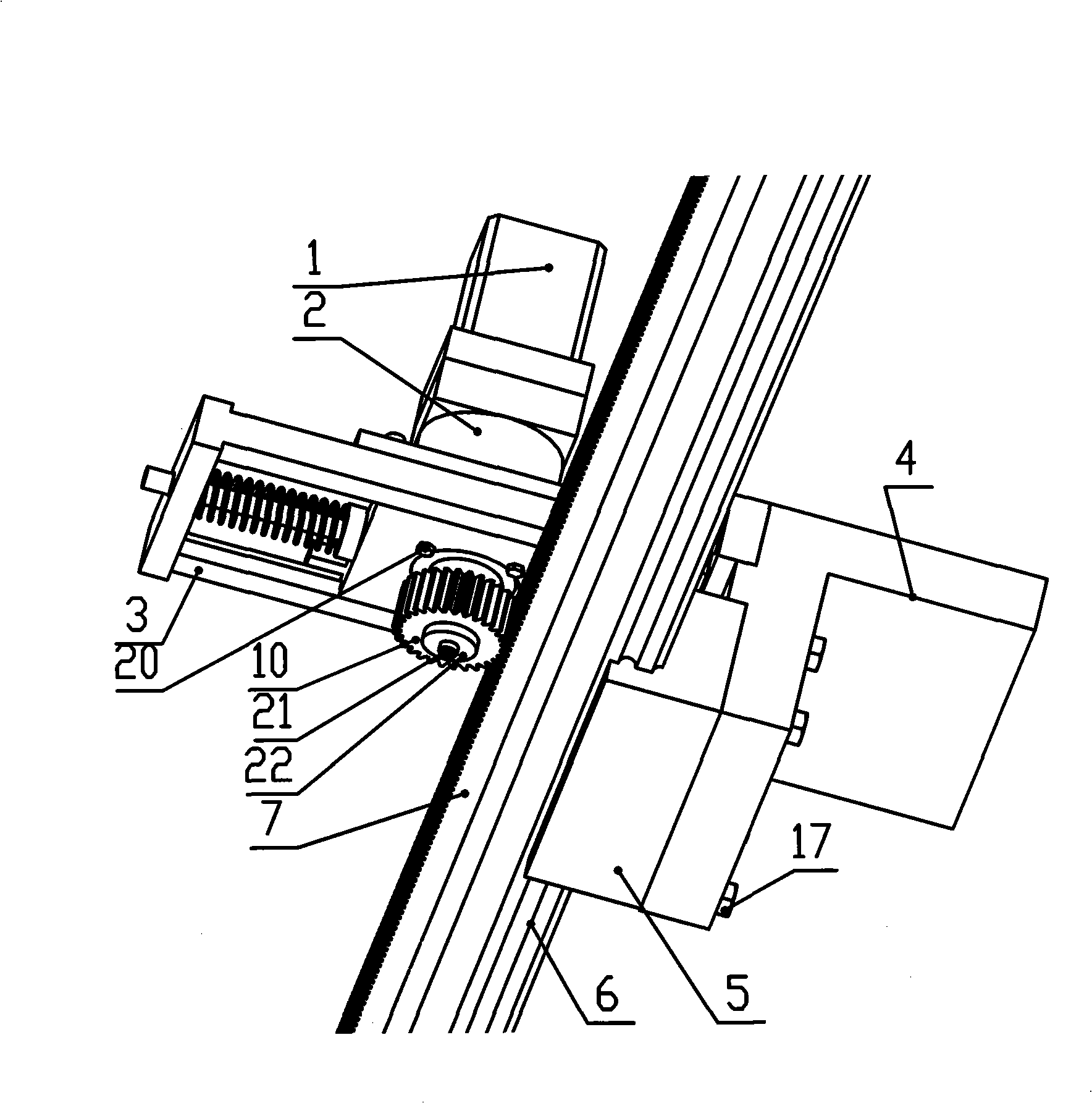

Leverage for reducing gear rack transmission backlash

The invention provides leverage for reducing gear rack transmission backlash, comprising a rack, a gear, a gear transmission motor and a reducer. The invention is characterized in that a lever bracket is fixedly arranged on a moving body; one end of a lever is installed on the lever bracket via a plug; the gear is installed on an output shaft of the reducer which is installed in the middle part of the lever; the gear transmission motor is connected with the reducer; a through hole is arranged on the other end of the lever; screws are arranged in the through hole in series; a lever compression spring is sheathed on the screw and the lever is fixed on the moving body. The lever is arranged on the moving body of the invention and the assembly of the motor, the reducer and the gear is arranged on the lever; the lever only has one rotational degree of freedom around the plug axes and the gear installed on the lever is pressed toward the rack by the compression spring at the other end of the lever, therefore, the distance between the gear and the rack is shortened to the minimum, thereby reaching the aim of reducing the backlash of mutually meshed gear and rack and finally playing a role in reducing the backlash.

