Patents

Literature

633results about How to "Improve production takt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

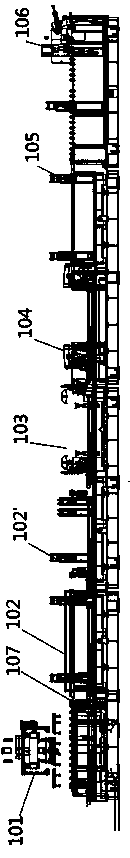

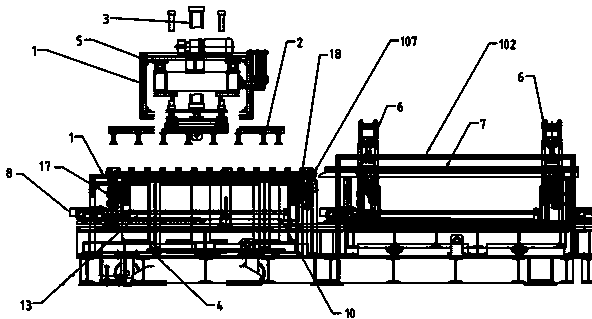

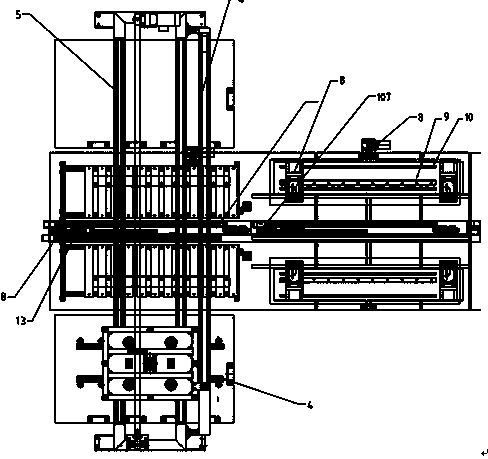

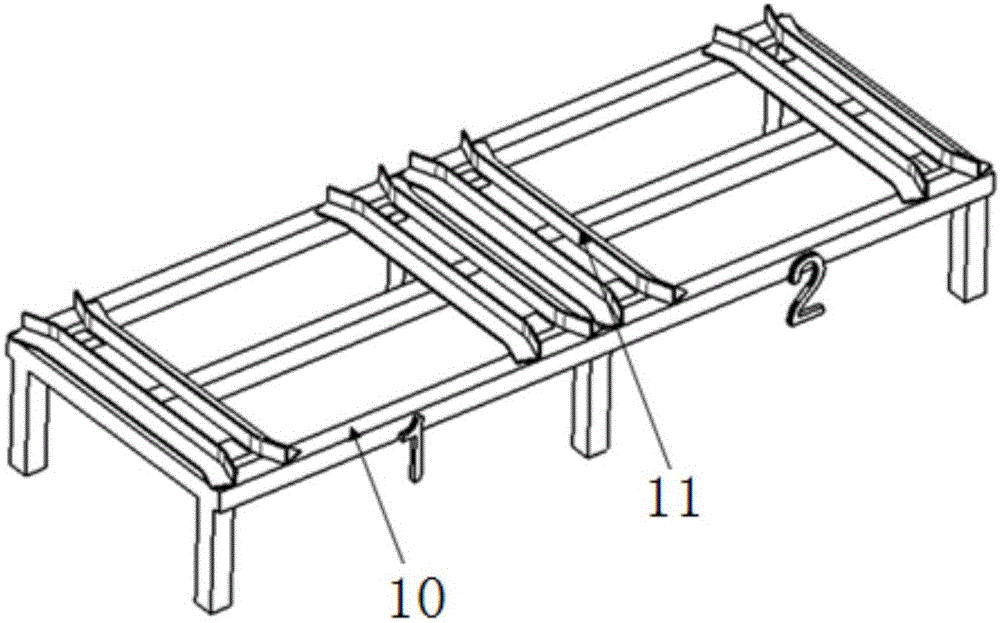

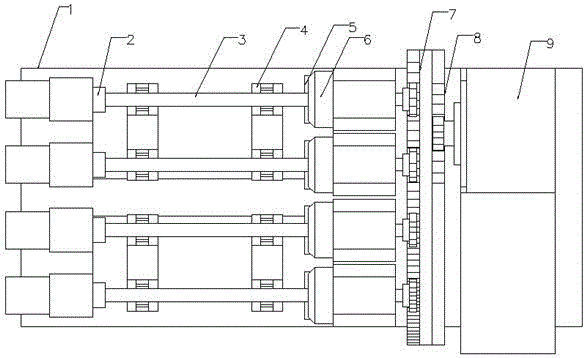

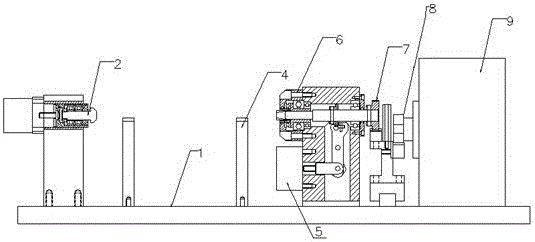

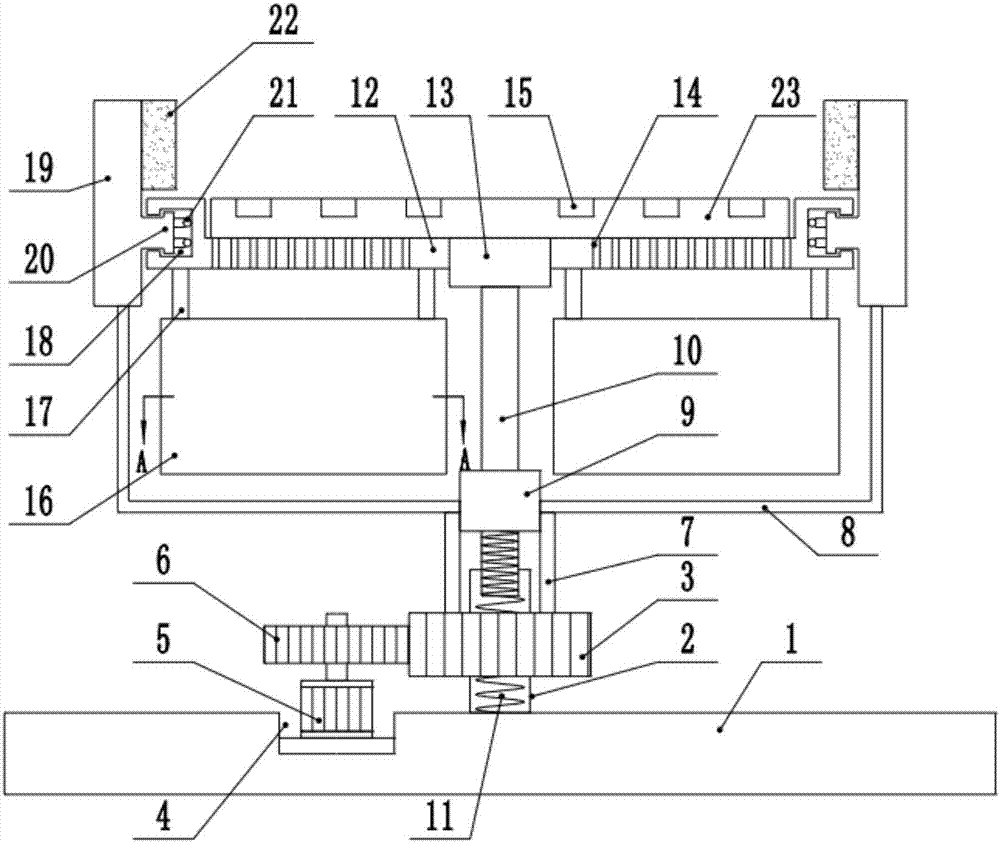

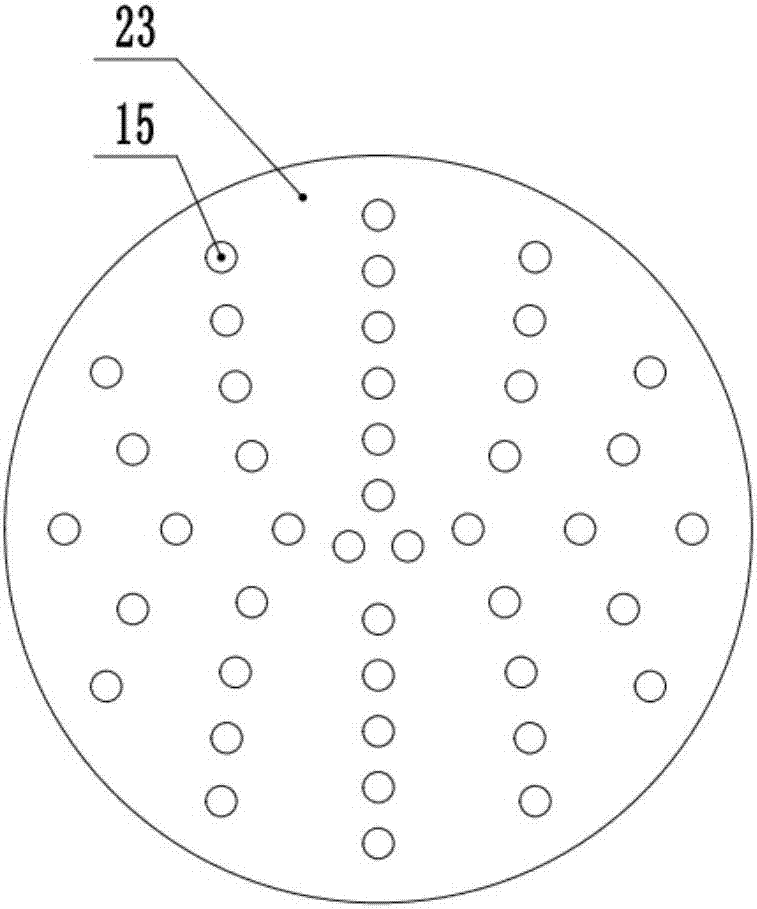

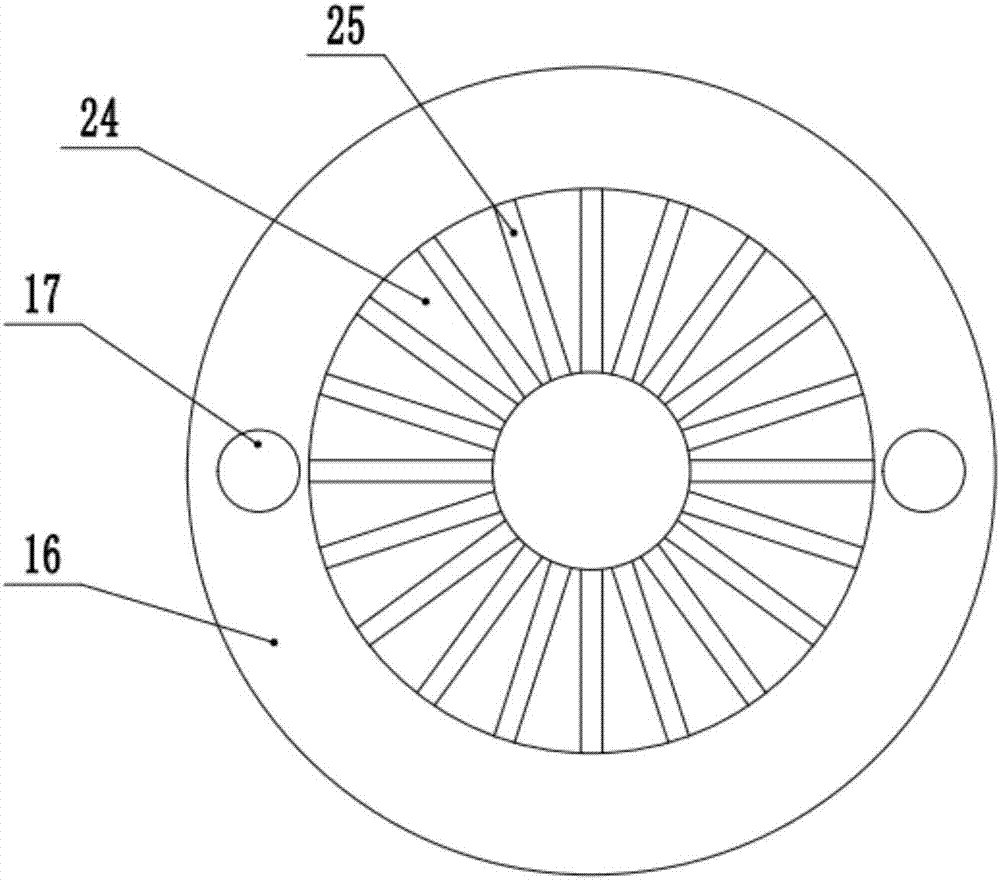

Automatic liner bottom plate forming production line

ActiveCN103480728AOvercome deviationOvercoming positioningMetal-working feeding devicesPositioning devicesProduction lineElectricity

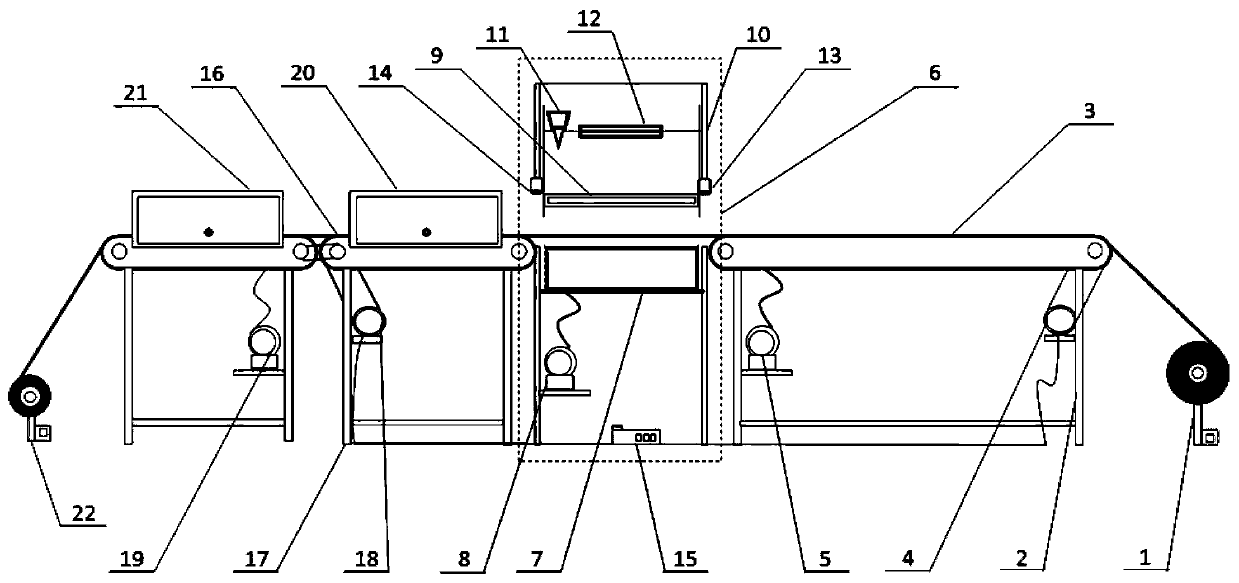

The invention discloses an automatic liner bottom plate forming production line. The automatic liner bottom plate forming production line is characterized by comprising an electric control cabinet, and an automatic feeding machine, a blanking machine station, a long edge bender station, a short edge bender station, a four-corner forming machine station and a Z-shaped bender station arrayed in sequence; liner bottom plates are clamped and sequentially conveyed to all the stations through a quintuplet servo conveying manipulator, and the electric control cabinet is electrically connected with an air cylinder and / or a servo motor of each station as well as a servo motor of the quintuplet servo conveying manipulator. By the production line, the quintuplet servo conveying manipulator is adopted for conveying so that the defect that plates deviate and are not positioned accurately during conveying is overcome; due to total fixed conveying, space for free mobility of the liner bottom plates is decreased, liner bottom plate quality is stable, and takt time is short; the servo motors are adopted to adjust the liner bottom plates, so that rapidness and reliability in adjustment are guaranteed.

Owner:ANHUI KECHANG MACHINERY MFG

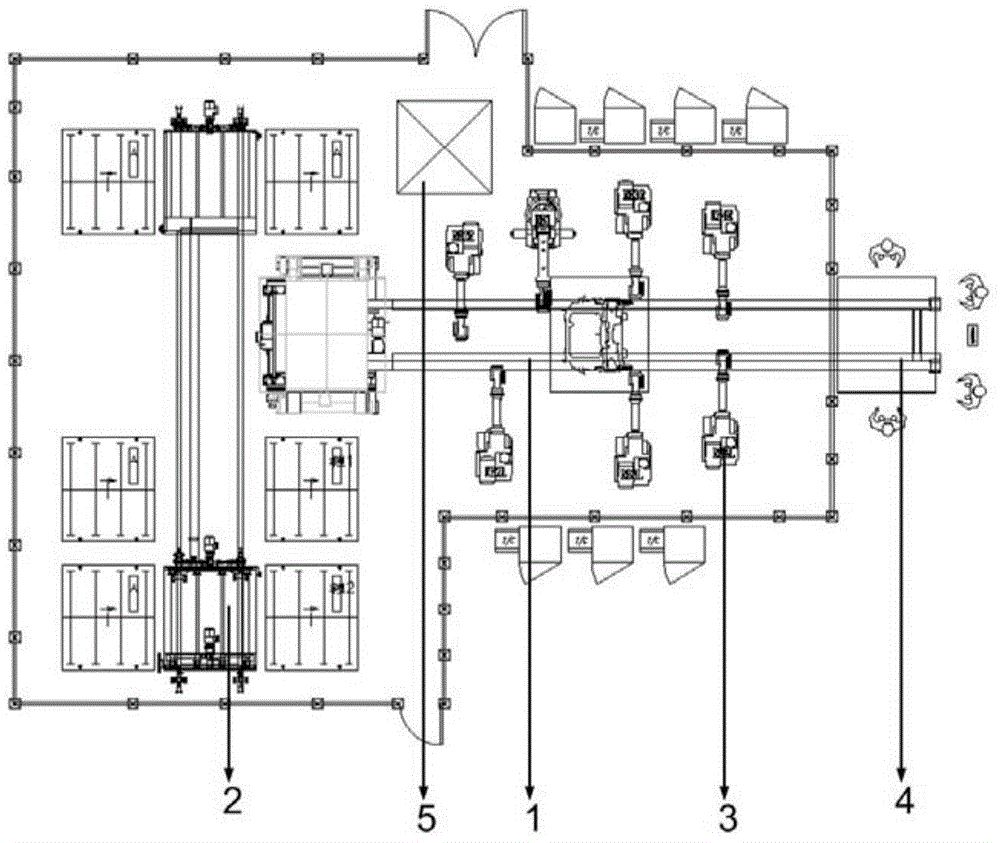

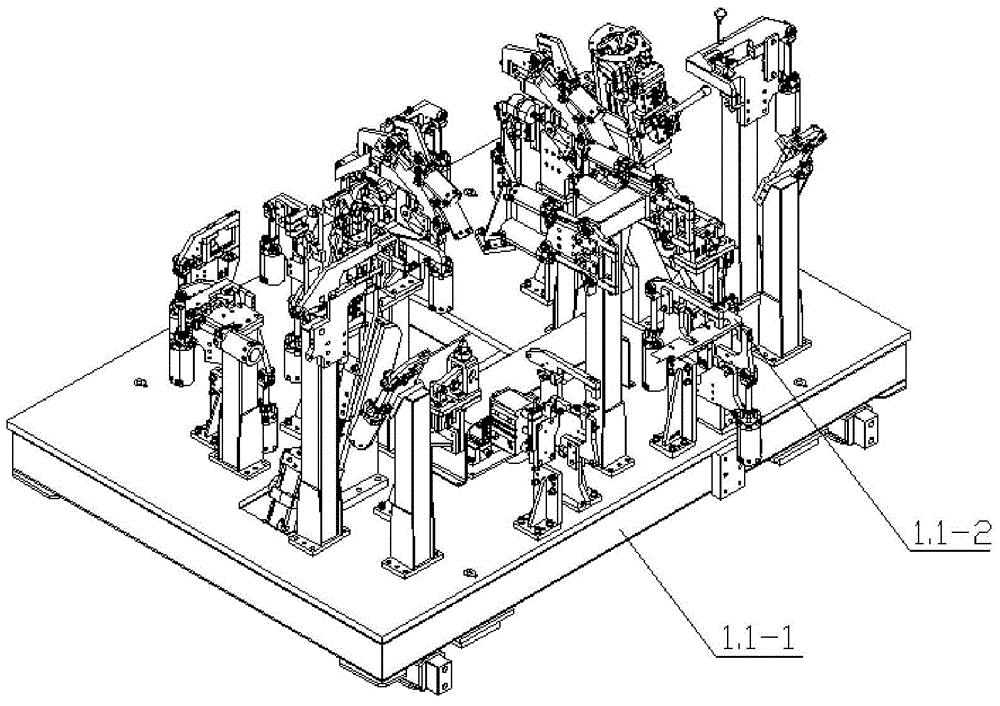

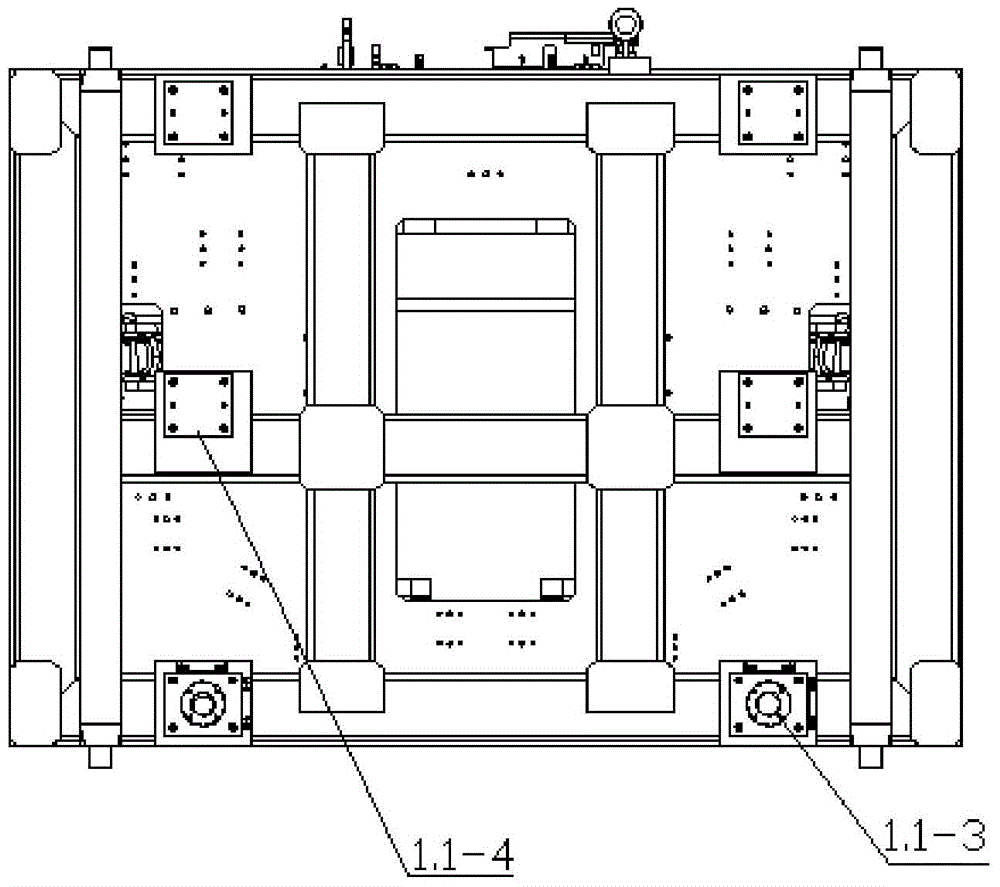

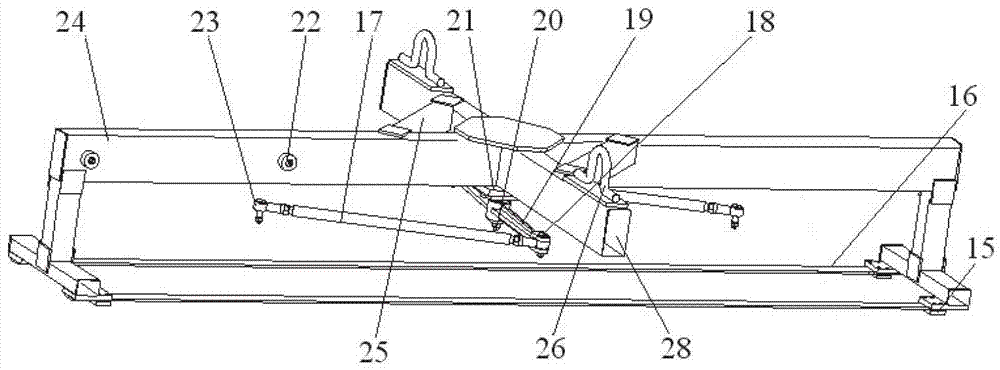

Automobile engine compartment welding production line

ActiveCN104400267AImprove production taktQuick switchWelding/cutting auxillary devicesAuxillary welding devicesProduction lineTime sequence

The invention relates to the technical field of automobile production, and discloses an automobile engine compartment welding production line, which comprises a follow fixture system, a fixture switching area, a welding area, a workpiece feeding area and a workpiece storage and conveying area, wherein the follow fixture system comprises a fixture body, a sliding base and a rail device, the sliding base is used for detachably fixing the fixture body, and slides on the rail device, the rail device is used for respectively communicating every two of the fixture switching area, the welding area and the workpiece feeding area, the welding area comprises at least one group of welding robots and at least one group of workpiece grabbing robots, and the workpiece storage and conveying area is arranged at one side adjacent to the welding area. Compared with the prior art, the automobile engine compartment welding production line has the advantages that the requirement that workpiece feeding and welding need to be performed according to time sequence is avoided, and the production pace is improved; in addition, the fixture switching area which is matched with the follow fixture system is additionally arranged, and a fixture can be conveniently replaced, so as to be suitable for the quick switching of different vehicle models.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

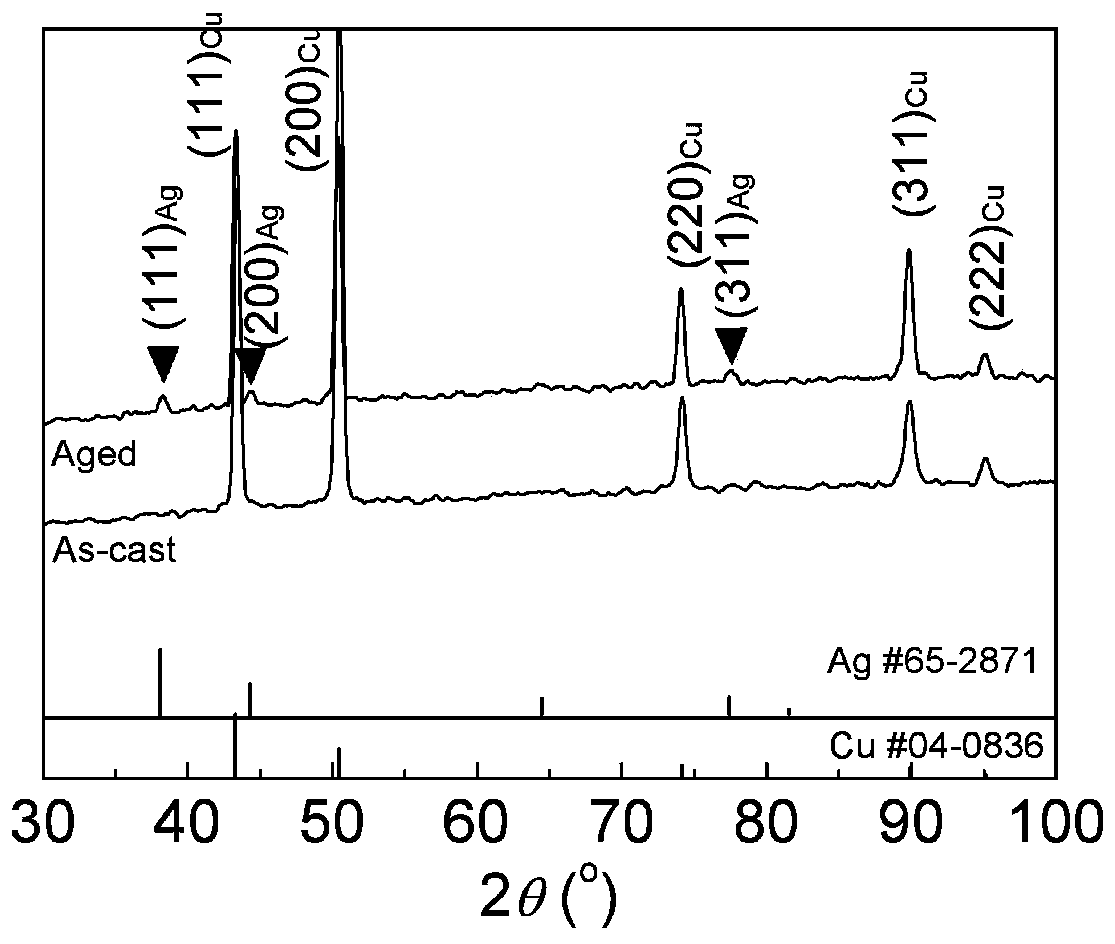

High-efficiency short-process preparation method of high-strength high-conductivity copper alloy

ActiveCN111363948AHigh strengthHigh crystal defectsIncreasing energy efficiencyElectro conductivitySupersaturated solid solution

The invention discloses a high-efficiency short-process preparation method of a high-strength high-conductivity copper alloy. The method comprises the following steps that (a), horizontal continuous casting is carried out to obtain an as-cast initial blank of the copper alloy, and alloy elements in the as-cast initial blank are kept in a supersaturated solid solution state; and (b), after the as-cast initial blank obtained in the step(a) is peeled, continuous extrusion, cold machining and aging annealing treatment are directly and sequentially carried out to obtain the copper alloy, and the alloy elements of the blank are kept in the supersaturated solid solution state in the continuous extrusion process. According to the method for continuously preparing the high-strength high-conductivity copper alloy, the process can be shortened, the energy consumption and the cost are reduced, the product forming rate is increased, and the high strength and the high conductivity of the copper alloy are guaranteed.

