Automobile spare part stamping die

A technology for stamping dies and auto parts, applied in the field of parts manufacturing, can solve problems such as increased scrap rate, waste of raw materials, non-standard workpieces, etc., and achieve the effects of reducing work intensity, improving safety, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

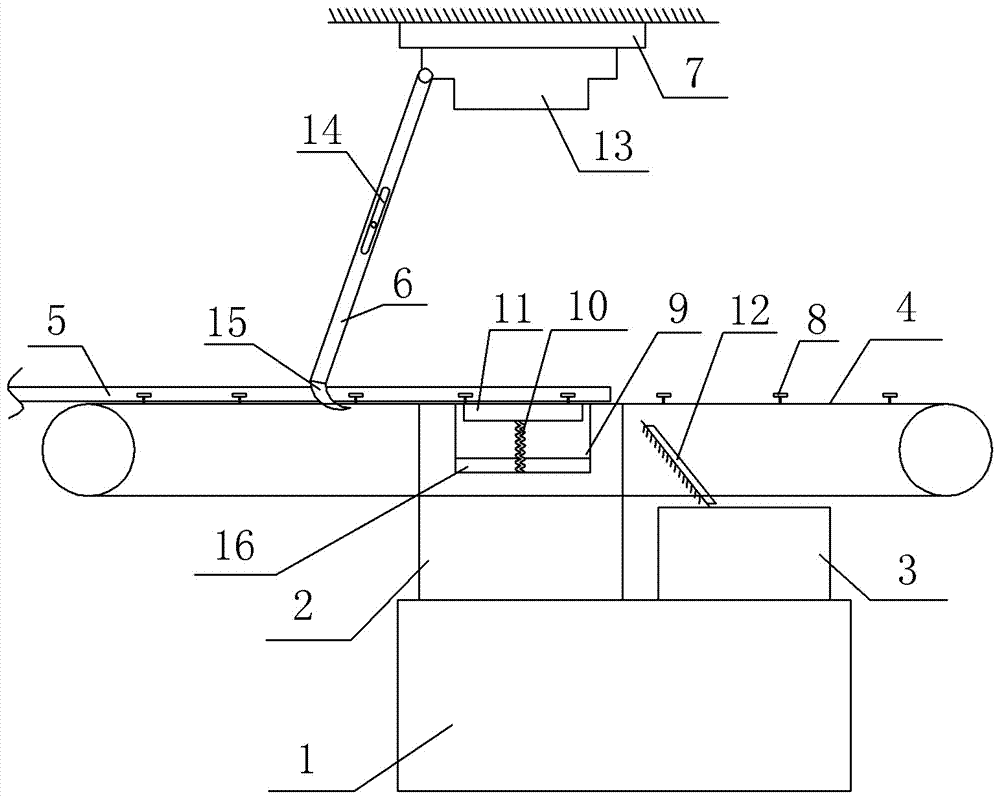

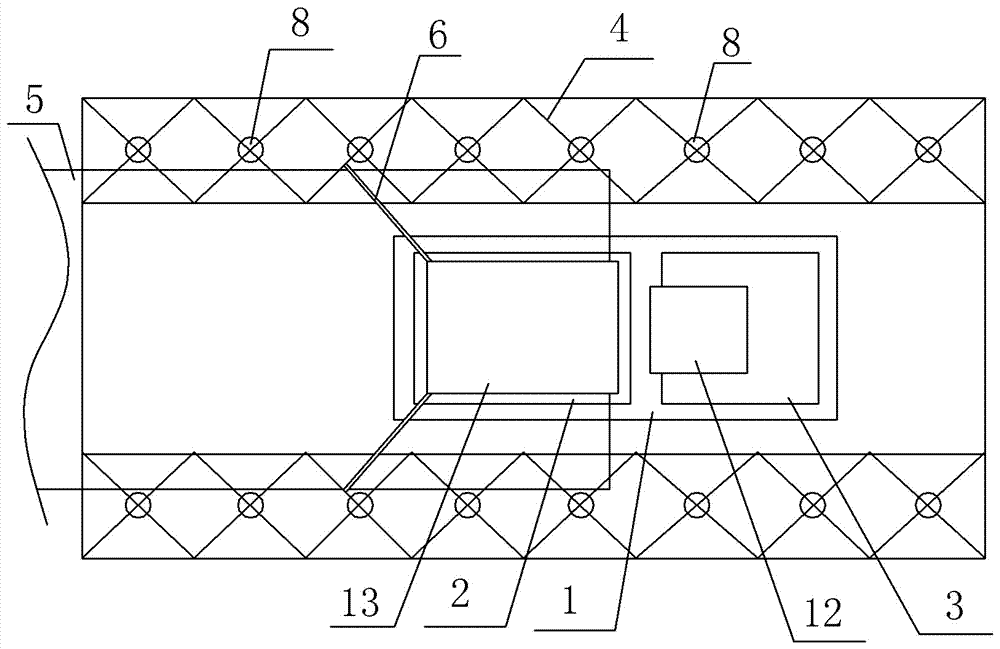

[0015] The reference signs in the drawings of the description include: base 1, lower mold 2, collection box 3, conveyor belt 4, steel plate 5, moving rod 6, press 7, guide wheel 8, groove 9, compression spring 10, support Block 11, buffer plate 12, punch 13, stroke hole 14, crotch 15, negative pressure machine 16.

[0016] Such as figure 1 , figure 2 A stamping die for auto parts shown includes a base 1, a lower die 2, a collection box 3, two conveyor belts 4, a steel plate 5, two moving rods 6, a press 7 and a frame from bottom to top. The lower mold 2 and the collection box 3 are fixed on the base 1, and the lower mold 2 is located on the left side of the collection box 3. The two conveying mesh belts 4 are parallel and horizontally arranged on the frame, the steel plate 5 is placed on the two conveying mesh belts 4, and the conveying mesh belts 4 on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com