Decorative film structure and decorative member

A structure and decorative film technology, applied in decorative structures, special decorative structures, decorative arts, etc., can solve the problems of complex processes, high mirror surface, and uncoordinated environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

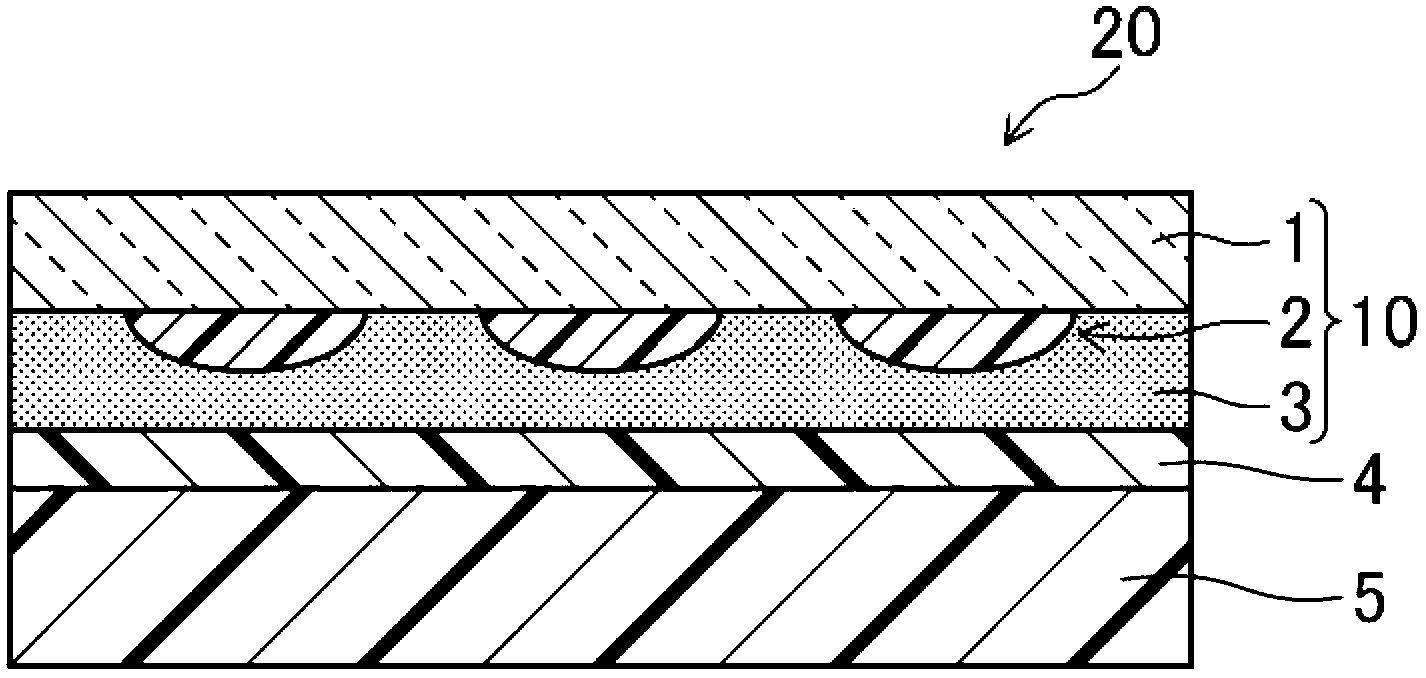

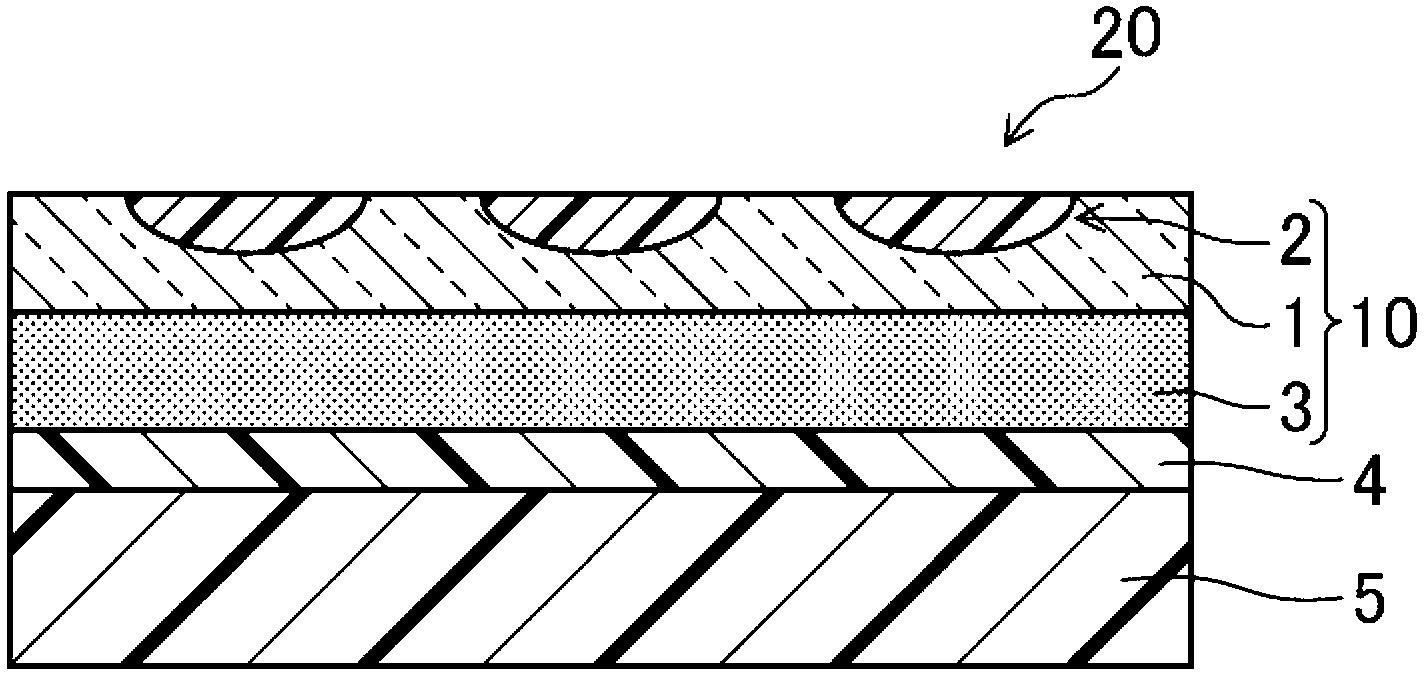

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

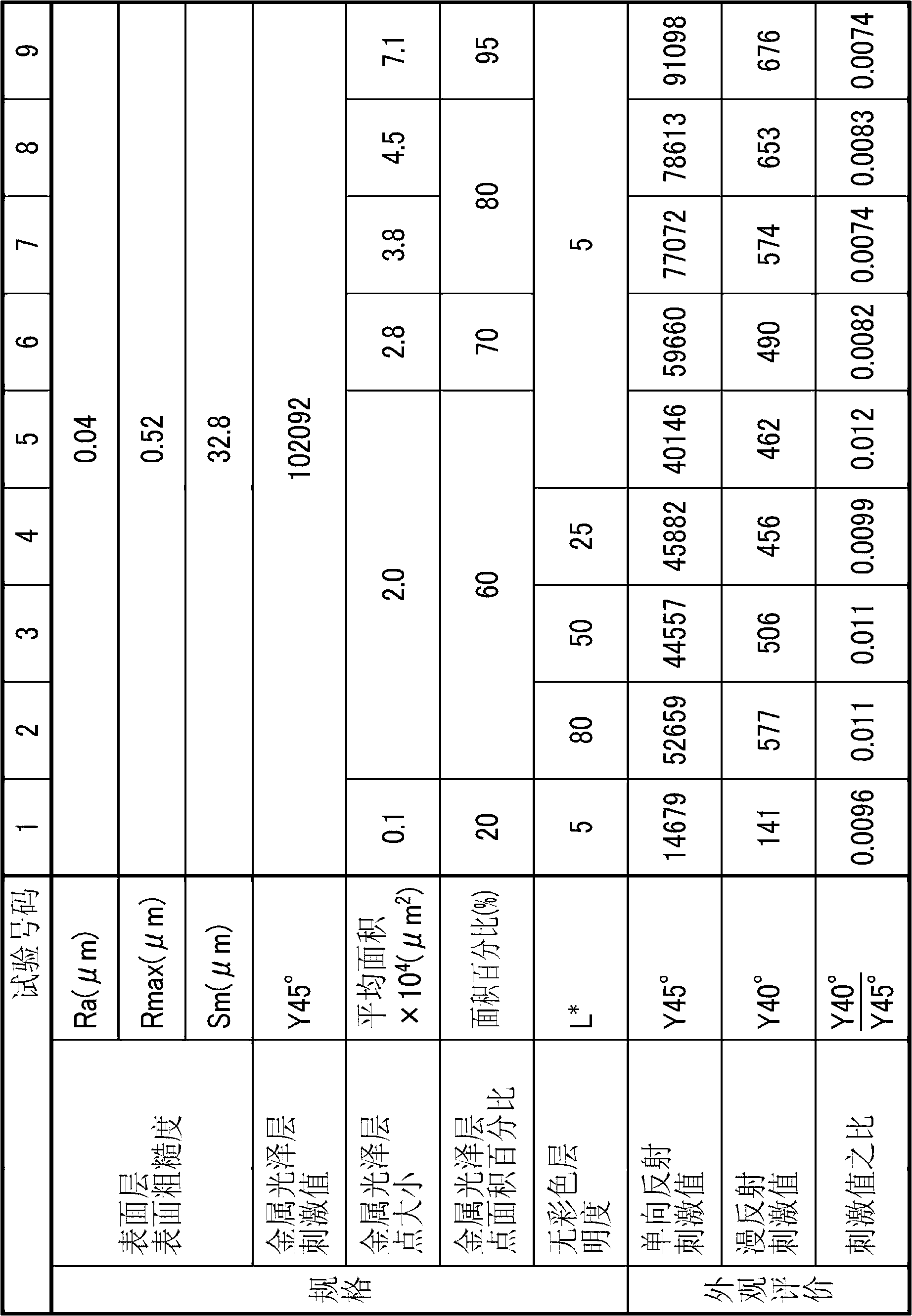

[0031] The inventors of the present application have conducted repeated development and research work with the aim of realizing a metal-polished surface-like appearance with a dull luminous texture without too much gloss using a decorative film structure composed of a plurality of laminated layers. As a result, the inventors of the present application focused their research on the fact that diffuse reflection, light absorption, and one-way reflection (specular reflection) of light incident on the decorative film structure are important factors in order to realize the metal-polished surface-like appearance. superior. The inventors of the present application have also found that diffuse reflection can be reproduced by adjusting the surface roughness of the surface layer of the decorative film structure, light absorption can be reproduced by using an achromatic l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com