Patents

Literature

51results about How to "Good collocation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

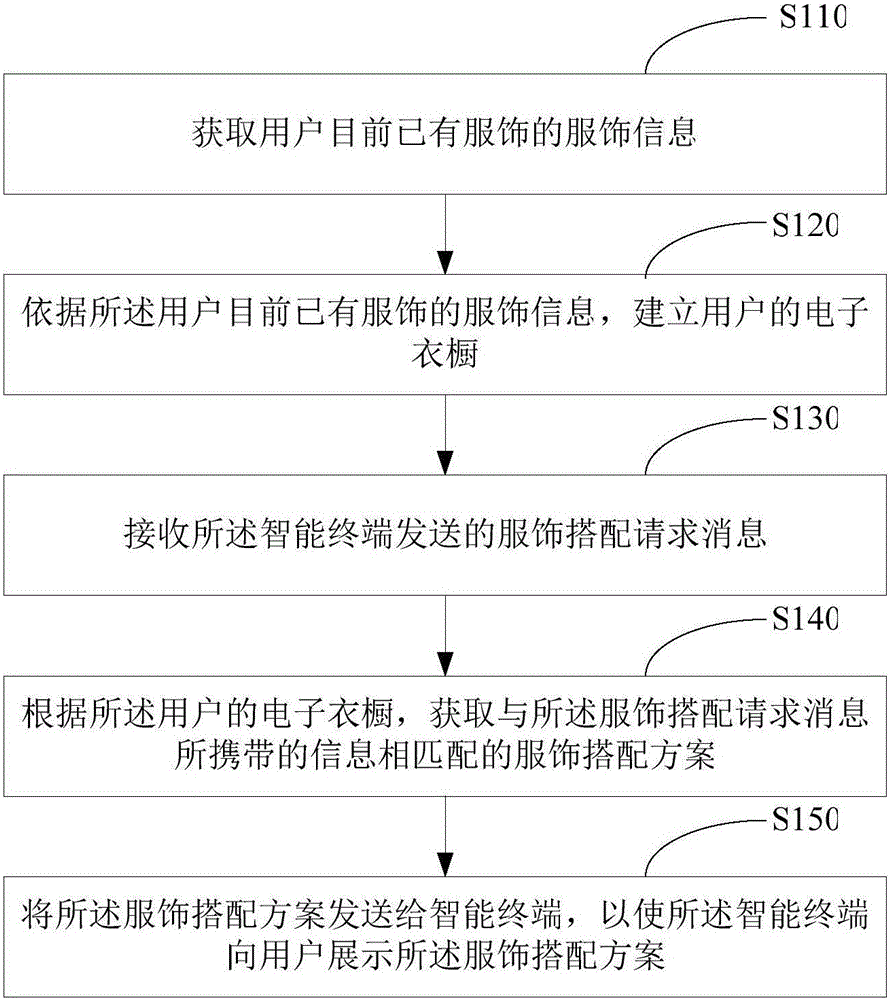

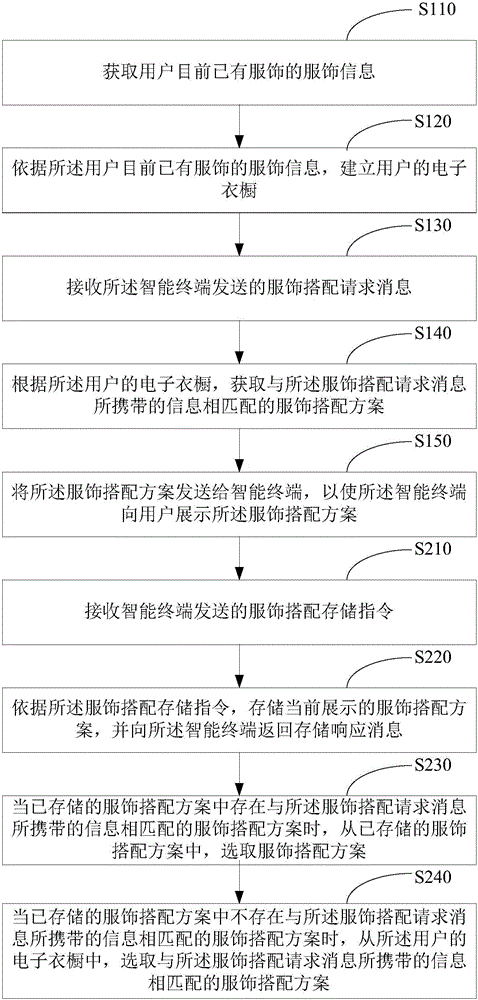

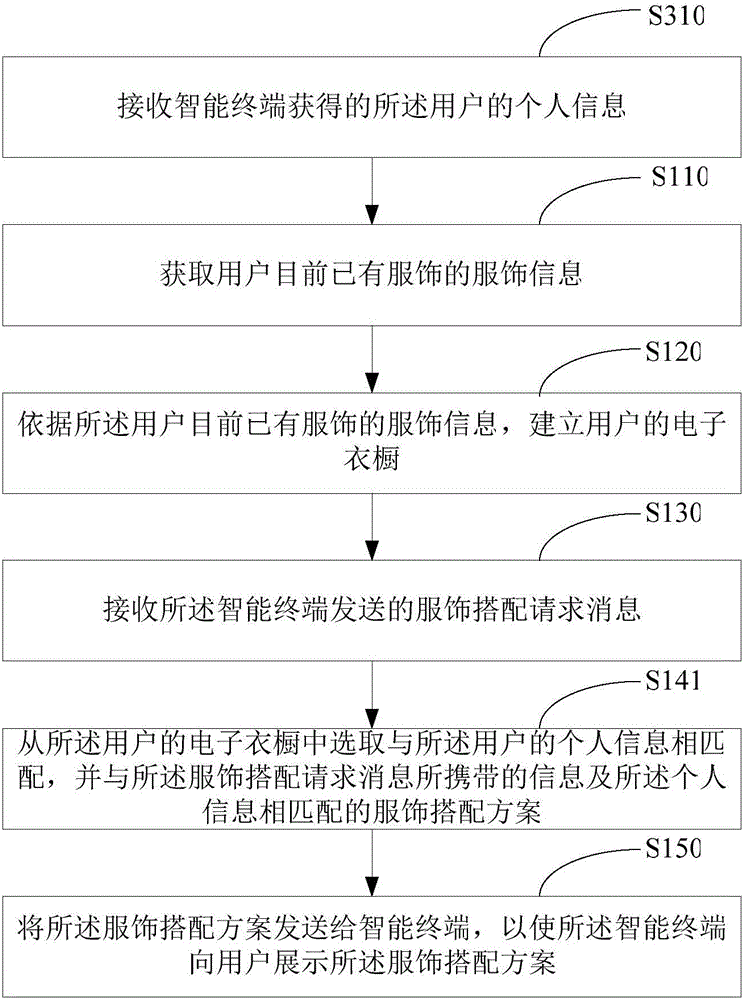

Costume-matching recommending method and device

InactiveCN104992343AShorten the timeGood collocation effectSpecial data processing applicationsMarketingWorld Wide WebEngineering

The embodiment of the invention discloses a costume-matching recommending method and device. A server obtains costume information of existing costume of a user and establishes an electronic wardrobe of the user according to the costume information; and when the server receives a costume-matching request message sent by an intelligent terminal, the server obtains a costume-matching scheme matched with the information carried by the costume-matching request message according to the electronic wardrobe of the user, and the costume-matching scheme is sent to the intelligent terminal so as to enable the intelligent terminal to display the costume-matching scheme. By adopting the method, the costume-matching scheme suitable for the request of the user is recommended to the user, the matching effect is good, and the user does not to try on clothes one by one, so that the time of the user is saved.

Owner:XIAOMI INC

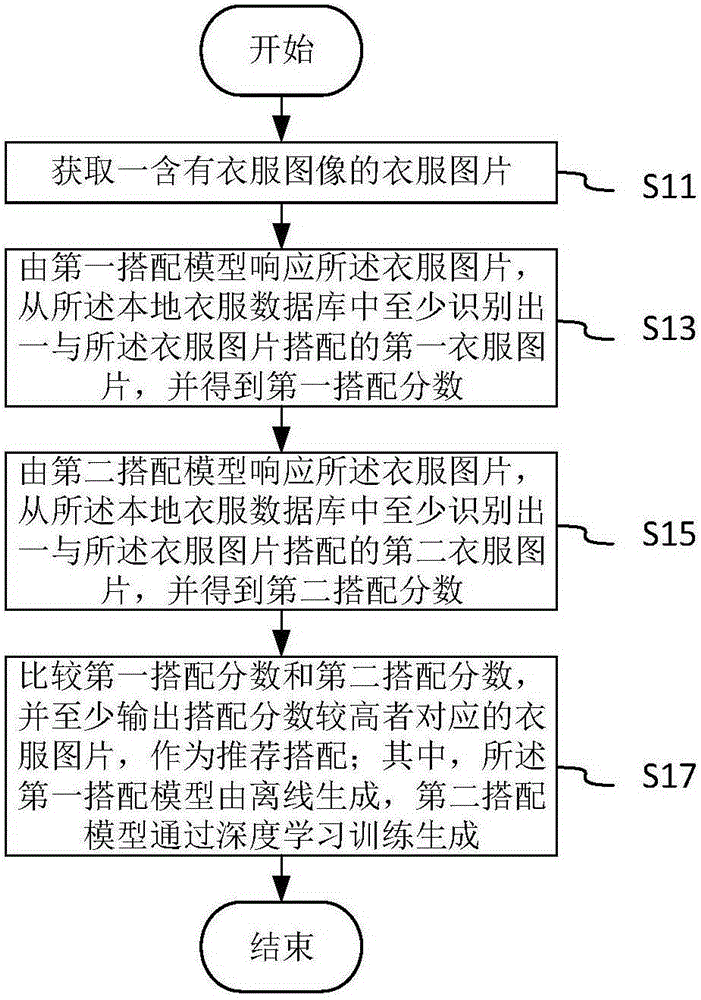

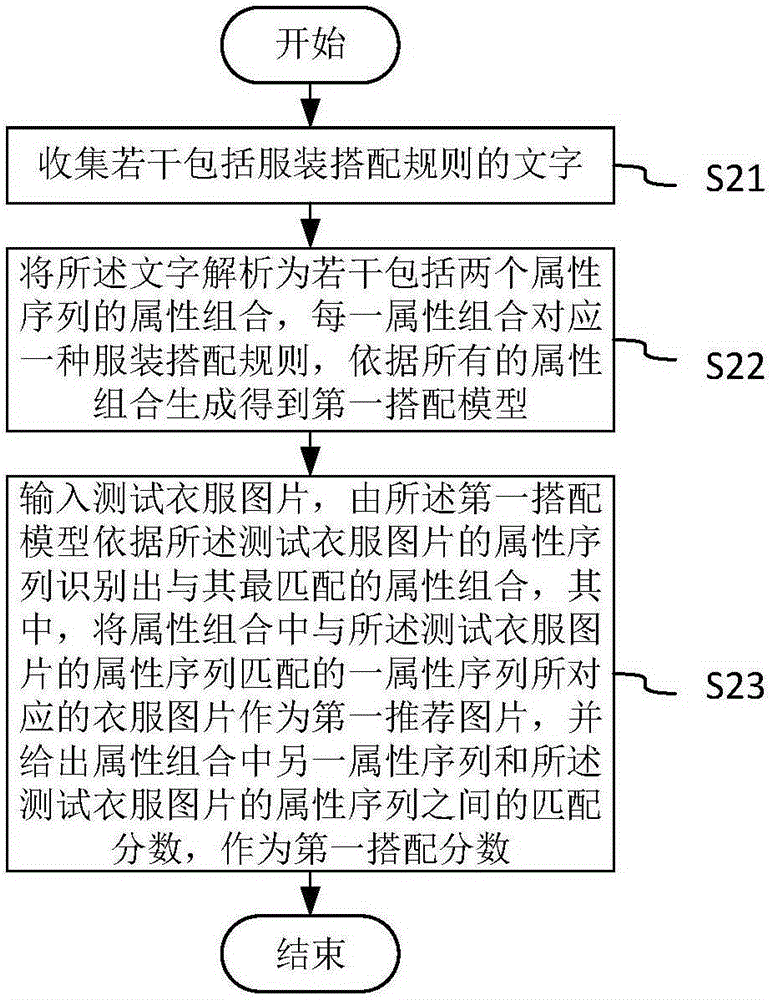

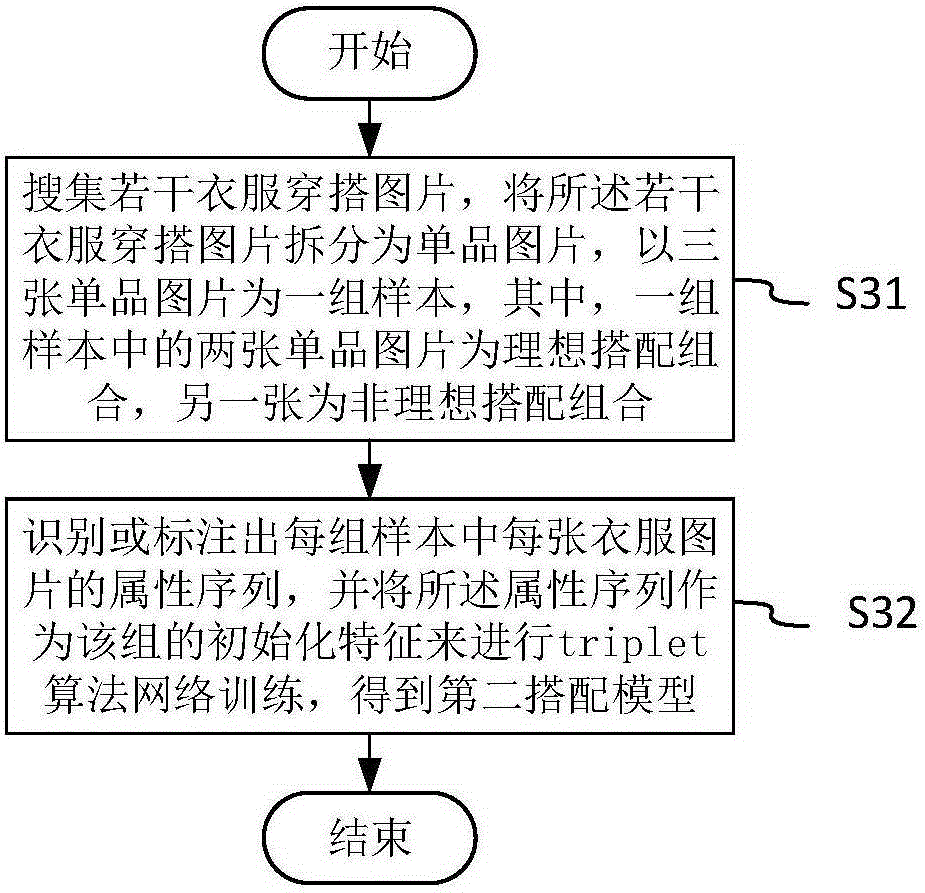

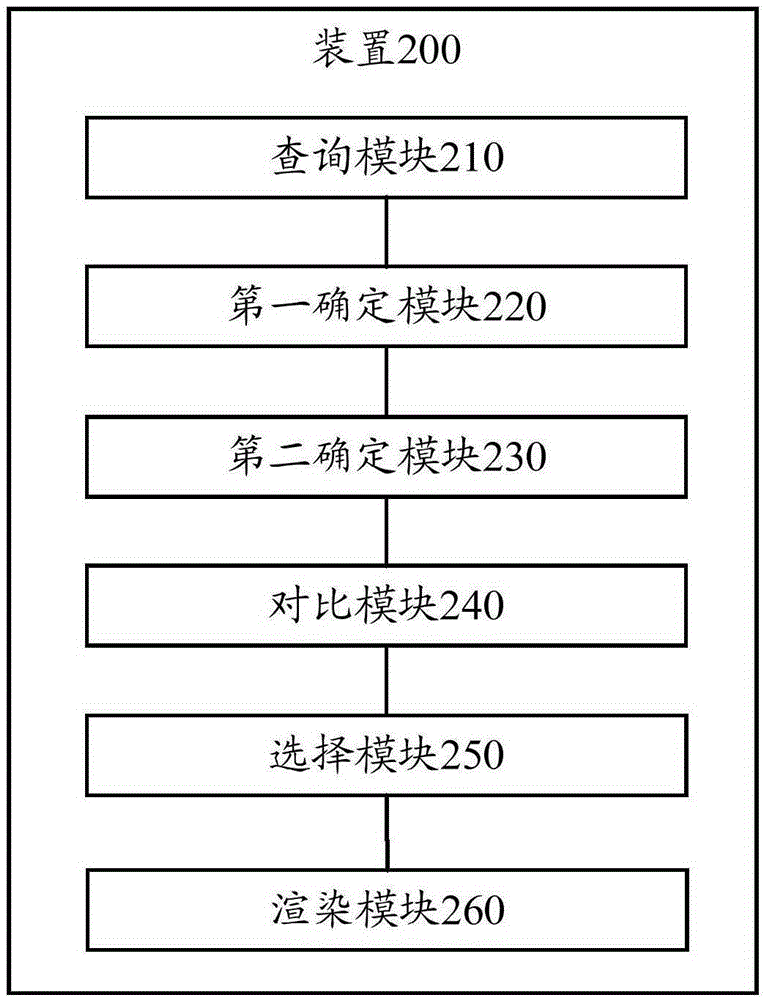

Picture processing based clothes matching method and apparatus

ActiveCN105224775AGood collocation effectSpecial data processing applicationsPattern recognitionMatching methods

The invention provides a picture processing based clothes matching method and apparatus. The method comprises: obtaining a clothes picture; at least identifying a first clothes picture matched with the clothes picture from a local clothes database by a first matching model in response to the clothes picture, and obtaining a first matching score; at least identifying a second clothes picture matched with the clothes picture from the local clothes database by a second matching model in response to the clothes picture, and obtaining a second matching score; and comparing the first matching score with the second matching score, and at least outputting the clothes picture corresponding to the relatively high matching score as recommended matching, wherein the first matching model is generated offline and the second matching model is generated through deep learning and training. According to the picture processing based clothes matching method and apparatus, texts and pictures comprising matching rules are separately trained to obtain two matching models, so that a better matching effect can be provided.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

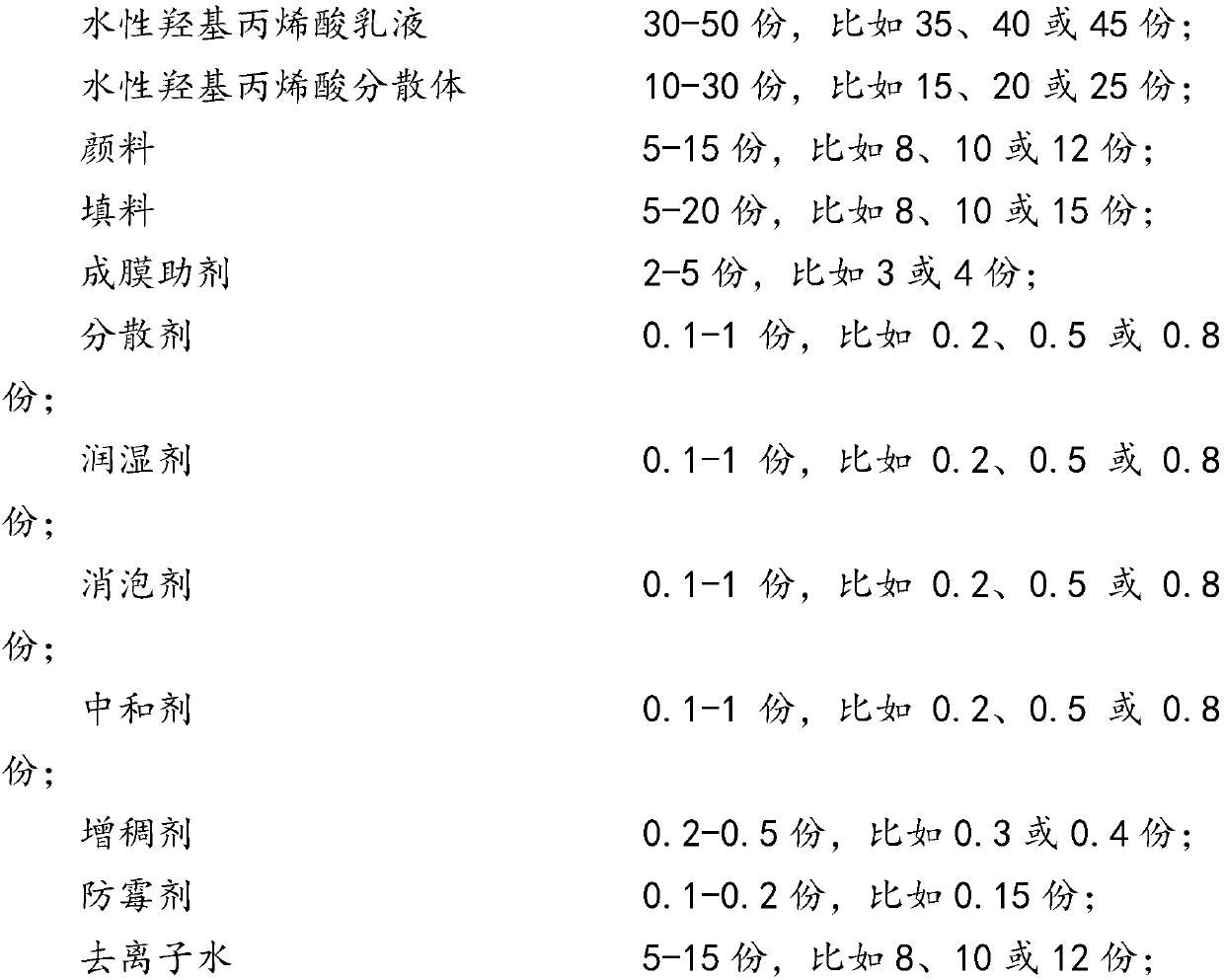

Composition for producing waterborne coating and coating system prepared from composition

