Machining method of vacuum booster shell of magnesium-aluminum alloy and punching mold for drawing molding

A vacuum booster, magnesium-aluminum alloy technology, applied in the field of stamping dies, can solve problems that affect product quality, mold life, poor ductility of magnesium-aluminum alloys, and difficult control of stamping pressure, etc., to solve wrinkling and cracking, high yield, and pressure uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

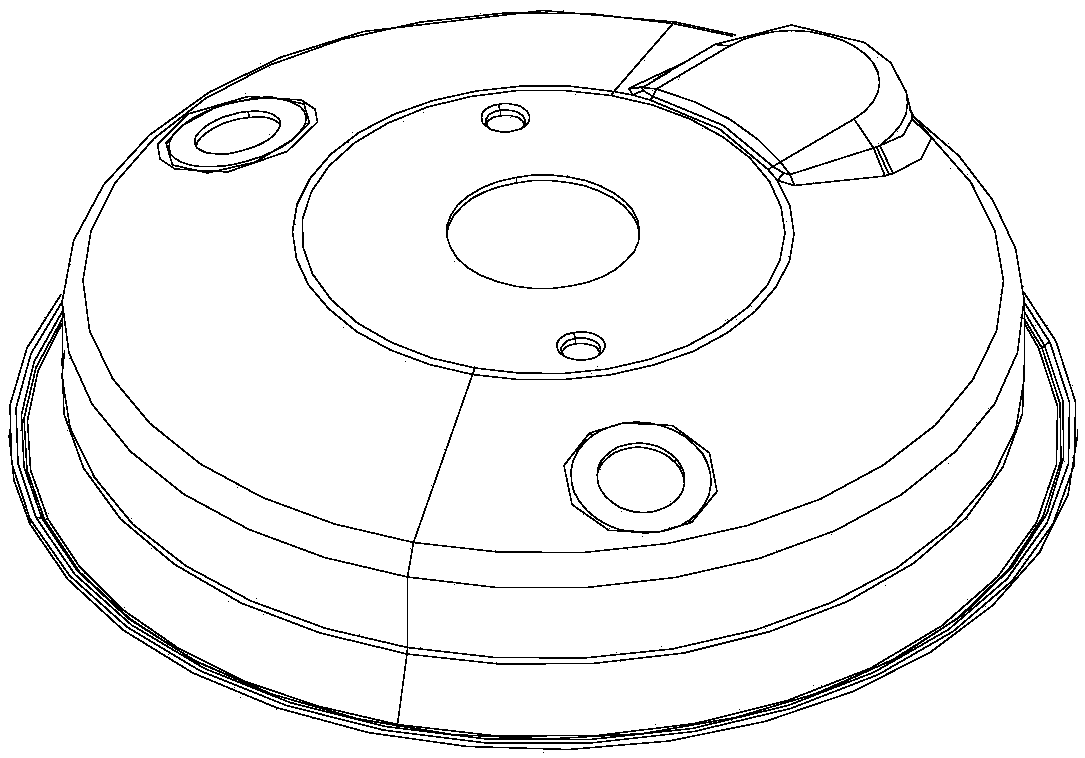

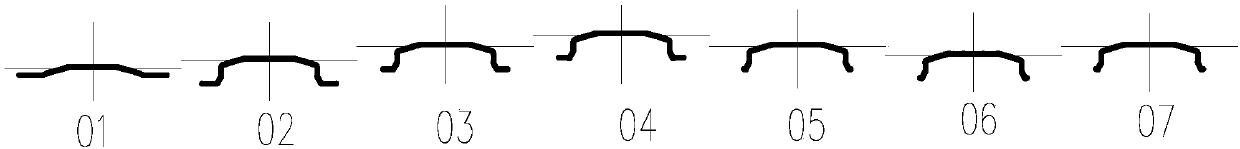

[0053] Stamping die embodiment 1, taking the primary stamping die for the front shell of the magnesium-aluminum alloy booster as an example, describe in detail the specific implementation of the stamping die for drawing and forming the magnesium-aluminum alloy booster shell in the present invention.

