Patents

Literature

142results about How to "Fast punching speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

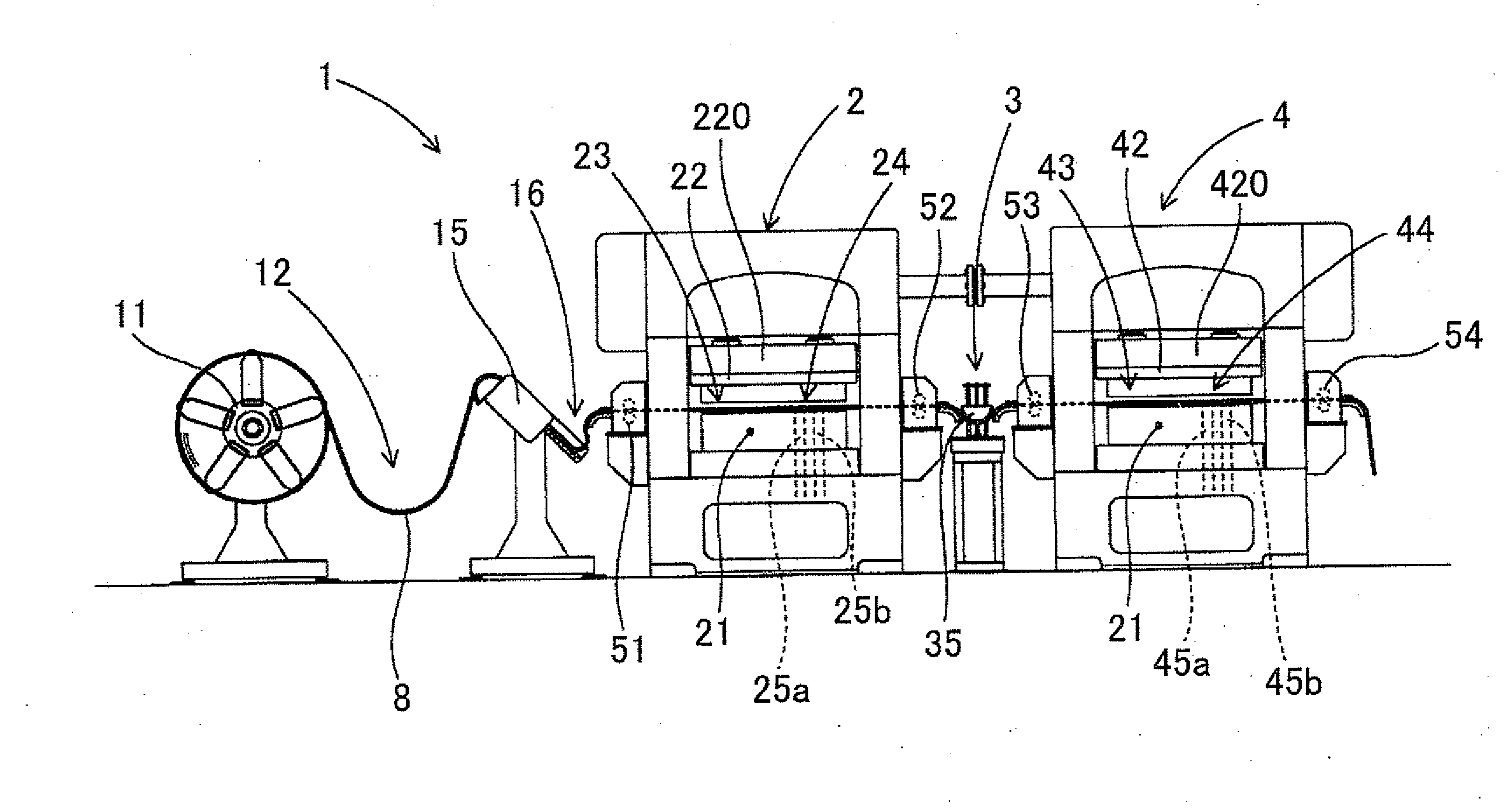

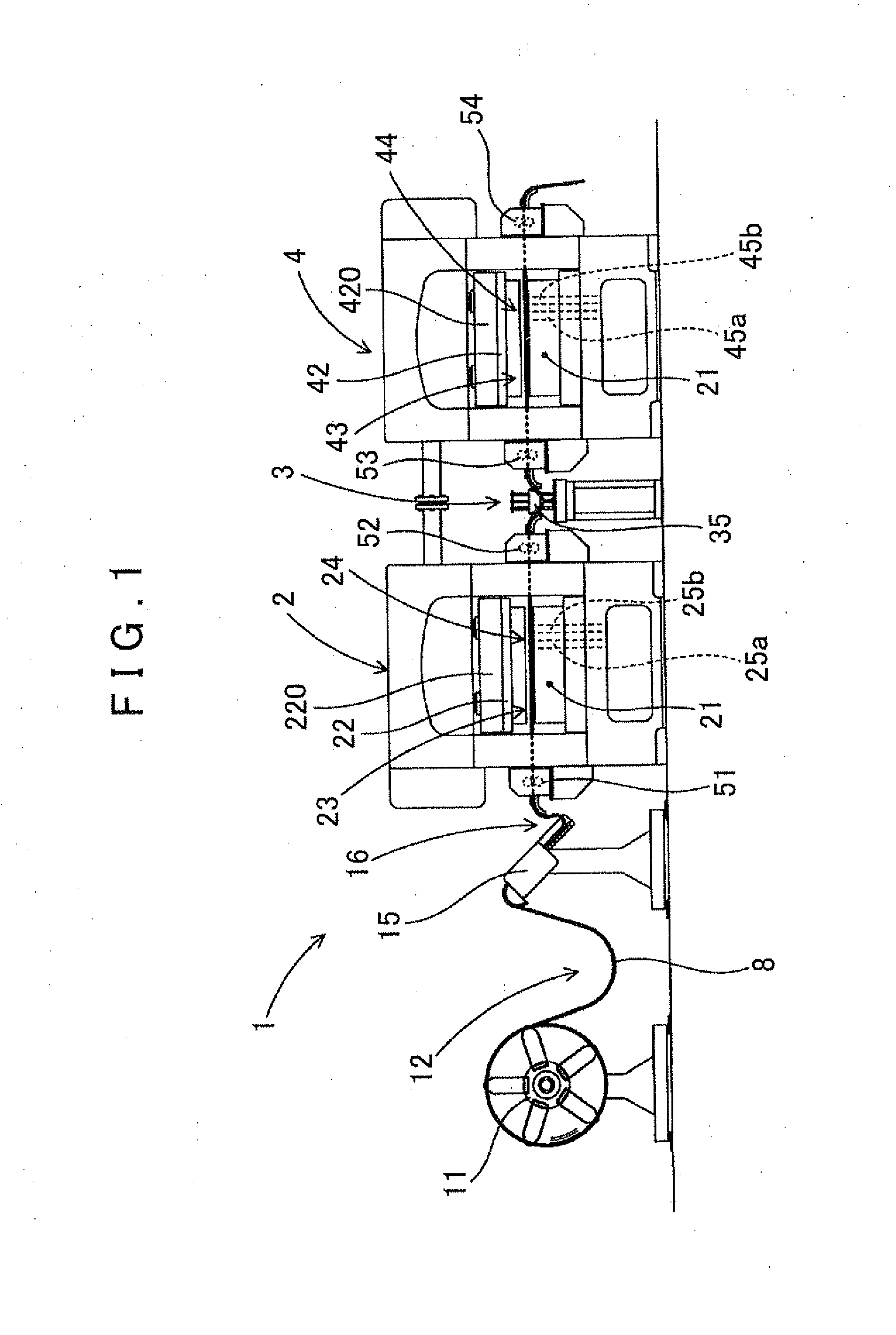

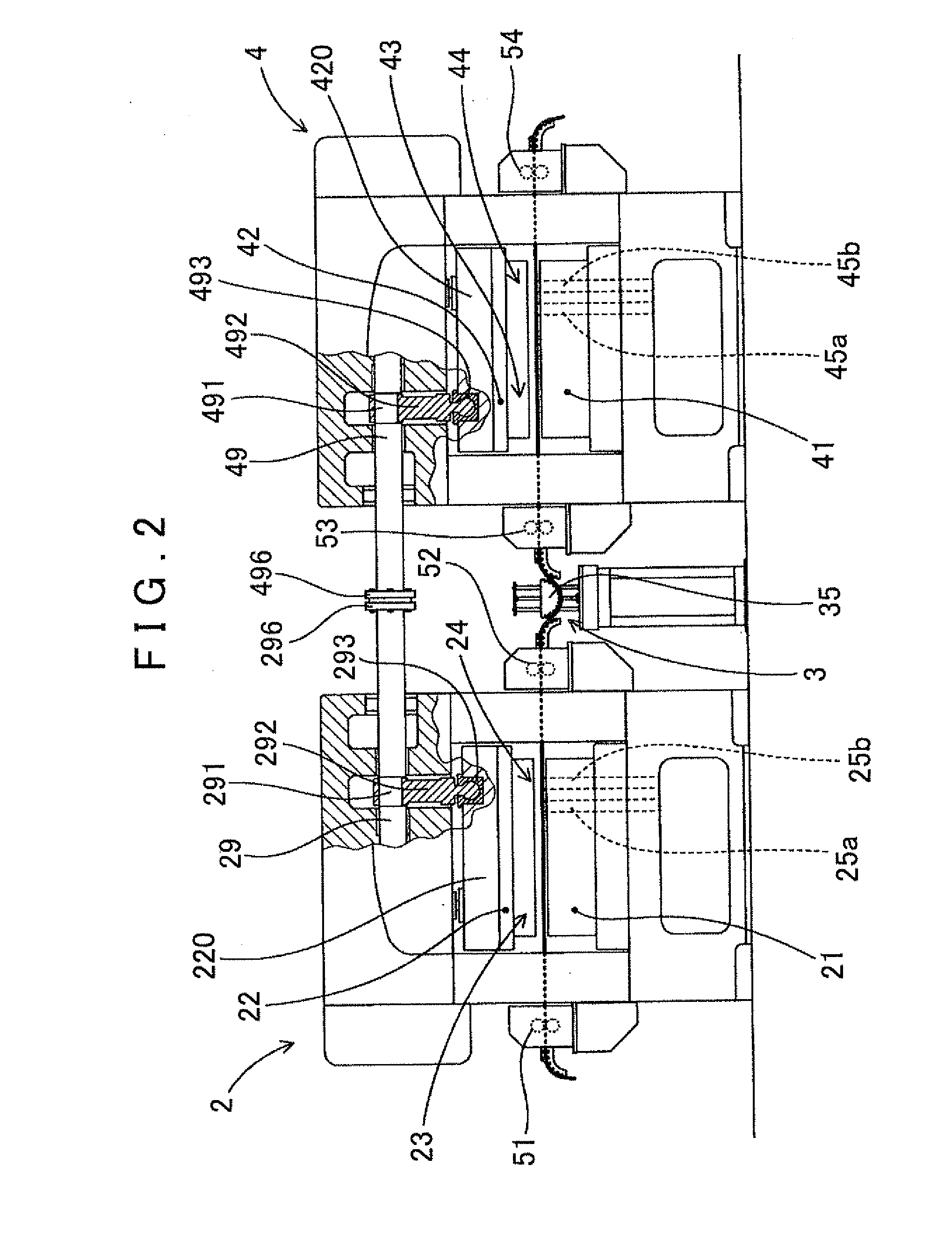

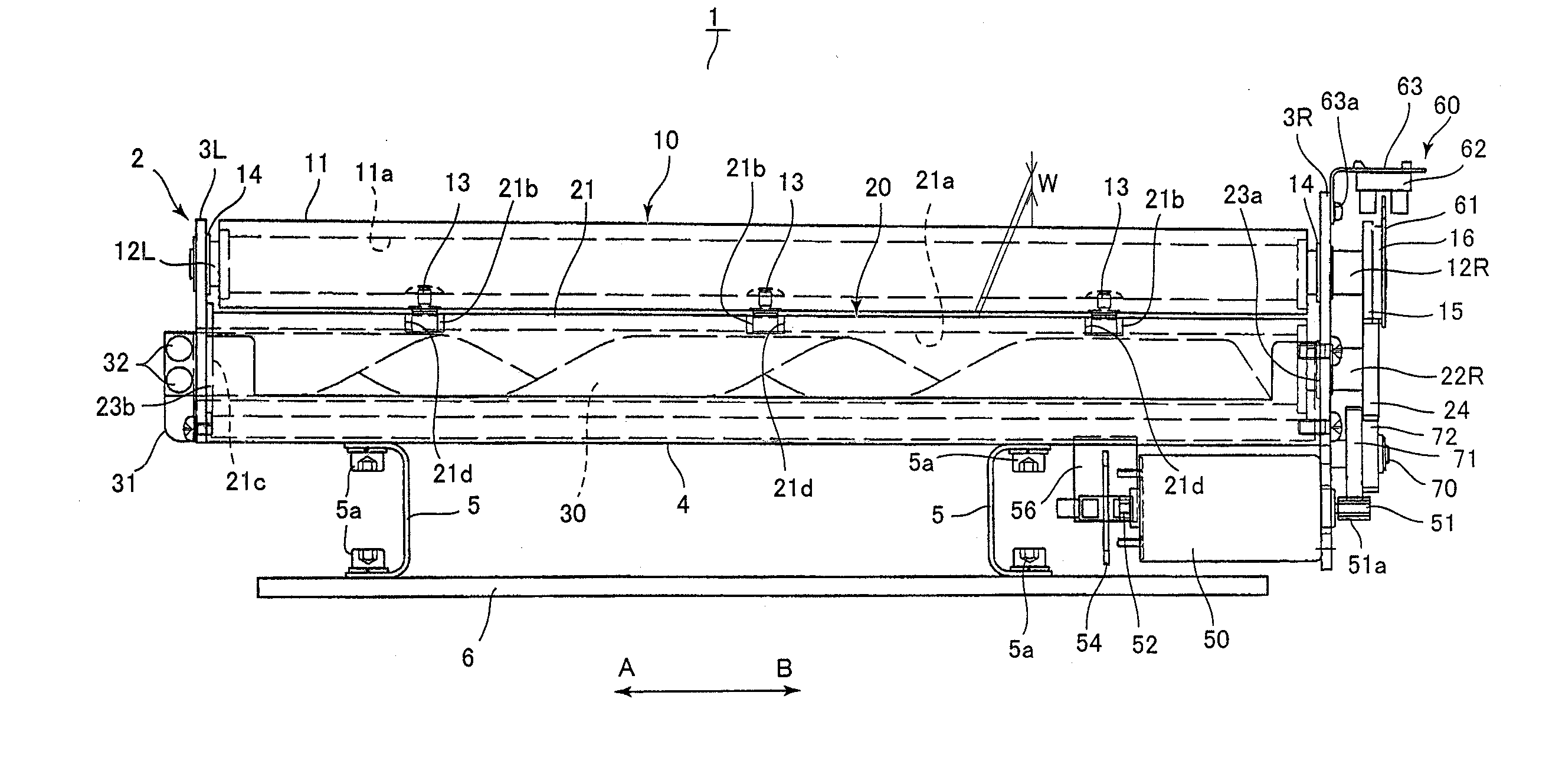

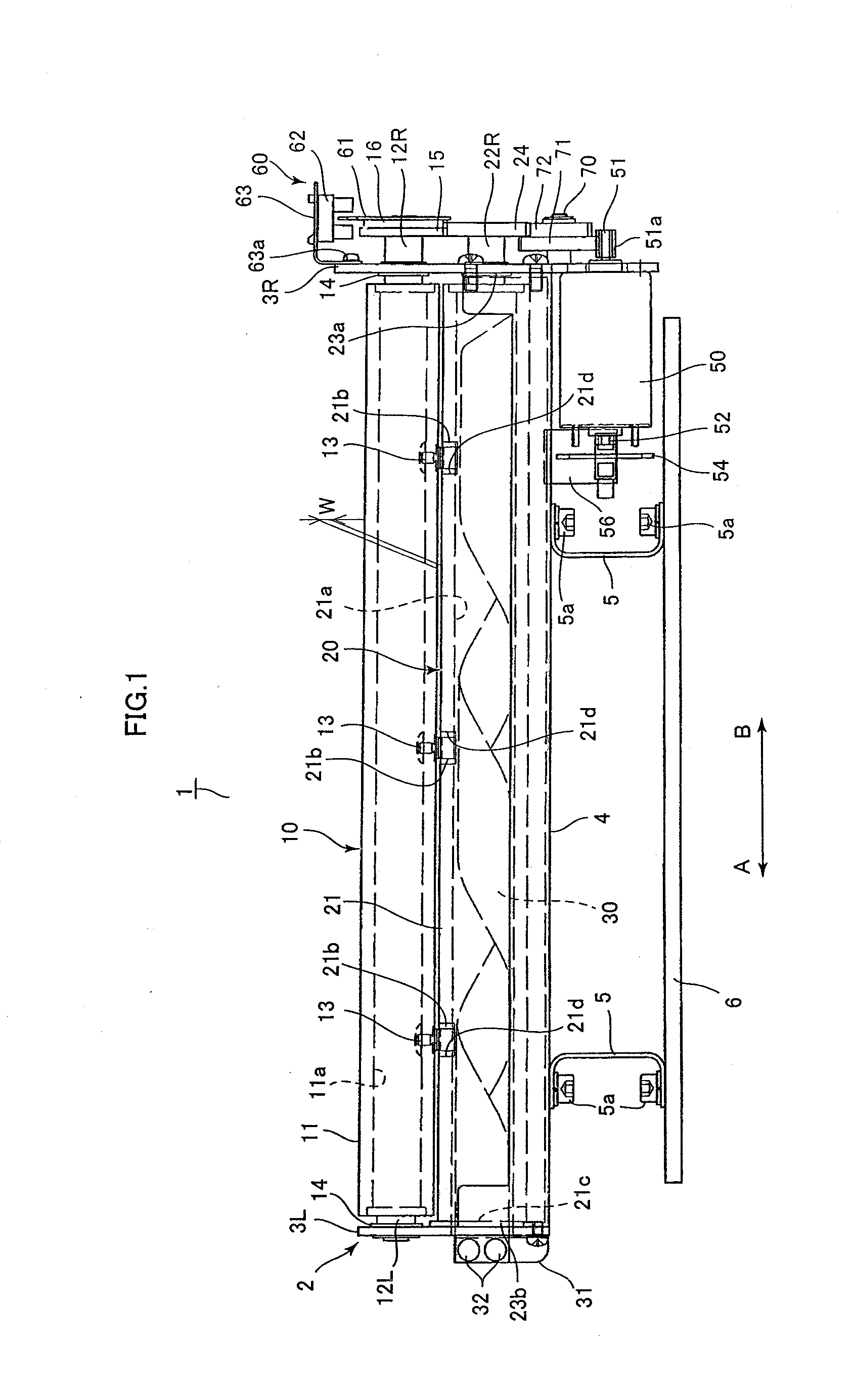

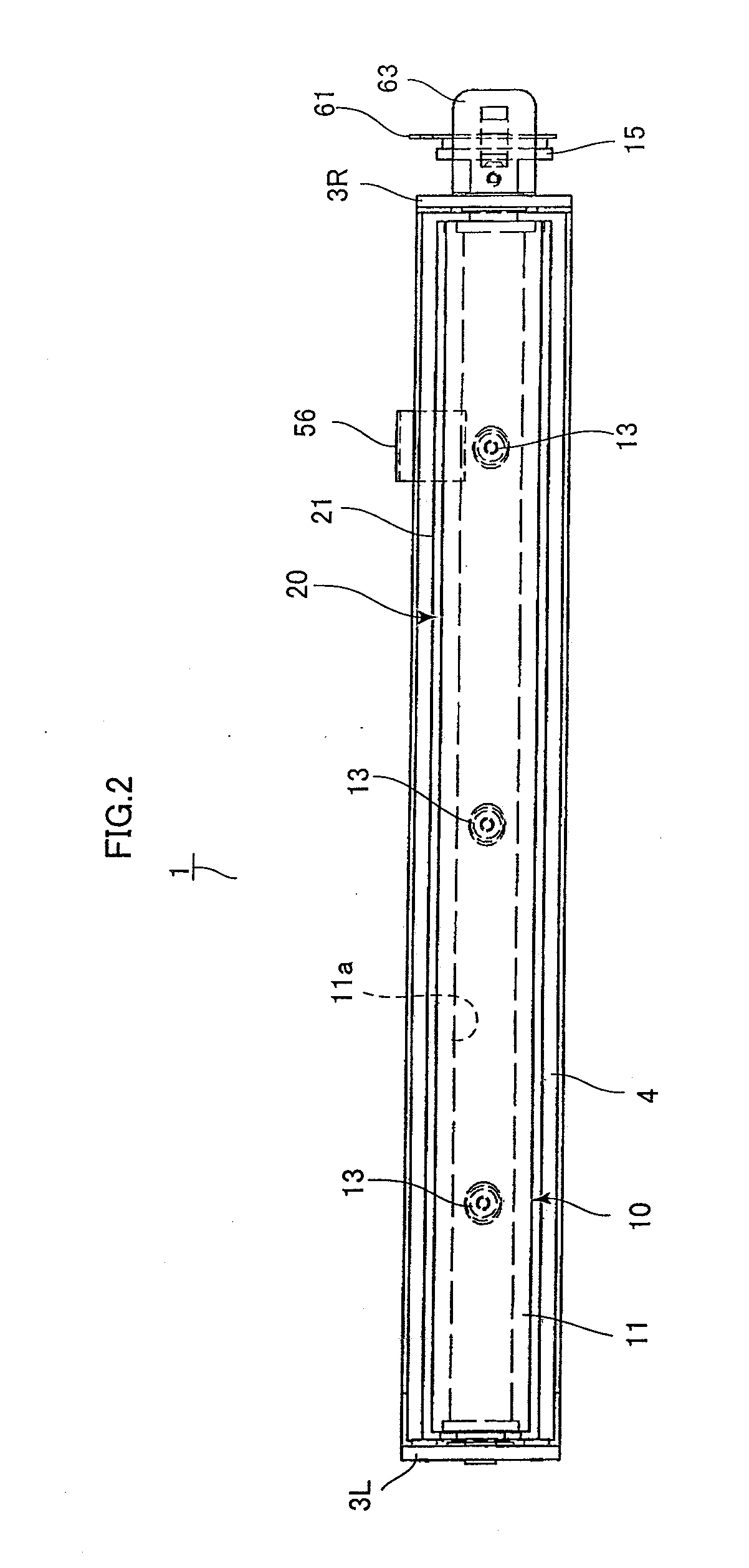

Laminated core punching apparatus

ActiveUS20110232076A1The relative position is appropriateRemarkable effectAssembly machinesOther manufacturing equipments/toolsSheet steelPunch press

