Patents

Literature

538 results about "Cadmium zinc telluride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cadmium zinc telluride, (CdZnTe) or CZT, is a compound of cadmium, zinc and tellurium or, more strictly speaking, an alloy of cadmium telluride and zinc telluride. A direct bandgap semiconductor, it is used in a variety of applications, including semiconductor radiation detectors, photorefractive gratings, electro-optic modulators, solar cells, and terahertz generation and detection. The band gap varies from approximately 1.4 to 2.2 eV, depending on composition.

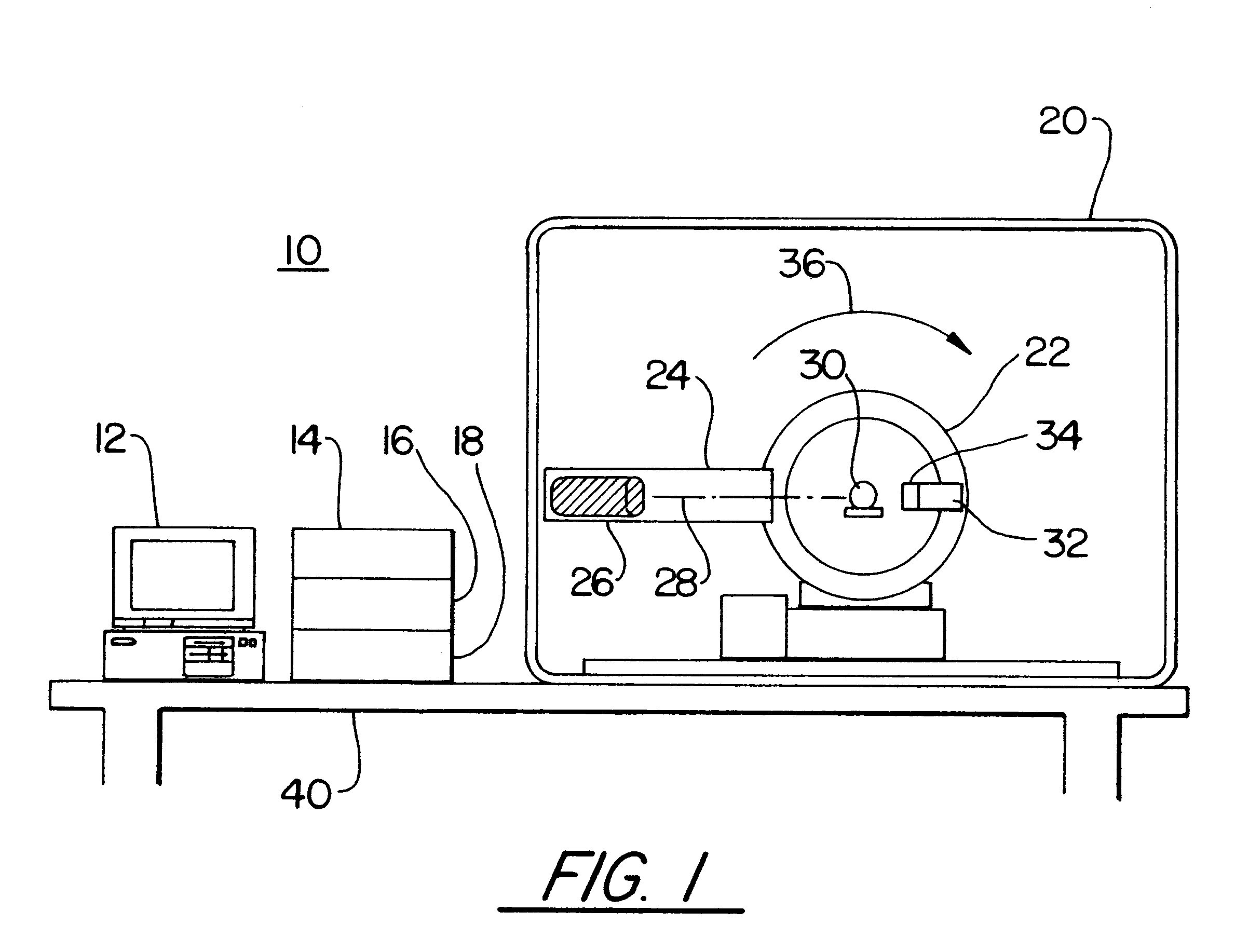

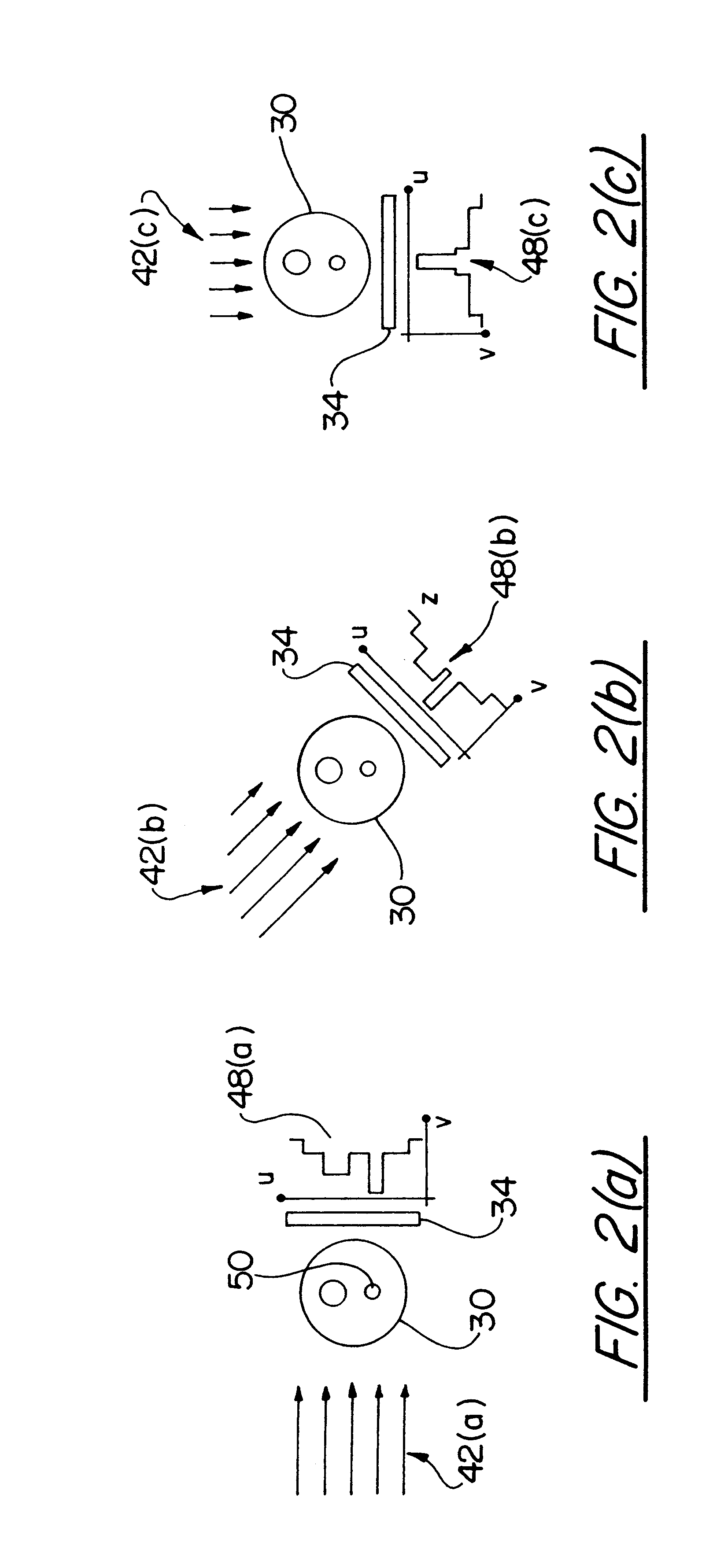

Simultaneous CT and SPECT tomography using CZT detectors

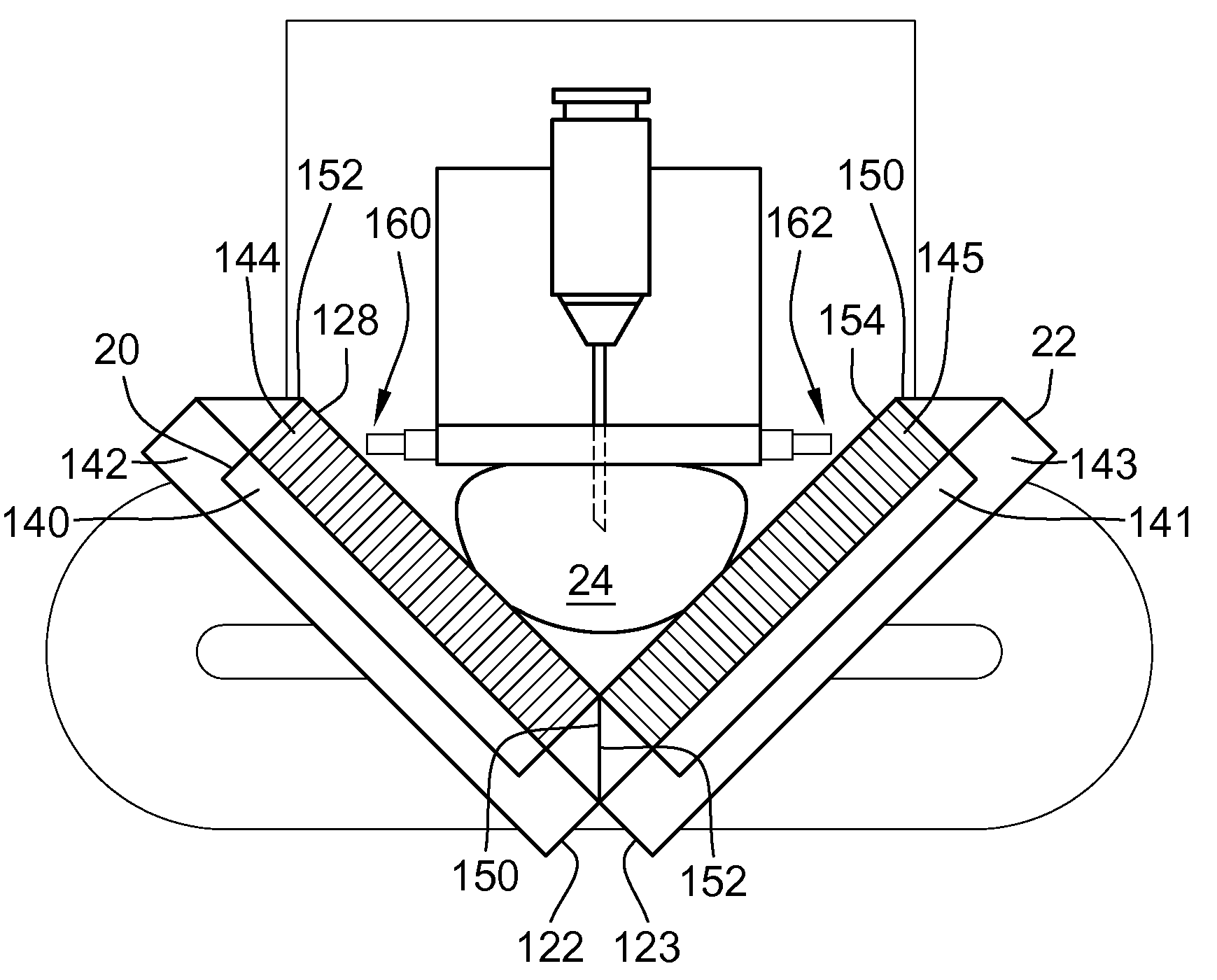

A method for simultaneous transmission x-ray computed tomography (CT) and single photon emission tomography (SPECT) comprises the steps of: injecting a subject with a tracer compound tagged with a gamma-ray emitting nuclide; directing an x-ray source toward the subject; rotating the x-ray source around the subject; emitting x-rays during the rotating step; rotating a cadmium zinc telluride (CZT) two-sided detector on an opposite side of the subject from the source; simultaneously detecting the position and energy of each pulsed x-ray and each emitted gamma-ray captured by the CZT detector; recording data for each position and each energy of each the captured x-ray and gamma-ray; and, creating CT and SPECT images from the recorded data. The transmitted energy levels of the x-rays lower are biased lower than energy levels of the gamma-rays. The x-ray source is operated in a continuous mode. The method can be implemented at ambient temperatures.

Owner:LOCKHEED MARTIN ENERGY SYST INC

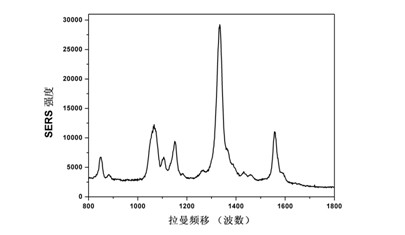

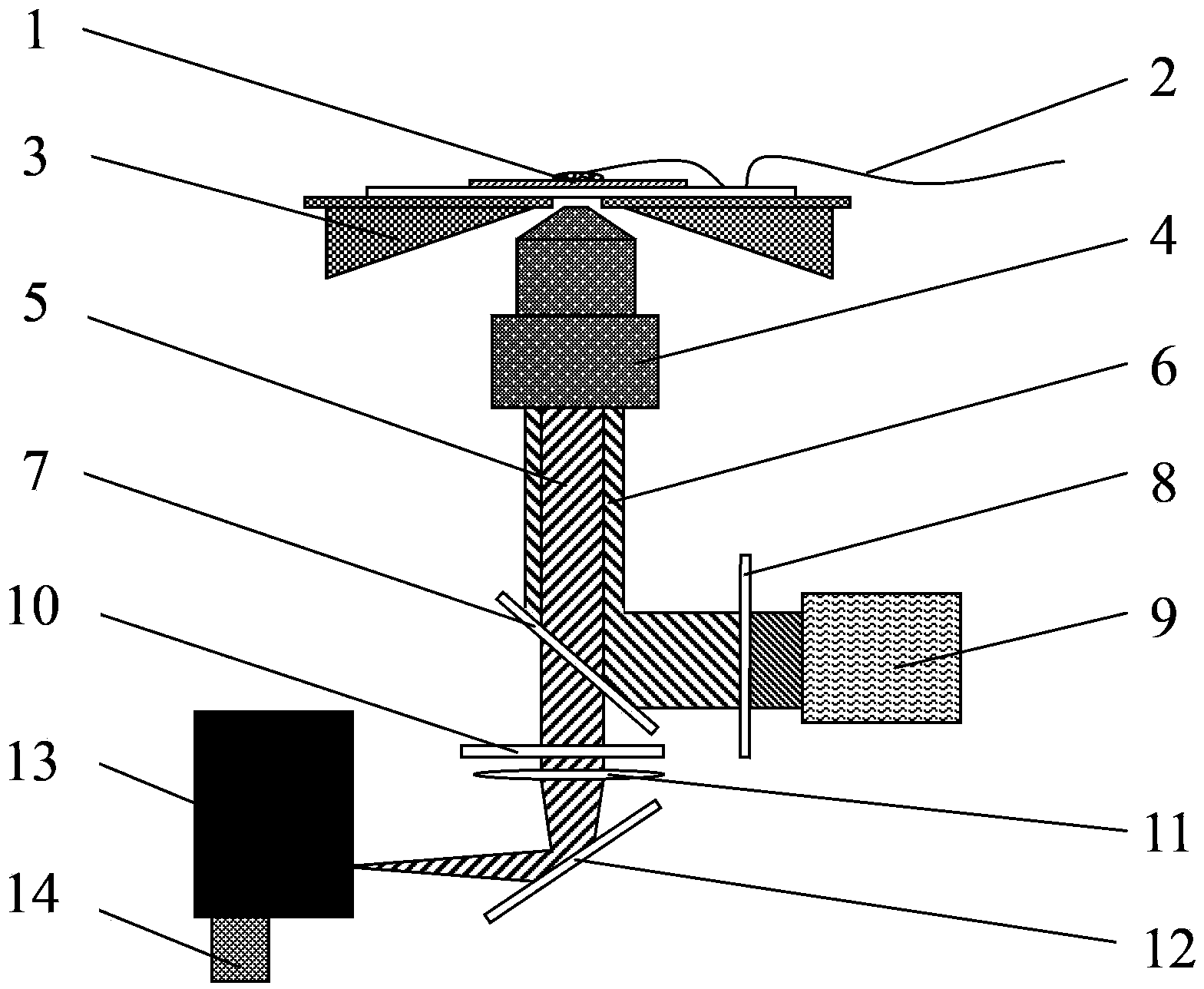

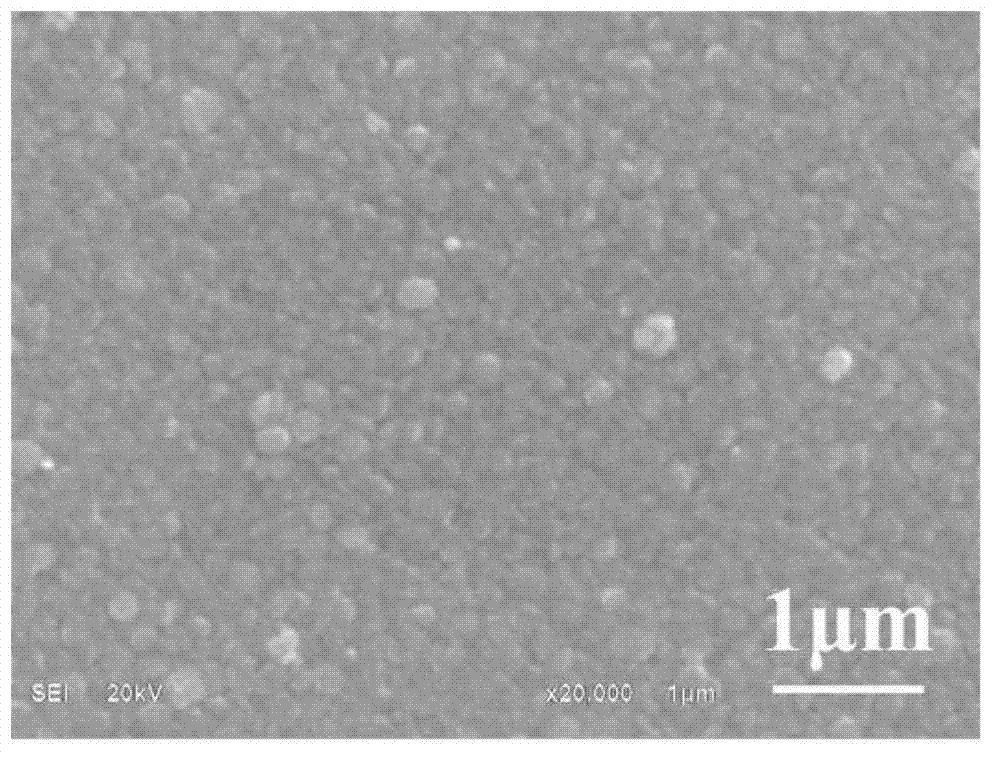

Preparation method of active radical with surface-enhanced Raman scattering (SERS) effect

InactiveCN102759520AQuick checkIncrease surface areaRaman scatteringChemical vapor depositionCadmium Cation

The invention provides a preparation method of an active radical with a surface-enhanced Raman scattering (SERS) effect, belongs to the technical field of spectrum detection, and relates to the preparation technology of the SERS active radical, which is rapid, has high sensitivity and performs a low trace detection function. The preparation method is characterized in that firstly, a nano porous silicon columnar array with a large specific surface area is prepared by utilizing a hydrothermal etching technology; afterwards, a nanowire structure of an II-VI group compound semiconductor (such as zinc oxide, titanium dioxide, cadmium sulfide, cadmium selenide, cadmium telluride, and the like) by utilizing a chemical vapor deposition method; and finally, nano particles of precious metal (such as gold, silver, copper and the like) are finally prepared on the nanowire structure by using a chemical reduction method, so as to obtain an active radical material. The preparation method has a wide application prospect in the aspects of clinical biomolecular fast recognition, trace chemical substance detection, biological sample analysis, and the like. The preparation method has the advantages that the preparation process of each material is simple, the condition is mild and the repetition rate reaches 100 percent.

Owner:BEIJING UNIV OF CHEM TECH

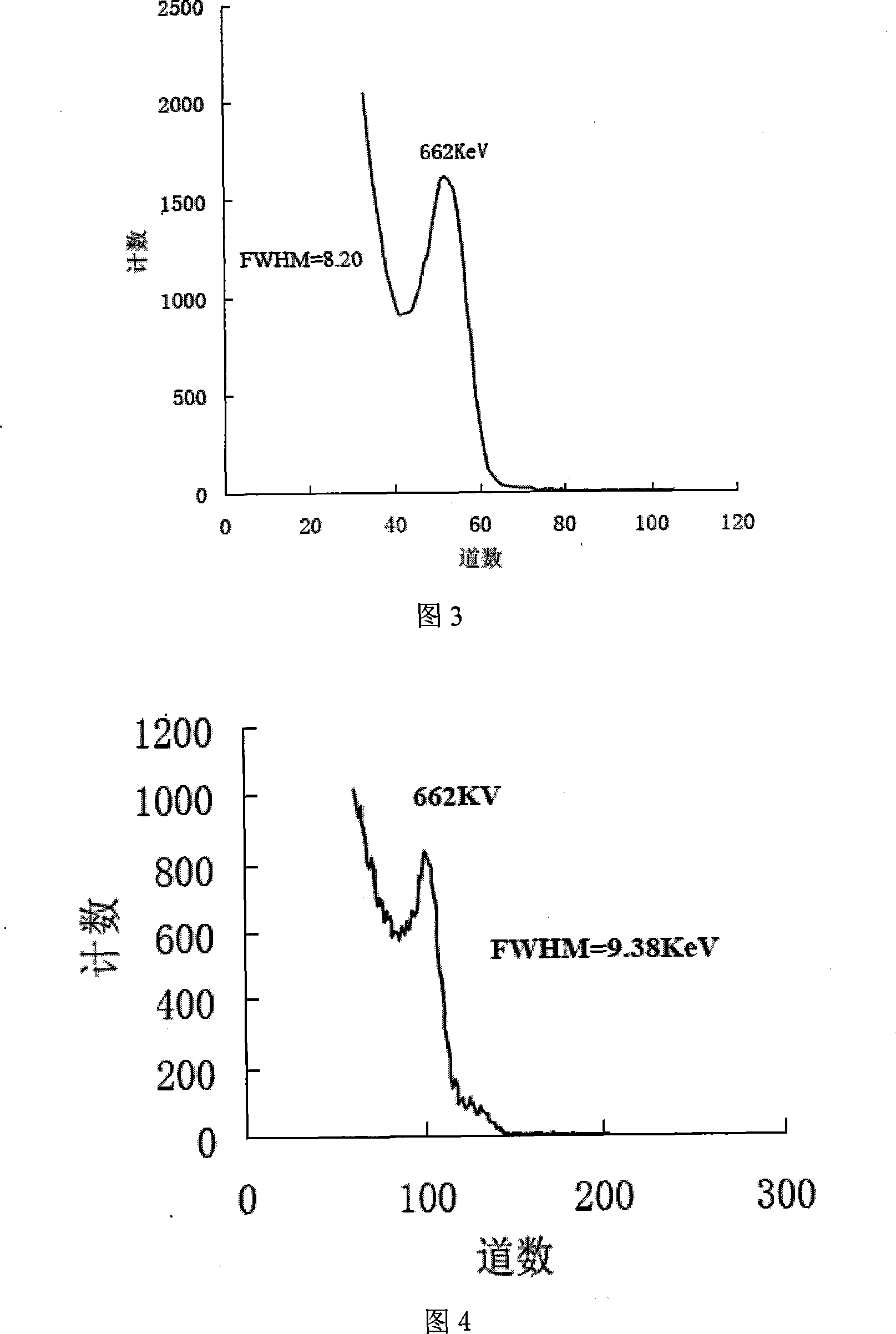

Segmented radiation detector with side shielding cathode

ActiveUS7223982B1Minimize electronic noiseGood detector energy resolutionFinal product manufactureSolid-state devicesX-rayCounting efficiency

A semiconductor radiation detector is provided for improved performance of pixels at the outer region of the crystal tile. The detector includes a semiconductor single crystal substrate with two major planar opposing surfaces separated by a substrate thickness. A cathode electrode covers one of the major surfaces extending around the sides of the substrate a fraction of the substrate thickness and insulated on the side portions by an insulating encapsulant. An exemplary example is given using Cadmium Zinc Telluride semiconductor, gold electrodes, and Humiseal encapsulant, with the side portions of the cathode extending approximately 40-60 percent of the substrate thickness. The example with CZT allows use of monolithic CZT detectors in X-ray and Gamma-ray applications at high bias voltage. The shielding electrode design is demonstrated to significantly improve gamma radiation detection of outer pixels of the array, including energy resolution and photopeak counting efficiency. The detector has performance of detector leakage current density less than 6 nA / mm2 at a bias potential of substantially 1400V, and responsive to gamma radiation such that the energy resolution full width half maximum of more than 90% of the pixels is less than 6%.

