Patents

Literature

329results about How to "Improve bagging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

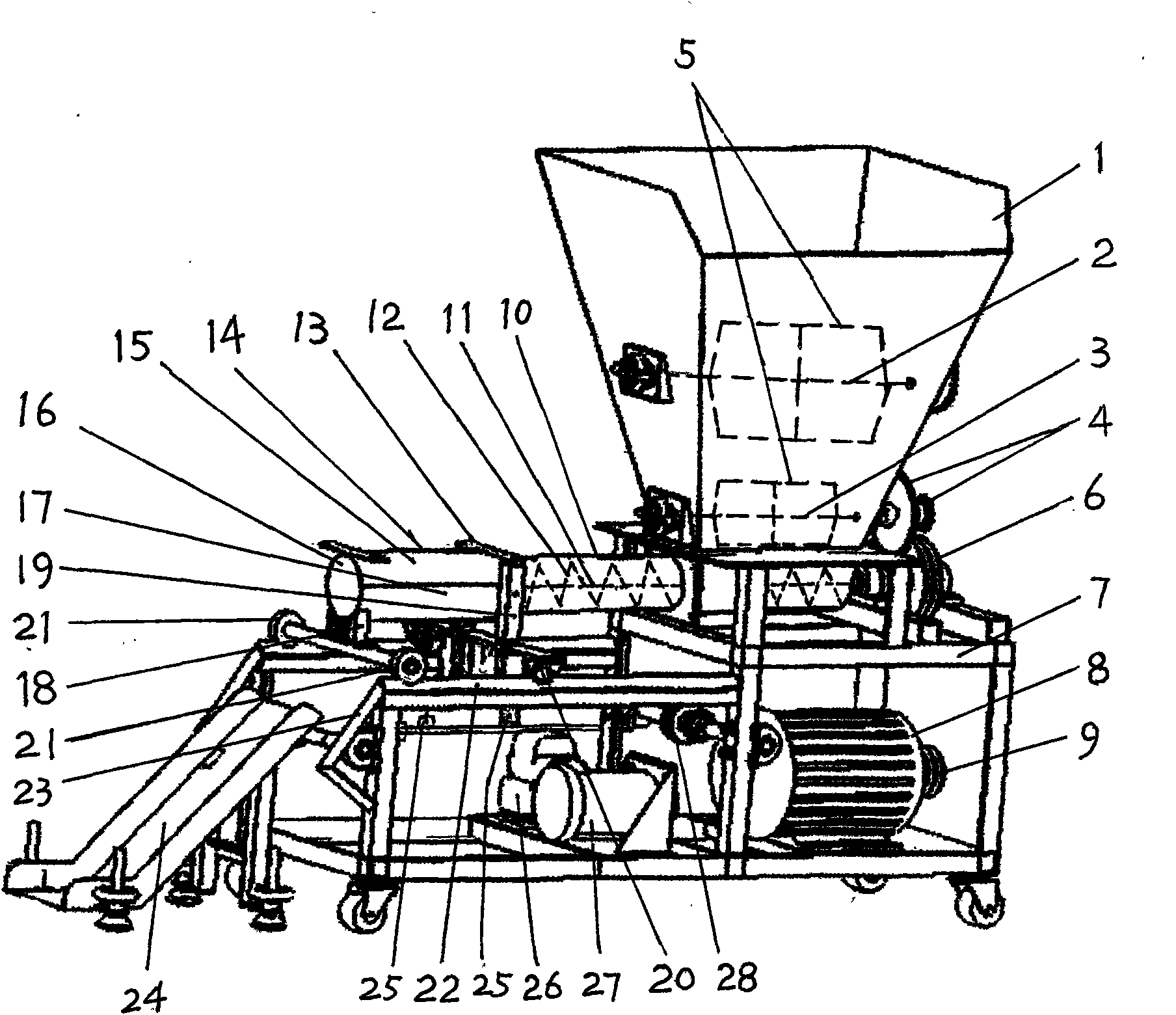

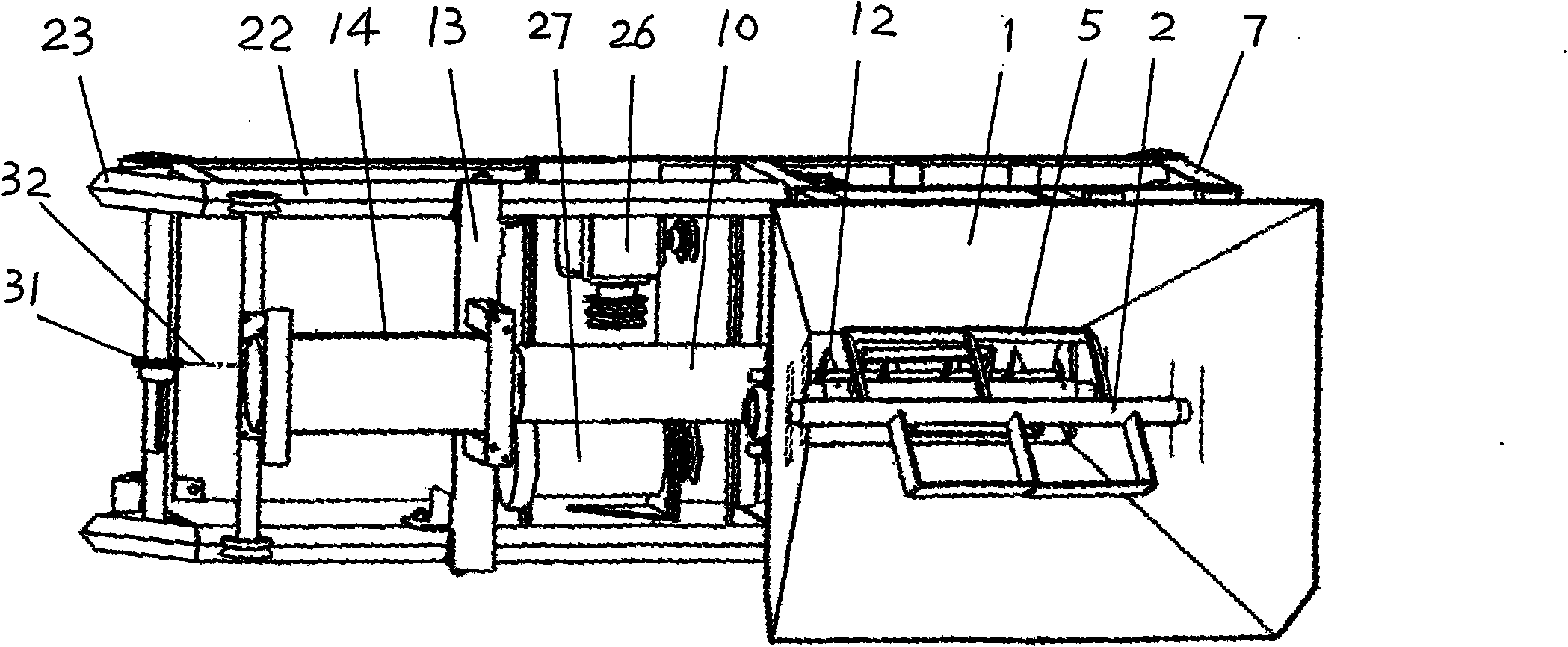

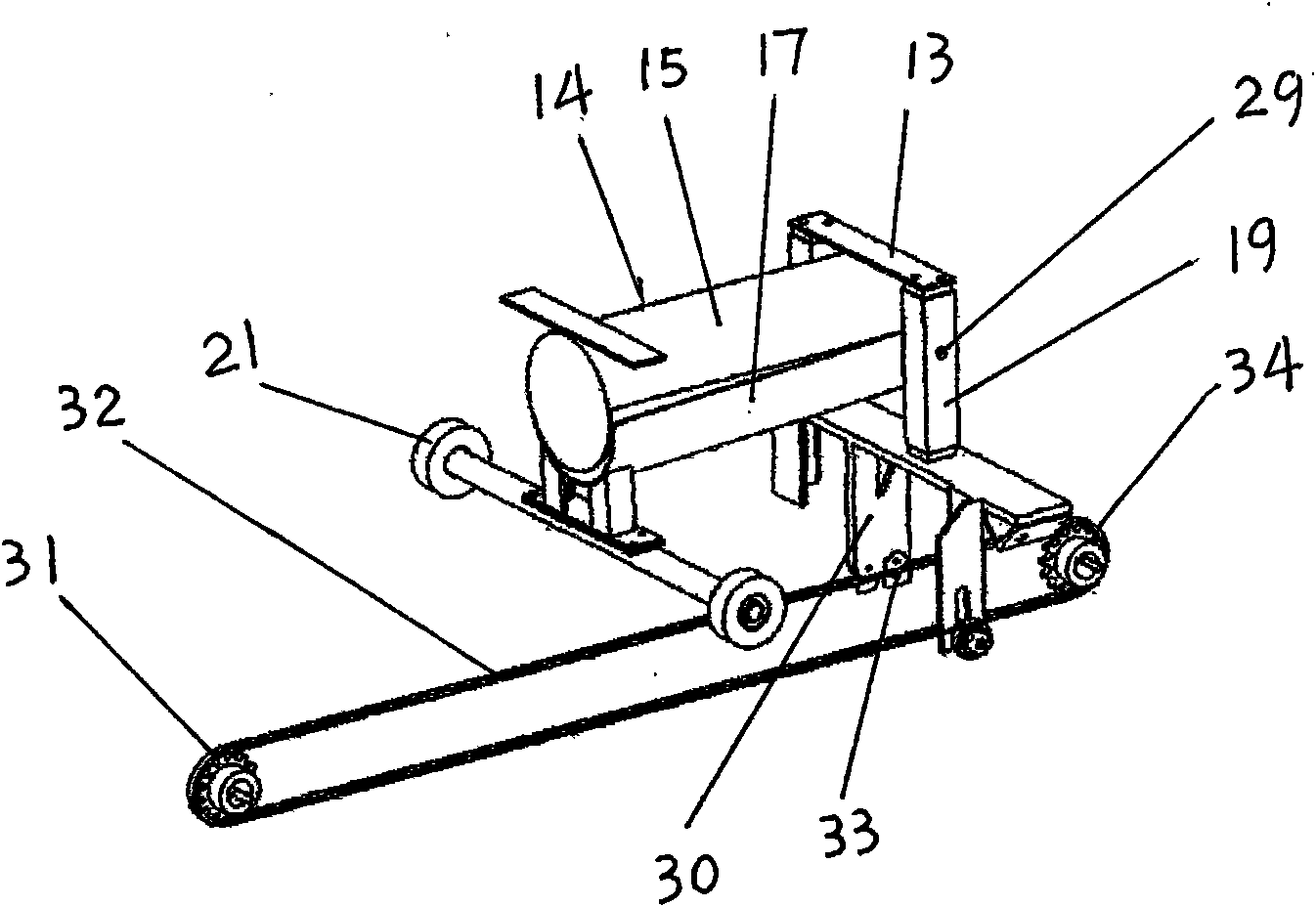

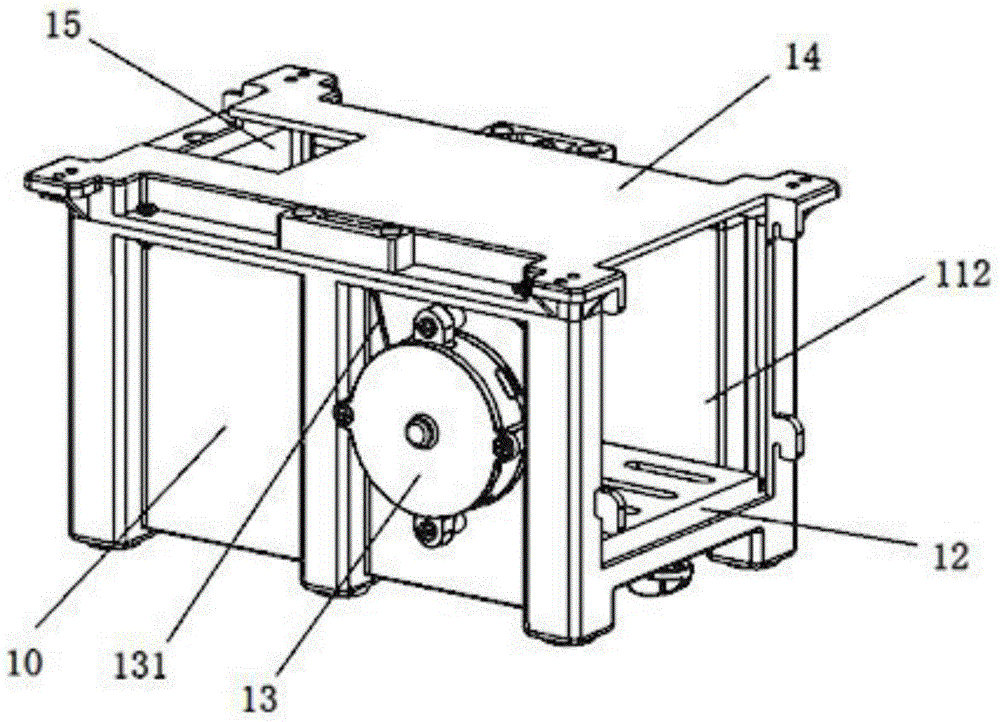

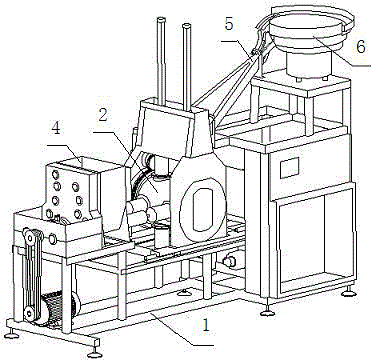

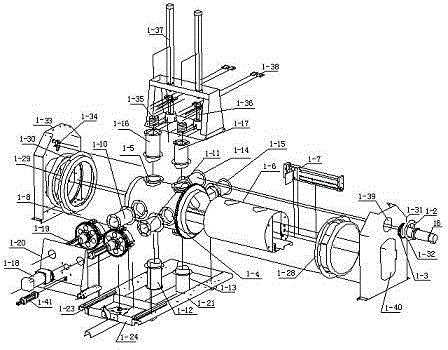

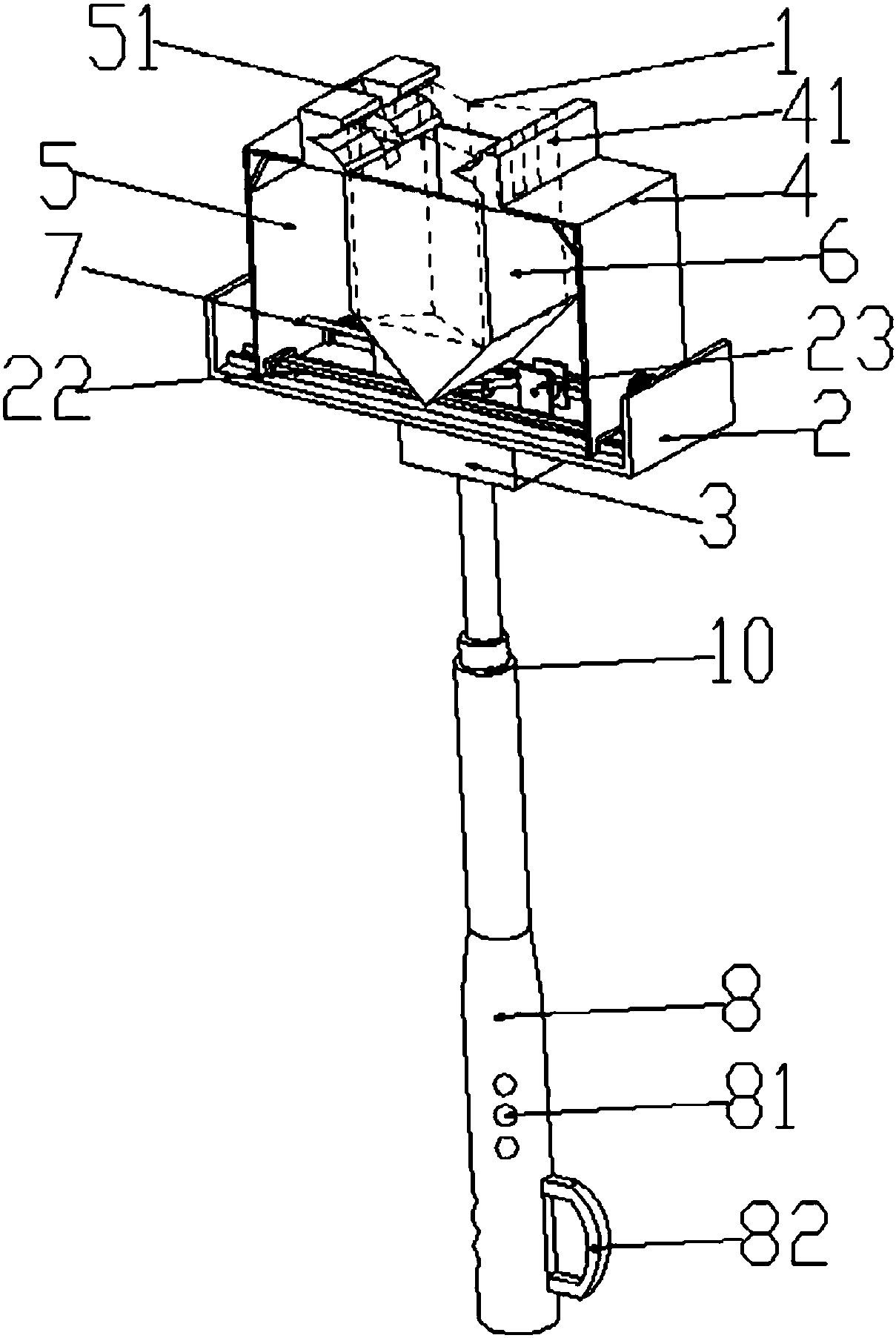

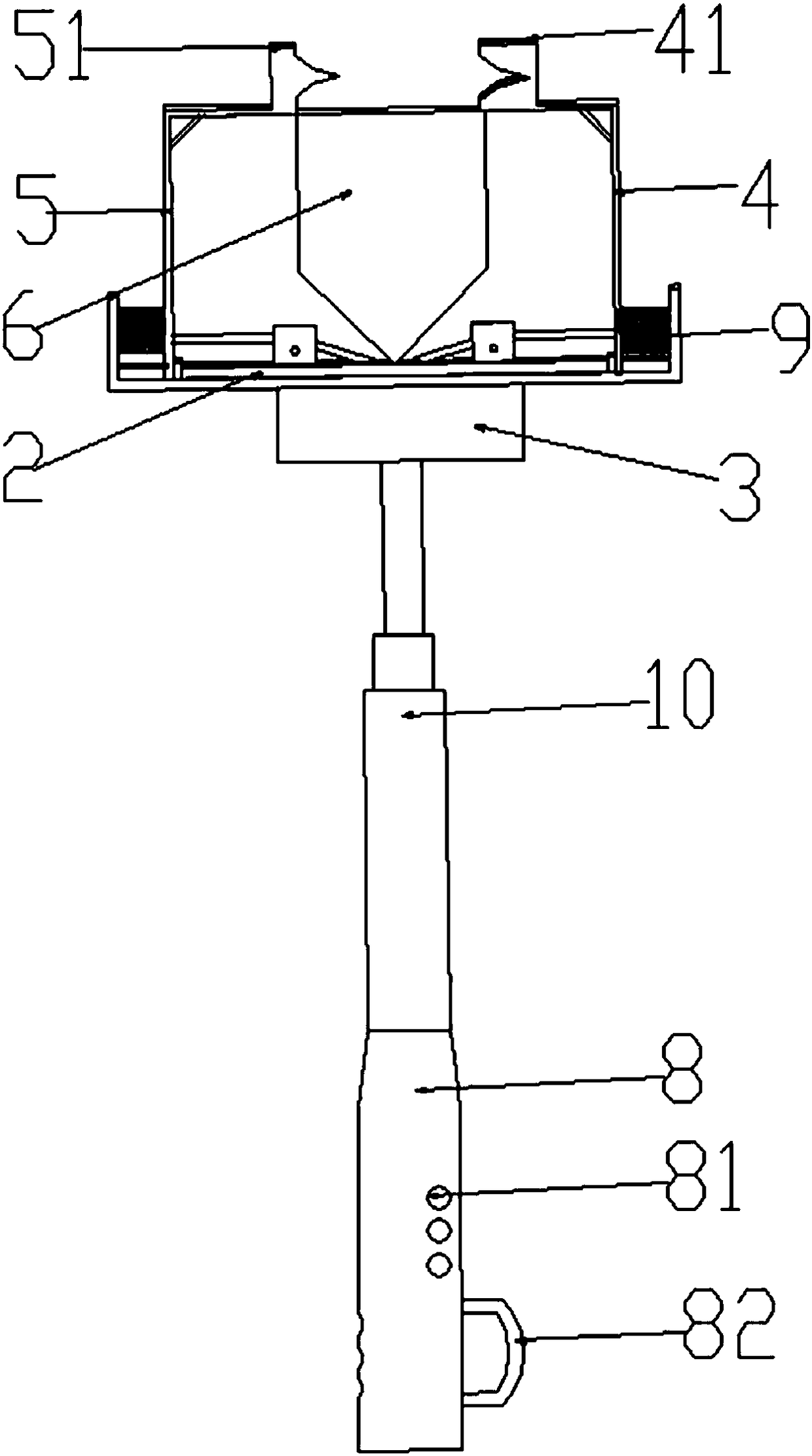

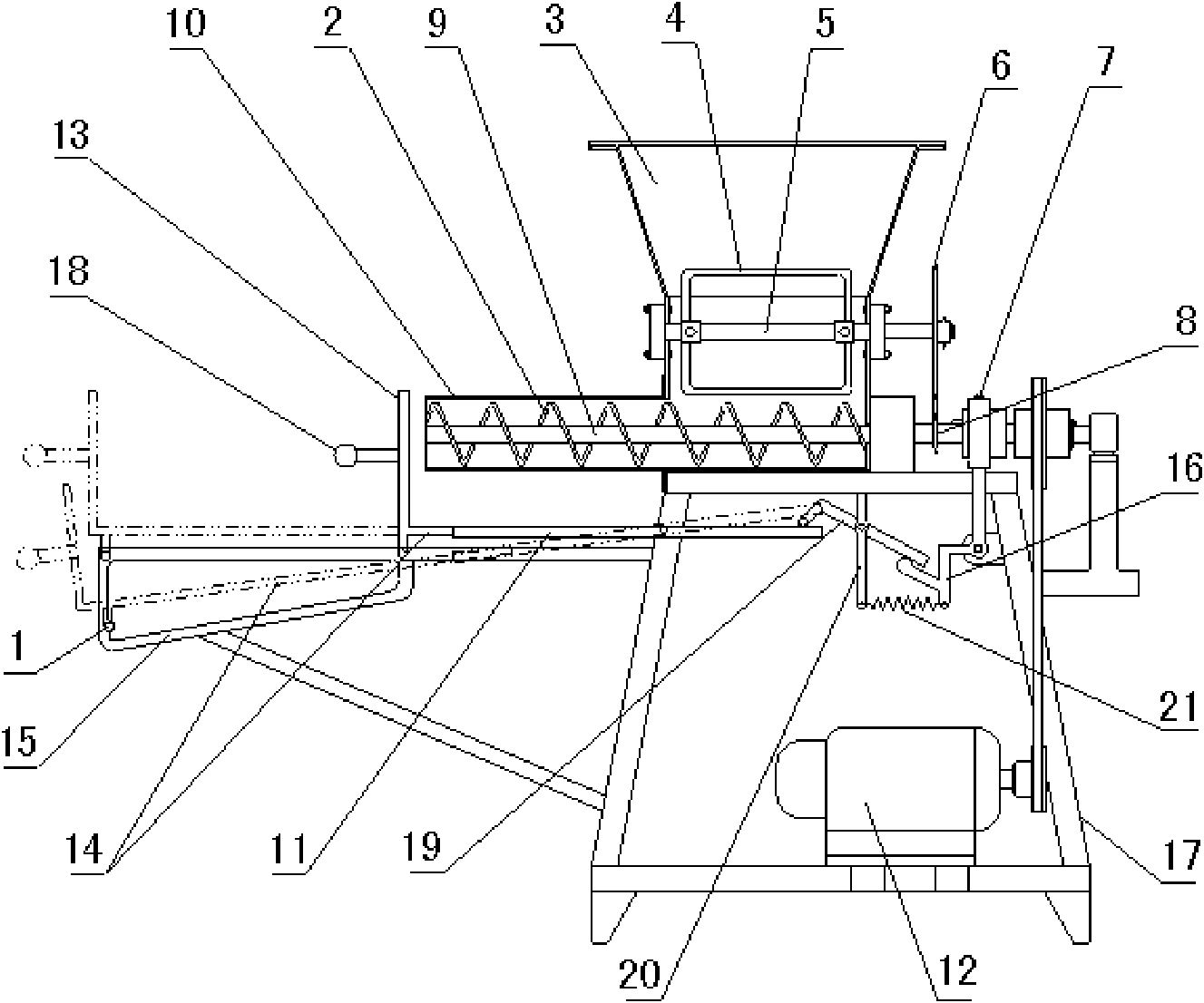

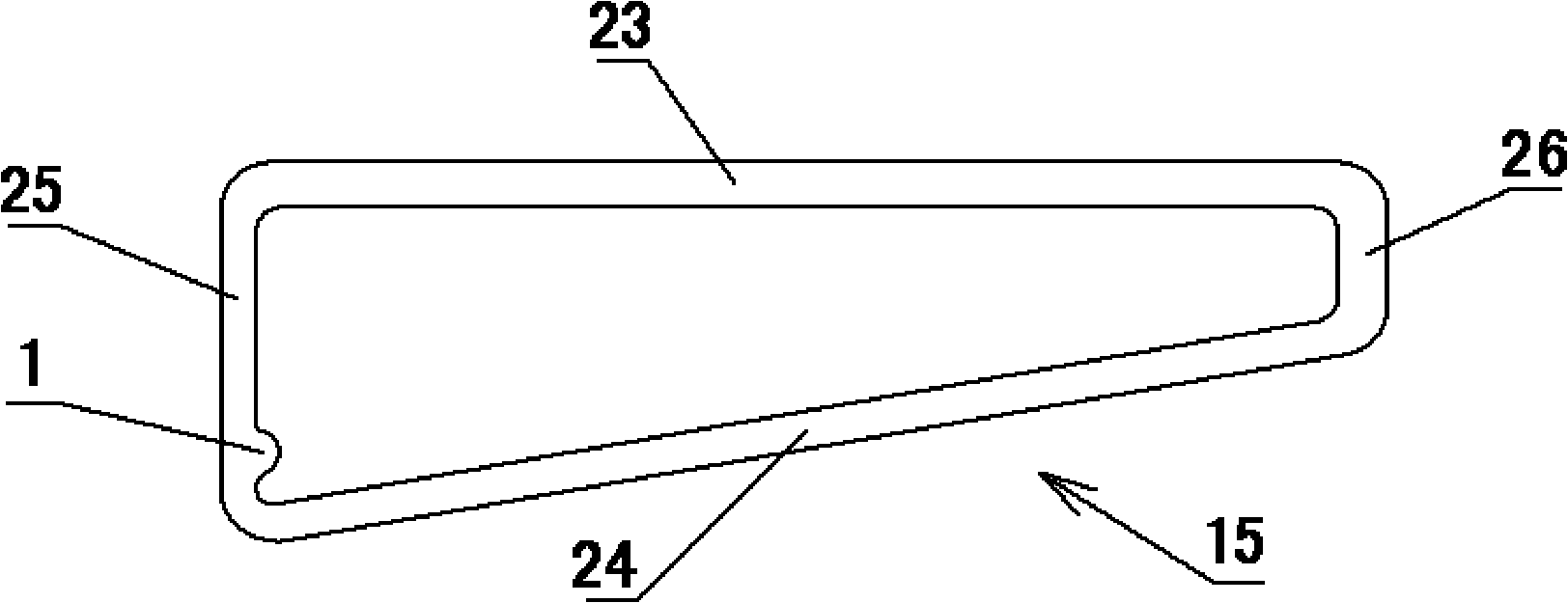

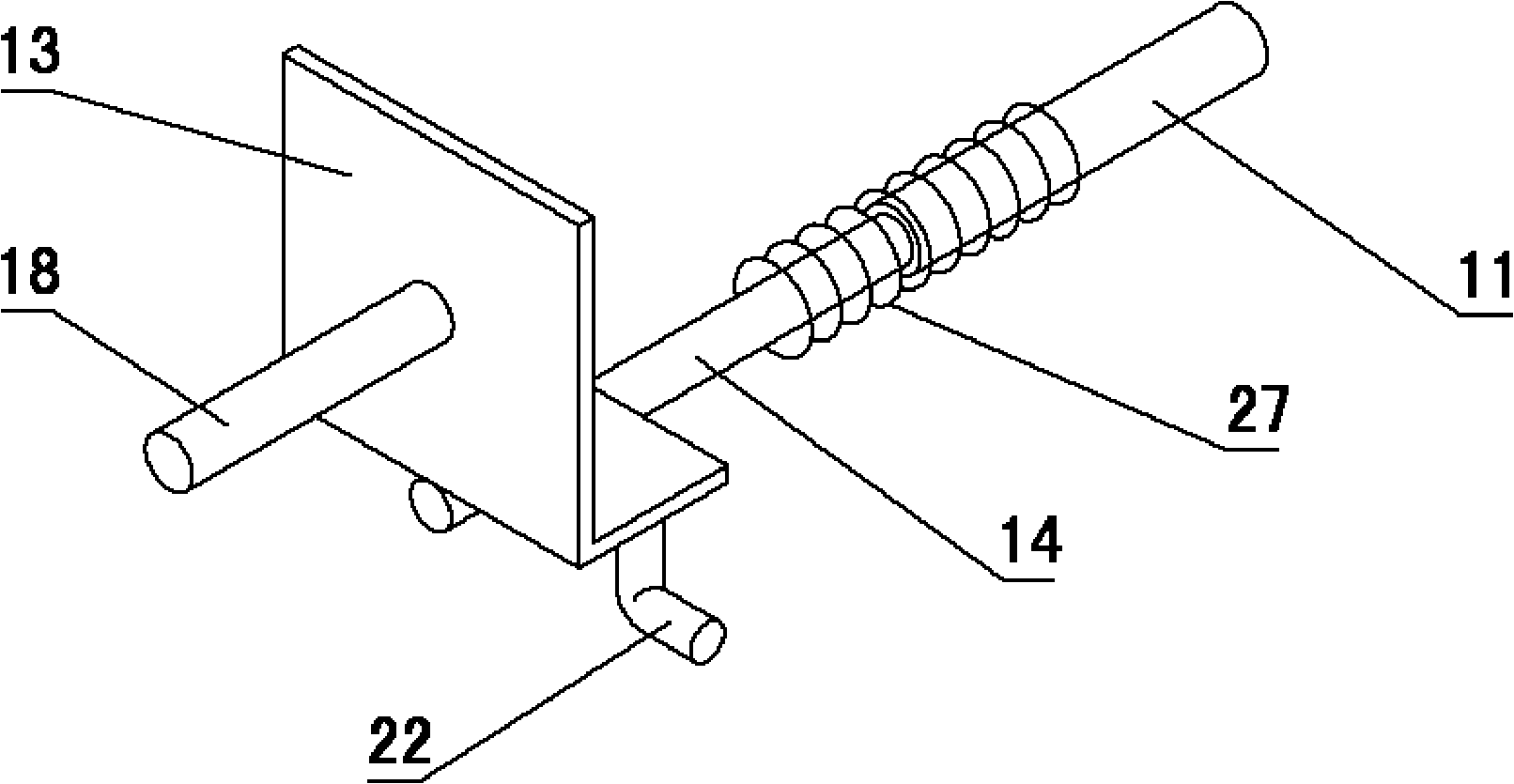

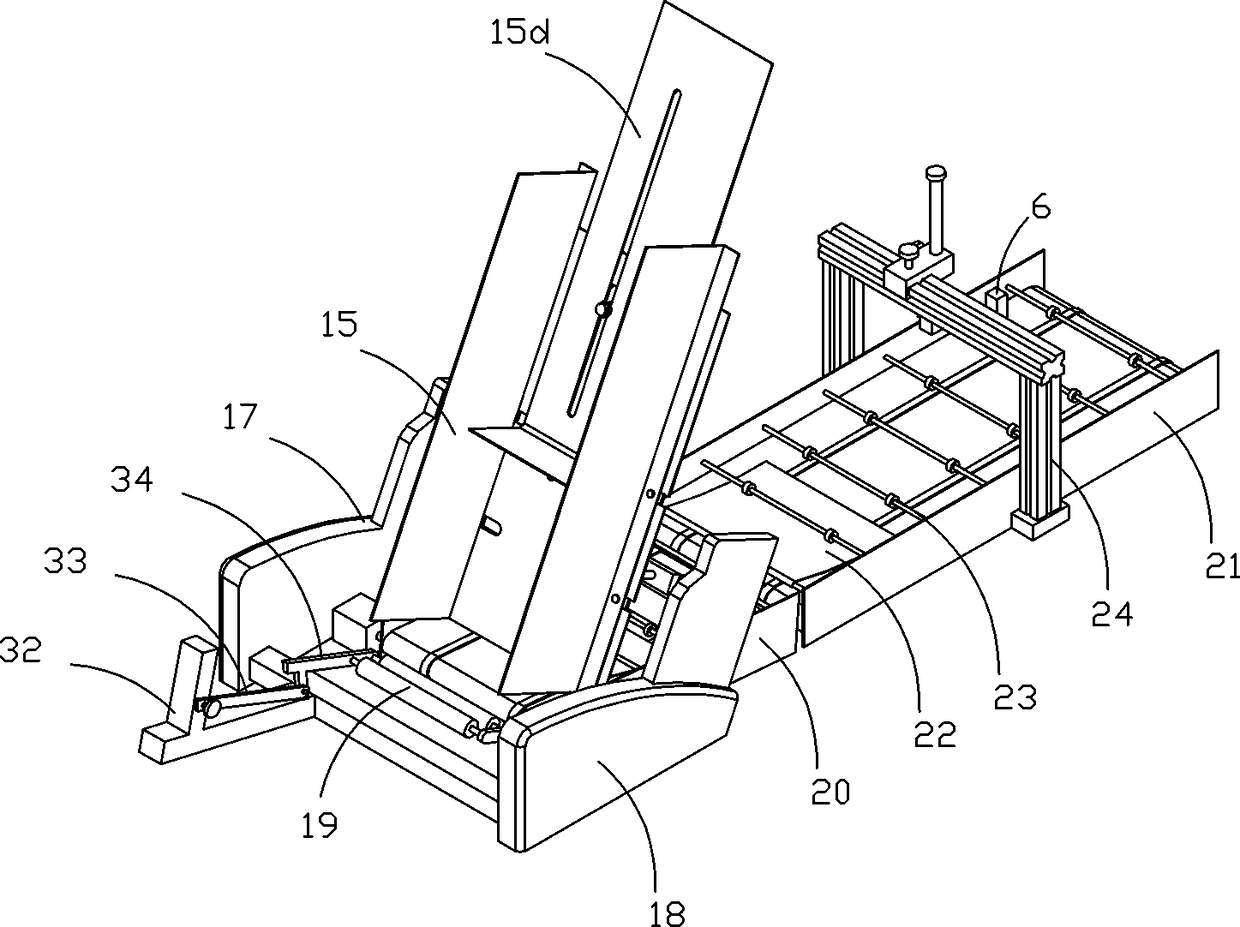

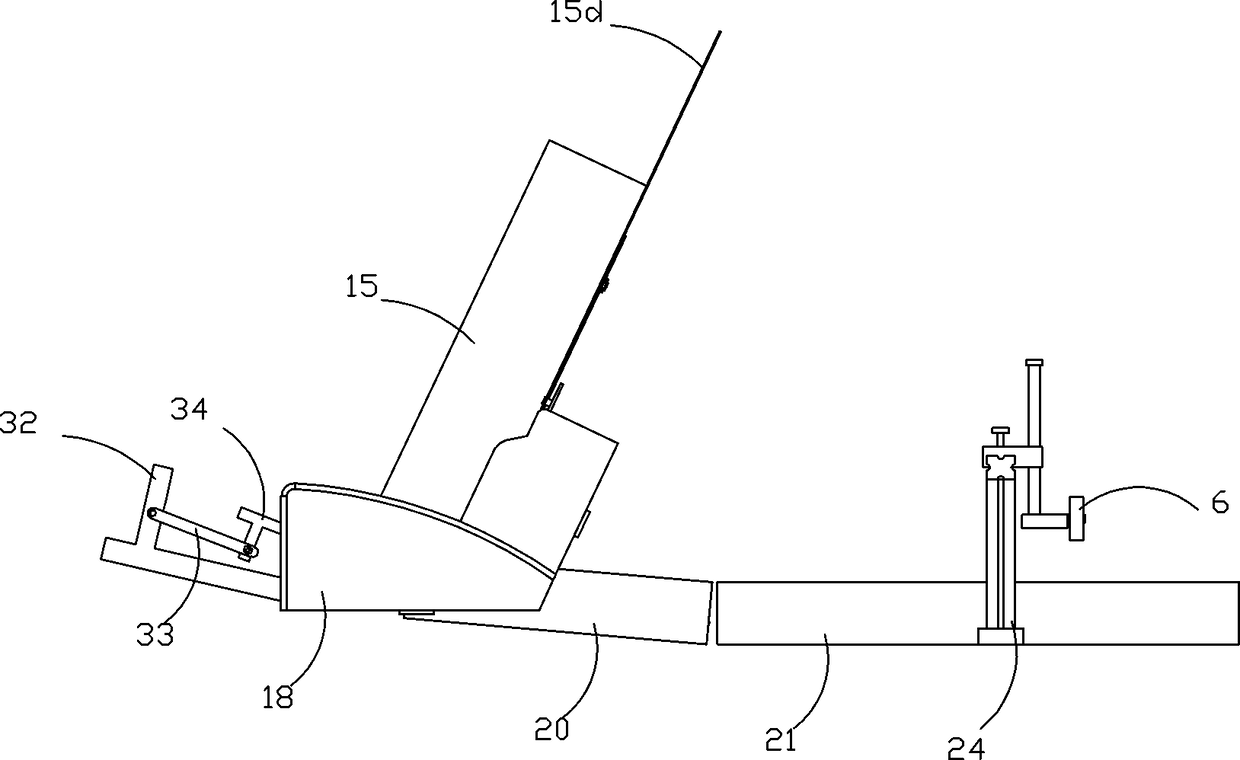

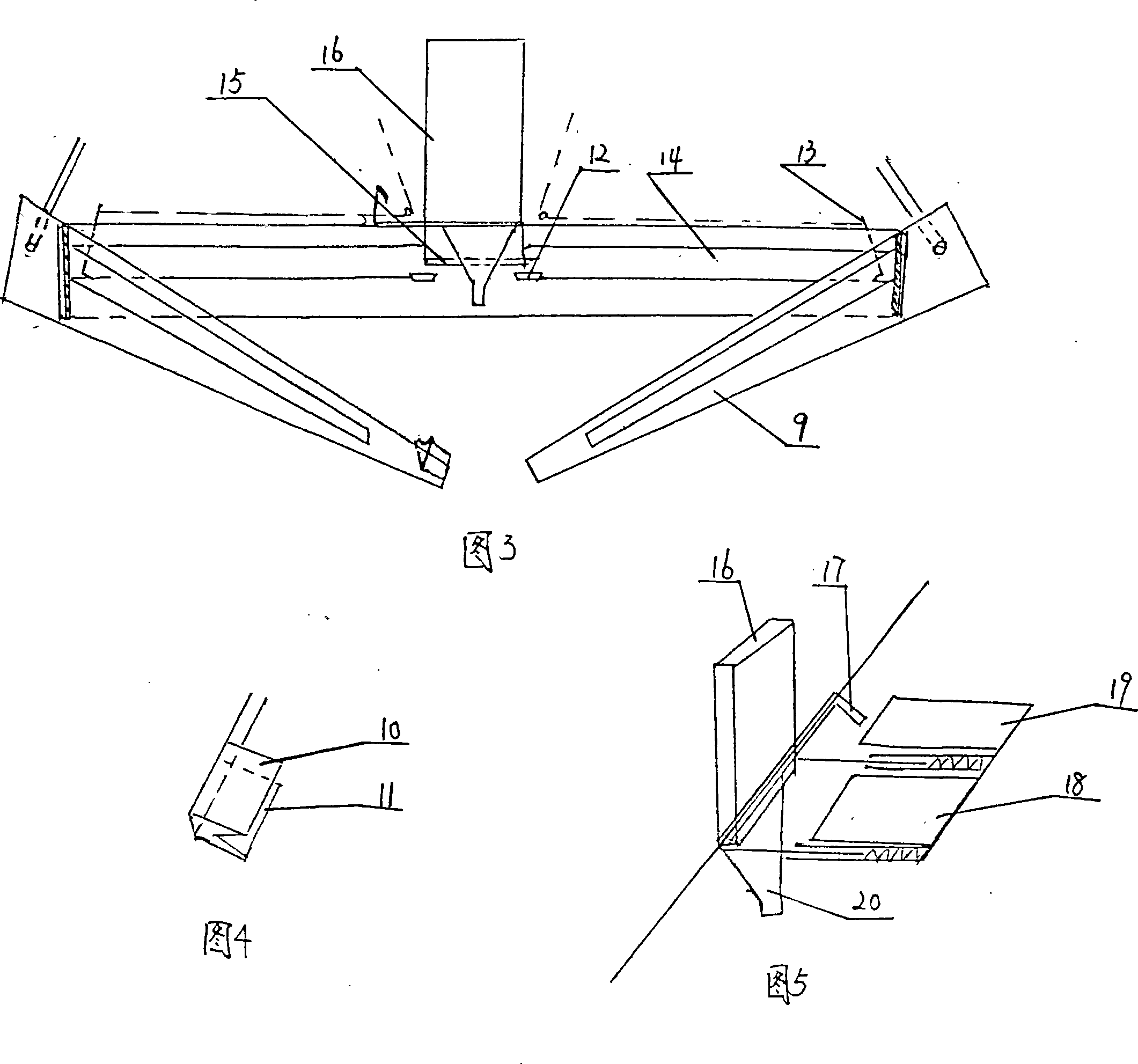

Full-automatic spiral edible mushroom cultivating material bagging machine

ActiveCN102113447AReduce labor intensityImprove bagging efficiencySolid materialHorticultureSEMI-CIRCLEEngineering

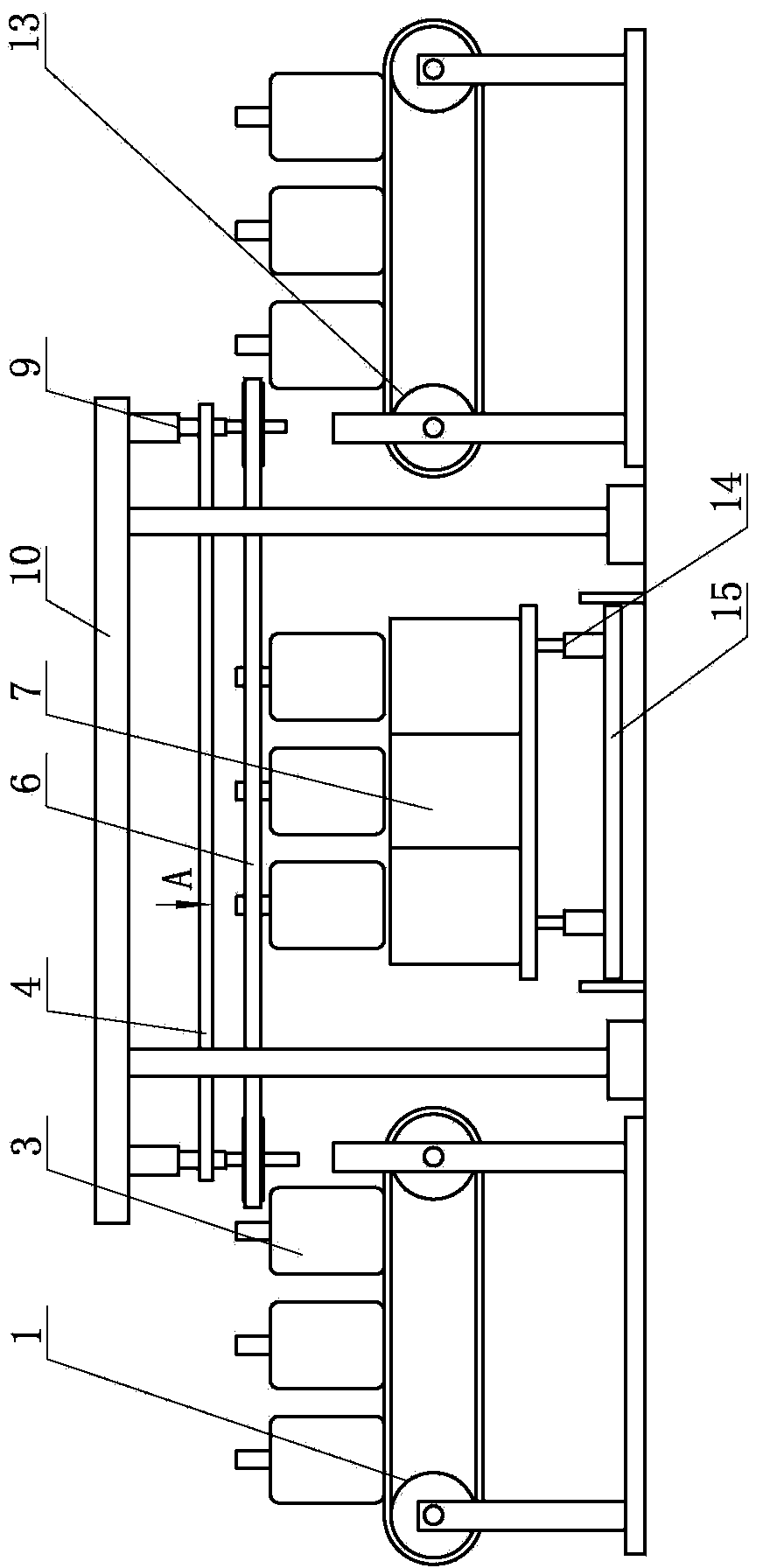

A full-automatic spiral edible mushroom cultivating material bagging machine comprises a rack, a loading motor, a power transmission mechanism, a spiral conveyer mechanism and a sliding trolley provided with a material bag model barrel, as well as a minitype motor which can rotate forwardly and reversely, wherein the sliding trolley is installed on a guide rail of the rack through front and rear guide wheels at the bottom; the power of the minitype motor is transmitted to the sliding trolley to move back and forth along with the guide rail of the rack through a belt and a chain wheel and chain transmission mechanism; the material bag model barrel comprises two upper and lower semi-circle groove-shaped frameworks which can be opened and closed; when in bagging, the sliding trolley can drive the material bag model barrel to move forwardly to be sheathed with a discharging barrel; the upper and lower two semi-circle groove-shaped frameworks of the material bag model barrel can clamp a material bag fully filled with a cultivating material, and