ActiveCN108034346AIncrease crosslink densityImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionCoating system

The invention discloses a composition for producing a waterborne coating. The composition comprises a component A and a component B, wherein the component A comprises a waterborne hydroxyl acrylic emulsion and a waterborne hydroxyl acrylic dispersion, and the component B comprises a waterborne isocyanate curing agent. By using the coating prepared from the composition disclosed by the invention, apaint film has excellent corrosion resistance even if no antirust coatings are provided, and the problem of system instability caused by hydrolysis of antirust filler is avoided; and meanwhile, the paint film is enabled to have excellent construction performance on the premise that the corrosion resistance of the paint film is guaranteed.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

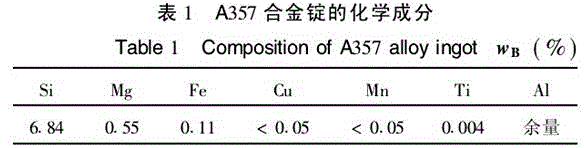

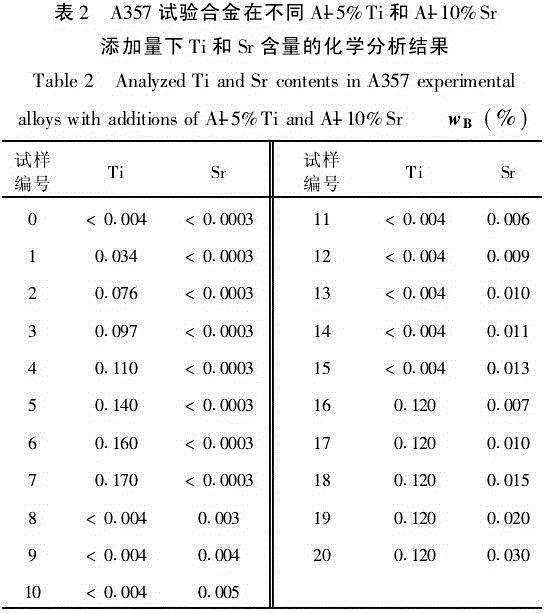

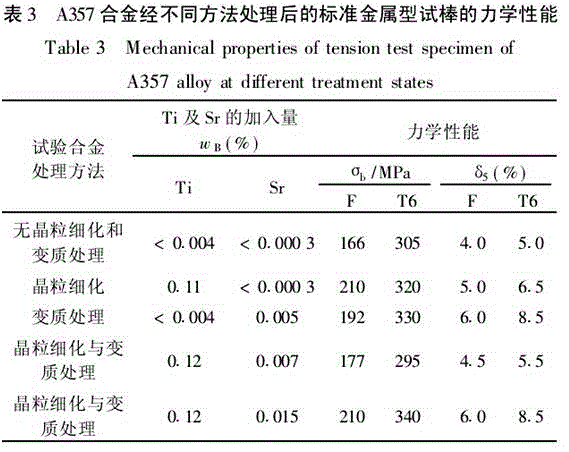

A357 aluminum alloy material containing alterant Sr and Ti and preparation method thereof

The invention discloses an A357 aluminum alloy material containing alterant Sr and Ti. The A357 aluminum alloy material is characterized by comprising the following raw materials in percentage by mass: 6-7 of Si, 0.4-0.6 of Mg, less than 0.05 of Cu, 0.12 of Ti, 0.01-0.015 of Sr, 0.2 of Fe, and the balance of Al.

Owner:温兴琴

Method for preparing hard alloy materials

The invention relates to a method for manufacturing hard alloy materials, which comprises the following steps: 1. taking the following raw material substances in percentage by weight: 10 to 20 percent of composite hard phase tungsten carbide powder in a particle form of 10 to 15 microns, 20 to 30 percent of composite hard phase tungsten carbide powder in a particle form of 5 to 10 microns, 20 to 30 percent of composite hard phase tungsten carbide powder in a particle form of 1.0 to 1.5 microns, 1.5 to 2 percent of chromium carbide powder and 25 to 30 percent of cobalt powder; and 2. mixing the raw material substances according to the mixture ratio, grinding, pressing and forming the materials, then, carrying out heat insulation for 30 minutes under the condition between 1500 DEG C and 1600 DEG C, and obtaining the hard alloy materials. The method provided by the invention is simple and reliable, and the produced hard alloy materials belong to the hard alloy materials with the advantages of wear resistance, impact resistance, stable quality and bicrystal corrosion resistance.

Owner:ZHUZHOU LIZHOU CEMENTED CARBIDE

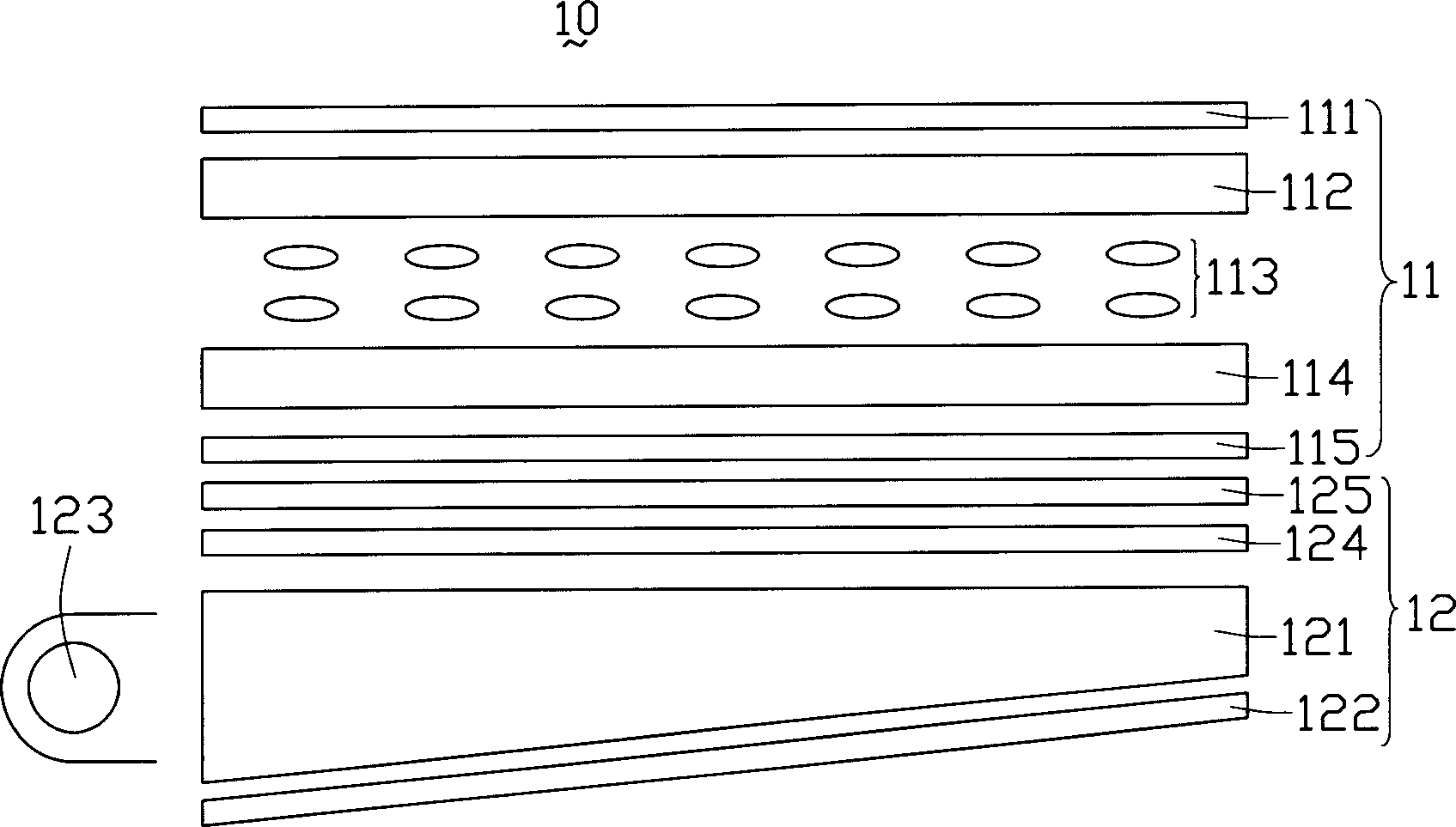

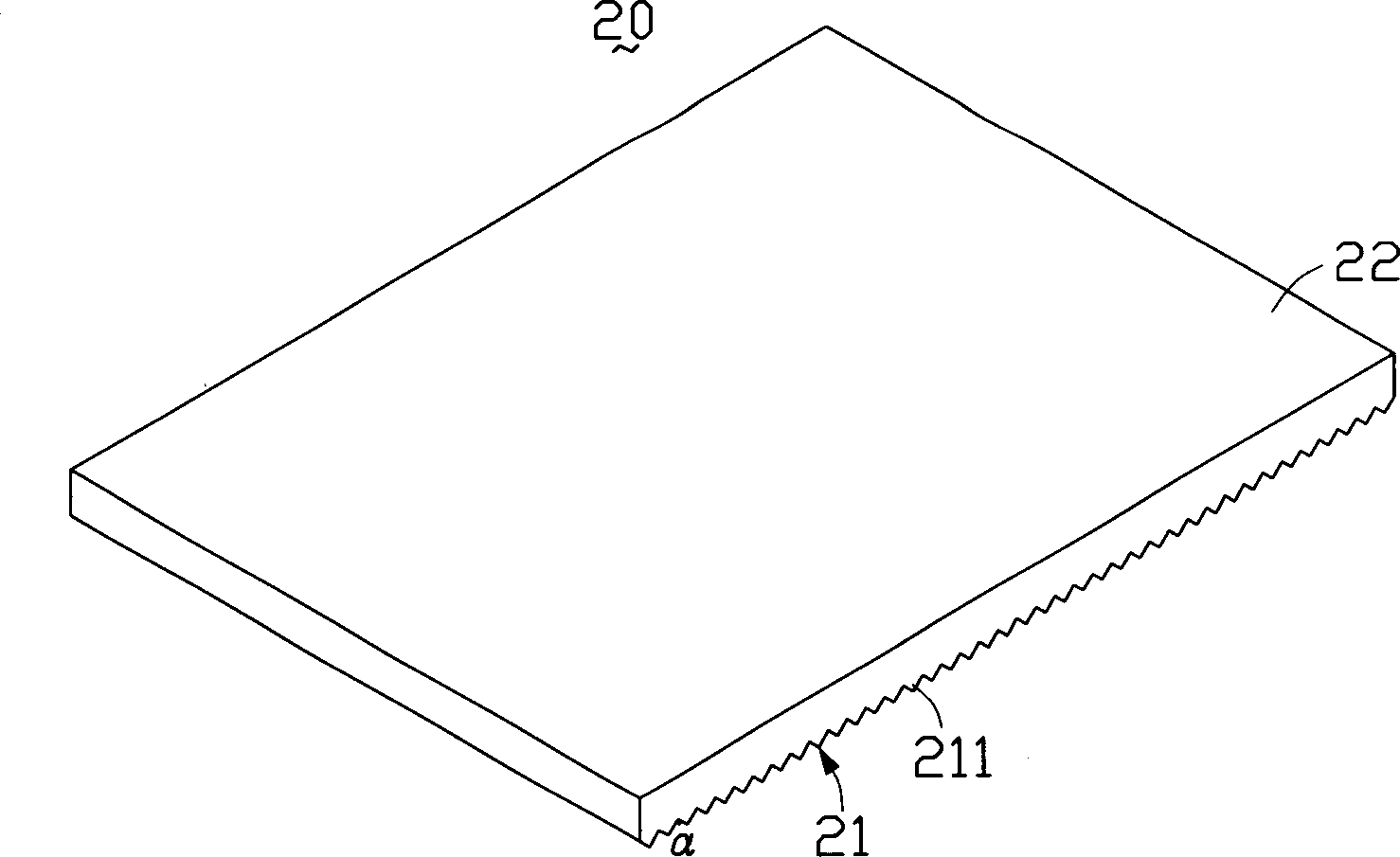

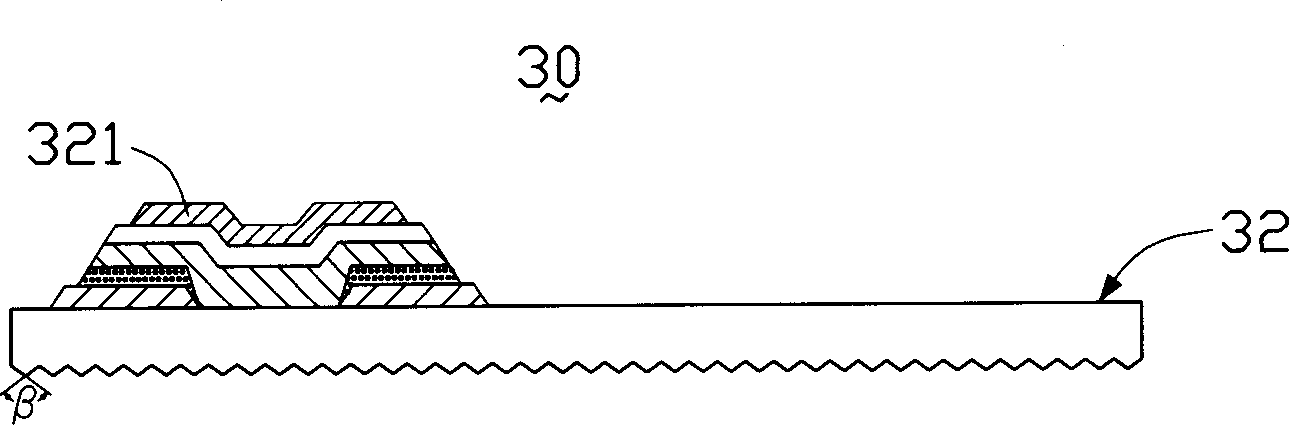

Glass substrate, liquid crystal display device and method for manufacturing glass substrate

InactiveCN1790126AReduce thicknessReduce weightTransistorStatic indicating devicesLiquid-crystal displayPrism

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

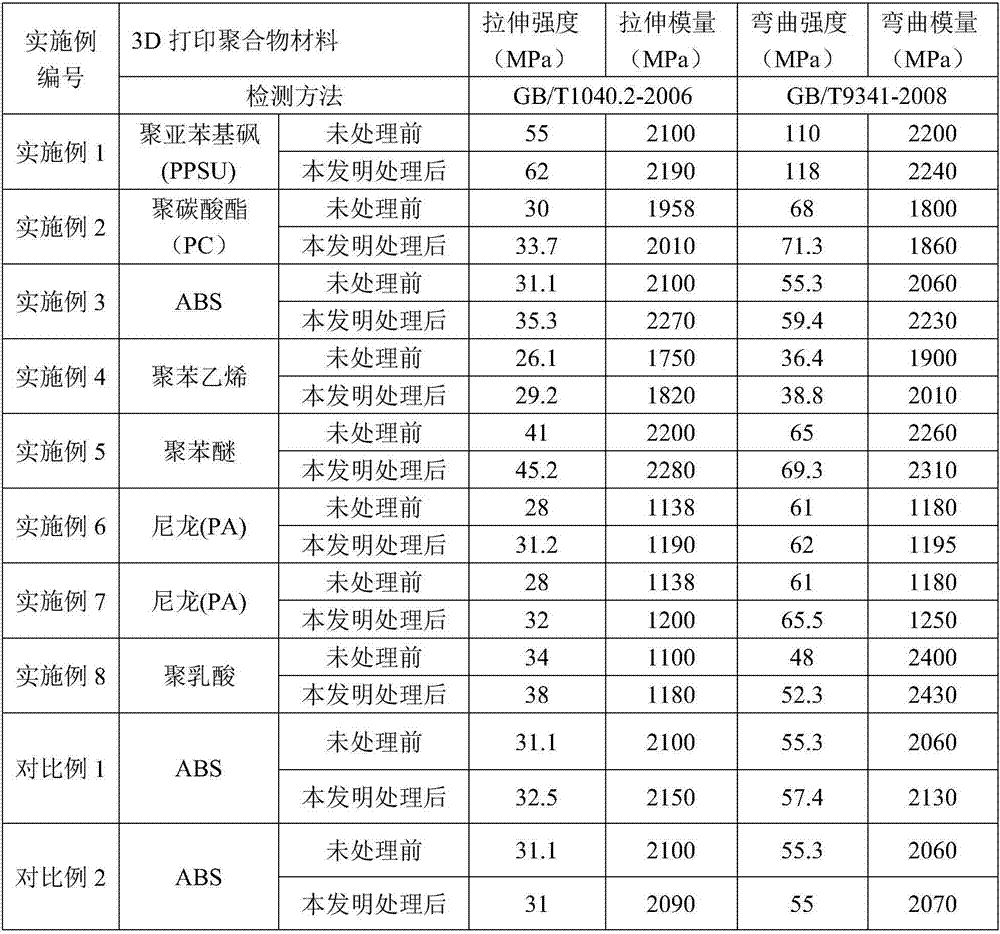

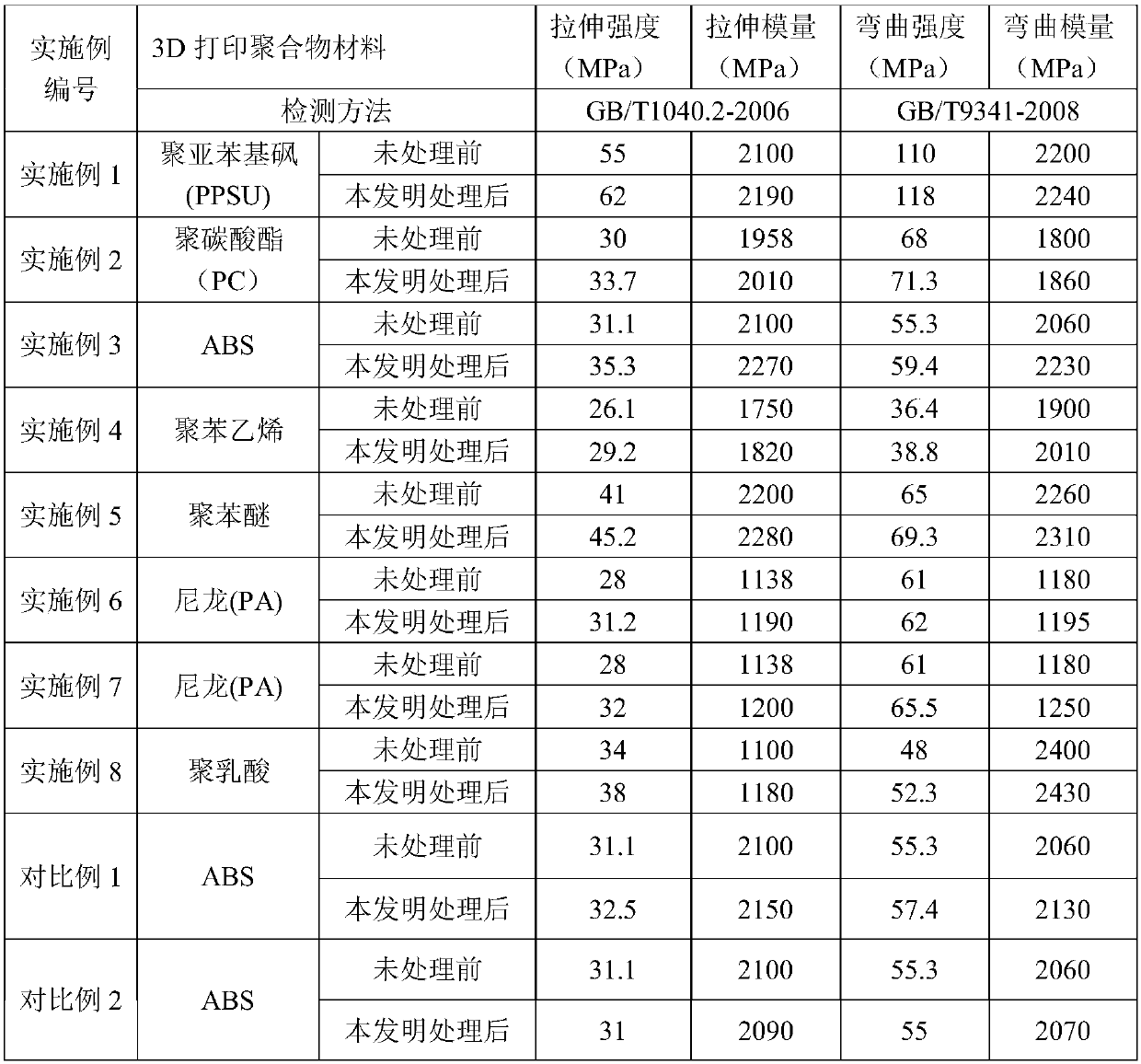

Aftertreatment method of 3D printing part

ActiveCN106965435AImprove mechanical propertiesImprove bindingAdditive manufacturing apparatus3D object support structuresHigh pressureSolvent

The invention provides an aftertreatment method of a 3D printing part and belongs to the technical field of 3D printing. The aftertreatment method of the 3D printing part comprises the following steps that (1), a certain amount of a micro-bead medium with micro holes is completely placed into a solvent, and stirring and standing are conducted for a certain time; (2), the micro-bead medium subjected to solvent adsorption is filtered out, and then the micro-bead medium subjected to solvent adsorption is placed into a micro-bead medium feeding device; (3), the micro-bead medium subjected to solvent adsorption is conveyed to a spray gun by the micro-bead medium feeding device; and (4), the micro-bead medium subjected to solvent adsorption and located in the sprayed gun is sprayed to the treated surface of the 3D printing part through high-pressure air to treat the surface of the 3D printing part, and the surface of the 3D printing part is composed of a polymer forming material. By adoption of the aftertreatment method of the 3D printing part, after the surface of the 3D printing part is treated, a smooth surface can be obtained, the mechanical property of the 3D printing part in the Z-axis forming direction can be improved, and the aftertreatment method of the 3D printing part has the outstanding beneficial effects.