Owner:REDLEN TECH

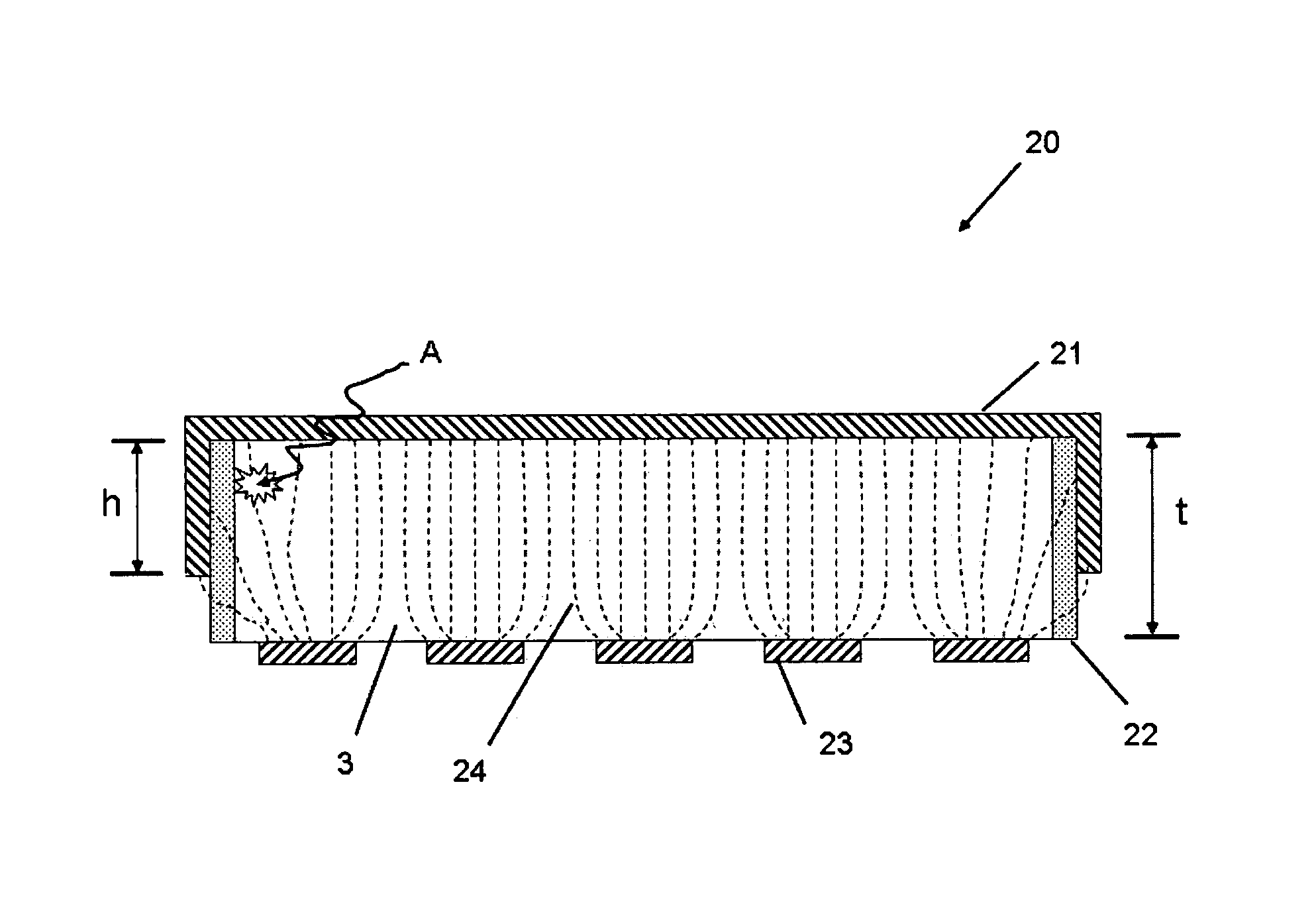

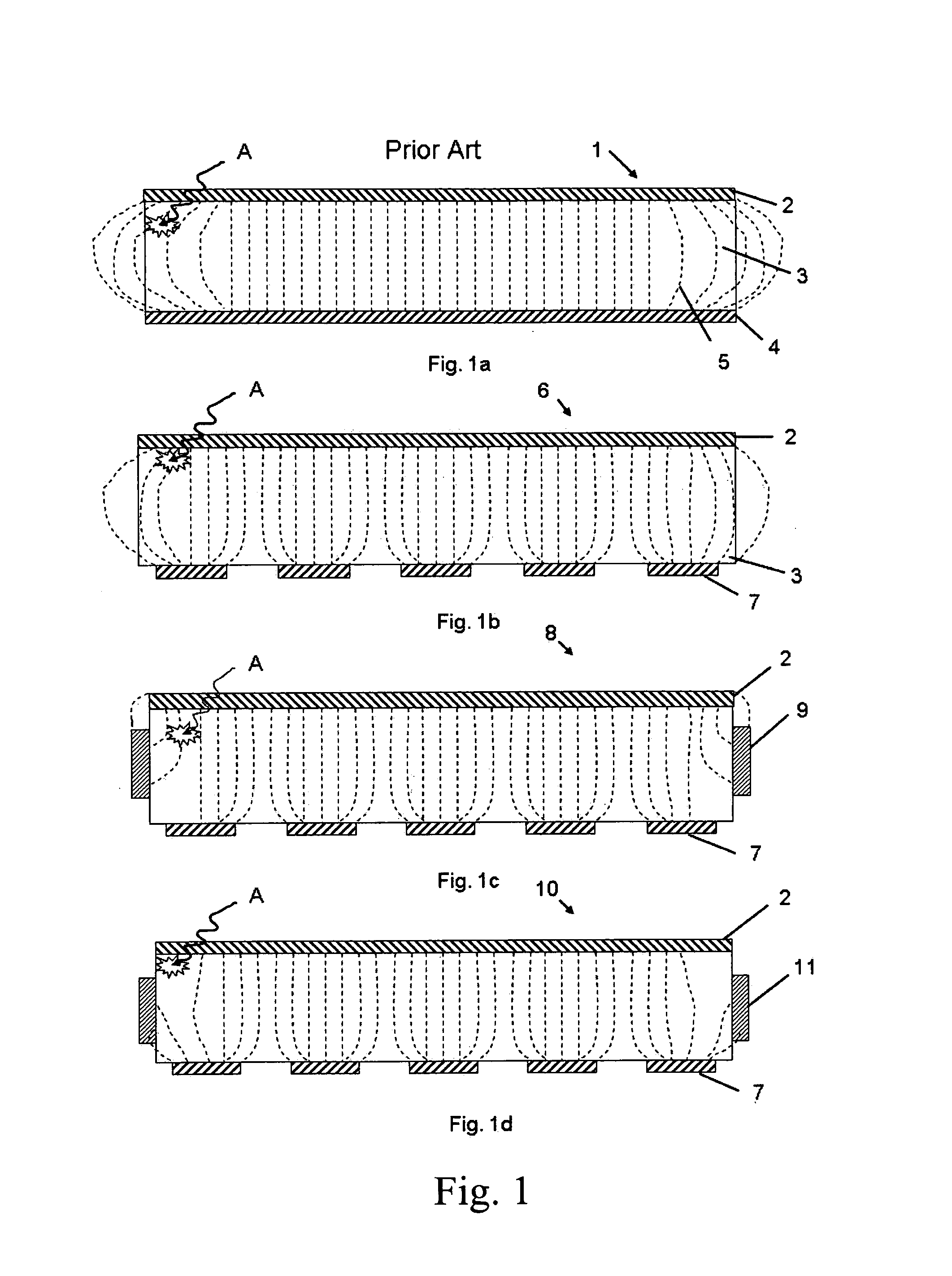

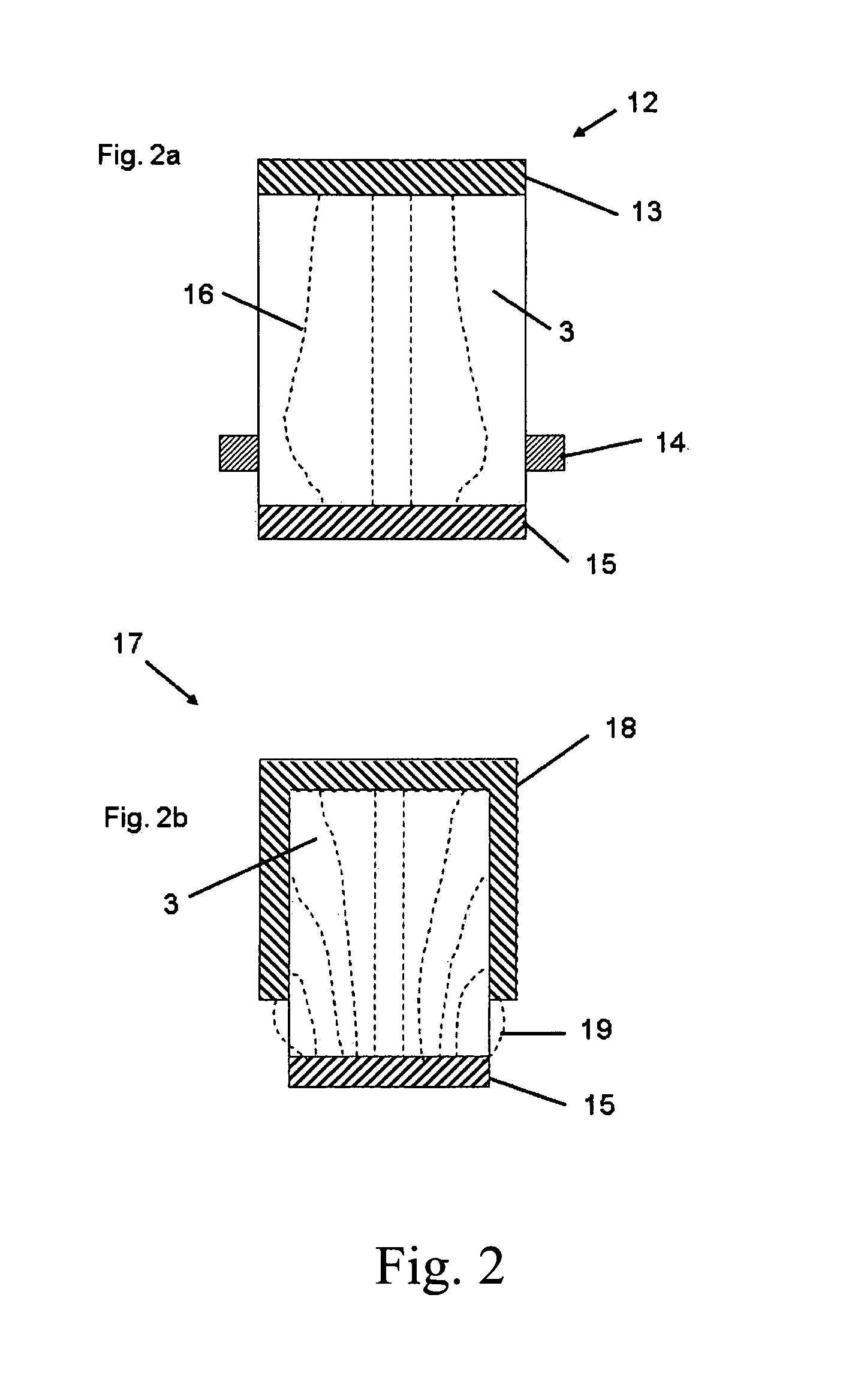

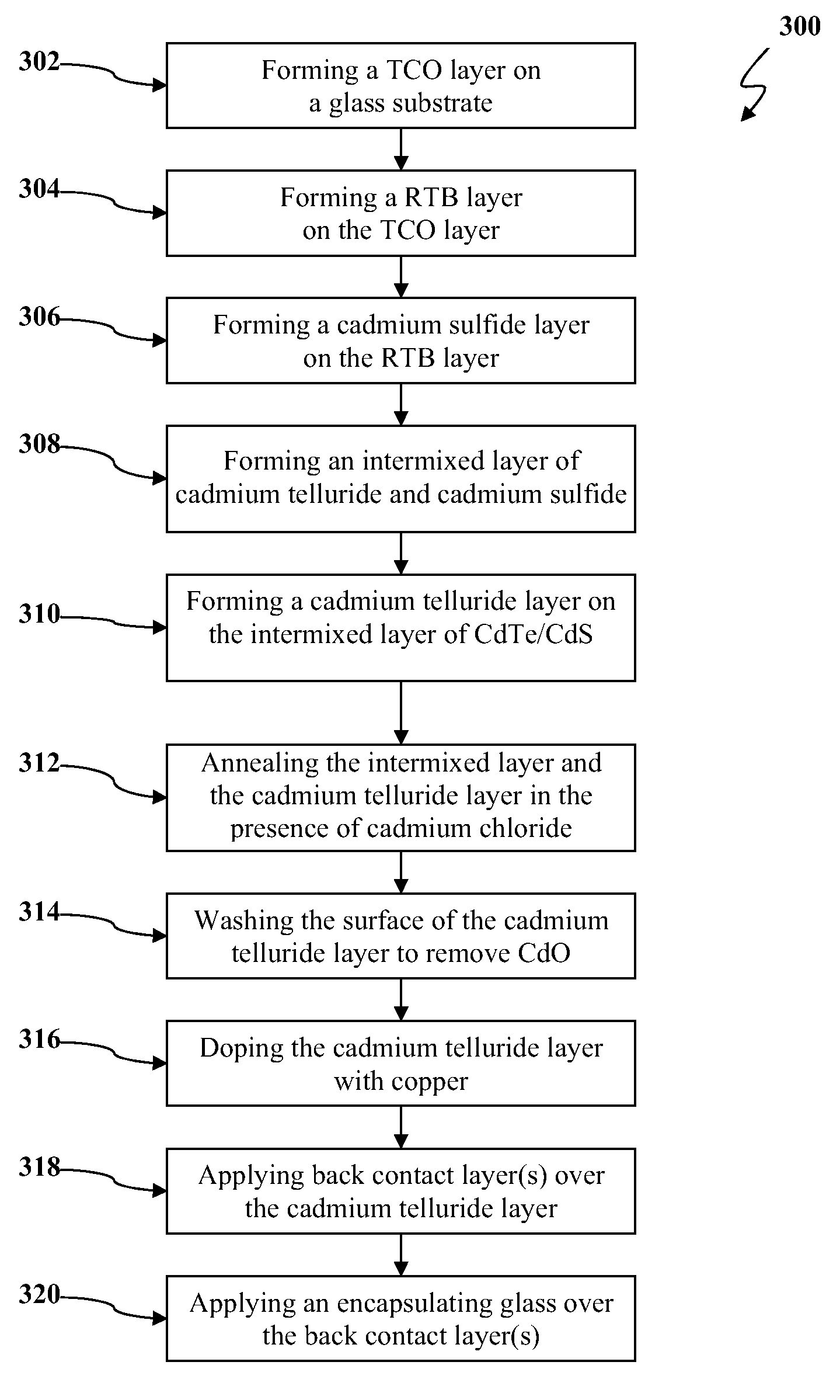

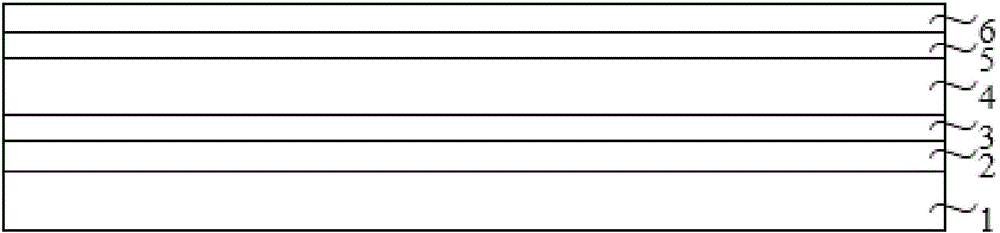

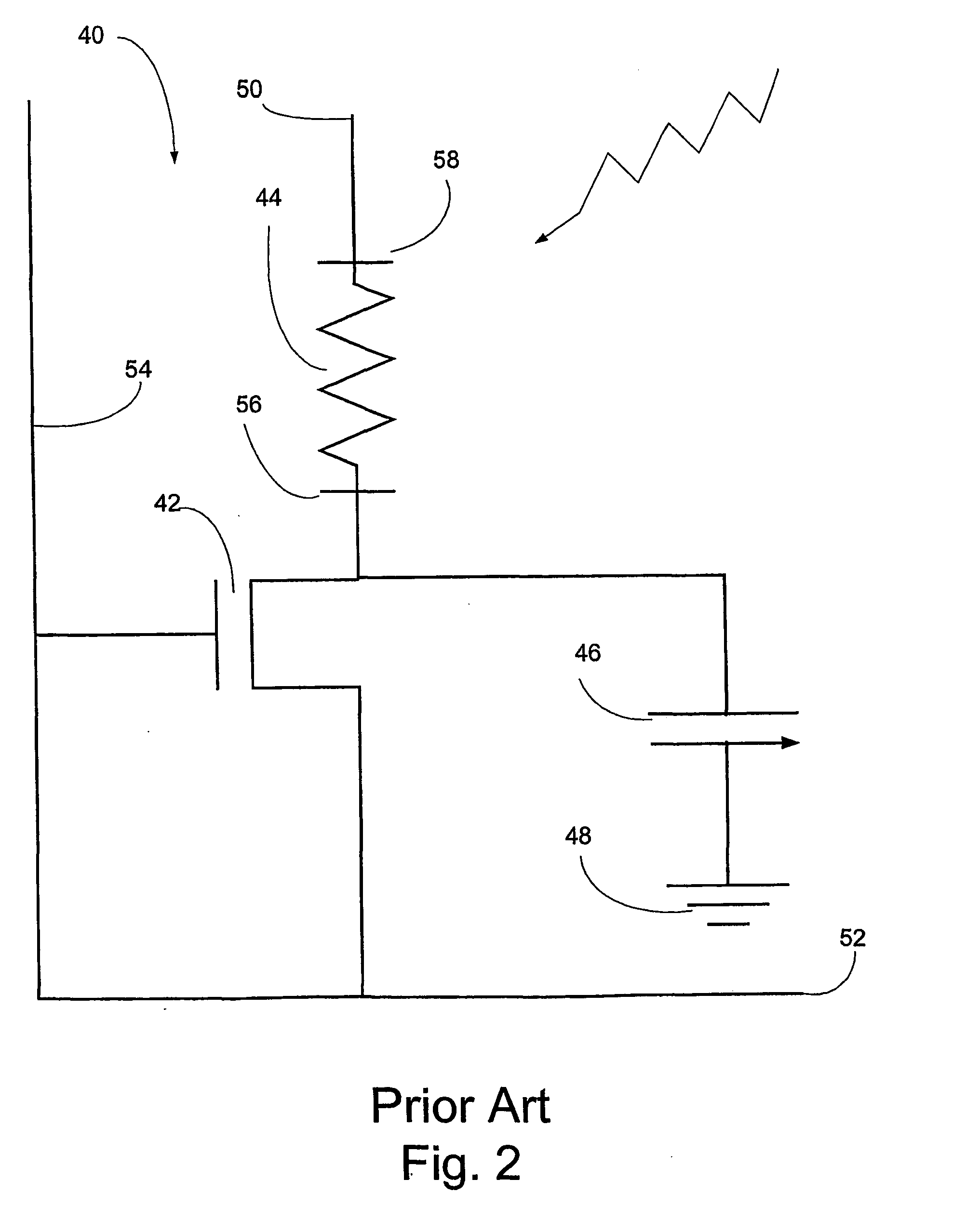

Systems and methods of intermixing cadmium sulfide layers and cadmium telluride layers for thin film photovoltaic devices

ActiveUS7939363B1Increasing tellurium concentrationReduce the concentration of sulfurFinal product manufactureVacuum evaporation coatingSource materialTe element

A process for manufacturing a cadmium telluride based thin film photovoltaic device having an intermixed layer is provided. The process can include introducing a substrate into a deposition chamber, wherein a window layer (e.g., a cadmium sulfide layer) is on a surface of the substrate. A sulfur-containing gas can be supplied to the deposition chamber. In addition, a source vapor can be supplied to the deposition chamber, wherein the source material comprises cadmium telluride. The sulfur-containing gas and the source vapor can be present within the deposition chamber to form an intermixed layer on the window layer. In one particular embodiment, for example, the intermixed layer generally can have an increasing tellurium concentration and decreasing sulfur concentration extending away from the window layer.An apparatus for sequential deposition of an intermixed thin film layer and a sublimated source material on a photovoltaic (PV) module substrate is also provided.

Owner:FIRST SOLAR INC (US)

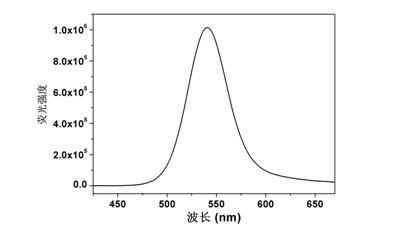

Dual-mode optical coding probe and preparation method thereof

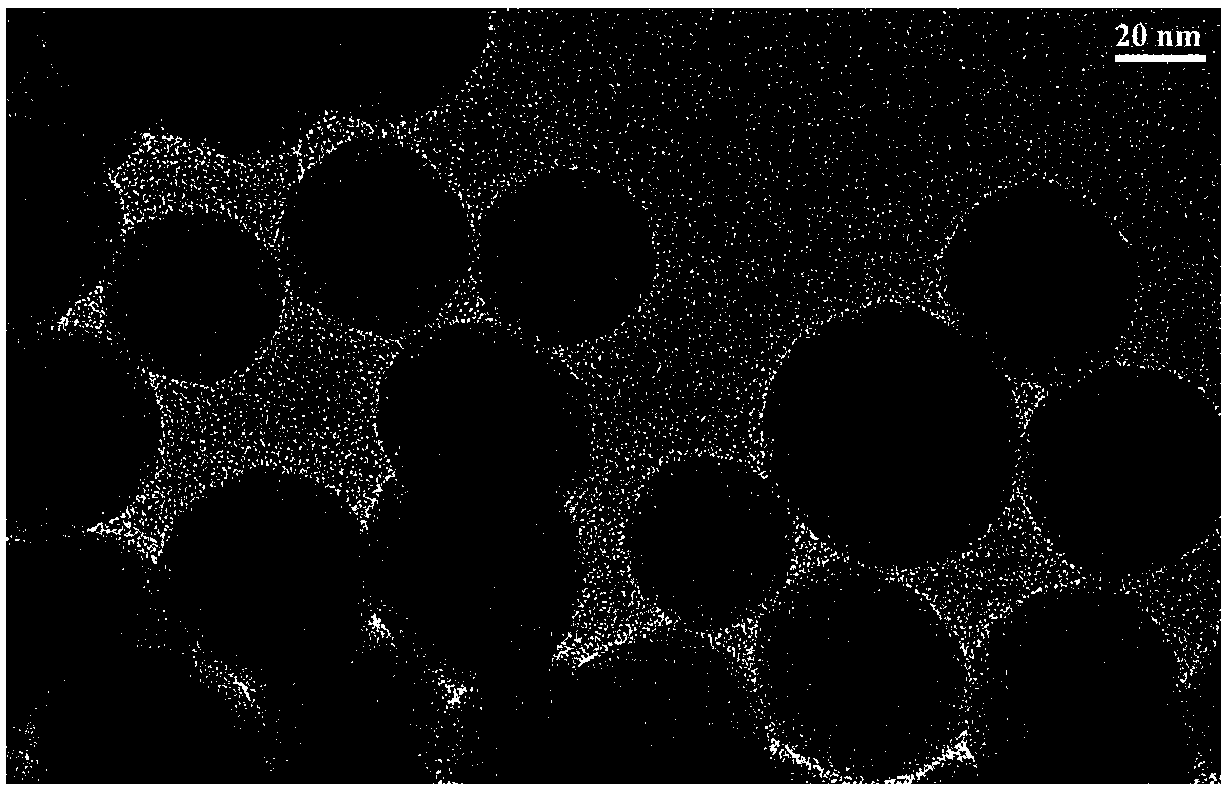

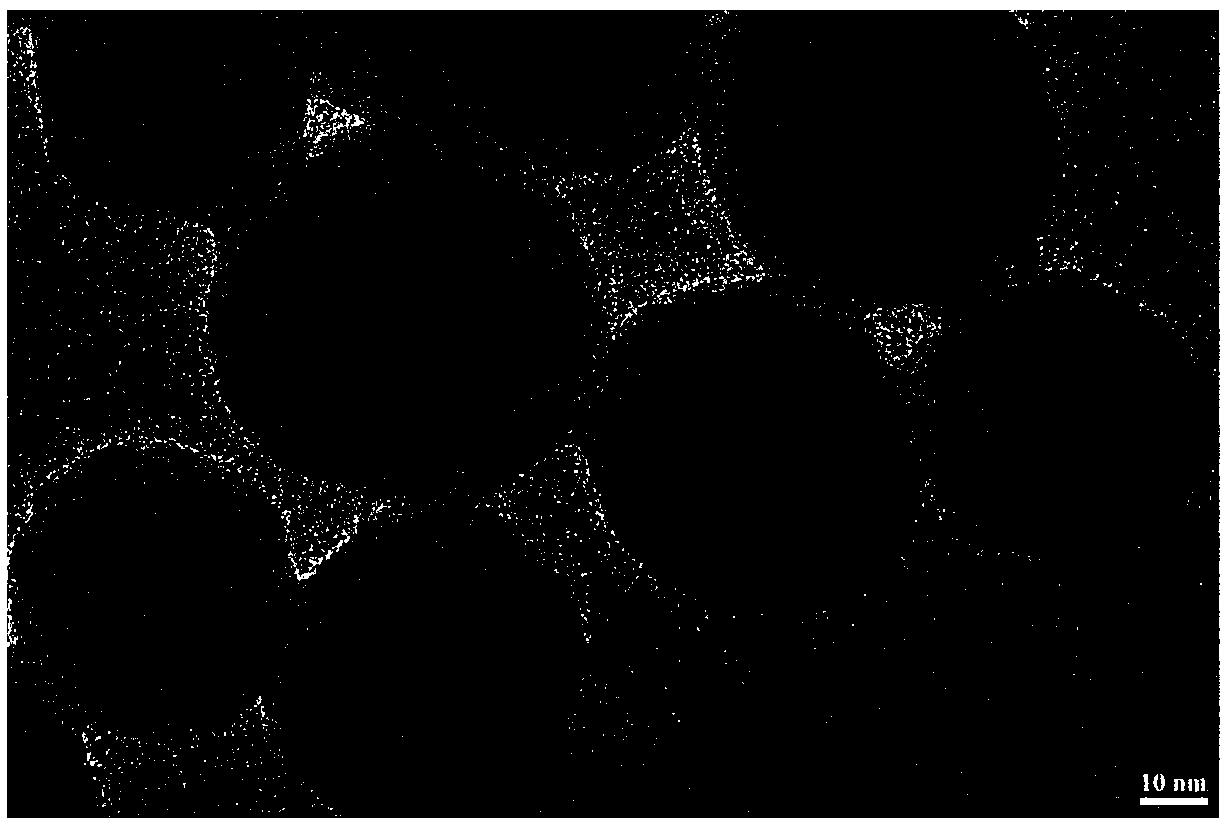

InactiveCN102559190AEnhancing Optical Encoding CapabilitiesCapable of joint codingRaman scatteringFluorescence/phosphorescenceGold nanorodFluorescence

The invention discloses a dual-mode optical coding probe and a preparation method thereof. The probe is in a three-layer core-shell structure, the first-layer core is a gold nano bar, the second-layer shell is silica, the third-layer shell is a cadmium telluride quantum dot, the second-layer shell is wrapped on the outer side of the first-layer core, the third-layer shell covers the outer side ofthe second-layer shell in a sticking mode, and the outer surface of the first-layer core is stuck with Raman molecules which are wrapped by the second-layer shell. The preparation method of the dual-mode optical coding probe comprises the following steps of: 1, preparing an original gold nano bar solution; 2, preparing gold nano bars marked by the Raman molecules; 3, preparing a gold nano bar andsilica metal medium composite nano ball solution; and 4, preparing the dual-mode optical coding probe. The dual-mode optical coding probe has the joint encoding capacity of fluorescence and SERS (Surface Enhanced Raman Scattering), and enhances the optical coding capacity. The preparation method of the dual-mode optical coding probe has a simple process and high repeatability.