retreat to the slope at the tail end of the guide rail of the rack; and the lower semi-circle groove-shaped framework can be unfolded downwards to loosen the material bag to slide on the floor automatically. With the material bagging machine, the degree of tightness and loading height of the material bag can be effectively controlled, the labor intensity can be lightened, and the bagging efficiency can be doubled.

Owner:临沂高新文旅发展有限公司

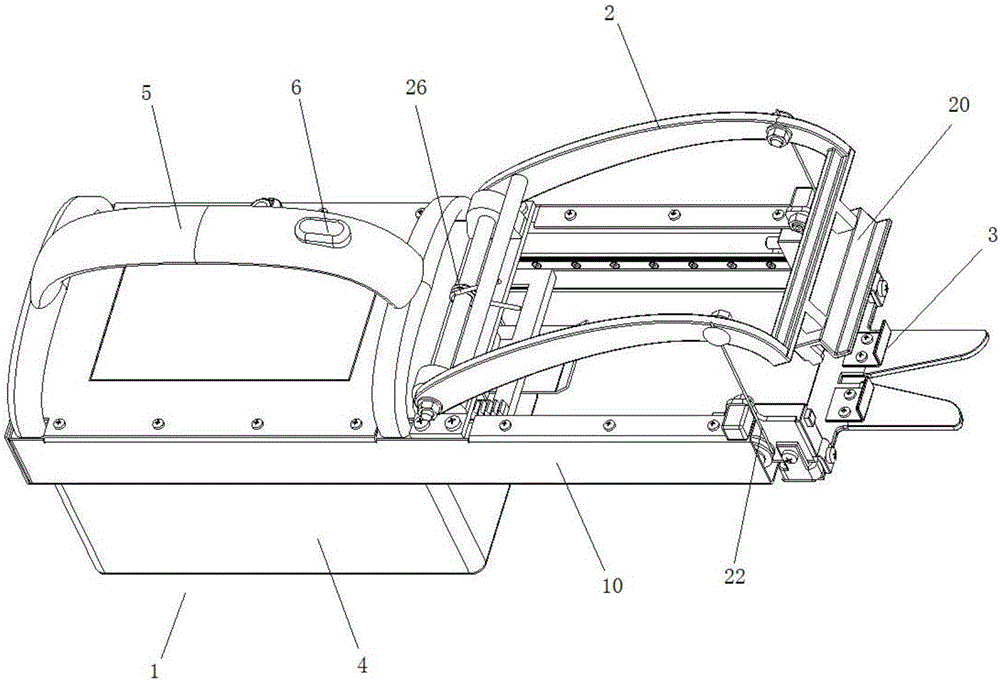

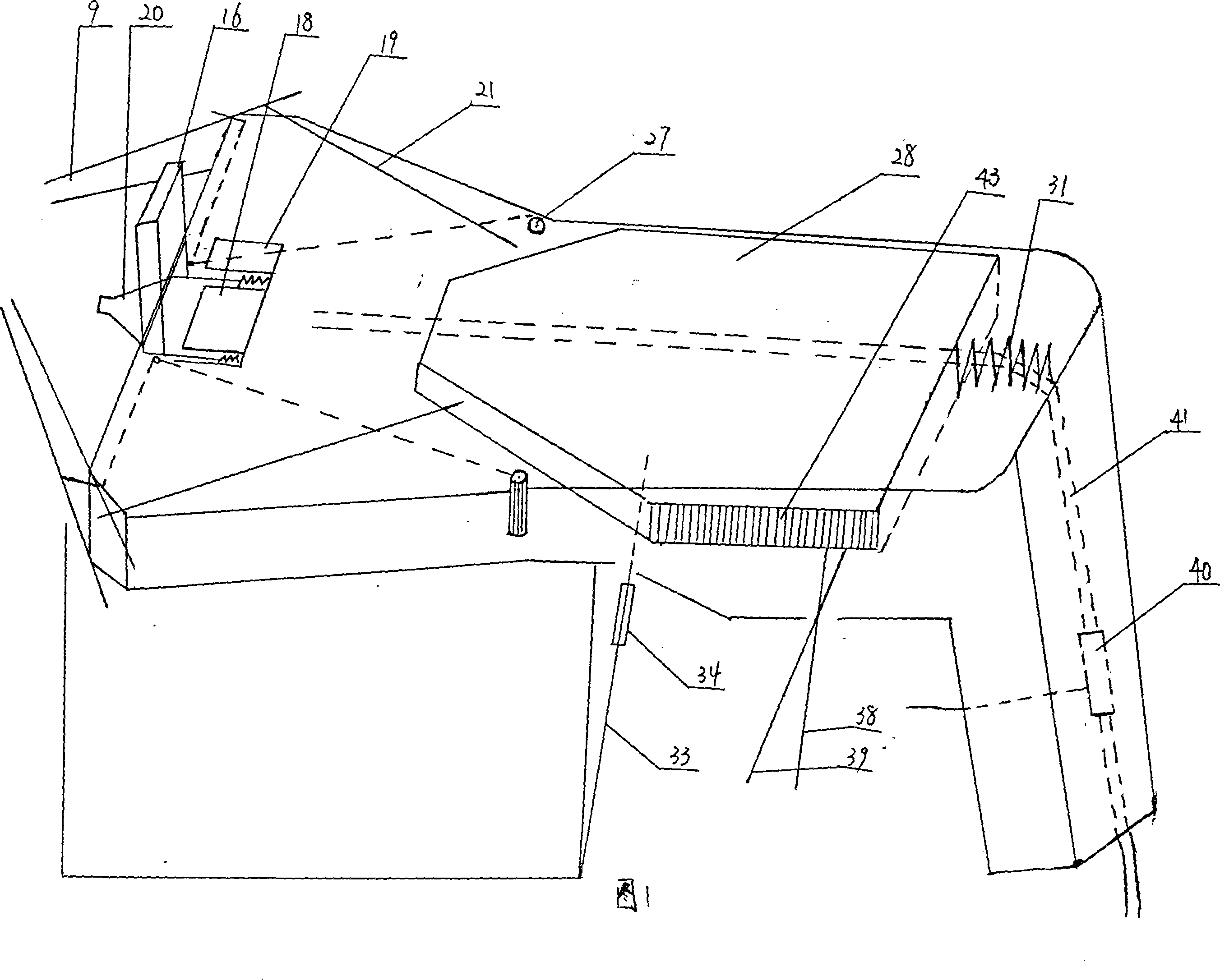

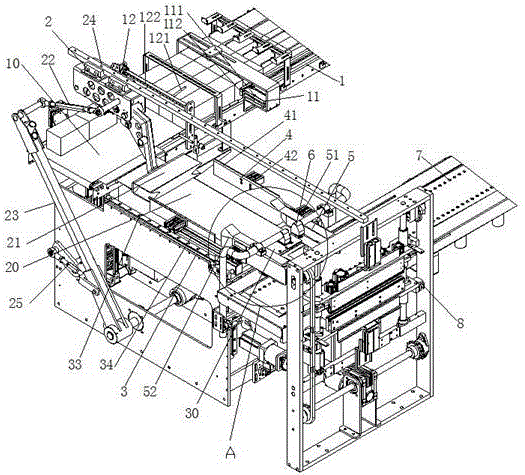

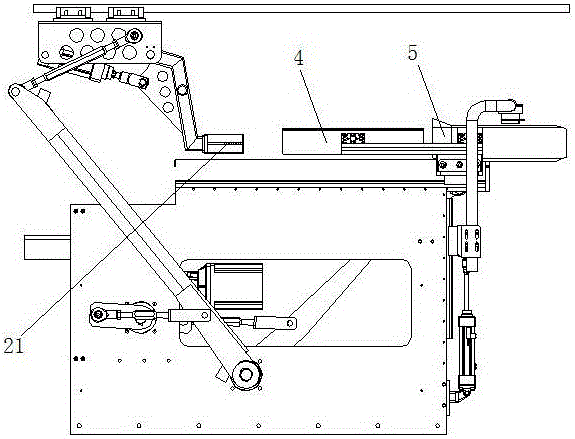

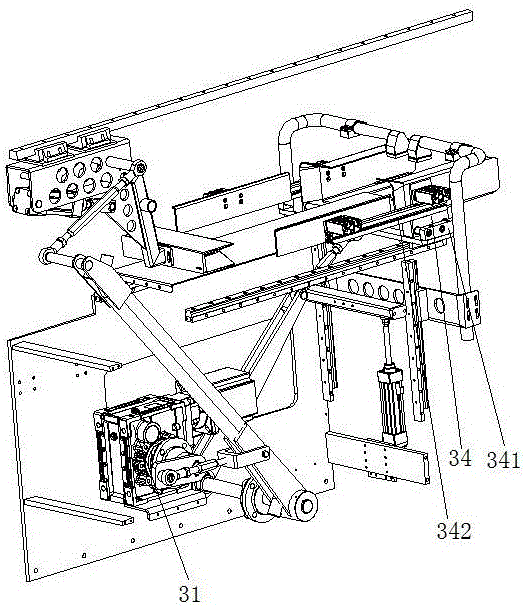

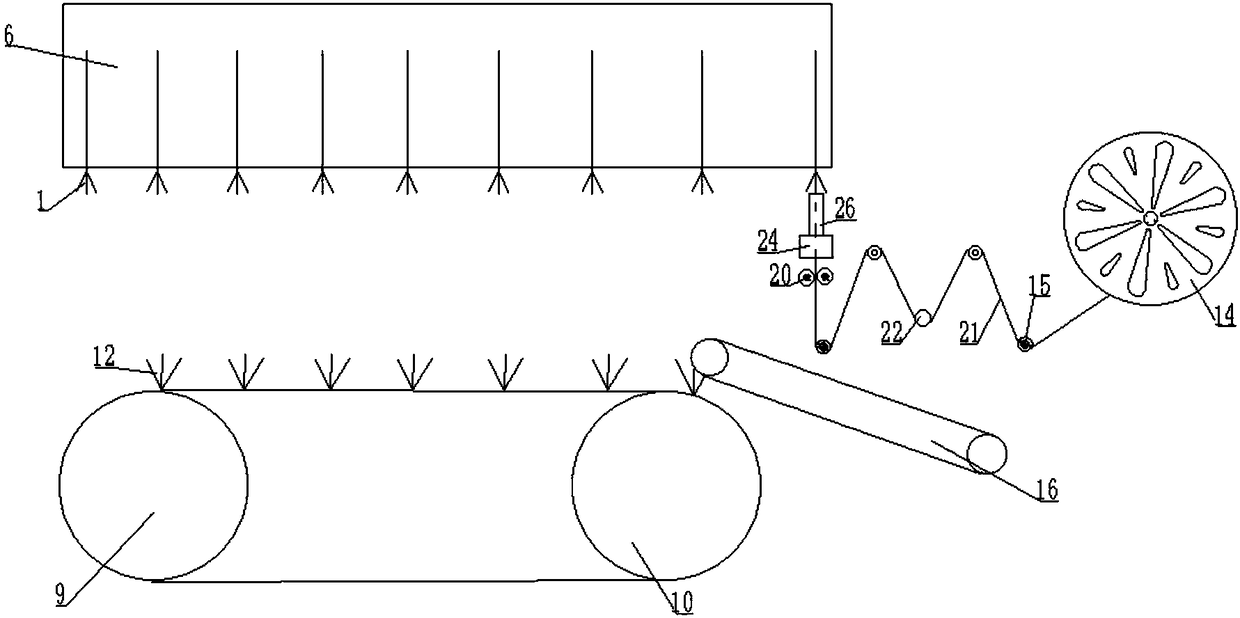

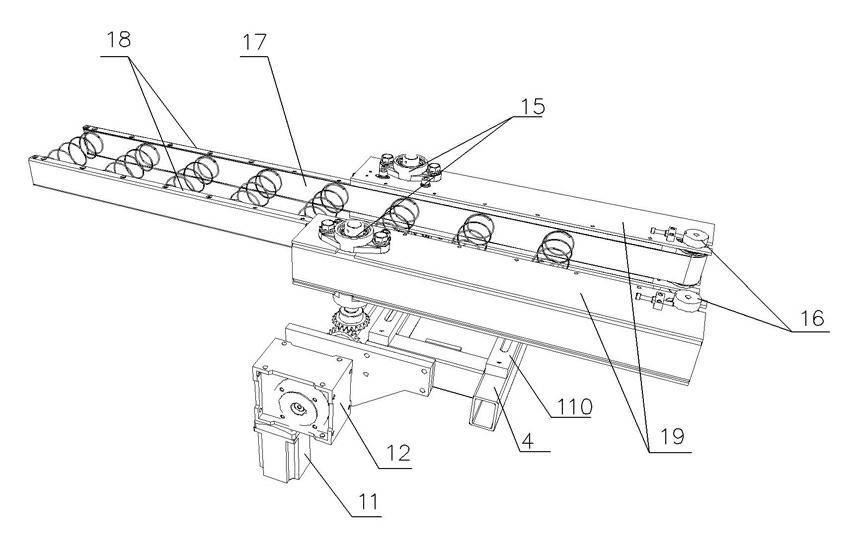

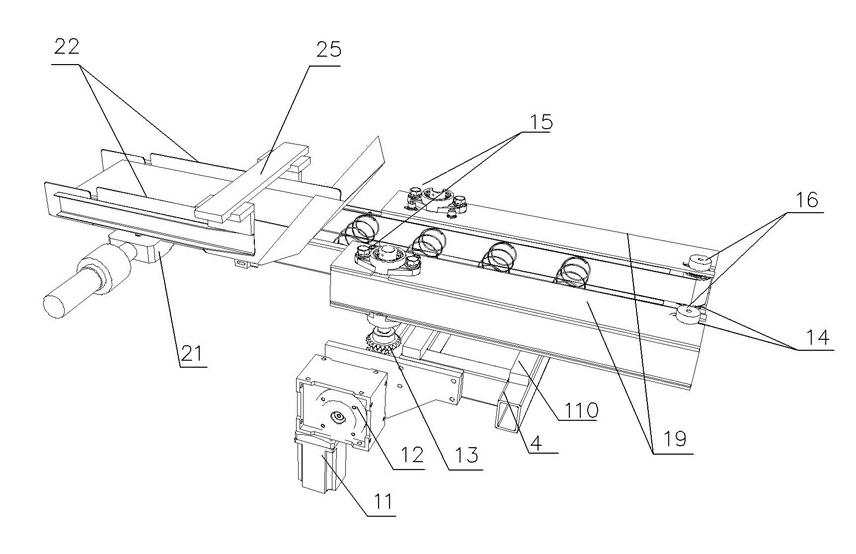

Young fruit bagging machine

InactiveCN104663336ASimple structureEasy to operatePlant protective coveringsReciprocating motionCoil spring

The invention discloses a young fruit bagging machine. The young fruit bagging machine comprises a body, wherein a coil spring bag-supporting mechanism used for storing bags is arranged below the body; a bag conveying mechanism used for grabbing the uppermost bag is arranged above the coil spring bag-supporting mechanism; a bag outlet is formed above the coil spring bag-supporting mechanism; the bag conveying mechanism is driven by a driving mechanism to repeatedly move between a bag-taking place and a bagging place; an intermittent mechanism used for switching action of the bag conveying mechanism and action of a bagging mechanism is arranged on the side of the body; the bagging mechanism comprises a bagging opening device used for opening a bag opening and a bag folding mechanism used for sealing the bag opening. The bagging machine provided by the invention is simple in structure, convenient to operate and relatively high in automation degree, mechanical bagging can be realized, and the bagging efficiency and the bagging quality are greatly improved.

