Mold mounting height adjusting device of press

A technology of die-loading height and adjusting device, which is applied to presses, manufacturing tools, etc., can solve the problem of affecting the stability of the bottom dead center of the machine tool slider, affecting product quality and production efficiency, and increasing the inertia of the movable part of the high-speed press slider. and other problems to achieve the effect of realizing product quality and production efficiency, reducing inertia and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

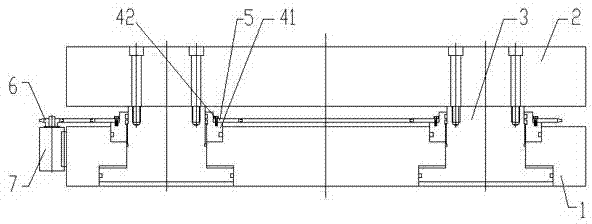

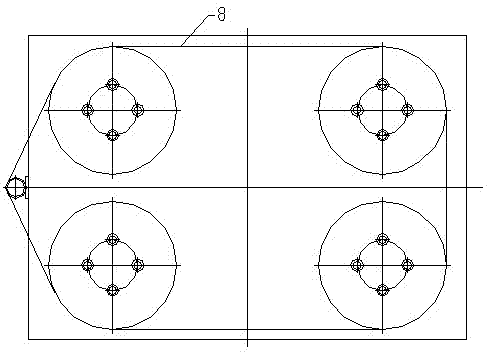

[0015] The present invention comprises a platform lower seat 1, a platform upper seat 2, and the platform upper seat 2 is connected with the platform lower seat 1 through a height adjustment seat 3;

[0016] The upper end of the height adjustment seat 3 is fixedly connected with the upper seat 2 on the table, and the height adjustment seat 3 is connected with the lower seat 1 of the table through a rotating device. The lifting part 42 is fixedly connected with the height adjustment seat 3 .

[0017] The horizontal part 41 is an adjustment nut, which is arranged in the mounting hole of the height adjustment seat 3, and the adjustment nut is driven to rotate by the motor 7 and the sprocket mechanism;

[0018] The lifting part 42 is a screw, and the screw moves up and down driven by the rotation of the adjusting nut.

[0019] A cavity for accommodating pressure oil is provided between the lower platen seat 1 and the height adjustment seat 3 .

[0020] The sprocket mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com