Owner:SOUTHEAST UNIV

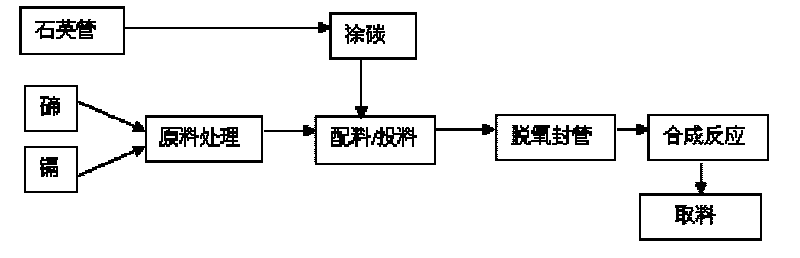

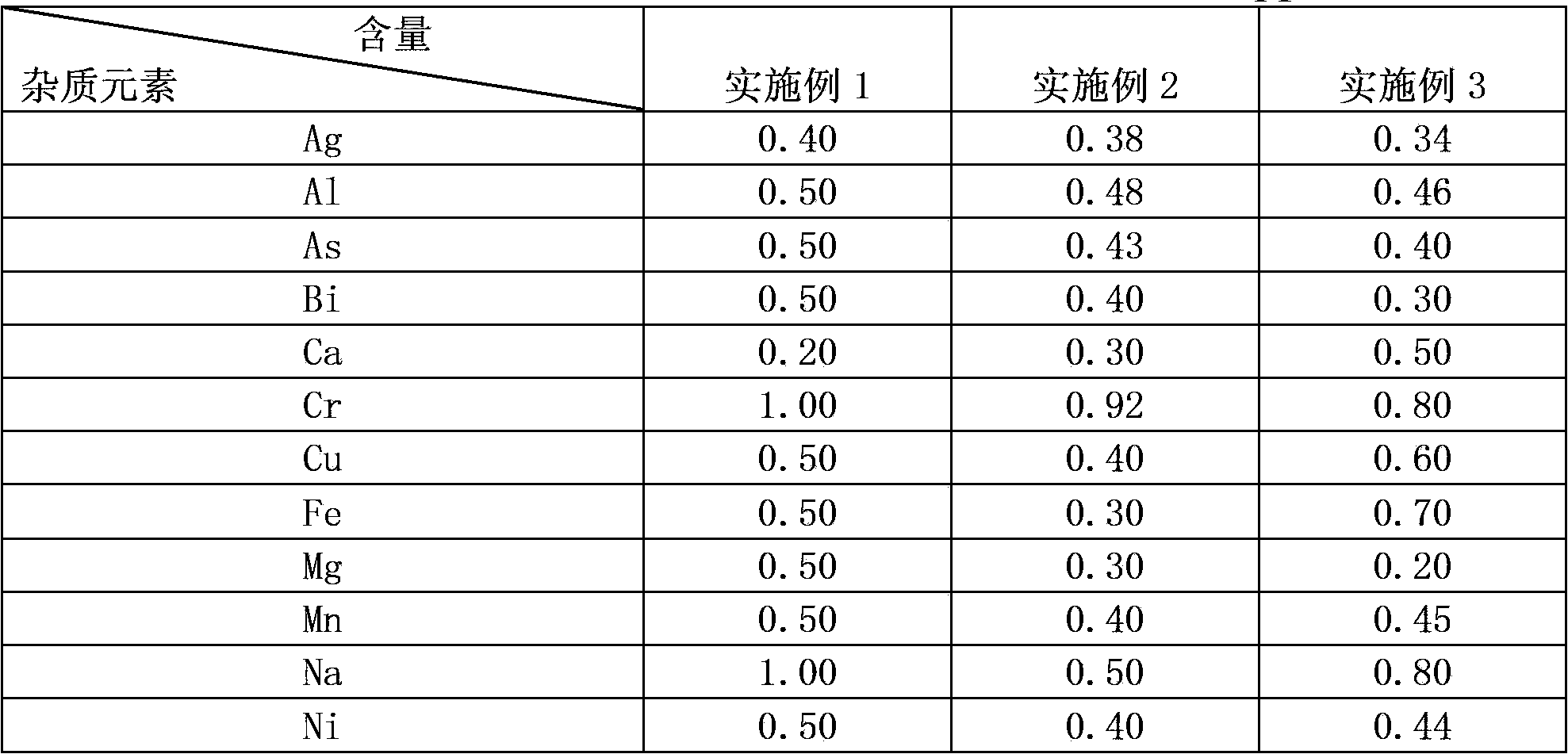

Method for preparing high-purity cadmium telluride

ActiveCN101734630AAvoid direct contactEvenly meltedBinary selenium/tellurium compoundsMolten stateMass ratio

The invention discloses a method for preparing high-purity cadmium telluride. The reaction process is carried out in a closed quartz tube with melting point above cadmium and tellurium and after carbon coating treatment, wherein the mass ratio of a 5N cadmium material to a 5N tellurium material is 1: 1.1-1.15. The method comprises the following steps: dividing the weighed tellurium material into N parts according to the charging times N, dividing the weighed cadmium material into N-1 parts, alternately adding each part of tellurium material and each part of cadmium material into the quartz tube and adding the tellurium material into the quartz tube firstly and lastly, removing oxygen after charging, sintering and sealing the tube by using a sealed bulb, and slowly performing high-temperature and high-pressure synthetic reaction. The method has the advantages that the contact area of the raw materials is larger in a molten state, the reaction speed is more sufficient compared with the solid raw material, the micro-sized crushing treatment for the raw materials is avoided, the shape requirement of the raw materials is relaxed, the preparation cost is greatly reduced, the purity of the raw material is ensured, the method is suitable for large-scale production, the synthetic conversion rate of the cadmium telluride can reach 98 to 99.5 percent, and the single-tube yield of 800 to 1,000 grams can be ensured by using the quartz tube with the inside diameter of 32 millimeters under the premise of safety.

Owner:中国东方电气集团有限公司

Preparation method of cadmium antimonide powder

The preparation method of cadmium telluride powder includes the following steps: firstly, mixing tellurium powder and cadmium powder according to chemical mixing ratio, grinding and stirring mixed material, placing the mixed material in the crucible under the condition of vacuum, heating to make the tellurium powder and cadmium powder produce chemical combination reaction to form cadmium telluride material, further grinding the obtained cadmium telluride material and mixing it further, and placing the cadmium telluride material in heating furnace to make annealing treatment so as to obtain the invented product.

Owner:XI AN JIAOTONG UNIV

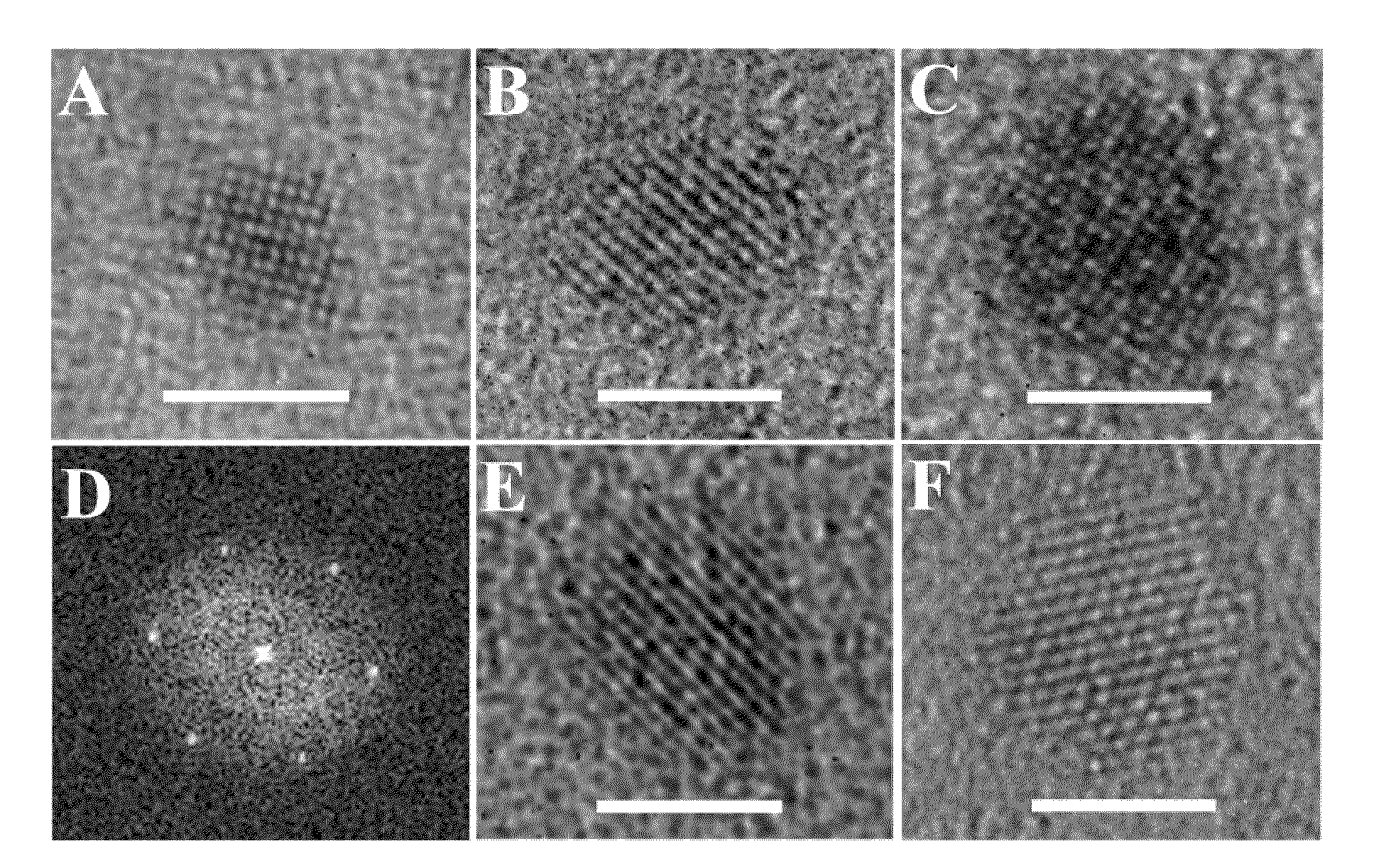

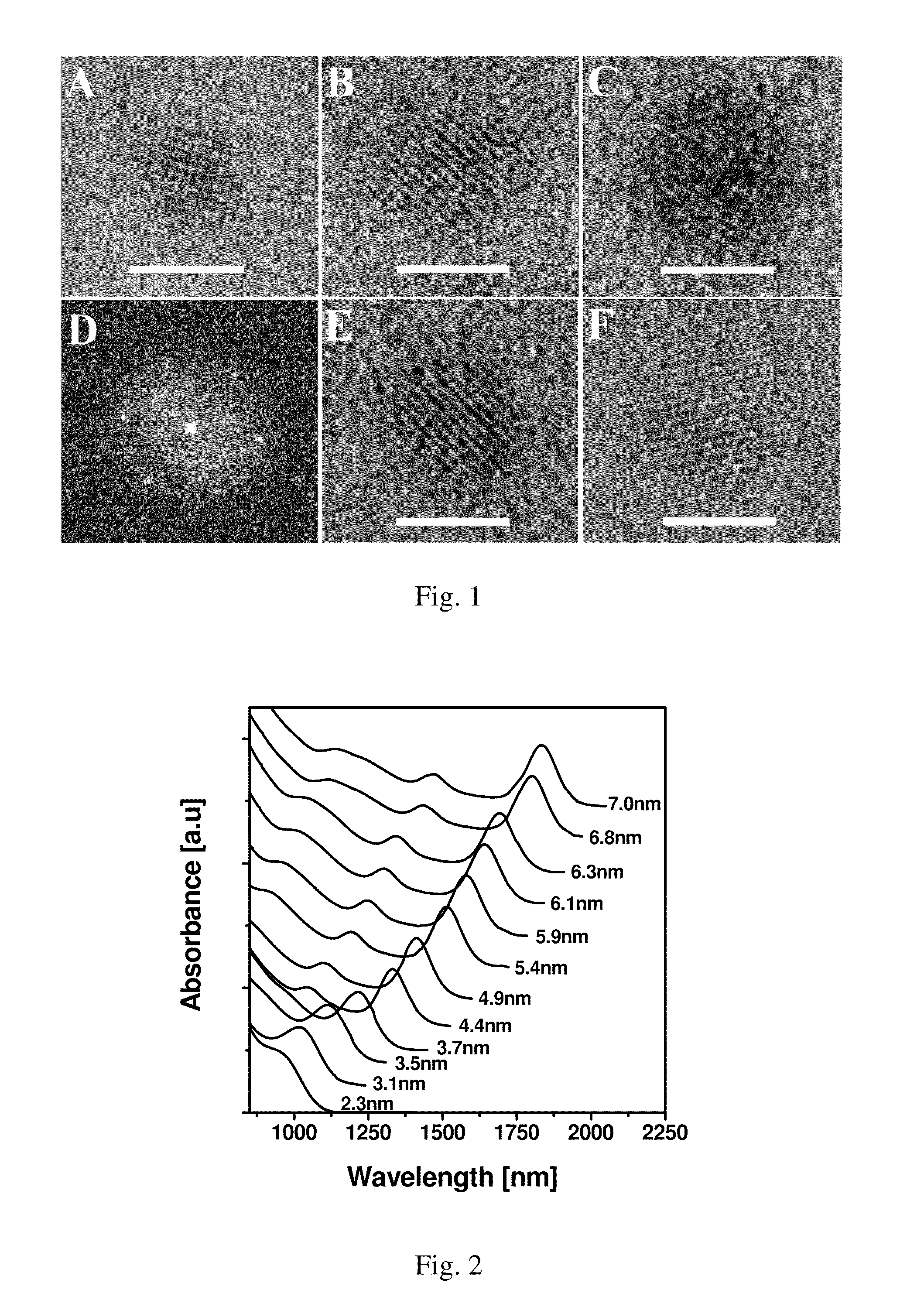

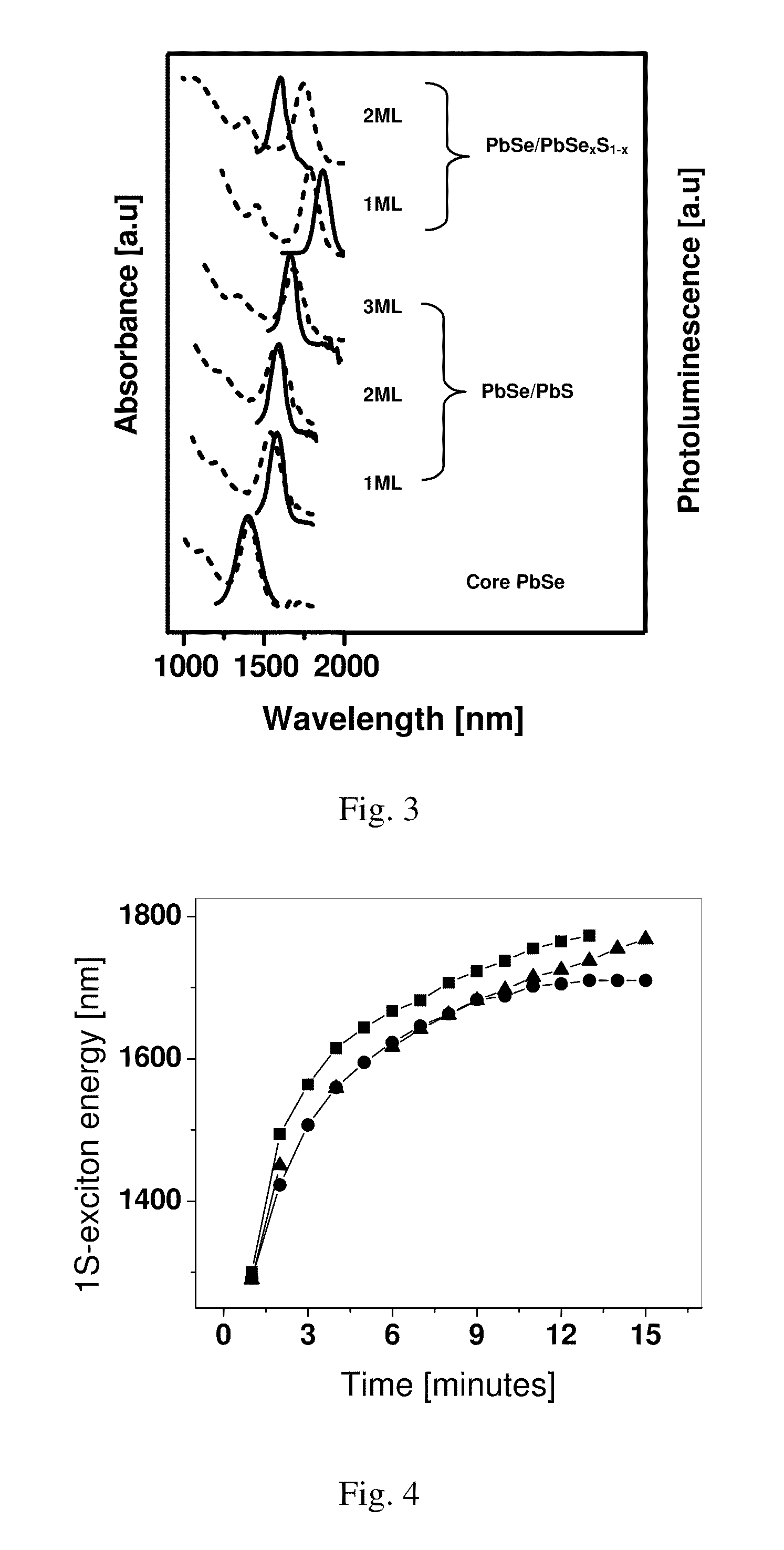

Core-alloyed shell semiconductor nanocrystals

InactiveUS20110006285A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationSemiconductor materialsSemiconductor nanocrystals

The invention relates to a core-alloyed shell semiconductor nanocrystal comprising: (i) a core of a semiconductor material having a selected band gap energy; (ii) a core-overcoating shell consisting of one or more layers comprised of an alloy of the said semiconductor of (i) and a second semiconductor; (iii) and an outer organic ligand layer, provided that the core semiconductor material is not HgTe. In certain embodiments, the core semiconductor material is PbSe and the alloy shell semiconductor material has the PbSexS1-x structure; or the core semiconductor material is CdTe and the alloy shell semiconductor material has either the CdTexSe1-x or CdTexS1-x structure.

Owner:TECHNION RES & DEV FOUND LTD

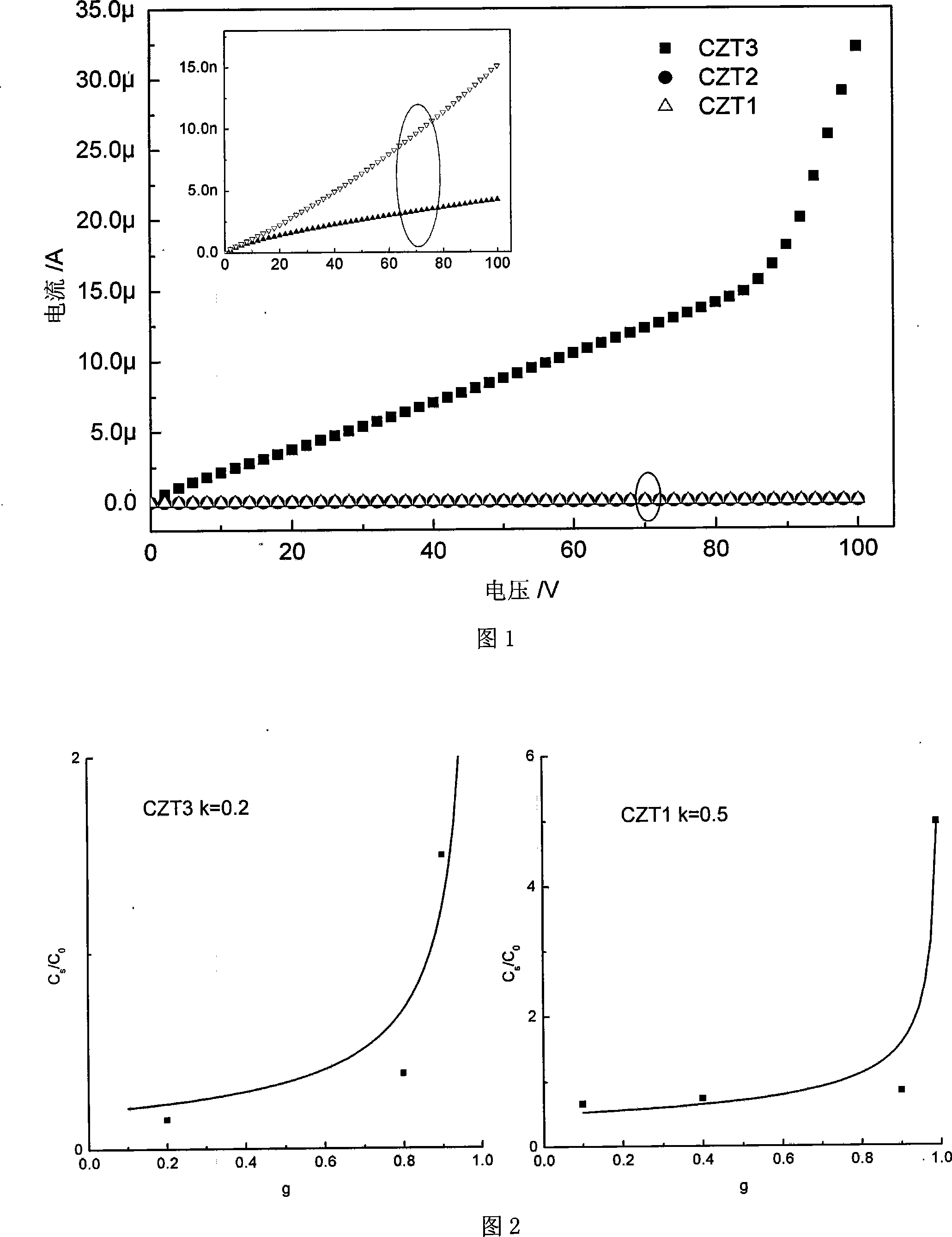

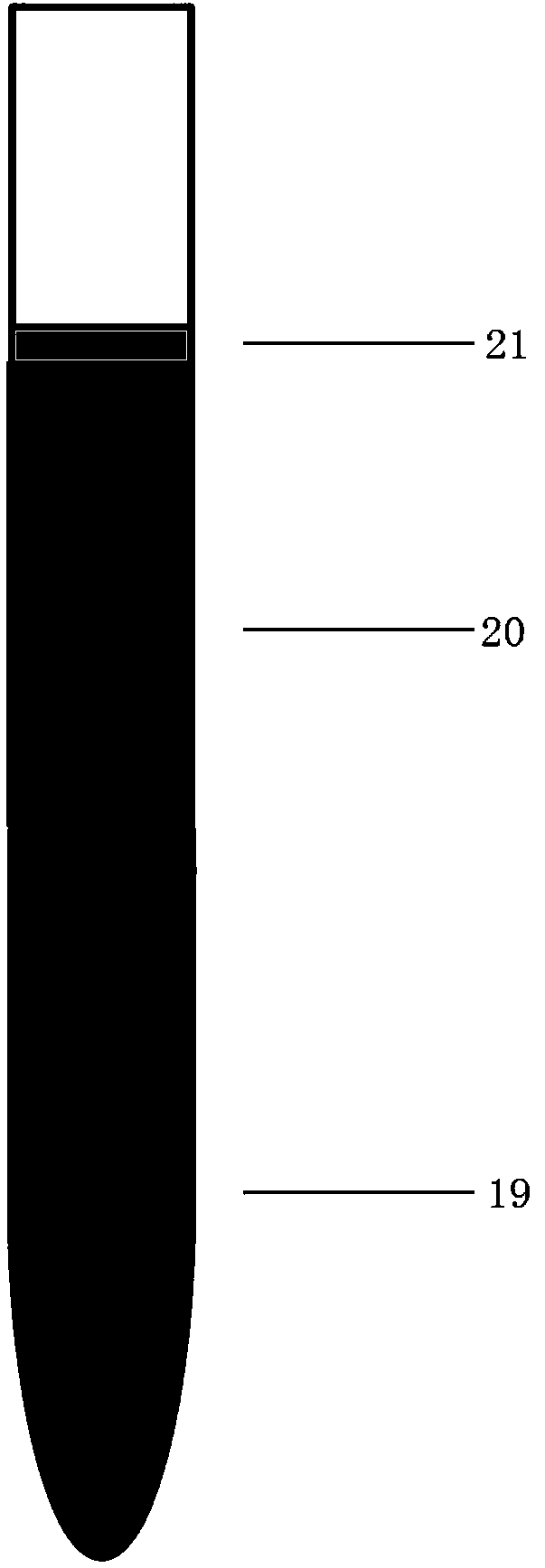

Method for preparing Te-Zn-Cd monocrystal in large volume

ActiveCN101092748ASmall sizeIncrease the single crystal ratePolycrystalline material growthFrom frozen solutionsCarbon filmRoom temperature

This invention discloses a method for preparing large-volume cadmium zinc telluride (CZT) single crystal. The method comprises: (1) selecting high-melting-point CZT single crystal as the seed crystal; (2) coating a carbon film on the inner side of a quartz ampoule, placing CZT seed crystal in the seed crystal bag at the bottom of the ampoule so that the seeding growth surface of CZT seed crystal is upward, then adding low-melting-point CZT polycrystal, vacuumizing the quartz ampoule, and sealing by welding; (3) placing the quartz ampoule into an ACRT-B type crystal growth apparatus, heating the temperatures of the high-temperature zone and the low-temperature zone to 1135-1145 deg.C and 1030-1040 deg.C within 18-20 h, overheating for 12-16h, and descending the supporting bar at a speed of 0.8 mm / h for 200-240 h; (4) cooling the high-temperature zone and the low-temperature zone to 870-890 deg. within 5-6 h, annealing the crystal ingot in situ for 144-168 h, then slowly cooling to 550-560 deg.C at a rate of 5 deg.C / h, shutting off the power source, and cooling to room temperature. The method can obtain large-volume CZT single crystal, and increase the single crystal ratio in the crystal ingot.