Owner:ZHEJIANG UNIV

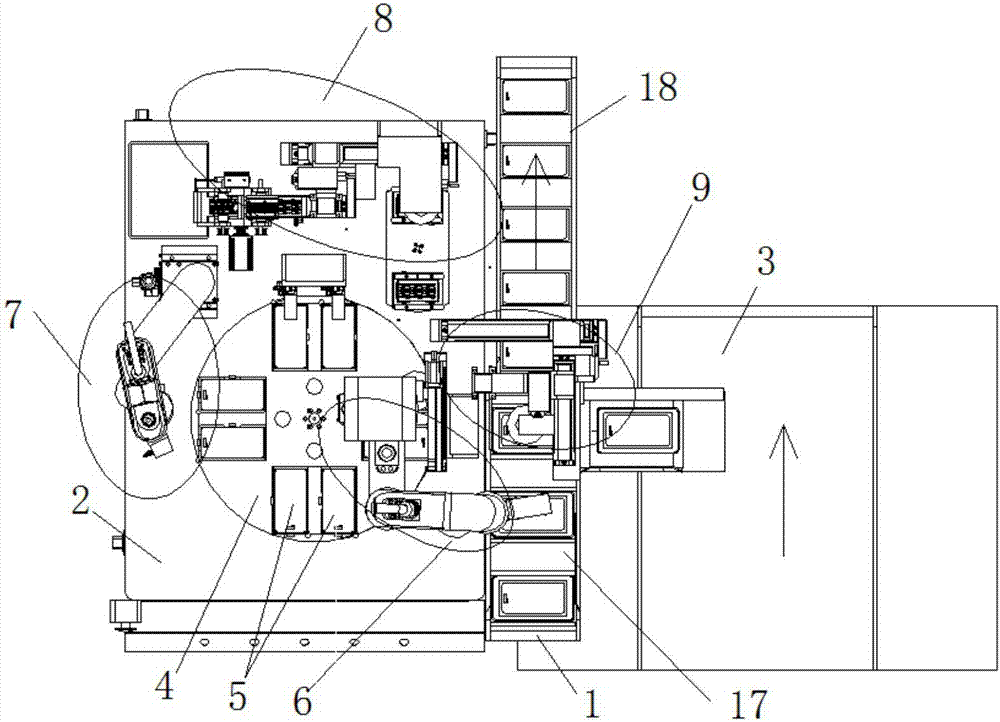

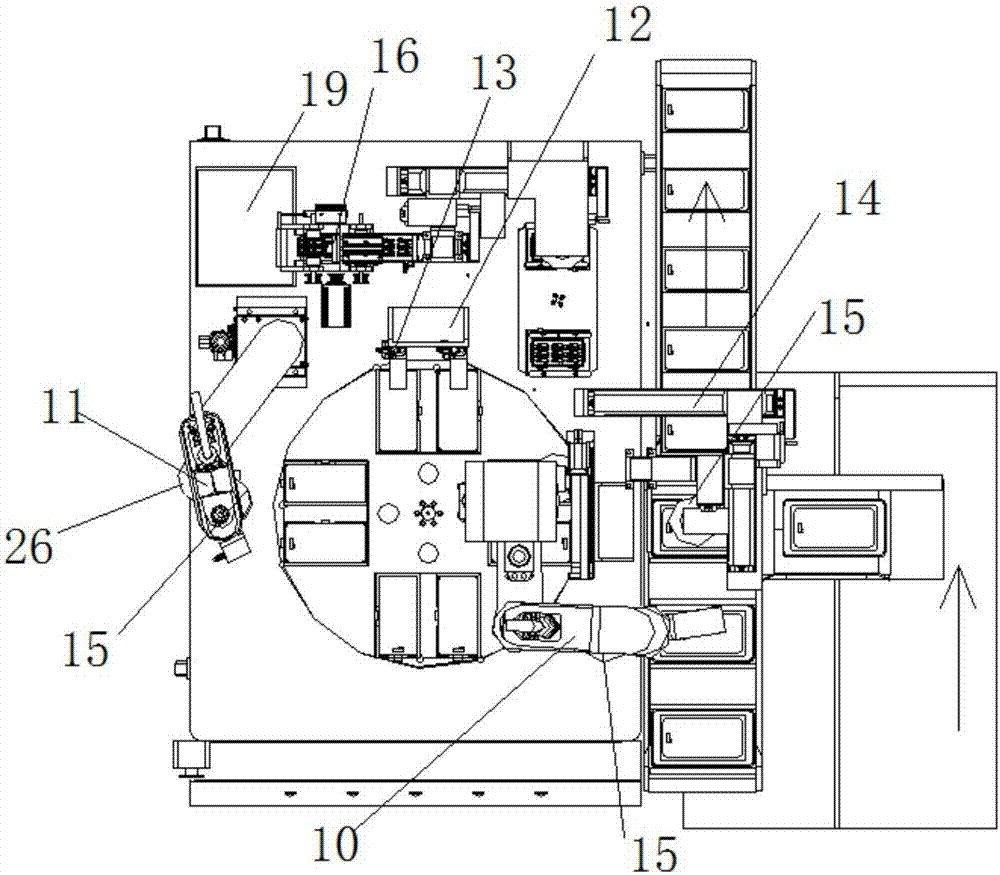

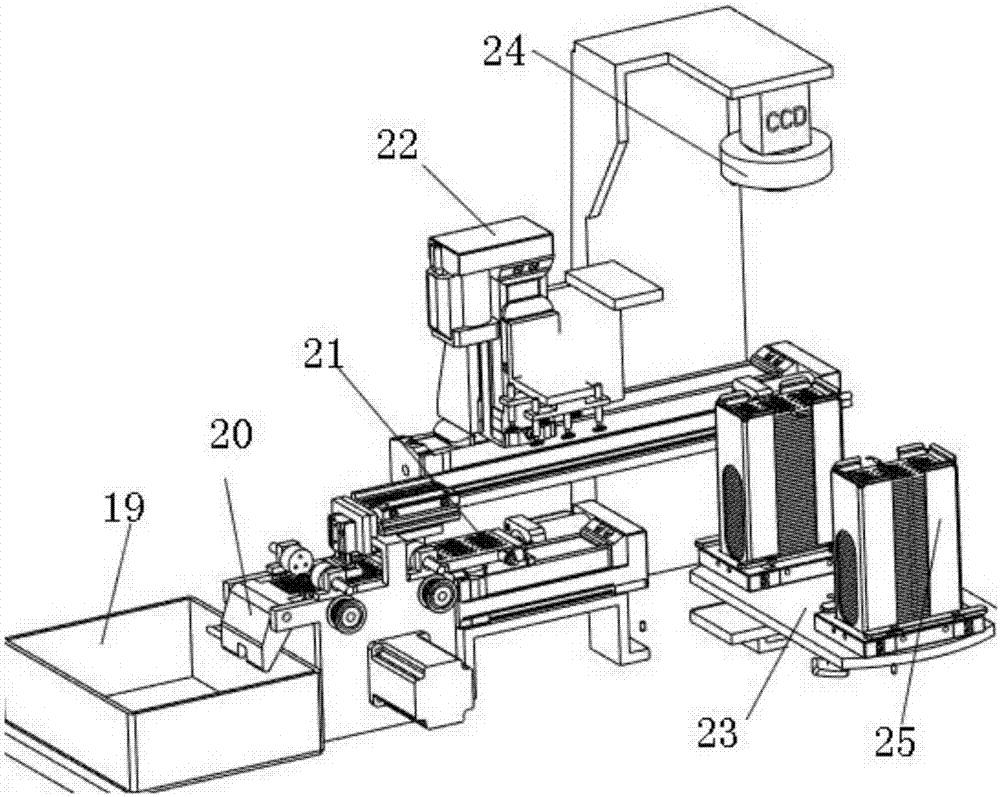

Automatic assembling machine for mobile phone receiver gauze

InactiveCN106925996AImprove assembly accuracyReduce labor costsAssembly machinesMetal working apparatusManipulatorMobile phone

The invention relates to the technical field of mobile phone assembling equipment, in particular to an automatic assembling machine for mobile phone receiver gauze. The automatic assembling machine for the mobile phone receiver gauze, disclosed by the invention, comprises a mobile phone conveying line, a working table arranged at one side of the mobile phone conveying line and a finished product conveying line arranged at the other side of the mobile phone conveying line, wherein a rotating disc is arranged on the working table, and jigs are arranged on the rotating disc in four directions; a first working station, a second working station, a third working station and a fourth working station are arranged on the working table and are located at the periphery of the rotating disc and at positions corresponding to the four directions; the first working station comprises a first working station manipulator and is used for placing mobile phones on the mobile phone conveying line into the jigs of the rotating disc; the second working station comprises a second working station manipulator and a second working station attached mechanism and is used for assembling the gauze on the mobile phones which are located in the jigs; the third working station comprises a cylinder and a pressure sensor and is used for reinforcing the fixation of the gauze on the mobile phones; and the fourth working station comprises a fourth working station manipulator and is used for detecting the assembling position of the gauze and placing detected mobile phone assemblies on the finished product conveying line.

Owner:北京正木激光设备有限公司

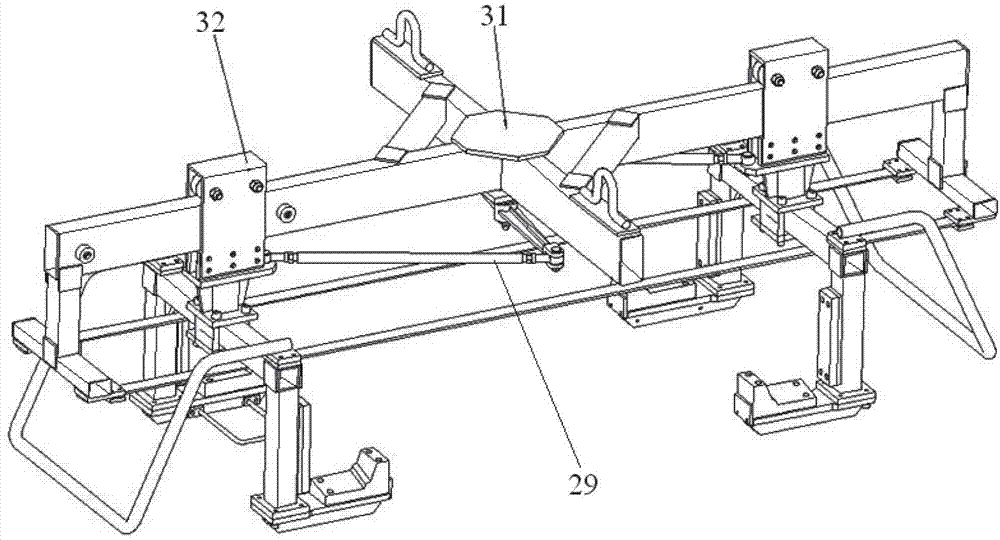

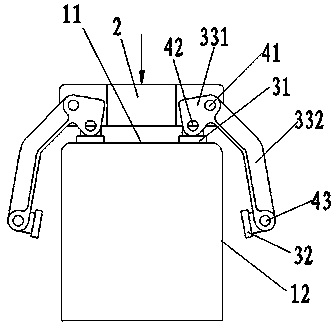

Automobile white body sling structure

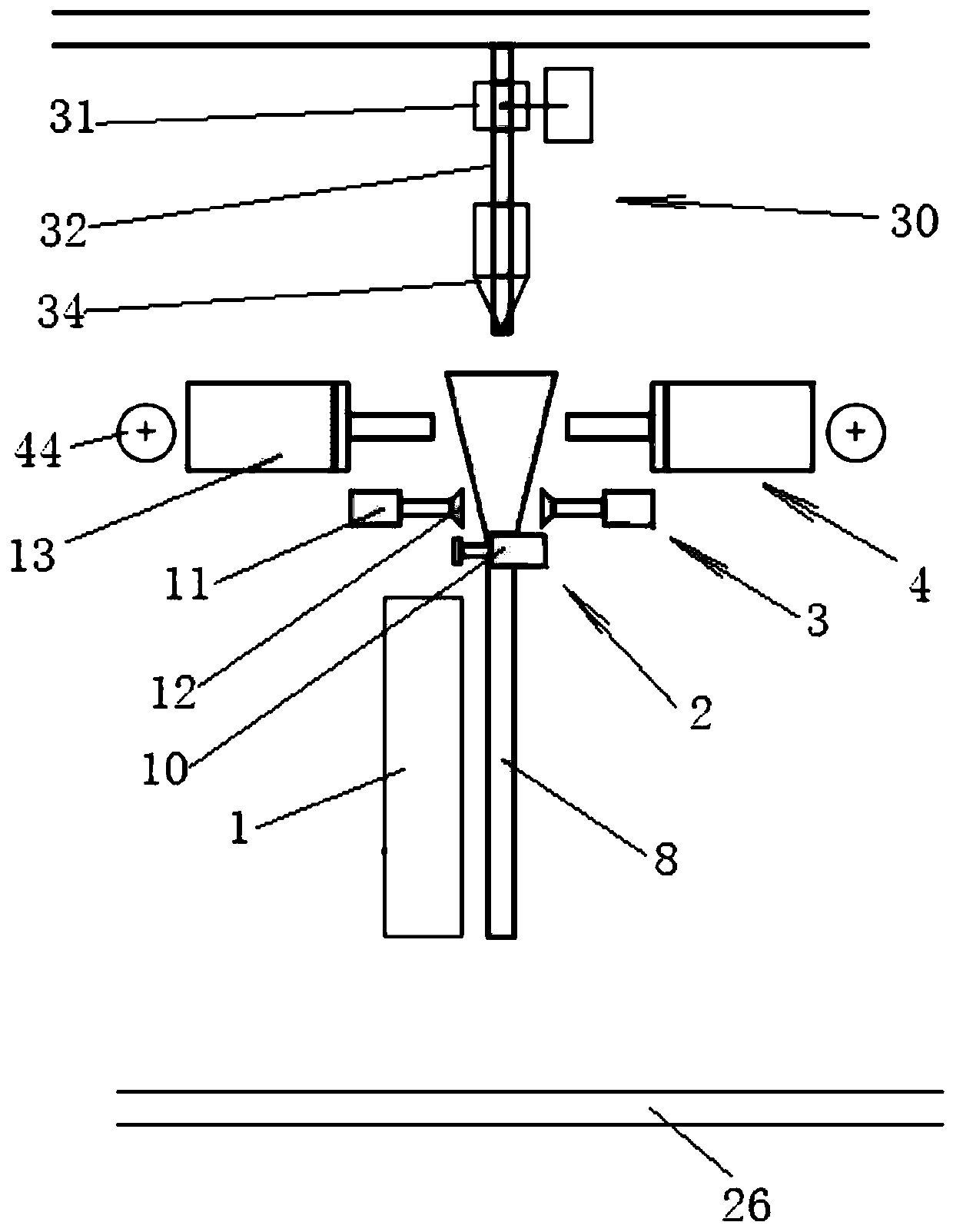

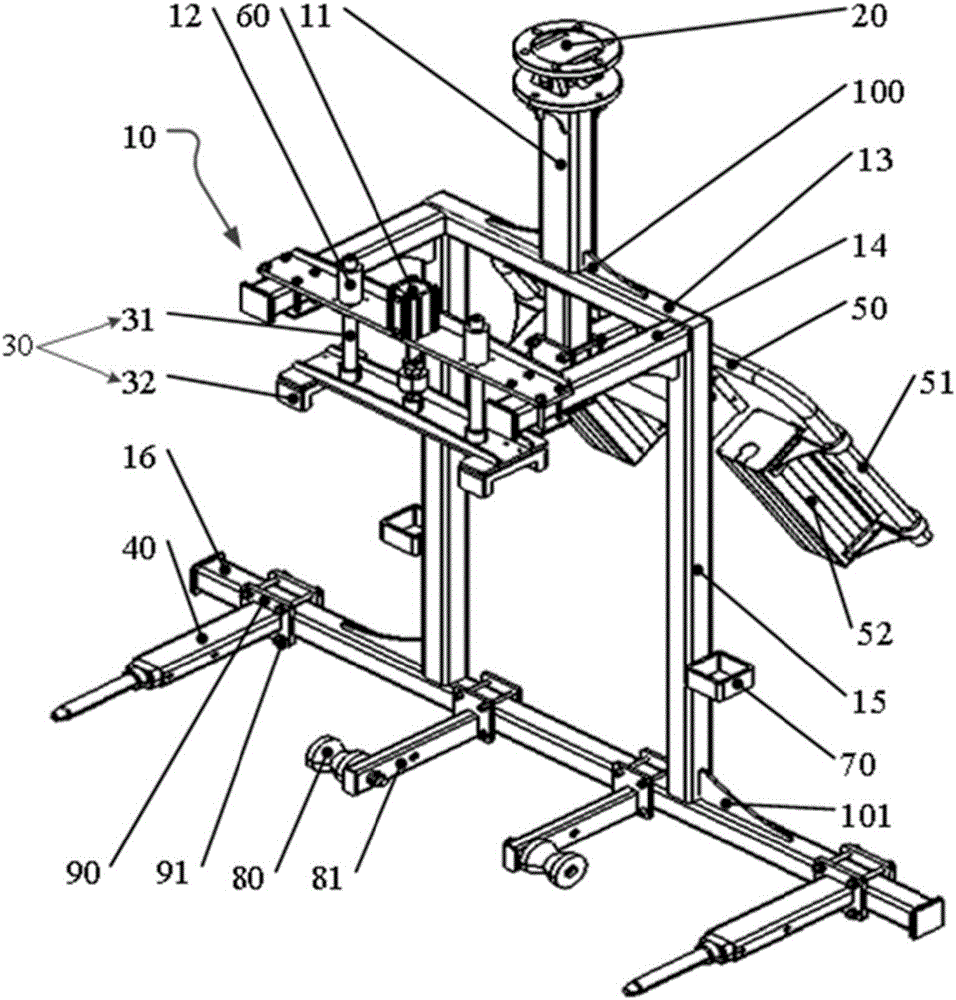

ActiveCN102963812AEasy to usePrevent bump deformationLoad-engaging elementsEngineeringFour-bar linkage

The invention discloses an automobile white body sling structure. A sling main body (31) is provided with a horizontal sling main beam (23) and two sliding hooks (32); the sliding hooks (32) are provided with sliding guide structures (10); and the sliding hooks (32) are arranged on the sling main beam (24) through the sliding guide structures (10). According to the technical scheme, a four-bar linkage is used, so that the use of the sling is more convenient, operation can be carried out at one side of the sling during the use, the synchronous advancement of the of the mechanisms at two sides of the sling is ensured, the production beat is accelerated and more stable and the requirement of batch production can be satisfied; the sling is correct in positioning, safe, reliable, high in efficiency and relatively low in cost; the sling can be effectively prevented from colliding with the automobile body to deform so that the automobile body is well protected; and a top beam at the side of the body of a crane is used, so that the automobile body has small possibility of deformation.

Owner:CHERY AUTOMOBILE CO LTD

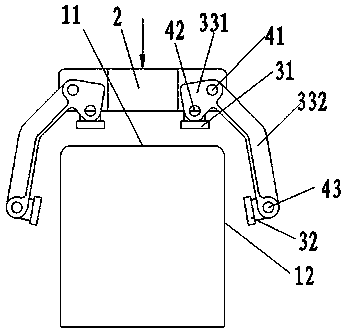

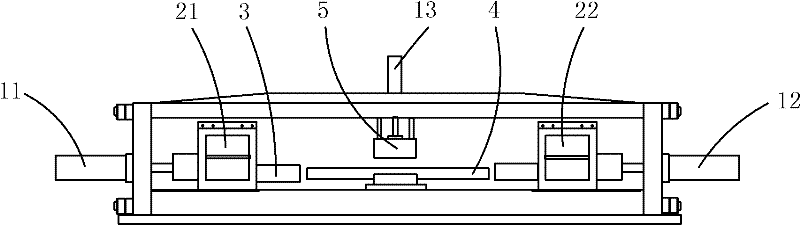

Self-floating type clamp iron for limiting core assembly pouring device

The invention discloses self-floating type clamp iron for limiting a core assembly pouring device. The self-floating type clamp iron comprises a clamp iron body and further comprises a self-floating type clamping mechanism, wherein the self-floating type clamping mechanism comprises clamping devices which are symmetrically arranged in a front-back manner and in a left-right manner; each clamping device comprises an upper pressing block, a side pressing block and a linkage structure; each linkage structure is movably connected with the clamp iron body; each upper pressing block is connected with the corresponding linkage structure, applies vertical acting force along the vertical direction and bears vertical reverse acting force under self-gravity acting force of the clamp iron body; each side pressing block is connected with the corresponding linkage structure, applies horizontal acting force along the horizontal direction and bears horizontal reverse acting force under vertical reverse acting force; a side mould of a core assembly is automatically clamped when an upper mould of the core assembly is compacted so as to realize the limitation of the core assembly pouring device (the core assembly), operation procedures are reduced and the production takt is accelerated.

Owner:SUZHOU MINGZHI TECH

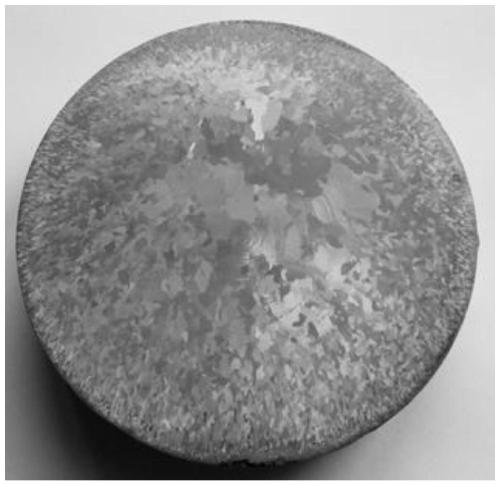

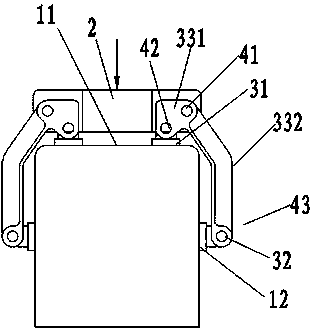

High strength and high toughness as-cast-condition QT800-5 nodular cast iron and production method thereof

ActiveCN108004460AWide range of applicationsImprove production taktProcess efficiency improvementFerrosiliconBismuth

The invention relates to high strength and high toughness as-cast-condition QT800-5 nodular cast iron and a method for forming the nodular cast iron through common clay sand. According to the method,pig iron for nodular cast iron, carbon waste steel and foundry returns serve as raw materials, a proper amount of copper, molybdenum, nickel, antimony or tin or other alloys are added in, an inductionelectric furnace is adopted for smelting iron melt, a rare earth ferrosiliconmagnesium alloy serves as a nodulizing agent, ferrosilicon, bariumsili and silicon bismuth are used for performing inoculation treatment, on a micro vibration compaction modeling machine, common clay sand is used for modeling, and the high strength and high toughness as-cast-condition QT800-5 nodular cast iron can be obtained through box removing after casting is performed for 30-60 min. The high strength and high toughness as-cast-condition QT800-5 nodular cast iron can meet the requirement of the market for high strength and high toughness as-cast-condition QT800-5 nodular cast iron pieces, and especially meets the requirement of the automobile industry for lightweight castings.