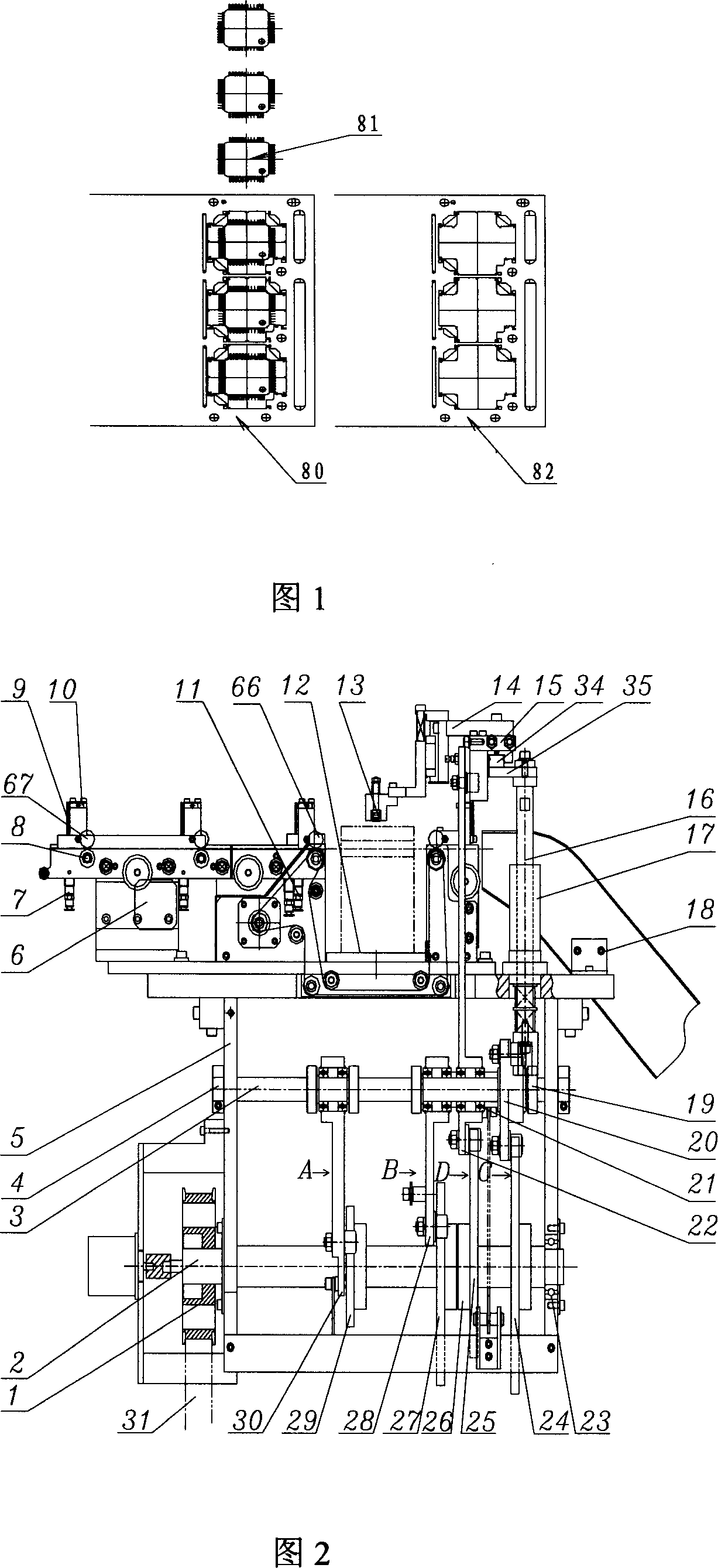

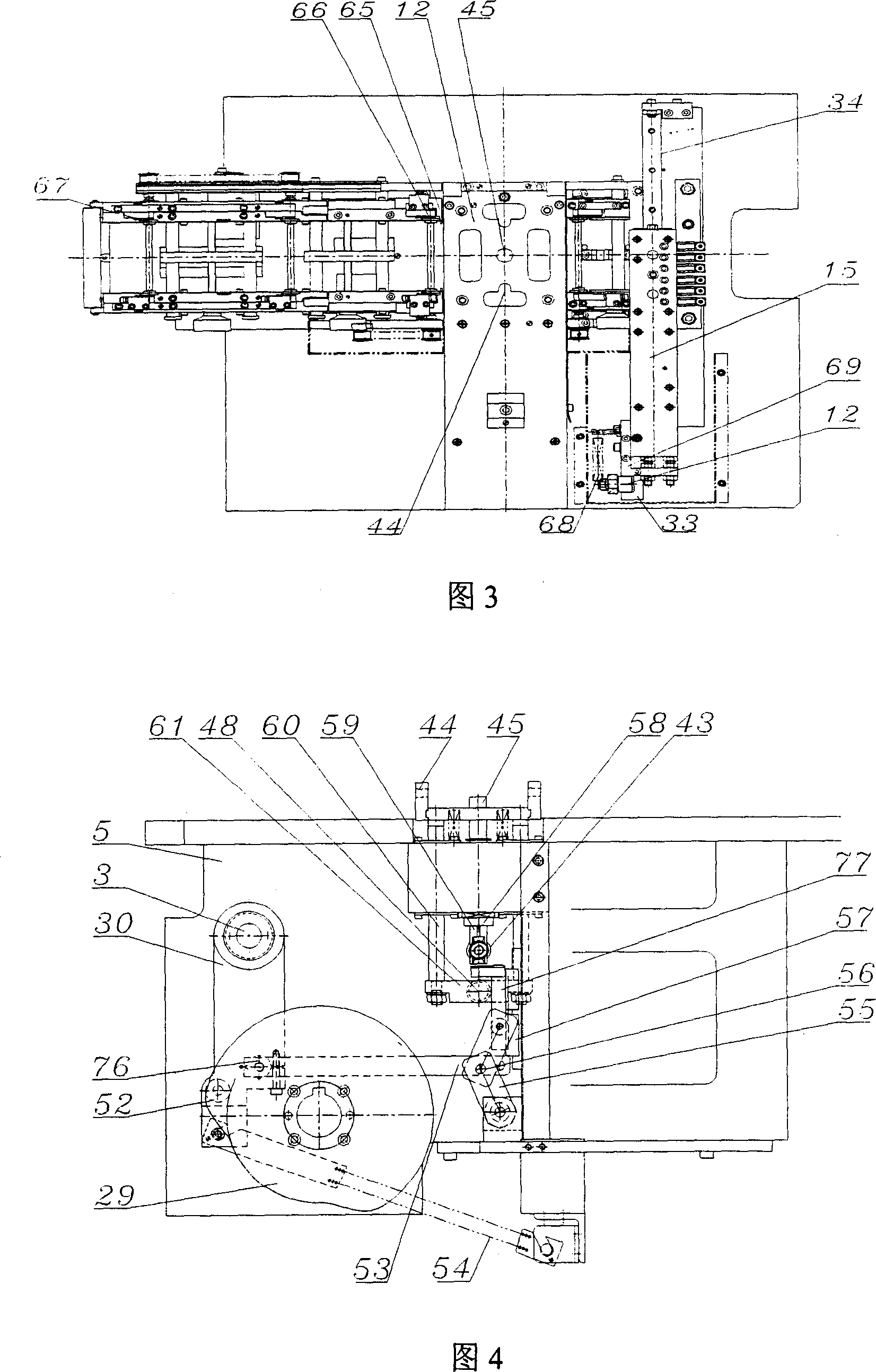

A laminated core punching apparatus, configured such that a stator-punching press machine that has a molding die performing a partial punching gradually approaches the shape of the stator core piece. There is a punching die to punching out the stator core piece from a strip-form steel plate, and two stator lamination stations. A rotor-punching press machine and a stator-punching press machine are constructed to operate synchronously. An intermediate loop portion capable of causing a strip-form steel plate to hang down in a loop is provided in order to adjust a length of the strip-form steel plate between the two press machines, and a loop guide portion that guides a loop locus of the strip-form steel plate from above so that the strip-form steel plate does not invert is disposed above the intermediate loop portion to be capable of ascending and descending.

Owner:NORITSU KIKAI SEISAKUSHO

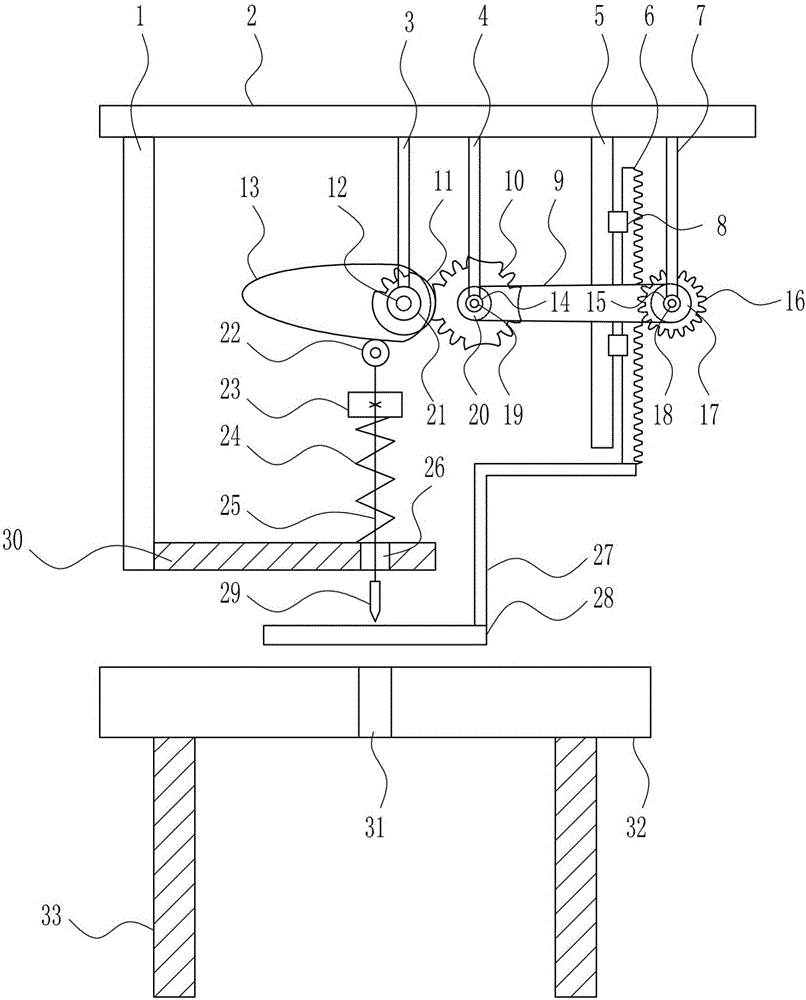

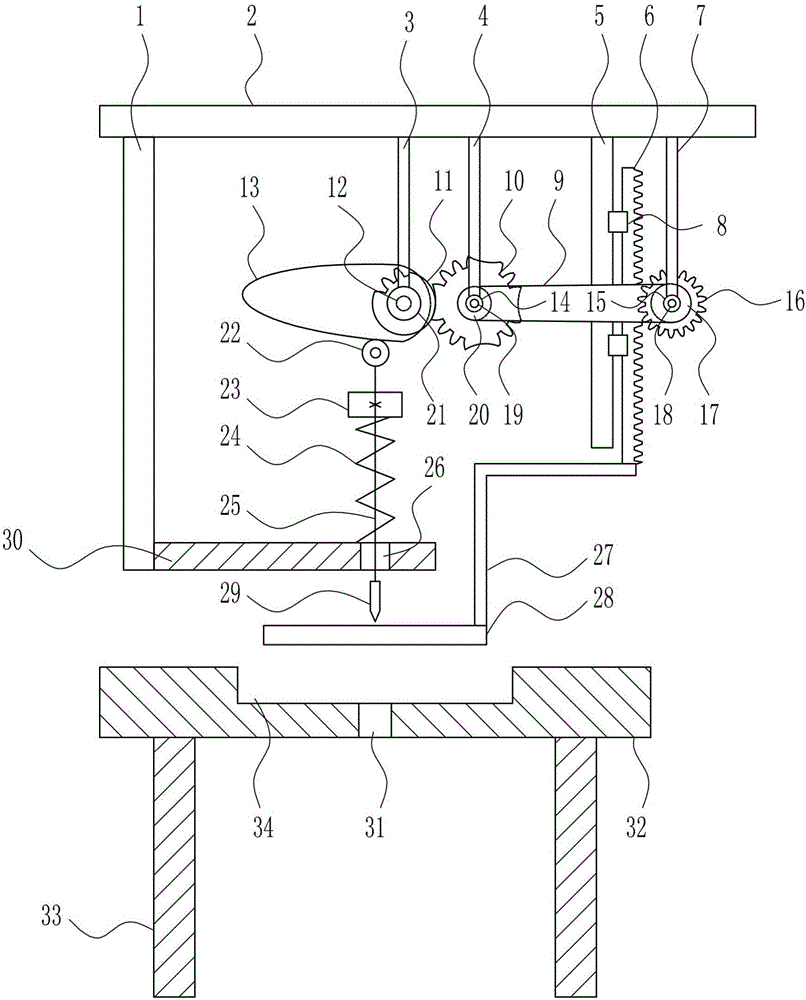

High precision punching device for hardware manufacturing

ActiveCN106180362AEasy to fixFast punching speedPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention relates to a punching device and particularly relates to a high precision punching device for hardware manufacturing. The invention solves the technical problem that the invention relates to the high precision punching device for hardware manufacturing, wherein the punching precision is relatively high. In order to solve the technical problem, the invention provides the high precision punching device for hardware manufacturing. The high precision punching device for hardware manufacturing comprises a first supporting rod, a top plate, a second supporting rod, a third supporting rod, a slide rail, a rack, a fourth supporting rod, a slide block, a flat belt, a first gear, a second gear, a first rotary shaft and the like; a through hole is formed in the middle of a shelf board, the top plate is arranged above the shelf board; the first supporting rod, the second supporting rod, the third supporting rod, the slide rail and the fourth supporting rod are successively arranged from left to right in the bottom of the top plate; a guide plate is arranged on the lower part of the right side of the first supporting rod, and a guide hole is formed in the guide plate. The punching device provided by the invention achieves relatively high punching precision.

Owner:盐城东方汽车广场投资发展有限公司

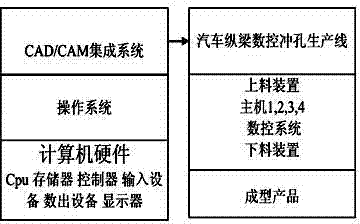

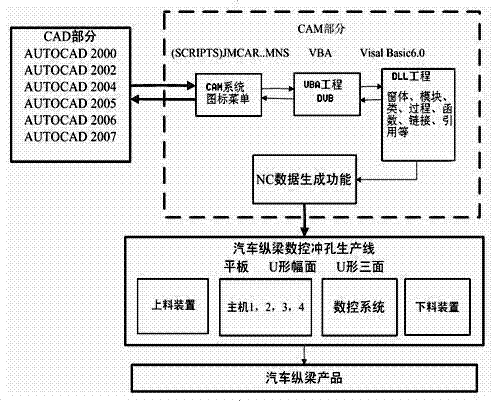

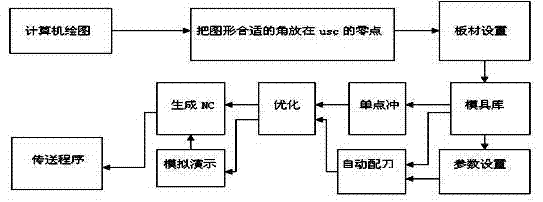

Method for constructing CAM (computer-aided manufacturing) system for punching for automobile girders

ActiveCN102707669ARealize integrationAvoid reducing service lifeProgramme controlComputer controlNumerical controlVisual Basic

A method for constructing a CAM (computer-aided manufacturing) system for punching for automobile girders is characterized by including selecting the types of used numerical-control punching production lines for the automobile girders; creating projects corresponding to the types of the numerical-control punching production lines for the automobile girders, building mathematical models of algorithms, and building generic modules; determining the types of the projects as Activex DII and compiling the types of the projects into types of dynamic linking libraries; writing and compiling interface programs connected with the dynamic linking libraries by VBA (visual basic for application); writing scripts for the various types of numerical-control punching production lines, and creating a CAM icon menu file and icons corresponding to various items; packaging various documents such as the CAM icon menu file, the interface programs written by the VBA, each class-generation DLL (dynamic linking library) compiled by VB (visual basic), development interfaces provided in the form of VB types, windows, the modules, the projects, an encryption method and instructions in a SETUP to form installation programs of the various types of numerical-control punching production lines for the automobile girders; and adding a CAM menu into a menu self-defining term in a CAD (computer-aided design).

Owner:广州市力鼎汽车零部件有限公司

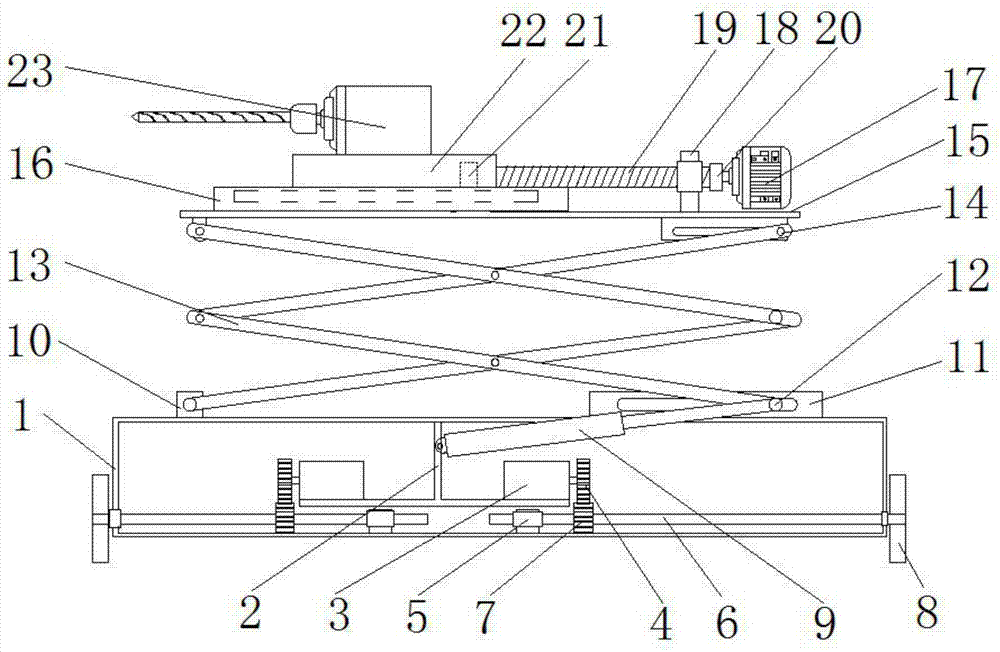

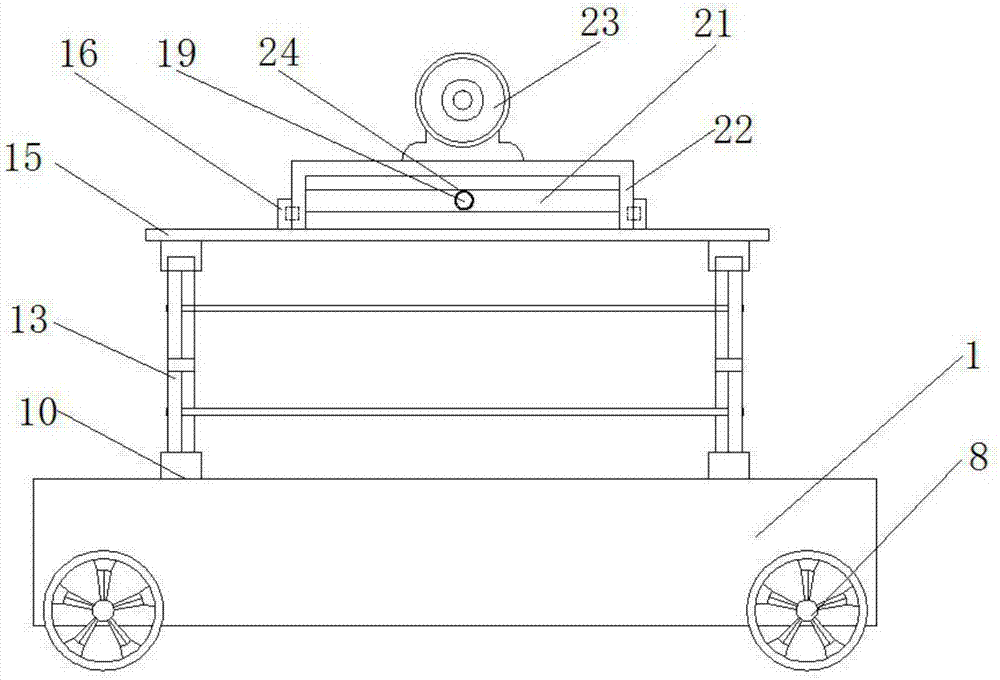

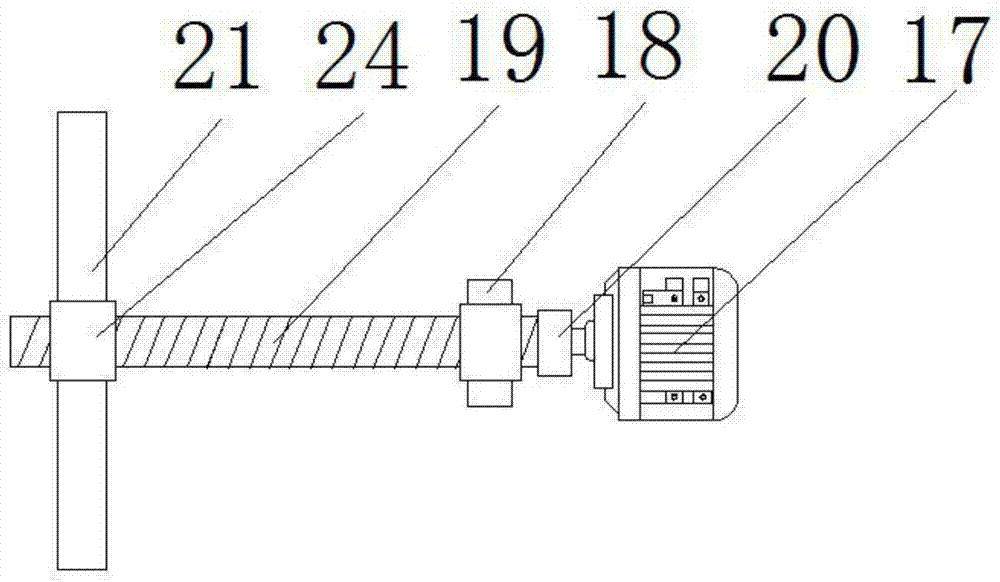

Automatic wall face drilling device

InactiveCN107378057AAvoid health effectsAvoid influencePortable power-driven toolsFeeding apparatusDrive wheelDrive shaft

The invention discloses an automatic wall drilling device, which comprises a box body, first motors are fixedly connected to both sides of the top of a T-shaped fixed plate on the inner wall of the box, and a shaft seat is fixedly connected to the bottom of the inner wall of the box, and the shaft seat rotates. A drive shaft is connected, one end of the drive shaft is fixedly connected to the drive wheel, the first motor is connected to the drive wheel through gear transmission, one side of the T-shaped fixed plate is connected to the hydraulic rod, and the top of the box is connected to the lifting frame in rotation. The top is rotatably connected with a lifting platform, one side of the top of the lifting platform is fixedly connected with a support plate, the support plate is slidingly connected with a moving frame, the top of the moving frame is fixedly connected with a drilling device, and the top of the lifting platform is fixedly connected with a second motor. One end of the output shaft of the second motor is fixedly connected with a screw rod. The invention relates to the field of electromechanical tools. The wall surface automatic drilling device realizes automatic feeding, improves hole quality and work efficiency, and protects the safety of construction personnel.

Owner:合肥恩腾电子科技有限公司

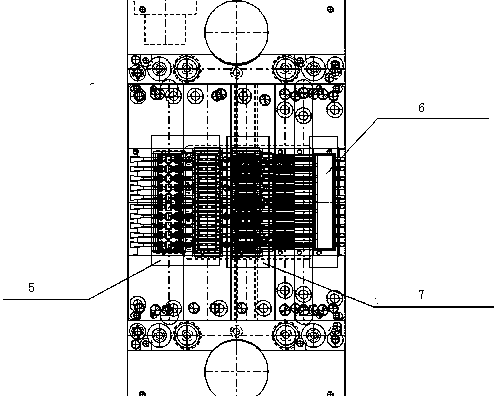

IC punching formation equipment

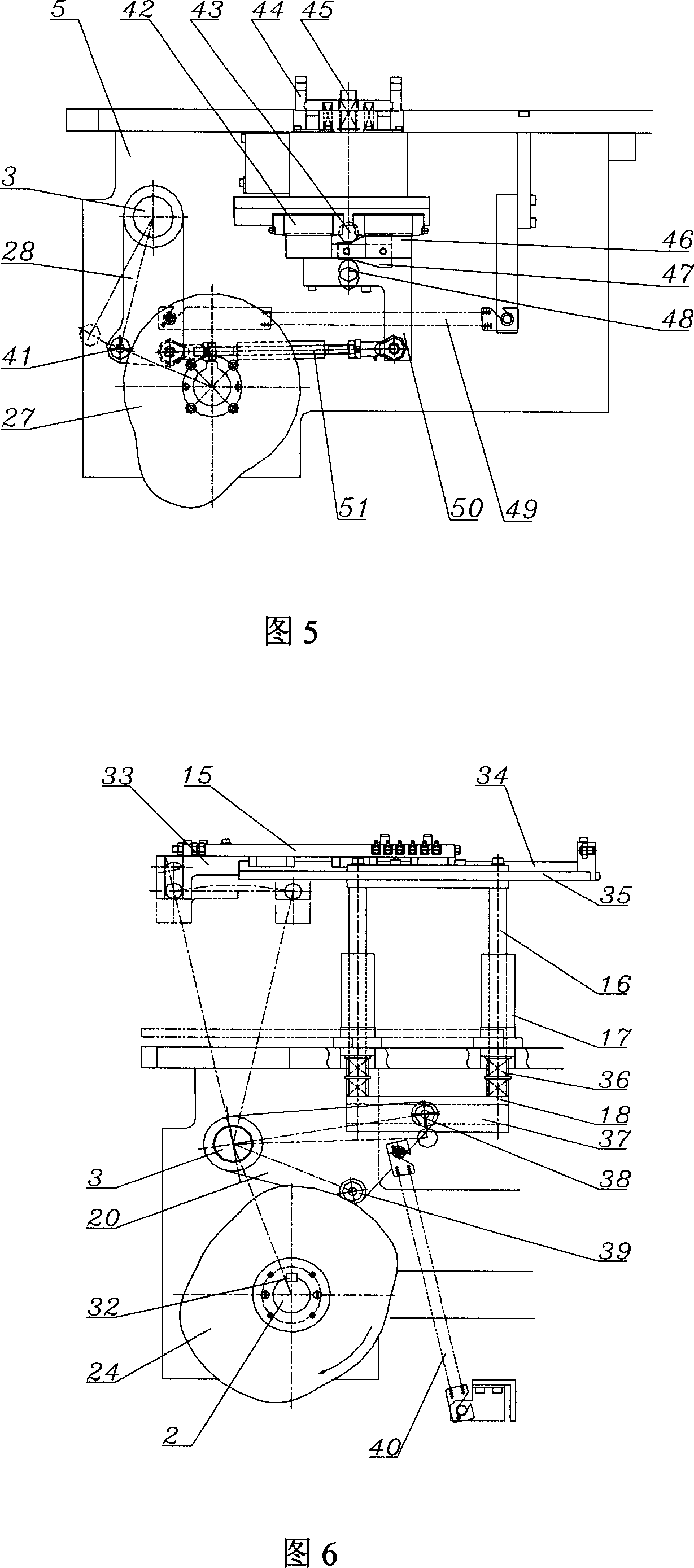

InactiveCN1986100AImprove coherenceImprove stabilityMetal-working feeding devicesStripping-off devicesPunchingCam

The IC punching formation equipment includes one feeder, one separator and one discharger. On the frame, there are cam shaft with fixed separation detecting cam, separating cam, vertical discharge cam and horizontal discharge cam; and oscillating arm shaft fixed to the cam shaft and with connected separation detecting oscillating arm, separating oscillating arm, vertical discharge oscillating arm and horizontal discharge oscillating arm. All the cams and all the oscillating arms cooperate to complete the separation detection, separation, discharge elevation and horizontal discharge moving of the lead frame separately. The present invention uses only one power source, and has high punching speed, high capacity and stable running.