Owner:IMDETEK

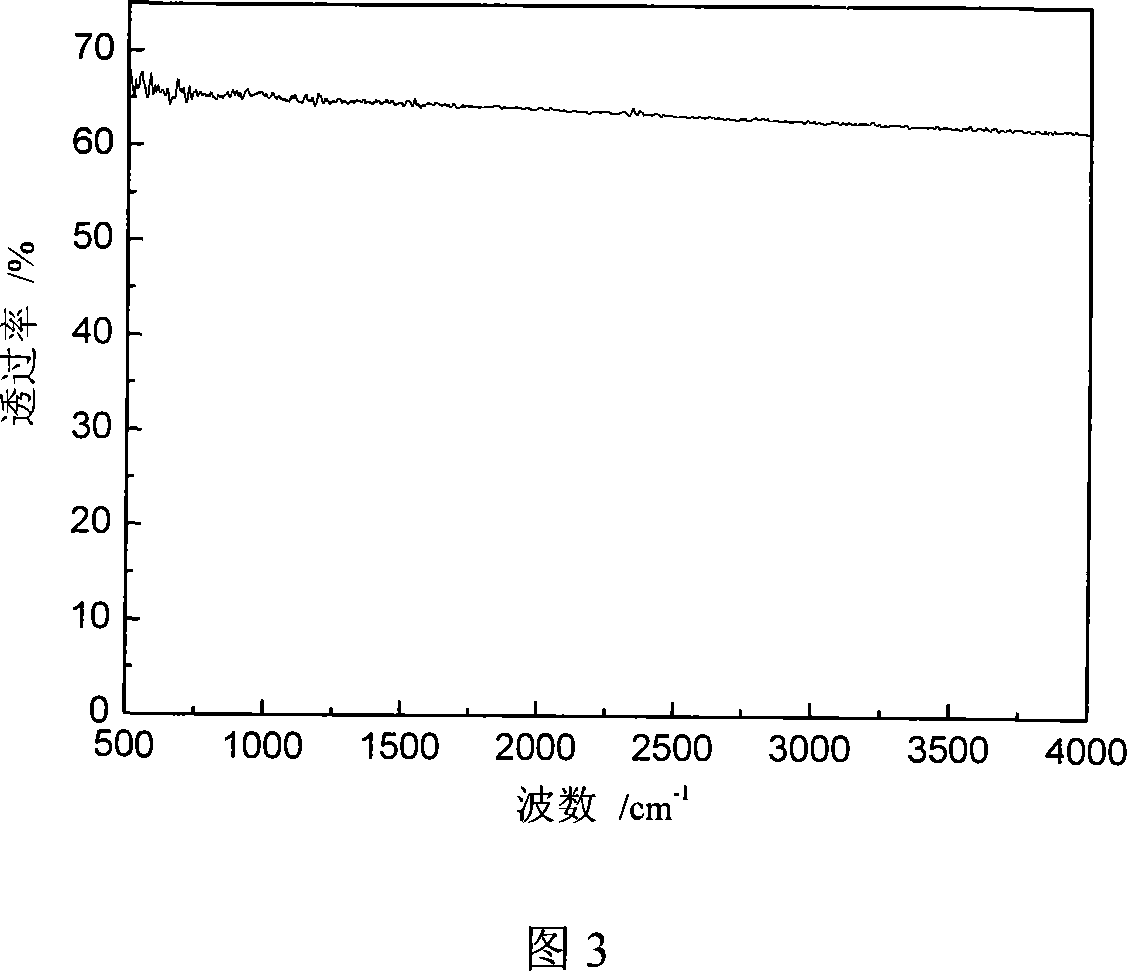

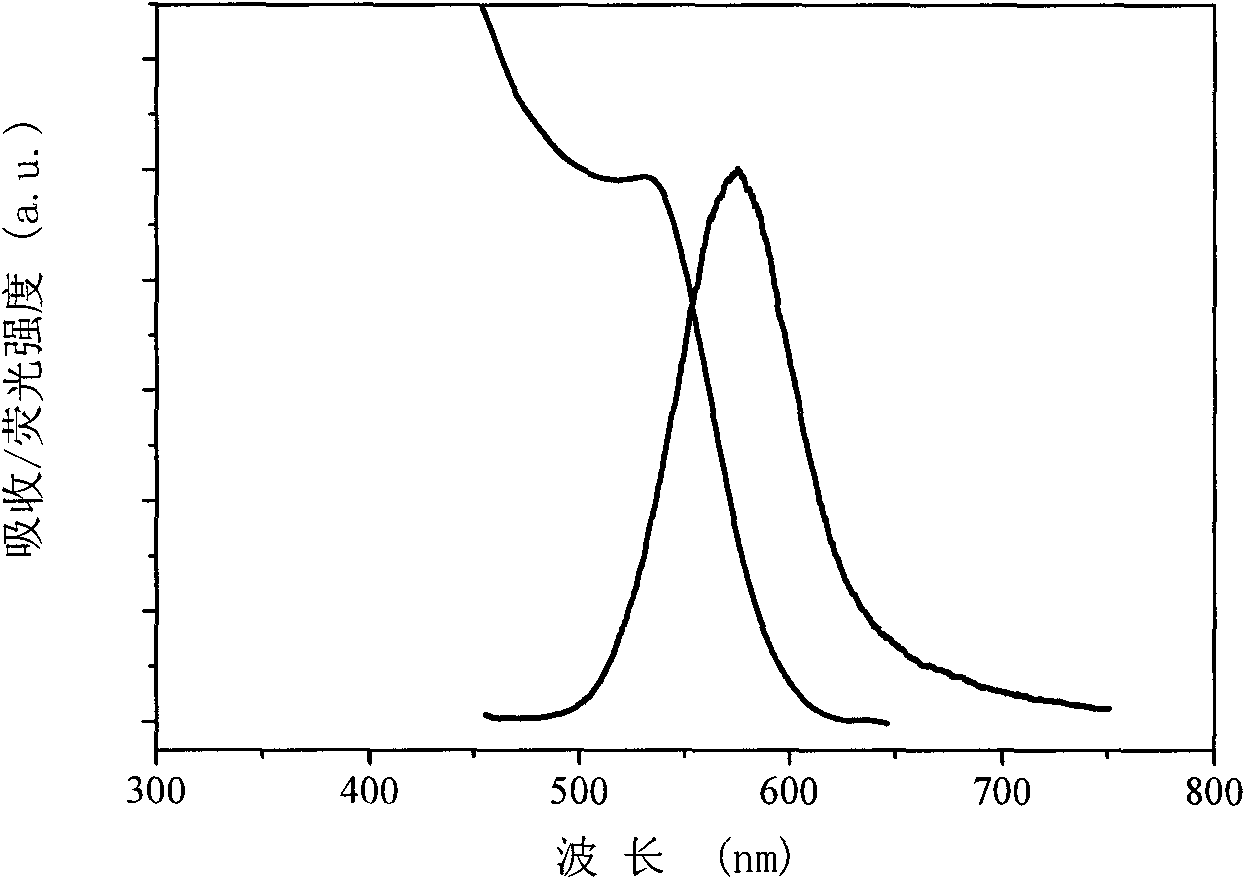

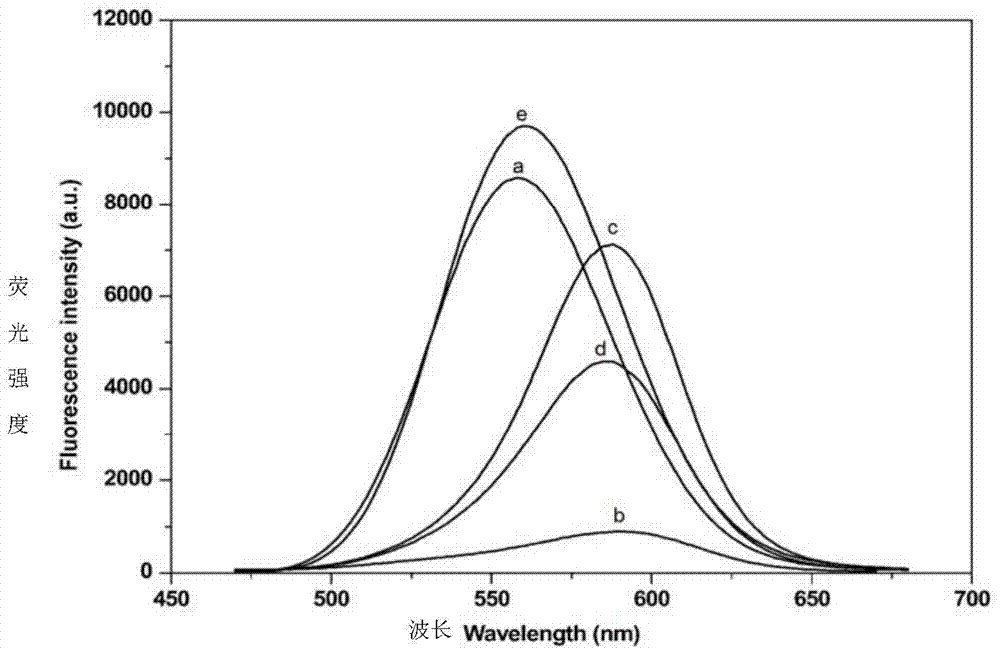

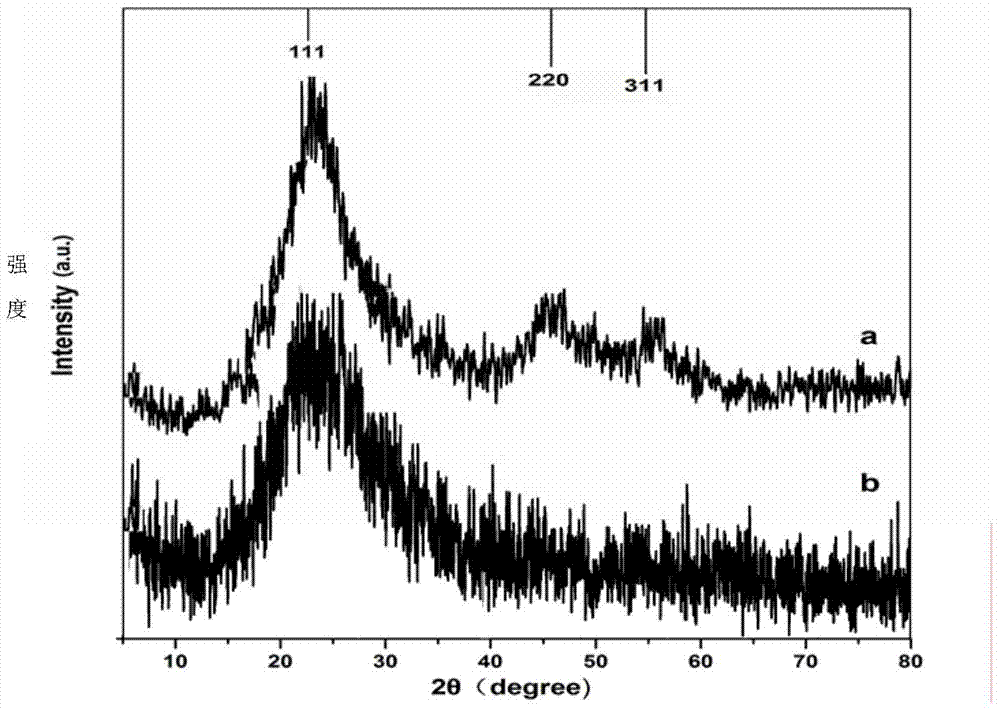

Non-contact-type temperature measurement method based on cadmium telluride quantum dot photoluminescence

InactiveCN103411703AAccurate and convenient measurementSolve problems limited by spatial scaleThermometers using physical/chemical changesLuminous intensityPhotoluminescence

Owner:XI AN JIAOTONG UNIV

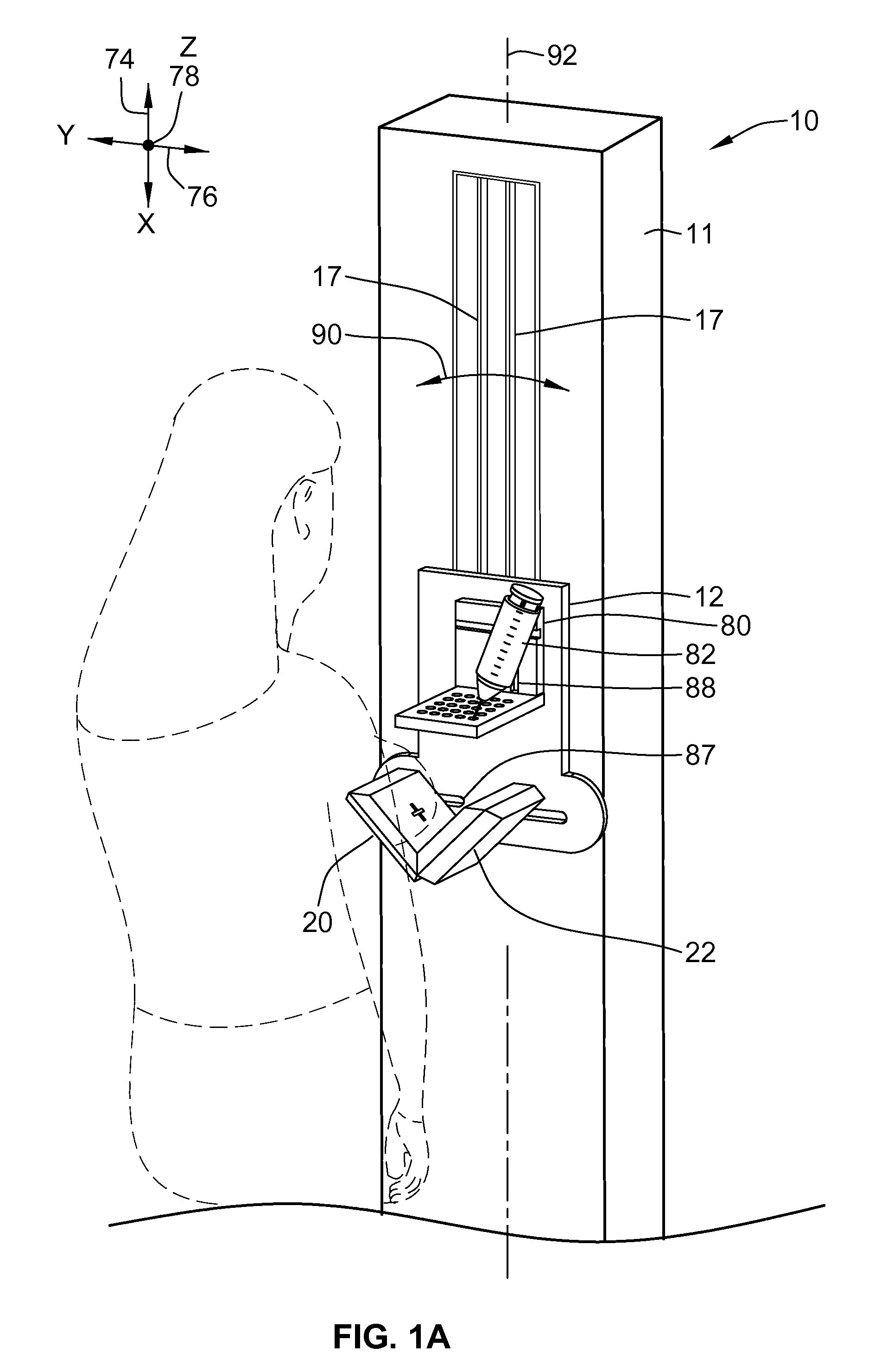

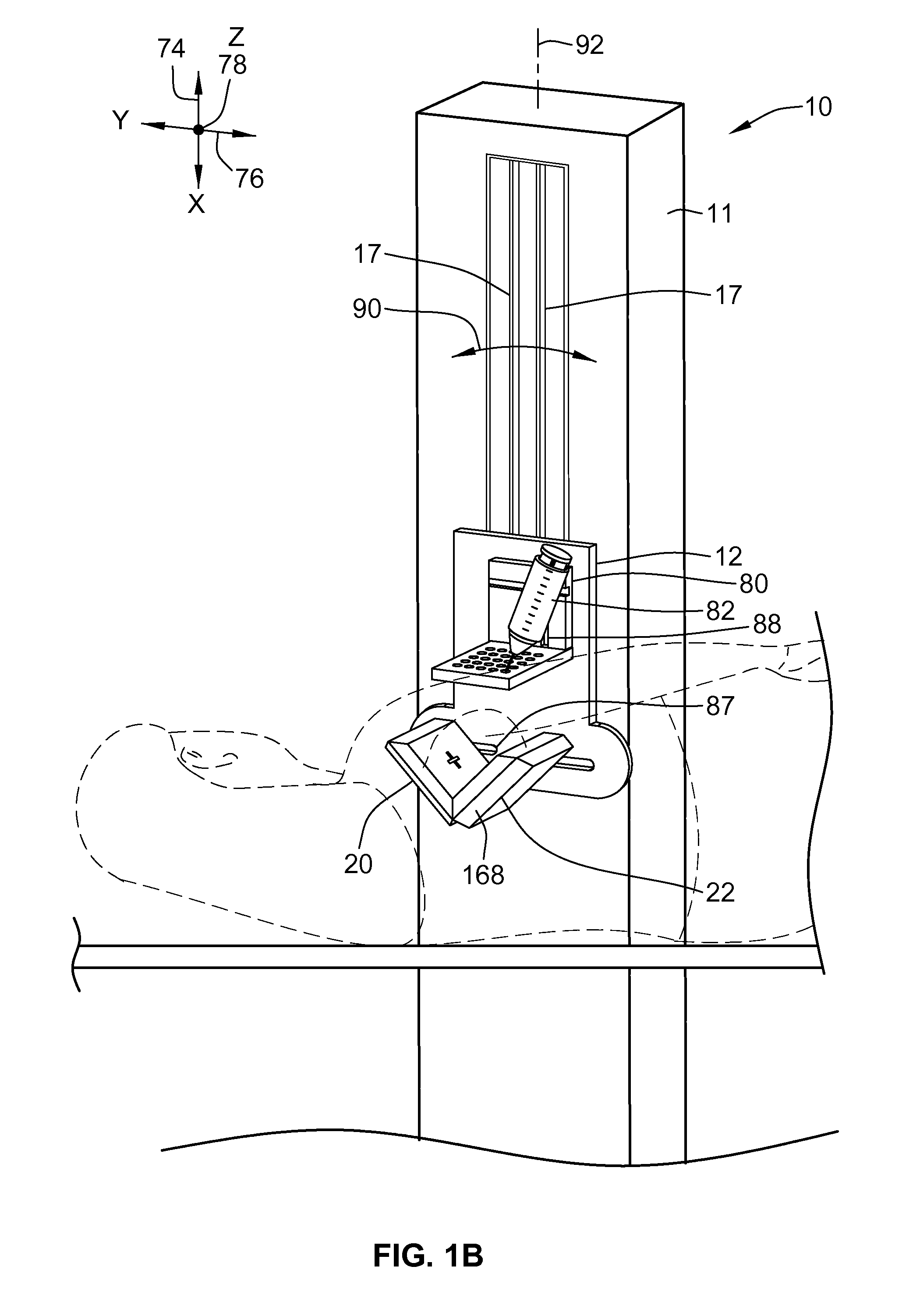

Gamma camera for performing nuclear mammography imaging

ActiveUS20100329419A1PhotometryMaterial analysis by optical meansMolecular imagingCadmium zinc telluride

A gamma camera for use in a molecular imaging system includes a housing, a cadmium zinc telluride (CZT) camera disposed within the housing, and at least one retractable wall coupled to the housing and adapted to secure an anatomy of interest in a field-of-view of the gamma camera. The gamma camera also includes a chamfered edge to enable the gamma camera to contact a second gamma camera when the gamma camera is positioned in an L-mode imaging configuration.

Owner:SMART BREAST CORP

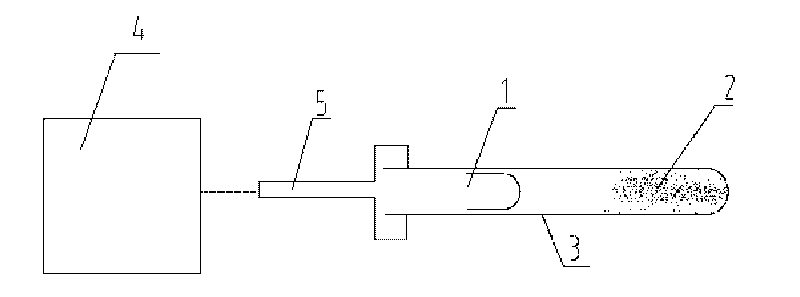

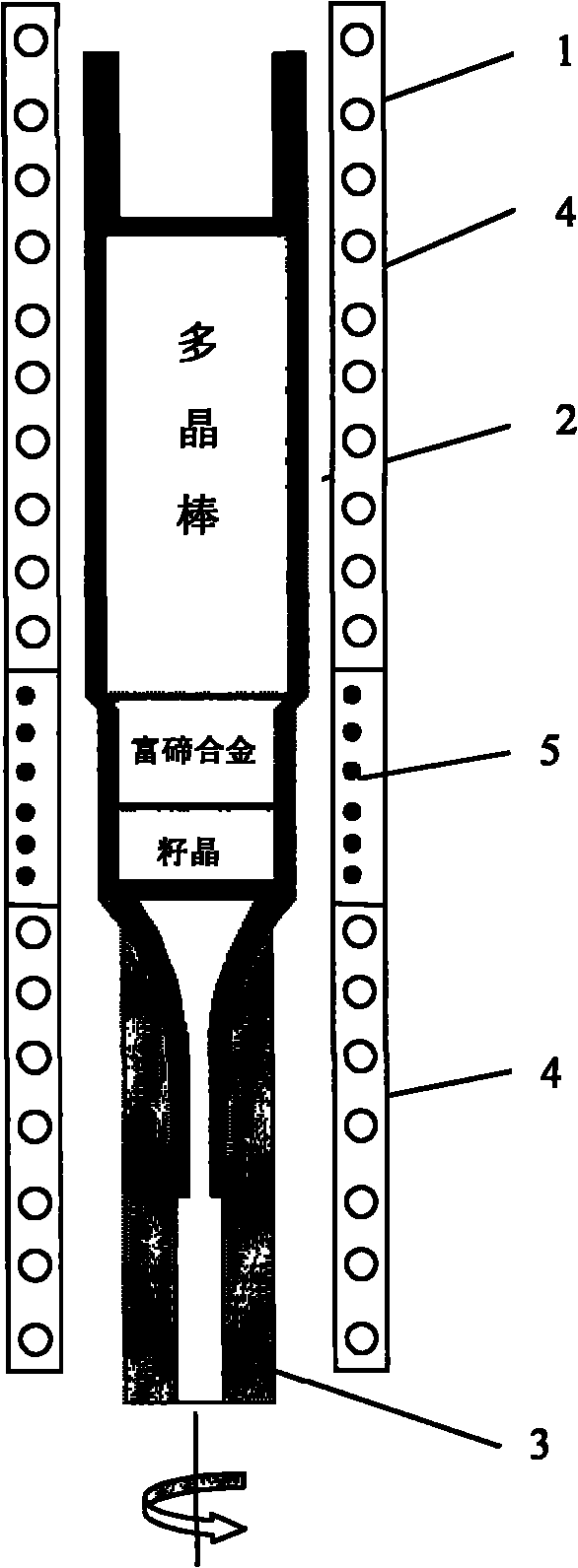

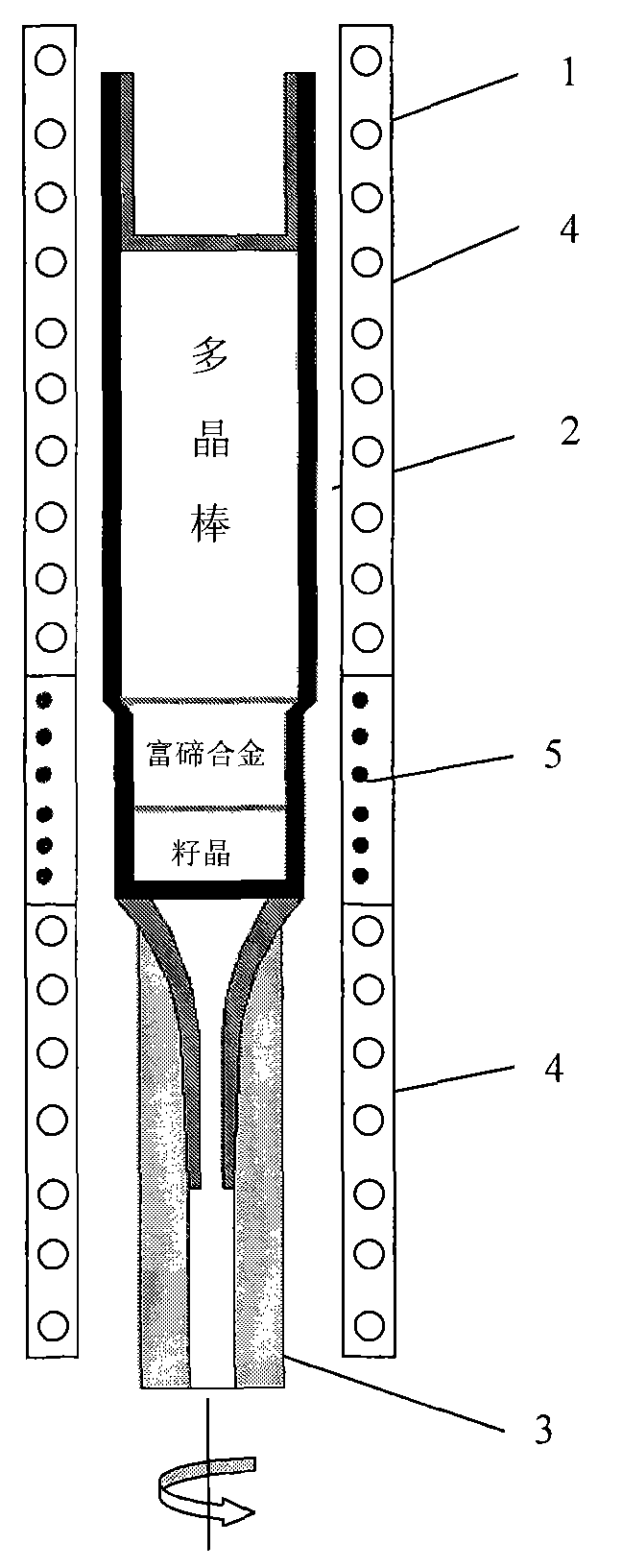

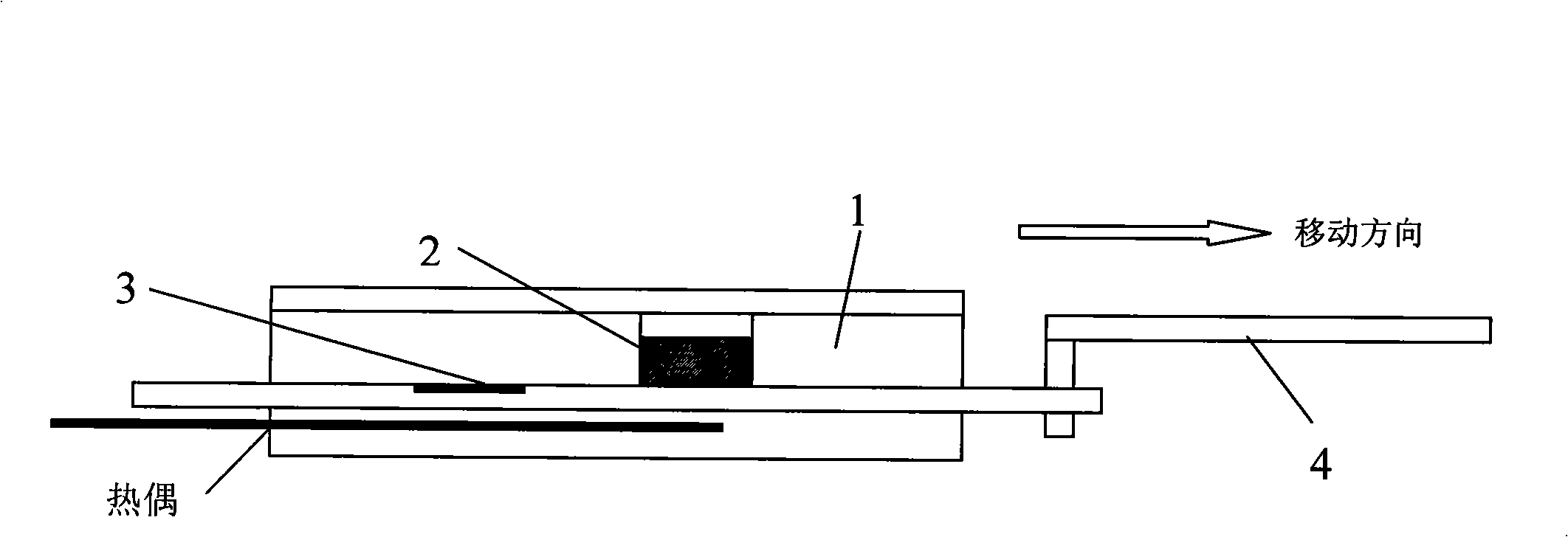

Method and device for growing cadmium zinc telluride crystals in mobile tellurium solvent melting zone

InactiveCN101871123AAchieve directed growthReduce contaminationPolycrystalline material growthBy zone-melting liquidsTe elementAlloy

The invention relates to a device and a method for growing cadmium zinc telluride crystals in a mobile tellurium solvent melting zone and belongs to the technical field of the growth of special crystals. The method is characterized by comprising the following steps of: feeding 99.99999 percent high-purity raw materials of which the stoichiometric proportion meets Cd1-xZnxTe (x=0.04-0.8) into two quartz tubes; adding 30 to 80 mass percent of excessive tellurium (Te) into one of the quartz tubes; vacuumizing and sealing the quartz tubes respectively and synthesizing materials in the quartz tubes to obtain polycrystalline rods and alloys rich in the Te in a rocking furnace; feeding seed crystals, the alloys rich in the Te and the polycrystalline rods into a long crystal tube, vacuumizing, sealing and placing the long crystal tube in a furnace body, wherein the alloys rich in the Te are positioned in a high-frequency induction heater at the temperature of 700 to 950 DEG C; raising the heater at a speed of 0.02 to 2mm / h and rotating the long crystal tube at the same time; and adding excessive Te in an alloy area rich in the Te to obviously reduce the melting point to ensure that the polycrystalline rods are continuously dissolved from the upper part of melt and cadmium zinc telluride single crystals are continuously precipitated from the lower part of the melt along with the rising. The method and the device for growing the cadmium zinc telluride crystals have the advantages of obviously reducing the growing temperature and the impurity concentration of the crystals.