Owner:WUHAN UNIV OF TECH +1

Forming method for banjo axle housing

ActiveCN105436350AEliminate product defectsImprove product qualityShaping toolsEngine componentsHydraulic cylinderEngineering

The invention discloses a forming method for a banjo axle housing. The forming method includes the following steps of (S1) blanking, (S2) extrusion of a shaft head, (S3) square pushing, (S4) manufacturing of a process groove, (S5) heating of a workpiece, (S6) radial expansion, (S7) shaping and (S8) upward resetting of a lower press sliding block and taking-out of the workpiece. According to the (S6), a wedge punch penetrates through a central hole of the lower press sliding block, pushes two radial expansion core molds to expand the radial direction of a workpiece central hole and axially squeezes the workpiece synchronously. According to the (S7), two axial shaping core molds are attached, the lower press sliding block moves downwards to enable the axial shaping core molds to be inserted into the position between two radial shaping core molds, an upper press sliding block moves downwards, and the wedge punch is inserted into the position between the two axial shaping core molds to shape the workpiece central hole and axially squeeze a hydraulic cylinder for axial limitation. The forming method integrates heat expansion and shaping, work procedures are reduced, a process chain is shortened, and the outline size accuracy is obviously improved.

Owner:吴志强 +1

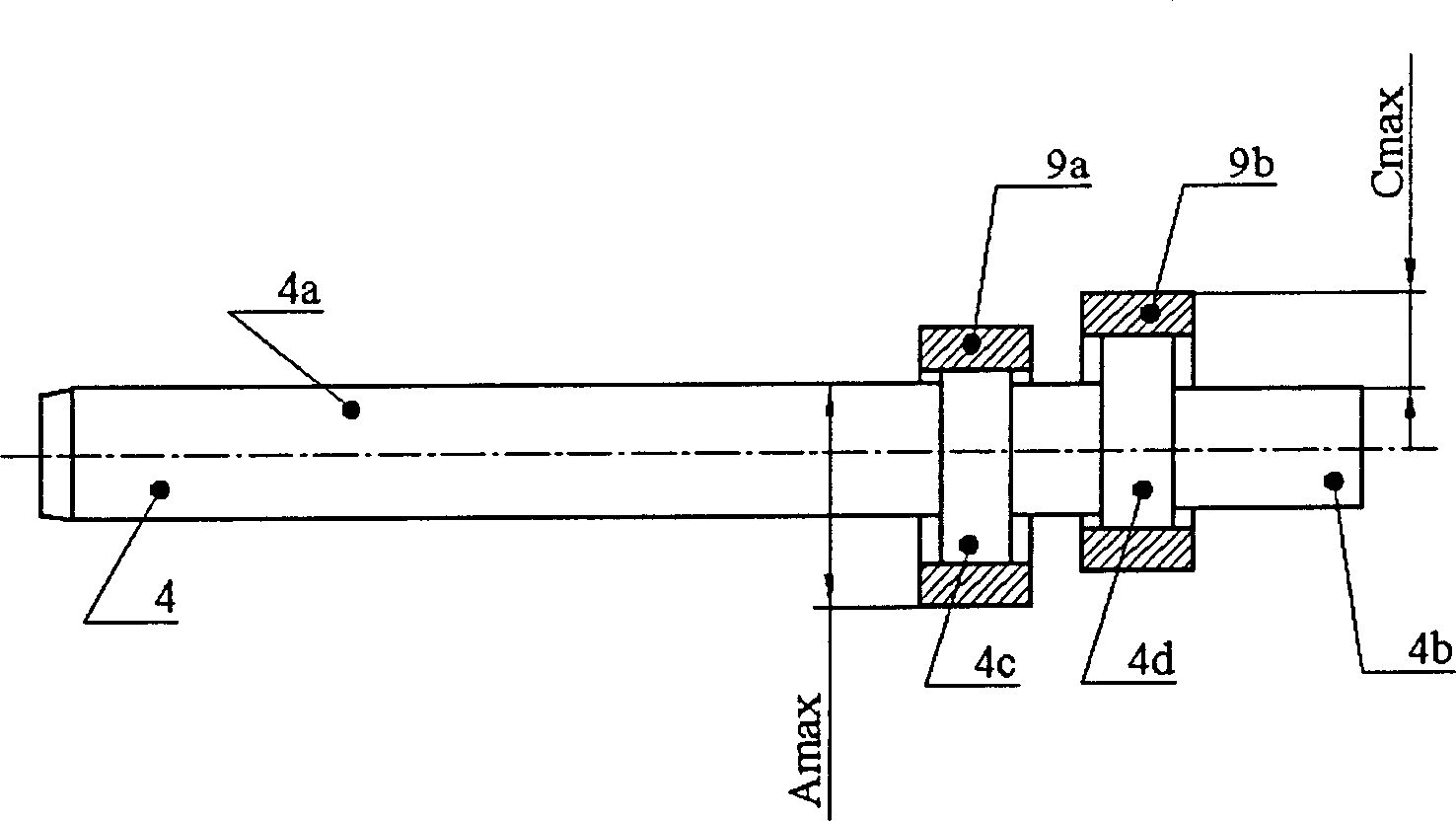

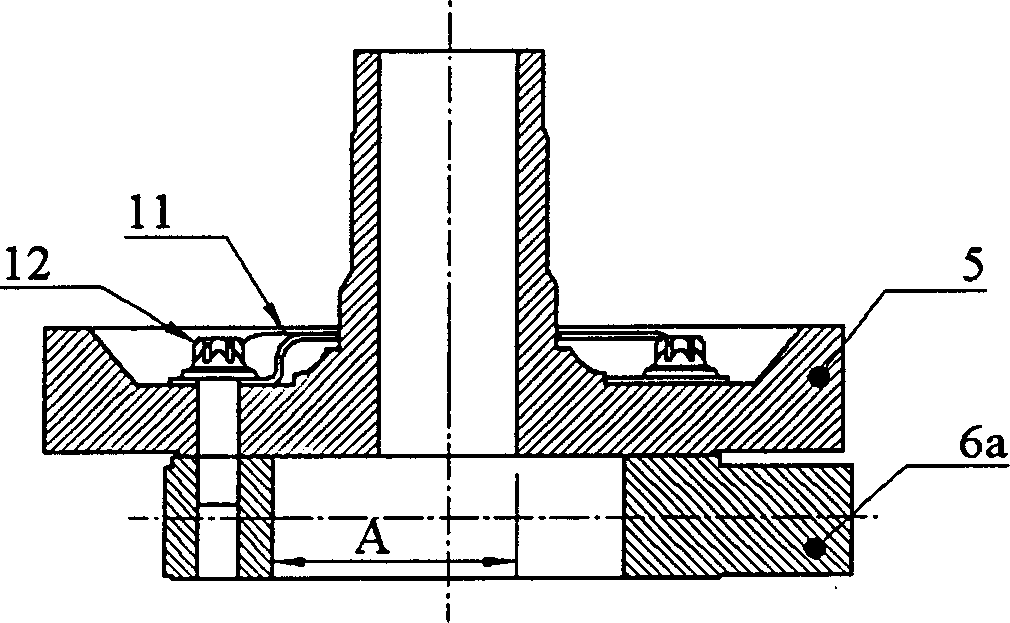

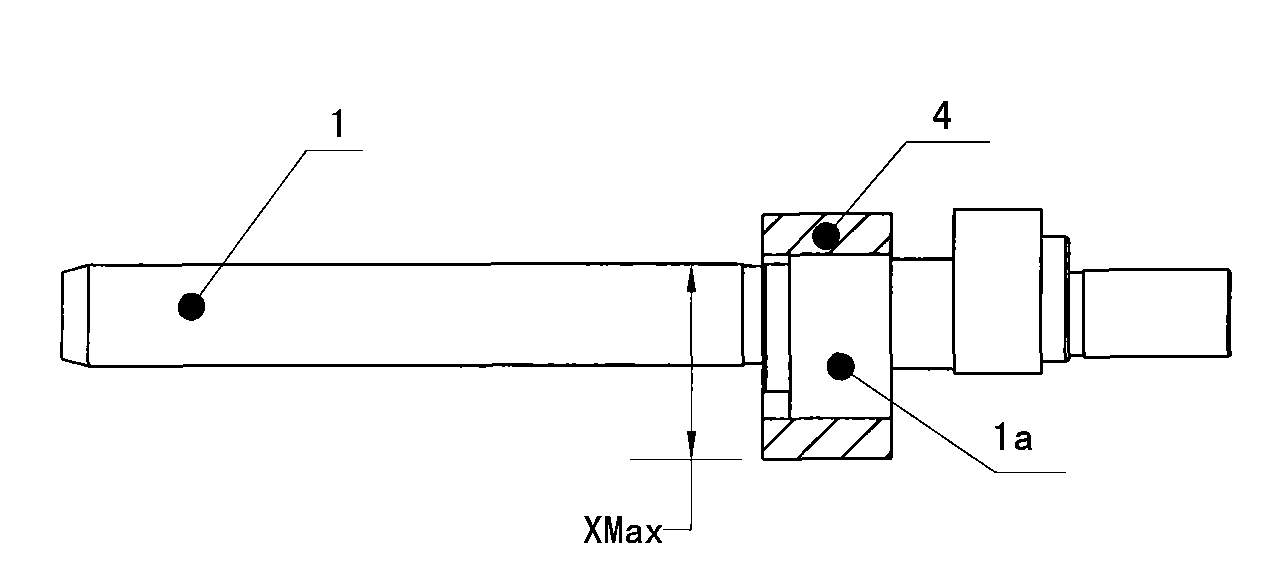

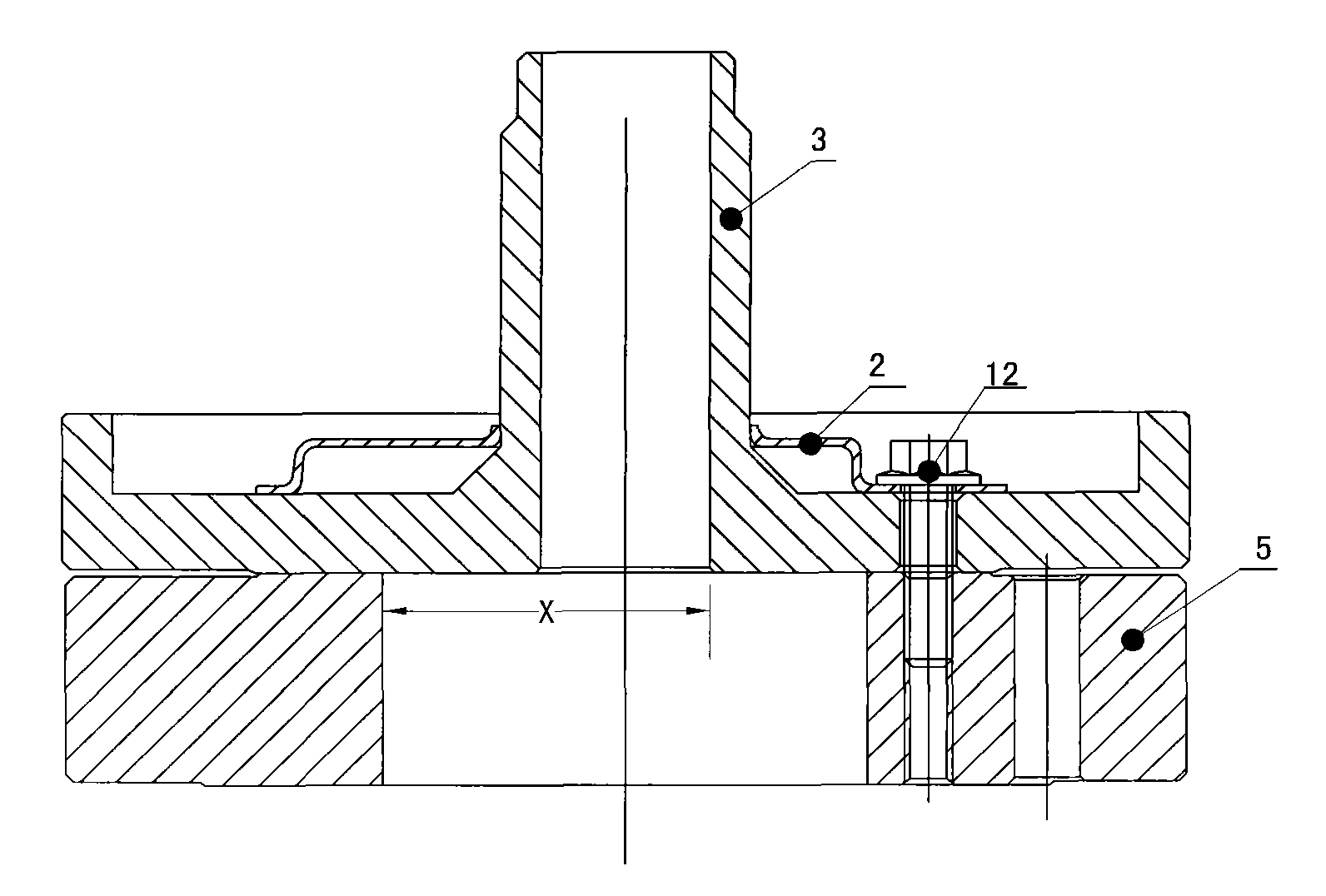

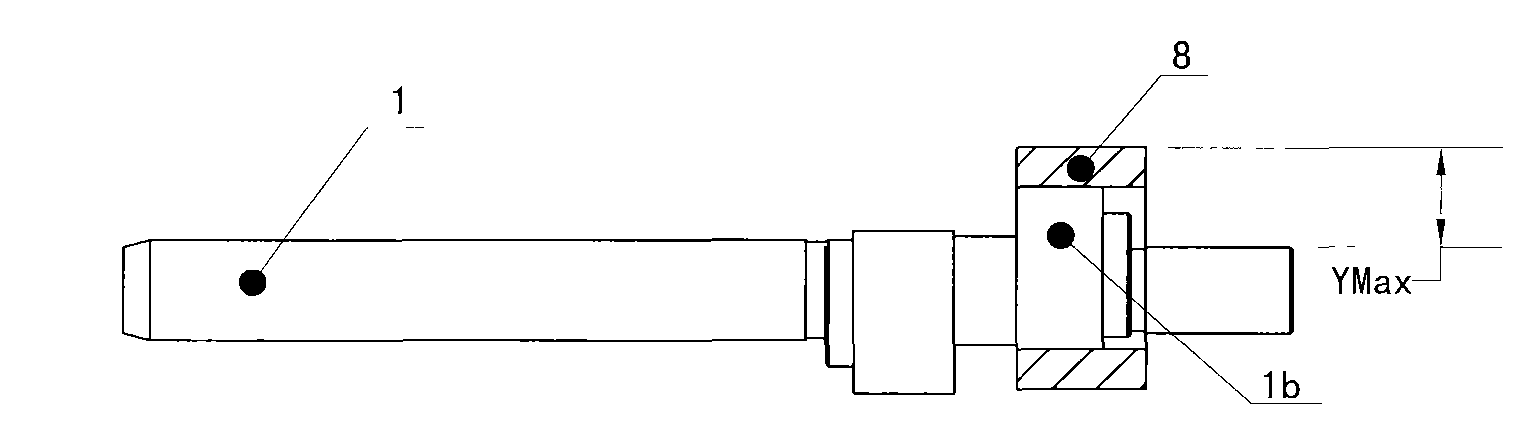

Method for assembling pump-body of compressor with revolving twin cylinder

ActiveCN1796790ASimple processReduce processRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMechanical engineeringCrankshaft

A method for assembling pump of double cylinder rotary compressor includes forming M assembly by confirming top and bottom eccentric dimension and setting top and bottom piston on them as well as measuring maximum distance of top piston outer diameter ( OD ) to long shaft another side OD and bottom piston OD to short shaft the same side OD, setting top silencer and top cylinder cover as well as top cylinder, regulating them and inserting piston and crankshaft; forming N assembly by setting intermediate plate and bottom cylinder, regulating and fixing them; laying bottom cylinder cover and bottom silencer down then fixing them.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Flexible splicing device for sidewalls of automobiles

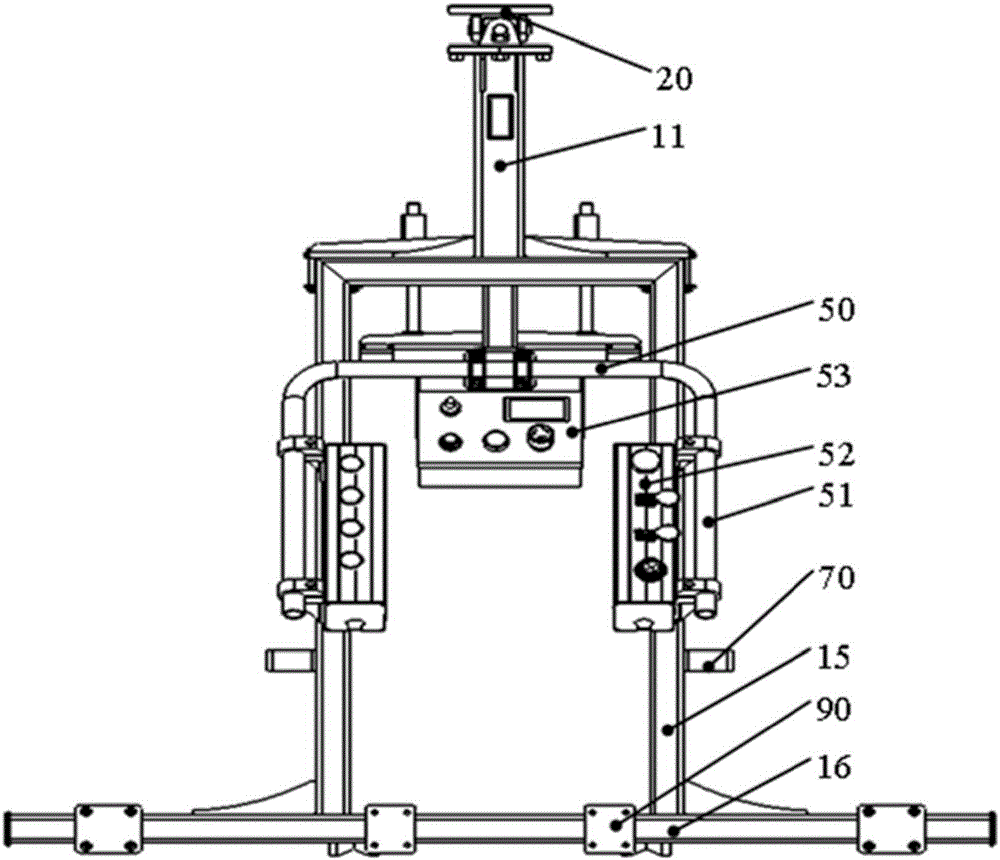

ActiveCN102581535AEasy to manufactureIncrease profitWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelBilateral symmetry

The invention relates to a flexible splicing device for sidewalls of automobiles, which comprises two base plates arranged in bilateral symmetry. A pair of slide rails is arranged on two sides of the top surface of each base plate, sliding platforms are arranged on the two pairs of side rails respectively, multi-surface rotating body supports are fixed at two ends of the top surface of each sliding platform respectively, multi-surface rotating bodies are arranged on the two multi-surface rotating body supports arranged on the same sliding platform, sidewall clamps are mounted on the multi-surface rotating bodies, a driven wheel is fixed at one end of a spindle of the multi-surface rotating bodies and in mesh connection with a driving wheel, the driving wheel is connected with a motor fixed on the top of the multi-surface rotating body support, and a multi-surface rotating body limit device is arranged below the other end of the spindle of the multi-surface rotating bodies. The flexible splicing device for sidewalls of automobiles has the advantages that switching among sidewalls is realized by a simple rotating device, and utilization rate of equipment is increased; in addition, the flexible splicing device for sidewalls of automobiles is simple in manufacturing and higher in practicality and flexibility, production speed can be improved effectively, and cost for development is reduced.

Owner:长城汽车股份有限公司平湖分公司

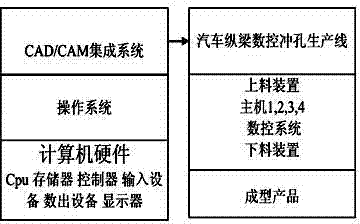

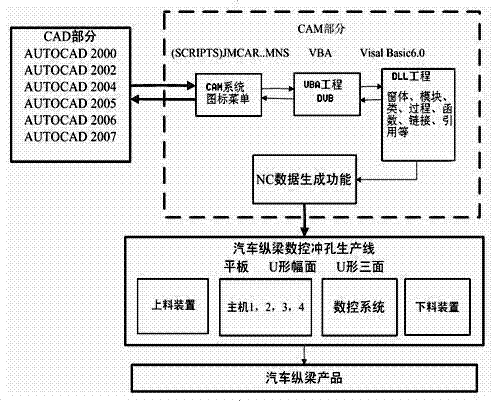

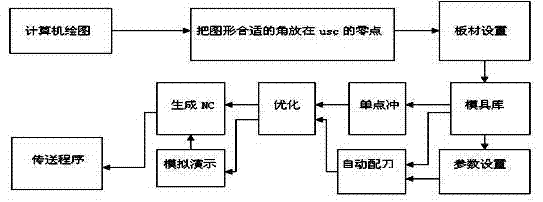

Method for constructing CAM (computer-aided manufacturing) system for punching for automobile girders

ActiveCN102707669ARealize integrationAvoid reducing service lifeProgramme controlComputer controlNumerical controlVisual Basic

A method for constructing a CAM (computer-aided manufacturing) system for punching for automobile girders is characterized by including selecting the types of used numerical-control punching production lines for the automobile girders; creating projects corresponding to the types of the numerical-control punching production lines for the automobile girders, building mathematical models of algorithms, and building generic modules; determining the types of the projects as Activex DII and compiling the types of the projects into types of dynamic linking libraries; writing and compiling interface programs connected with the dynamic linking libraries by VBA (visual basic for application); writing scripts for the various types of numerical-control punching production lines, and creating a CAM icon menu file and icons corresponding to various items; packaging various documents such as the CAM icon menu file, the interface programs written by the VBA, each class-generation DLL (dynamic linking library) compiled by VB (visual basic), development interfaces provided in the form of VB types, windows, the modules, the projects, an encryption method and instructions in a SETUP to form installation programs of the various types of numerical-control punching production lines for the automobile girders; and adding a CAM menu into a menu self-defining term in a CAD (computer-aided design).

