Front Lamp for vehicle

A technology of headlights and vehicles, applied in the direction of vehicle lighting systems, headlights, vehicle components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below using the drawings.

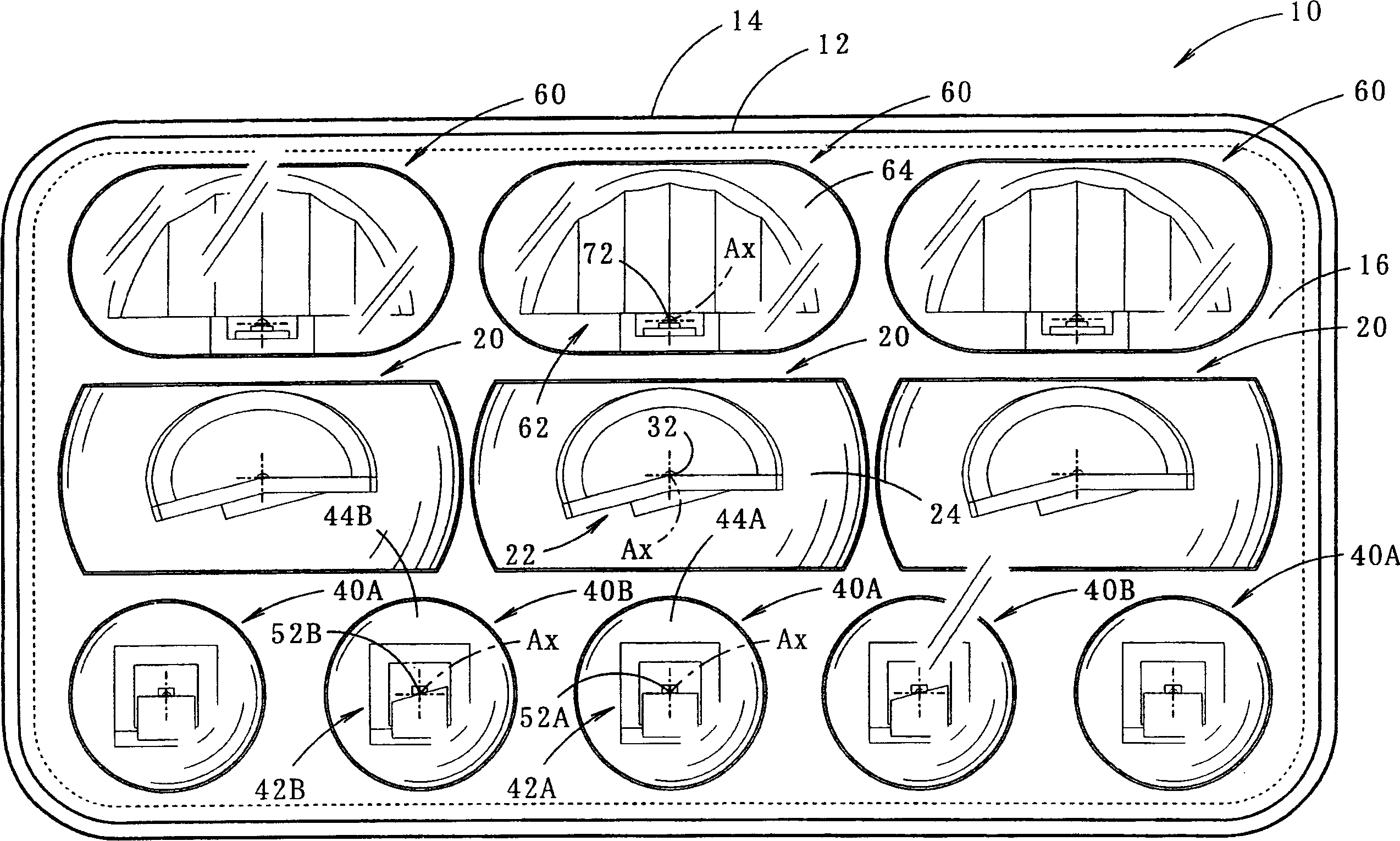

[0038] figure 1 It is a front view showing a vehicle headlamp 10 according to an embodiment of the present invention

[0039] This vehicle headlamp 10 is a headlamp for low beams. In an interior lamp formed by a transparent light-transmitting cover 12 and a lamp body 14, 11 lamp units 20, 40A, 40B, and 60 are covered in three stages above and below. containment.