Owner:冷羽夏

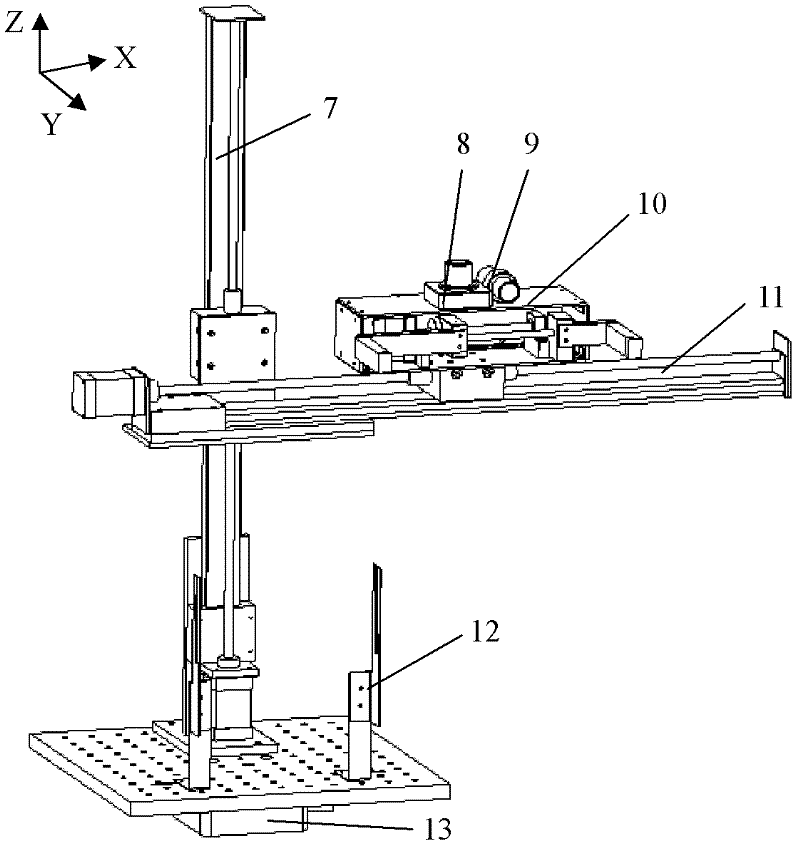

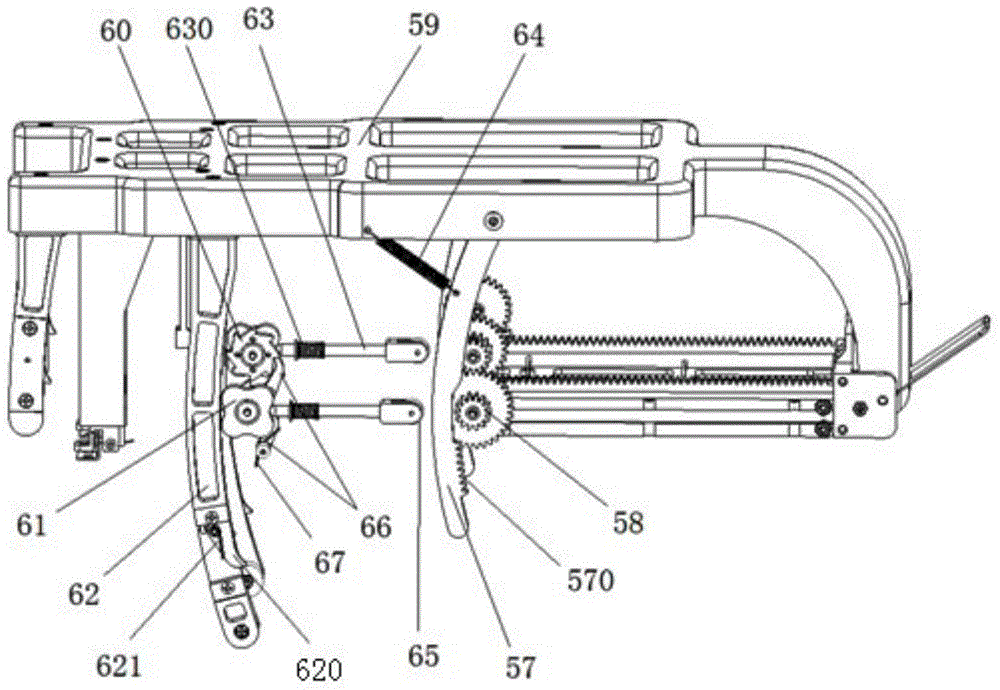

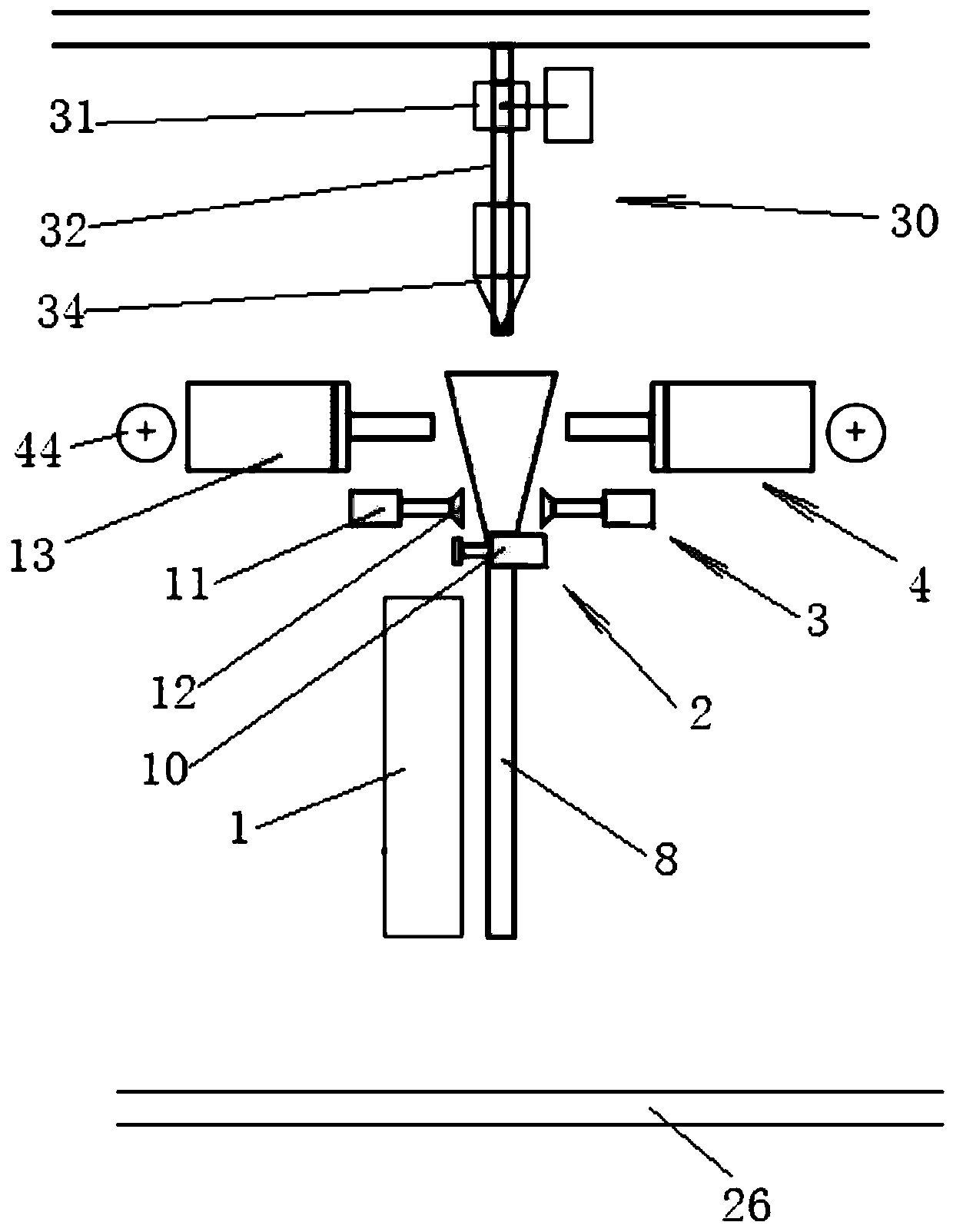

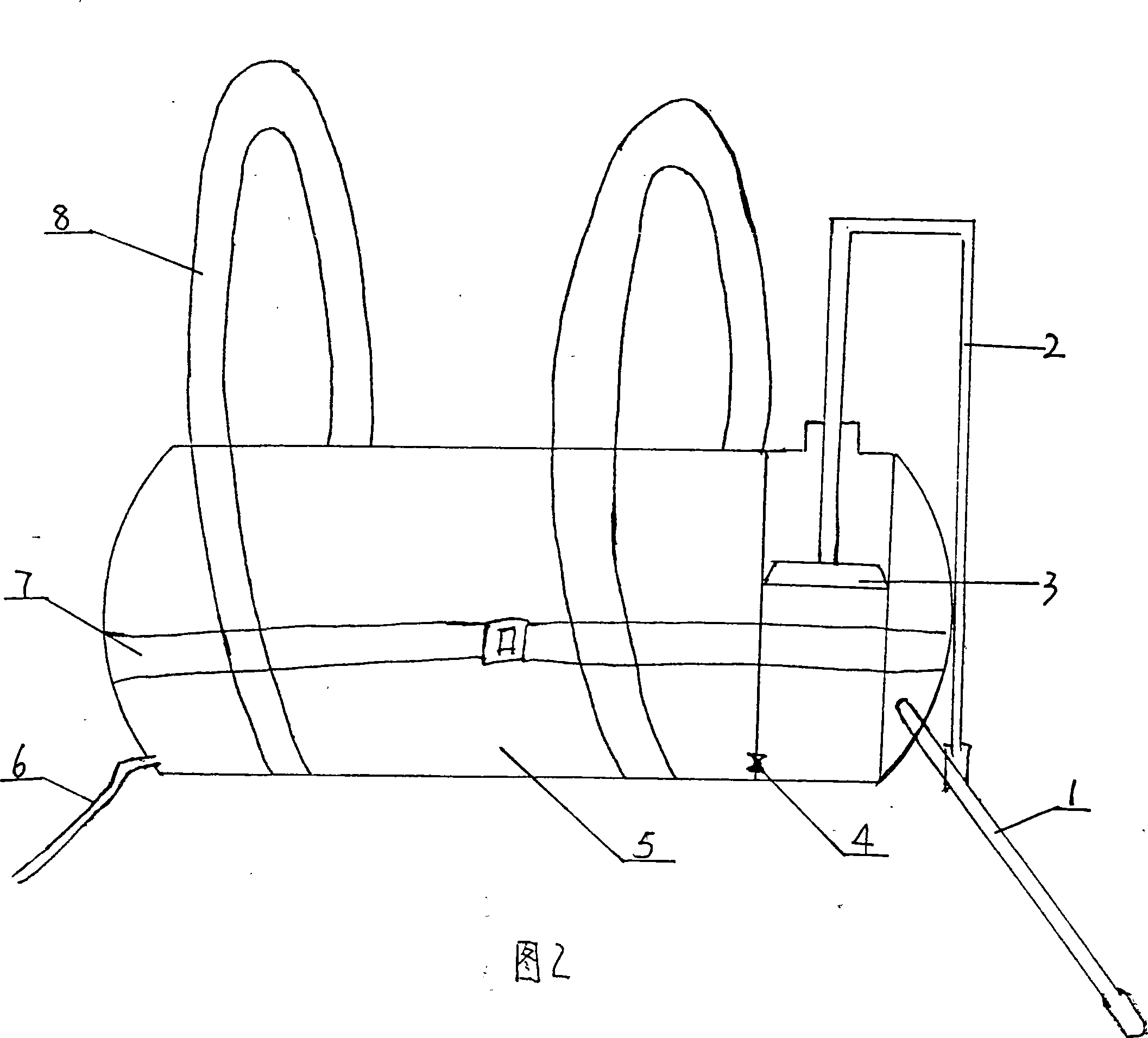

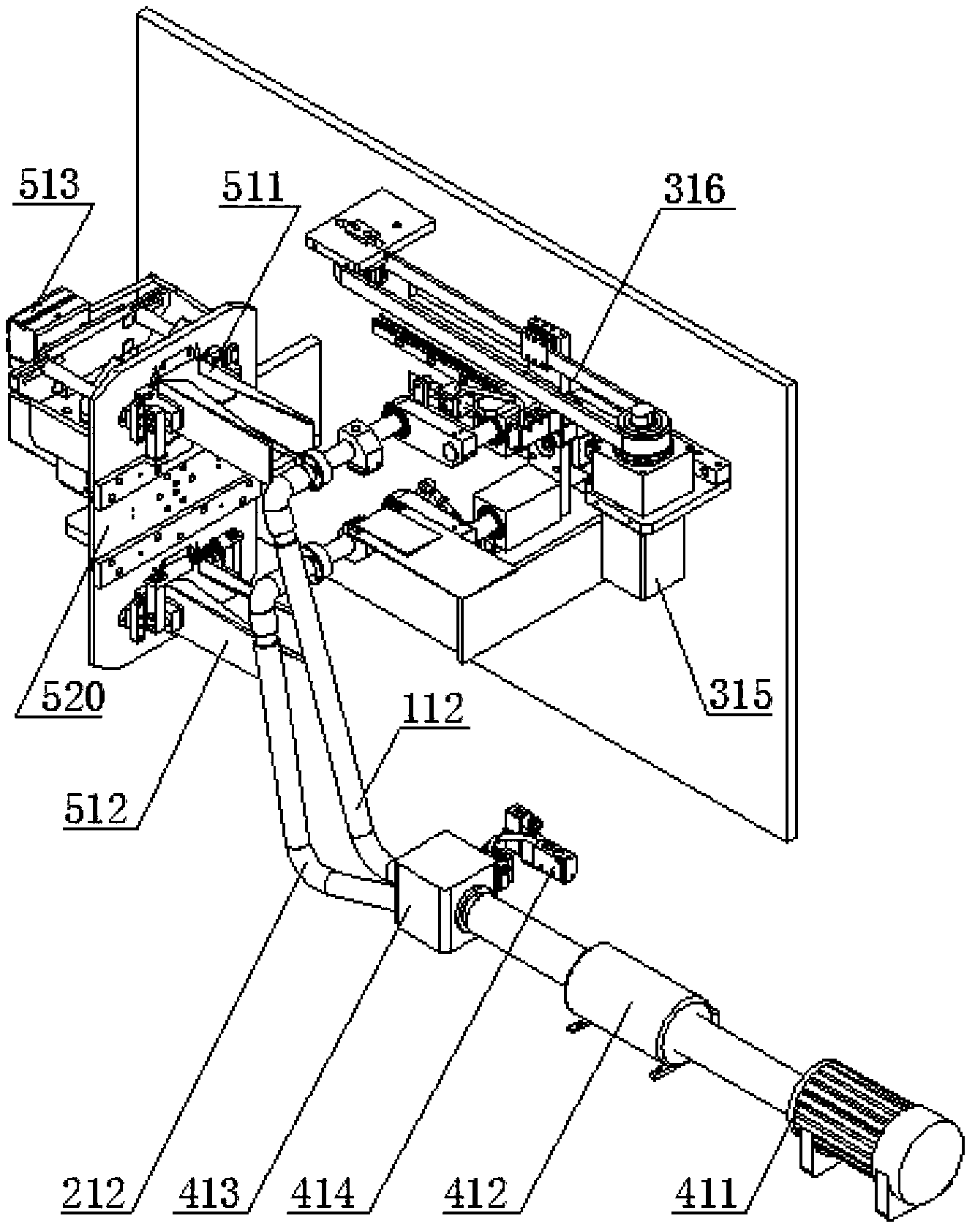

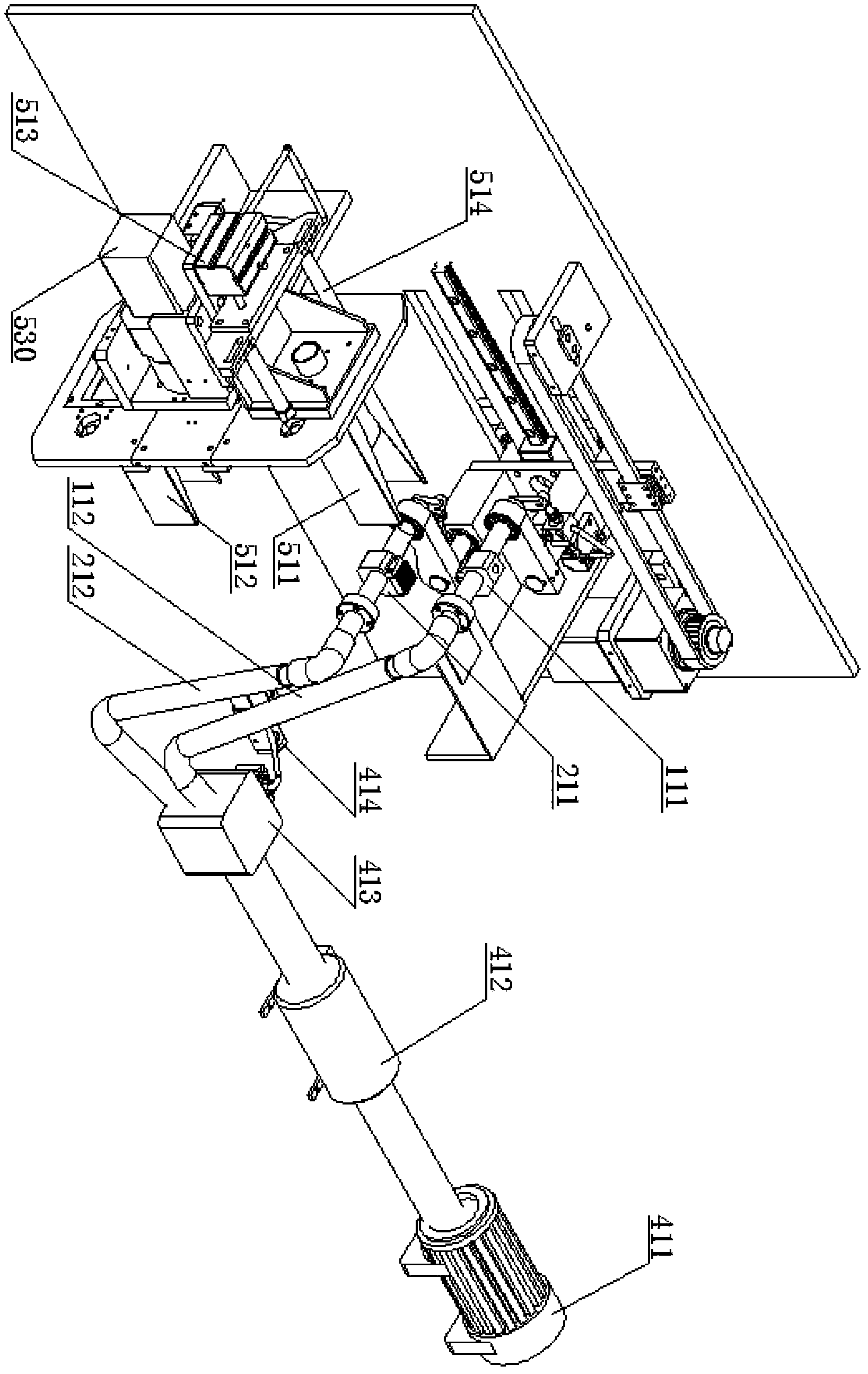

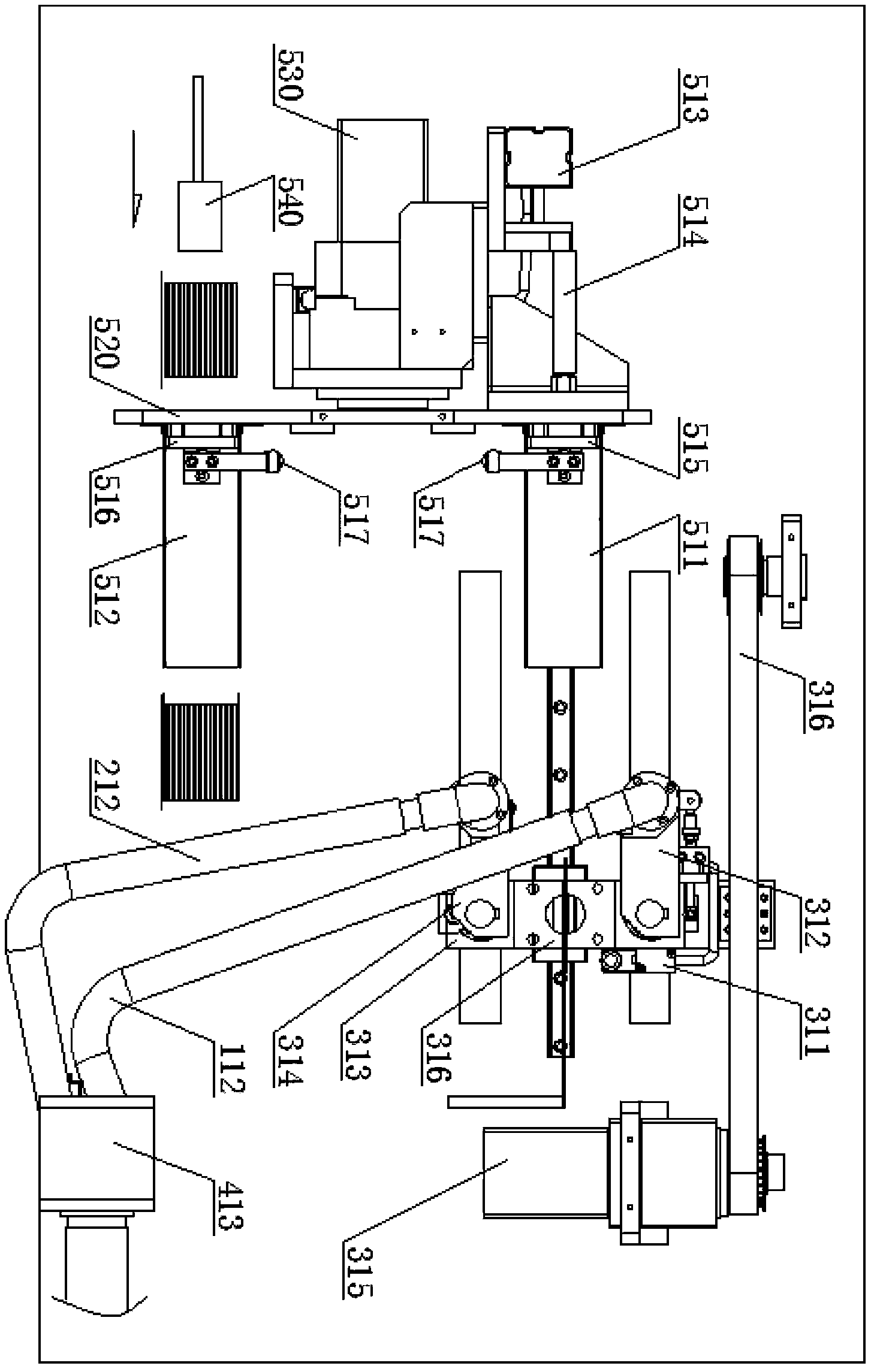

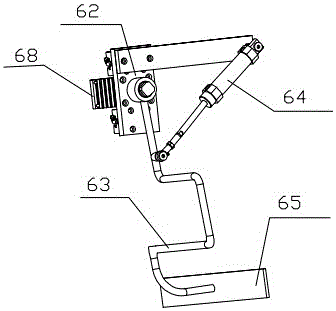

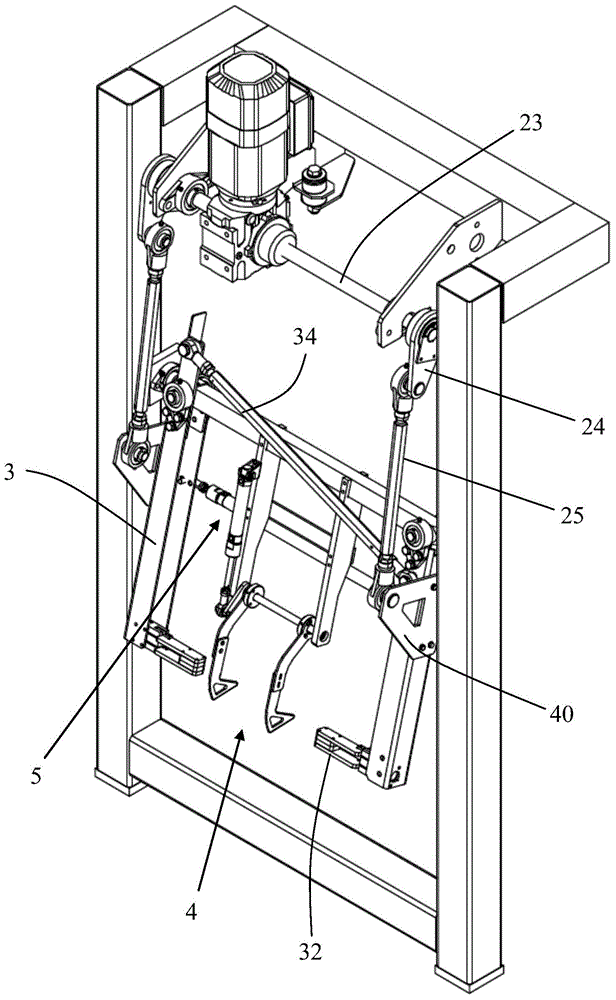

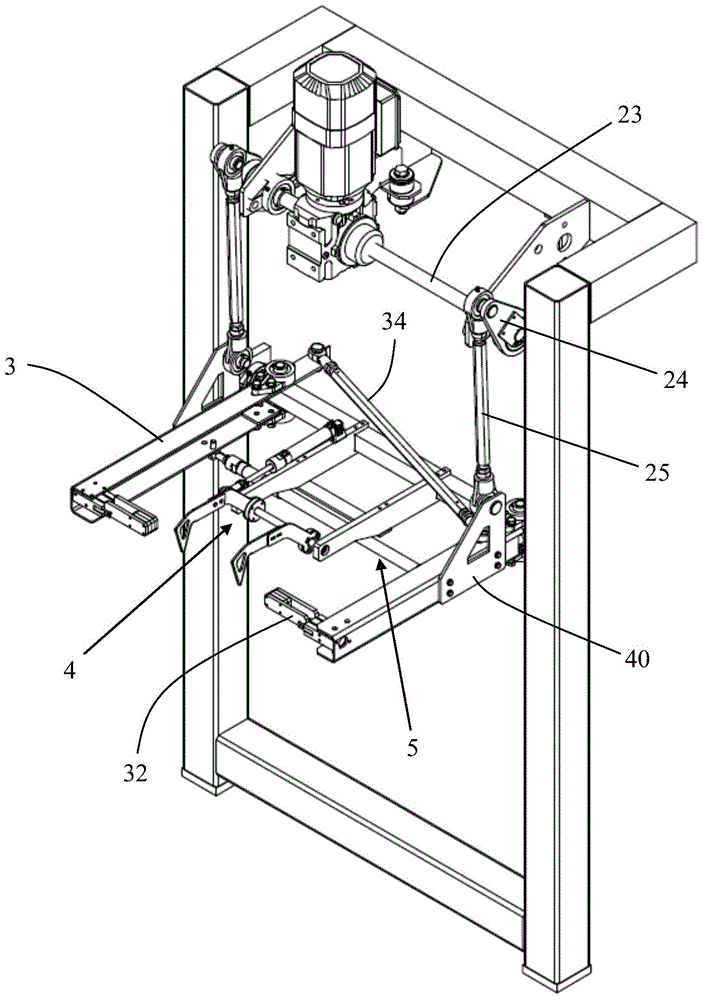

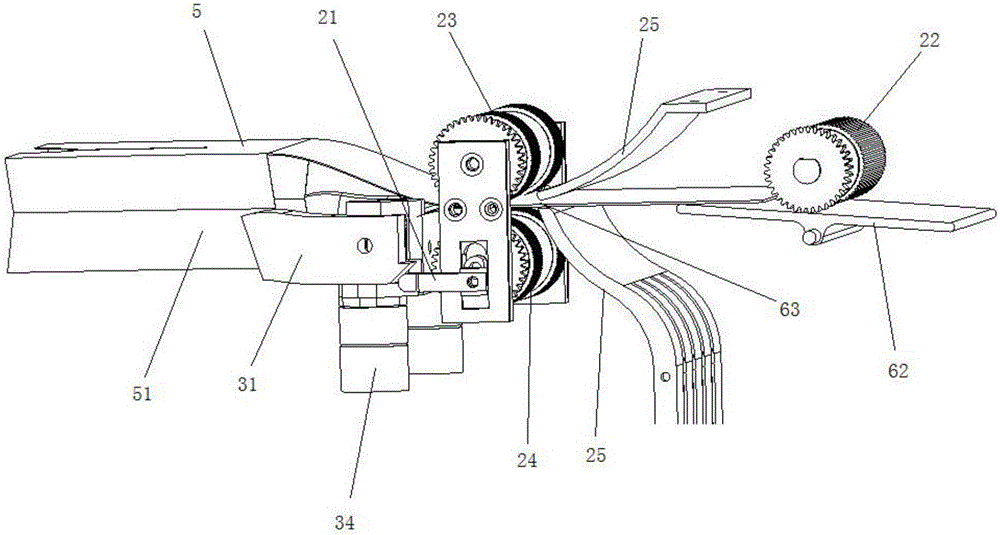

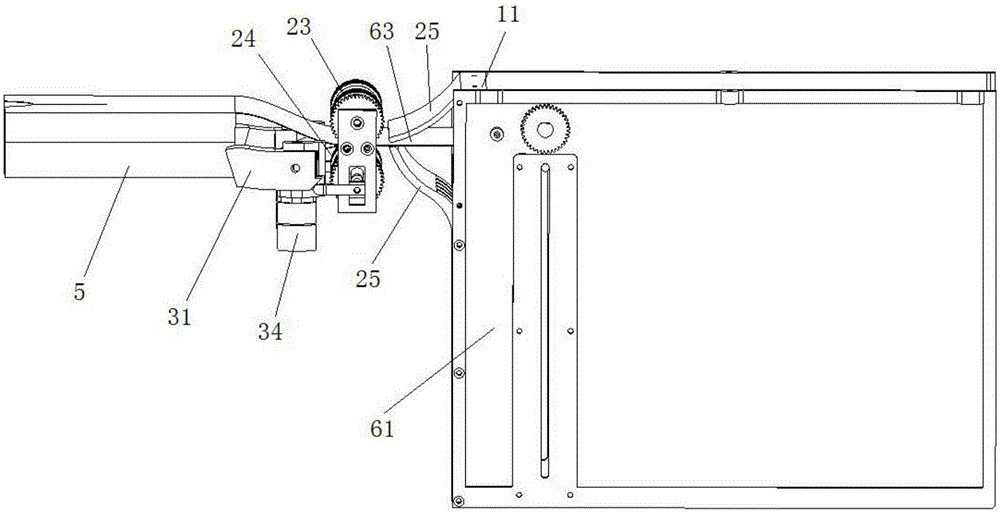

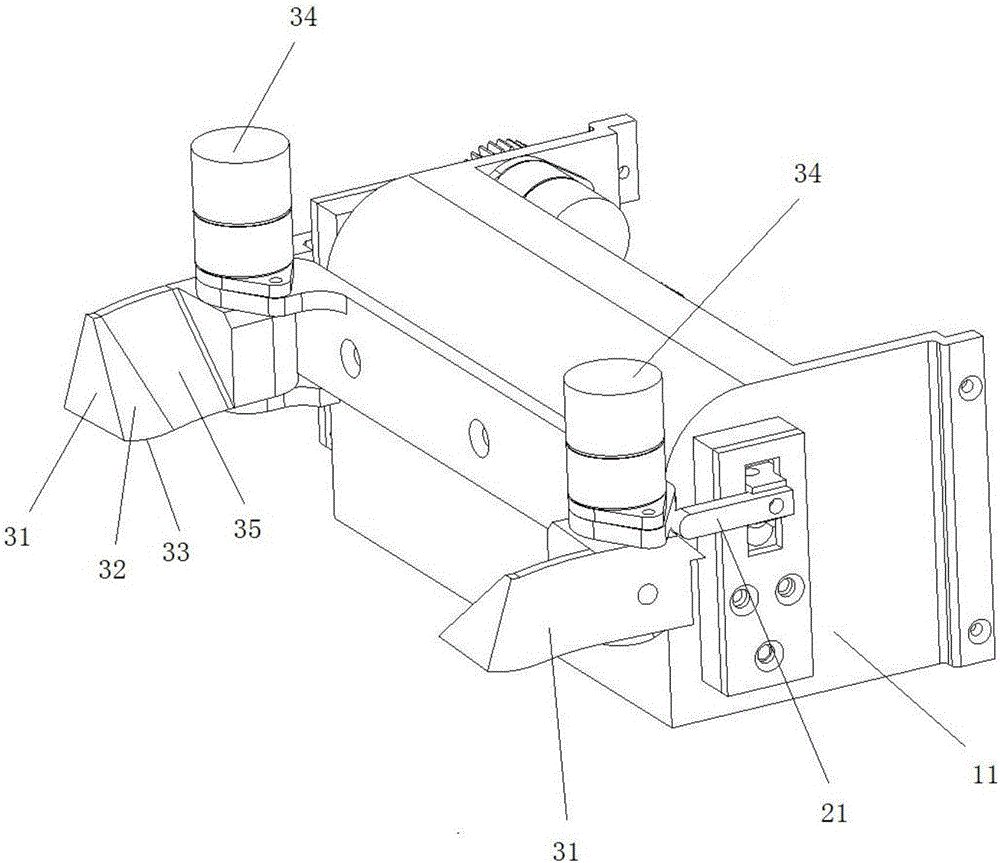

Manipulator for covering bags for grapes

InactiveCN102224797AHigh degree of automationImprove bagging efficiencyPlant protective coveringsRotary stageAgricultural engineering

The invention discloses a manipulator for covering bags for grapes, belonging to the technical field of modern agriculture equipment. The manipulator comprises a rotating platform, a vertical slide rail, a horizontal slide rail, an end actuator and a bag bracket, wherein the vertical slide rail is arranged on the rotating platform and is vertical to the rotating platform; the horizontal slide rail is arranged on the vertical slide rail and is vertical to the vertical slide rail; the end actuator is arranged on the horizontal slide rail and is used for fetching bags and covering bags for grapes; and the bag bracket is arranged on the rotating platform and use for containing bags. The manipulator for covering bags for grapes in the invention has high automation degree, conforms to the development direction of the modern agriculture equipment technology, is high in bag covering efficiency, greatly reduces the labor intensity, and has a compact structure and high reliability.

Owner:CHINA AGRI UNIV

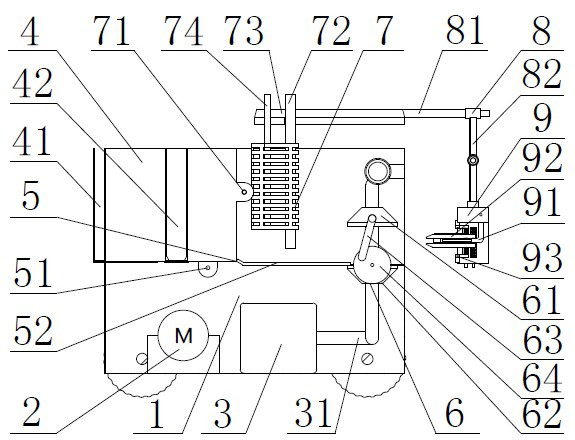

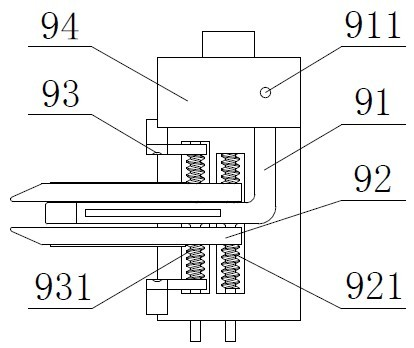

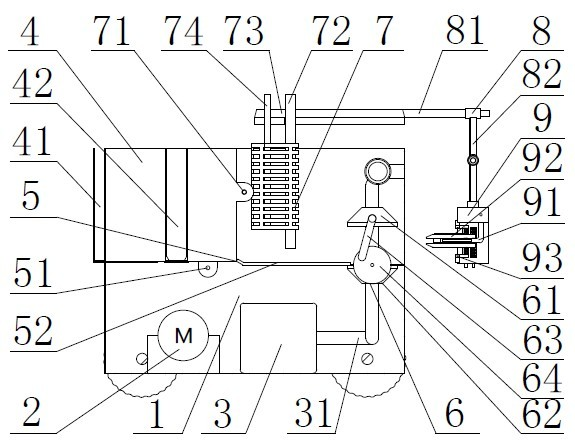

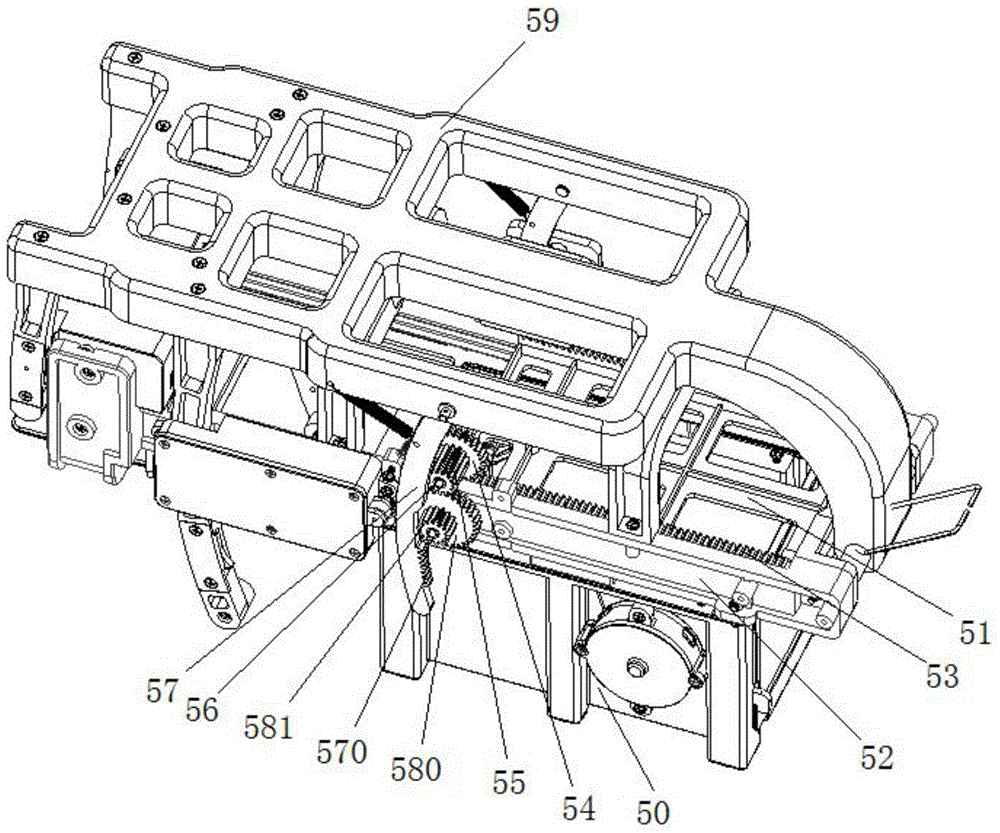

Fruit bagging robot

ActiveCN102077774AMeet the use requirementsEasy to usePlant protective coveringsBody compartmentPulp and paper industry

The invention relates to a fruit bagging robot comprising a carriage and an engine fixed at the bottom of the carriage as well as a bag storage box fixed at the top of the carriage and a paper bag conveying device. The paper bag conveying device comprises a friction wheel and a paper bag conveying platform, wherein the friction wheel is driven by the engine and fixed outside an opening at the bottom of the bag storage box; the paper bag conveying platform is fixed in parallel with the bag storage box, a suction device for strutting a paper bag is mounted at one side of the bag storage box far from the paper bag conveying platform; one side of the bag storage box is articulated with a fence supporting frame through a sliding pair perpendicular to the paper bag direction, a pair of longitudinal rack and drawer guide rails are fixed at the inner side of the fence supporting frame which is internally provided with a slideway platform which moves up and down through the rack, and one side of the slideway platform is connected with a manipulator for strutting and fastening bags through a mechanical arm. The invention is convenient to use and the bagging efficiency is greatly improved.

Owner:日照新睿招商发展有限公司

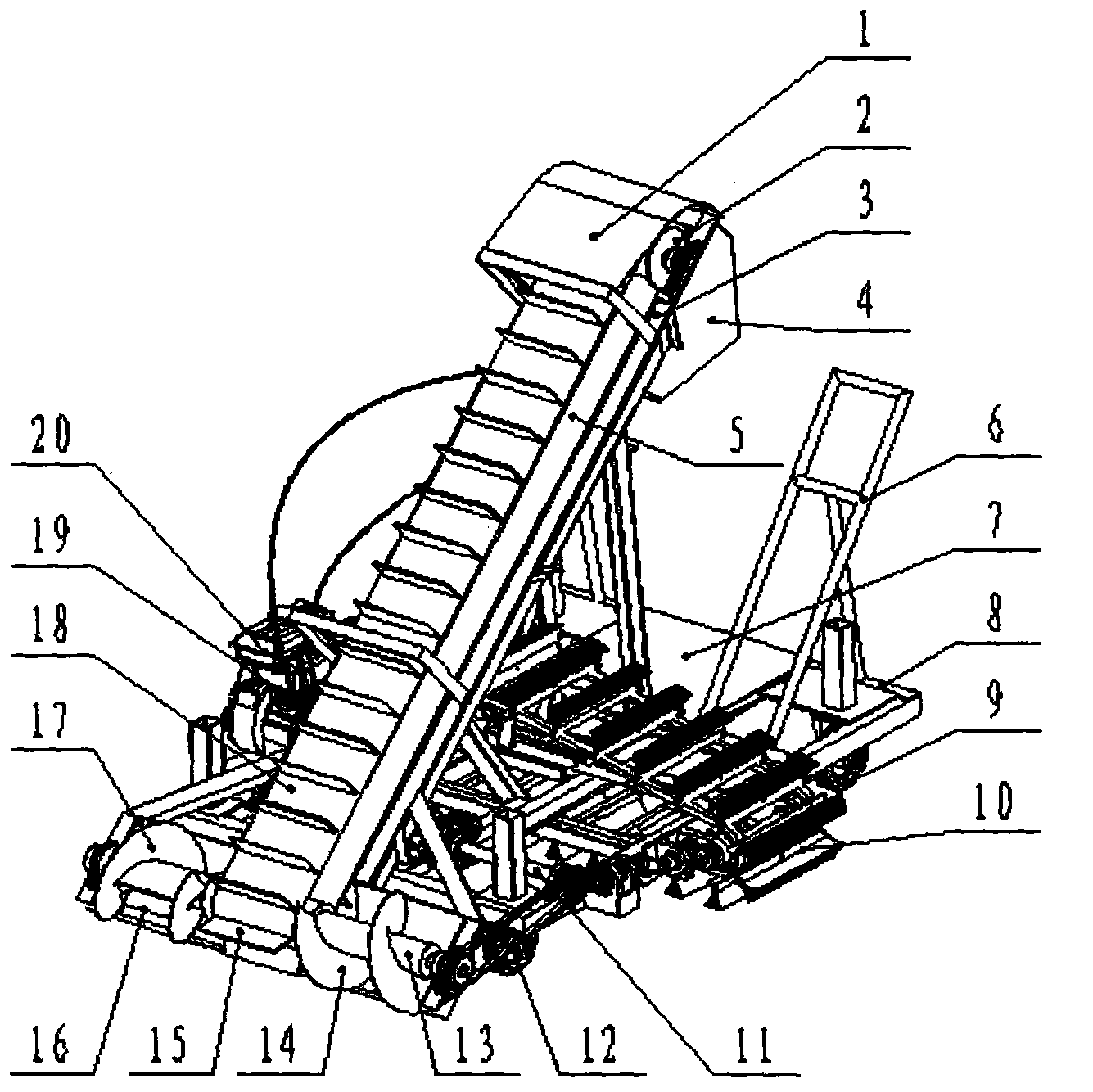

Cereal bagging machine for sunning ground

The invention provides a cereal bagging machine for a sunning ground. The cereal bagging machine comprises a frame and an engine, wherein a transmission device, a cleaning device and a differential traveling device are arranged below the frame, and an obliquely arranged conveying device is arranged above the frame; the front end of the conveying device is provided with a spiral conveying shaft, and the back end of the conveying device is provided with back roller wheels; the left and right sides of the spiral conveying shaft are provided with left and right spiral blades, and the heights of the back roller wheels is more than the height of the spiral conveying shaft; a conveyor belt is arranged between back roller wheels and the spiral conveying shaft, and a cereal tank and a discharge port are arranged at the back roller wheels; a bag filled with cereal is connected onto the discharge port. Checkered plates for bearing the bag filled with cereal are arranged above the frame and are arranged under the discharge port. The cereal bagging machine for the sunning ground has the characteristics of simple structure, high bagging efficiency, high degree of automation, low processing cost, great promotion potential, convenience in maintenance and the like.

