Patents

Literature

206results about How to "Improve stamping quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

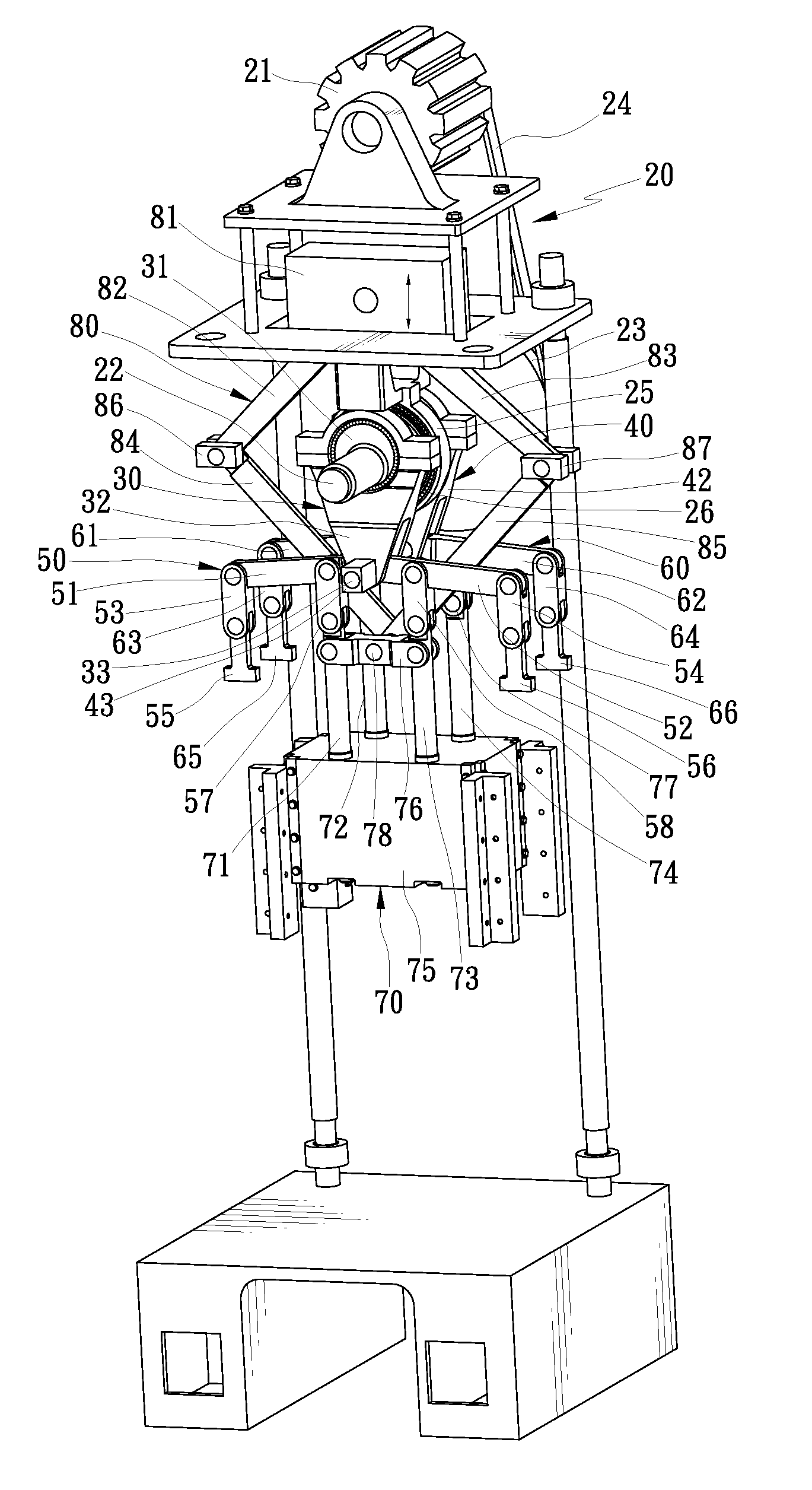

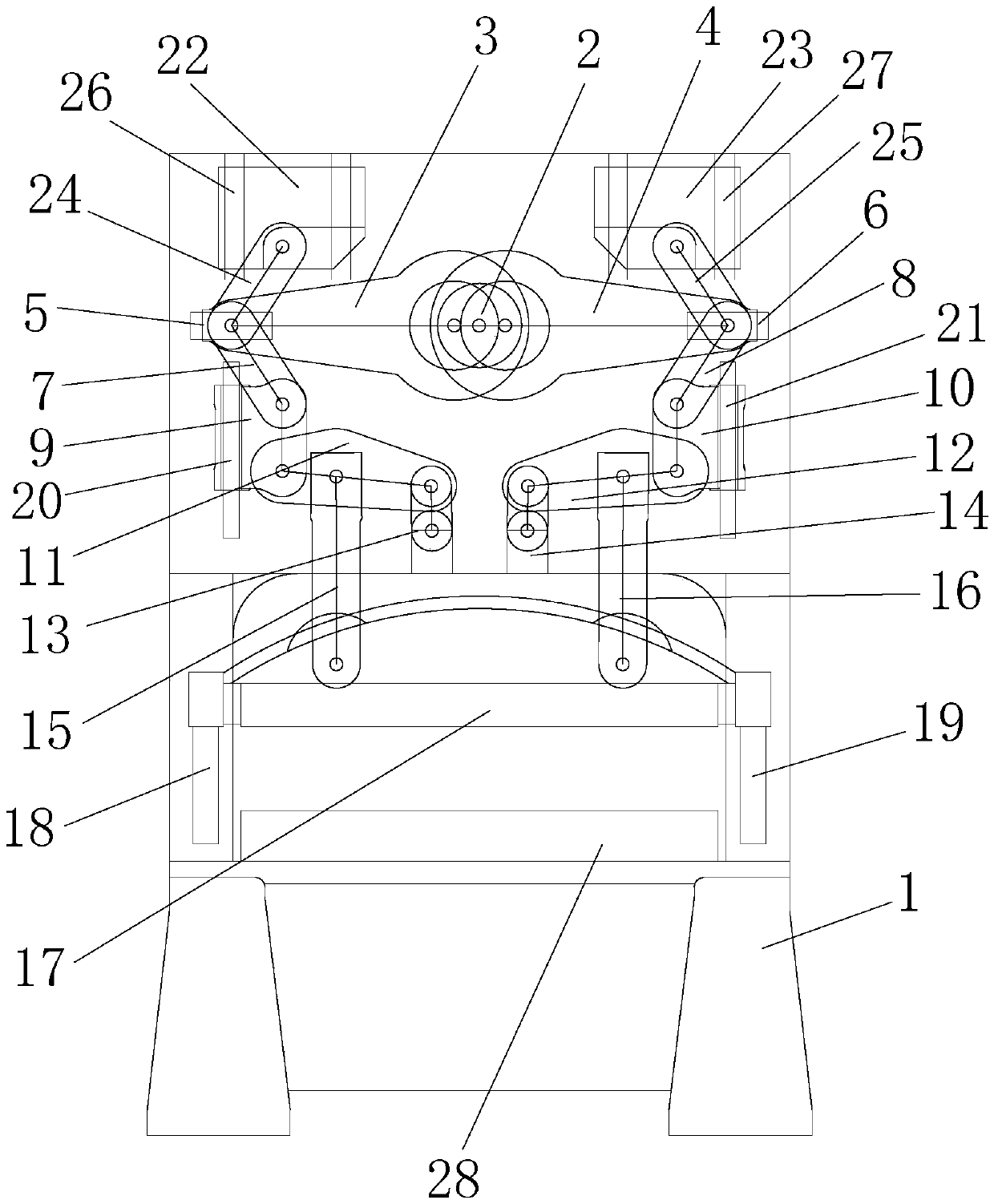

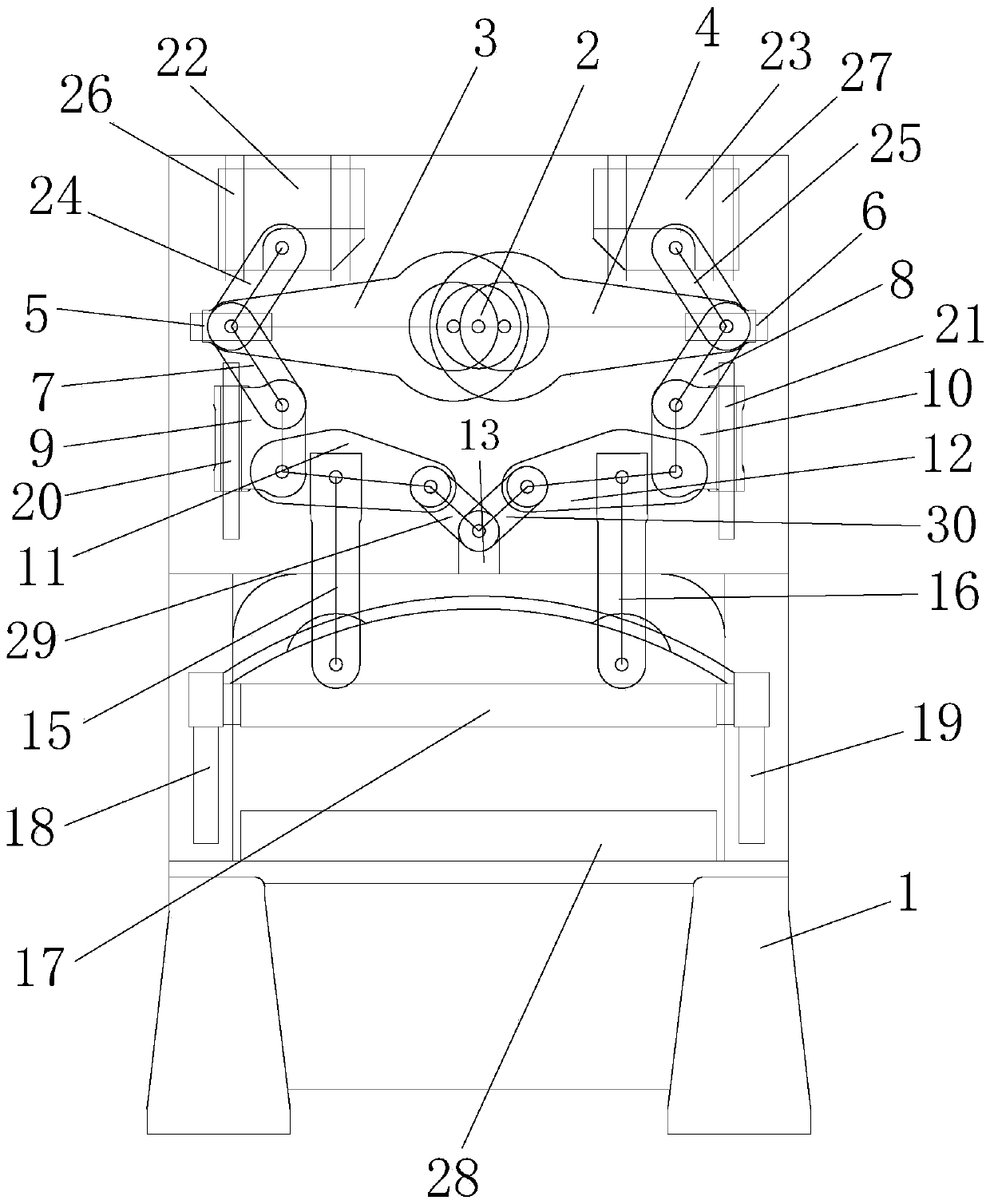

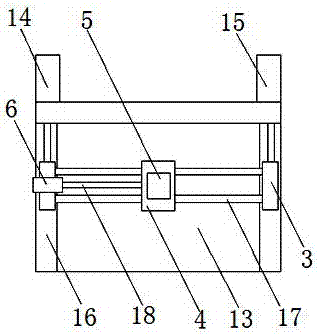

Multi-linkage press

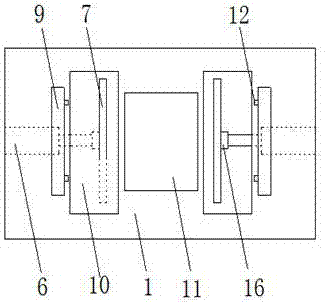

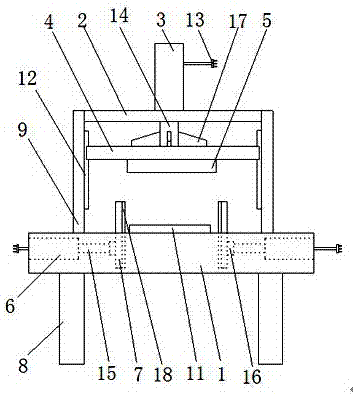

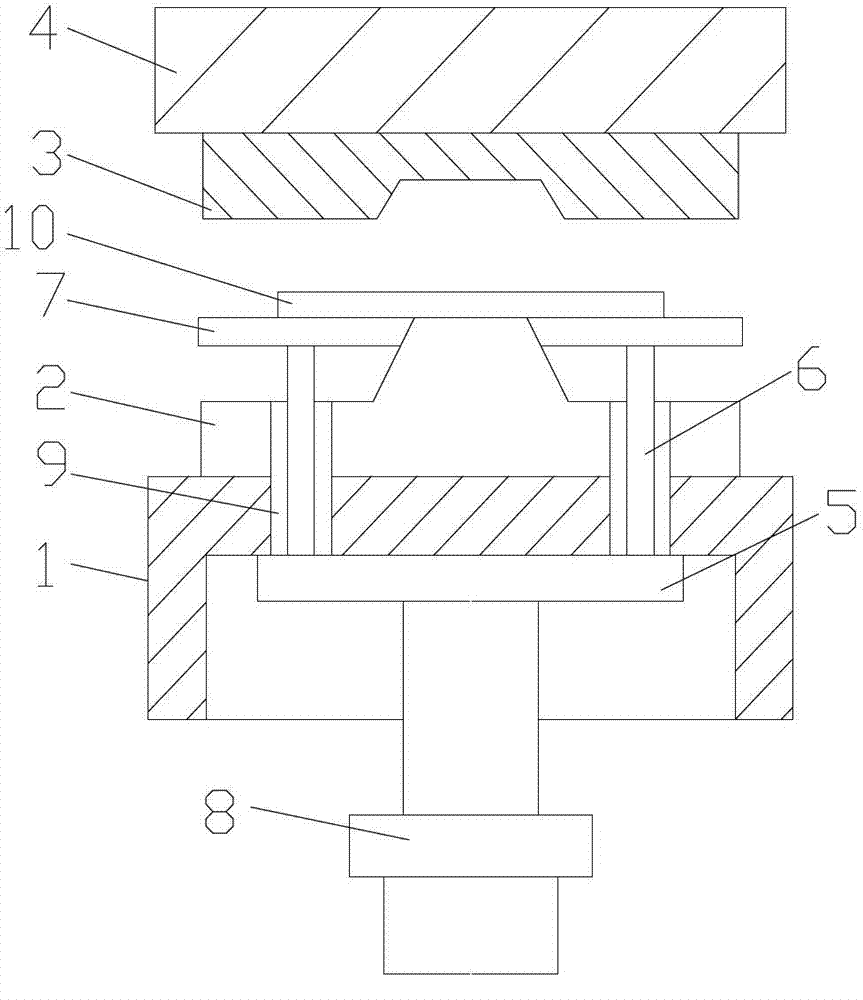

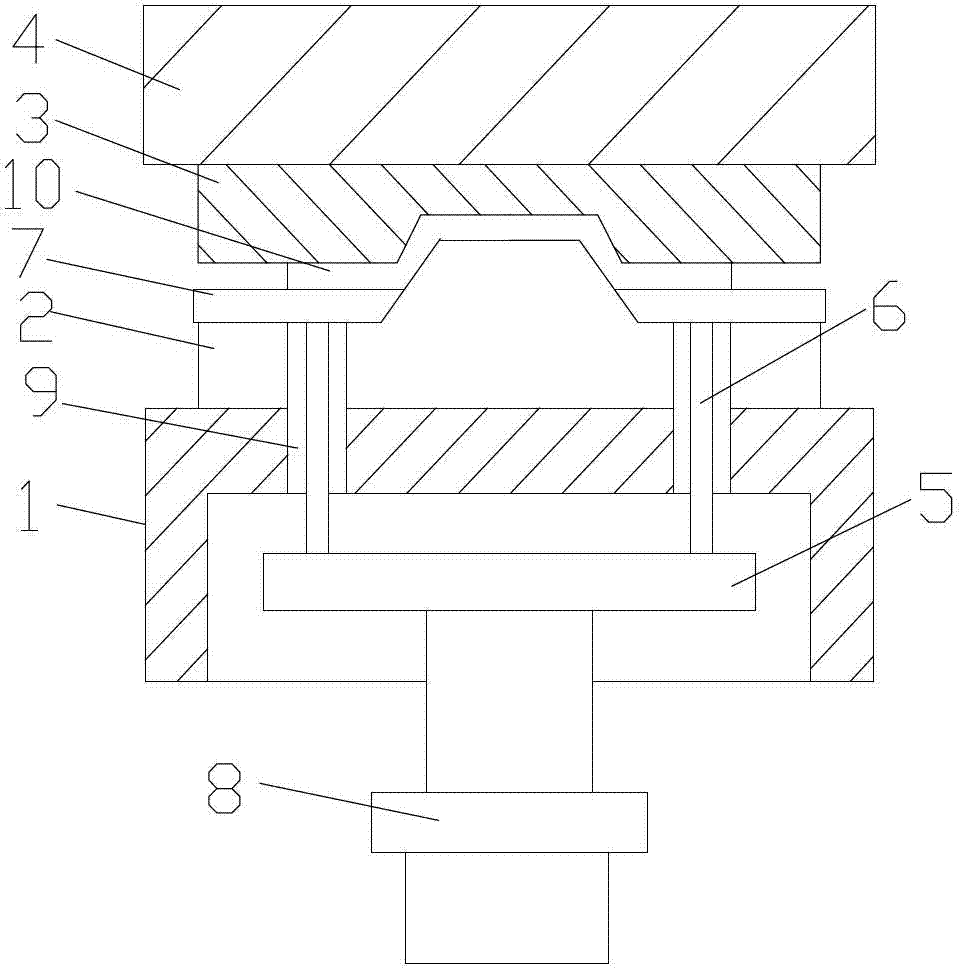

A multi-linkage press contains a power transmission mechanism includes a rotary shaft driven by a power source; at least two eccentric wheel mechanisms including at least two eccentric wheels, each of the eccentric wheels including a crank sliding set to drive a first sliding block connected with a connecting rod; at least two multi-link mechanisms axially connected on the connecting rod and axially connected with two leveraged linkage assemblies; a sliding assembly including a slidable body with at least four longitudinal plungers, the four longitudinal plungers being axially connected with the two leveraged linkage assemblies to drive a slidable body to operate vertically, and between two of the four longitudinal plungers being connected a first connecting pillar, between another two of the four longitudinal plungers being connected a second connecting pillar, between the first connecting pillar and the second connecting pillar being coupled an axial shank.

