Full-automatic fruit mesh bag sleeving system

A fully automatic, mesh bag technology, applied in the field of fruit mesh bag bagging system, automatic fruit mesh bag bagging system field, can solve the problem of not being able to clamp, difficult to disengage the mesh bag, and difficult to fit the mesh bag in the The problem of high-quality fruit, to achieve the effect of improving the efficiency of bagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

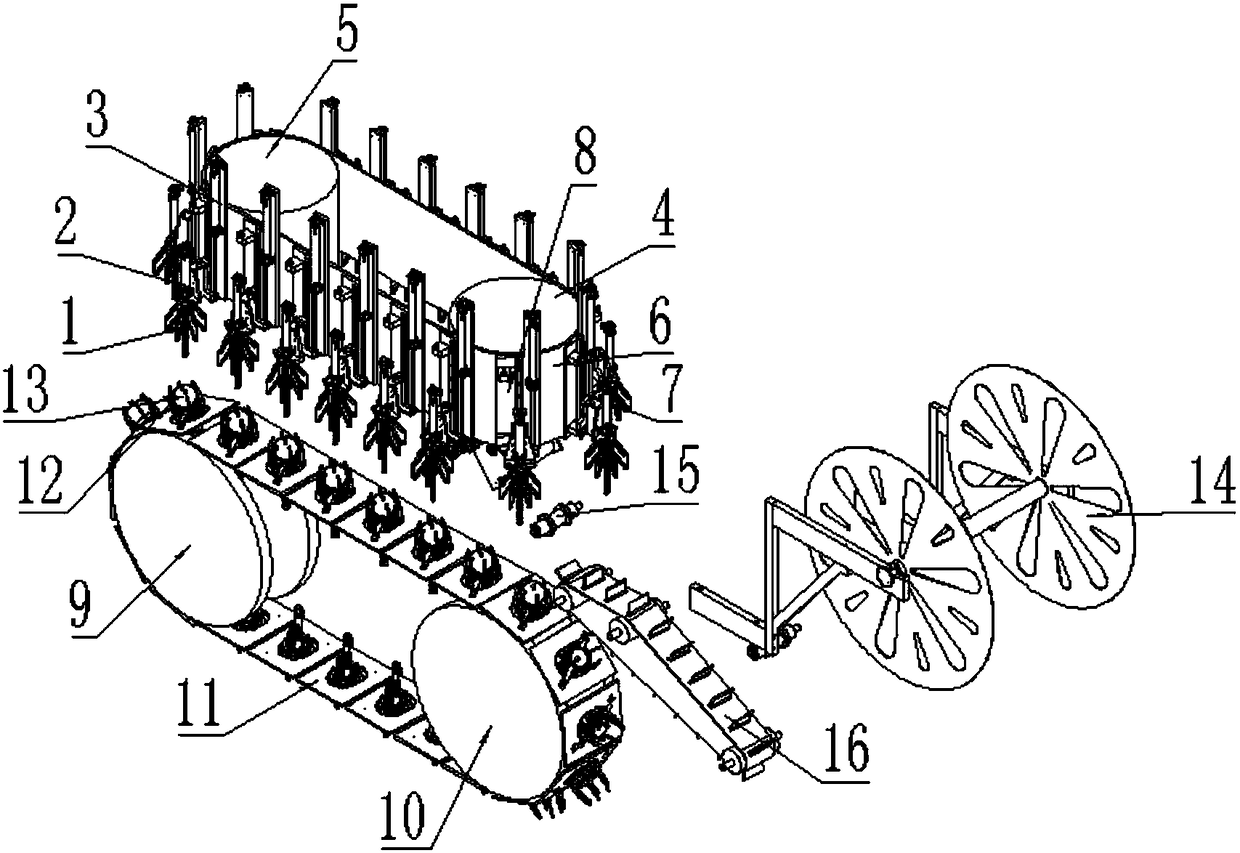

[0151] Such as Figure 1-3 As shown in 1, a fully automatic fruit net bag bagging system includes a bag-holding conveying device and a pinch-off conveying device, and the bag-holding conveying device is arranged above the pinch-off conveying device;