Owner:YICHUN UNIVERSITY

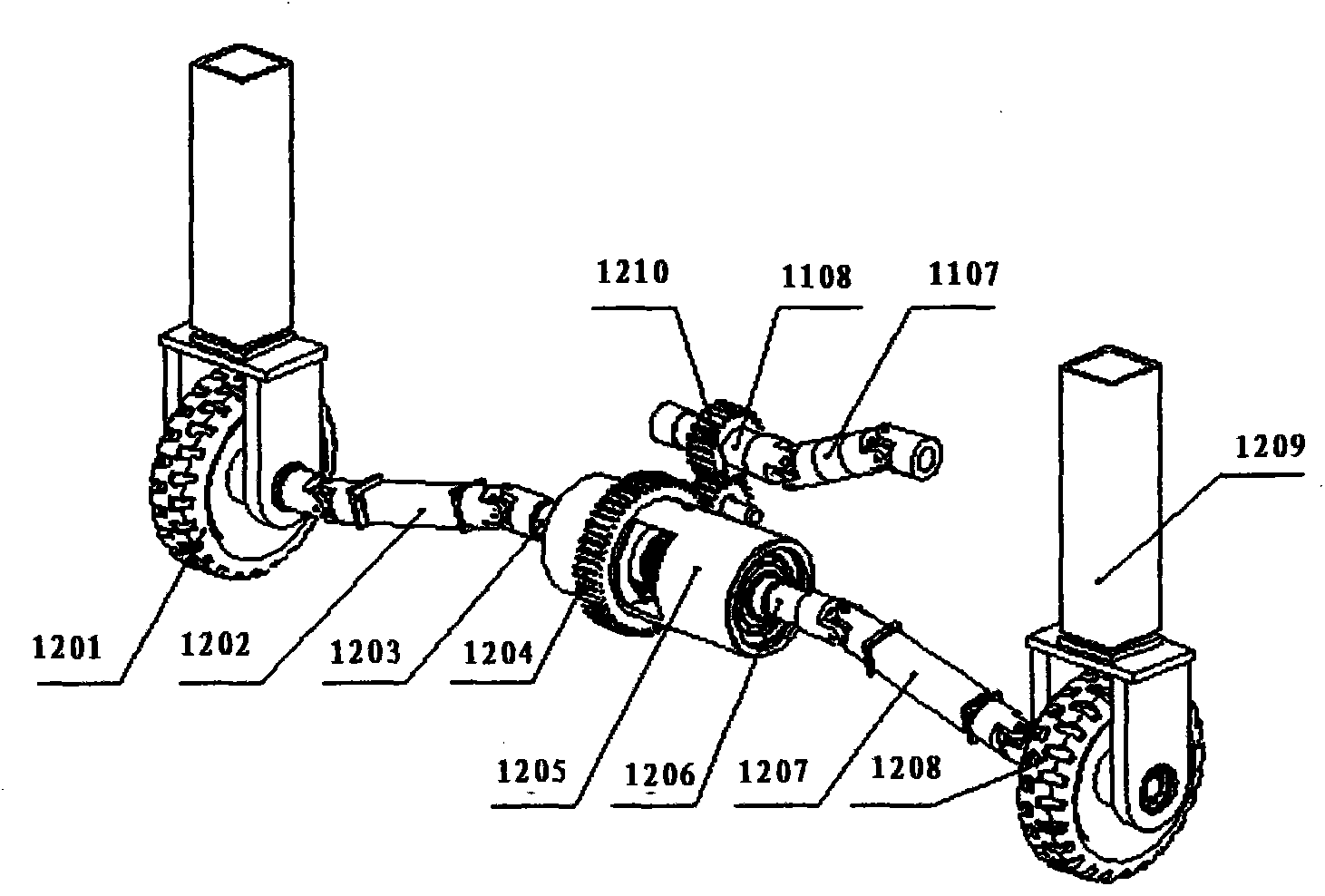

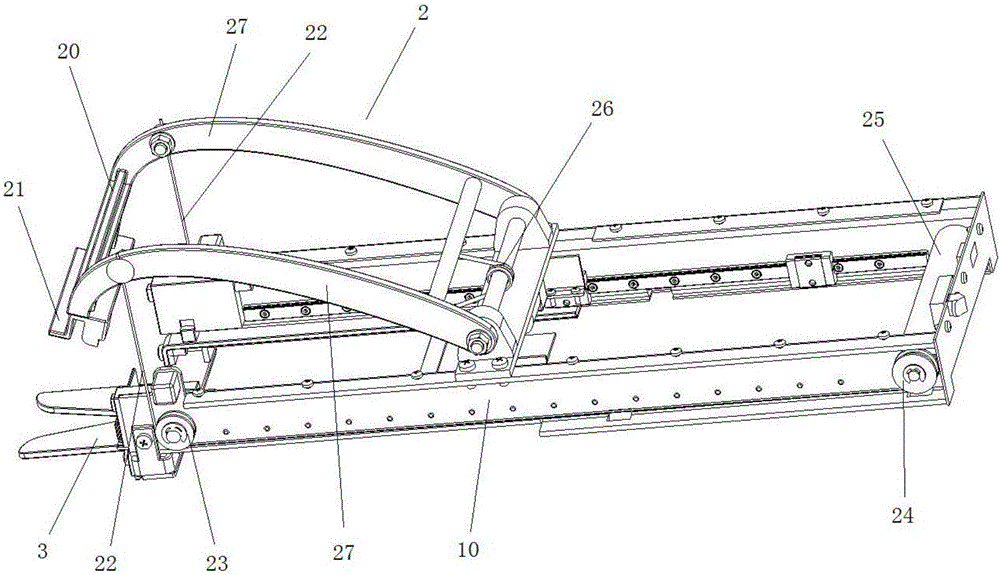

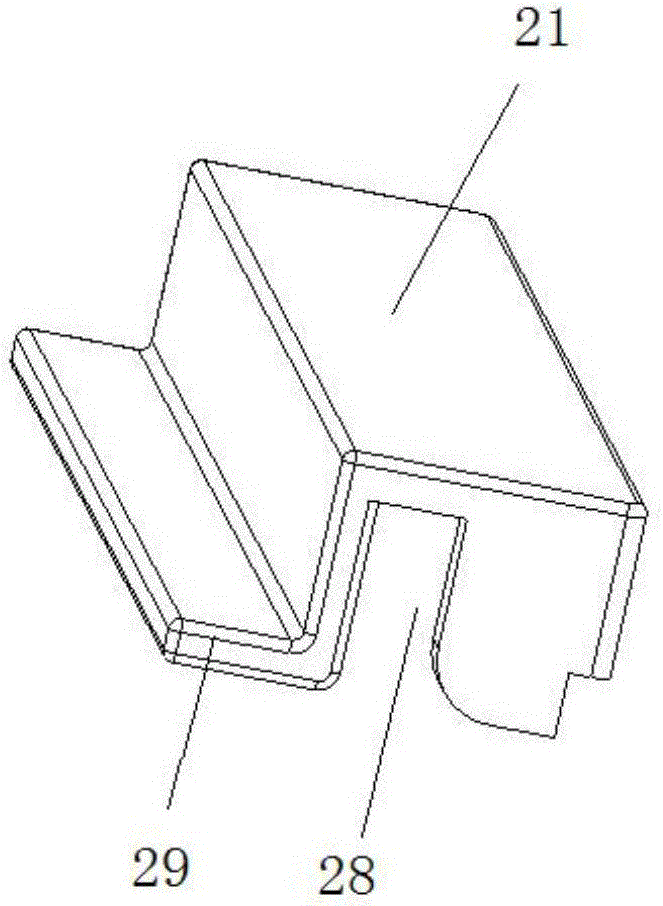

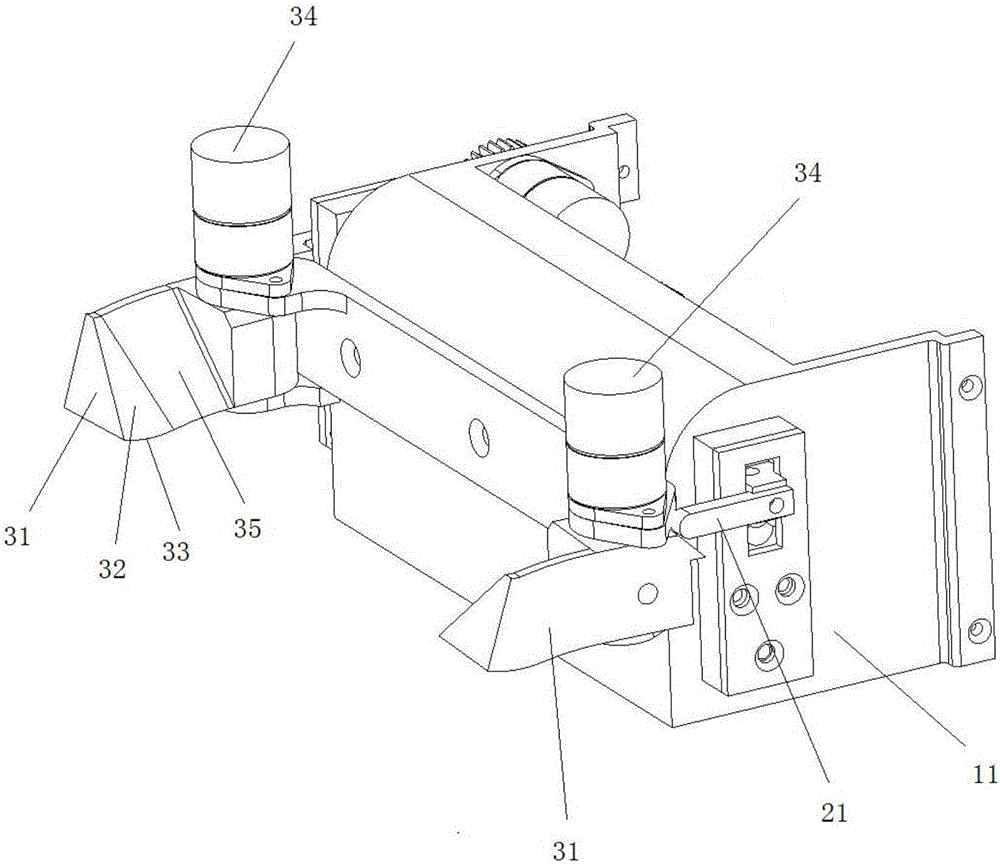

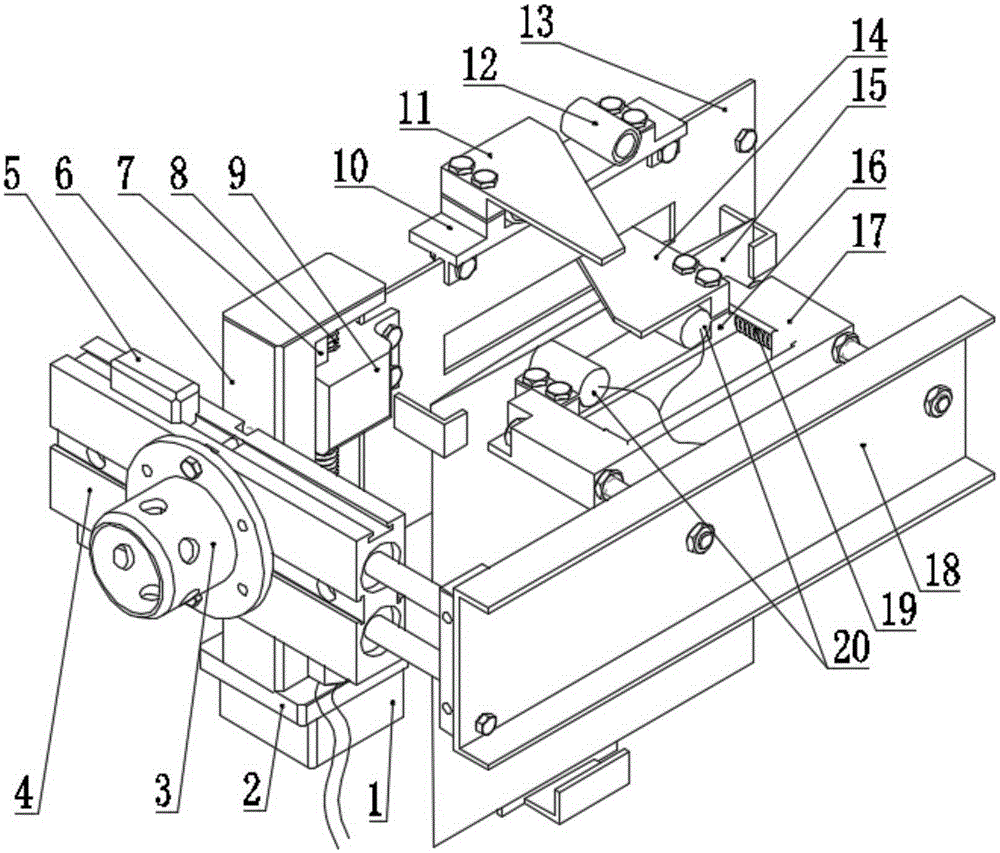

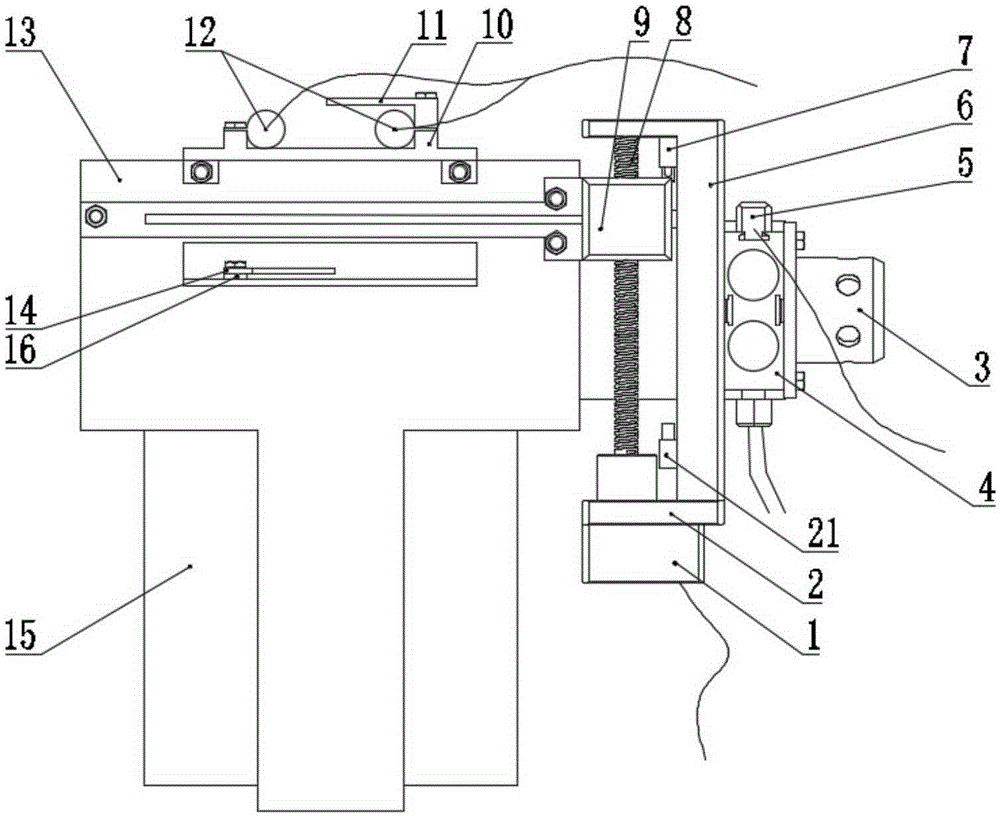

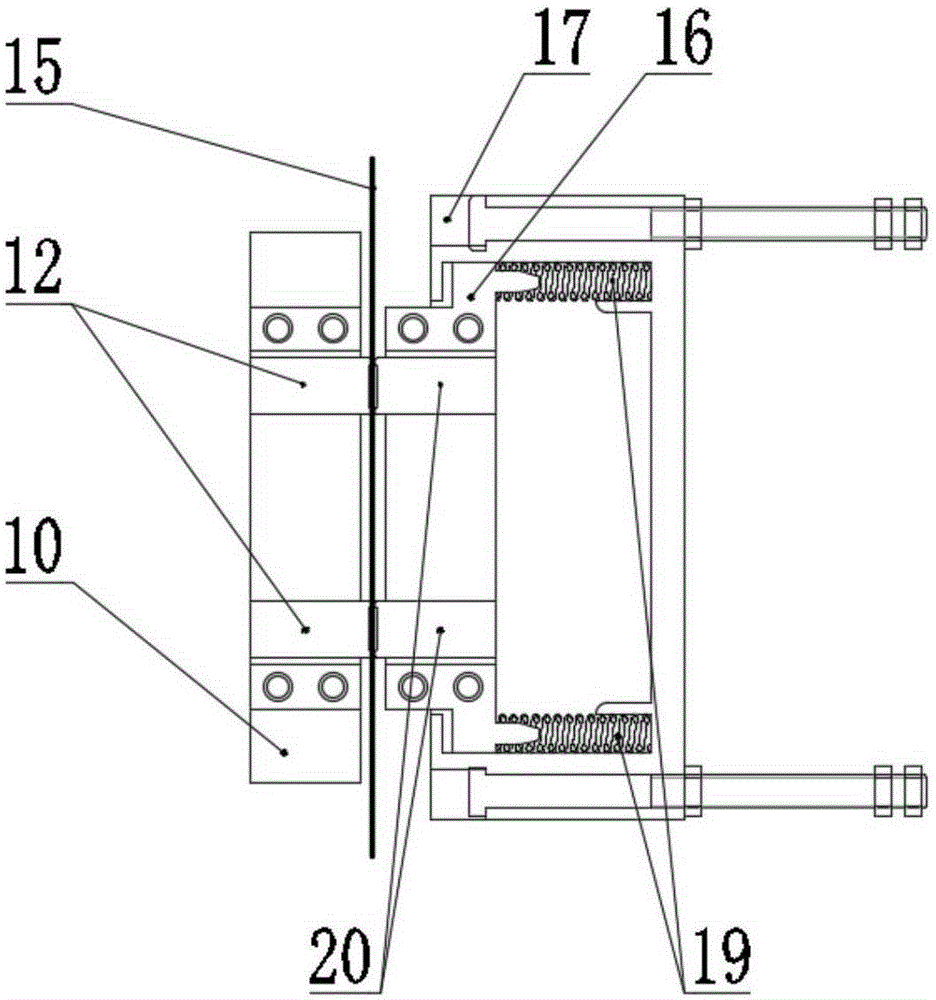

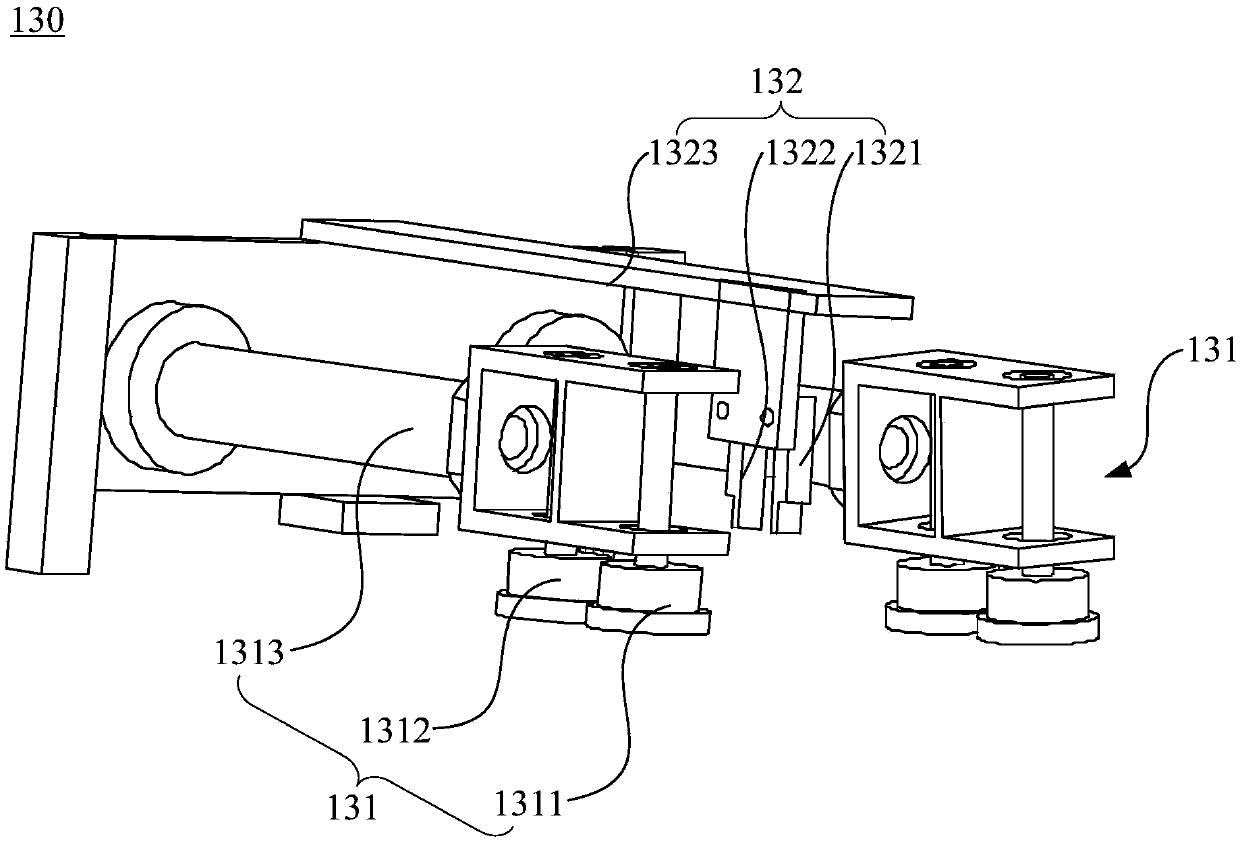

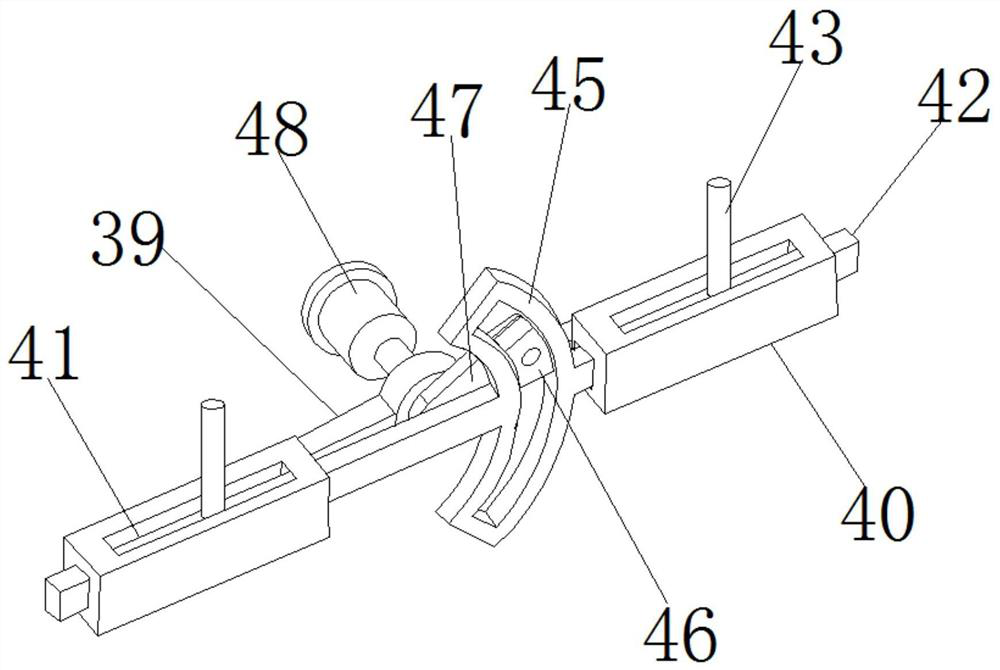

Transmission mechanism of fruitlet bagging machine

The invention discloses a transmission mechanism of a fruitlet bagging machine. The transmission mechanism comprises an upper arm, wherein a first torsion spring for driving the upper arm to rotate far away from the upper side of the bagging machine is arranged on a hinged shaft of the upper arm, a push arm for driving a bag delivery mechanism, an intermittent push rod for driving an intermittent mechanism to rotate, and an adsorption pull rod for driving a bag opening device to move are arranged sequentially from the hinged shaft of the upper arm to the free end of the upper arm, and the intermittent mechanism is used for switching actions of the bag delivery mechanism and the bag opening device. The transmission mechanism of the fruitlet bagging machine can link the bag delivery mechanism with the bag opening device, the bag delivery and the preparation for bag opening can be realized by pressing the upper arm once, and therefore, through the bag opening device, the bagging efficiency can be improved, and the bagging workload and cost can be lowered.

