Heat pipe shell manufacturing method

A manufacturing method and shell technology, which are used in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as breakage, deformation of heat pipe shells, and difficulty in controlling accuracy, and achieve high shape freedom and prevent deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

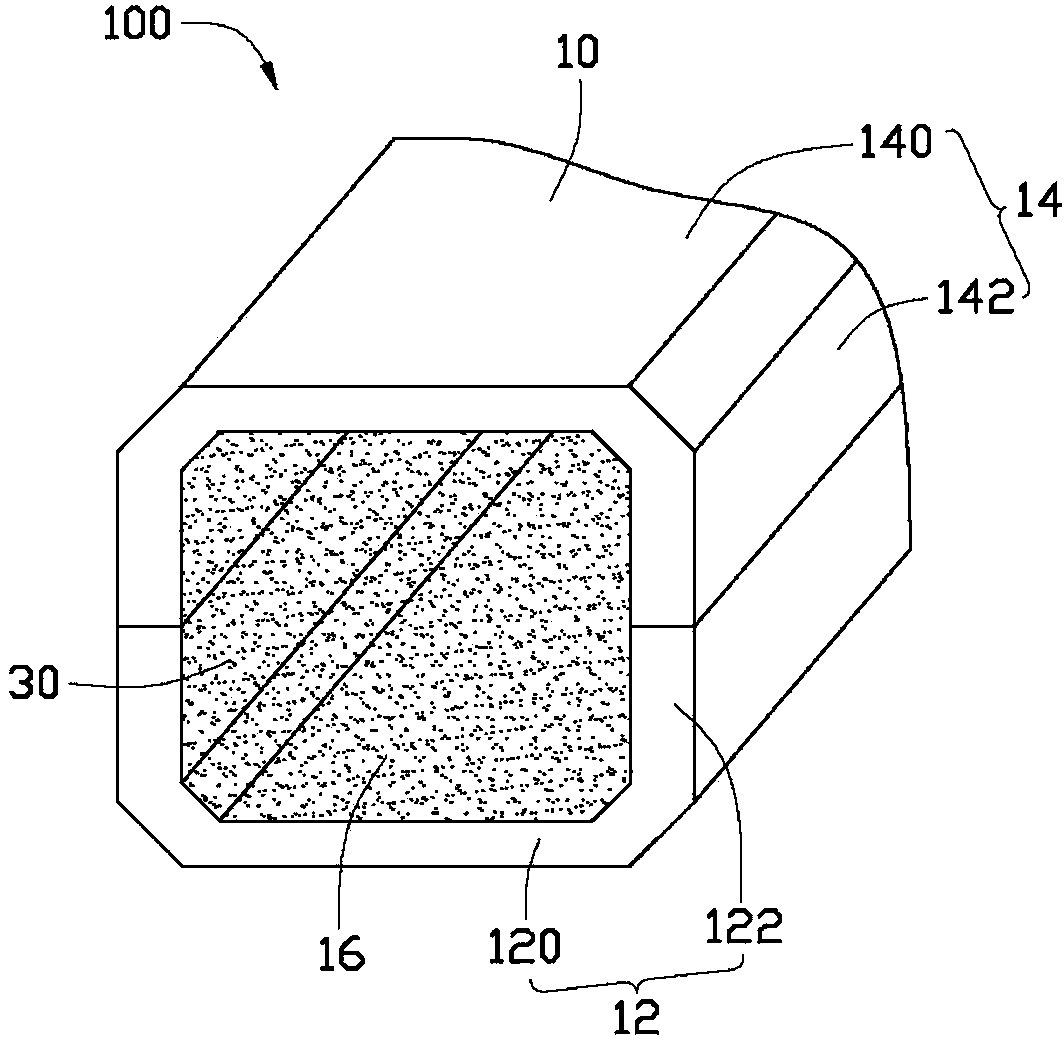

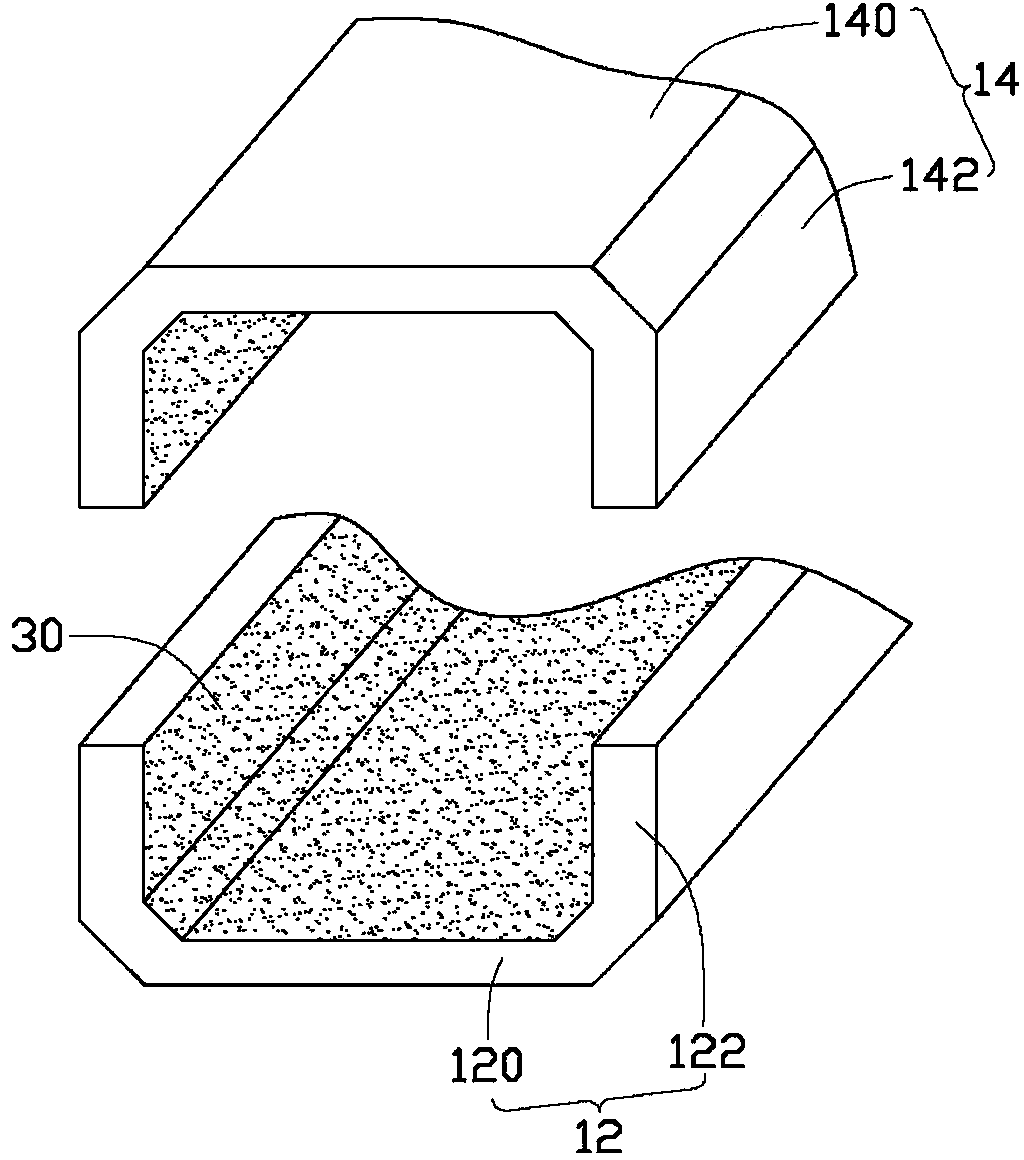

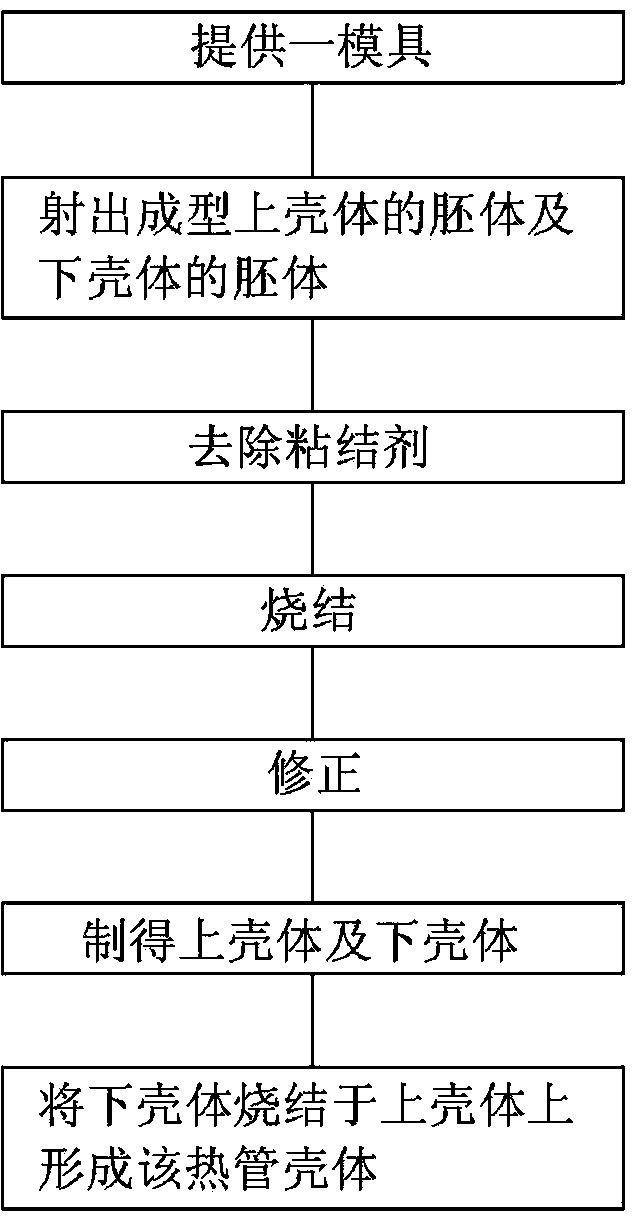

[0012] figure 1 It is a schematic axial cross-sectional view of an embodiment of the heat pipe of the present invention. The heat pipe 100 includes a housing 10 and a capillary structure 30 attached to the inner wall of the housing 10 .

[0013] Please also see figure 2 , the cross-section of the housing 10 is flat, and it can be made of metal materials with good thermal conductivity such as copper or aluminum. The housing 10 includes a lower housing 12 and an upper housing 14 disposed on the lower housing 12 . The lower casing 12 includes a bottom wall 120 and two side walls 122 extending upward from two opposite sides of the bottom wall 120 . The upper housing 14 includes a top wall 140 corresponding to the bottom wall 120 of the lower housing 12 and two side walls 142 extending downward from opposite sides of the top wall 140 . The two sidewalls 142 of the upper casing 14 are fixedly connected with the two sidewalls 122 of the lower casing 12 to form a receiving space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com