Patents

Literature

50results about How to "High degree of freedom of shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

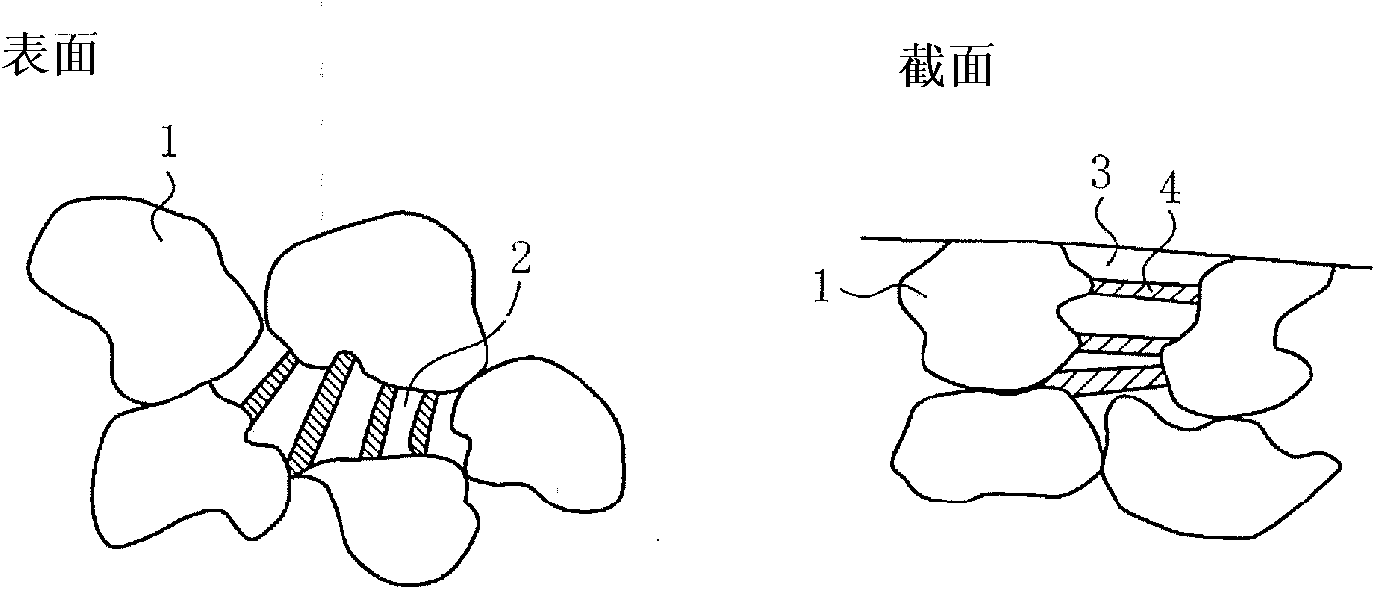

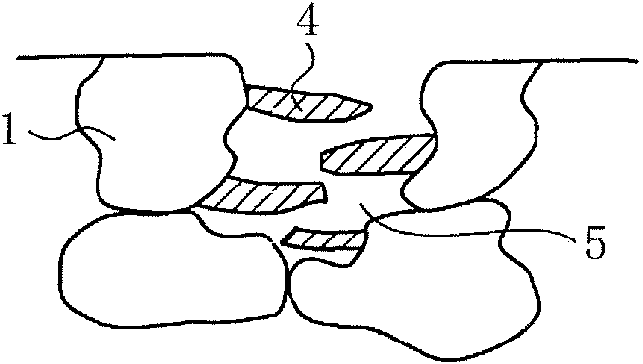

Method of laser joining of aluminum alloy member and resin member

InactiveCN102712136AImprove joint strengthEffective anchoring effectAdhesive processes with surface pretreatmentLaser beam welding apparatusUltimate tensile strengthBonding strength

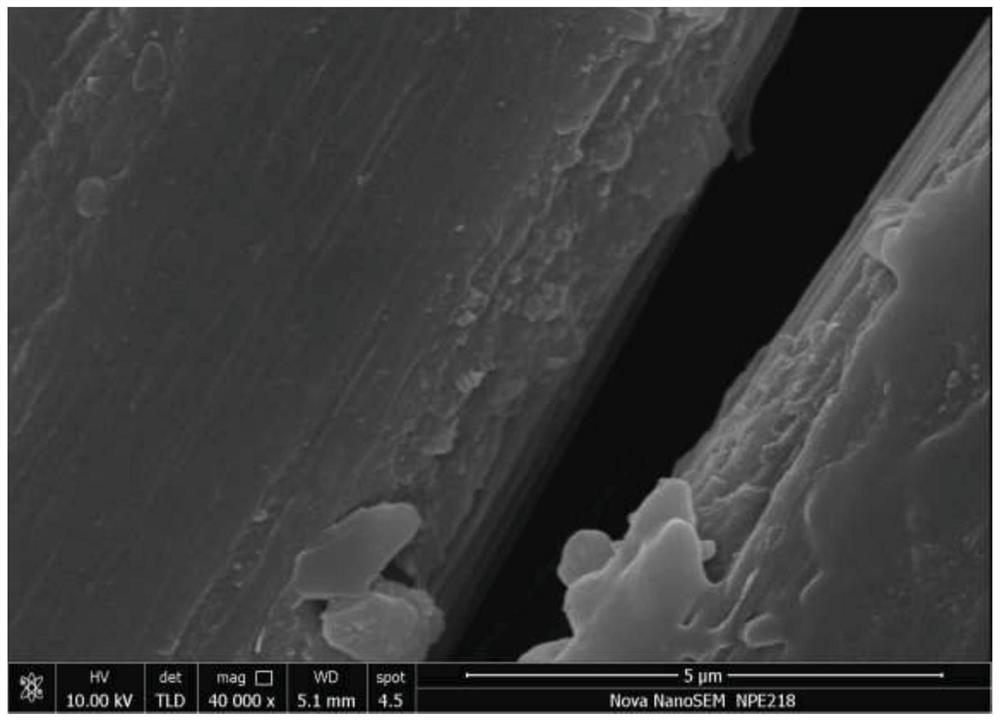

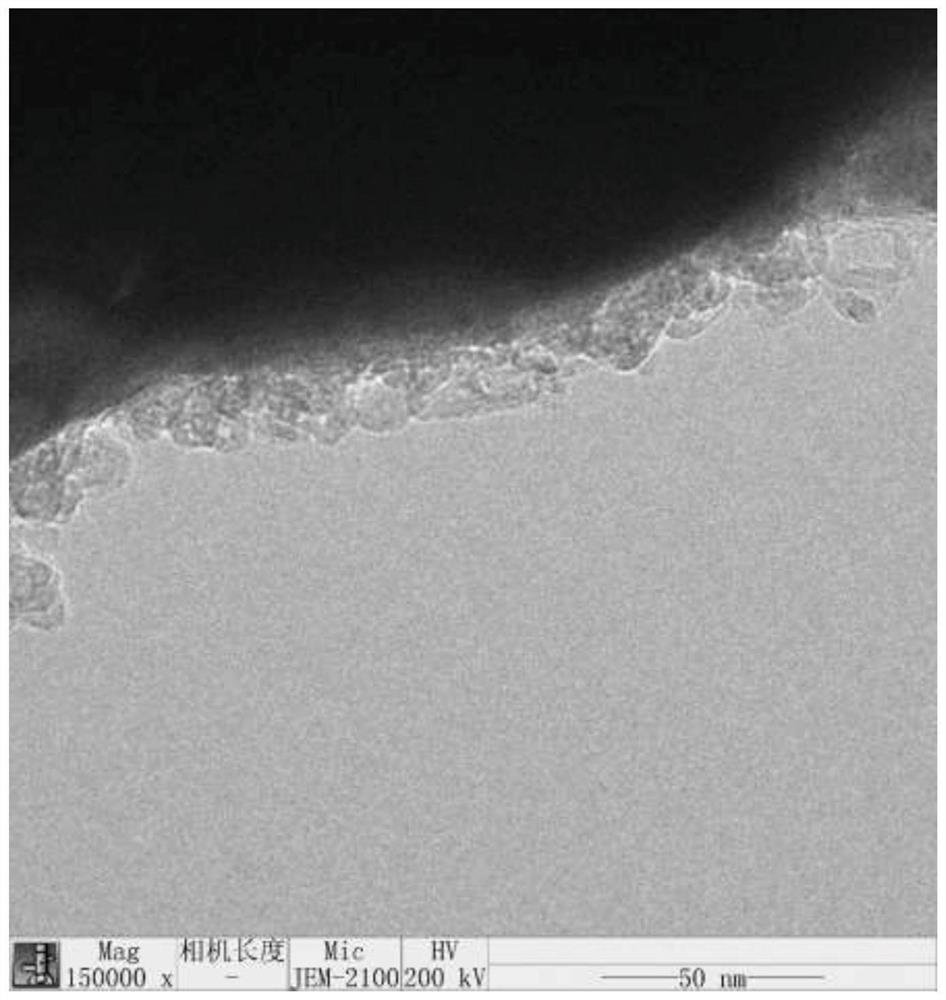

By laser joining using a member with a complicated surface shape as the aluminum alloy member, a composite is obtained having increased bonding strength with the resin member. After forming asperities by etching treatment on the surface of the aluminum alloy member to be joined, one surface of said aluminum alloy member is placed on the resin member, and then a laser is irradiated onto the other surface of said aluminum alloy member, softening the resin member contacting the aluminum alloy member and filling the aforementioned asperities with said resin. Blasting may be optionally performed before etching.

Owner:NIPPON LIGHT METAL CO LTD

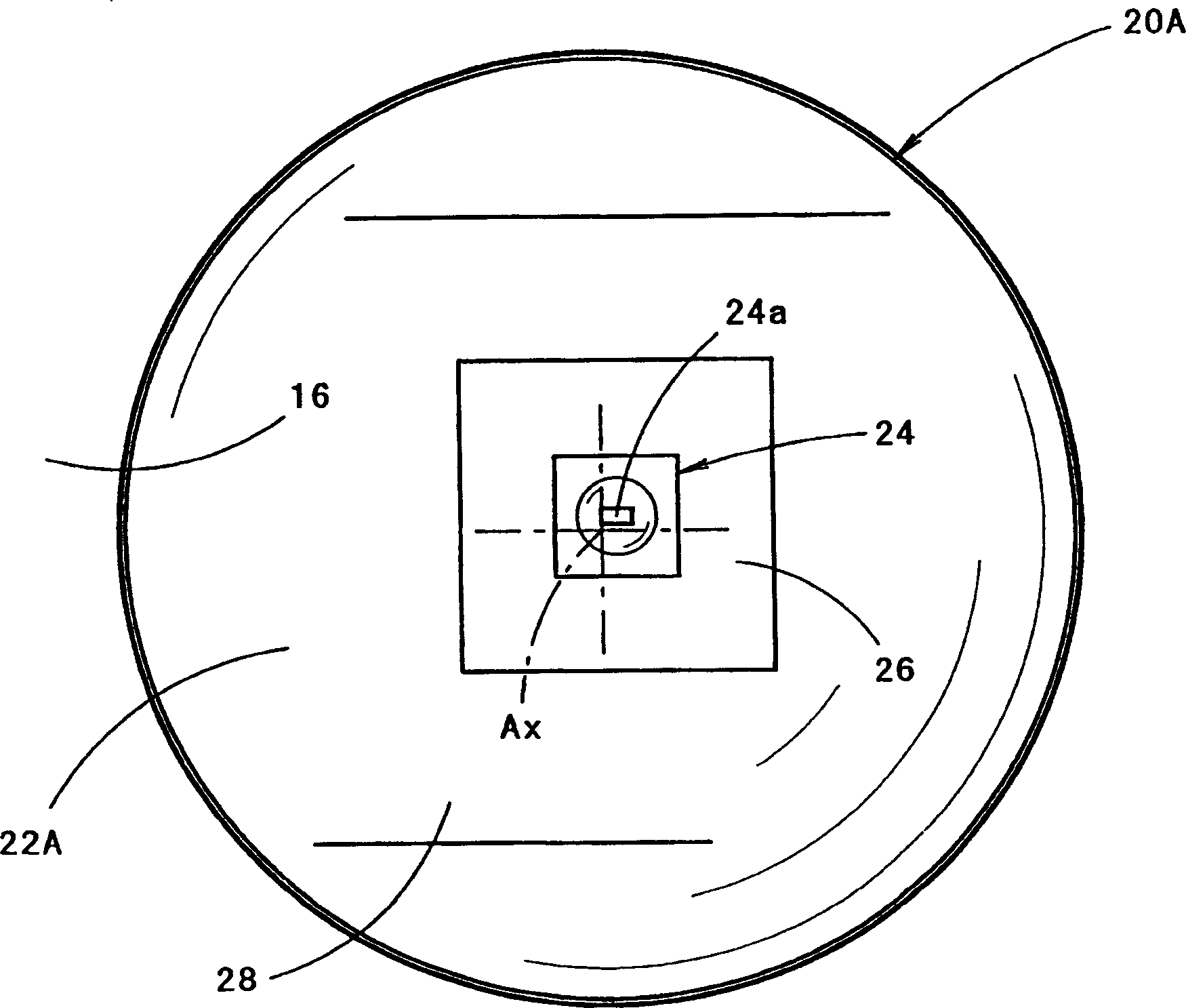

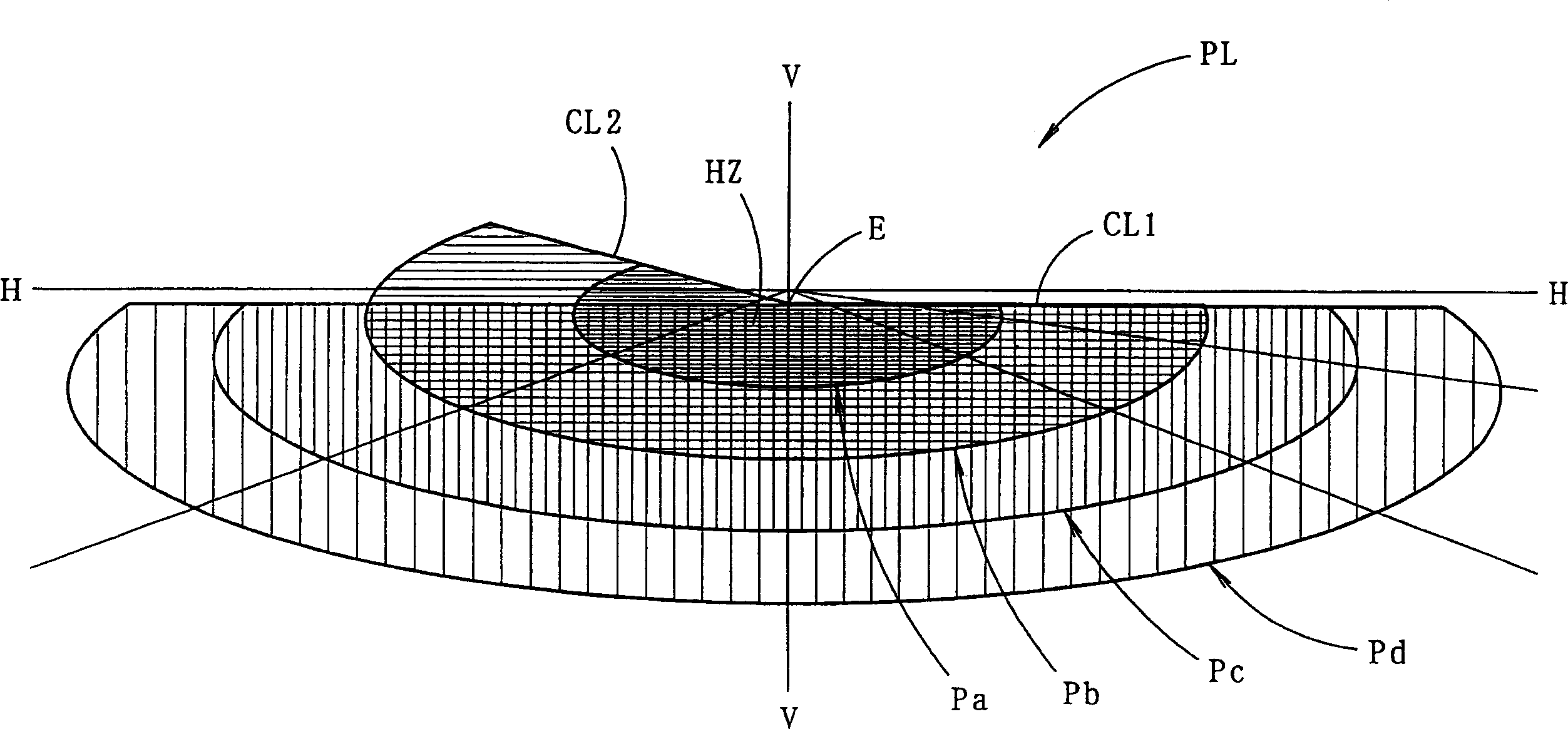

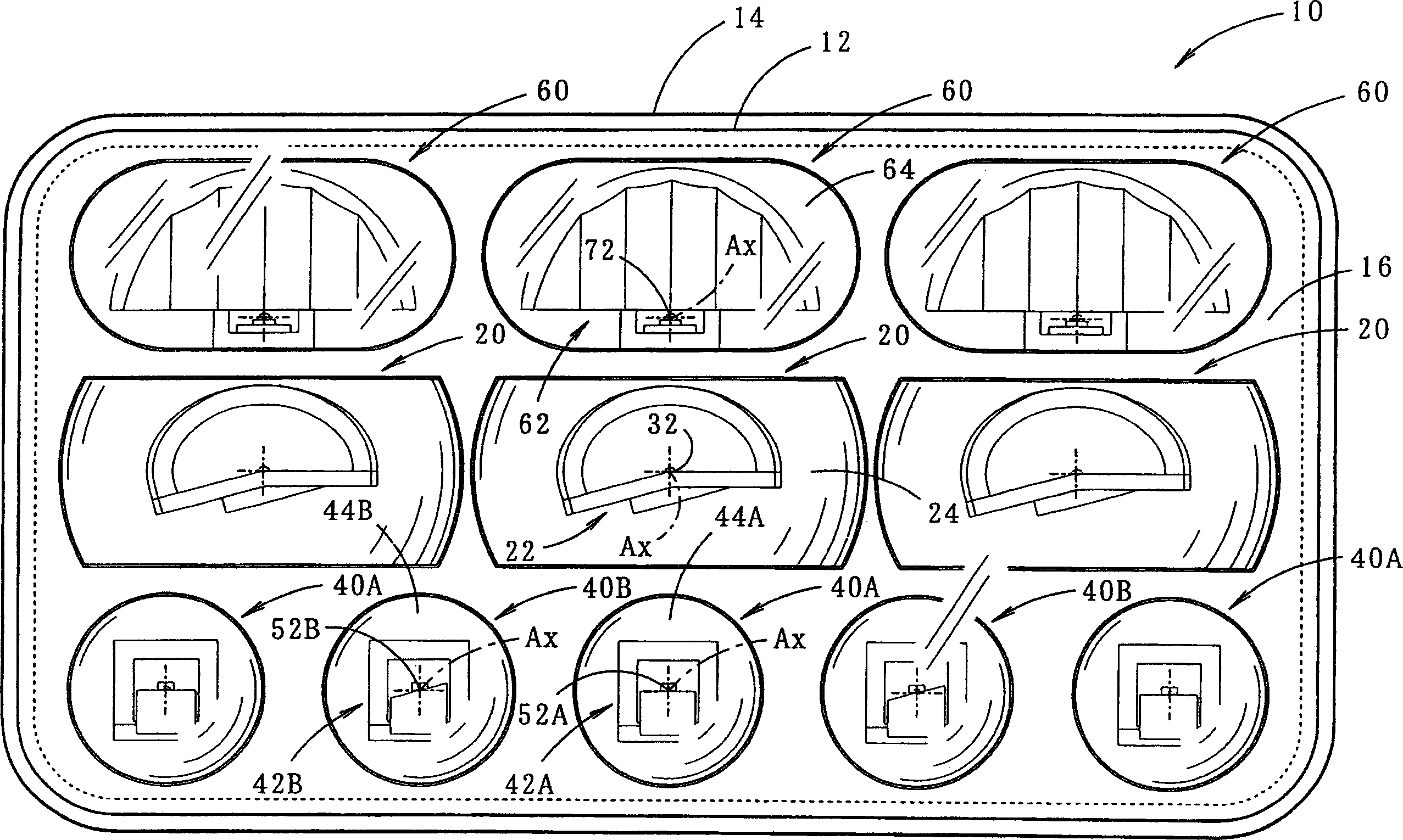

Front Lamp for vehicle

InactiveCN1487232AHigh degree of freedom of shapeAchieve compactnessVehicle headlampsPoint-like light sourceDirect illuminationLight-emitting diode

The headlamp has multiple lamp units (20,40A,40B,60) each using light-emitting diodes (LED) as light sources. One type of lamp unit (20) uses a reflector and a lens to produce a convergent beam combining direct and reflected light, another type (40A,40B) uses a convergent lens to produce direct illumination, and the third type (60) delivers only reflected light.

Owner:KOITO MFG CO LTD

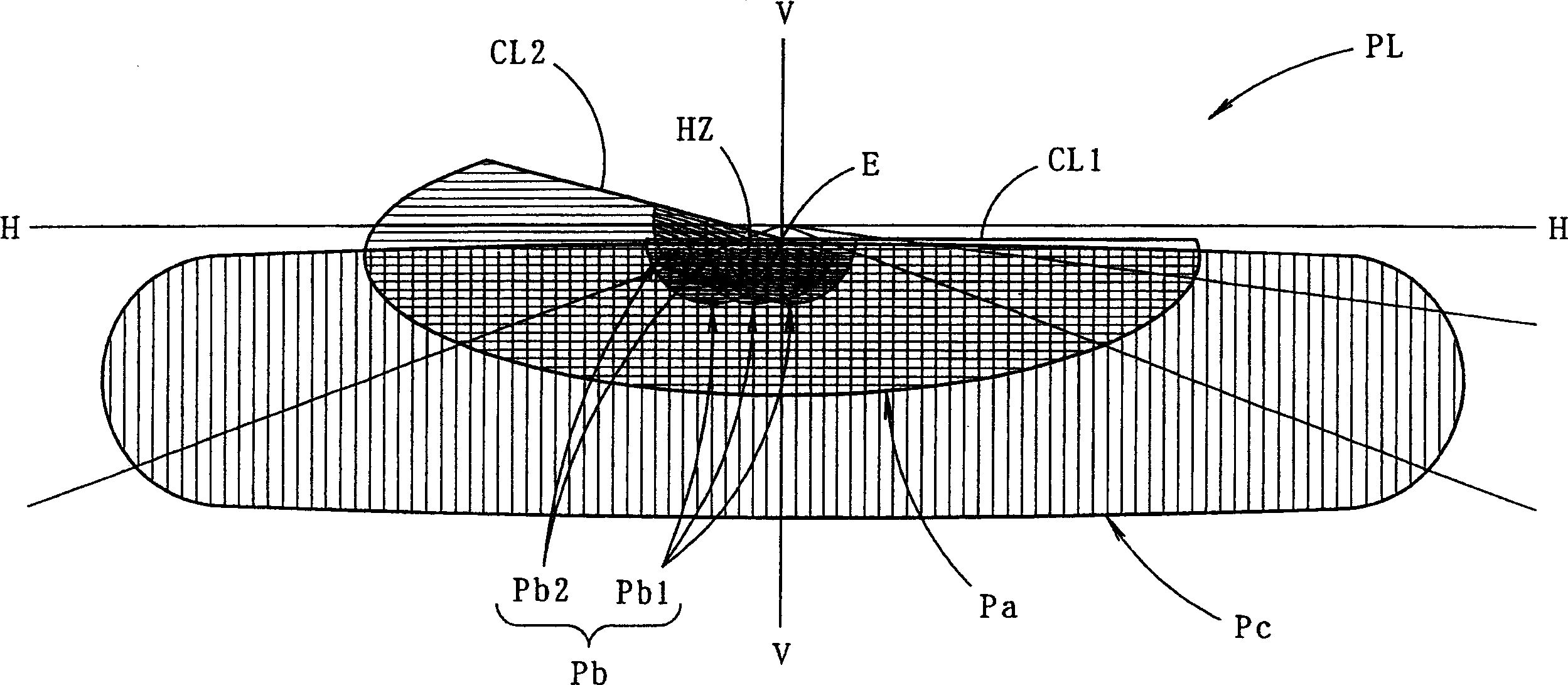

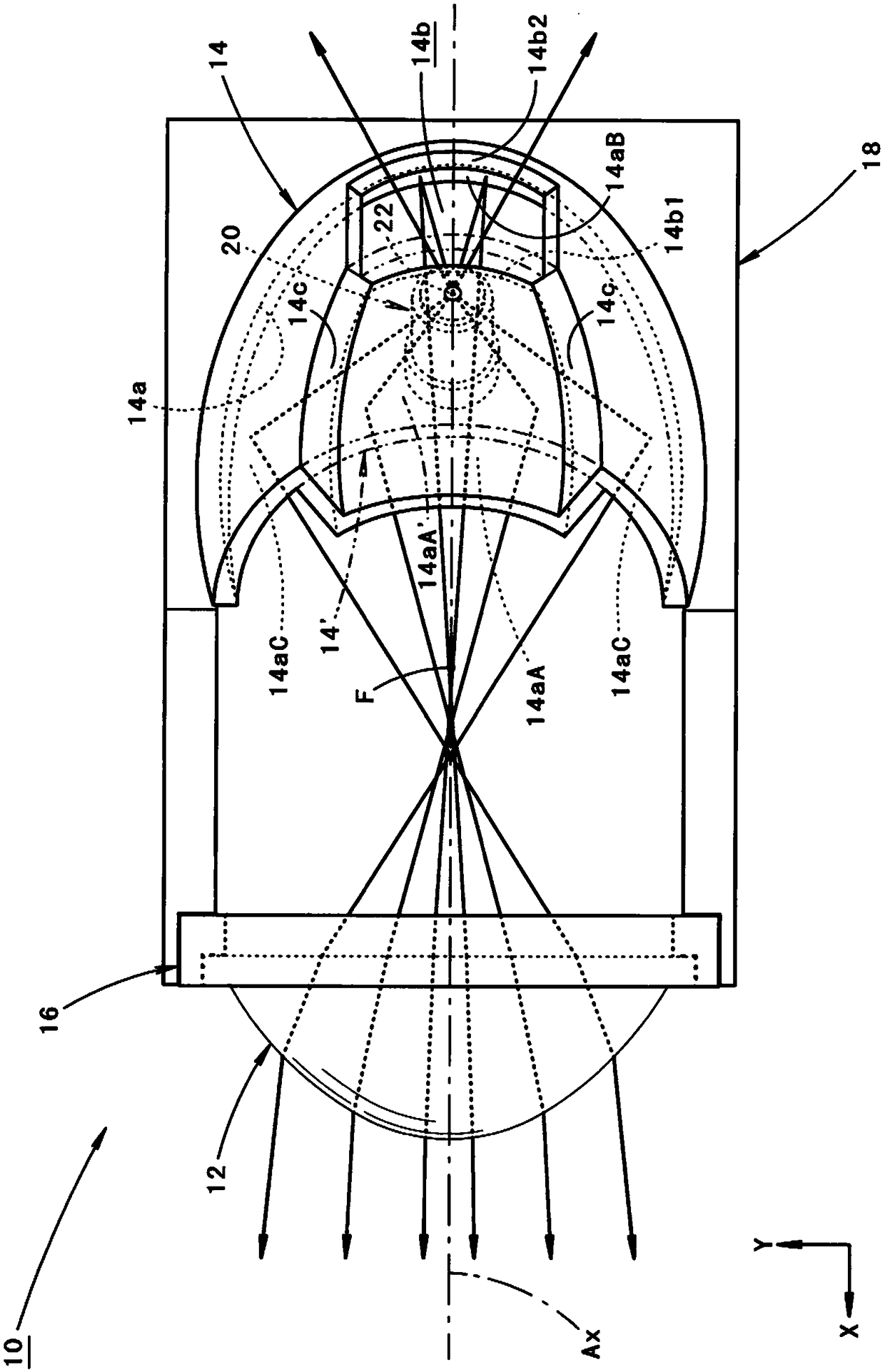

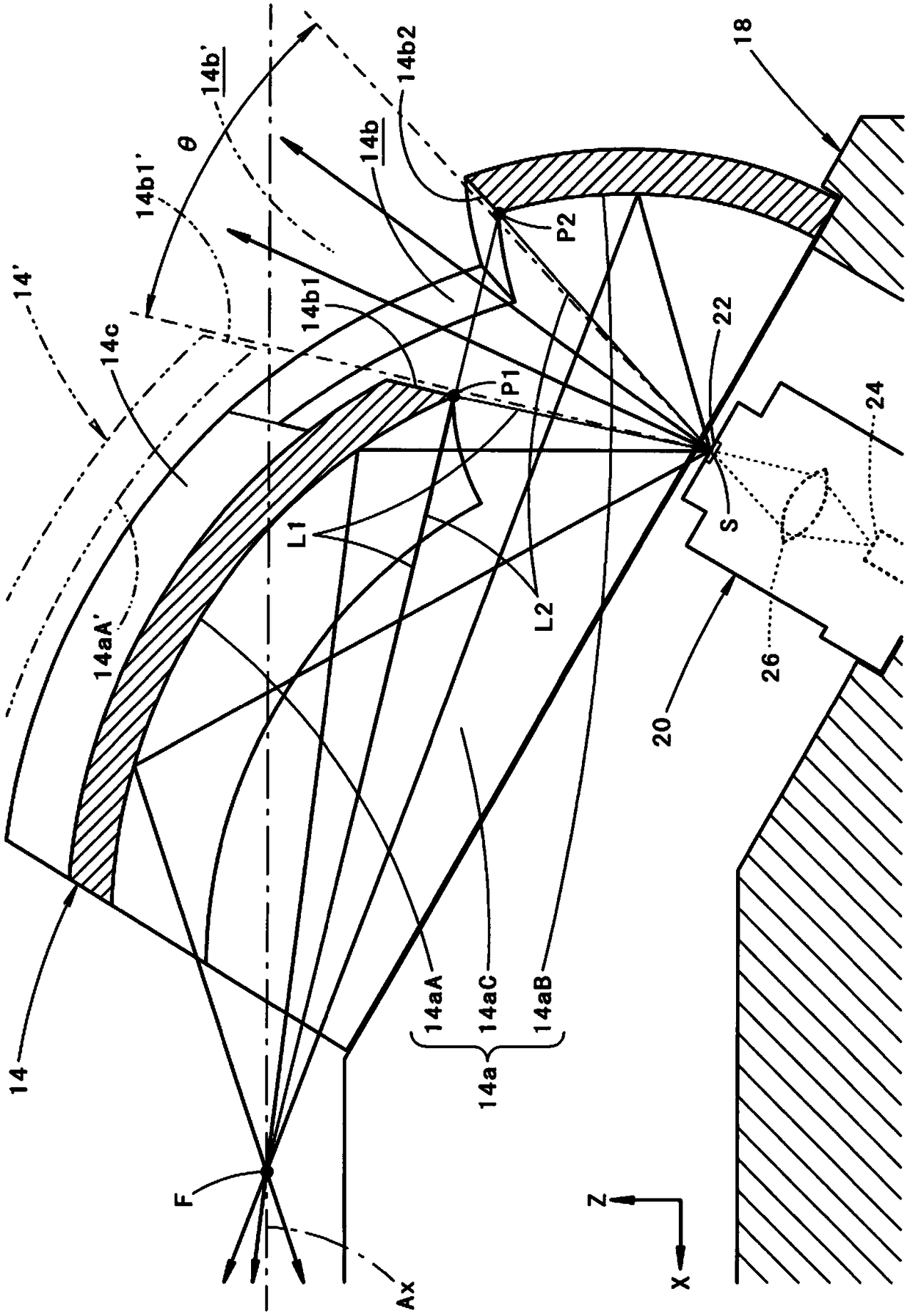

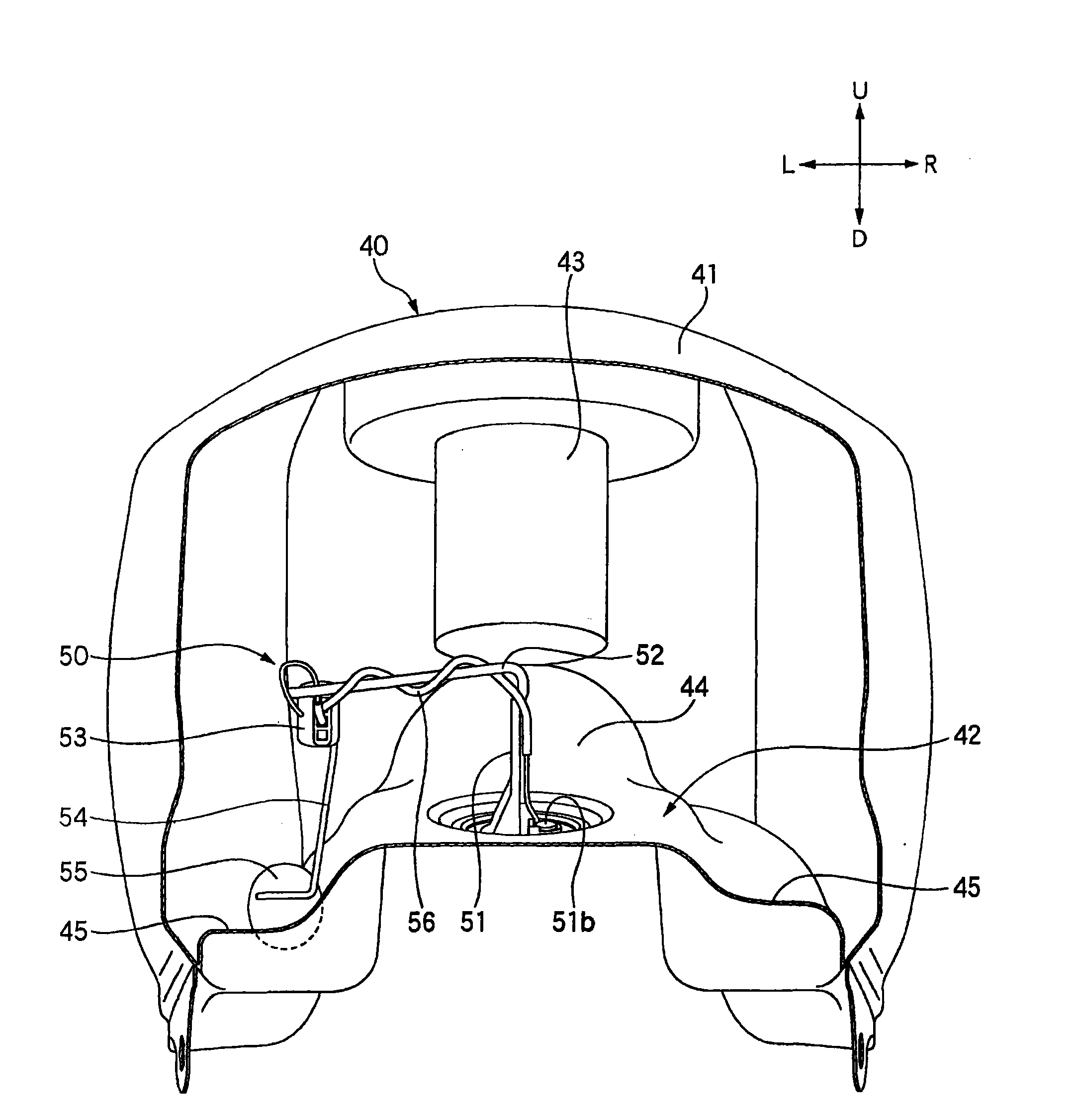

Headlamp of vehicle

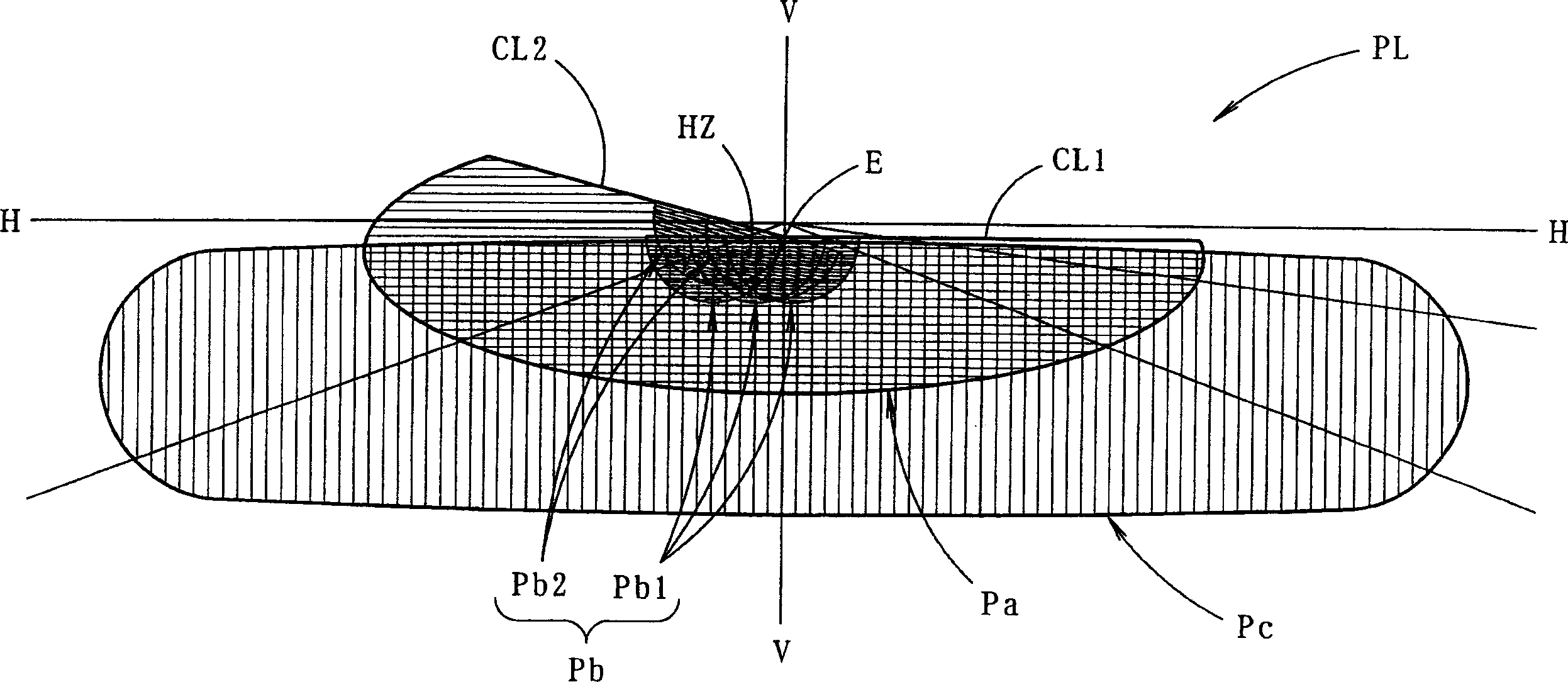

InactiveCN1540201ABrightness distribution can be set arbitrarilyGlare suppressionVehicle headlampsPoint-like light sourceLight irradiationEffect light

There are provided five first lighting units for carrying out light irradiation to form a horizontal cutoff line. Each of the first lighting units has such a structure that includes a first light source formed by a light emitting diode provided to face forward in such a manner that one side of a rectangular light emitting chip is extended in a horizontal direction, and first projection lenses provided in front thereof and serving to project the image of the first light source as an inverted image forward from the lighting units. Consequently, the inverted image of the first light source projected forward from the lighting unit is an almost rectangular image having an upper edge extended almost horizontally. These are provided with a shift from each other in the horizontal direction, thereby forming a horizontal cutoff line. Two additional rows of lighting units provide light for an oblique cutoff line and a diffuse light pattern, respectively.

