Modularized B-axis turning and milling composite functional unit

A composite function and modular technology, applied in the direction of driving device, feeding device, other manufacturing equipment/tools, etc., can solve the problems of thermally deformed gears, hazards, narrow processing capacity range of turning and milling heads, etc., to ensure rigidity and processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

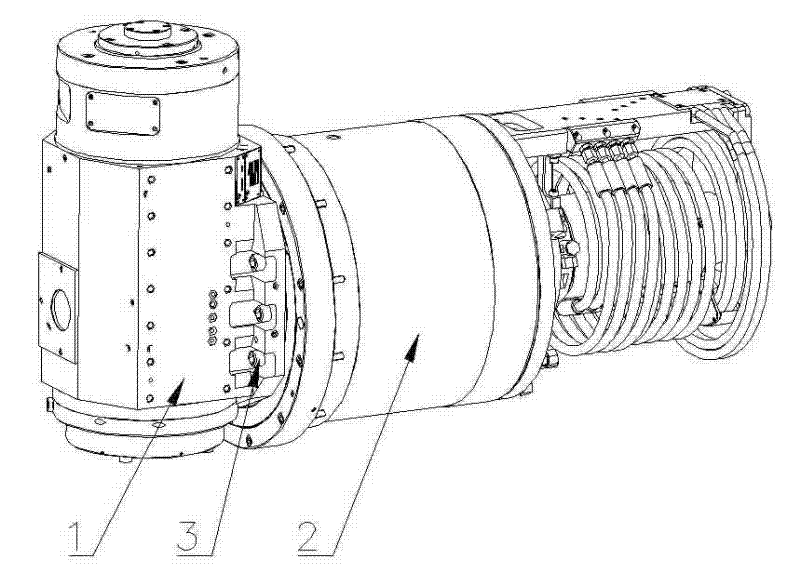

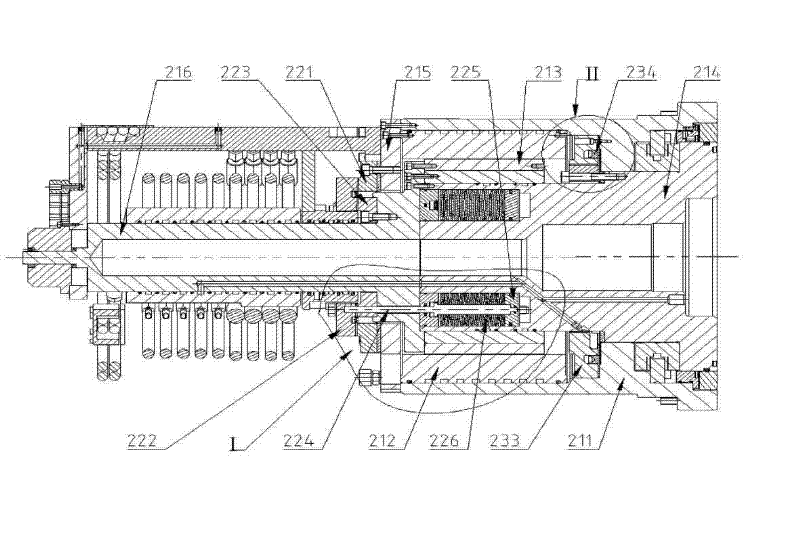

[0025] like figure 1 and figure 2 As shown, the present invention creates a modularized B-axis turning-milling compound functional unit consisting of a turning-milling head module 1 and a B-axis module 2 . Turning and milling head module 1 can be installed with turning tools, milling cutters, drills and other processing tools. B-axis module 2 can swing along the B-axis driven by the motor. Turning and milling head module 1 is connected to the flange of B-axis module 2 through bolts 3 on shaft 214.

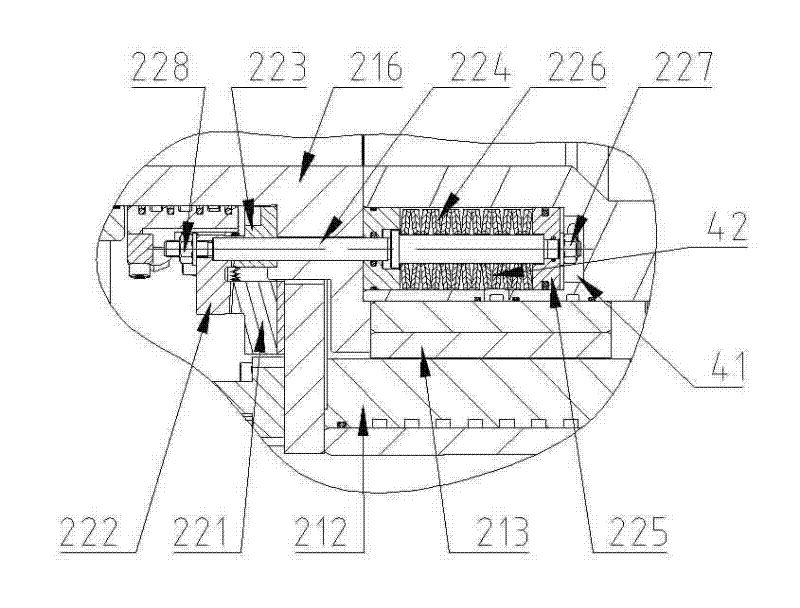

[0026] The B-axis module 2 mainly includes: a motor drive device, a three-ring indexing structure and a brake structure. Its motor drive device such as figure 2 As shown, the motor stator 212 of the B-axis module 2 is fixed on the rear cover 215 of the B-axis module 2 by screws, the motor stator 212 and the rear cover 215 are installed together in the box body 211, and the rear cover 215 is fixed on the box body by screws 211 on. The motor rotor 213 is fixed on the shaft 216...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com