Owner:TONGLING TRINITY TECH

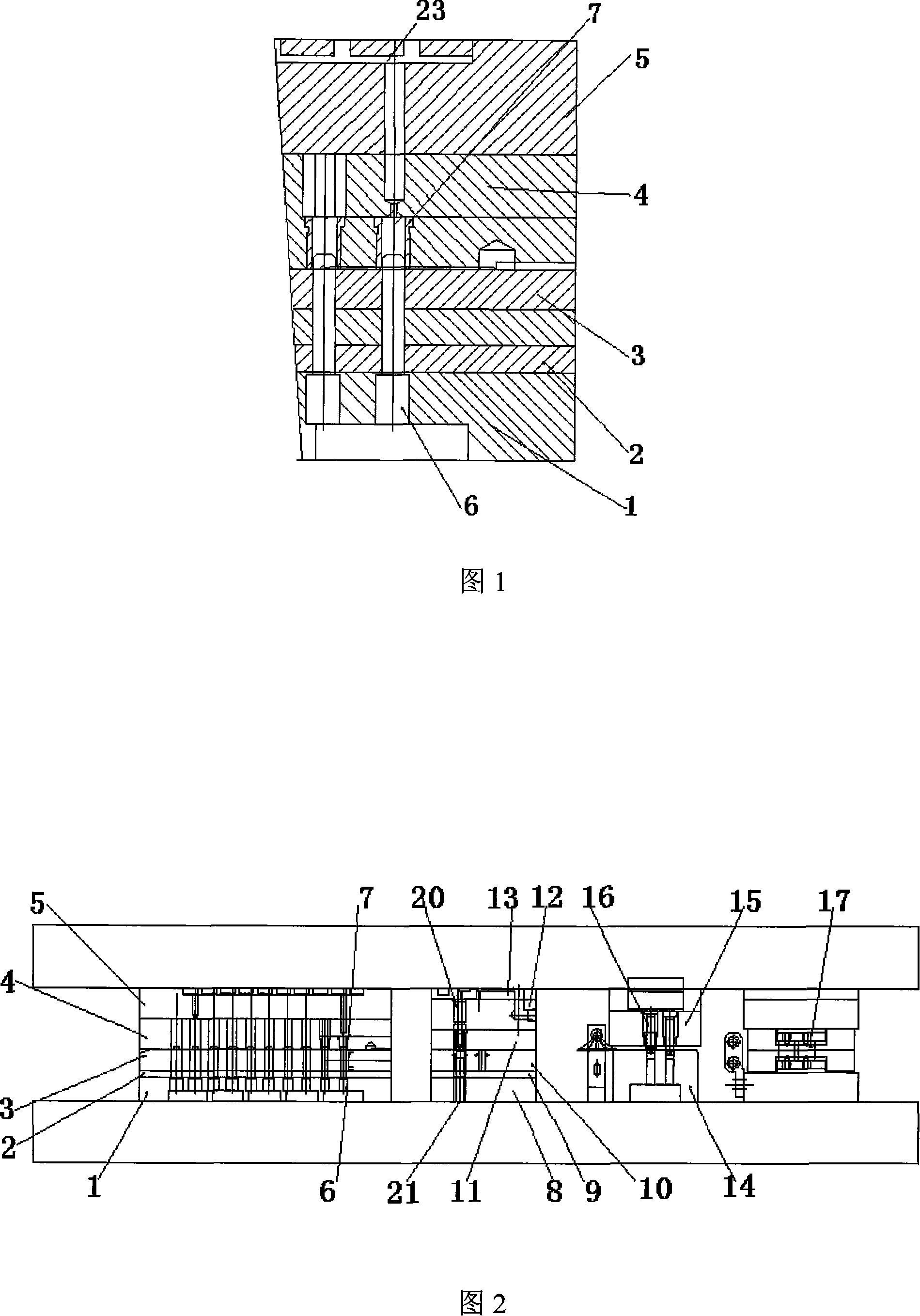

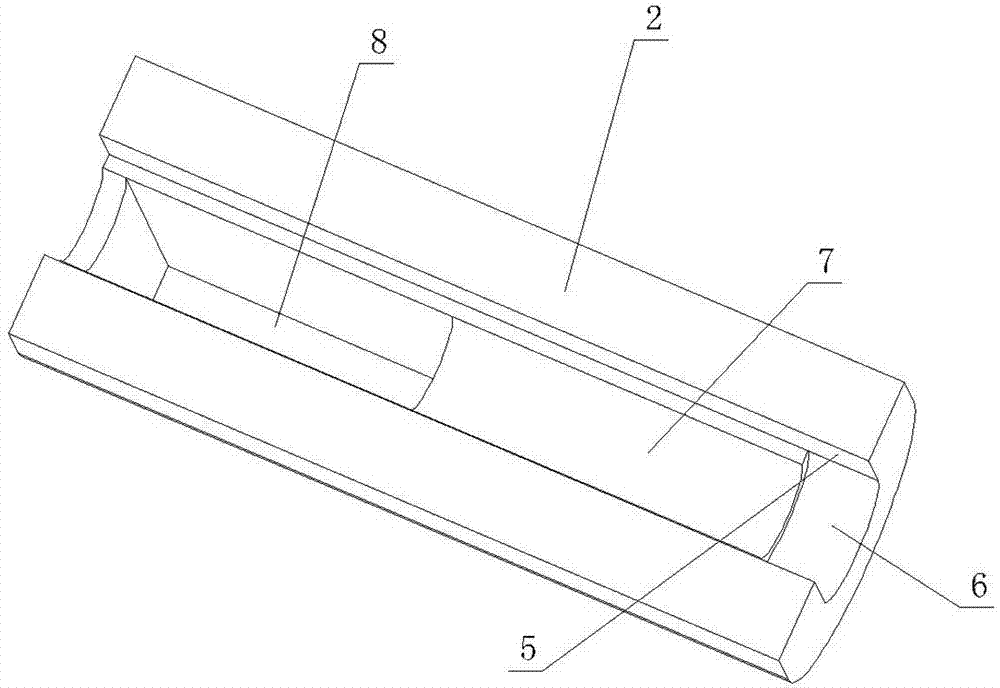

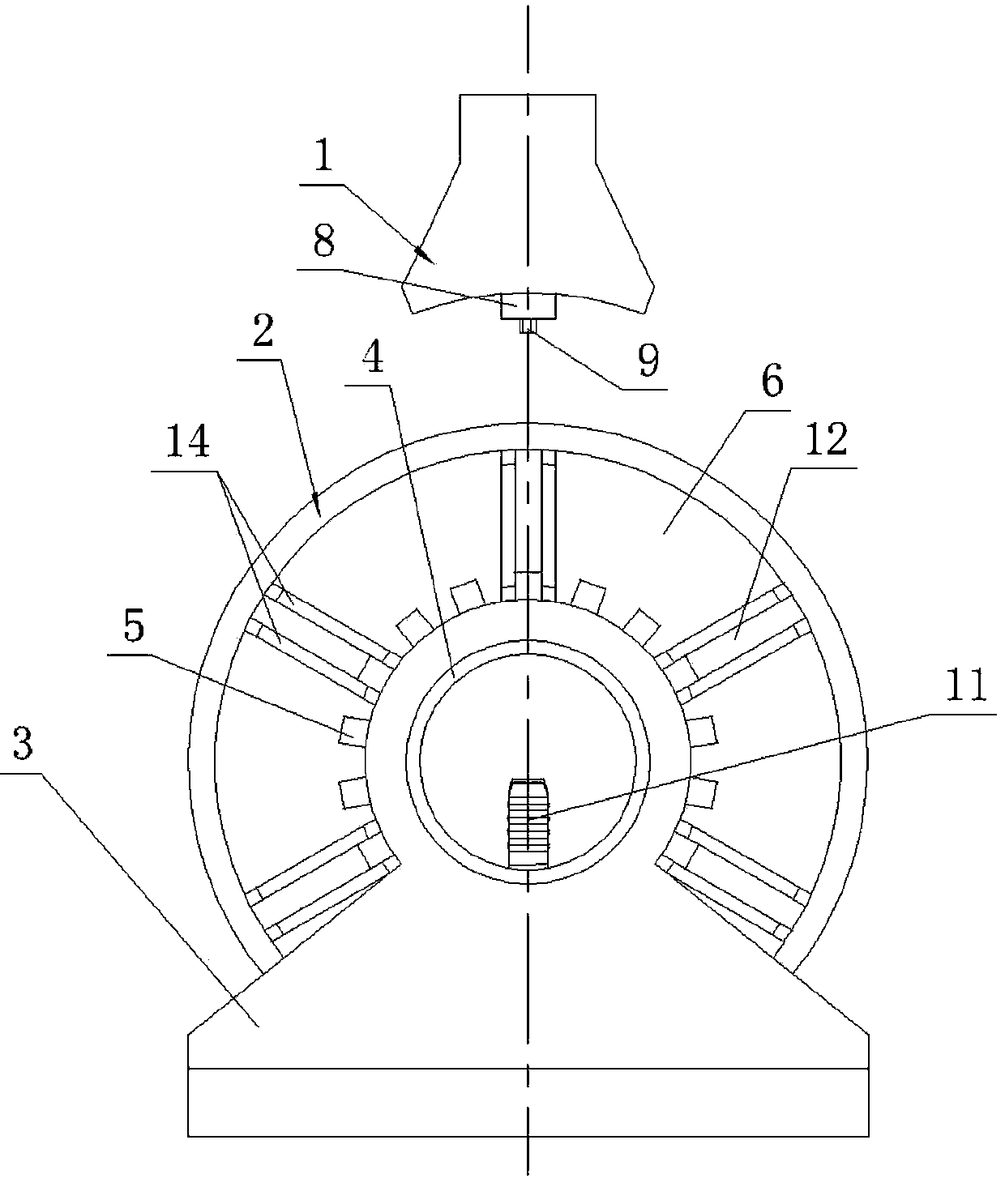

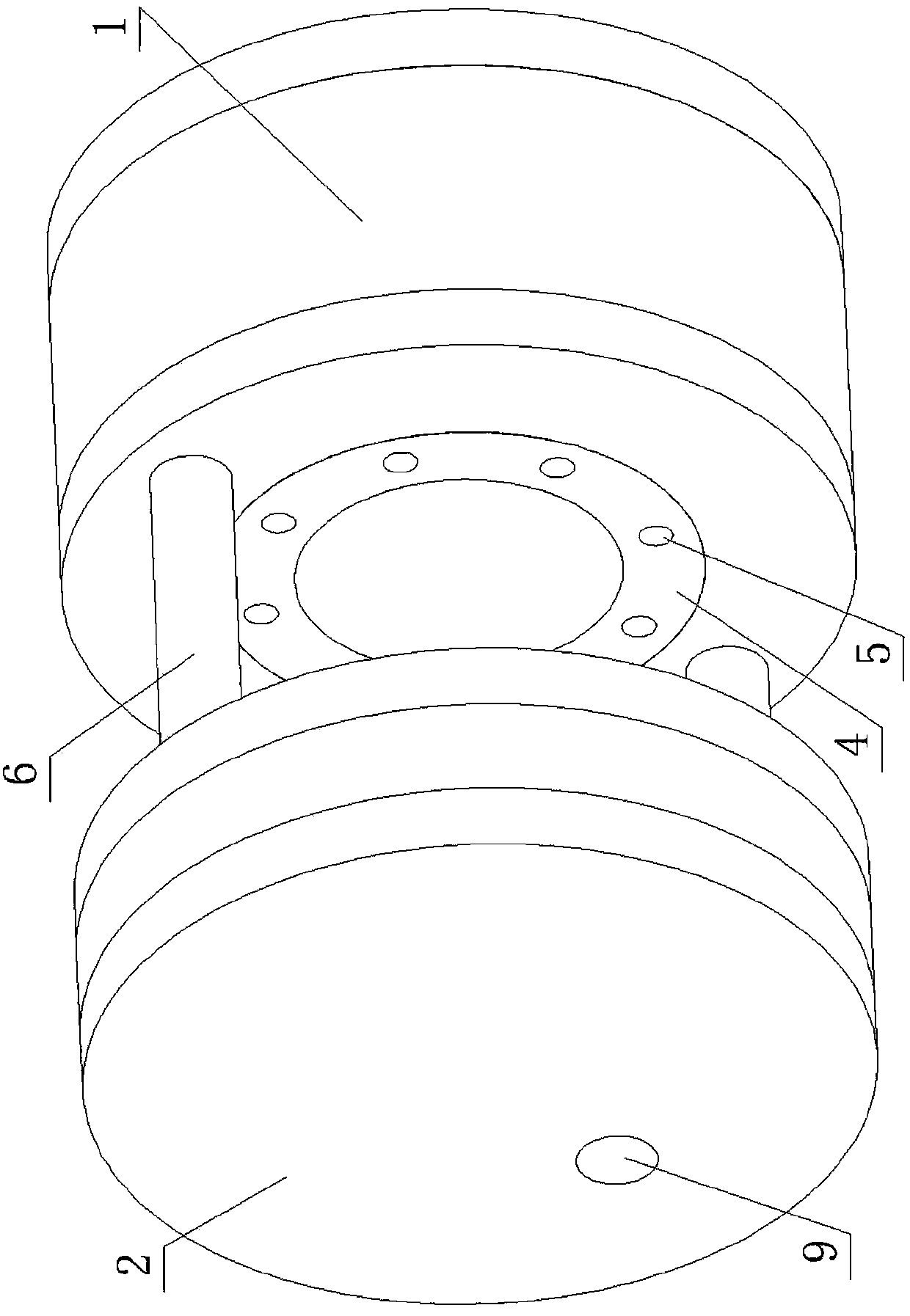

Stamping die

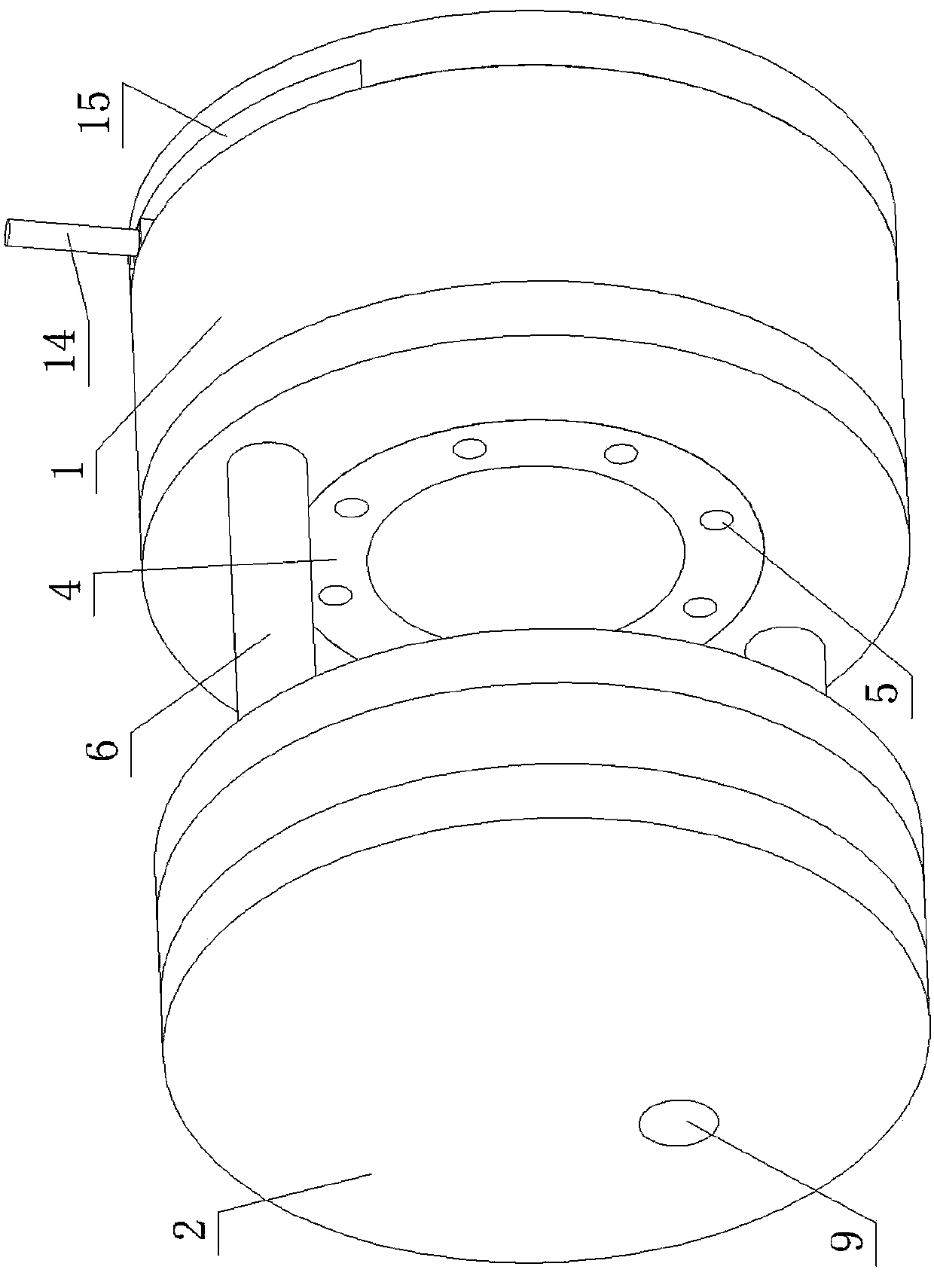

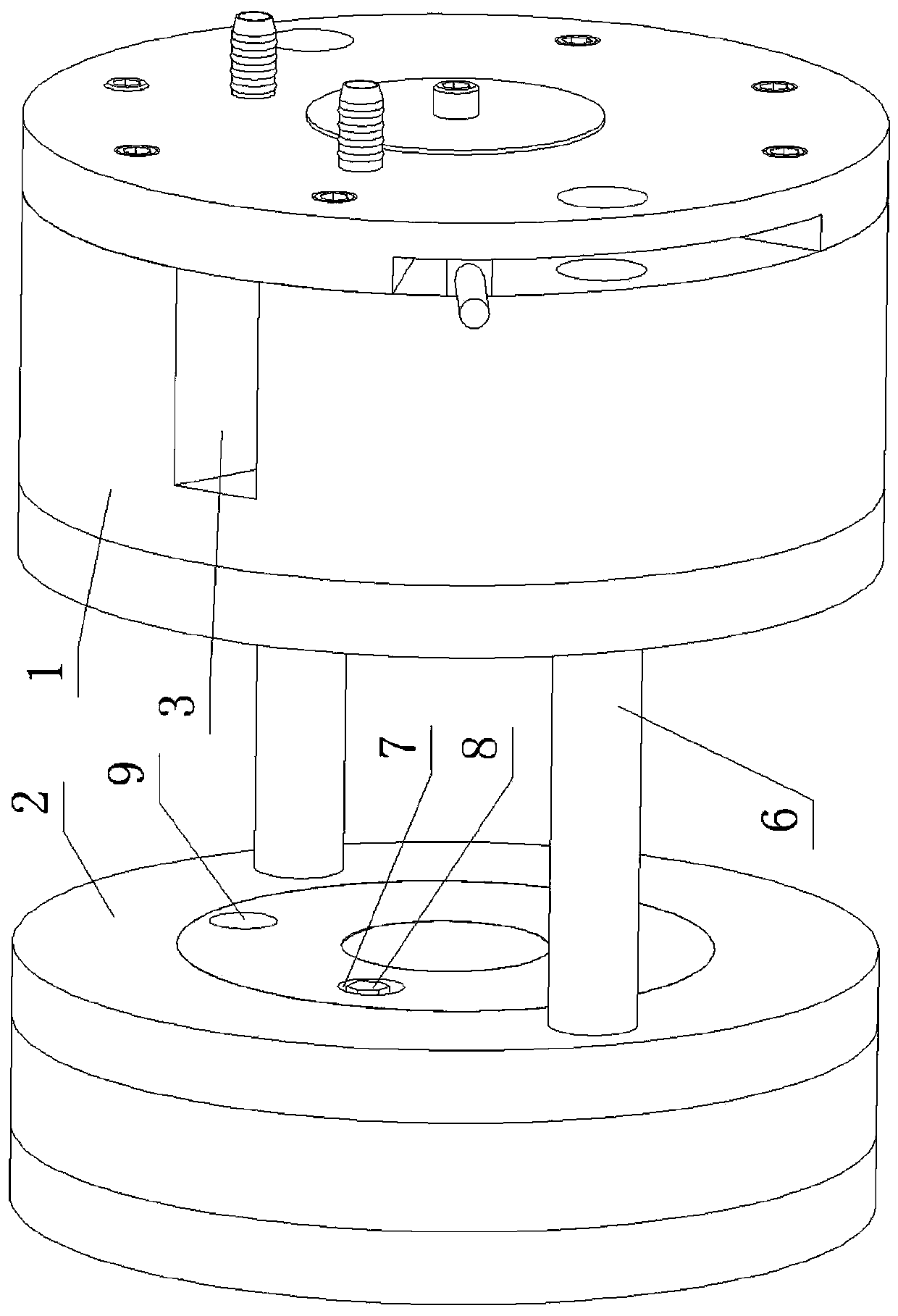

InactiveCN103418685AShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsStripping-off devicesSpray nozzleEngineering

The invention discloses a stamping die which comprises a cylindrical die shell (1) and a punch (2). The cylindrical die shell (1) is provided with a radial material falling channel, a rotary table (4) is matched in the cylindrical die shell (1) in a rotatable mode, the rotary table (4) is provided with a plurality of circular through holes (5), the punch (2) is arranged on a guide column (6) in a sliding fit mode, the punch (2) is provided with a second cylindrical pit (7), a hexagonal prism protrusion (8) is arranged at the pit bottom of the second cylindrical pit (7), and a material discharging hole (9) is further formed in the punch (2). The radial material falling channel is communicated with one circular through hole (5), and the second cylindrical pit (7) right faces one circular through hole (5). The material discharging hole (9) right faces another circular through hole (5), and the cylindrical die shell (1) is provided with a second sprayer (11) for spraying stamped and formed screws (18) into the material discharging hole (9). The stamping die is high in stamping process speed and efficiency, safe, and convenient to use.

Owner:广州市烁烨金属制品有限公司

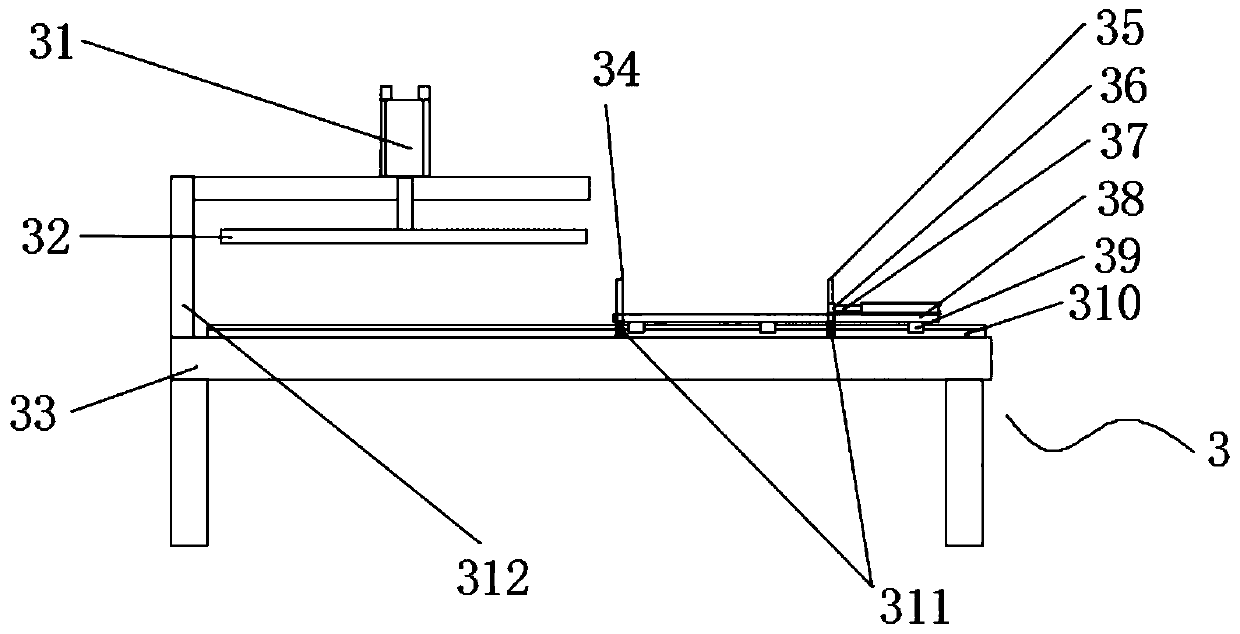

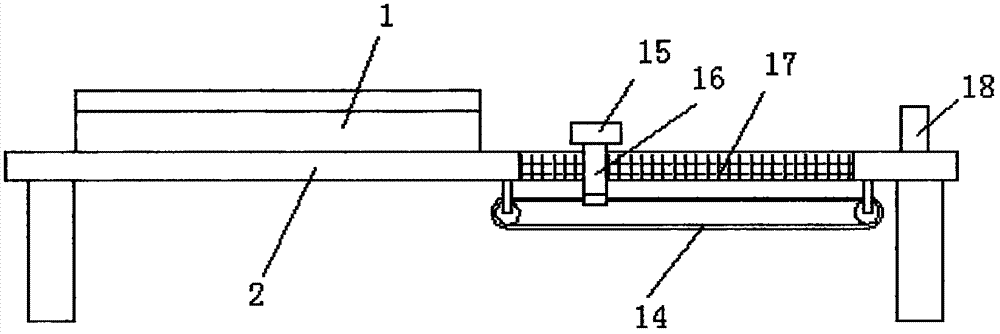

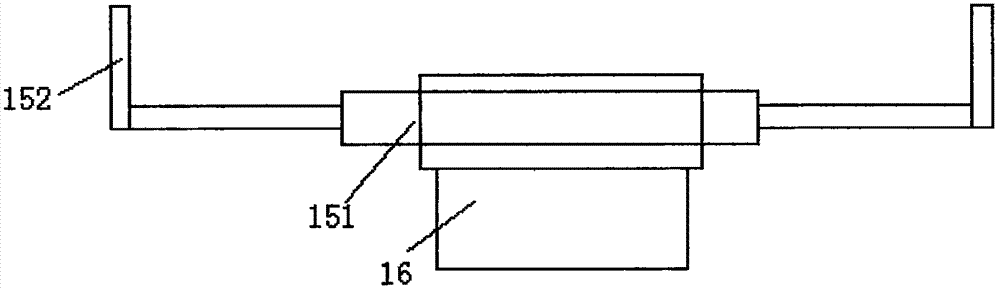

Semi-automatic production line for bamboo wood production

ActiveCN110126037AFast punching speedDie-cut uniform sizeEdge grinding machinesPlywood pressesWood productionSurface grinding

The invention discloses a semi-automatic production line for bamboo wood production. The semi-automatic production line comprises a propelling assembly, a punching and cutting assembly, a hot pressingassembly and a grinding assembly, wherein the propelling assembly is arranged at the bottom side of the punching assembly, the propelling assembly comprises a first bearing plate, a movable plate, afirst sliding block, a fixing block, a first screw rod, a first sliding rail and a propelling motor. According to the line, after bamboo is peeled and soaked, the punching and cutting assembly is usedfor carrying out straightening punching and cutting, punching and cutting is high speed, and uniform in size, so that the loss of materials is reduced; after punching and cutting is finished, the hotpressing assembly is used for extruding and shaping after gluing and stacking, the pressure is uniform, the shape is regular after extrusion and sizing, other treatment is not needed, cutting can beconducted directly, simplicity, convenience and rapidness are achieved; after cutting is finished, the whole bamboo wood can be subjected to surface grinding and side edge grinding through the grinding assembly, the grinding efficiency is high, and the grinding degree is uniform; and through the semi-automatic production line, management is facilitated, the automation degree is improved, the running efficiency is improved, and the productivity is improved.