Owner:KOITO MFG CO LTD

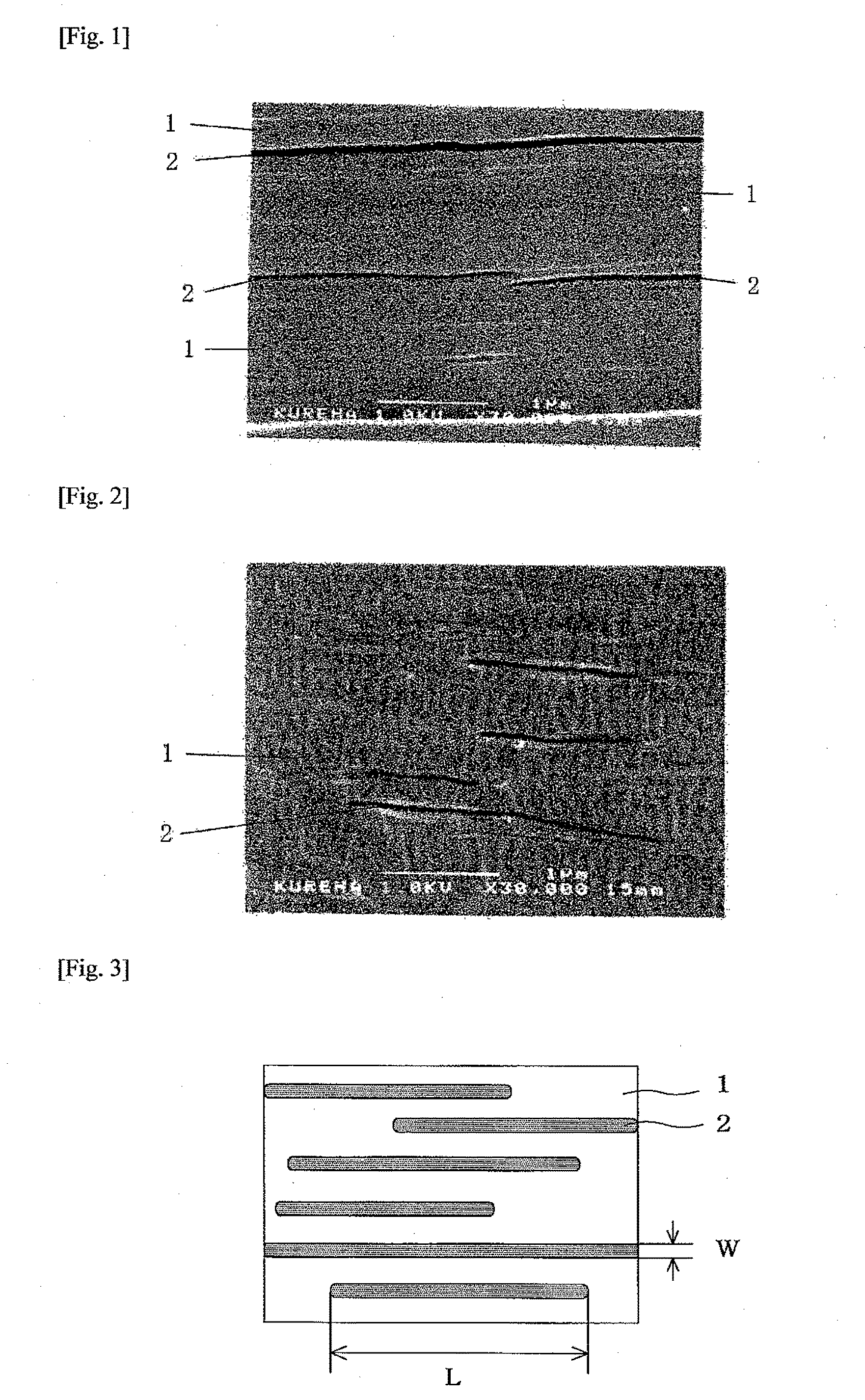

Polypropylene Resin Composition, Formed Product Composed of the Resin Composition, and Production Process of the Formed Product

InactiveUS20100286317A1Excellent gas barrier propertyExcellent formTyresOrganic dyesPolypropylenePolymer chemistry

A polypropylene resin composition containing a resin component composed of 55 to 99% by mass of polypropylene and 1 to 45% by mass of polyglycolic acid, and a reactive compatibilizing agent in a proportion of 0.3 to 30 parts by mass per 100 parts by mass of the resin component; a formed product composed of the polypropylene resin composition, wherein a dispersed phase of the polyglycolic acid residing in the morphology that the polyglycolic acid is dispersed as individually independent thin films exists in a matrix of the polypropylene; and a production process of the formed product.

Owner:KUREHA KAGAKU KOGYO KK

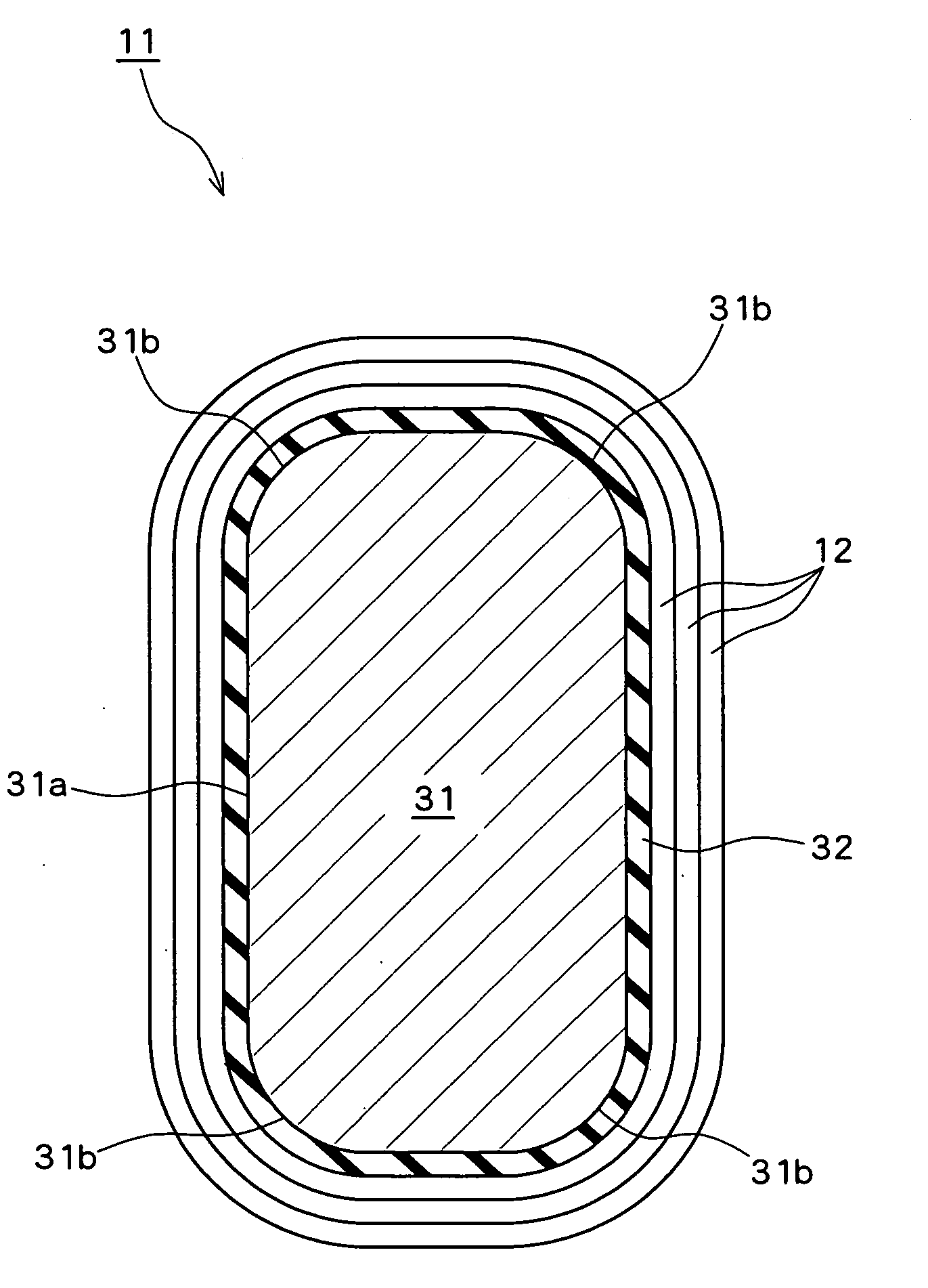

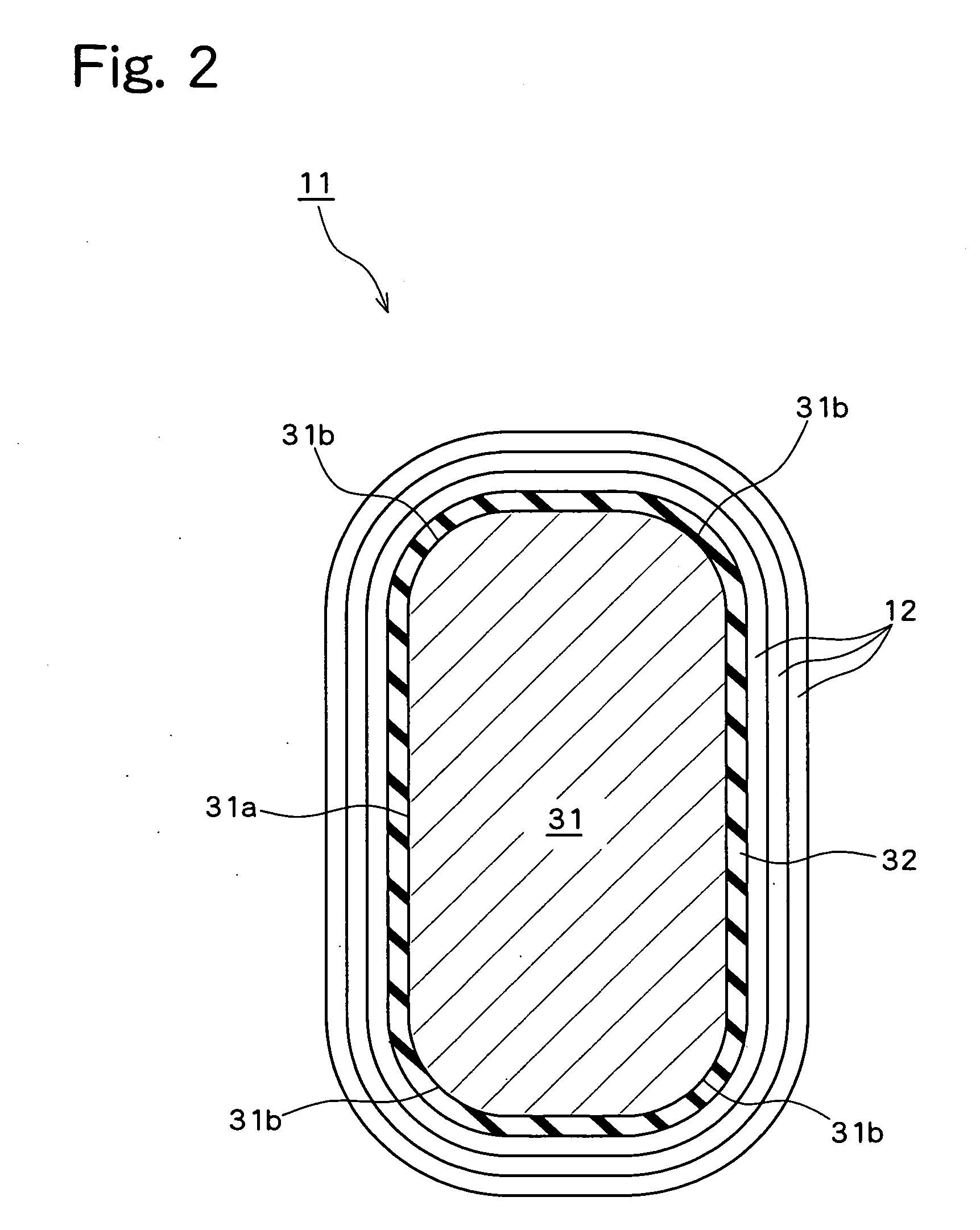

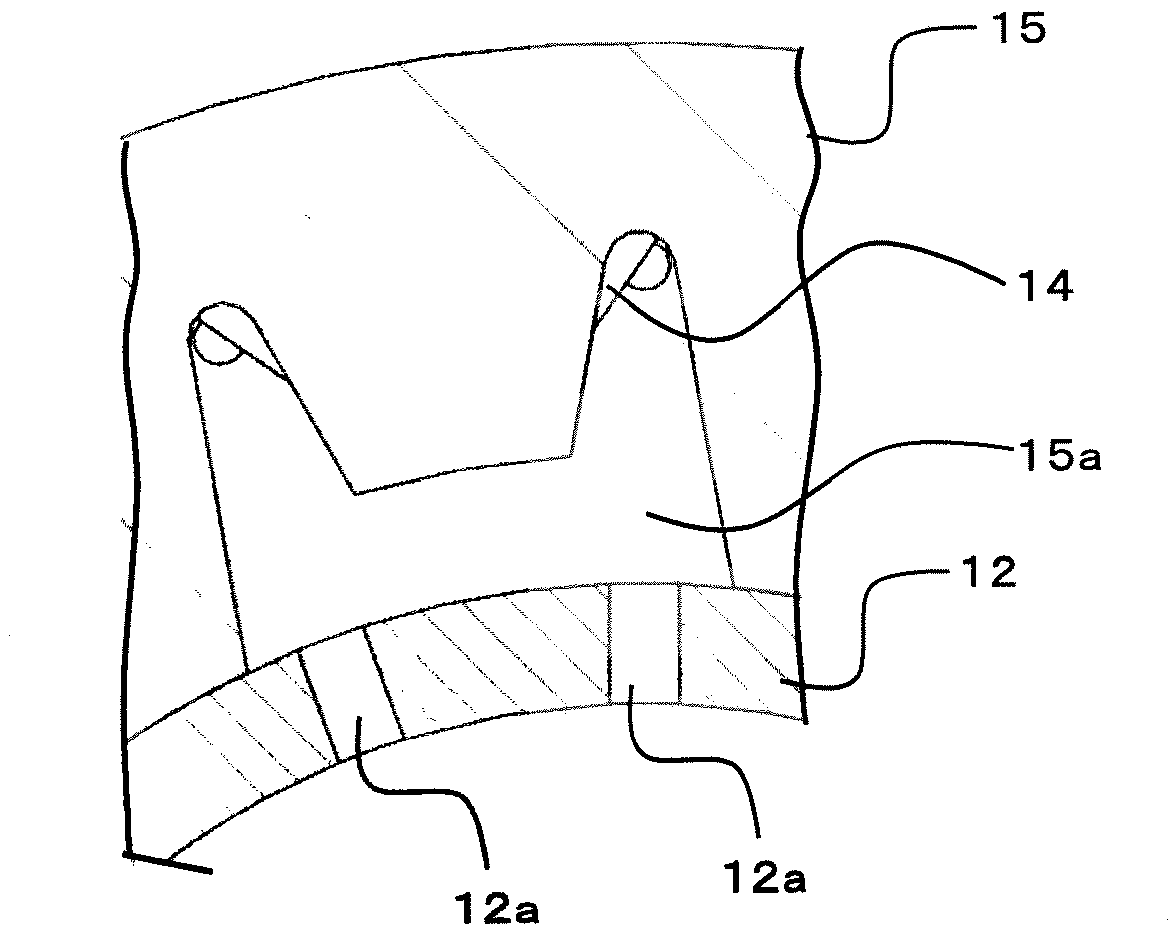

Core and method for producing core

InactiveUS20090121820A1Improve heat resistanceHigh degree of freedom of shapeManufacturing dynamo-electric machinesTransformers/inductances magnetic coresMaterials scienceMagnetic core

Disclosed is a highly heat-resistant core which has a dust core as a base body. A dust core obtained by press-molding magnetic powder particles particles each of which are covered with an insulating film is used as the base body. An inorganic heat-resistant insulating film is formed on at least a part of a surface of the dust core which faces a winding wire.

Owner:TOYOTA JIDOSHA KK

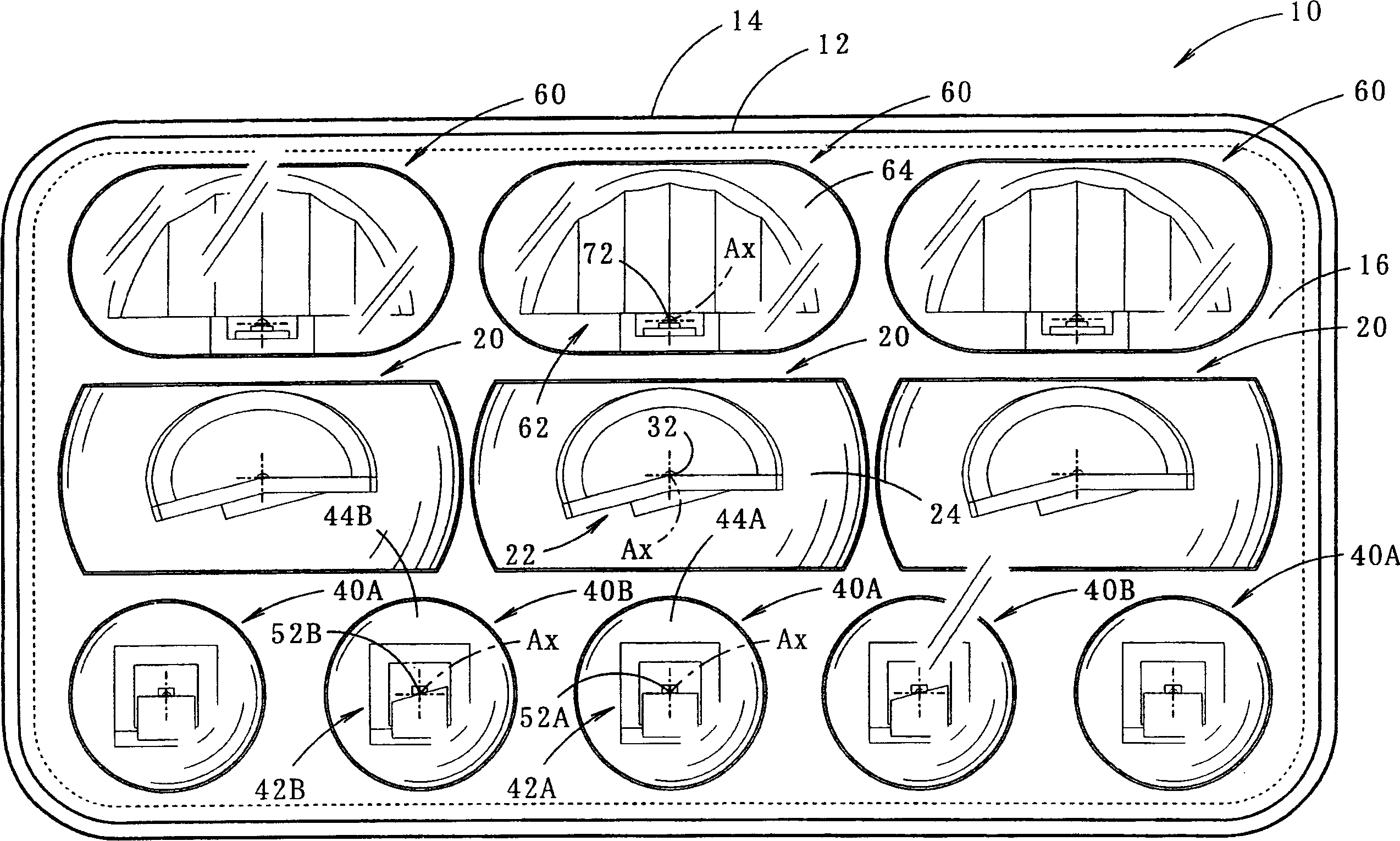

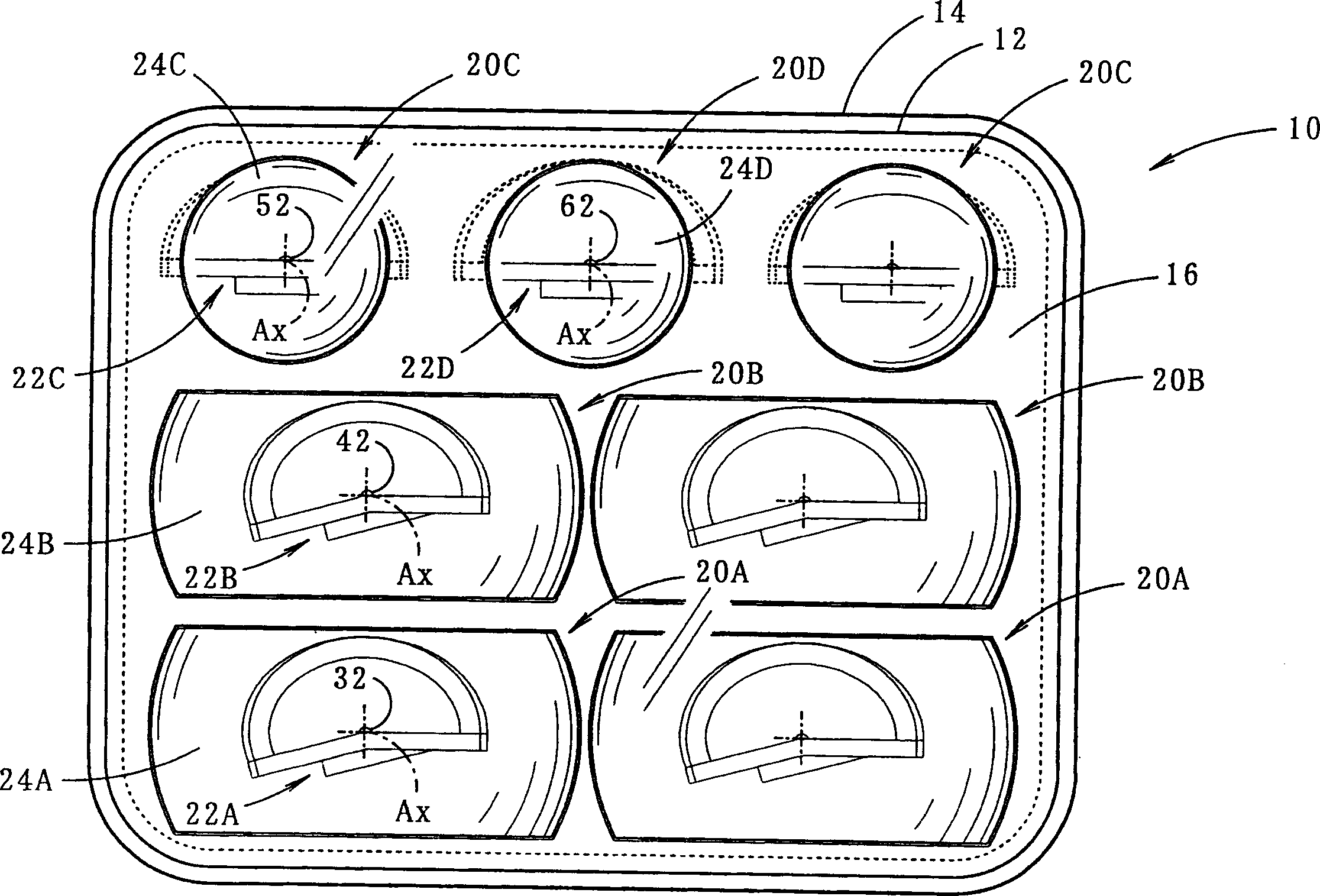

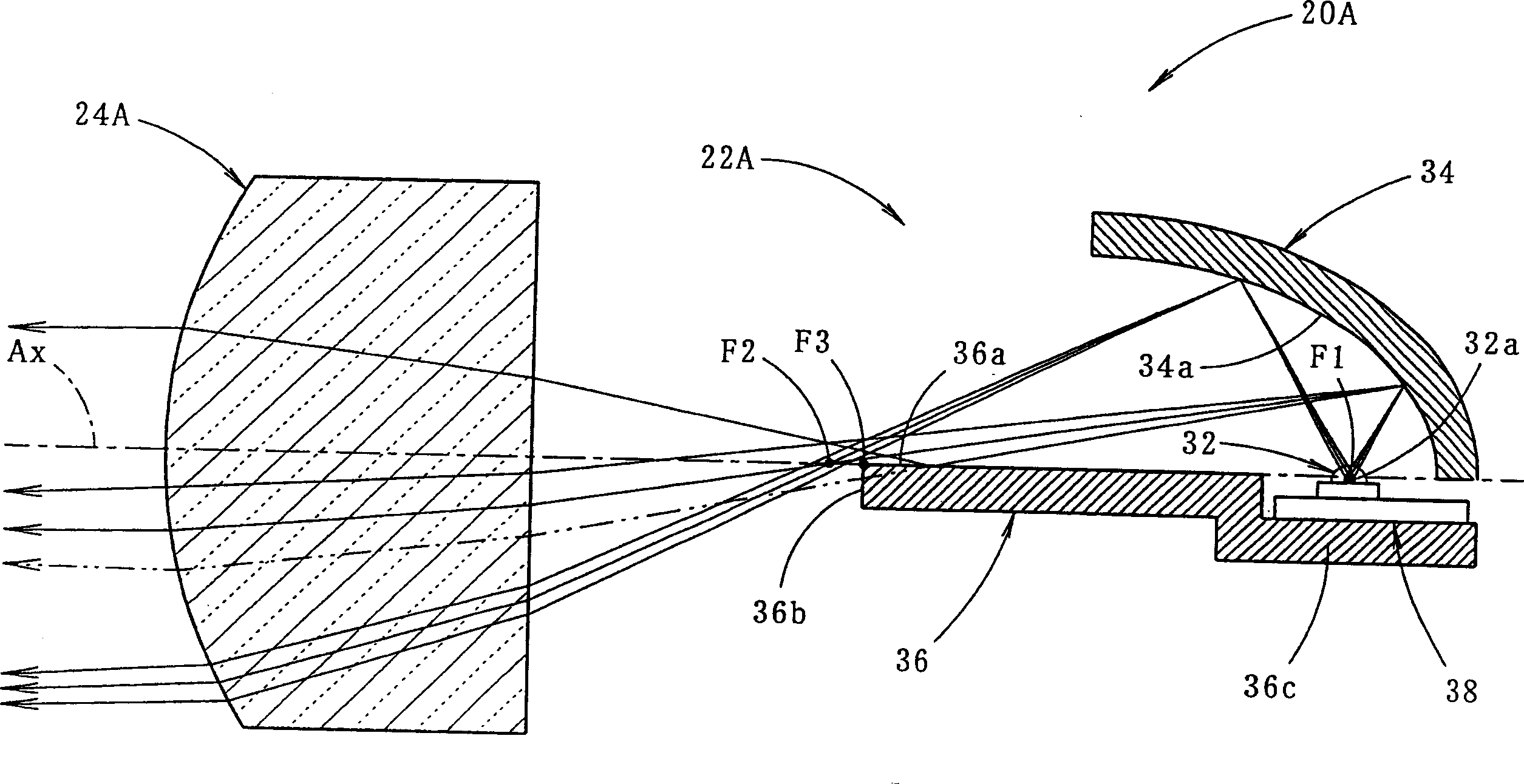

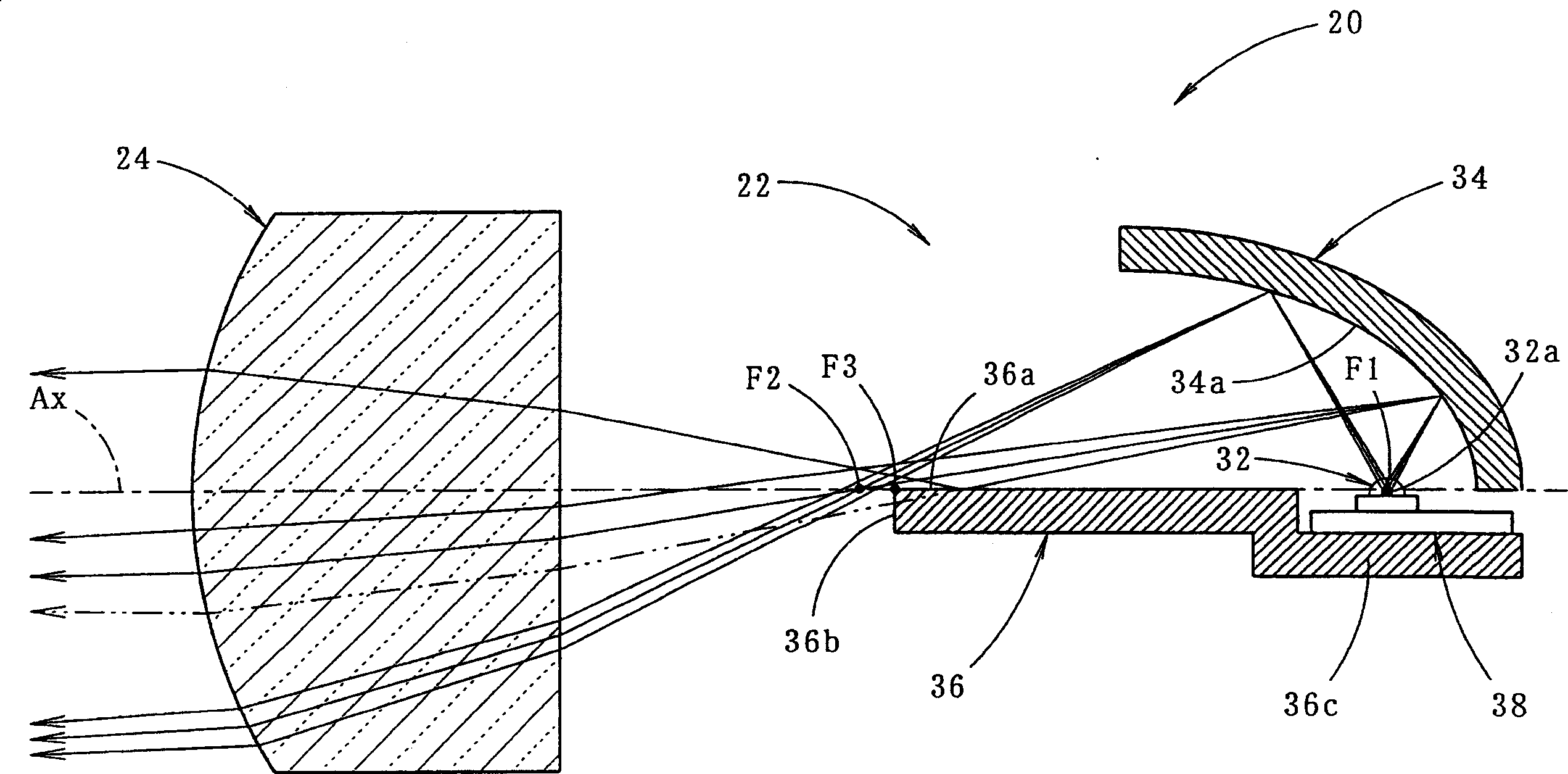

Front lamp for vehicle

InactiveCN1487233ALarge luminous areaGuaranteed BrightnessVehicle headlampsPoint-like light sourceLuminous intensityEffect light