Owner:HARBIN ENG UNIV

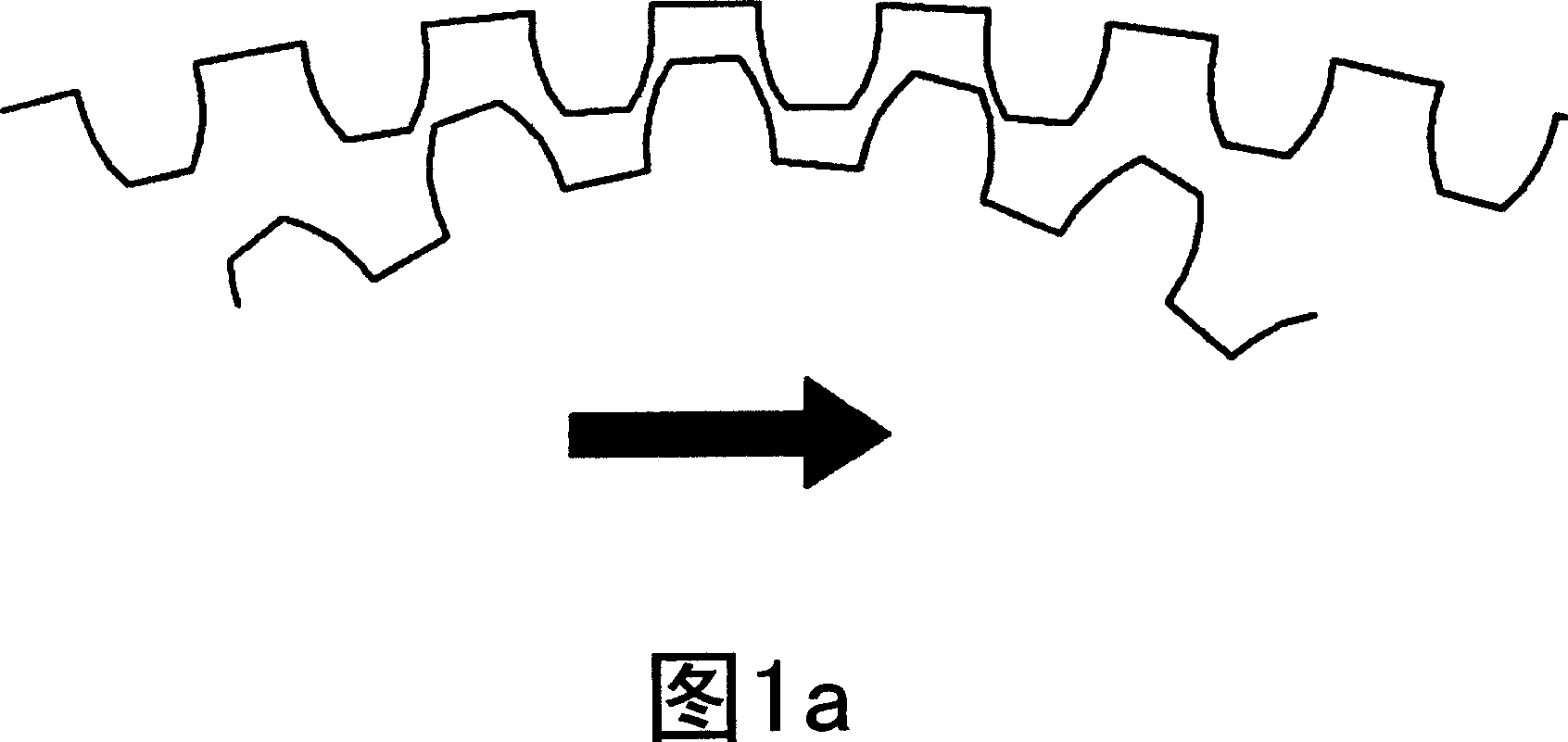

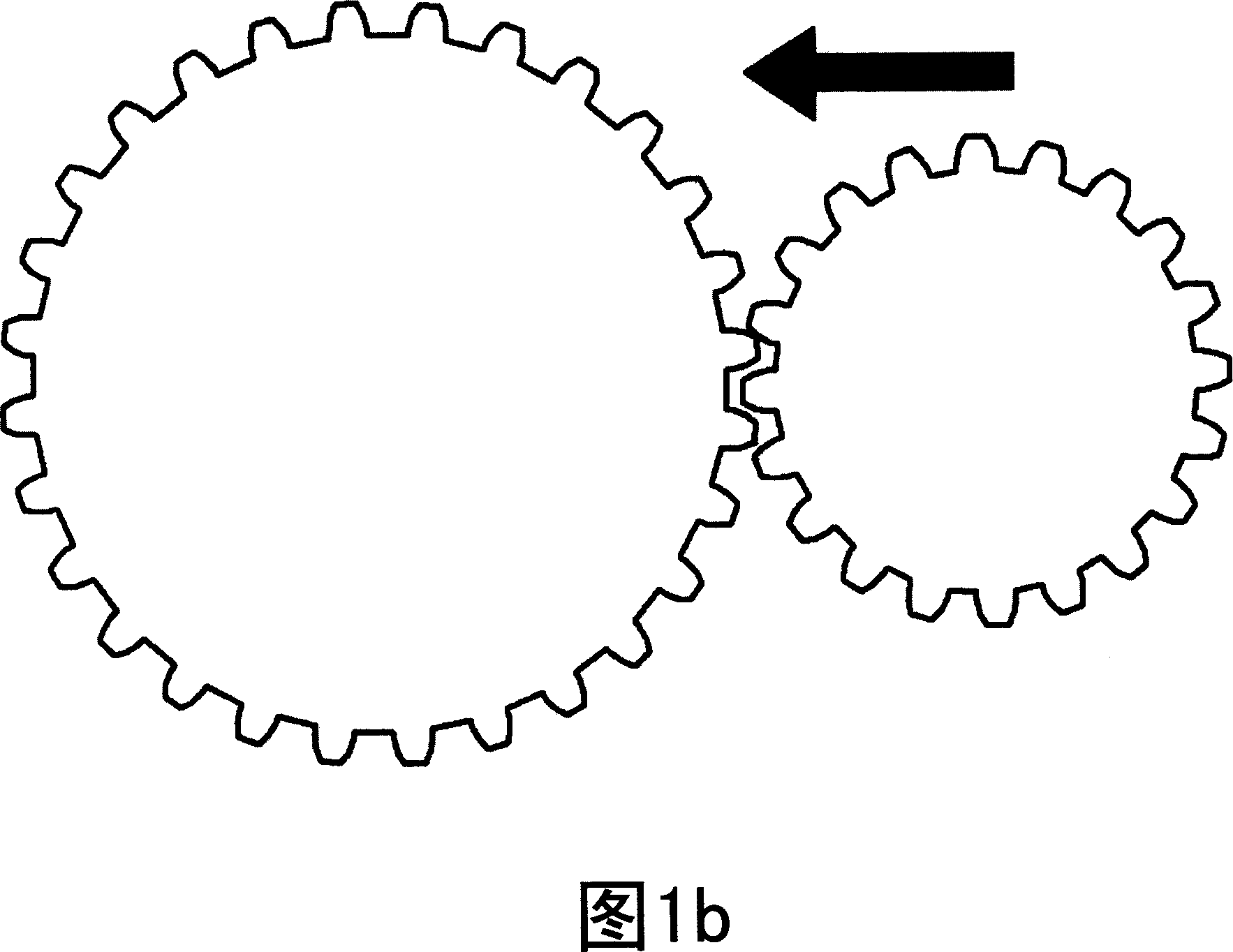

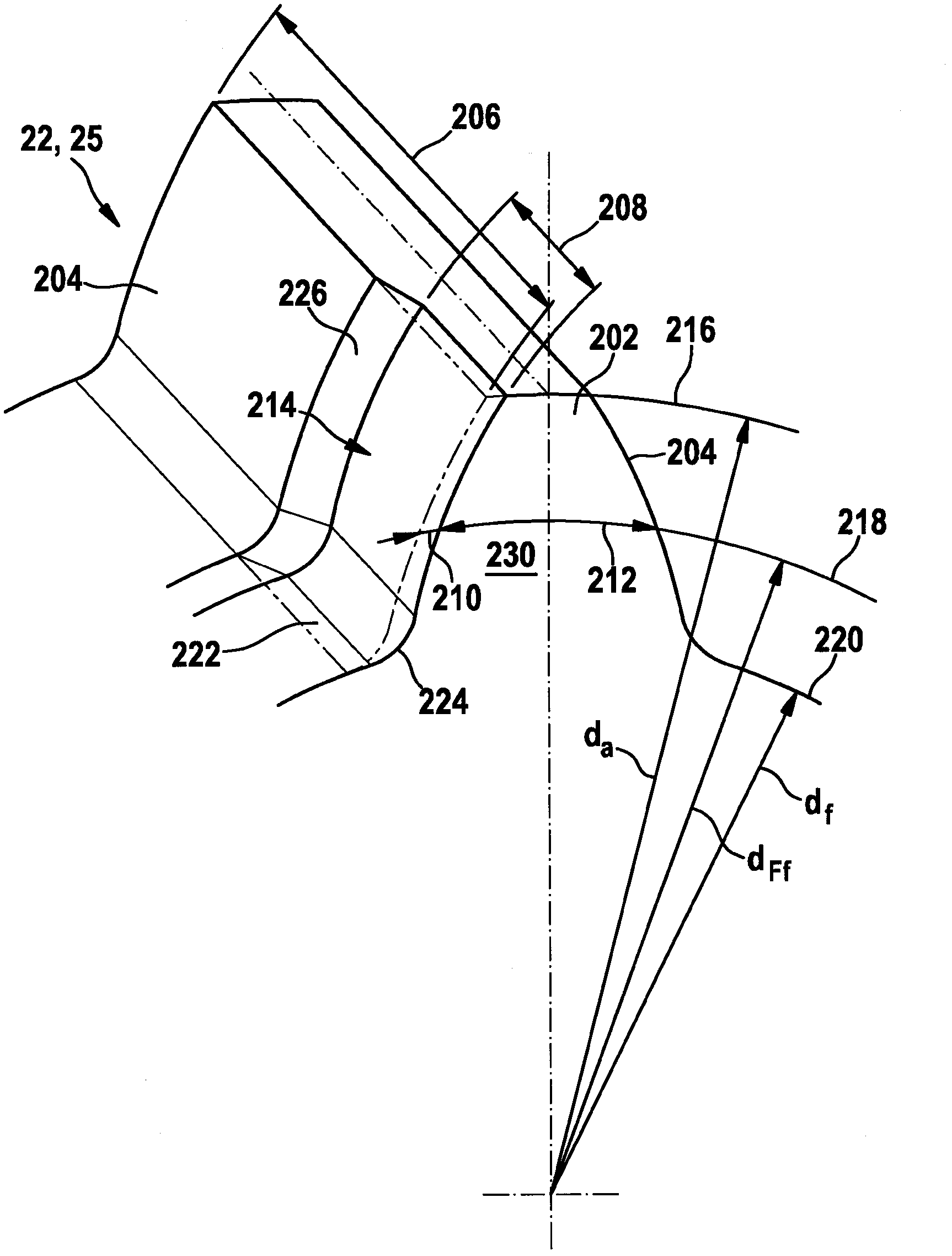

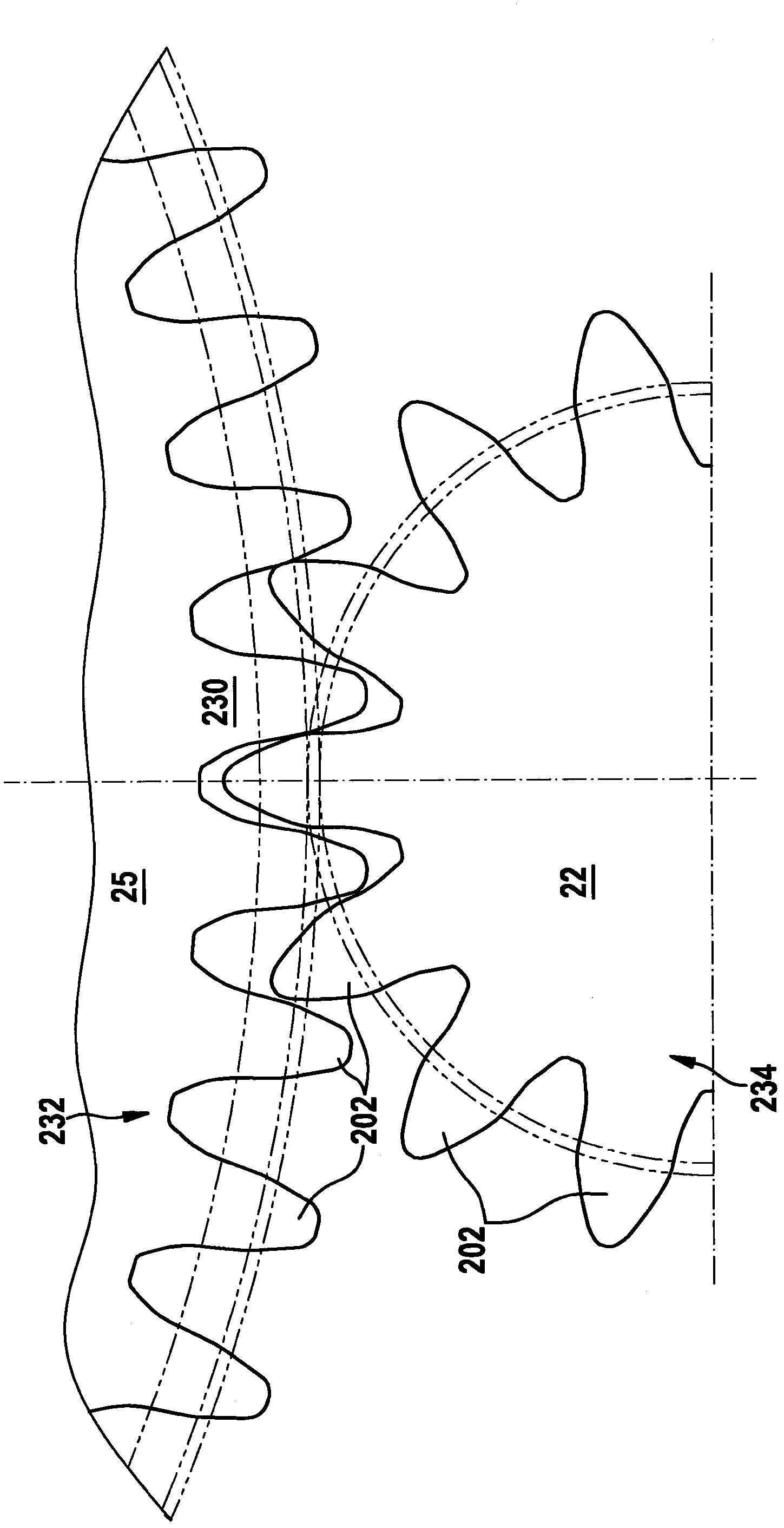

Noise-optimized toothing system

ActiveCN102918257AImprove noiseImproved vibration characteristicsPower operated startersGear vibration/noise dampingElectric machineInternal combustion engine

The invention relates to an electric machine, in particular a starter device (10) for an internal combustion engine. The electric machine comprises a noise-optimized toothing system (232, 234) of two gearwheels (22, 25) which can be brought into engagement with one another. The noise-optimized toothing system (232, 234) is configured as an extra-deep toothing system on at least one of the gearwheels (22, 25). The extra-deep toothing system has an asymmetrical toothing profile (214).