Owner:METAL INDS RES & DEV CENT

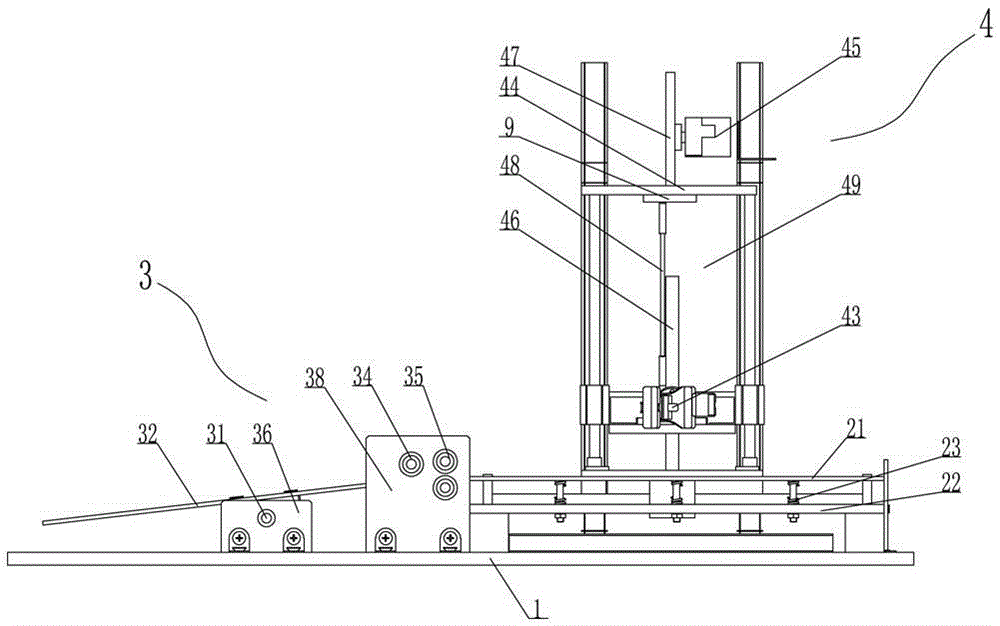

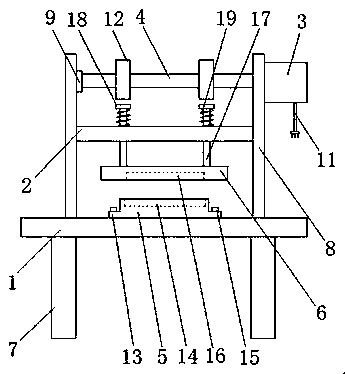

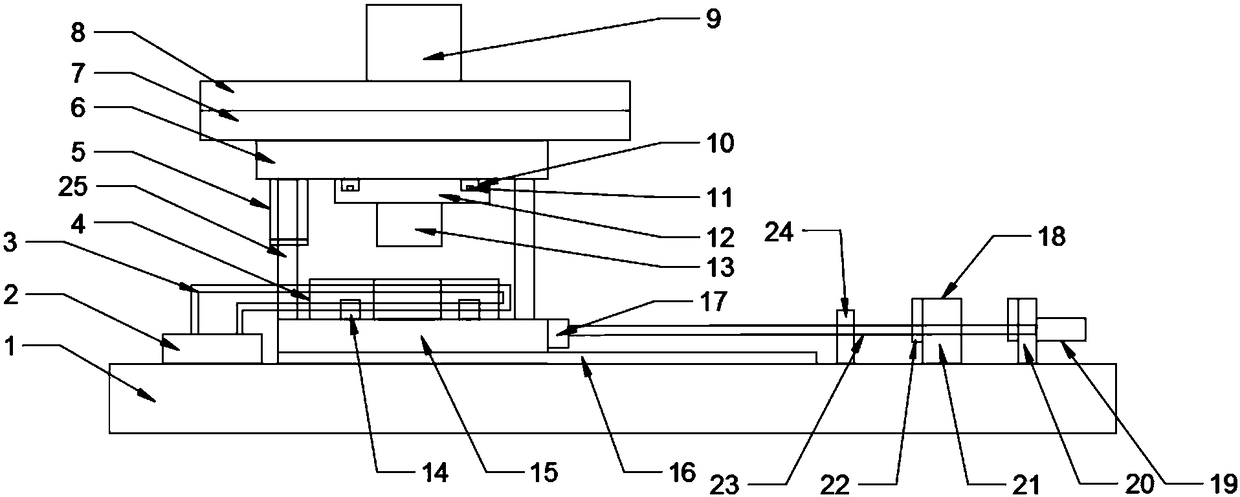

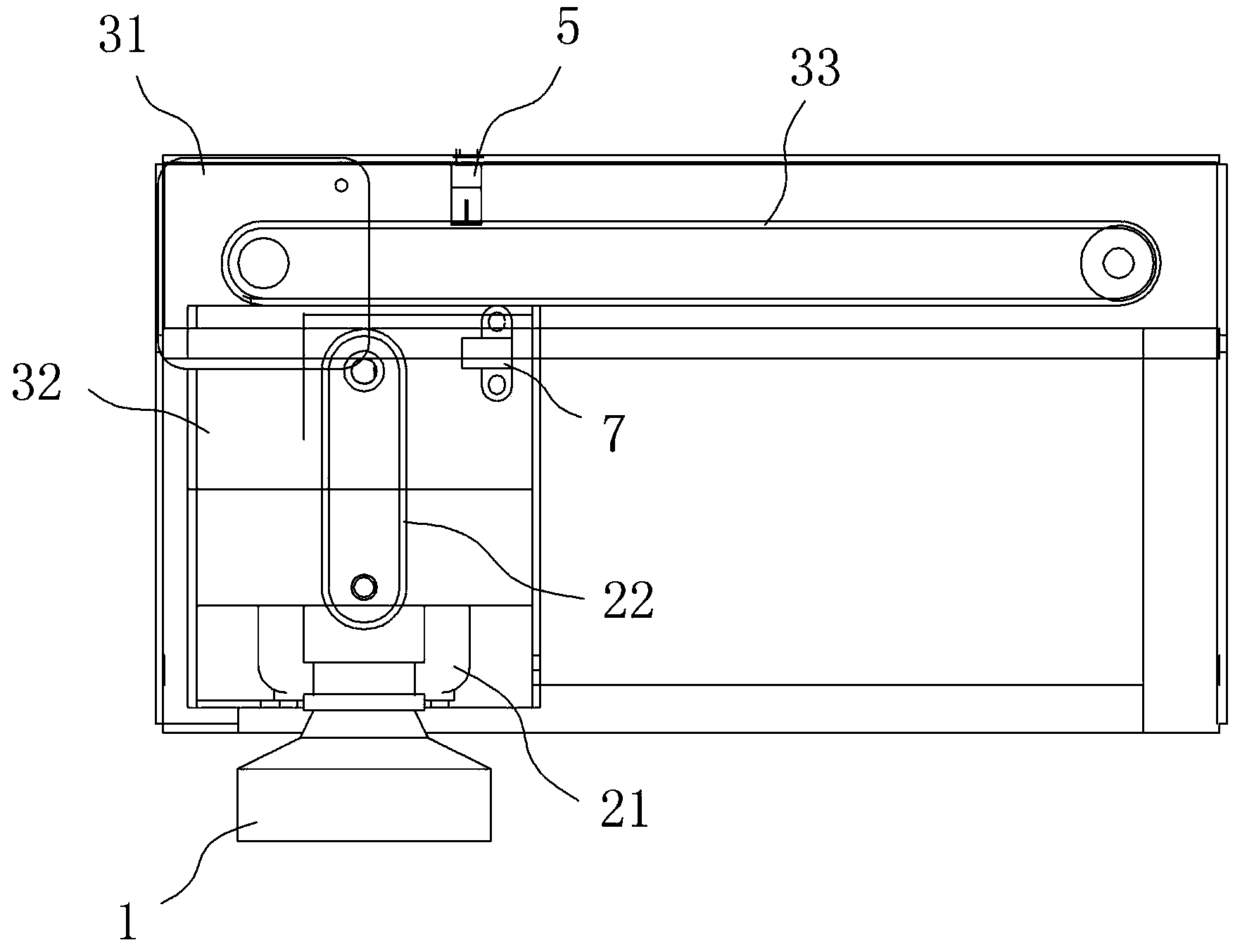

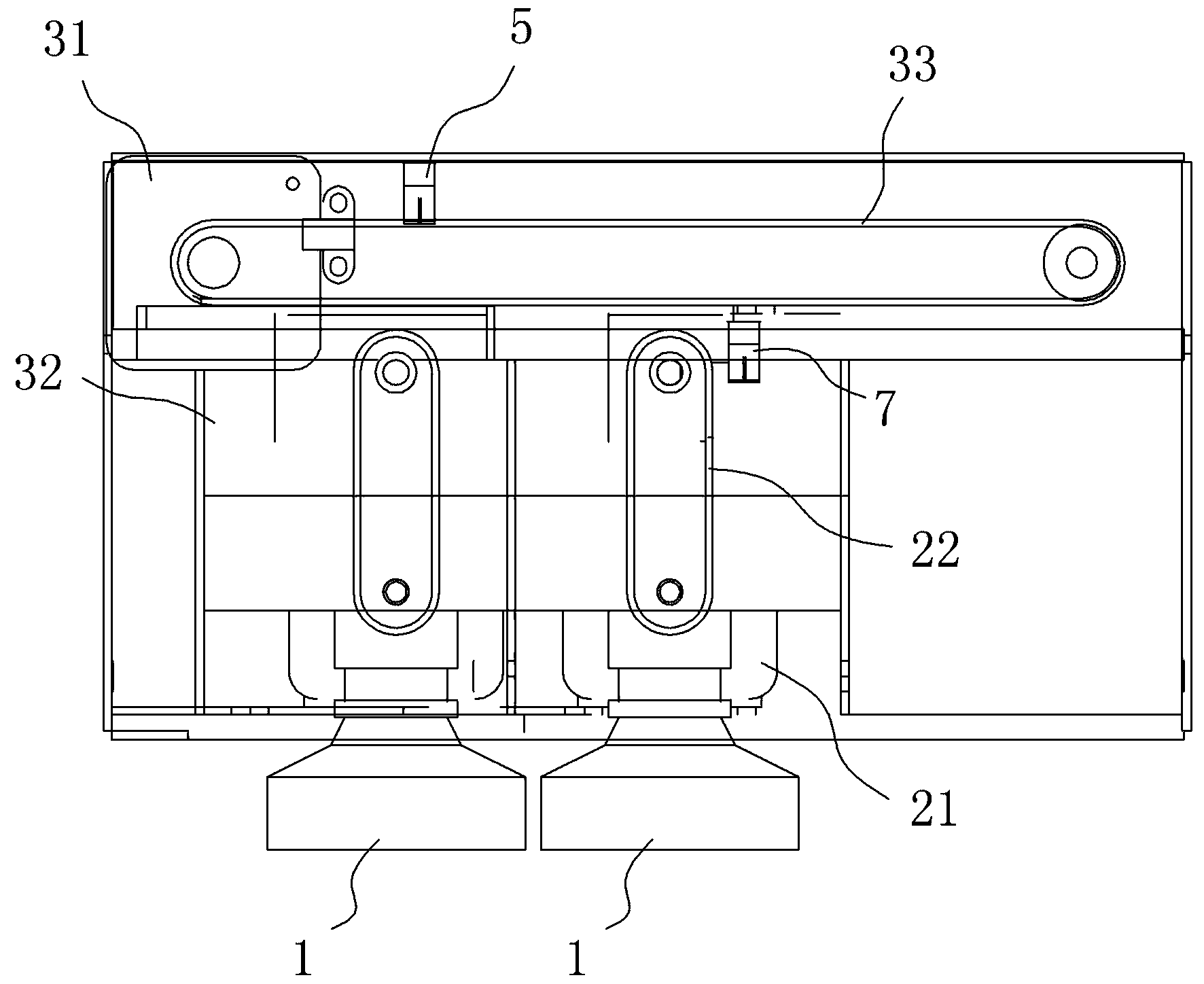

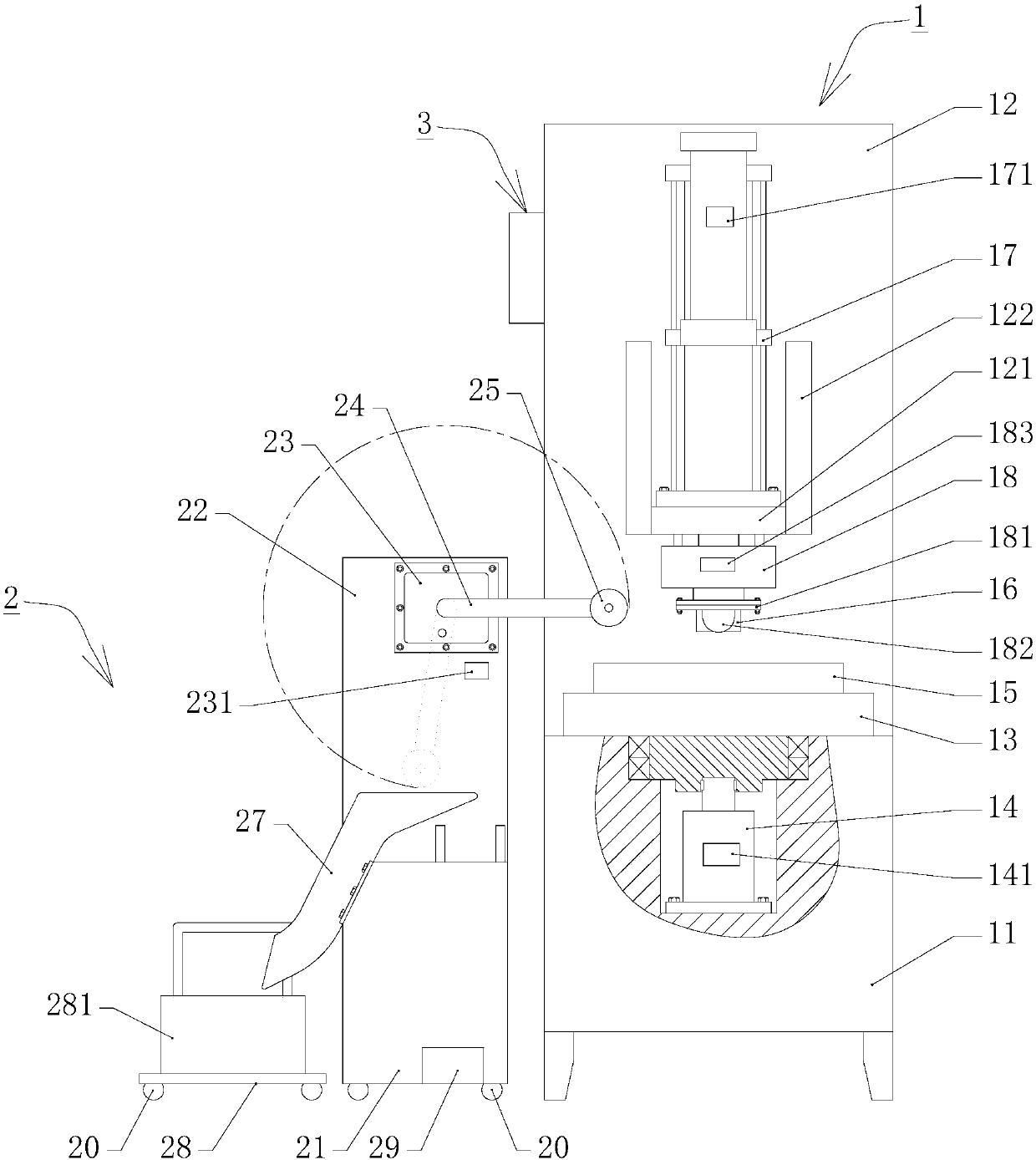

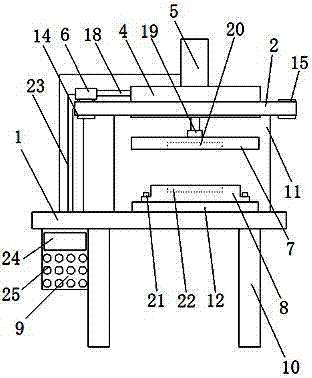

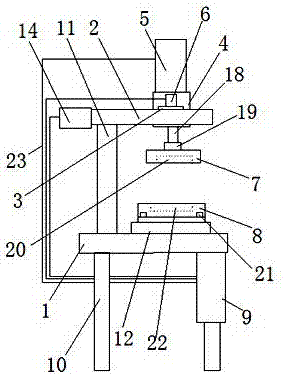

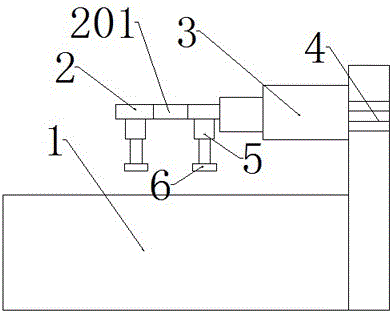

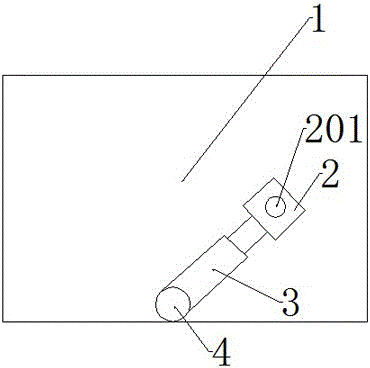

Adjustable automatic stamping machine

InactiveCN105252920AImprove stamping efficiencyImprove stamping qualityStampingEngineeringMechanical engineering

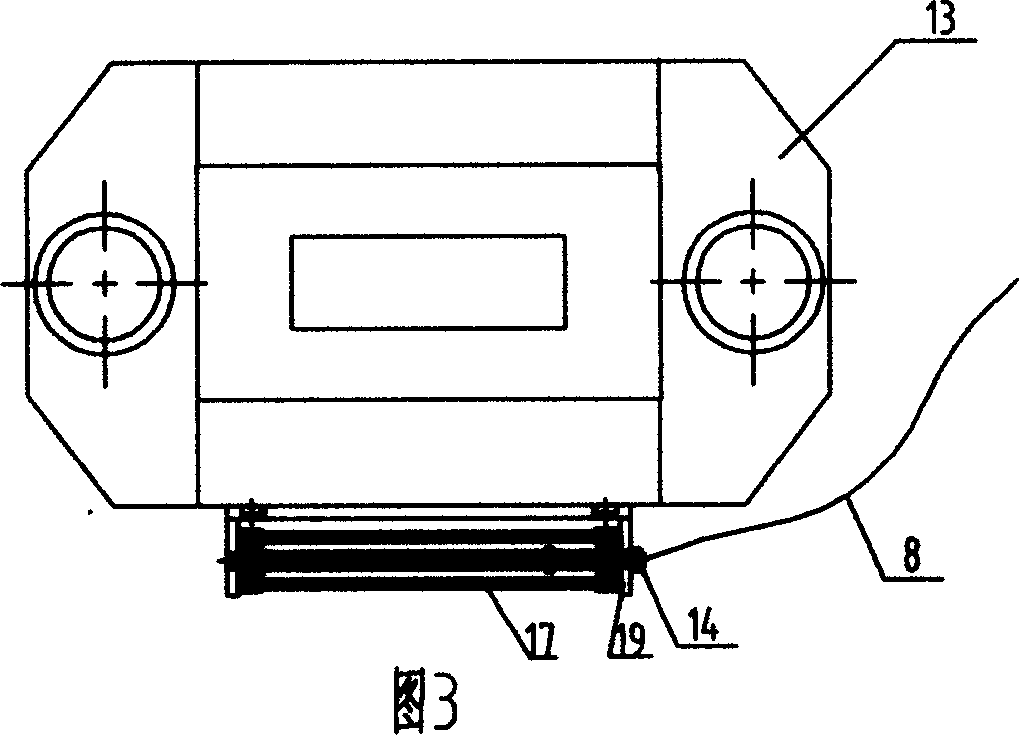

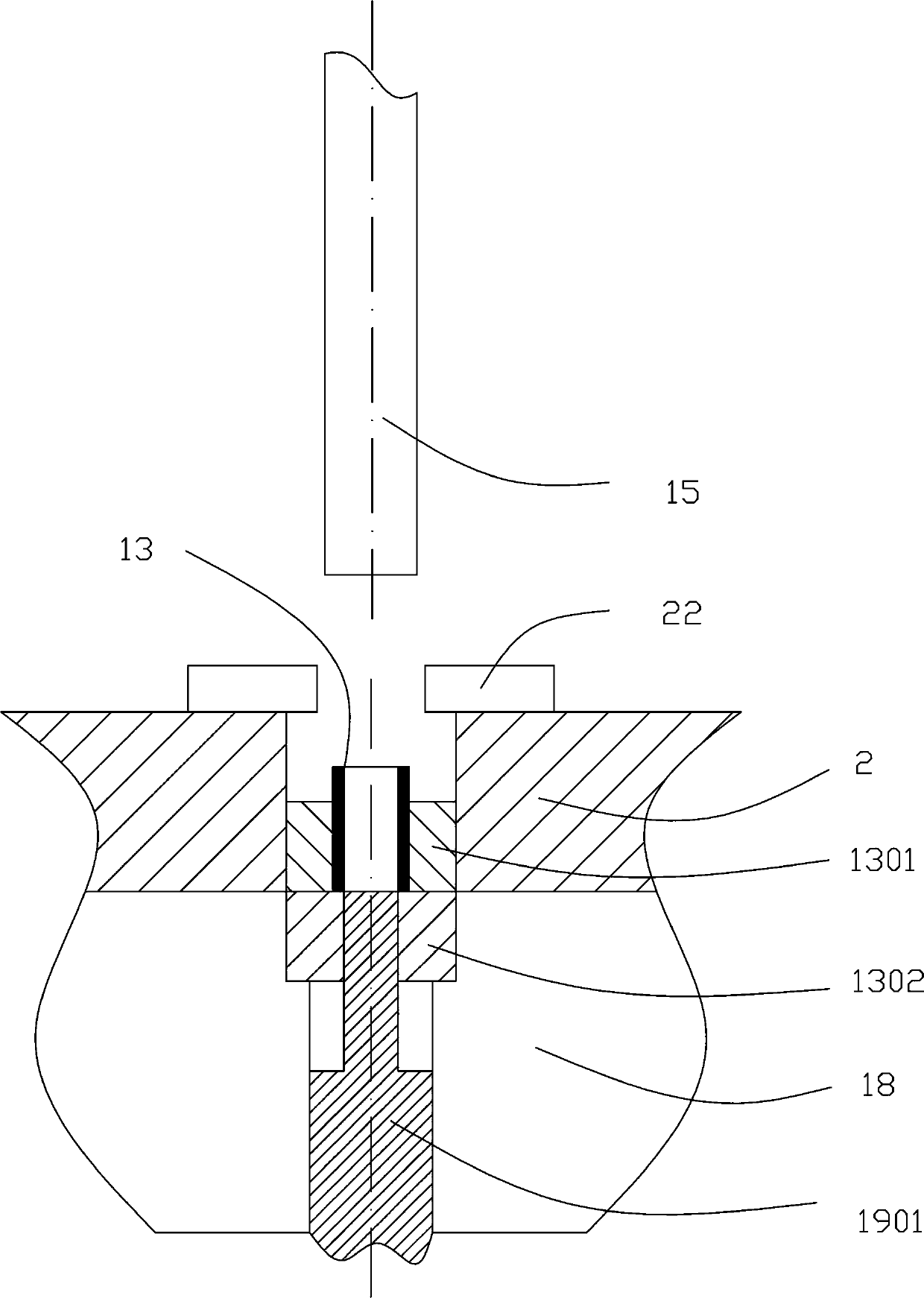

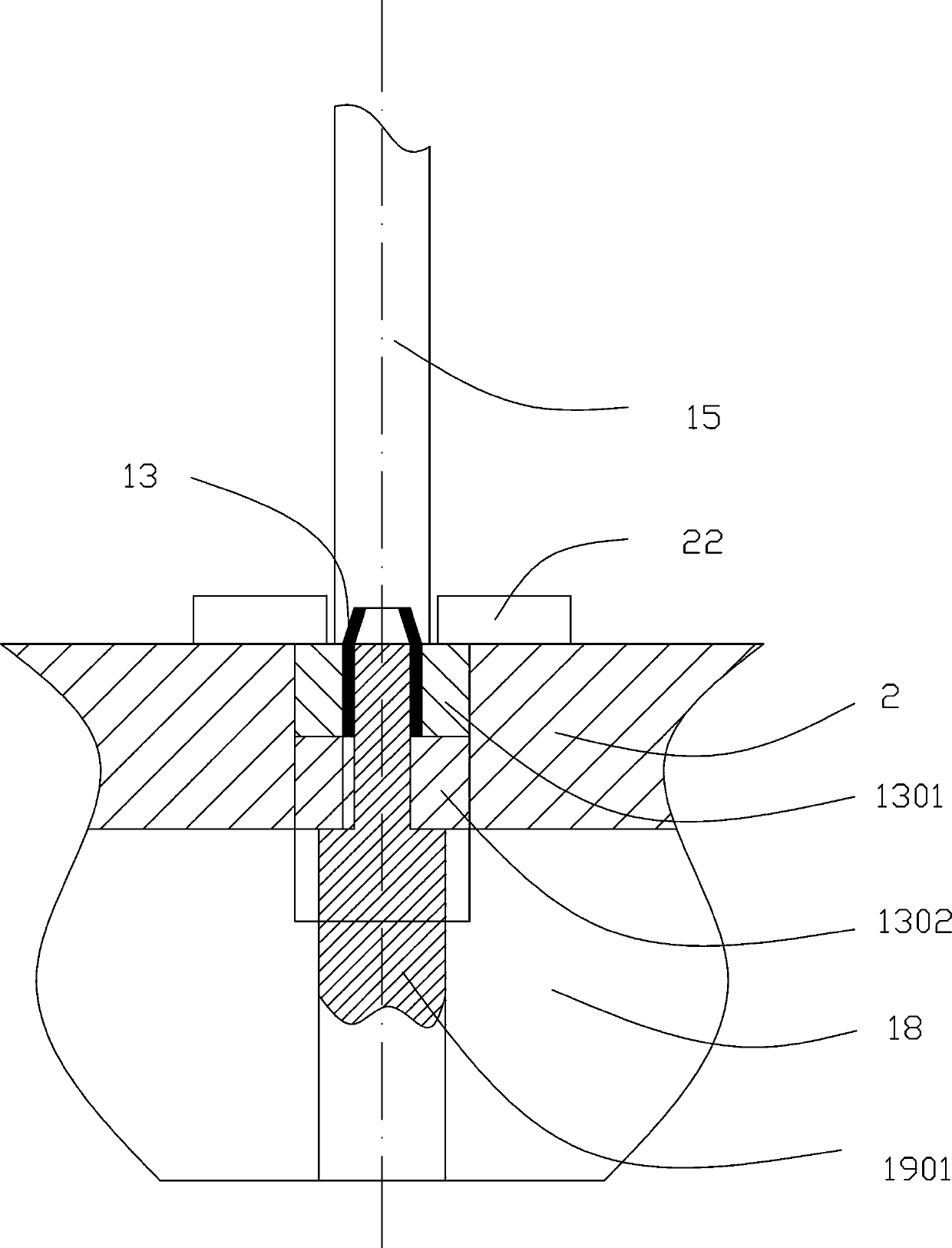

The invention relates to an adjustable automatic stamping machine. The adjustable automatic stamping machine comprises a stamping machine base. A stamping platform is arranged on the stamping machine base. A paper conveying mechanism is arranged on one side of the stamping platform. The paper outlet of the paper conveying mechanism is right opposite to the stamping platform. An automatic stamping mechanism is arranged on the rear side of the stamping platform. The automatic stamping mechanism comprises a movable block. A rotating shaft is transversely arranged on the movable block. One end of the rotating shaft extends to the portion above the stamping platform and is provided with a gripper used for clamping a stamp. An inkpad box fixing plate is arranged above the gripper. The automatic stamping mechanism further comprises a lifting mechanism used for driving the movable bock to vertically rise and fall, and a stamp turning mechanism which can drive the stamp to be turned upwards to be dipped with inkpad when the movable block rises, and can drive the stamp to be turned downwards to conduct stamping when the movable block falls. The adjustable automatic stamping machine has the beneficial effects of being high in stamping efficiency, high in universality, and the like, and therefore the labor intensity of office staff can be effectively lowered, and the work efficiency can be effectively improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

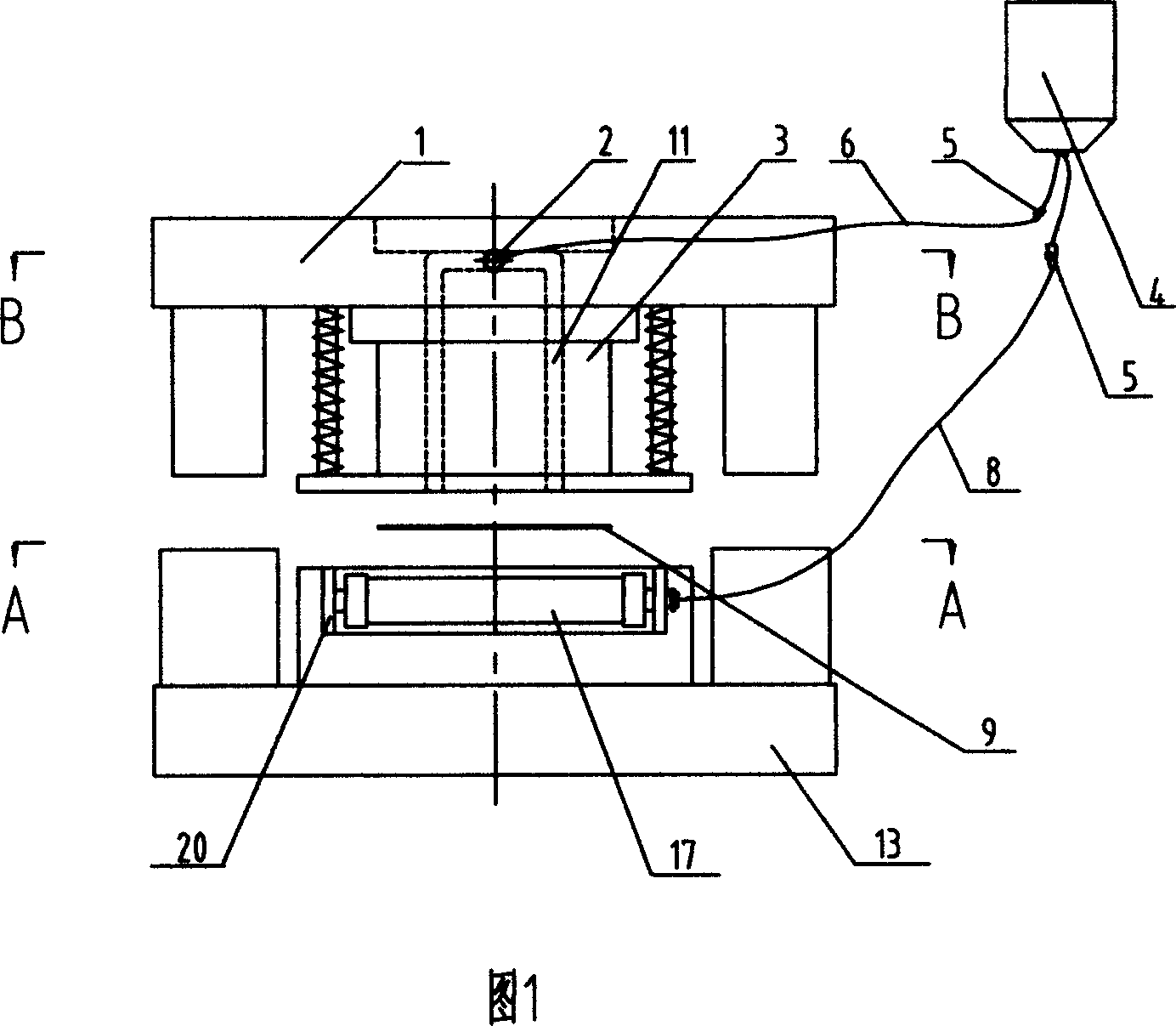

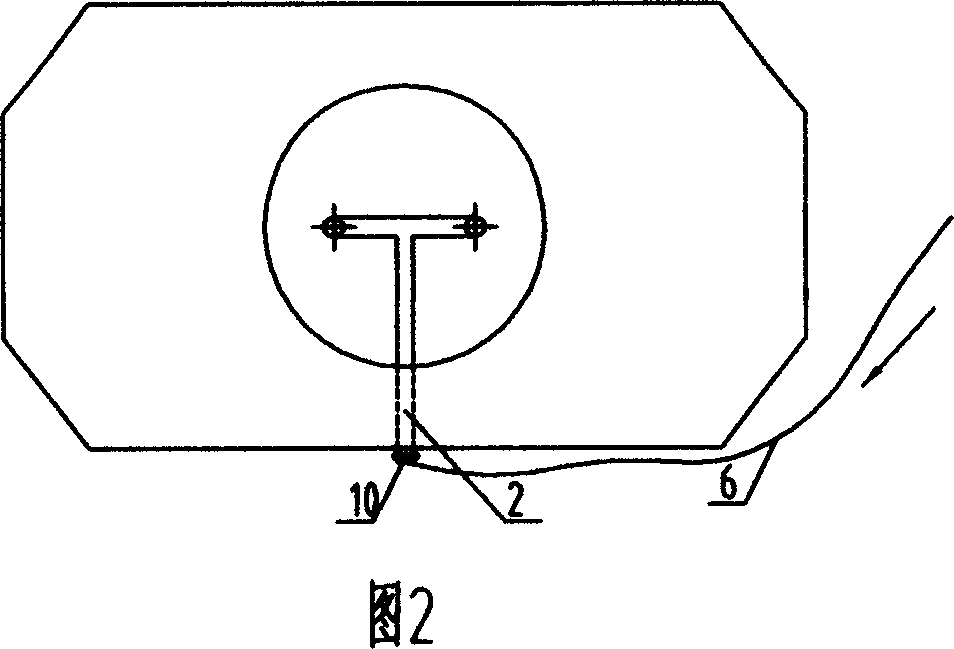

Automatic lubricating device for stamping die

InactiveCN1923399AEvenly lubricatedExtended service lifeShaping toolsEngine lubricationBlanketOil storage

The invention relates to an automatically lubricant device of punch mould, which comprises upper and lower mould bases, and upper and lower moulds. Wherein, the upper and lower moulds are fixed with upper and lower mould bases; the upper mould has several through holes through the upper and lower ends; the upper mould base has relative holes; said holes are connected to one oil inlet of upper mould base; the oil inlet via one oil tube with one flux adjust switch is connected to the oil storage device which is higher than upper mould base; one end of lower mould base at material feeding end is mounted with one roller whose surface has blanket to lubricant the lower surface; the wall of roller has several small through holes; one end of spindle axle of roller has oil inlet via another oil tube with flux adjust switch connected to the oil storage device. The invention can lubricant the punch mould and sheet, to improve their service life and punch quality.

