Novel commercial automobile wheel differential mechanism assembly and assembling method

A differential and assembly technology, applied in differential transmissions, transmissions, belts/chains/gears, etc., can solve the problems of broken feedback connecting bolts, complicated processing and assembly processes, affecting production rhythms, etc., to increase transmission. Efficiency and reliability, eliminating the breakage of connecting bolts, beneficial to the production organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] A new commercial inter-wheel differential assembly according to the present invention will be further described below in conjunction with the accompanying drawings.

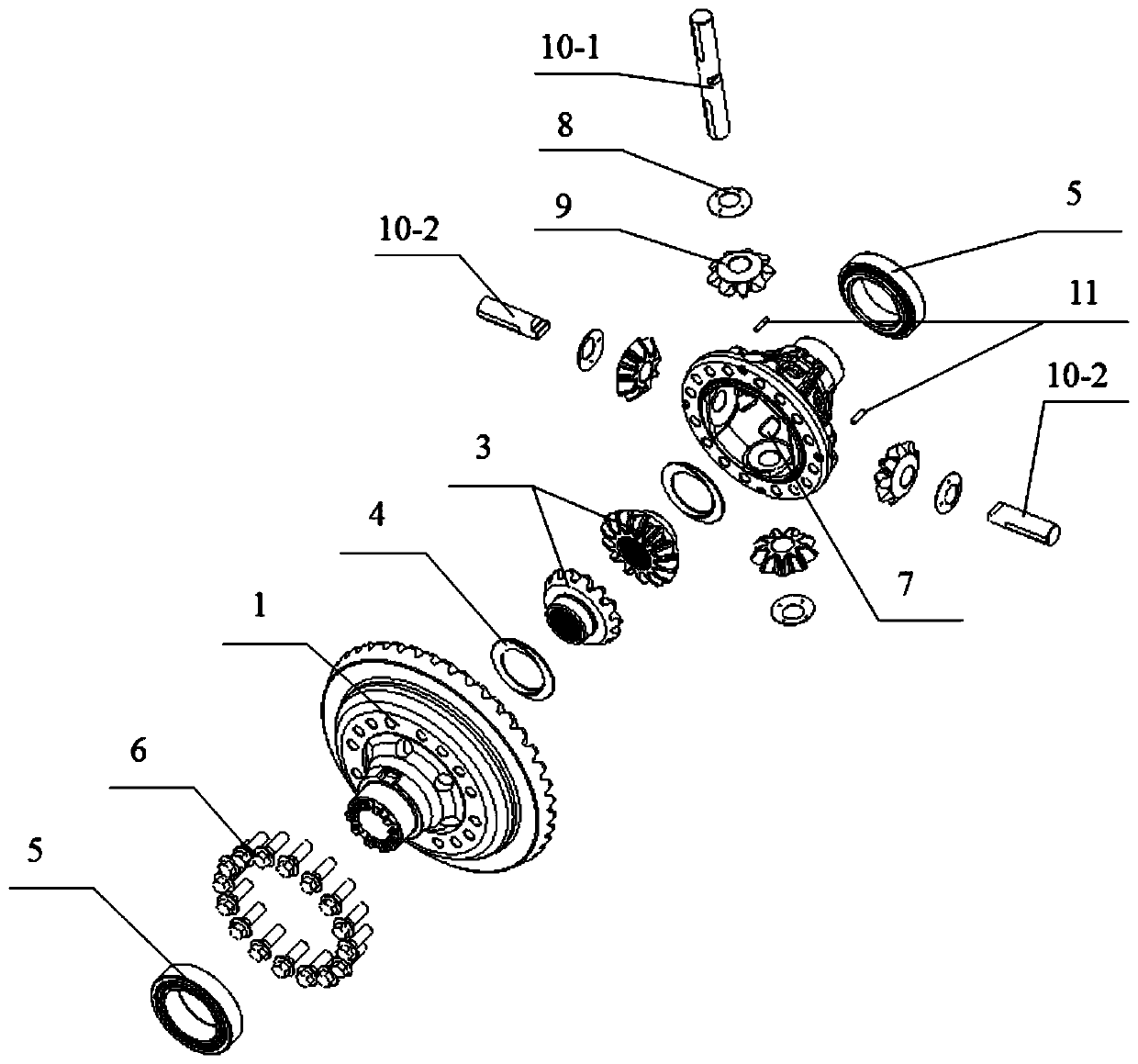

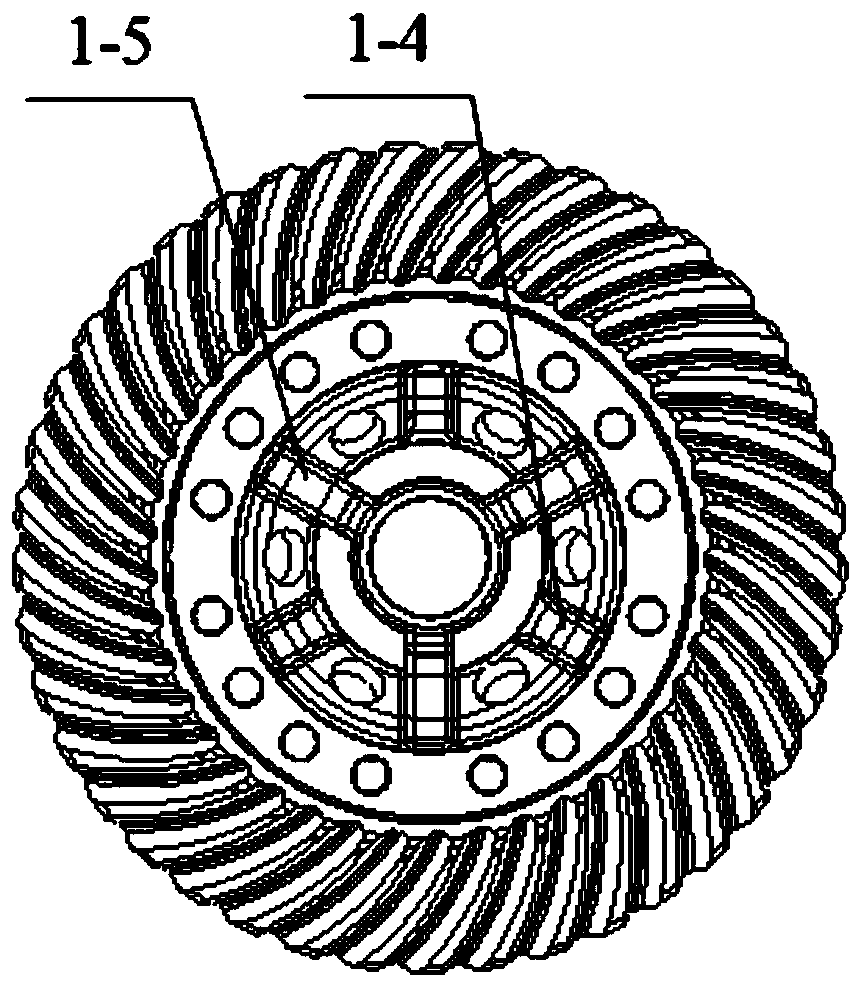

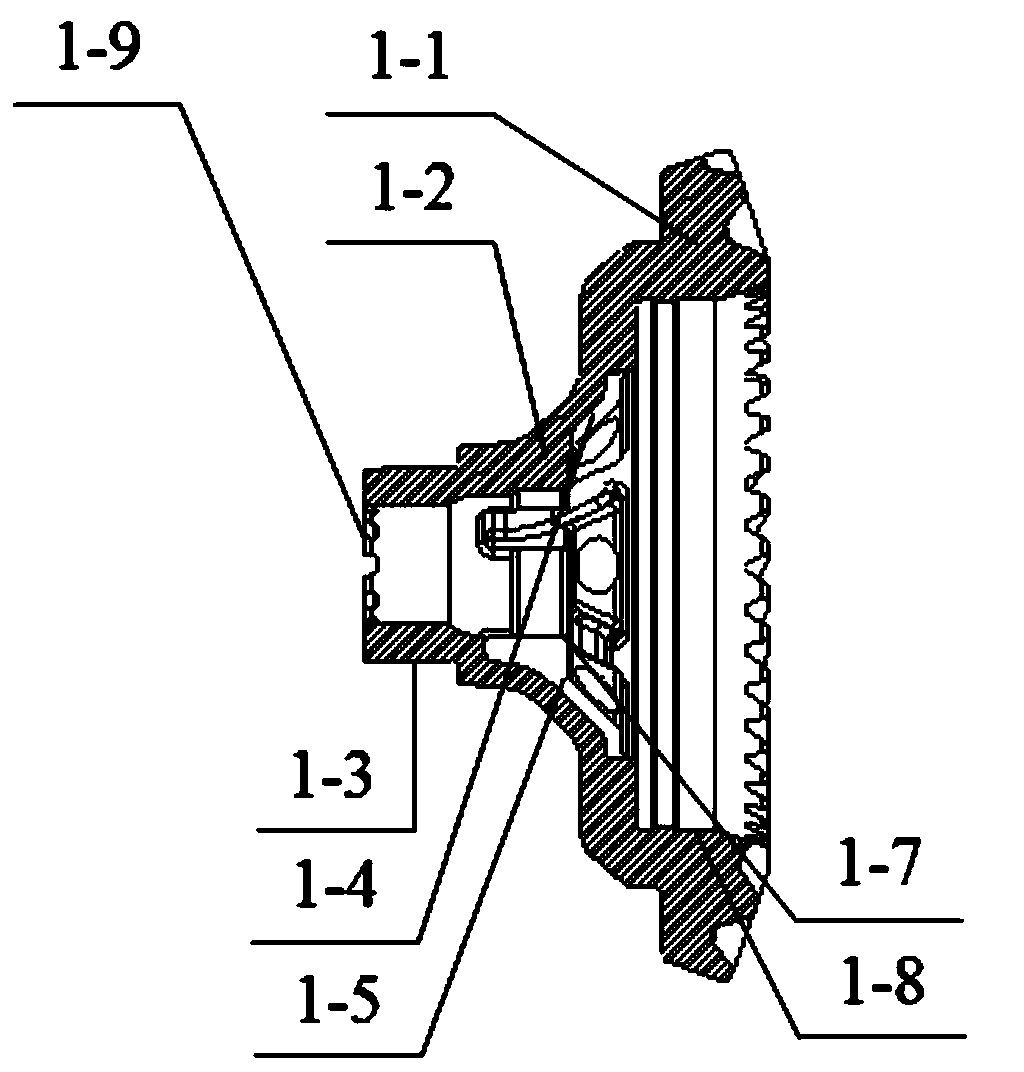

[0050] as attached figure 1 , 3a , 3b and instructions attached Figure 9 As shown, a novel commercial inter-wheel differential assembly according to the present invention includes an integral driven bevel gear 1, a differential right housing assembly 2 and a differential bearing 5; the differential right Shell assembly 2 includes side gear 3, side gear gasket 4, differential right case 7, anti-rotation planetary gear gasket 8, planetary gear 9, anti-rotation cross shaft assembly 10 and elastic cylindrical pin 11; The left end of the one-piece driven bevel gear 1 is installed with a differential bearing 5 along the outside of the diameter direction; the right housing assembly 2 of the differential is arranged on the right side of the one-piece driven bevel gear 1; The right end of the differential righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com