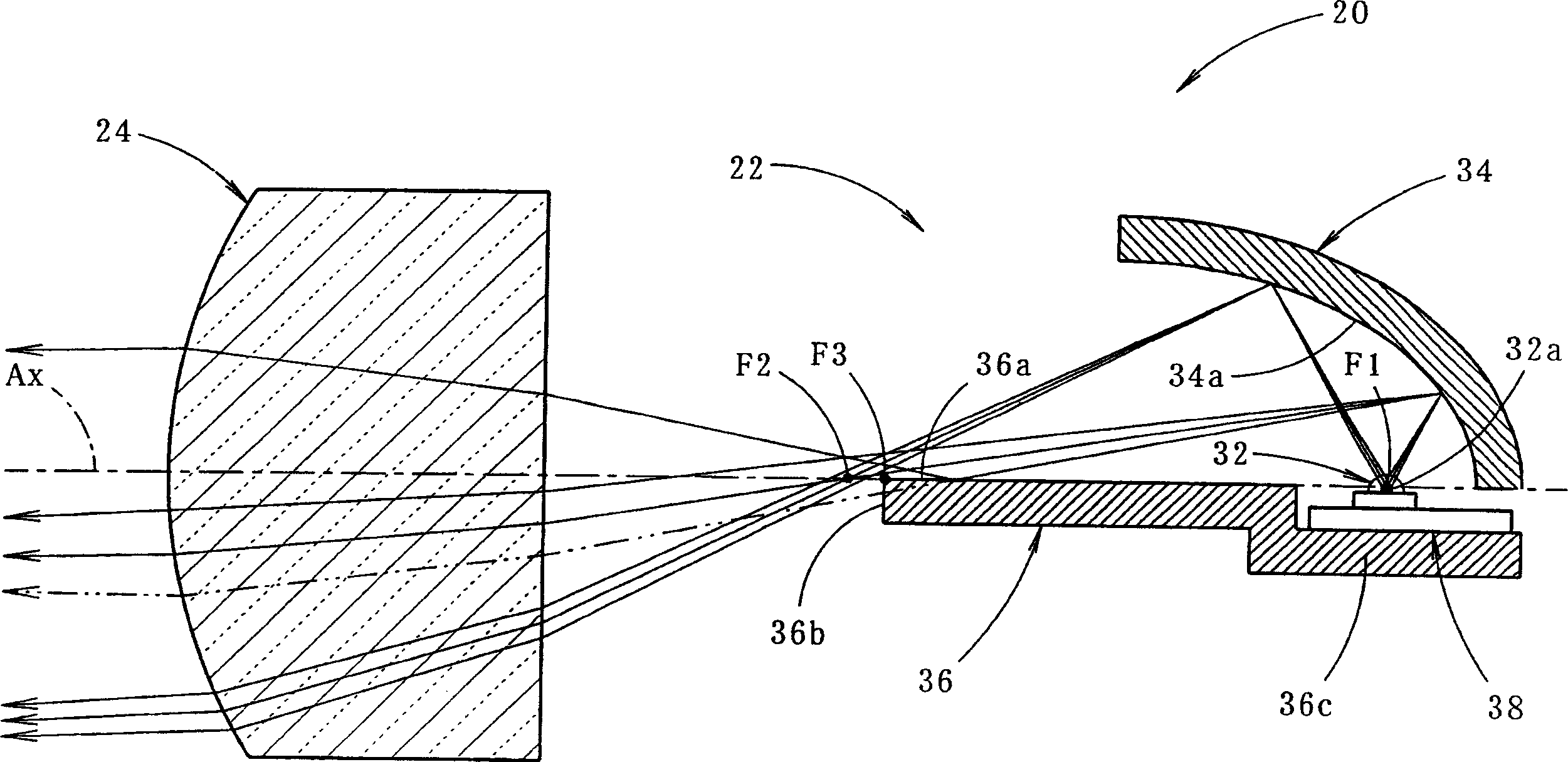

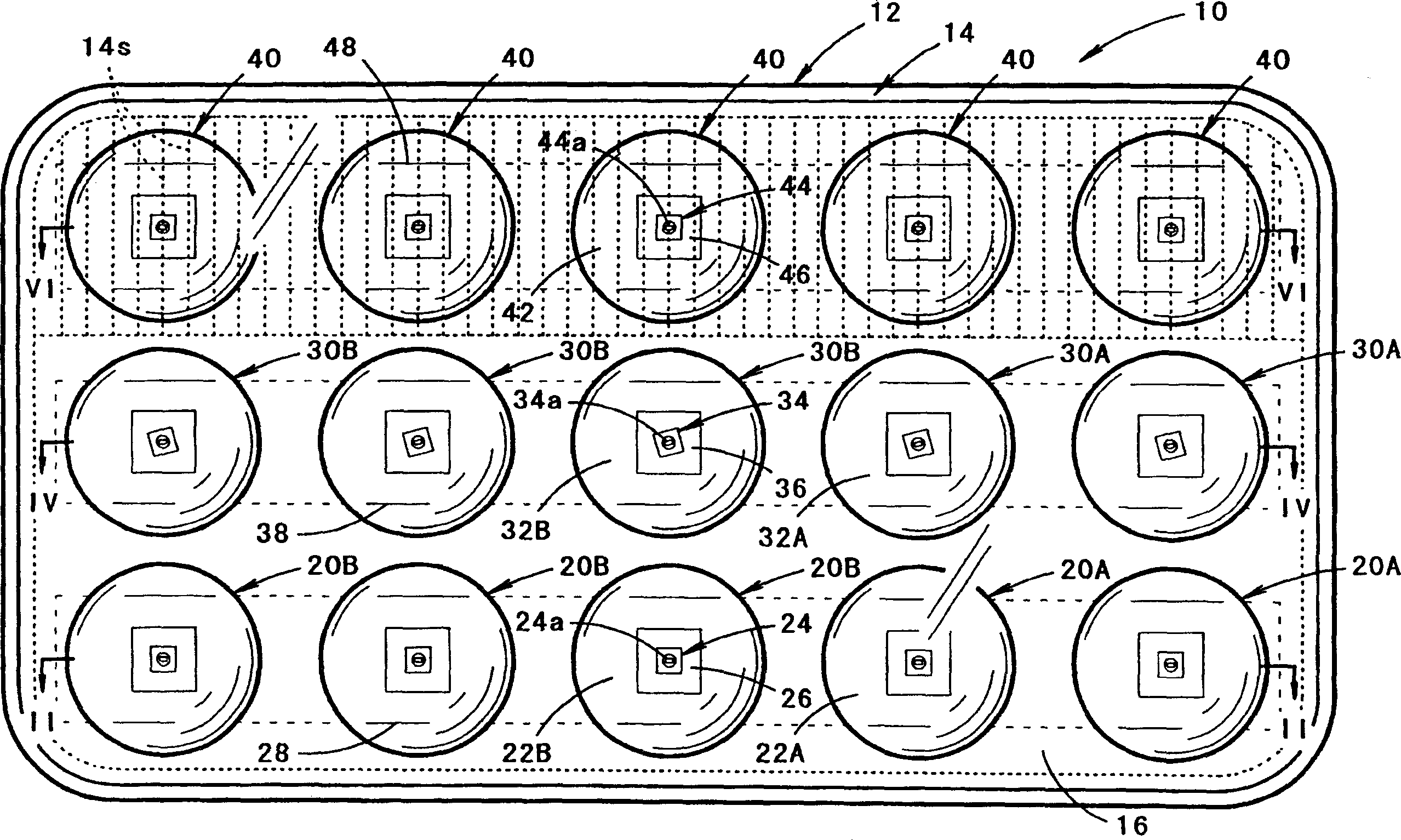

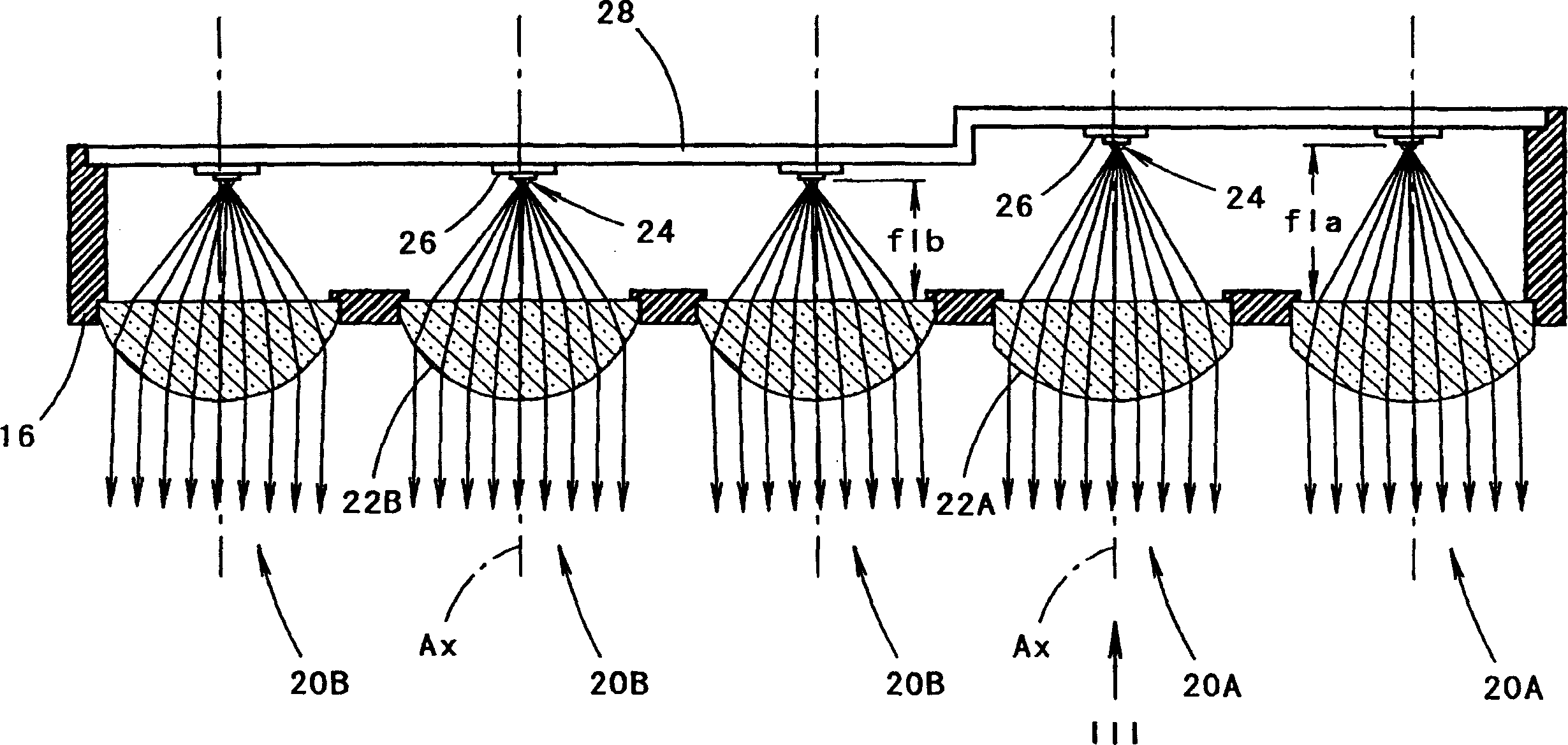

Headlight for vehicle. To allow a headlight for vehicle, which is configured so as to form a predetermined light distribution pattern, to control light intensity distribution of the light distribution pattern finely even if the headlight uses semiconductor light emitting elements as light sources. The headlight for vehicle comprises a plurality of lighting fixture units (20A, 20B, 20C, and 20D), which have light emitting diodes (32, 42, 52, and 62) as light sources respectively. The lighting fixture unit (20A) and the lighting fixture units (20B, 20C, and 20D) are used as a plurality of lighting fixture units, where the lighting fixture unit (20A) have a light emitting diode (32), on which a single light emitting chip (32a) is mounted, as a light source, and the lighting fixture units (20B, 20C, and 20D) have light emitting diodes (42, 52, and 62), on which light emitting chips (42a, 52a, and 62a) are mounted respectively, as light sources. Furthermore, a hot zone is formed by the radiation of the light from the lighting fixture unit (20A), and a diffusion region is formed by the radiation of the light from the lighting fixture units (20B, 20C, and 20D).

Owner:KOITO MFG CO LTD

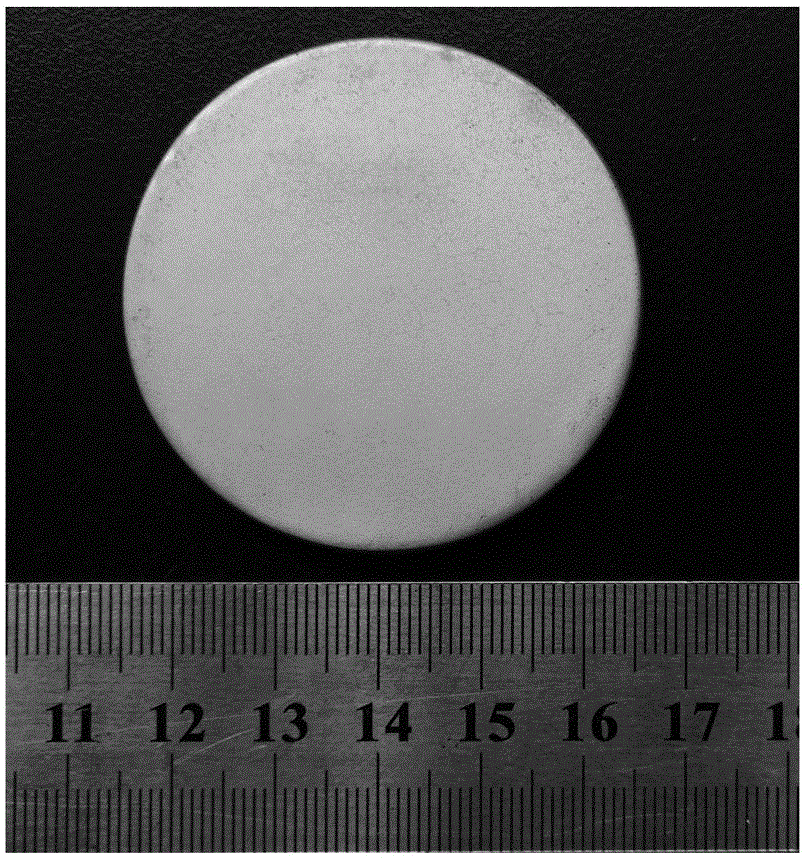

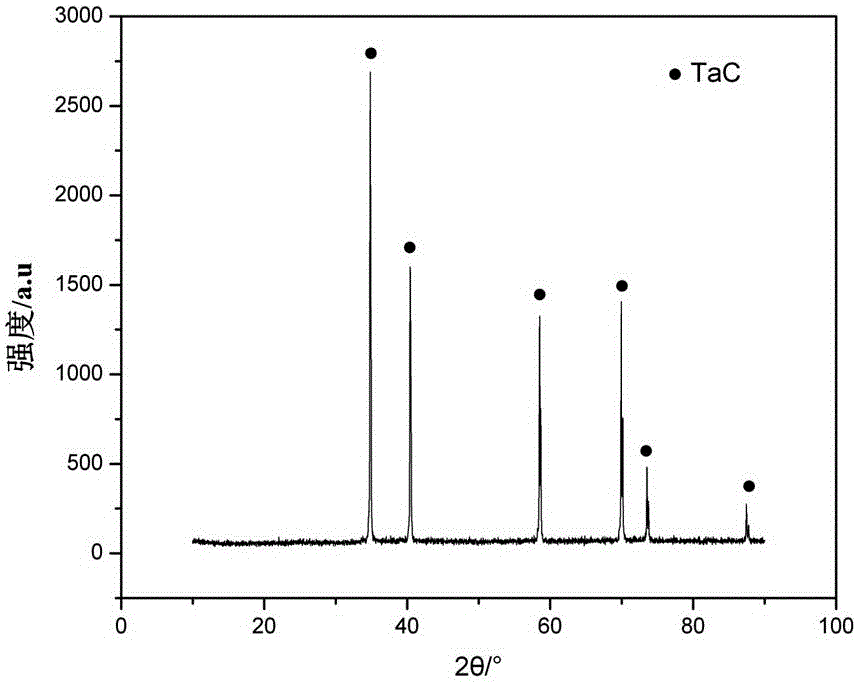

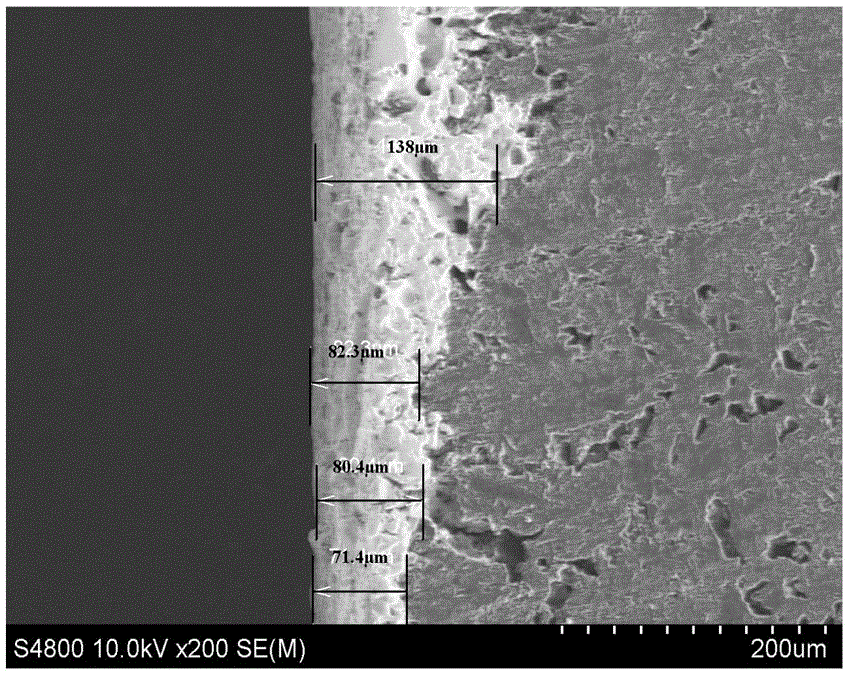

Carbon substrate surface TaC coating layer and preparation method thereof

InactiveCN106298448AHigh bonding strengthNo thermal stressSemiconductor/solid-state device manufacturingIn situ reactionDecomposition

The invention discloses a carbon substrate surface TaC coating layer and a preparation method thereof. The carbon substrate surface TaC coating layer comprises TaC generated by in-situ reaction of a hybrid complex of Ta and C and carbon of a carbon substrate, and TaC generated by decomposition of the hybrid complex of Ta and C. The preparation method comprises the following steps of (1) synthesizing a TaC precursor; (2) preparing TaC precursor paste; and (3) performing high-temperature segmented thermal processing. The carbon substrate surface TaC coating layer has the advantages of high bonding strength with the substrate, high crystallinity, uniformity, compactness, corrosion resistance, remarkable thermal stability and the like. The preparation method is simple in requirement on a process device, short in period and low in cost and has wide adaptability.

Owner:NAT UNIV OF DEFENSE TECH

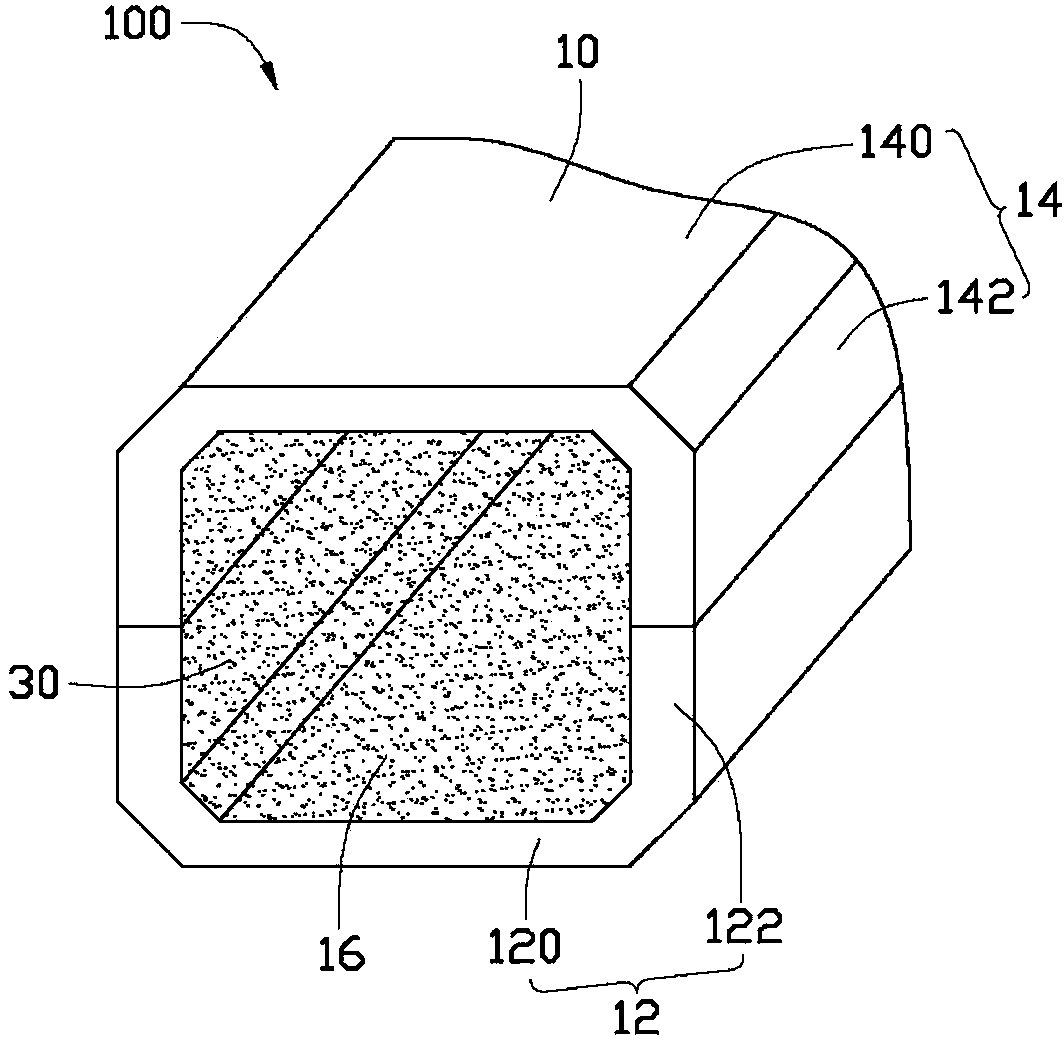

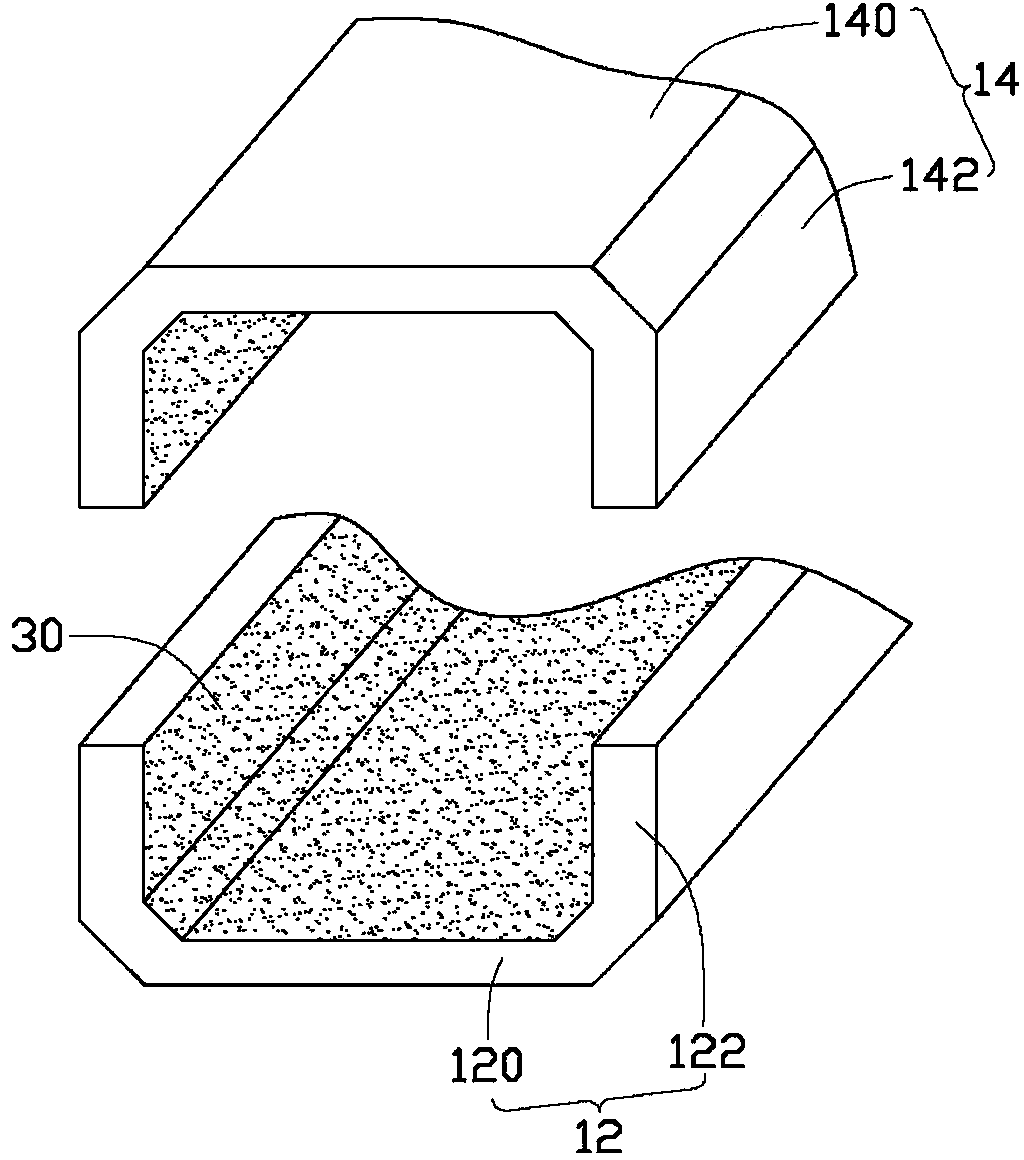

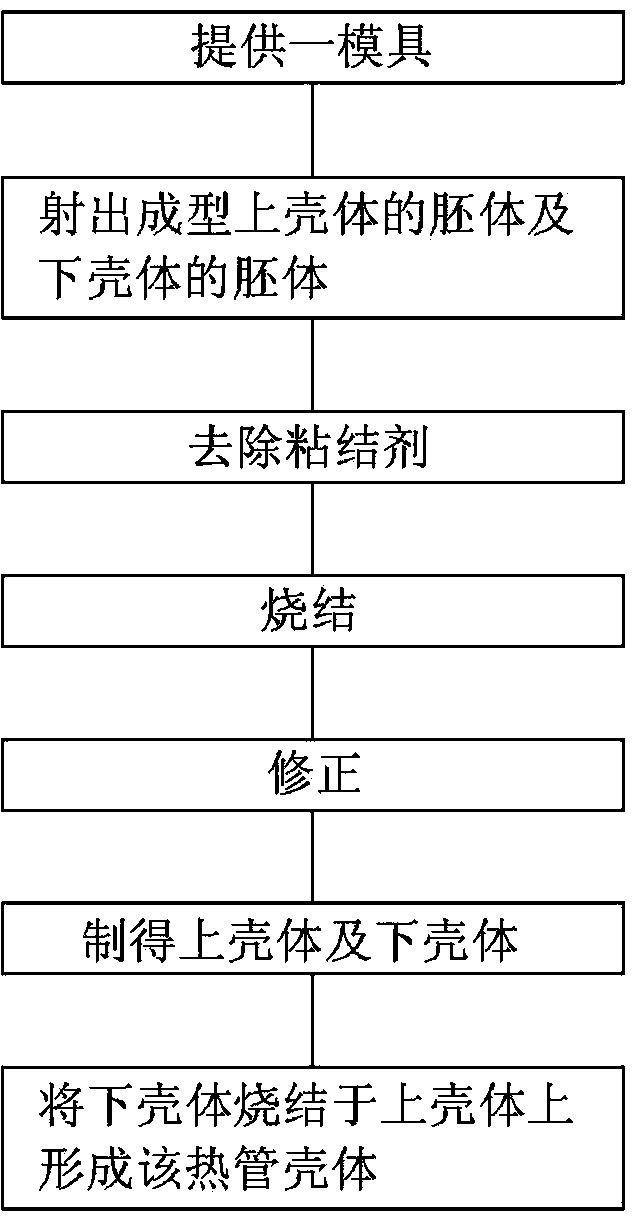

Heat pipe shell manufacturing method

ActiveCN103372650AAvoid deformationHigh melting pointIndirect heat exchangersInjection mouldingMetal powder

Disclosed is a heat pipe shell manufacturing method. The method includes the following steps: providing a mould; injecting a mixture of metal powder and melted binder into the mould by means of injection moulding to form a blank of an upper shell and a blank of a lower shell; removing the binder in the blank of the upper shell and the blank of the lower shell; sintering the blanks of the upper shell and the lower shell to obtain the upper shell and the lower shell; assembling the upper shell on the lower shell to form a shell. By the heat pipe shell manufacturing method, subsequent processing amount is effectively reduced, and manufacturing of high-melting-point, high-strength and complex-shape parts is facilitated better as compared with other forming modes.

Owner:迁安市彩旭杰汽车服务有限公司

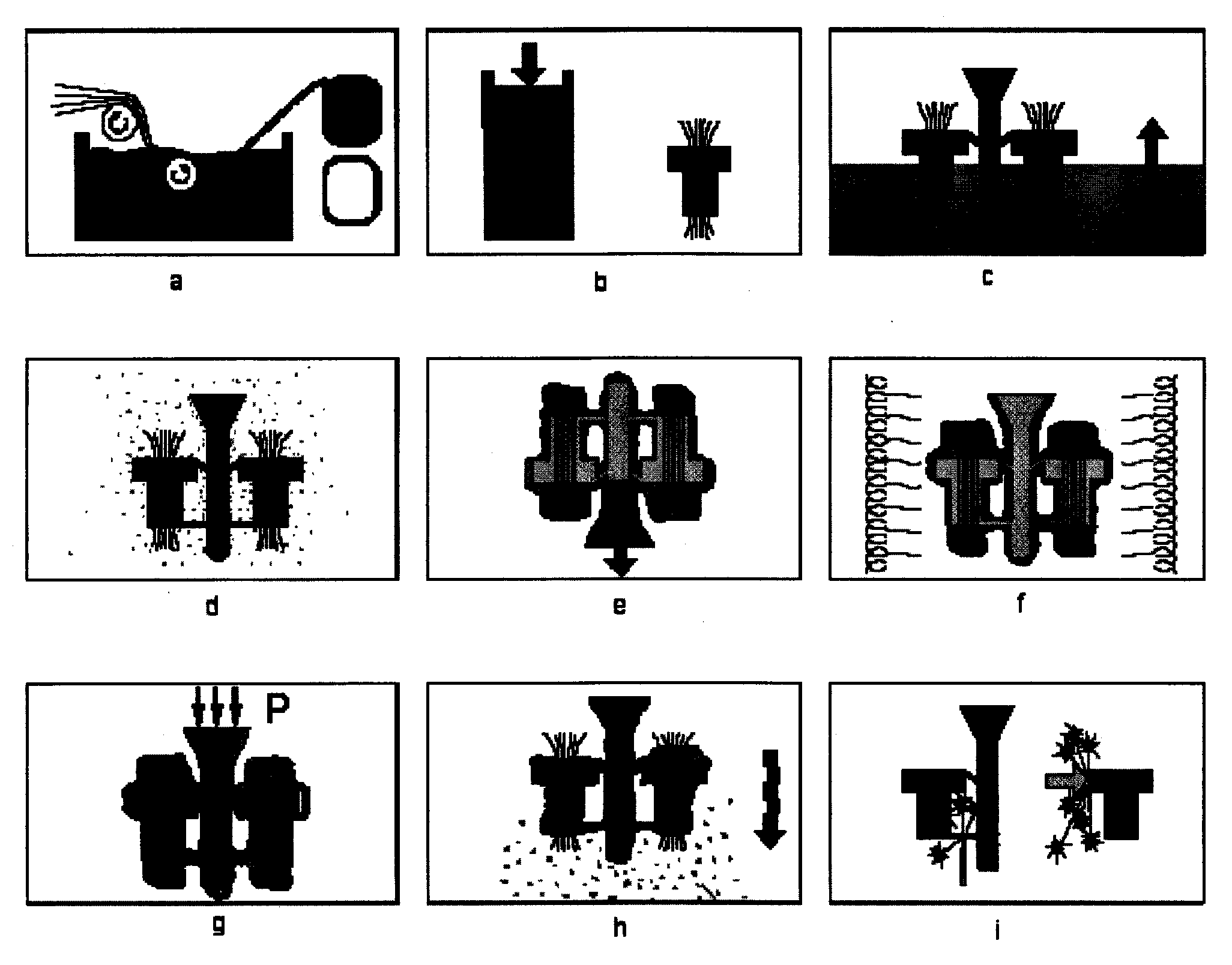

Method for preparing continuous-fiber partially-reinforced aluminum alloy parts

The invention relates to a preparation technology of precise alloy castings, in particular to a method for preparing continuous-fiber partially-reinforced aluminum alloy parts. The method comprises the following steps: putting fiber bundles in a high-temperature wax pool; arranging the fiber bundles in a corresponding part of a part wax pattern when a wax layer is fully cooled to the room temperature; then, directly manufacturing the part wax pattern with reinforced fibers on a wax injector; welding and combining with a casting system to be an integral wax pattern system; forming a ceramic pattern shell outside the wax pattern system by a plurality of times of dipping and sand-suspension cycles; fully drying the ceramic pattern shell for dewaxing and roasting; casting a liquid aluminum alloy on the ceramic pattern shell; immediately pressing a pattern shell molded cavity with argon after casting is finished; and fully solidifying and cooling to obtain the continuous-fiber partially-reinforced aluminum alloy parts. The invention does not need to specially manufacture a prefabricated fiber model and favorably solves the problems of treating, aligning and arranging fiber yarn in a casting model.