Owner:广州市力鼎汽车零部件有限公司

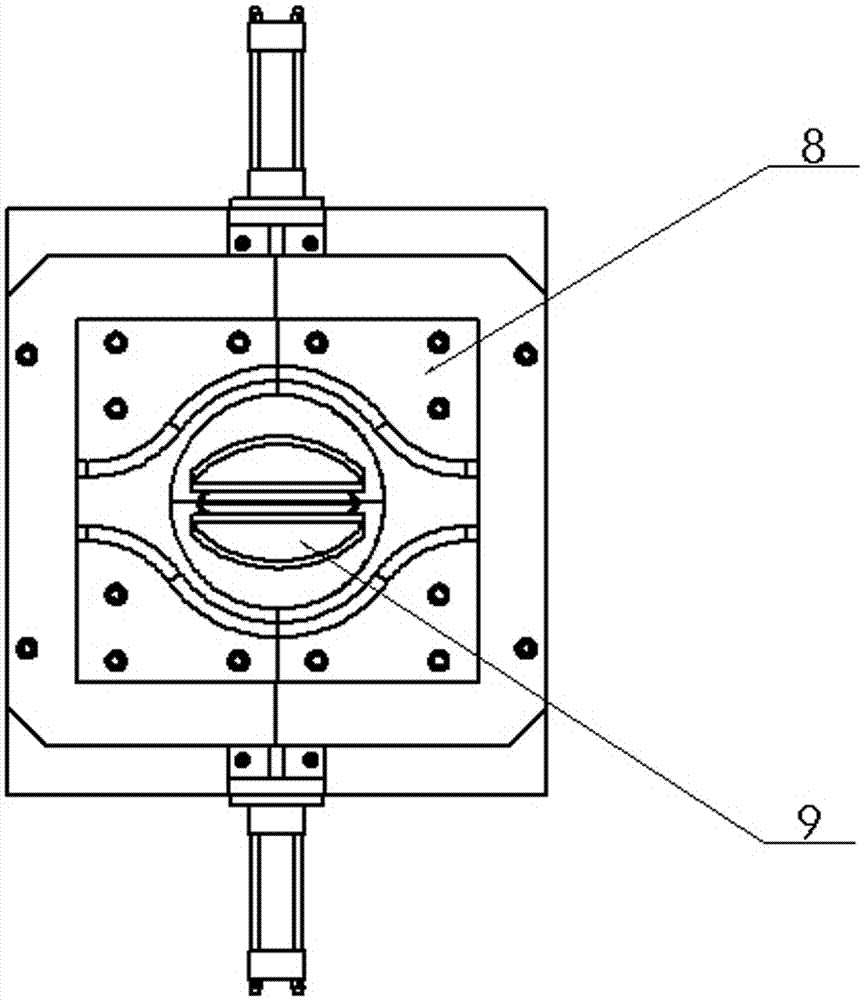

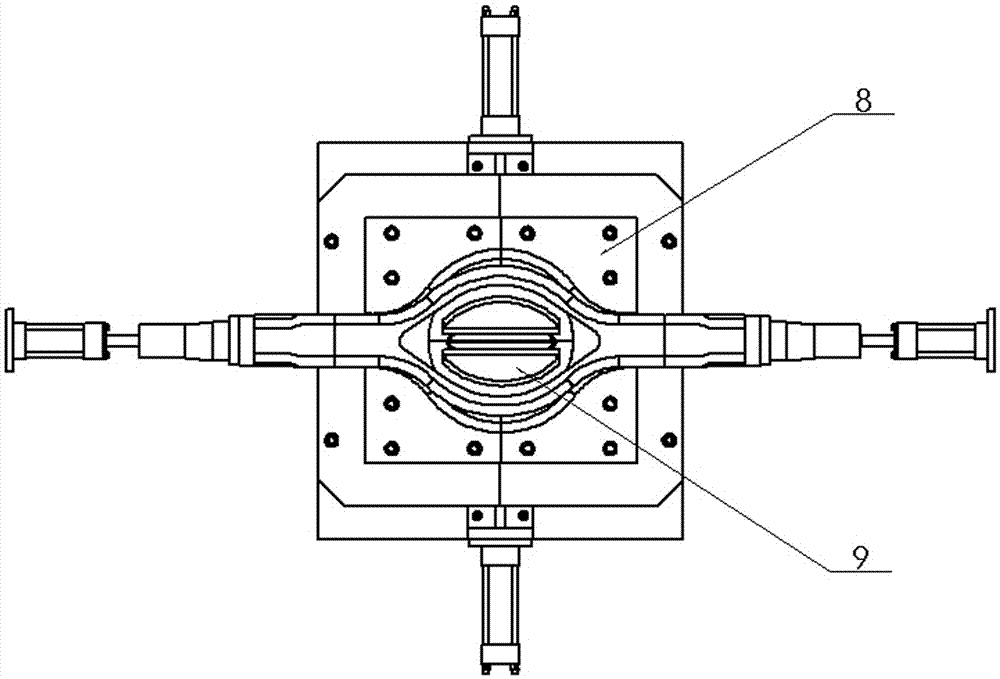

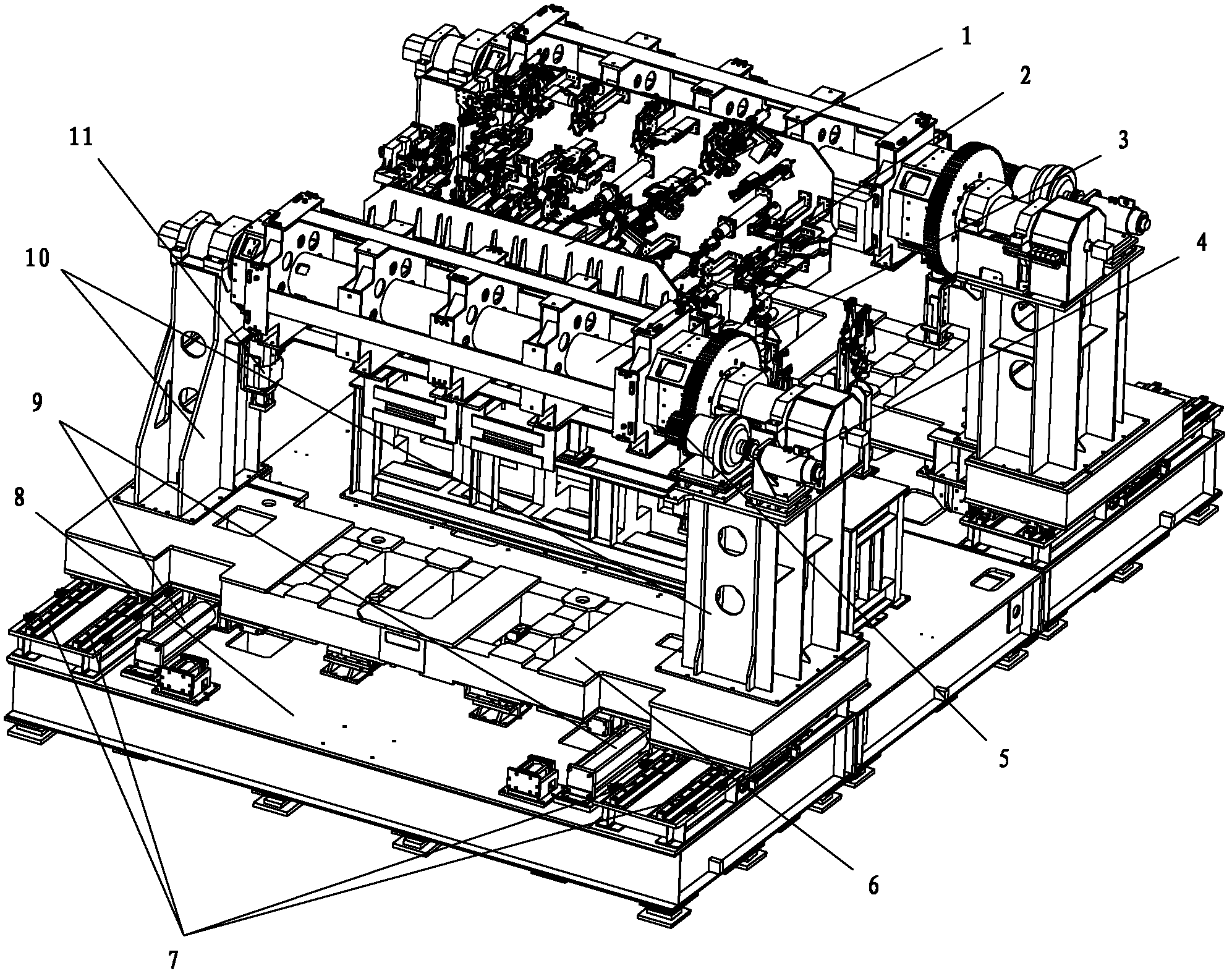

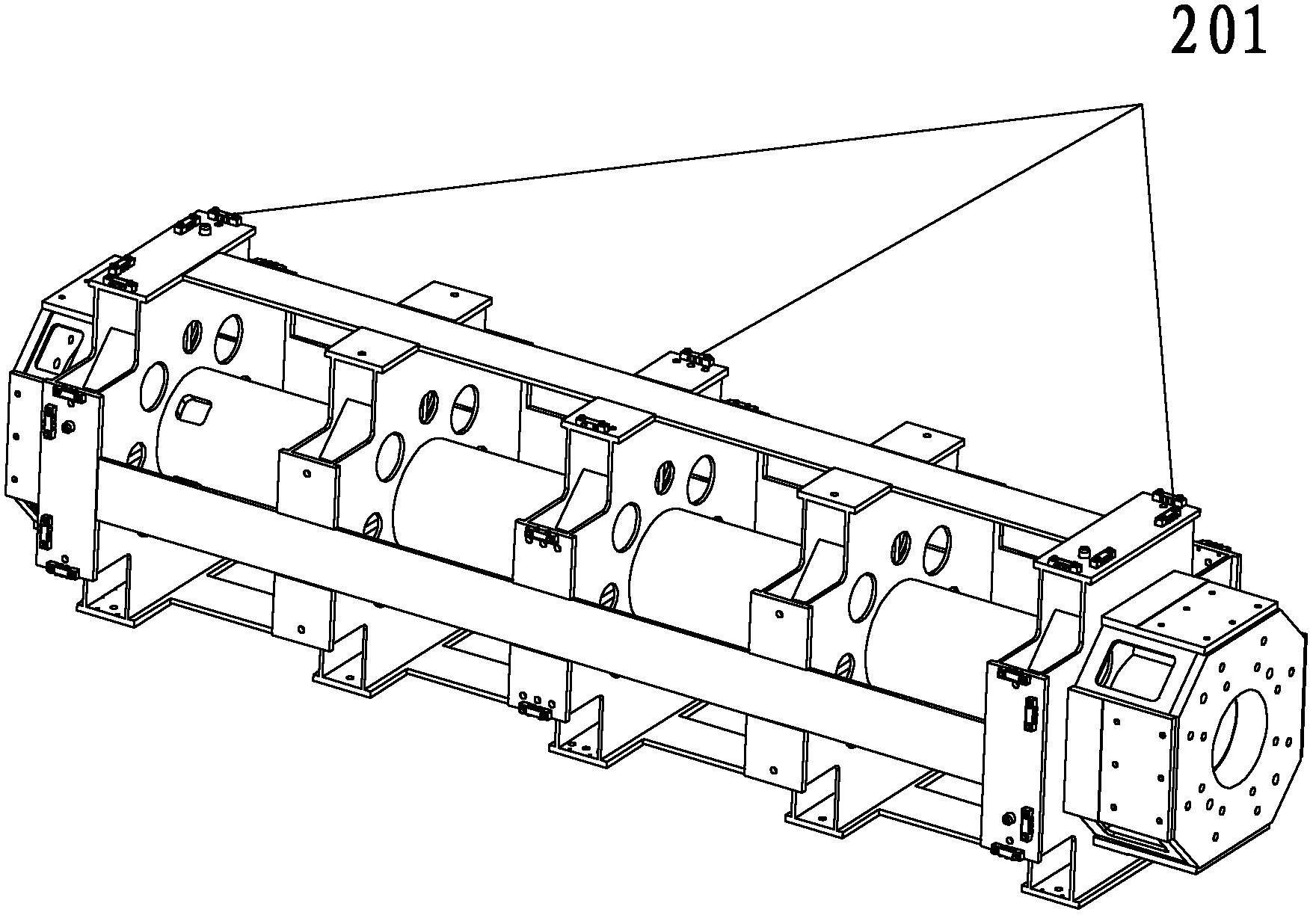

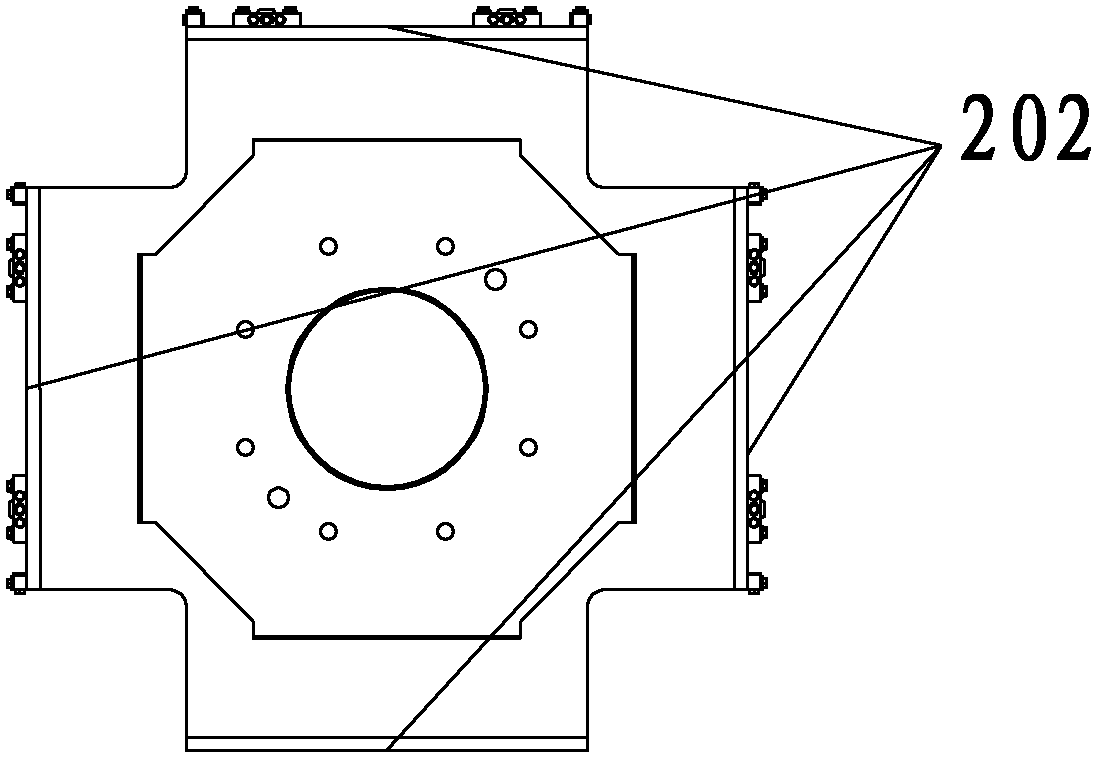

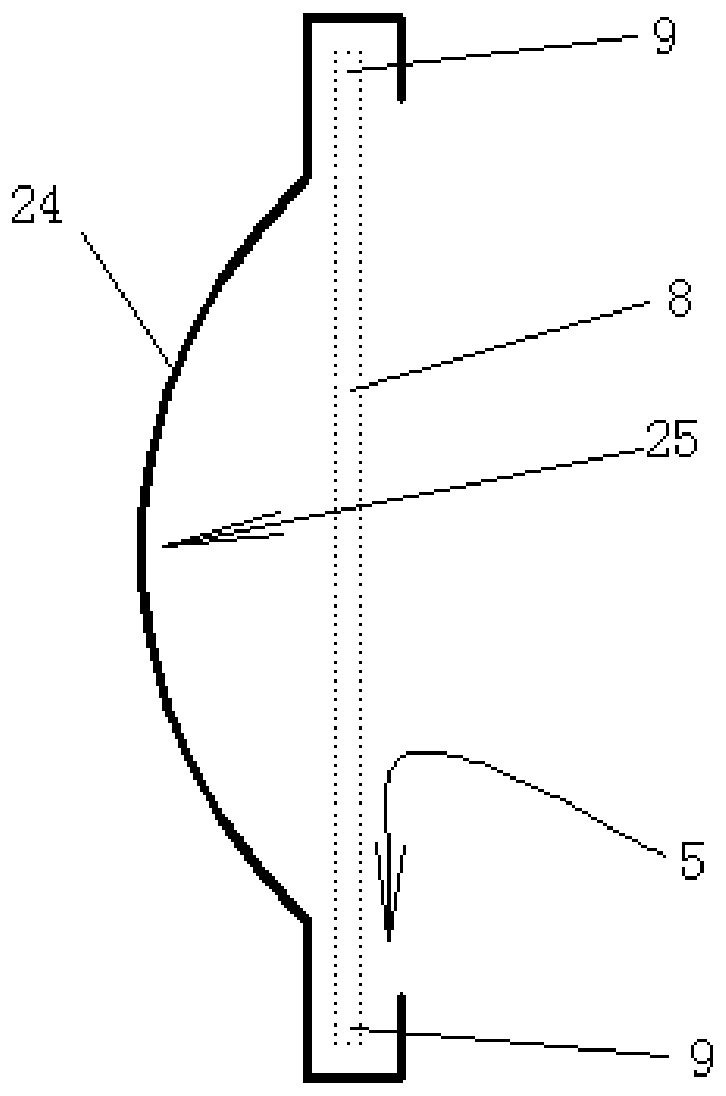

Semitrailer integral axle tube extrusion moulding equipment and method

InactiveCN102172658AIncrease productivityReduce manufacturing costExtrusion profiling toolsIntermediate frequencyPulp and paper industry

The invention relates to semitrailer integral axle tube extrusion moulding equipment, comprising a hydraulic machine and an intermediate frequency heating furnace, wherein the two ends of the rack of the hydraulic machine are respectively provided with a first slide seat and a second slide seat, the first slide seat is connected with a first cylinder of the hydraulic machine, the second slide seat is connected with a second cylinder of the hydraulic machine, and the first and second slide seats are provided with mould replacing wheel discs; and the top of the rack of the hydraulic machine is also provided with a clamping device for an axle tube. The axle tube extrusion moulding equipment provided by the invention has high production efficiency and has the advantages of high product processing accuracy, good integral mechanical property and stable product quality compared with the traditional hot spinning process. A steel pipe blank is directly moulded at axle heads at the two ends in an extruding way by virtue of the hydraulic machine, and various welding defects existing in subsection moulding are avoided, thus the bearing capacity of a car axle is greatly improved.

Owner:GUANGDONG FUWA HEAVY IND

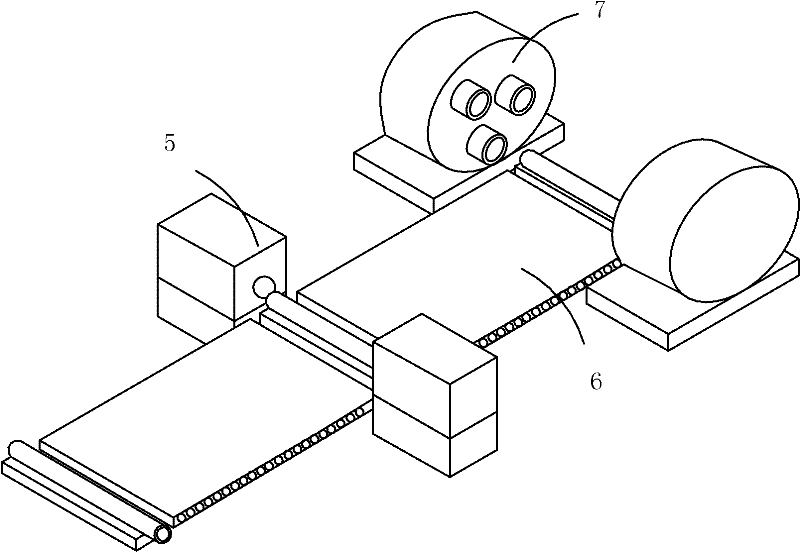

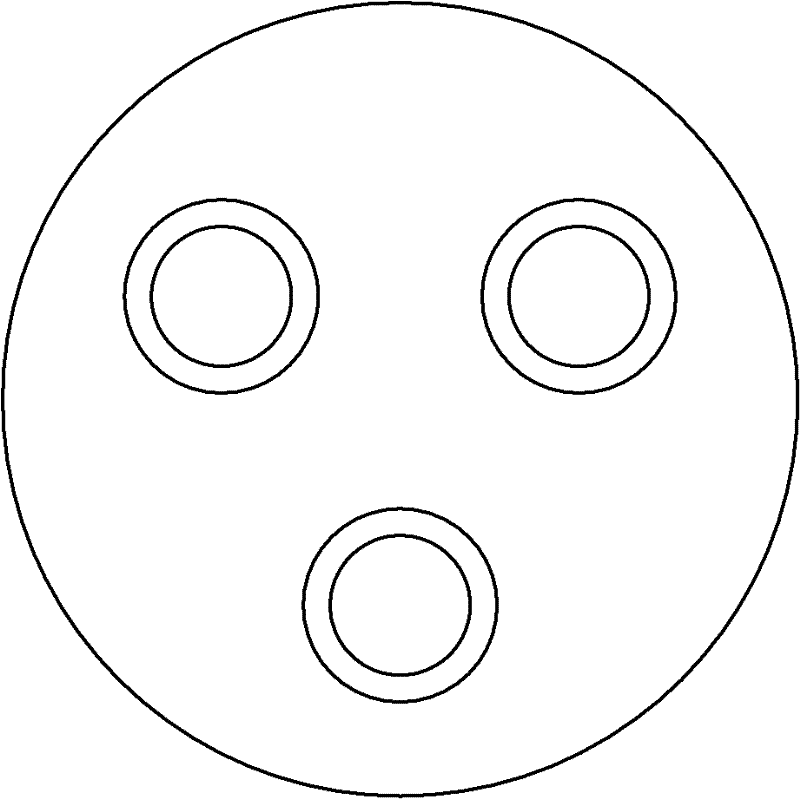

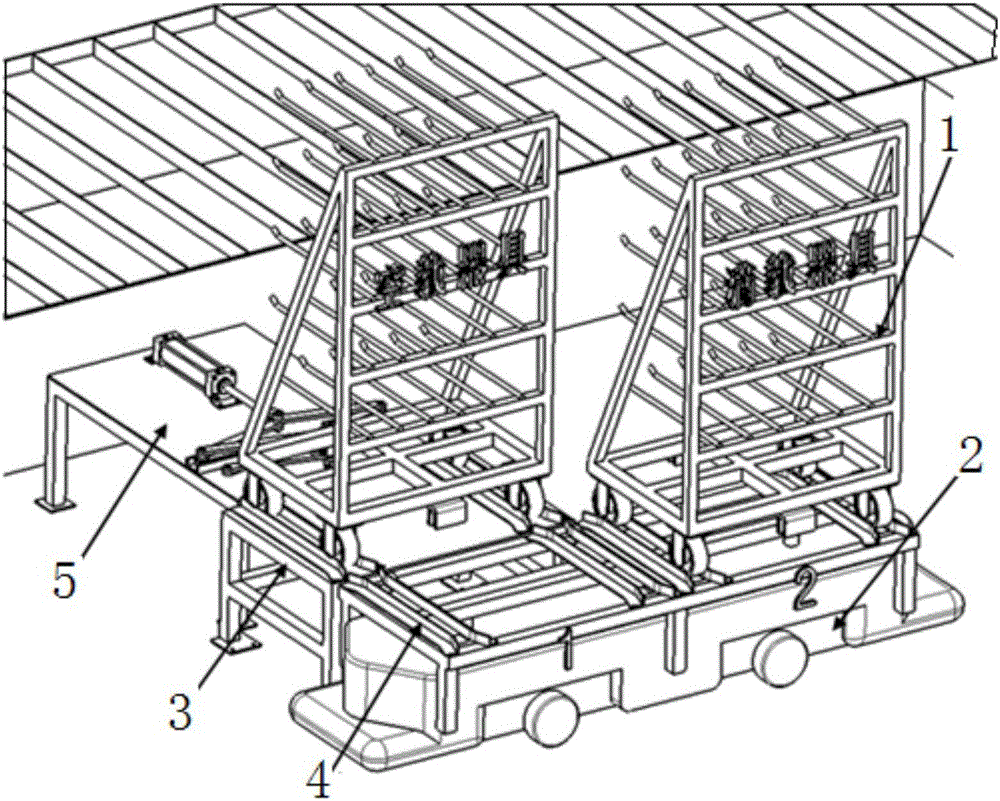

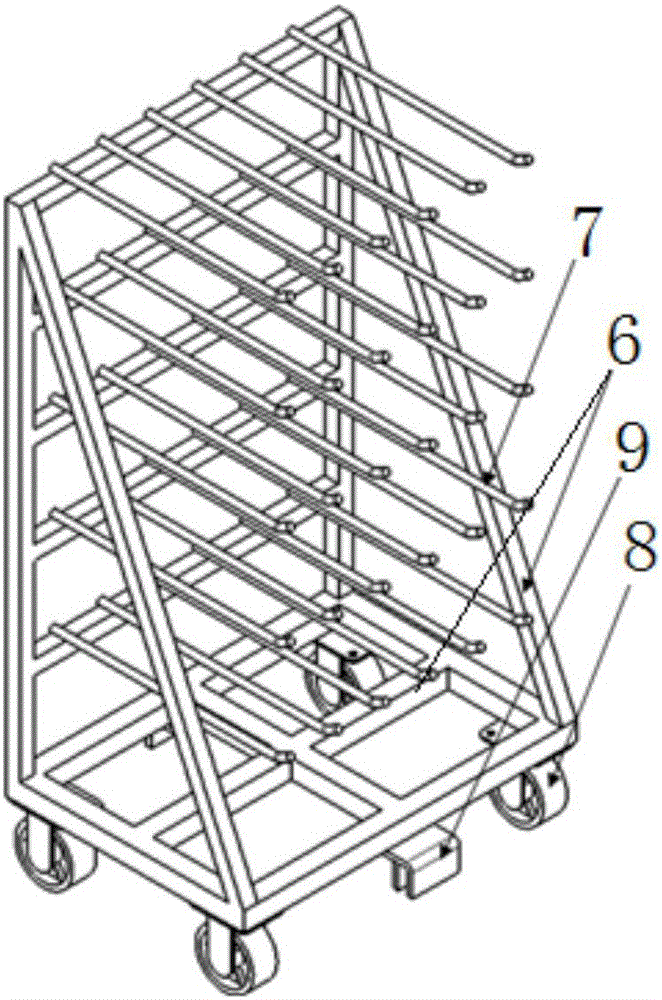

Automatic conveying system and method for car body coating auxiliary tools

ActiveCN105692096APrecise positioningSave human effortMechanical conveyorsProduction lineEngineering

The invention discloses an automatic conveying system and method for car body coating auxiliary tools. The conveying system comprises tool racks for loading the coating auxiliary tools and an AGV trolley; the AVG trolley is provided with a tray for conveying the tool racks; and the conveying system further comprises an automatic docking mechanism and a line edge workbench, wherein the automatic docking mechanism is arranged on the edge of a coating production line and used for unloading and loading the tool racks, and the line edge workbench is docked with the tray for containing the unloaded tool racks. According to the automatic conveying method of the car body coating auxiliary tools, the car body coating auxiliary tools are automatically conveyed through the automatic conveying system for the car body coating auxiliary tools; automatic conveying is achieved in the whole conveying process, positioning is accurate, labor is saved, production rhythm can be improved, and the equipment use rate and production efficiency are improved.