Owner:SHANGHAI UNIV

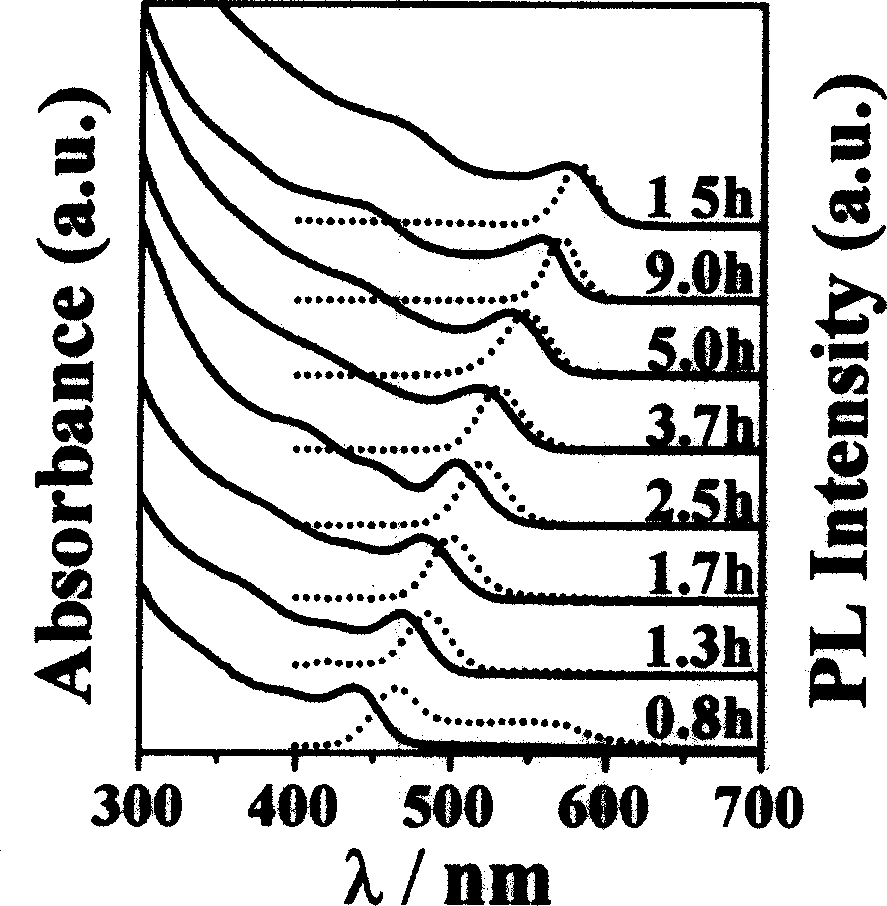

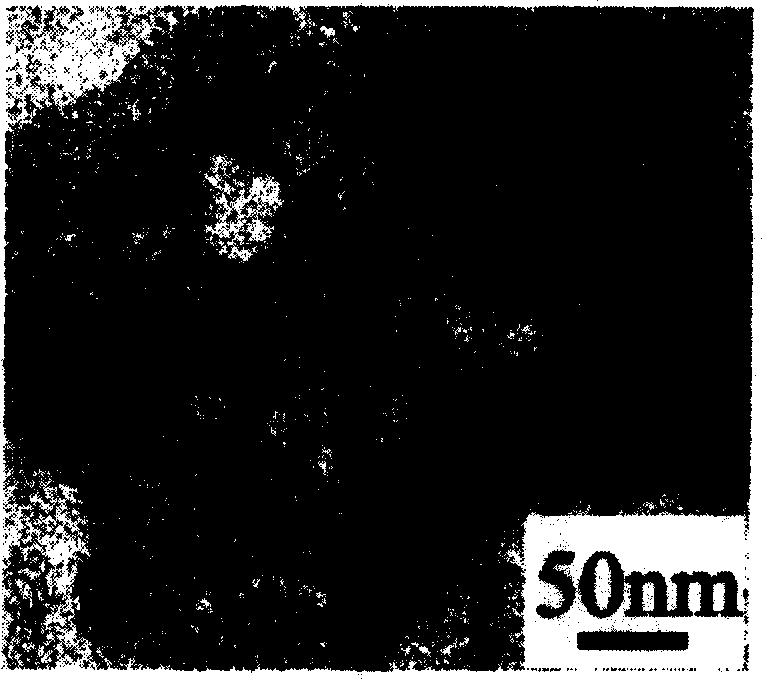

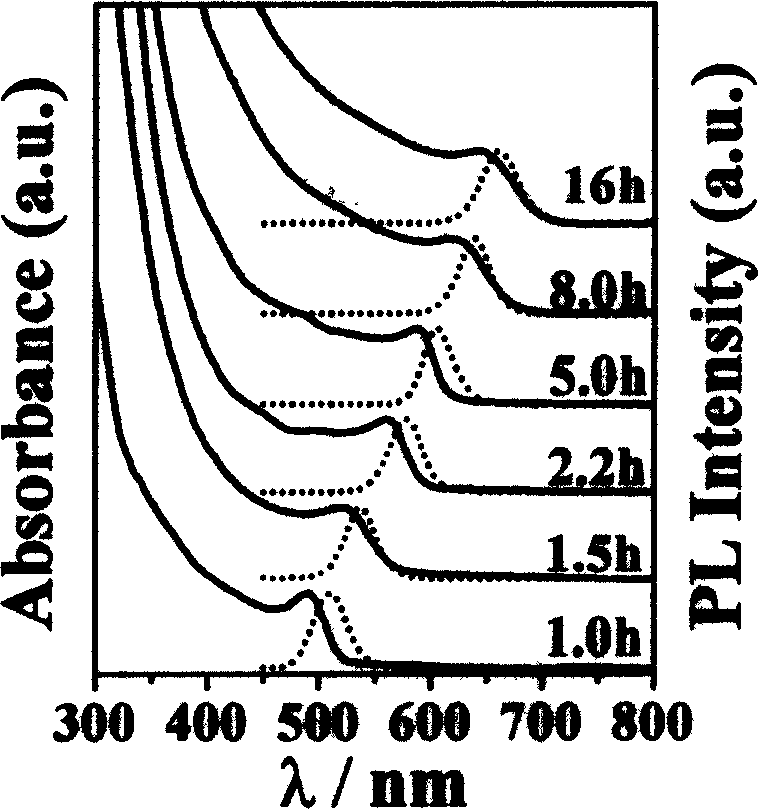

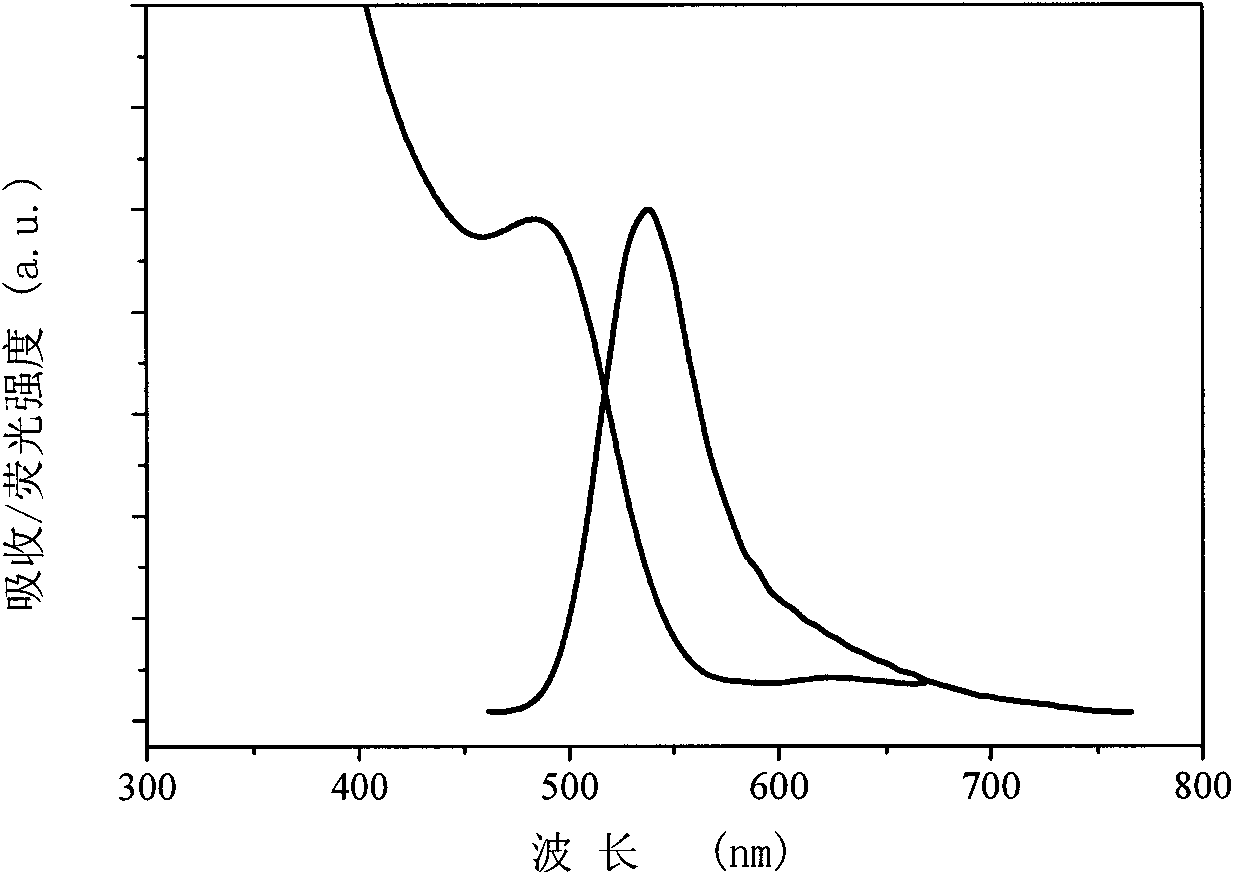

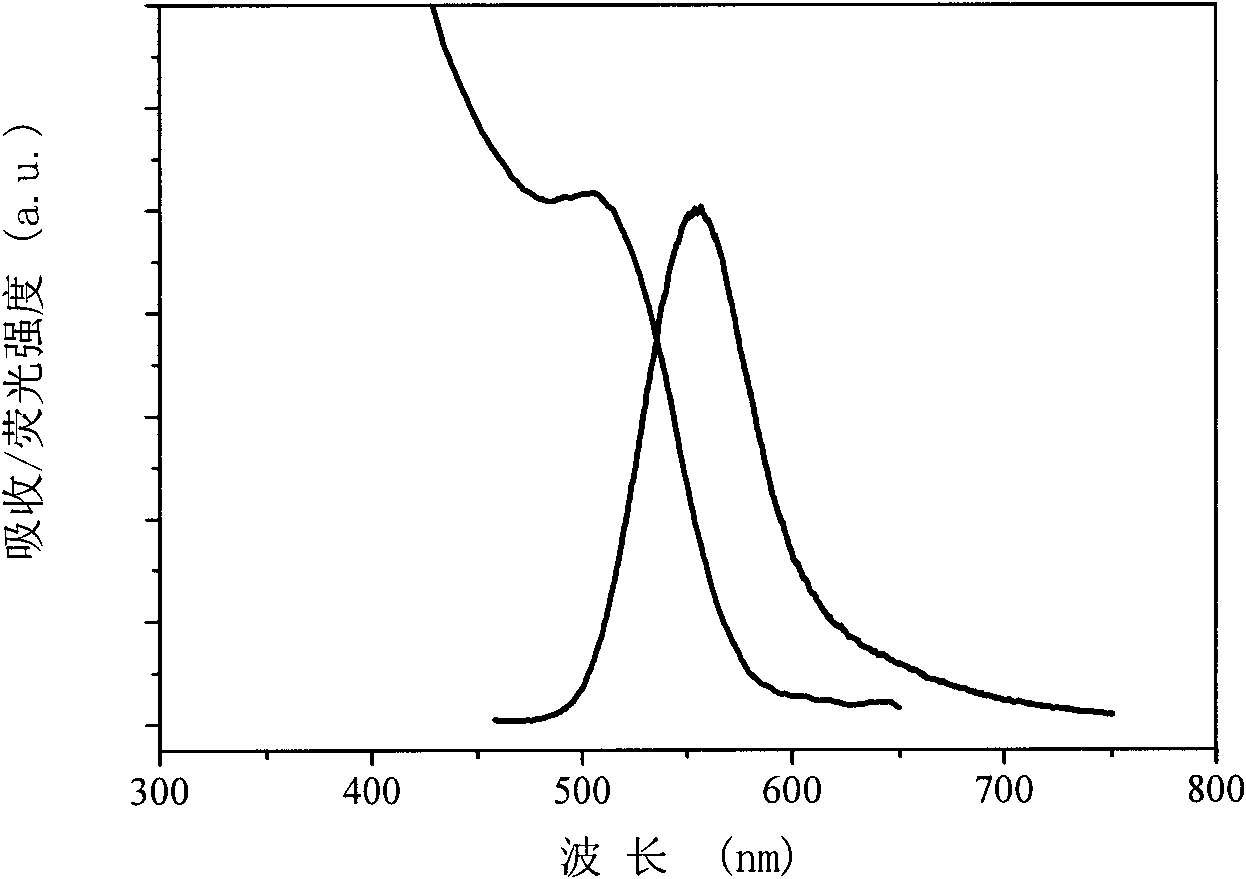

Synthesis method for cadmium selenide and cadmium telluride quantum dot

InactiveCN1631793ANarrow size distributionReduce consumptionCadmium compoundsBinary selenium/tellurium compoundsFluorescenceSynthesis methods

The invention belongs to the method for compounding cadmium selenide and quanta of cadmium telluride, which is: use cadmium oxide containing 2~18 carbon atom as cadmium source, selenium powder as selenium source and tellurium powder as tellurium source, and the mol ratio of cadmiumsource and selenium source or tellurium source is 5:1-1:5, dissolve the selenium and tellurium powder with tricapryl phosphine, make oleic acid, and tricapryl phosphine oxide as enveloping agent and the mol ratio of cadmium source and enveloping agent is 1:2-1:6, use benzene, toluene, cyclohexane, normal hexane and normal heptane as solvent, under the condition that the density of cadmium source is 0.001-0.015M, the temperature in autoclave is 140-180deg.C, heat them for 0.8-16 hours and obtain cadmium selenide and quanta of cadmium telluride with different sizes by changing the reaction time. The cadmium selenide and quanta of cadmium telluride has narrower size distribution which is shown as narrower shooting of fluorescence whose half-peak width of quanta of cadmium selenide is 22-33nm and that of quanta of cadmium telluride is 29-35nm.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Mixed sputtering target of cadmium sulfide and cadmium telluride and methods of their use

Mixed targets are generally disclosed for sputtering an intermixed layer of cadmium sulfide and cadmium telluride. The mixed target can include cadmium sulfide, and cadmium telluride. Methods of forming the mixed target are also provided. For example, a powdered blend can be formed from powdered cadmium sulfide and powdered cadmium telluride, and pressed into a mixed target Methods are also generally disclosed for manufacturing a cadmium telluride based thin film photovoltaic device having an intermixed layer. For example, a mixed target of cadmium sulfide and cadmium telluride can be sputtered directly on a cadmium sulfide layer to form an intermixed layer, and a cadmium telluride layer can be formed on the intermixed layer.

Owner:FIRST SOLAR INC (US)

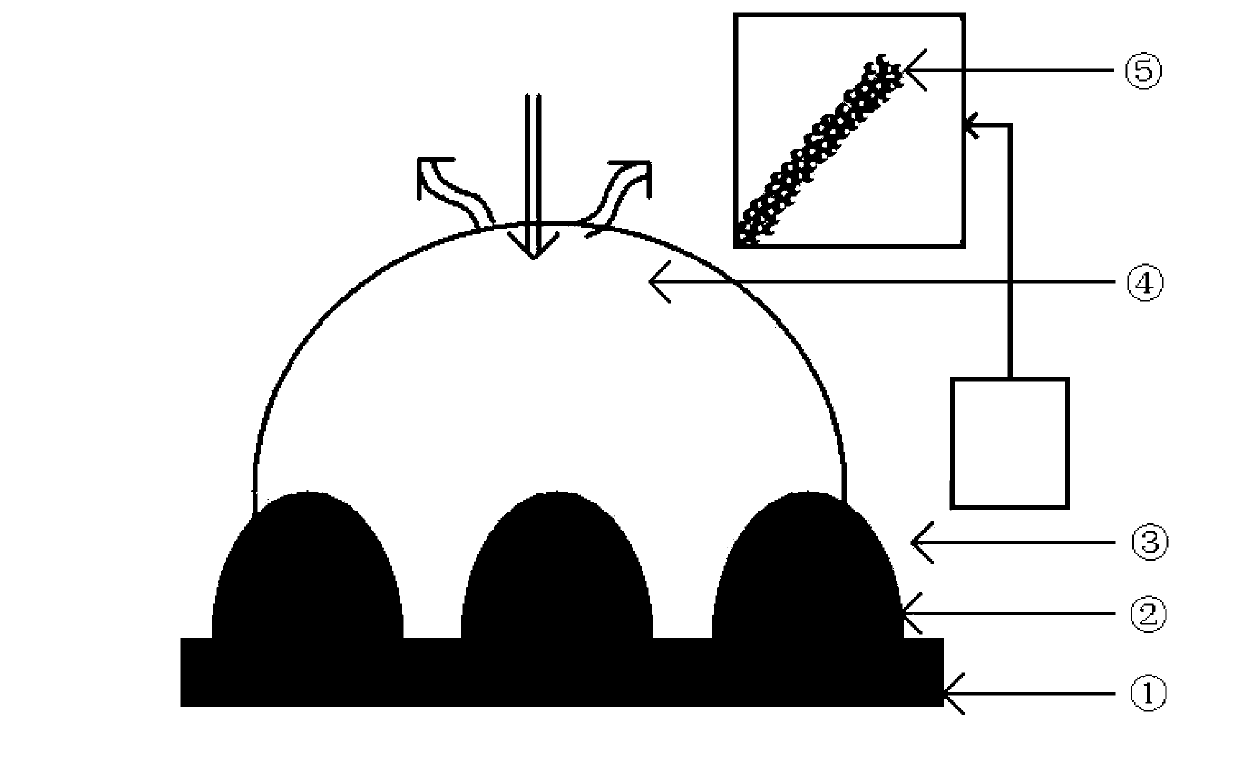

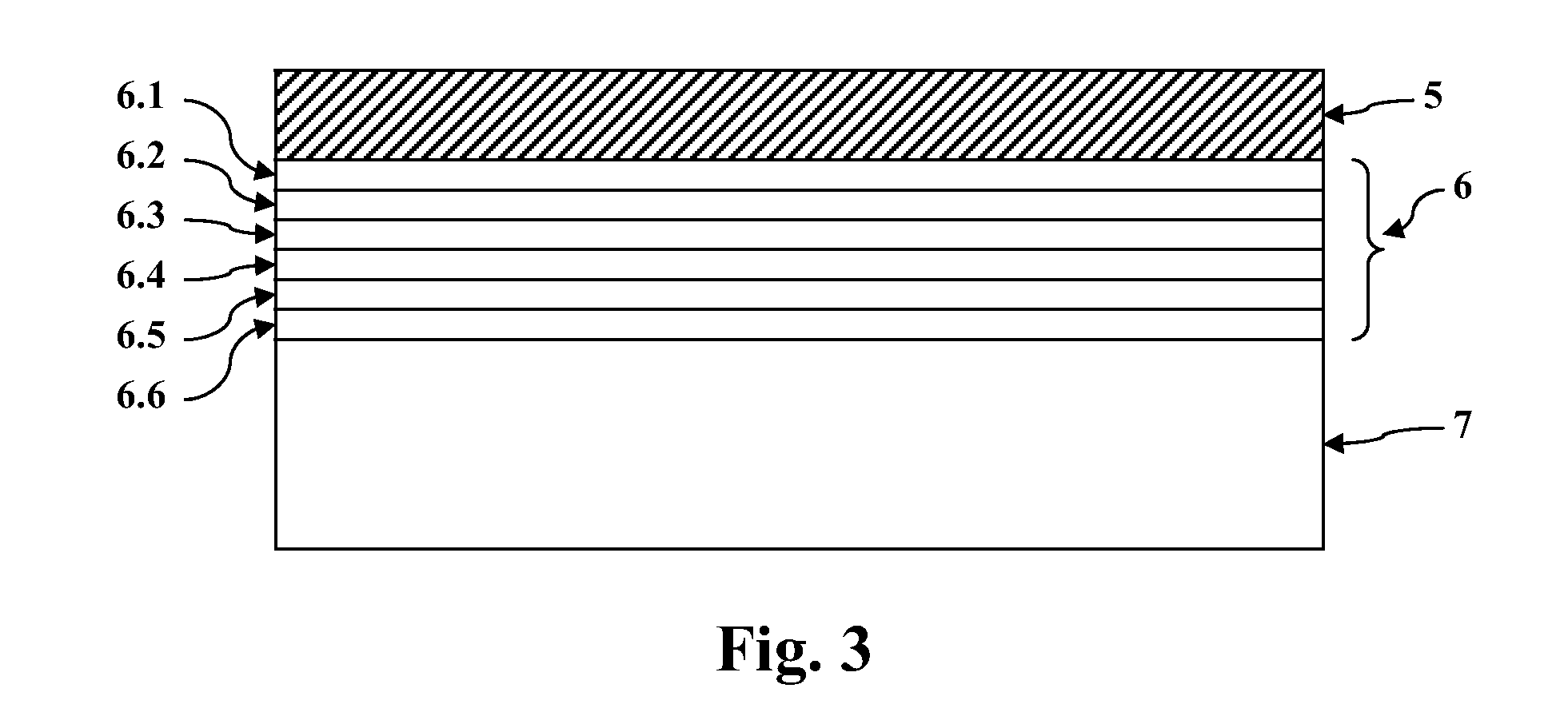

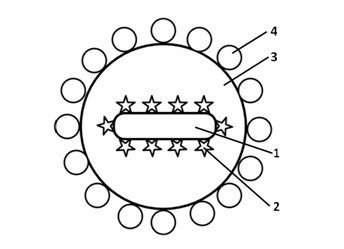

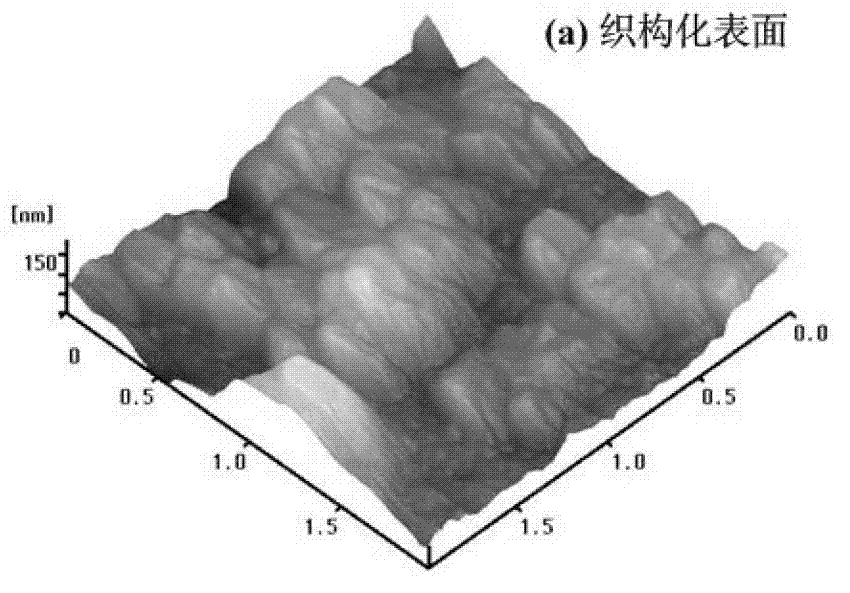

Cadmium telluride thin-film battery and manufacturing method thereof

ActiveCN102779864AShorten the optical pathEnhanced light absorptionFinal product manufactureSemiconductor devicesElectrical batteryPhysics

The invention discloses a perform-optimized cadmium telluride thin-film battery and a manufacturing method for the cadmium telluride thin-film battery, wherein the cadmium telluride thin-film battery comprises a substrate and an epitaxy lamination layer; the epitaxy layer lamination sequentially consists of a conducting layer, a window layer, a light-absorbing layer, a back barrier layer and a back electrode from the bottom up; the window layer is of a textured cadmium sulfide thin-film layer; the light-absorbing layer is of a cadmium telluride thin-film layer, the back barrier layer is of a zinc telluride / copper-doped zinc telluride composite layer or a mercury telluride / copper-doped mercury telluride composite thin-film layer, and the back electrode is of one or more of graphite slurry or graphene slurry thin-film layer or copper thin-film layer, nickel thin-film layer, copper-nickel alloy thin-film layer and molybdenum thin-film layer. According to the cadmium telluride thin-film battery provided by the invention, the window area is textured and an optical path of a light-transmitting area is reduced, and thus a light-absorbing capacity is further improved and the better light-trapping effect is realized.