Owner:SICHUAN KUOCHENG TECH CO LTD

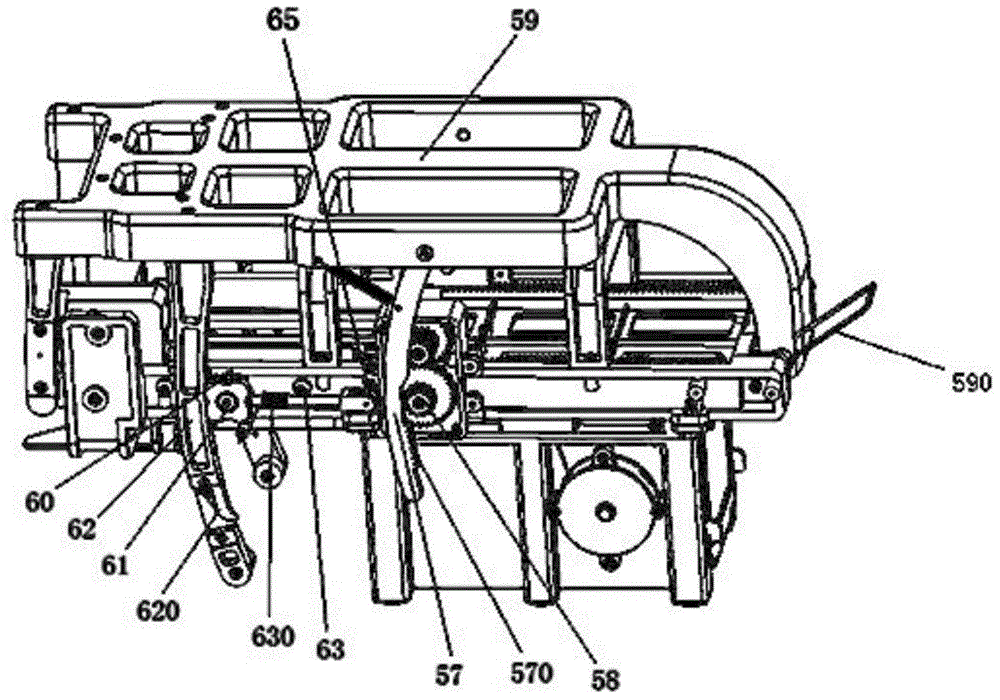

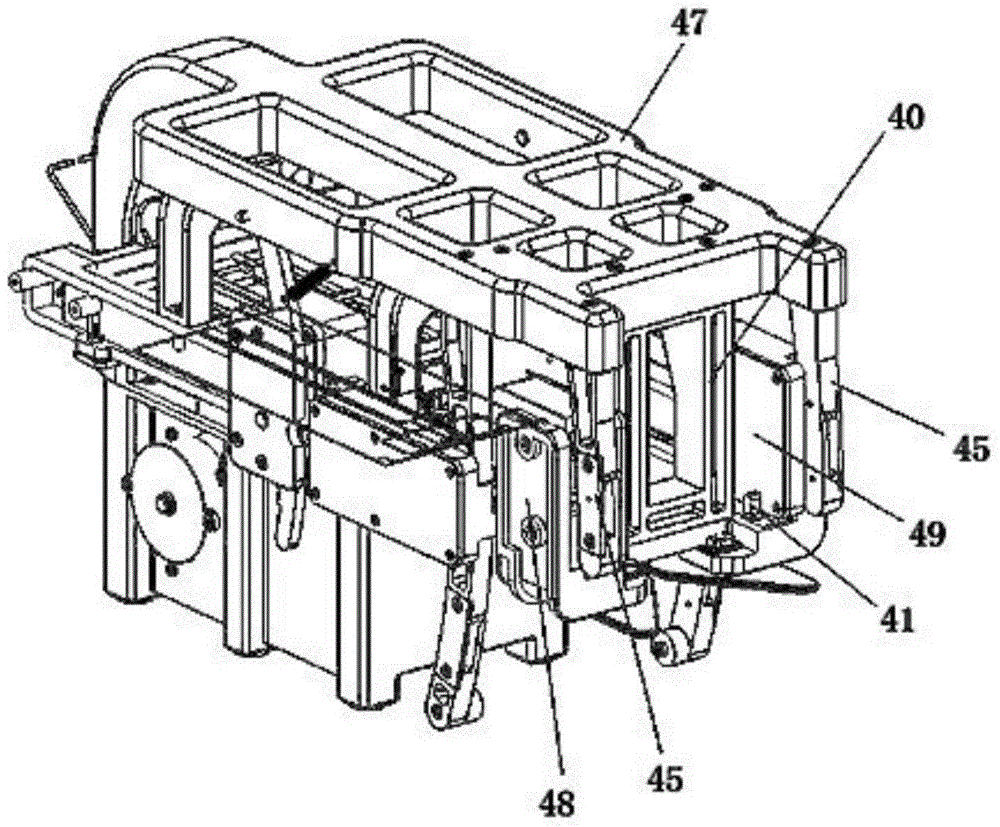

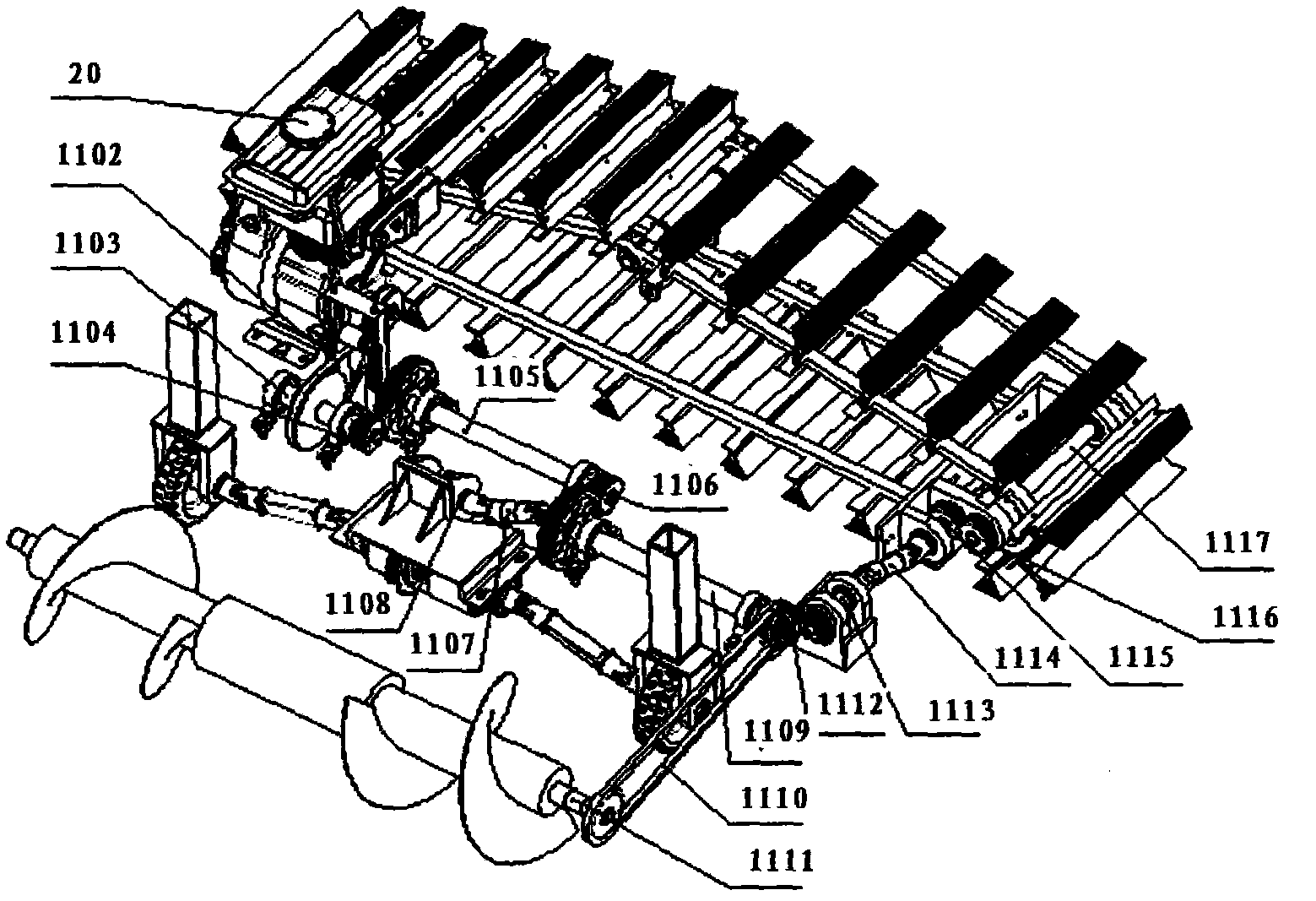

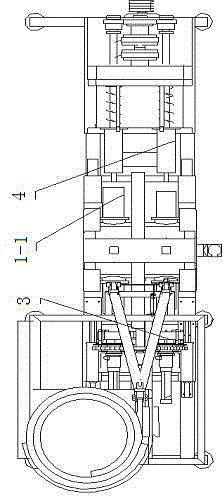

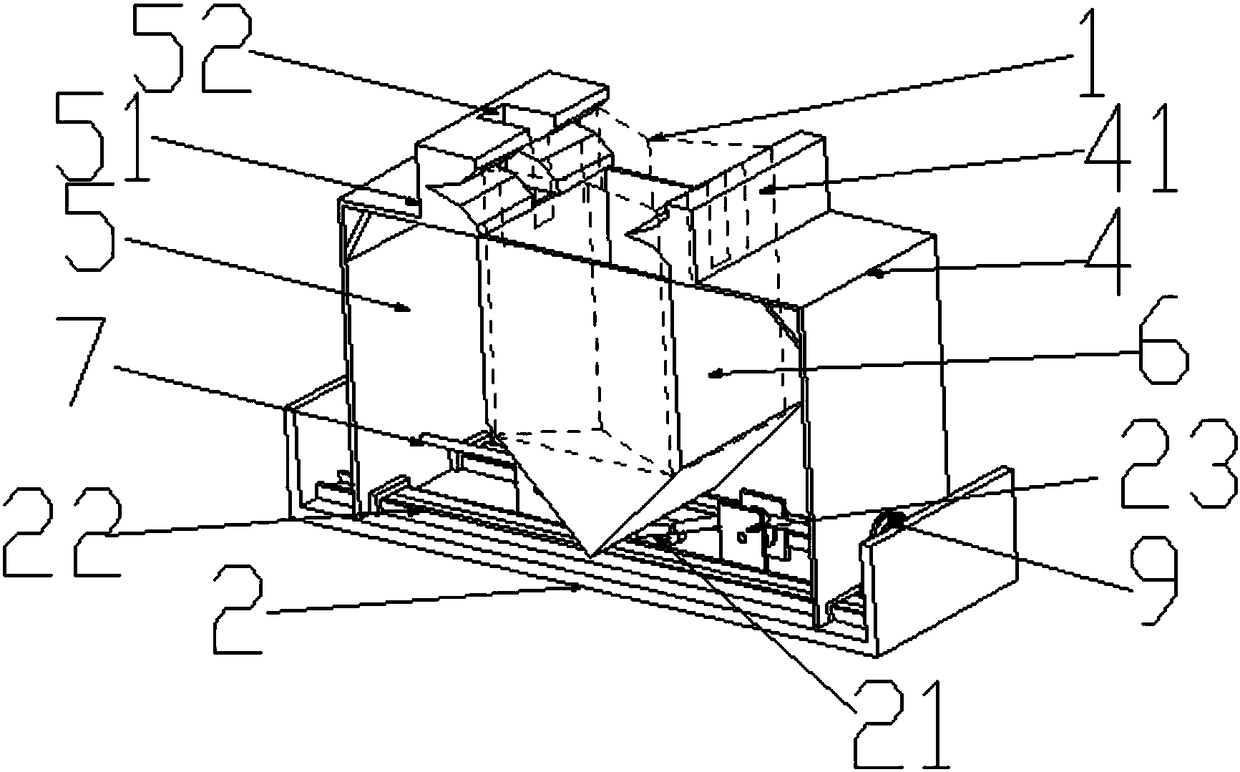

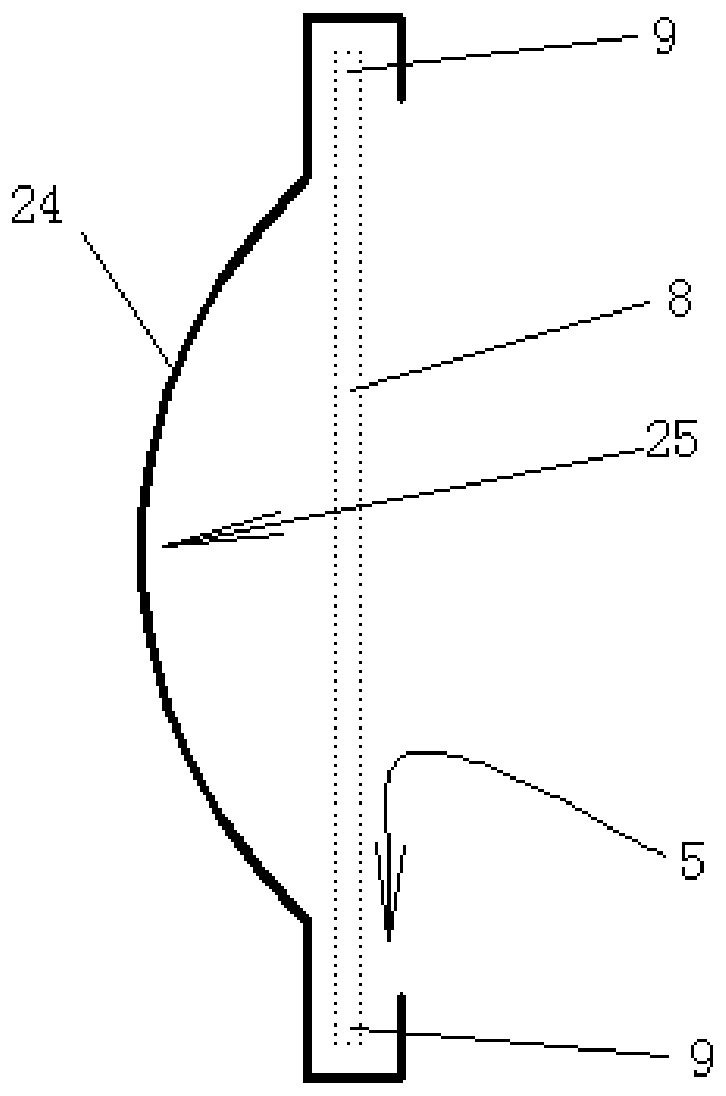

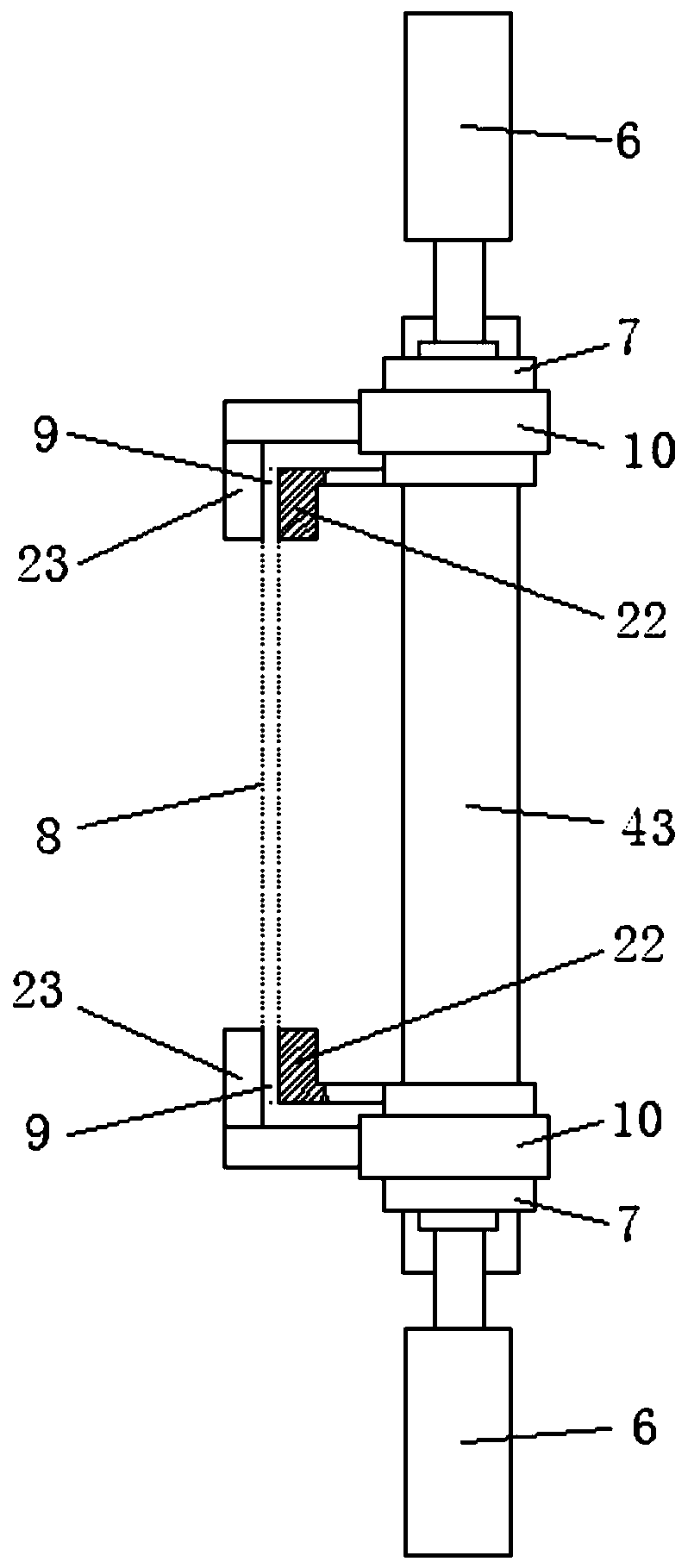

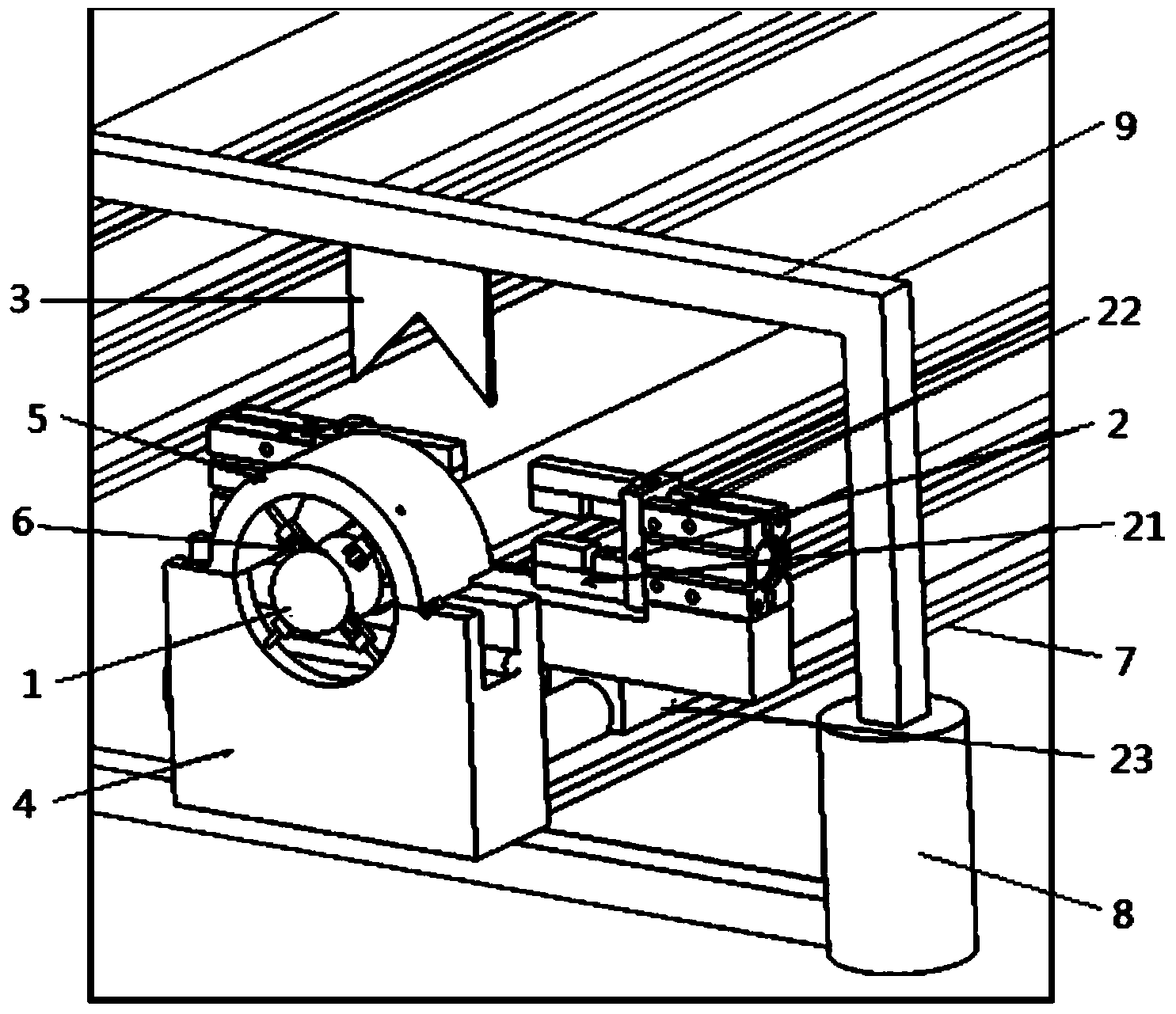

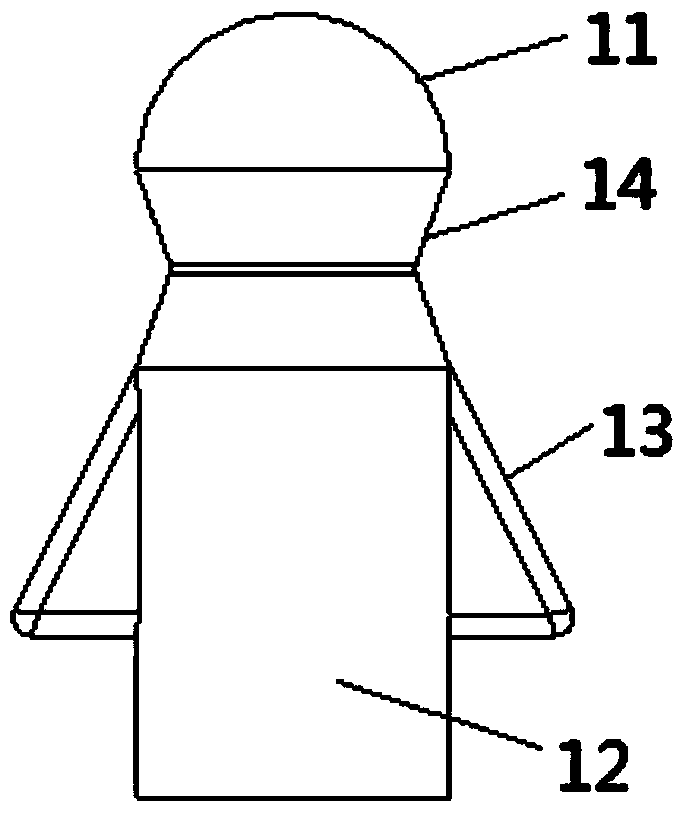

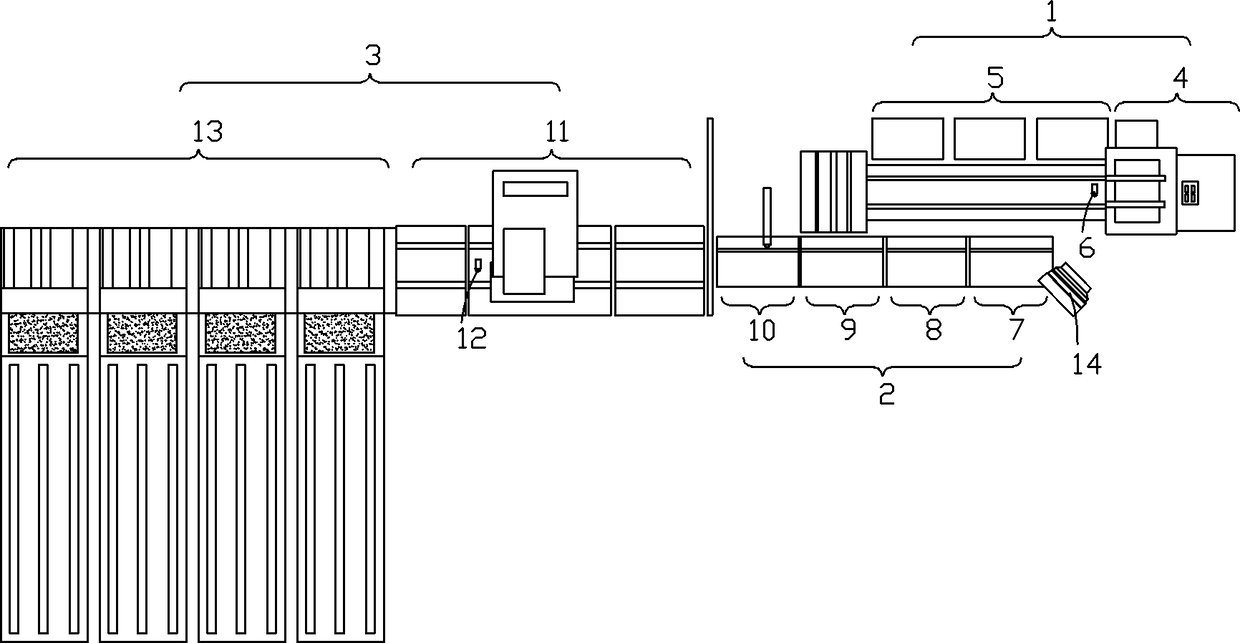

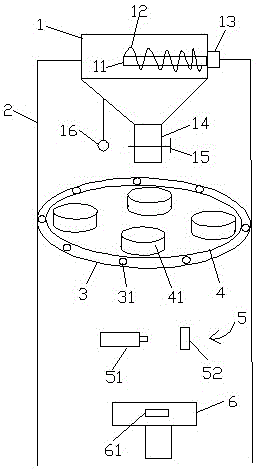

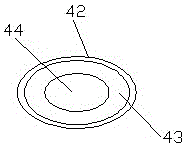

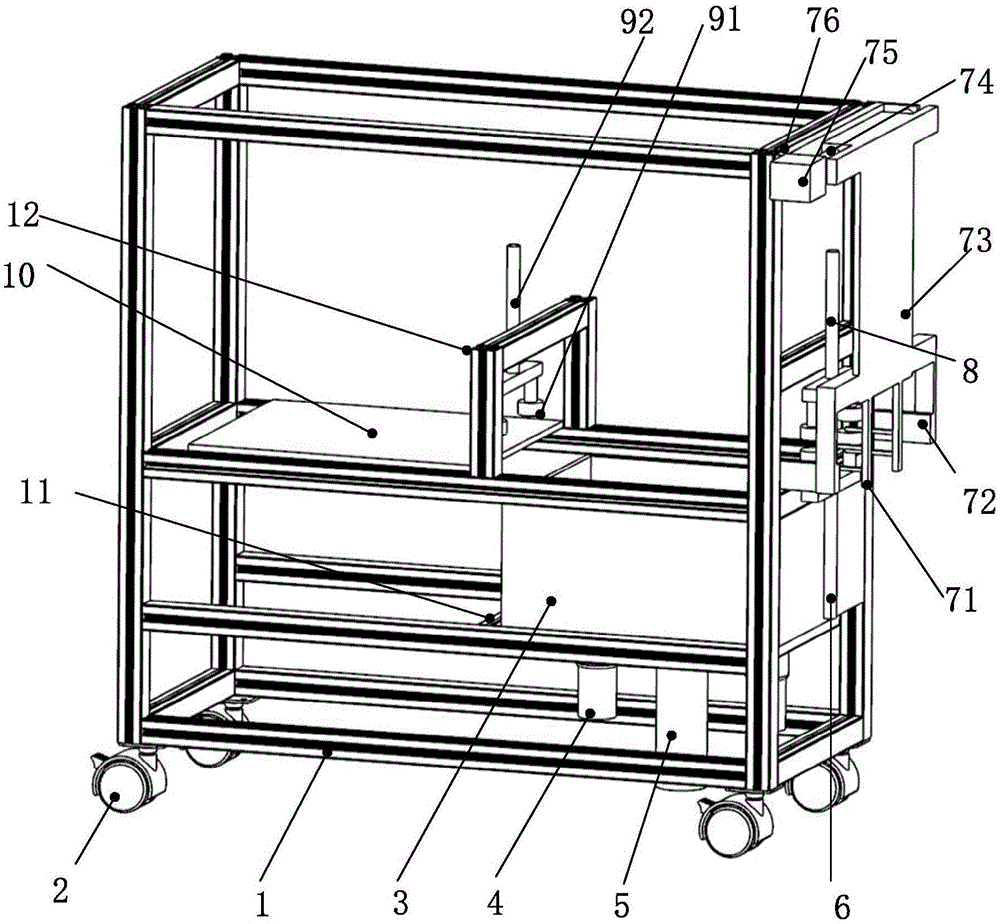

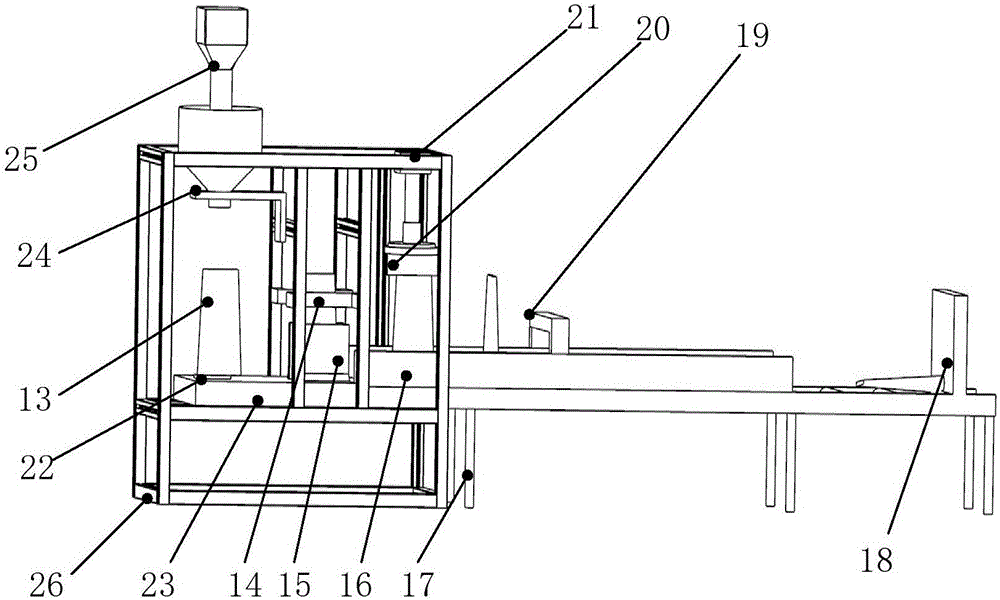

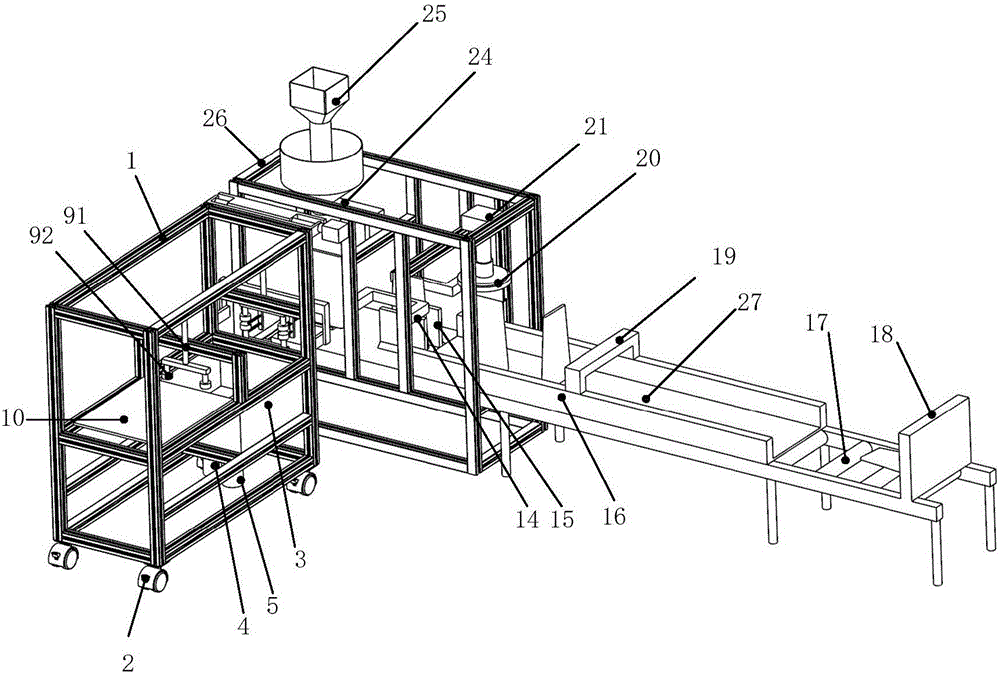

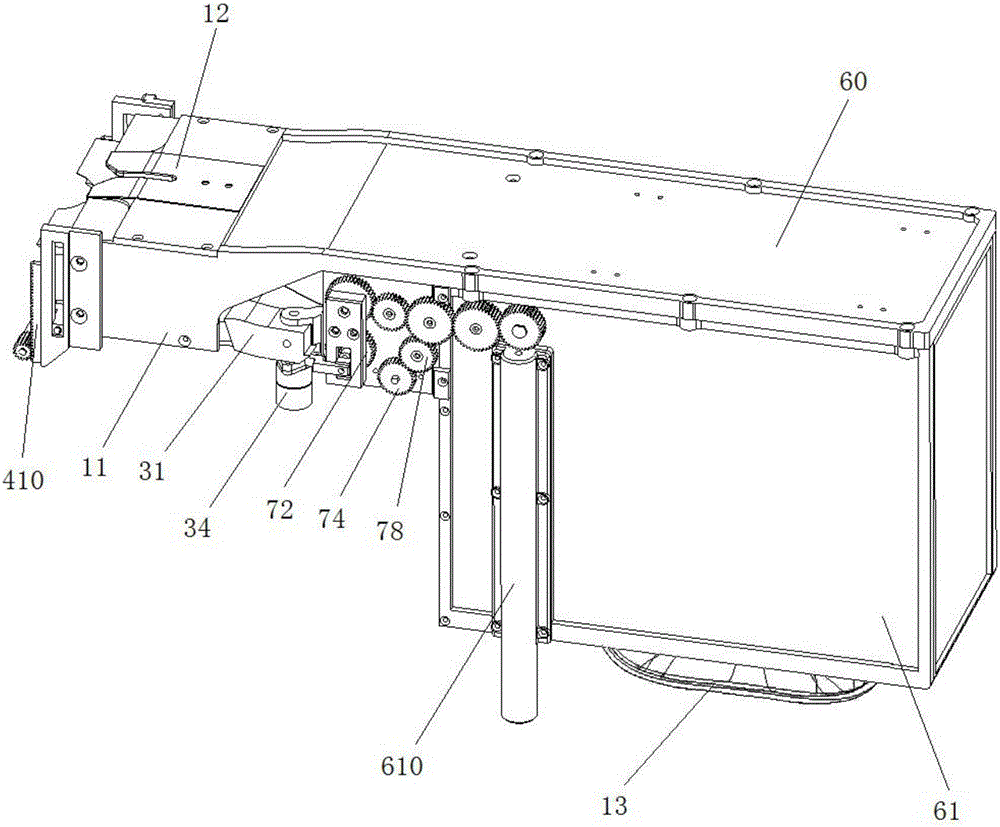

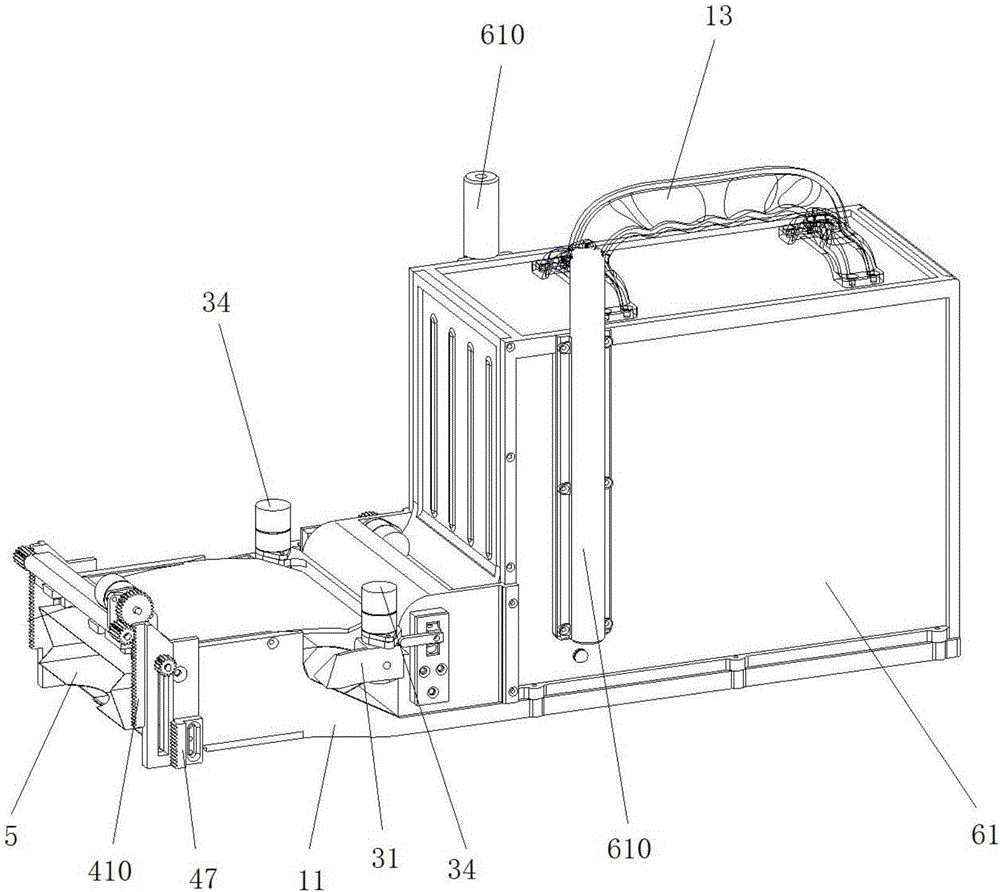

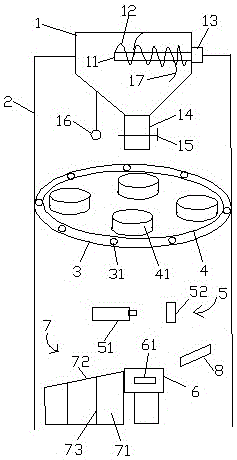

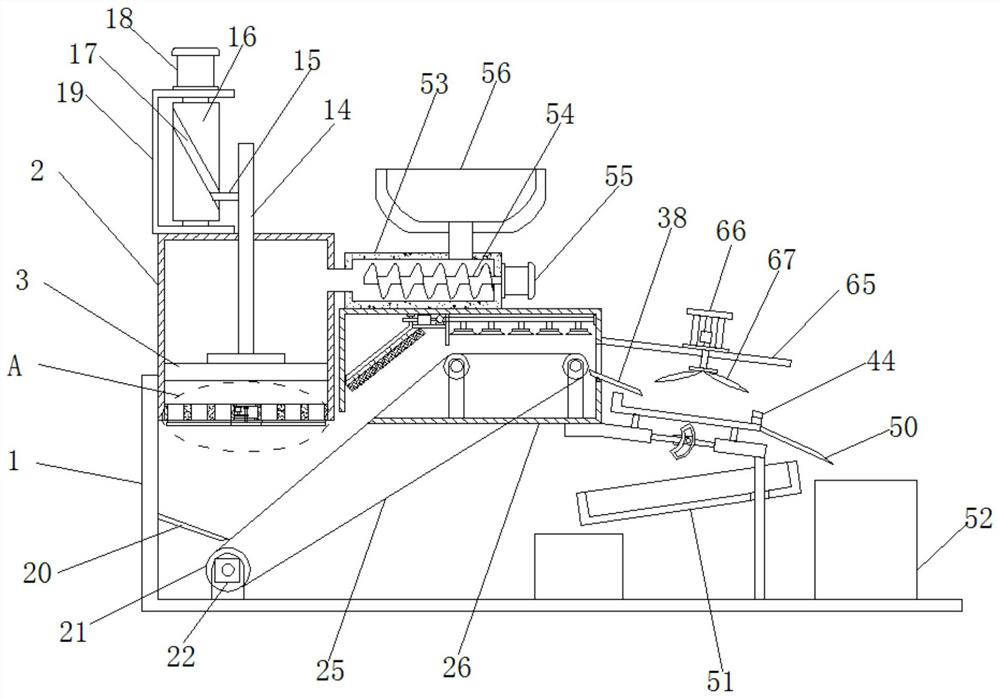

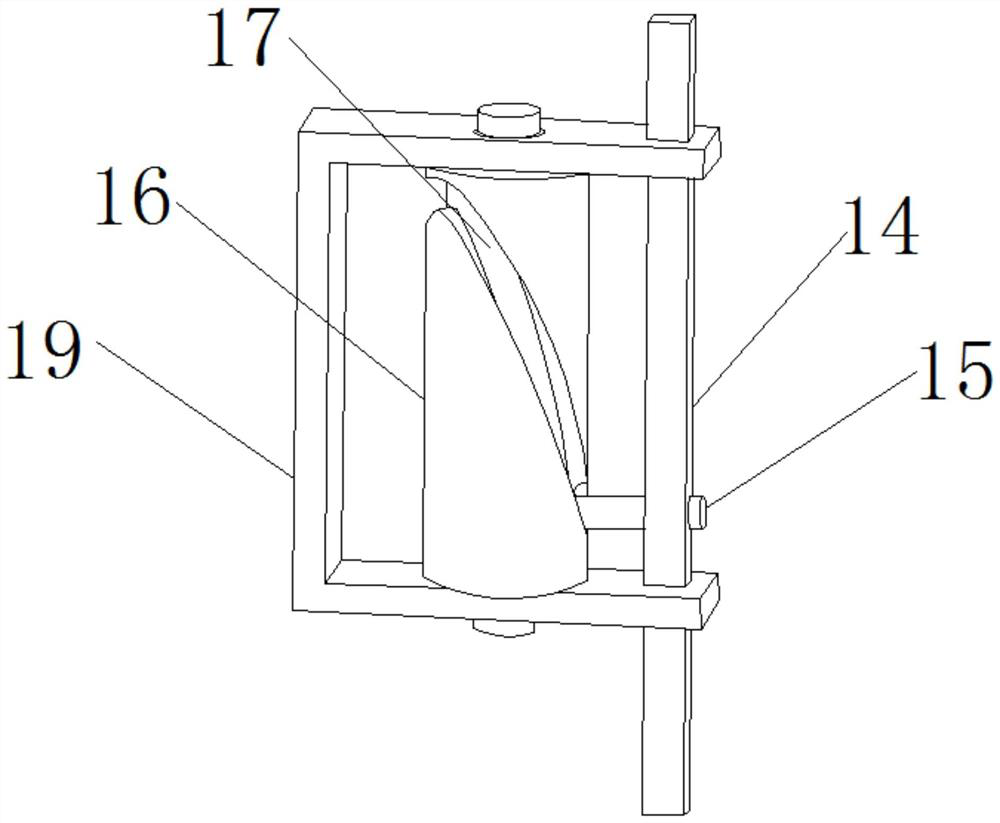

Integrated multi-station rotary bag filler of edible fungi cylinder and packing method

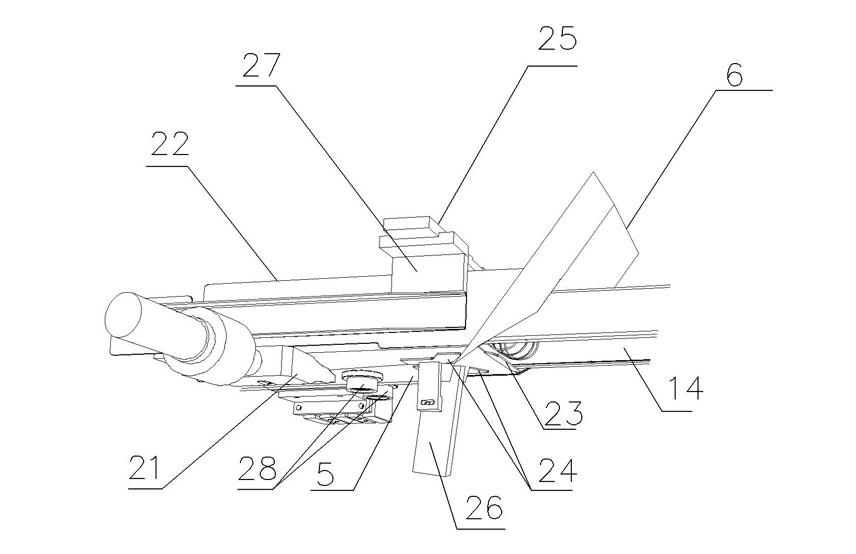