Owner:CHERY AUTOMOBILE CO LTD

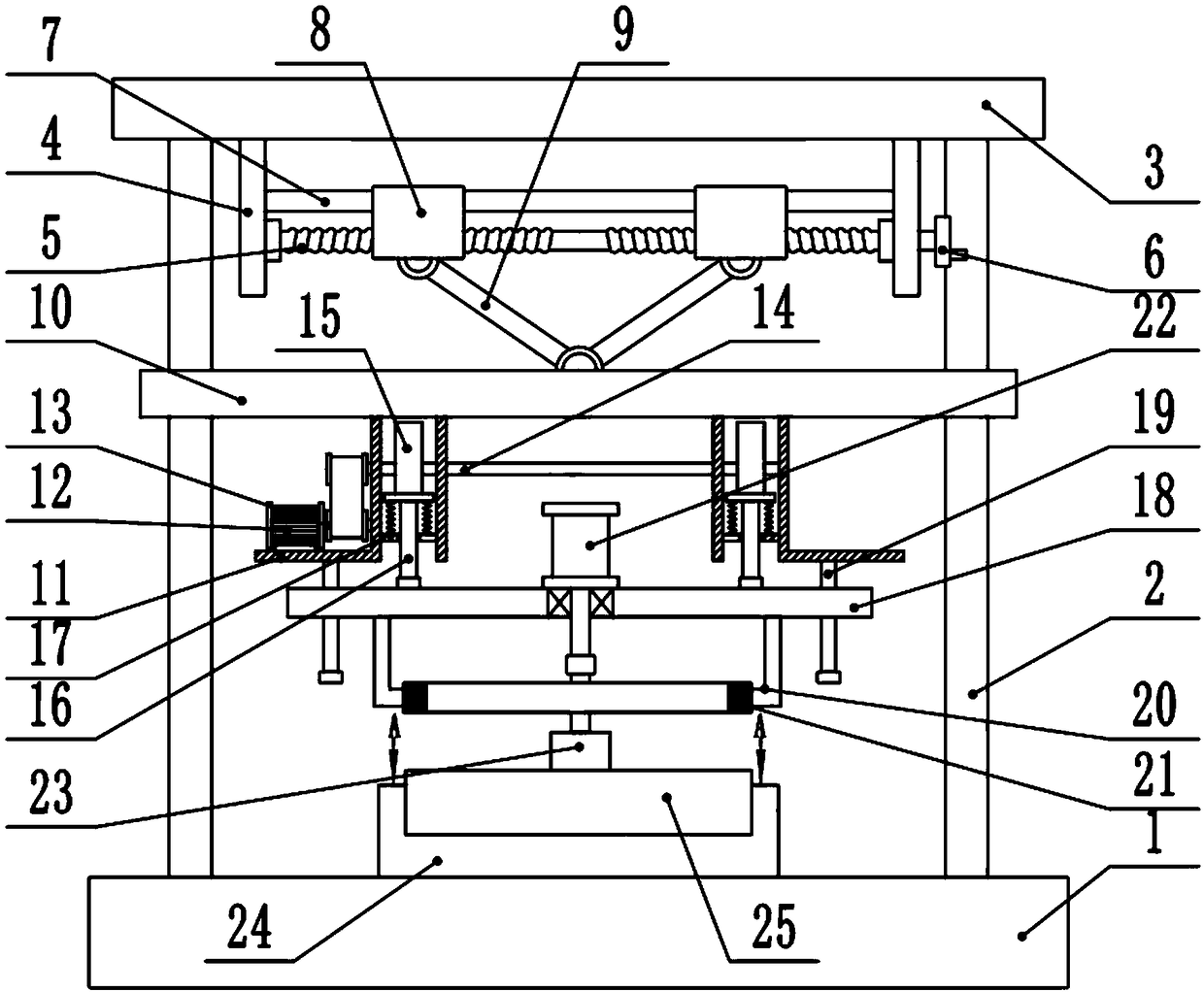

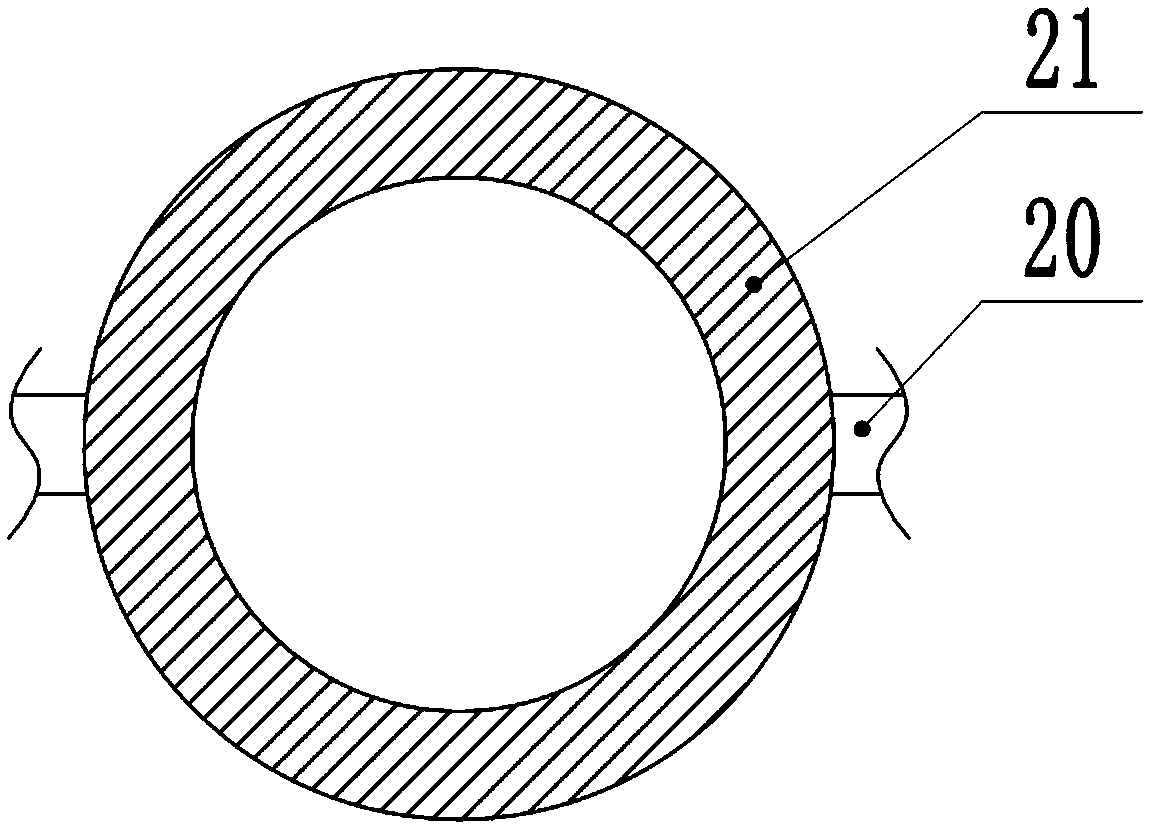

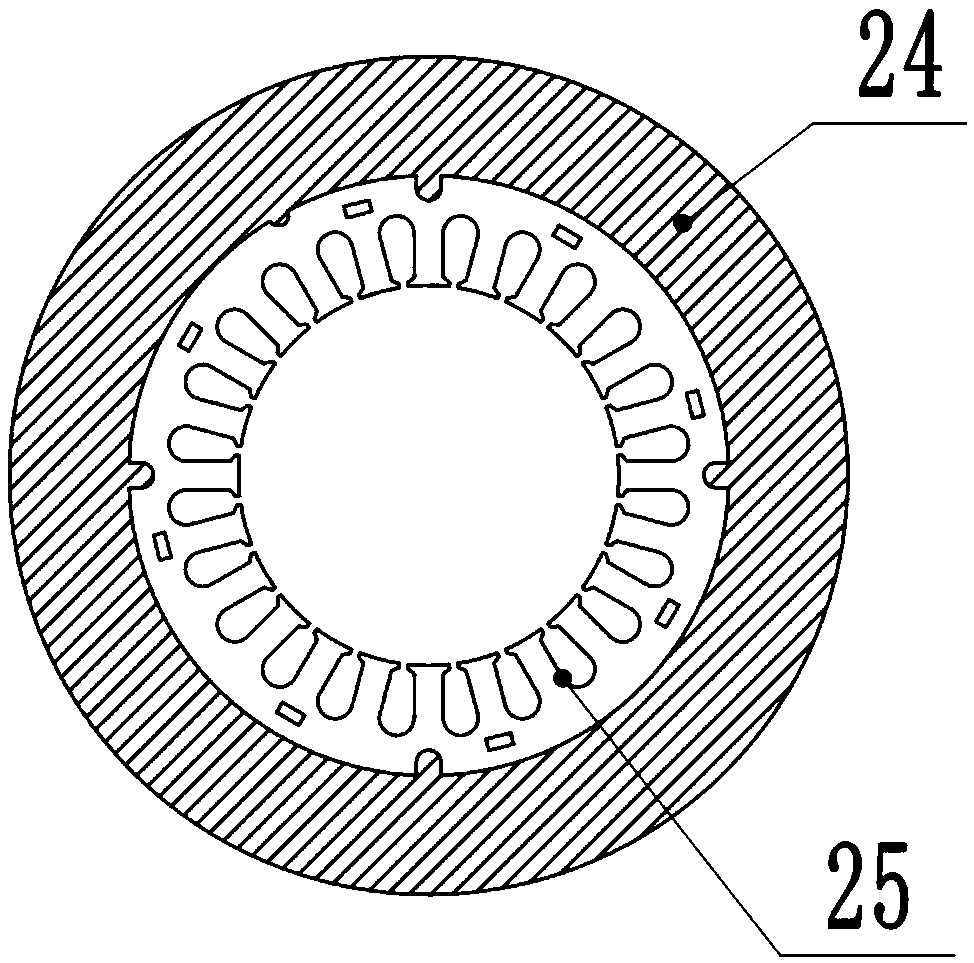

Stator iron core flattening and inner cavity polishing device for screw lifting type duct machine

InactiveCN109176177AImprove versatilityImprove work efficiencyRevolution surface grinding machinesGrinding drivesCouplingBall screw

The invention discloses a stator iron core flattening and inner cavity polishing device for a screw lifting type duct machine. The stator iron core flattening and inner cavity polishing device comprises a base, a ball screw, a lifting plate, a driving motor, a flattening block, a polishing motor and a polishing brush; a fixing rod is welded to the lower side of a sliding plate, and the other end of the fixing rod is fixedly connected with the flattening block; the polishing motor is fixedly mounted in the center of the upper side of the sliding plate; the polishing brush is fixedly mounted atthe lower end of an output shaft of the polishing motor through a coupling; and soft steel wires are evenly distributed on the outer circle of the polishing brush. According to the stator iron core flattening and inner cavity polishing device, the heights of the polishing brush and the flattening block can be adjusted so as to meet inner circle cavity clearing and flattening work of stator iron cores with different stack thicknesses, and thus the universality of the device is greatly improved; and inner circle cavity clearing and flattening work can be conducted simultaneously, the two workingprocedures are integrated, the work efficiency is greatly improved, and the production beat is accelerated.

Owner:杜鑫

Machining position-adjustable valve body grinding device

InactiveCN108747694AReduce labor intensityImprove production taktGrinding drivesGrinding machinesLocking mechanismDrive motor

The invention relates to a machining position-adjustable valve body grinding device. The device comprises a base plate; the base plate is provided with a bevel gear ring and a ring groove concentrically distributed with the bevel gear ring; the ring groove is slidingly connected with multiple polishing mechanisms uniformly distributed; a positioning table is arranged in the circle center of the bevel gear ring; multiple clamping mechanisms for fixing valve bodies are annularly arranged on the positioning table; the polishing mechanisms comprise bearing tables, pushing cylinders, support rings,spline shafts, grinding wheels, mounting sleeves and bevel gears; slide blocks cooperating with the ring groove and locking mechanisms cooperating with the outer groove wall of the ring groove are arranged at the bottom of the bearing tables; the bevel gear ring is coaxially provided with a gear ring; the gear ring is engaged with a driving gear; and the driving gear is connected with a driving motor. The device can realize synchronous grinding of multiple end surfaces of the valve bodies, can be adjusted to adapt to the end surfaces with different included angles, is simple in operation andconvenient to use, greatly relieves the labor intensity of workers, and improves the working efficiency.

Owner:WUHU JIENUO TECH

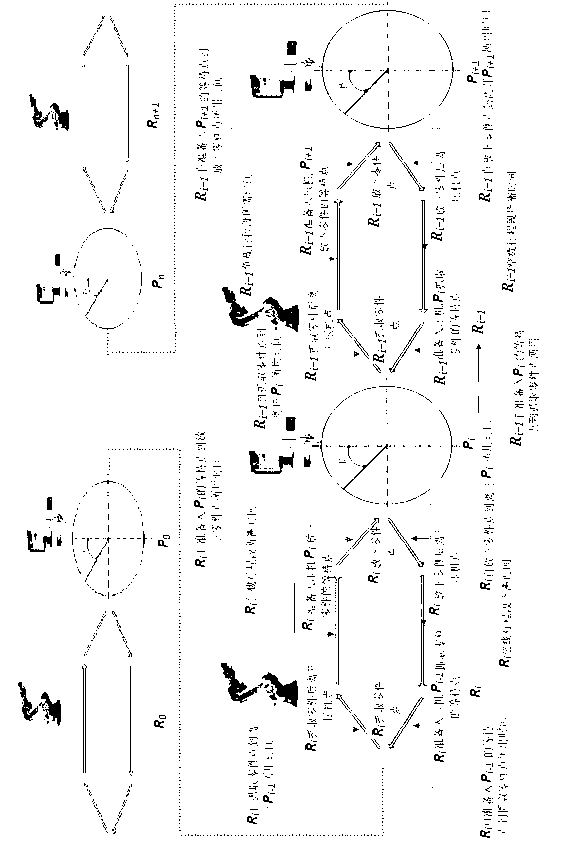

Press-robot synchronous movement coordination method

InactiveCN103213127AImprove motor coordinationImprove coordinationProgramme-controlled manipulatorMetal-working feeding devicesMovement controlOverlap ratio

The invention relates to a press-robot synchronous movement coordination method. The method comprises the following steps of automatically adjusting a non-load section locus ROM (Read Only Memory) between a point at which a robot Ri lays down parts and then departs from a press Pi and a holding point at which the robot Ri is ready to enter a press Pi-1 to grab the parts; automatically adjusting a load section locus ROM between a point at which the robot Ri grabs the parts and then departs from the press Pi-1 and a holding point at which the Ri is ready to enter the press Pi and lays down the parts; and enabling a blanking robot Ri+1 to enter a mold in advance before a sliding block arrives at 360 degrees, i.e., when the crank angle of the press Pi enters the beta moment, the robot Ri+1 waits beside the mold. According to the method, the non-load stoke section speed of the robot is automatically adjusted according to a synchronous movement control algorithm, so that the press-robot coordination is increased, a press and robot synchronizing function is realized, the overlap ratio between the feeding and blanking movements of the robot and the movement of the press is maximized, and the purpose of improving the production metre and the production efficiency of a positive line through smoothly switching the speed of the robot is achieved.

Owner:QILU UNIV OF TECH

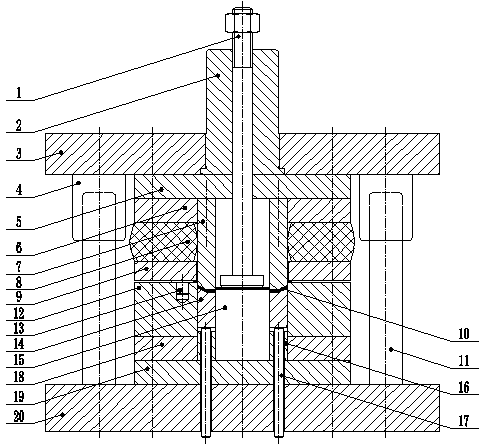

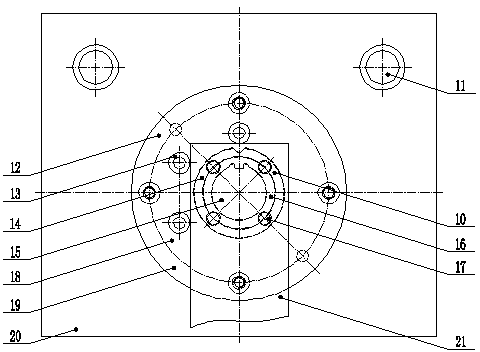

Automobile tray bearing nut locking gasket blanking-molding-punching composite die and process thereof

The invention discloses an automobile tray bearing nut locking gasket blanking-molding-punching composite die. The automobile tray bearing nut locking gasket blanking-molding-punching composite die comprises an upper die and a lower die, wherein the upper die comprises a die handle, an upper template, an upper base plate, an upper fixing plate and an upper discharging plate which are tightly connected in sequence from top to bottom; a blanking-molding-punching punch-die is arranged inside the upper fixing plate; the lower die comprises a blanking female die, a punching male die outer fixing plate, a lower base plate and a lower template which are tightly connected in sequence from top to bottom; a molding female die is arranged in the middle of the blanking female die; a punching male die inner fixing plate is arranged in the middle of the punching male die outer fixing plate; a punching male die is arranged in the middle of the punching male die inner fixing plate; the blanking-molding-punching punch-die, the molding female die and the punching male die form a molding die cavity for workpieces. The molding male die and the punching female die are compounded integrally, so that molding and punching are realized during blanking of blanks, the blank molding and punching processes are stable, and regular appearances and stable strength performance of bearing nut locking gaskets are ensured.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

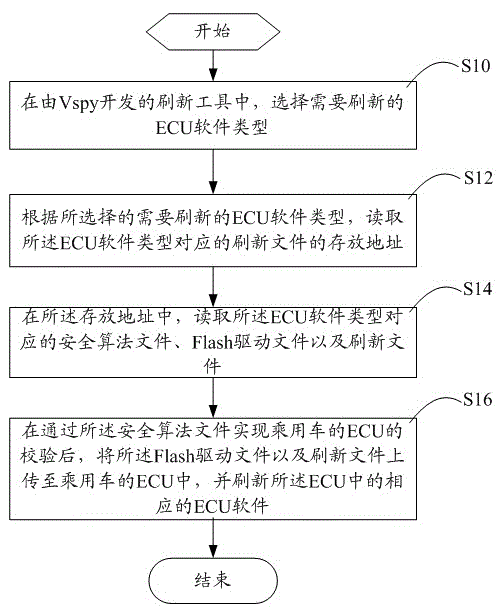

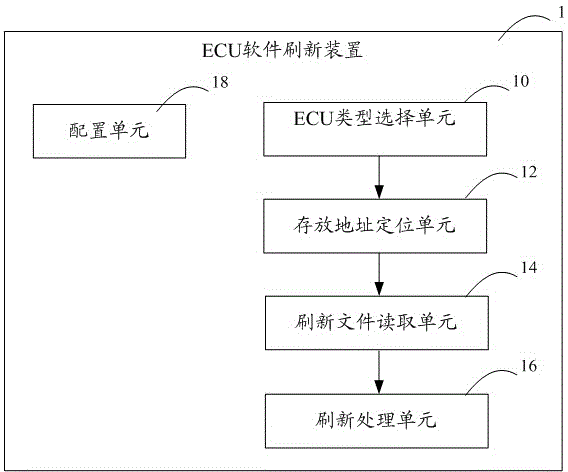

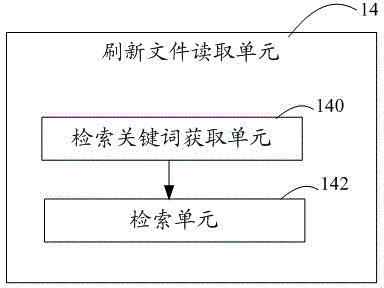

Vspy-based ECU software refreshing method and Vspy-based software refreshing device

ActiveCN105573148AReduce development costsIncrease success rateProgramme control in sequence/logic controllersConfidentialitySoftware

An embodiment of the invention provides a Vspy-based ECU software refreshing method which comprises the steps of selecting the type of the ECU software to be refreshed in a refreshing tool which is developed based on Vspy; according to the selected type of the ECU software to be refreshed, reading the storage address of a refreshing file which corresponds with the type of the ECU software; in the storage address, reading a safe algorithm file which corresponds with the type of the ECU software, a Flash driving file and a refreshing file to be uploaded; uploading the refreshing file to the ECU of a passenger vehicle, and refreshing the corresponding ECU software in the ECU. The embodiment of the invention correspondingly provides a Vspy-based software refreshing device. The Vspy-based ECU software refreshing method and the Vspy-based software refreshing device have advantages of reducing refreshing cost of the ECU software, increasing refreshing speed, improving refreshing success rate, reducing dependence on a provider and improving confidentiality.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

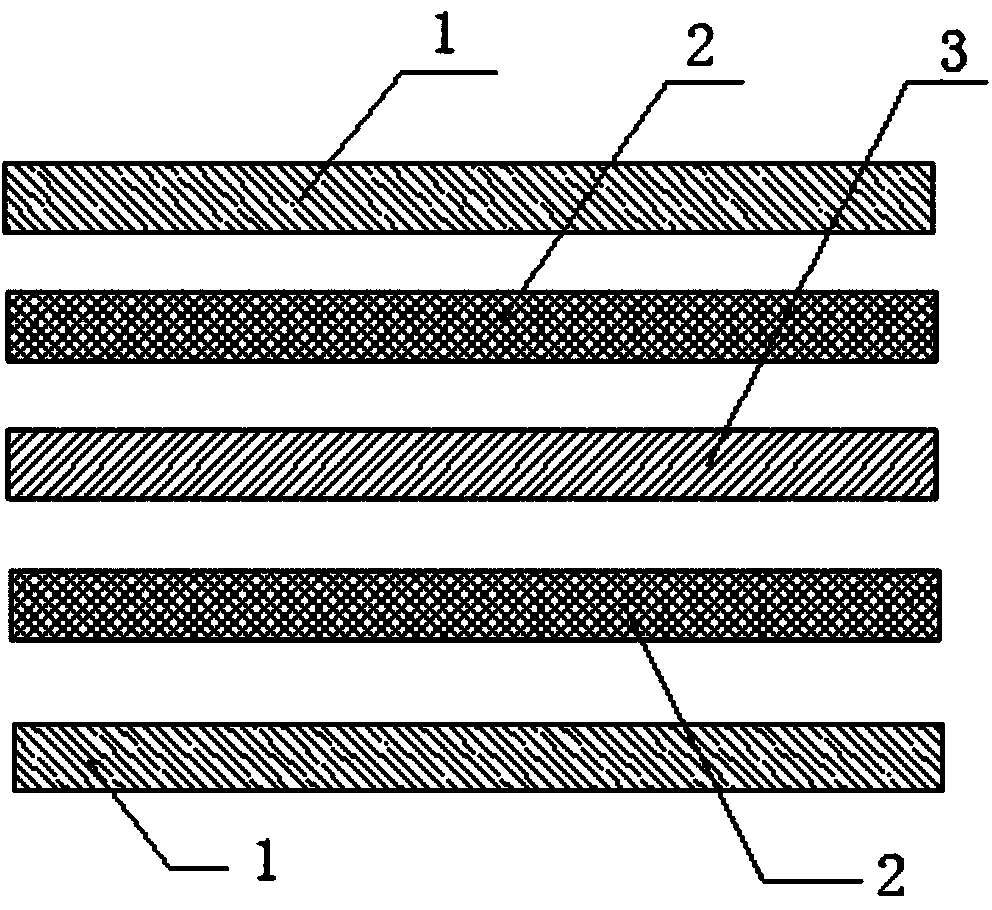

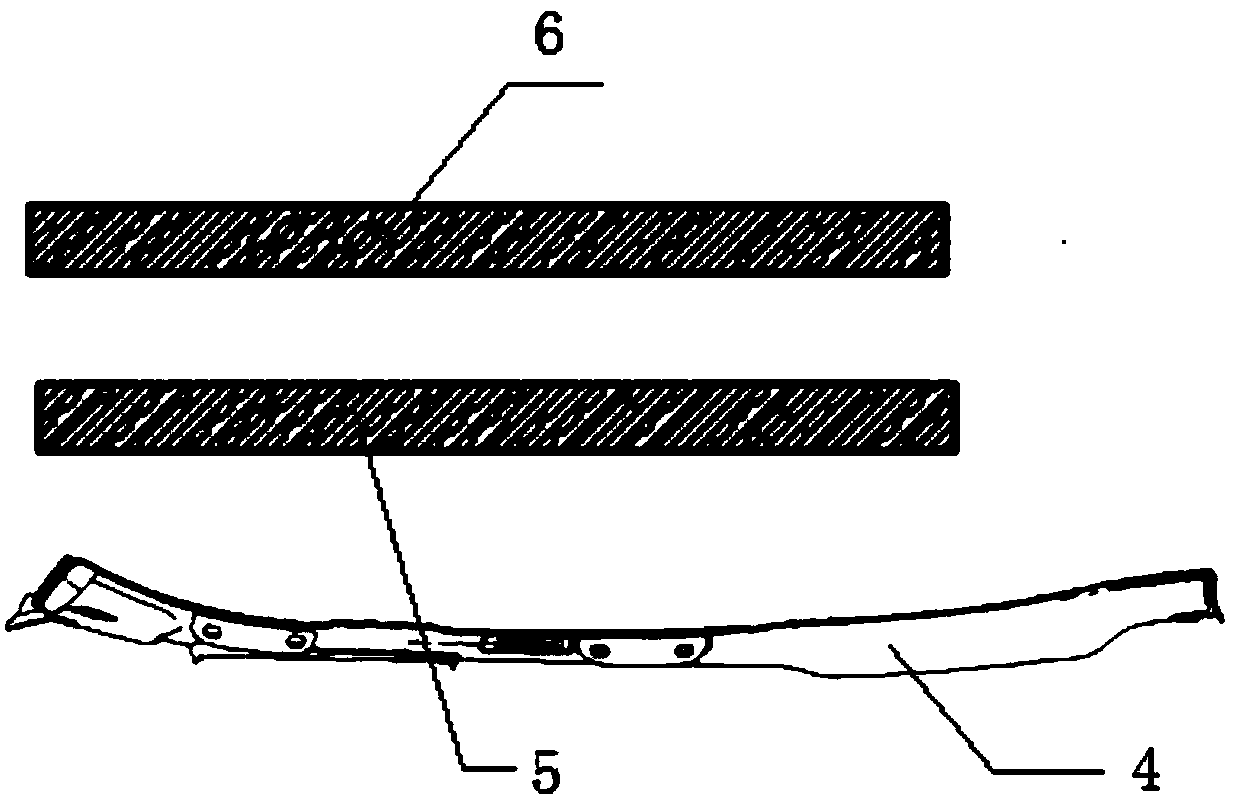

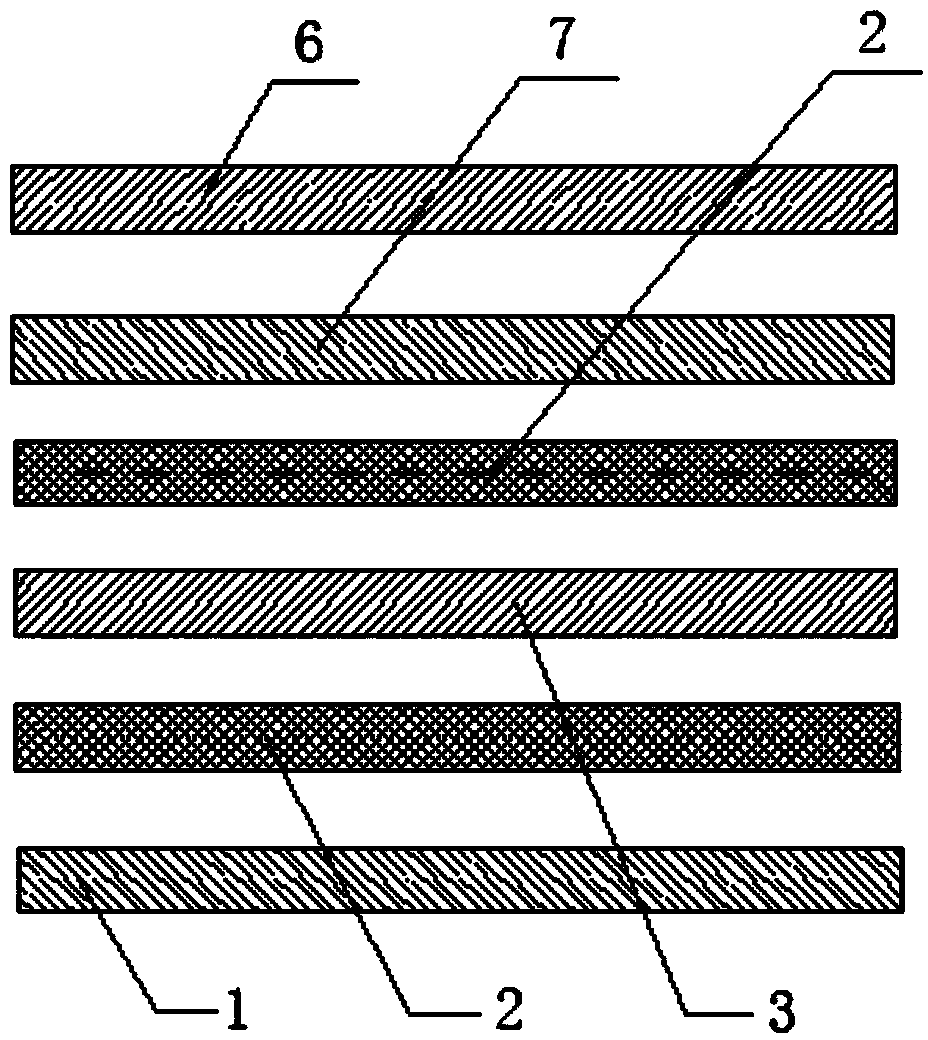

Novel vehicle roof and production process thereof

InactiveCN103921504AReduce a lot of volatilizationReduce VOC performanceLaminationLamination apparatusGlass fiberProduction rate