Owner:SEG AUTOMOTIVE GERMANY GMBH

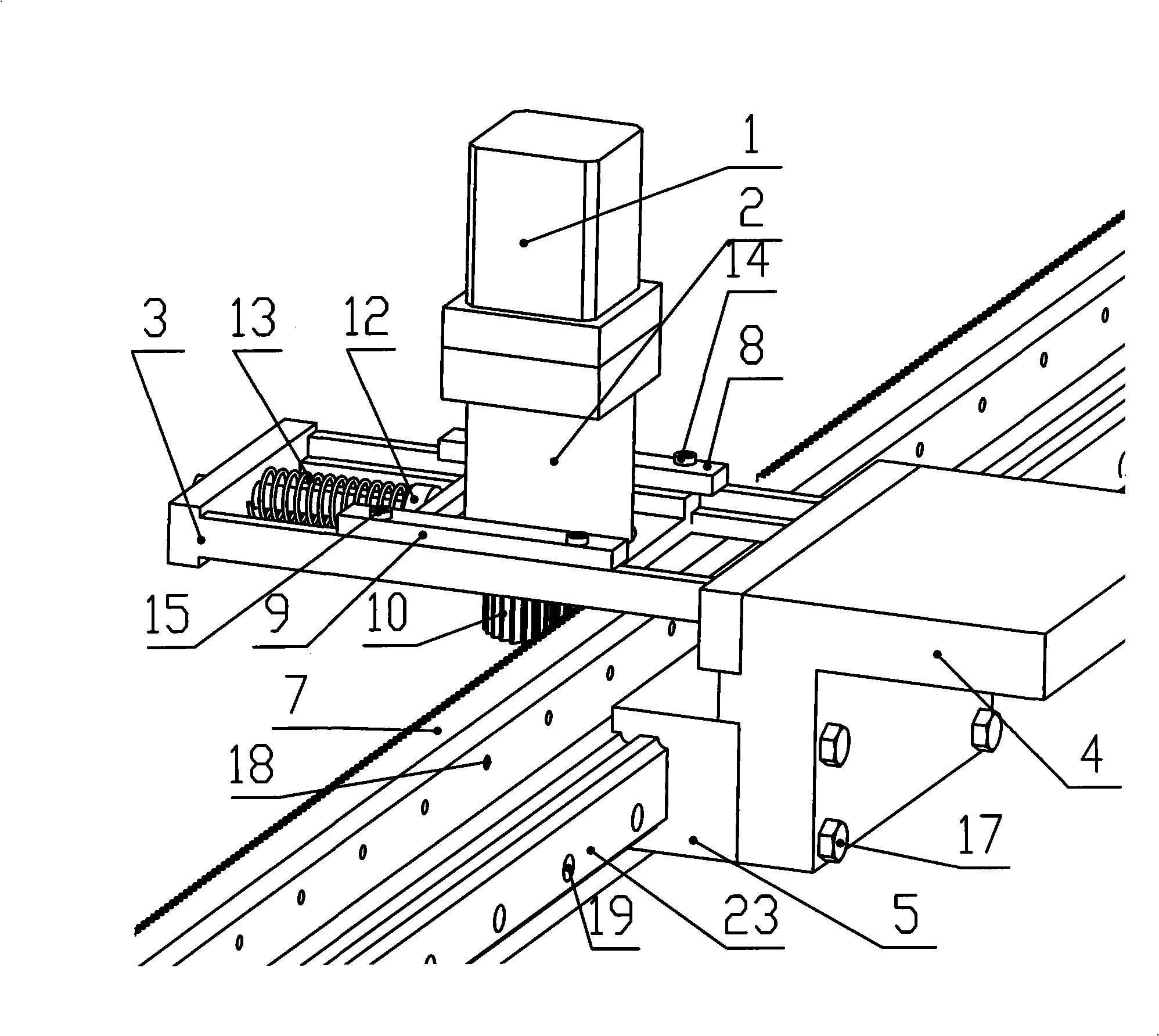

Slide block mechanism for reducing transmission backlash of rack and pinion

InactiveCN101526132AReduce transmission backlashEmpty back smallGearing detailsGear wheelReduction drive

The invention provides a slide block mechanism for reducing transmission backlash of rack and pinion. The mechanism comprises a pinion, a rack, a decelerator and a motor, the pinion is mounted on the output shaft of the decelerator, the motor or the decelerator is connected with the decelerator, the decelerator is mounted on the slide block, the slide block is glidingly mounted on a bracket and has one movement freedom degree only, the bracket is mounted on a movable member, and a compression spring is provided between the slide block and the bracket. The invention provides a new method, which is safe and reliable and is convenient for mounting, for reducing lateral clearance of the rack and the pinion; the compression spring is employed to minimize the distance between the pinion, which is mounted on the output shaft of the decelerator on the slide block, and the rack, which is meshed with the pinion, thus realizing the objective of reducing the backlash.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com