Owner:桂东众意竹木开发有限公司

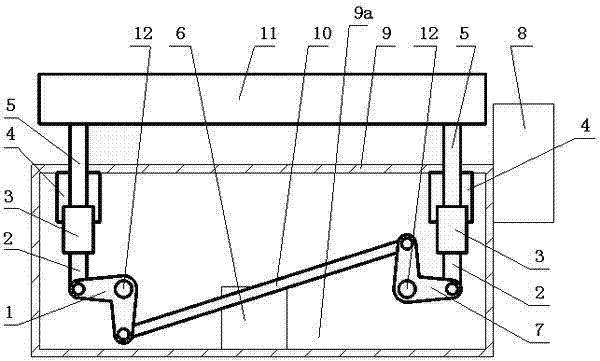

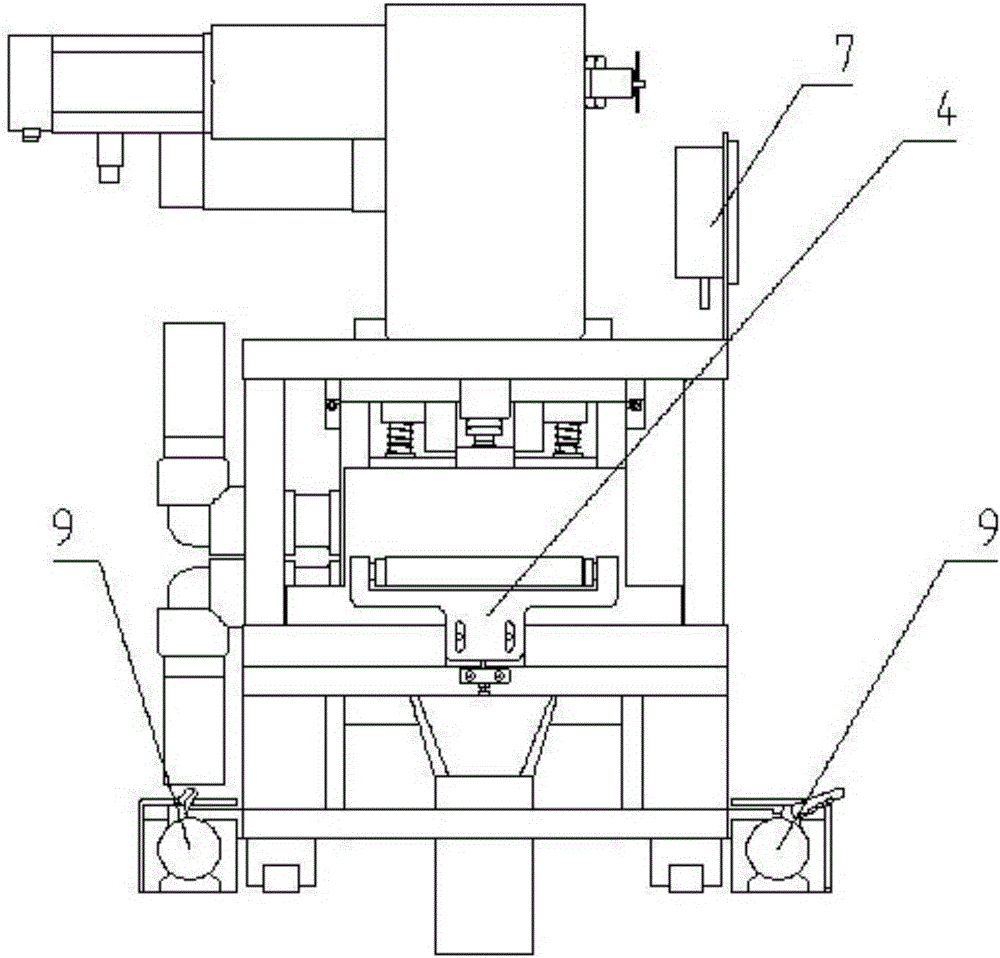

Precision four-post hydraulic cutting machine

InactiveCN102363308AGuaranteed synchronous actionCompact structureMetal working apparatusMachineCylinder block

The invention relates to a precision four-post hydraulic cutting machine, which comprises a machine body containing an oil tank, a pressure back and upright posts arranged in four corner holes of the machine body; the lower ends of two upright posts at the left and right sides are connected with a hinge seat, and the upper ends of the upright posts are fixedly connected with the lower end of the pressure back respectively; a cylinder is arranged between the upper end of the machine body and the hinge seat, the cylinder body of the cylinder is fixedly connected with the upper end of the machine body, and a piston rod of the cylinder is fixedly connected with the hinge seat; a linkage assembly is arranged below the hinge seat in the machine body; the linkage assembly comprises two groups of C-shaped rocker arms and linkage arms; the opening of the first C-shaped rocker arm positioned at the left side of the machine body is downward, the middle part of the first C-shaped rocker arm is hinged with the machine body, and the left end of the first C-shaped rocker arm is hinged with the hinge seat of the left side in the machine body; the opening of the second C-shaped rocker arm positioned at the right side of the machine body is upward, the middle part of the second C-shaped rocker arm is hinged with the machine body, and the right end of the second C-shaped rocker arm is hinged with the hinge seat of the right side in the machine body; and the right end of the first C-shaped rocker arm is in transmission connection with the left end of the second C-shaped rocker arm through the linkage arms.

Owner:QUZHOU TAIWEI PRECISE MASCH CO LTD

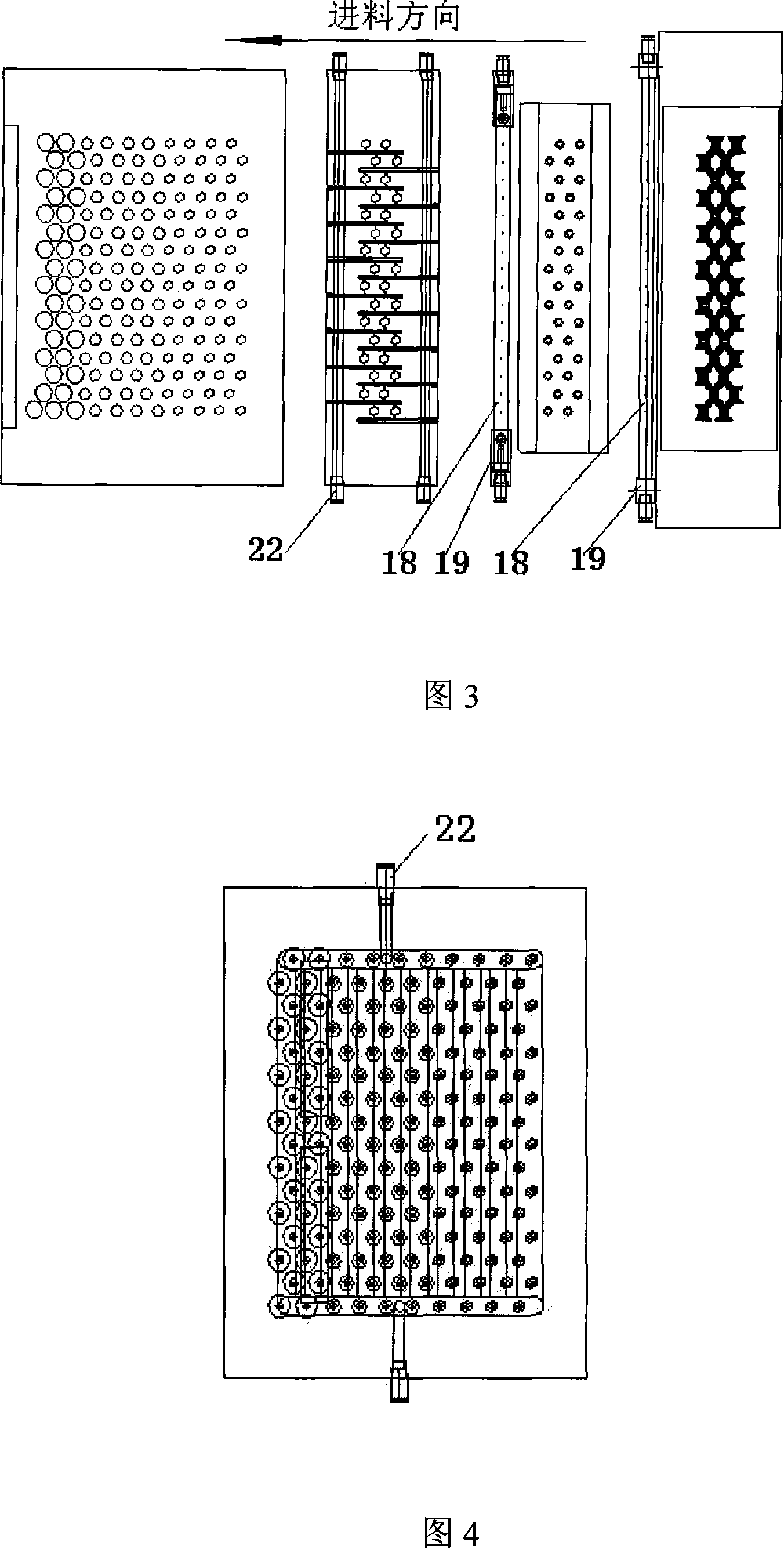

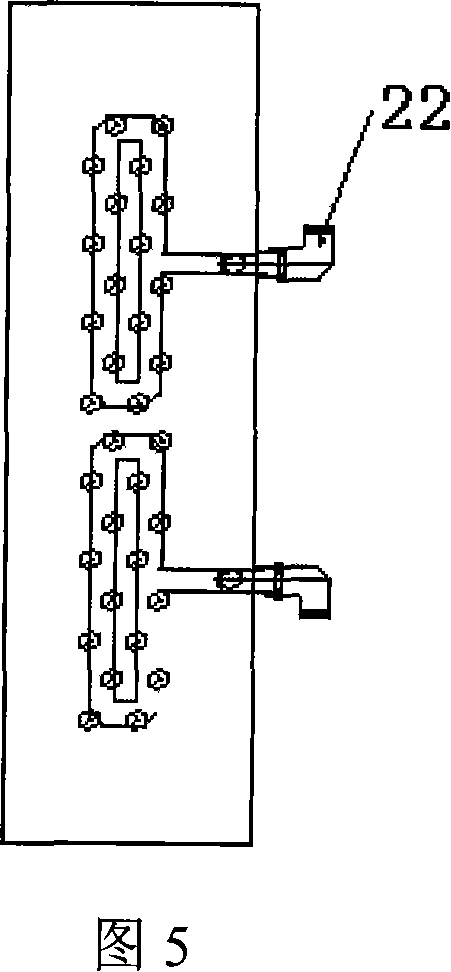

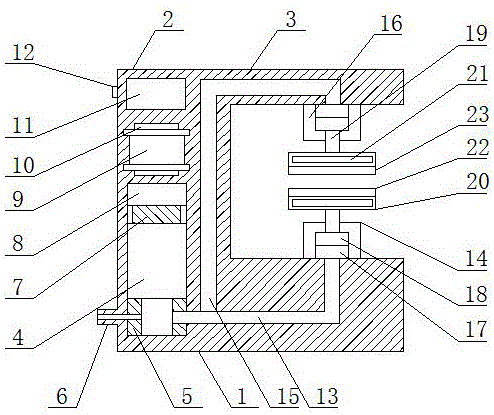

Thin band high speed stamping die and method for controlling oil-gas jetting

InactiveCN101121187AFast punching speedImprove securityShaping toolsStripping-off devicesPunch pressControl system

The present invention discloses a thin belting high-speed die; every submodule in the thin belting high-speed die is equipped with a high-pressure oil gas supply closed path (23) and connected with an oil gas supply control system of a high-speed punch. An elongated die air supply supporting block (5) is equipped between an elongated concave die fixing plate (4) and a mold frame which are equipped on an elongated submodule; the elongated concave die fixing plate (4), elongated air supply supporting block (5) and elongated concave dies (7) are equipped with communicated oil gas closed paths; oil gas closed path of every concave die is gathered to an elongated common path equipped on the elongated die air supply supporting block (5) and the elongated common path is communicated with the high-pressure oil gas supply closed path 23 of the high-speed punch high-pressure oil gas supply control system. By adopting the technical proposal mentioned above, the punching speed of the thin belting is increased in the process of high-speed punching and the punching precision is ensured; the safety performance of the die is excellent which prevents the cutting edge of the punch-die from being damaged by the punching waste material.

Owner:黄山三佳谊华精密机械有限公司

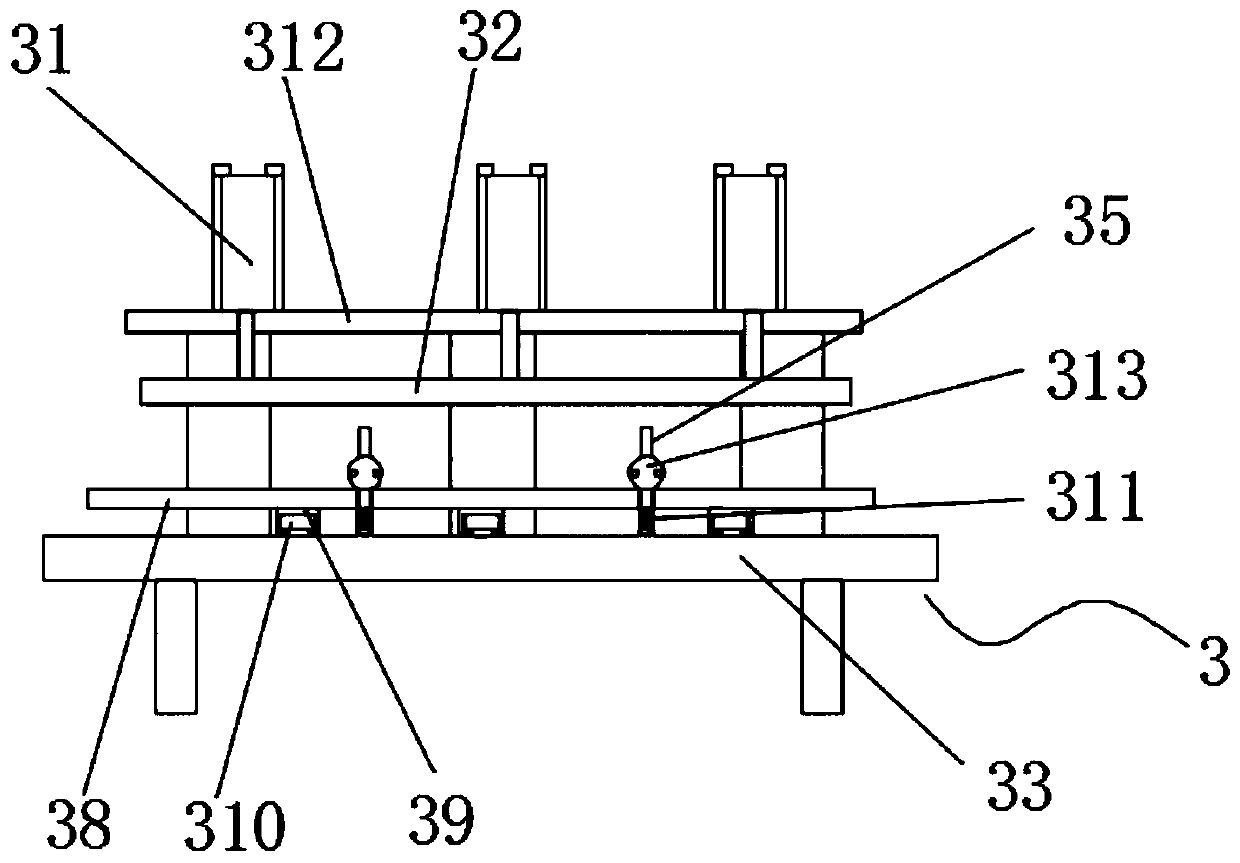

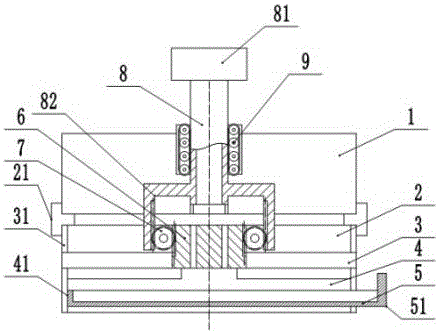

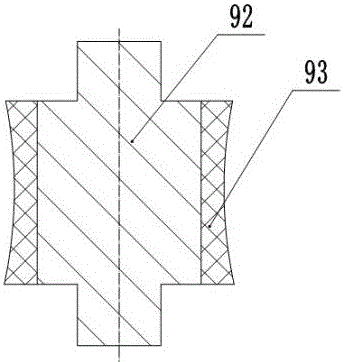

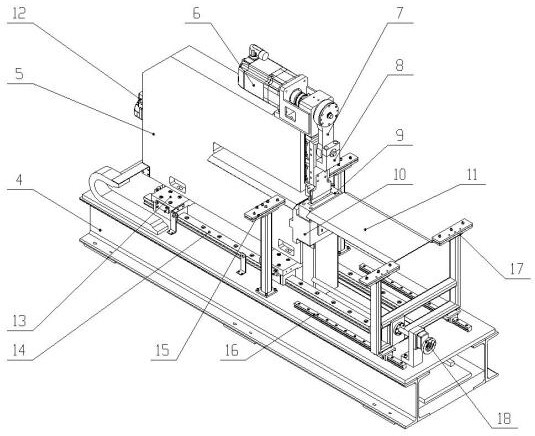

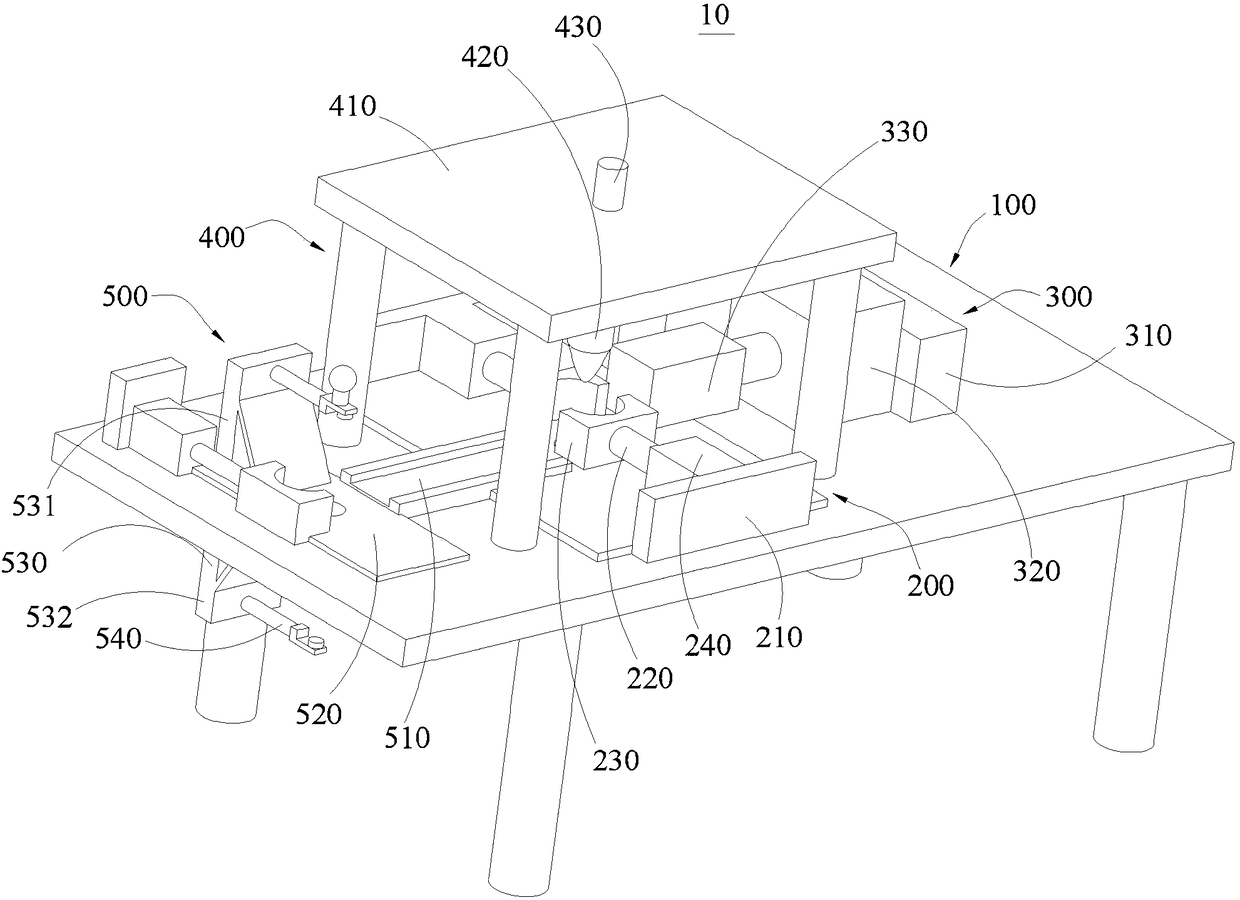

Pole piece punching device of piece stacking machine

ActiveCN106270109ATo switch functionEfficient removalCleaning using toolsCleaning using gasesPunchingPole piece

The invention relates to a pole piece punching device of a piece stacking machine. The pole piece punching device of the piece stacking machine comprises a pole lug die stamping mechanism and a cut-off die stamping mechanism. The pole piece punching device is characterized in that the pole lug die stamping mechanism comprises an anode forming mold installed on a first supporting frame and a forming drive mechanism connected with the anode forming mold; the cut-off die stamping mechanism comprises an anode cut-off die installed on a second supporting frame, a main drive mechanism and a cut-off drive mechanism connected with the anode cut-off die; the main drive mechanism comprises an upper pressure roller and a lower pressure roller, and the axis ends of the upper pressure roller and the lower pressure roller are connected with a power source; the upper pressure roller and the lower pressure roller are rotationally arranged between a left supporting seat and a right supporting seat, and the left supporting seat and the right supporting seat are arranged on a bottom board; and the bottom board is slidably arranged on the second supporting frame and connected with the output end of a main drive deviation correcting power mechanism. By means of the pole piece punching device, the problem that due to errors in the pole piece punching process, the pole piece punching quality and efficiency are low can be solved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Small portable two-way telescopic stamping device

The invention discloses a small portable two-way telescopic stamping device. The device comprises a bottom blocky shell, a middle supporting shell arranged on one side of the upper surface of the bottom blocky shell and a top blocky shell; a hollow structure is arranged in the middle supporting shell, an iron core of which the surface is provided with a coil in a winding mode is fixed to the position, located over the hollow structure, of the middle supporting shell, a storage battery is fixed to the position, located over the iron core, inside the middle supporting shell, and a group of controllers are fixed to the side face of the middle supporting shell. According to the small portable two-way telescopic stamping device, internal hydraulic oil is extruded through the electromagnetic working principle and the principle that like magnetic poles repel each other and unlike magnetic poles attract each other; due to the fact that the transforming speed between the magnetic poles is high and large magnetic force is formed, the formed stamping speed is high, and the stamping power is high; in addition, due to the fact that the device achieves two-way stamping, the relative speed of an upper die block and a lower die block at the contacting moment is 1-2 times that of a one-way stamping device, and then the stamping range of the device is effectively widened.