The invention provides a novel vehicle roof, which is formed by sequentially combining a composite knitted fabric, a fiberglass mat, a foam plate, another fiberglass mat and a bottom-layer non-woven fabric from top to bottom by adhesive films. The invention also provides a process for producing the novel vehicle roof. According to the production process, the advantages of simple procedure, high production rate and the like of a dry forming process and the advantages of roof forming performance higher than that of the dry forming process, lightweight roof and the like of a wet forming process are combined, namely the production process is used for forming the novel vehicle roof under a dry condition in a wet forming way (namely a cold material and a hot die). The VOC (volatile organic compound) performance of the roof is weakened, and the NVH (noise vibration and harshness) performance of the roof is improved; the novel vehicle roof and the production process have the advantages of high product forming performance, lightweight product, capability of improving the production rate of the product, less environmental pollution and the like.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

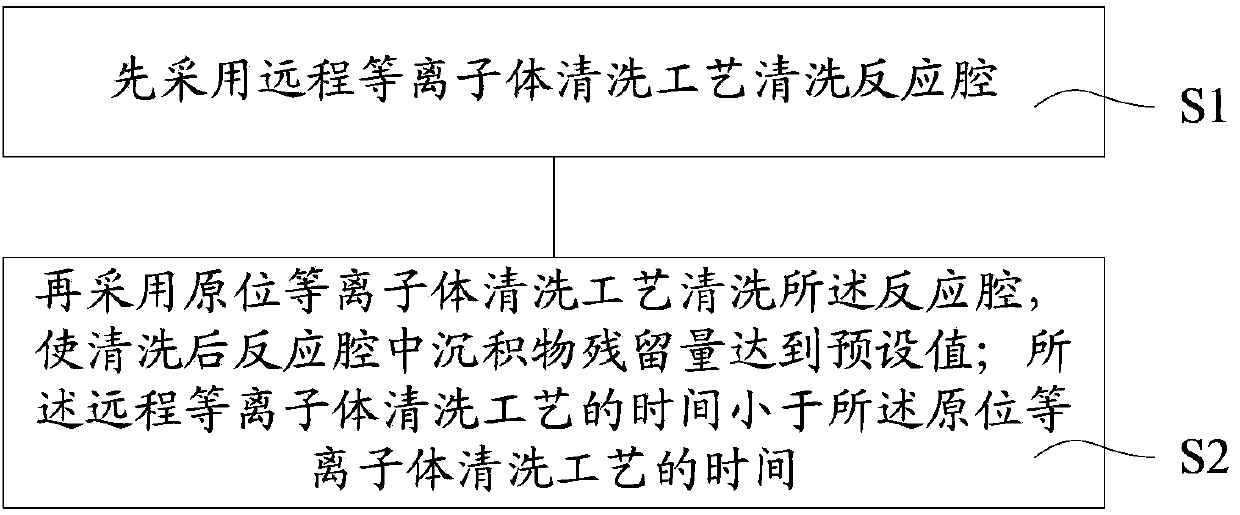

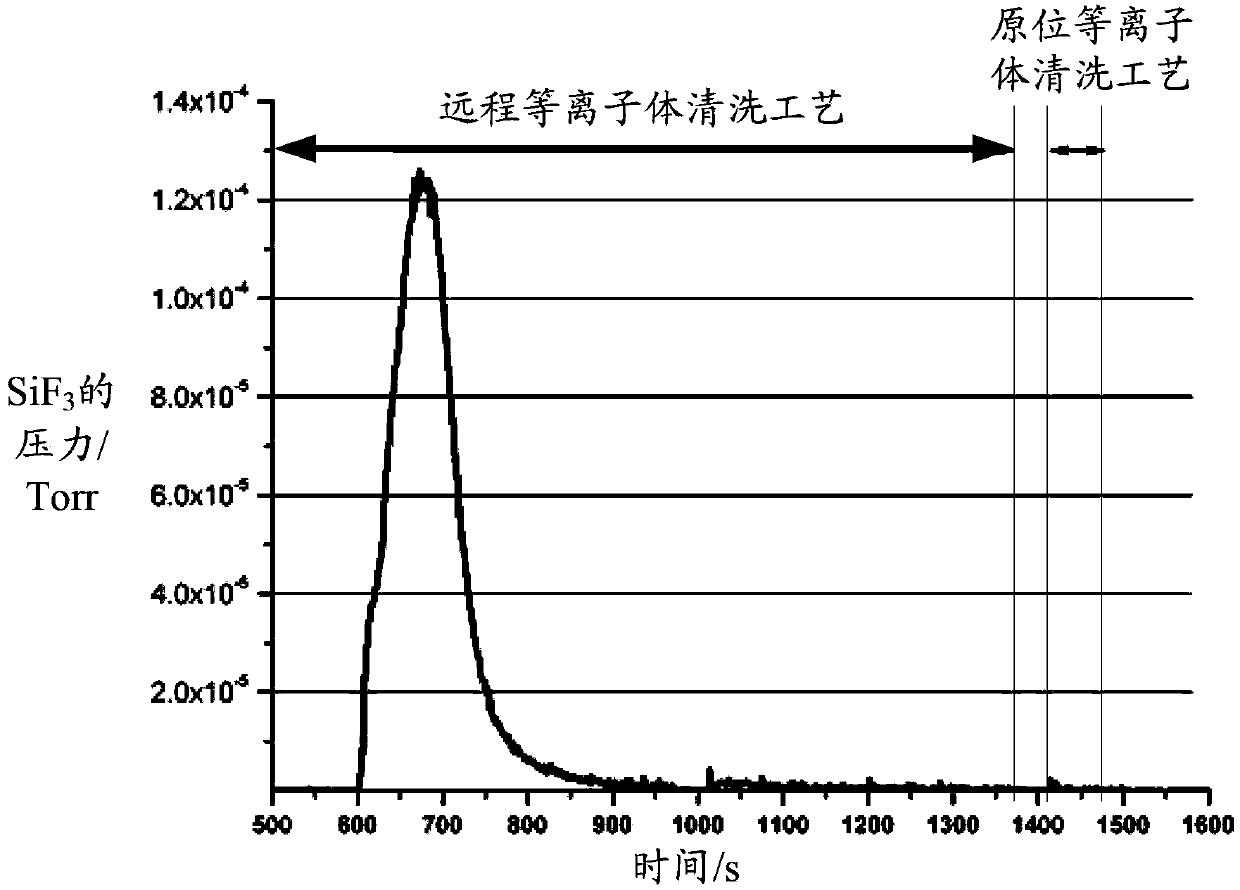

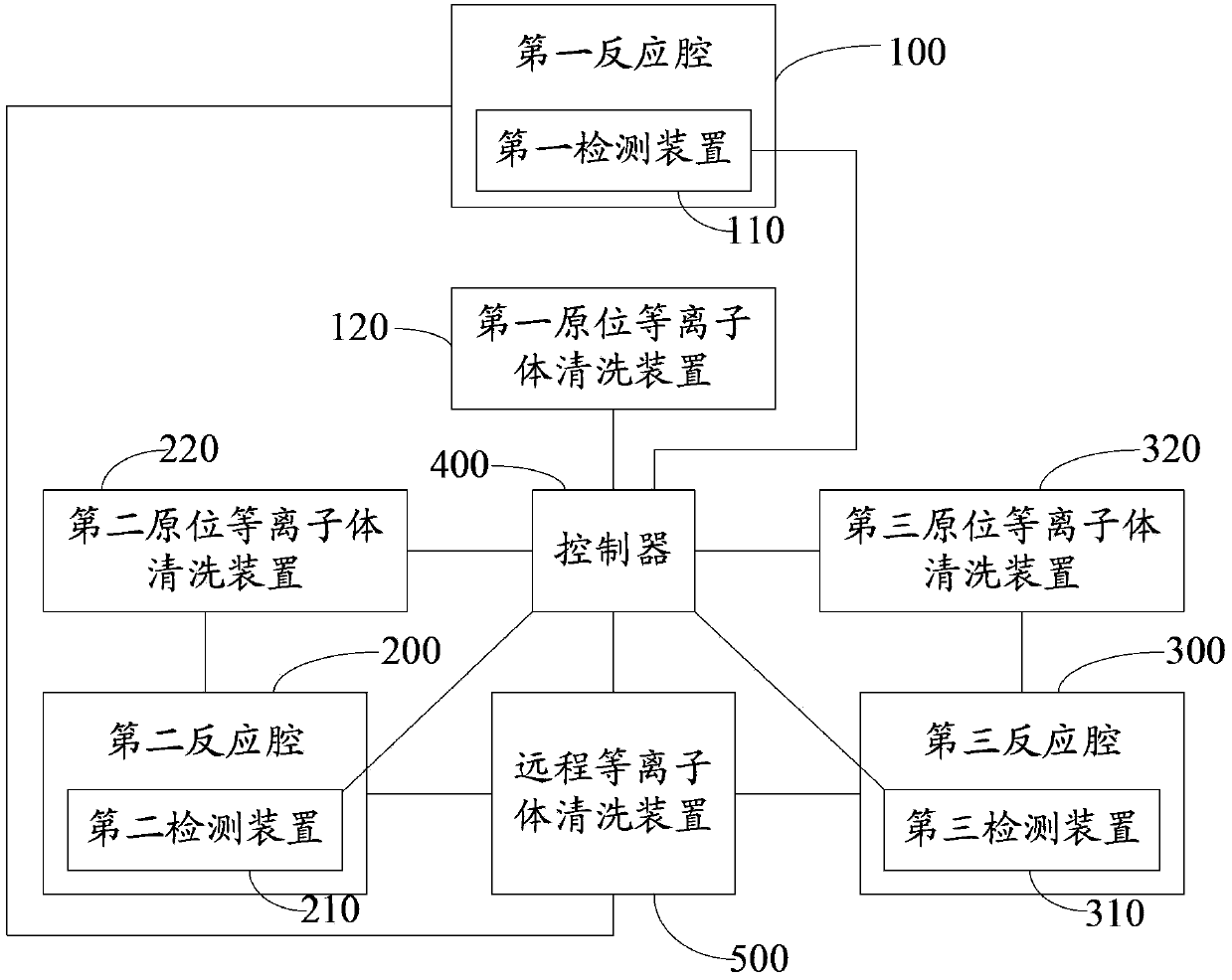

Cleaning method and cleaning system of reaction cavity

ActiveCN103374710AExtend cleaning timeShorten cleaning timeChemical vapor deposition coatingRemote plasmaOrganic chemistry

The invention discloses a cleaning method and a cleaning system of a reaction cavity. The cleaning method of the reaction cavity comprises the following steps of: firstly cleaning the reaction cavity by adopting a long-distance plasma body cleaning process, cleaning the reaction cavity by adopting a normal position plasma body cleaning process, enabling the sediment residual quantity in the reaction cavity after cleaning to achieve a preset value, wherein the time of the long-distance plasma body cleaning process is less than that of the normal position plasma body cleaning process. The cleaning method and the cleaning system provided by the invention have the advantages that the cleaning time is reduced, the cleaning uniformity is improved, and the use amount of the cleaning gas is also reduced.

Owner:理想万里晖真空装备(泰兴)有限公司

Ink automatic bagging mechanism

PendingCN109911321ARealize mechanized workImprove bagging efficiencyWrapper twisting/gatheringProduction lineEngineering

The invention relates to the technical field of ink bag type filling automatic production lines and discloses an ink automatic bagging mechanism. The ink automatic bagging mechanism comprises a bag feeding guide seat, a bag clamping assembly, a bag opening assembly, a bag sealing assembly and an ink filling and charging device which are sequentially arranged from the bottom to top; a guide grooveis formed in the bag feeding guide seat and is formed in an erecting manner; the bag clamping assembly comprises a pair of movable bases and a pair of bag clamping air cylinders; the pair of movable bases is driven by a pair of bag opening folding and tightening air cylinders; the pair of bag clamping air cylinders is correspondingly connected with the pair of movable bases; the bag opening assembly comprises a pair of bag sucking air cylinders correspondingly placed on the two sides of the outer surface of a bag; the front ends of the bag sucking air cylinders are connected with bag opening sucking discs; and the bag sealing assembly comprises heat-sealing devices which are driven by a pair of bag sealing air cylinders. Bag type automatic filling of ink can be achieved, so that residues after the ink is used are reduced, and the purposes that waste of an ink resource is reduced and the environmental pollution is reduced are achieved.

Owner:江阴市惠法特机械有限公司

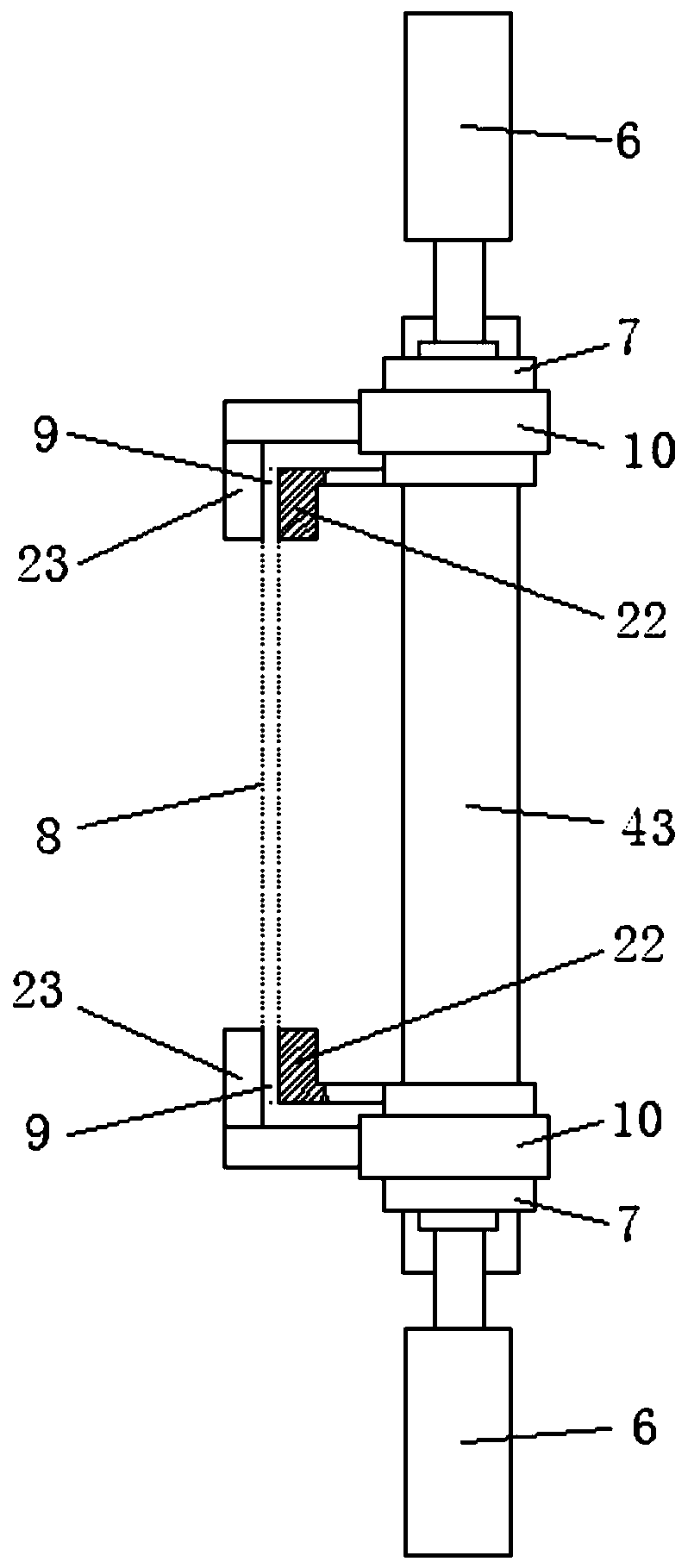

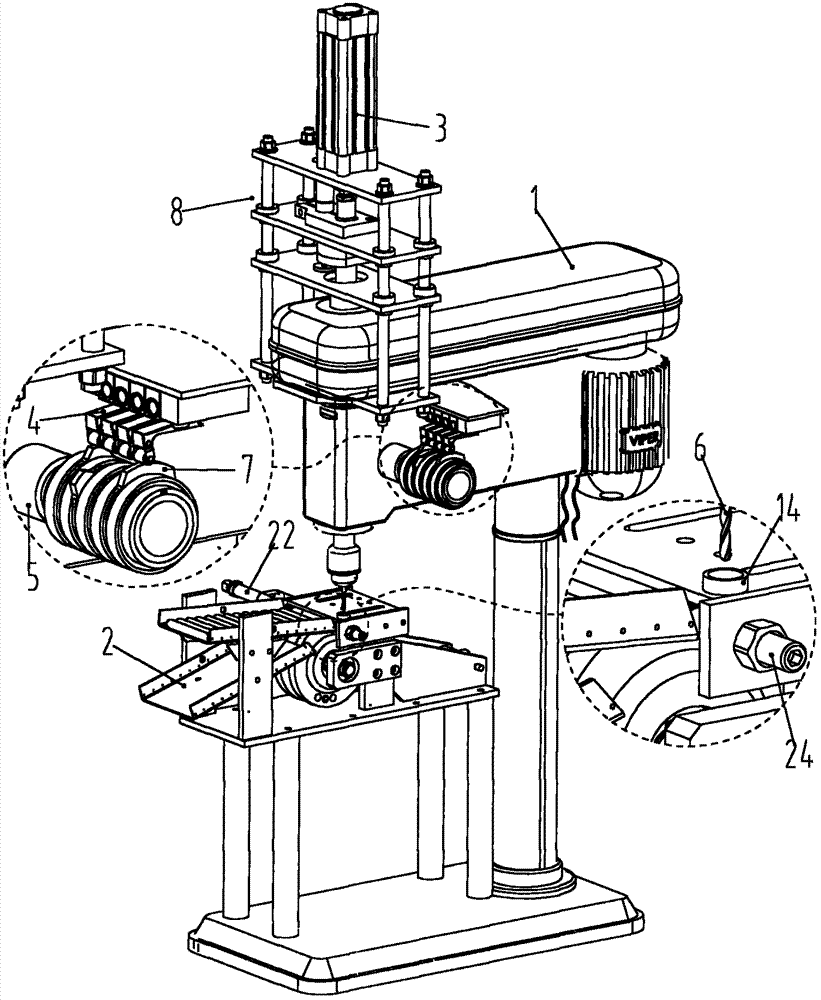

Full-automatic drilling automatic machine

InactiveCN104722793AKeep performance stableLow failure rateWork clamping meansFeeding apparatusManufacturing technologyEngineering

The invention relates to the technical field of the machining and manufacturing technology, in particular to a device for drilling holes in a workpiece. A full-automatic drilling automatic machine comprises a bench mill, an automatic tool and a feed mechanism, wherein the automatic tool is fixedly connected to the bench mill, the feed mechanism is fixedly connected to the bench mill, a mandrel is arranged at the center of a cam, and a groove capable of containing the workpiece is formed in the radial surface of the cam and is of a triangular structure; a baffle is arranged above the cam in the extending direction of a feed hopper. By means of the full-automatic drilling automatic machine, holes are drilled in the workpiece, the bench mill is automatically refitted, the workpiece is machined in a full-automatic and unmanned mode, the automatic feeding, clamping, drilling and discharging are achieved, and the full-automatic drilling automatic machine is compact in structure, small in occupied area, economical and practical.