InactiveCN104875924APrecise Control of Vertical RotationBag tightSolid materialCultivating equipmentsAgricultural engineeringScrew conveyor

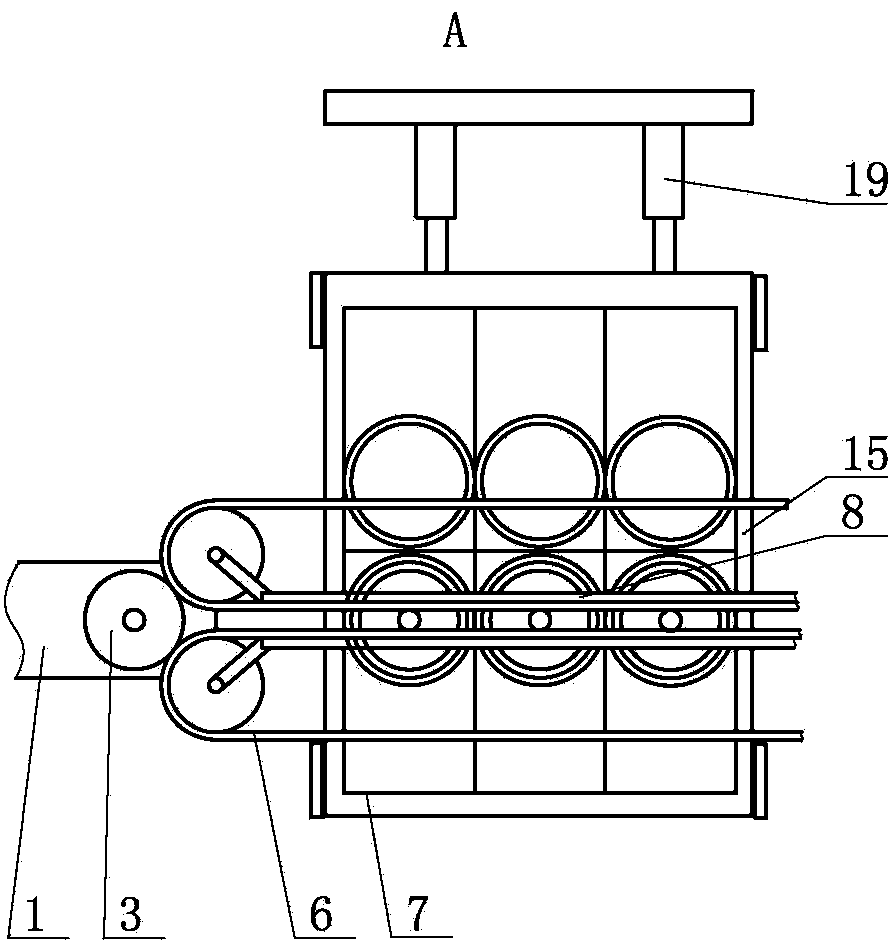

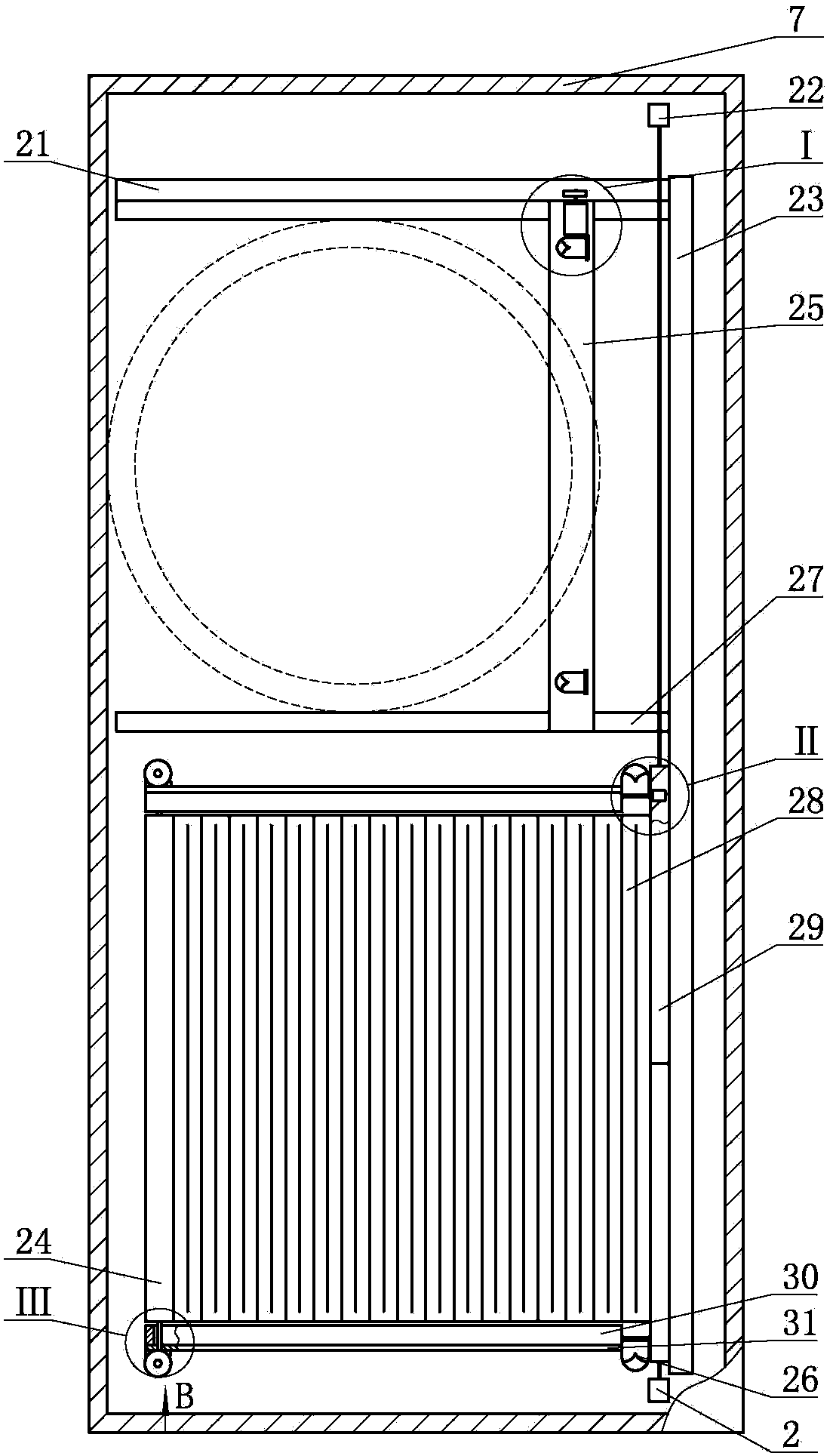

The invention discloses an integrated multi-station rotary bag filler of an edible fungi cylinder and a packing method. The integrated multi-station rotary bag filler of the edible fungi cylinder comprises a frame, a drum device, a hole former and a discharging device, wherein the upper part of the frame is connected with the discharging device, the hole former and the drum device, the drum device is provided with a rotary drum provided with a shape drum, and the lower part of the rotary drum device is connected with a sliding frame connected with the hole former; the drum device is connected with a rod arrangement device through a rod taking device, and the discharge device is provided with a spiral conveying mechanism which is arranged in a driving device.