Owner:JIANGSU UNIV

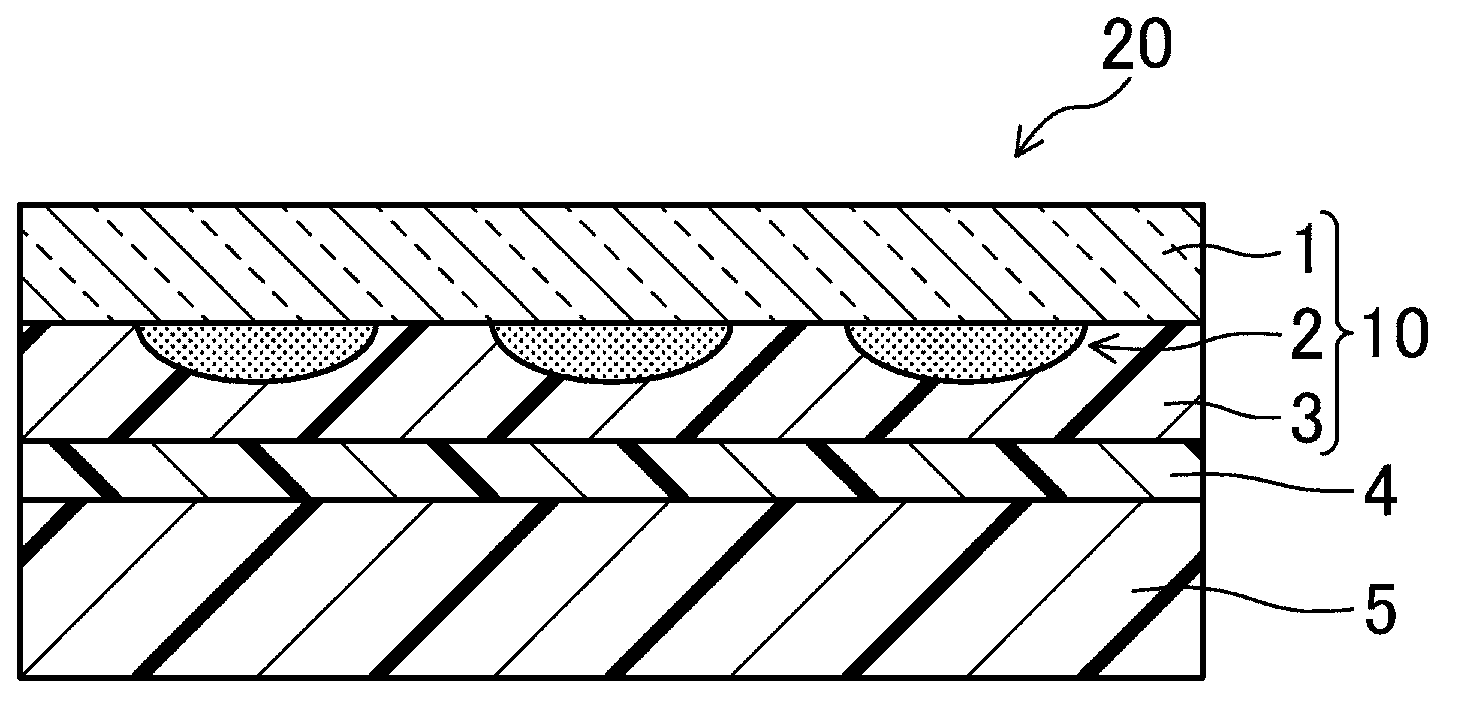

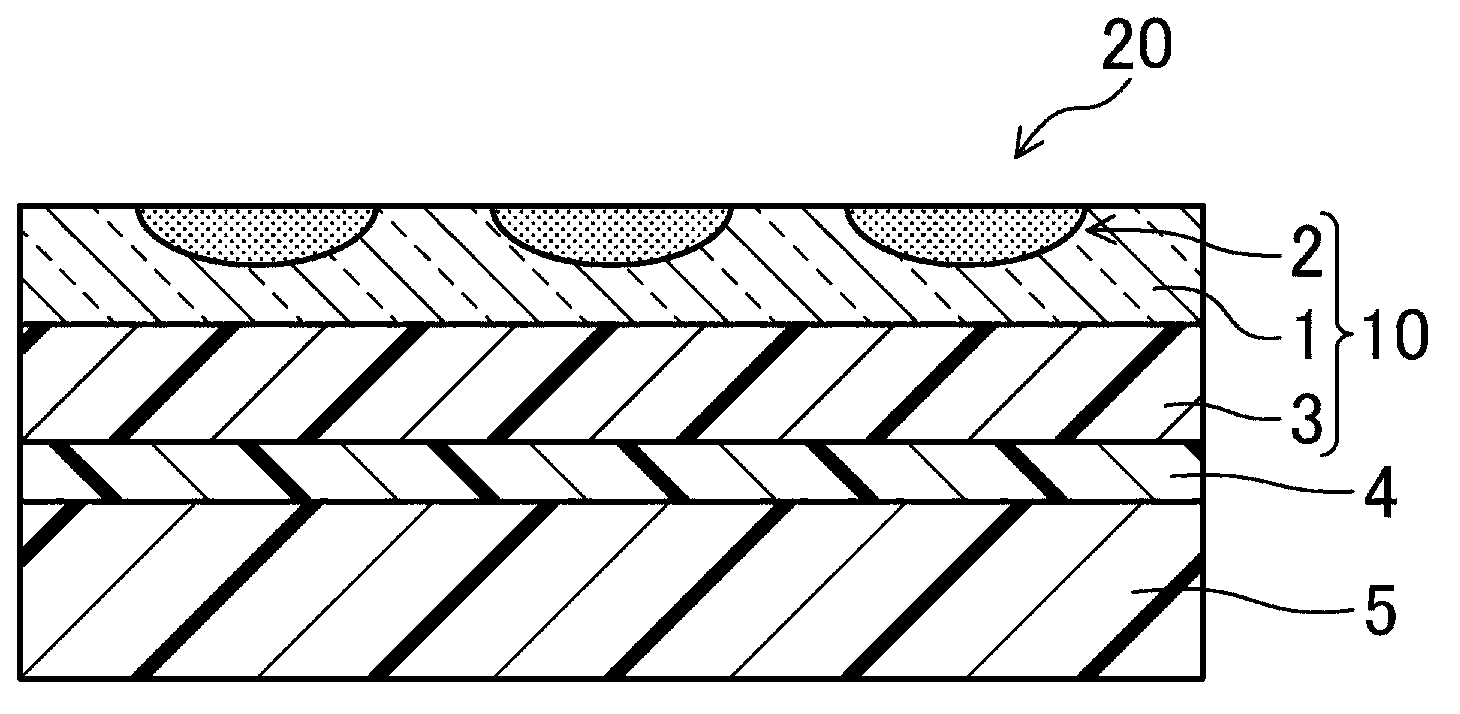

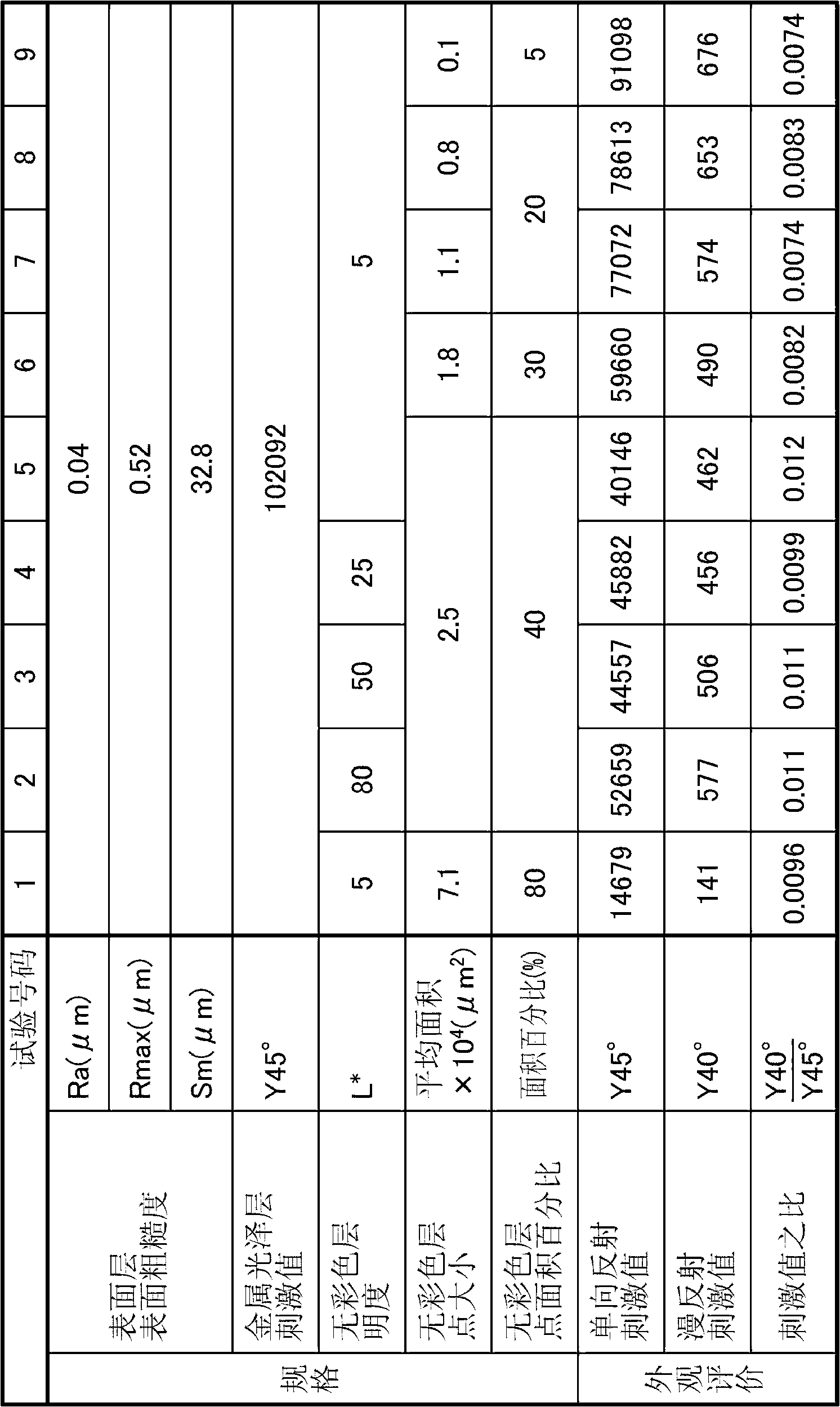

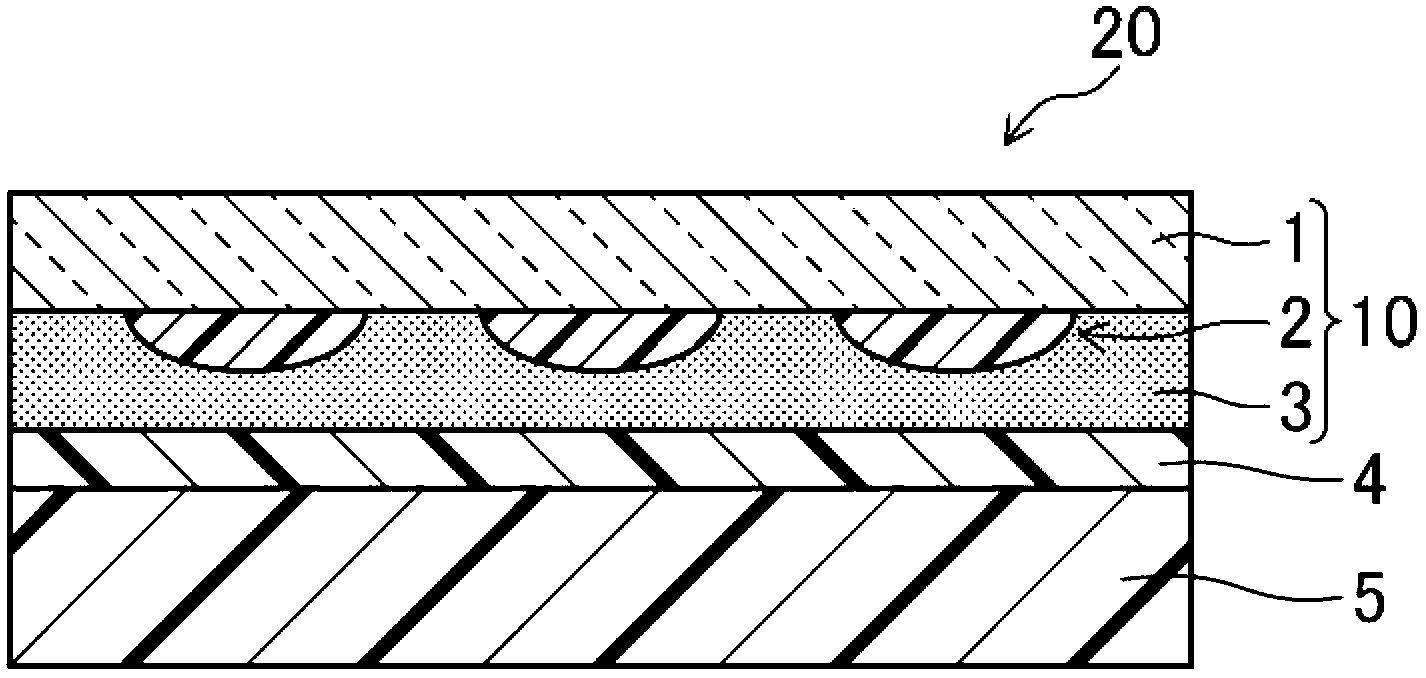

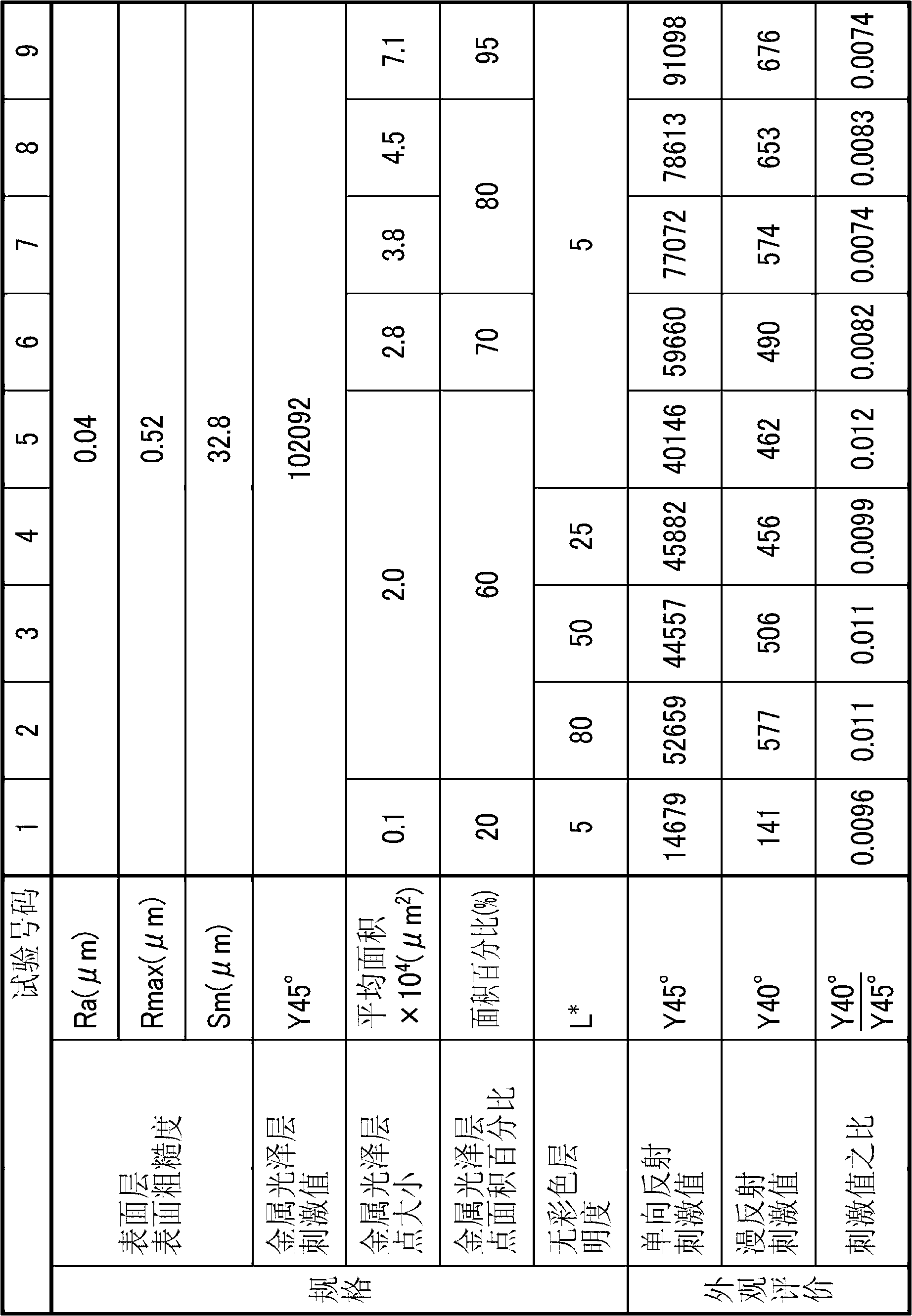

Decorative film structure and decorative member

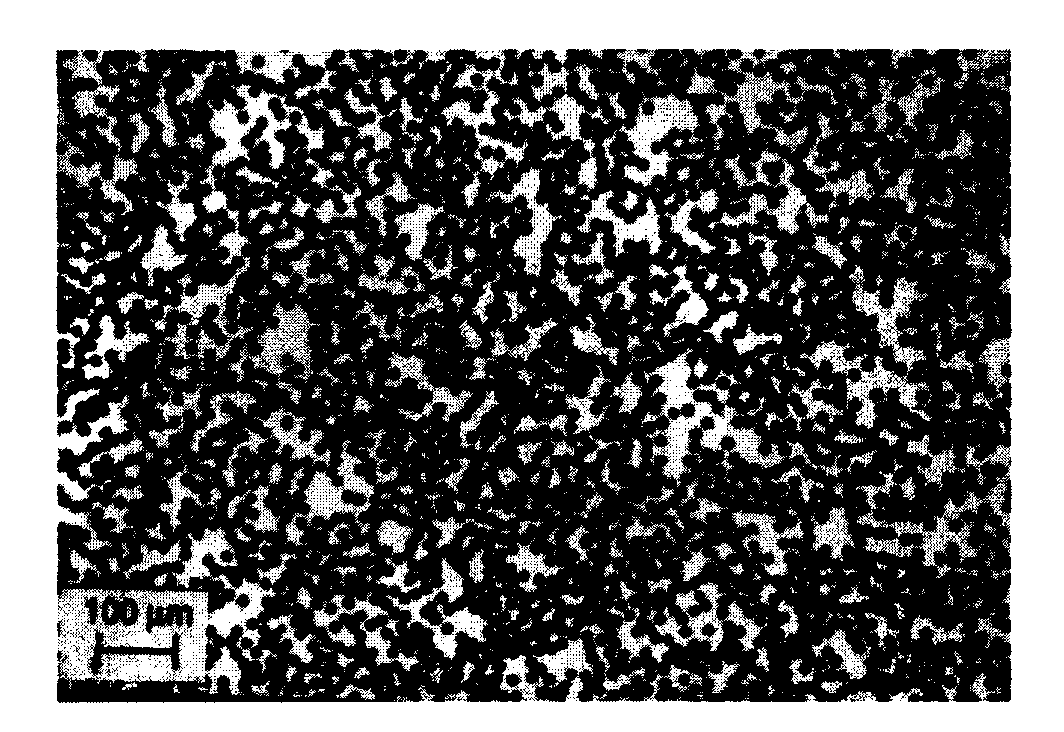

ActiveCN102909923AHigh degree of freedom of shapeLayered product treatmentSynthetic resin layered productsSurface layerSurface roughness

The invention discloses a decorative film structure (10) which includes: a surface layer (1) constituted by a transparent or translucent resin layer; an achromatic layer (2) constituted by dots provided on a back surface of the surface layer (1); and a metal luster layer (3) provided on the back surface of the surface layer (1) to fill a gap between the dots. As surface roughness of a front surface of the surface layer, an Ra is 2 [mu]m or less and either an Rmax is 4 [mu]m or less or a Sm is 50 [mu]m or more. A lightness L* of the achromatic layer (2) is 0-80. An area of each dot when viewed from a front side of the surface layer (1) is 10-3-105 [mu]m2. A dot area percentage per a unit area when viewed from the front side of the surface layer is 1-80%. A stimulus value Y45 DEG of the metal luster layer (3) is 10000 or more.

Owner:ISHII HYOKI +1

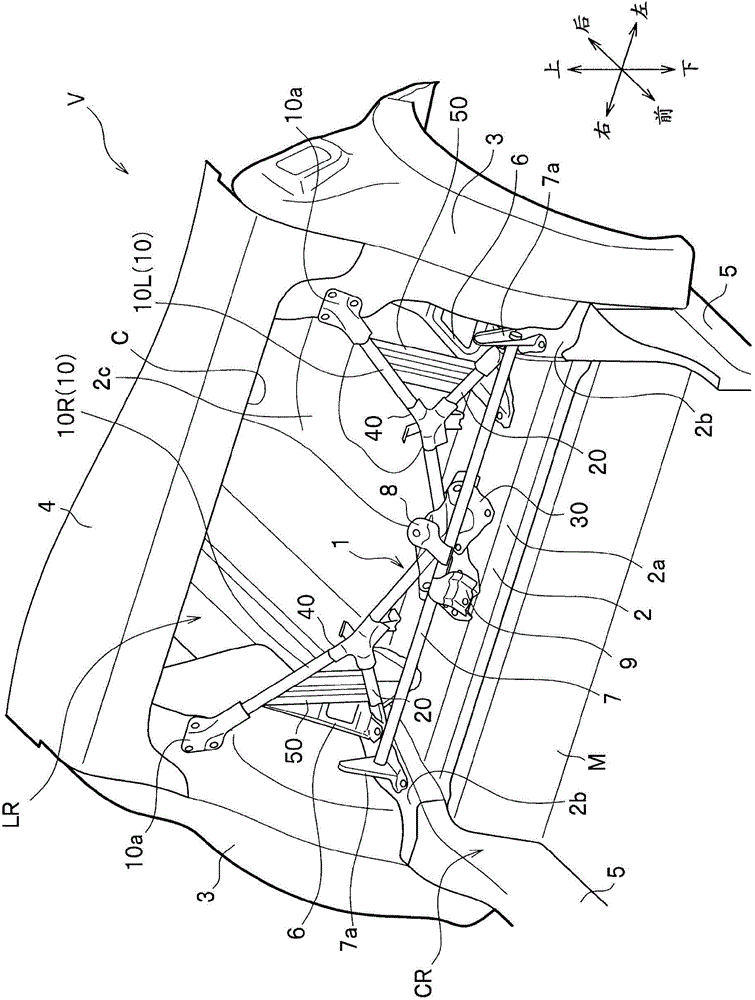

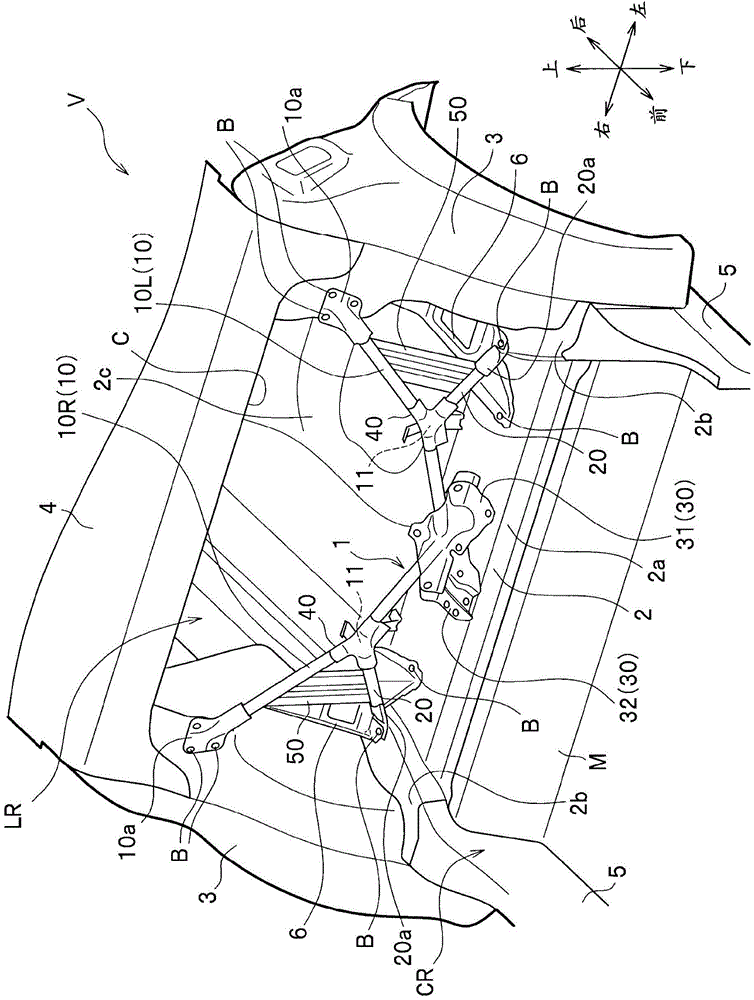

Vehicle body rear structure

ActiveCN104015809AHigh degree of freedom of shapeEnsure rigiditySuperstructure subunitsEngineeringUltimate tensile strength

The invention provides a vehicle body rear structure which does not interfere with a connection function of a trunk and ensures rigity and strength of the rear part of a vehicle body. The vehicle body rear structure is provided with a baseplate panel (2), a pair of rear-wheel covers (3) standing on two ends of a vehicle width direction of the baseplate panel (2), a rear parcel shelf (4) making the upper ends of the rear-wheel covers (3) extend along a vehicle width direction in a connected manner, a trunk connected opening portion (C) which is formed by the baseplate panel (2), the rear-wheel covers (3), and the rear parcel shelf (4), and a first reinforcing component (10) and a second reinforcing component (20) reinforcing the trunk connected opening portion (C). The first reinforcing component (10) is connected with the baseplate panel (2) and the upper end side of the rear-wheel covers (3), and is provided with a bending portion (11) on the middle of a length direction. The second reinforcing component (20) is connected with the baseplate panel (2) and the bending portion (11).

Owner:HONDA MOTOR CO LTD

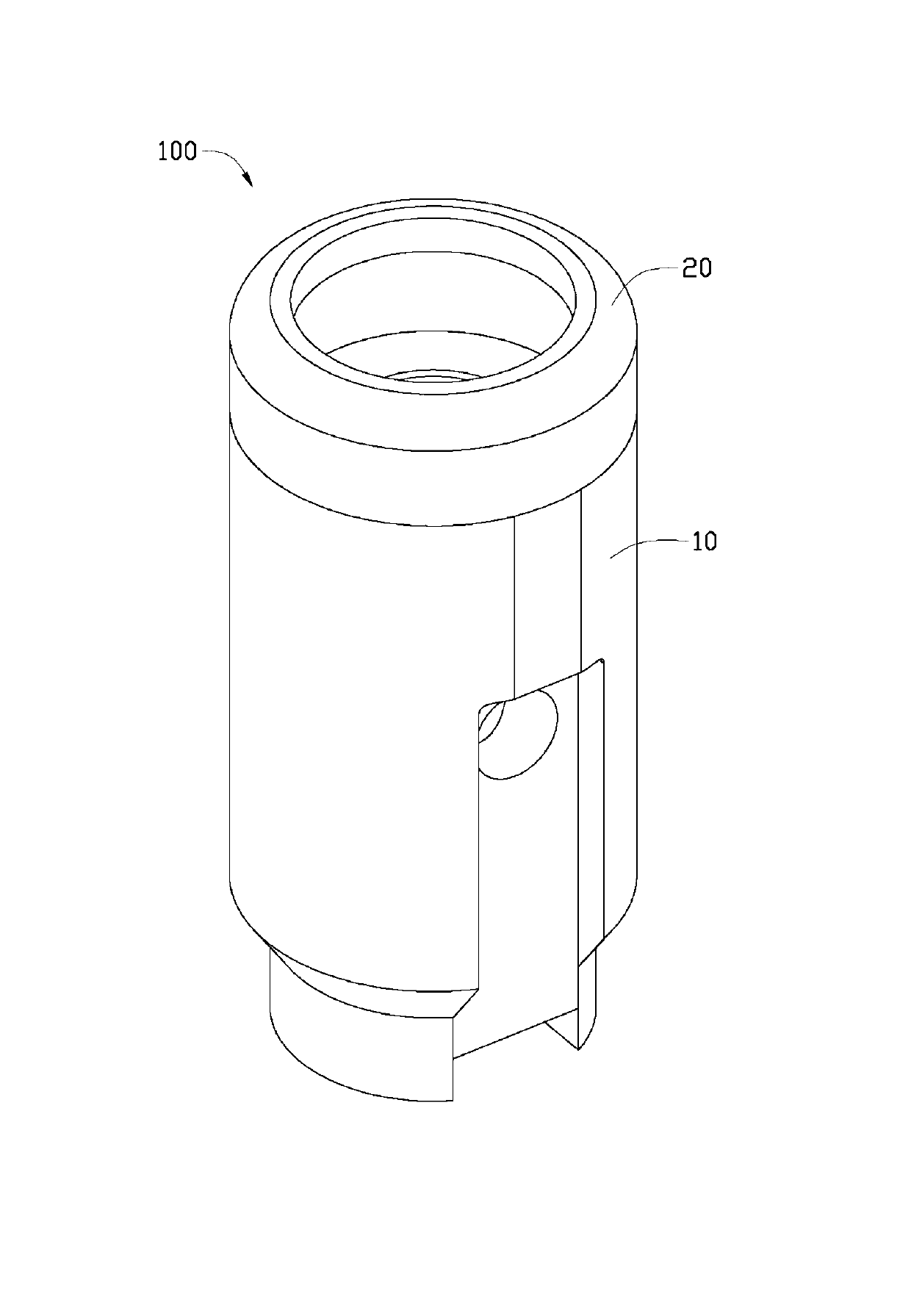

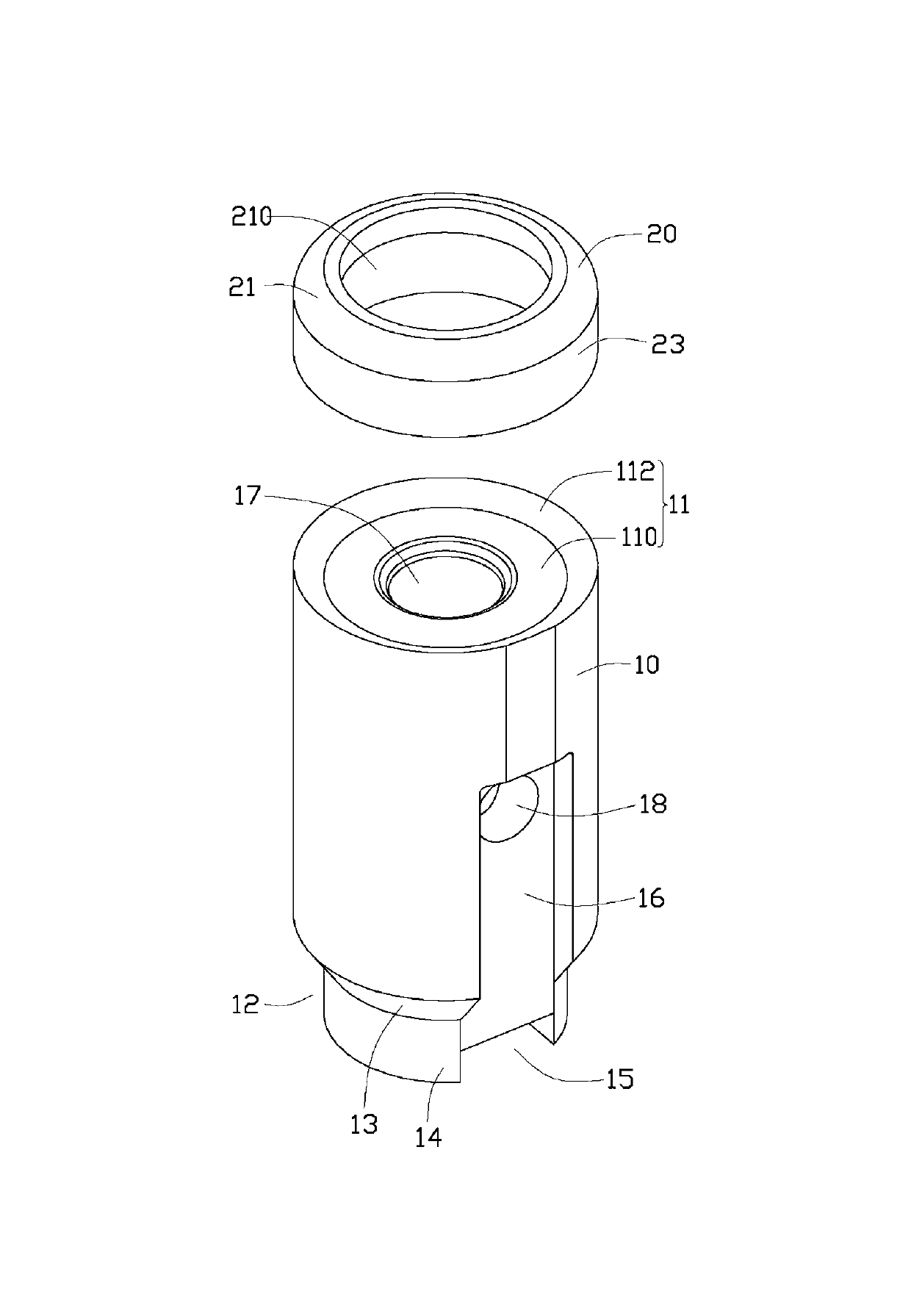

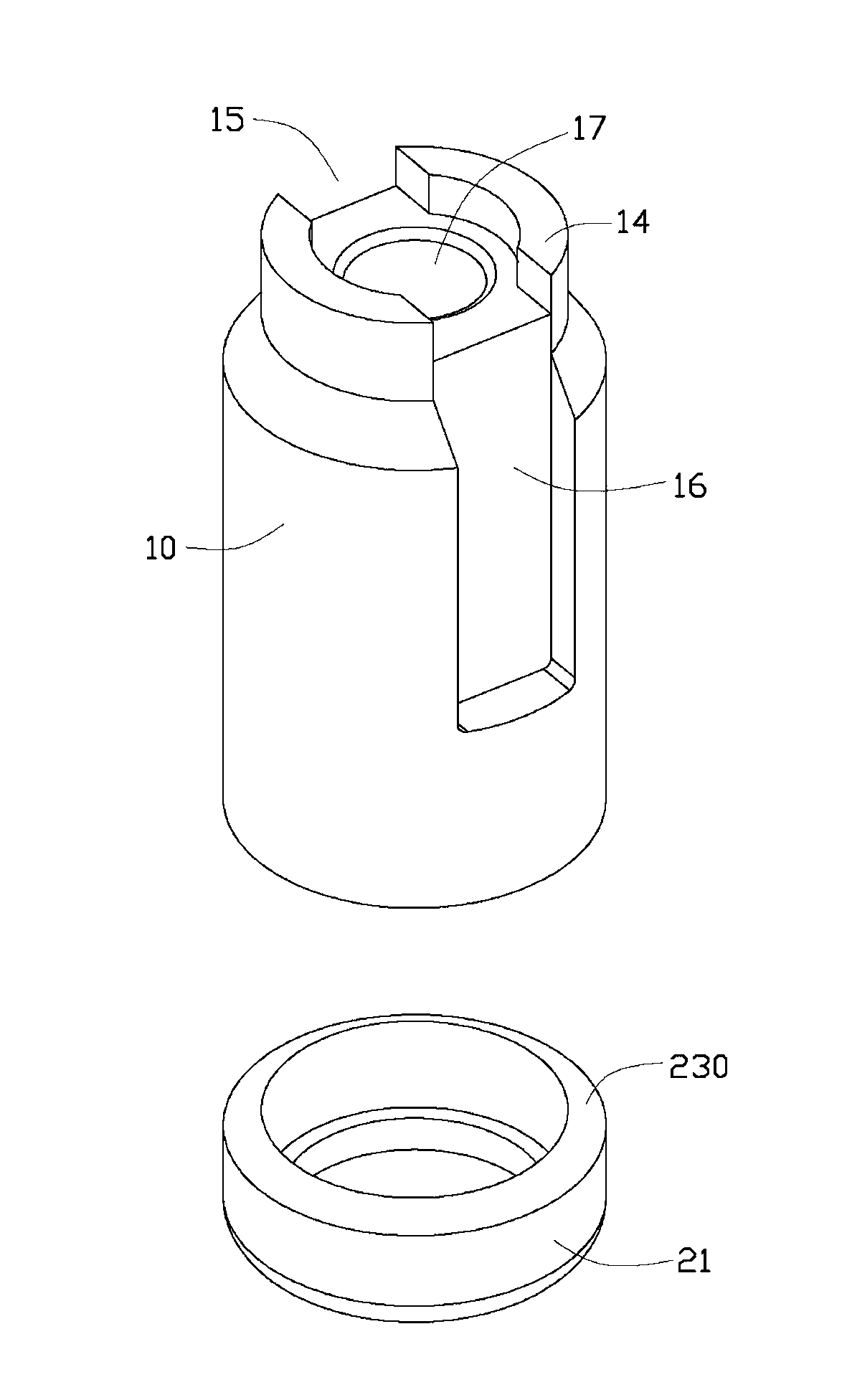

Production method of bearing device

A production method of a bearing device comprises the steps as follows: providing a bearing mold; injecting a mixture of metal powder and a fusion binder into the bearing mold in an injection molding mode to form a bearing body blank and an upper cover blank respectively; removing the binder in the bearing body blank and the upper cover blank; sintering the bearing body blank and the upper cover blank to produce a bearing body and an upper cover; and assembling the upper cover on the bearing body to form the bearing device. The production method of the bearing device reduces follow-up processing amount effectively and can produce parts with high melting point, high strength and complex shape more conveniently compared with other molding modes.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