Owner:WENZHOU POLYTECHNIC

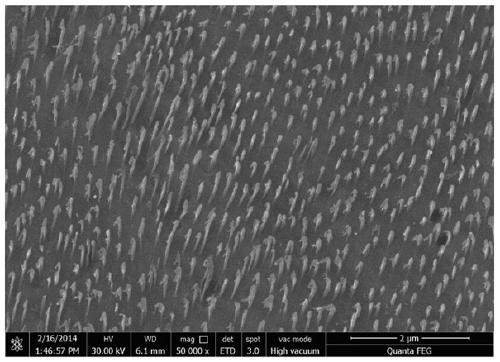

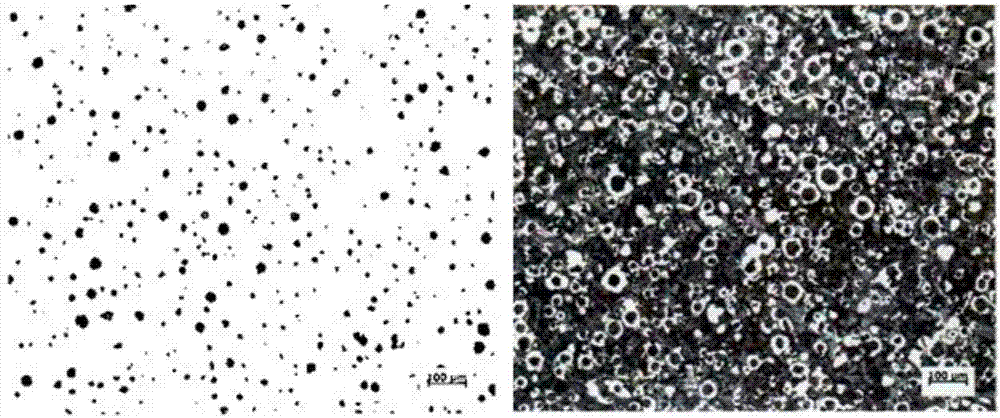

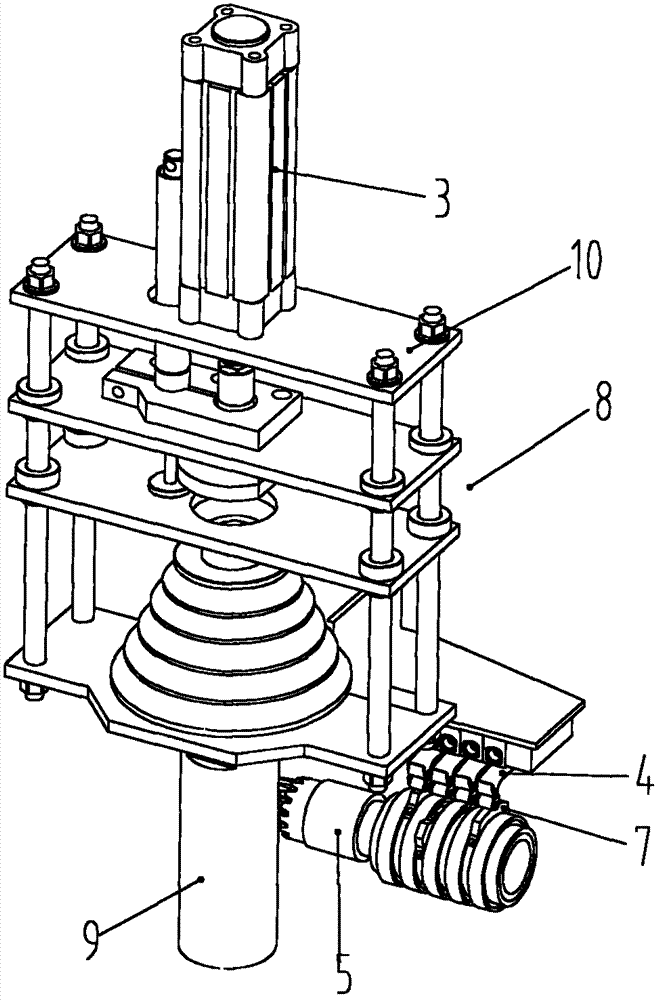

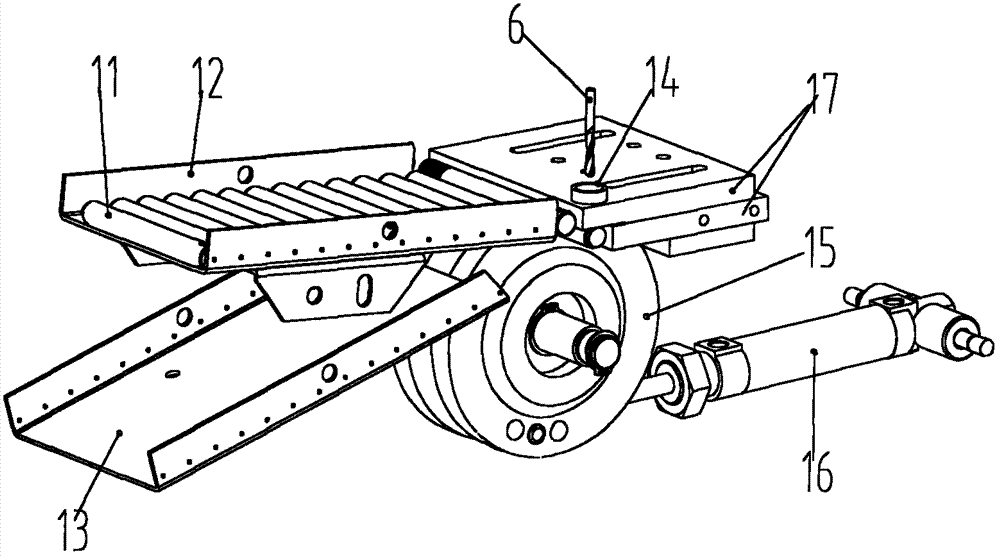

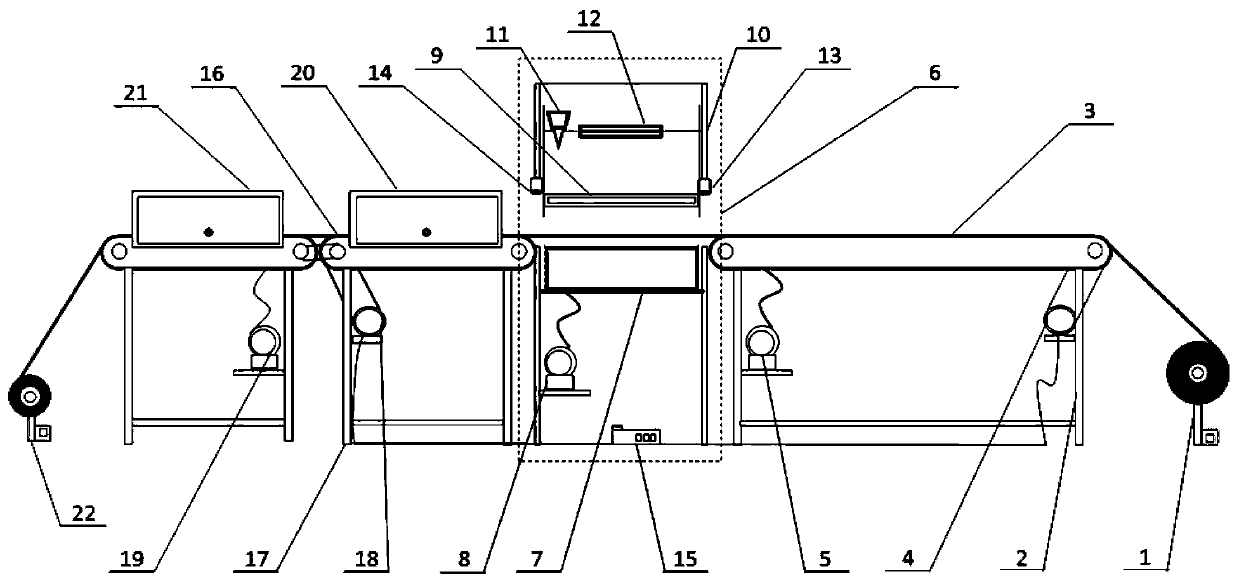

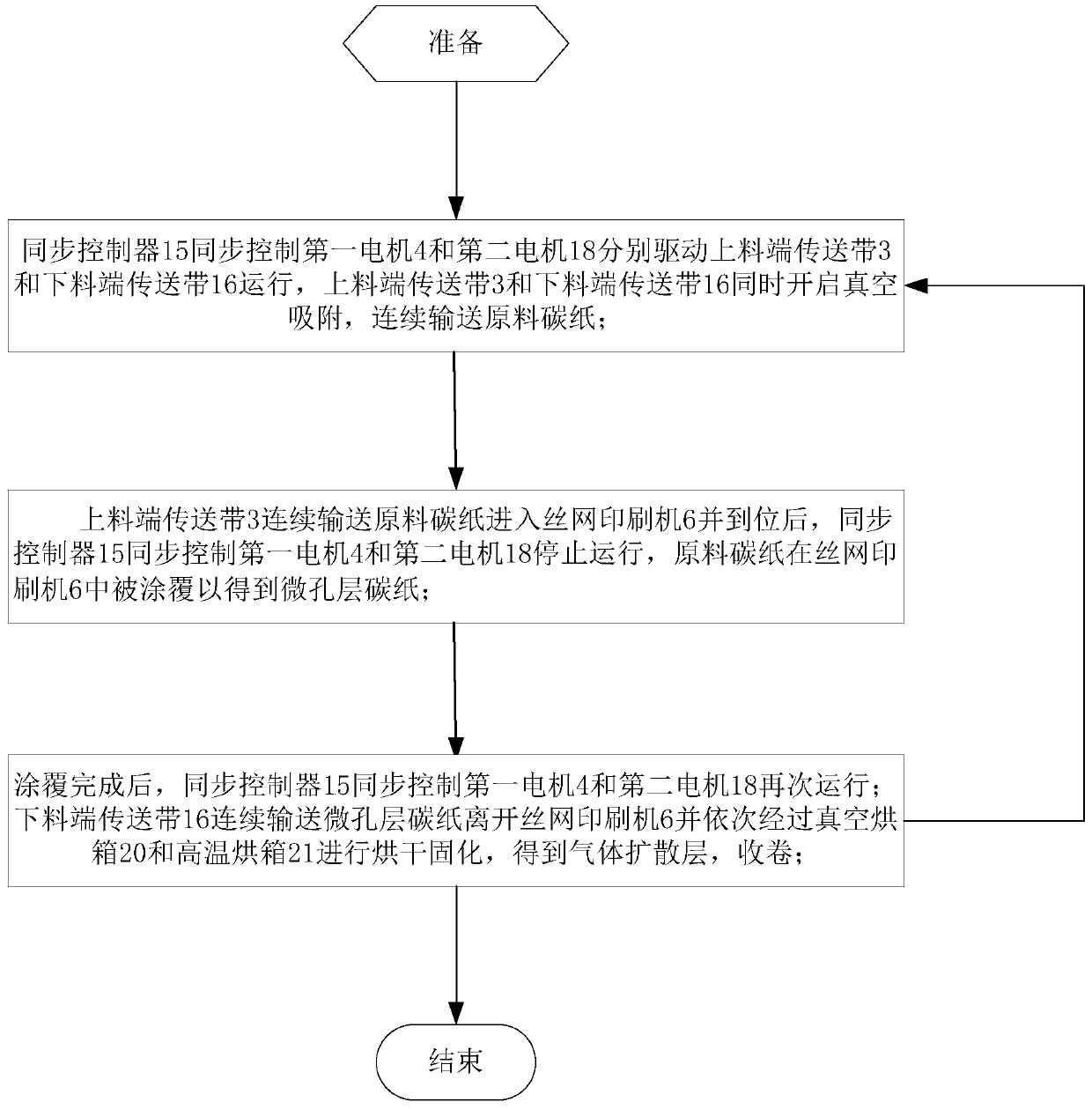

Device and method for continuously preparing gas diffusion layer of fuel cell

ActiveCN111146450AStable and continuous deliveryImprove production taktCell electrodesScreen printersScreen printingFuel cells

The invention belongs to the technical field of fuel cells, and discloses a device and a method for continuously preparing a gas diffusion layer of a fuel cell. The device comprises: a feeding end conveying belt which is driven by a first motor to continuously convey raw material carbon paper from a raw material carbon paper support; a screen printing machine which is used for coating to obtain microporous layer carbon paper; a discharging end conveying belt which is driven by a second motor to operate and continuously convey the microporous layer carbon paper to sequentially pass through thevacuum drying oven and the high-temperature atmosphere drying oven to obtain a gas diffusion layer to roll the gas diffusion layer; a feeding end conveying belt which is connected with a first vacuumpump, wherein the discharging end conveying belt is connected with a second vacuum pump; and a synchronous controller which controls the first motor and the second motor to start and stop synchronously. The feeding end conveying belt and the discharging end conveying belt are connected with the first vacuum pump and the second vacuum pump correspondingly to provide vacuum adsorption, and stable and continuous conveying of raw material carbon paper is guaranteed; the synchronous start and stop of the first motor and the second motor are beneficial to accelerating the production takt and realizing the continuous coating of the raw material carbon paper.

Owner:FAW JIEFANG AUTOMOTIVE CO

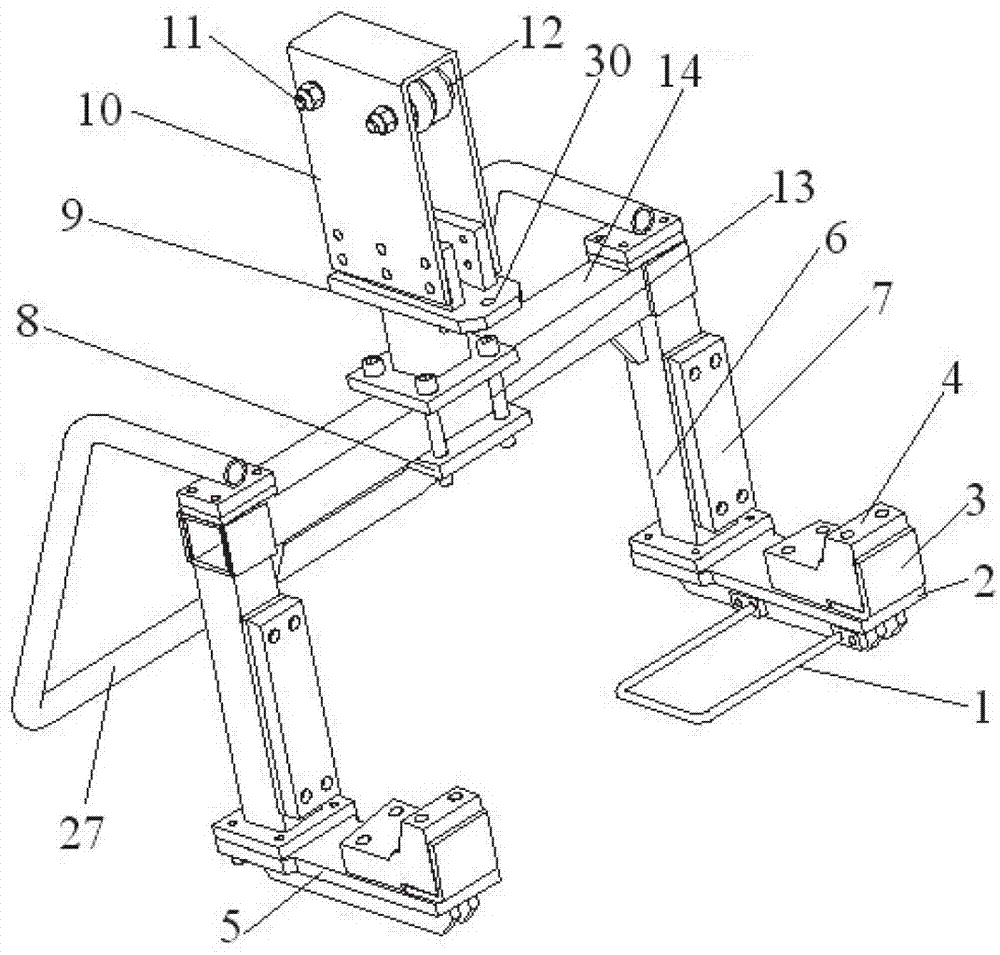

Assembling clamp for automobile front end module

ActiveCN106112458AEasy to useImprove work efficiencyMetal working apparatusEngineeringOperation safety

The invention provides an assembling clamp for an automobile front end module. The assembling clamp comprises a support, a clamping claw, positioning parts and a drive part. The clamping claw is perpendicularly fixed to the first side of the top end of the support and can move along the longitudinal axis of the support. The positioning parts are detachably connected with the bottom end of the support. One end of the drive part is fixedly connected with the support, and the other end of the drive part is fixedly connected with the clamping claw. During use, the positions of the positioning parts are adjusted so as to correspond to the positions of positioning holes in the automobile front end module, then the positioning parts are used for positioning the automobile front end module, the drive part is started to act so that the clamping claw and the positioning parts can be matched to clamp the automobile front end module and move the automobile front end module to the position in front of an automobile body, the positioning parts are aligned with longitudinal beam round holes in the front of the automobile body, and finally the automobile front end module is assembled. Compared with the prior art, only one operator is needed, in addition, the drive part is used for achieving automation, the working efficiency is improved, the production takt is accelerated, meanwhile, manual carrying is not needed, and operation safety coefficients are increased.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

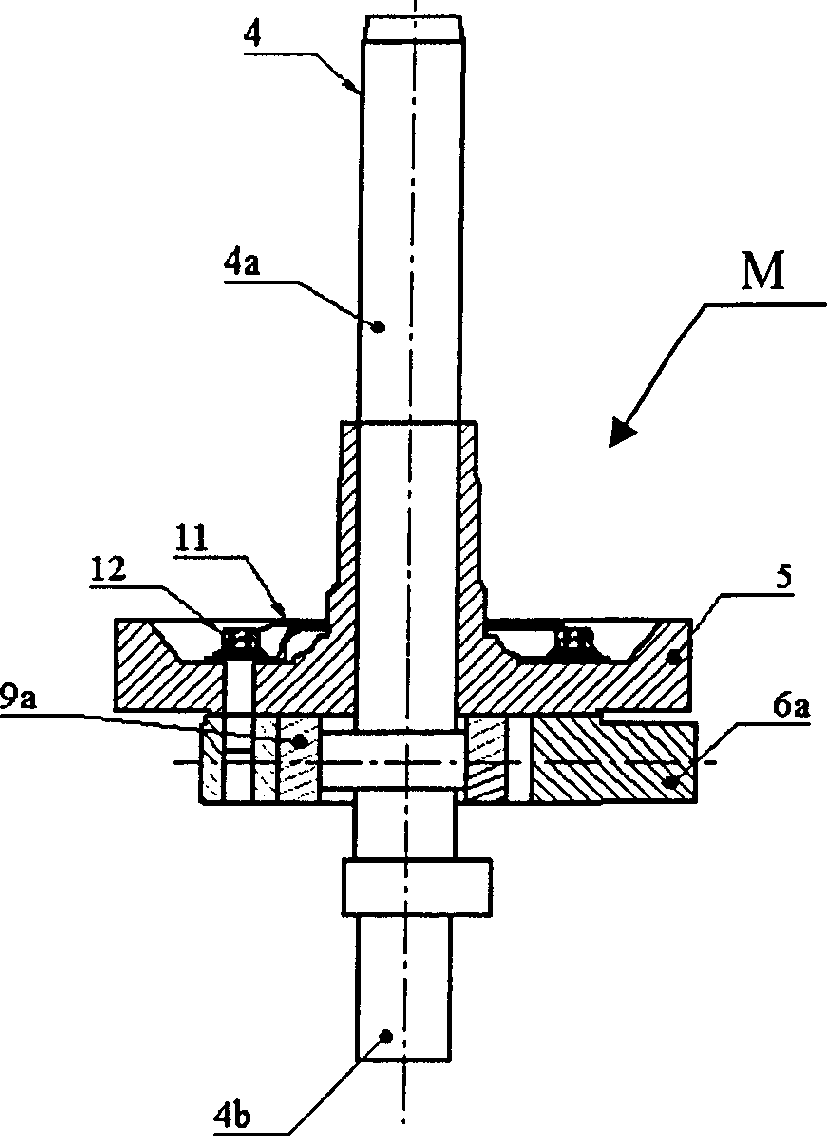

Method for assembling pump body of double-cylinder rotary compressor

InactiveCN101929462ASimple processGuaranteed assembly qualityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMinor axisCrankshaft

The invention provides a method for assembling a pump body of a double-cylinder rotary compressor. The method can enhance the precision of the pump body assembly gap, has the advantages of simple procedure and low cost, can ensure the assembly quality and can meet the requirements for large batch production. The method comprises the following steps: adjustment of upper eccentric gap: adjusting the difference, namely the value of the upper eccentric gap between the maximum distance from the outer diameter of an upper roller to the outer diameter at the opposite side of the major axis of the crank shaft and the distance from the inner circle of the upper cylinder to the inner circle of the upper flange at the opposite side, so that the value of the upper eccentric gap is within the preset range of 10-50 mu m; adjustment of lower eccentric gap: adjusting the difference, namely the value of the lower eccentric gap between the maximum distance from the outer diameter of the lower roller to the outer diameter at the same side of the minor axis of the crank shaft and the distance from the inner circle of the lower cylinder to the outer circle at the same side of the minor axis of the crank shaft, so that the value of the lower eccentric gap is within the preset range of 10-50 mu m; and concentric assembly: concentrically assembling the upper flange and the lower flange.

Owner:GREE ELECTRIC APPLIANCES INC

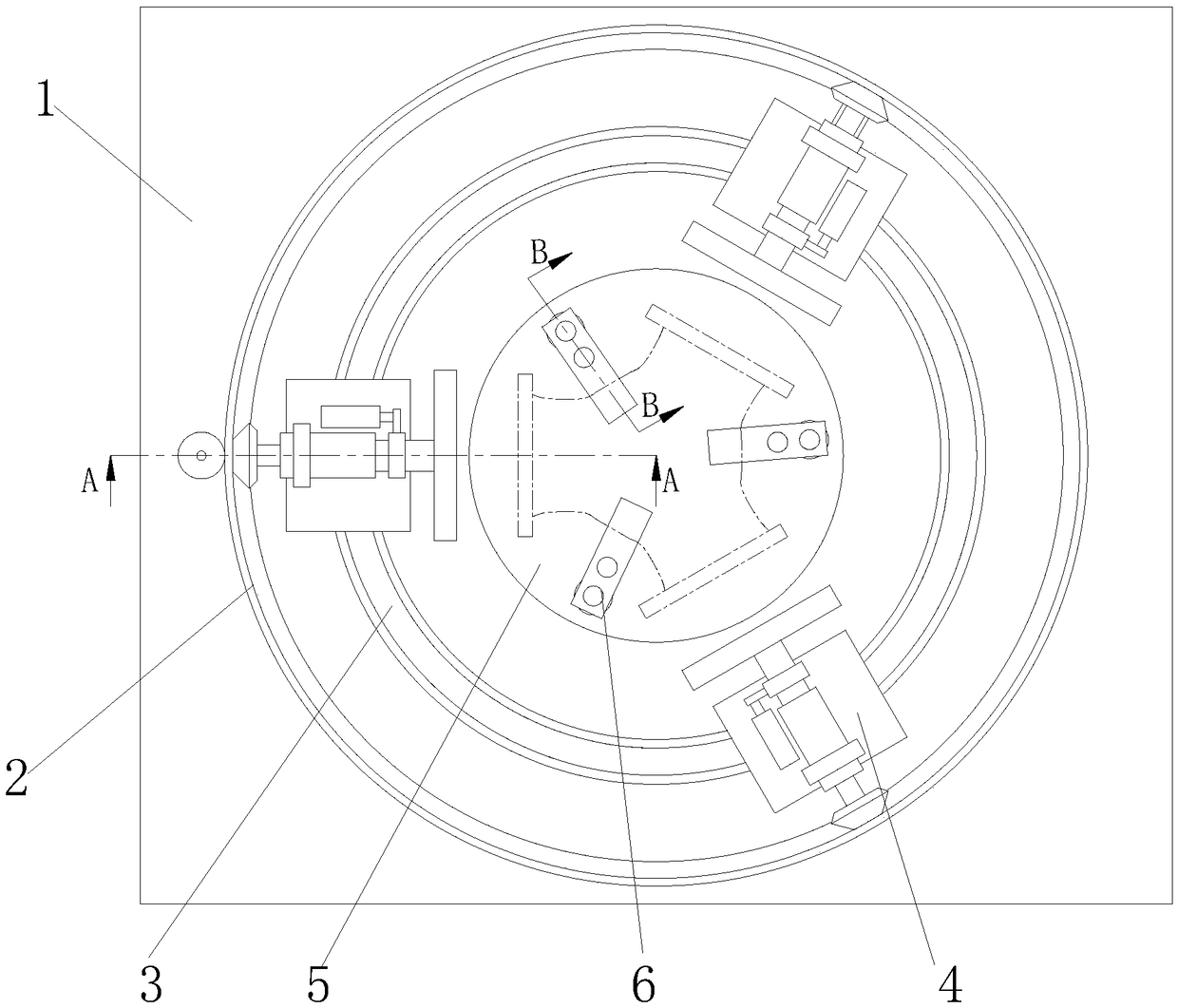

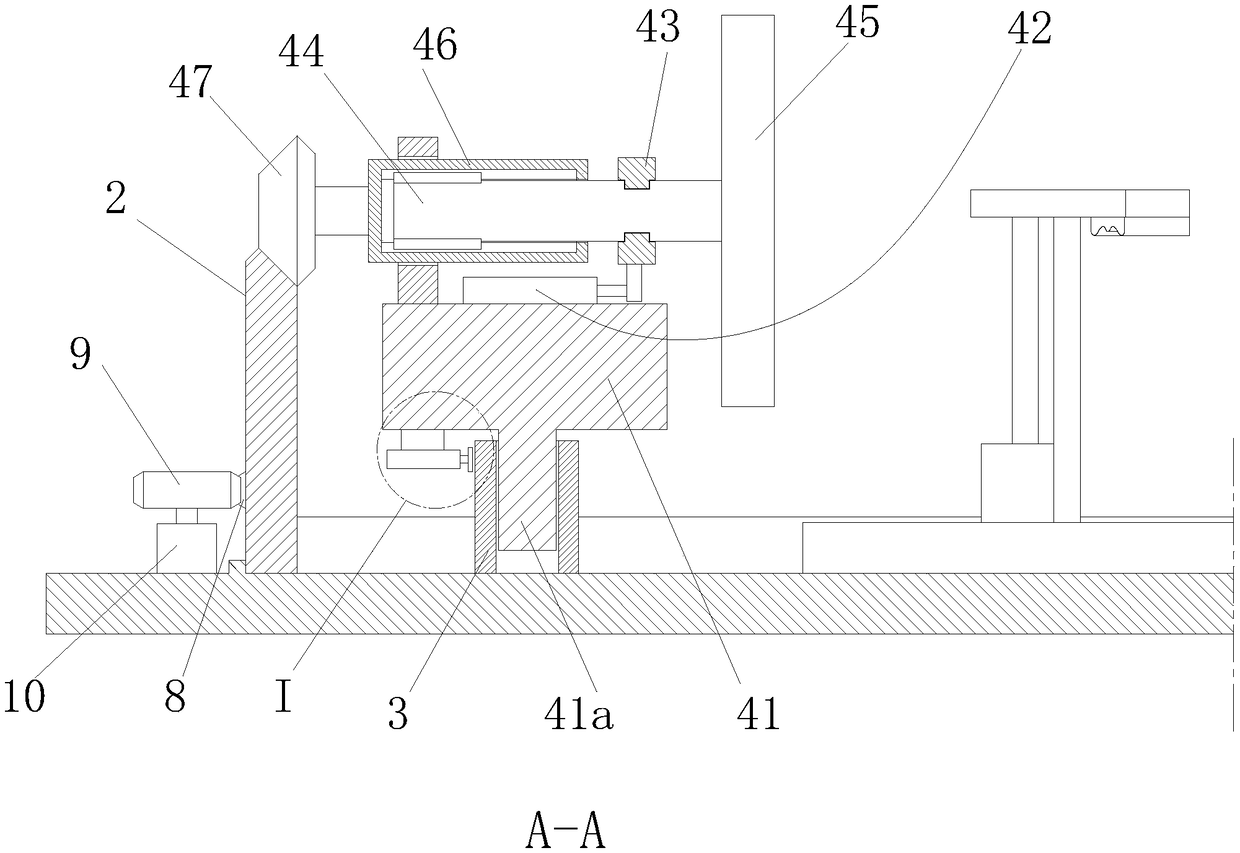

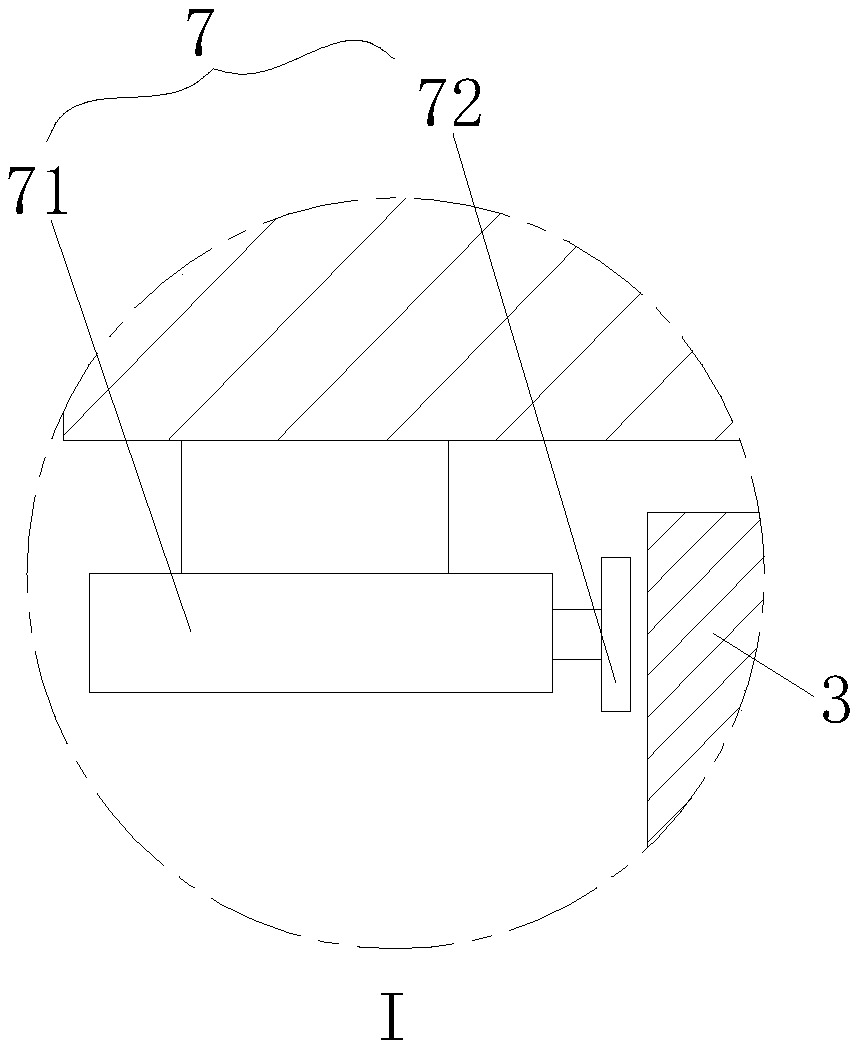

Multiple workpiece processing clamp

InactiveCN105108536ACNC adjustment linkage indexing is accurateSave hands-on timeWork clamping meansExpansion mandrelsNumerical controlGear wheel

The present invention discloses a multiple workpiece processing clamp. The processing clamp comprises a clamp base plate, positioning clamping cylinders A, rotatable positioning and clamping mechanisms, positioning clamping cylinders B, drive gear racks, a driven gear rack and a dividing apparatus, wherein one end of an upper surface of the clamp base plate is connected with a support plate, the upper surface of the clamp base plate is connected with auxiliary support plates through screws and is provided with a housing internally provided with the rotatable positioning and clamping mechanisms, the positioning clamping cylinders B are disposed at a lower part of one end of the housing, the rotatable positioning and clamping mechanisms are internally provided with expanding core shafts, one end of each expanding core shaft is provided with a gear, the drive gear racks and the drive gear rack are connected, and the dividing apparatus is connected and arranged on the gear of the drive gear rack. Four workpieces are processed at the same time, scale division is accurate through numerical control linkage, manual operating time is saved, production speed is raised, and the production efficiency is raised by four times.

