Cadmium telluride power generation glass

A cadmium telluride and glass technology, which is applied in the field of solar cells, can solve the problems of affecting the coating of transparent oxide layer, low light transmission efficiency, and process limitation, and achieve excellent matching effect, high light transmittance, and industrial controllability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

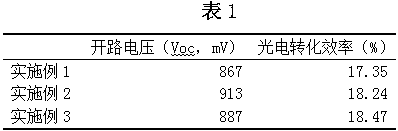

Embodiment 1

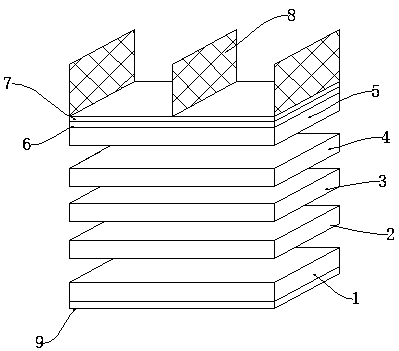

[0022] as attached figure 1 As shown, a cadmium telluride power generation glass includes a glass substrate 1, a transparent oxide layer 2, a window layer 3, an absorption layer 4, and a back contact electrode 5 from bottom to top; the glass substrate 1 is borosilicate glass with a thickness of 2mm , the outer surface of the borosilicate glass is coated with an anti-reflection film 9 with a thickness of 50nm and a refractive index of 1.3, and the transparent oxide layer is Sn-doped In 2 o 3 The window layer is a CdS layer with a thickness of 0.4 μm, the absorber layer is a CdTe layer with a thickness of 3 μm, and the back contact electrode is a carbon nanotube deposited with metal Al, wherein the power generation glass is on the glass substrate 1, transparent oxide layer 2, After the window layer 3 and the absorbing layer 4 are sequentially deposited to form thin films, the Ar-CdCl 2 Heat treatment, the temperature of heat treatment is 380°C. The back side of the back conta...

Embodiment 2

[0024] A cadmium telluride power generation glass, comprising a glass substrate, a transparent oxide layer, a window layer, an absorbing layer, and a back contact electrode from bottom to top; the glass substrate is borosilicate glass with a thickness of 3 mm, and the outer surface of the borosilicate glass is coated with Anti-reflection film with a thickness of 80mm and a refractive index of 1.5, and the transparent oxide layer is Sn-doped In 2 o 3 film, with SnO deposited between the transparent oxide layer and the window layer 2 thin film, SnO 2 and In 2 o 3 The weight ratio is 1:9, the window layer is a CdS layer with a thickness of 0.4 μm, the absorber layer is a CdTe layer with a thickness of 3 μm, and the back contact electrode is a carbon nanotube deposited with metal Al. Among them, the power generation glass is on a glass substrate, After the transparent oxide layer, the window layer and the absorbing layer were deposited sequentially to form a thin film, the Ar-...

Embodiment 3

[0026] A cadmium telluride power generation glass, comprising a glass substrate, a transparent oxide layer, a window layer, an absorbing layer, and a back contact electrode from bottom to top; the glass substrate is borosilicate glass with a thickness of 2.5 mm, and the outer surface of the borosilicate glass is coated with There is a hydrophobic layer, and the transparent oxide layer is Sn-doped In 2 o 3 film, with SnO deposited between the transparent oxide layer and the window layer 2 thin film, SnO 2 and In 2 o 3 The weight ratio is 1:8.5, the window layer is a CdS layer with a thickness of 0.45 μm, the absorber layer is a CdTe layer with a thickness of 4 μm, and the back contact electrode is a carbon nanotube deposited with metal Al. Among them, the power generation glass is on a glass substrate, After the transparent oxide layer, the window layer and the absorbing layer were deposited sequentially to form a thin film, the Ar-CdCl 2 Heat treatment, the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com