Aluminum ring processing device

A processing device and aluminum ring technology, applied in the field of stamping dies, can solve the problems of operator fatigue, insufficient cutting of aluminum ring thin slices, unsuitable for large-scale processing, etc., to achieve reliable aluminum ring processing device and high stamping speed , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

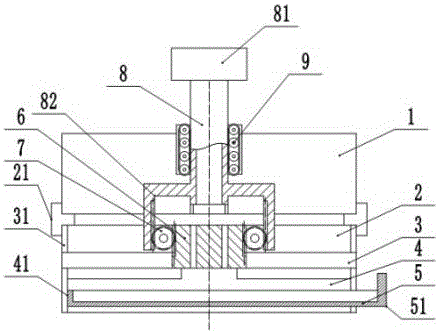

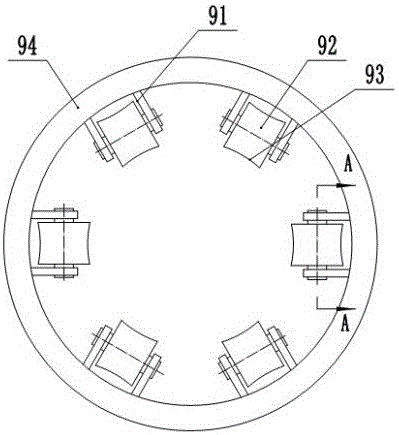

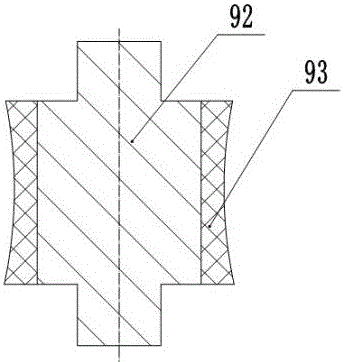

[0017] The reference signs in the drawings of the description include: upper mold 1, lower mold 2, first support block 21, support plate 3, bottom plate 4, drawer plate 5, handle 51, forming column 6, gear 7, pressure column 8, pressure Block 81, mounting frame 82, sliding sleeve mechanism 9, bracing frame 91, pulley 92, belt 93, sleeve 94.

[0018] The embodiment is basically as attached figure 1 Shown:

[0019] The aluminum ring processing device in this program includes a lower mold 2 and an upper mold 1 arranged on the lower mold 2, and both sides of the upper mold 1 and the lower mold 2 are inserted with a first support block 21, the first support block 21 The cross-section is "convex" shape, and the convex part of the first support block 21 of "convex" shape is inserted between the upper mold 1 and the lower mold 2, which can limit the horizontal movement between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com