Owner:伊春技师学院

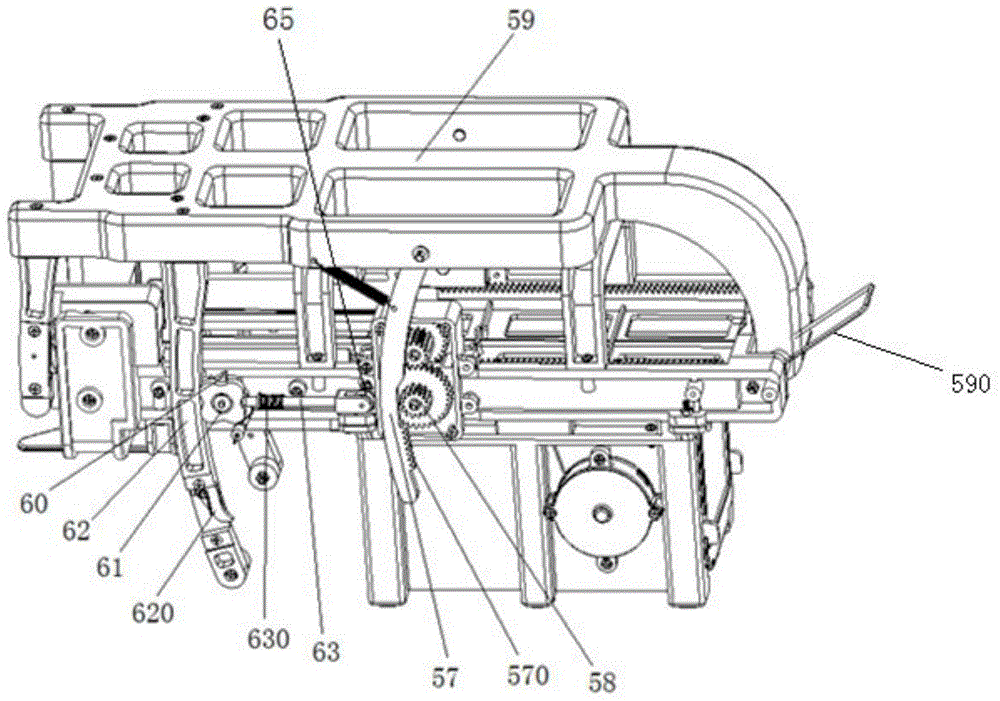

Automatic young fruit bagging machine

ActiveCN105918025AAvoid harmAvoid accidental breakagePlant protective coveringsDrive wheelElectric machinery

The invention discloses an automatic young fruit bagging machine. The automatic young fruit bagging machine comprises an upper press fit frame and a fork plate device, wherein the upper press fit frame comprises a pressing fork; one end of the pressing fork is hinged to a frame; a pressure plate is arranged at the other end of the pressing fork; the pressure plate is arranged above the fork plate device; a bag storing box is arranged below the frame; an automatic bag loading device is arranged in the bag storing box; an automatic bag feeding device is arranged at the upper end of the bag storing box; a handle is arranged above the frame; the handle is provided with a control switch; the fork plate device is provided with two fork plates stretching in a V shape; one end of the pressing fork is fixedly connected with a stay cord; the stay cord is connected to a driving wheel at the back end of the frame after crossing a driven wheel; the driving wheel is driven by a motor; the control switch is used for controlling the motor to rotate forwards or backwards. By adopting the automatic young fruit bagging machine, automatic press fit bagging can be realized, thereby increasing the bagging efficiency, and lowering the labor intensity; a V-shaped opening design is adopted at the front end of the fork plate device, so that the problem of fracture of fruit stems in a bagging process is effectively solved.

Owner:好果子农业科技(北京)有限公司

Fruit bagging device

The invention discloses a fruit bagging device. The fruit bagging device comprises a bag and bagging mechanism. The fruit bagging device has the advantages that a fruit farmer only needs to open the bag, place the bag into the bagging mechanism, starts a telescopic rod to extend a fruit sleeve to a to-be-bagged fruit and bag the to-be-bagged fruit with the bag and start a rope tightening mechanismto tighten a pull rope so as to drive a first slide plate and second slide plate to move towards the fruit sleeve to allow a convex tooth block and a concave tooth to close a bag opening, and a steelwire on the bag is bent under the meshing of the convex tooth block and the concave tooth block to seal the bag, the whole bagging and bag opening sealing process is simple and fast, fruit farmer operation is facilitated, the bagging device can effectively increase fruit bagging efficiency as compared with manual bagging, and high safety performance is achieved due to the fact that the fruit farmer does not need to climb fruit trees.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Ink automatic bagging mechanism

PendingCN109911321ARealize mechanized workImprove bagging efficiencyWrapper twisting/gatheringProduction lineEngineering

The invention relates to the technical field of ink bag type filling automatic production lines and discloses an ink automatic bagging mechanism. The ink automatic bagging mechanism comprises a bag feeding guide seat, a bag clamping assembly, a bag opening assembly, a bag sealing assembly and an ink filling and charging device which are sequentially arranged from the bottom to top; a guide grooveis formed in the bag feeding guide seat and is formed in an erecting manner; the bag clamping assembly comprises a pair of movable bases and a pair of bag clamping air cylinders; the pair of movable bases is driven by a pair of bag opening folding and tightening air cylinders; the pair of bag clamping air cylinders is correspondingly connected with the pair of movable bases; the bag opening assembly comprises a pair of bag sucking air cylinders correspondingly placed on the two sides of the outer surface of a bag; the front ends of the bag sucking air cylinders are connected with bag opening sucking discs; and the bag sealing assembly comprises heat-sealing devices which are driven by a pair of bag sealing air cylinders. Bag type automatic filling of ink can be achieved, so that residues after the ink is used are reduced, and the purposes that waste of an ink resource is reduced and the environmental pollution is reduced are achieved.

Owner:江阴市惠法特机械有限公司

Aluminum pipe bagging device

ActiveCN103625667AReduce labor intensitySave human effortIndividual articlesEngineeringMechanical engineering

The invention discloses an aluminum pipe bagging device. A guide jig capable of spreading a bag to be open is arranged at the front end of an aluminum pipe, a clamping jig capable of clamping the head end of the bag and capable of moving along the length of an aluminum pipe is arranged behind the guide jig, a cut-off tool capable of cutting the bag off is arranged above the front end of the aluminum pipe, the guide jig is sleeved with the head end of the whole roll of the bag, the bag is spread to be open through the guide jig, the clamping jig is used for clamping the head end of the bag, the bag is pulled by the clamping jig from front to rear, and meanwhile is continuously unrolled and spread to be open, and the aluminum pipe is sleeved with the bag, when the whole aluminum pipe is bagged, the bag is cut off by adopting the cut-off tool, and then the bagged aluminum pipe is removed, and un-bagged aluminum pipe is located, the head end of the bag is clamped again by adopting the clamping jig, and repetitive operation is carried out. Thus, according to the aluminum pipe bagging device provided by the invention, mechanical bagging of the aluminum pipe with a treated anode is realized, the labor intensity is alleviated, the labor force is saved, and the bagging efficiency and economic benefits are improved.

Owner:昆山市工业技术研究院有限责任公司

Automatic quantitative bagging machine

InactiveCN101836554AImprove bagging efficiencyIncrease productionSolid materialHorticultureEconomic benefitsEngineering

The invention discloses an automatic quantitative bagging machine, which comprises a machine frame, a feeding device and a discharging device. The discharging device comprises a discharging pipe and an auger arranged in the discharging pipe; an auger shaft is provided with a clutch; one side near a discharge hole of the discharging pipe is provided with a bag supporting frame; the bag supporting frame is provided with a sliding shaft; a guide slot is formed near the discharge hole of the discharging pipe; the bag supporting frame is connected on the guide slot through the sliding shaft in a sliding way; the bottom of the bag supporting frame is provided with a connecting rod; the connecting rod is connected with a loop bar hinged on the machine frame in a sliding way; an elastic structure is arranged between the connecting rod and the loop bar; and the loop bar is connected with the clutch through a control mechanism. The automatic quantitative bagging machine effectively solves the problems of influence on yield and quality of edible fungus due to nonuniform tightness and inconsistent lengths of fungus bags bagged by the conventional bagging machine. Meanwhile, the bagging machine has the advantages of high efficiency, great improvement on production conditions, reduction of production cost and obvious improvement of economic benefit.

Owner:苏和生

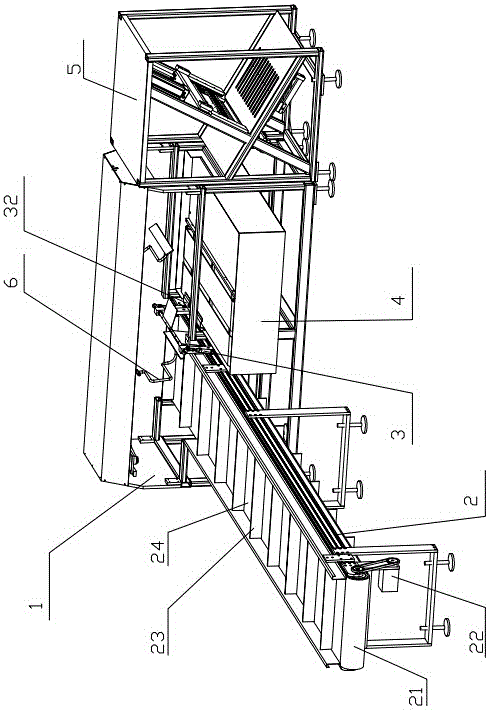

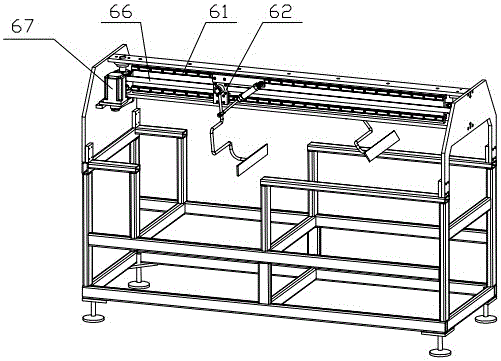

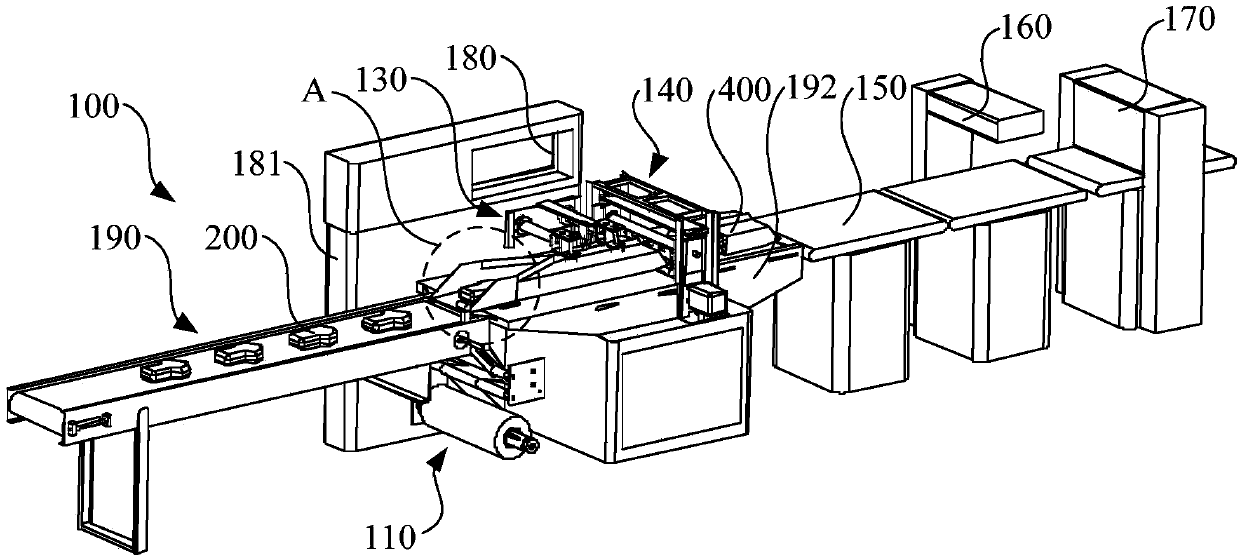

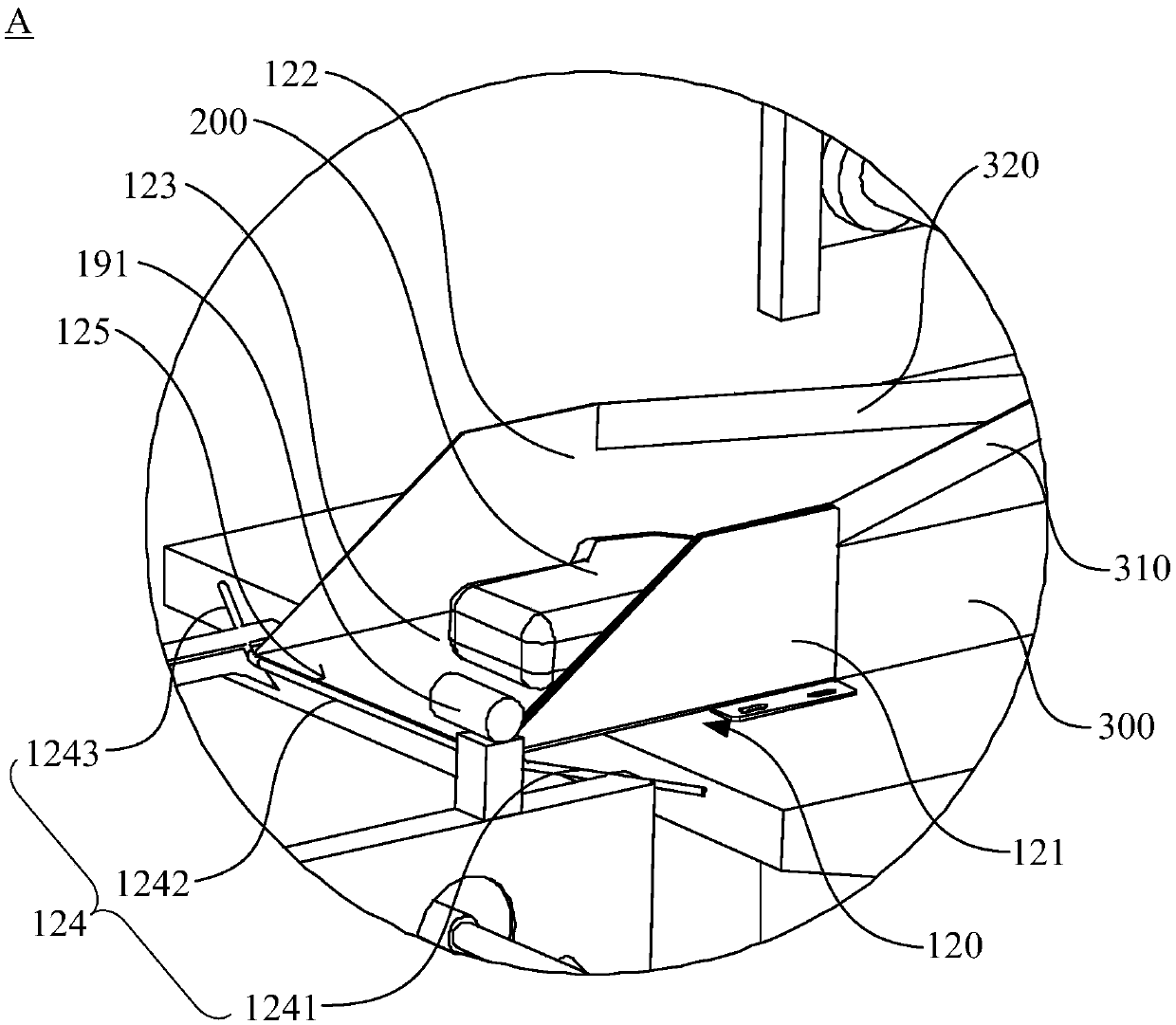

Automatic mail packaging and sorting production line

PendingCN108906640AImprove packaging efficiencyImprove sorting efficiencySortingIndividual articlesProduction linePersonal computer

The invention discloses an automatic mail packaging and sorting production line. The automatic mail packaging and sorting production line comprises a conveying line A, a conveying line B and a conveying line C. A letter conveying device and an insert feeding device are sequentially arranged on the conveying line A, and a bar code scanner A is arranged. An envelope feeding device, an envelope sealing cover unsealing device, a letter bagging device and an envelope sealing device are sequentially arranged on the conveying line B. A mail address tag pasting device is arranged on the conveying lineC, and a bar code scanner B is arranged. A mail sorting device is arranged at the tail end of the conveying line C. The bar code scanner A and the bar code scanner B are in communication connection with an industrial personal computer, and the industrial personal computer controls the mail address tag pasting device and the mail sorting device in real time. According to the automatic mail packaging and sorting production line, the links of letter and envelope feeding, mail bagging operation and subsequent mail sorting on a mail packaging production line are updated and optimized, the efficiency of mail packaging and sorting is greatly improved, the workload of workers is greatly reduced, and the work intensity of the workers is reduced.

Owner:中国邮政速递物流股份有限公司黄石市分公司

Device for fruit bagging

InactiveCN101167432AOutstanding FeaturesHighlight significant progressPlant protective coveringsEngineeringGas chamber

The invention discloses a fruit bagging device, which comprises a main body operating part and a gas compression storage part, which is characterized in that the gas storage chamber (5) of the gas compression storage part inflates the fruit bag through an air outlet hose (6), and the main body operates In part, the pulling of the right trigger (38) and the left trigger (39) drives the outer transmission member (28) and the inner transmission member (29) to move forward, so that the bag feeder (32), the front action arm (9), the inflation port (20), the front action arm transmission rod (21), the mouth stopper (13), the inflation switch (40), and the staple pressing sheet (18) act to complete the bagging process. The device is light, Durable, fast and reliable, it adopts the characteristics of three-point support, inflatable bag support and binding and sealing in the bagging process. The whole bagging process is smooth, standard, fast, easy and efficient, and the bags produced are standard, beautiful and Strong, resistant to weather and pests.

Owner:孙康云

Bagging system and bagging method thereof

ActiveCN103448951AOvercome the problem of easy bagging failureImprove bagging efficiencyPackagingEngineeringPower unit

The invention relates to a bagging system comprising a negative pressure opening system and a bagging device. The negative pressure opening system comprises an upper suction device, a lower suction device, a suction device power system and a negative pressure generator. The upper suction device comprises an upper suction nozzle part and an upper suction hose. The lower suction device comprises a lower suction nozzle part and a lower suction hose. The suction device power system comprises an opening power unit and a sleeving power unit. The negative pressure generator comprises a suction fan. The bagging unit comprises an opening device, a bagging transfer plate, a transfer plate motor and a bagging part. The opening device comprises a pair of upper opening plates. The bagging transfer plate between the upper opening plates is provided with an upper bagging through hole. A bagging method of the bagging system includes the steps of opening, sleeving, bagging and the like. The bagging system and the bagging method thereof have the advantages that a negative pressure adsorption positioning scheme and full-automatic mechanical operation help increase bagging efficiency, and the bagging system and the bagging method thereof are suitable for large-scale batch production.

Owner:安徽御流包装机械有限公司

Automatic sand and gravel bagging machine

InactiveCN106167105AImprove bagging efficiencyAccurate measurementLarge containersWrapper twisting/gatheringEngineeringNail plate

The invention discloses an automatic sand and gravel bagging machine which comprises a hopper, a fixed frame, a rotating plate fixing base, a rotating plate, a tying machine and a jacking table. A discharge port is formed in the bottom of the hopper and provided with an electromagnetic valve. A vibration swing hammer is arranged on the side wall of the hopper or the fixed frame. The rotating plate fixing base is coaxially arranged below the hopper. The outer side wall of the rotating plate fixing base is fixedly connected with the fixed frame. A plurality of woven bag fixing bases are arranged on the rotating plate. Each woven bag fixing base comprises a through hole, an electromagnet and a metal pressing block, wherein when the electromagnet is powered on, the metal pressing block can attract the electromagnet. The tying machine is arranged below the rotating plate and coaxial with the discharge port. The tying machine comprises an opening sealing machine head and a nail plate. A weighing sensor connected with the electromagnetic valve is arranged on the jacking table. By means of the machine, material blockage can not easily happen, blocking materials or wall-sticking materials can be automatically removed, the bagging amount can be automatically controlled, and bagging efficiency is high. The automatic opening sealing operation of sand and gravel bags can be achieved, opening sealing efficiency is high, opening sealing quality is good, and material leakage can not easily happen.

Owner:许陈菲

Bagging machine

ActiveCN105129119AEasy to assembleImprove bagging efficiencyWrapper twisting/gatheringIndividual articlesEngineeringFood packaging

The invention discloses a bagging machine and solves the problems that existing food packaging is troublesome in bagging and low in efficiency. The bagging machine comprises a rack, a feeding device, a blowing device, a belt conveying device and a belt ironing device, wherein the belt conveying device is used for containing a packaging bag, and the belt ironing device is used for conducting heat-sealing on an opening of the packaging bag, the feeding device and the belt conveying device are arranged in parallel, the belt ironing device is arranged behind the belt conveying device, the feeding device comprises a conveying belt and a first driving part which drives the conveying belt to move, the conveying belt is provided with multiple partition plates, a containing cavity used for containing a part to be packaged is formed between every two adjacent partition plates, the blowing device comprises blowing pipes used for blowing the packaging bag open and a limitation mechanism used for limiting the packaging bag, the rack is provided with a transversely-pushing device which is used for pushing the part to be packaged into the packaging bag, and the transversely-pushing device is also used for pushing the packaging bag to the belt ironing device. The bagging mechanism is convenient to assemble, high in bagging efficiency and low in intensity, materials are not needed to be carried, and the bagged materials are flat and orderly.

Owner:温州市华泽机械有限公司

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

Full-automatic drug packaging device

ActiveCN106347765AFast supplyPrecise control of bag supply heightSolid materialEngineeringConveyor belt

The invention provides a full-automatic drug packaging device. The full-automatic drug packaging device comprises a bag taking machine frame, a bag feeding mechanism, a bag sucking mechanism, a bag opening mechanism, a bag conveying mechanism, a packaging machine frame, a weighing and loading mechanism and a bag sealing mechanism. The bag feeding mechanism comprises a bag feeding drawer, a guiding rod, a bag feeding servo motor and a bag feeding lead screw. The bag opening mechanism comprises an upper separation unit and a lower separation unit which are vertically and oppositely arranged. The bag conveying mechanism comprises two opening expanding claws, an opening expanding claw driving unit, two top blocks, a supporting plate, a rotating rod, a bag conveying servo motor and a connecting plate. The weighing and loading mechanism comprises a loading conveyor belt, a rationed packaging scale, a feeding hopper and a hopper support. The bag sealing mechanism comprises a sealing machine, a bag sealing pneumatic clamping plate, a packaging bag conveyor belt, a steering pneumatic clamping plate, a motor, a roller conveying device, side baffles, a front baffle and a tail baffle. The full-automatic drug packaging device integrates weighing and packaging and is simple in structure, low in manufacturing cost, low in operation cost, high in working efficiency, safe, sanitary and capable of being widely applied to automatic packaging of various products.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV +1

Novel young fruit bagging machine

InactiveCN106416850AShorten the timeImprove bagging efficiencyPlant protective coveringsEngineeringOpening - action

The invention discloses a novel young fruit bagging machine which comprises a rack, a case cover, a bag storage case and a bag conveying mechanism,a bag sealing device is arranged at the front end of the rack, a bag opening device is arranged in the bag conveying process of the bagging machine and comprises two segmentation blocks, the segmentation blocks are hinged to the rack, a segmentation surface is arranged near the inner side at a free end of each segmentation block, segmentation blades at the lower ends or in the middles of the corresponding segmentation surfaces directly face folding gaps on the side surfaces of a bag, the two segmentation blocks rotate around hinged shafts to get close to or be far from the folding gaps on the side surface of the bag, and when the folding gaps on the side surfaces of the bag are cut by the segmentation blades, and the segmentation surfaces are vertically separated and unfolded from the front surface and the back surface of the bag for guiding the bag from the two sides. According to the novel young fruit bagging machine, the bag opening action is completed in the process of conveying the bag from the bag storage case to the bagging position, the fruit bagging operation is directly carried out after the bag is conveyed in the position, the time for opening an opening of the bag is saved, and the bagging efficiency is improved.

