Salvia miltiorrhiza flower beer and brewing method thereof

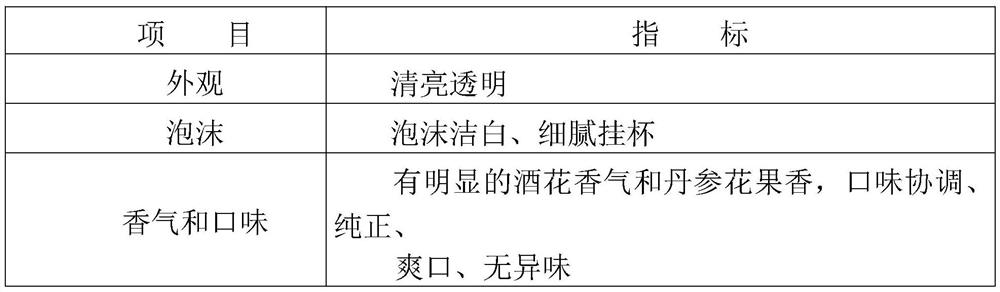

A technology of flower beer and salvia miltiorrhiza, applied in the field of salvia miltiorrhiza flower beer and its brewing, to achieve the effects of harmonious taste, delicate foam, and rich variety of colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Get 5300 grams of malt and pulverize through a malt grinder, requiring that the wheat skin is broken but not broken, take 2900 grams of rice and pulverize through a rice grinder, and the crushed particle size is below 1mm. Add 12 liters of water to the gelatinization pot, put in 2900 grams of rice flour at a water temperature of 48°C, add amylase to enzymatically hydrolyze it; raise the temperature to 90°C, keep it warm for 10 minutes, then raise the temperature and boil for 30 minutes. This process needs to start the mixer. Add 24 liters of warm water at 51°C to the mash pot, add 5,300 grams of crushed malt, and keep warm at 50°C for about 50 minutes to decompose the protein. Pump the gelatinized mash into the saccharification pot, saccharify at about 65°C for 60 minutes, raise the mash to 78°C for 10 minutes after passing the iodine test, add 78°C water to the filter plate, and pump the mash into the filter tank, Stand still for 10 minutes, reflux for 15 minutes, filt...

Embodiment 2

[0023] Take 1,000 grams of malt and 3,800 grams of malt for crushing in a grinder, requiring the barley to be broken but not broken. Take 2,600 grams of rice and grind it with a rice grinder, with a particle size of less than 1 mm. Add 10 liters of water to the gelatinization pot, put in 2600 grams of rice flour at a water temperature of 50°C, add amylase to enzymatically hydrolyze; raise the temperature to 90°C, keep it warm for 10 minutes, and then heat up and boil for 30 minutes. This process needs to start the mixer.

[0024] Add 18 liters of warm water at 50°C to the mash pot, add 4,800 grams of crushed malt, and keep warm at 50°C for about 50 minutes to decompose the protein. Pump the gelatinized mash into the mash pot, saccharify at about 65°C for 60 minutes, raise the mash to about 78°C for 10 minutes after passing the iodine test, add 78°C water to the filter plate, and pump the mash into the filter tank , stand still for 10 minutes, reflux for 16 minutes, filter the ...

Embodiment 3

[0026] Take 1750 kg of first-grade malt and pulverize it through a malt grinder, requiring the barley to be broken but not broken; take 950 kg of rice and grind it through a rice grinder, and the crushed particle size is below 1mm. Add 3200 liters of water to the gelatinization pot, add 950 kg of rice flour at a water temperature of 50°C, add amylase, heat up to 90°C, keep warm for 10 minutes, then heat up and boil for 30 minutes. This process needs to start the mixer.

[0027] Add 7,000 liters of water into the mash pot, heat up to 51°C, add 1,750 kg of broken malt, and keep warm at 50°C for 50 minutes to decompose the protein.

[0028] Pump the gelatinized mash into the mash pot, saccharify at about 65°C for 55 minutes, raise the mash to about 78°C for 10 minutes after passing the iodine test, add 78°C water to the filter plate, and pump the mash into the filter tank , stand still for 10 minutes, reflux for 15 minutes, filter the wort into the boiling pot, add water to the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com