Owner:SUN YAT SEN UNIV

Method for preparing water-soluble CdTe quantum dots

ActiveCN101870459AGood water solubilityImprove stabilityLuminescent compositionsBinary selenium/tellurium compoundsTe elementCadmium Cation

The invention discloses a method for preparing water-soluble cadmium telluride (CdTe) quantum dots, and belongs to the field of nano-technology preparation. In the method, sodium tellurite serves as a tellurium source; cadmium chloride serves as a cadmium source; mercaptopropionic acid serves as a coordination agent; sodium hexametaphosphate serves as an auxiliary stabilizing agent; and the water-soluble CdTe quantum dots are prepared by only one step of reducing the sodium tellurite by using hydrazine hydrate in an aqueous phase system. The method has the characteristics of simple and practical operation, mild condition and low toxicity; and quantum dots with different sizes and emission wavelengths can be obtained by a method for controlling a reaction time.

Owner:SHANDONG UNIV

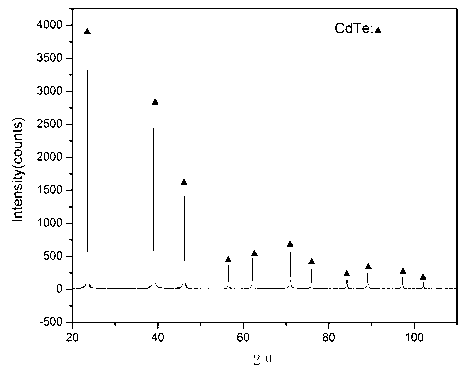

Preparation method for cadmium telluride

ActiveCN103420346AFully synthesizedSynthetic heating evenlyCadmium compoundsMetal selenides/telluridesMercury cadmium tellurideRoom temperature

The invention provides a preparation method for cadmium telluride. The method comprises a first synthesis and a second synthesis. The first synthesis comprises steps: tellurium and cadmium are mixed and placed in a first graphite boat; the first graphite boat is then placed in a first quartz tube; the first quartz tube is then placed in a first synthetic furnace; a first inert gas is introduced to empty air in the first quartz tube; a first multi-section heating and heat preservation process is carried out, the first inert gas is introduced in the front section and a first reducing gas is introduced in the back section; after the synthetic reaction, the first synthetic furnace is cooled to room temperature in sections, the first reducing gas is introduced in the front section and the first inert gas is introduced in the back section; first synthetics are obtained. The second synthesis comprises steps: the first synthetics are placed in a second graphite boat; the second graphite boat is then placed in a second quartz tube; the second quartz tube is then placed in a second synthetic furnace; a second inert gas is introduced to empty air in second first quartz tube; a second multi-section heating and heat preservation process is carried out, a second inert gas is introduced in the front section and a second reducing gas is introduced in the back section; after the synthetic reaction, heating is stopped, the second synthetic furnace is cooled to room temperature in sections, the second reducing gas is introduced in the front section and the second inert gas is introduced in the back section; second synthetics are obtained.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

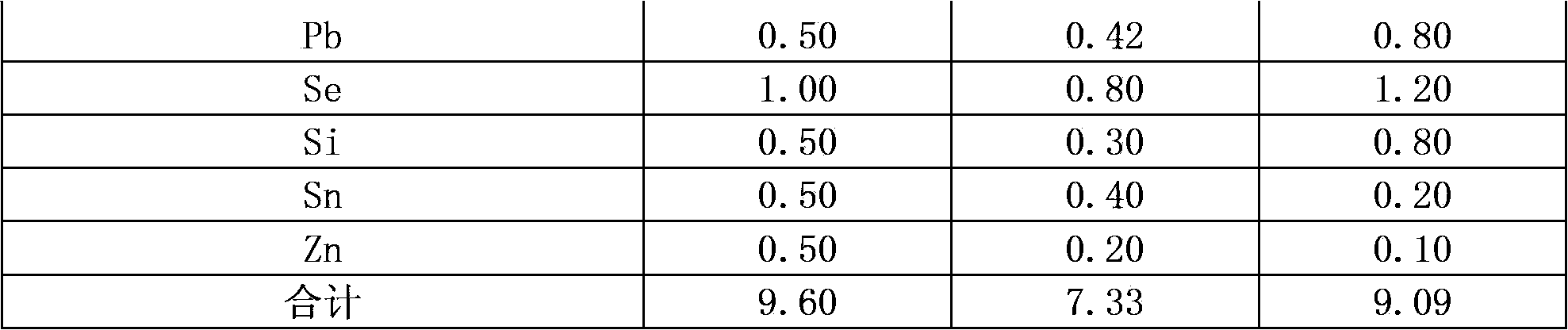

P-aminophenol imprinted polymer on surface of cadmium telluride quantum dot as well as preparation method and application thereof

InactiveCN103539945AHigh selectivityIncrease heightOther chemical processesFluorescence/phosphorescenceCadmium zinc tellurideMaterials science

The invention relates to a p-aminophenol imprinted polymer on the surface of a cadmium telluride quantum dot as well as a preparation method and application thereof. The preparation method comprises the following steps: I, synthesizing the cadmium telluride quantum dot CdTeQDs with a fluorescence characteristic and carrying out silanized modification on the surface; II, preparing the p-aminophenol imprinted polymer on the surface of the cadmium telluride quantum dot; and III, removing template molecules to obtain the p-aminophenol imprinted polymer on the surface of the cadmium telluride quantum dot CdTe@SiO2@MIP. Test results show that the limit of detection of CdTe@SiO2@MIPsQDs synthesized by the method to template molecules can reach 0.02 mu m. Fluorescence detection is quickly and simply carried out by using a fluorospectro photometer in a time-saving manner.

Owner:NANJING MEDICAL UNIV

Method for manufacturing high resistivity tellurium-zincium-cadmium crystal

ActiveCN101220514AImprove uniformityIncrease profitPolycrystalline material growthSingle crystal growth detailsBridgman methodSingle crystal

The invention discloses a preparing method of high resistivity cadmium zinc telluride crystal. The method is characterized by comprising the following steps: according to stoichiometric ratio, the material which satisfies Cd0.9Zn0.1Te and the purity of which is 99.99999 percent are put in the inside of a super pure silica pot, and excessive Te with the mass percent of 0.5 percent to 2 percent and In with the volume concentration of (1-6) multiplied by 10<18>cm<-3> are added in the pot; the inside of the silica pot is vacuum-pumped and sealed; the silica pot is put in a synthesis furnace to synthesize raw materials; the pot is put in a five-section crystal growth furnace to grow crystal by the descending vertical Bridgman method. The method adopts the five-section normal pressure single crystal growth furnace and excessive Te is added in the crystal growth process, therefore the method provides enough deep level TeCd<2 plus> for the growth of Cd1-xZnxTe crystal, reduces production cost and obtains stable Cd1-xZnxTe crystal with high resistivity. At the same time, the partition ratio of In in Cd0.9Zn0.1Te crystal ingot approaches 1, thus causing the resistivity change of Cd0.9Zn0.1Te crystal ingot less and improving the uniformity and utilization rate of Cd0.9Zn0.1Te crystal.

Owner:IMDETEK

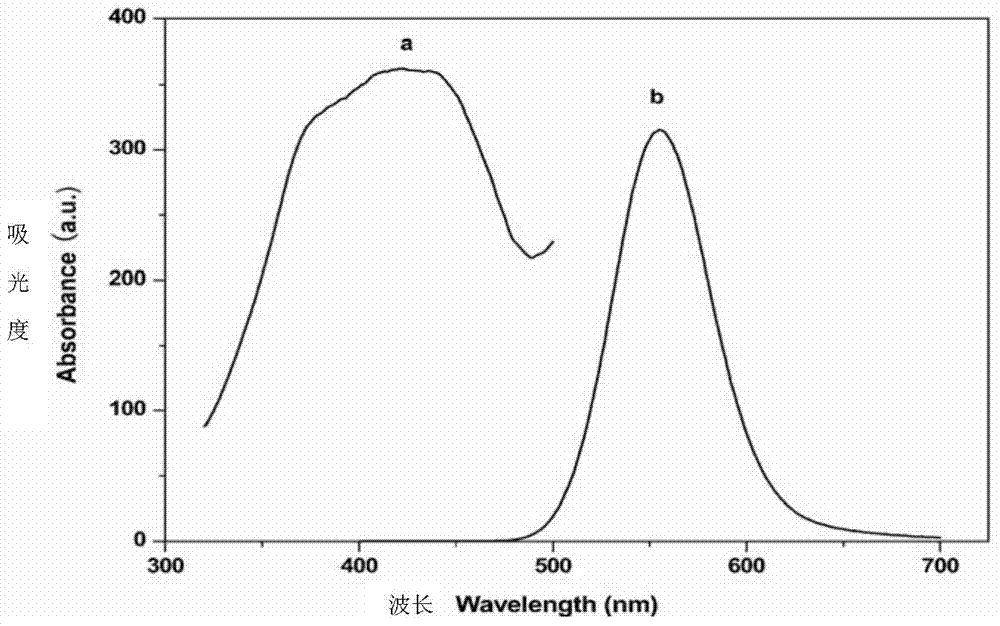

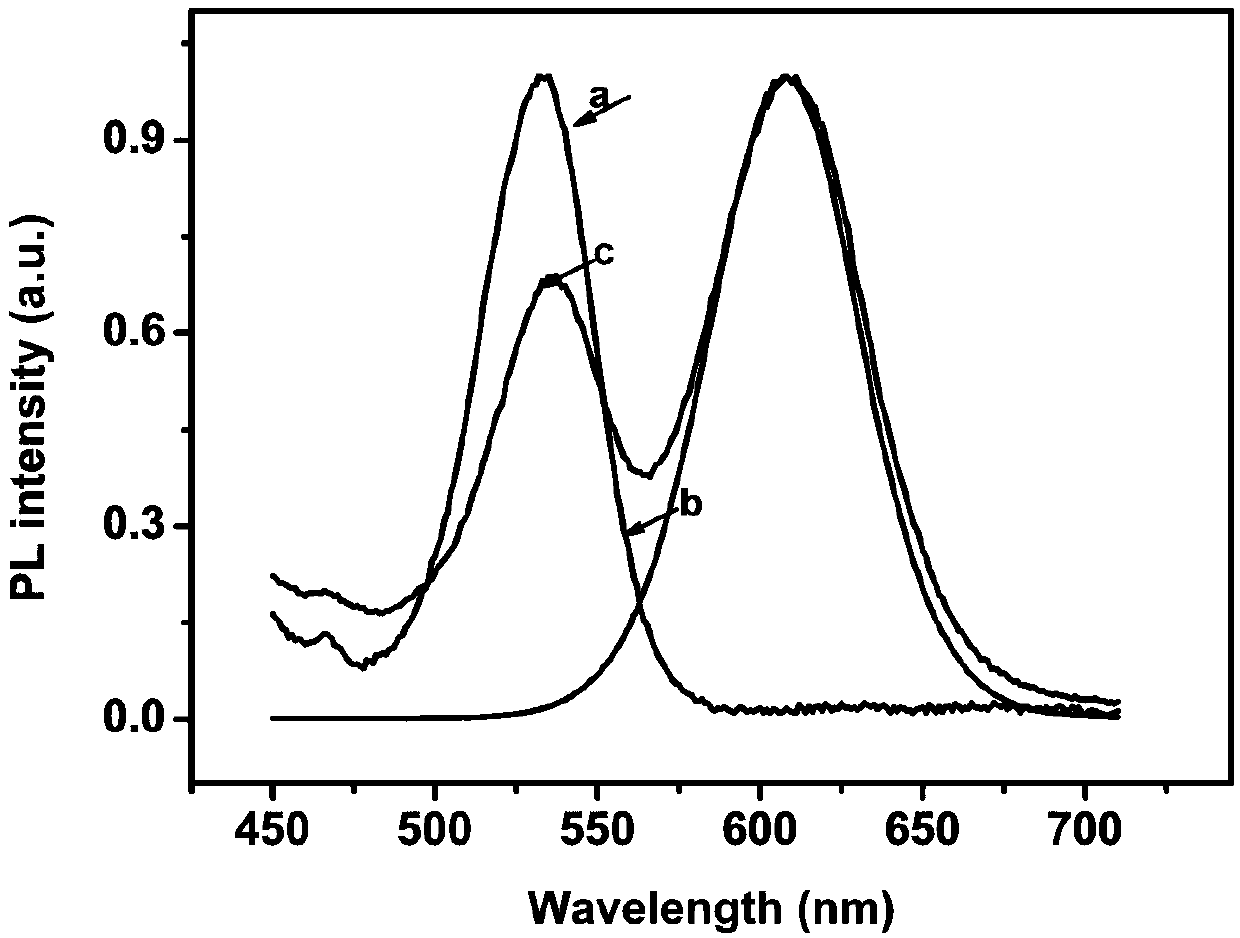

Ratiometric fluorescent probe and preparation thereof, and application of ratiometric fluorescent probe in detection of glutathione

InactiveCN107603593AThe synthesis method is simpleShort timeMaterial nanotechnologyNanoopticsSilica nanoparticlesMicrosphere

The invention discloses a ratiometric fluorescent probe and a preparation thereof, and an application of the ratiometric fluorescent probe in detection of glutathione. The ratiometric fluorescent probe is prepared through the following steps: with green quantum dots as cores, carrying out embedding in silica nanoparticles, then subjecting the surface of the silica nanoparticles to amination modification, and covalently coupling red quantum dots onto the amination modified surface of the silica nanoparticles so as to obtain the ratiometric fluorescent probe, wherein the green quantum dots are cadmium telluride quantum dots modified by N-acetyl-L-cysteine. According to the invention, a St ber method is utilized to prepare quantum dot embedded silica nanoparticles, so the synthetic method issimple and has less time consumption. The probe provided by the invention has low detection limit and can realize specific detection during detection of GSH; meanwhile, the probe has advantages like simple preparation and good stability, reduces the detection limit of glutathione to 45 nM, and provides convenience for rapid visual detection.

Owner:ZHEJIANG UNIV OF TECH

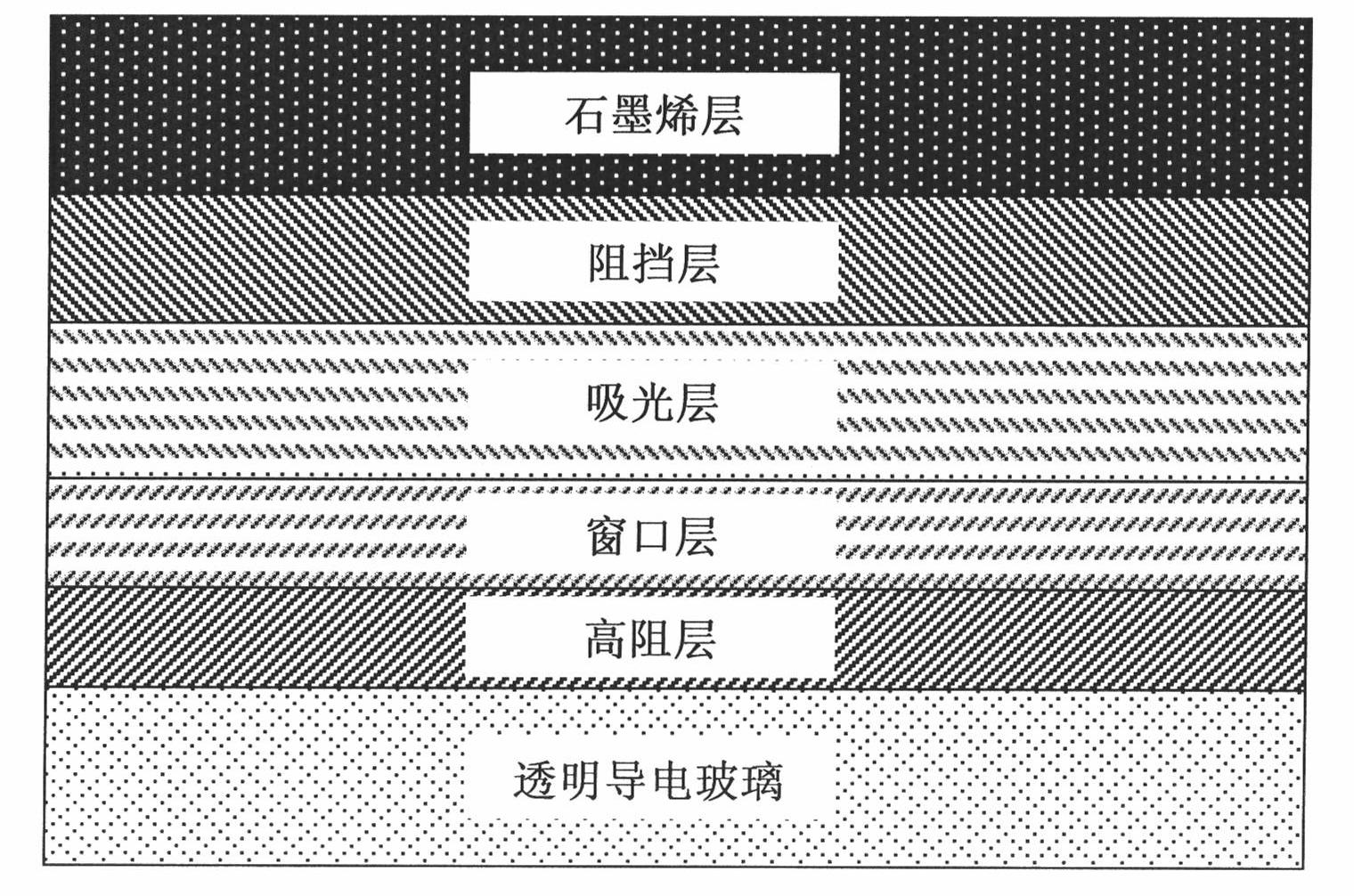

Back contact electrode in cadmium telluride membrane solar cell structure and preparation method thereof

ActiveCN102074590AContinuously adjustable carrier concentrationFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention relates to a back contact electrode in a CdTe membrane solar cell structure. The electrode comprises a transparent conductive glass layer, a window layer, a light absorbing layer and a blocking layer and is characterized in that: a graphene membrane layer serving as the back contact electrode is prepared on the back face of an anti-insertion layer; and the thickness of the graphene layer is between 0.1 mu m and 1 millimeter. A preparation method of the back contact electrode comprises preparation of the transparent conductive glass layer, preparation of the window layer, preparation of the light absorbing layer and preparation of the blocking layer and is characterized by comprising the following steps of: adding an adhesive into graphene so as to prepare graphene slurry; and preparing the graphene slurry into a graphene layer. The back contact electrode and the preparation method have the advantages that: a process adopted by the preparation method is compatible with the conventional CdTe cell process, and a new measure for realizing a low-cost, high-performance and large-scale CdTe cell is provided.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Improving back-contact performance of group VI containing solar cells by utilizing a nanoscale interfacial layer

InactiveUS8309387B2Improve efficiencyContact stabilityFinal product manufactureSemiconductor/solid-state device manufacturingElectricityCadmium fluoride

Owner:FOREHAND DAVID

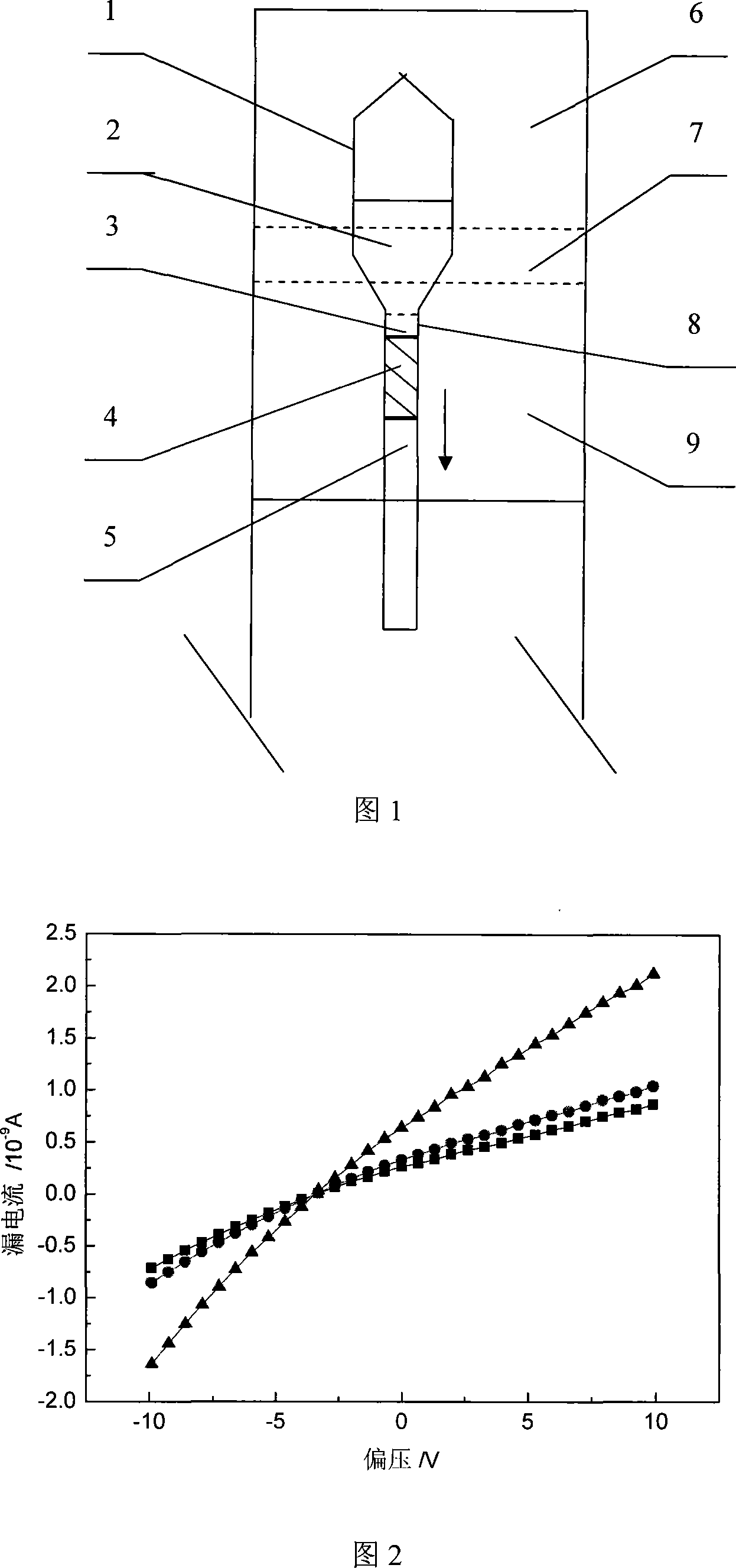

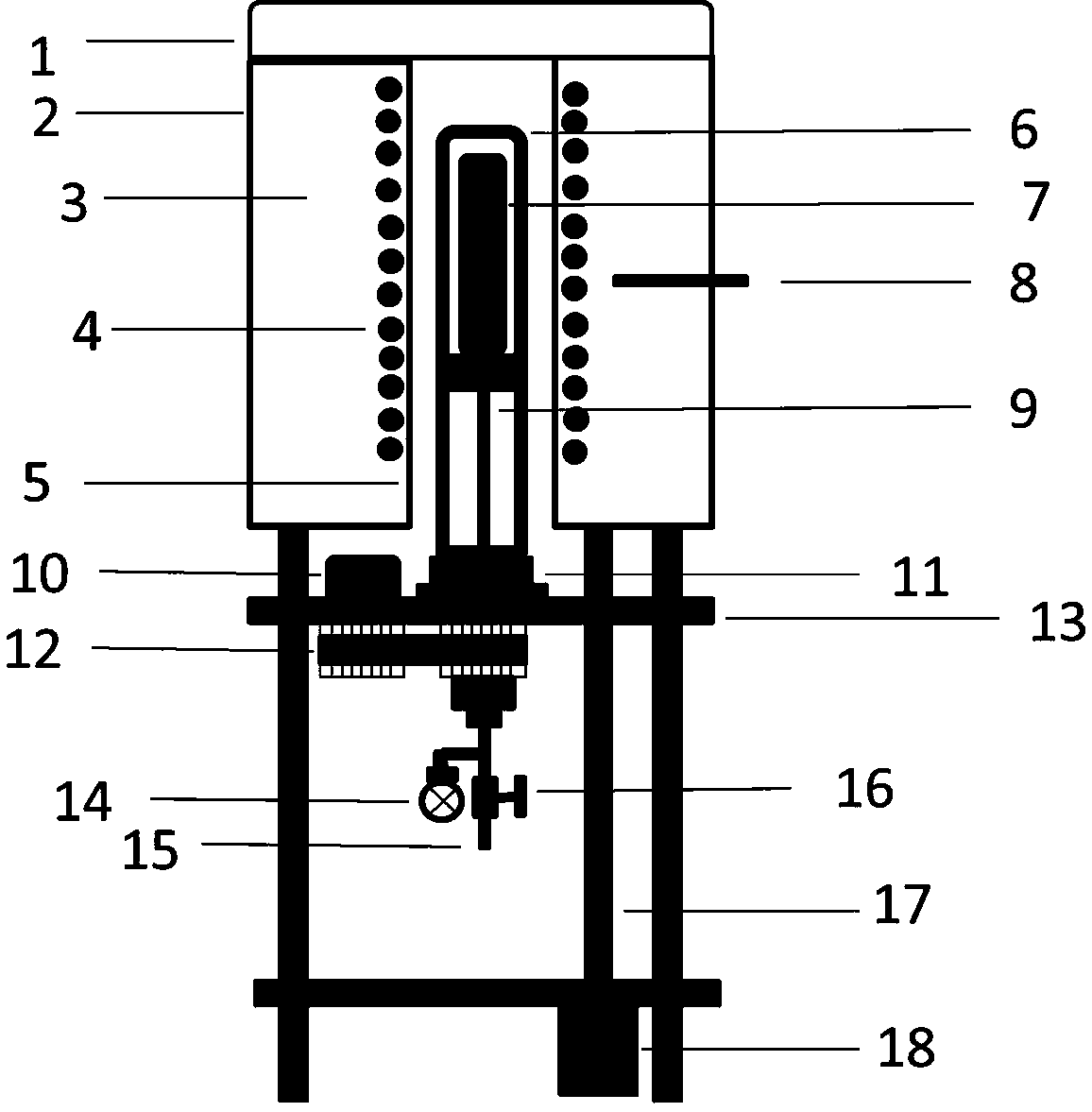

Device and method capable of increasing synthesizing stability of cadmium zinc telluride polycrystals

ActiveCN107904662AReduce pressure difference between inside and outsideAvoid explosive situationsPolycrystalline material growthSingle crystal growth detailsShielding gasCadmium zinc telluride

The invention discloses a device and method capable of increasing the synthesizing stability of cadmium zinc telluride polycrystals and aims to solve the problem that quartz tube explosion occurs easily during the synthesizing of cadmium zinc telluride, and the tube cracking accident is caused. The device and method is characterized in that protective gas is filled into a pressure-maintaining inner container, the internal and external pressure difference of a quartz crucible is balanced or lowered by regulating the gas filling pressure in the pressure-maintaining inner container, raw materialreaction rate is controlled by crystal material distribution, temperature gradient setting or furnace tube ascending and descending, and crystal growth is performed through the temperature gradient setting and the furnace tube ascending and descending. The device and method has the advantages that crucible explosion can be avoided effectively, reaction conditions are mild, phenomena such as tube cracking are avoided effectively, corresponding preparation requirements can be satisfied, and the device and method is promising in application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

CdTe solar cell manufacturing method capable of reducing defect density

InactiveCN106252432AReduce defect densityImprove performanceFinal product manufacturePhotovoltaic energy generationCadmium zinc tellurideThermal treatment

The invention discloses a CdTe solar cell manufacturing method capable of reducing defect density. The method comprises the following steps: (A) a substrate is provided; (B) a transparent conductive oxide thin film is deposited on the substrate; (C) a window layer CdS thin film is deposited; (D) an absorption layer CdTe thin film is deposited on the CdS thin film; (E) a CdCl2 solution is sprayed on the surface of the CdTe thin film, and then thermal treatment is carried out; (F) a solution containing nitric acid is used for etching the CdTe thin film after thermal treatment; and (G) PECVD plasma treatment is carried out on the etched CdTe thin film to passivate defects. According to the method of the invention, during the CdTe solar cell manufacturing process, plasma treatment is introduced to passivate the defects, the defect density of the CdTe thin film is effectively reduced, the material performance is improved, the photoelectric conversion efficiency of the CdTe thin film solar cell is further improved, and the cell performance is improved.