Owner:周文婧

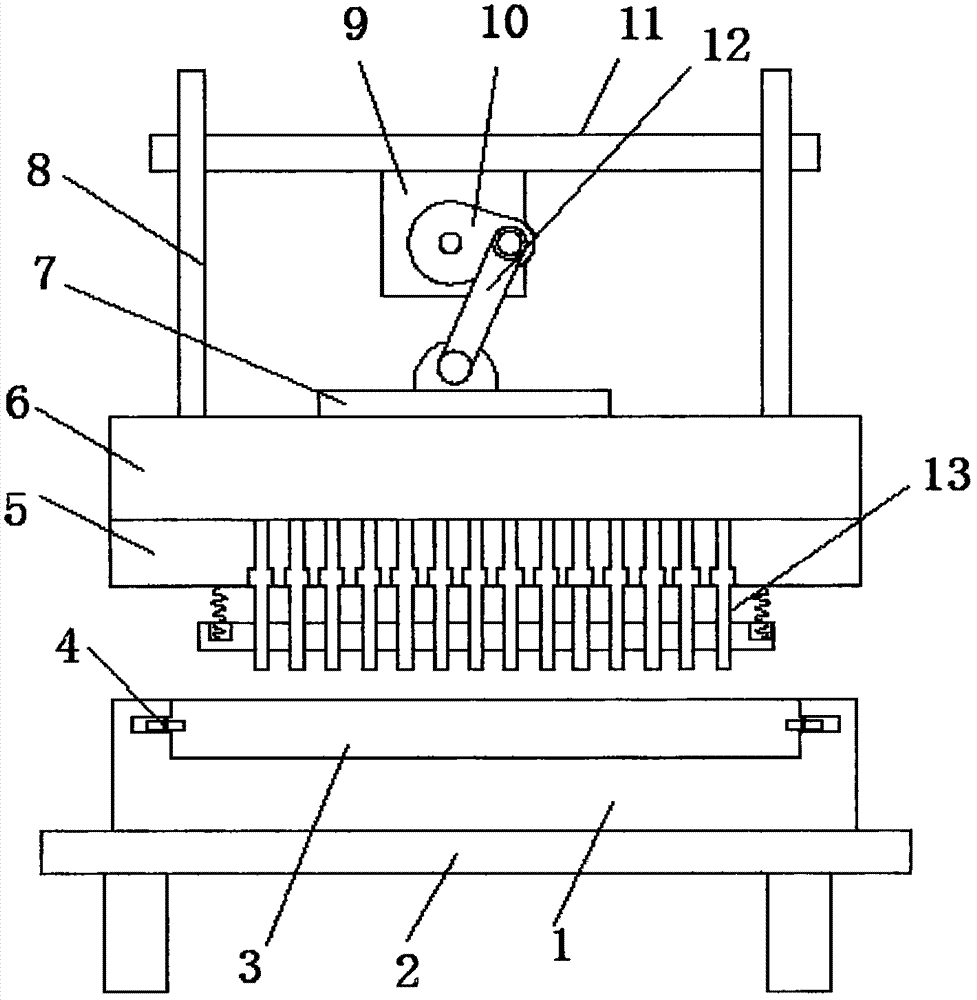

High-speed trademark cutting punch

InactiveCN104029252AImprove reliabilityFast punching speedMetal working apparatusPunch pressTrademark

The invention discloses a high-speed trademark cutting punch which comprises a rack, a tabletop, a conveying mechanism, a lower die, an upper die, an upper support, guide column guide sleeves, springs, a motor and a cam. The tabletop is arranged on the rack, the conveying mechanism is mounted on the tabletop, the lower die is arranged on the tabletop, the upper support is arranged on the rack, the upper die is arranged below the upper support, the guide column guide sleeves are arranged around the upper support, the springs are connected on the outer sides of the guide column guide sleeves in a sleeved manner, the motor is arranged on the rack, the cam is arranged at the front end of the motor, and the edge of the cam contacts with the upper support. By the above mode, the high-speed trademark cutting punch has the advantages of high reliability, compact structure, high adaptability, high punching speed, accuracy in positioning, simplicity in maintaining, cleanliness and the like, and has wide market prospect in the field of punch equipment.

Owner:吴中区甪直渡岘工艺品厂

Aluminum ring processing device

The invention belongs to the technical field of stamping dies, and discloses an aluminum ring processing device. The aluminum ring processing device comprises a lower die, and an upper die arranged on the lower die, wherein a through hole is formed in the middle part of the upper die; a pressing column is in slide connection with the inside of the through hole; an opened groove is formed in axis of the pressing column; a pressing block is connected to the top end of the pressing column; a forming column is in slide connection with the middle part of the lower die, and a forming groove is formed in the axis of the forming column; the forming column is abutted with the pressing column; symmetric mounting racks consisting of transverse parts and vertical parts are connected to the side surface of the pressing column; racks are arranged on the vertical parts; two gears which are engaged with the racks are connected with a rotating shaft in the lower die; racks which are engaged with the gears are arranged on two side surfaces of the forming column. According to the abovementioned scheme, the aluminum ring processing device has the advantages that the stamping speed in aluminum ring processing is increased; an aluminum sheet can be fully cut during stamping, so that the aluminum ring can be prevented from being pulled and deformed, and as a result, the aluminum ring processing accuracy can be improved; in addition, more force can be saved for an operator, and the fatigue can be reduced.

Owner:CHONGQING YOUBO MACHINERY MFG

Processing method for rolling casting device

The invention relates to the field of sand casting, particularly to a processing method for a rolling casting device. The processing method comprises the following steps: a casting box is manufactured through moulding, the casting box is fixed on a rolling box in the rolling casting device, positioned by utilizing a chuck plate, and integrally fixed by utilizing a pressing plate, and the casting operation is automatically completed sequentially through pouring, liquid steel solidifying, demoulding and clearing processes. According to the invention, rapid rotation of the rolling box is utilized, so that the punching speed of the liquid steel is increased, the casting defects are reduced, and the quality of casting is improved, and compared with the traditional technology, the number of sand box dies is greatly reduced, the casting period is shortened, the casting cost is decreased, and the batch of casting is realized.

Owner:JIANGSU BIAOXIN KUBOTA IND

Hardware stamping component capable of discharging rapidly

ActiveCN107838261AImprove stamping qualityFast punching speedShaping toolsMetal-working feeding devicesHydraulic cylinderControl system

The invention discloses a hardware stamping component capable of discharging rapidly. The hardware stamping component comprises a stamping device and a discharging device, and the discharging device is arranged beside the stamping device; the stamping device consists of a base, a rear box body, a rotary worktable, a stepping motor, a lower mold, an upper mold, a hydraulic cylinder and a telescopicair cylinder; the discharging device consists of a base body, a supporting vertical plate, a swing air cylinder, a connecting rod, an electromagnet, a low-speed motor, a discharging pipeline, a material receiving trolley and a power supply; and the stamping component further comprises a control system. According to the stamping component, a form of combining the hydraulic cylinder with the telescopic cylinder is adopted, forming can be achieved by one-time stamping, so that the stamping speed is improved; and the discharging device adopts a mode that the electromagnet swings along with the swinging air cylinder, the electromagnet is electrified and sucks a stamped hardware from the lower mold, the control system controls the electromagnet to be powered off so that the hardware on the electromagnet can automatically falls into the discharging pipeline, then slides into a material receiving box, and therefore, automatic discharging is realized, and the discharging strength is greatly reduced.

Owner:HAIYAN HONGQIANG HARDWARE MFG CO LTD

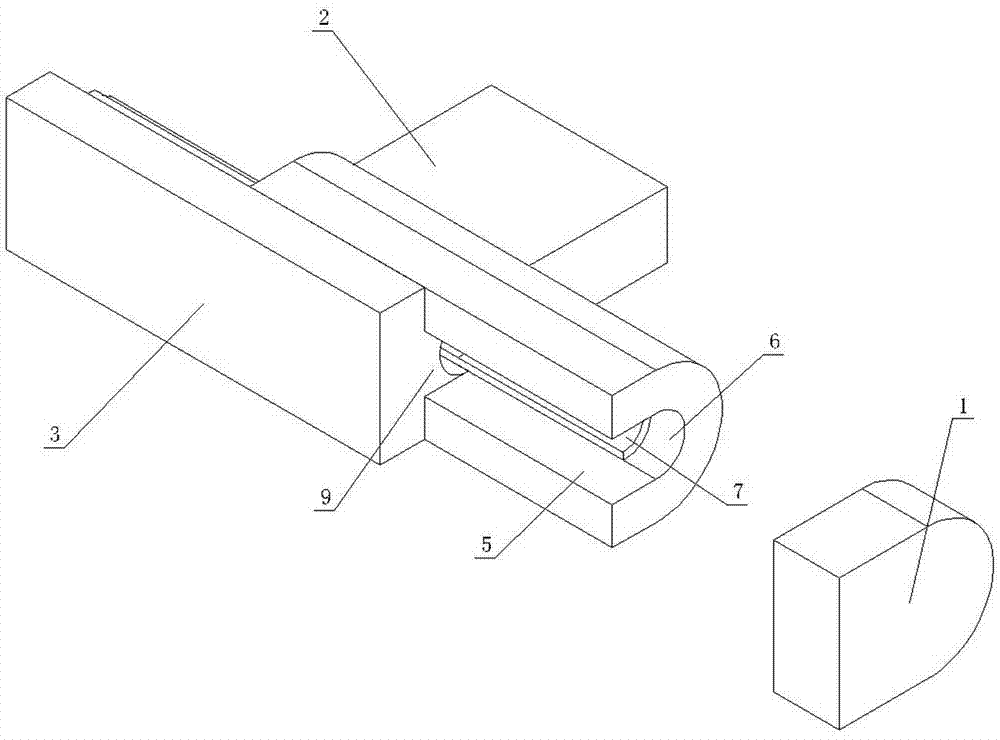

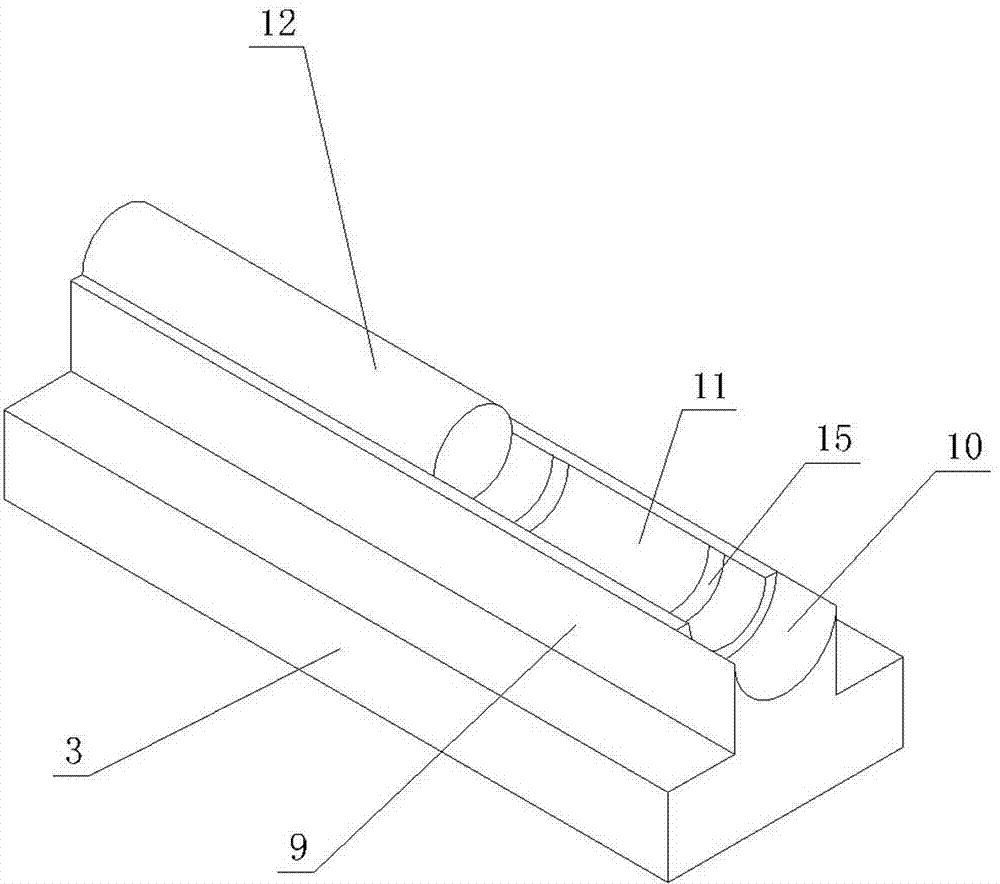

Die capable of continuously punching long screws

ActiveCN103495665AShort tripReduce energy consumptionShaping toolsStripping-off devicesPunchingEngineering

The invention discloses a die capable of continuously punching long screws. The die comprises a front punch (1), an upper die casing (2) and a lower die casing (3). A guide groove penetrating through the upper die casing (2) is arranged on the upper die casing (2), the guide groove is provided with a first upper semicircle groove (6) and a second upper semicircle groove (7), a vertical blanking channel (8) is formed in the upper die casing (2), the lower die casing (3) is provided with a guide protruded stripe, the guide protruded stripe is provided with a first lower semicircle groove (10) and a second lower semicircle groove (11), a long screw head cavity (13) is formed by the first upper semicircle groove (6), the first lower semicircle groove (10), a rear end face of the front punch (1) and an inner hexagonal protrusion (4), and a long screw rod cavity (14) is formed by the second upper semicircle groove (7), a second lower semicircle groove (11) and a blocking column (12). The die is short in die opening and closing stroke, prevents a round bar used for punching the long screws from being bent in a punching process, is high in speed, is high in efficiency and is convenient to demould.