Owner:CHONGQING QIANWEI SCI & TECH GRP

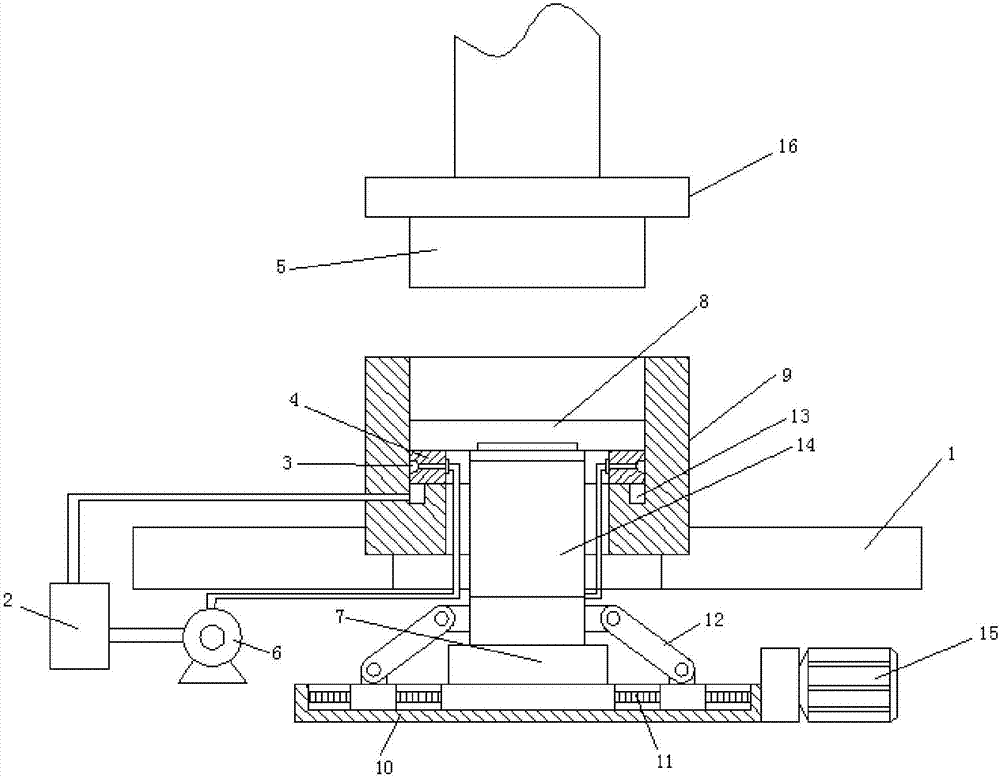

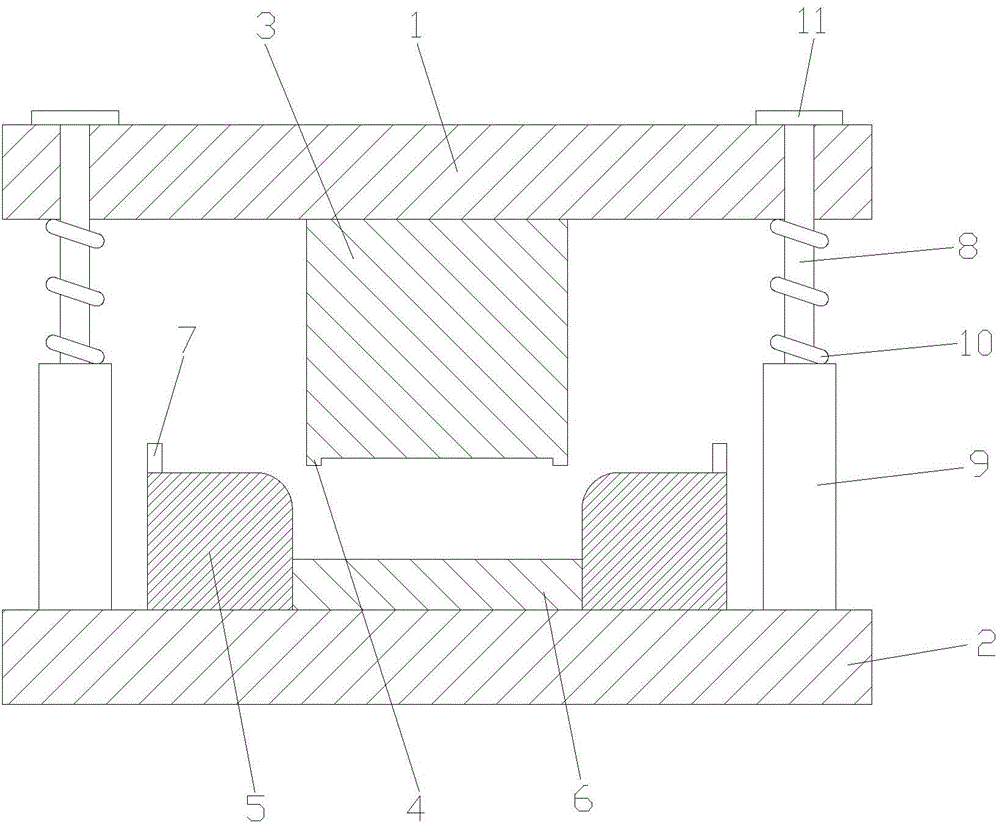

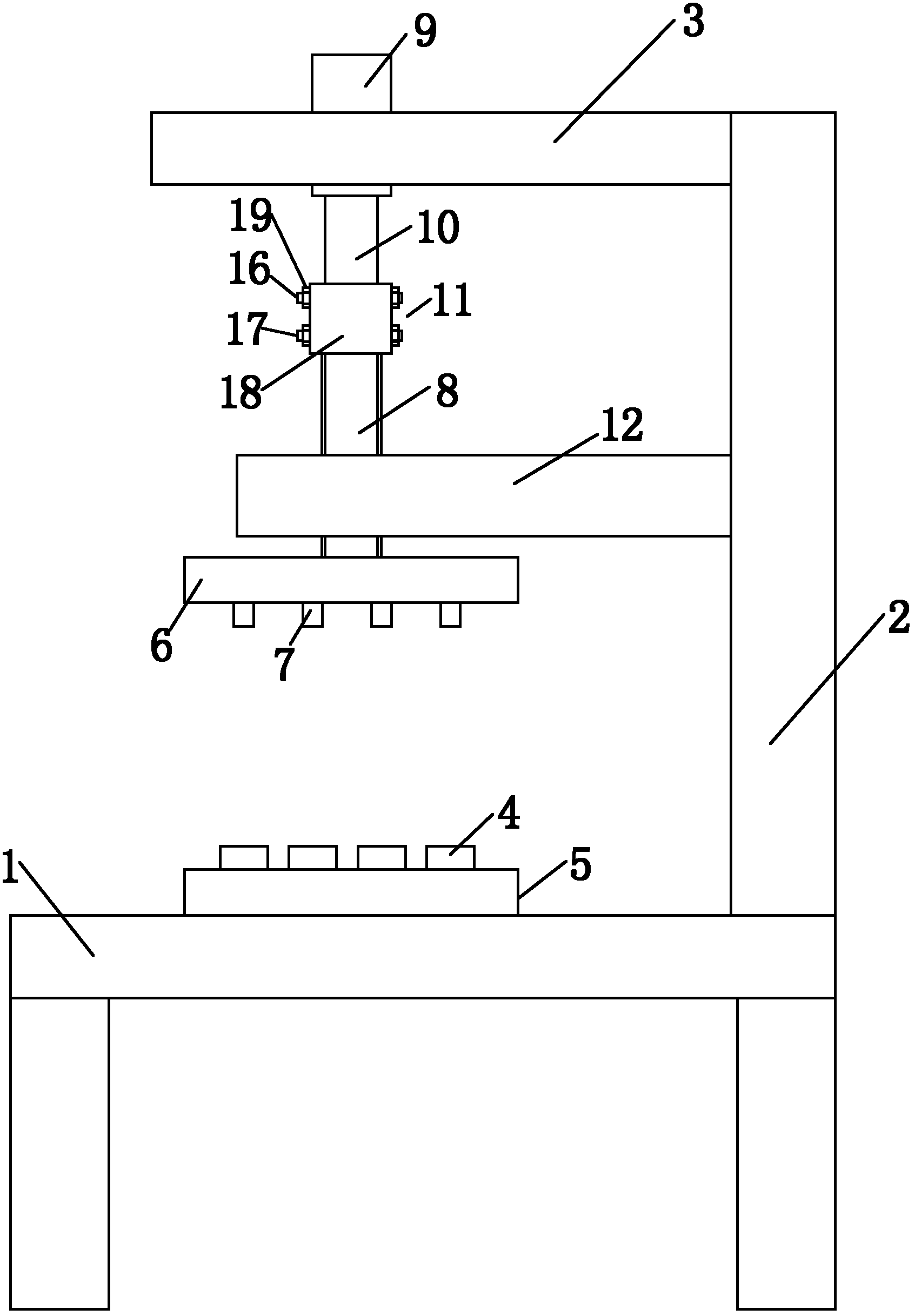

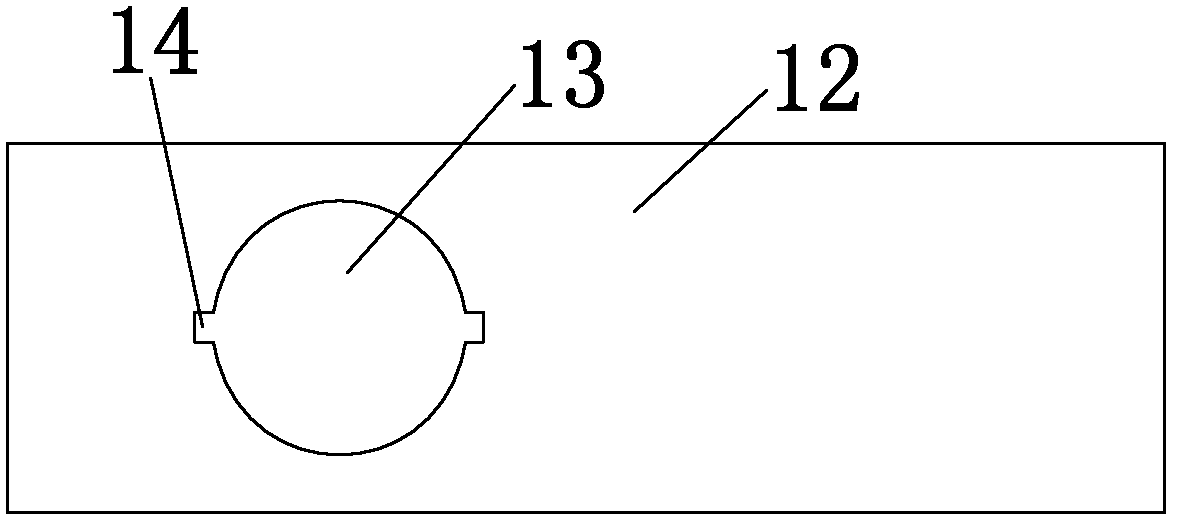

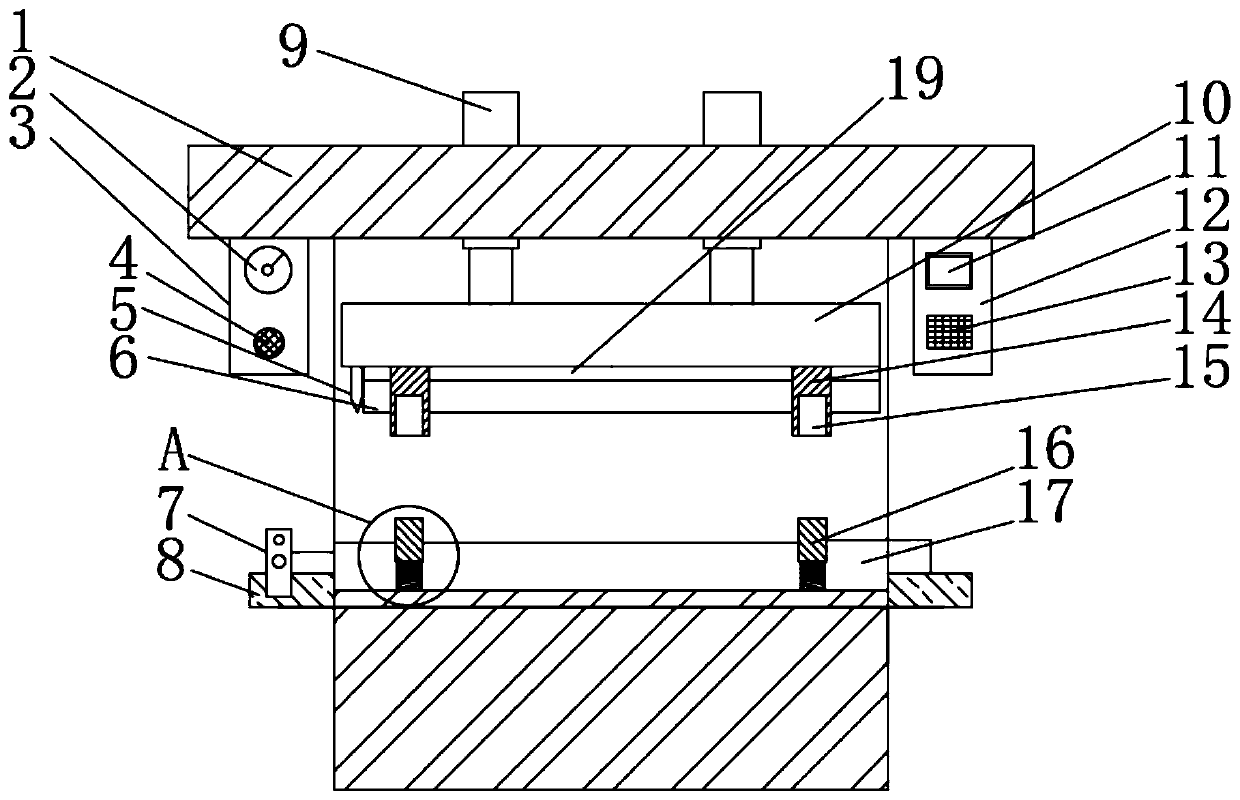

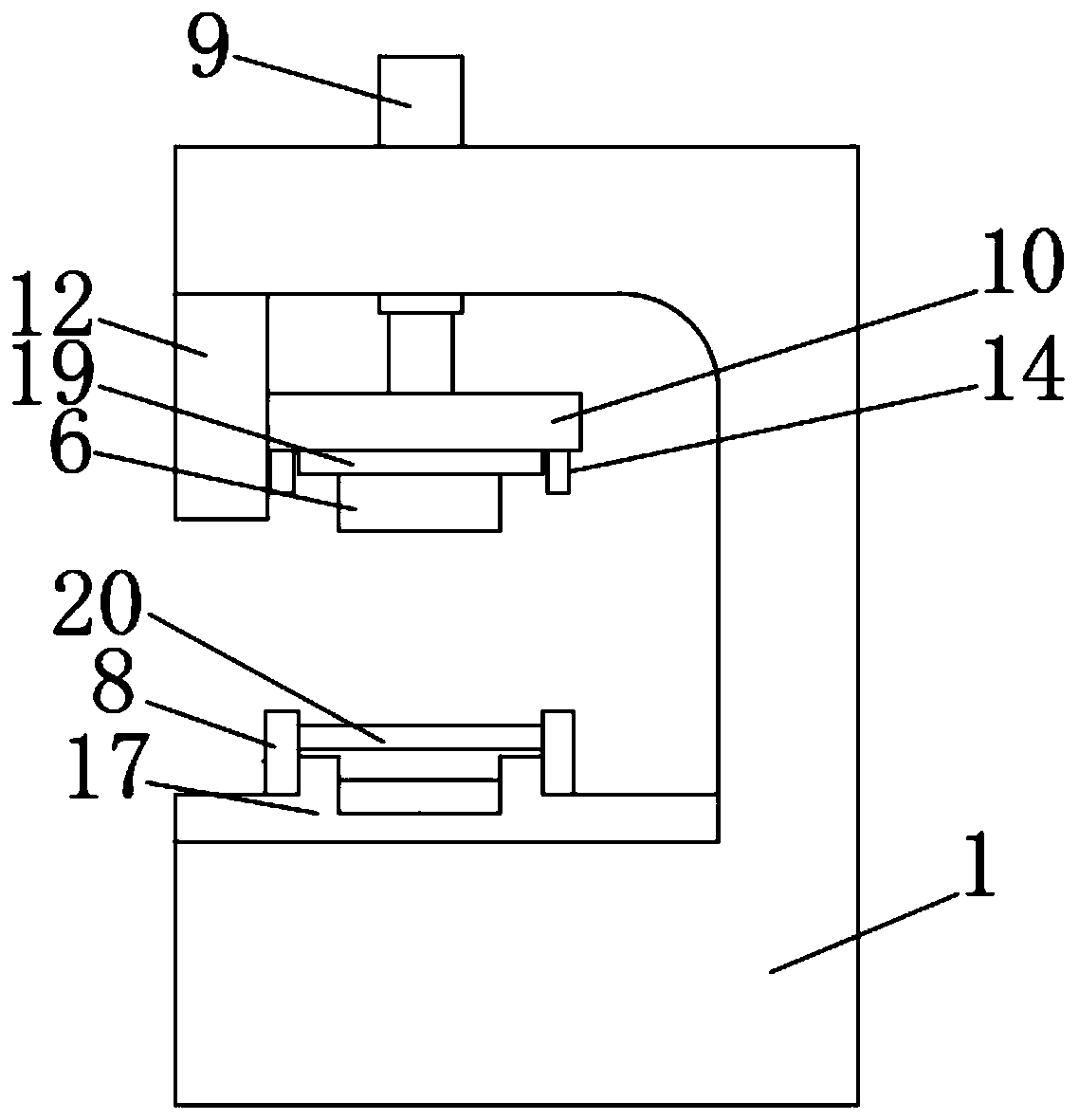

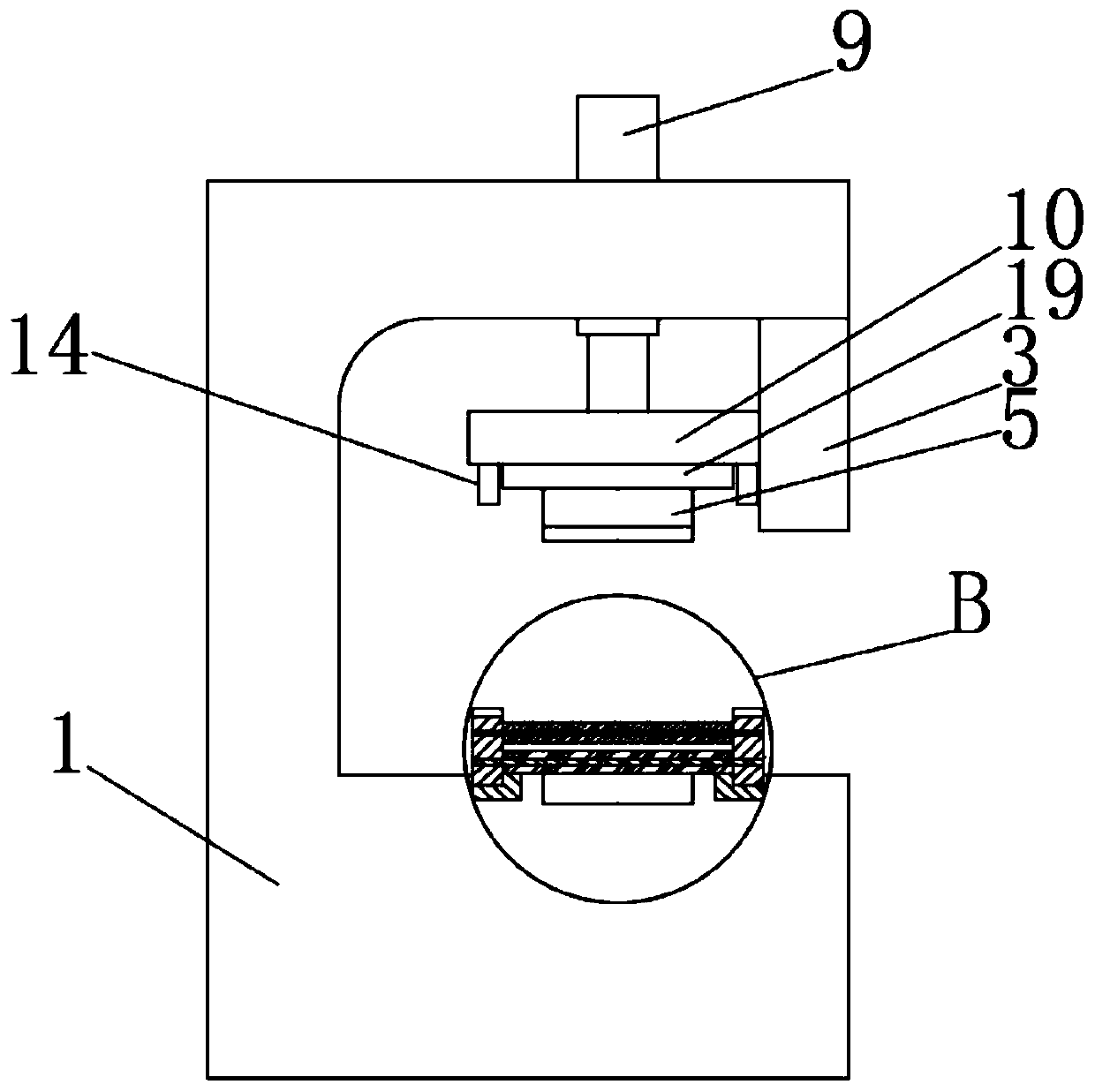

Stamping machining equipment

ActiveCN110238276AAchieve separationAvoid stickingShaping toolsPress ramHydraulic cylinderEngineering

