Polythiophene compound/carbon fiber cloth water decomposition oxygen production electrode and preparation method thereof

A carbon fiber cloth and polythiophene technology, which is applied in the field of polythiophene compound/carbon fiber cloth for decomposing water for oxygen production and its preparation, can solve the problems of electrochemical stability obstacles of polymer electrodes, and achieves large-scale production and is easy to use. Control, high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the polythiophene compound / carbon fiber cloth splitting water and oxygen production electrode of the present invention comprises the following steps.

[0034] First, an acetonitrile solution was prepared by dissolving a thiophene-based monomer and lithium perchlorate as an electrolyte in acetonitrile. In an embodiment of the present invention, the thiophene monomer used is at least one selected from thiophene and thiophene whose position 3 is substituted by an alkyl chain with 1-6 carbon atoms. The concentration of lithium perchlorate in the acetonitrile solution is 0.1-0.2 mol / L, and the concentration of thiophene monomers is 0.005-0.01 mol / L.

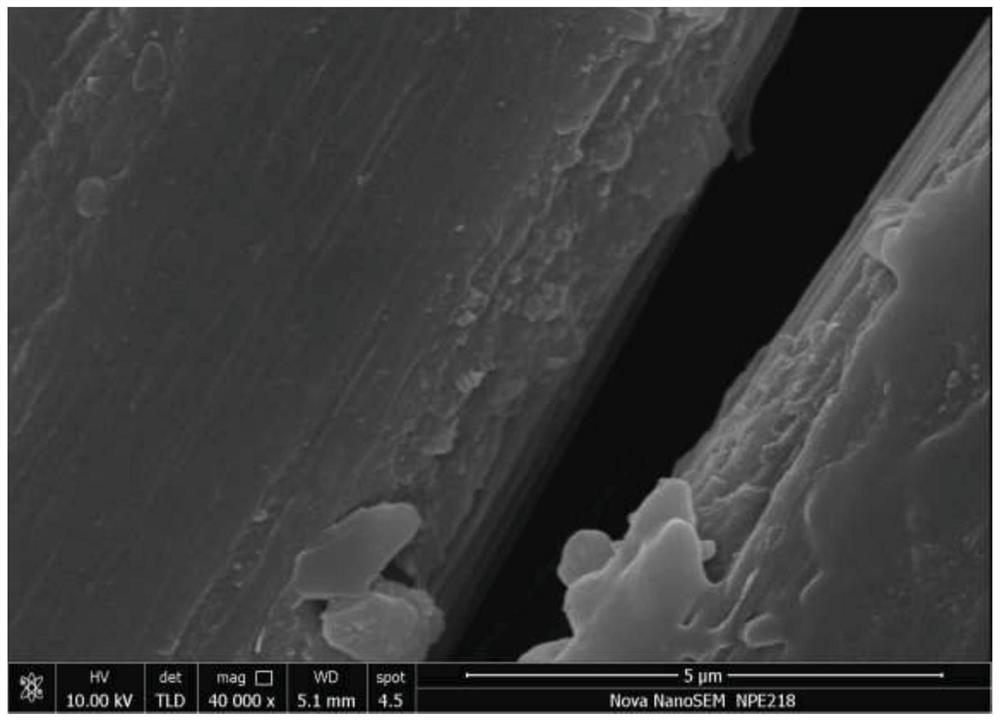

[0035] Ultrasonic treatment of carbon fiber cloth with nitric acid, dipping an appropriate area of carbon fiber cloth in the acetonitrile solution, using carbon fiber cloth as a working electrode, and using a constant voltage electrochemical deposition method to polymerize thiophene as a monomer on t...