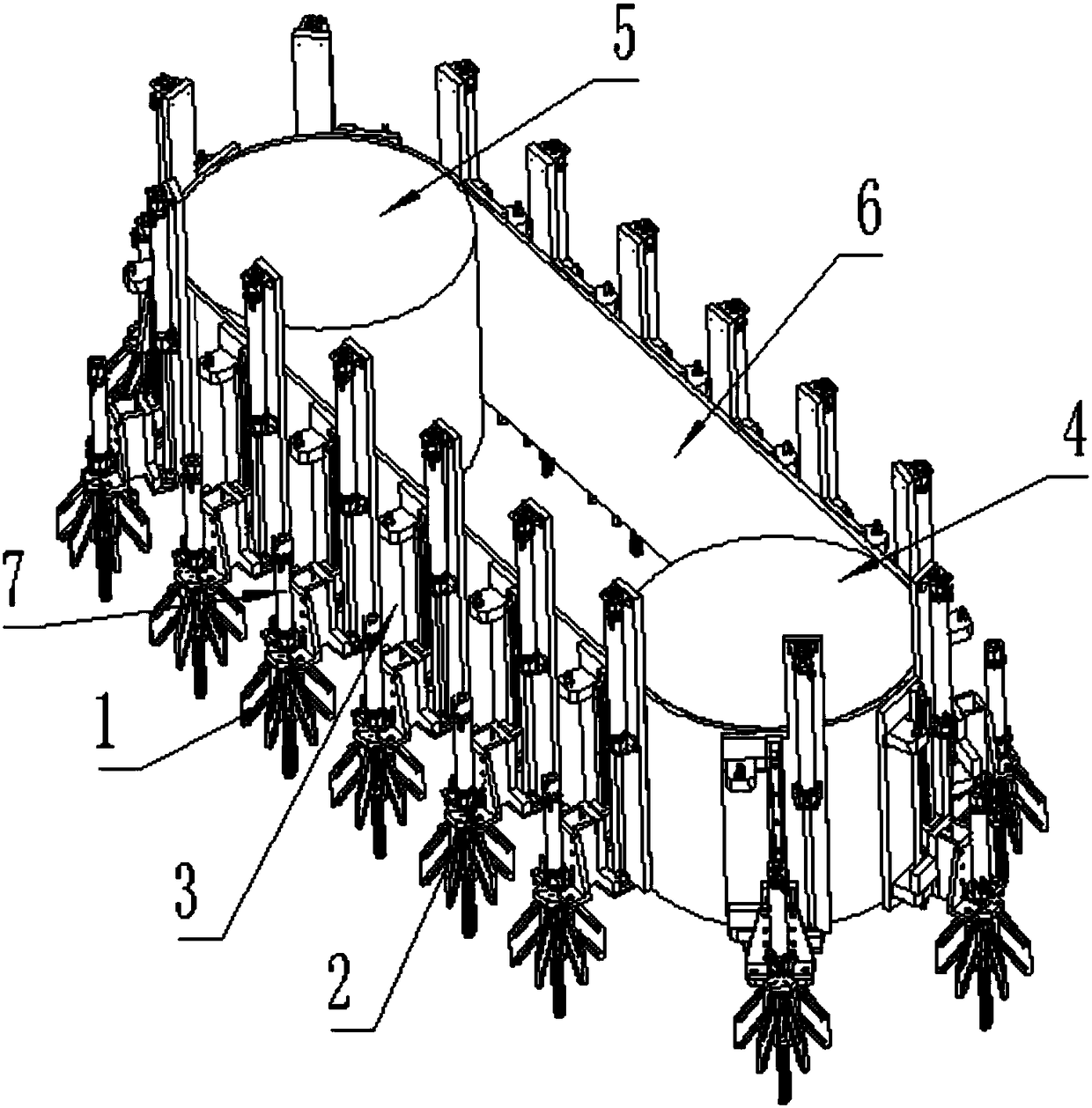

[0152] The bag-stretching conveying device includes a plurality of bag-stretching assemblies and a bag-stretching conveying mechanism, a plurality of the bag-stretching assemblies are uniformly installed on the bag-stretching conveying mechanism, and the bag-stretching conveying mechanism can drive the bag-stretching assembly to make Circular movement;

[0153] The pinch-off conveying device includes a plurality of pinch-off assemblies and a pinch-off conveying mechanism, a plurality of the pinch-off assemblies are evenly installed on the pinch-off conveying mechanism, and the pinch-off conveying mechanism can drive the pinch-off assembly to perform Circular movement;

[0154] The bag support assembly includes a bag support mec...