Owner:JIANGSU HAOJIA STAINLESS STEEL STANDARD PARTS

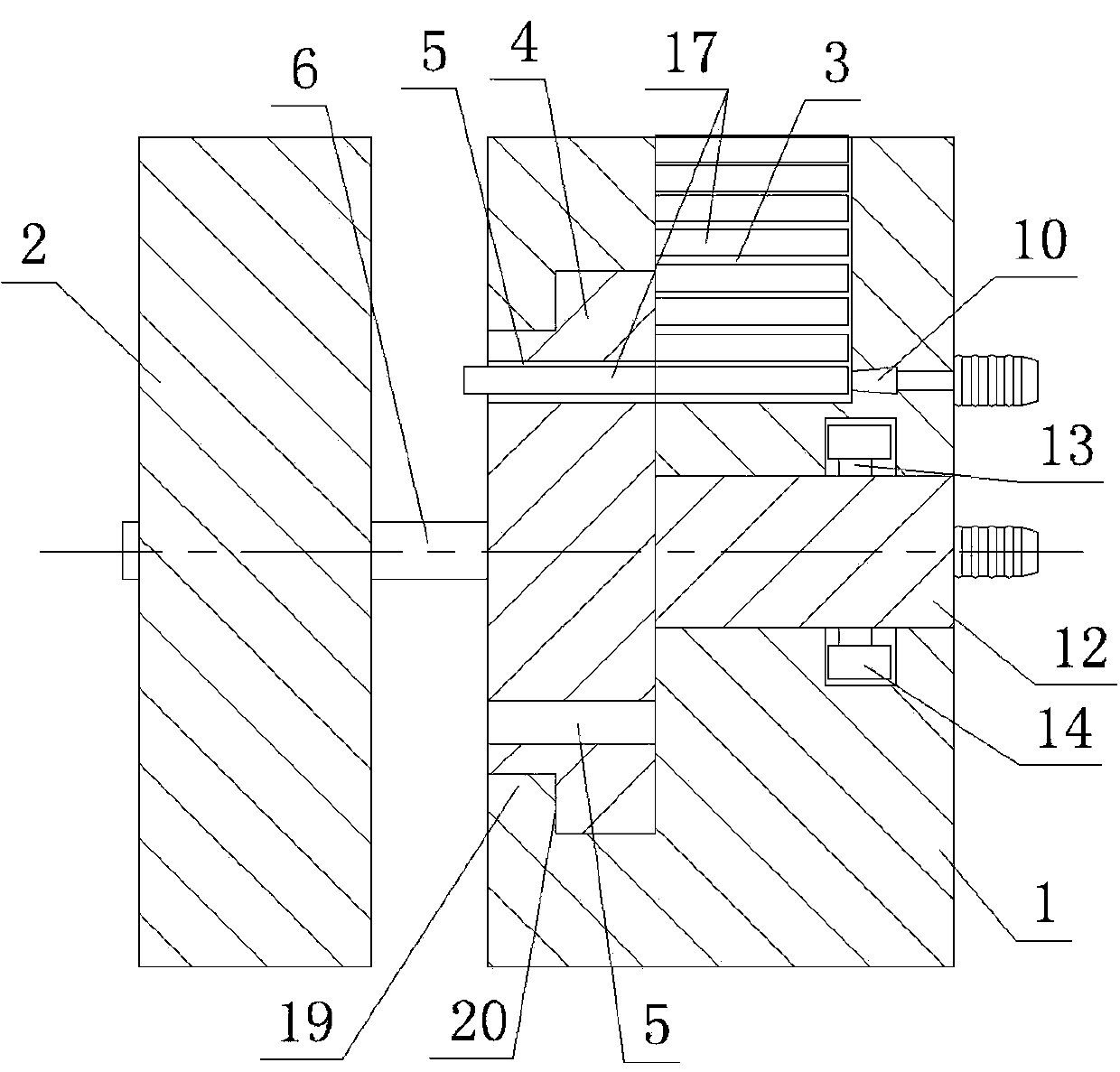

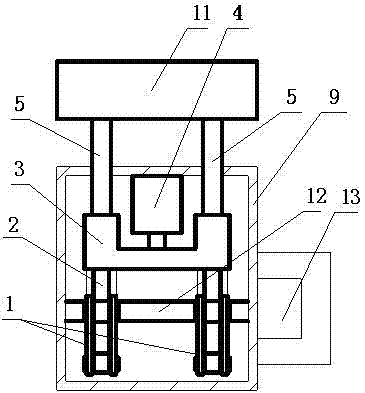

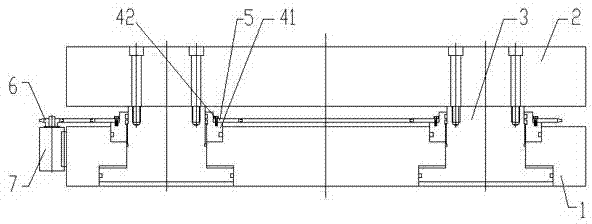

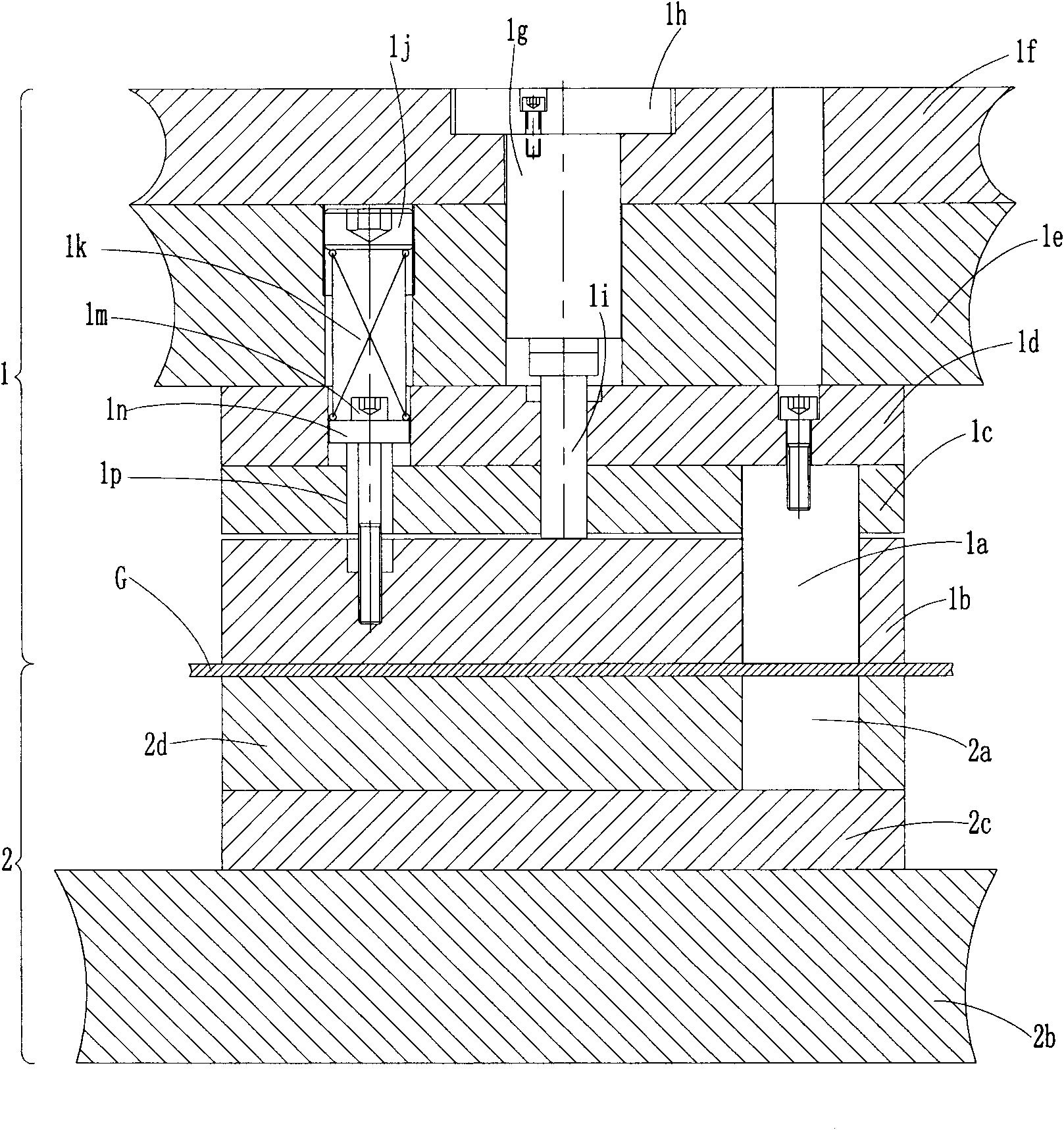

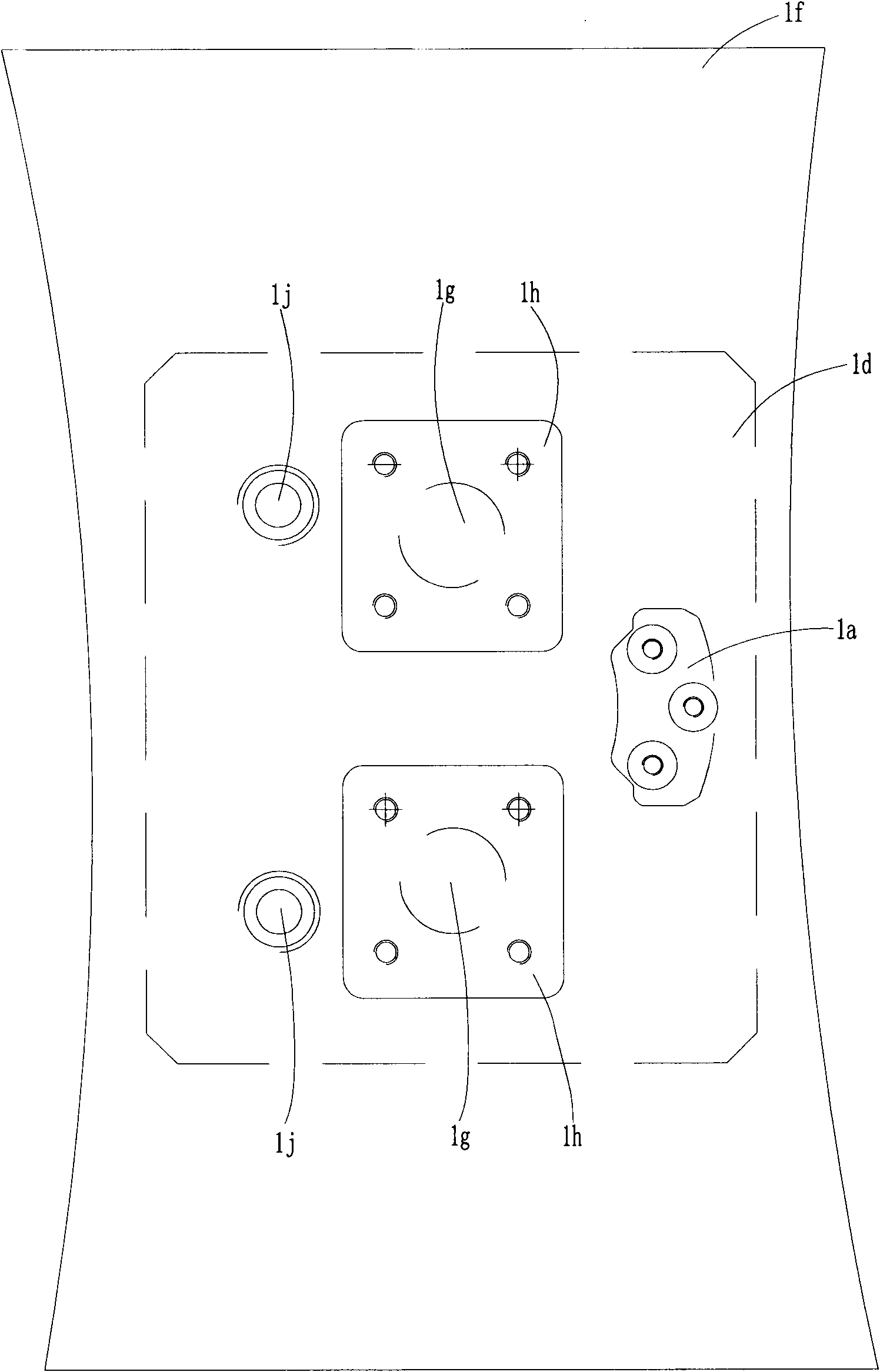

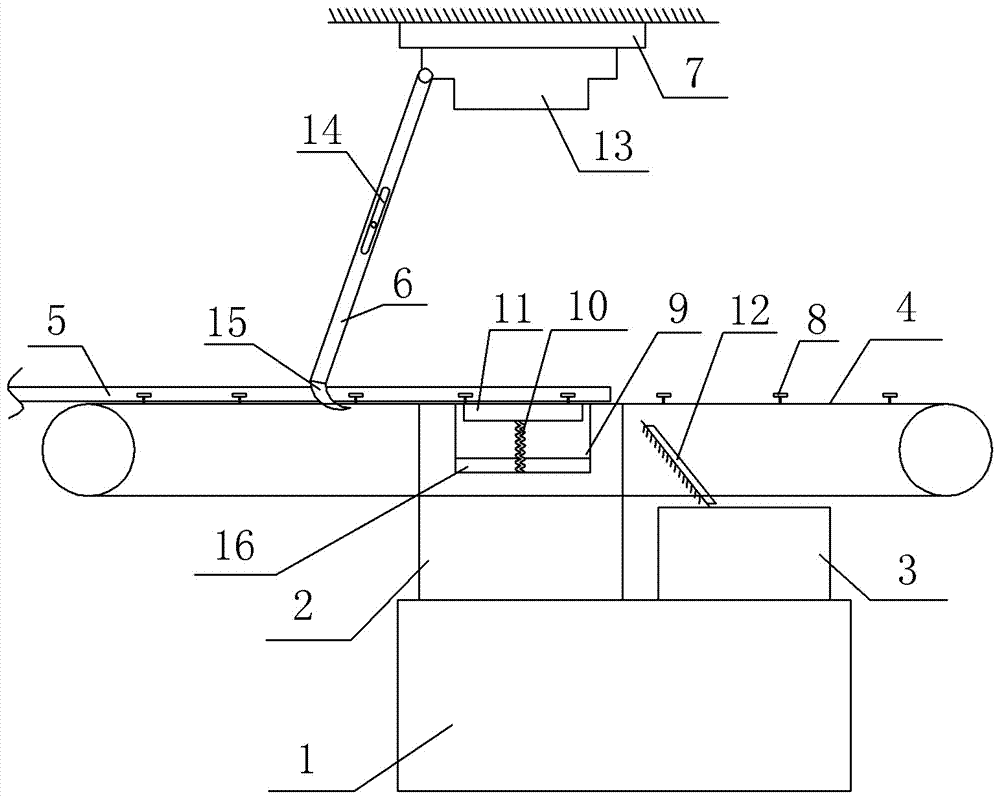

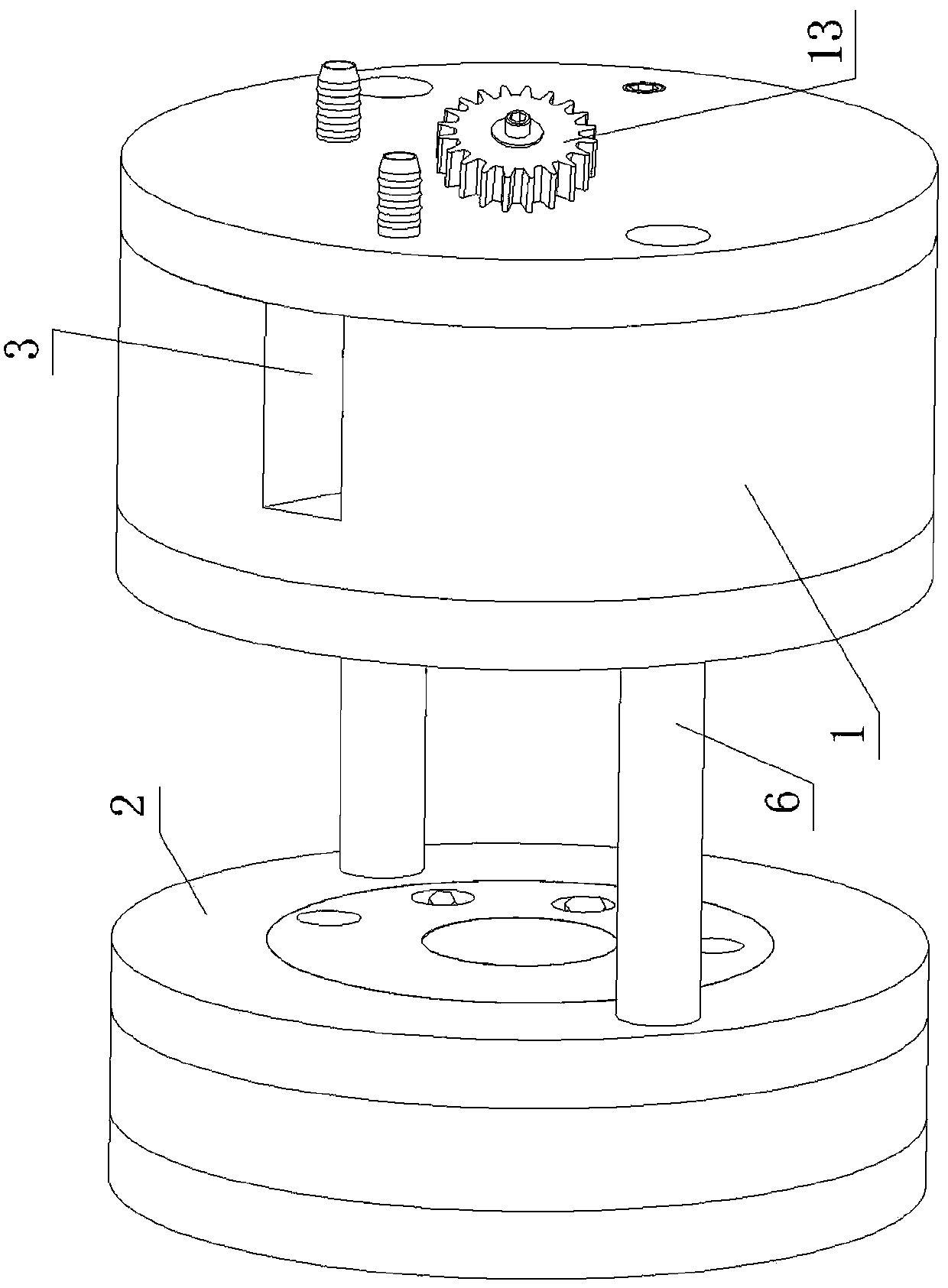

Mold mounting height adjusting device of press

InactiveCN104708846AFast punching speedImprove quality and efficiencyPressesPunchingReciprocating motion

The invention relates to a mold mounting height adjusting device of a press. The device comprises a table plate lower base (1) and a table plate upper base (2), wherein the table plate upper base (2) is connected with the table plate lower base (1) through a height adjusting base (3); the upper end of the height adjusting base (3) is fixedly connected with the table plate upper base (2); the height adjusting base (3) is connected with the table plate lower base (1) through a rotating device; the rotating device comprises a revolving horizontal part (41), and a lifting part (42) in threaded connection with the horizontal part (41) to realize vertical motion; and the lifting part (42) is fixedly connected with the height adjusting base (3). The mold mounting height adjusting structure is mounted on the stationary table plate lower base, so that the adjustment of the mold mounting height can be realized, and the mass of a reciprocating part on a slide block is reduced to the greatest extent; the inertia of the slide block can rise the punching speed of the high-speed press and can improve the dead point stability of the slide block under the condition of high-speed operation; and finally, the improvement of the quality of products punched by the high-speed press and the production efficiency can be realized.

Owner:YANGZHOU FORGING MACHINE TOOL

High-speed micro hole punching die

The invention discloses a high-speed micro hole punching die. The high-speed micro hole punching die comprises a base and a fixing plate; a supporting column is welded to each of the four corners of the bottom end of the base; the fixing plate is arranged above the base; a lower die base is fixed to one side of the top end of the base; a hole punching groove is formed in the top end of the lower die base; the side walls of the two sides of the hole punching groove are each provided with an installing groove; a plurality of guiding wheels are rotationally connected in each installing groove; a horizontally arranged conveying belt is arranged on one side of the bottom end of the base; a first through hole is formed above the conveying belt and is located in the base; a connecting column is fixed to the side wall of the top end of the conveying belt through a screw; the top end of the connecting column penetrates the first through hole and is connected with a clamping device; the connecting column is in sliding connection with the side wall of the first through hole; the clamping device is arranged at the top end of the connecting column; and the side, away from the lower die base, of the first through hole is provided with a supporting block. The high-speed micro hole punching die can drive a to-be-punched part to fast move on the lower die base, punching is convenient, punches on an upper die base can be driven to fast and repeatedly to perform downward punching, and the punching speed is high.

Owner:昆山钣源冲压技术有限公司

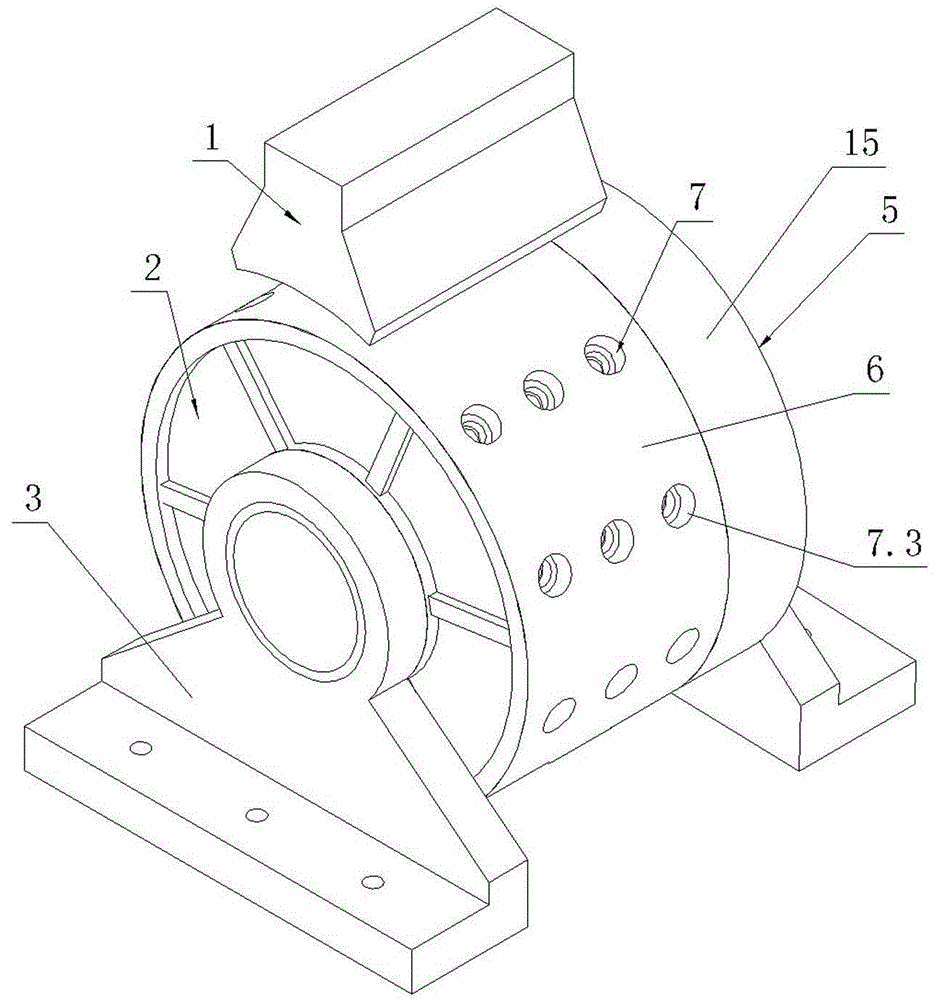

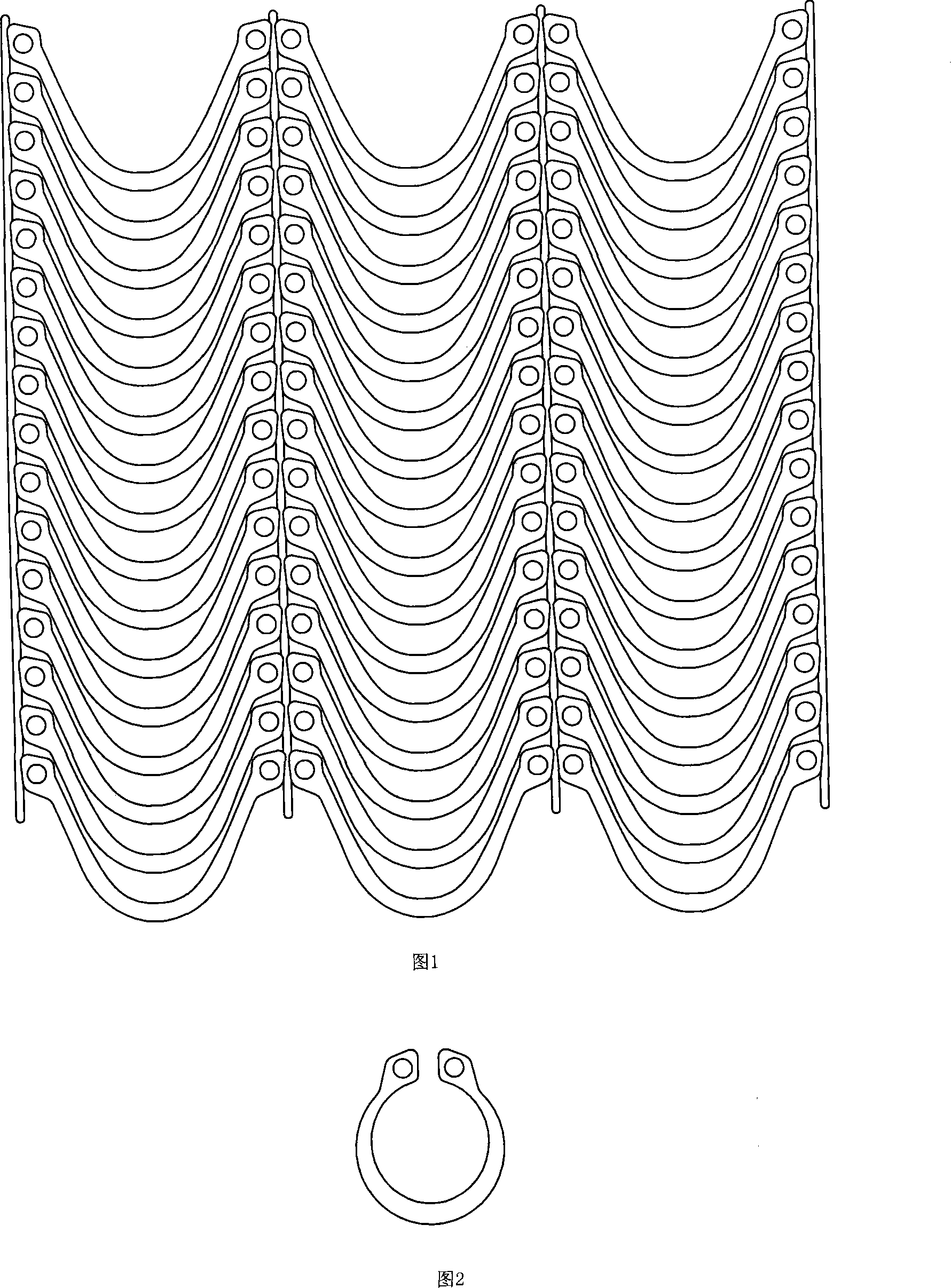

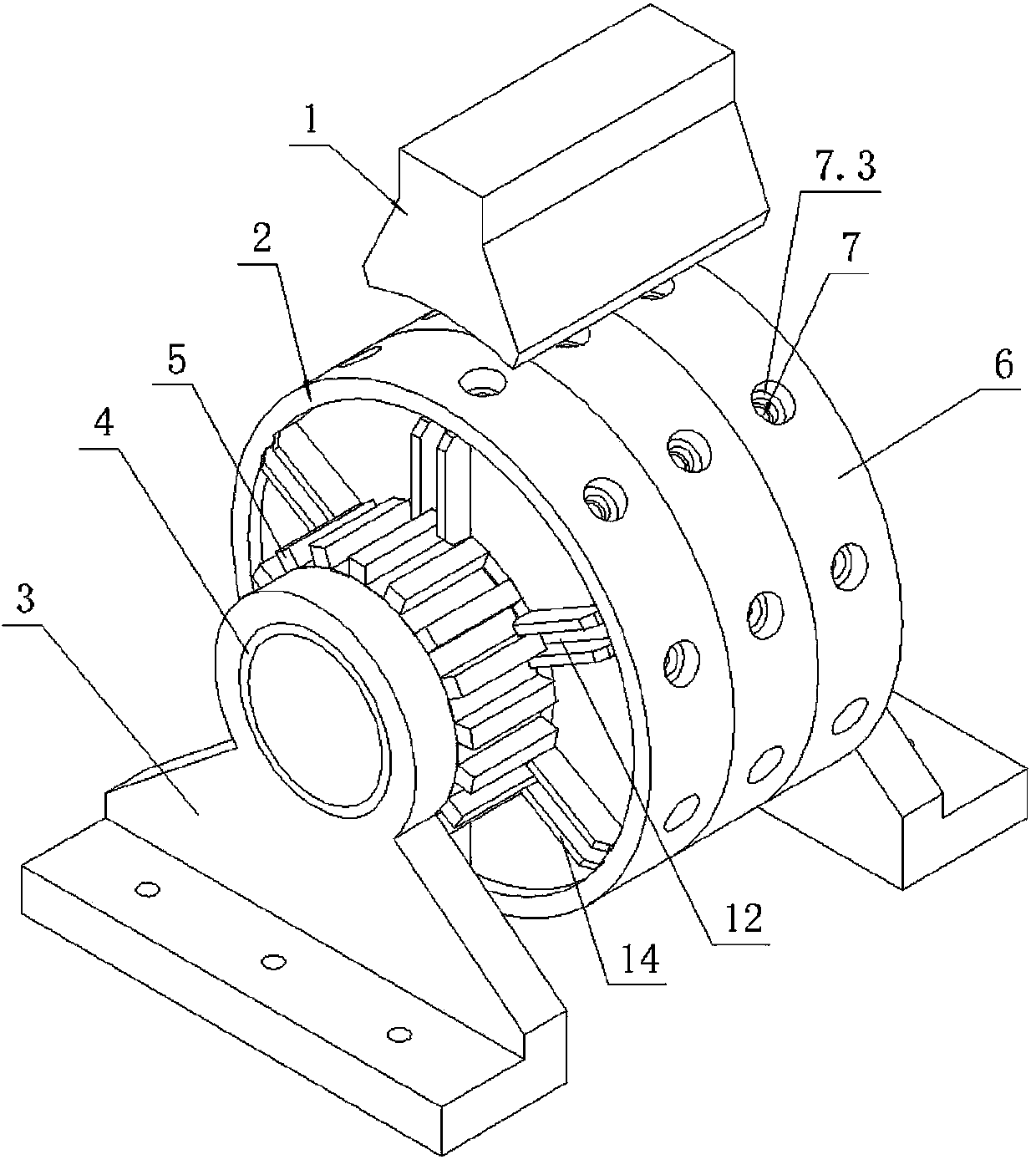

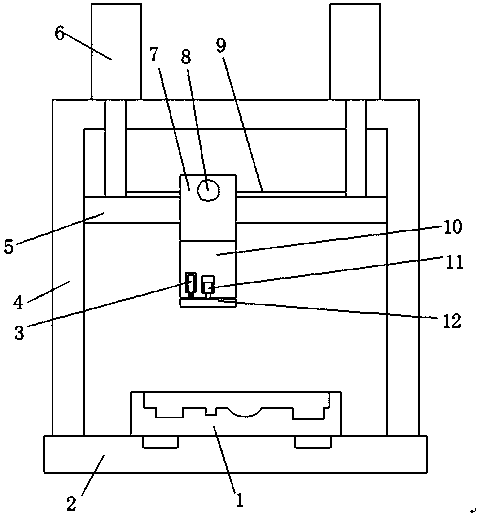

Stamping die

InactiveCN103599986AImprove work efficiencyFast punching speedShaping toolsNutsStamping processImpeller

The invention discloses a stamping die which comprises a punch and a formwork. The formwork comprises two supports (3), a spindle (4), a pneumatic disc and a rotating drum (6). Two ends of the spindle (4) are fixed with the two supports (3), the rotating drum (6) is provided with a center hole, the spindle (4) is rotatably sleeved with the rotating drum (6) through the center hole, the pneumatic disc comprises a disc casing and an impeller located in the disc casing, an end wall of the disc casing is fixed with the spindle (4), the spindle (4) is rotatably sleeved with the impeller and is in circumferential limitation with the rotating drum (6), the rotating drum (6) is provided with a plurality of radial through holes (7), the punch is provided with a plurality of punching columns, the lower end of every punching column is provided with a hexagonal prism protrusion, all the punching columns are distributed in a row, the whole row of punching columns are opposite to a row of radial through holes (7) at the highest position of the rotating drum (6), and a circumferential wall of the disc casing is provided with a first nozzle for blowing blades of the impeller. The stamping die is quick in speed in the stamping process, high in efficiency, safe and convenient.

Owner:XINGHUA TIEXIN ELECTRONICS ENG

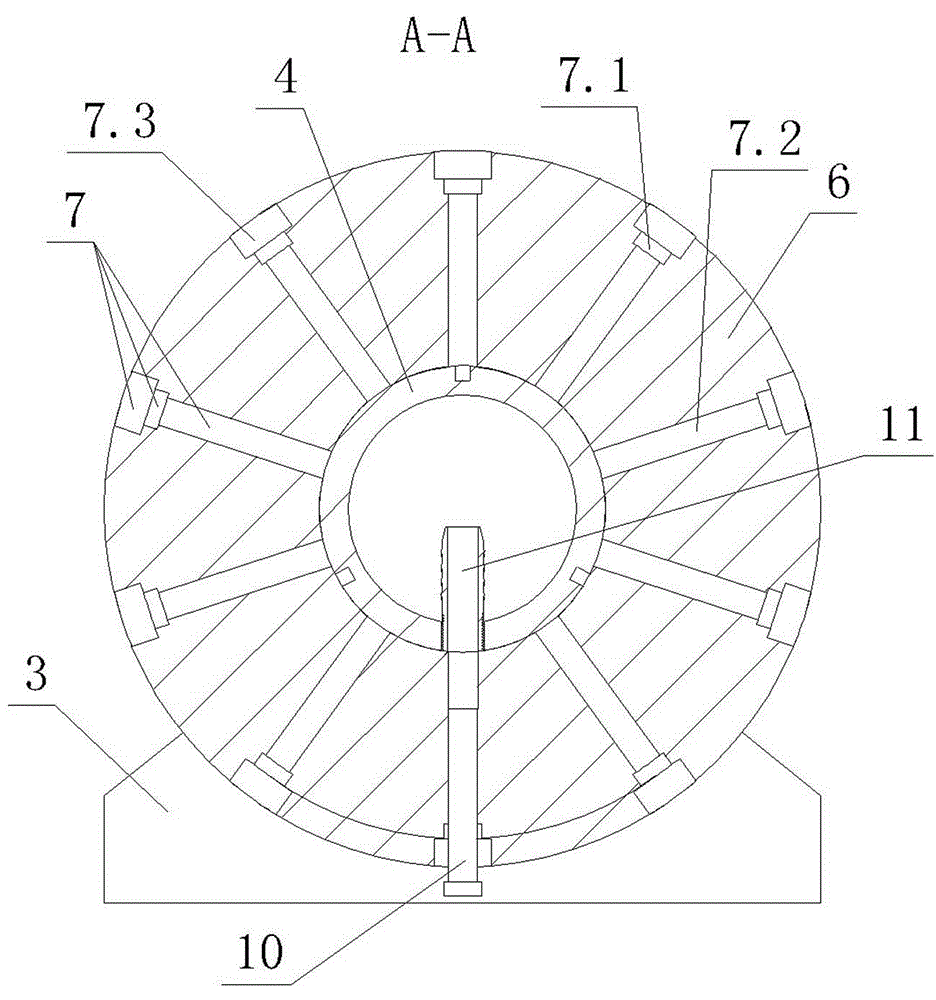

Preparing technique of back-up ring

InactiveCN101176899AIncrease profitFast punching speedMetal-working apparatusPunch pressMaterial consumption

The invention discloses a manufacturing process of a retaining ring, which is characterized in that a mold is first installed on a punching machine, and after the strip is taken and placed on the punching machine, the strip is punched into a shape with a certain curvature by using the mold of the punching machine. The arc-shaped strip, and finally the arc-shaped strip with a certain curvature is curled into a circle with an opening by punching equipment, which becomes a kind of retaining ring. Adopting this technology to make the retaining ring has high speed and high safety, especially reduces material consumption by more than 30%, and will be widely used in the standard part manufacturing industry.

