Automatic production equipment of bagged springs

A technology for automatic production and pocket springs, which is used in household appliances, applications, interiors, etc., can solve problems such as the decline of the efficiency of pocket spring machines, and achieve the effect of increasing production efficiency and increasing the speed of making springs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

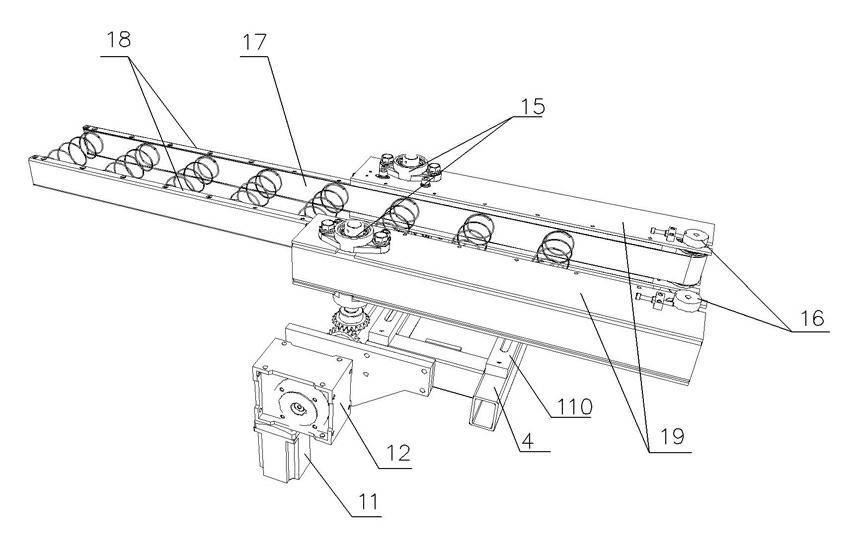

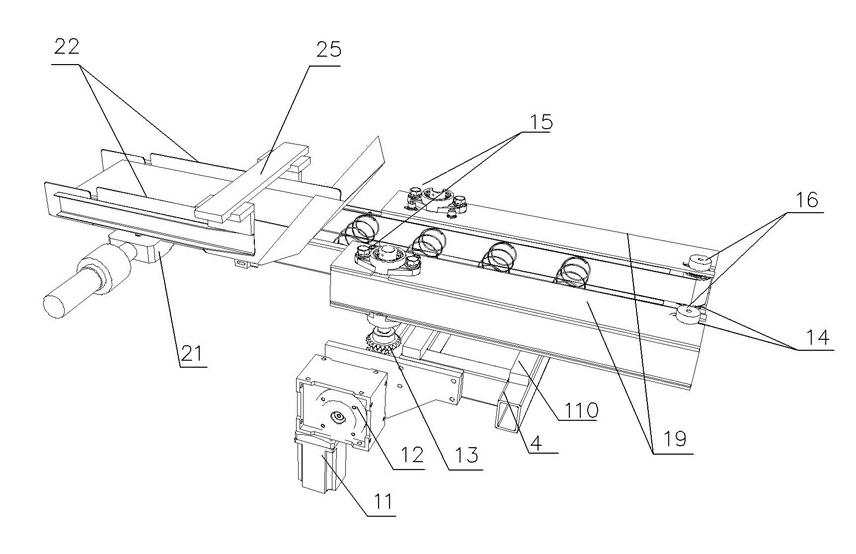

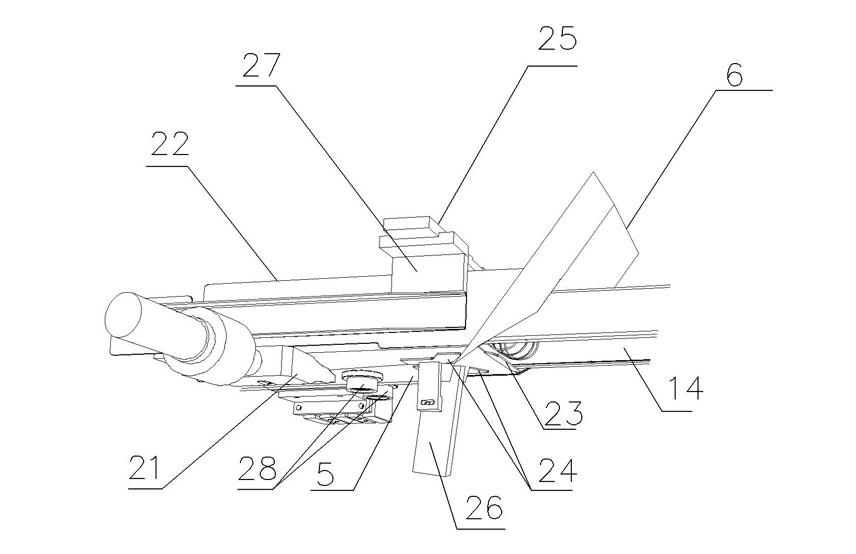

[0033] combine Figure 1~Figure 12 , the preferred embodiments of the present invention will be described in further detail.

[0034] An automatic pocket spring production equipment includes a spring conveying mechanism 1 connected to an automatic spring coiling machine, a transverse sealing and cutting mechanism 2, and a longitudinal sealing and cutting mechanism 3. The spring conveying mechanism 1 automatically conveys the spring from the coiled spring in the spring coiling machine, and packs, seals and cuts the spring at the conveying end.

[0035] The main improvement points in the present invention are to solve the problem of bagging and efficient sealing and cutting. combine figure 1 with figure 2 The spring conveying mechanism 1 includes a servo motor 11 and a reducer 12 installed on the frame 4, two pairs of helical gears 13 on the left and right, a belt conveying mechanism frame 14, a driving pulley 15 and a driven pulley 16, a belt 17, and a guard plate 18 , Spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com