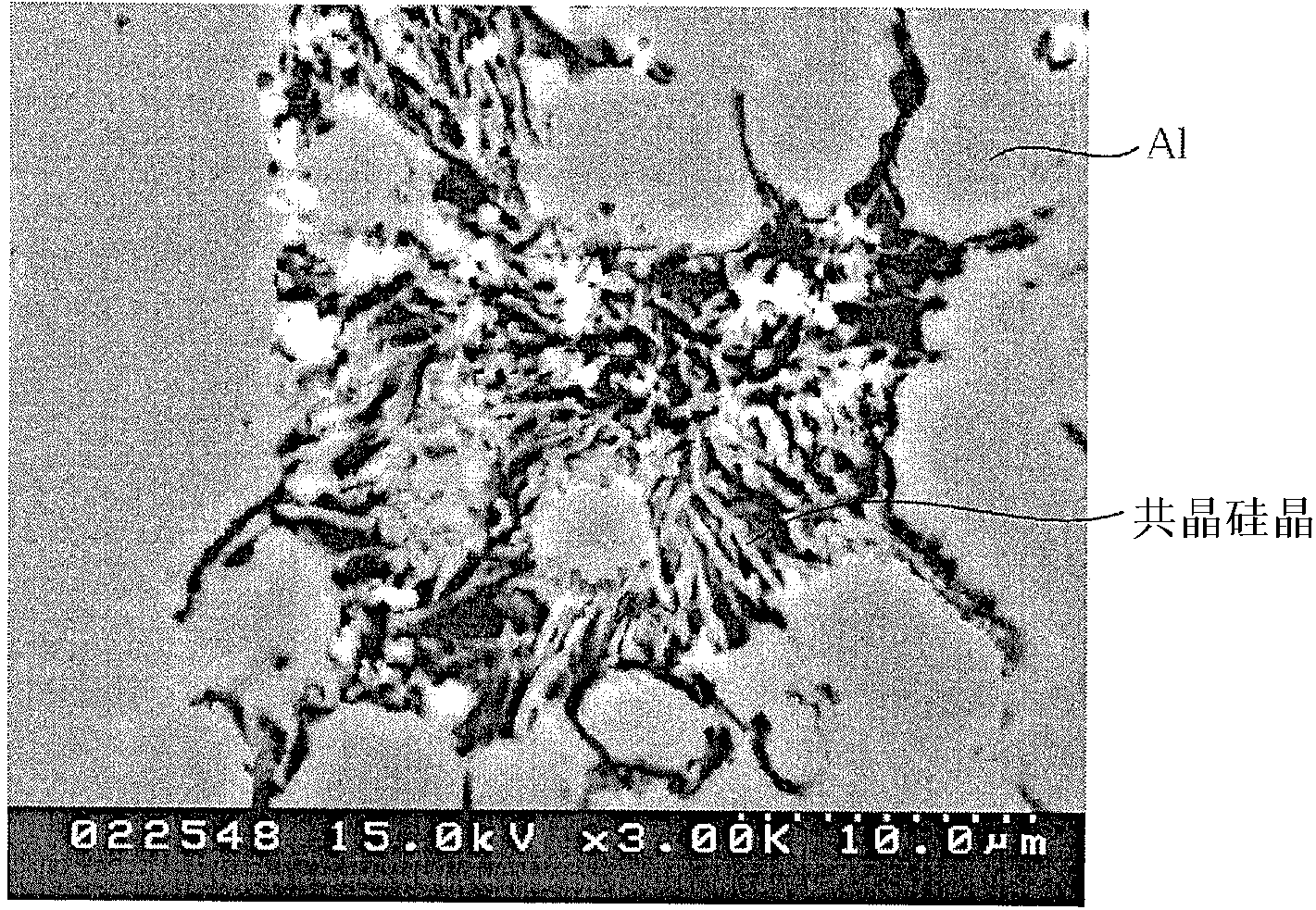

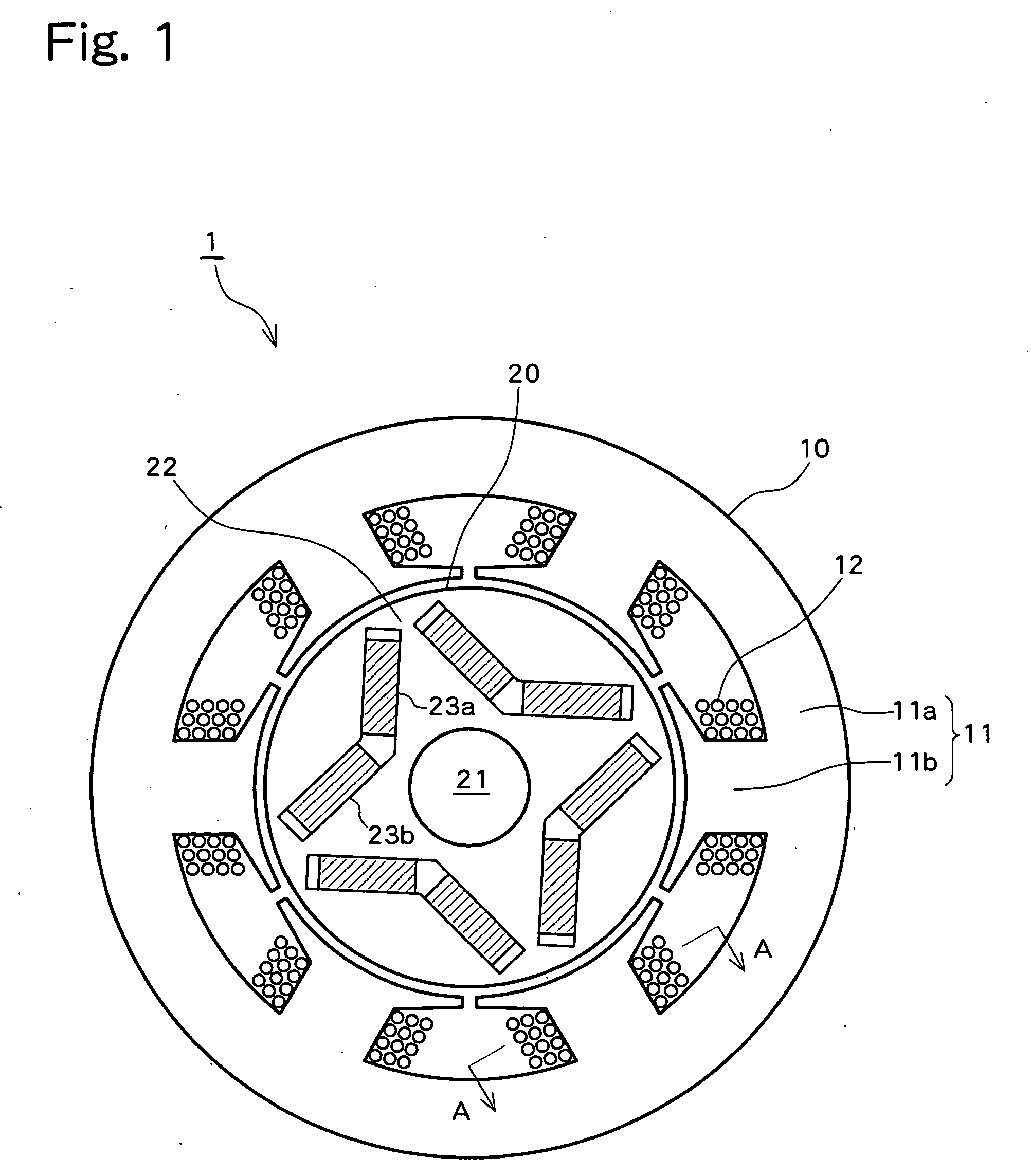

Headlight for vehicle

InactiveCN1490554AHigh degree of freedom of shapeAchieve compactnessVehicle headlampsPoint-like light sourceLight-emitting diodeSemiconductor

The headlamp (10) has multiple lamp units (20,40A,40B,60) each using light-emitting diodes (LED) as light sources. One unit (20) forms the low beam cutoff, another (40A,40B) forms the high intensity zone and the third unit (60) forms the diffusion region. The reflector profile for the intense unit directs light straight ahead and for the low beam unit directs light below the low beam cut-off.

Owner:KOITO MFG CO LTD

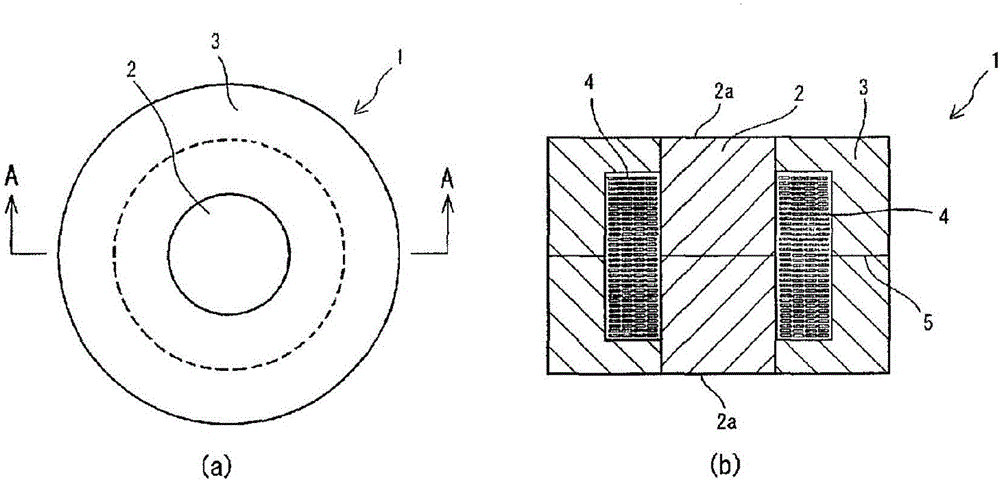

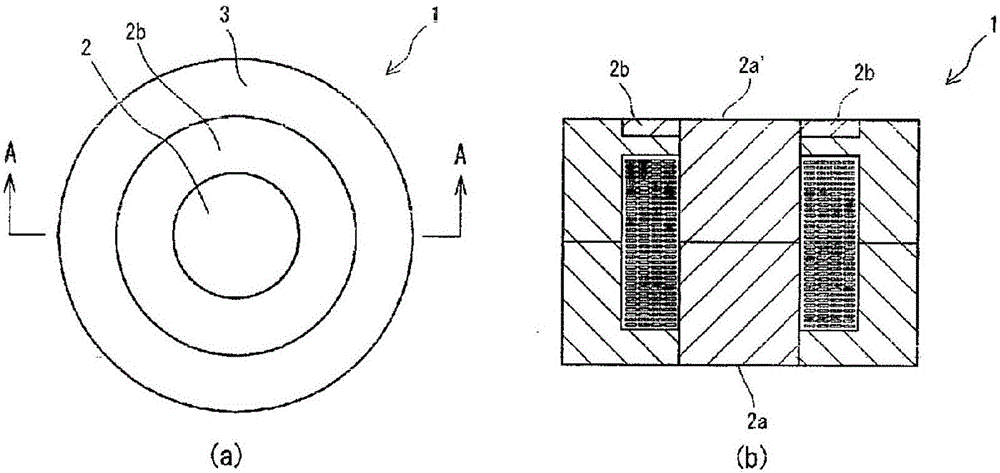

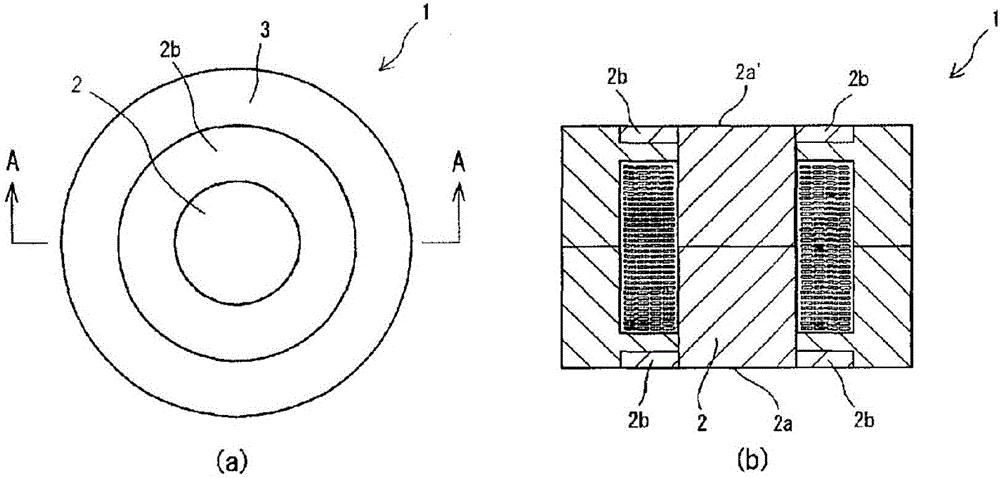

Magnetic element

ActiveCN106104718ASuppress feverAny shapeTransformers/inductances magnetic coresMagnetic materialsProduction rateMagnetic flux

Provided is a magnetic element which exhibits excellent producibility and suppresses heat generation caused by iron loss. A magnetic element provided with a magnetic body though which magnetic flux produced by a coil (4) passes, wherein: this magnetic body is a joined body obtained by joining magnetic bodies to one another which are bisected in the axial direction of the coil; a section exhibiting high heat generation caused by iron loss or a section exhibiting poor heat-dissipation properties constitutes a compression-molded magnetic body (2), while a section other than this compression-molded magnetic body constitutes an injection-molded magnetic body (3); and the compression-molded magnetic body and the injection-molded magnetic body are joined to one another. Furthermore, the compression-molded magnetic body is exposed on the surface of the magnetic body.

Owner:NTN CORP

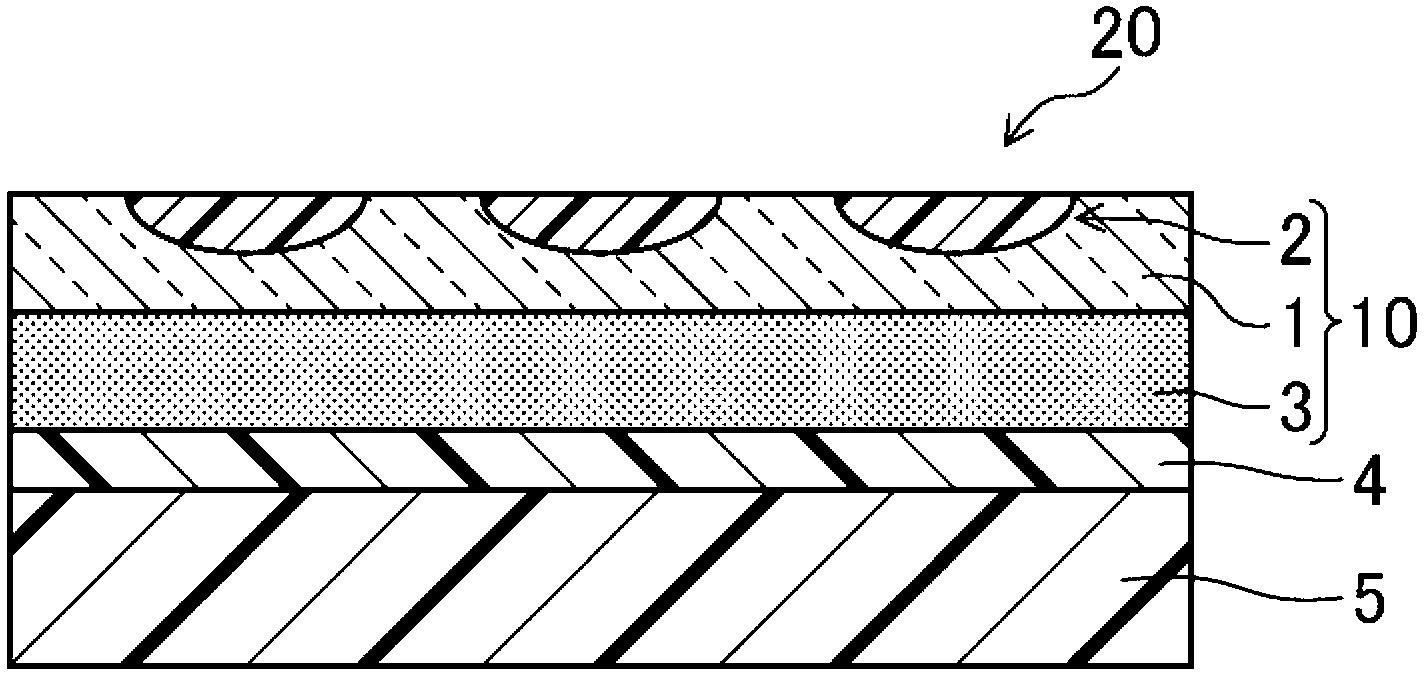

Decorative film structure and decorative member

ActiveCN102910022AHigh degree of freedom of shapeLayered product treatmentOrnamental structuresSurface layerSurface roughness

The invention discloses a decorative film structure (10) includes: a surface layer (1) constituted by a transparent or translucent resin layer; a metal luster layer (2) constituted by dots provided on a back surface of the surface layer (1); and an achromatic layer (3) provided on the back surface of the surface layer (1) to fill a gap between the dots. As surface roughness of a front surface of the surface layer, an Ra is 2 [mu]m or less and either an Rmax is 4 [mu]m or less or a Sm is 50 [mu]m or more. A stimulus value Y45 DEG of the metal luster layer is 10000 or more. An area of each dot when viewed from a front side of the surface layer is 10-3-105 [mu]m2. A dot area percentage per a unit area when viewed from the front side of the surface layer is 20-99%. A lightness L* of the achromatic layer is 0-80. As a result, the metal polished surface-style appearance of less strong luster and dim glowing texture is realized.

Owner:ISHII HYOKI +1

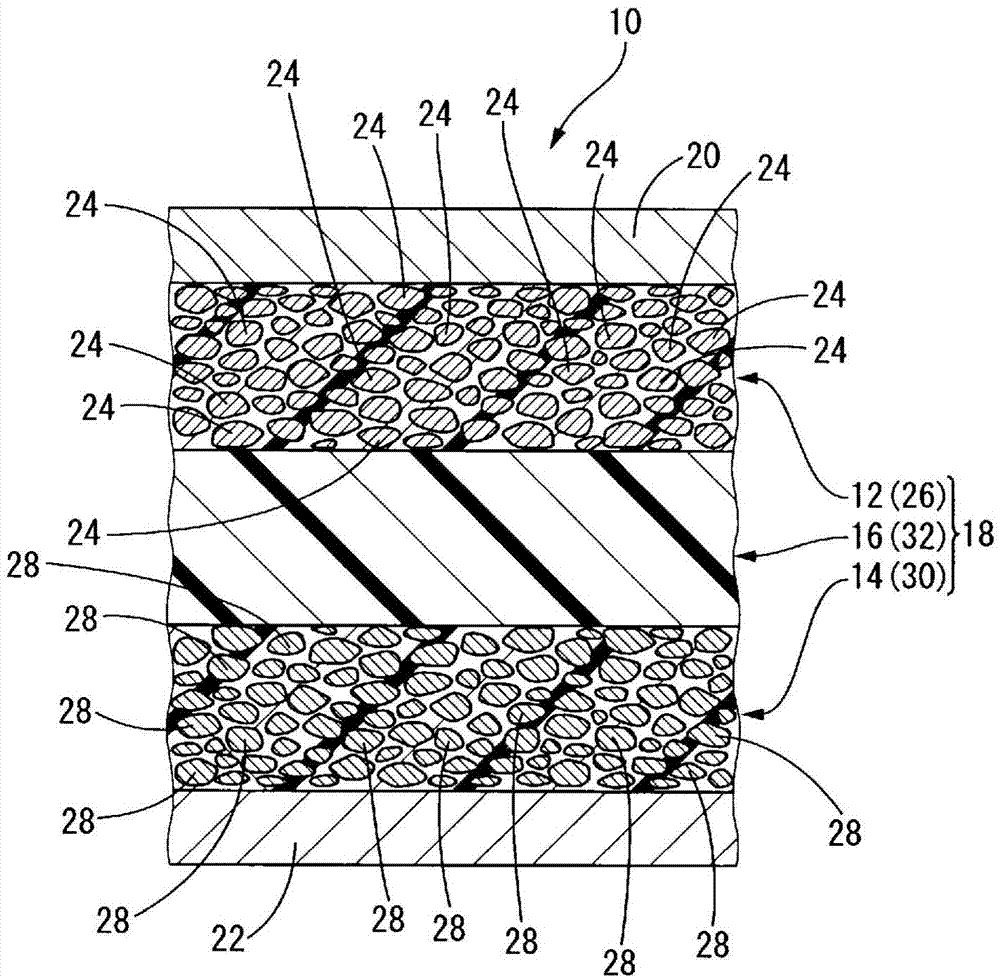

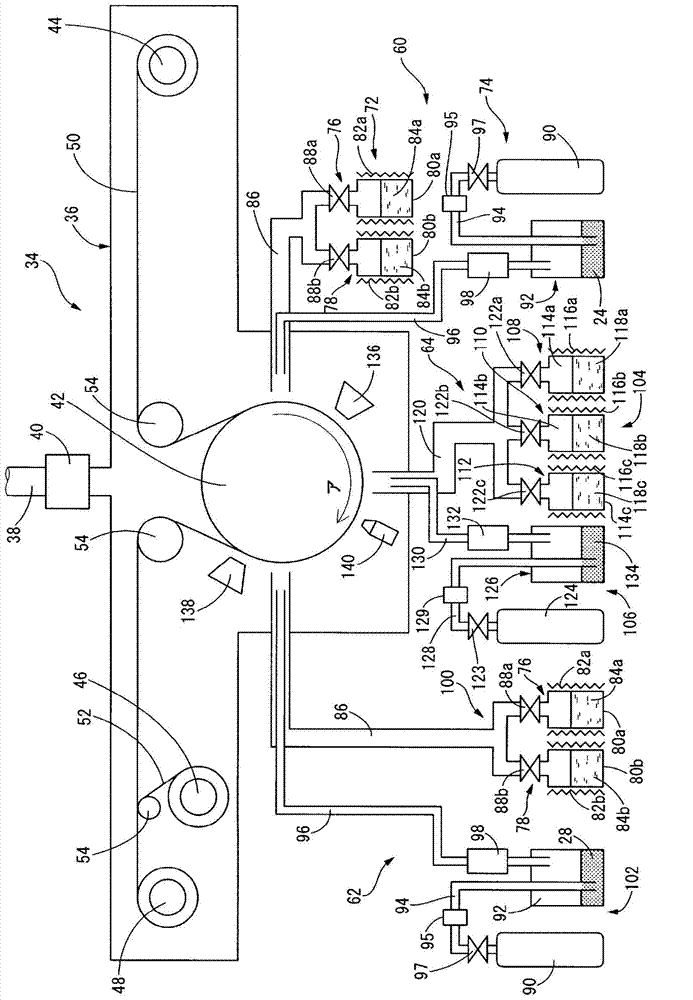

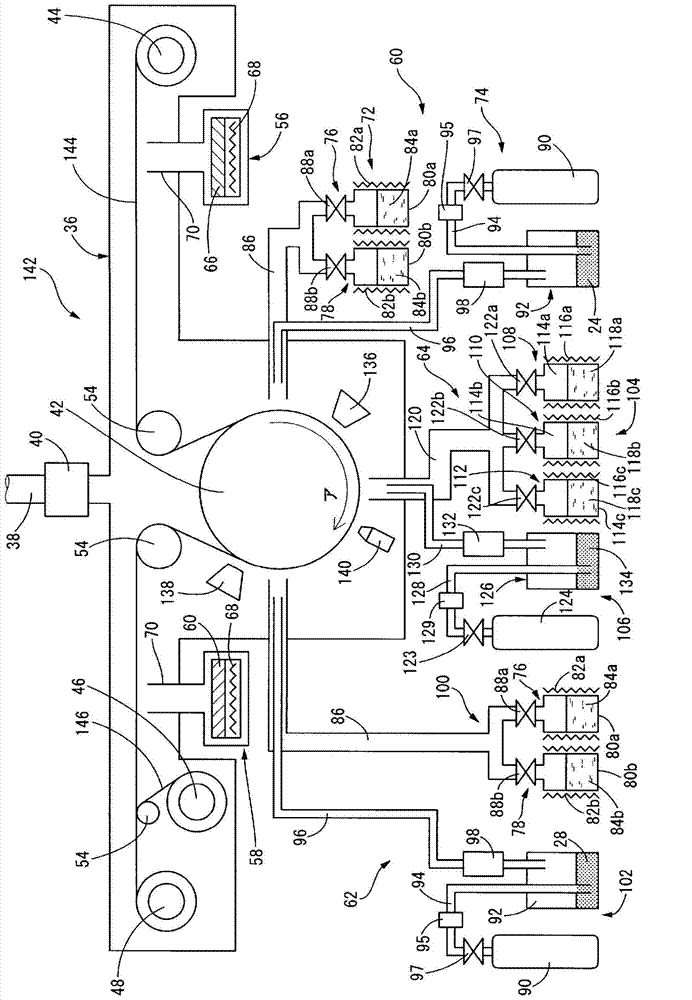

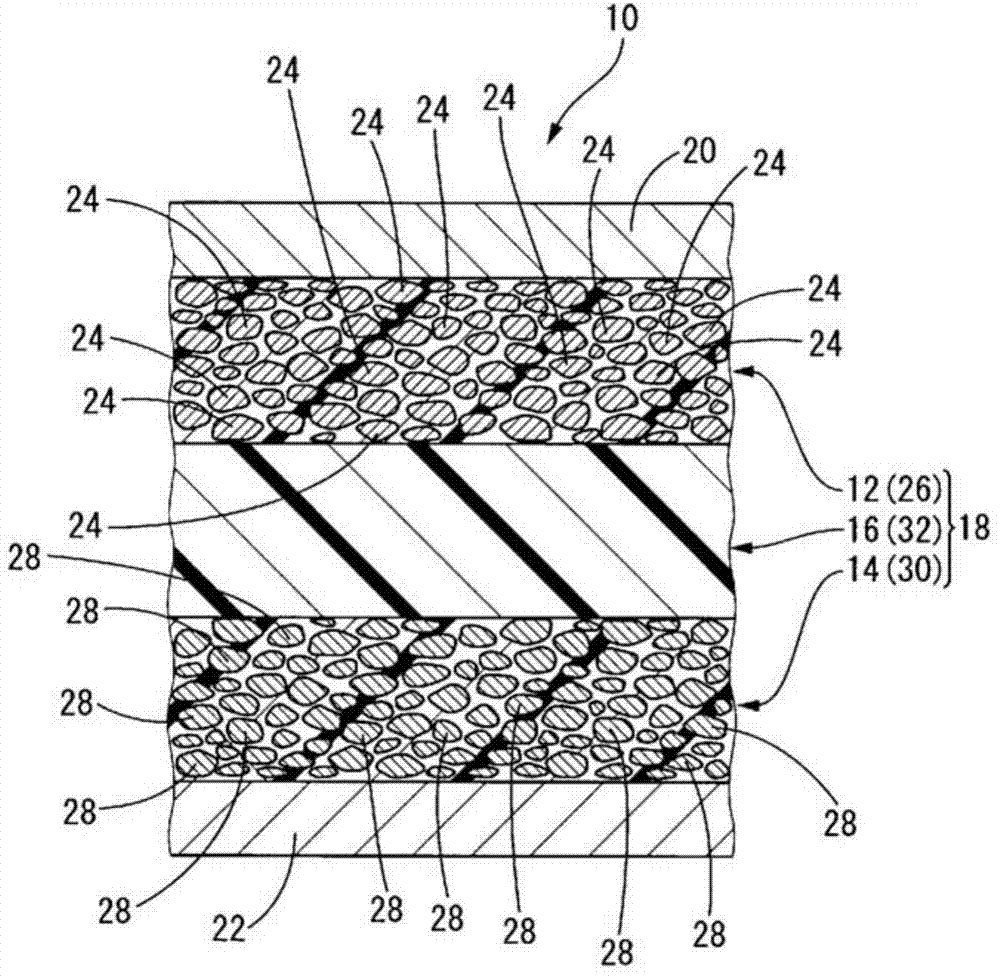

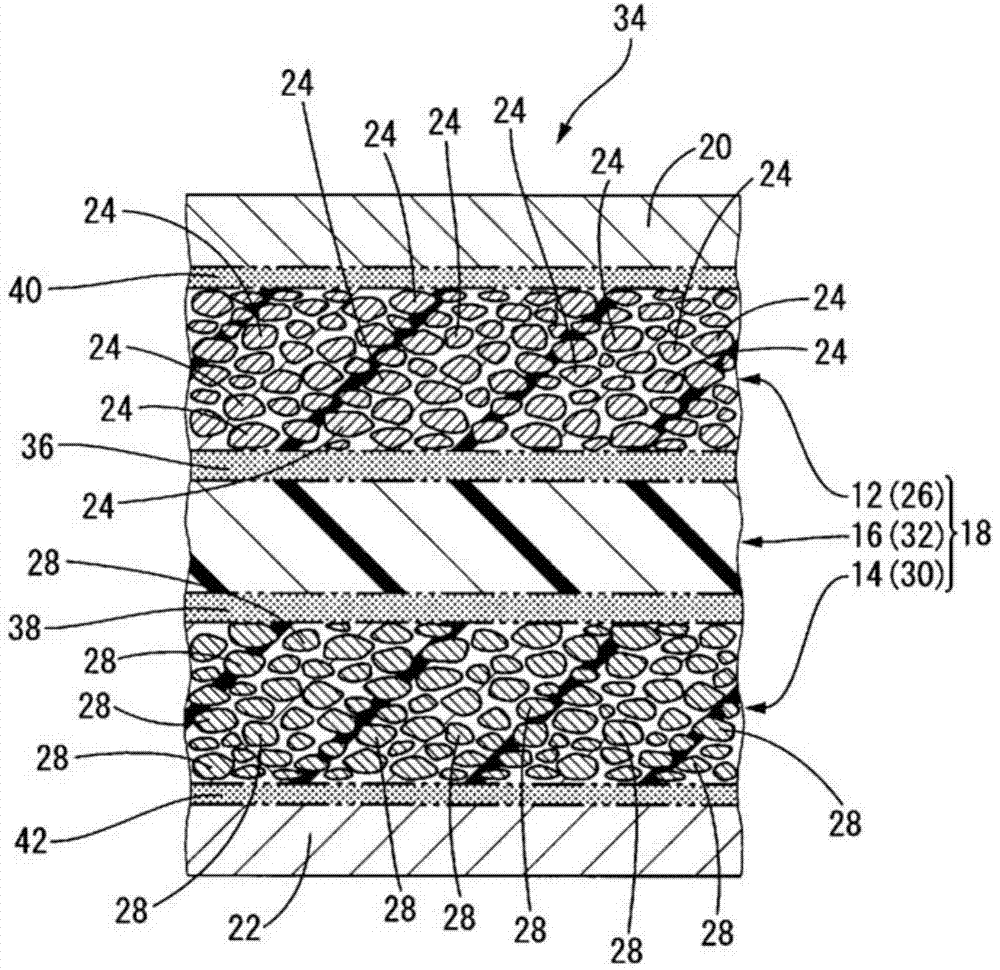

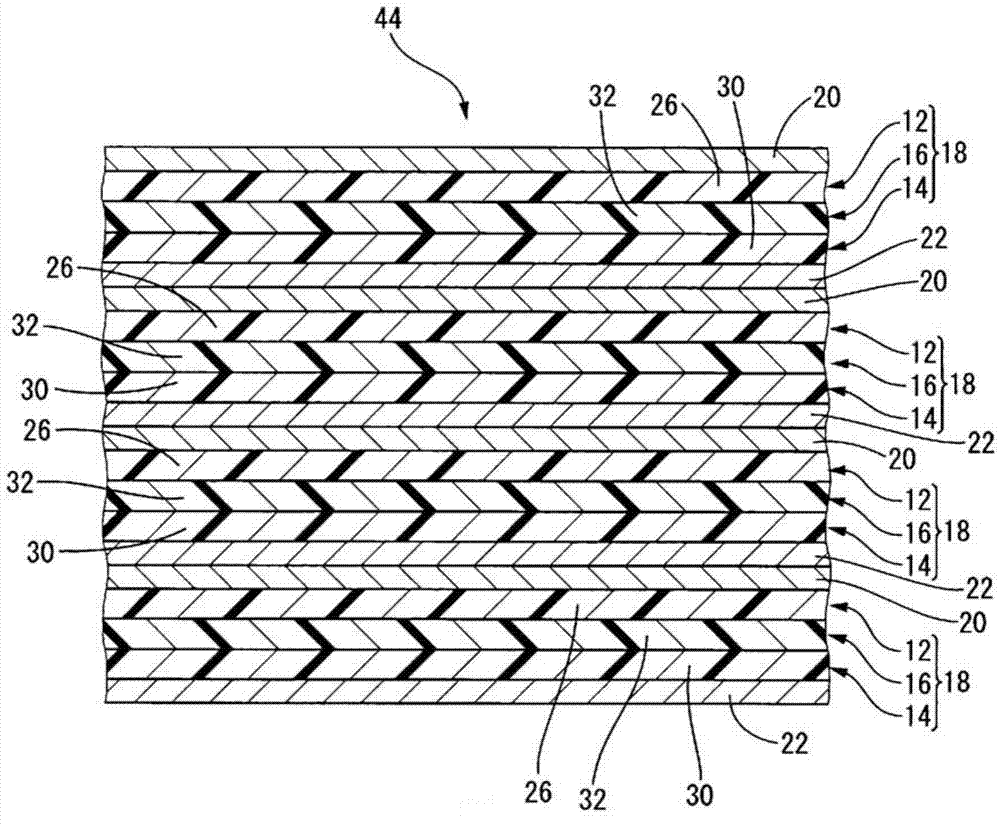

Process and device for producing lithium-ion secondary battery

InactiveCN104247132AHigh film forming rateEasy to manufactureFinal product manufactureLi-accumulatorsLithiumReduced size

Provided is a technique that is capable of efficiently and inexpensively producing a lithium-ion secondary battery in which stable battery performance and a high degree of freedom in shape are ensured and which can be made to have an improved output density and a reduced size. While forming a first vapor-deposited polymer film layer (26), a positive active material (24) is incorporated into the first vapor-deposited polymer film layer (26), thereby forming a positive-electrode layer (12). Meanwhile, while forming a second vapor-deposited polymer film layer (30), a negative active material (28) is incorporated into the second vapor-deposited polymer film layer (30), thereby forming a negative electrode layer (14). Furthermore, while forming a third vapor-deposited polymer film layer (32), a substance that imparts lithium-ion conductivity is incorporated into the third vapor-deposited polymer film layer (32), thereby forming a solid electrolyte layer (16). The positive electrode layer (12) and the negative electrode layer (14) are thereby superposed through the solid electrolyte layer (16) to form a layered object (18), and a lithium-ion secondary battery (10) having the layered object (18) is produced.