Owner:陈福星

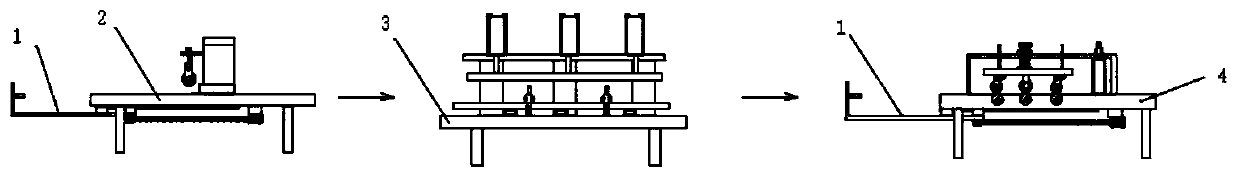

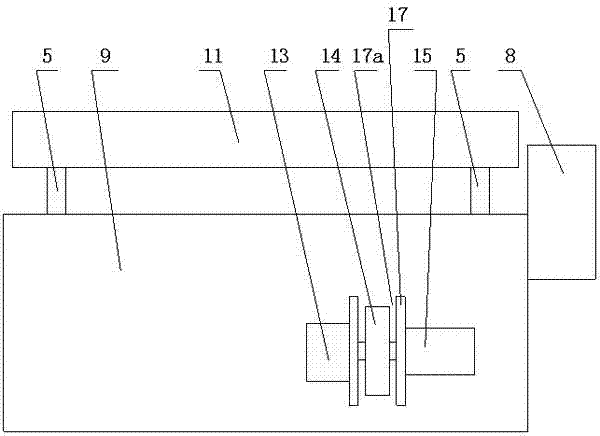

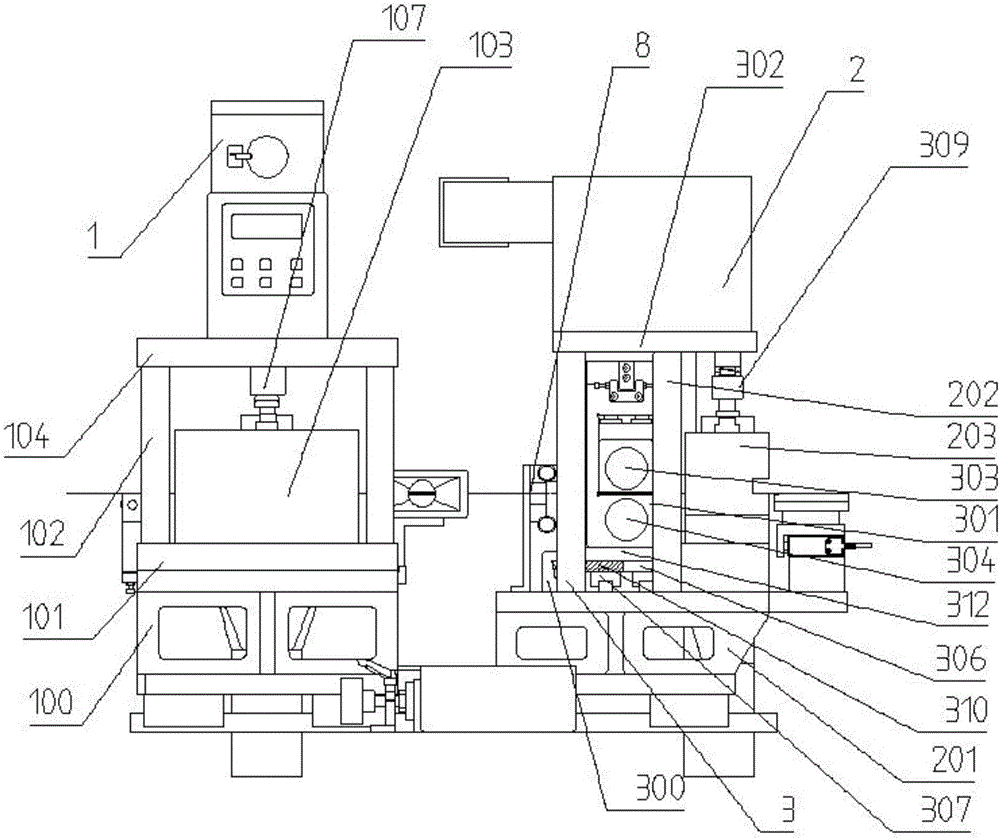

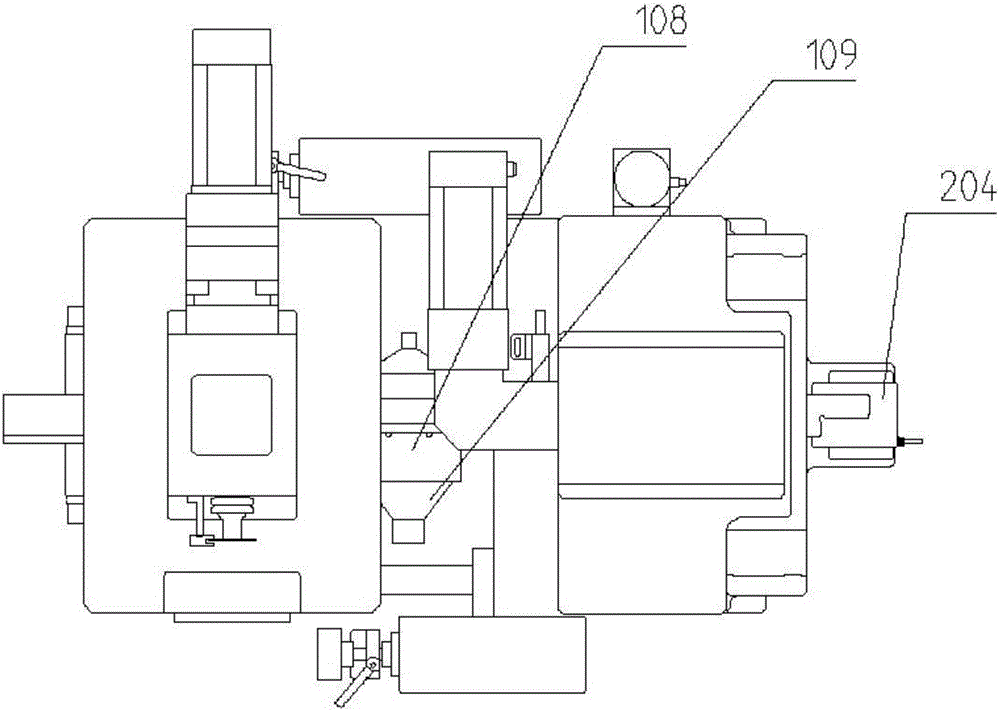

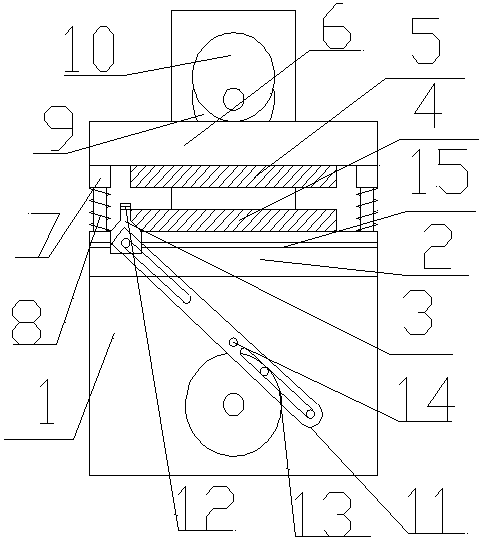

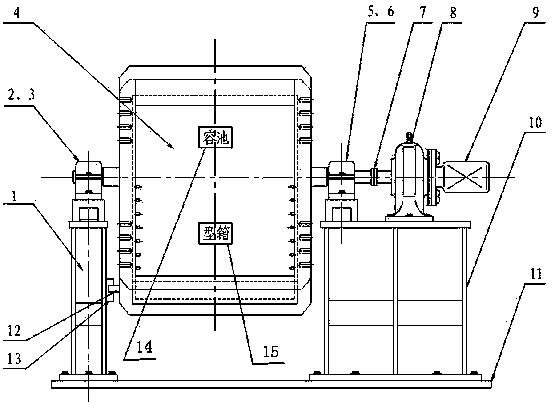

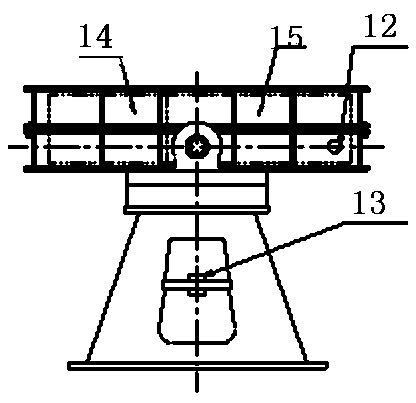

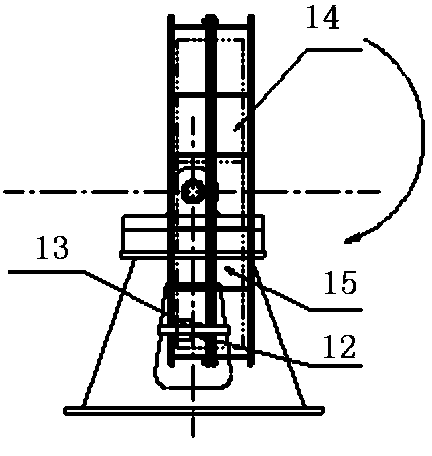

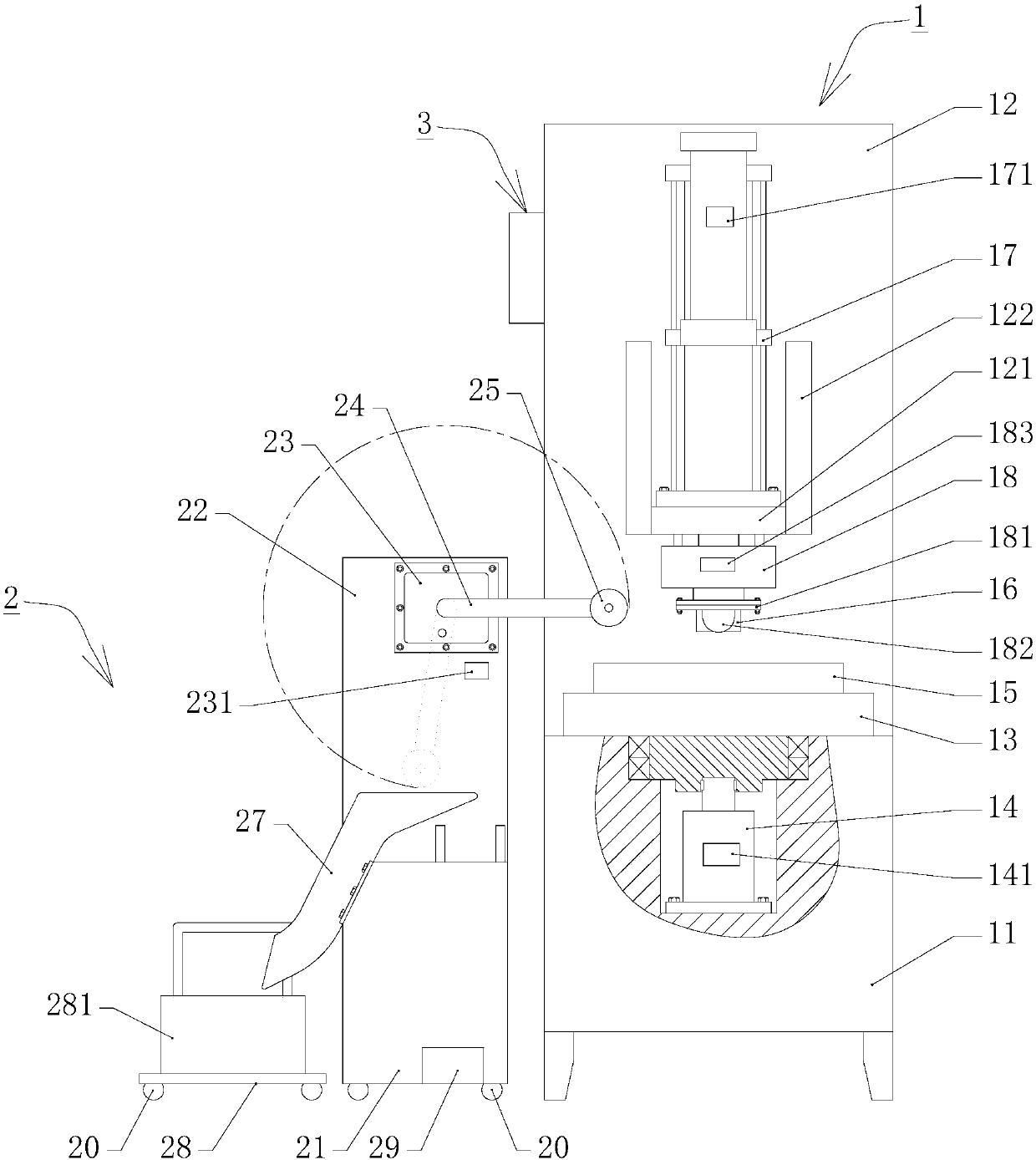

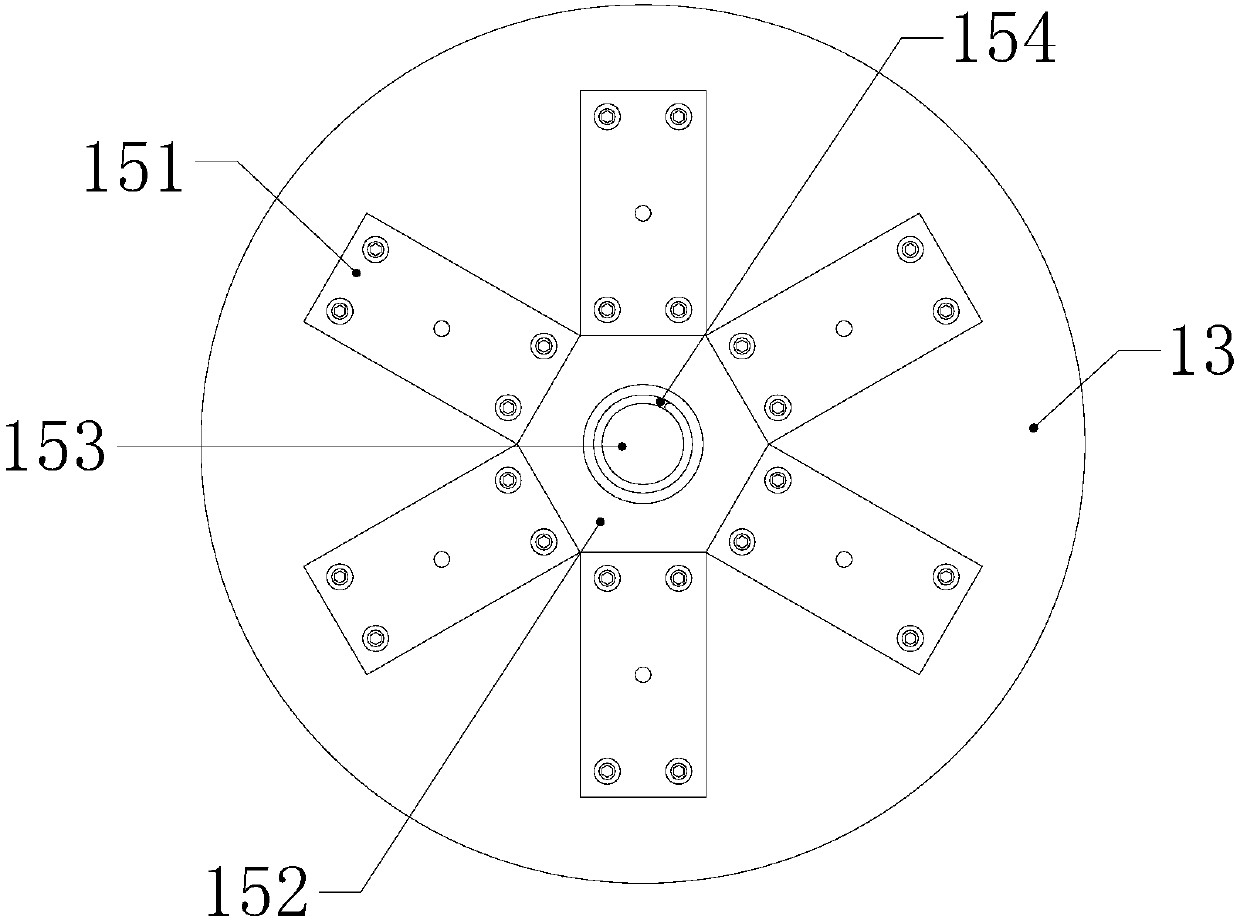

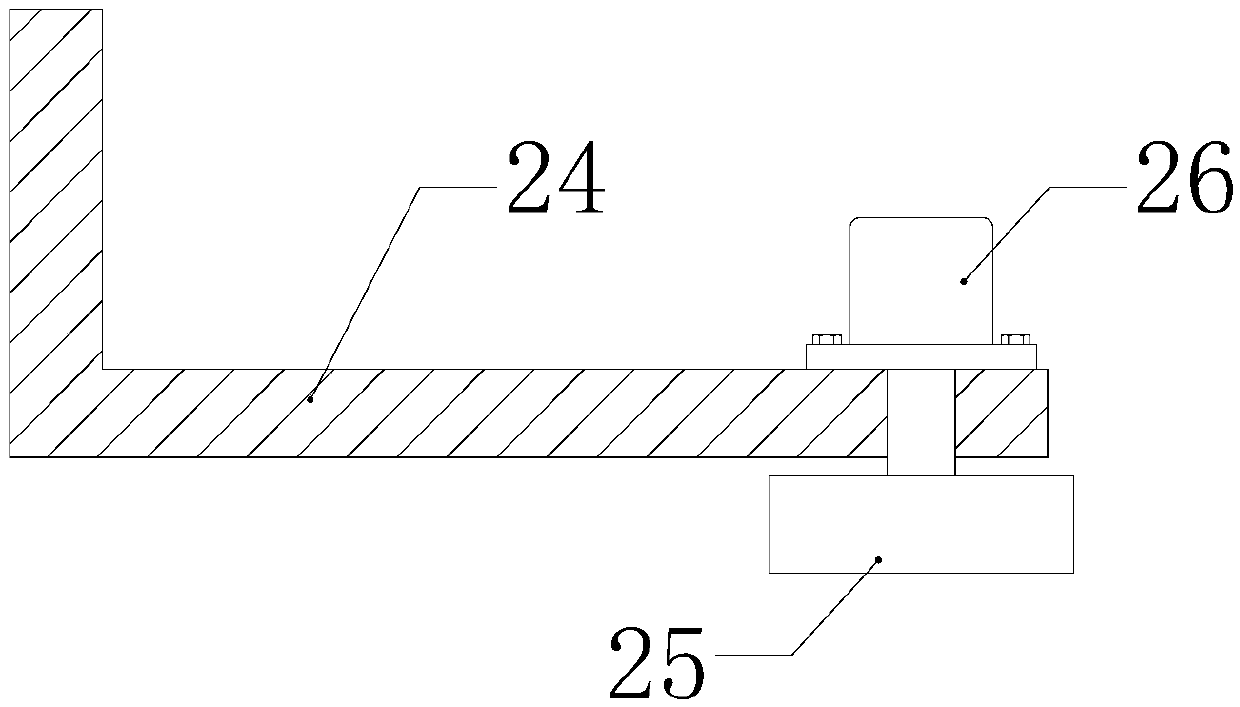

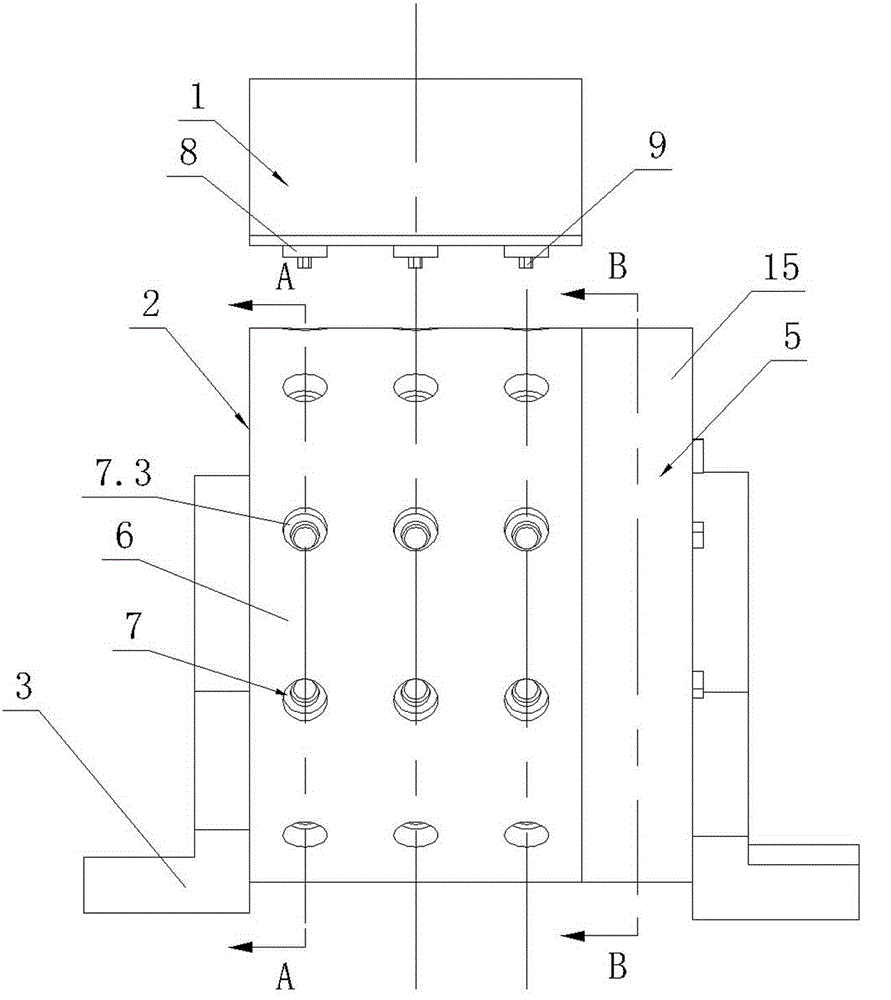

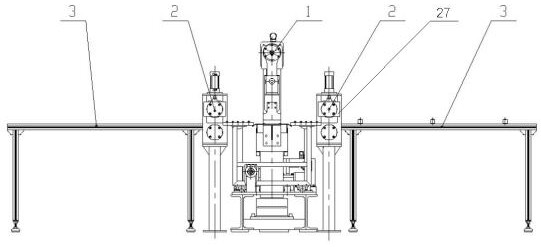

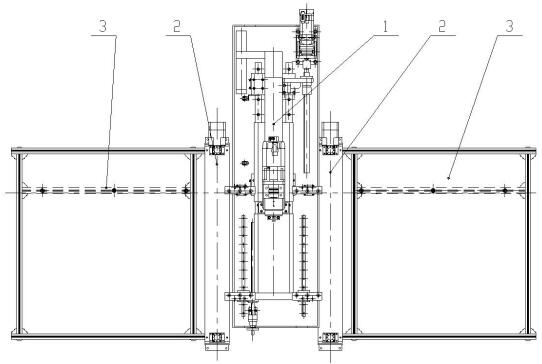

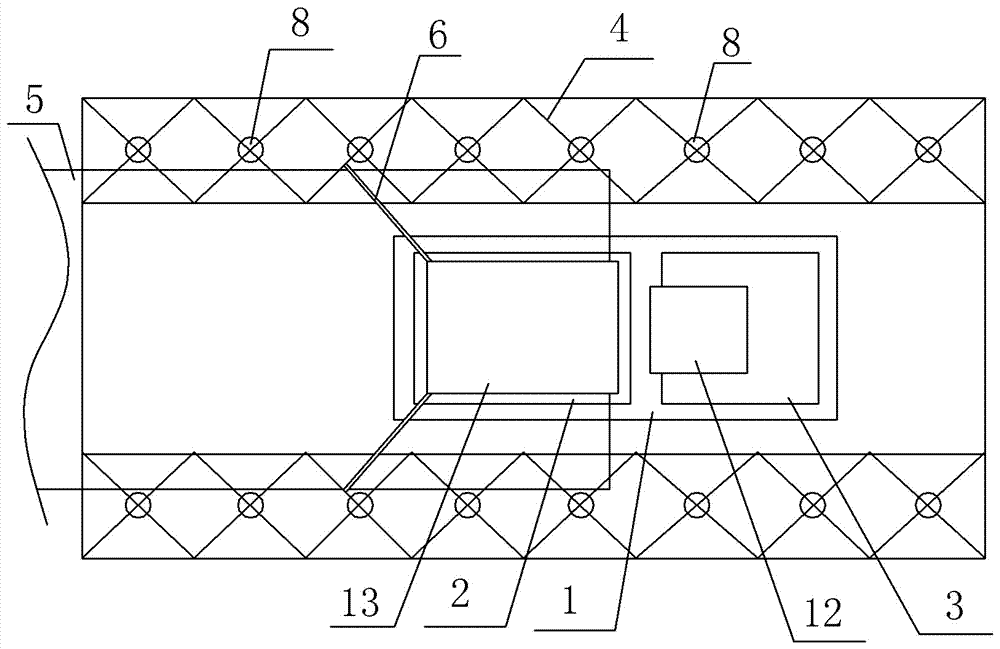

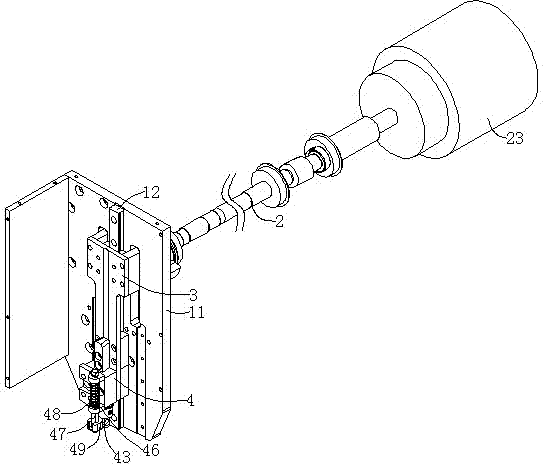

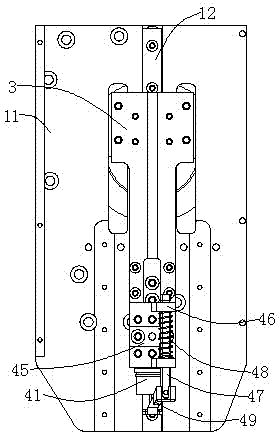

Blanking equipment and method for machining transformer iron core oil groove

PendingCN112191732AGuaranteed parallelismGuaranteed accuracyMetal-working feeding devicesStripping-off devicesPunch pressTransformer

The invention discloses blanking equipment and method for machining a transformer iron core oil groove. The blanking equipment for machining the transformer iron core oil groove comprises a notching punch press (1), material pulling and feeding devices (2), object carrying platforms (3) and a control assembly; wherein two material pulling and feeding devices (2) are arranged, and the two materialpulling and feeding devices (2) are separately arranged at the feeding side and the discharging side of the notching punch press (1); two object carrying platforms (3) are arranged, and the two objectcarrying platforms (3) are separately arranged on the side of the two material pulling and feeding devices (2) away from the notching punch press (1); the working face of the notching punch press (1), the working faces of the material pulling and feeding devices (2) and the upper end faces of the object carrying platforms (3) are located on the same horizontal plane; and the notching punch press(1) and the material pulling and feeding devices (2) are electrically connected to the control assembly.