Owner:四川长虹智能制造技术有限公司

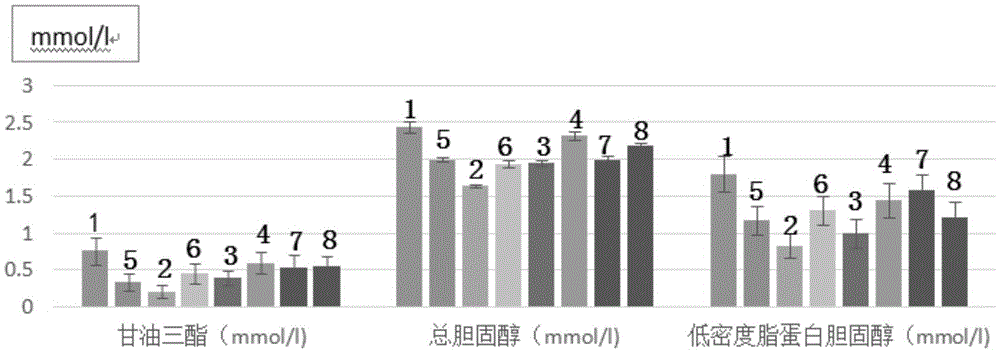

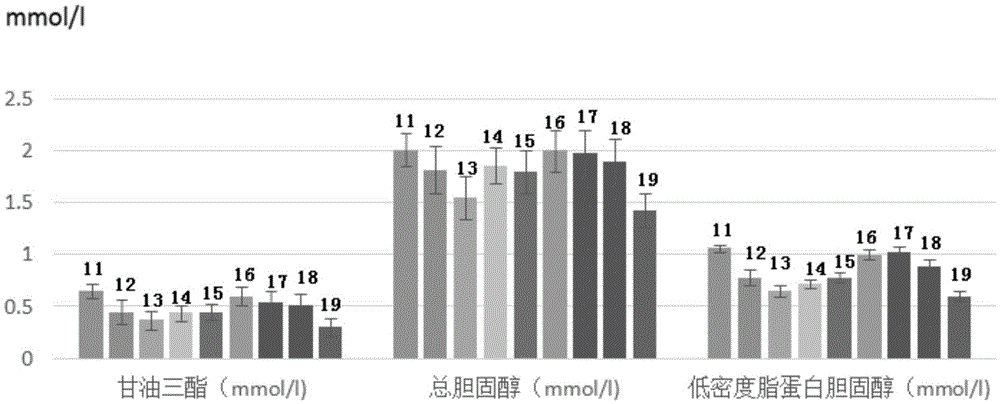

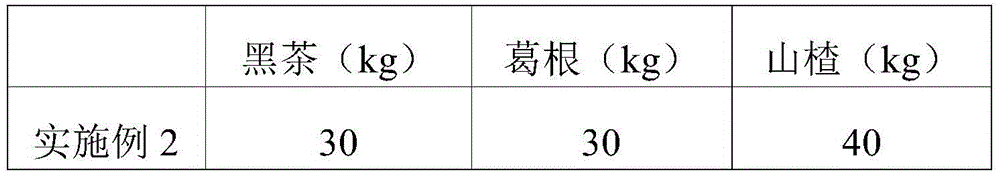

Functional health-care drink composition with effect of reducing blood fat and application thereof

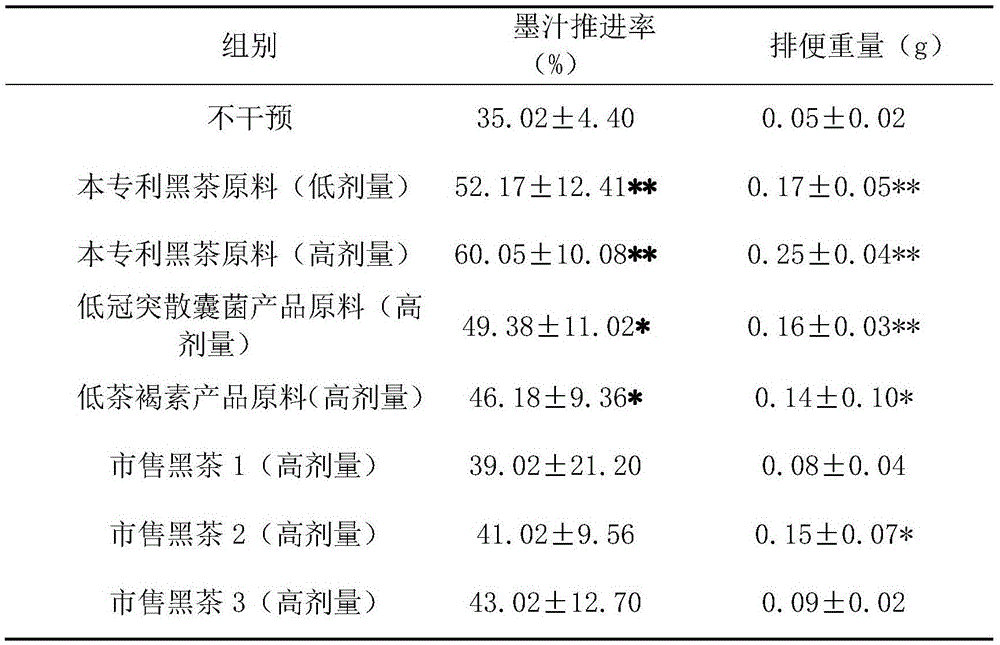

InactiveCN105660906AGood collocationGood collocation effectPre-extraction tea treatmentRed yeast riceFunctional health

The invention relates to a functional health-care drink composition with an effect of reducing blood fat. The materials of the functional health-care drink composition include the following components in parts by weight: component A: the component A is black tea, and is 30 to 100 parts by weight; component B: the component B is one or the combination of a few of lobed kudzuvine root, balsampear fruits, hawthorns, solomonseal rhizome, barbary wolfberry fruits and red yeast rice, and is 0 to 70 parts by weight. A teabag, solid instant beverage, liquid beverage or combination thereof prepared from the drink composition or teabags, solid instant powder and liquid beverage prepared respectively from the component A and / or the component B in the drink composition and then packaged in combination for use have the effect of helping reduce blood fat.

Owner:中国土产畜产进出口有限责任公司

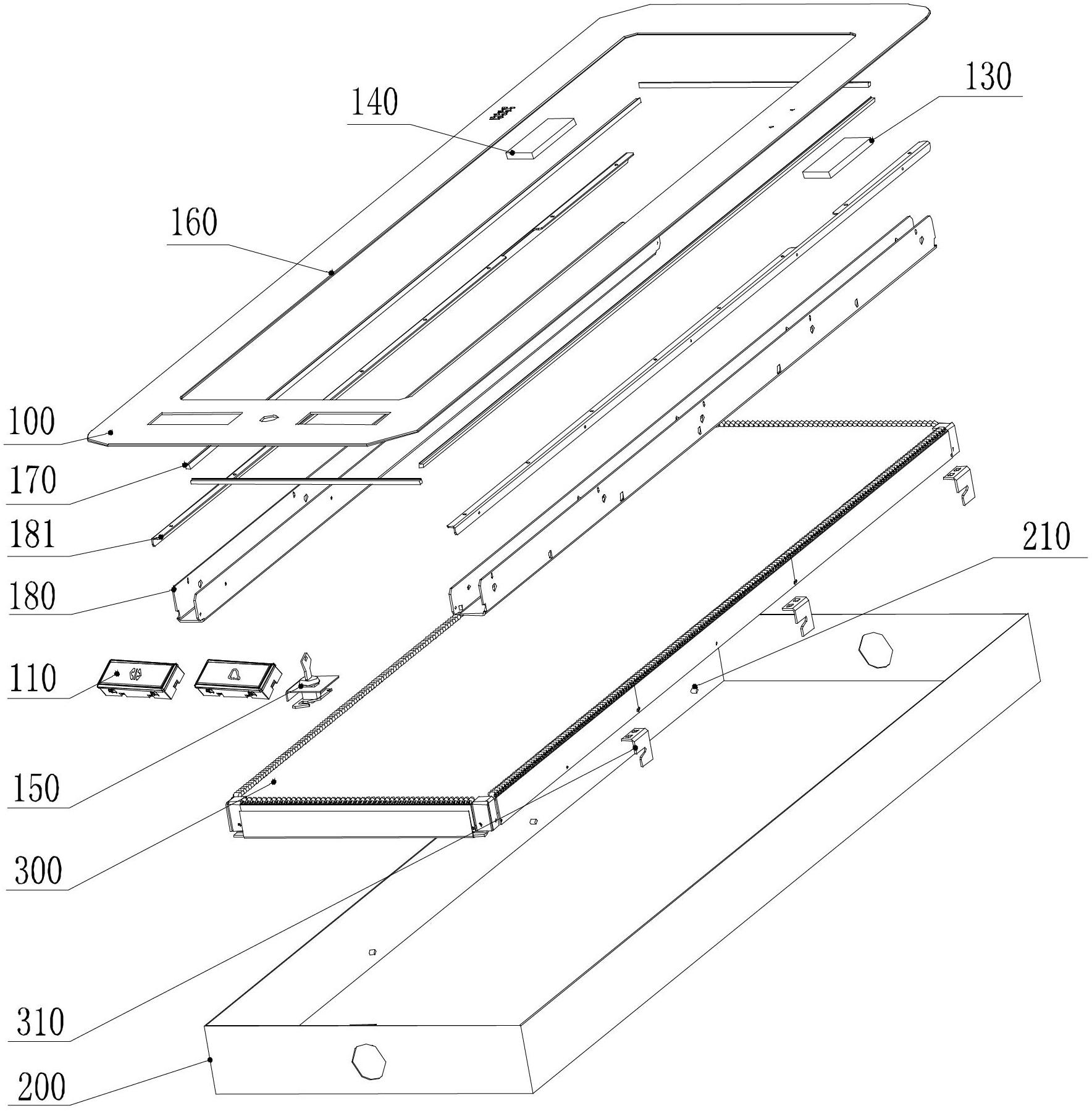

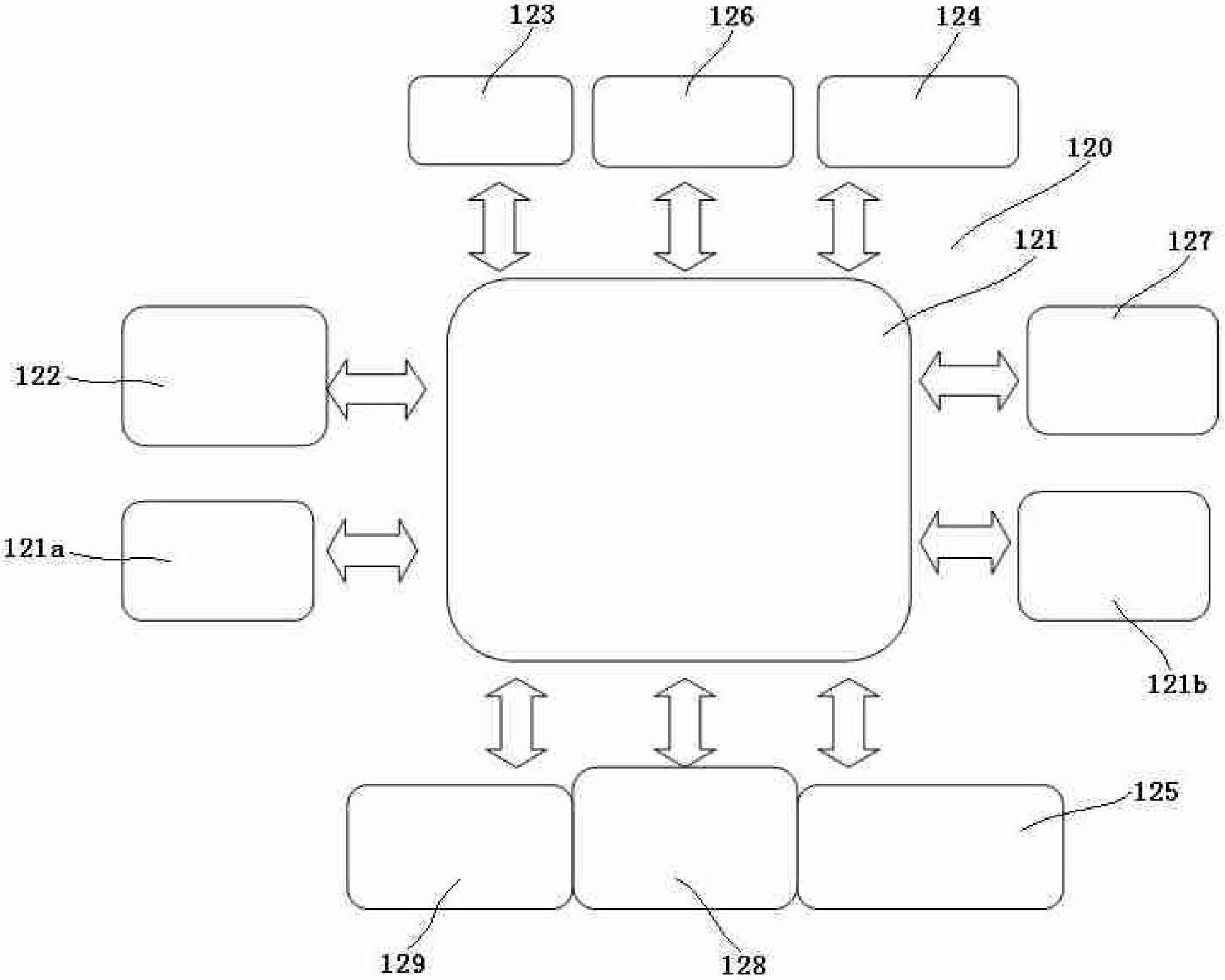

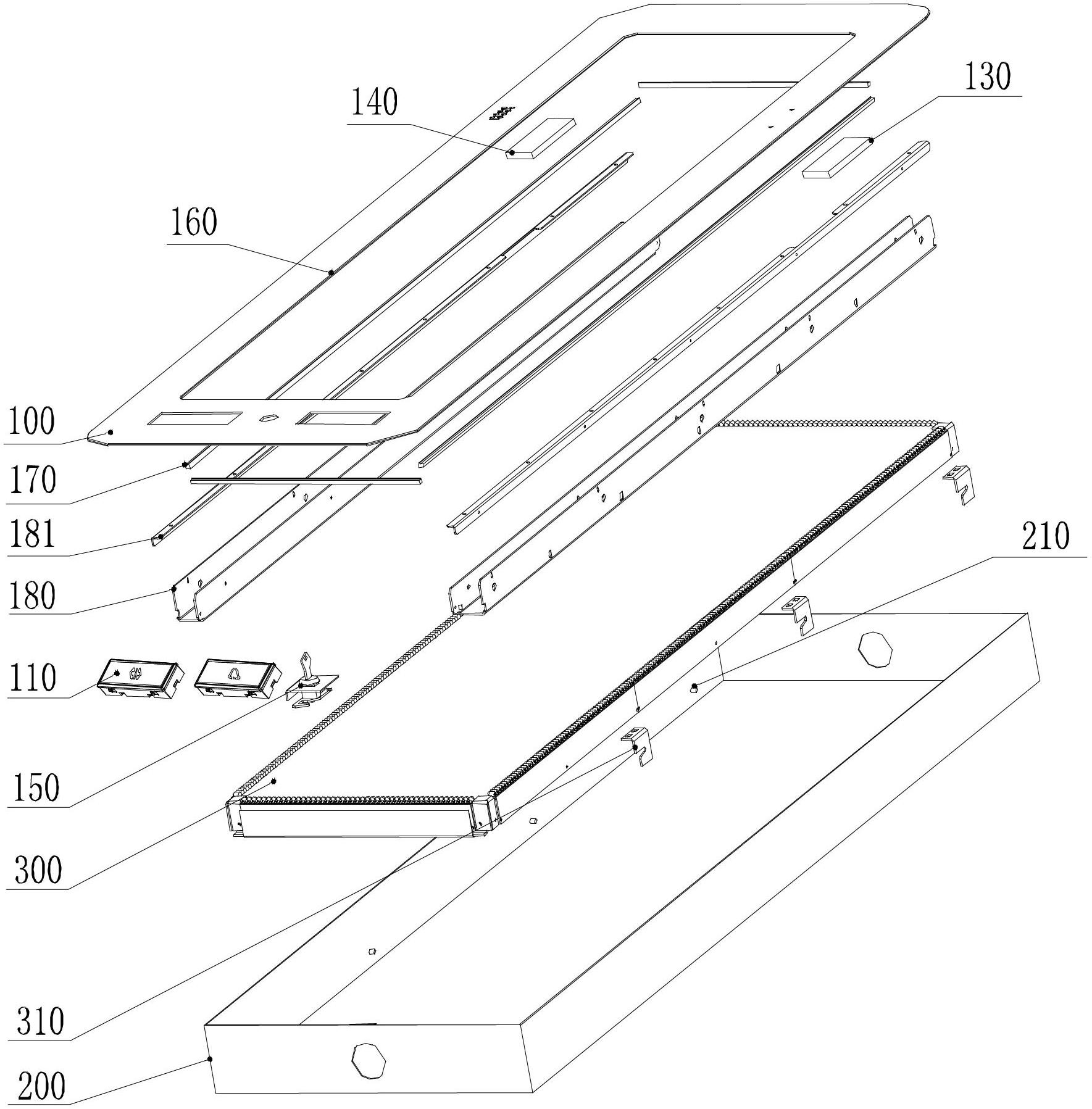

Elevator steering hand wheel with large-size touch screen

The invention aims to disclose an elevator steering hand wheel with a large-size touch screen. The elevator steering hand wheel with the large-size touch screen comprises a panel and a box body component, wherein a touch display component is arranged in the box body component; a control unit, a camera device and an interphone are arranged in the box body component; the camera device and the interphone are connected with a control unit respectively; a press button and a lock component are arranged at the lower part of the panel; and a mounting hole corresponding to the touch display component is formed in the middle of the panel. Compared with the prior art, the elevator steering hand wheel with the large-size touch screen has abundant external interfaces and a super multimedia function, brings good use experience for terminal customers, has an innovative appearance, high grade and a good matching effect, can facilitate use of function addition by the expandable interface design and fulfills the aim of the invention.