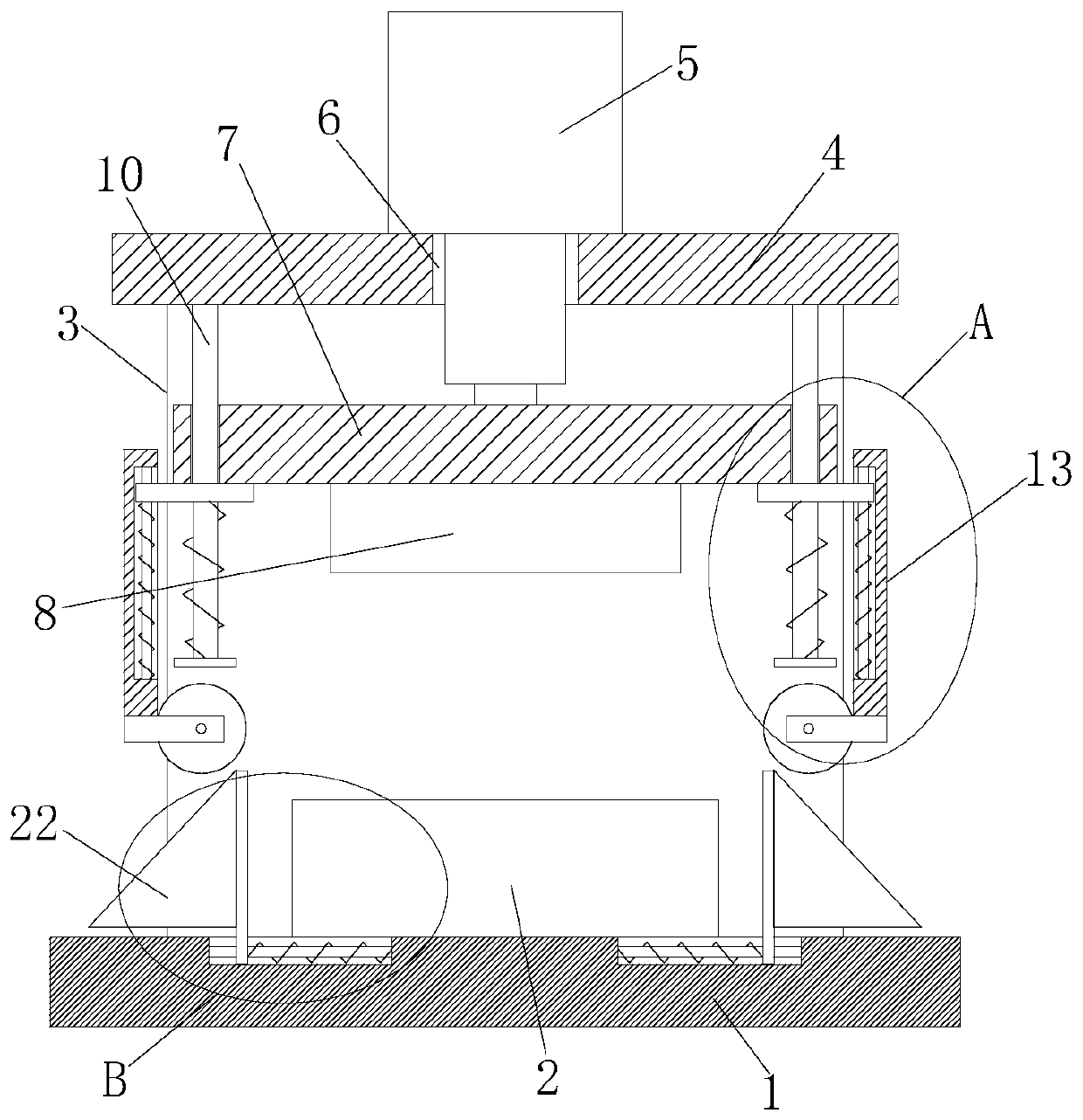

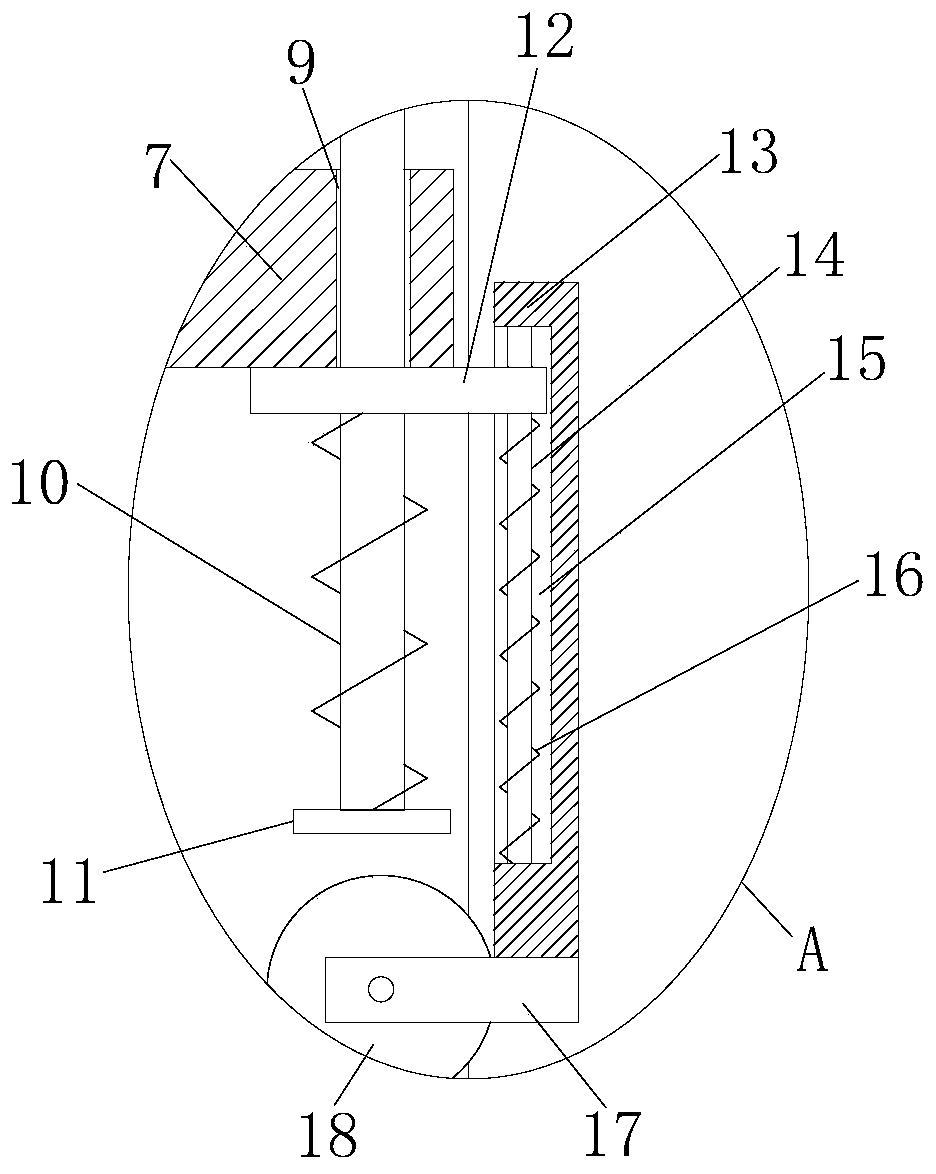

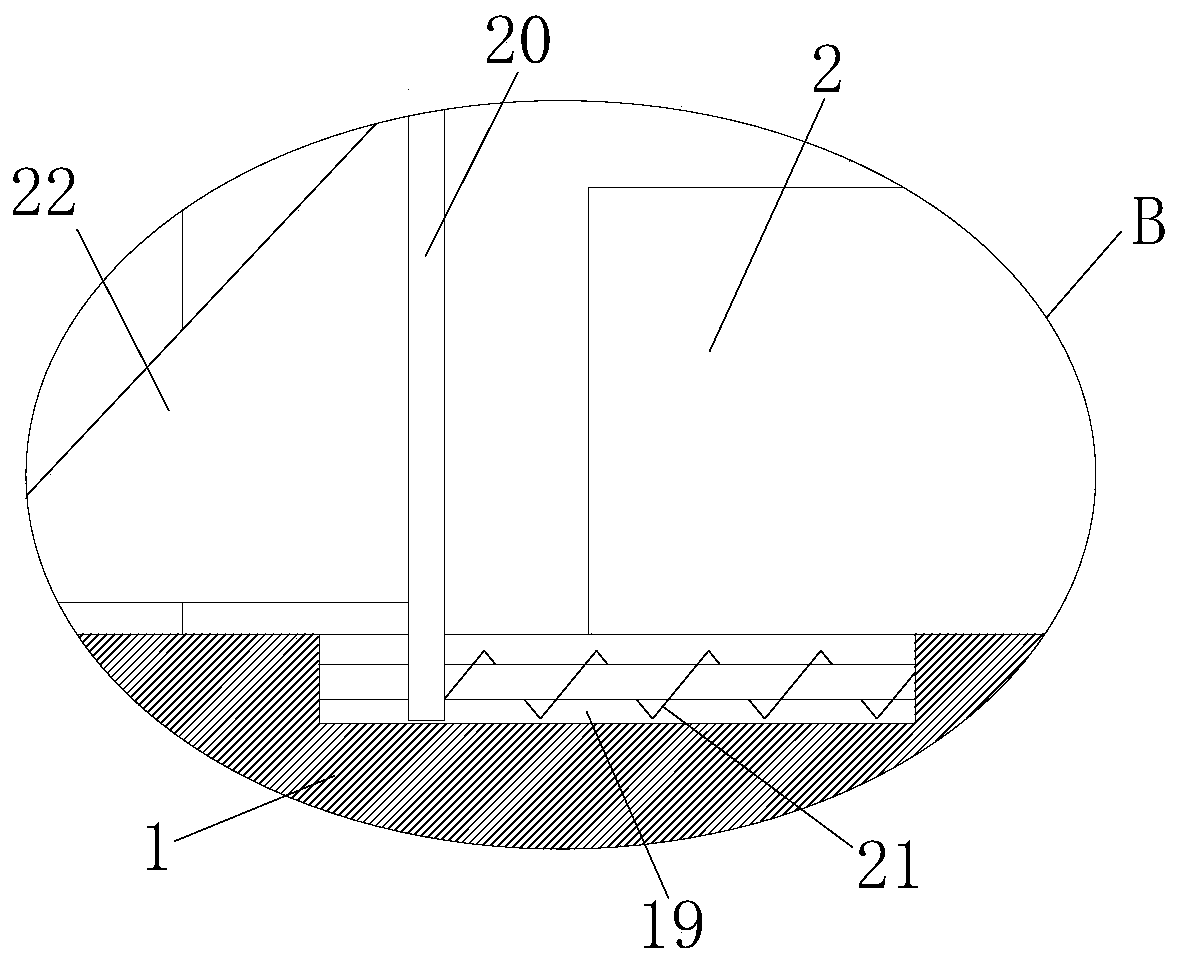

The invention belongs to the technical field of machining, particularly relates to stamping machining equipment, and aims to solve the problems that the stamping quality is affected by unstable clamping and easy offset of an existing stamping plate, the stamping plate easily adheres to a pressing block after the stamping is completed, and time and labor are wasted to separate the stamping plate. According to the scheme, the stamping machining equipment comprises a machining table, wherein the stamping plate is arranged at the top of the machining table, the top of the machining table is fixedly provided with two fixing plates, the tops of the two fixing plates are fixedly provided with a same top plate, a hydraulic cylinder is fixedly arranged at the top of the top plate, a through hole is formed in the top plate, a piston rod of the hydraulic cylinder penetrates through the through hole to extend below the top plate and is fixedly provided with a lifting plate, and a pressing block is fixedly arranged at the bottom of the lifting plate. The stamping machining equipment is simple in structure, the stamping plate can be clamped, the problem of offset of the stamping plate is avoided, the stamping quality of the stamping plate is improved, and meanwhile, the stamping plate and the pressing block can be conveniently separated, and the problem that the pressing block adheres to the stamping plate is solved.

Owner:苏州茂速拓机械科技有限公司

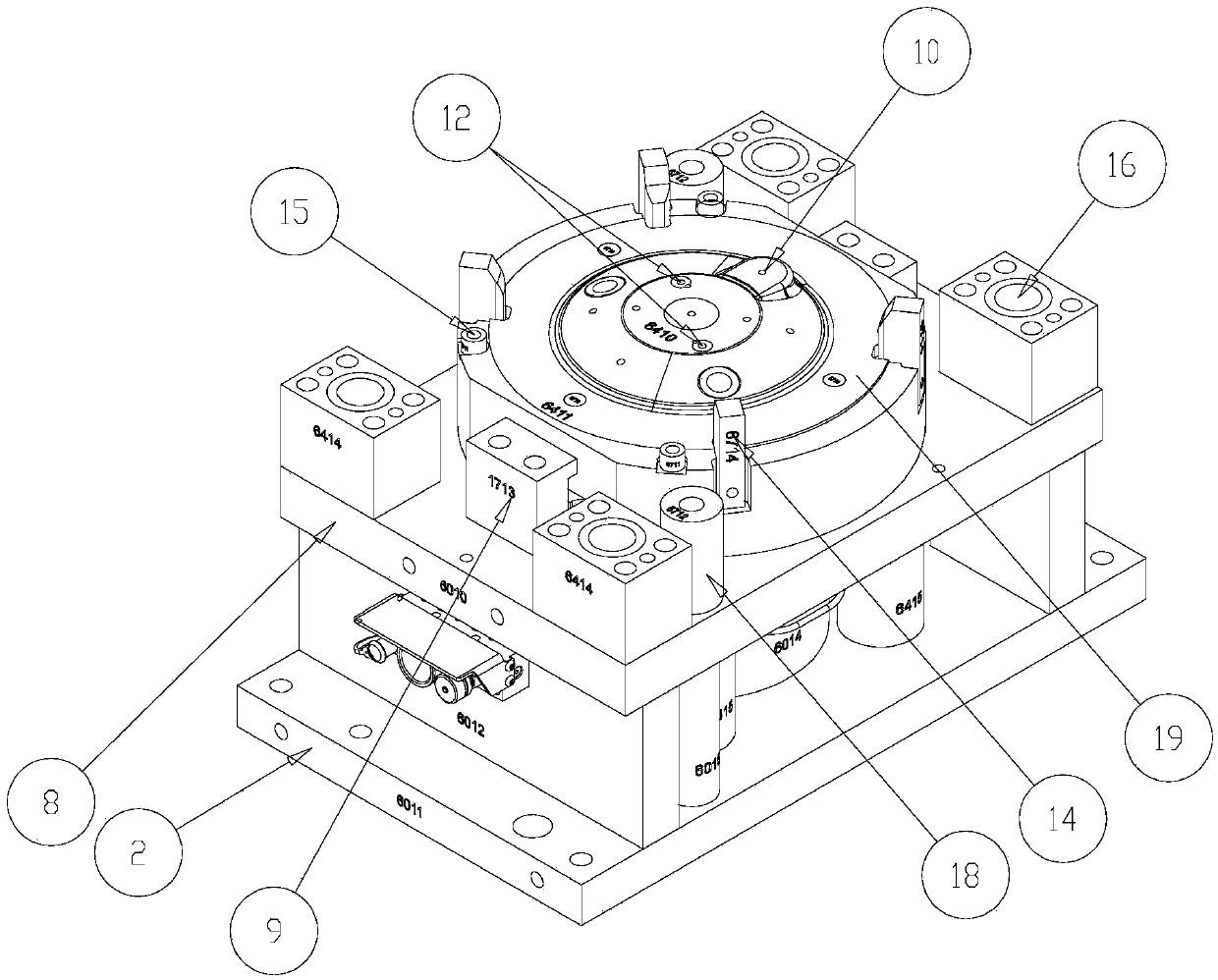

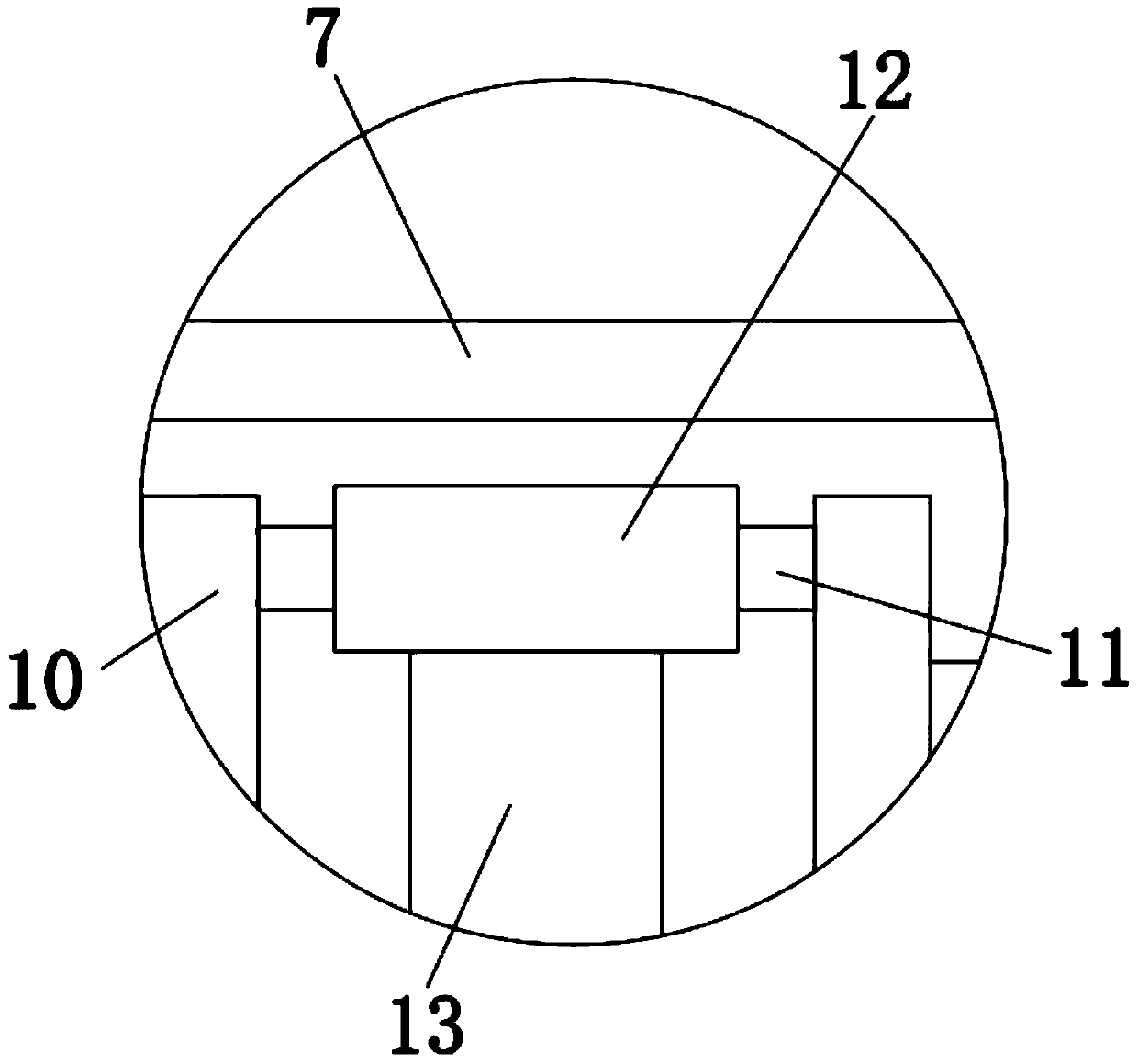

Air conditioner connecting pipe punching machine

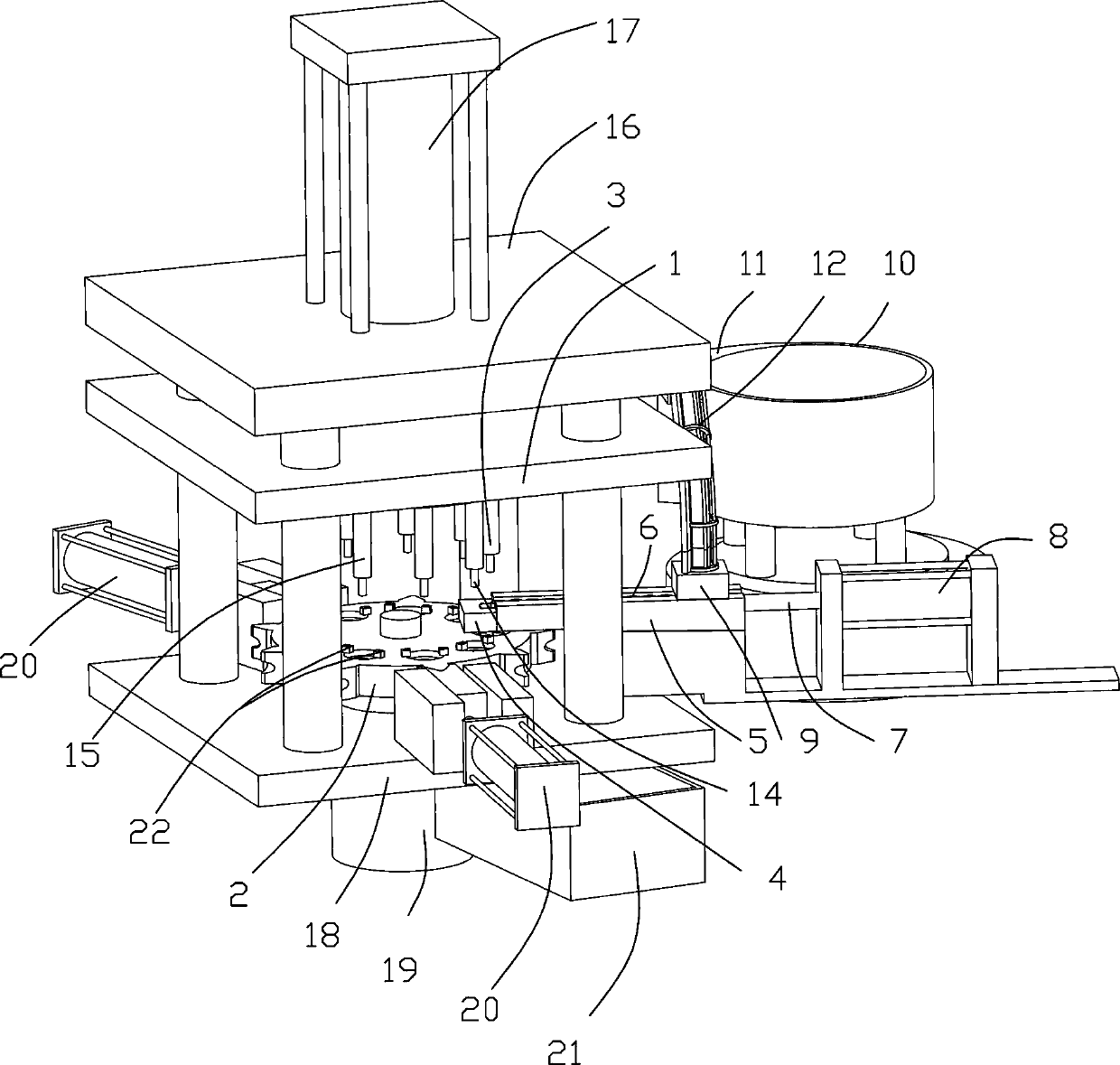

InactiveCN104209387AImprove stamping qualityHigh degree of automationMetal-working feeding devicesPositioning devicesPunchingStructural engineering

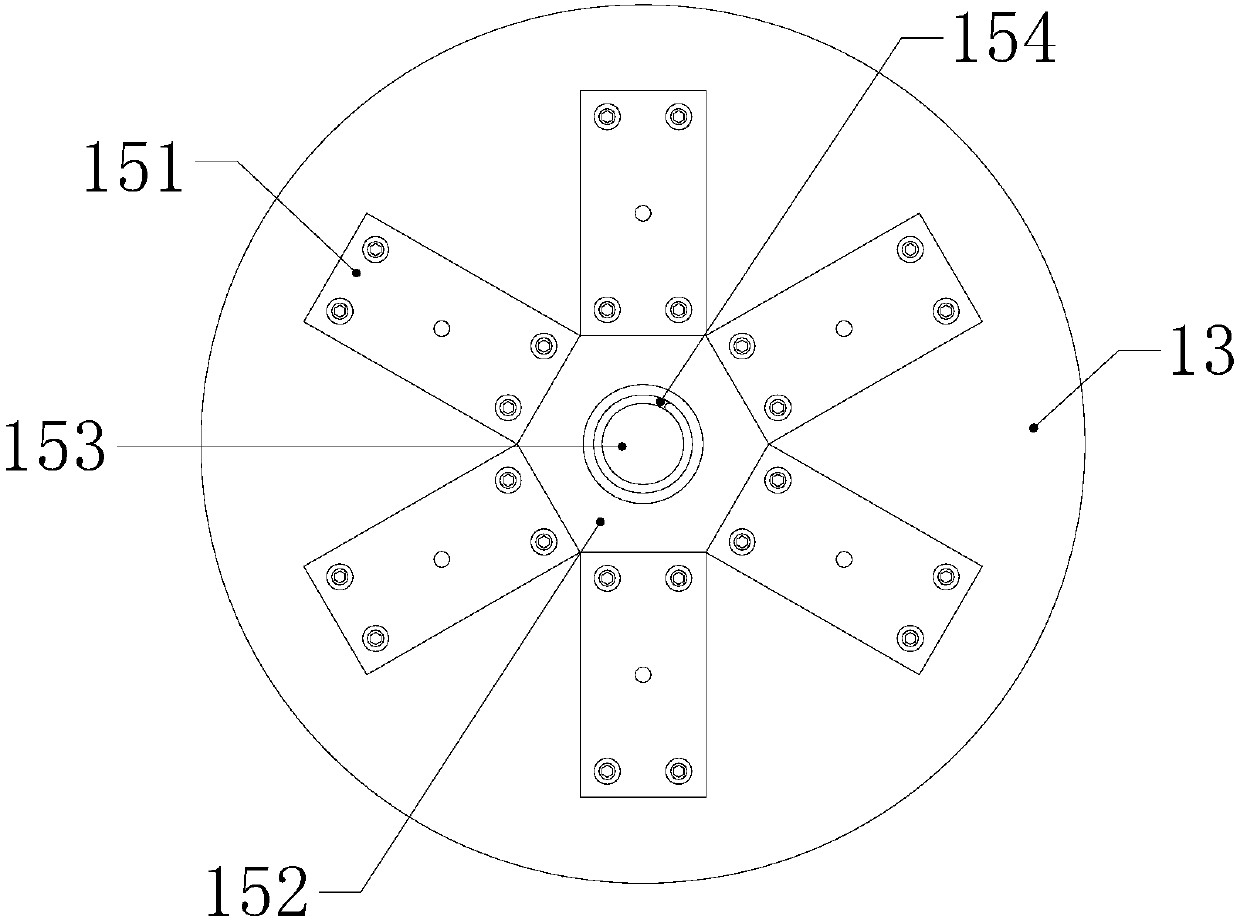

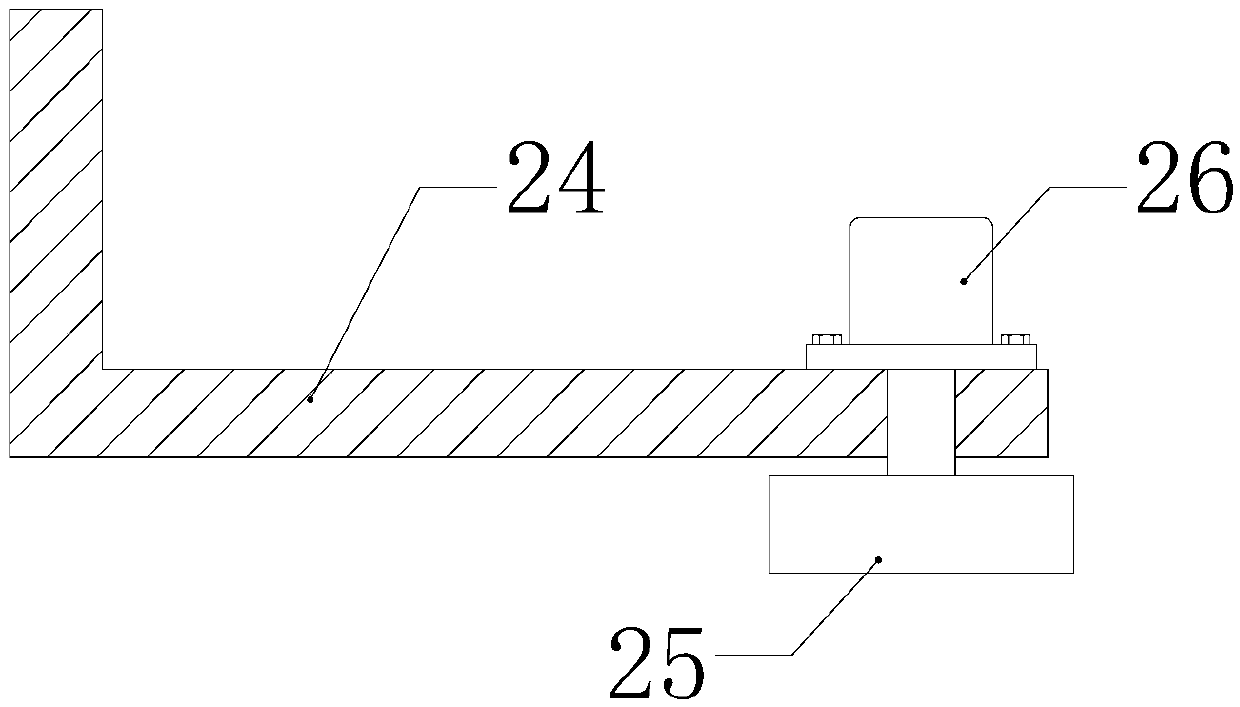

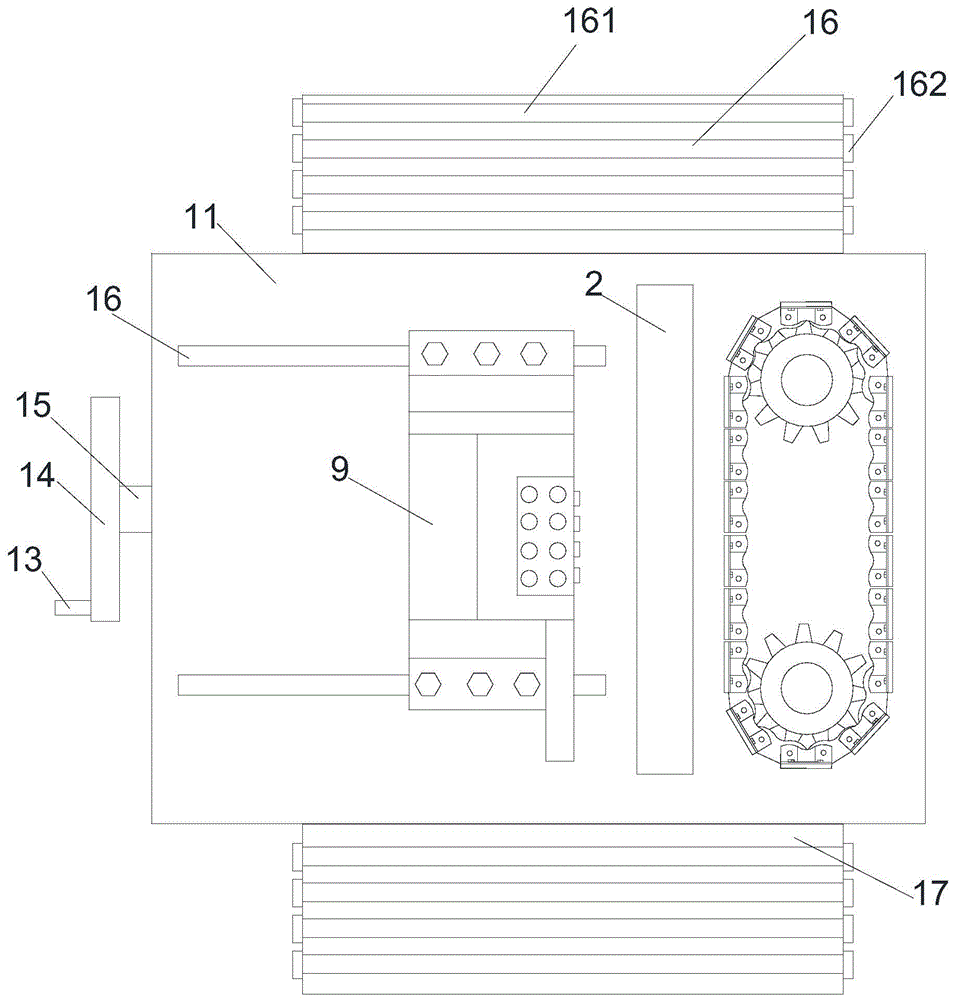

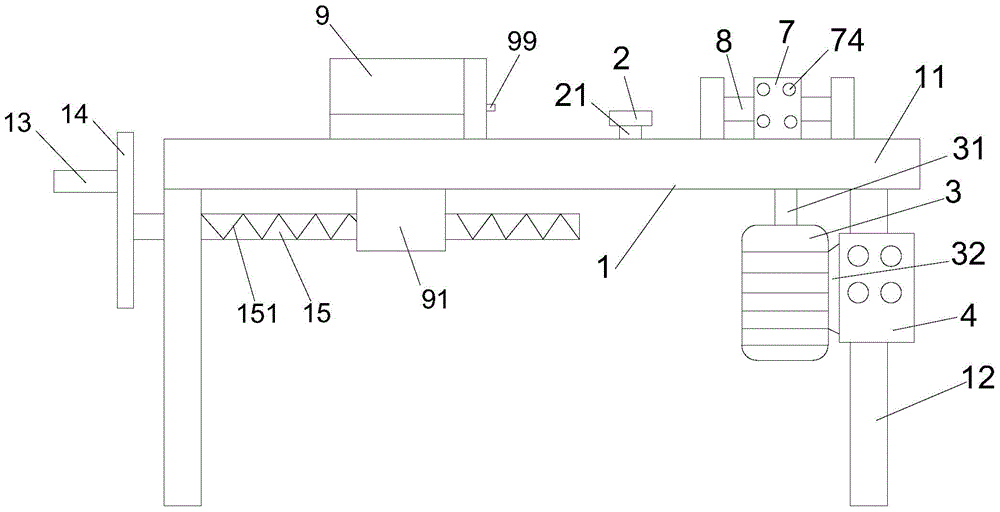

The invention provides an air conditioner connecting pipe punching machine. The air conditioner connecting pipe punching machine comprises a support and a control device, wherein the support is vertically provided with guide columns, the guide columns are provided with an upper mold holder which can move up and down along the vertical direction, the bottom of the upper die frame is provided with a plurality of punching molds corresponding to punching workstations, an intermittent rotating plate is arranged right below the punching molds, the rotating plate is internally provided with positioning holes and positioning molds corresponding to the positions of the punching molds, a fixed plate which is fixed on the support is arranged below the rotating plate, a lower mold which is arranged below the positioning molds is arranged in the fixed plate, the lower mold comprises a jacket and an ejector rod which is inserted into the jacket, and the circumferential side of the rotating plate is also provided with a limiting mechanism and an automatic feeding device which are matched with the side wall of the rotating plate. The air conditioner connecting pipe punching machine is good in punching quality, high in automation degree and capable of realizing automatic feeding, eliminating the potential safety hazard of the manual operation and better guaranteeing the safety of workers.

