Panel stretching die component for metal stamping

A technology for processing molds and panels, applied in the field of metal stamping panel parts drawing and processing mold components and molds, can solve the problems of being stuck in the lower mold sleeve, deformation of thin plate parts, deformation and fracture, etc., to avoid deformation and increase ejection. The effect of applying force on the area and improving the stamping quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

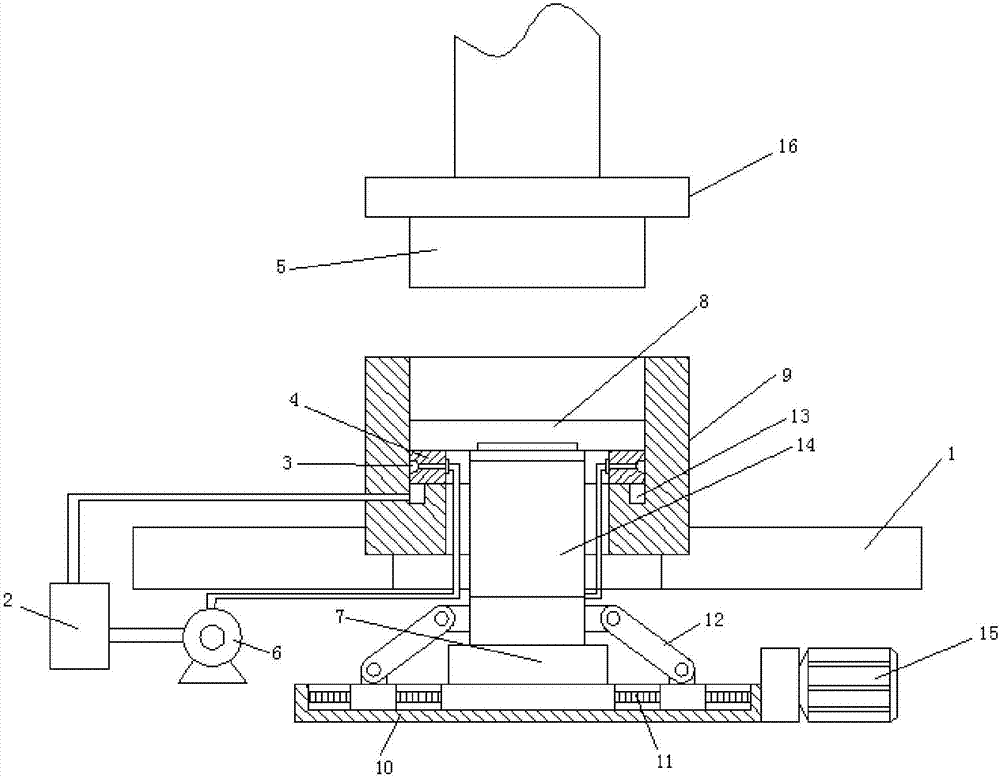

[0015] Such as figure 1 As shown, a metal stamping panel member drawing processing mold assembly includes a lower mold base 1, a liquid storage tank 2, an oil supply pump 6, a top material base 10, an upper mold base 16 and a lower mold sleeve 9, and the upper mold The lower surface of the seat 16 is fixedly connected with the punch 5, the lower mold cover 9 is fixed on the lower mold base 1 and the inner surface of the lower mold cover 9 is contacted with a bottom plate 8, and the edge of the lower surface of the bottom plate 8 is fixedly provided with a support ring plate 4. The side of the support ring plate 4 is in contact with the inner wall of the lower mold case 9, and the side of the lower die case 9 is provided with a ring groove 3, and the liquid outlet of the oil supply pump 6 is connected to the inner wall of the support ring plate 4 through a pipeline. The inner ring surface communicates with the annular groove 3, and the inner wall of the lower mold case 9 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com