Owner:SHANGHAI BST ELECTRIC

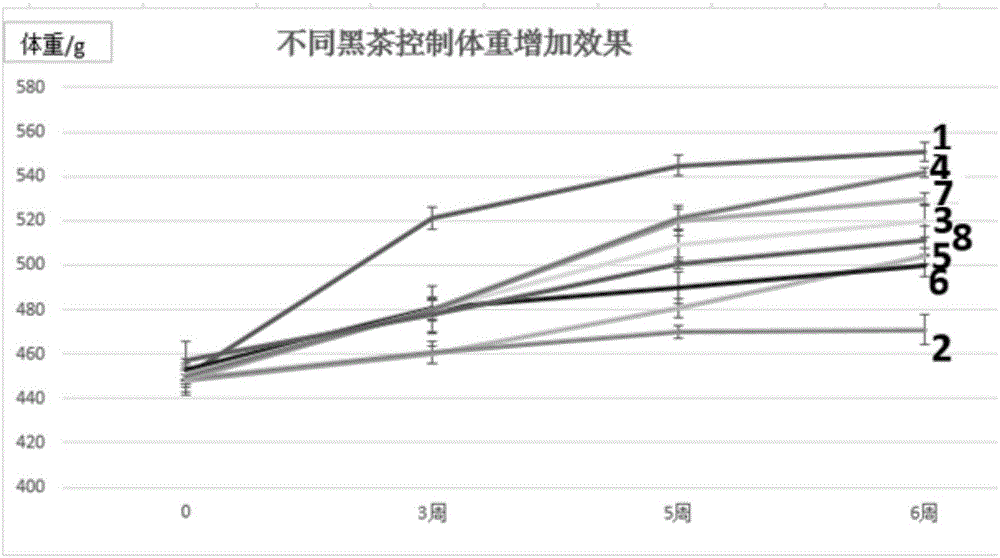

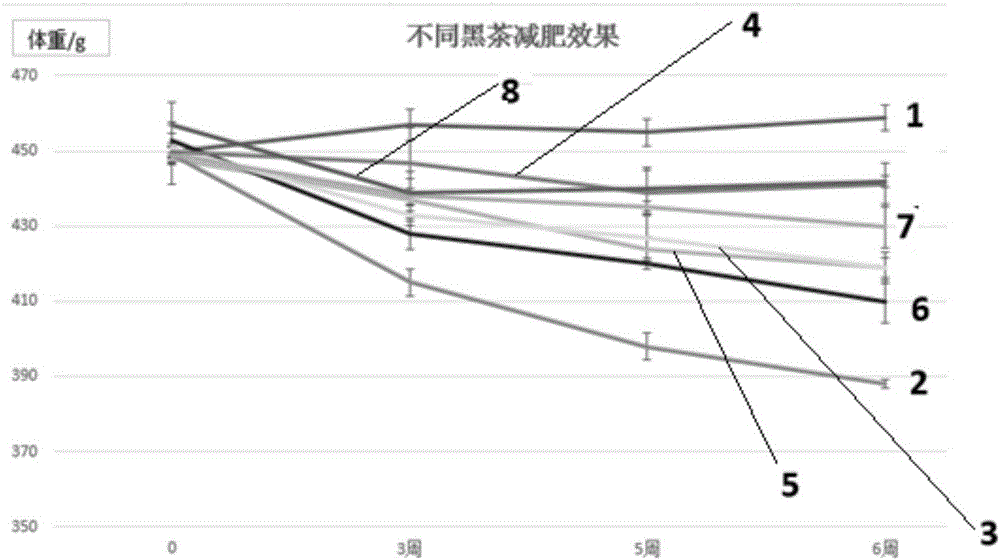

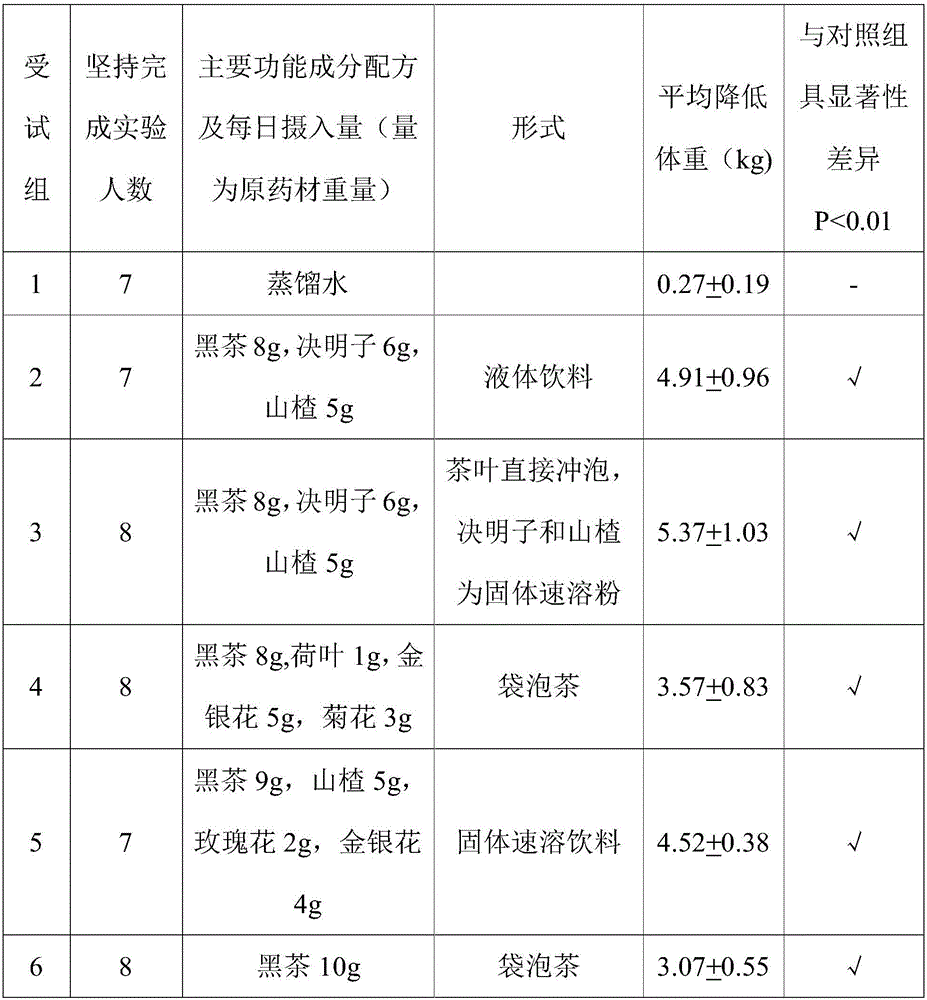

Drink composition having weight-reducing function and application thereof

InactiveCN105707318AGood collocation effectGood for healthPre-extraction tea treatmentHawthorn fruitOfficinalis

The invention relates to a drink composition having the weight-reducing function. The drink composition is prepared from, by weight, 30-100 parts of a component A and 0-70 parts of a component B, wherein the component A is dark tea; the component B is one of or a combination of lotus leaves, flos lonicerae, flos chrysanthemi indici, cassia seeds, hawthorn fruits, flos rosae rugosae, balsamper fruits and radix polygonati officinalis; the drink composition is prepared into tea bags, solid instant drinks, liquid drinks or a combination thereof, or the component A and / or the component B in the drink composition are each prepared into tea bags, solid instant powder and liquid drinks and then combined to be packaged and used, and the drink has the health efficacyof assisting in weight reduction.

Owner:中国土产畜产进出口有限责任公司

Sewage filter screen for adsorbing gas soluble in water

InactiveCN106540491AImprove adsorption capacityImprove adsorption speedOther chemical processesWater contaminantsAluminateFiber

The invention discloses a sewage filter screen for adsorbing a gas soluble in water. A main body of the sewage filter screen is a steel filter screen; the steel filter screen is filled with a formaldehyde adsorbent in a production process; the formaldehyde adsorbent is prepared from the following raw materials in parts by weight: 8-15 parts of calcium carbonate fibers, 20-40 parts of tetrabutyl titanate, 3-5 parts of silica sol, 6-8 parts of calcium aluminate, 60-80 parts of volcanic, 6-9 parts of PA6 nylon powder, 3-4 parts of gelatin, 1-3 parts of ammonium bicarbonate, 10-15 parts of scindapsus aureus residue powder, 5-8 parts of coal slag and a defined amount of deionized water. The sewage filter screen for adsorbing the gas soluble in water provided by the invention is characterized in that the main body is the steel filter screen, the steel filter screen is filled with the formaldehyde adsorbent in the production process and the formaldehyde adsorbent has ultrahigh adsorption capacity and adsorption speed.

Owner:WUHU HANGDA NETWORK IND CO LTD

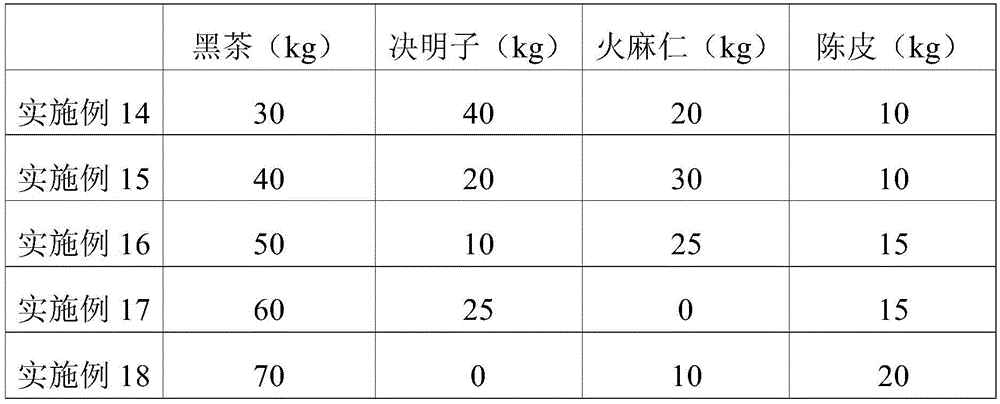

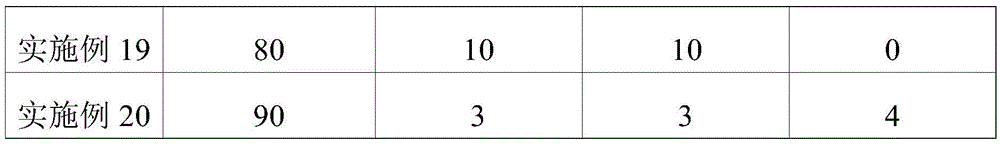

Functional health care beverage composition with purgation effect and application thereof

InactiveCN105558155AGood collocation effectGood for healthPre-extraction tea treatmentCannabisMedicine

The invention relates to a functional health care beverage composition with a purgation effect. The functional health care beverage composition is prepared from, by weight, 30-100 parts of a component A, namely, black tea, and 0-70 parts of a component B which is one of or a composition of several of lotus leaves, yam, radish seeds, hawthorn, fructus cannabis, Semen Cassiae and tangerine peel. The beverage composition is prepared into tea bags, solid instant beverage, liquid beverage or other compositions, or the component A and / or the component B in the beverage composition are each prepared into tea bags, solid instant powder and liquid beverages and then packaged in a combined mode for use, and the functional heath care beverage with the purgation effect has the function of relaxing bowels.

Owner:中国土产畜产进出口有限责任公司

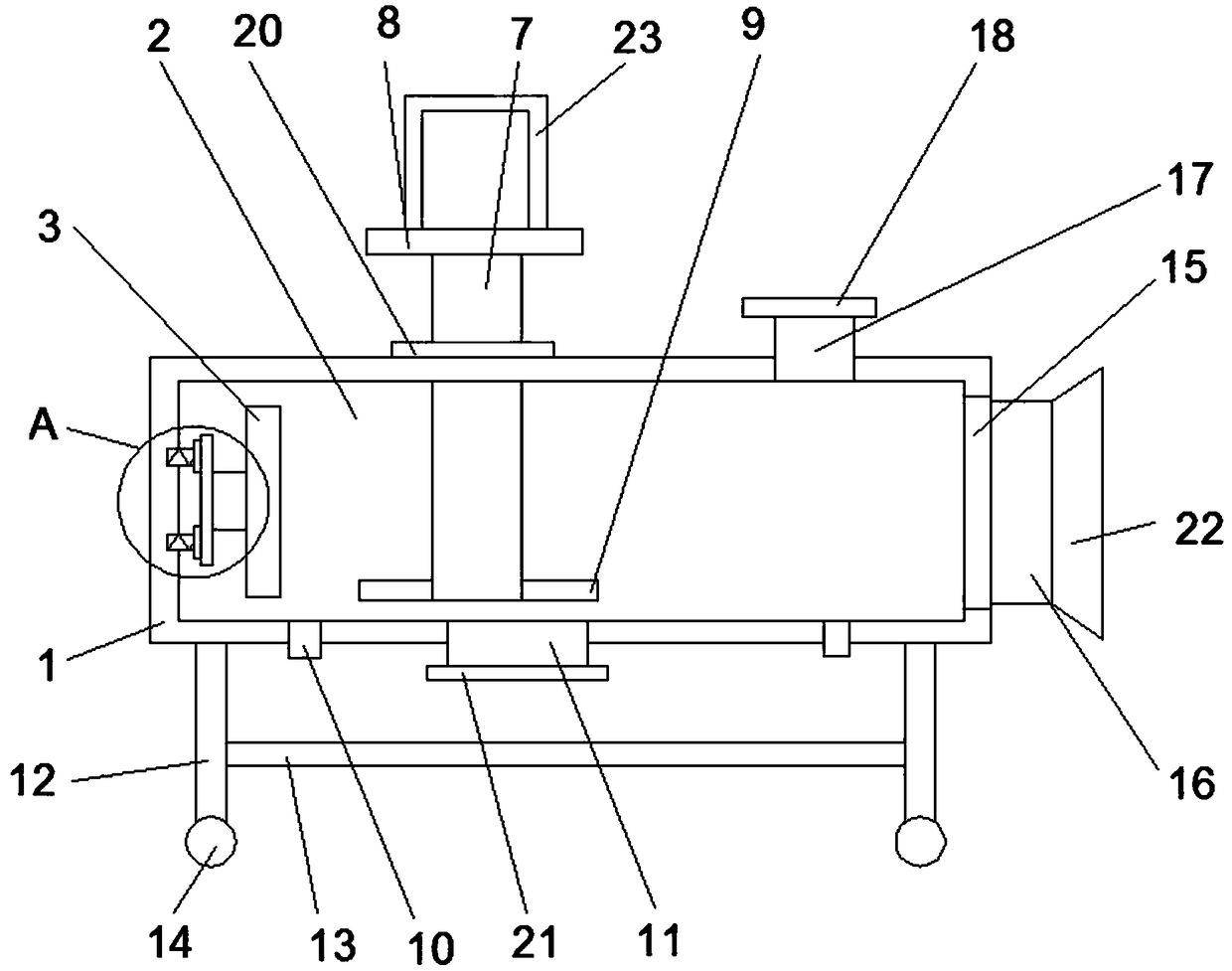

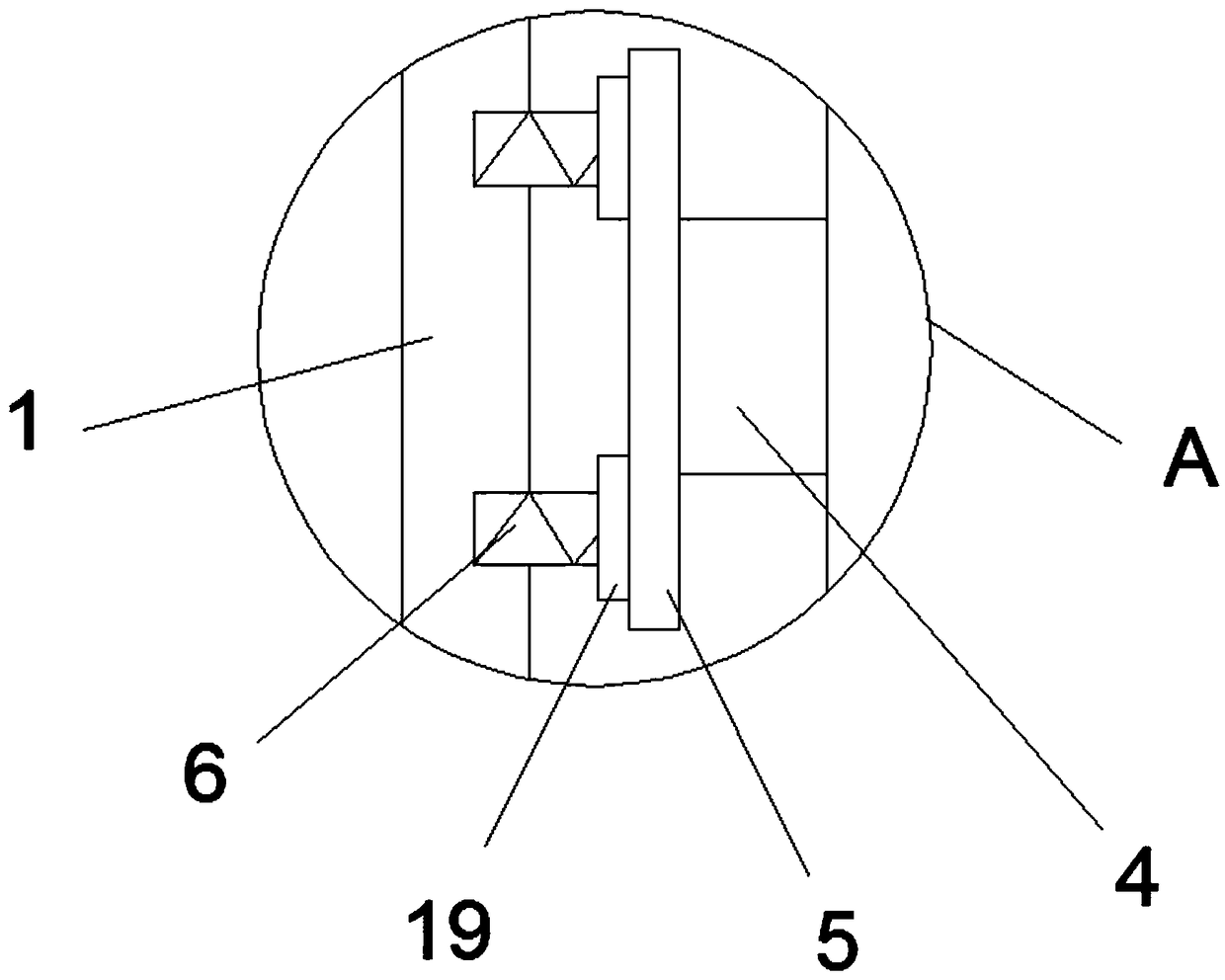

Brick paving machine

PendingCN108716178AGood effectEasy to assemble and disassembleRoads maintainenceMechanical engineeringMental detachment

The invention discloses a brick paving machine which comprises a traveling part, wherein a transfer part is arranged above the traveling part; an extension part is arranged on one side of the transferpart; a leveling part is arranged on one side of the traveling part; an adsorption part is arranged on one side of the transfer part; the brick paving machine further comprises a conveying device; and the conveying device is connected with the side face of a rack of the brick paving machine. The invention has the positive effects that the equipment belongs to an assembly type, the components canbe independently used and can also be matched with other brick paving machines, and the matching effect of the brick paving machine is excellent. Due to matched use of the conveying device and the brick paving machine, brick blocks of different sizes can be rapidly transferred, and detachment is convenient. Due to the sucker type paved brick blocks, the brick blocks can be rapidly and accurately put into needed positions. The complete machine can avoid obstacles by the rack on the traveling part, and the extension part is increased, so that the paving area can be enlarged, and the extension part is folded to avoid the obstacles by adopting the hinges.

