Barrelled water packing machine and barrelled water packing method

A bottled water and packaging machine technology, applied in packaging, transportation and packaging, single objects and other directions, can solve the problems of large space occupation, low work efficiency, leaking sleeves, etc., to reduce space occupation, improve work efficiency, and reduce work the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

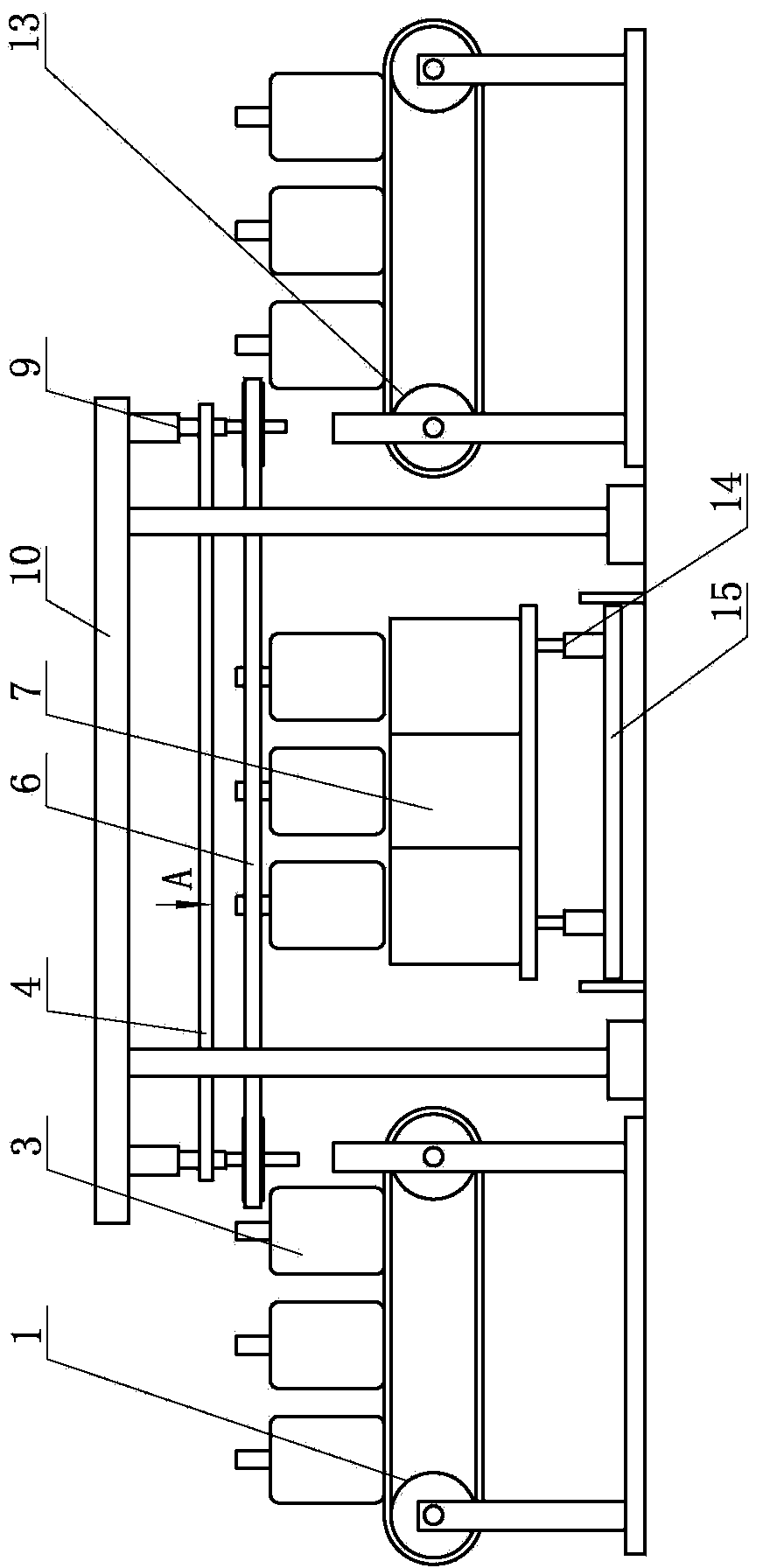

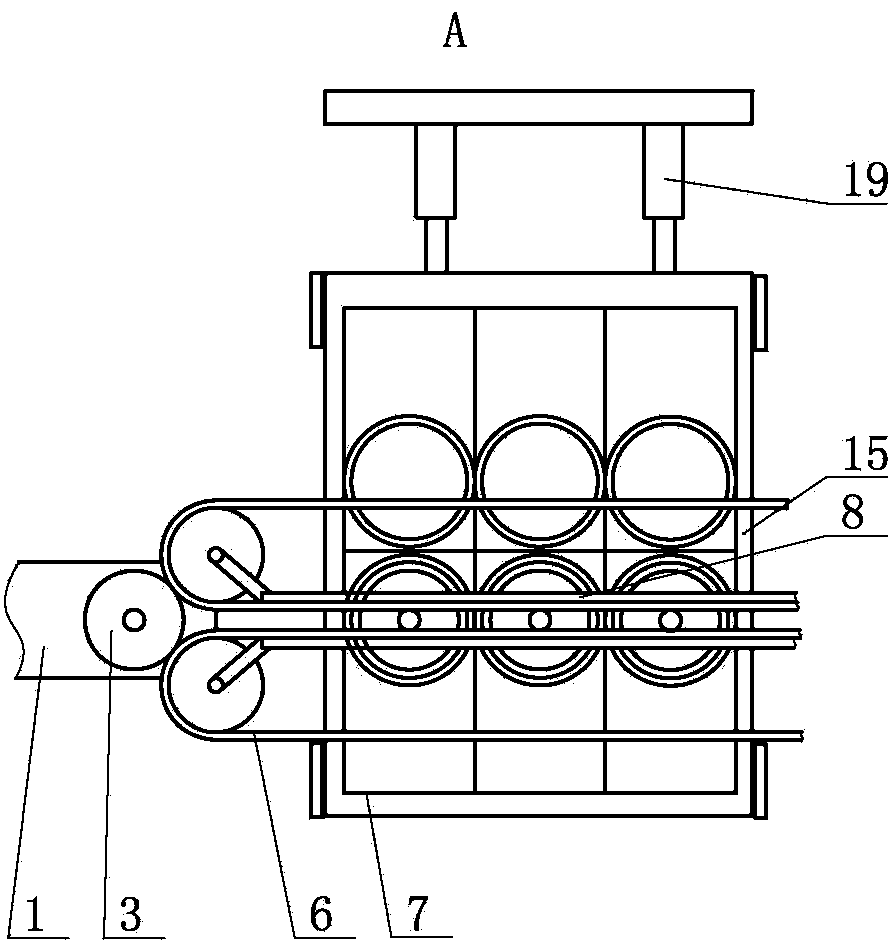