Owner:KOJIMA PRESS IND CO LTD

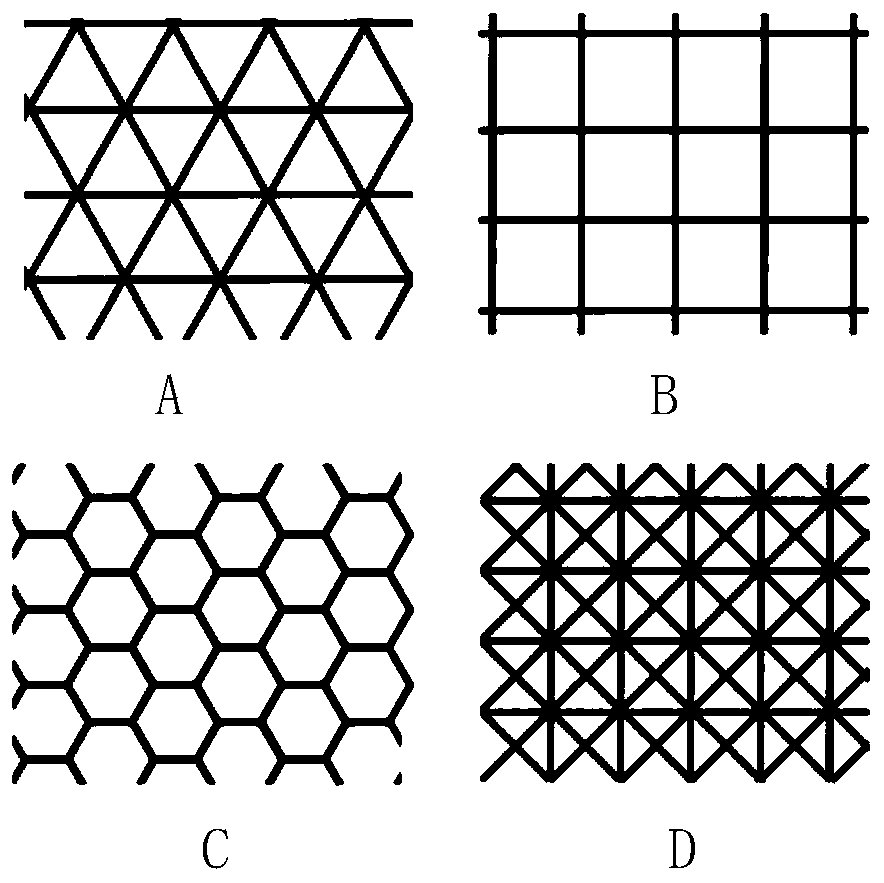

3D printing preparation method of lens hood with high light absorption capacity for star sensor

ActiveCN111016160AEfficient preparation process characteristicsStable preparation process characteristicsAdditive manufacturing apparatus3D object support structuresMacroscopic scaleEngineering

The invention provides a 3D printing preparation method of a lens hood with high light absorption capacity for a star sensor, belongs to the field of stray light restraint of a space optical system, and solves the problems that the existing lens hood is difficult in machining, low in size precision and damaged in vibration test. A high-performance polymer matrix material with the natural color isblackened; and integrated rapid forming is carried out on a complicated high light absorption lens hood through the 3D printing technology, so that traditional split type forming is effectively avoided. On the basis of ensuring the macroscopic size precision and the mechanical property, a coarse and porous micro surface structure is obtained through regulating, controlling and optimizing the technological parameters of 3D printing, the special texture structure can remarkably increase the optical length and provide a sufficient internal space; the light realizes efficient absorption through generating multiple times of reflection and scattering on the concave surface of a single tiny pit, so that light reflection on the surface of a cavity is weakened, the stray light eliminating capacityof the lens hood is remarkably improved, and the using requirements of the space star sensor system can be met.

Owner:HARBIN INST OF TECH

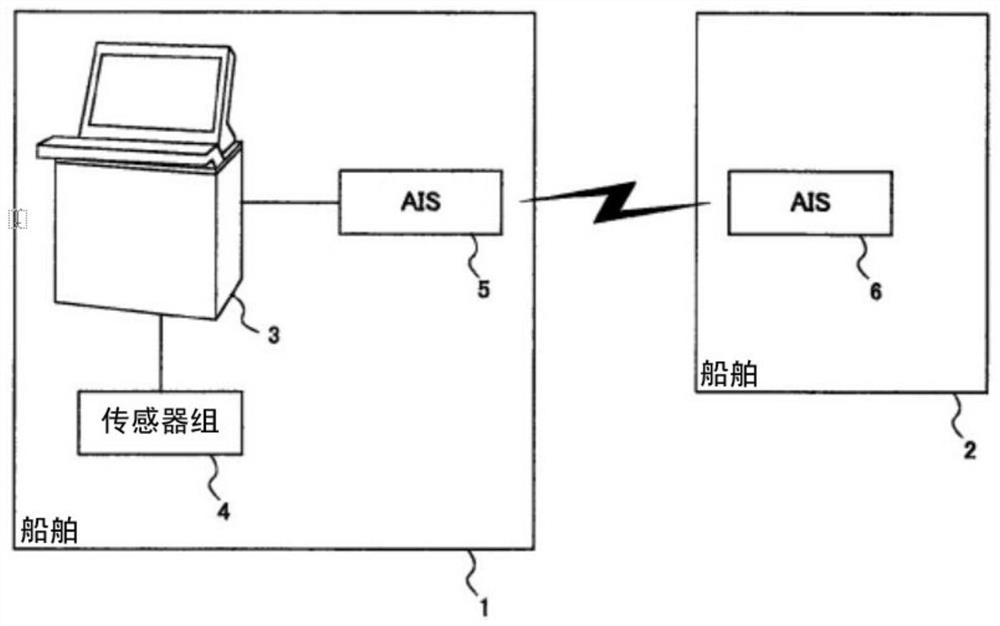

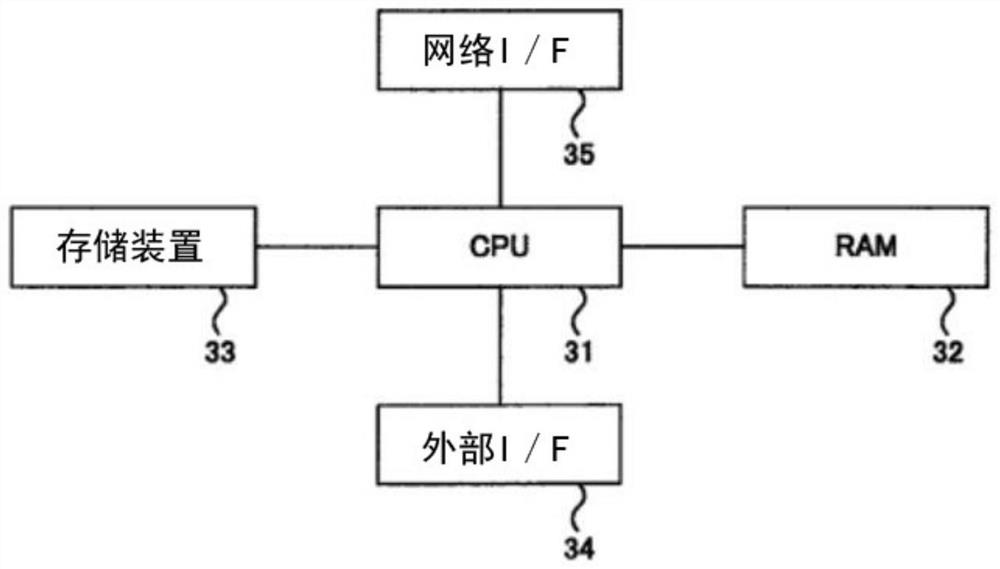

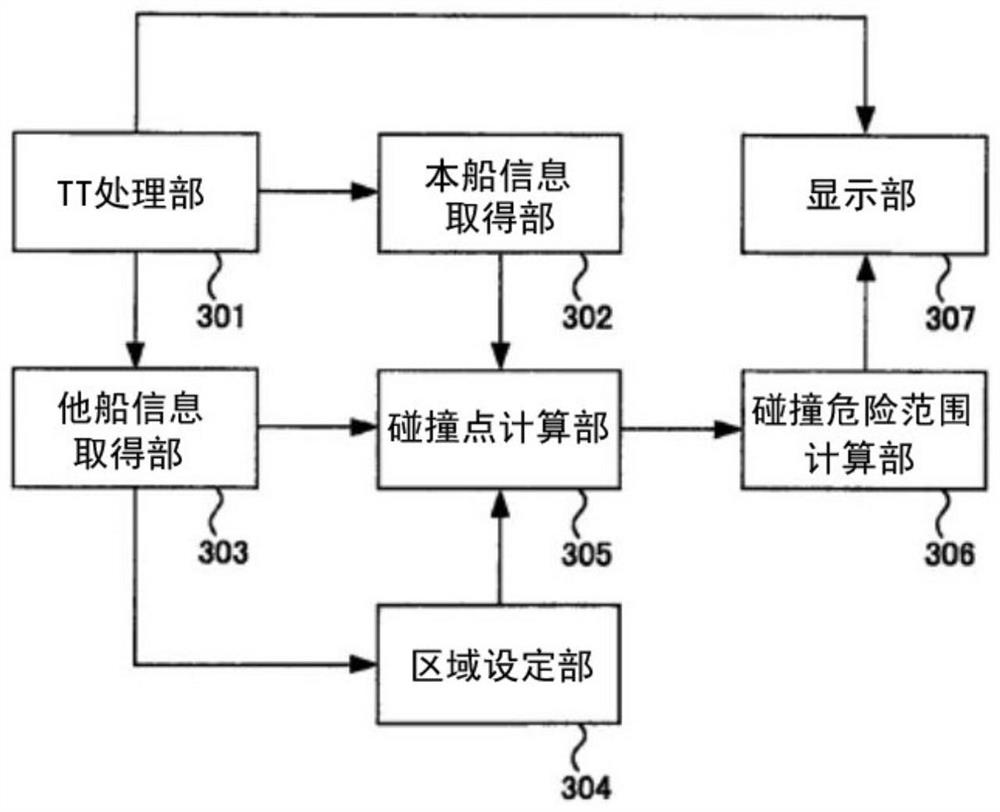

Ship navigation assistance device

ActiveCN111971726AHigh degree of freedom of shapeSecure collision hazard rangeNavigational calculation instrumentsNavigational aid arrangementsMarine engineeringClassical mechanics

A ship navigation assistance device is provided with: an area setting unit (304) for setting, with respect to a different ship, a polygonal safe passing area which is configured by a plurality of vertexes and surrounds the different ship; a collision point calculation unit (305) for calculating, on the basis of the speed of an own ship, a relative position of the own ship to the different ship, and a speed vector of the different ship, a collision point between each of the plurality of vertexes which constitute the safe passing area and the own ship; and a collision danger range calculation unit (306) for calculating a collision danger range by connecting a plurality of collision points calculated by the collision point calculation unit (305).

Owner:TOKYO KEIKI

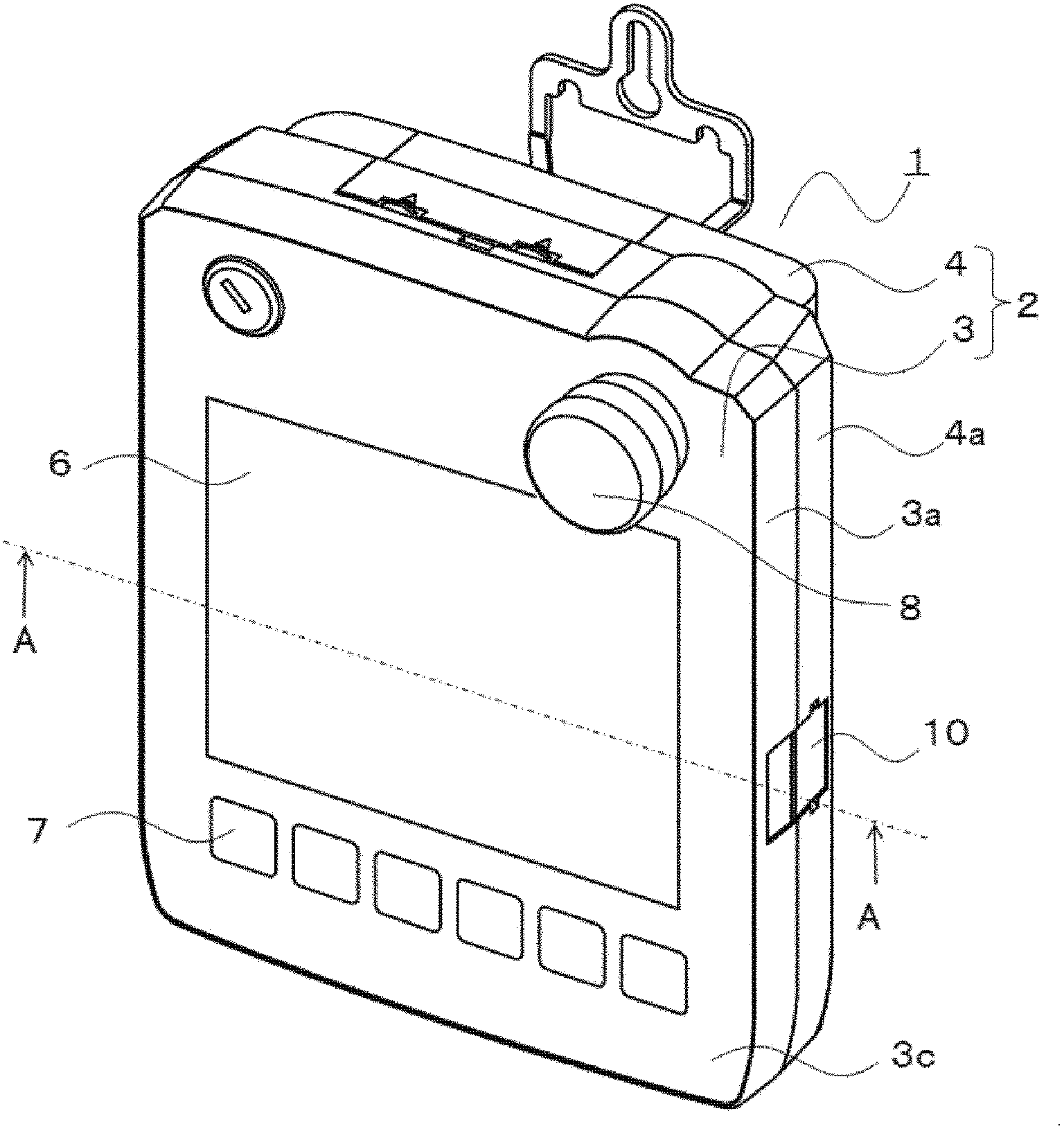

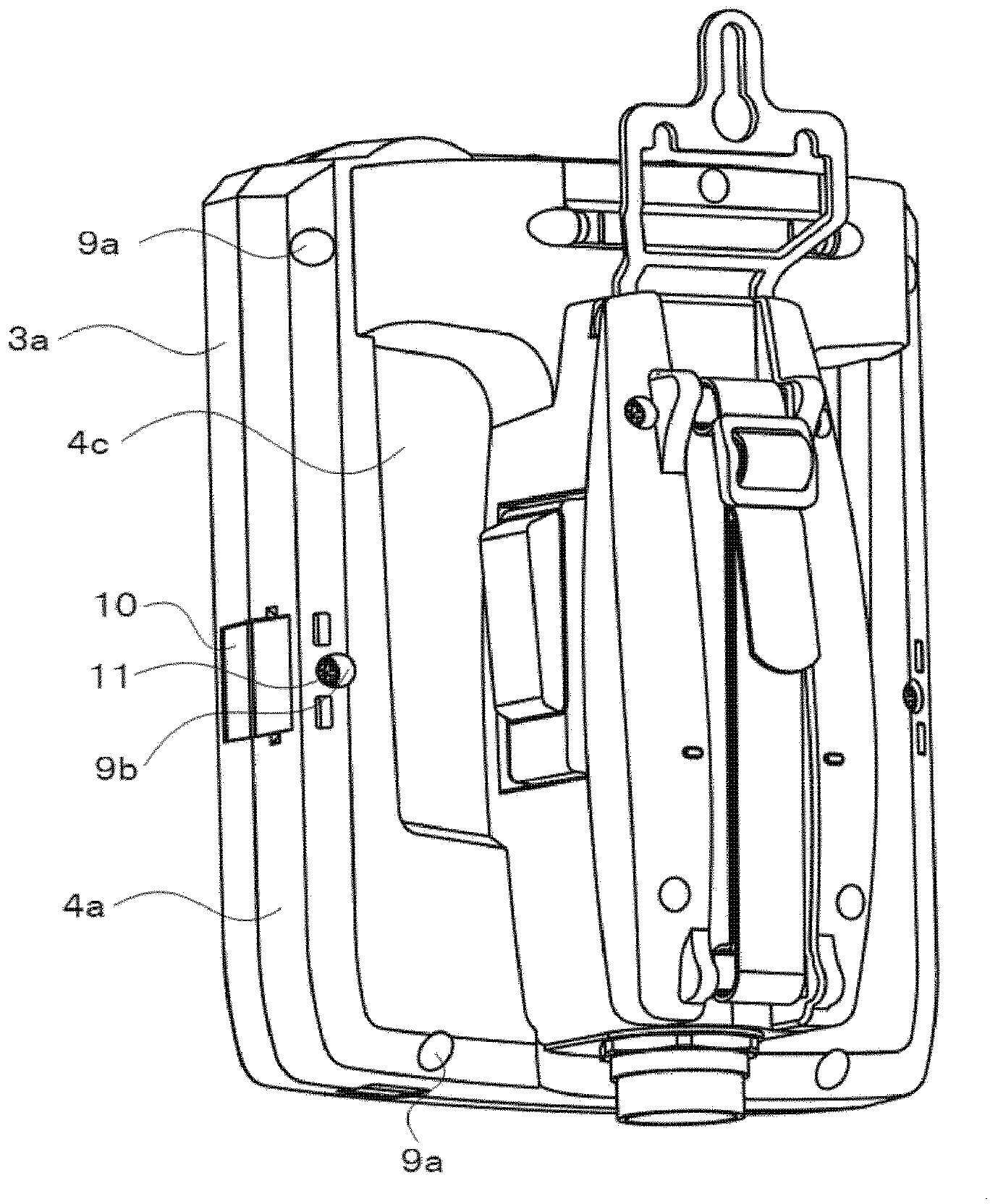

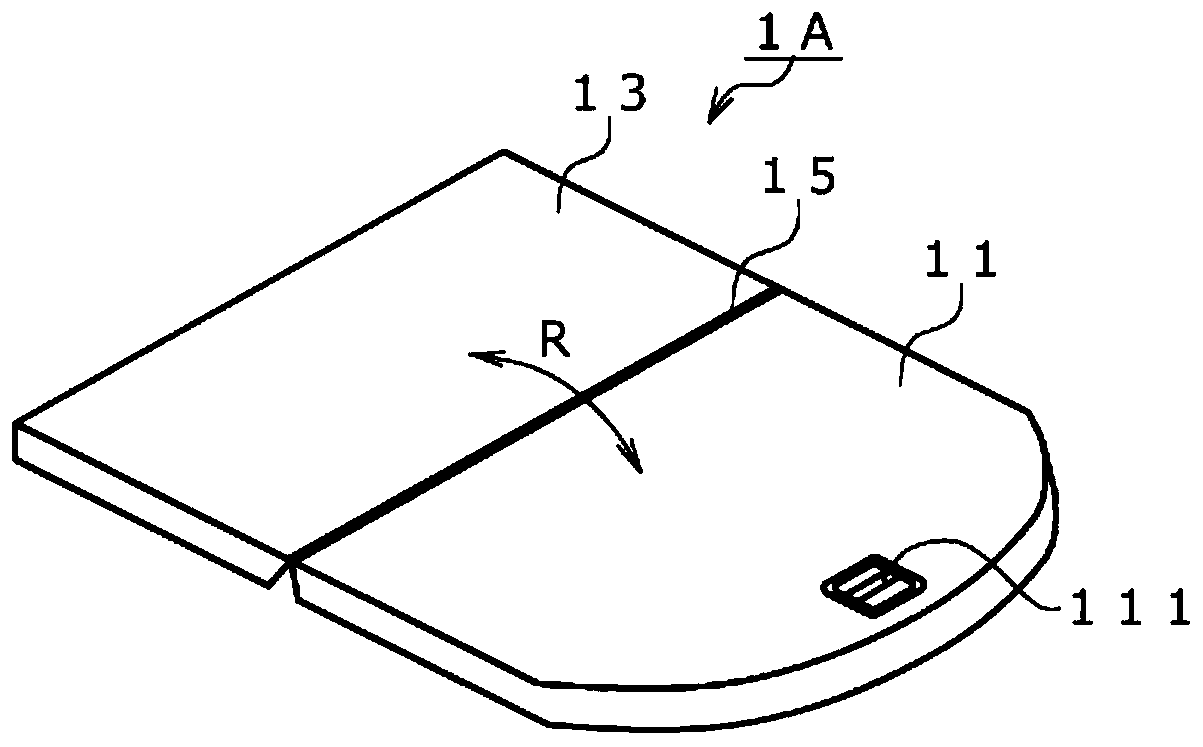

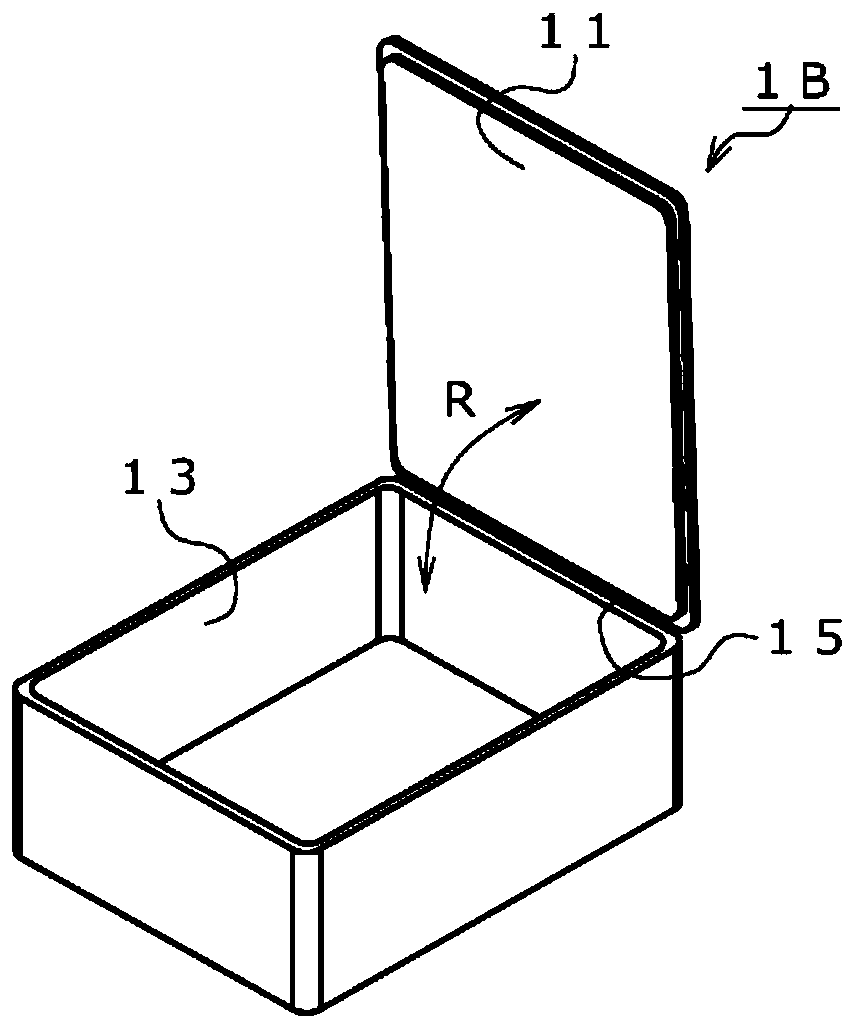

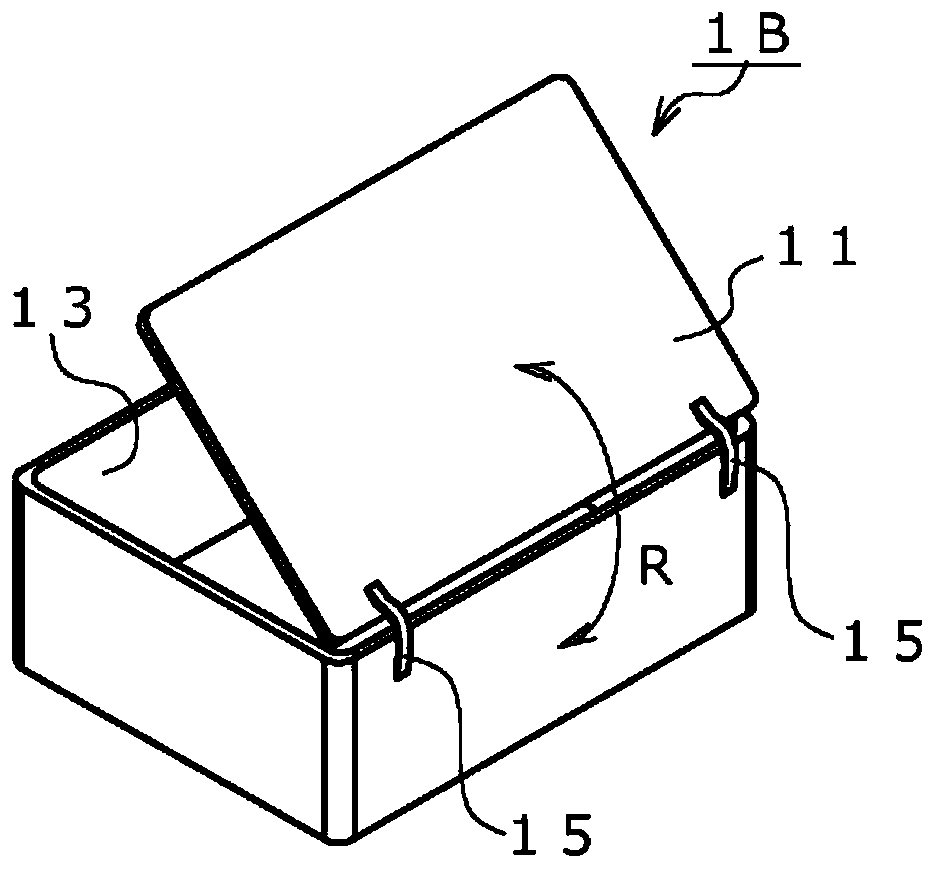

Portable display

ActiveCN104053322AConfiguration highHigh degree of freedom of shapeCasings/cabinets/drawers detailsDigital output to display deviceDisplay deviceEngineering