Owner:PINGYUAN GAIFENG MACHINERY EQUIP CO LTD

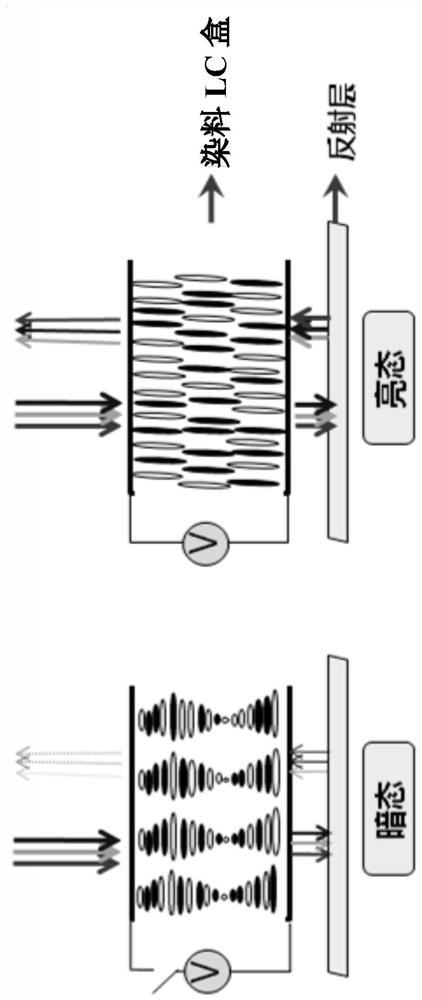

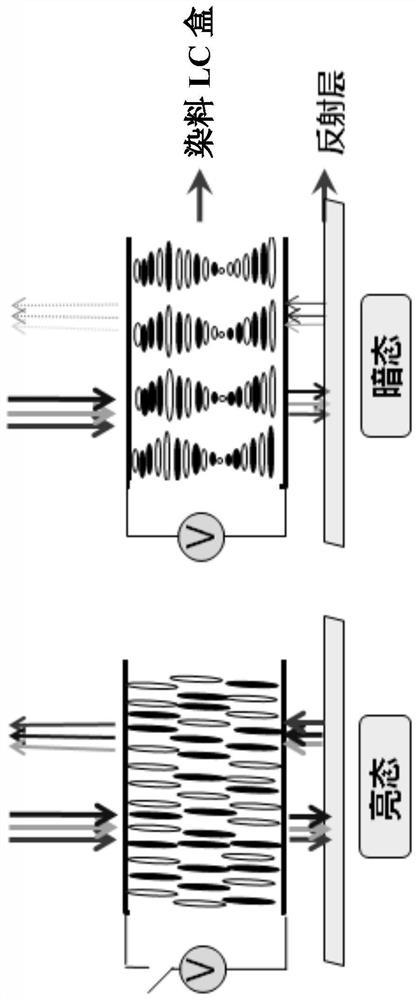

Reflective liquid crystal display device including dye liquid crystal composition

ActiveCN111856828AImprove solubilityIncrease contrastLiquid crystal compositionsNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a reflective liquid crystal display device including a dye liquid crystal composition. The reflective liquid crystal display device sequentially comprises an upper substrate, an upper conducting layer, an upper orientation layer, a dye liquid crystal composition layer, a lower orientation layer, a lower conducting layer, a lower substrate and a reflecting layer from top tobottom, the reflective liquid crystal display device does not contain a polaroid, the dye liquid crystal composition layer contains a liquid crystal composition, a chiral agent and a dichroic dye, theclearing point of the liquid crystal composition is not lower than 100 DEG C, and K33 / K22 is larger than 2. The reflective liquid crystal display device including the dye liquid crystal composition provided by the invention has the advantages of high contrast ratio, high reliability, wide operating temperature range, wide viewing angle, good low-temperature stability, wide application range, no phase dislocation under intermediate-state voltage and the like; meanwhile, the defects that a traditional reflective display device needs to use a polarizer, a brightness enhancement film, a phase retarder and the like, the cost is increased, and the visual angle characteristic is poor are overcome.

Owner:JIANGSU HECHENG DISPLAY TECHCO

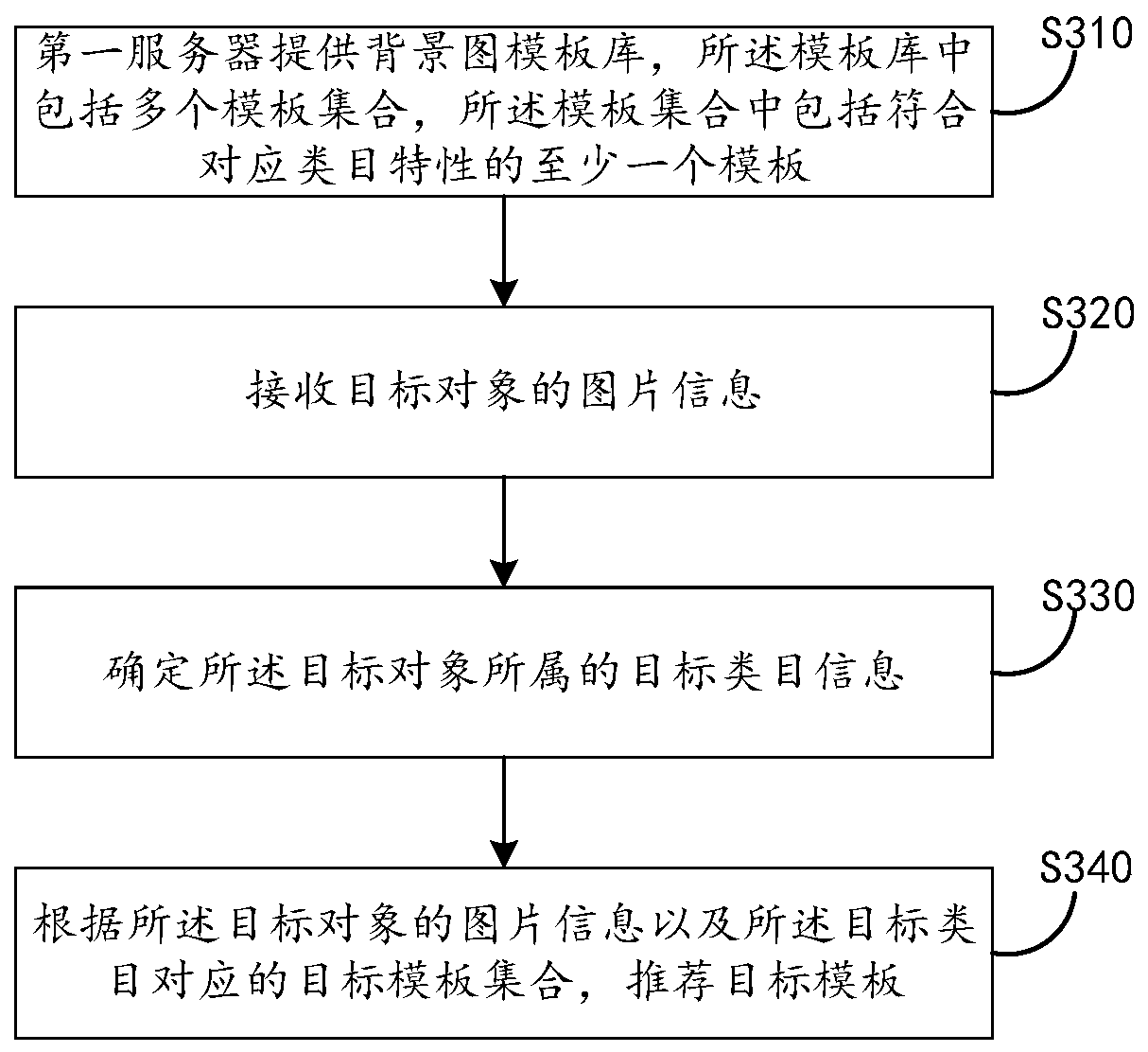

Template matching information recommendation method and device and electronic equipment

PendingCN111580788APage content design is more automated and intelligentHigh coordination and integrationSoftware designExecution for user interfacesTemplate matchingSoftware engineering

The embodiment of the invention discloses a template matching information recommendation method and device and electronic equipment, and the method comprises the steps of a first server providing a background image template library, the template library comprising a plurality of template sets, and each template set comprising at least one template meeting the characteristics of a corresponding category; receiving picture information of the target object; determining target category information to which the target object belongs; and recommending a target template according to the picture information of the target object and the target template set corresponding to the target category. Through the embodiment of the invention, the page content design can be more automatic and intelligent, and the synthesized picture has higher coordination and fusion degree.

Owner:ALIBABA GRP HLDG LTD

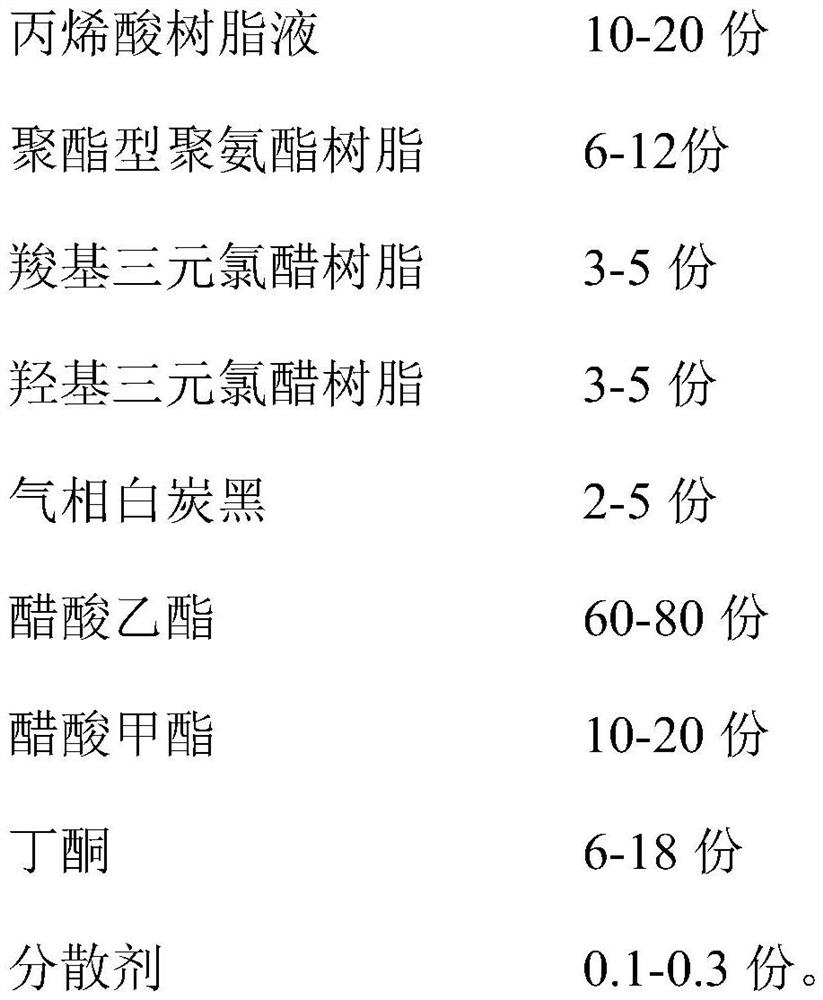

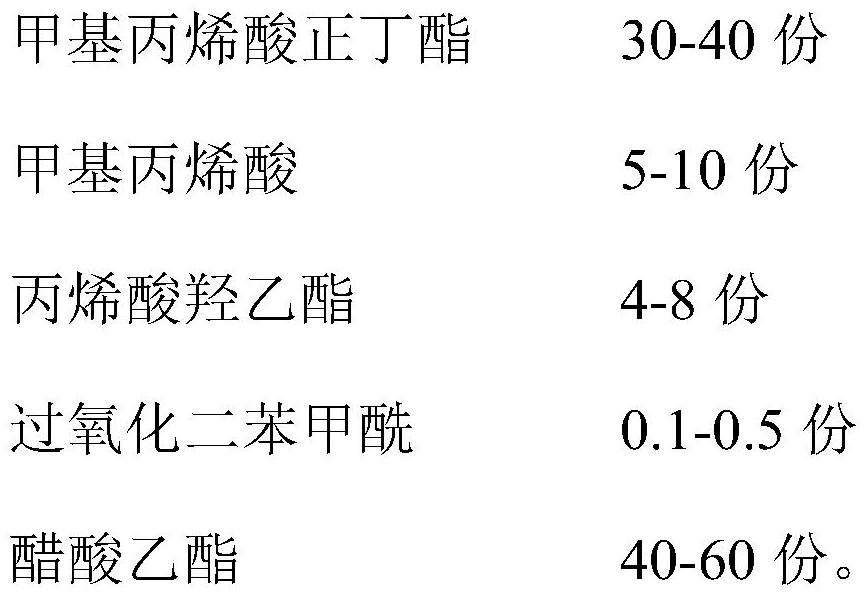

Protective layer coating for cold wave printing film as well as preparation method and use method of protective layer coating

ActiveCN112521821AImprove stabilityUnique metallic lusterPolyurea/polyurethane coatingsPolyesterAcrylic resin

The invention provides a protective layer coating for a cold wave printing film as well as a preparation method and a use method of the protective layer coating. The protective layer coating is prepared from the following components in parts by weight: 10-20 parts of acrylic resin liquid, 6-12 parts of polyester type polyurethane resin, 3-5 parts of carboxyl ternary vinyl chloride-vinyl acetate resin, 3-5 parts of hydroxyl ternary vinyl chloride-vinyl acetate resin, 2-5 parts of fumed silica, 60-80 parts of ethyl acetate, 10-20 parts of methyl acetate, 6-18 parts of butanone and 0.1-0.3 part of dispersing agent. When the protective layer coating for a cold wave printing film is used for preparing a cold wave printing film, the surface of the film layer is fine, uniform and free of after-tack, the high-temperature and high-humidity resistance is excellent, and the stability is high; the adhesive force on an aluminized layer and a UV cold wave adhesive layer is strong, the fastness is good, the trimmed edges are tidy, the details are clear, and the cold wave requirements of pretreated or untreated non-shrink paper are met; and a cold wave product has unique metallic luster and has the effects of large field and small fineness, and the production process and the product are low in VOCs.