Owner:吉林博仁科技有限责任公司

Rough polishing device for edge of motor end cover cake

InactiveCN107283250AEasy to fixAvoid strainEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses a rough polishing device for the edge of a motor end cover cake. The rough polishing device comprises a device body. A base is arranged at the bottom of the device body. A fixing sleeve is arranged above the base. A containing groove is formed in the base, and a motor is arranged on the inner side of the containing groove. The device body is provided with a rotating rod, and a bottom plate is arranged on the top of the rotating rod. A connecting seat is arranged at the middle position of the bottom plate, and a carrying plate is arranged above the bottom plate. A permanent magnet is arranged on the upper end face of the carrying plate, a rotating die is arranged on the device body, and a grinding wheel is arranged on the inner wall of the rotating die. The rough polishing device is simple in structure and convenient to use, preliminary polishing is conducted on the edge of the cake under the effect of the device body, the phenomenon that burr trimmings exist, and consequently the hands of operators are pulled to be injured is avoided, and the safety performance is improved; and in addition, fixing of the cake is very convenient when the device body works, no special fastening equipment needs to be used, trouble operation is reduced, the work efficiency is effectively improved, the product takt is accelerated, and practicability is high.

Owner:侯飞燕

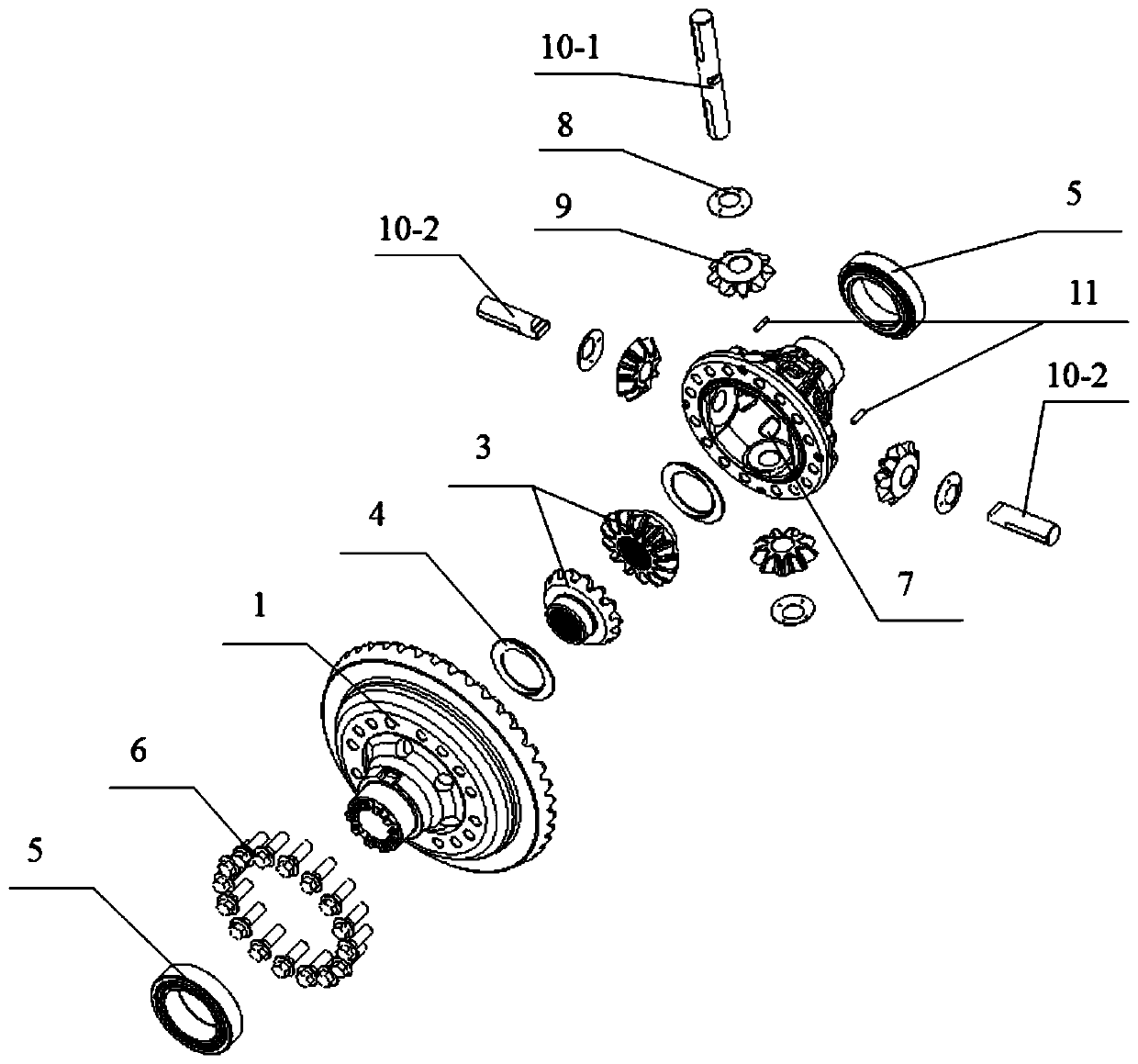

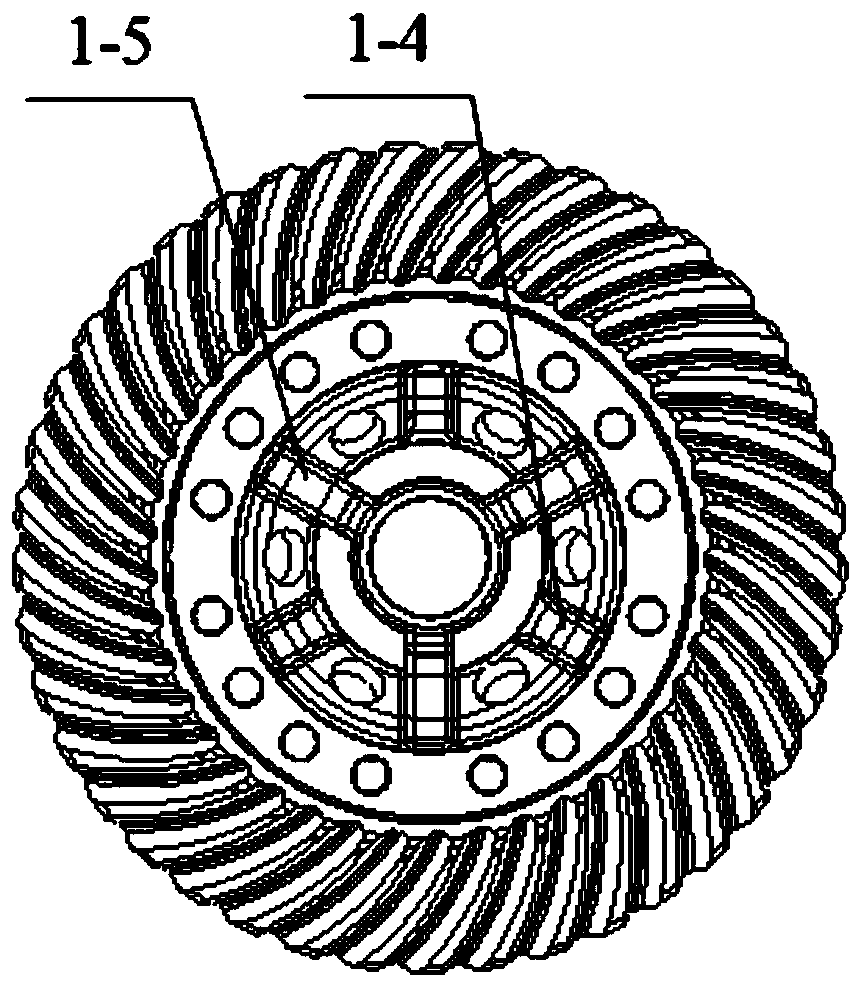

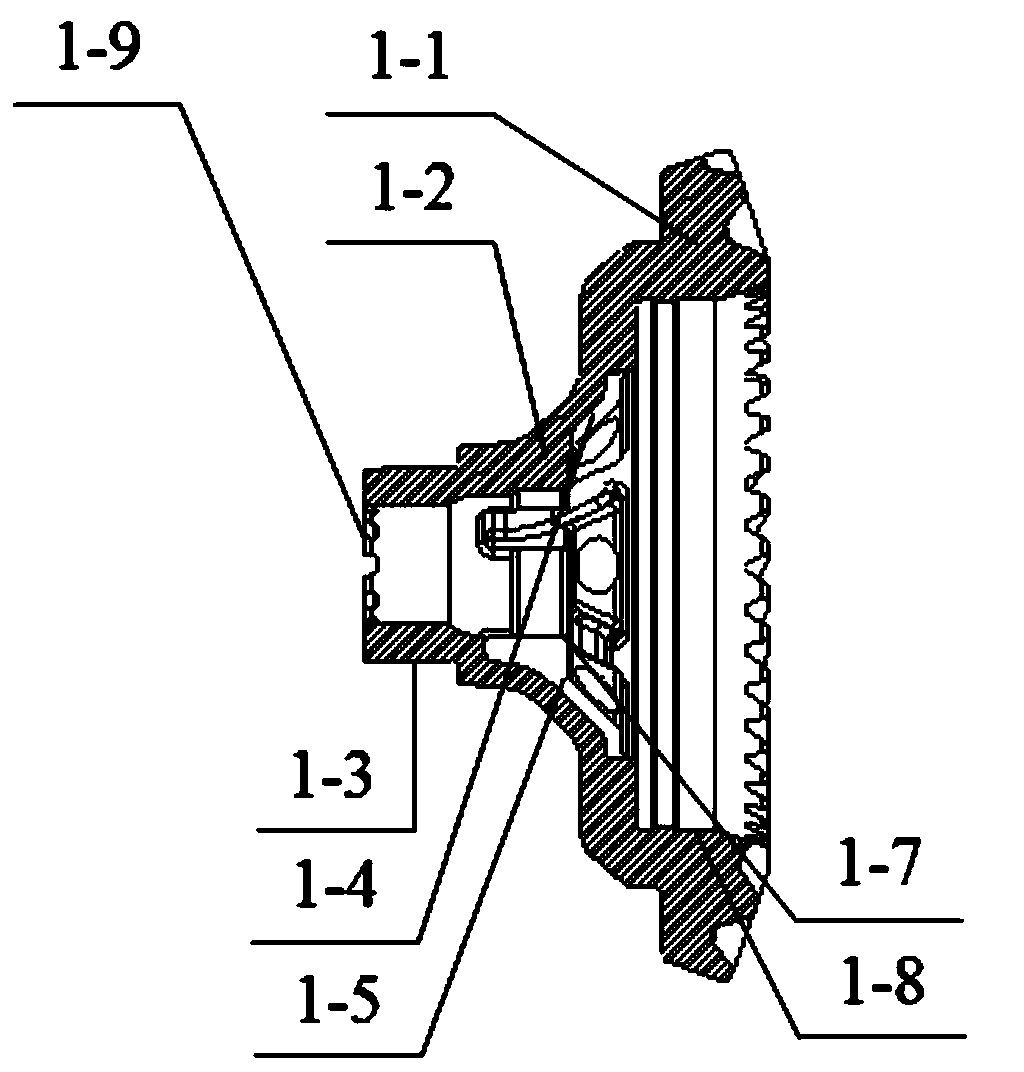

Novel commercial automobile wheel differential mechanism assembly and assembling method

PendingCN109973611AGuaranteed to workImprove organizational efficiencyDifferential gearingsCar manufacturingEngineering

The invention discloses a novel commercial automobile wheel differential mechanism assembly and an assembling method, and belongs to the technical field of automobile manufacturing. According to the wheel differential mechanism assembly and the assembling method, an integrated structure of a driven bevel gear and a left shell of the differential mechanism is adopted, an anti-rotation cross shaft assembly is integrated on a right shell of the differential mechanism, and a good lubricating system is arranged, so that the phenomena that the driven bevel gear is broken during connecting bolts, a driving bevel gear and the driven bevel gear are in collision with each other, and a spherical surface of a planetary gear of the differential mechanism is seriously worn can be eliminated; connectingparts are also reduced, processing and assembly processes are convenient, the production takt is improved, and the transmission efficiency and the reliability of the product are improved; compared with an original structure, the weight is reduced by 7.9%, and the cost is reduced by about 6%; and compared with an wheel differential mechanism assembly with different speed ratios, the right shell ofthe differential mechanism can be commonly used and interchanged, so that the organization production is facilitated, the interchangeability of the product and the organization efficiency of spare parts are also improved, and therefore the purposes of light weight, economy and refined production are achieved.

Owner:FAW JIEFANG AUTOMOTIVE CO

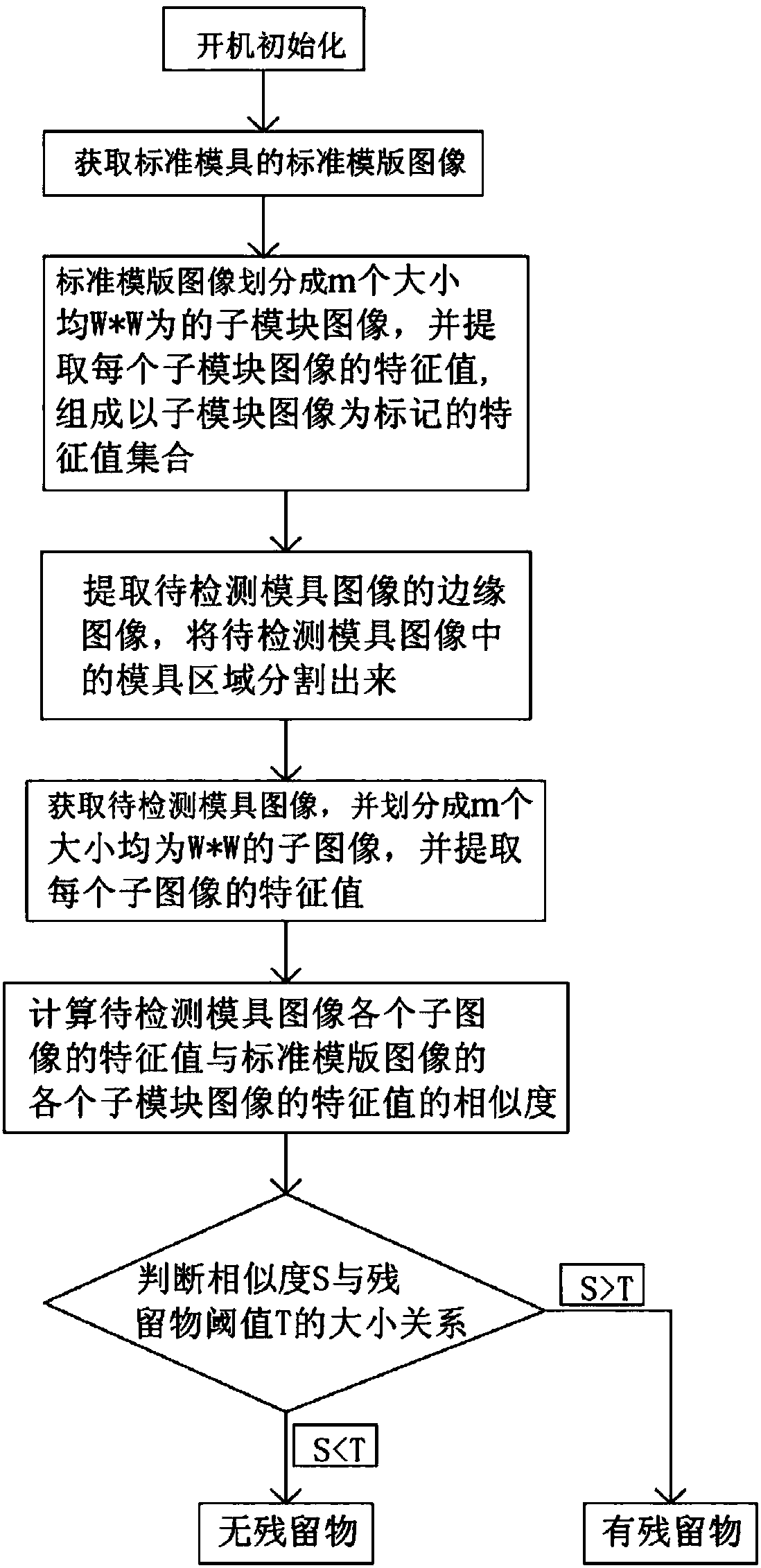

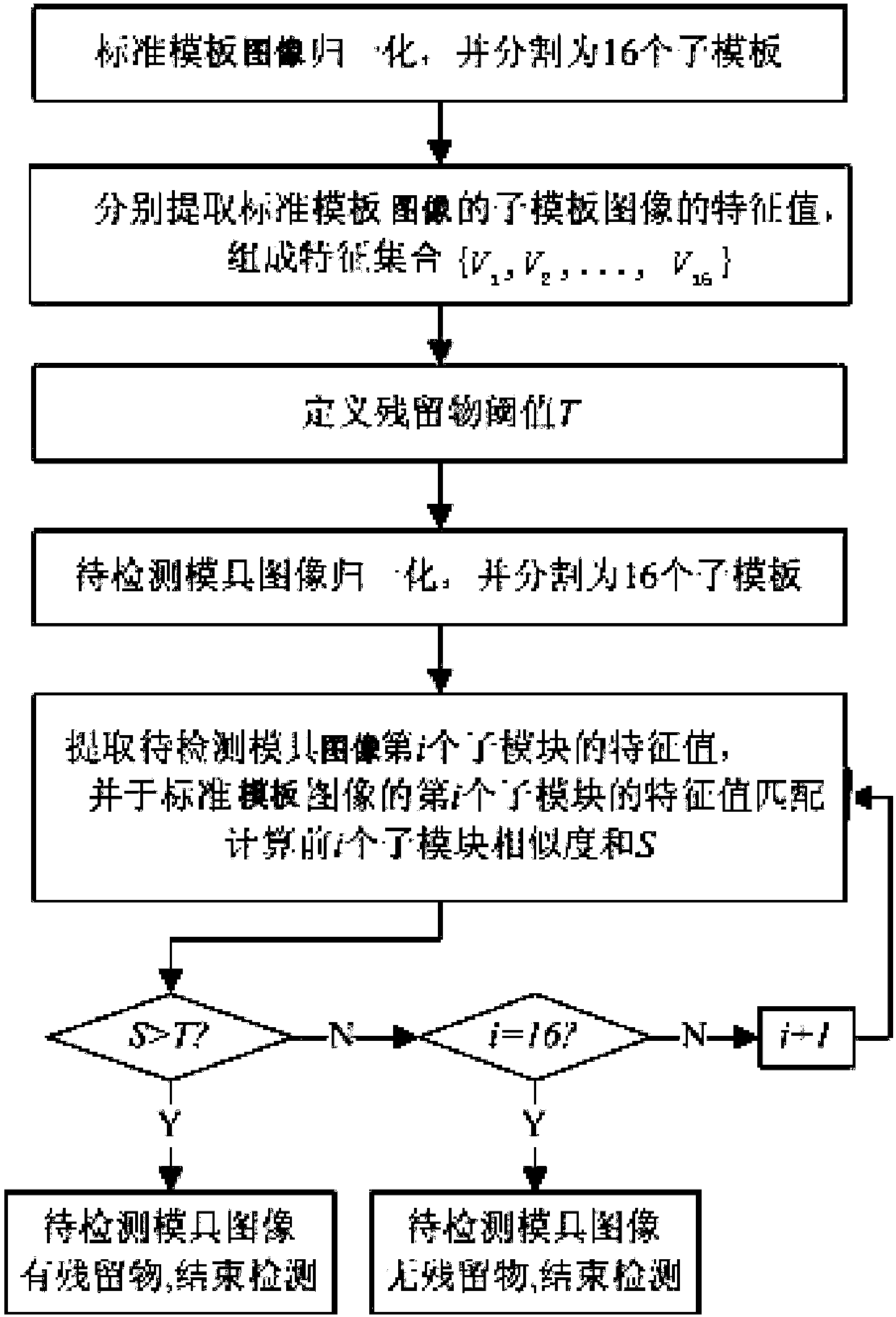

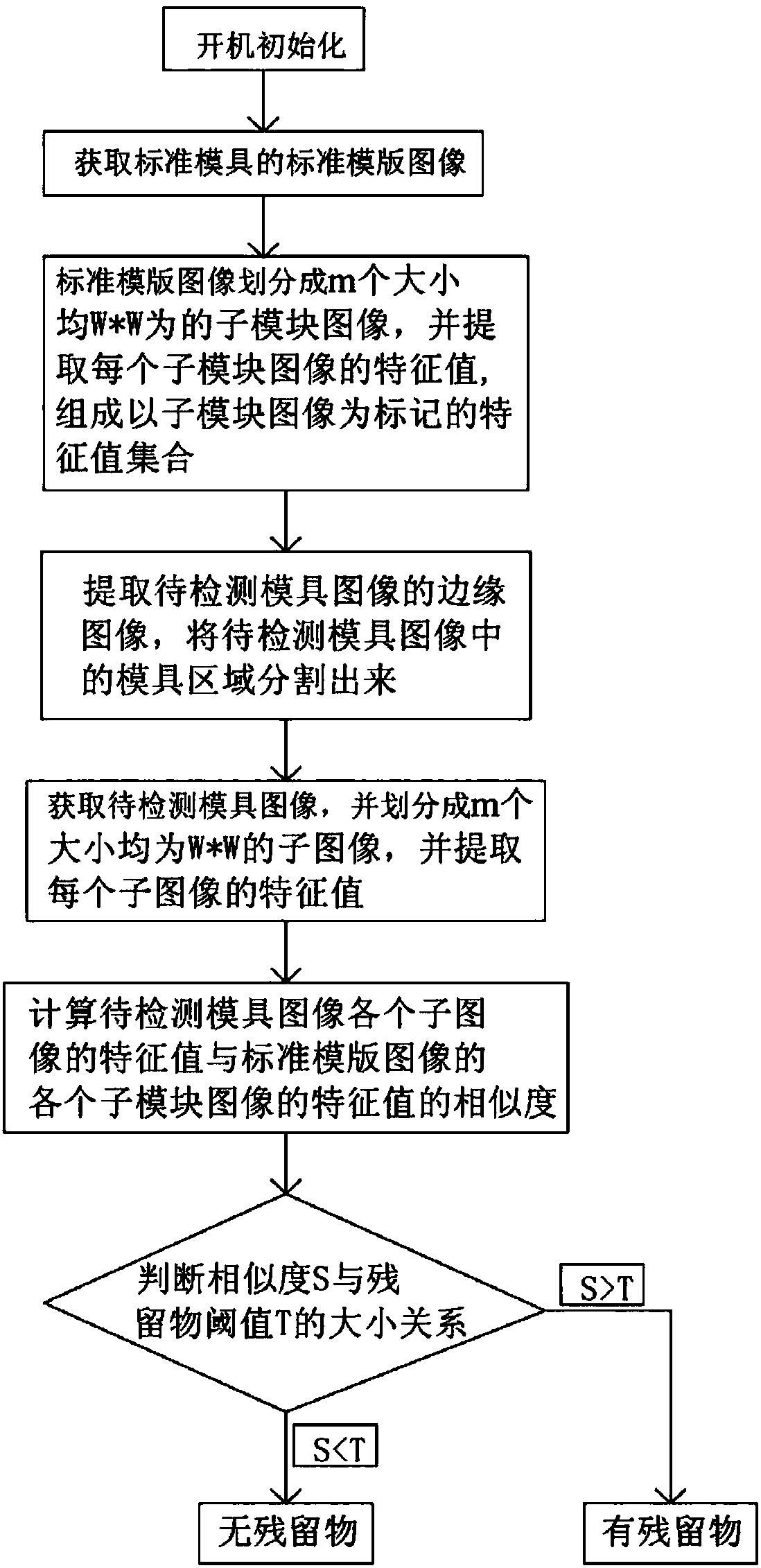

Mold detection method for electric injection molding machine

InactiveCN106778779AQuick checkAccurate detectionCharacter and pattern recognitionImage segmentationComputer vision

The invention discloses a mold detection method for an electric injection molding machine. The method comprises the steps of obtaining a residue-free rectangular standard mold image as a standard template image, removing a background region of the standard template image to obtain a mold region, normalizing the size of the standard template image to LXL, segmenting the standard template image into m sub-template images with the sizes of WXW, and extracting an eigenvalue of each sub-template image; collecting a to-be-detected mold image after mold opening, extracting an edge image of the to-be-detected mold image, and segmenting out the mold region of the image; normalizing the to-be-detected mold image to LXL, segmenting the to-be-detected mold image into m sub-images with the sizes of WXW, and extracting an eigenvalue of each sub-image; and comparing the eigenvalues of the sub-template images of the standard template image with the eigenvalues of the sub-images of the to-be-detected mold image to obtain a status of residues of the to-be-detected mold image. According to the method, the status of the residues in a mold can be quickly and accurately detected, so that the detection efficiency is improved and the automation degree of the mold processing industry is increased.

Owner:GUANGDONG INST OF INTELLIGENT MFG

Quick zinc sulfate electroplating process

A quick zinc sulfate electroplating process comprises the following steps: firstly, removing oil on a work piece, washing the workpiece by water, acid and water respectively, then soaking the workpiece into electroplating liquid in a galvanizing bath, taking out the work piece, washing the workpiece by water, then passivating the workpiece, washing the workpiece by water again, and drying the workpiece with hot wind. Content of chemical materials in each liter of the electroplating liquid is as follows: 80 to 150 grams of zinc sulfate, 120 to 180 grams of potassium chloride, 25 to 30 grams of buffer, 1 to 2 grams of additive and 20 to 25 grams of lustre-coating agent. The workpiece is soaked in the electroplating liquid for 10 to 15 minutes at a temperature of between 5 and 60 DEG C, and the pH value of the electroplating liquid is 4 to 5. The technical conditions of soaking the workpiece in the electroplating liquid in order to galvanize are as follows: the current density is 2 to 5A / dm; the cathode motion speed is 15 to 20 times per minute. By using the process to galvanize the workpiece, the deposition velocity is quick; dispersive power is good; corrosion resistance is strong; electroplating time is reduced by 60 percent; processing cost is reduced by 30 percent; production efficiency is high; and economic benefit is good.

Owner:梁新中

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com