Method for modifying the flanks of a tooth of a gear wheel with the aid of a tool

A technology for dressing wheels and gear teeth, applied in the direction of gear tooth manufacturing devices, manufacturing tools, components with teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

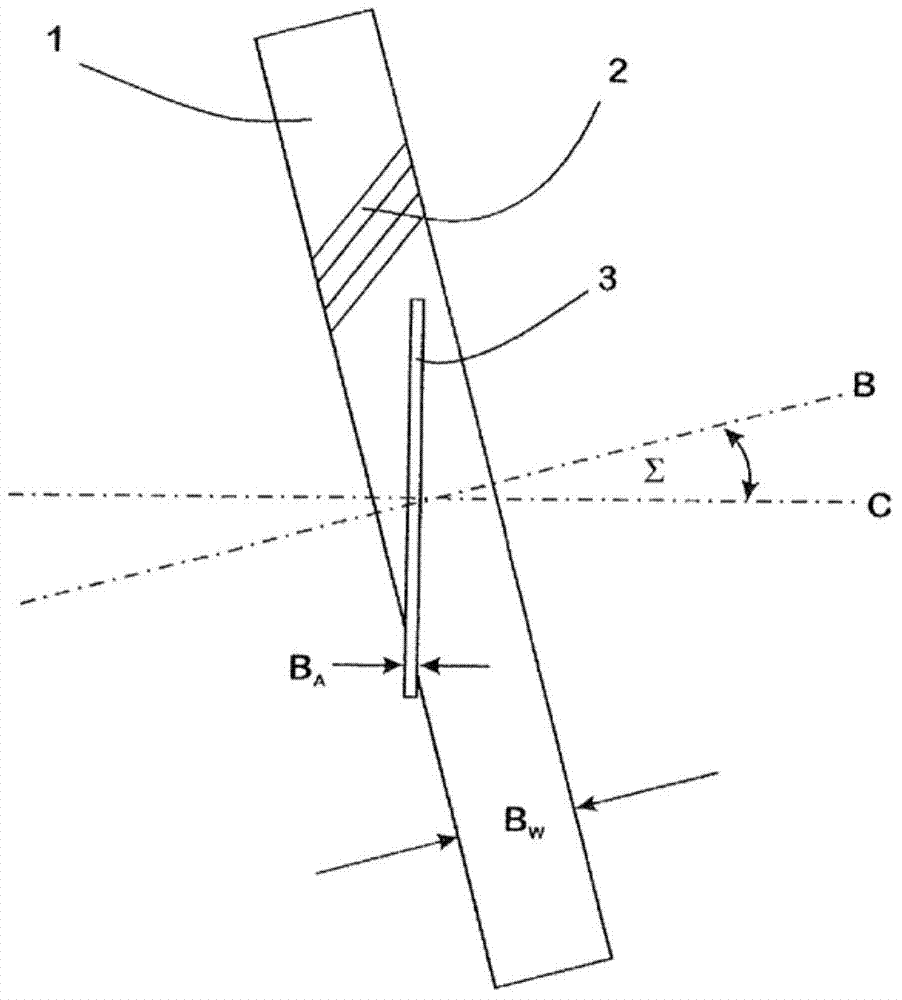

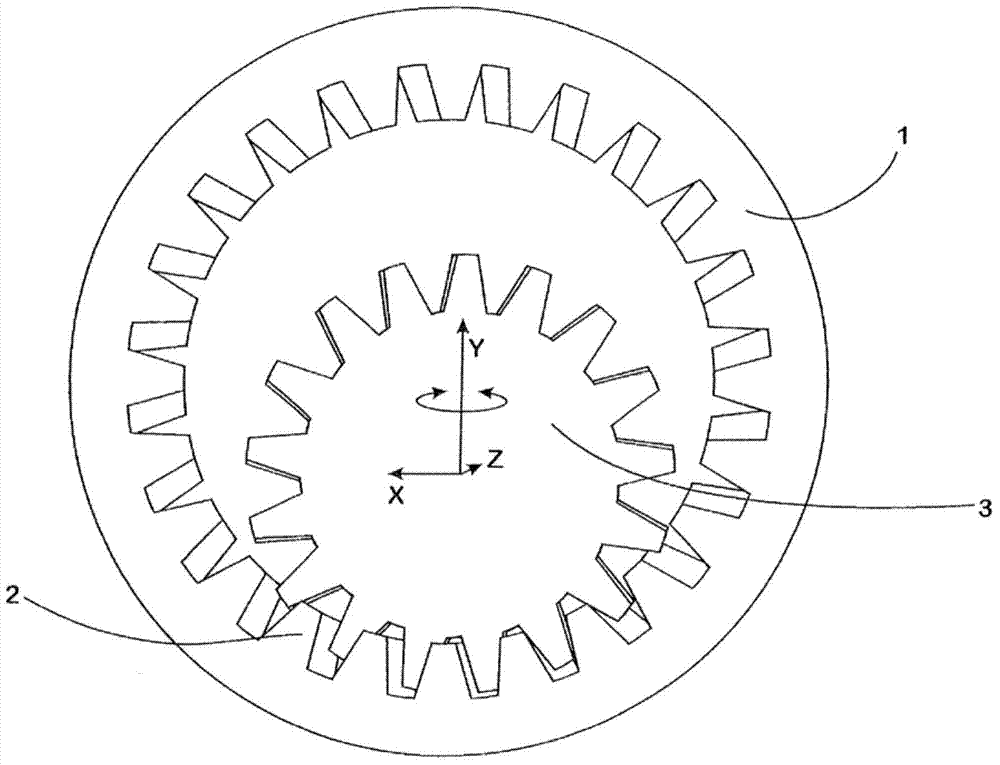

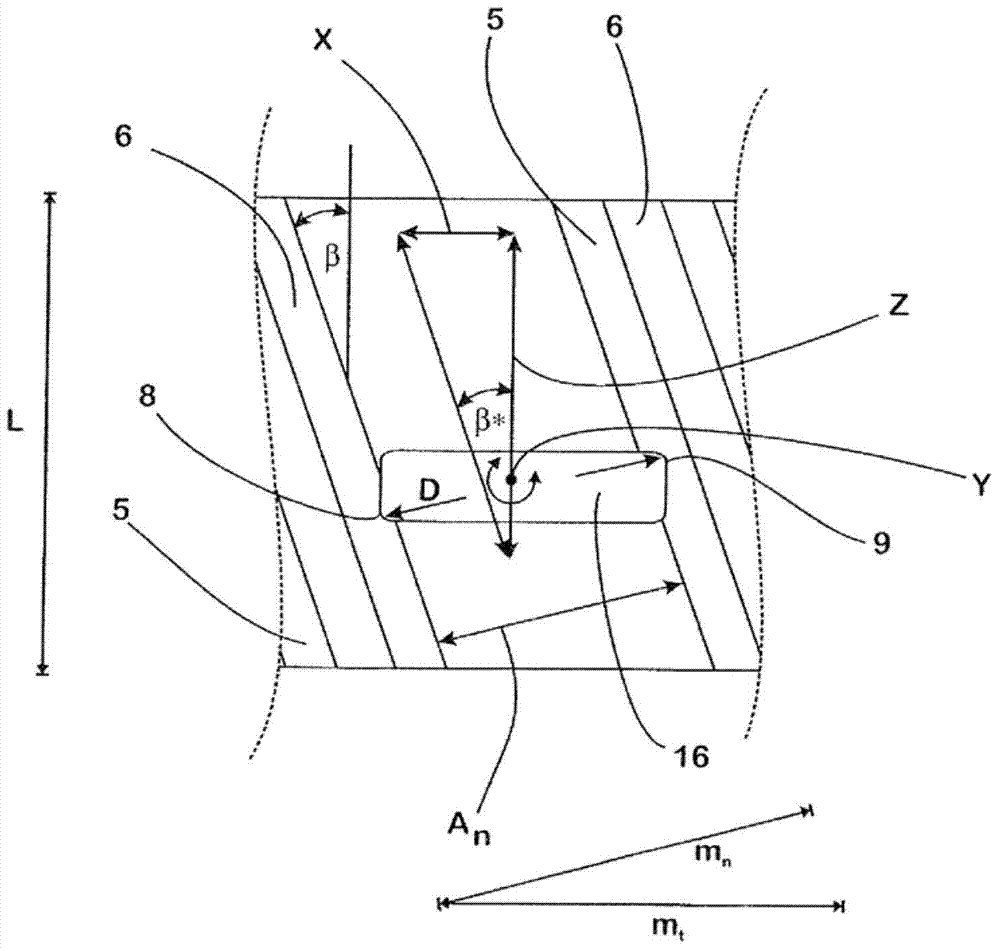

[0032] exist figure 1 The tool 1 shown in is used for honing the toothing of a gear Z with external helical toothing. For this purpose, the tool is of annular construction and has internally beveled toothing 2 .

[0033] A dressing wheel 3 is provided for dressing the tool 1 .

[0034] Width B of dressing wheel 3 A Usually less than the width B of the tool 1 to be trimmed W one-eighth of. so that the dressing wheel 3 in order to run over the width B of the tool 1 W Then it must be correspondingly larger than the width B of the dressing wheel 3 A Eight times the length L, while moving in the direction of its rotation axis C (moving axis Z or Z direction).

[0035] In the figures, neither the spatial arrangement nor the width ratio are shown in a proportionally correct manner.

[0036] In order to adjust the dressing wheel relative to the tool 1 to be dressed in the Z direction and perpendicular thereto in the X direction (movement axis X), an individually controllable ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com