Owner:CECEP XIAN QIYUAN MECHANICAL & EIECTRICAL EQUIP CO LTD

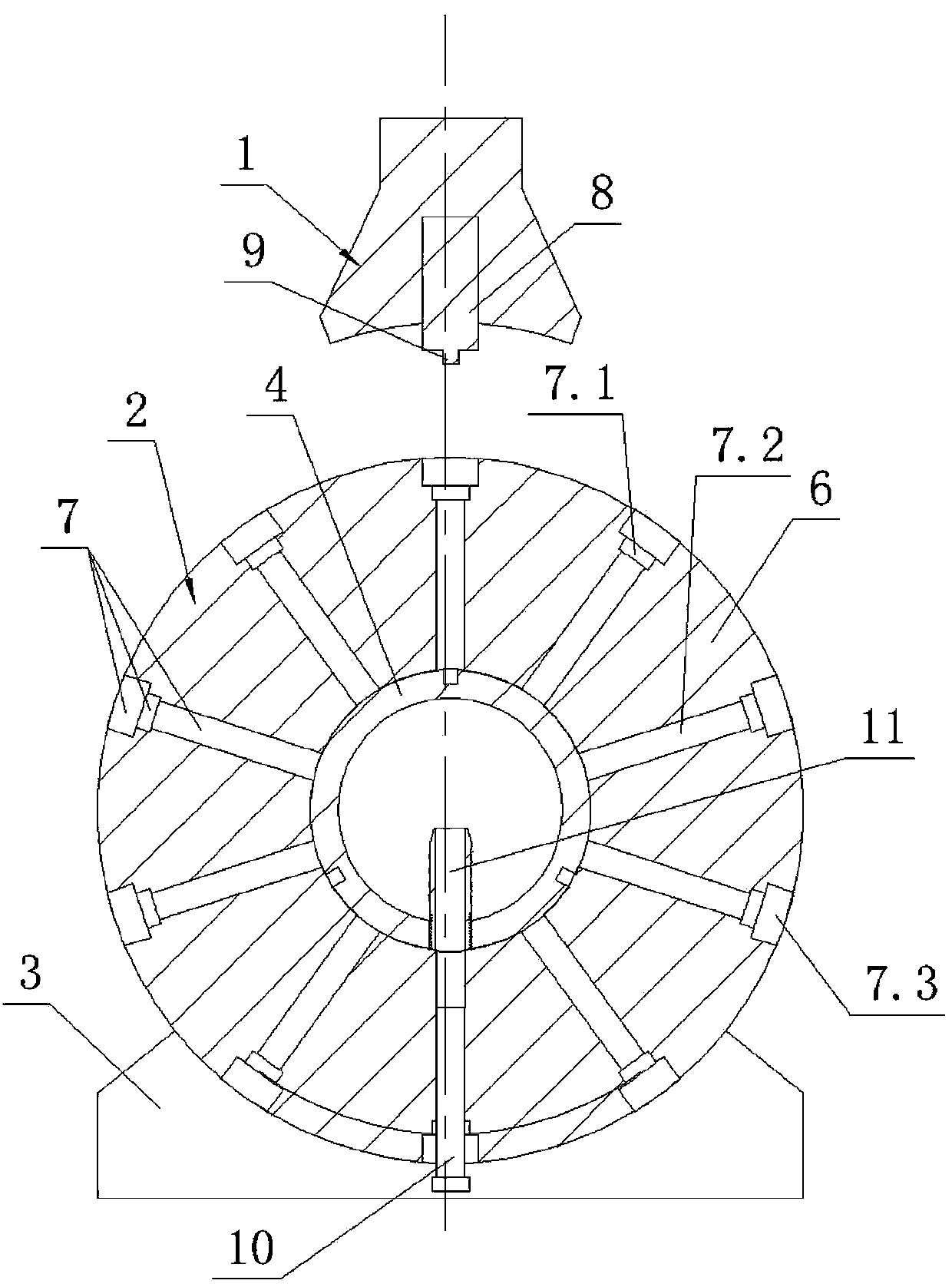

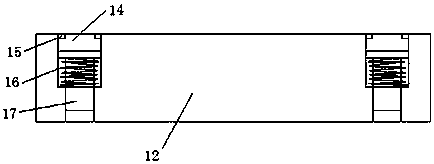

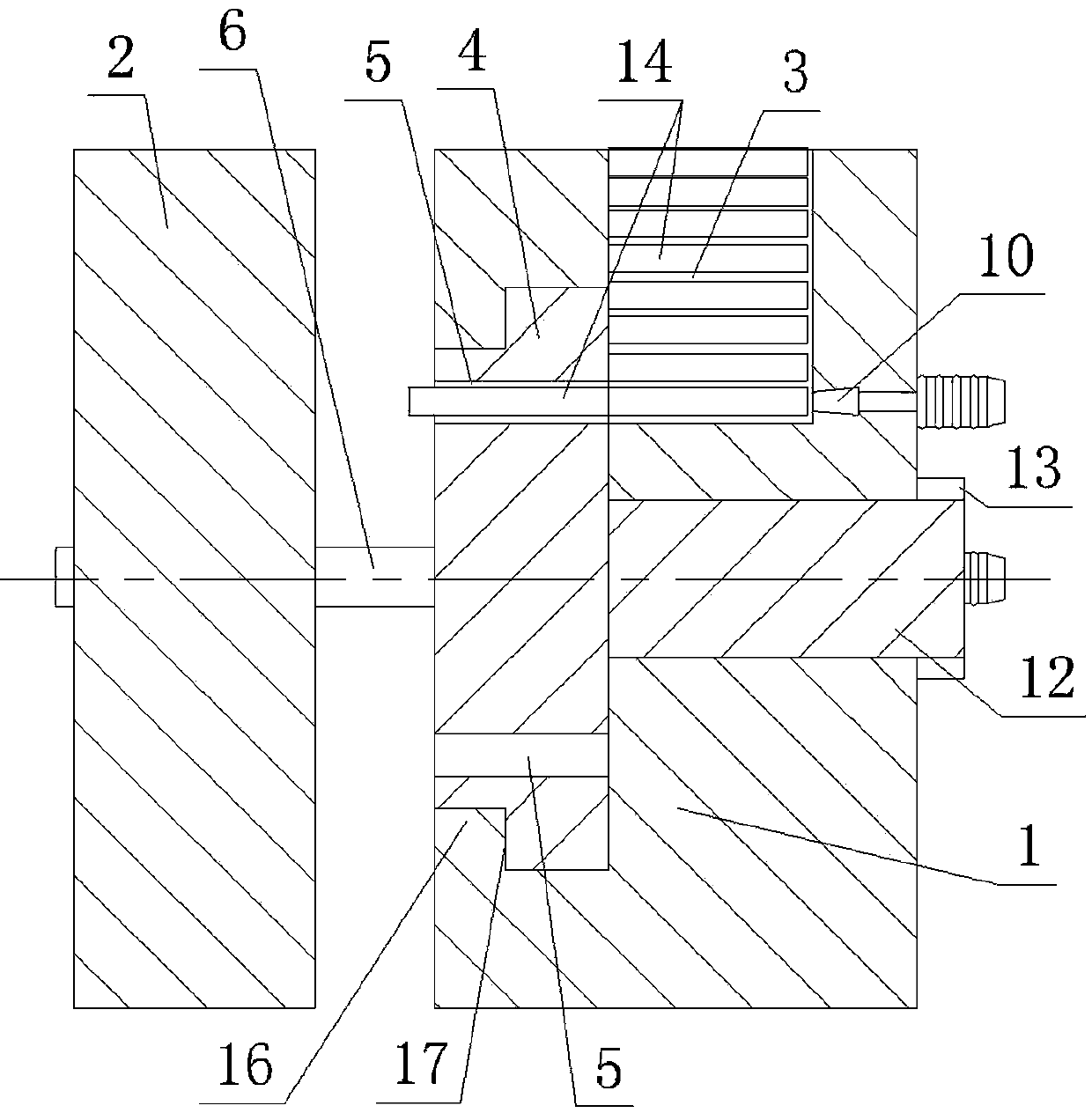

Stamping tool

InactiveCN103464644AShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsEngineeringNozzle

The invention discloses a stamping tool comprising a punch (1) and a die shell (2). The die shell (2) comprises two supports (3), a rotary shaft (4), a transmission gear and at least two rotary plates (6). Two ends of the rotary shaft (4) are fixed to the two supports (3) respectively. The transmission gear and all rotary plates (6) are rotatably fitted to the rotary shaft (4) in a sleeving manner. The outer peripheral surface of the each rotary plate (6) is provided with a plurality of radial through holes (7). The punch (1) is provided with at least two stamping posts (8) as many as the rotary plates (6). The stamping posts (8) are arranged in a row and right face a highest row of radial through holes (7) in the rotary plates (6). The rotary shaft (4) is further connected with a nozzle (11). The stamping tool is high in stamping speed, efficient, safe, and handy.

Owner:泰州市凌峰机电设备有限公司

Air conditioner shell stamping bed with punch automatic conversion function

InactiveCN107552627AAchieve up and down left and right movementEasy to moveShaping toolsEngineeringMechanical engineering

The invention discloses an air conditioner shell stamping bed with a punch automatic conversion function. The air conditioner shell stamping bed comprises a base, a lower die seat and a fixing frame are mounted at the top end of the base, and the fixing frame is located outside the lower die seat. The vertical section of the fixing frame is in a U shape, the top end of the fixing frame is fixedlyprovided with two second air cylinders through supports, and a horizontally-arranged mounting plate is welded to piston rods of the second air cylinders and slidably connected with the inner walls ofthe two sides of the fixing frame. The top end of the mounting plate is provided with a horizontally-arranged rack, the mounting plate is sleeved with a movable frame, and the inner wall of the movable frame is slidably connected with the side wall of the mounting plate. A first motor is fixed to the outer wall of one side of the movable frame through a screw, an output shaft of the first motor isin shaft connection with a gear, and the gear is located in the movable frame. Up-down and left-right movement of punches can be achieved, front-back movement of the lower die seat is achieved, moving is convenient, rapid switching of the multiple punches can be achieved, the stamping speed is high, and the work efficiency is high.

Owner:滁州华宇机件有限公司

Punching mechanism of screw holes

PendingCN108380919AFast punching speedImprove drilling efficiencyMeasurement/indication equipmentsPositioning apparatusPunchingEngineering

The invention discloses a punching mechanism of screw holes. The punching mechanism comprises a punching detection platform, a locating device, a pushing device, a punching device and a detection device, wherein the locating device, the pushing device, the punching device and the detection device are arranged on the punching detection platform separately, the locating device comprises two oppositelocating assemblies, each locating assembly comprises a fixed plate, a telescopic rod, a screw fixing block and a driver, the fixed plates are arranged on the punching detection platform, the telescopic rods are arranged on the drivers, the drivers are arranged on the fixed plates, and the screw fixing blocks are arranged on the telescopic rods. By means of the punching mechanism of the screw holes, through the arrangement of a punching detection assembly, whether through holes of screws are completely punched or not can be detected, it can be guaranteed that each screw can be completely punched, the punching speed of the screws is increased, and the punching efficiency of the screws is improved.

Owner:黄慧婵

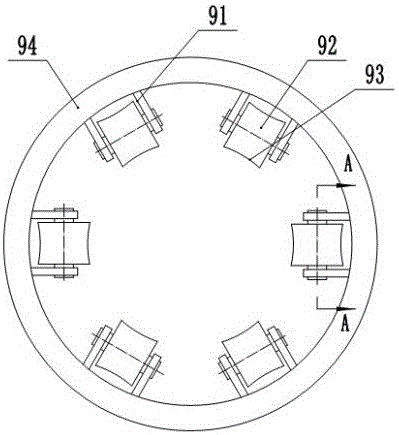

Punching unit

InactiveUS20100275754A1Improve rigidityQuality improvementShearing machinesMetal working apparatusPunchingEngineering

There is provided a punching unit that is readily adjusted, is capable of always punching high quality holes through sheets and is steadily capable of discharging punch chips. A punch shaft and a die shaft are disposed vertically in parallel between side plates and these very punch shaft and the die shaft compose structural members (reinforcing members) of the punching unit. The die shaft has a die shaft body formed into a hollow cylinder and is provided with dies that correspond to the punches of the punch shaft at an outer peripheral surface thereof while fitting into die holes penetrating to the hollow section. A chip discharging screw plate fixed to the right side plate is disposed in the hollow section of the die shaft. Punch chips are transported along slopes of the chip discharging screw plate and discharged out of an opening when the die shaft rotates.

Owner:DAIDO KOGYO CO LTD

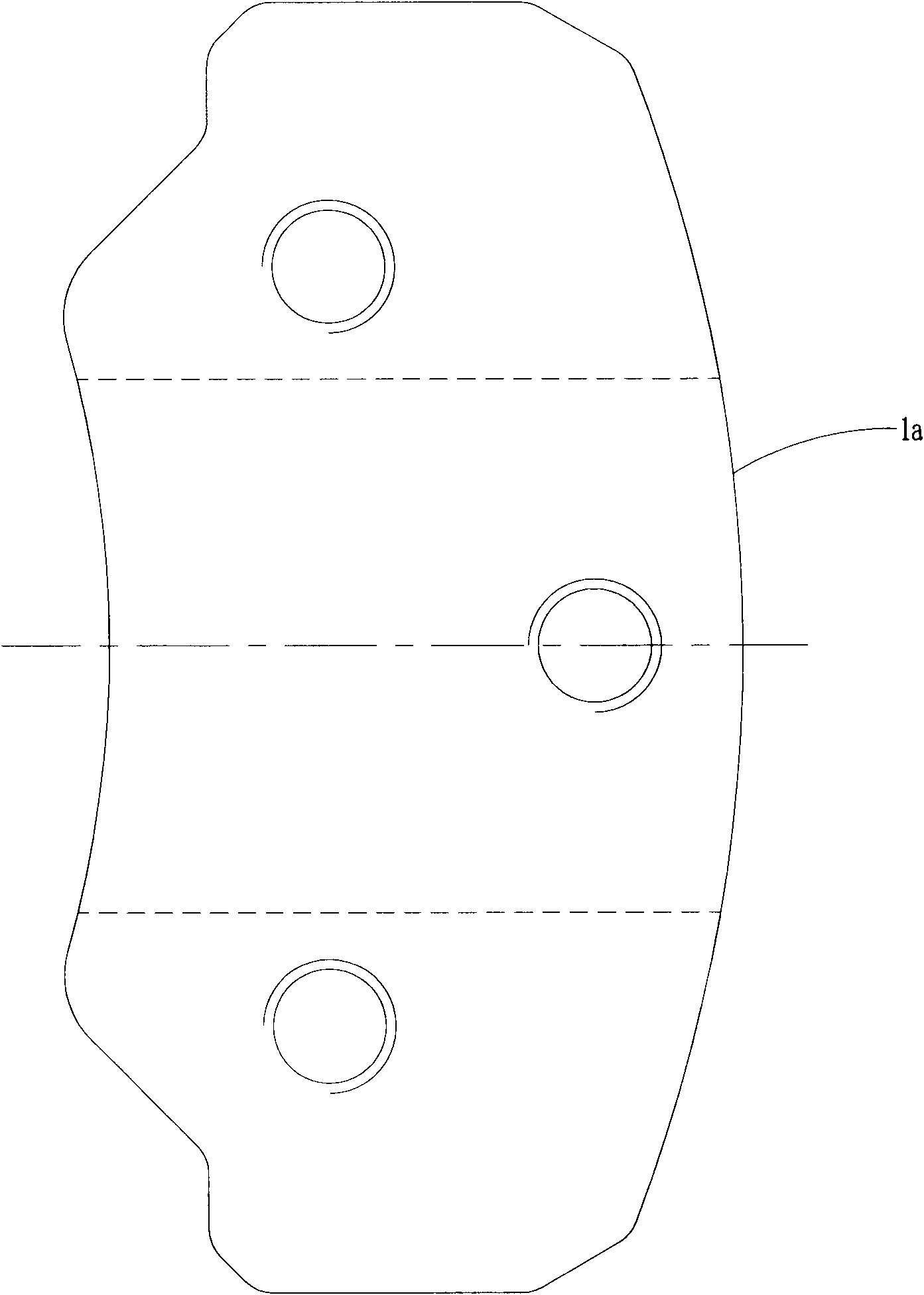

Steel back leveling die

ActiveCN101898216AGuaranteed flatnessDimensional stabilityShaping toolsLeveling effectHeight difference

The invention relates to the technical field of an automobile brake sheet stamping die, in particular to a steel back leveling die used in progressive dies. The steel back leveling die comprises a leveling male die and a leveling female die, wherein the leveling male die is provided with an upper leveling block, and the leveling female die is provided with a lower leveling block; the working surface of the upper leveling block comprises a first inclined surface, a first plane surface and a second inclined surface, wherein the first plane surface is higher than the first inclined surface and the second inclined surface, and the height difference between the first plane surface and each of the first inclined surface and the second inclined surface is 0.1-0.25mm; the working surface of the lower leveling block comprises a third inclined surface, a second plane surface and a fourth inclined surface, wherein the second plane surface is lower than the third inclined surface and the fourth inclined surface, and the height difference between the second plane surface and each of the third inclined surface and the fourth inclined surface is 0.1-0.25mm; and in the leveling process, the first inclined surface is matched with the third inclined surface, the second inclined surface is matched with the fourth inclined surface, and the first plane surface is matched with the second plane surface. The die has the advantage that the upper leveling block and the lower leveling block are mutually matched to level a feed belt; and compared with the prior art, the manual leveling step is omitted, thus the leveling uniformity is strong, the leveling effect is better, and the outline dimension of the steel back is stable.

Owner:ANHUI TATFOOK INTELLIGENT AIR CONDITIONING TECH CO LTD

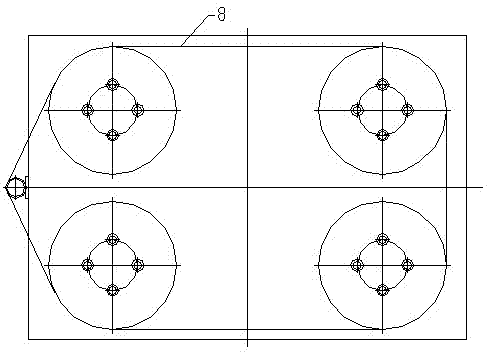

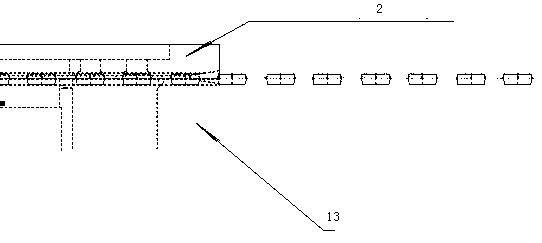

Punching forming die of high-density packaged SOT type lead frame and using method thereof

InactiveCN109127853AGet quicklyFast feedingMetal-working feeding devicesPositioning devicesPunchingHigh density

The invention discloses a punching forming die of high-density packaged SOT type lead frame and a using method of the punching forming die. The punching forming die comprises a punching forming die body (1), a feeding cover plate (2), feeding tracks (3) and roller wheel feeding mechanisms (4), wherein the feeding cover plate (2) is positioned in the punching forming die body, the feeding tracks (3) are positioned at the two ends of the punching forming die body, and the roller wheel feeding mechanisms (4) are positioned at the two ends of the punching forming die body. The punching forming diebody is internally divided into a punching stage (5), a pin forming stage (6) and a formed product blanking port (7) in the advancing direction of the lead frame. The roller wheel feeding mechanism comprises a front roller wheel feeding mechanism and a rear roller wheel feeding mechanism, wherein the front roller wheel feeding mechanism is positioned in front of the punching forming die body, andthe rear roller wheel feeding mechanism is positioned behind the punching forming die body. The punching forming die body comprises an upper die and a lower die, and the gap between the feeding coverplate and the lower die is 0.1-0.2mm. The punching forming die has the beneficial effects that a claw-free die and a high-speed feeding mode are used to realize the movement of the high-density SOT packaging lead frame in the die according to a set step distance.

Owner:TONGLING SANJIA YAMADA TECH

Automobile spare part stamping die

ActiveCN107377737ARealize automatic collectionImprove stabilityMetal-working feeding devicesPositioning devicesSheet steelEngineering

The invention relates to the field of spare part stamping, in particular to an automobile spare part stamping die. The automobile spare part stamping die comprises a machine frame, a punch, a base, a lower die, conveying net belts, moving rods, a collection box, a supporting block and a negative pressure machine. A groove is formed in the lower die. The supporting block and the negative pressure machine are arranged in the groove. A compressed spring is fixed to the lower end face of the supporting block, and the free end of the compressed spring is fixed to the bottom of the groove. In the natural stretching and contracting state of the compressed spring, the upper end face of the supporting block is flush with the upper surface of the lower die. The conveying net belts are horizontally arranged on the machine frame and are flush with the upper surface of the lower die. The moving rods are hinged to the machine frame. One ends of the moving rods are hinged to the punch, and the other ends of the moving rods are fixedly connected with hooks. According to the technical scheme, automatic equidistance movement of steel plates is facilitated, automobile spare parts can be reset into stamping holes of the steel plates automatically through the compressed spring and the supporting block after stamping, then the compressed spring and the supporting block are matched with the conveying net belts, the moving rods and the punch, and therefore the automobile spare parts can be collected automatically, the labor intensity is relieved and safety is improved.

Owner:YANCHENG TONGJI AUTO PARTS CO LTD

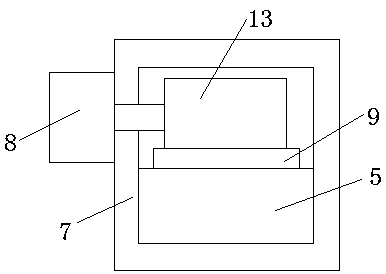

Continuous composite stamping die

ActiveCN103418713AShort tripPut an end to the safety hazard of smashing and injuring people's handsPinsNailsPunchingStamping process

The invention discloses a continuous composite stamping die which comprises a cylindrical die case (1) and a punch pin (2). A radial blanking channel is formed in the cylindrical die case (1), a rotary table (4) which is in running fit with the cylindrical die case (1) is arranged in the cylindrical die case (1), a plurality of round through holes (5) are formed in the rotary table (4), a screw head portion cavity (7), a punching hexagonal socket hole cavity, an expansive hexagonal socket hole cavity, a chamfer cavity, a calibrator cavity and a discharging hole (9) are sequentially arranged on the same circumference of the end face, close to the cylindrical die case (1), of the punch pin (2), the discharging hole (9) penetrates through the punch pin (2) in the axial direction, the lowest end of the radial blanking channel is communicated with one round through hole (5), and the other six round through holes directly face towards the above five cavities and the discharging hole (9) one to one respectively. The continuous composite stamping die enables stamping processes to be fast, efficient, safe and convenient.

Owner:信阳汉华光电科技有限公司

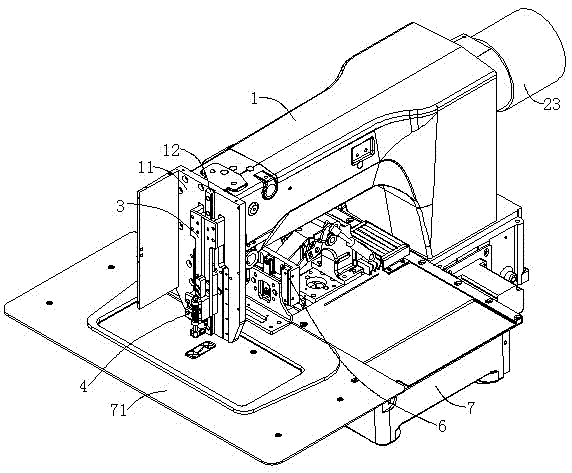

Punching machine

The invention discloses a punching machine, which comprises a main shaft which is arranged in a handpiece and driven by a driving motor to rotate, a longitudinal transmission base which is arranged in the handpiece in a sliding manner and driven by the main shaft through a transmission mechanism to do up-and-down motion, a punching cutter which is fixedly arranged on the longitudinal transmissionbase and used for punching a material, a workbench which is arranged below the handpiece and used for holding the material, and a material conveying mechanism which is arranged on the workbench and used for clamping the material, wherein the material conveying mechanism can do feeding motion in the horizontal X direction and the horizontal Y direction under the driving of a material conveying driving mechanism and can convey a punching part of the material to a position below the punching cutter; and under the driving of the driving motor, the longitudinal transmission base drives the punching cutter to move downwards and punch the material.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com