Method for preparing continuous-fiber partially-reinforced aluminum alloy parts

A technology of aluminum alloy parts and local reinforcement, applied in the field of preparation of aluminum alloy precision castings, can solve the problems of high cost, difficult to control the arrangement and distribution, difficult to prepare prefabricated parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

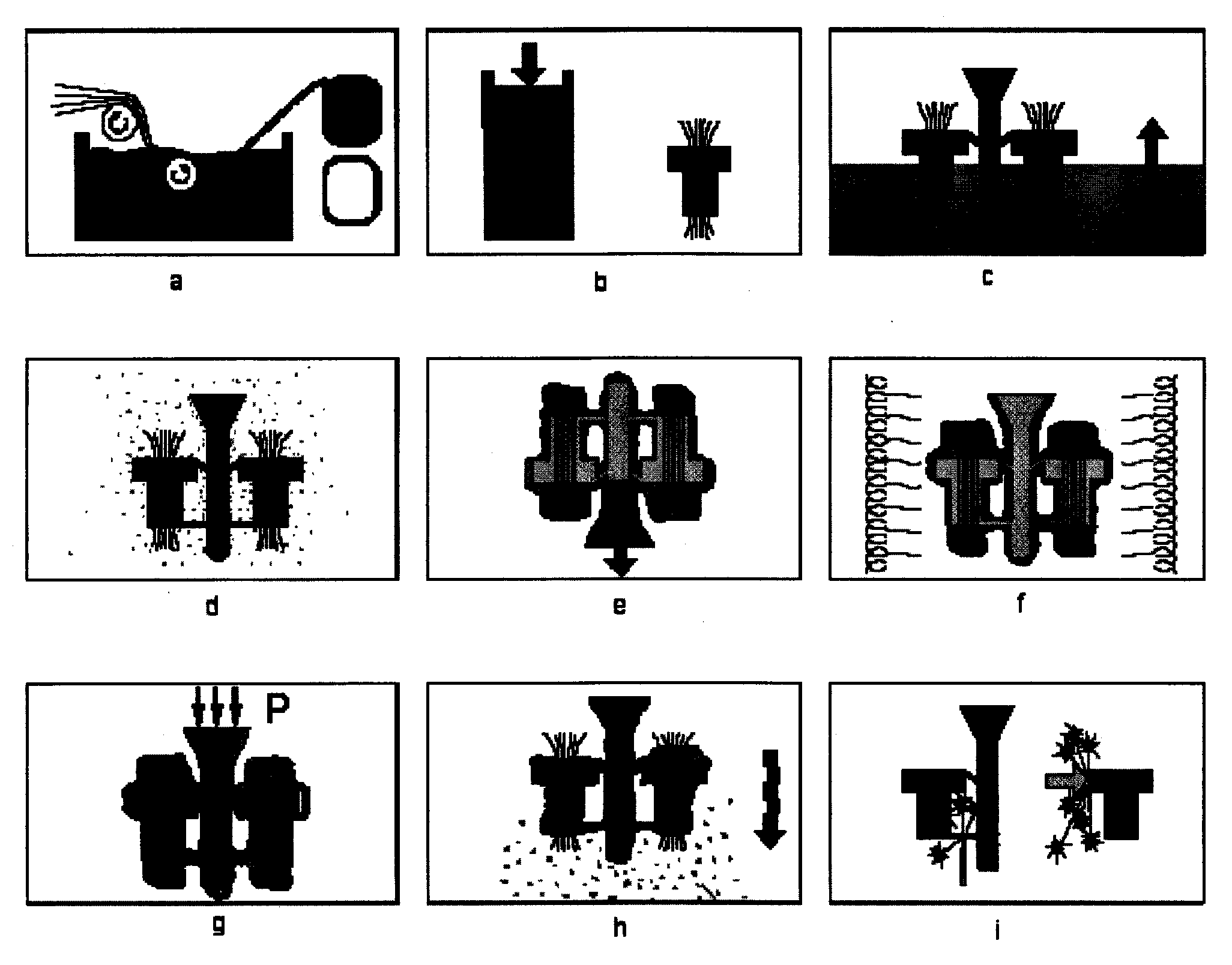

Method used

Image

Examples

Embodiment 1

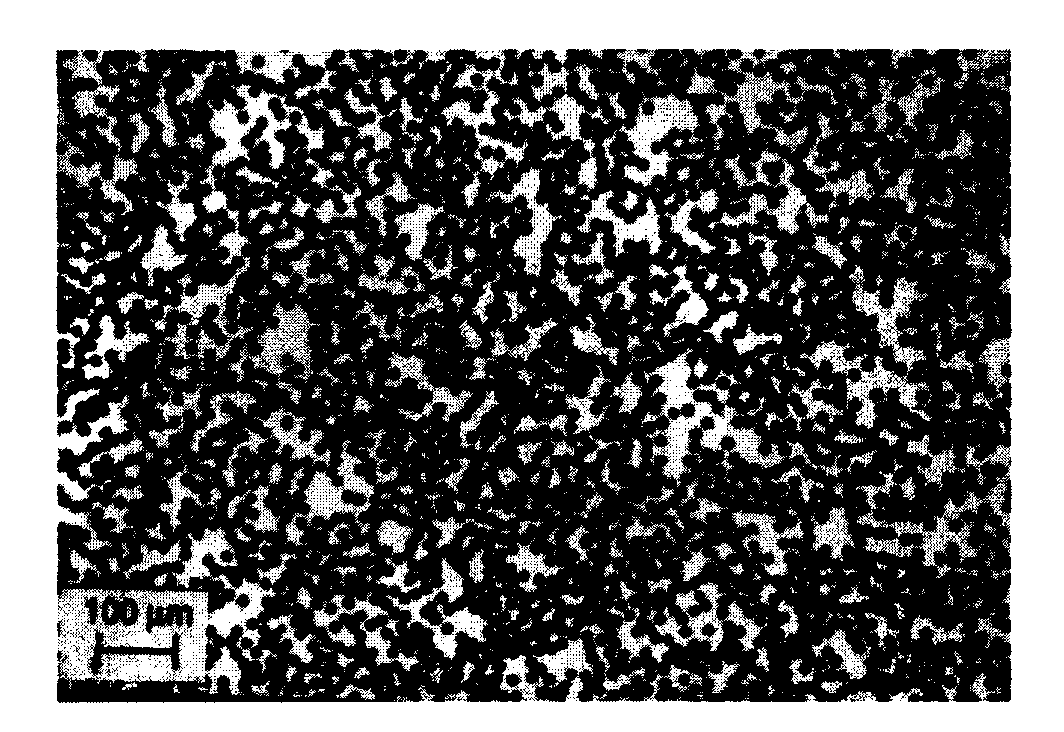

[0018] According to the process of the above invention, 50% volume fraction γ-Al is produced 2 O 3 Fiber (produced by Sumitomo Chemical Company, Japan, model Altex SN, fiber diameter 15μm, tensile strength 1.8GPa) reinforced aluminum alloy (Al-6%Zn-1%Mg-0.1%Cu) test bar, test block and continuous fiber Partially reinforced aluminum alloy test block. figure 2 a is the blank photos of these three samples, figure 2 b is the processed sample. The test bars and small test blocks are integrally reinforced by continuous fibers for performance testing. The large test block is locally reinforced by continuous fibers, the middle of the test block is a reinforced area, and both sides are non-reinforced areas. The use of the test block can verify the process feasibility of the present invention and measure the macroscopic internal stress in the reinforced area and the non-reinforced area. The measured tensile strength and elastic modulus of the 50% fiber reinforced aluminum alloy composi...

Embodiment 2

[0020] The fiber locally reinforced aluminum alloy sports bicycle crank connecting rod produced by the invention replaces the original high-strength forged steel parts, and the weight can be reduced by about 69%. The middle part of the connecting rod adopts 45% volume percentage γ-Al 2 O 3 The fiber (produced by Sumitomo Chemical Company, Japan, model Altex SN, fiber diameter 15μm, tensile strength 1.8GPa) is locally reinforced, and the matrix material is cast aluminum silicon alloy. The ceramic slurry adopts zircon powder refractory material and silica sol binder, the surface layer (two layers) is made of zircon powder (particle size 0.25mm), and the reinforcement layer is mollite powder (particle size 0.8-1.4mm) , The mold shell has 8 layers and the thickness is about 20mm. Dewaxing is carried out in a steam kettle with a pressure of 0.6 MPa and a pressure holding time of 90 seconds. The mold shell is fired in an electric furnace, and the firing temperature is 850°C. Since ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com