Embodiment 1

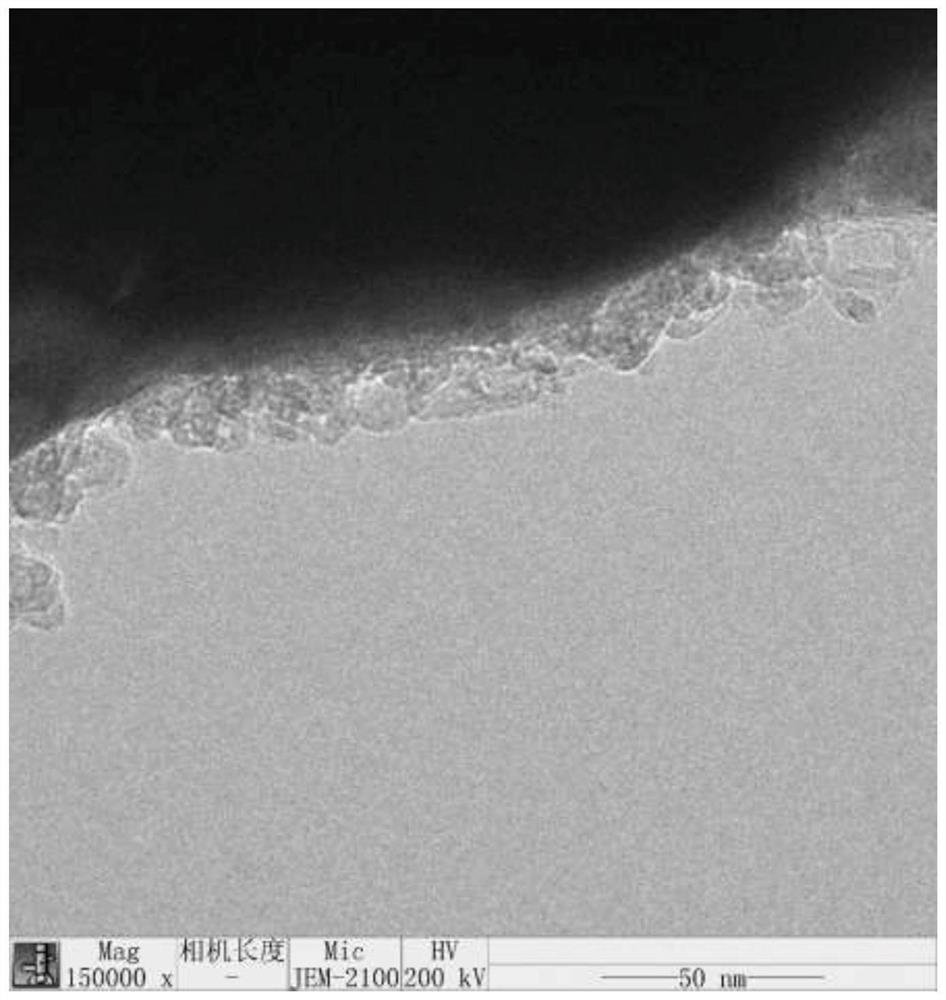

[0037] A 0.5cm×0.5cm carbon fiber cloth (as a practical example, the actual area is more clearly recorded.) was ultrasonically treated with 1mol / L nitric acid for 5 minutes, and then ultrasonically cleaned with ethanol and water for later use. In the acetonitrile solution containing 0.1mol / L lithium perchlorate and 0.005M thiophene monomer, carbon fiber cloth treated with nitric acid was used as the working electrode, titanium mesh and saturated calomel electrode were used as the counter electrode and reference electrode to form three electrodes System, under the applied voltage of 1.73V, conduct constant current deposition for 3 hours, so that thiophene monomers are polymerized on the carbon fiber cloth in situ to form a polythiophene film. After the electrodeposition process, the working electrode was taken out and soaked in pure water for 30 minutes to remove impurities, and then air-dried to obtain a polythiophene / carbon fiber cloth decomposing water oxygen production elect...

Embodiment 2

[0039] A 0.5cm×0.5cm carbon fiber cloth was ultrasonically treated with 1mol / L nitric acid for 5 minutes, and then ultrasonically cleaned with ethanol and water for later use. In the acetonitrile solution containing 0.1mol / L lithium perchlorate and 0.005mol / L thiophene monomer, the carbon fiber cloth treated with nitric acid was used as the working electrode, and the titanium mesh and saturated calomel electrode were used as the counter electrode and reference electrode. Three-electrode system, galvanostatic deposition at an applied voltage of 1.73 V for 0.5 h. After the electrodeposition process, the working electrode was taken out and soaked in pure water for 30 minutes to remove impurities, and then air-dried to obtain a polythiophene / carbon fiber cloth decomposing water oxygen production electrode. The thickness of the polythiophene film was 20nm. Under the voltage of 1.7V relative to the standard hydrogen electrode, the current density of the obtained polythiophene / carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com