Owner:ZHEJIANG PULISI AUTO PARTS

Adjustable punching device applied to workpieces

InactiveCN107413913AImprove stabilityImprove stamping qualityMetal-working feeding devicesPositioning devicesPunchingPiston rod

The invention discloses an adjustable stamping device applied to workpieces, which includes an operation table, a fixed plate, a cylinder one, a slider, a pressing block, a cylinder two and a fastening plate, and is characterized in that the operation table is set on the bracket Above, the fixed plate is set between the vertical plate and the vertical plate, the cylinder one is set on the fixed plate, the slider is set on the piston rod one and the power cord, and the pressing block is set on the slide On the block, the cylinder 2 is set in the console, and the fastening plate is set in the limit groove. In the present invention, a limiting groove is arranged on the operating table, and a fastening plate connected with the piston rod 2 of the cylinder 2 is arranged in the limiting groove, and the workpiece to be stamped is placed on the bearing platform, and the workpiece can be clamped by the fastening plate , improve the stability of the workpiece in the stamping process, enhance the stamping quality of the workpiece, set a limit rod on the vertical plate, through the limit rod, the stability of the slider in the process of rising or falling can be improved, and the stamping quality of the workpiece can be further improved .

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

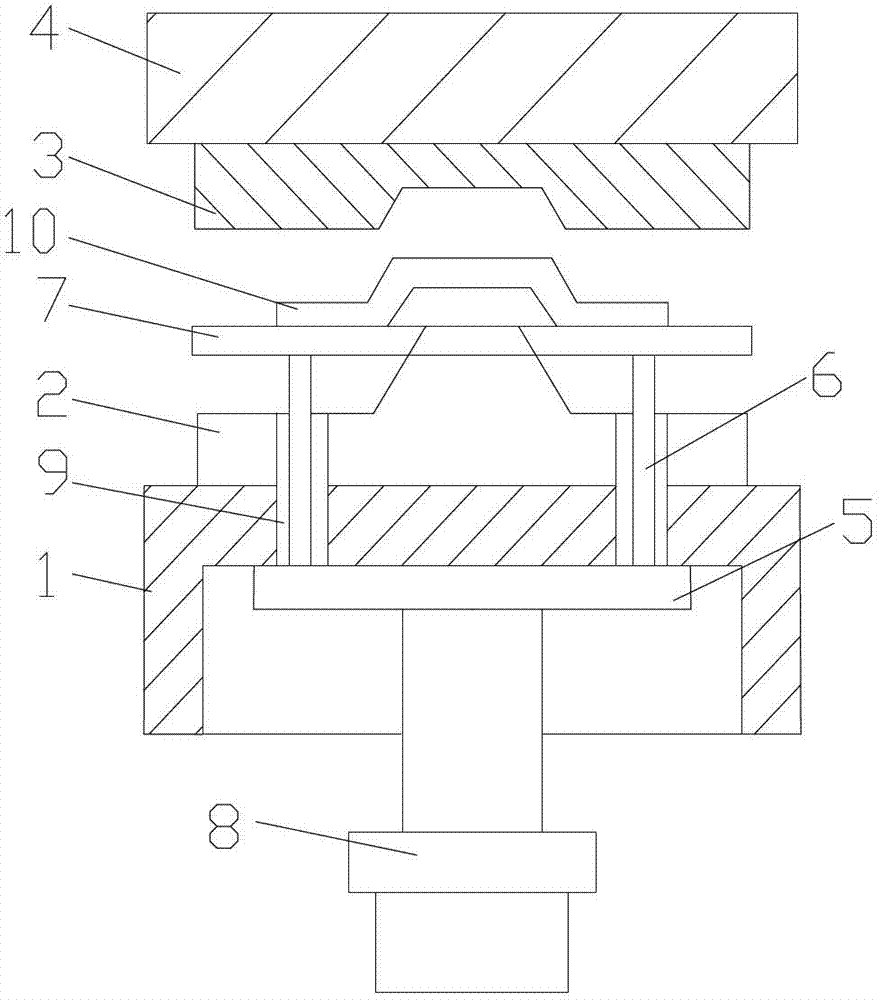

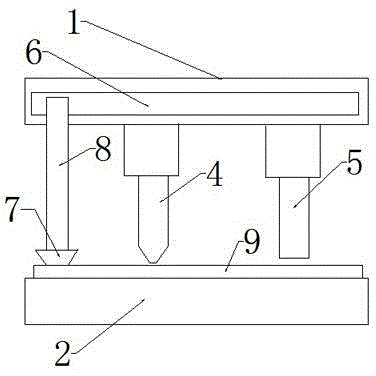

Stamping device for thin plate

InactiveCN102896192AEasy to removeSimple structureShaping toolsEjection devicesSmall footprintEngineering

The invention relates to a stamping device for a thin plate for processing the thin plate. A hydraulic stamping press comprises an operation platform, a lower raised mould and an upper concave mould, wherein the lower raised mould is fixedly arranged on an upper end face of the operation platform; the upper concave mould is located above the lower raised mould and is matched with the lower raised mould; the upper concave mould is fixedly arranged on a moving block which is capable of vertically reciprocating; a lifting plate is arranged under the operation platform; at least two guiding jacking rods are fixedly arranged on the upper end face of the lifting plate; the upper ends of the guiding jacking rods pass through the operation platform and the lower ends are exposed above the lower raised mould; a workpiece loading flat plate is fixedly arranged on the guiding jacking rods which are exposed out of the lower raised mould; the middle part of the workpiece loading flat plate is provided with an avoiding hole and a driving cylinder; a raised mould on the lower raised mould passes through the avoiding hole; the driving cylinder is arranged under the operation platform and is used for driving the lifting plate to vertically reciprocate; and an upper end of a stretching rod of the driving cylinder is fixedly arranged with the lower end face of the lifting plate. The stamping device has the advantages of simple structure, convenience in operation, easiness in mounting and dismounting, positioning accuracy, high stamping quality and small occupied area.

Owner:CHANGZHOU LIWEI KNIFE

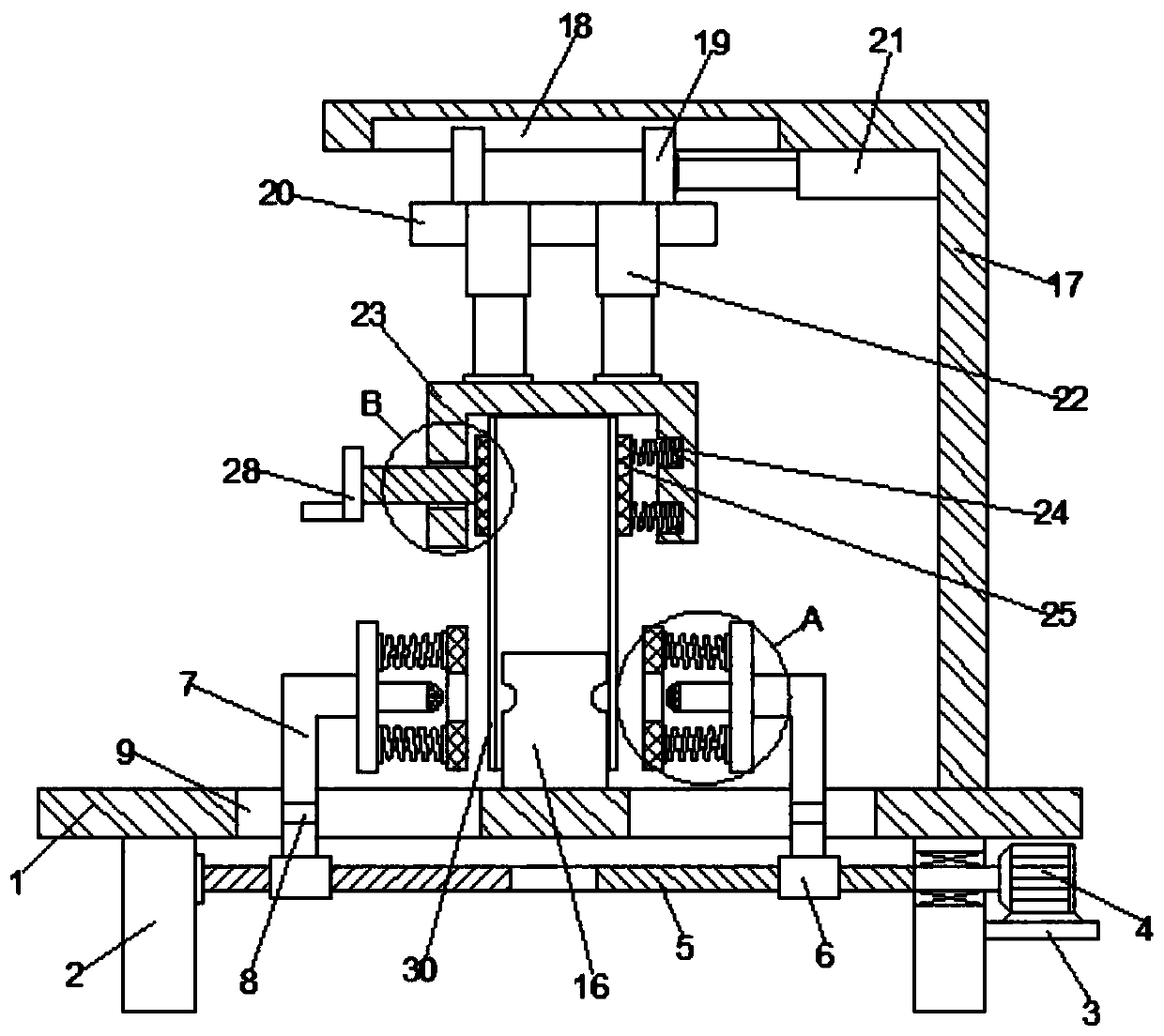

Novel pressure machine suitable for workpiece machining

InactiveCN107552624AImprove stamping qualityImprove work efficiencyShaping toolsPress ramPunchingDrive shaft

The invention discloses a novel pressure machine suitable for workpiece machining. The novel pressure machine comprises an operation table, a fixing plate, a motor, a transmission shaft, a lower cushion block and an upper pressing block, and is characterized in that the operation table is arranged on supports; the fixing plate is arranged between vertical plates, and the motor is arranged on one of the vertical plates; one end of the transmission shaft is arranged in a bearing, and the other end of the transmission shaft is connected with the motor; a mounting plate and a bearing groove are arranged on the lower cushion block; and the upper pressing block is provided with a punching groove and connecting rods. According to the novel pressure machine, cams are arranged on the transmission shaft of the motor, the cams can intermittently press base plates on the connecting rods, so that the connecting rods drive the upper pressing block to descend, a workpiece on the lower cushion block is punched, and therefore working efficiency of the press machine is improved, and stamping quality of the workpiece on the press machine is improved; and springs are arranged on the connecting rods between the base plates and the fixing plate, the upper pressing block can be bounced up through the springs, so that the working efficiency of the press machine is improved.

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

Constant-temperature stamping equipment with automatic discharging function

InactiveCN108580627AAvoid affecting productionSuitable temperature rangeShaping toolsNon-rotating vibration suppressionHydraulic cylinderEngineering

The invention discloses constant-temperature stamping equipment with an automatic discharging function. The constant-temperature stamping equipment comprises a base, a cooling device, an upper die assembly, a lower die assembly and a discharging device. The upper die assembly comprises an upper die connecting plate, an upper die base plate, an upper die seat and a male die. A hydraulic cylinder isarranged on the upper die seat, and a guide rail is arranged on the base. The lower die assembly comprises a lower die sliding block and a lower die fixing plate, and the lower die fixing plate is arranged on the guide rail. A female die is arranged on the position, corresponding to the male die, of the lower die sliding block. The discharging device is mounted on one side of the base, and the cooling device is connected with a circuitous pipeline which is arranged in the lower die sliding block. A stroke protecting mechanism is arranged between the male die and the female die. The female diecan keep the appropriate temperature range, thus the stamping quality is improved, and the service life of the equipment is prolonged; and the pneumatic mode is adopted, noise is small, discharging is convenient, and it is guaranteed that the equipment operates stably.