Owner:ZHONGSHAN RUIKE NEW ENERGY CO LTD

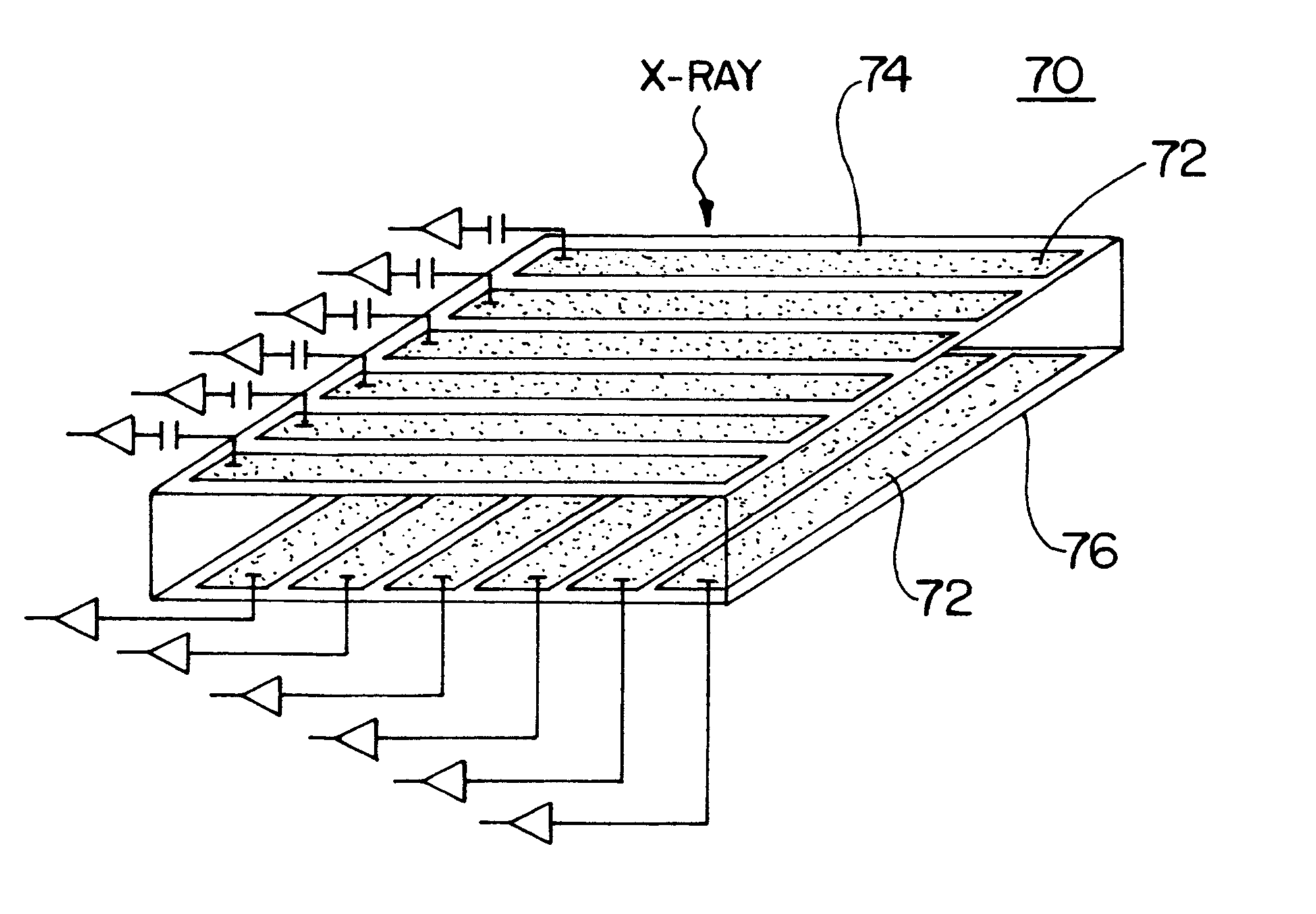

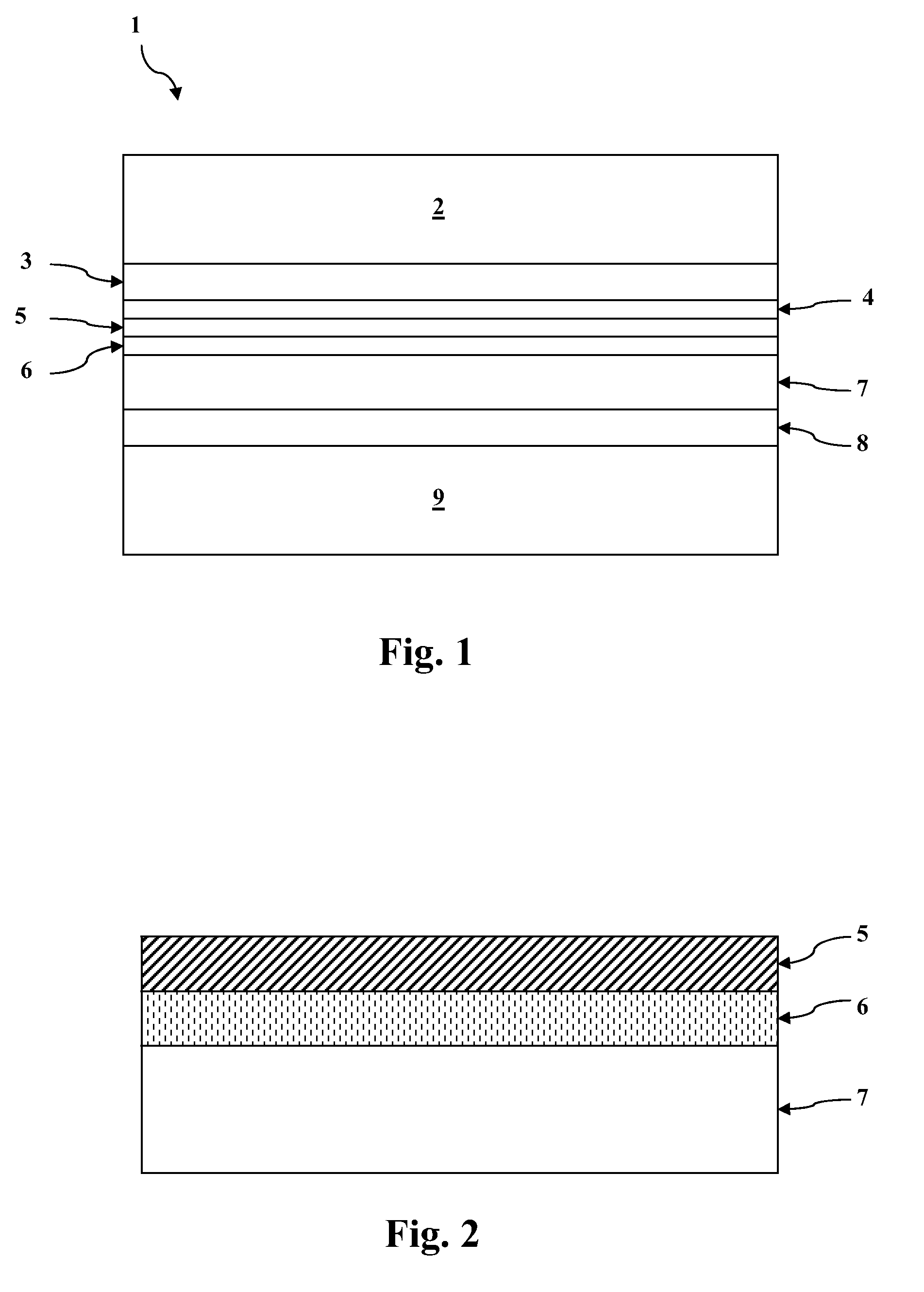

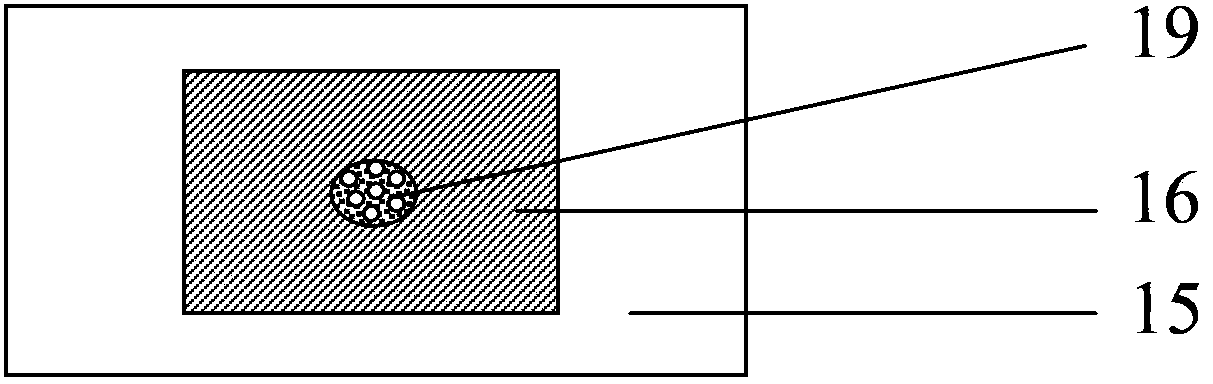

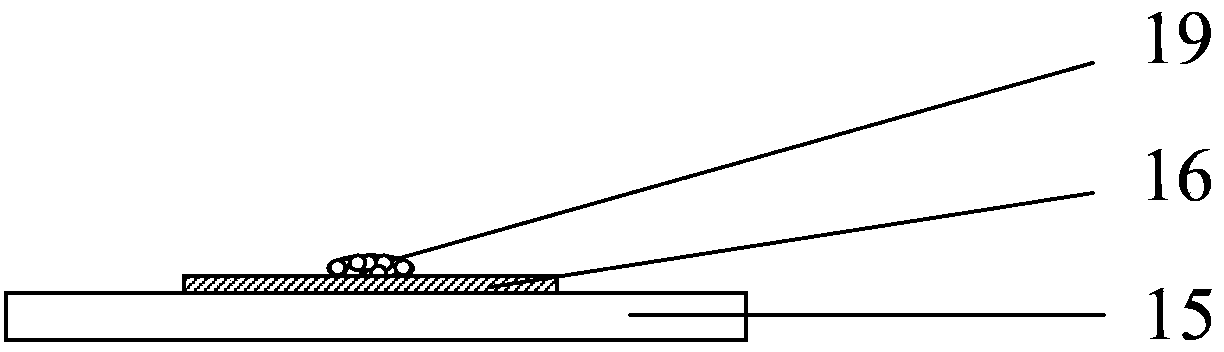

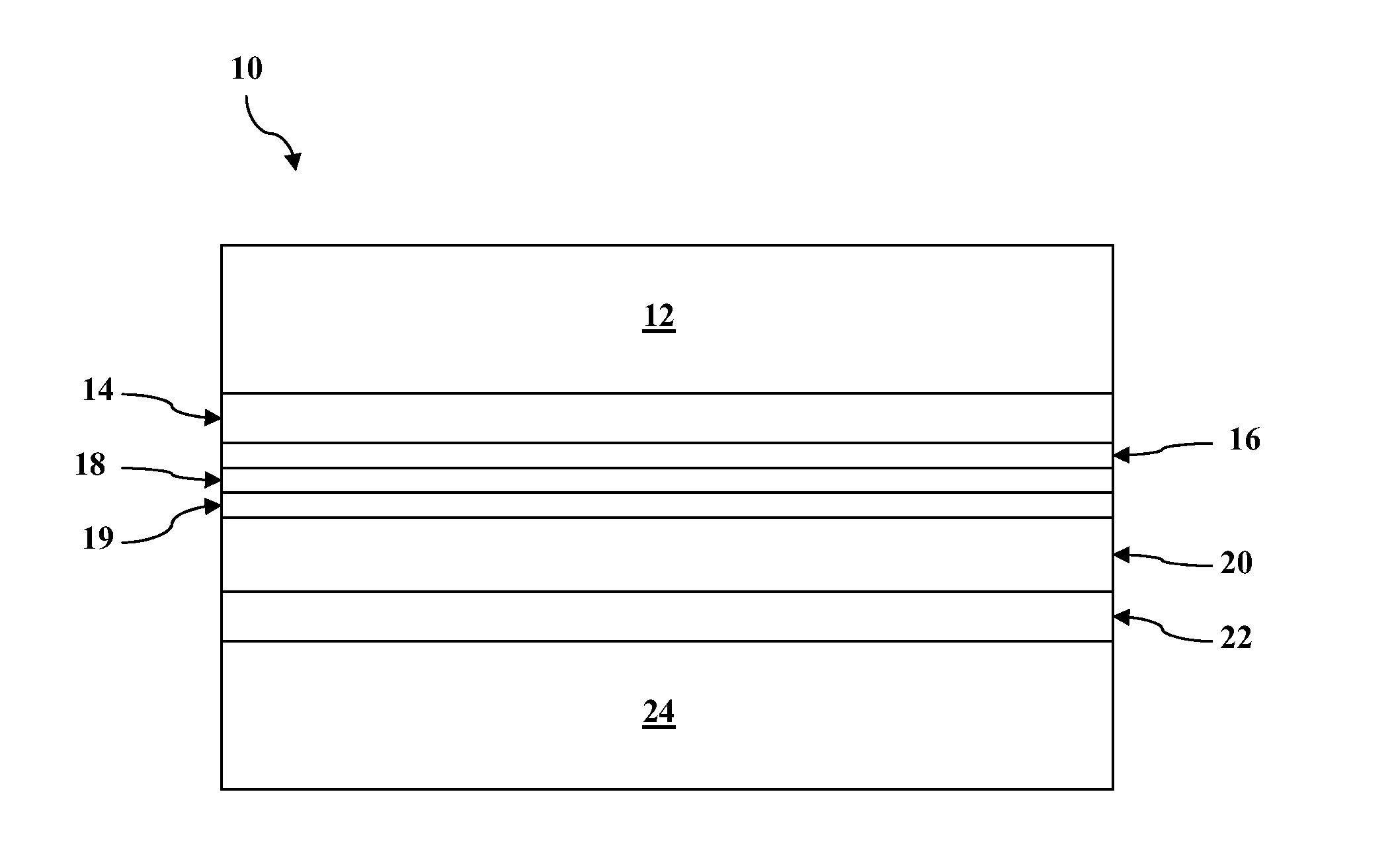

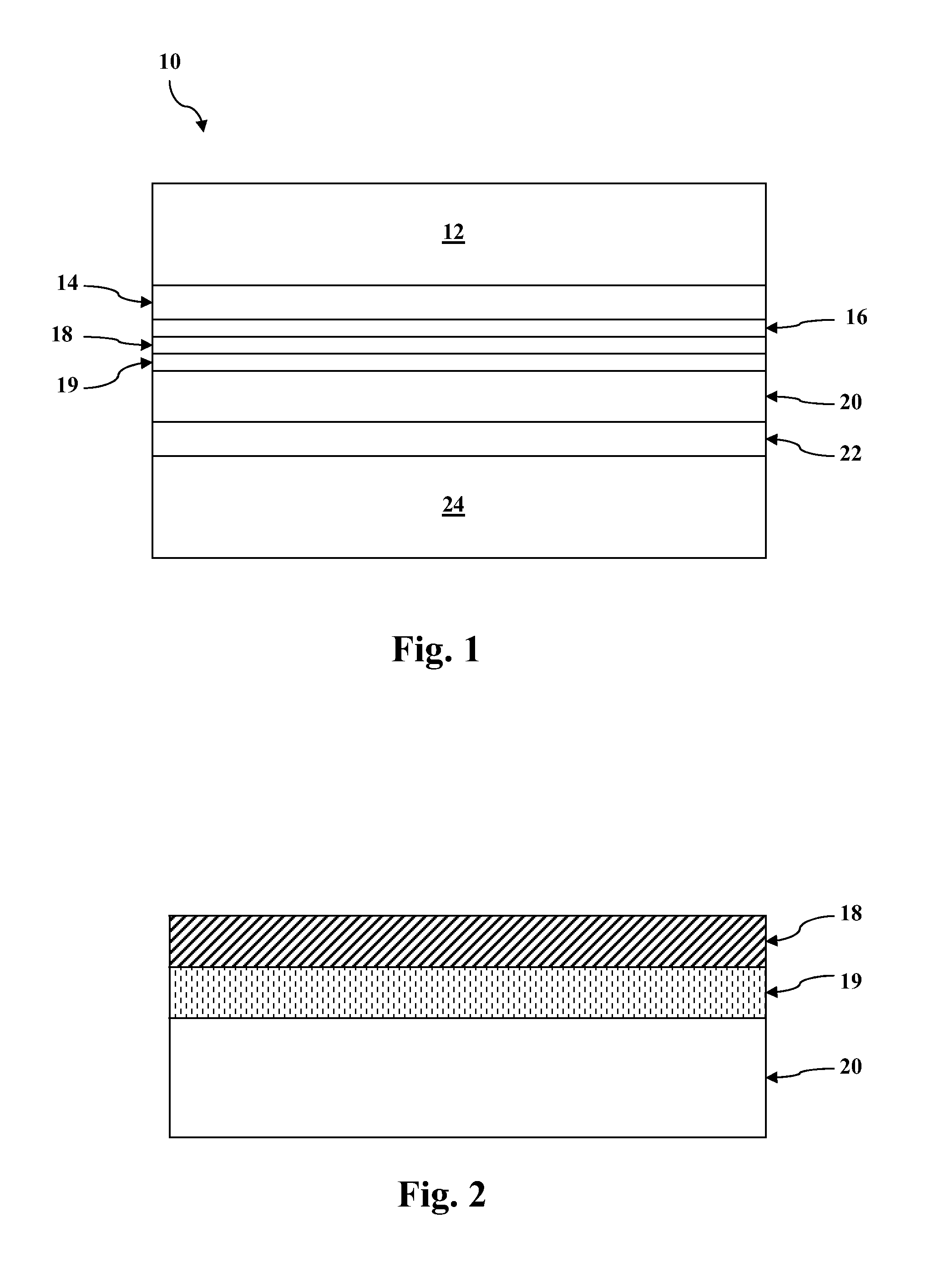

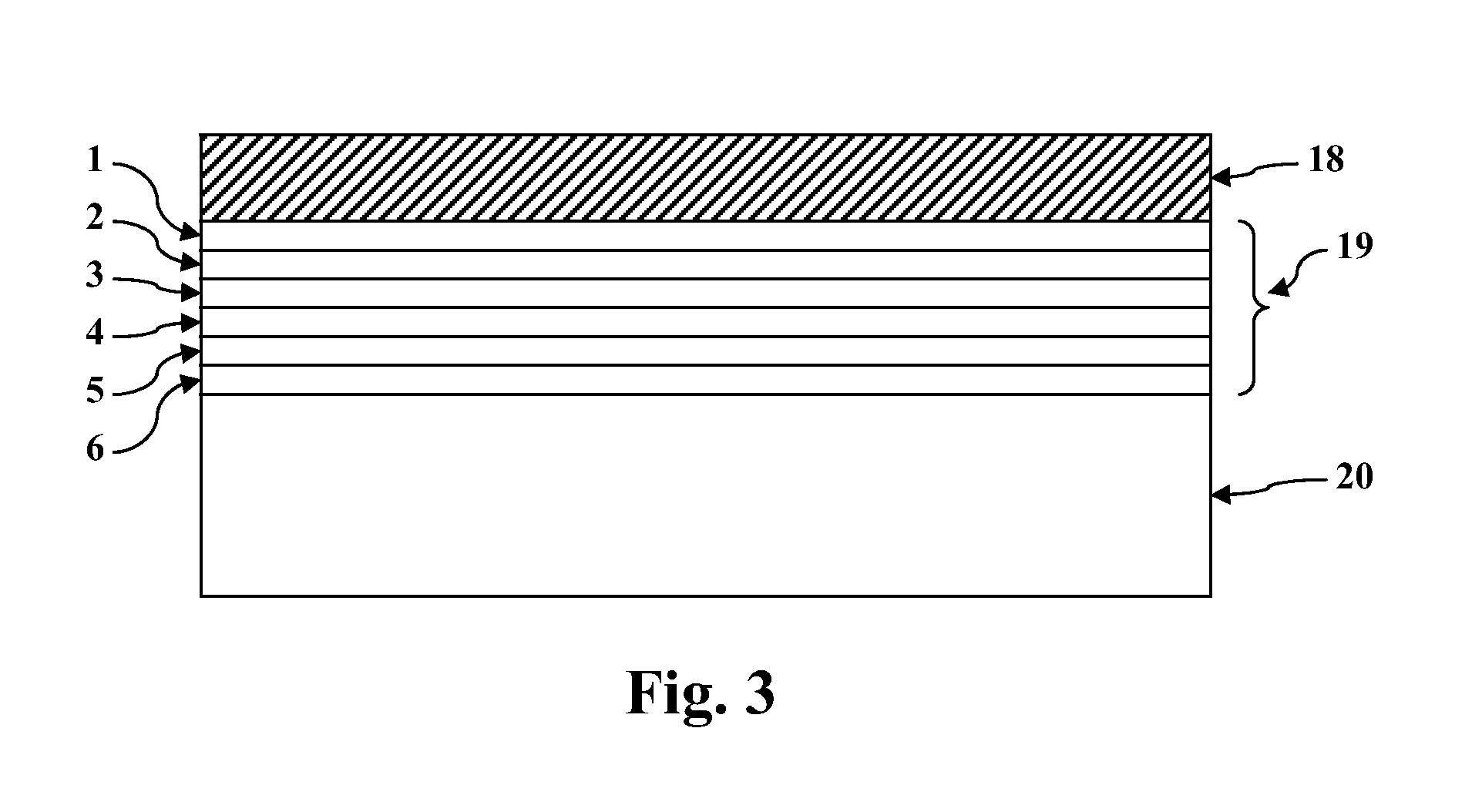

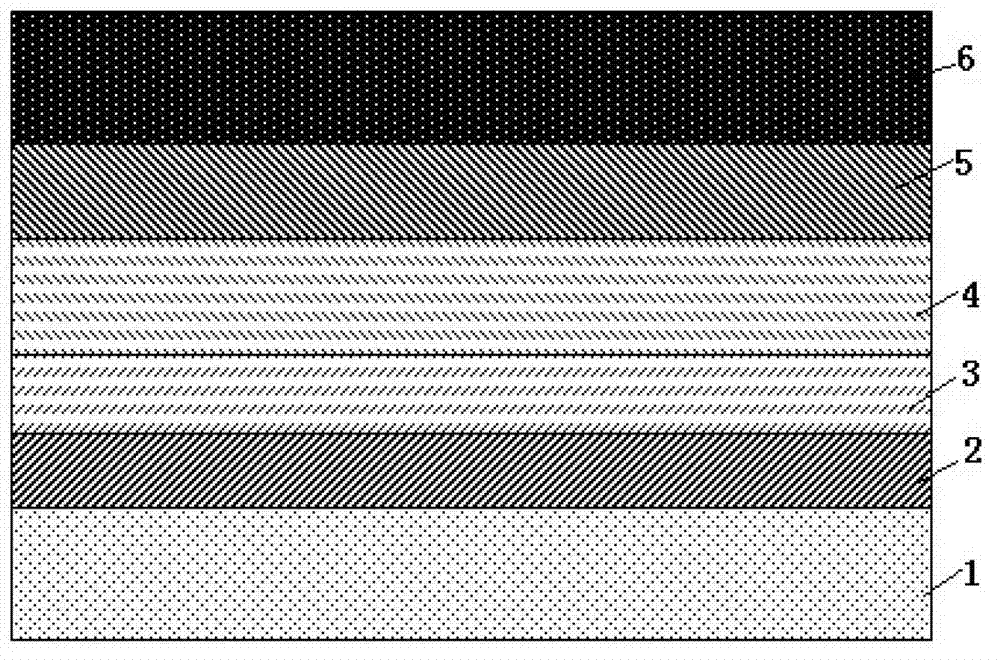

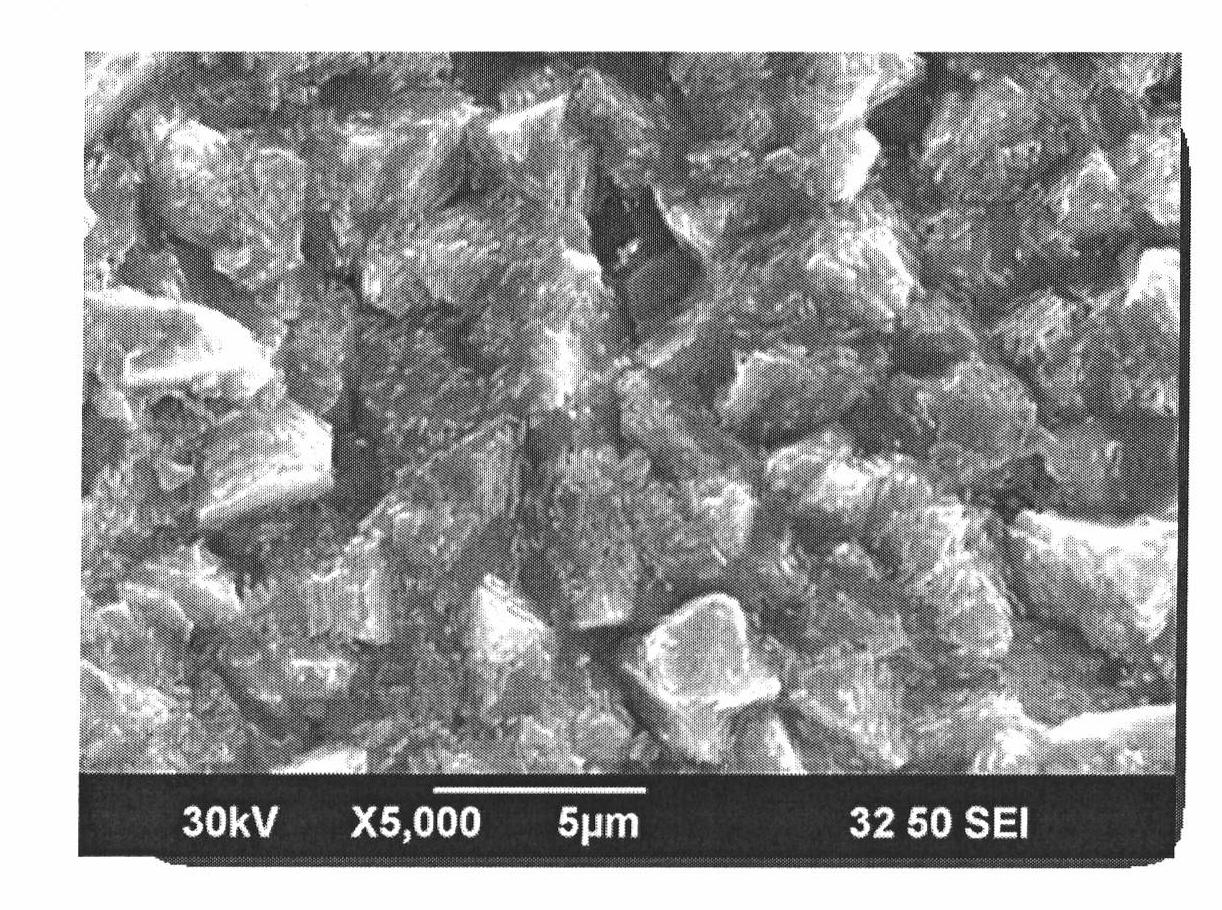

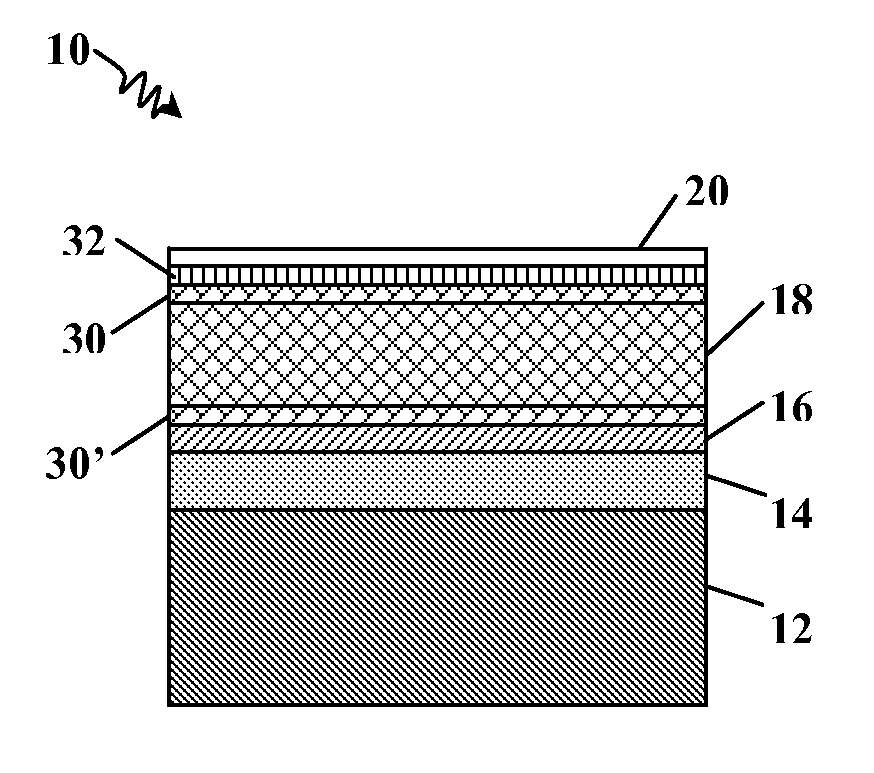

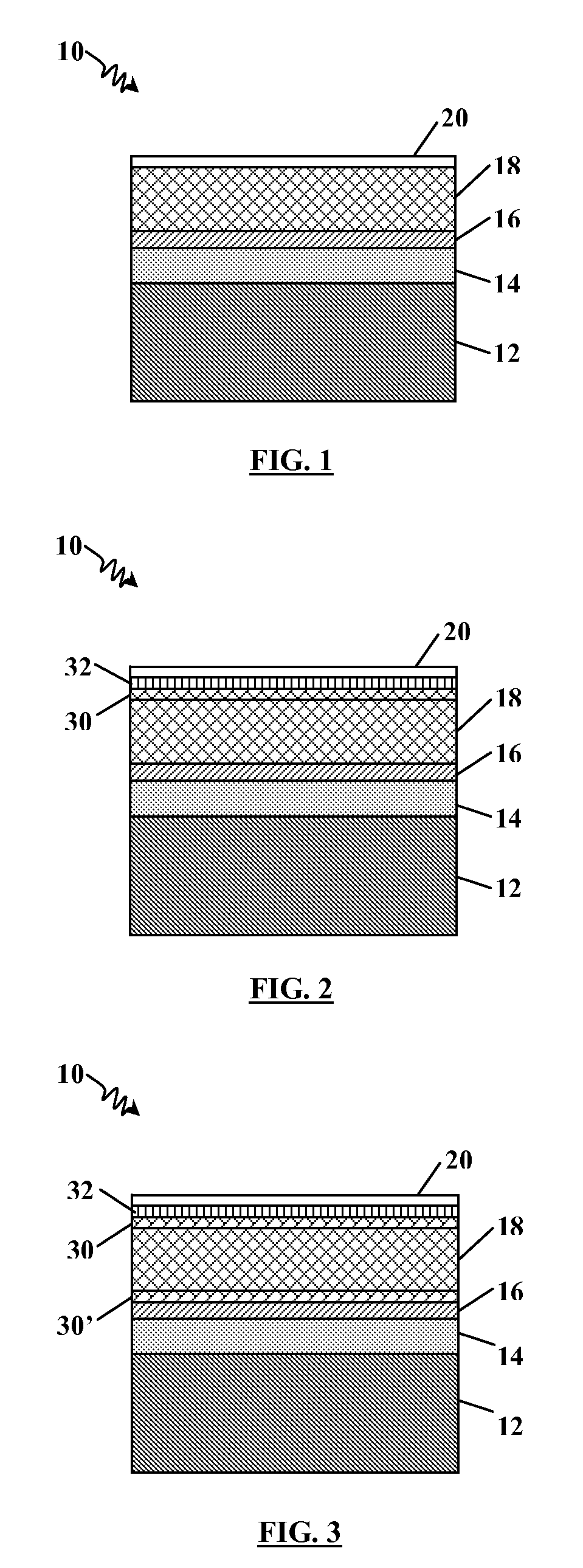

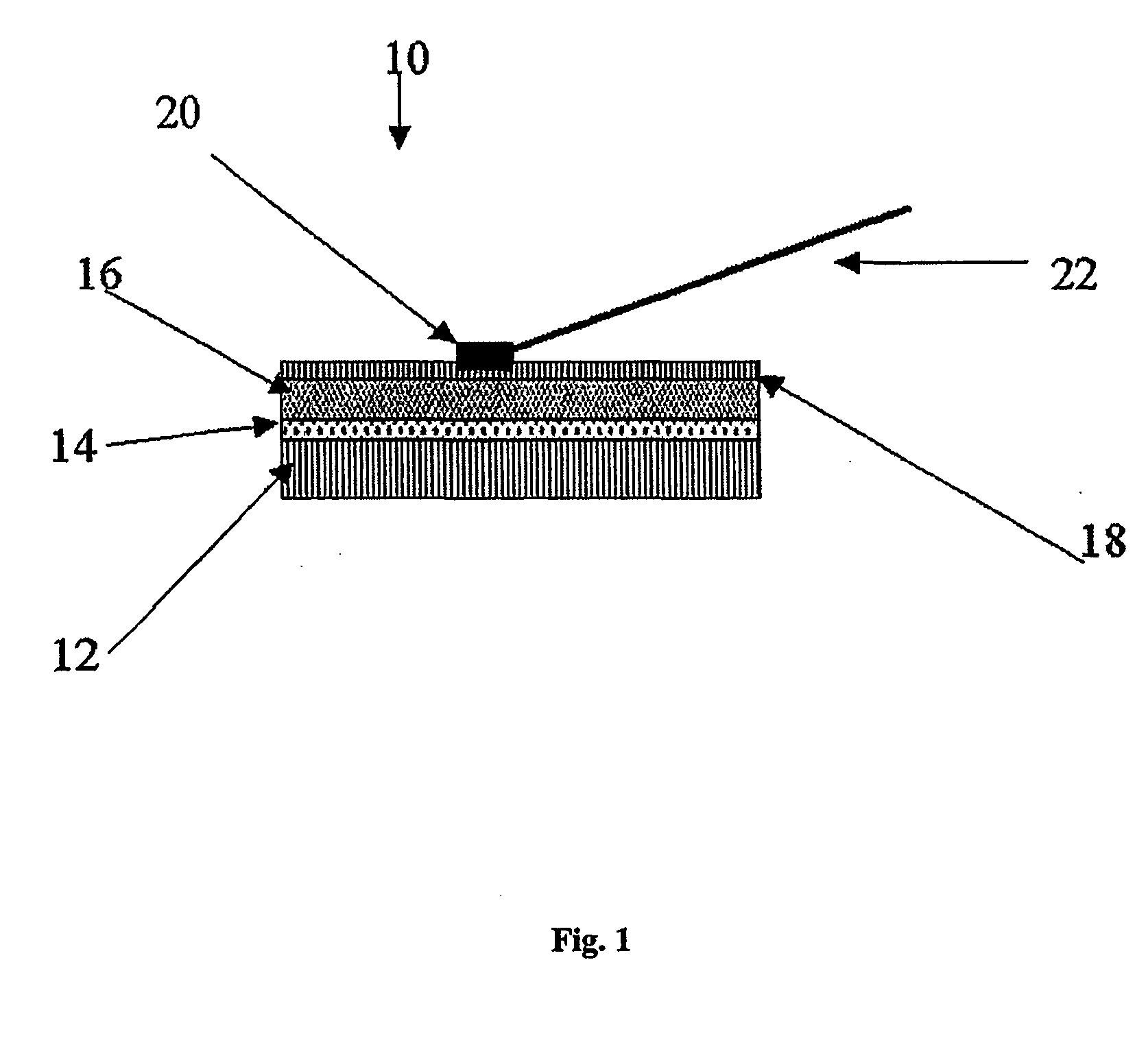

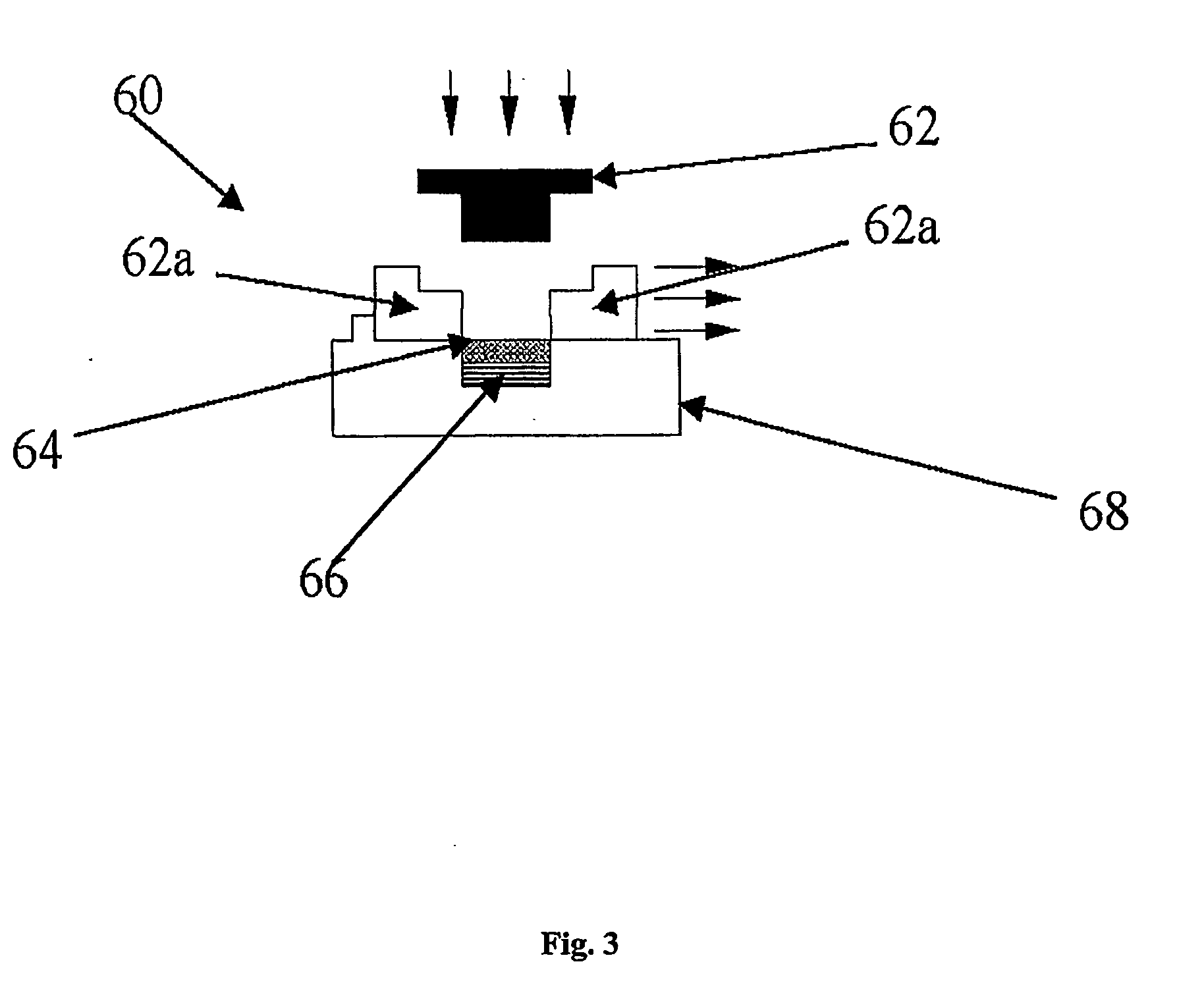

Wide band gap semiconductor composite detector plates for x-ray digital radiography

InactiveUS20050118527A1Direct signal conversionHigh sensitivitySolid-state devicesPhotomechanical apparatusParticulatesX-ray

An imaging composition for radiation detection systems which includes an admixture of at least one non-heat treated, non-ground particulate semiconductor with a polymeric binder. The non-heat treated, non-ground particulate semiconductor is selected from mercuric iodide, lead iodide, bismuth iodide, thallium bromide and cadmium-zinc-telluride (CZT), and at least 90% of the semiconductor particulates have a grain size of less than 100 microns in their largest dimension. A radiation detector plate (10) for an imaging system includes a substrate (12) which serves as an electrode, at least one imaging composition layer (16) applied onto the substrate (12), and a second electrode (18) which is in electrical connection with the imaging composition (16) and connected (20, 22) to a high voltage bias.