Embodiment 2

[0190] The difference from Embodiment 1 is that the opening and closing mechanism includes a sliding frame 12-81, a spring telescopic rod 12-83 and a spring 12-85, and the sliding frame 12-81 is arranged on the clamping claw 12-81. 1, the sliding frame 12-81 is fixedly connected with the carrying plate 12-3 or the pinch-off chain plate by connecting the mounting plate 12-9, and the sliding frame 12-81 is provided with a plurality of chute 12- 811, a slider 12-82 is installed in the chute 12-811, the inner end 12-822 of the slider is a free end, and the outer end 12-821 presses against the lower end of the clamping claw 12-1 or the spring The inner end of telescopic rod 12-83;

[0191] The inner end of the spring telescopic rod 12-83 is hinged with the lower end of the clamping claw 12-1, and the outer end passes through the guide block 12-84, and the spring telescopic rod 12-83 can be positioned on the guide block 12-84. 84, the guide block 12-84 is installed on the lower end...

Embodiment 3

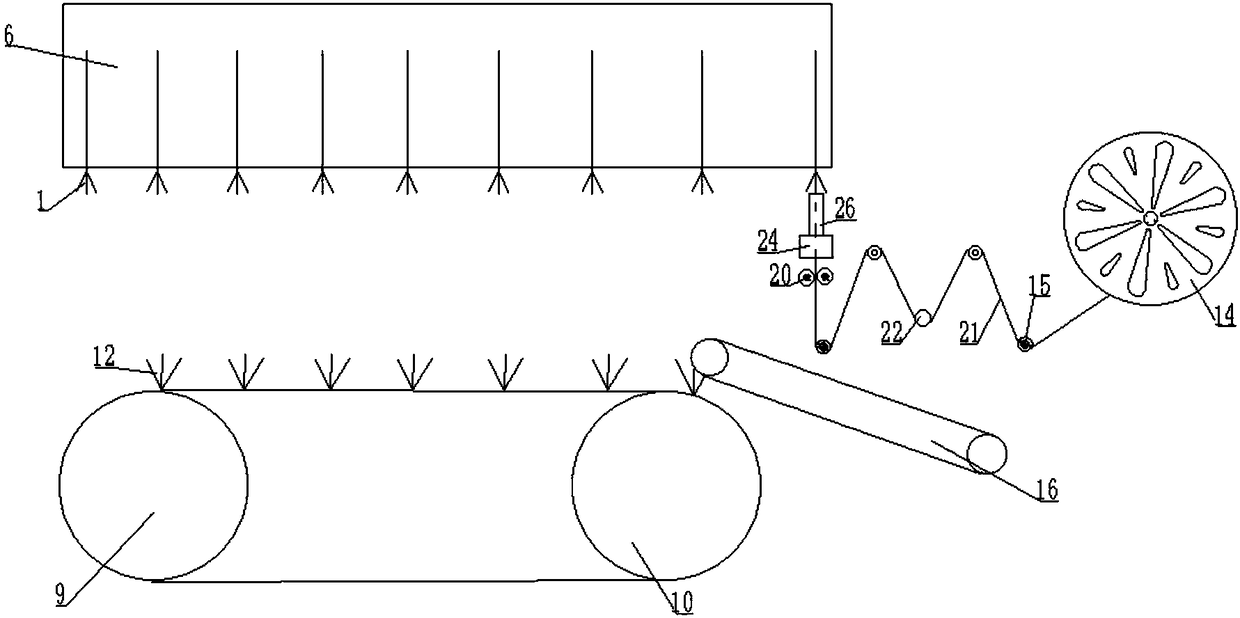

[0198] The difference from Embodiment 1 is that the net bag conveying mechanism also includes a compensating mechanism 22, and the compensating mechanism 22 includes two support rollers 22-1 arranged between the two guide rollers 15 and two The gravity roller 22-2 between the support rollers 22-1, the axes of the two support rollers 22-1 are parallel to the axes of the two guide rollers 15, and the height of the two support rollers 22-1 is As for the guide roller 15, the two support rollers 22-1 are mounted on the conveying frame body 19 through bearings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com