Owner:上海绘兰材料科技有限公司

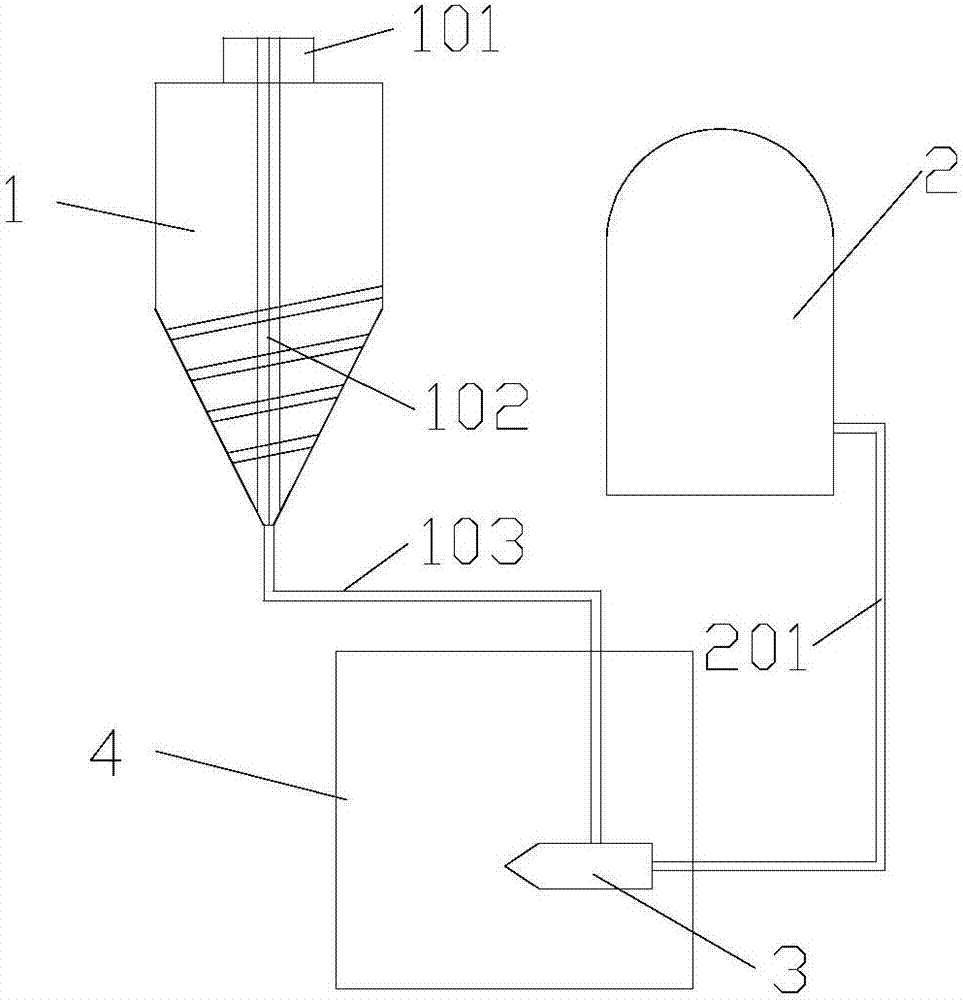

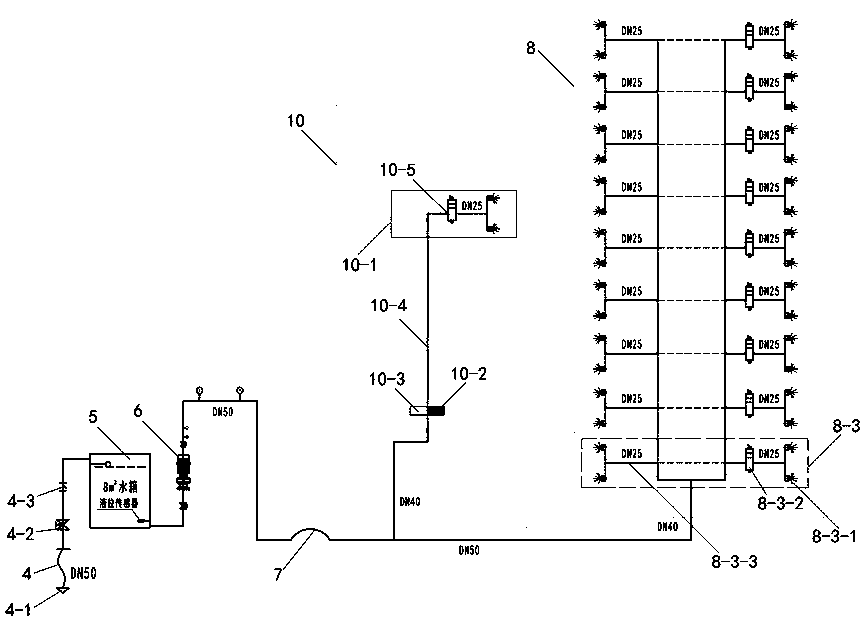

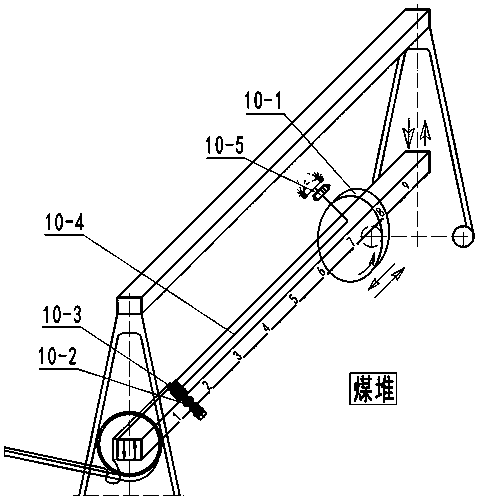

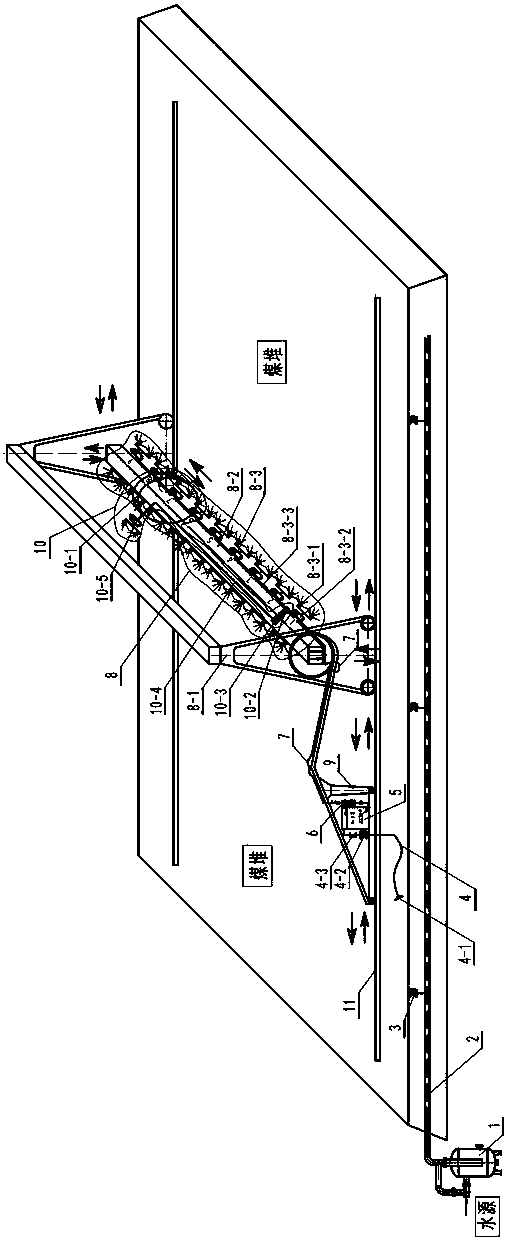

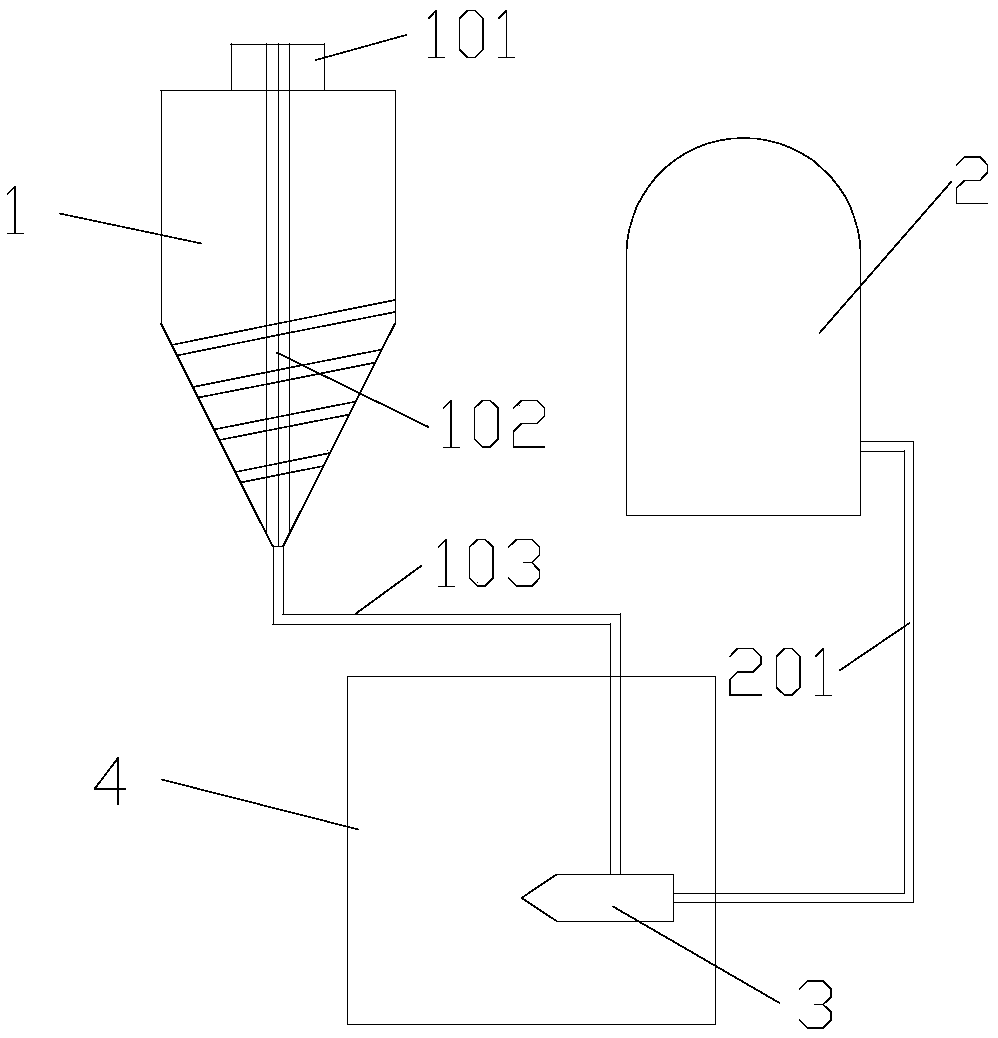

Dust settling system of bucket wheel machine of coal yard in thermal power plant as well as dust settling method for the system

PendingCN109701337ASolve the problem of severe dust generationSolve the problem of severe dustHuman health protectionUsing liquid separation agentSpontaneous combustionWater source

The invention relates to a dust settling system of a bucket wheel machine of a coal yard in a thermal power plant as well as a dust settling method for the system. The system includes: a cyclone dirtremover connected to a water source, a water supply pipe connected to the water source and the cyclone dirt remover, at least three stop valves which are arranged on the water supply pipe, a first hose connected to the stop valves on the water supply pipe, an automatic water tank connected to the first hose, a water pump which is connected to the automatic water tank and provided with a frequency-varying voltage stabilizing function, a second hose connected to the other end of the water pump, a coal piling spray apparatus connected to the second hose, a bucket wheel machine tail cart used forarranging the automatic water tank and connecting the second hose, and a coal fetching spray apparatus arranged on a bucket wheel machine movable crossbeam. The system solves the problem of dust pollution treatment of the coal yard in the thermal power plant. By means of the system, a workplace and surrounding environment can be cleaned, and a problem of serious waste of coal resources is solved;the system also can prevent spontaneous combustion of a coal pile.

Owner:四平市巨鹏热能设备有限公司

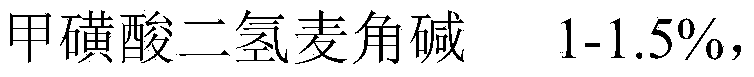

Dihydroergotoxine methanesulfonate sustained release tablet and preparation method thereof

InactiveCN103860507AGood bioavailabilityThe process is simpleNervous disorderPharmaceutical delivery mechanismBioavailabilityBuoyancy

The invention provides a dihydroergotoxine methanesulfonate sustained release tablet. The dihydroergotoxine methanesulfonate sustained release tablet comprises the following components in parts by weight: 1%-1.5% of dihydroergotoxine methanesulfonate, 70%-90% of sustained release agent, 8%-28% of expanding agent and 0.5%-1% of lubricating agent, wherein in the product obtained according to the formula, the sustained release agent can form a gel in water, the expanding agent can expand rapidly in water to ensure that the tablet is finally expanded to 10-20 times of the size of an original tablet; the volume of the tablet produces buoyancy to enable the tablet to float on a gastric fluid; with slow dissolution of the gel, a main drug releases slowly in vivo to achieve the sustained release effect. Besides, the main drug can be dissolved and absorbed in medicine liquid to achieve good bioavailability. The invention also provides a preparation method of the dihydroergotoxine methanesulfonate sustained release tablet. The preparation method is simple in process and suitable for popularization.

Owner:珠海天翼医药技术开发有限公司

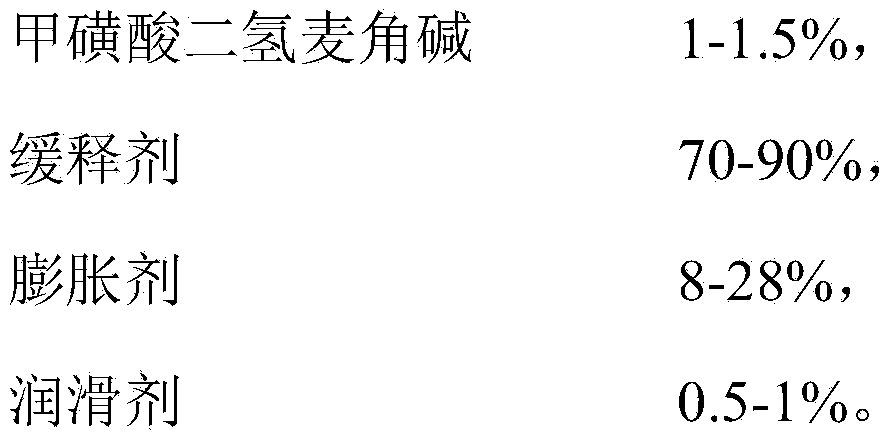

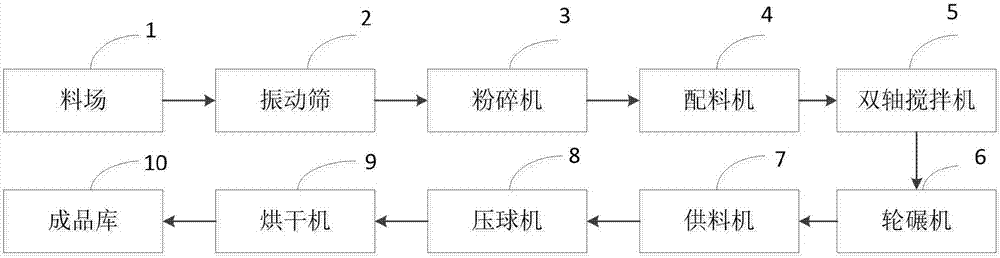

Large-scale coal briquette producing equipment and method

The invention belongs to the field of coal production, and discloses large-scale coal briquette producing equipment and a large-scale coal briquette producing method. The large-scale coal briquette producing method comprises the following steps: screening raw materials, and filtering to remove impurities; pulverizing the raw materials, and conveying the raw materials to a dosing machine by using a conveyor belt; dosing the raw materials; stirring to effectively mix the components; crushing or mixing the materials; timely supplementing the raw materials in shortage; treating mineral tailings, and pressing a difficultly shaped powdery material. A control unit and an image acquisition unit are inlaid onto a control valve of the dosing machine; the image acquisition unit is connected with the control unit in a wired or wireless way; the large-scale coal briquette producing equipment comprises a material field, a vibrating screen, a pulverizer, the dosing machine, a double-shaft stirrer, a wheel mill, a feeding machine, a ball pressing machine, a drying machine and a finished product warehouse. Through the large-scale coal briquette producing equipment and the large-scale coal briquette producing method, coal briquettes can be produced on a large scale and the characteristic of automatic production can be achieved, therefore, manpower and material resources are saved.

Owner:府谷县新亚新能源科技发展有限责任公司

Straight-through water pump detection device

InactiveCN108757427AEasy to useAvoid damagePump testingPositive-displacement liquid enginesEngineeringGasket

The invention discloses a straight-through water pump detection device. The device comprises a shell, a detection groove is formed in the inner part of the shell, a sealing gasket is arranged on one side of the detection groove, one side, close to the inner wall of the shell, of the sealing gasket is provided with a fixing rod , one end, far away from the sealing gasket, of the fixing rod is provided with a spring plate, one side, away from the fixing rod, of the spring plate is provided with a plurality of springs matched with the shell, an adjusting rod is arranged at the top end of the shell in a penetrating mode, a force bearing plate is arranged at the top end of the adjusting rod, an adjusting plate is arranged at the bottom end of the adjusting rod, a plurality of detection holes are formed in the bottom end of the shell, a water drain hole is formed in the middle of the bottom end of the shell, a plurality of supporting rods are arranged on each of the two sides of the bottom end of the shell, a connecting rod is arranged between every two supporting rods, moving wheels are arranged at the bottom ends of the supporting rods, and one side, far away from the sealing gasket, of the shell is provided with an opening. The device has the beneficial effects that the shell, the detection groove, the adjusting rod, the sealing gasket, the water drain hole, the detection holes and the opening are arranged, so that the device has better matching performance.

Owner:芜湖绿琼农业科技有限公司

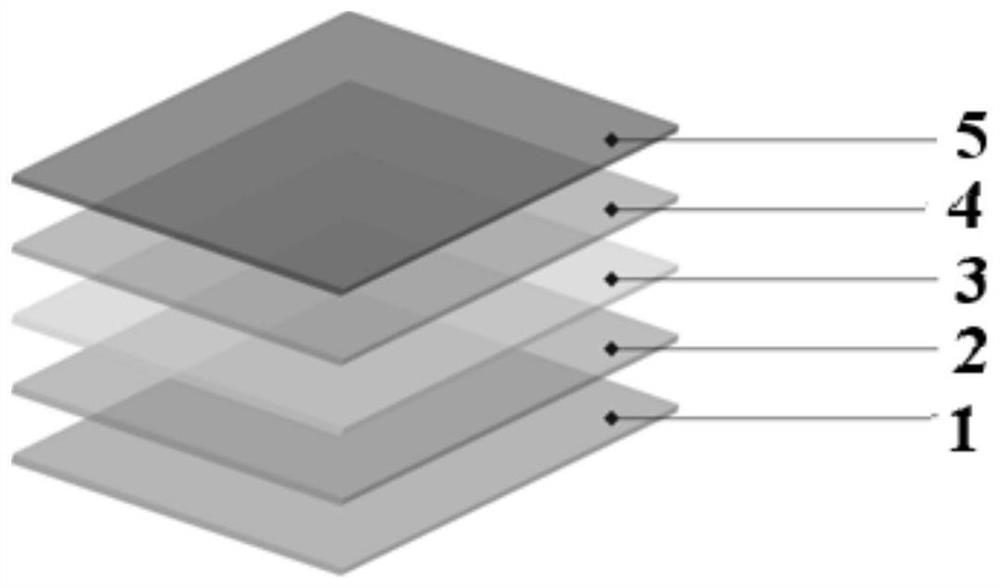

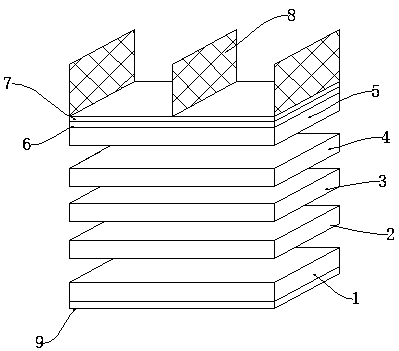

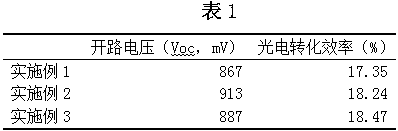

Cadmium telluride power generation glass

PendingCN110176503AHigh light transmittanceImprove conductivityPhotovoltaic energy generationSemiconductor devicesOptical transmittanceTemperature resistance

The present invention relates to the field of solar cells, in particular to cadmium telluride power generation glass. The cadmium telluride power generation glass successively comprises a glass substrate, a transparent oxide layer, a window layer, an absorption layer and a back contact electrode from bottom to top. The glass substrate is the borosilicate glass with a thickness of 2-3mm; the transparent oxide layer is a Sn-doped In<2>O<3> film; the window layer is the CdS layer with a thickness of 0.4-0.5mum; and the absorption layer is a CdTe layer with a thickness of 3-5mum. For the cadmium telluride power generation glass proposed by the invention, the glass substrate has high light transmittance; the high temperature resistance is good; and the transparent oxide layer with better lighttransmittance is cooperatively used so that the photoelectric conversion efficiency of the power generation glass is greatly improved.

Owner:浙江力晟玻璃科技有限公司

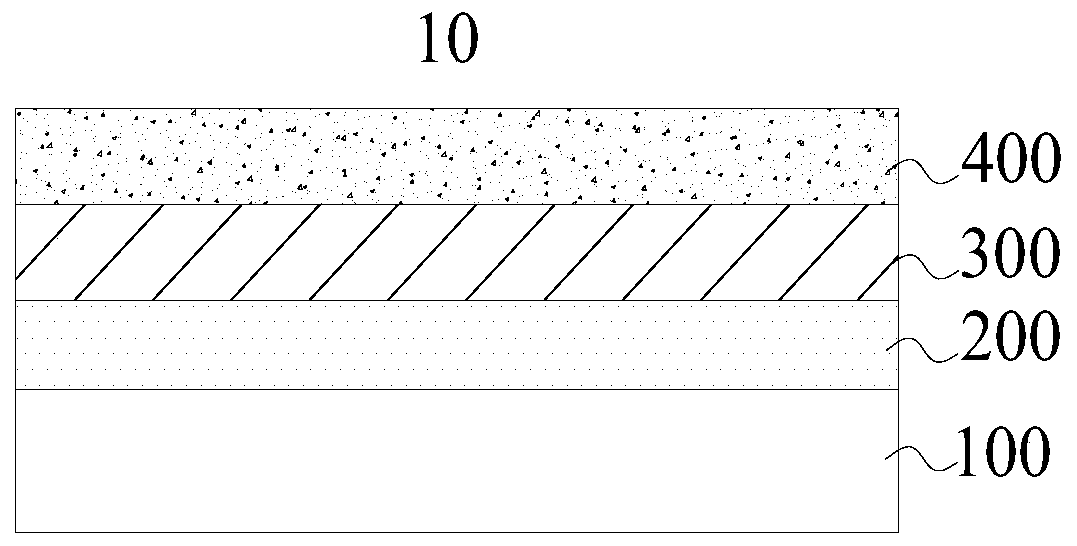

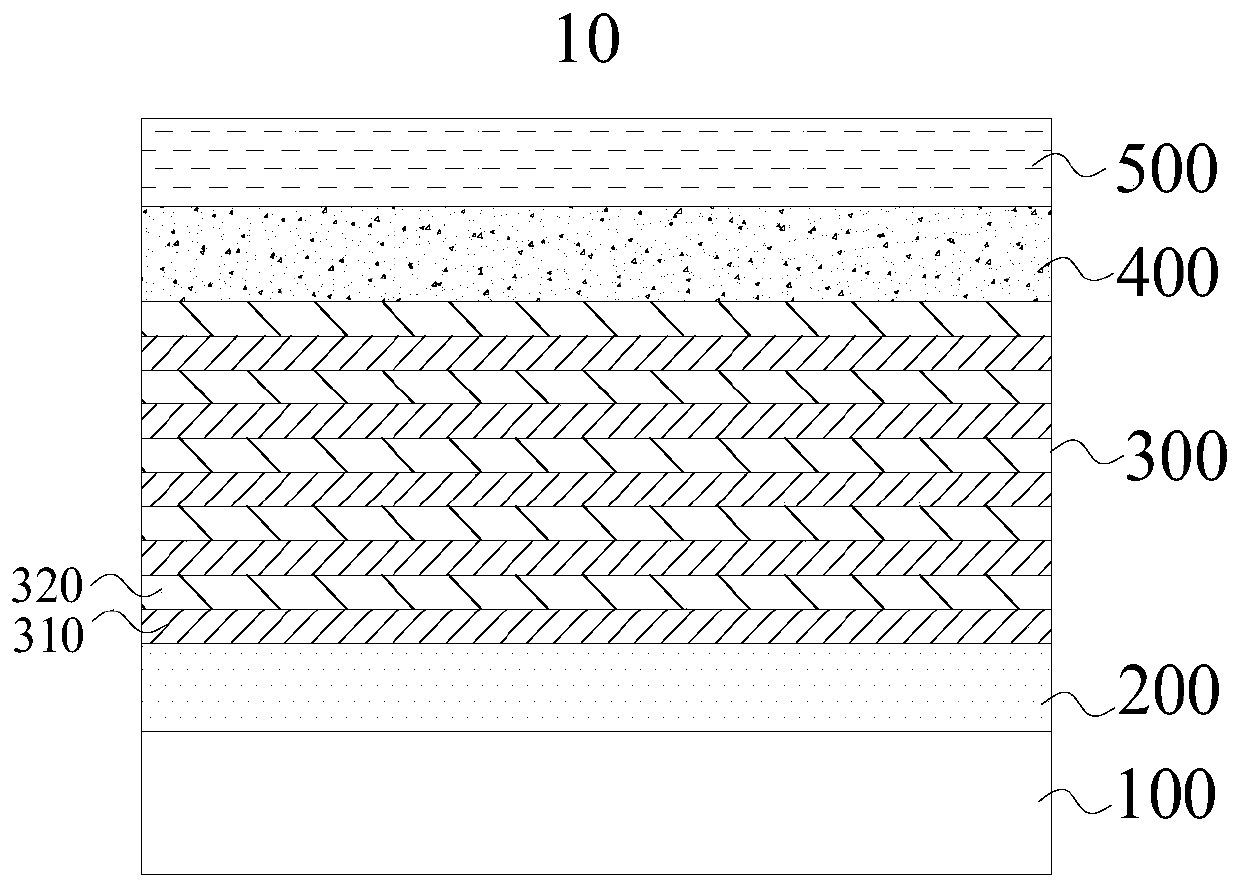

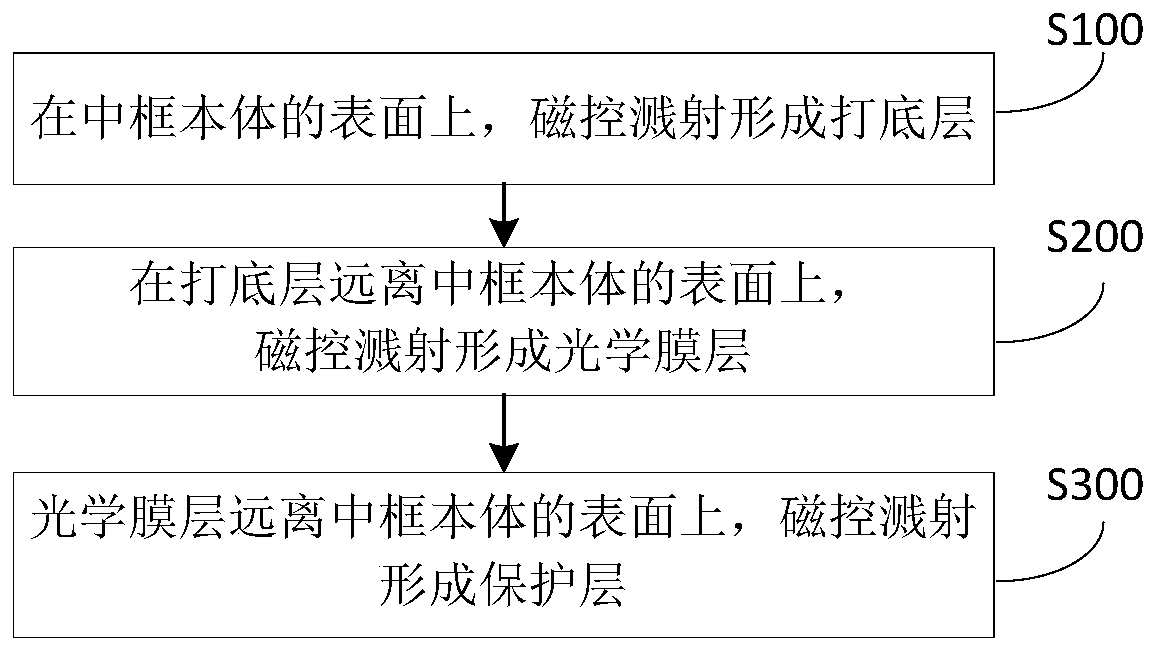

Middle frame of electronic equipment, manufacturing method thereof and electronic equipment