Owner:四川果果袋科技有限公司

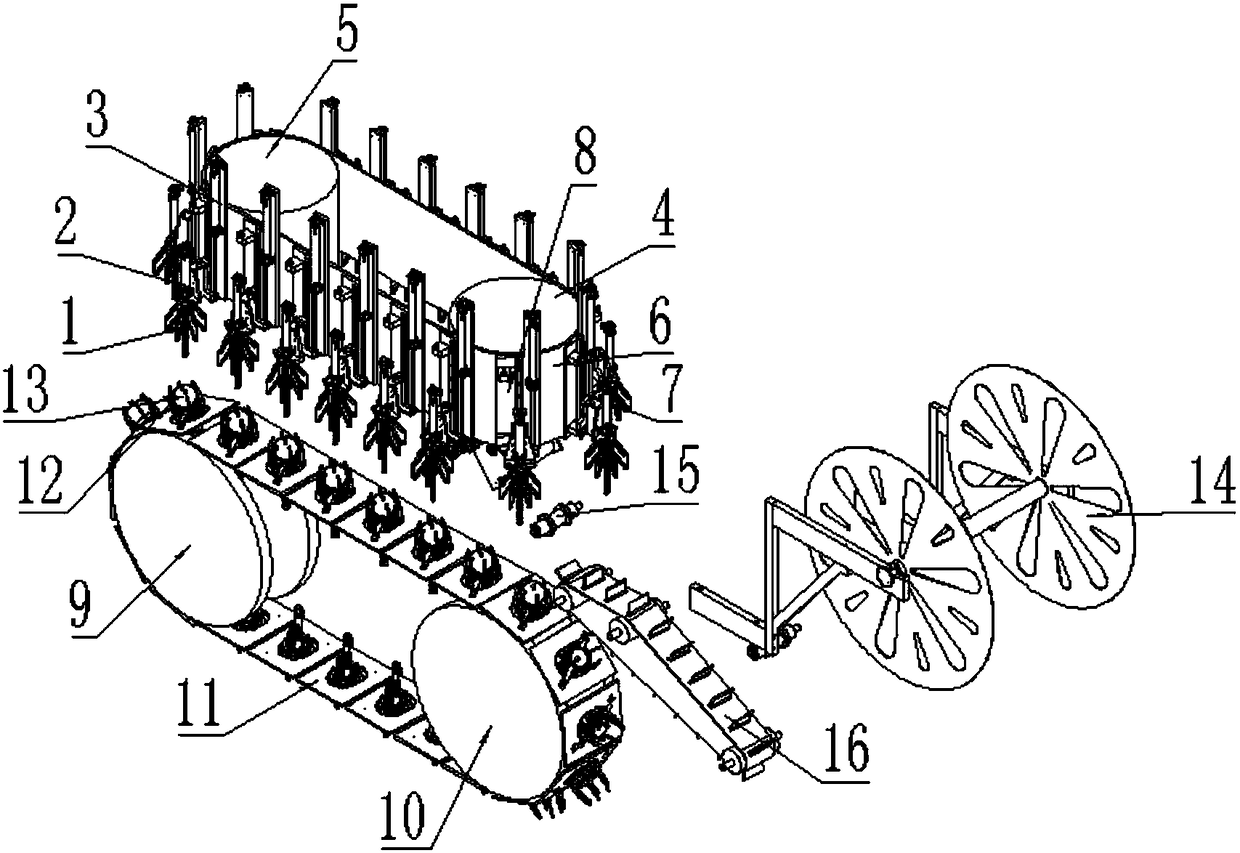

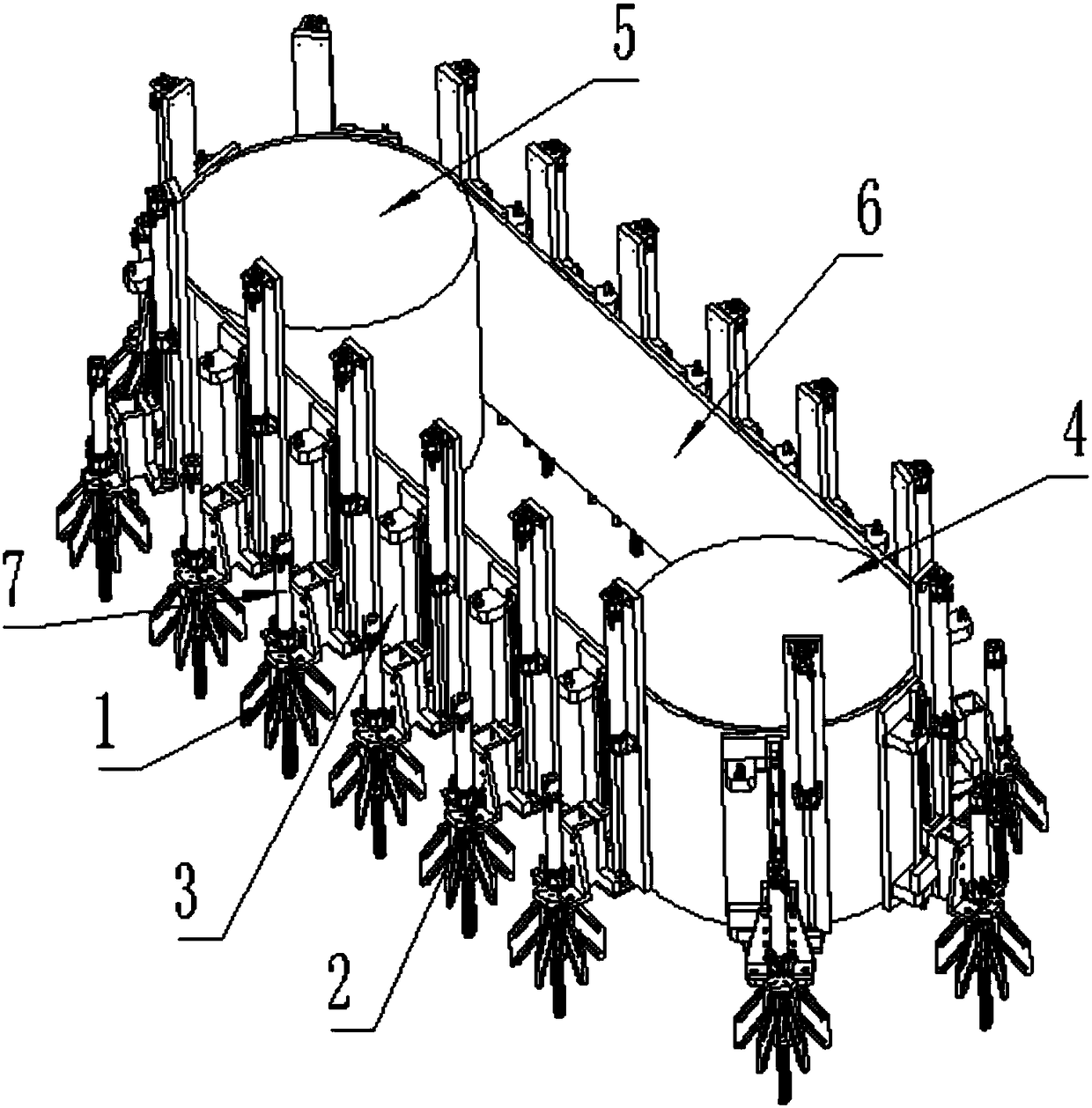

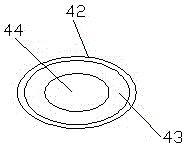

Full-automatic fruit mesh bag sleeving system

PendingCN108482730AImprove bagging efficiencyReduce contact areaPackaging fruits/vegetablesWaste collection and transferEngineeringMechanical engineering

The invention relates to a full-automatic fruit mesh bag sleeving system which comprises a bag opening conveying device and a clamping and separation conveying device. The bag opening conveying devicecomprises multiple bag opening assemblies and a bag opening conveying mechanism. The multiple bag opening assemblies are evenly mounted on the bag opening conveying mechanism. The clamping and separation conveying device comprises multiple clamping and separation assemblies and a clamping and separation conveying mechanism, and the multiple clamping and separation assemblies are evenly mounted onthe clamping and separation conveying mechanism. Each bag opening assembly comprises a bag opening mechanism and a bag opening lifting mechanism. Each bag opening mechanism comprises a bag opening drive mechanism and multiple bag opening claws evenly distributed along a round. Each clamping and separation assembly comprises a clamping and separation mechanism and a clamping and separation drive mechanism. Each clamping and separation mechanism comprises multiple clamping and separation claws evenly distributed along a round. The clamping and separation claws and the bag opening claws are staggered in the circumferential direction. The lower ends of the clamping and separation claws are hinged to opening and closing mechanisms. The clamping and separation drive mechanisms are driven by theopening and closing mechanisms to drive the clamping and separation claws to be opened and closed. When the clamping and separation claws and the bag opening claws are in fruit bagging stations, thecenter axes of the clamping and separation claws are aligned to those of the bag opening claws.

Owner:烟台梦现自动化设备有限公司

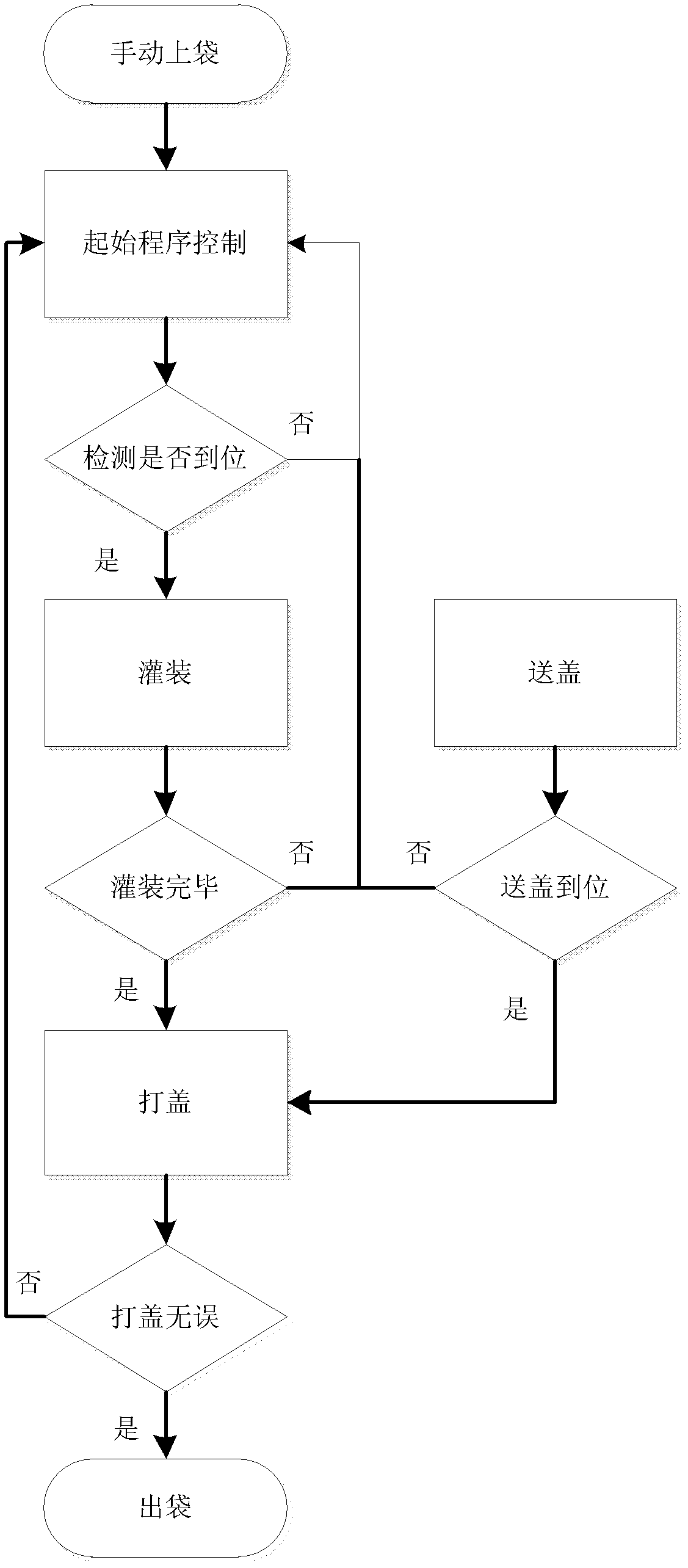

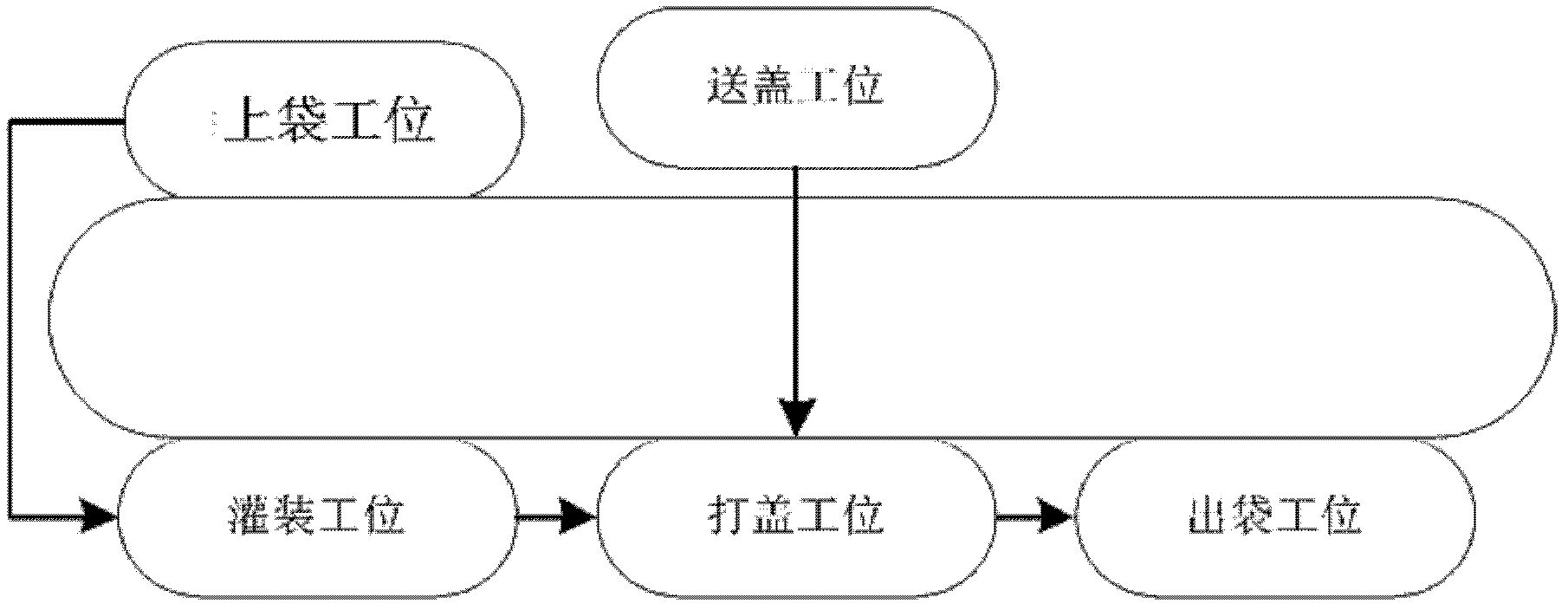

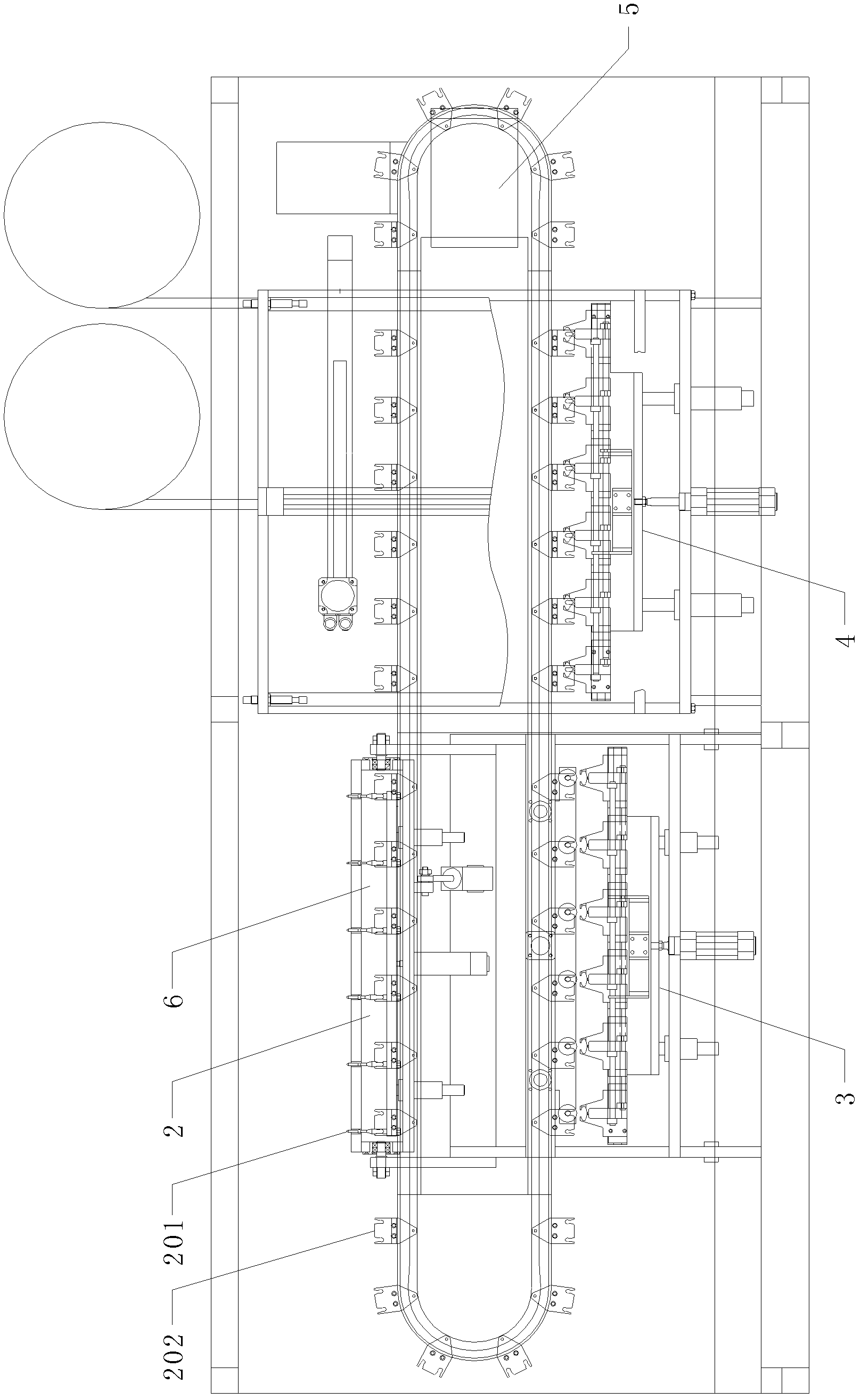

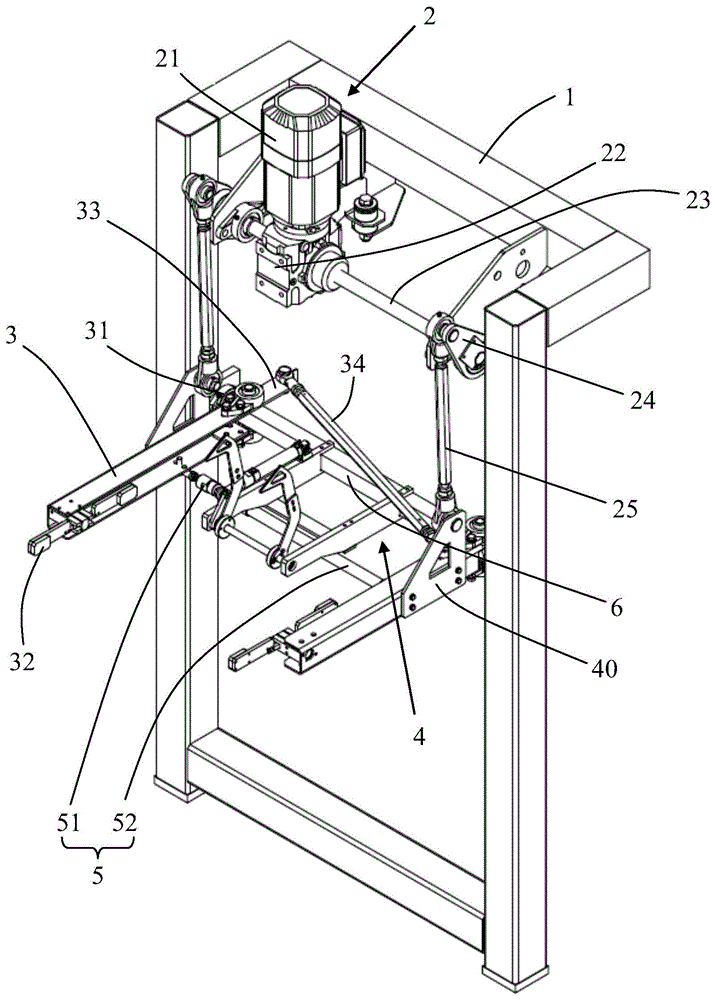

Soft bag automatic filling equipment for transfusion and method for filling transfusion soft bag

ActiveCN102616394AFast bagging processComfortable baggingPackaging automatic controlLiquid materialVertical planeRobot hand

The invention relates to soft bag automatic filling equipment for transfusion and a method for filling a transfusion soft bag. The soft bag automatic filling equipment comprises a rack and a PLC (Programmable Logic Controller). A bag feeding station and a bag transmission mechanism are arranged on the rack; at least one splicing opening is arranged at the bag feeding station; at least one clamping mechanical arm is arranged on the bag transmission mechanism; and the splicing opening is movably connected with the rack; the splicing opening is connected with a bag turnover mechanism; the bag turnover mechanism is connected with the PLC and drives the slicing opening to rotate along a vertical plane. The splicing opening is movably connected with the rack and can rotate along the vertical plane under the driving of the bag turnover mechanism, so that inclined angles of the splicing opening in an axial direction and a horizontal direction are adjustable, and a bag feeding process is faster and more comfortable. Particularly, when operators with different heights operate the soft bag automatic filling equipment to feed the soft bag, the inclined angels of the splicing opening can be adjusted to be comfortable according to the height of the operator and the height of the splicing opening, so that the operation comfort and the bag feeding efficient can be improved.

Owner:CHENGDU QINGSHAN LIKANG PHARMA CO LTD

Barrelled water packing machine and barrelled water packing method

InactiveCN103770958AReduce work intensityGuaranteed qualityIndividual articlesTransmission beltEngineering

Owner:王园伟

Fruit tree fruit-bagging device

The invention relates to the field of modern agriculture intelligent equipment and discloses a fruit tree fruit-bagging device which comprises a double-shaft cylinder, a guide rail, a driving motor, a sliding block, a screw rod, a supporting rib plate, a bag hanging plate, an upper electromagnet support and a lower electromagnet support. The guide rail is arranged vertically, the double-shaft cylinder is vertically fixed on one side of the guide rail, the piston extending-out end of the double-shaft cylinder is connected with the supporting rib plate, the screw rod is vertically arranged in the guide rail, and an output shaft of the driving motor is connected with the bottom of the screw rod. The sliding block is provided with a threaded hole and is in screw-thread fit connection with the screw rod, a horizontal connecting rod is arranged on the other side of the sliding block towards the guide rail, the bag hanging plate is fixedly connected with the horizontal connecting rod, and bent supporting plates are arranged on the two sides of the upper portion of one side and the bottom of the bag hanging plate respectively to form a paper bag storage space. One side of the bag hanging plate provided with the bent supporting plates is arranged towards the supporting rib plate. According to the fruit tree fruit-bagging device, the fruit-bagging automation can be achieved, the fruit tree fruit-bagging efficiency is improved, the fruit tree fruit-bagging quality is guaranteed, and fruit growers' labor intensity and production cost are lowered.

Owner:CHINA AGRI UNIV

Bagging system and bagging method

PendingCN109515854AFast and stable baggingImprove bagging efficiencyWrapping material feeding apparatusWrappingVacuum pumpingEngineering

The invention discloses a bagging system and a bagging method. A film supply mechanism is used for conveying a packaging film to a bagging piece, the bagging piece is used for bending a first side edge and a second side edge oppositely arranged on the packaging film, and since the first side edge and the second side edge of the packaging film are bent, a first bag sealing device is conveniently used for conducting seal connection on the first side edge and the second side edge on the packaging film, a product is wrapped in the packaging film, and the two ends of the packaging film are still inan open state at the time; then, a second bag sealing device cuts the packaging film into a plurality of packaging units, one opening end of each packaging unit is sealed, packaging bags are formed,and single-side sealing of the packaging bags is achieved; and finally, a vacuum pumping machine is used for conducting vacuum pumping on the packaging bags from the opening positions of the packagingbags. Accordingly, through the bagging system, the products can be subjected to rapid and stable bagging operation.

Owner:GUANGZHOU YONGHEXIANG AUTOMATION EQUIP TECH CO LTD

Automatic sand-gravel aggregate bagging and conveying device

InactiveCN106184844AUniform loadEasy dischargeSolid materialPackaging automatic controlSolenoid valveFixed frame

Owner:许陈菲

Bag feeding mechanism

The invention provides a bag feeding mechanism comprising a rack, a main drive mechanism installed on the rack, two rotary arms, a bag expanding part and a fine tuning mechanism. The two rotary arms turn up and down around a supporting base under the drive of the main drive mechanism; the tail ends of the two rotary arms are provided with clamping parts used for clamping bag openings of packaging bags; the bag expanding part turns up and down along with the rotary arms and is inserted in the bag openings and is used for expanding the bag openings of the packaging bags when the clamping parts clamp the packaging bags and turn upwards; the fine tuning mechanism is disposed between the rotary arms and used for driving the rotary arms to transversely move when the clamping parts clamp the bag openings of the packaging bags so as to tension the bag openings of the packaging bags; the fine tuning mechanism moves in a telescopic mode after the bag expanding part is inserted into the bag openings, the rotary arms are driven to transversely move, the two sides of the bag opening of each packaging bag are tensioned under the common action of the clamping parts and a conical blade, so that each bag opening becomes a regular rectangular opening, materials can be sleeved with the packaging bags conveniently, and accordingly bag sleeving efficiency is improved; meanwhile, a motor and a speed reducer are used for taking the place of a servo motor, and accordingly manufacturing cost of the bag feeding mechanism is lowered.

Owner:无锡市开维物流装备有限责任公司

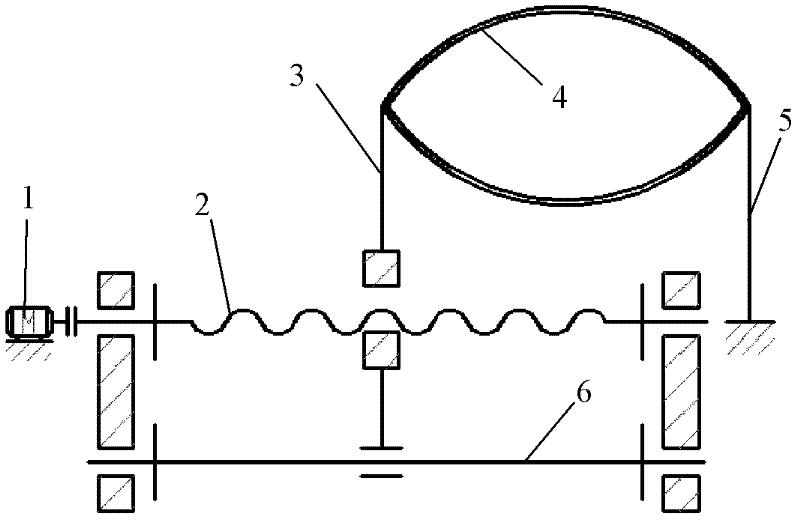

Automatic production equipment of bagged springs

ActiveCN102417152ASolve the problem of pocket compressionSolve the shortcomings of poor stabilityUpholsteryMotor drive

The invention mainly discloses automatic production equipment of bagged springs, which comprises a spring conveying mechanism connected onto an automatic spring coiling machine, and a movable bagging sealing and cutting mechanism of the bagged springs, wherein the movable bagging sealing and cutting mechanism of the bagged springs is connected with the spring conveying mechanism, and the spring conveying mechanism comprises two spring conveying racks; a belt propped against the end surface of the spring is arranged on each spring conveying rack, and a motor drives the belt to clamp the springs to convey forwards; the movable bagging sealing and cutting mechanism of the bagged springs comprises a transverse sealing and cutting mechanism and a longitudinal sealing and cutting mechanism, and the transverse sealing and cutting mechanism allows non-woven cloth with an opening down to be coated on the tail end of the spring conveying rack, and transversely seals and cuts the non-woven cloth; and the longitudinal sealing and cutting mechanism can move back and forth at an outlet of the transverse sealing and cutting mechanism and longitudinally seal and cut a non-woven cloth bag. The springs are stably conveyed from the spring coiling machine and are bagged into the non-woven bag, and spreading, sealing and cutting are carried out in a public time, so that the bagging efficiency is greatly improved.

Owner:SHAOXING HUAJIAN MATTRESS MACHINERY

Soft-shelled turtle feed processing device and using method thereof

ActiveCN111842136AAchieve secondary dryingEasy to recycleSievingFeeding-stuffBiotechnologyAnimal science

The invention discloses a soft-shelled turtle feed processing device and a using method thereof. The soft-shelled turtle feed processing device comprises a support frame; a pelletizing extruding device is arranged on one side of the top of the support frame; a material pushing device is arranged on one side of the pelletizing extruding device; a dehumidifying and drying device is arranged below the material pushing device; a screening device is arranged on the side, far away from the pelletizing extruding device, of the dehumidifying and drying device; a conveyer is arranged below the pelletizing extruding device; the pelletizing extruding device comprises an extruding cylinder; and an extruding plate is arranged in the extruding cylinder. The soft-shelled turtle feed processing device hasthe following benefits: the soft-shelled turtle feed processing device is simple in structure, can carry out integrated processing including extruding, pelletizing, dehumidifying, drying, radiating cooling, screening and bagging on feed, avoids the situation that a working staff carries the feed during the feed processing process, also avoids change and alternated application of multiple equipment, greatly lowers the labor intensity of a working staff, reduces cost investment, and greatly improves the working efficiency of feed processing and production.

Owner:福建大昌盛饲料有限公司

Bag conveying mechanism for bagging machine

InactiveCN106416849AShorten the timeSolve inaccuratePlant protective coveringsArticle separationEngineeringMechanical engineering

The invention discloses a bag conveying mechanism for a bagging machine. The bag conveying mechanism comprises a bag discharging and paper rubbing wheel arranged above an inner cavity of a bag storage box, wherein the bag discharging and paper rubbing wheel is in contact with an uppermost folded bag in the bag storage box; a support plate is arranged in the bag storage box; bags stacked into piles up and down are placed in a cavity between the support plate and the bag discharging and paper rubbing wheel; the support plate is driven by an elastic mechanism to jack up the bags to one side of the bag discharging and paper rubbing wheel; the bag discharging and paper rubbing wheel rotates forwards to rub out the bag in contact with the bag discharging and paper rubbing wheel from a bag outlet of the bag storage box; a conveying wheel is arranged at the bag outlet outside the bag storage box; an upper conveying wheel and a lower conveying wheel of the conveying wheel rotate in opposite directions to push the bag to a bagging and sealing mechanism. The bag conveying mechanism provided by the invention creatively conveys the bags on the bagging machine in a form of paper rubbing wheel, has good bag conveying effect, and ensures the stable and orderly operation of the bagging machine.

Owner:冷羽夏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com