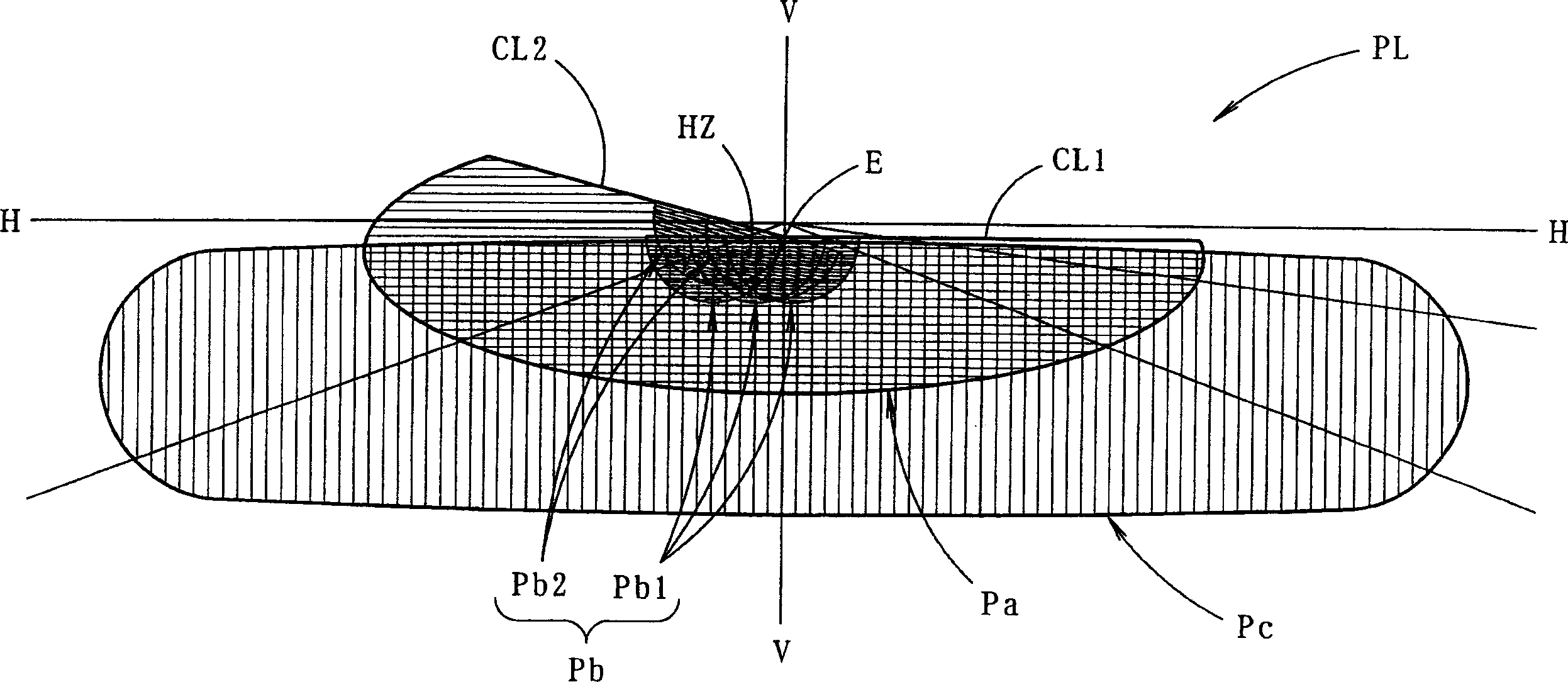

[0040] figure 2 It is a perspective view of a low beam illumination pattern PL formed on a virtual vertical screen arranged at a position 25 mm in front of the lamp by the illumination of the vehicle headlamp 10 described above.

[0041] The illumination pattern PL for low beam is a left illumination pattern having horizontal and inclined cutting lines CL1 and CL2 at the upper edge thereof. The position of the inflection point E, which is the focus of the two cutting lines, is set at about 0.5 to 0.6° below the vanishing po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com