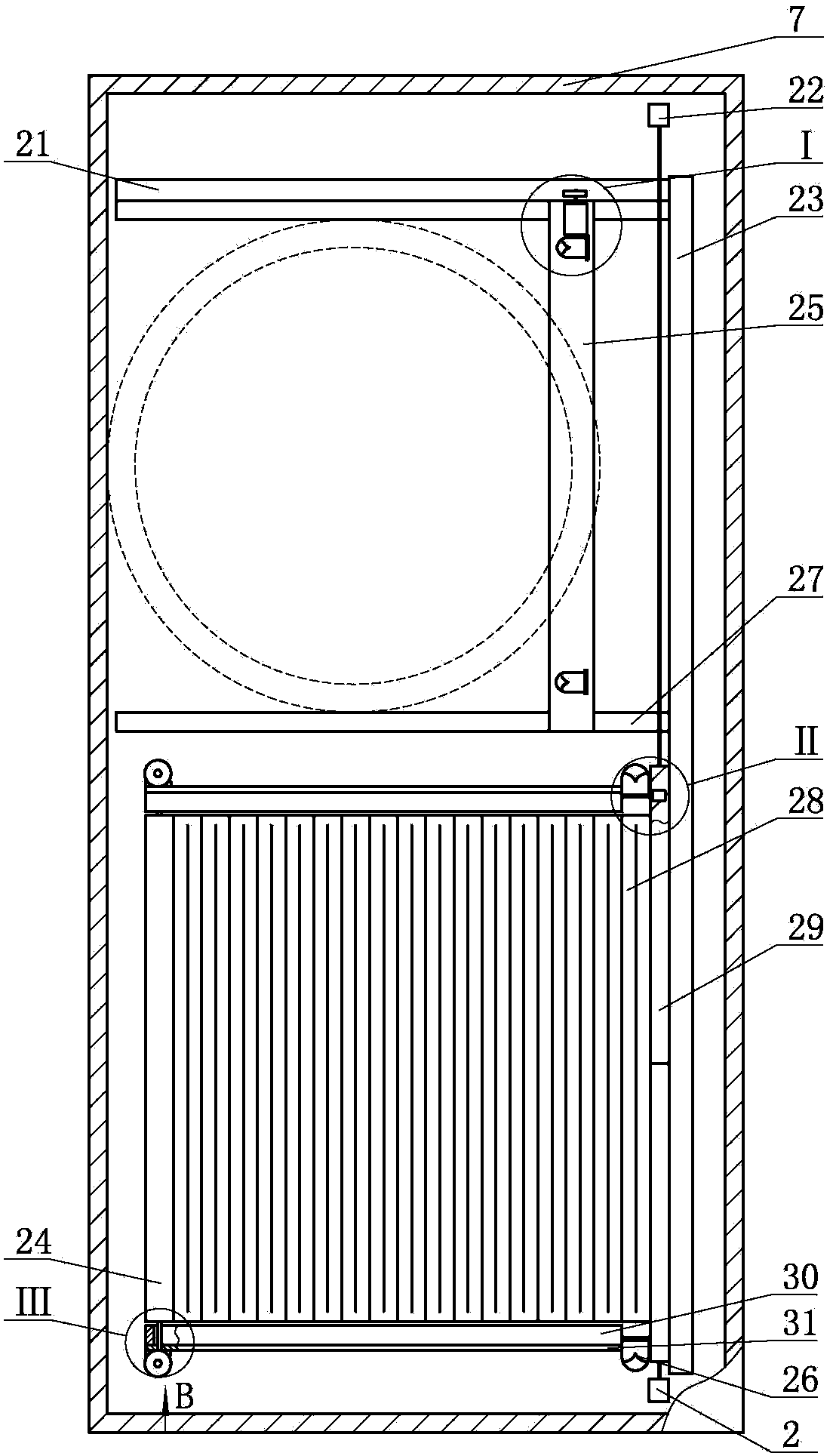

[0010] bottled water packaging machine, such as figure 1 with figure 2 As shown, it includes a bucket carrying device and a bagging device. The bagging device is located at the bottom of the bucket carrying device, and a lifting device is installed on the bucket carrying device or the bagging device. The bucket carrying device includes two parallel support bars 8, and the sides of the support bar 8 Conveyor belt 6 is set at the top, and support rod and conveyer belt 6 are all installed on the bucket frame 4, and bucket bag 28 is set in the bagging device, and the sack of bucket bag 28 is provided with tightening rubber band 5. The bagging device can be a single opening of the bucket bag, and then match the bucket bag with the bucket, or as image 3 As shown, in order to realize the continuity of bagging, the bagging device includes several bagging devices, each bagging device includes a housing 7, and a first slide rail 23 is arranged on one side of the housing 7, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com