InactiveCN111139431AImprove wear resistanceImprove bindingVacuum evaporation coatingCasings/cabinets/drawers detailsDiamond-like carbonProtection layer

The invention provides a middle frame of electronic equipment, a manufacturing method of the middle frame of the electronic equipment and the electronic equipment. The middle frame comprises a middleframe body, a base layer, an optical film layer and a protective layer. A material forming the middle frame body comprises an aluminum alloy. The base layer is arranged on the surface of the middle frame body. The optical film layer is arranged on the surface, far away from the middle frame body, of the base layer. The protective layer is arranged on the surface, far away from the middle frame body, of the optical film layer. A material forming the protective layer comprises diamond-like carbon. According to the middle frame, the manufacturing method and the electronic equipment, by additionally arranging the optical film layer on the aluminum alloy middle frame body, the colorful effect that the color can be changed under the observation at different angles can be achieved, the bonding force is improved between the optical film layer and the middle frame body through the base layer, and diamond-like protective layer is applied to the outer surface of the optical film layer, so that the anti-falling performance and the wear resistance of the middle frame are better.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Full spectrum color mixing method for water-based coating

The invention discloses a full spectrum color mixing method for a water-based coating. The method comprises the following steps: performing computer color mixing by adopting three kinds of basic colorpaste, wherein the computer color mixing step comprises several sub-steps: making basic color chips, recording the basic color chips, acquiring main formula data, setting correction formula parameters and blending the composite color paste; and importing the formula data into a full-automatic color mixing machine to blend and produce composite color paste, and adding auxiliary color paste into the composite color paste to correct colors. Therefore, the finally mixed water-based coating is saturated in color and high in coordination degree with ambient colors, and the coating is more presentable after the colorfulness is properly reduced.

Owner:成都科尔玛色彩科技有限公司

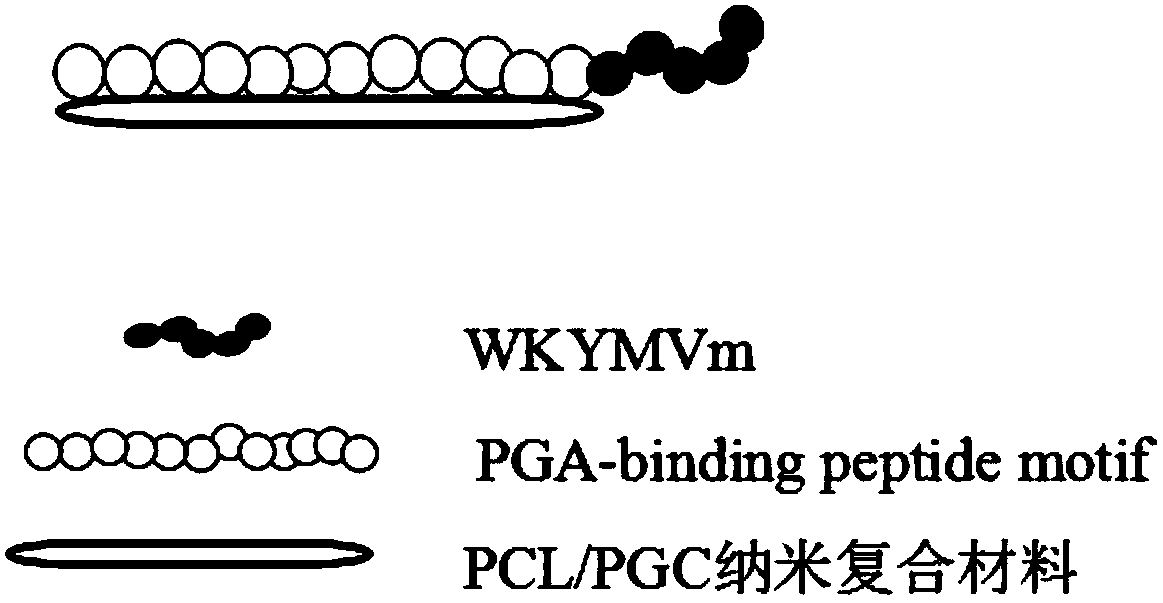

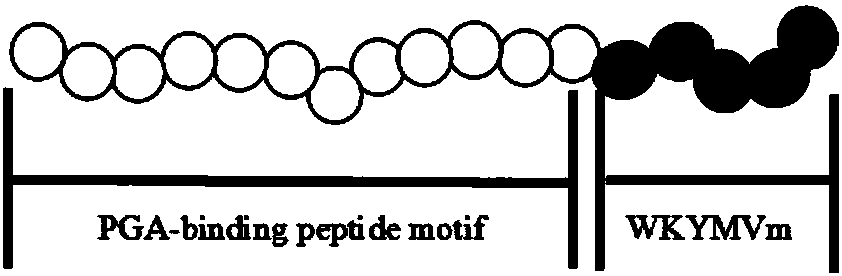

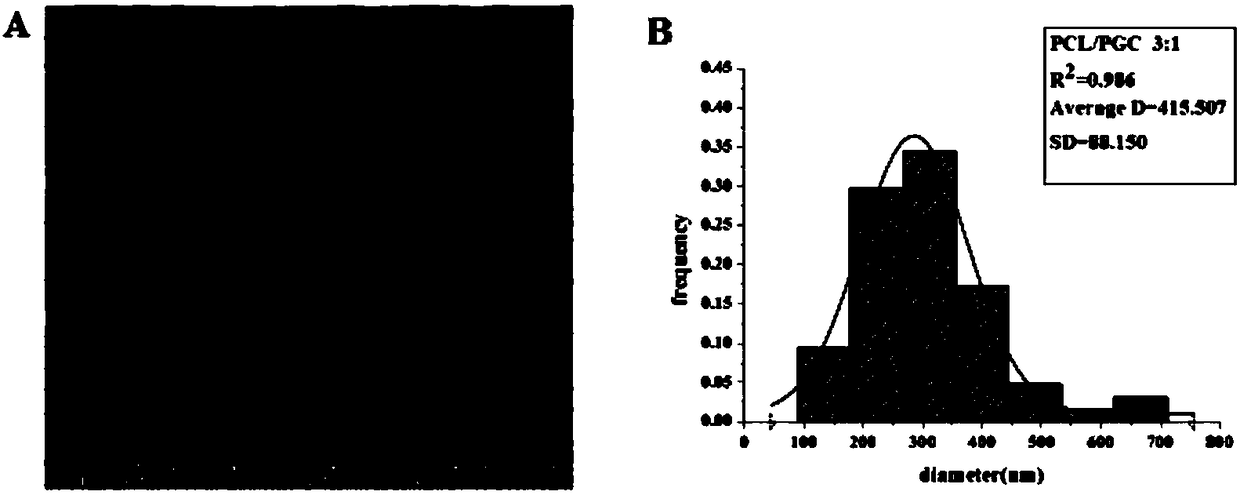

Polypeptide capable of efficiently inducing neogenesis of vascular tissues and use thereof

ActiveCN108191960AHigh selectivityHigh affinityPeptide preparation methodsDepsipeptidesVascular tissueNeogenesis

The invention relates to a polypeptide capable of efficiently inducing neogenesis of vascular tissues. The polypeptide is characterized in that a polypeptide sequence is as follows: SCNSSSYSWYCWFGGSSPSWKYMVm-NH2. The polypeptide has high selectivity and strong affinity to a specific artificial composite material, can be non-covalently combined with the specific artificial composite material quickly, efficiently and stably, achieves modification of the artificial composite material in one step, and make the material have a biological function which significantly promotes the neogenesis of bloodvessels.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

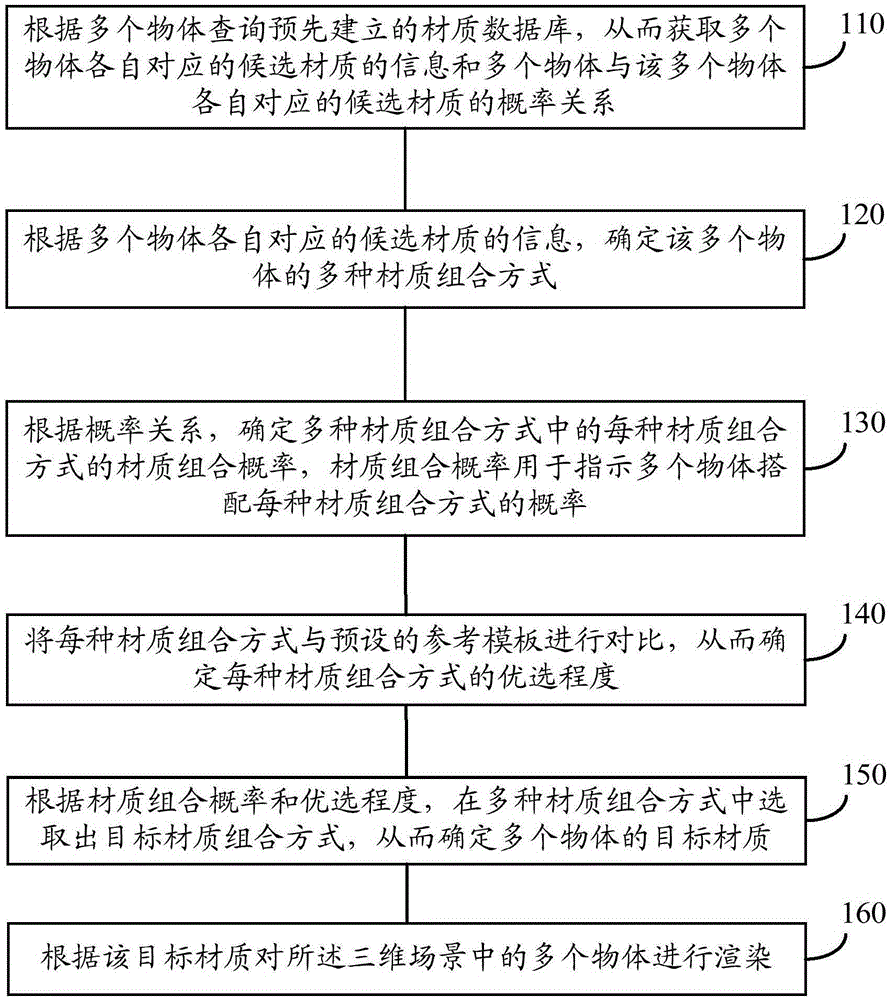

Method and device for selecting materials for objects in 3D scene

The invention provides a method and device for selecting materials for objects in a 3D scene. The method comprises that a material database is inquired to obtain information of candidate materials corresponding to the objects and probabilistic relations between the objects and the corresponding candidate materials; according to the information of the candidate materials corresponding to the objects, different material combination manners of the objects are determined; according to the probabilistic relations, the material combination probability of each of the multiple material combination manner is determined; each material combination manner is compared with a preset reference template, and the preferable degree of each material combination manner is determined; according to the material combination probabilities and the preferable degrees, a target material combination manner is selected form the material combination manners; and the objects are rendered according to a target material. Thus, the target material of a better matching effect can be selected for the objects.

Owner:HUAWEI TECH CO LTD +1

A post-processing method for 3D printed parts

ActiveCN106965435BImprove mechanical propertiesImprove bindingAdditive manufacturing apparatus3D object support structuresSolventHigh pressure

The invention provides an aftertreatment method of a 3D printing part and belongs to the technical field of 3D printing. The aftertreatment method of the 3D printing part comprises the following steps that (1), a certain amount of a micro-bead medium with micro holes is completely placed into a solvent, and stirring and standing are conducted for a certain time; (2), the micro-bead medium subjected to solvent adsorption is filtered out, and then the micro-bead medium subjected to solvent adsorption is placed into a micro-bead medium feeding device; (3), the micro-bead medium subjected to solvent adsorption is conveyed to a spray gun by the micro-bead medium feeding device; and (4), the micro-bead medium subjected to solvent adsorption and located in the sprayed gun is sprayed to the treated surface of the 3D printing part through high-pressure air to treat the surface of the 3D printing part, and the surface of the 3D printing part is composed of a polymer forming material. By adoption of the aftertreatment method of the 3D printing part, after the surface of the 3D printing part is treated, a smooth surface can be obtained, the mechanical property of the 3D printing part in the Z-axis forming direction can be improved, and the aftertreatment method of the 3D printing part has the outstanding beneficial effects.