Owner:MITSUBISHI ELECTRIC CORP

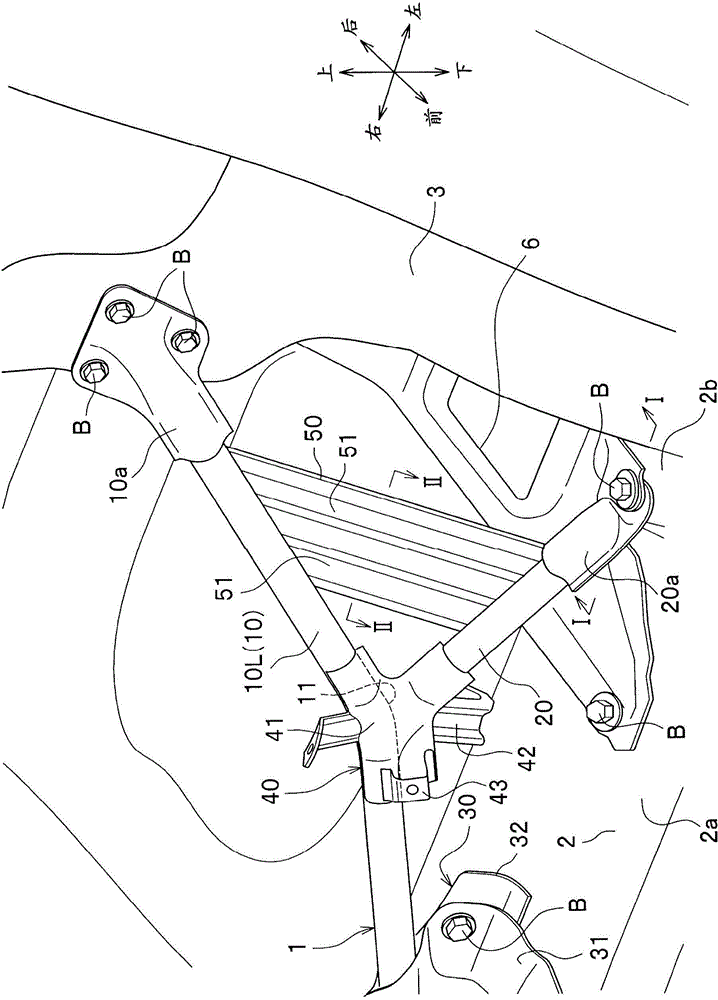

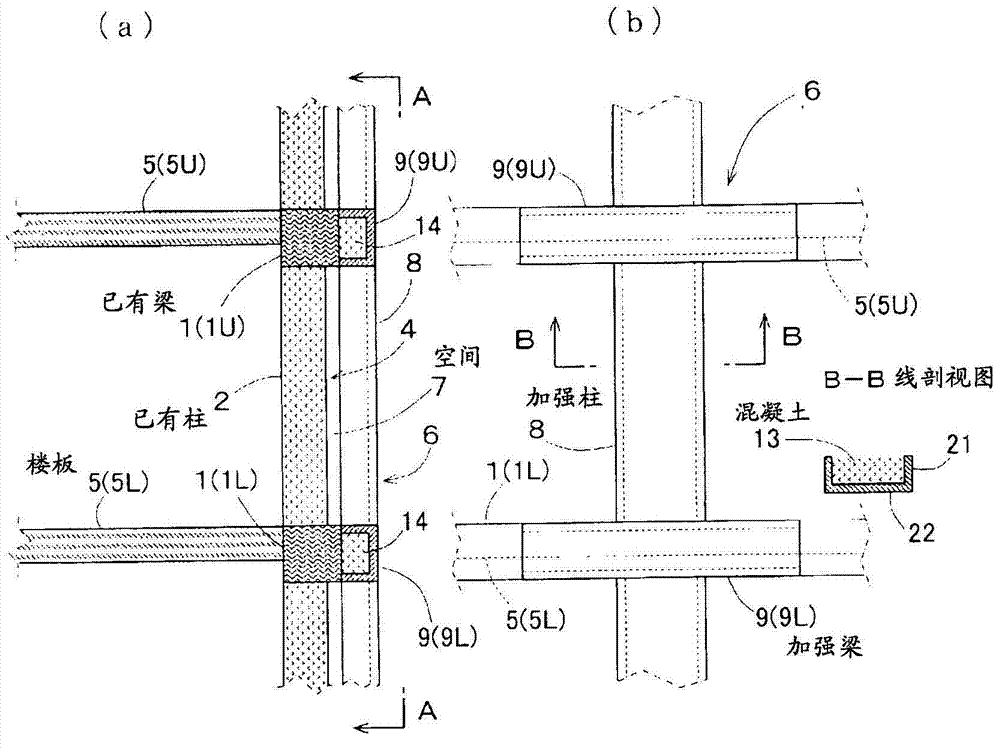

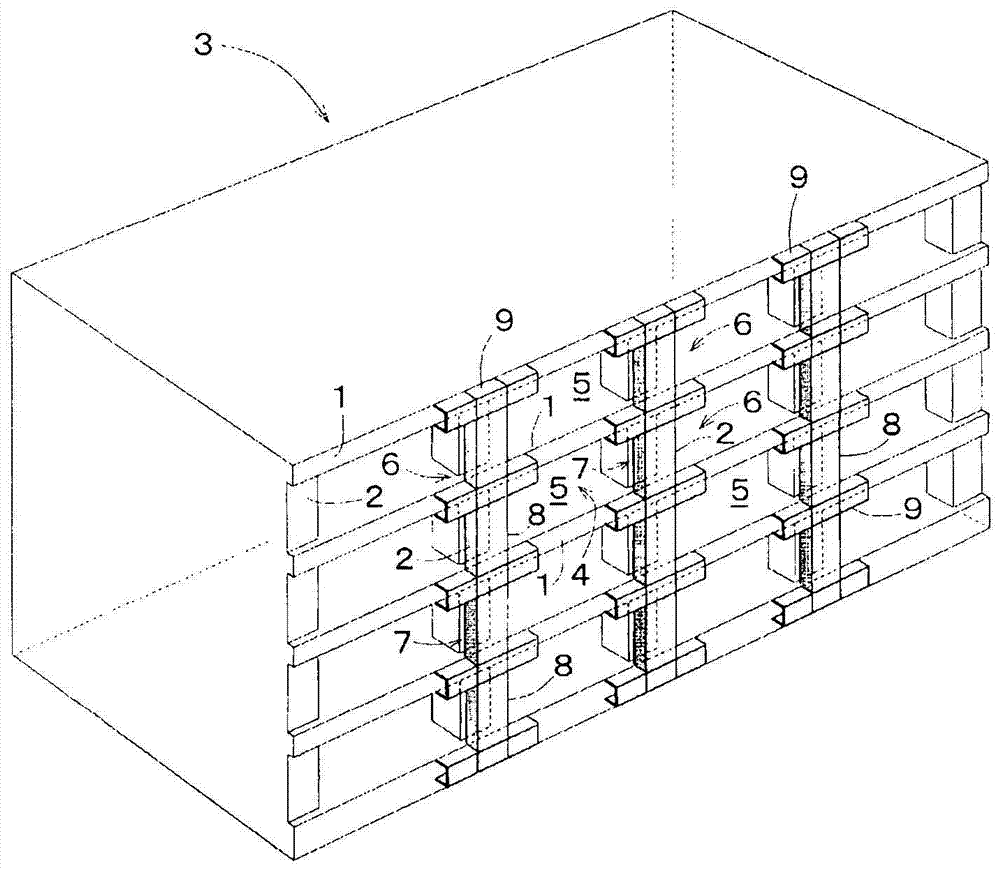

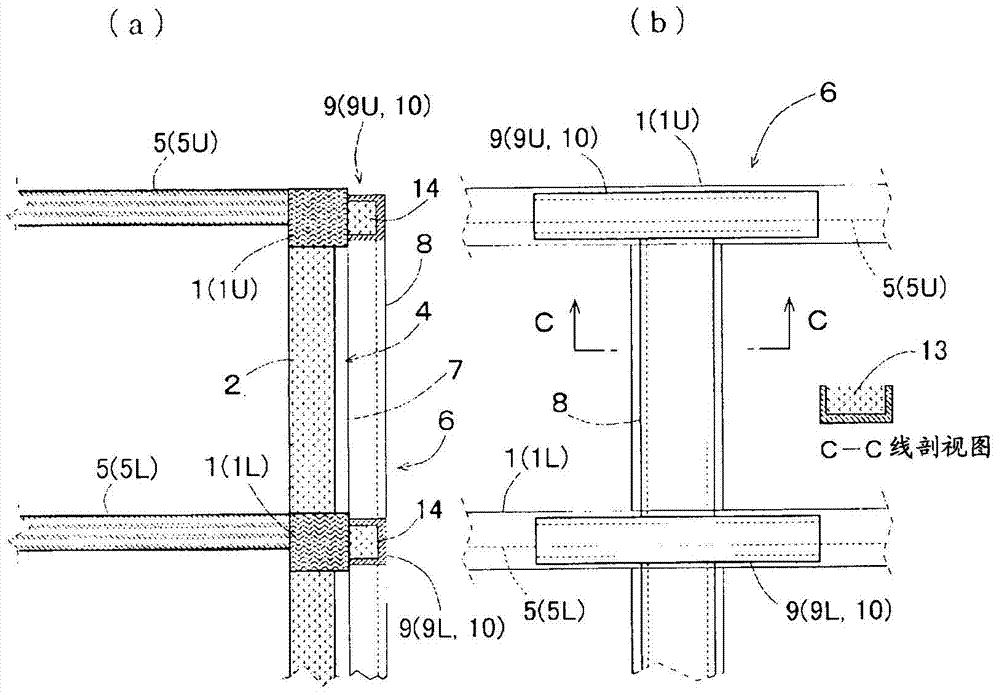

Aseismic reinforcing structure

ActiveCN104508219ACrack suppressionGuarantee structureBuilding repairsShock proofingFloor slabUpper floor

[Problem] To provide an aseismic reinforcing structure capable of improving the aseismic performance of an existing column without causing a crack in the existing column by a reinforcing column for the existing column and existing beams. [Solution] A reinforcing column (8) is erected at a position outside an existing column (2) located on the building outer wall side of an existing building so as to face the existing column with a space (7) therebetween. The lower portion of the reinforcing column (8) is linked to a reinforcing beam (9L) fastened to an existing beam (1L) integrated with a floor slab (5L). The upper portion of the reinforcing column (8) is linked to a reinforcing beam (9U) fastened to an existing beam (1U) integrated with an upper-floor floor slab (5U). The reinforcing beams (9) fastened to the same existing beam are discontinuous with right and left adjacent reinforcing beams thereof. Even if a difference occurs between the deformation of the reinforcing column and the deformation of the existing column when external force acts, the existing column is little affected by the deformation of the reinforcing column, and hence the occurrence of a crack in the existing column can be reduced to a minimum.

Owner:JFE CIVIL ENG & CONSTR +1

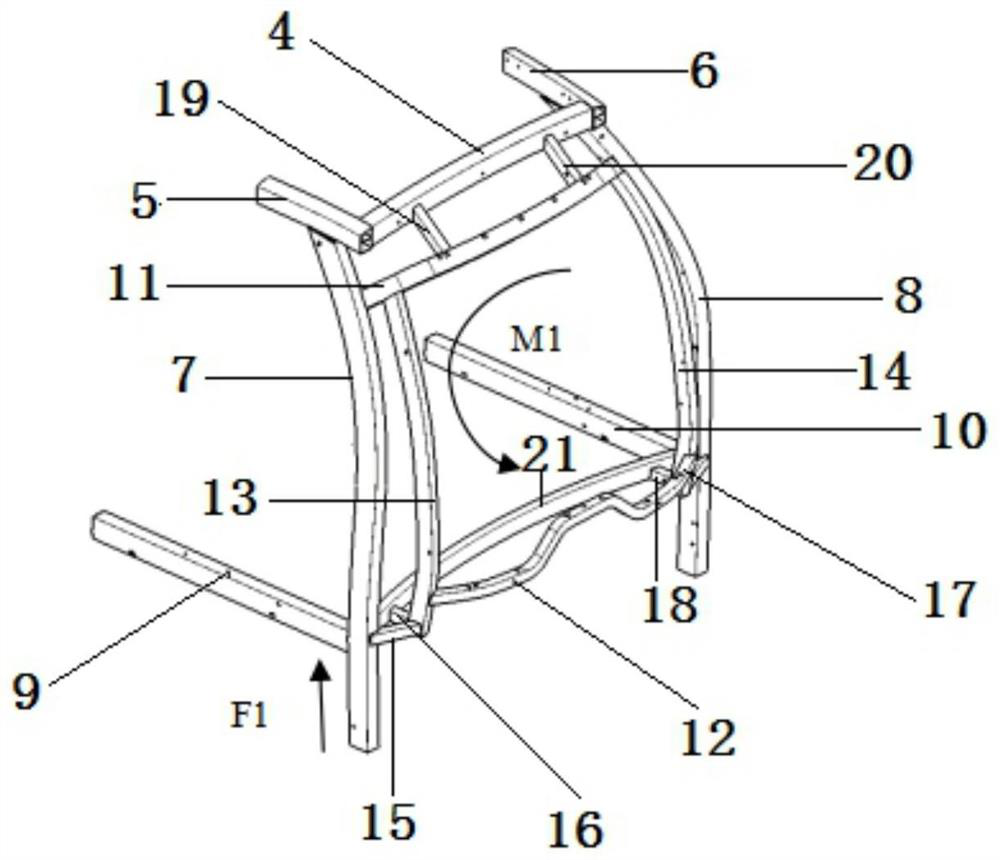

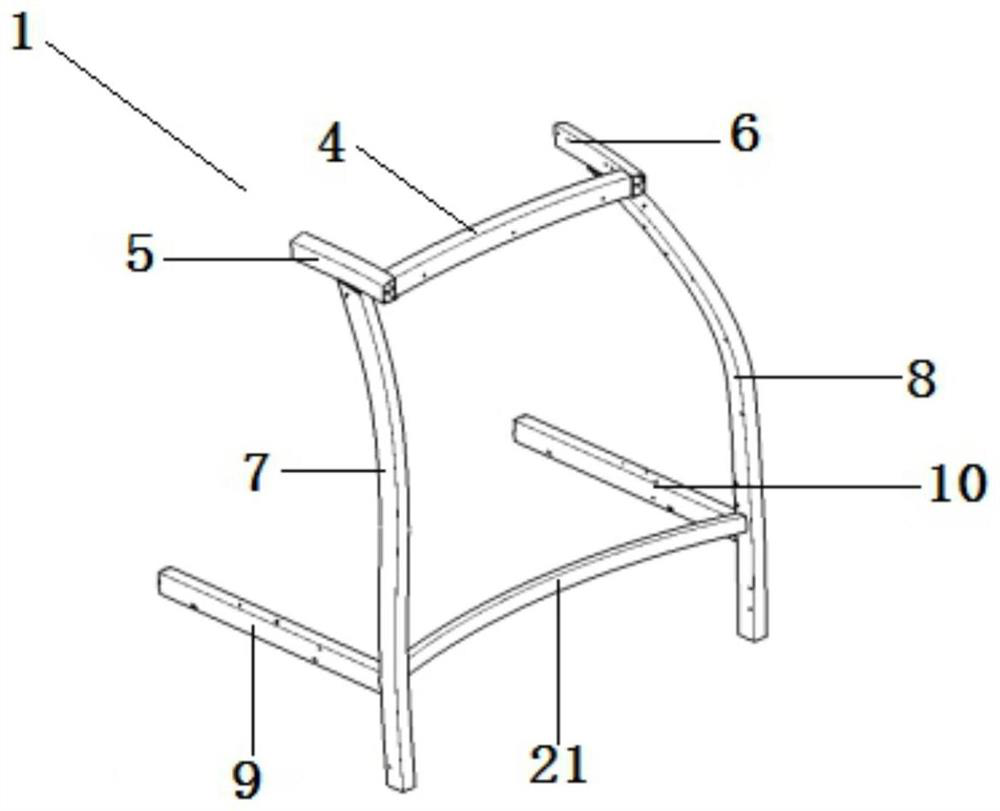

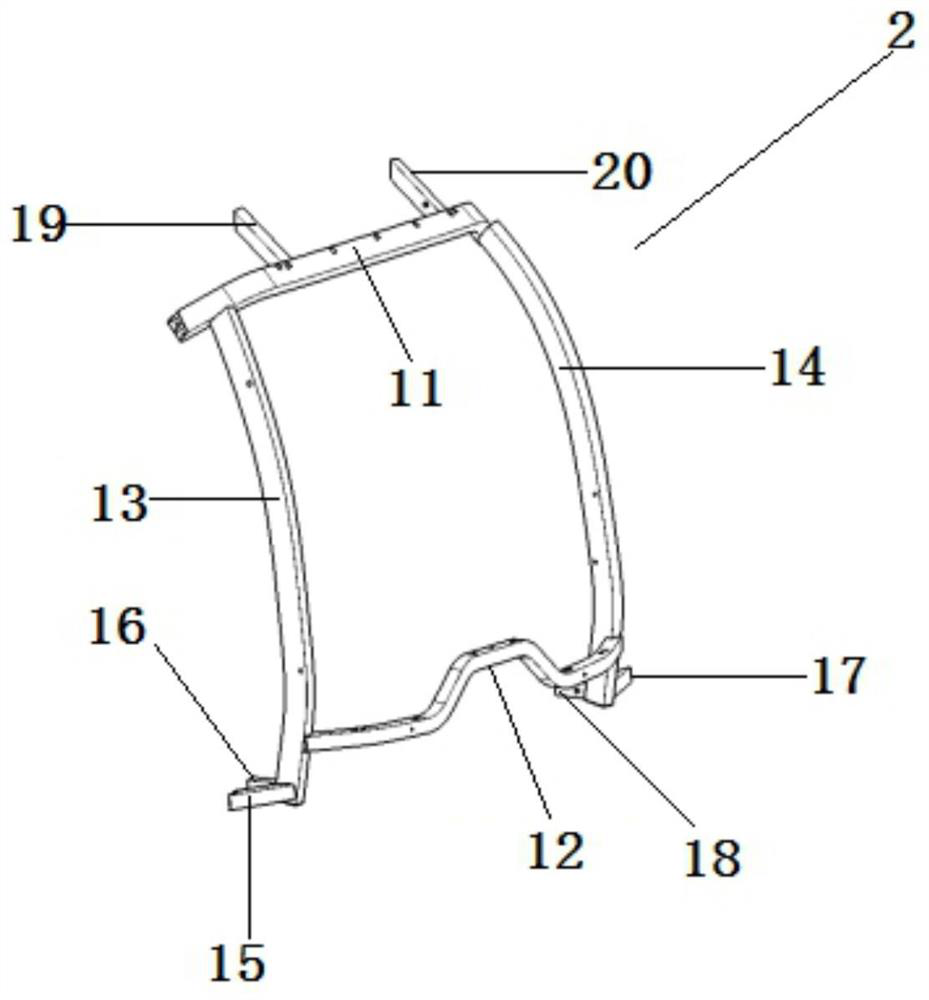

Double-ring type reinforcing structure of rear air window

PendingCN112937692AIncrease viewing areaImprove viewing experienceSuperstructure subunitsStructural engineeringWindshield

The invention discloses a double-ring type reinforcing structure of a rear air window. The structure comprises a top cover supporting beam assembly, a vehicle body D column and a vehicle body lower framework, the top cover supporting beam assembly located at the tail portion of a vehicle, the vehicle body D column and the vehicle body lower framework located at the tail portion of the vehicle are fixed to form a first longitudinal annular structure, a second longitudinal annular structure is fixed to the first longitudinal annular structure, and rear windshield glass is bonded and fixed to the second longitudinal annular structure. According to the invention, the combination of the two longitudinal annular structures is adopted, a traditional installation structure of rear air window assembly glass and sheet metal parts is replaced, the visual area of a rear air window is greatly increased, and the viewing experience of passengers is improved. The peripheral structure of the rear air window is constructed by adopting section bars, so that the cost of stamping part dies is reduced, and meanwhile, light weight is realized.

Owner:DONGFENG MOTOR GRP

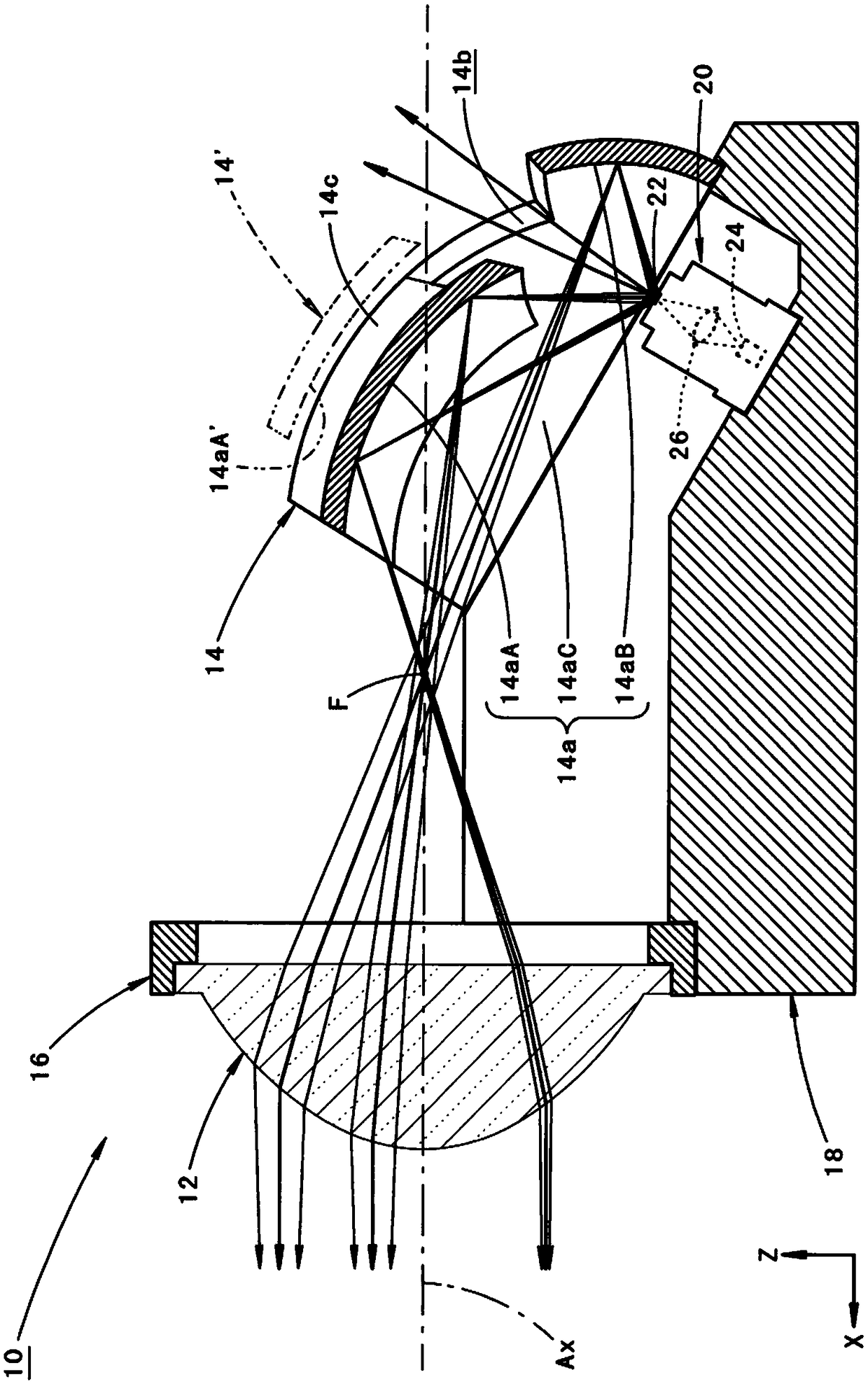

Vehicle lamp

ActiveCN109140375AImprove beam utilizationImprove concentrationVehicle headlampsOptical signallingDistribution patternLight beam

In a projection type vehicle lamp configured to reflect light from an illuminator that emits light by laser irradiation by a mirror, a bright light distribution pattern can be formed even when an opening is formed in the mirror. As the mirror, an opening is formed in a portion on an extension line of the optical path of the laser light from the laser light emitting element toward the illuminator.In addition, the reflection surface of the mirror is formed such that the first reflection region located on the front side of the opening is displaced toward the illuminator 22 side with respect to the second reflection region located on the rear side of the opening. Therefore, compared with the case where the first reflection region is formed in a curved shape in which the second reflection region is extended as it is, the solid angle based on the emission center of the illuminator is ensured to be large, and the improvement is made. The beam utilization of the outgoing light from the illuminant.

Owner:KOITO MFG CO LTD

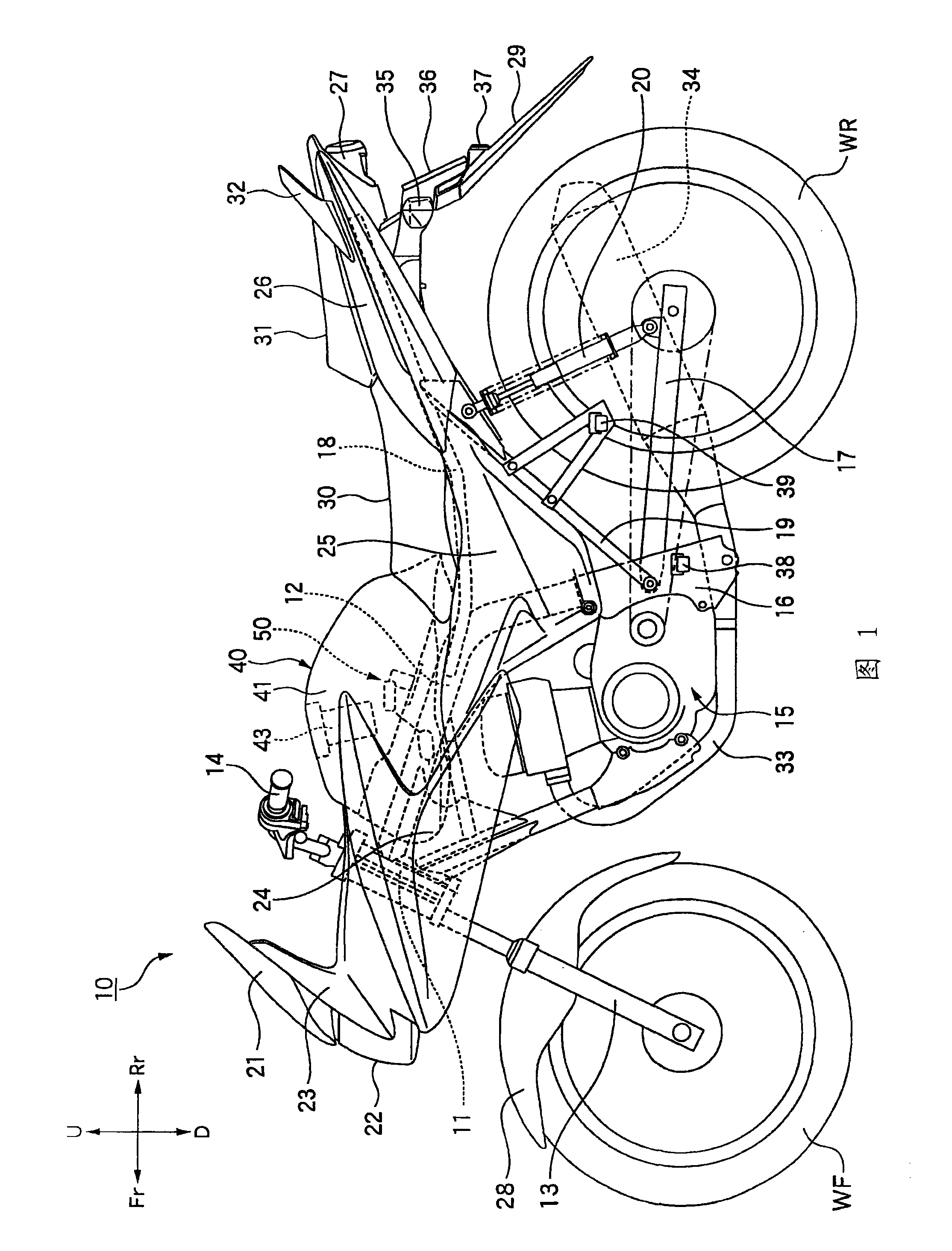

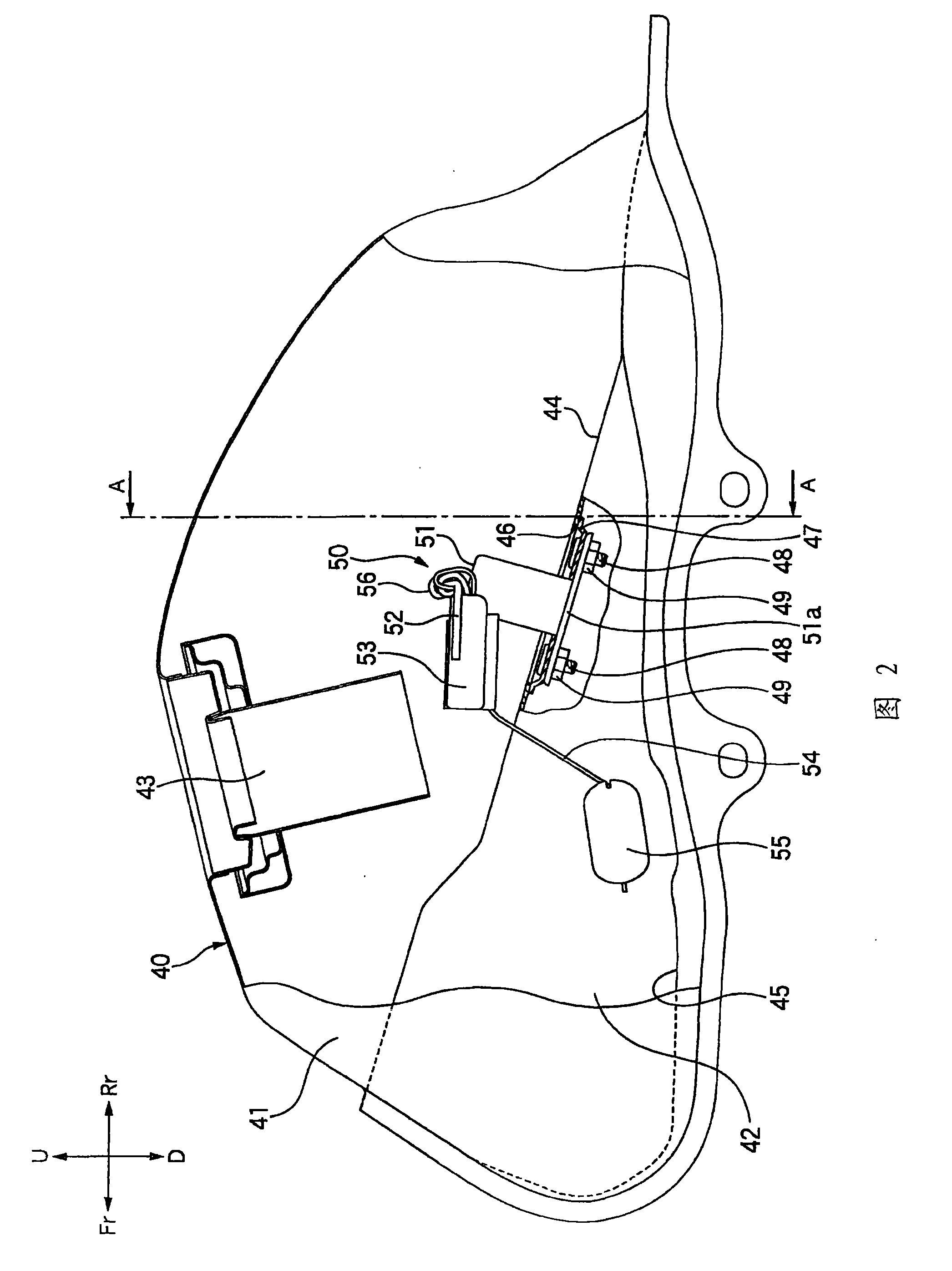

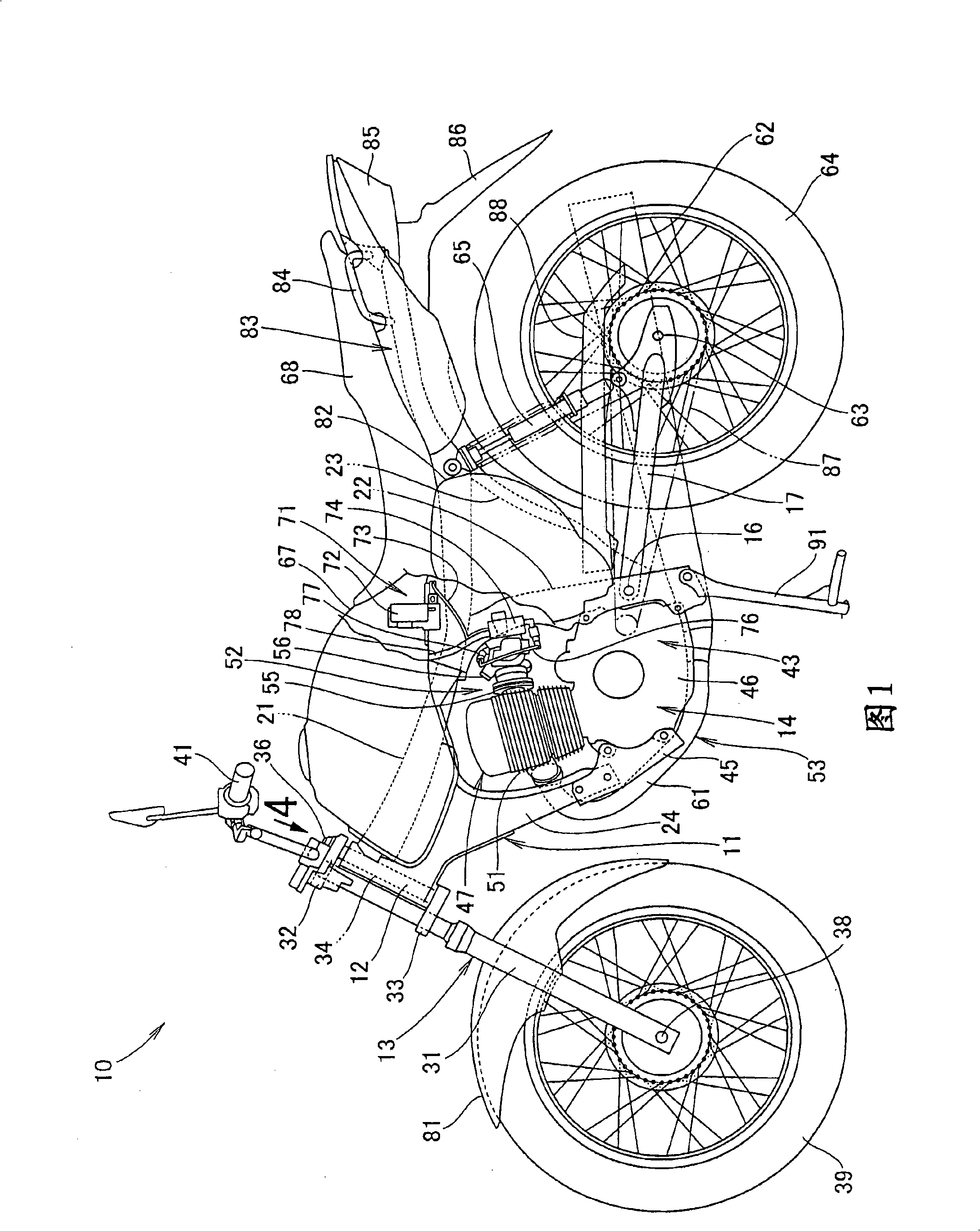

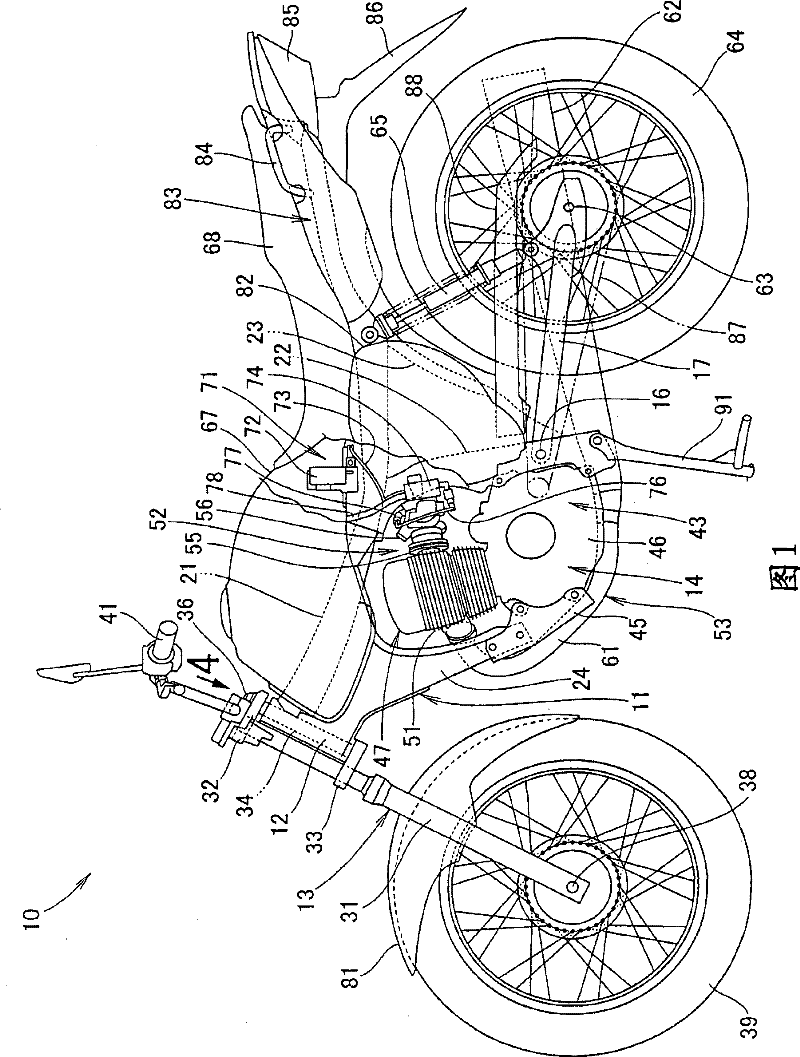

Automatic bicycle

InactiveCN101513909AHigh degree of freedom of shapeImprove layout freedomOptical signalFuel tanksElectrical resistance and conductanceEngineering

The invention provides an automatic bicycle capable of shortening length of a rotation member, namely a sensor arm, minimizing a floating member, enhancing shape freedom of a fuel box and arrangement freedom of a fuel sensor. The fuel sensor comprises a sensor body member disposed on the fuel box, an arm member extending outwards along the width direction of the bicycle from the top of the sensor body, a sensor resistor body disposed on outer terminal along the bicycle width direction of the arm member, a sensor arm rotatably disposed on the sensor resistor body detecting deflection angle by the sensor resistor body, a floating member disposed on the sensor arm front end portion, wherein the sensor body member and the sensor resistor member are configured as overlapped seeing from the lateral side of the bicycle.