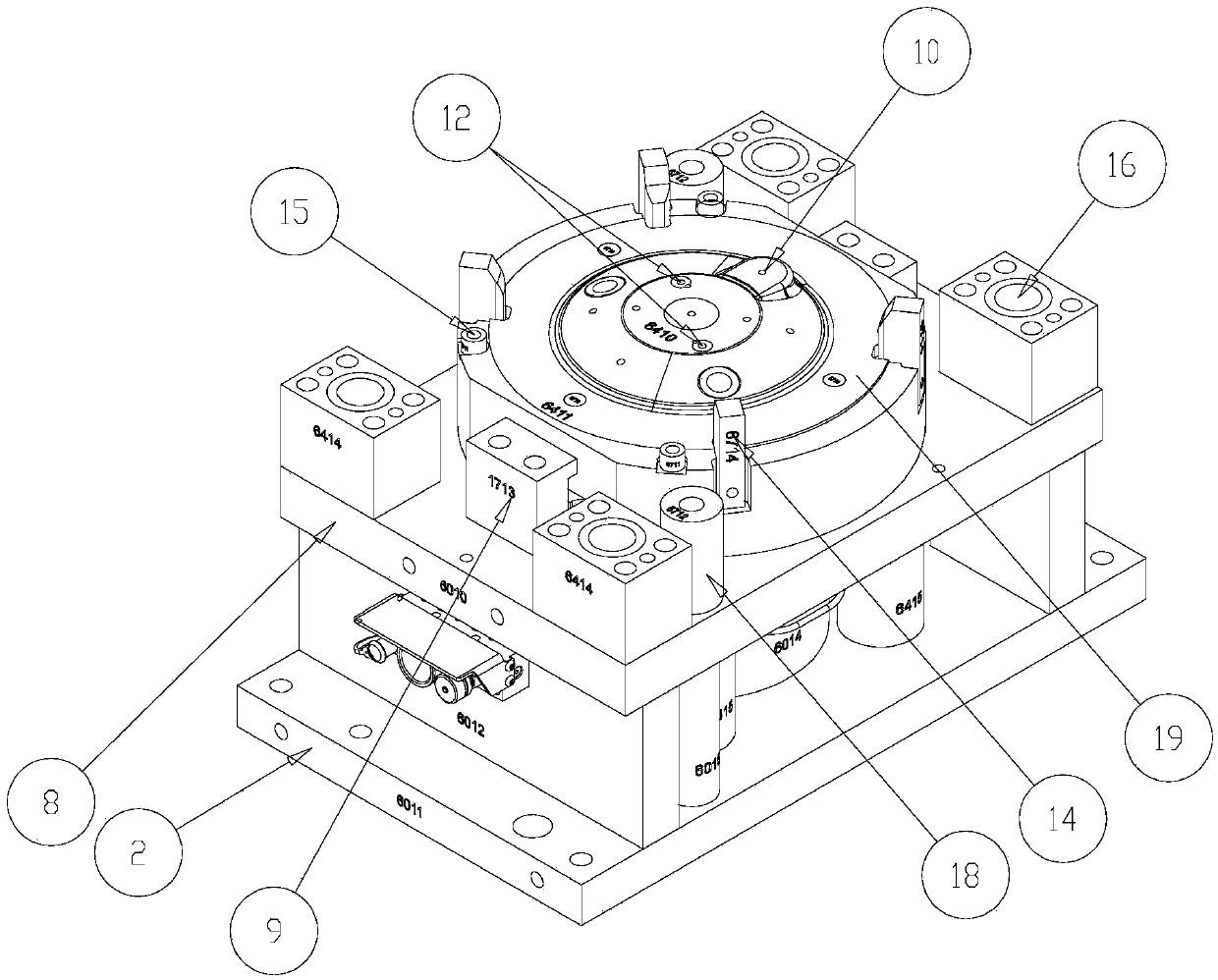

[0054] Such as Figure 3-5 As shown, a primary stamping die for the front casing of a magnesium-aluminum alloy booster includes an upper mold base 1 and a lower mold base 2 .

[0055] The upper mold base 1 is provided with an upper mounting seat 3, the upper mounting seat 3 is provided with an upper forming block 4, the upper forming block 4 is provided with a forming groove, and the upper forming block 4 is provided with four workpiece positioning grooves 41 around the upper forming block 4. The block 4 is provided with two punches 5 for punching the top of the workpiece, and the upper forming block 4 is provided with at least two floating pressing pins 6 at positions correspond...

Embodiment 2

[0061] Stamping die embodiment 2, taking the upper side stamping die of the magnesium-aluminum alloy booster front shell as an example, describes in detail the specific implementation of the stamping die for drawing and forming the magnesium-aluminum alloy booster shell in the present invention.

[0062] Such as Figure 6-8 As shown, a stamping mold for the upper side of the front shell of a magnesium-aluminum alloy booster, a stamping mold for the upper side of the front shell of a magnesium-aluminum alloy booster, including an upper mold base 1 and a lower mold base 2, The upper mold base 1 is provided with an upper mounting seat 3, the upper mounting seat 3 is provided with an upper forming block 4, the middle part of the upper forming block 4 is provided with a forming groove, and the lower surface of the upper forming block 4 is provided with a ring of pressing parts on the outer periphery of the forming groove , the upper molding block 4 is provided with four floating pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com