Owner:YANCHENG CHUANLIU AUTO PARTS CO LTD

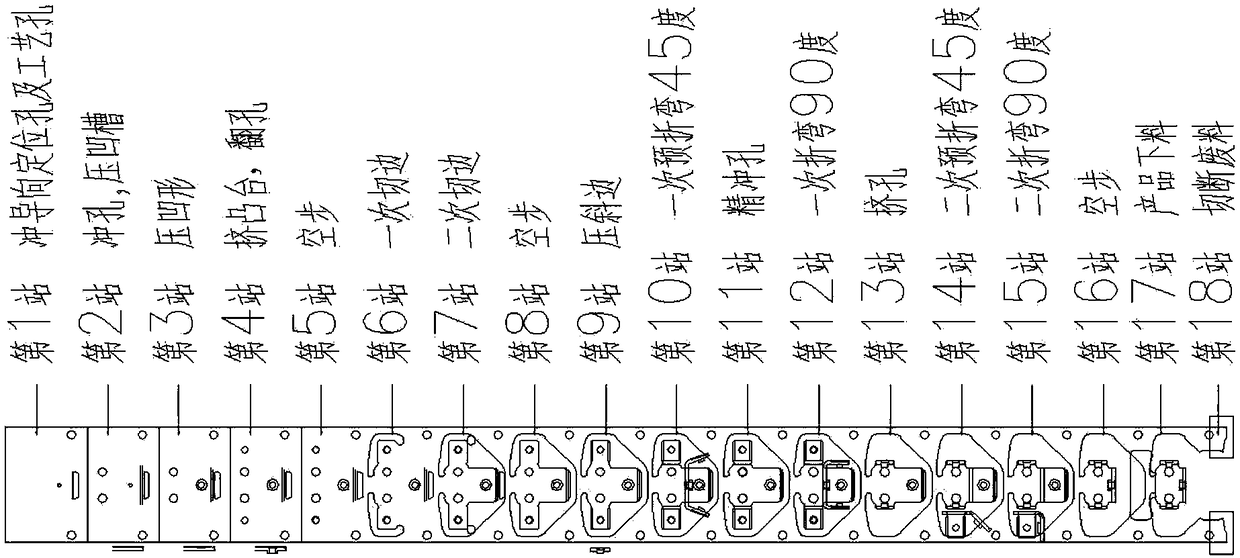

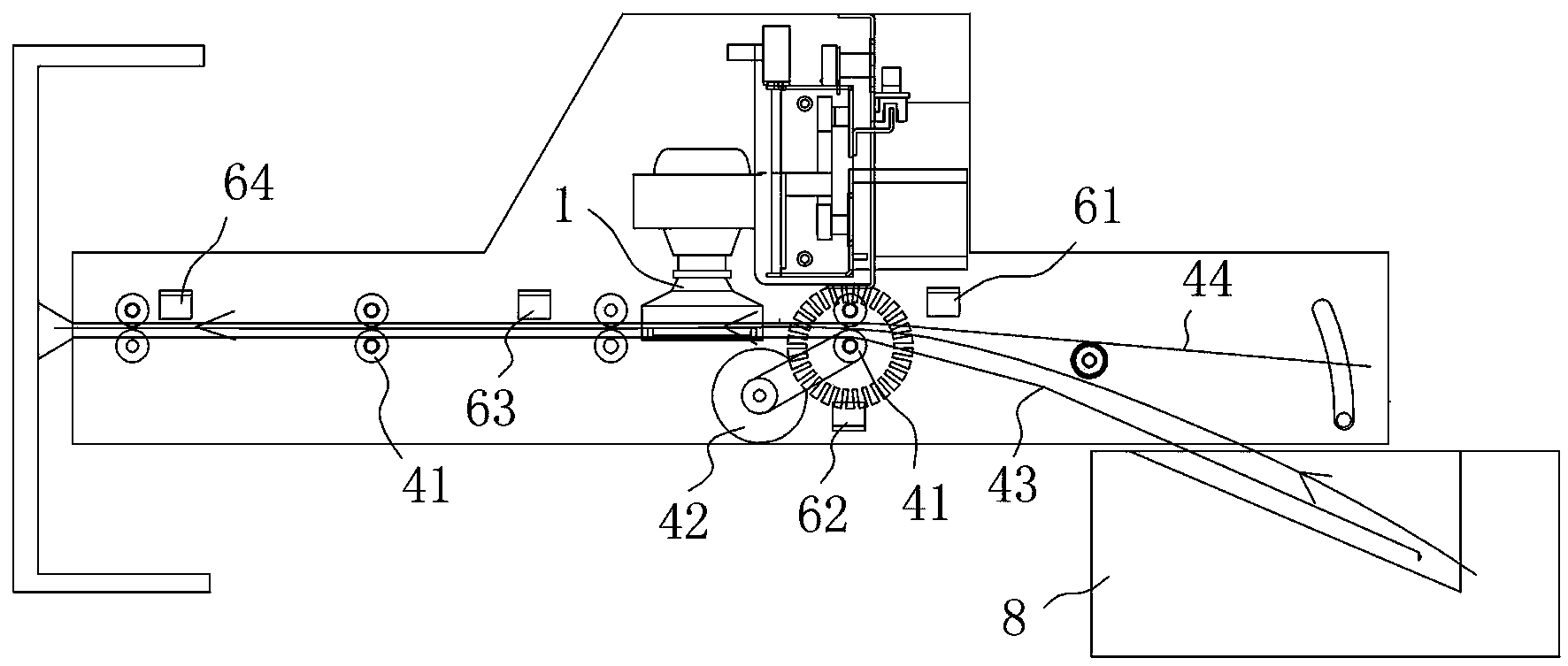

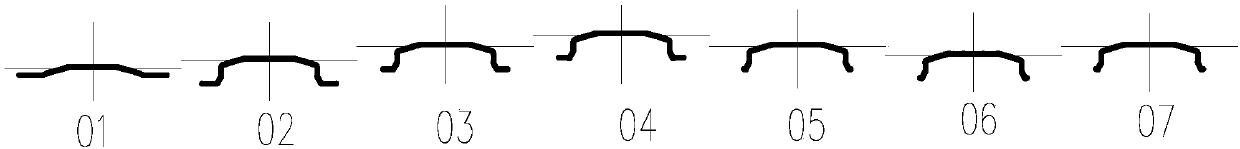

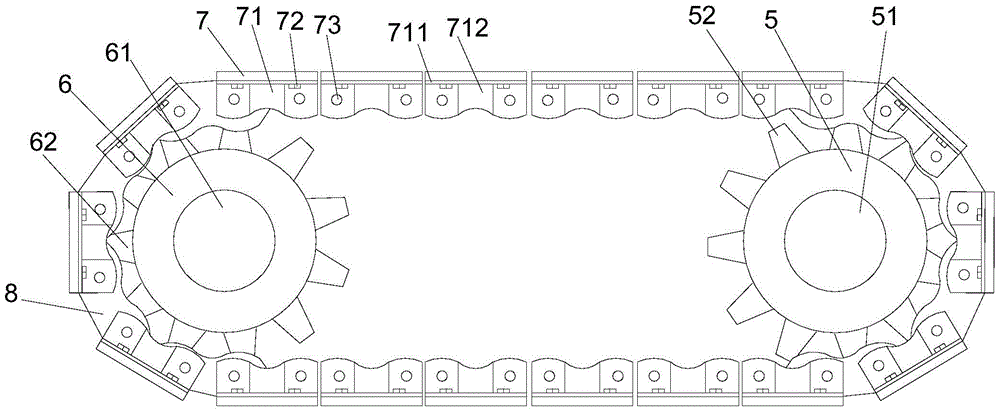

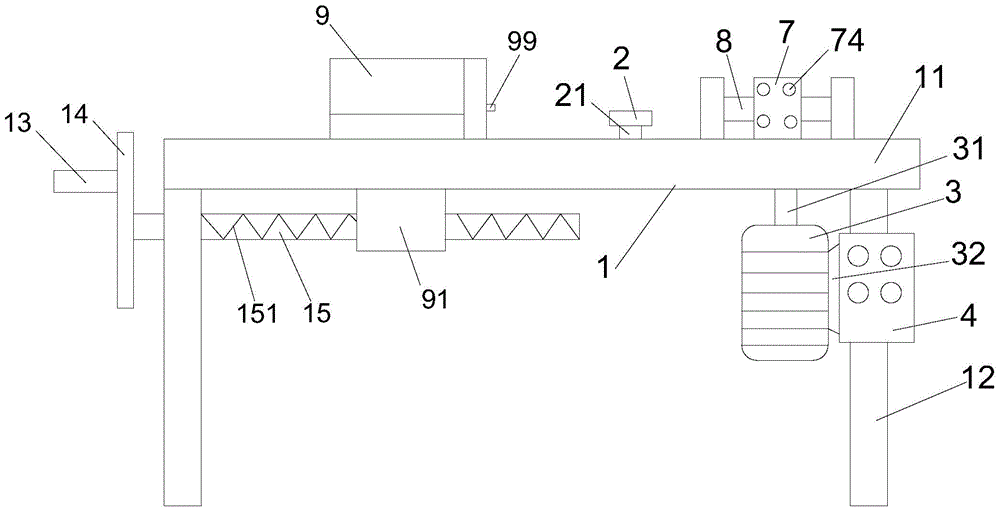

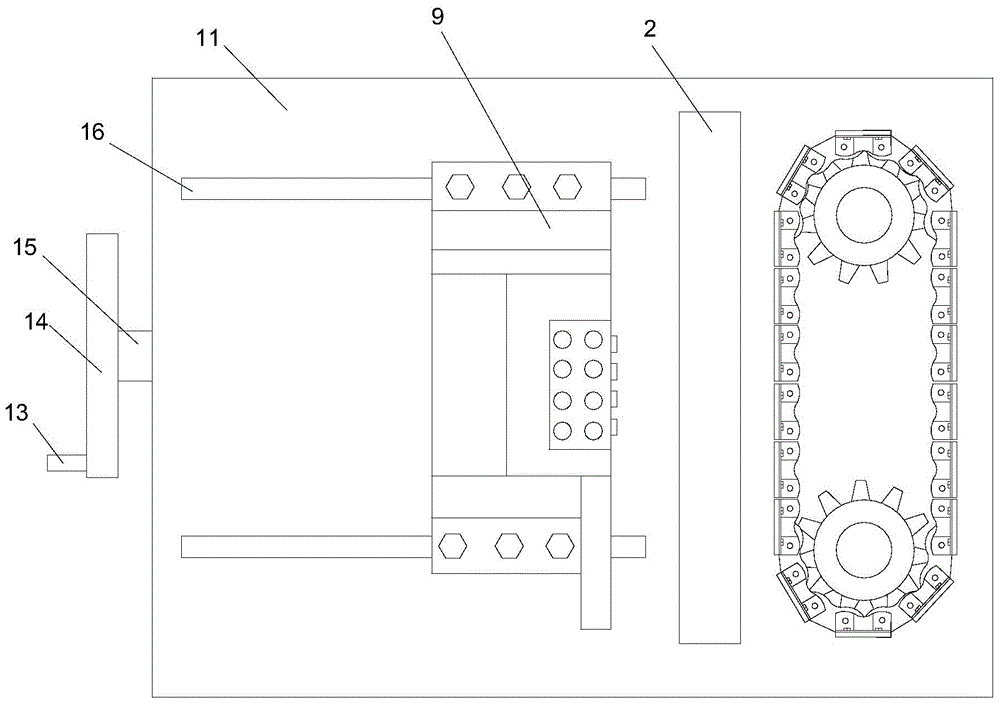

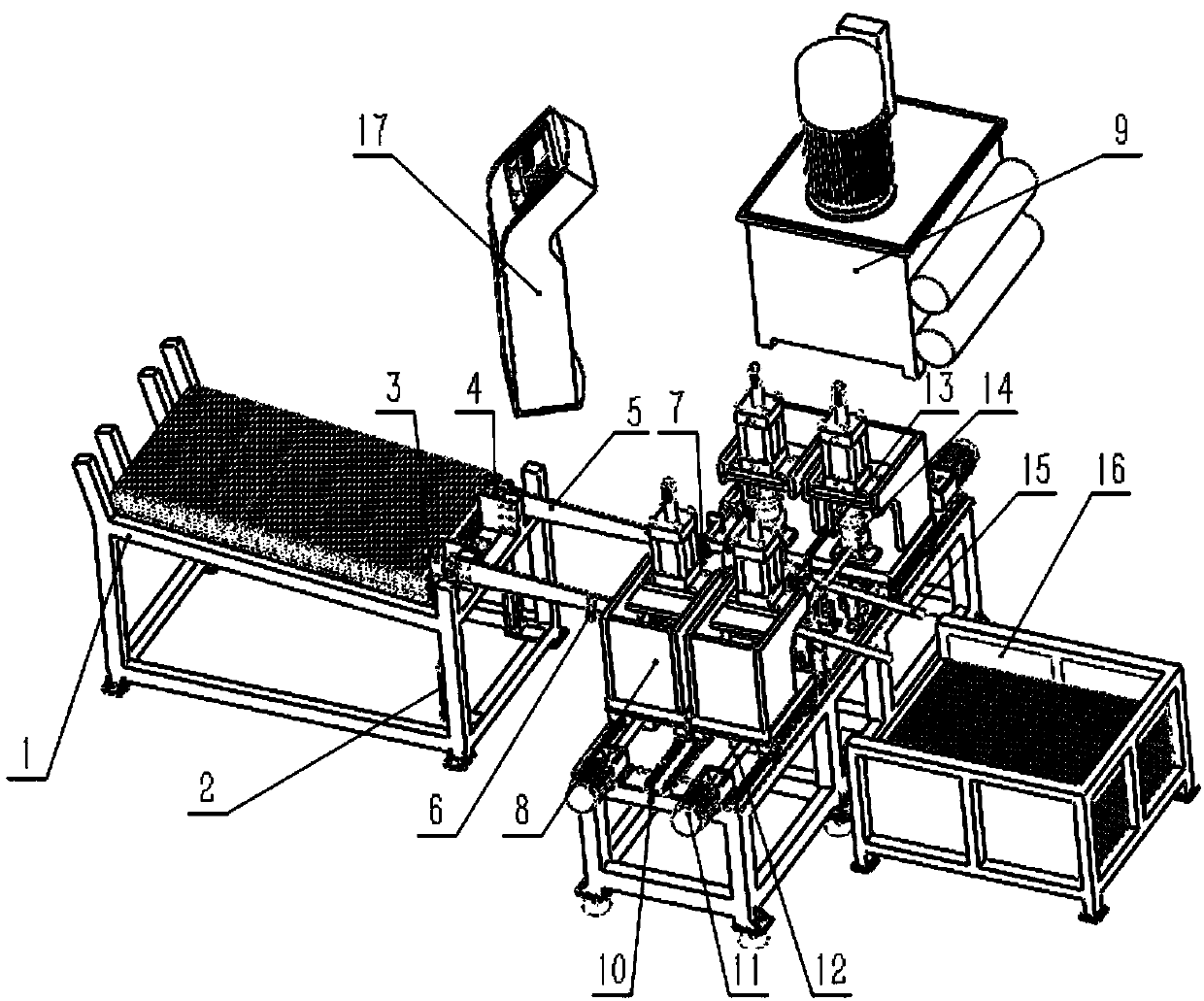

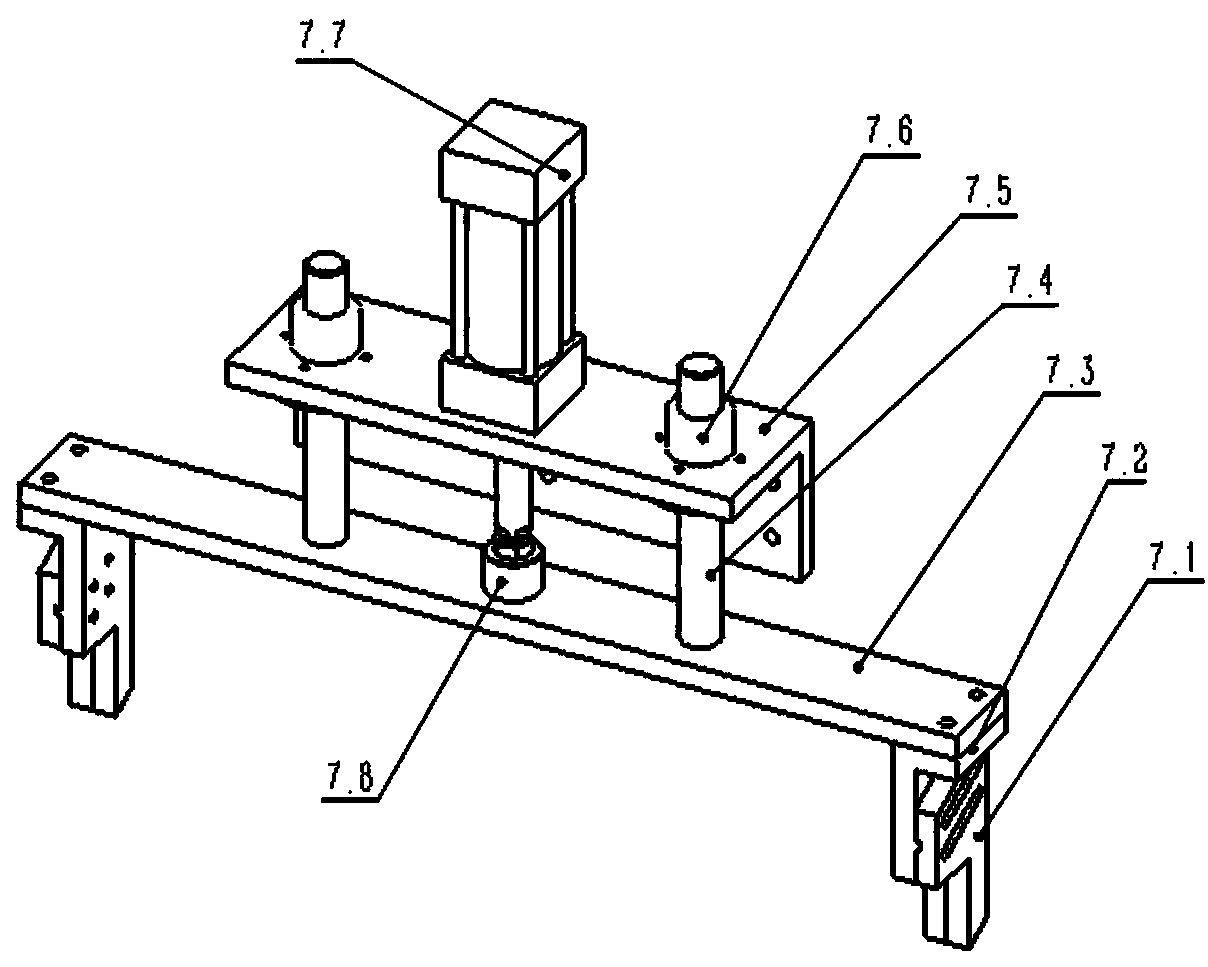

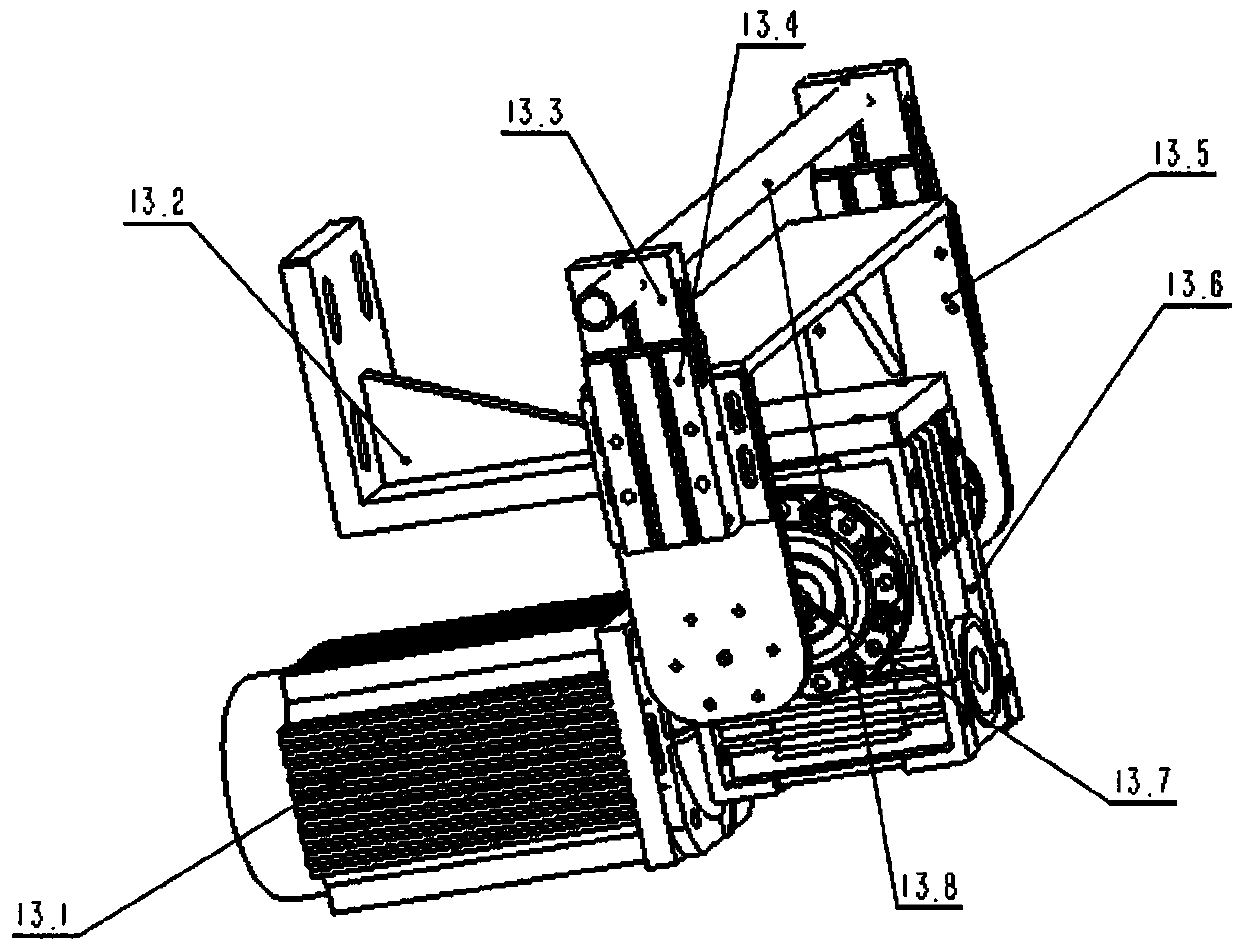

Integrated stamping forming process for attached plate of film clamping chain

ActiveCN108262439AImprove step positioning accuracyEnsure stamping stabilityMetal chainsProcess qualityEngineering

The invention discloses an integrated stamping forming process for an attached plate of a film clamping chain. The integrated stamping forming process comprises the following processing steps of: a, stamping guide positioning holes and a process hole; b, stamping and pressing a groove, and stamping an inner hole of the attached plate; c, stamping and concaving, extruding a lug boss and performinghole-flanging; d, trimming twice; e, pressing a bevel edge; f, pre-bending by 45 degrees for a first time, performing fine stamping and bending by 90 degrees for a first time; g, performing hole extrusion; h, pre-bending by 45 degrees for a second time and pre-bending by 90 degrees for a second time; i, performing product blanking; and j, cutting off waste. In case of reducing equipment and procedures needed for processing, the integrated stamping forming process improves the attached plate groove processing quality, the lug boss processing quality, bending precision and comprehensive quality,and improves the qualification rate of stamping and processing an attached plate part.

Owner:HANGZHOU DONGHUA CHAIN GRP

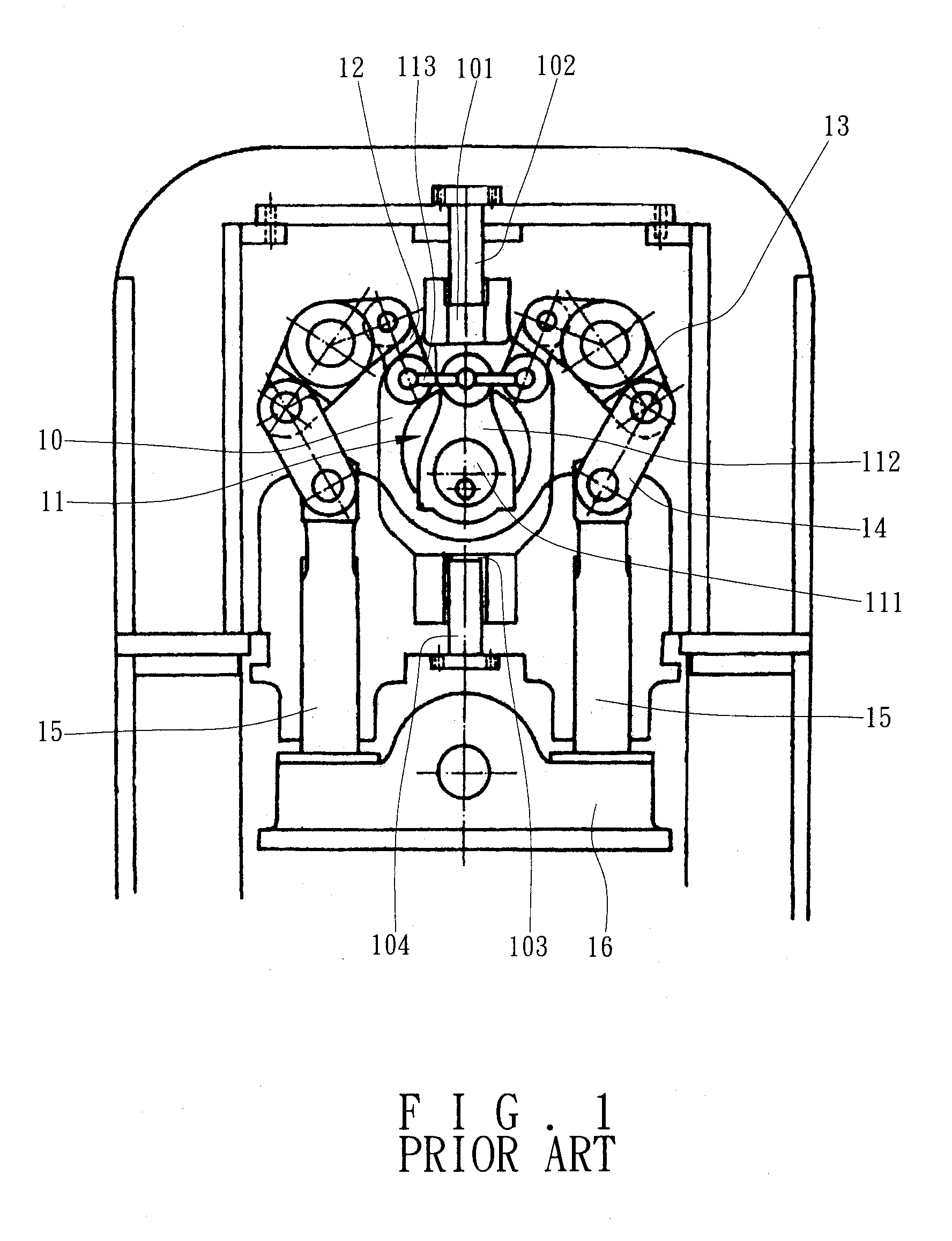

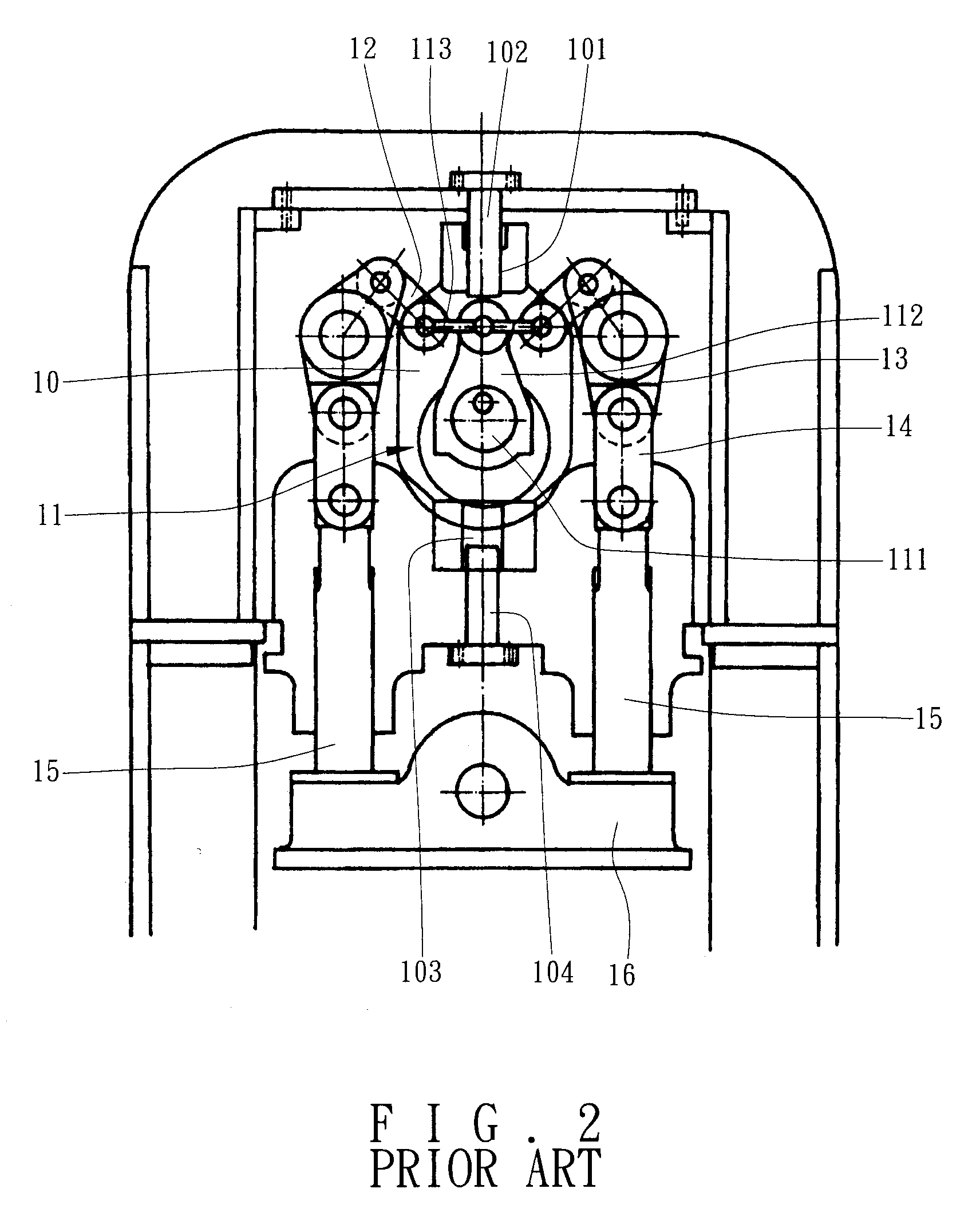

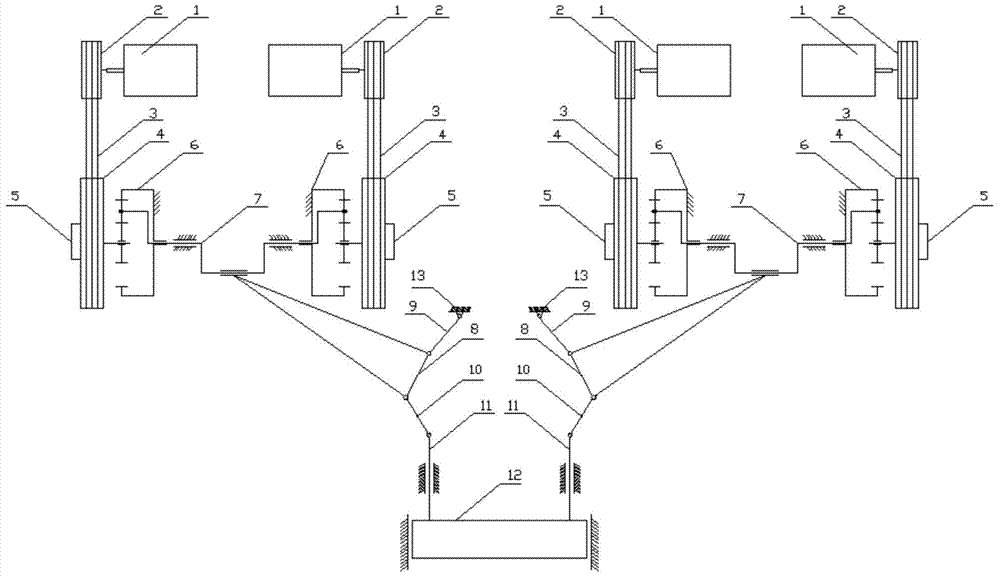

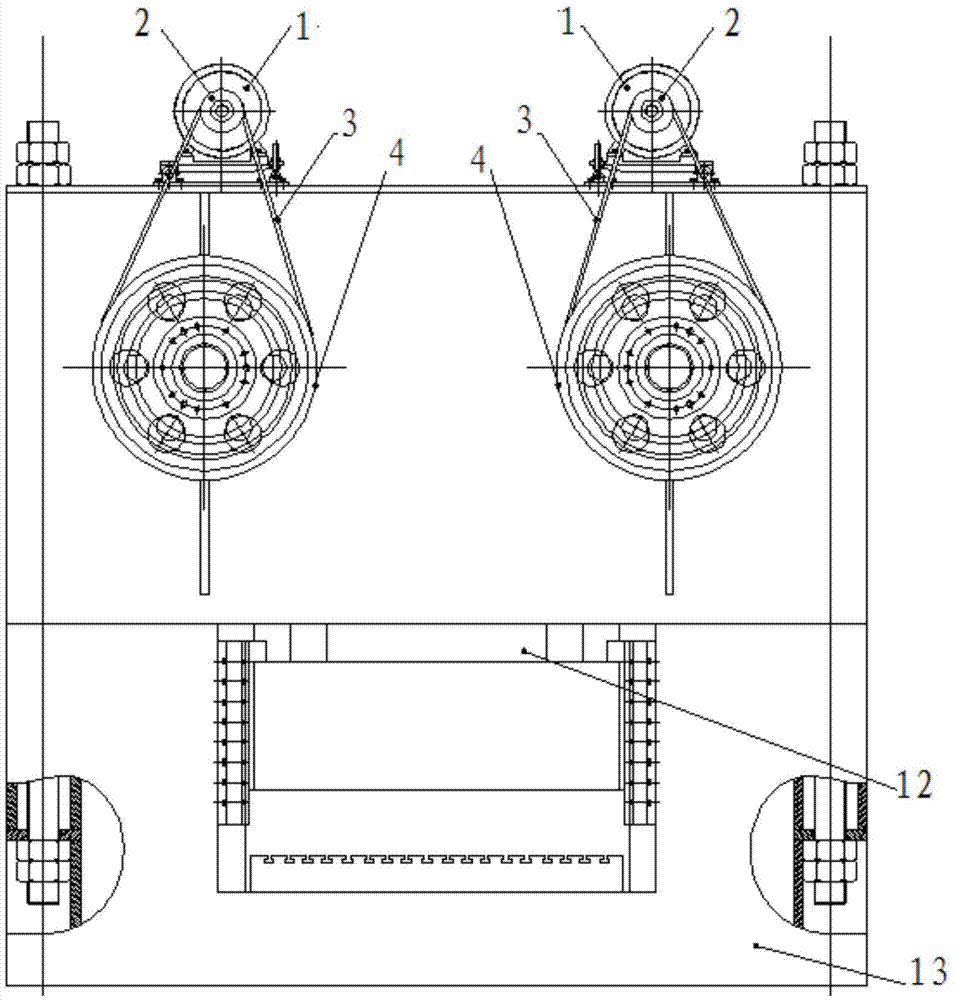

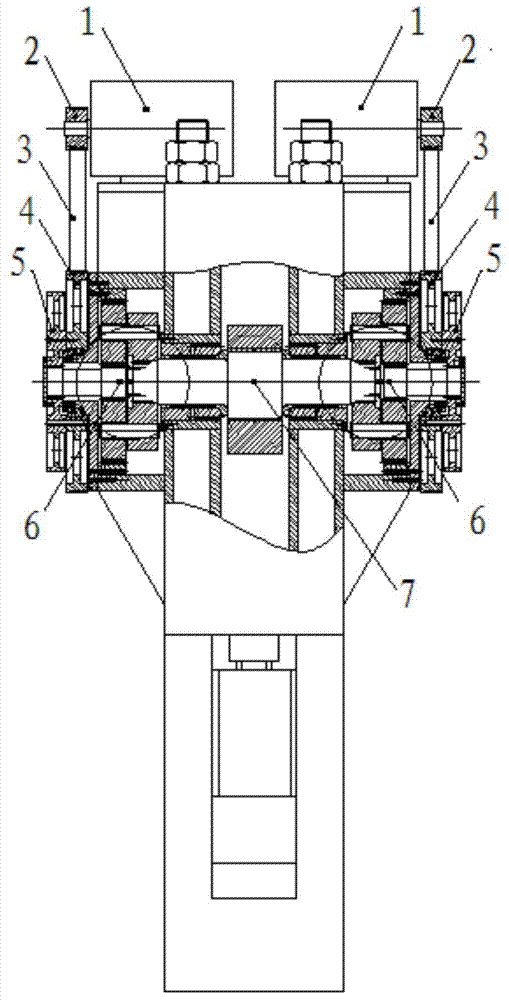

Drive system applicable to large-tonnage servo direct-driven hot die forging press

Disclosed is a drive system applicable to a large-tonnage servo direct-driven hot die forging press. The drive system comprises four sets of drive mechanisms and two sets of actuating mechanisms. The drive mechanisms are in multilateral layout, each set of the drive mechanism comprises a servo motor, an output shaft of each servo motor is connected with a large belt wheel through a small belt wheel and a drive belt, the outer side of each large belt wheel is connected with a brake, and the inner side of each large belt wheel is connected with an input shaft of a planetary gear reducer. Two sets of toggle link mechanisms are adopted as the actuating mechanisms, each set of toggle link mechanism is composed of a crank, a triangular connecting link, an upper toggle link and a lower toggle link which are connected, output ends of the four planetary gear reducers are connected with two ends of the two cranks respectively, one end of each triangular connecting link is directly sleeved on the corresponding crank, the upper end of each triangular connecting link is connected onto an upper crossbeam of the hot die forging press through the corresponding upper toggle link, and the lower end of each triangular connecting link is connected with a slider through the corresponding lower toggle link and a guide plunger type connecting link. By the drive system, torque needed for forging can be lowered remarkably, the requirement on motor power is lowered, and bearing capacity and working efficiency of the hot die forging press are improved.

Owner:XI AN JIAOTONG UNIV

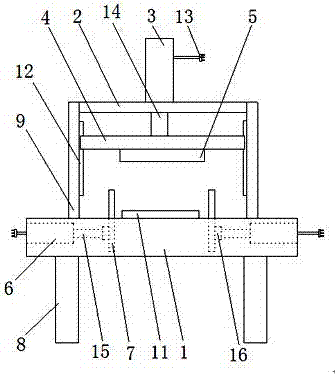

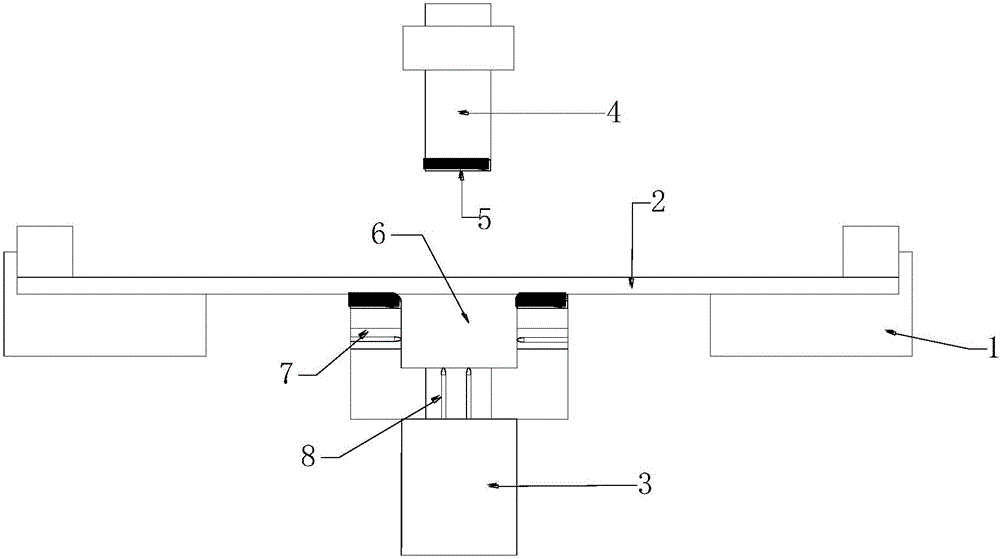

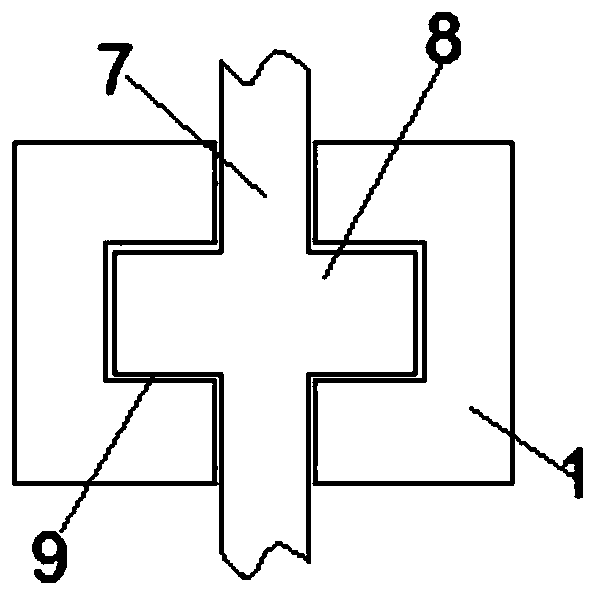

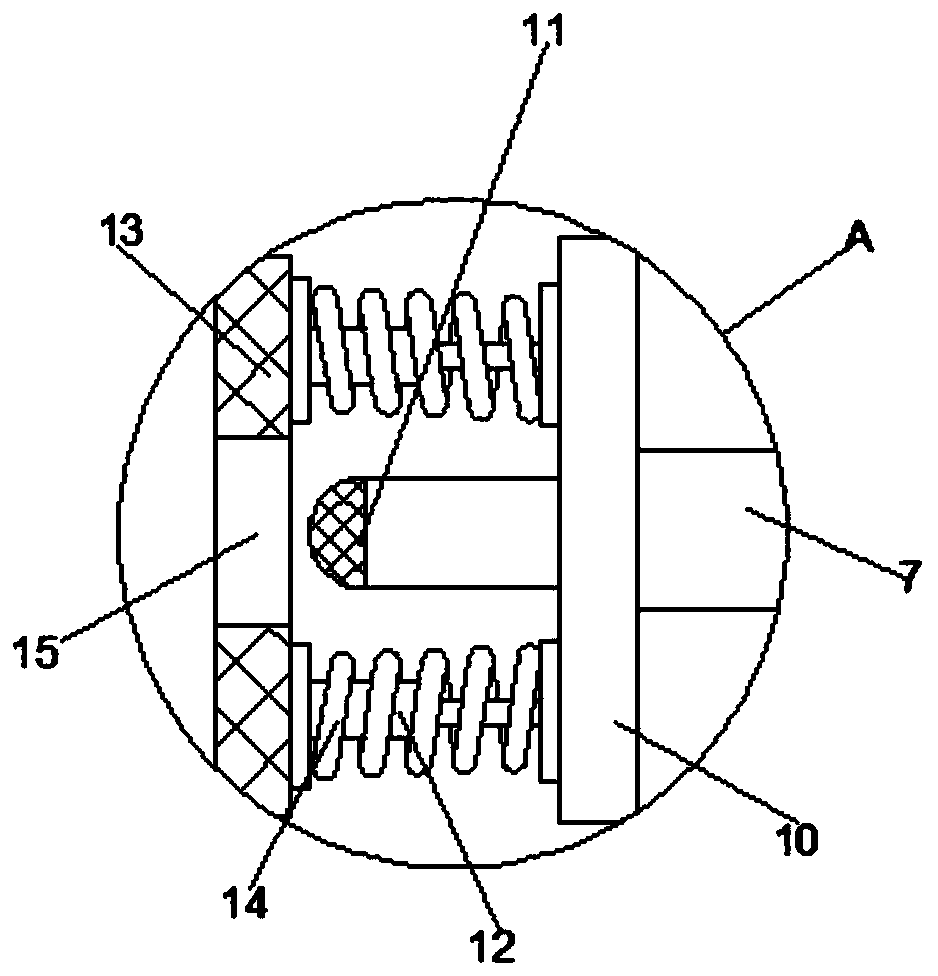

Sealing device

ActiveCN104057737AImprove work efficiencyImprove stamping qualityStampingPulp and paper industryPaper sheet

Owner:GUANGZHOU KINGTELLER TECHNOLOGY CO LTD

Panel stretching die component for metal stamping

InactiveCN107127260AIncrease the ejection force areaAvoid deformationShaping toolsEjection devicesPunchingLiquid storage tank

The invention discloses a panel component drawing processing mold assembly for metal stamping, which comprises a lower mold base, a liquid storage tank, an oil supply pump, a jacking base, an upper mold base and a lower mold sleeve, and the lower surface of the upper mold base is fixedly connected with a punch , the lower die set is fixed on the lower die base and the inner surface of the lower die set is contacted with a bottom plate, the edge of the lower surface of the bottom plate is fixed with a support ring plate, the side of the lower die set is provided with a ring groove, and the liquid outlet of the oil supply pump passes through The pipeline communicates with the ring groove from the inner ring surface of the supporting ring plate, and the inner wall of the lower die sleeve is provided with an oil collecting groove, the oil collecting groove is connected to the liquid storage tank through the pipeline, and the oil inlet of the oil supply pump is connected to the liquid storage tank through the pipeline. This kind of metal stamping panel parts stretching processing mold assembly uses the inner bottom surface of the lower mold sleeve as the ejection surface to increase the ejection force area to avoid deformation, and brush the side wall with lubricating oil or remove it while ejecting. The mold agent assists in demoulding while protecting the surface of the mold and the surface of the workpiece to improve the stamping quality of the product.