Owner:HONDA MOTOR CO LTD

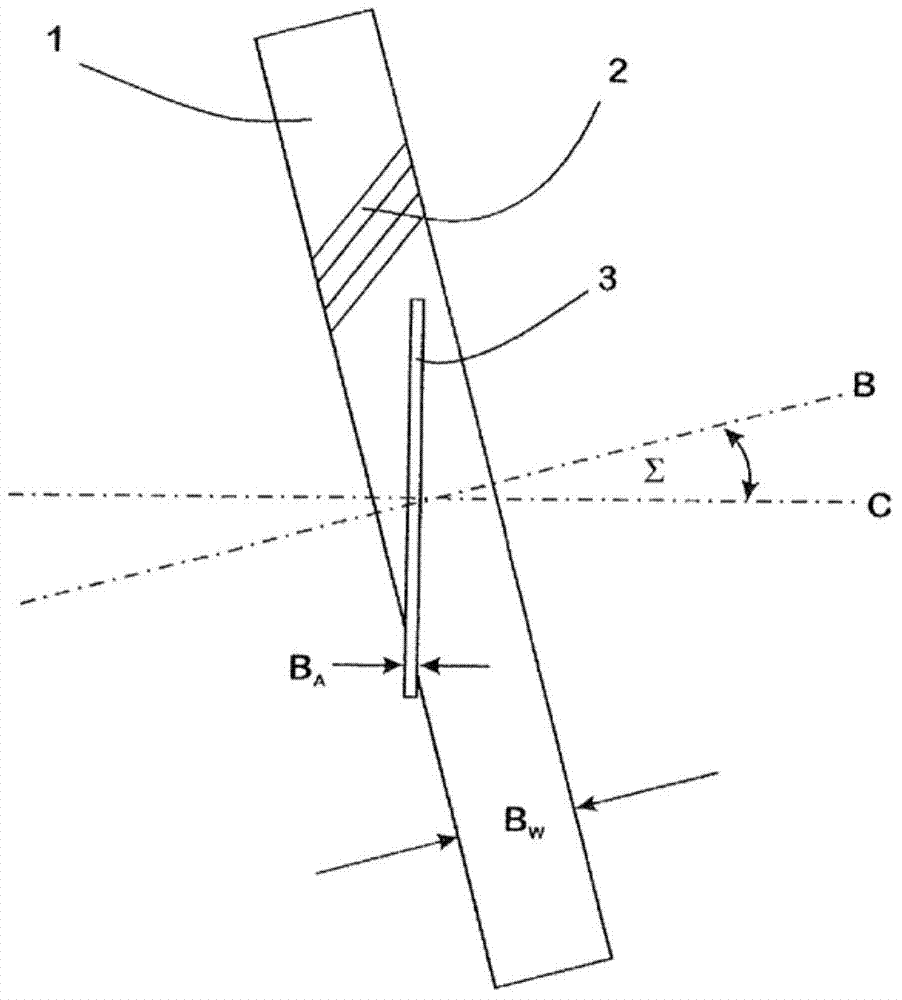

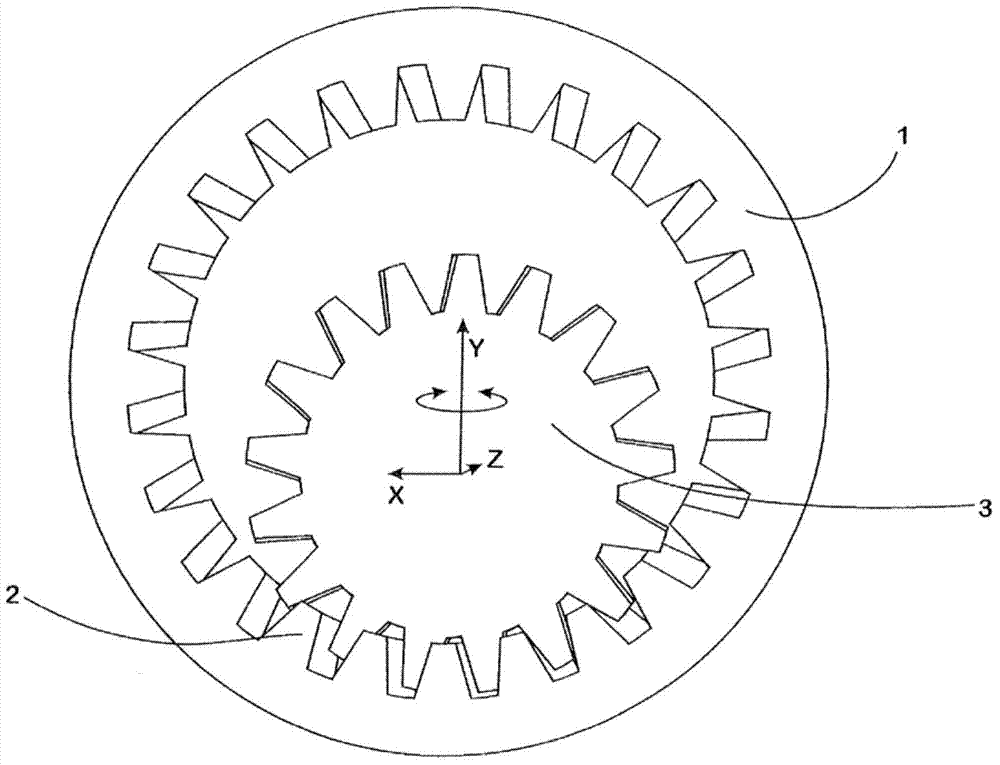

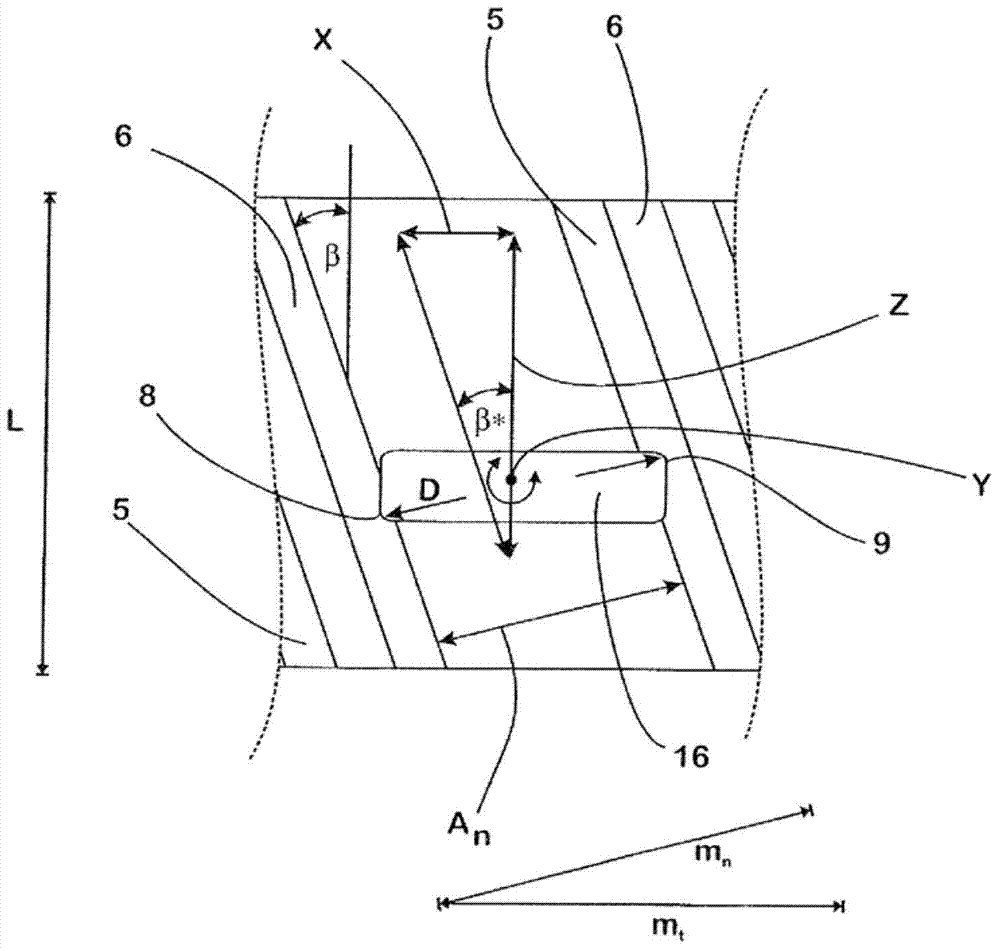

Method for modifying the flanks of a tooth of a gear wheel with the aid of a tool

The invention relates to a method for modifying the geometry of gear wheel tooth flanks using a tool having a toothing that engages with the gear wheel (ZR) during precision machining. In this case, a profile that varies over the width (Bw) of the tool (1) is produced on the tool (1) in that, during a dressing operation, a dressing wheel (3) is moved along the tooth flank (5) of the tooth (6) to be dressed. The width of the teeth (16) of the dressing wheel (3) is much smaller than the width (Bw) of the tool (1). Therefore, in order to pass over the width (Bw) of the tool (1), it must be moved by a length (L) corresponding to a multiple of the width (BA) of the teeth (16) of the dressing wheel (3). After dressing, the precision machining of the gear wheel (ZR) using the tool (1) takes place. Since, in the process, the dressing wheel (3) is moved with a changing pitch and a changing crossed axes angle (Σ) with respect to the tool (1), the modification of the tooth flank geometry can be transferred to the tool (1). During the subsequent precision machining, a modification of the crossed axes angle (Σ) takes place during the machining process, said modification being dependent on the helix angle of the tool (1), with the helix angle of the tool (1) being compensated, said helix angle changing over the width of the teeth (16) of the tool.

Owner:PRAWEMA ANTRIEBSTECHN

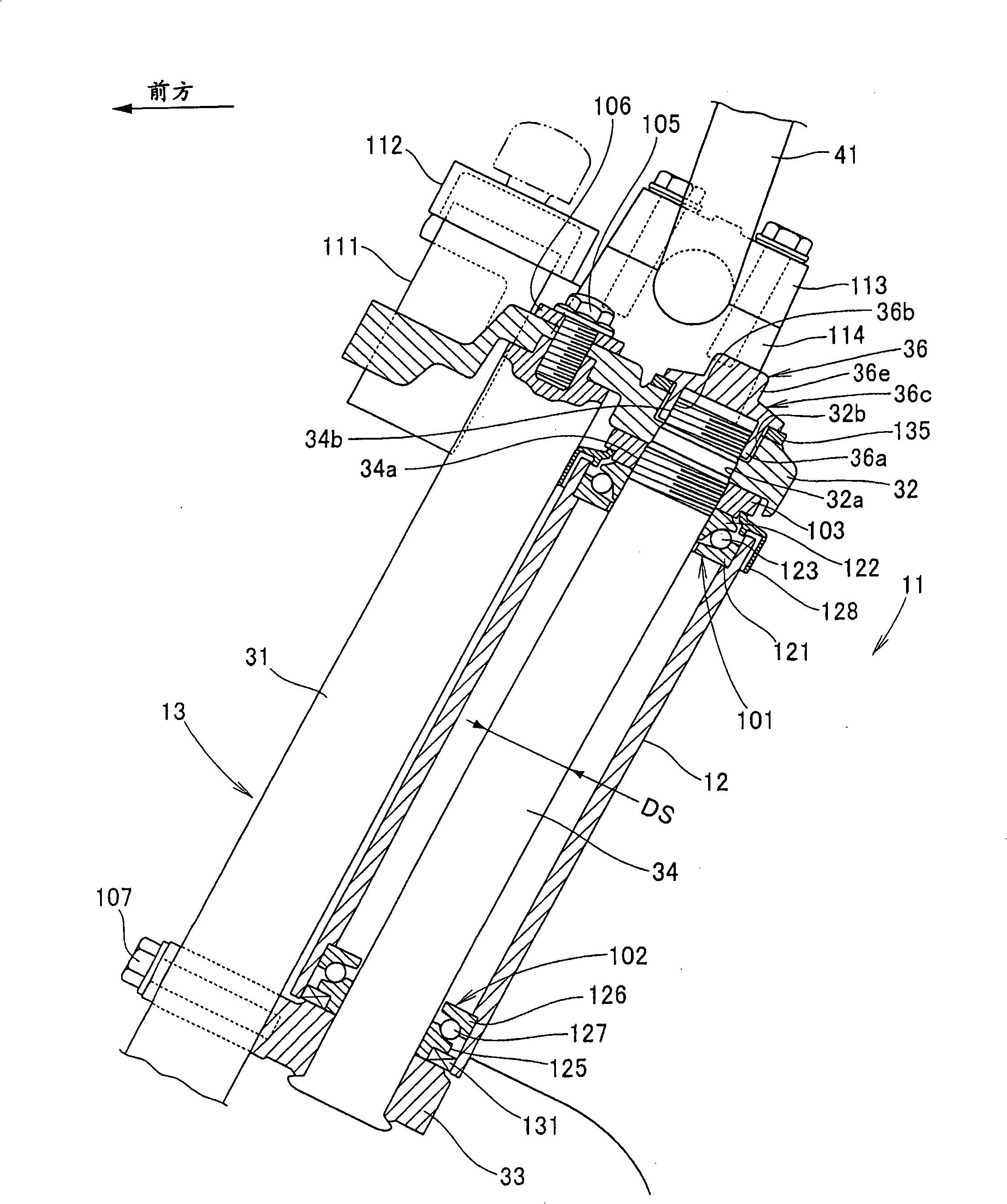

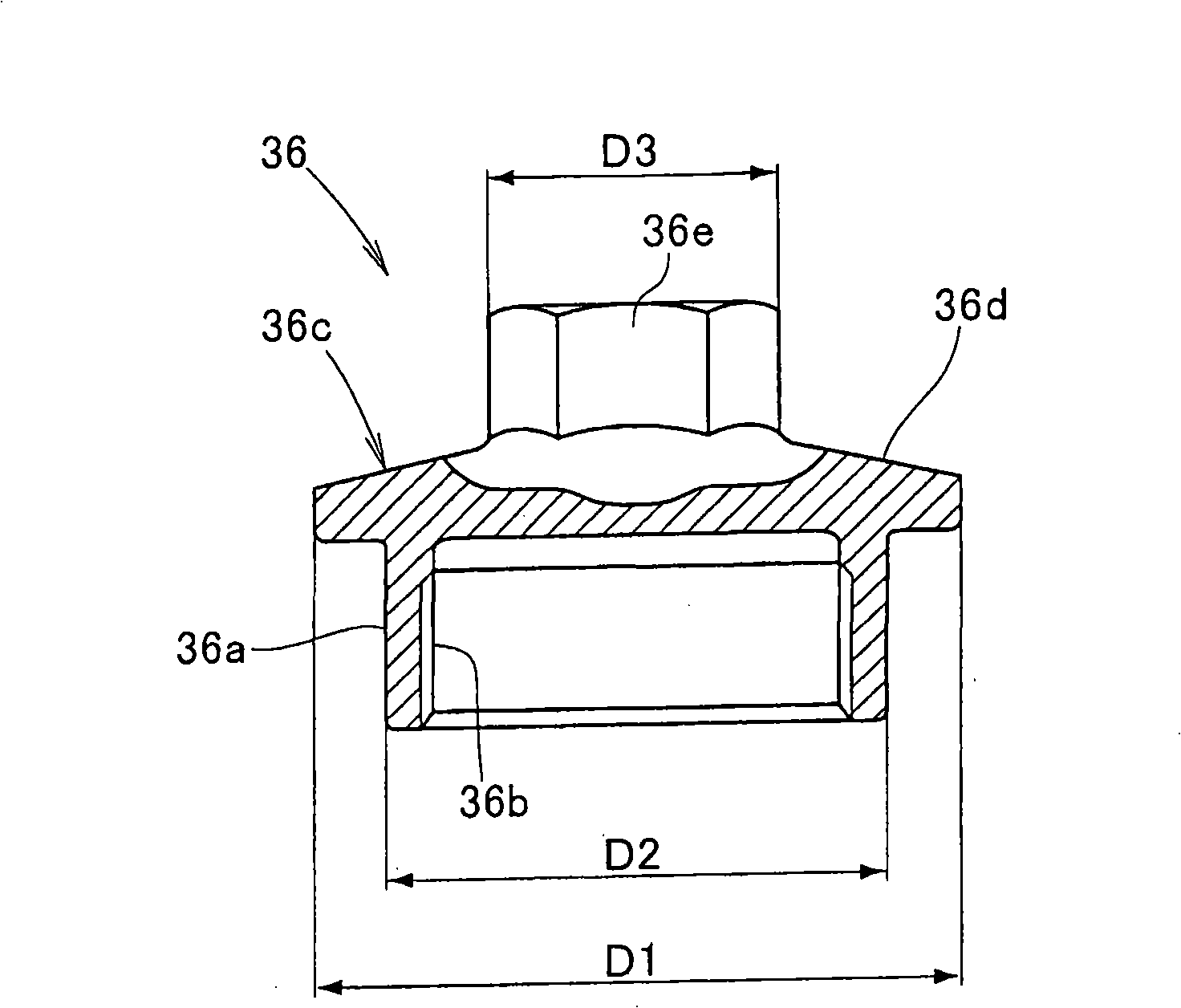

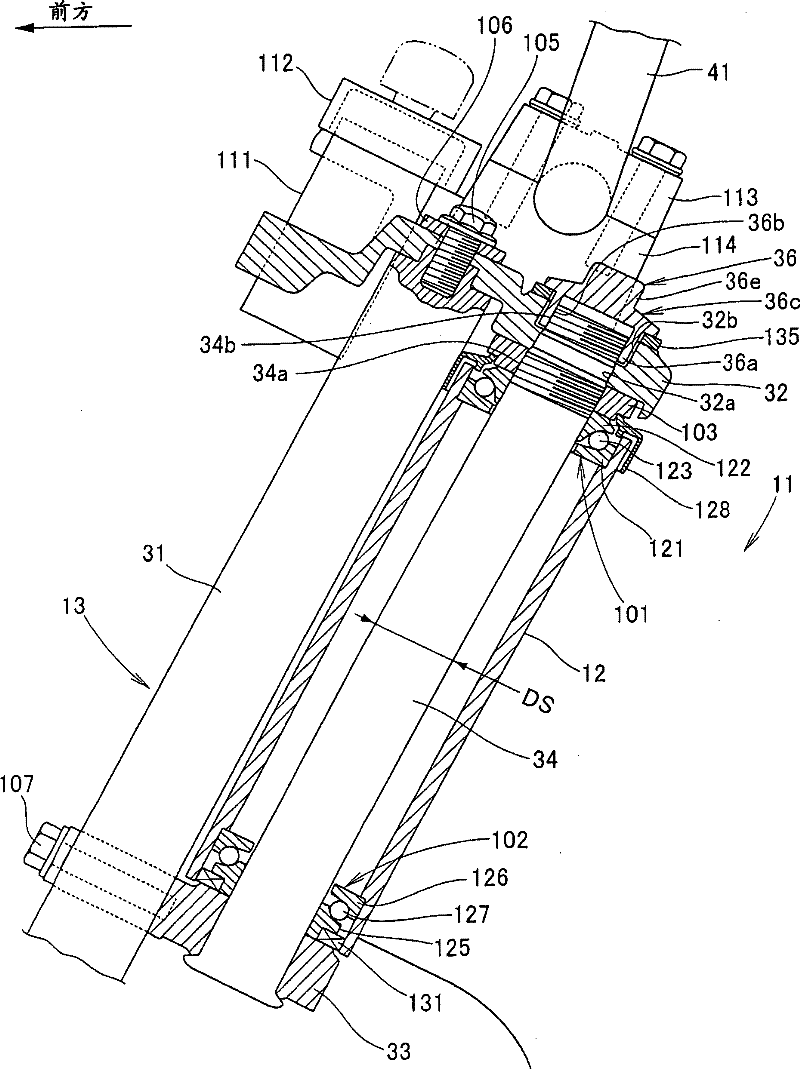

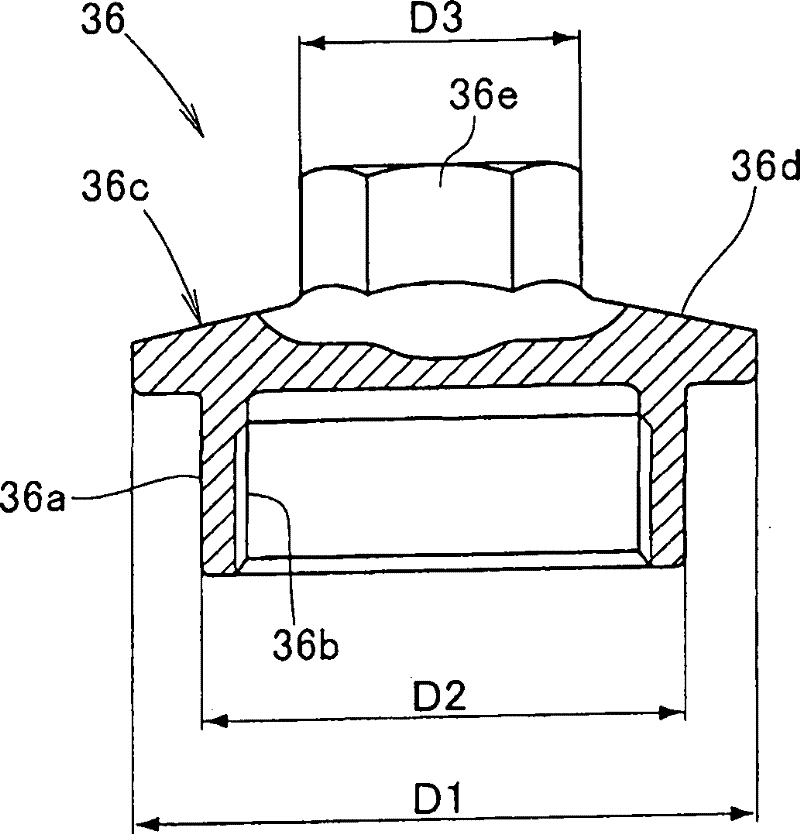

Fastening connection structure of vehicle steering rod

ActiveCN101301919AHigh degree of freedom of shapeIncrease freedomSteering deviceScrew threadControl theory

The invention provides a securing connection construct of direction operating rod of the vehicle which is able to increase the shape freedom degree, configuration freedom degree and other design freedom degree and the production freedom degree of the parts configured around the covered bridge. The direction operating rod (34) is mounted on the covered bridge (32) by a screw cap (36); the screw cap (36) comprises a cylinder part (36a) and a cover part (36c) integrally arranged on the end of the cylinder part (36a); inner periphery of the cylinder part (36a) is formed with a negative thread (36b) in screw connection with an external thread (34b) formed at the end of the direction operating rod (34); and a nut part (36e) is integrally formed on the cover part (36c).

Owner:HONDA MOTOR CO LTD

Lithium-ion secondary battery

InactiveCN104205468AHigh film forming rateImprove battery performanceNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumReduced size

Provided is a lithium-ion secondary battery in which stable battery performance is ensured and a high degree of freedom in shape can be effectively exhibited and which can be advantageously made to have an improved output density, improved bending strength, and reduced size. This battery can be produced in a short cycle time and at low cost by means of the simplest possible equipment. The battery has been configured so as to have a layered object (18) which comprises a positive-electrode layer (12) constituted of a first vapor-deposited polymer film layer (26) containing a positive active material (24), a negative-electrode layer (14) constituted of a second vapor-deposited polymer film layer (30) containing a negative active material (28), and a solid electrolyte layer (16) constituted of a third vapor-deposited polymer film layer (32) having lithium-ion conductivity, the layer (12) and the layer (14) having been superposed through the layer (16).

Owner:KOJIMA PRESS IND CO LTD

Molded article and method for producing same

InactiveCN110494474ACompatible with fatigue resistanceTaking into account the mechanical strengthElastomerPolyolefin

The present invention addresses the problem of providing: a molded article equipped with a repeatedly movable part having both of fatigue resistance and mechanical strength; and a method for producinga molded article, whereby it becomes possible to improve the flexibility of designing of a mold and the flexibility of the shape of the molded article and also it becomes possible to reduce the number of steps. The molded article is equipped with a repeatedly movable part 15 which can be bent or curved repeatedly, wherein the repeatedly movable part 15 is formed from a thermoplastic resin composition containing a polyolefin resin, a polyamide resin and a modified elastomer having a group reactive with the polyamide resin. The method is a method for producing a molded article equipped with a repeatedly movable part that can be bent or curved repeatedly, said method being characterized in that a thermoplastic resin composition containing a polyolefin resin, a polyamide resin and a modifiedelastomer having a group reactive with the polyamide resin is used as a molded material for the repeatedly movable part.

Owner:TOYOTA BOSHOKU KK

Fastening connection structure of vehicle steering rod

ActiveCN101301919BHigh degree of freedom of shapeIncrease freedomSteering deviceScrew threadControl theory

The invention provides a securing connection construct of direction operating rod of the vehicle which is able to increase the shape freedom degree, configuration freedom degree and other design freedom degree and the production freedom degree of the parts configured around the covered bridge. The direction operating rod (34) is mounted on the covered bridge (32) by a screw cap (36); the screw cap (36) comprises a cylinder part (36a) and a cover part (36c) integrally arranged on the end of the cylinder part (36a); inner periphery of the cylinder part (36a) is formed with a negative thread (36b) in screw connection with an external thread (34b) formed at the end of the direction operating rod (34); and a nut part (36e) is integrally formed on the cover part (36c).

Owner:HONDA MOTOR CO LTD

Polythiophene compound/carbon fiber cloth water decomposition oxygen production electrode and preparation method thereof

PendingCN113337833AHigh activityImprove stabilityEnergy inputElectrolytic organic material coatingFiberCarbon fibers

The invention relates to a polythiophene compound / carbon fiber cloth water decomposition oxygen production electrode and a preparation method thereof. In the preparation method, a thiophene monomer, lithium perchlorate and carbon fiber cloth are used as raw materials, and the polythiophene compound / carbon fiber cloth composite oxygen production electrode is obtained by an electrochemical deposition method. The method has the characteristics of being simple in manufacturing process, green, safe, low in cost and good in performance, and industrial production can be realized. The product has very wide application potential in the fields of electro-catalysis water decomposition, energy conversion, storage and the like.

Owner:TOYOTA JIDOSHA KK +1

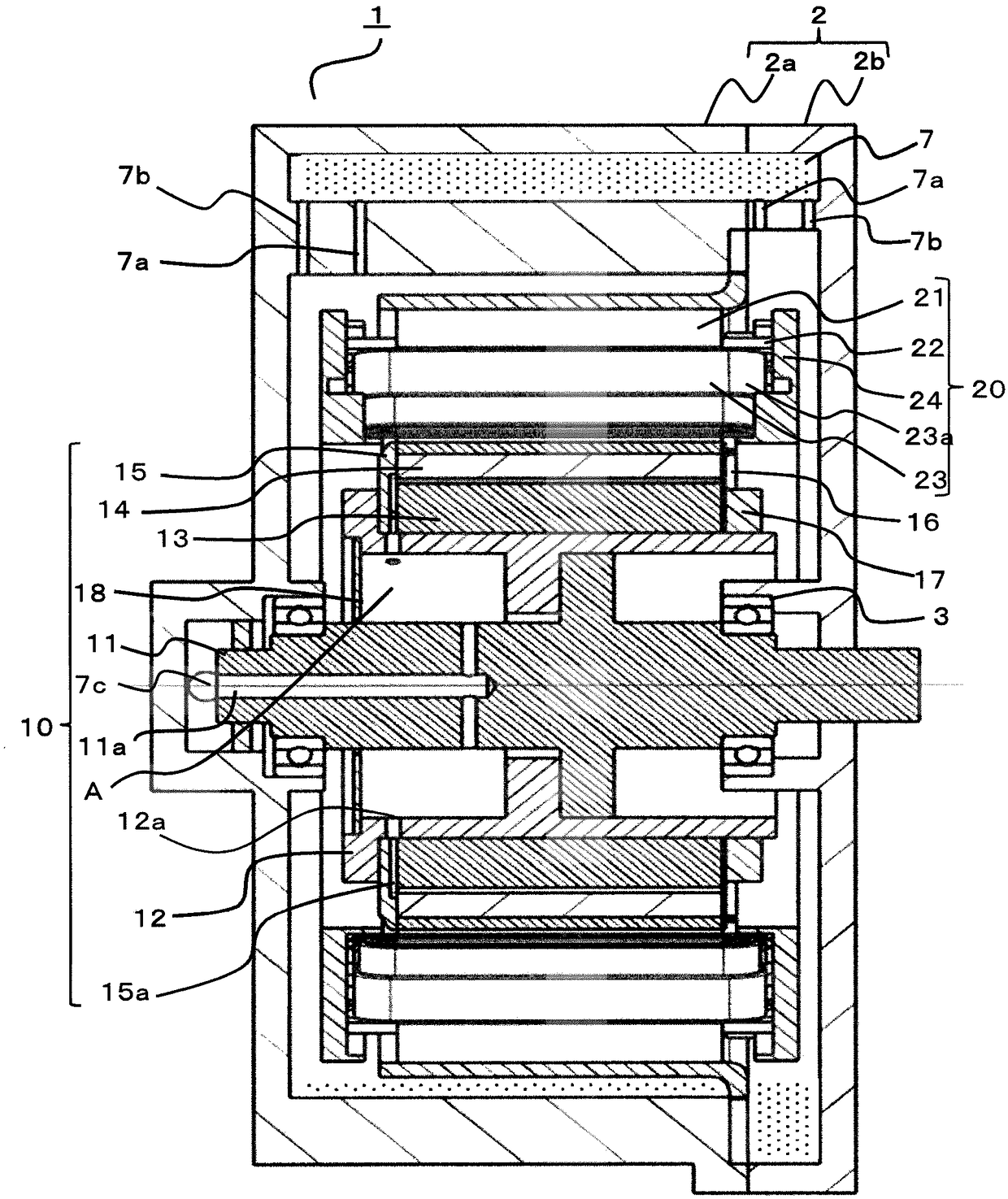

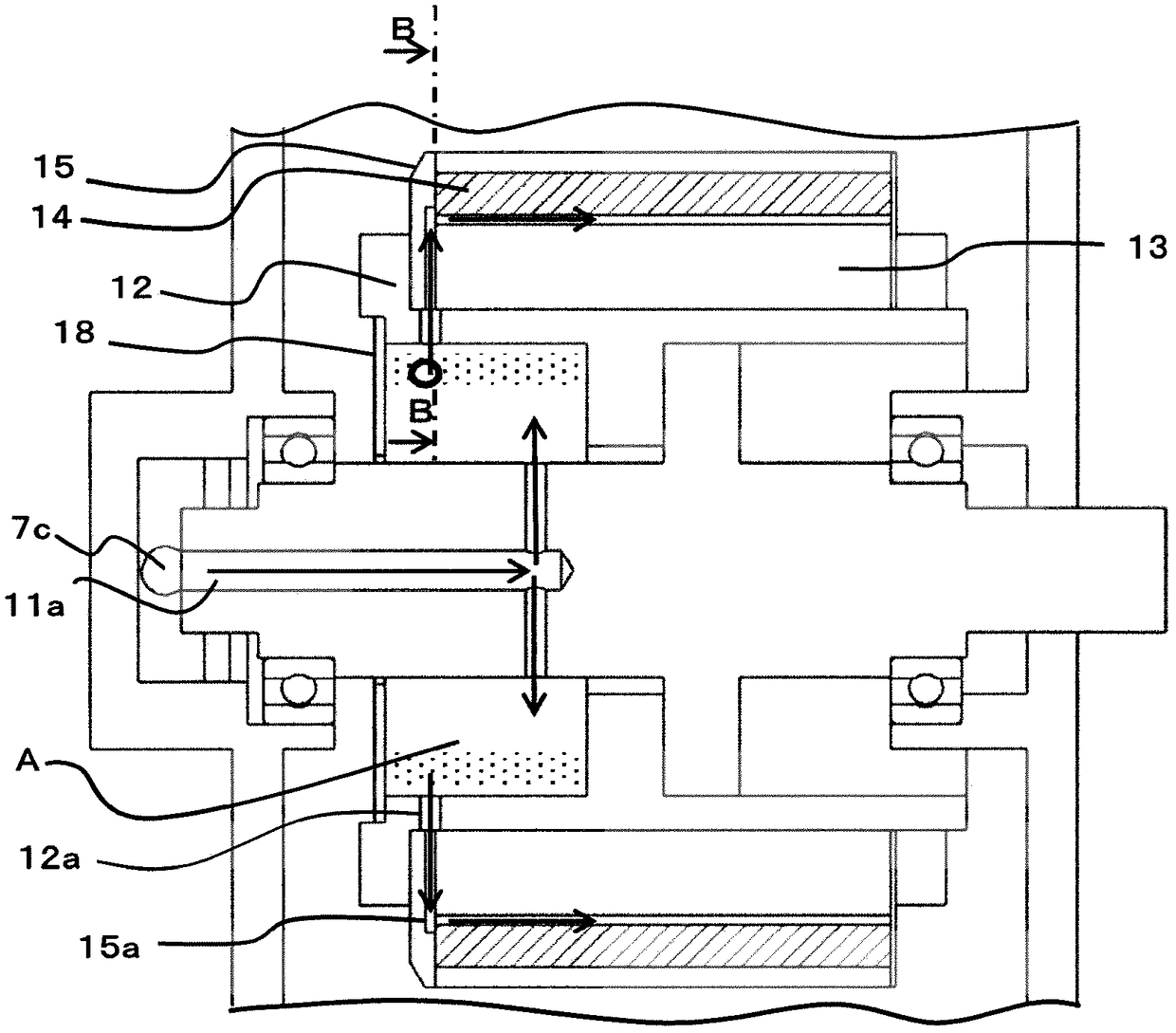

rotating electrical machine

ActiveCN107240985BShorten the length of the oil circuitEasy to processMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com