Numerical control three-tip carpenter's drill tapping machine

A technology of opening machine and drill bit, which is applied in drilling tool accessories, metal processing equipment, drilling/drilling equipment, etc. It can solve the problems of grinding wheel breakage, large error, poor precision, etc., and achieve the effect of completely consistent trimming shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

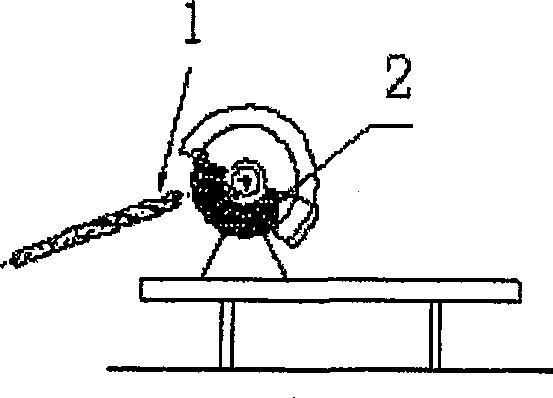

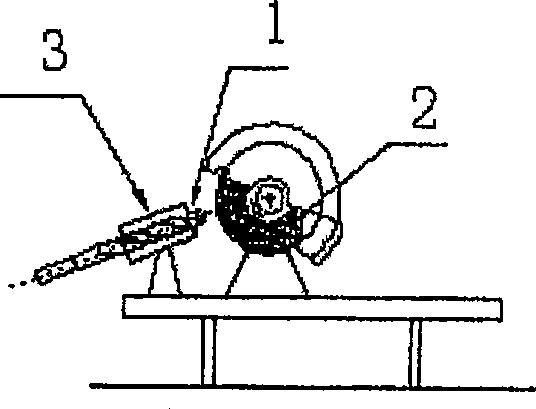

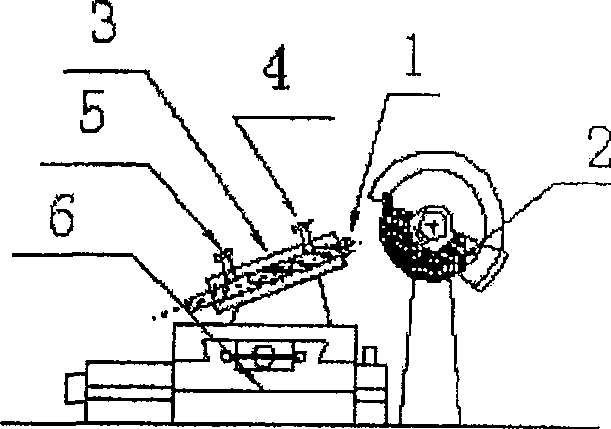

[0024] A numerically controlled drill opening machine according to the present invention includes a frame 11 , a grinding wheel 12 , a clamping device 13 , a feeding device 14 , a controller 15 and a grinding wheel shape trimming device 16 . The emery wheel 12 and the feeding device 14 are all installed on the frame 11, and the frame 11 is provided with a control switch 17; Clamping device 13 is arranged on the feeding device 14, and clamping device 13 comprises collet 131, indexing head 132 and clamping cylinder 133, is used for the collet 131 of fixing drill bit and is used for the indexing head 132 of controlling drill bit angle All are connected with clamping cylinder 133. The feed device 14 is connected with the feed motor 141 and can be close to or away from the emery wheel 12; in order to ensure the accuracy of the drill bit feed, the feed motor is a precision subdivision stepping motor. The grinding wheel shape dressing device 16 is used for dressing the worn grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com