Owner:邹小辉

Sheet metal stamping device with heating function

InactiveCN106623569AImprove thermal conductivityEvenly heatedShaping toolsMetal working apparatusManufacturing cost reductionEngineering

The invention relates to a sheet metal stamping device with a heating function. The sheet metal stamping device is characterized in that a sheet metal part is mounted on a stamping supporting seat transversely, a stamping die with a stamping cavity is mounted below the sheet metal part, a stamping head is arranged above the sheet metal part, a high-temperature heating device is mounted in a die orifice of the stamping die, a heating device is mounted in the top of the stamping head, a heat insulation cavity communicated with the stamping cavity is formed in the side face and the bottom surface of the stamping die, and an ultrasonic wave crack detection head is mounted in the heat insulation cavity. The sheet metal stamping device with the heating function has the advantages that since the stamped sheet metal part is subjected to high-temperature heat treatment in the whole stamping process, stamped portions of the sheet metal part are heated fully and evenly, crack generation can be reduced effectively and stamping quality is improved; the ultrasonic wave crack detection head is used for comprehensively detecting whether deformation portions of sheet metal have cracks or not without later detection, and accordingly sheet metal parts with the cracks can be discovered in the first time, production efficiency can be improved effectively and manufacturing cost is reduced.

Owner:重庆高威汽车科技有限公司

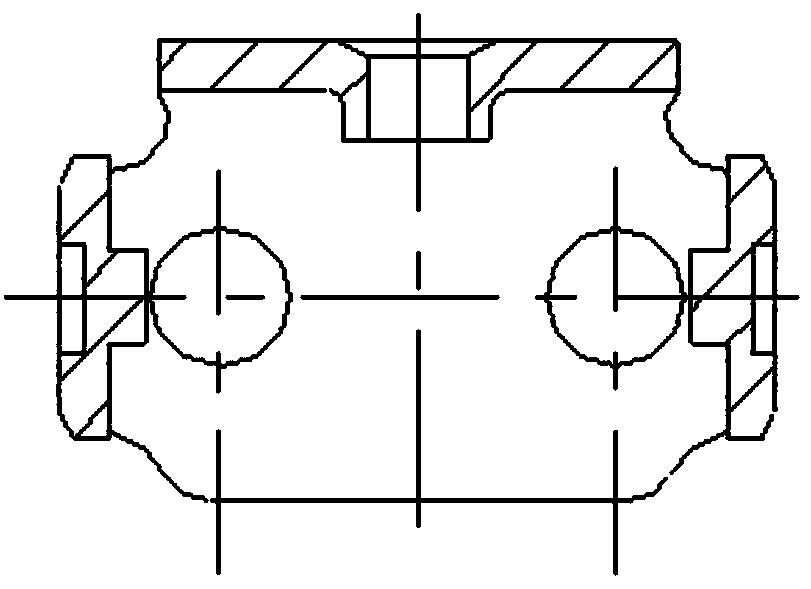

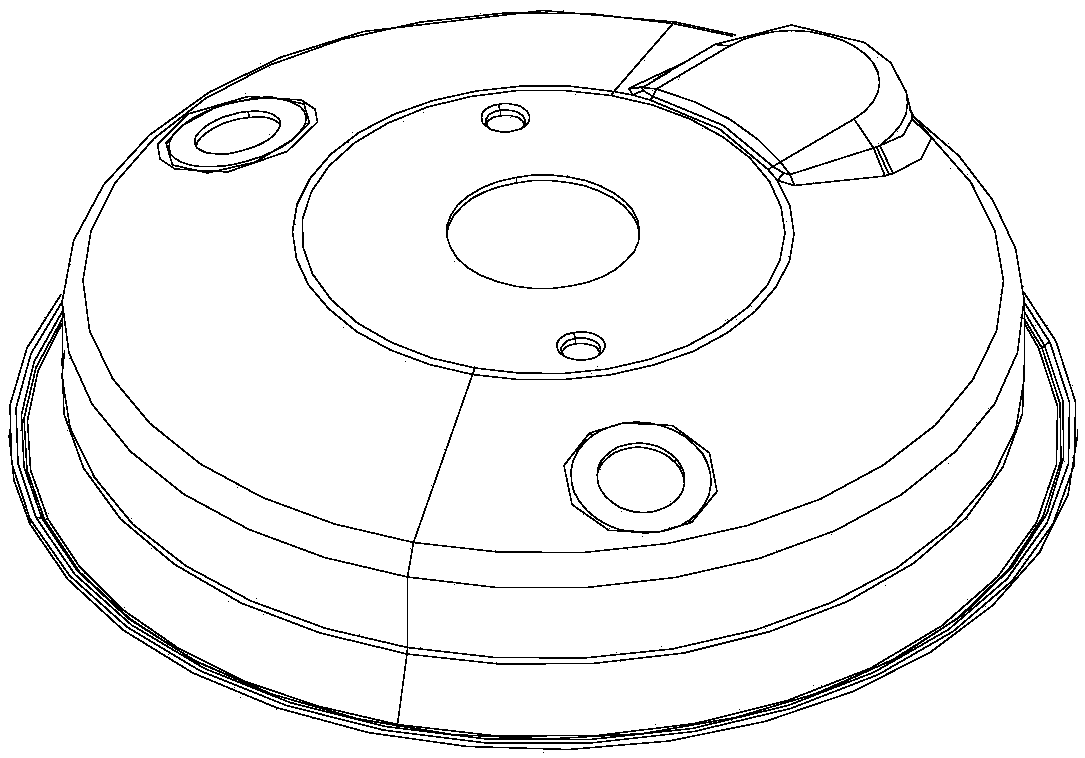

Machining method of vacuum booster shell of magnesium-aluminum alloy and punching mold for drawing molding

The invention discloses a machining method of a vacuum booster shell of a magnesium-aluminum alloy. Proper raw materials are selected; pressing force P in each drawing procedure of workpieces and pressing force P' in each shaping procedure of the workpieces are precisely calculated; then, analog models are built in analysis software for simulation analysis to determine precise deformation in eachpunching procedure; punching molds in each procedure are manufactured according to analysis results for trial production and adjustment according to punching conditions until qualified products are produced; and then, the large-batch punching production is performed. The machining method can guarantee machining of high-quality magnesium-aluminum alloy booster shells, and realizes lightness of thebooster shells; and the magnesium-aluminum alloy shells produced by the method are high in yield, so that the product production cost is greatly reduced. The invention further discloses a punching mold structure of the shells.

Owner:苏州金鸿顺汽车部件股份有限公司

Hardware stamping component capable of discharging rapidly

ActiveCN107838261AImprove stamping qualityFast punching speedShaping toolsMetal-working feeding devicesHydraulic cylinderControl system

The invention discloses a hardware stamping component capable of discharging rapidly. The hardware stamping component comprises a stamping device and a discharging device, and the discharging device is arranged beside the stamping device; the stamping device consists of a base, a rear box body, a rotary worktable, a stepping motor, a lower mold, an upper mold, a hydraulic cylinder and a telescopicair cylinder; the discharging device consists of a base body, a supporting vertical plate, a swing air cylinder, a connecting rod, an electromagnet, a low-speed motor, a discharging pipeline, a material receiving trolley and a power supply; and the stamping component further comprises a control system. According to the stamping component, a form of combining the hydraulic cylinder with the telescopic cylinder is adopted, forming can be achieved by one-time stamping, so that the stamping speed is improved; and the discharging device adopts a mode that the electromagnet swings along with the swinging air cylinder, the electromagnet is electrified and sucks a stamped hardware from the lower mold, the control system controls the electromagnet to be powered off so that the hardware on the electromagnet can automatically falls into the discharging pipeline, then slides into a material receiving box, and therefore, automatic discharging is realized, and the discharging strength is greatly reduced.

Owner:HAIYAN HONGQIANG HARDWARE MFG CO LTD

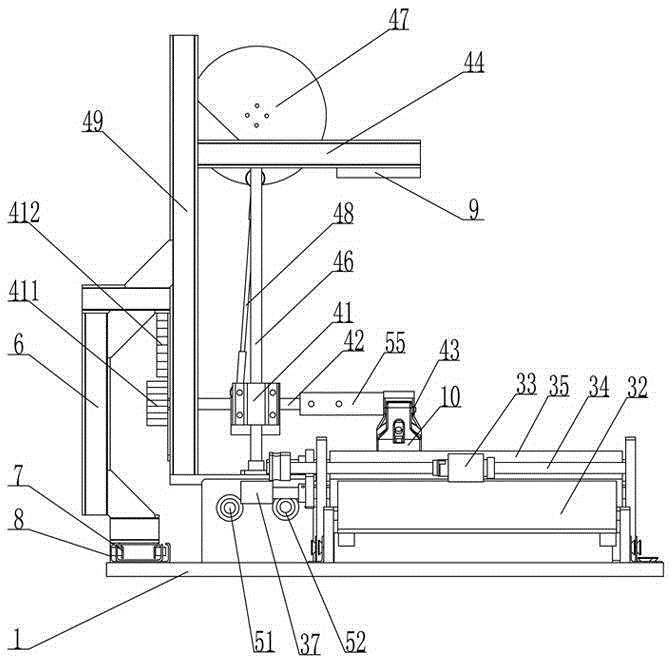

Steel seal stamping machine with automatic feeding and discharging functions

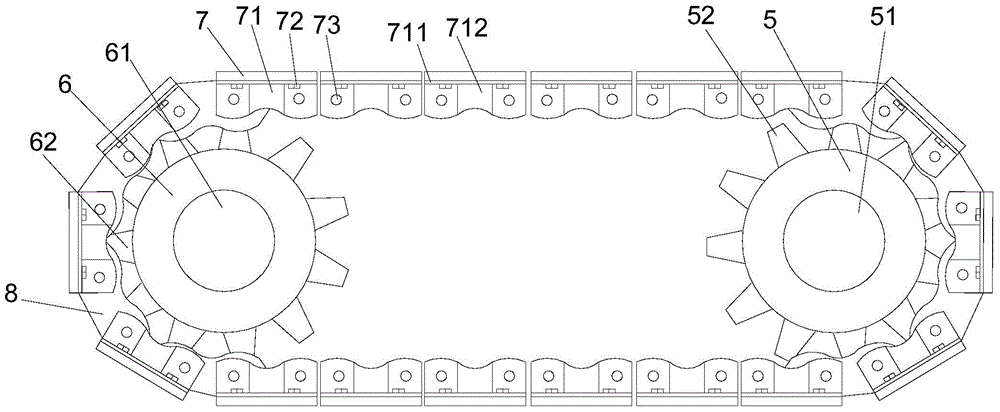

InactiveCN105035638ASimple structureAccurate transmission ratioConveyorsConveyor partsElectric machineryMotor shaft

The invention provides a steel seal stamping machine with automatic feeding and discharging functions. The steel seal stamping machine comprises a working table, a supporting plate, a motor, a controller, a driving wheel, a driven wheel, a plurality of conveying plates, a chain and a steel seal stamping device. The working table further comprises a table top, table legs, a rocking handle, a rotating disc, a slide rod and track grooves, the rocking handle is fixedly connected with the rotating disc, the rotating disc and the slide rod are fixedly connected, the driving wheel is arranged above the table top, a motor shaft penetrates through the table top and is connected with the driving wheel, and the driven wheel is located above the table top. The steel seal stamping machine is simple in structure; as the chain is used for transmission, it is ensured that the transmission ratio is accurate, the transfer power is large, force exerted on the shaft is small, and the transmission efficiency is high; the steel seal stamping machine can work in an atrocious environment, the rotating speed can be controlled by the controller, the automation degree is high, the rotating speed is appropriate, steel seals can be replaced, and the steel seal stamping machine is wide in application range, high in the steel seal stamping quality, capable of automatically feeding and discharging materials and high in working efficiency.

Owner:浙江亚泰连接盘制造有限公司

Metal plate pressure tank bending die

The invention discloses a metal plate pressure tank bending die which comprises an upper die plate, a lower die plate, a guide post device, a male die, a female die component and projecting strips. The upper die plate is connected with the lower die plate through the guide post device, the male die is arranged below the upper die plate, the female die component is arranged on the lower die plate and comprises two female die blocks, a bottom plate and positioning blocks, the bottom plate is arranged between the two female die blocks, the height of each female die block is larger than that of the bottom plate, the positioning blocks are arranged on the female die blocks, the projecting strips are arranged on the lower surface of the male die close to two ends of the female die blocks, and connecting angles of the inner slide faces and the upper surfaces of the female die blocks are circular angles. The metal plate pressure tank bending die is fine in punching effect, high in punching efficiency and suitable for batch punching and does not easily rebound, and punching quality is improved.

Owner:吴中区光福华宇钣金厂

Novel punching machine

The invention relates to a novel punching machine. The novel punching machine comprises a rack, a driving device, a crank shaft, a first crank shaft connection rod, a second crank shaft connection rod, a first horizontal guide block, a second horizontal guide block, a first adapter coupling connection rod, a second adapter coupling connection rod, a first vertical guide connection rod, a second vertical guide connection rod, a first lever, a second lever, a first mold adjusting connection plate, a second mold adjusting connection plate, a first slide block connection rod, a second slide block connection rod, a slide block and a worktable, wherein the driving device is in driving connection with the crank shaft; the crank shaft is in drive connection with the first crank shaft connection rod, and the second crank shaft connection rod respectively; and the slide block is located above the worktable. The novel punching machine provided by the invention has the advantages of simple structure, small inertia and high precision; the staying time of a bottom dead center is long, a punching surface of a punched workpiece is smooth and the quality of the punched workpiece is improved; and a stressed reversed impact force is small, abrasion to equipment is small and the service life of the equipment is prolonged.

Owner:MINGXUDONGGUAN PRECISION MACHINARY CO LTD

Adjustable press machine

Disclosed is an adjustable press machine. The adjustable press machine comprises an operating platform, an adjusting frame, sliding blocks, a fixing block, a first air cylinder, a second air cylinder, a stamping plate, a lower cushion plate and a control cabinet. The adjustable press machine is characterized in that the operating platform is arranged on a support, the adjusting frame is arranged on a fixing plate, and an adjusting cavity, a third air cylinder and a fourth air cylinder are arranged on the adjusting frame. According to the adjustable press machine, sliding channels are formed in the two sides of the adjusting frame, the sliding blocks are arranged on the sliding channels, a connecting rod is arranged between the sliding blocks, and the fixing block is arranged on the connecting rod; the second air cylinder on one sliding block is connected with the fixing block through the connecting rod, and therefore the fixing block can be adjusted to slide back and forth on the connecting rod through the second air cylinder; the sliding blocks are connected with connecting rods of the third air cylinder and the fourth air cylinder, and can move on the sliding channels through the third air cylinder and the fourth air cylinder, the position of the fixing block in the adjusting frame can be adjusted, then the position of the stamping plate can be adjusted, and therefore the adjustable press machine is suitable for different processed workpieces, and the application range of the press machine is broadened.

Owner:芜湖瑞德机械科技有限公司

Integrated stamping equipment

InactiveCN104889240AImprove stamping qualitySave human effortMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses integrated stamping equipment. The integrated stamping equipment comprises an upper stamping seat, a lower stamping seat used for placing a product, a punching device located onto the upper stamping seat, a deburring device located onto the upper stamping seat and a conveying device fixed onto the upper stamping seat and used for conveying a part to positions of the above punching device and of the deburring device. The conveying device comprises a suction part for sucking up the part and a movable part which is fixed onto the upper stamping seat and drives the suction part to move. The integrated stamping equipment has following beneficial effects: the integrated stamping equipment is capable of automatically conveying the part to a punch press for punching and then conveying the part to the deburring device for stamping and deburring without manpower; and the integrated stamping equipment, with punching and deburring functions, has high stamping quality and obtains effects of saving manpower and increasing working efficiency.

Owner:昆山—邦泰汽车零部件制造有限公司

Plastic part punching machine

InactiveCN102490206AOrientation is accurateStamping precisionMetal working apparatusPunchingEngineering

The invention belongs to the technical field of punching machines, and particularly relates to a plastic part punching machine, which comprises a lower base, a support disposed vertically on the lower base and an upper base disposed at the upper end of the support. A lower punching disc provided with a plurality of punching dies is disposed on the upper end face of the lower base. An upper punching disc matched with a punching disc is disposed below the upper base. The lower end face of the upper punching disc is provided with punching heads which correspond to the punching dies on the lower punching disc one to one. A guide rod is fixedly arranged at the upper end of the upper punching disc, a punching cylinder is fixedly arranged below the upper base, and a piston rod of the punching cylinder is fixedly connected with the guide rod through a connector. During punching, a plurality of parts to be punched are correspondingly placed on the plurality of punching dies of the lower punching disc, the punching cylinder is started, the piston rod of the punching cylinder drives the upper punching disc downwards to enable the plurality of punching heads on the lower end face of the lower punching disc to correspond to the respective punching dies of the lower punching disc for punching, and accordingly a plurality of parts can be punched at one time and punching efficiency is improved.

Owner:常州鑫鹏工具制造有限公司

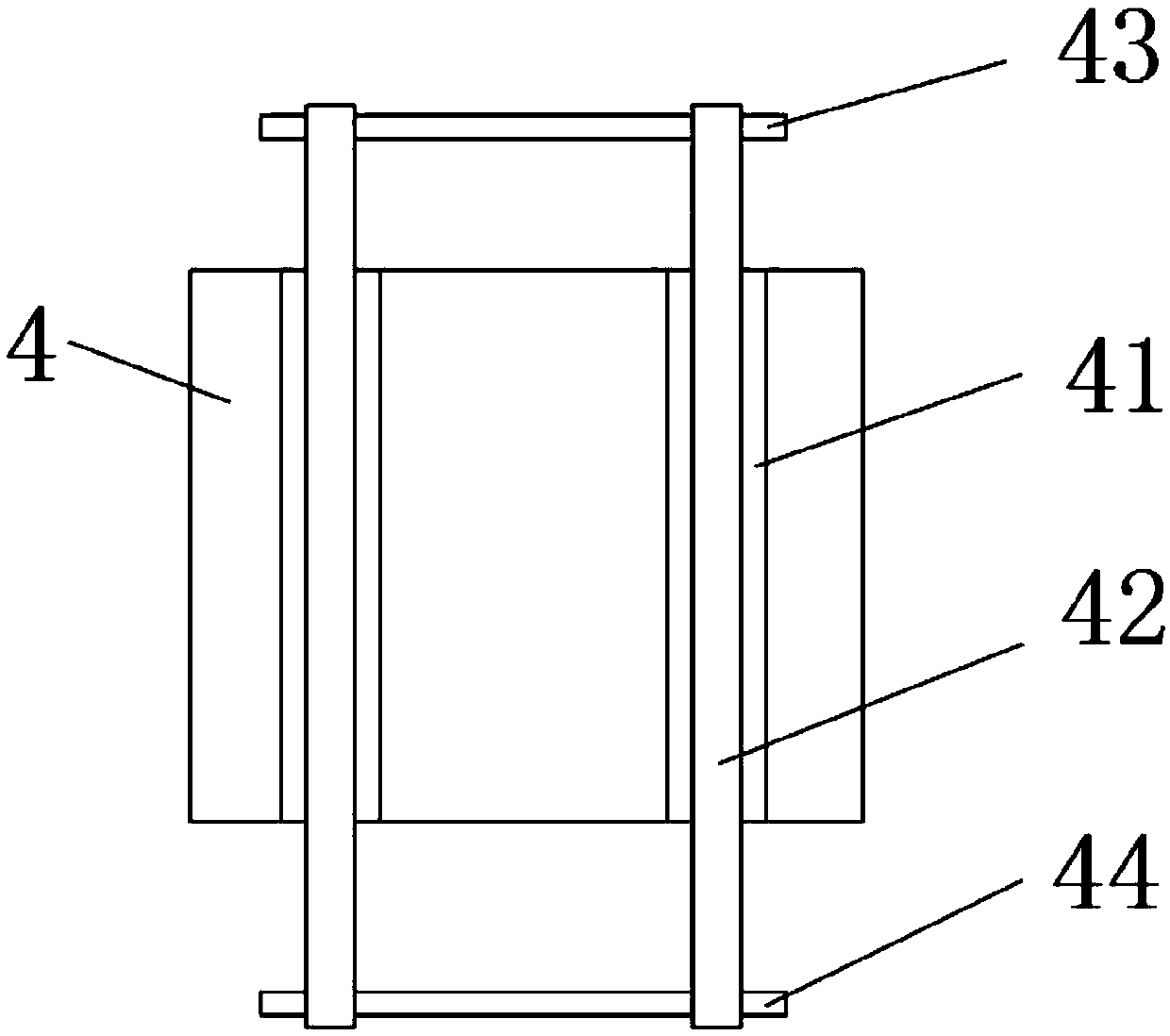

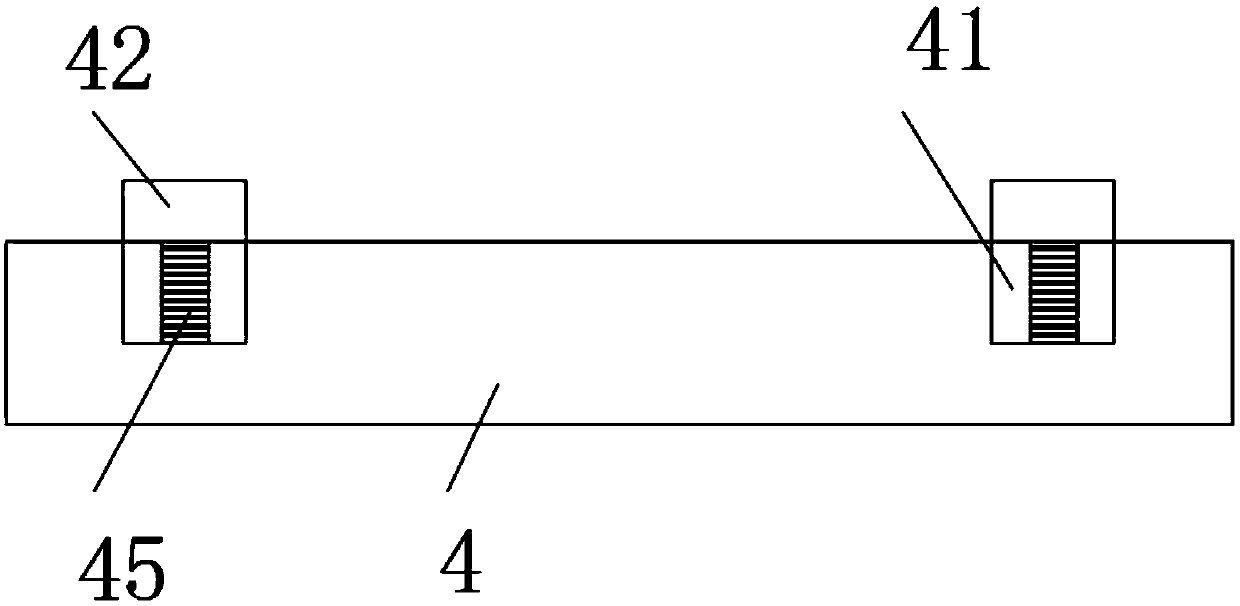

Mica tube punch forming device and operation method thereof

InactiveCN111469523AIntegrity guaranteedGuaranteed stabilityLamination ancillary operationsControlling laminationStructural engineeringMechanical engineering

The invention provides a mica tube punch forming device and an operation method thereof. The mica tube punch forming device comprises a bottom plate and a top plate, connecting frames are fixedly connected to the two sides of the bottom of the top plate correspondingly, hydraulic telescopic rods are fixedly connected to the tops of the inner walls of the two connecting frames correspondingly, pushing blocks are fixedly connected to the bottom ends of the two hydraulic telescopic rods correspondingly, and the two sides of each pushing block are slidably connected with the two sides of the innerwall of the corresponding connecting frame correspondingly. The invention provides the mica tube punch forming device and the operation method thereof. Automated fixation, convenient installation, good fixing effect, the stability between an upper module and a lower module during the operation of the device are ensured, stamping quality is excellent; and meanwhile, mounting and dismounting are convenient, modules of different sizes can be fixed conveniently, the distance between the upper module and the lower module can be adjusted and controlled after the modules are replaced according to the size of the mica tube, the stamping integrity is guaranteed, the practicability of the equipment is improved, and wide application and popularization are facilitated.