Owner:四川长虹智能制造技术有限公司

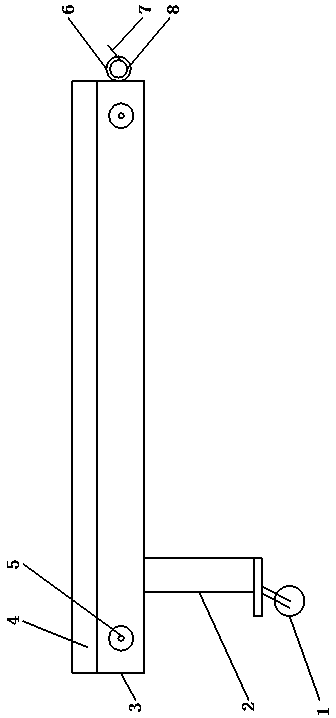

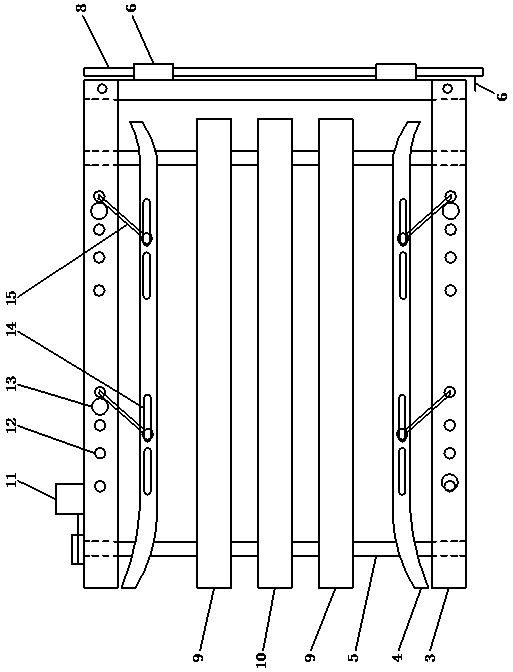

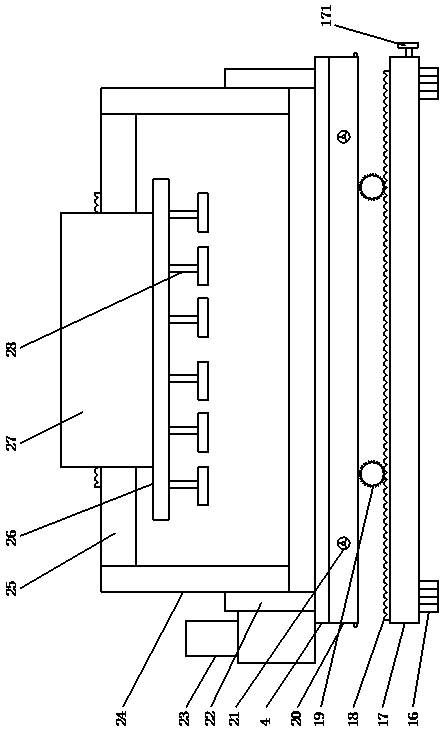

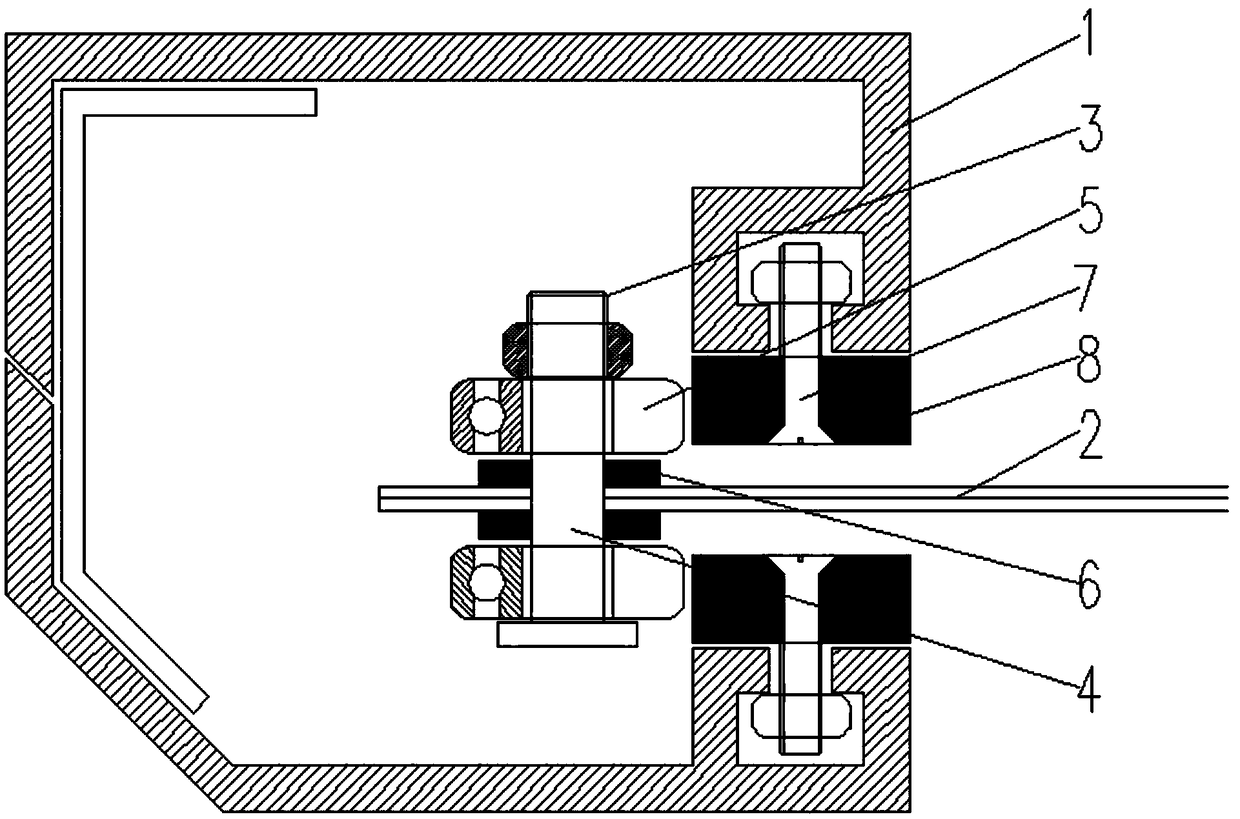

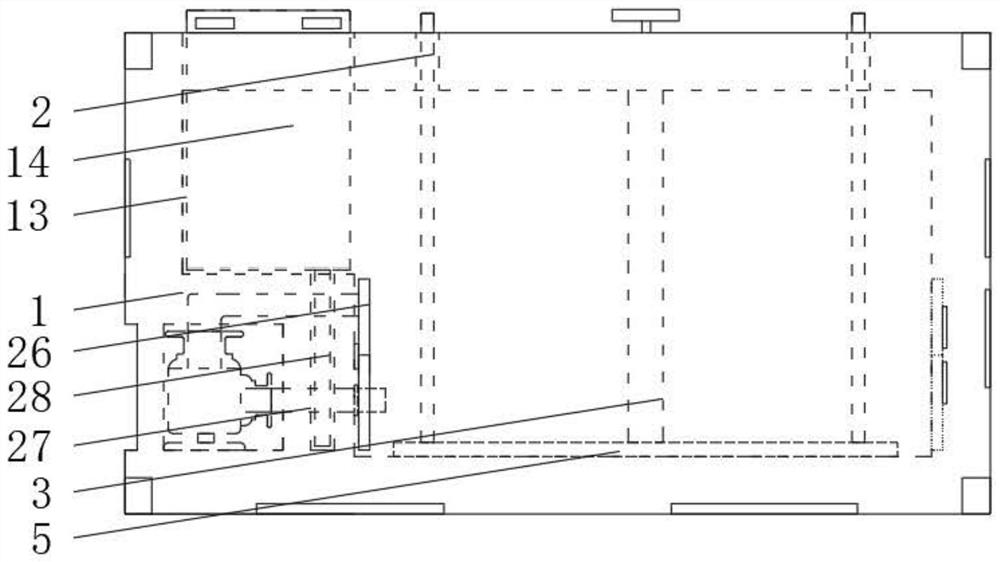

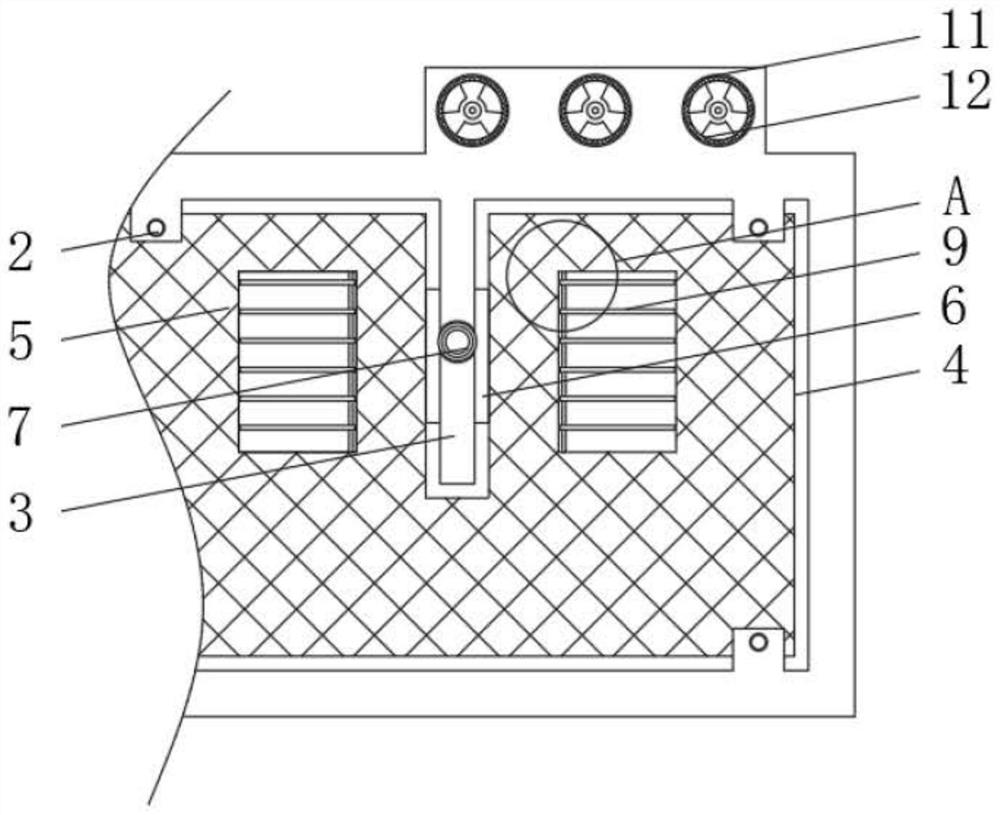

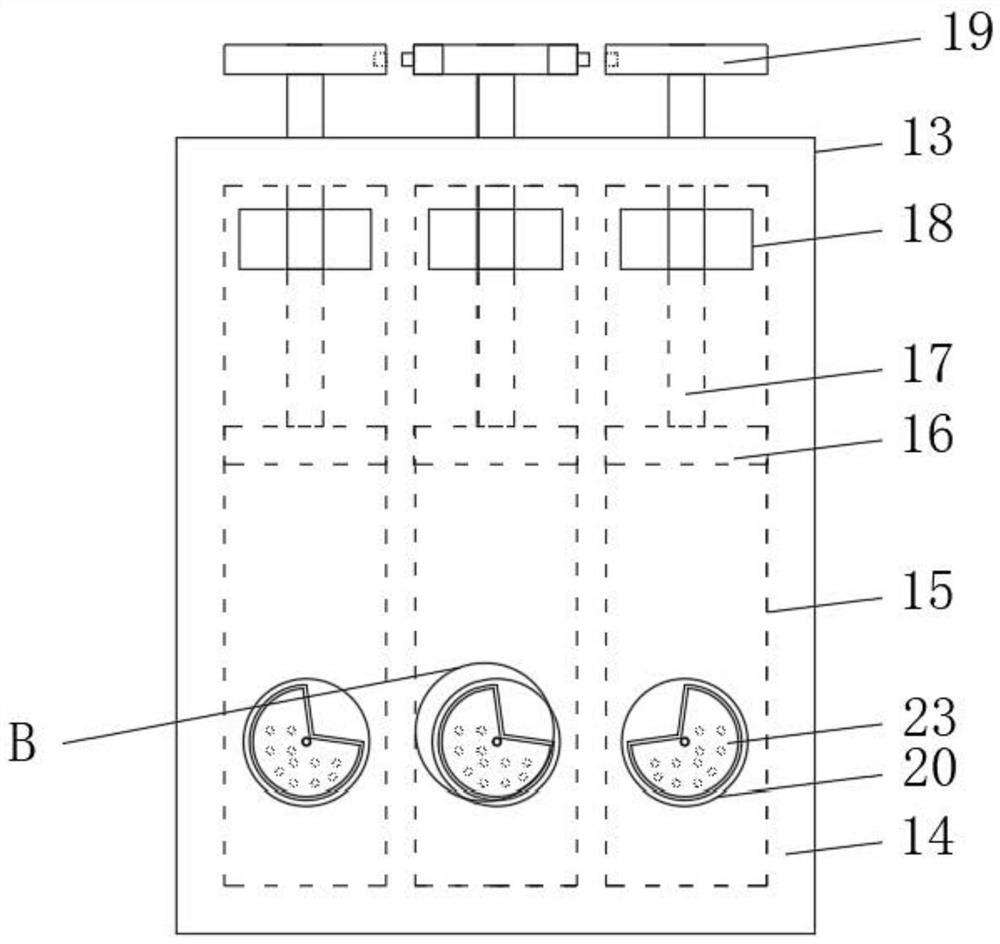

Thread-off proof mechanism for quick rolling door track

PendingCN108625764AGuaranteed uptimeImprove wind resistanceDoor/window protective devicesMechanical engineeringDrop out

The invention relates to the technical field of door and window structures and particularly discloses a thread-off proof mechanism for a quick rolling door track. The thread-off proof mechanism includes a set of semi-closed tracks (1) which is arranged in vertical juxtaposition and a cord fabric (2); one or more rolling components (3) are arranged at the side portion of the cord fabric; and the rolling components are arranged in the semi-closed tracks and the size of each rolling component is larger than the size of an opening caliber of each semi-closed track. The thread-off proof mechanism for the quick rolling door track has the characteristics that the structure is simple, the wind-resistant performance is better and the cord fabric does not drop out of the track.

Owner:浙江启门科技有限公司

A kind of corundum crucible and preparation method thereof

A corundum crucible and a preparation method thereof belong to the technical field of induction furnaces. It is characterized in that the composition of raw materials by weight is: 60-70 parts of corundum, 20-25 parts of spinel, 3-8 parts of activated alumina, 2-5 parts of fused magnesia, 5-10 parts of andalusite, binder 5~8 servings. The SiO formed by the decomposition of andalusite introduced in the corundum crucible of the present invention 2 Al with fine powder of corundum sand and fine alumina powder 2 o 3 The mullite network formed by reaction sintering is interspersed between the alumina aggregates, which improves the thermal shock and strength of the product. The introduction of alumina micropowder and andalusite micropowder advances the mullitization temperature to less than 1000°C, and the product has strong medium and high temperature strength. The spinel introduced in the matrix and the spinel formed in situ enhance the erosion resistance and permeability resistance of the alkaline slag.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

Cleaning device with good cleaning effect for electric industrial vehicle accessory repairing

InactiveCN112495915AGood collocation effectEasy to useCleaning using liquidsEngineeringStructural engineering

The invention relates to a cleaning device with a good cleaning effect for electric industrial vehicle accessory repairing. The cleaning device comprises a base body and an end storage mechanism, inner strips are arranged on the periphery of the base body, and a middle jacking column is arranged in the middle of the base body; a butt joint mechanism is arranged on the outer side of the bottom endof the middle jacking column, and a side assembly groove is formed in the right side of the rear end of the base body; and the inner side end of the side assembly groove is arranged with a groove inner plate seat, the end storage mechanism is installed at the left end of the base body, and an inner sealing mechanism is installed at the front end of the bottom of the end storage mechanism. The cleaning device with the good cleaning effect for electric industrial vehicle accessory repairing has the beneficial effects that the position of an inner piston can be adjusted through mutual matched sliding between a box inner cavity and the inner piston, the inner piston extrudes cleaning liquid such as detergent added into the box inner cavity, an upper screw base can be conveniently pressed downthrough the design of the upper screw base, then the piston rod is pressed, and the inner piston is pushed to move downwards, so that the effect of adding and extruding the cleaning liquid is achieved.

Owner:HENGYANG LIMEI BATTERY VEHICLES MFG CO LTD

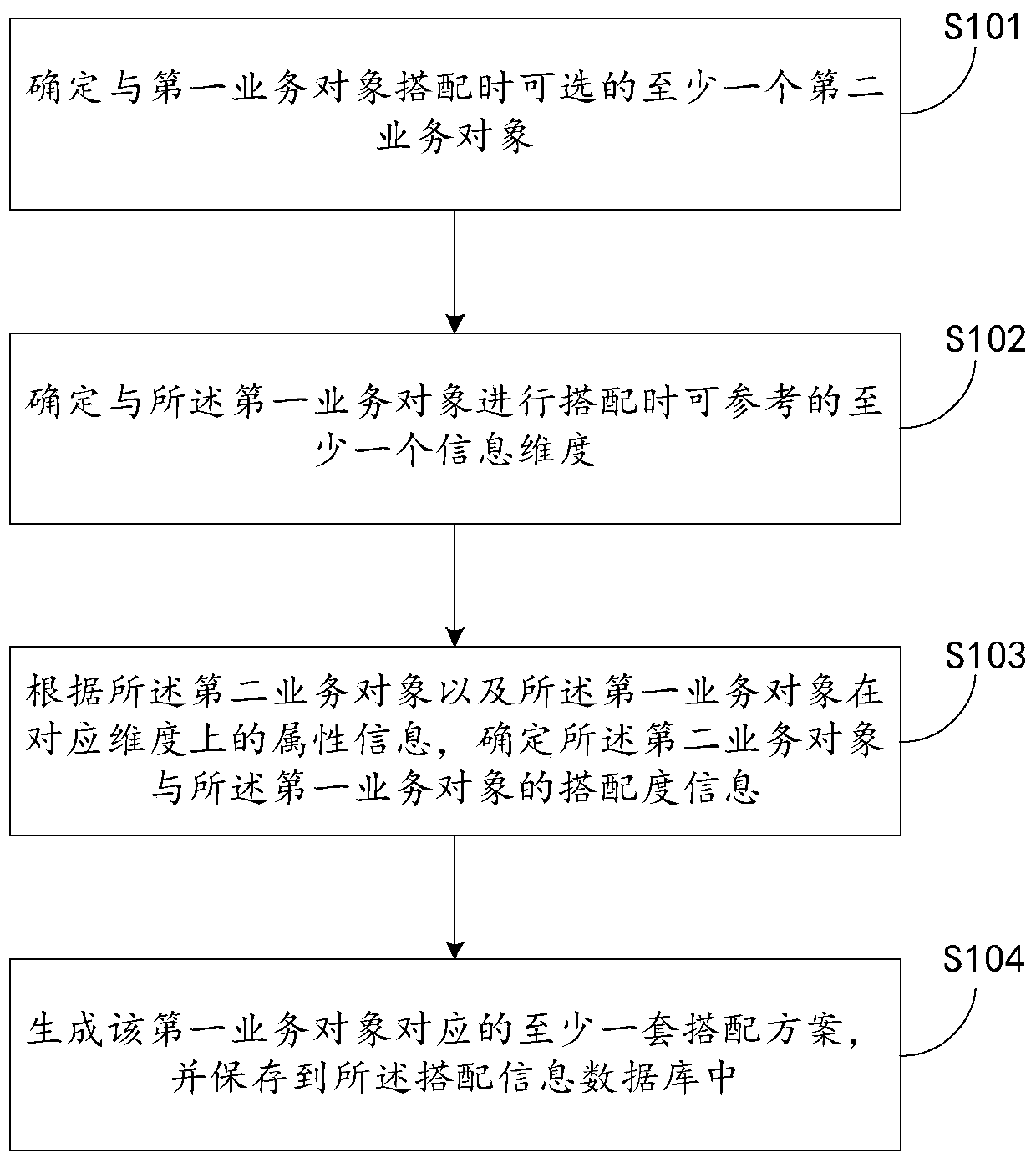

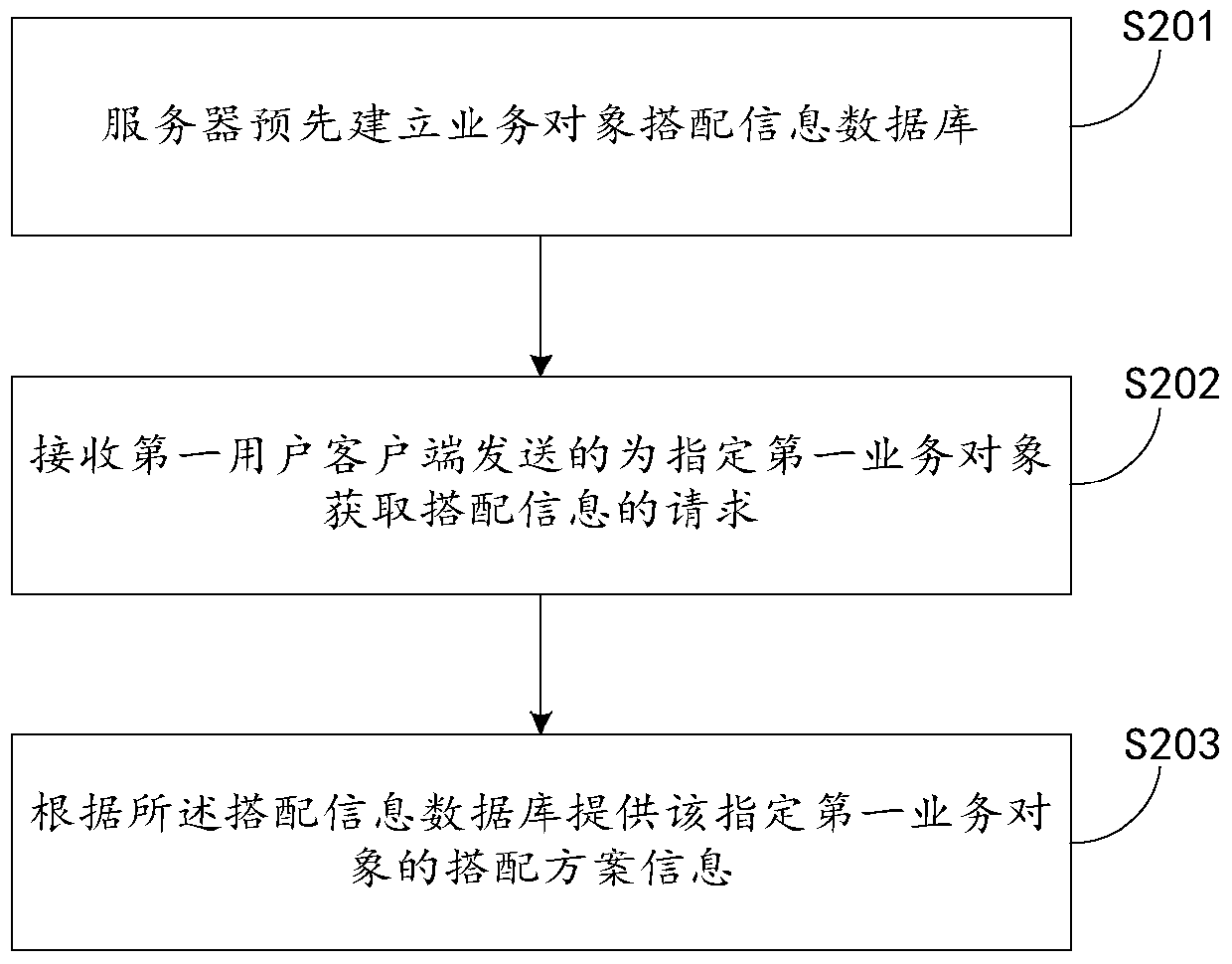

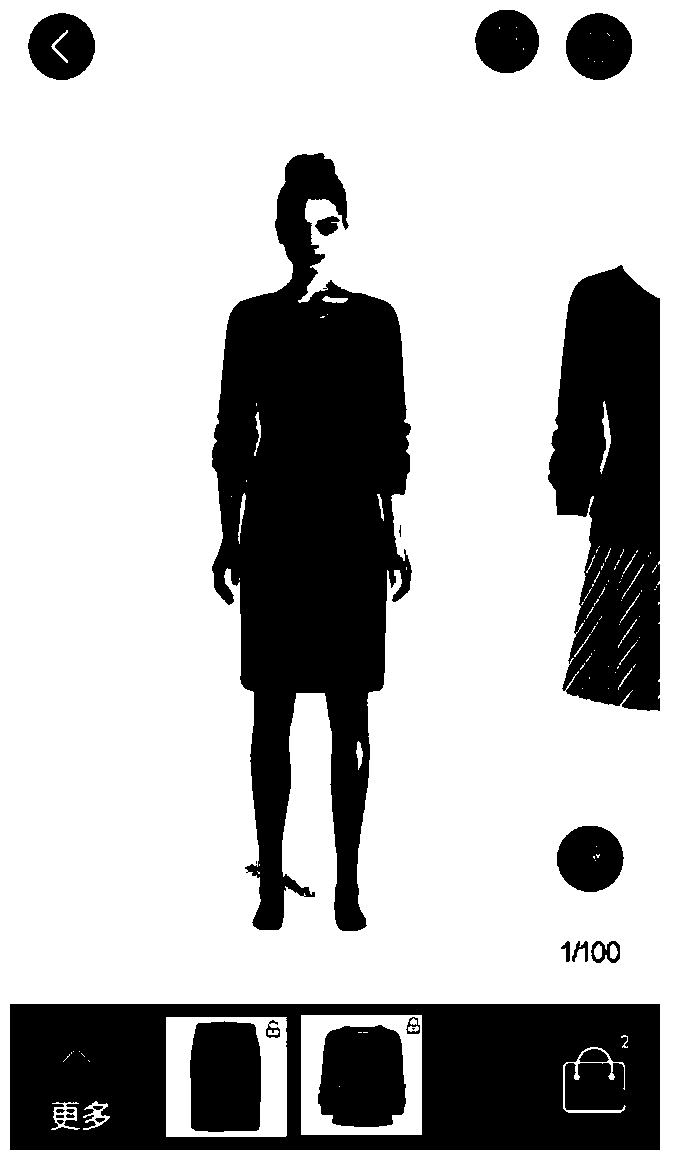

Method and device for providing business object collocation information

ActiveCN106294420BGood collocation effectReduce access pressureDigital data information retrievalCommerceWorkloadComputer science

Methods and apparatuses for providing matching information of a business object are disclosed in the embodiments of the present disclosure. A method includes pre-establishing a matching information database of business objects of a fashion category by a server, the matching information database storing respective one or more matching proposals corresponding to first business objects, and the matching proposals including respective second business objects that matches with the first business objects and corresponding matching degree information; receiving a request for obtaining matching information of a specific first business object from a first user client; and providing information of a matching proposal of the specific first business object according to the matching information database. The embodiments of the present disclosure can save resources used by user operations such as switching between categories, and help reducing the access pressure and workload of a server.

Owner:ALIBABA GRP HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com