Owner:扬州瑞宏电工电气有限公司

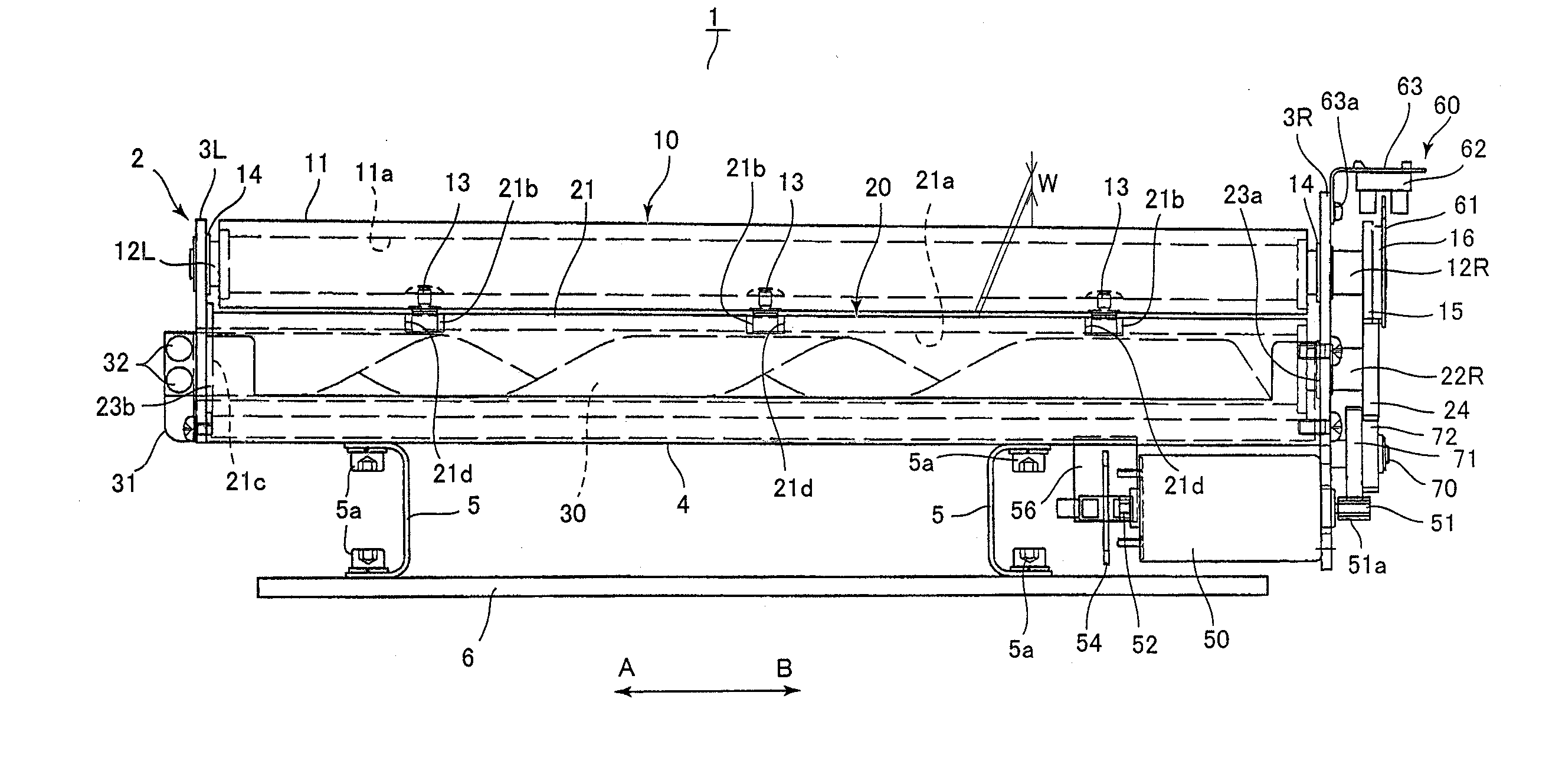

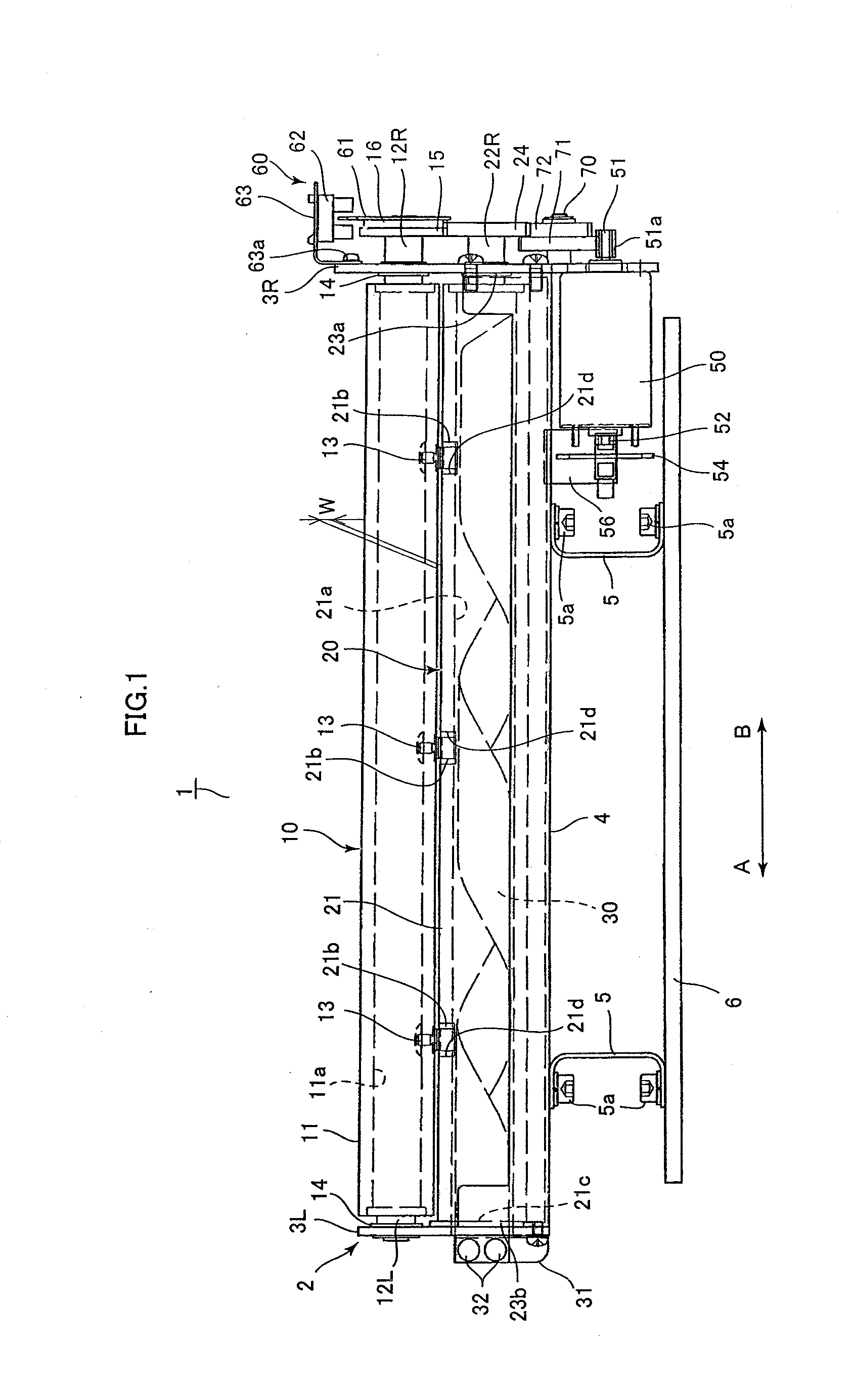

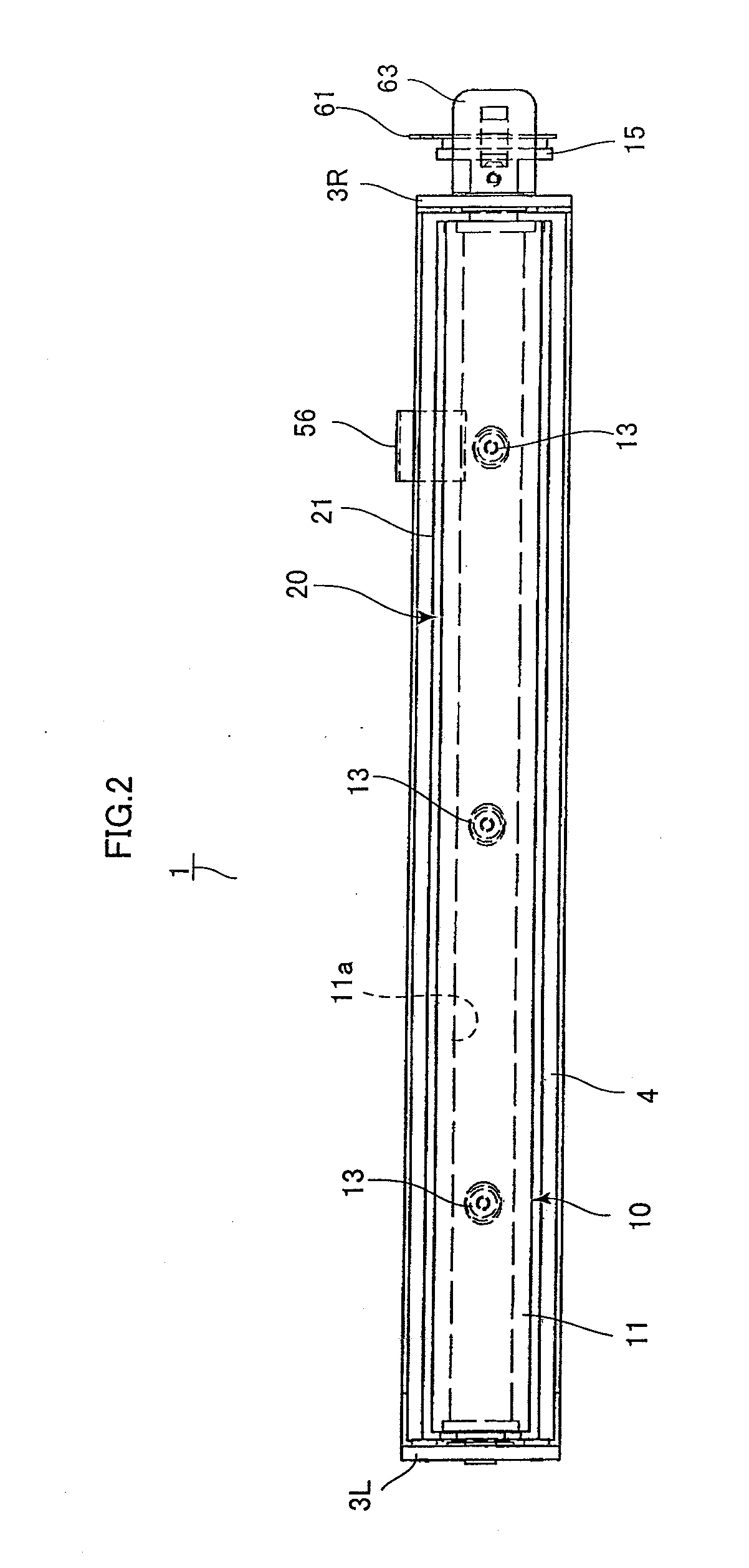

Punching unit

InactiveUS20100275754A1Improve rigidityQuality improvementShearing machinesMetal working apparatusPunchingEngineering

There is provided a punching unit that is readily adjusted, is capable of always punching high quality holes through sheets and is steadily capable of discharging punch chips. A punch shaft and a die shaft are disposed vertically in parallel between side plates and these very punch shaft and the die shaft compose structural members (reinforcing members) of the punching unit. The die shaft has a die shaft body formed into a hollow cylinder and is provided with dies that correspond to the punches of the punch shaft at an outer peripheral surface thereof while fitting into die holes penetrating to the hollow section. A chip discharging screw plate fixed to the right side plate is disposed in the hollow section of the die shaft. Punch chips are transported along slopes of the chip discharging screw plate and discharged out of an opening when the die shaft rotates.

Owner:DAIDO KOGYO CO LTD

Nano-copper connecting piece efficient pneumatic stamping device for factory production

InactiveCN110918737AAvoid damageUniform punching forceMetal-working feeding devicesStripping-off devicesStampingManufacturing engineering

The invention discloses a nano-copper connecting piece efficient pneumatic stamping device for factory production. A machine body is included. Universal wheels are movably installed on a lower portionof the machine body. A base is fixedly installed at an upper end of the machine body. A bearing plate is movably installed in the middle of an outer surface of an upper end of the base, grooves are arranged in two sides of the outer surface of the upper end of the bearing plate, a fixing frame is fixedly installed on one side of the outer surface of the upper end of the base, a pneumatic box is movably installed at the upper end of the fixing frame, and a top pressing plate is movably installed at the lower end of the pneumatic box. By using the nano-copper connecting piece efficient pneumatic stamping device for factory production, the stamping device can carry out continuous stamping through feeding of a conveying belt, labor intensity is reduced while a production capacity is greatly improved, stamping is more stable, chippings on the bearing plate can be removed through a waste gas exhausted by an air cylinder, dust in air is effectively filtered during air inflow, and a situationthat the air cylinder is damaged due to a fact that the dust enters into the air cylinder is avoided.

Owner:JIANGYIN SANLING METAL PROD

Steel seal stamping machine

The invention provides a steel seal stamping machine. The steel seal stamping machine comprises a work table, a supporting plate, a motor, a controller, a driving wheel, a driven wheel, a plurality of conveying plates, a chain and a steel seal stamping device. The work table further comprises a table top, table legs, an operating crank, a rotating disc, a sliding rod and rail grooves. The table top is supported by the table legs. The operating crank is fixedly connected with the rotating disc. The rotating disc is fixedly connected with the sliding rod. The driving wheel is located above the table top. A shaft of the motor penetrates through the table top to be connected with the driving wheel. The driven wheel is located above the table top. The multiple conveying plates are connected together through the chain. The steel seal stamping machine is simple in structure; as transmission is achieved through the chain, the accurate transmission ratio is guaranteed, and the transmitted power is large; in addition, as force acting on the shaft is small, the transmission efficiency is high, and the steel seal stamping machine can work in the severe environment; as the rotating speed can be controlled through the controller, the automation degree is high, and the rotating speed is proper; in addition, as a steel seal stamp can be replaced, the application range is wide, and the steel seal stamping quality is good.

Owner:浙江亚泰连接盘制造有限公司

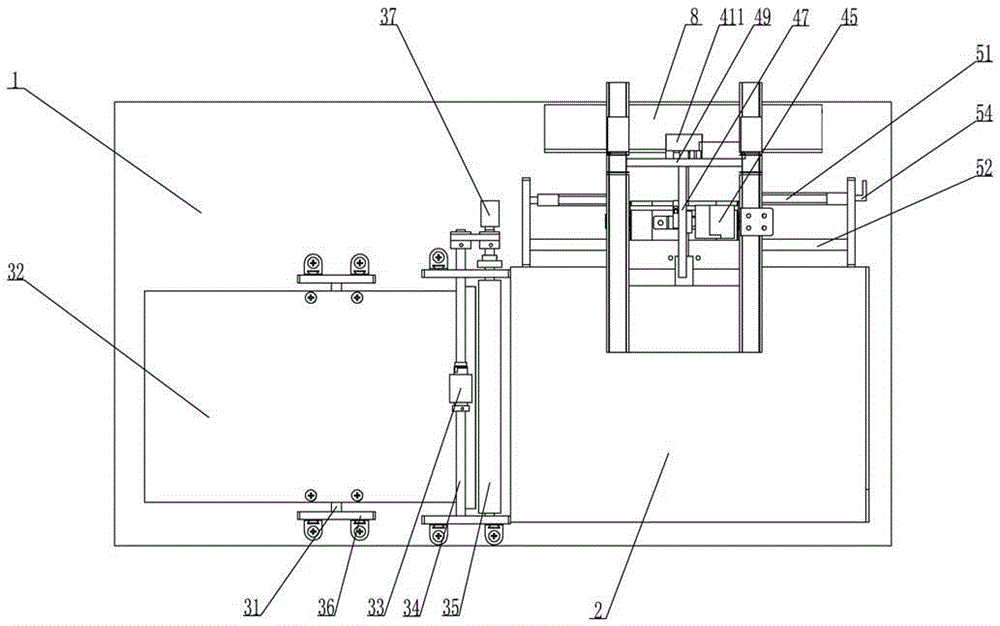

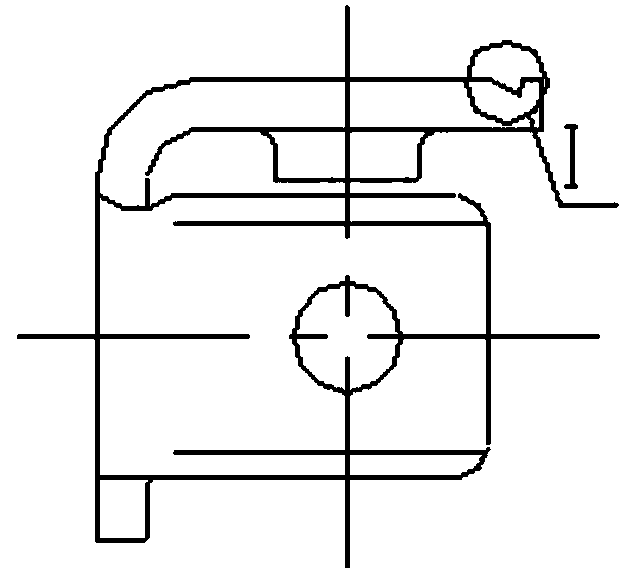

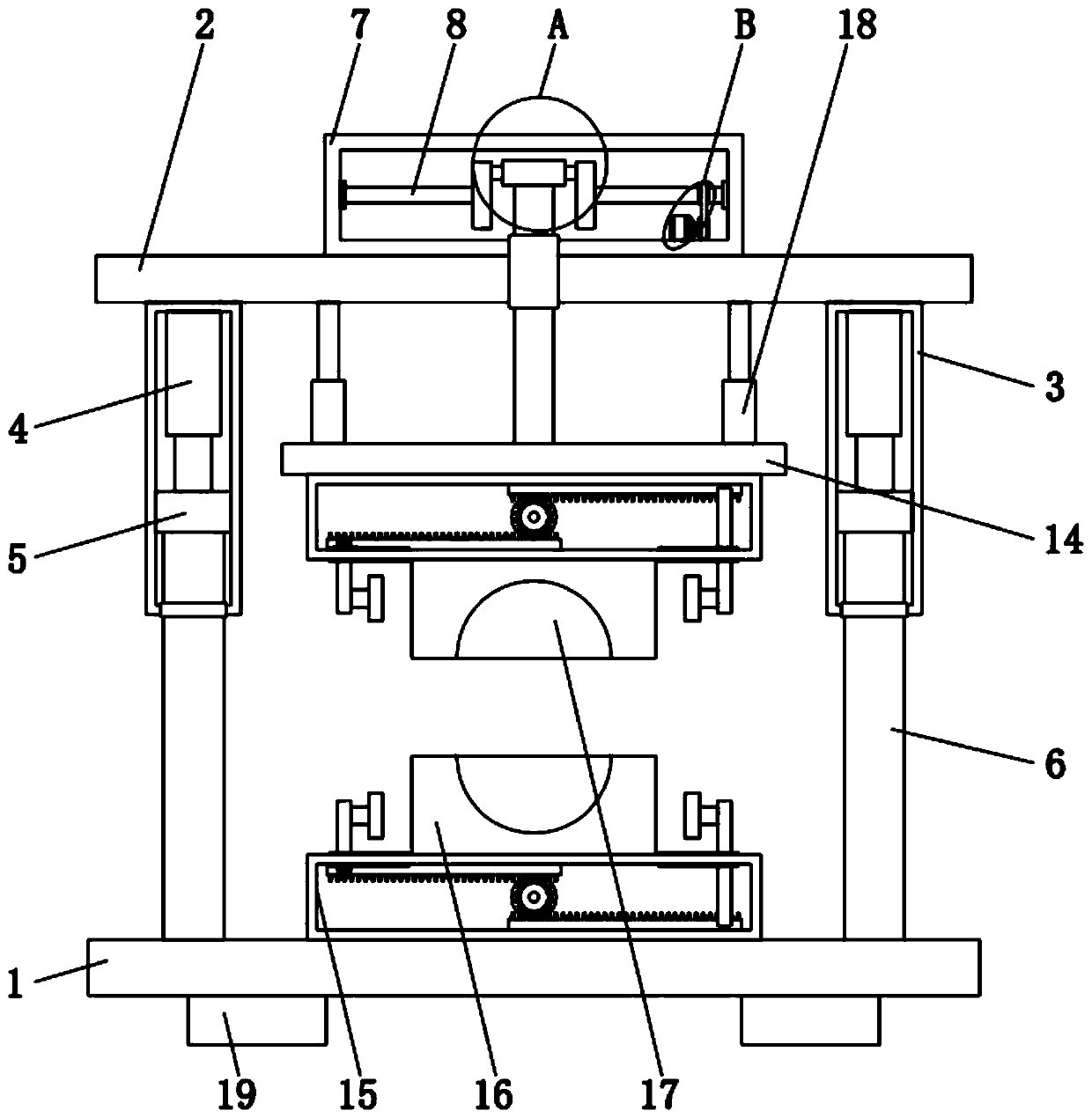

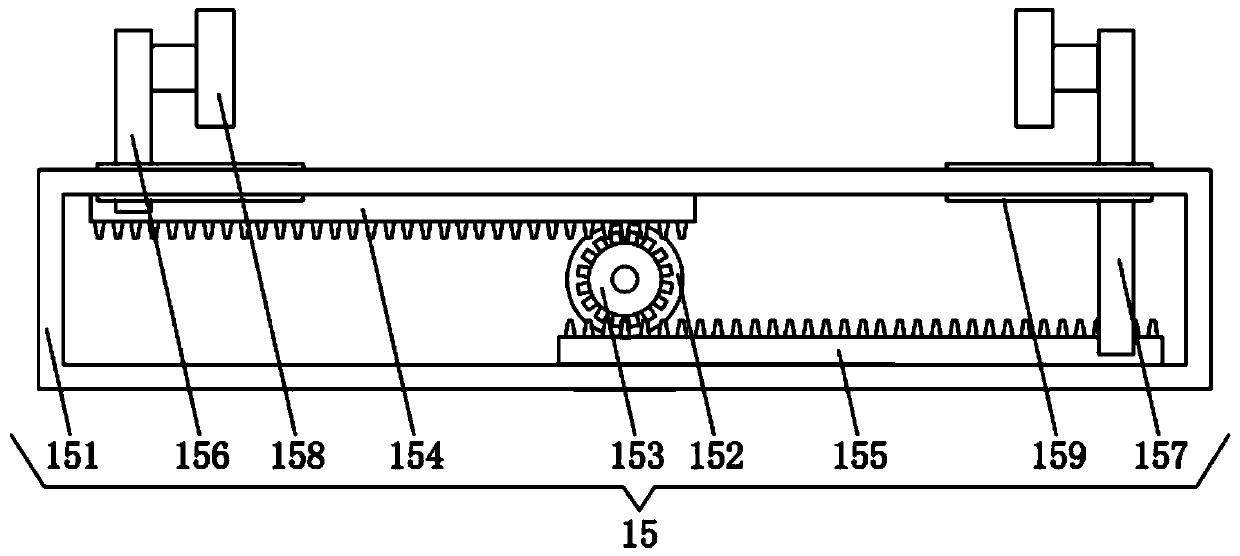

Automatic punching integrated unit for four intersecting lines at two ends of circular pipes

The invention relates to an automatic punching integrated unit for four intersecting lines at two ends of circular pipes and belongs to the technical field of automation, and automatic punching of theintersecting lines of the circular pipes which are perpendicularly intersected is achieved. The automatic punching integrated unit comprises a stock bin frame, four station moving hydraulic punchingunits, a material transferring part, a finished product stock bin, a hydraulic station, a CNC control center and the like. The automatic punching integrated unit mainly comprises air cylinders, gears,racks, a material guide mechanism, buffer plates, a material jacking mechanism, four station machining mechanisms, a hydraulic control workstation, a linear guide way, a servo motor, a ball screw, a180-degree turnover mechanism, a circular pipe punching die, a discharge guide rail, a finished product stock bin and the CNC control center. The automatic punching integrated unit is designed for modern agricultural development and integrates multiple working procedures of feeding, punching and discharging. The automatic punching integrated unit is good in consistence of processed products, highin precision, easy to operate, high in automation degree and machining and producing efficiency and capable of adapting to machining of circular pipes with various pipe diameters and lengths.

Owner:山东金博利达精密机械有限公司

Punch for processing bus duct

InactiveCN110773618AControl the direction of entry and exitAvoid offsetNon-rotating vibration suppressionShaping safety devicesPunchingClassical mechanics

The invention discloses a punch for processing a bus duct and relates to the field of punches. The punch comprises a punch supporting seat. An air cylinder is inserted to the top of the punch supporting seat, a detection box is fixedly connected to the left side of the top wall of the punch supporting seat, an operating box is fixedly connected to the right side of the top wall in the punch supporting seat, the bottom end of the air cylinder is fixedly connected to a connecting plate, and a breaking connecting block is fixedly connected to the middle of the bottom of the connecting plate. By mounting a spring at the bottom of a second connecting column and arranging the spring corresponding to a first connecting column, a shock absorbing effect of the punch during punching is exerted, so that the service life of the punch is prolonged. As the air cylinder moves up and down, punching power is brought to the punch effectively, so that the work efficiency of the punch is improved. By arranging a pressure gage on the detection box, the pressure value of the punch during punching can be mastered timely.

Owner:YANGZHOU JUNRUI CHUANGZHI IND DESIGN

Stamping device for bicycle pipe fitting machining

InactiveCN111036751AAvoid manual rotationEasy to fixShaping toolsMetal-working feeding devicesPipe fittingElectric machinery

The invention relates to the technical field of bicycle pipe fitting machining and particularly relates to a stamping device for bicycle pipe fitting machining. The device comprises a base; supportingseats are symmetrically arranged at a bottom of the base; a fixed plate is arranged in the middle of a right supporting seat; a driving motor is mounted on the fixed plate; a screw is arranged at anoutput end of the driving motor; the screw penetrates an upper portion of the right supporting base and is rotationally connected with a left supporting base; the screw is symmetrically sleeved with nuts; and L-shaped rods are symmetrically arranged at tops of the nuts. The invention provides a stamping device for bicycle pipe fitting machining. Under the action of a first clamping block and a second clamping block, the effect of clamping a pipe fitting body is achieved; the fixing effect is good, the punching precision is improved, the effect of adjusting the punching position of the pipe fitting body is achieved under the action of a first driving air cylinder and a second driving air cylinder, an effect of adjusting a punching position of the pipe fitting body is achieved, different positions of a pipe fitting can be punched, meanwhile, punching is completed in the left direction and the right direction of the pipe fitting body, and the working efficiency is improved.

Owner:湖州屹鼎自动化科技有限公司

Punching calibration workbench

InactiveCN105689580AQuick calibrationEasy CalibrationMetal-working feeding devicesPositioning devicesPunchingPass rate

The invention discloses a punching calibration workbench. The punching calibration workbench comprises a calibration plate, a telescopic part, a rotary part and a tight-pressing assembly. The calibration plate is arranged on the punching calibration workbench and fixed through the telescopic part. The rotary part id fixed to the telescopic part. The tight-pressing assembly is fixed under the calibration plate and used for tightly pressing a to-be-punched part. The calibration plate is provided with a calibration through hole. A punching head penetrates through the calibration through hole. The punching calibration workbench provided by the invention is used for calibrating a punching part and making the punching part be aligned with a punching point. The punching calibration workbench can extend to any positions of the to-be-punched part, so that the to-be-punched part is calibrated fast and conveniently, and accordingly the product pass rate is increased. According to the punching calibration workbench, in order to achieve the effect that the to-be-punched part does not move in the punching process, the tight-pressing assembly is arranged under the calibration plate, so that accurate punching is ensured, and the punching quality is improved. In addition, the punching calibration workbench is simple in structure and low in cost.

Owner:KUNSHAN YIBANGTAI AUTO PART MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com