Owner:REAL TIME RADIOGRAPHY

Substrate material for mercury cadmium telluride material growth by liquid phase epitaxy method and preparation thereof

InactiveCN101348941AImprove lattice qualityQuality improvementPolycrystalline material growthLiquid-phase epitaxial-layer growthMaterial growthProcess equipment

The invention relates to a substrate material used for the growth of a mercury cadmium telluride material by a liquid phase epitaxy method. On the basis of the prior substrate material, a layer of cadmium zinc telluride single-crystal film completely matched with the lattice constant of mercury cadmium telluride is grown. The substrate material of the invention has the advantages that an epitaxial film has high lattice quality, and compositions can be flexibly adjusted according to the lattice constants of short wave, medium wave and long wave mercury cadmium telluride materials; meanwhile, the cadmium zinc telluride film has even compositions; the method adopts mature process, and has the advantages of simpler process equipment, short process cycle and low cost; and the substrate material with large area, high quality and high composition evenness can be provided for an infrared focal plane detector.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

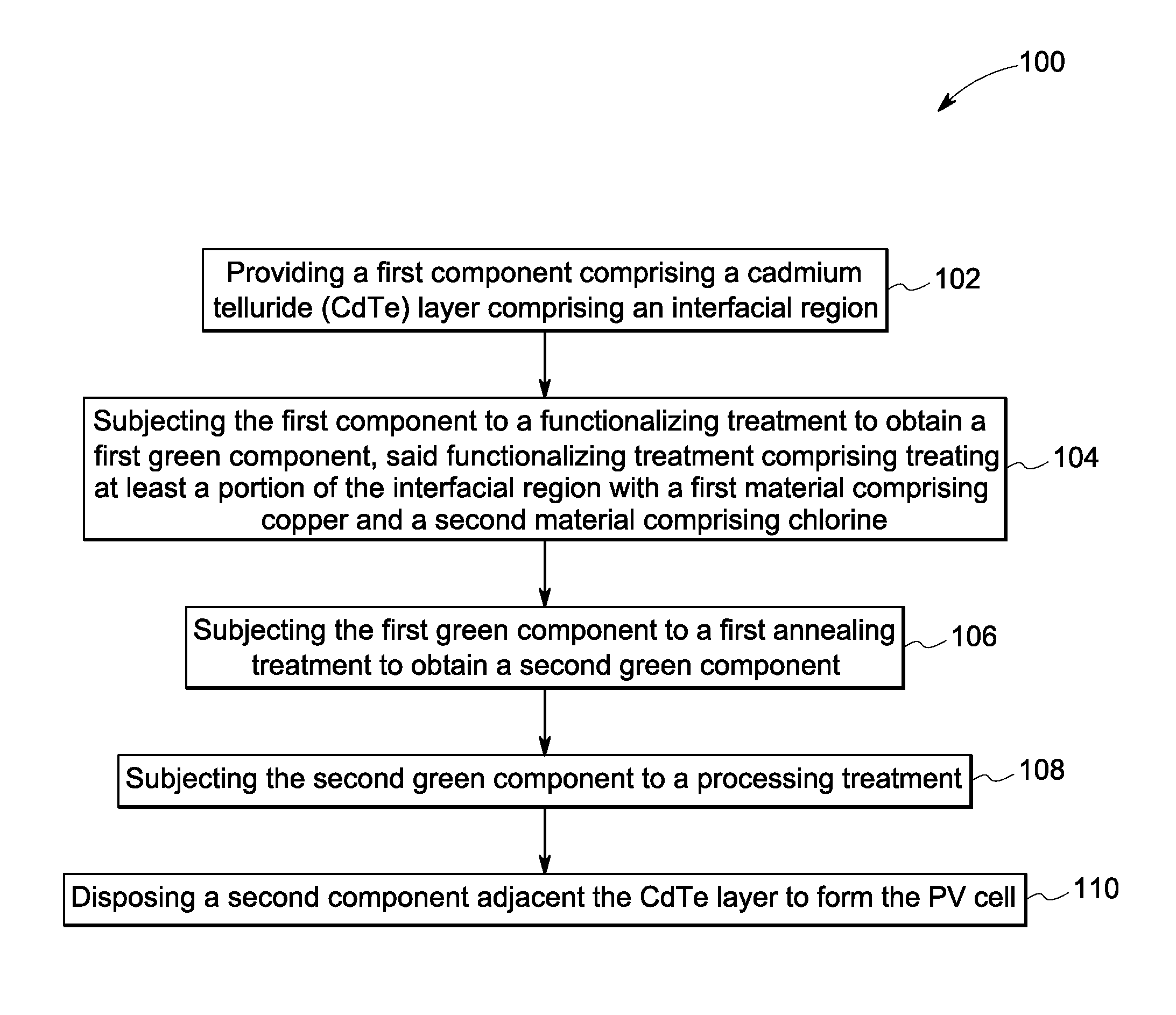

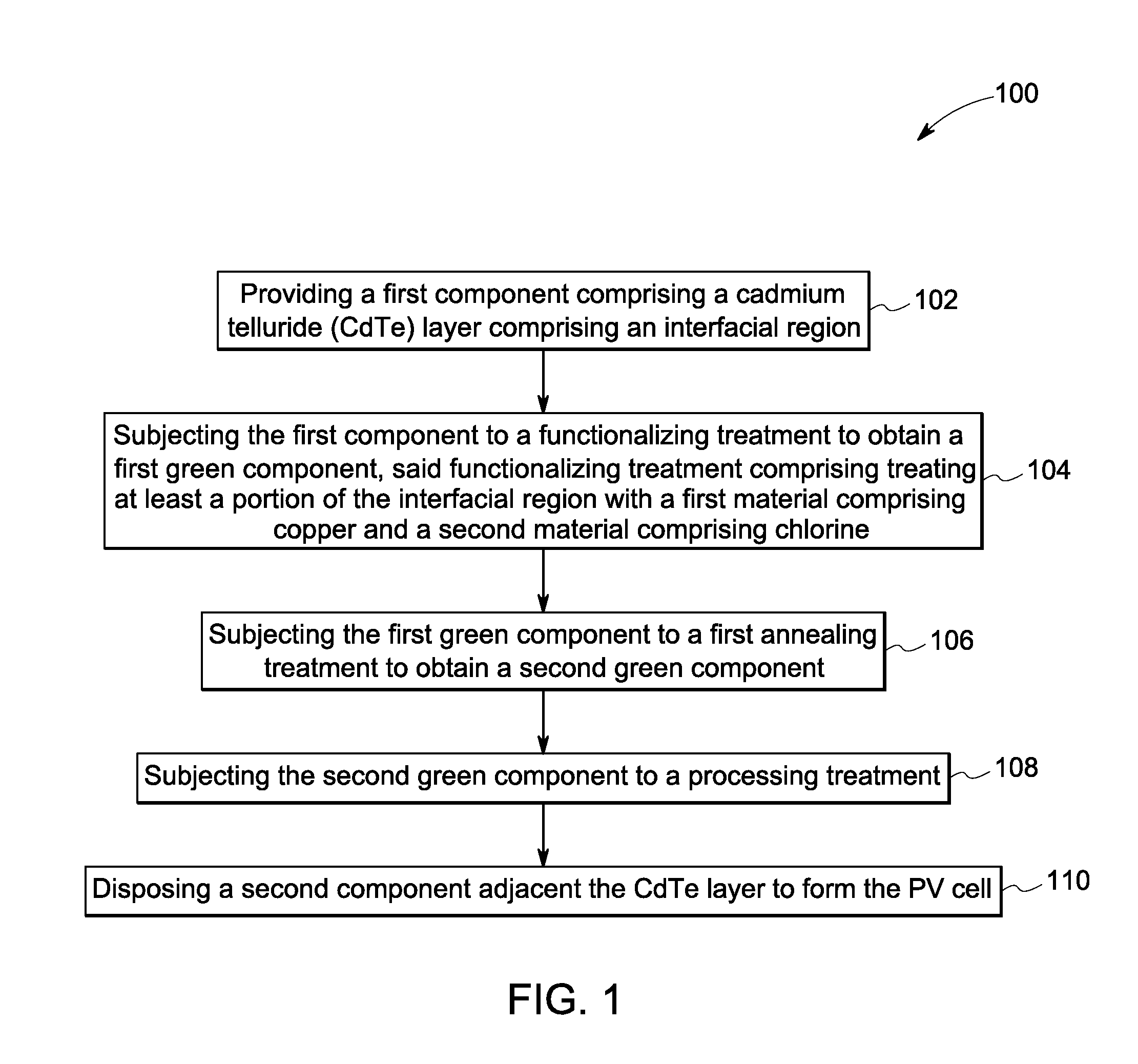

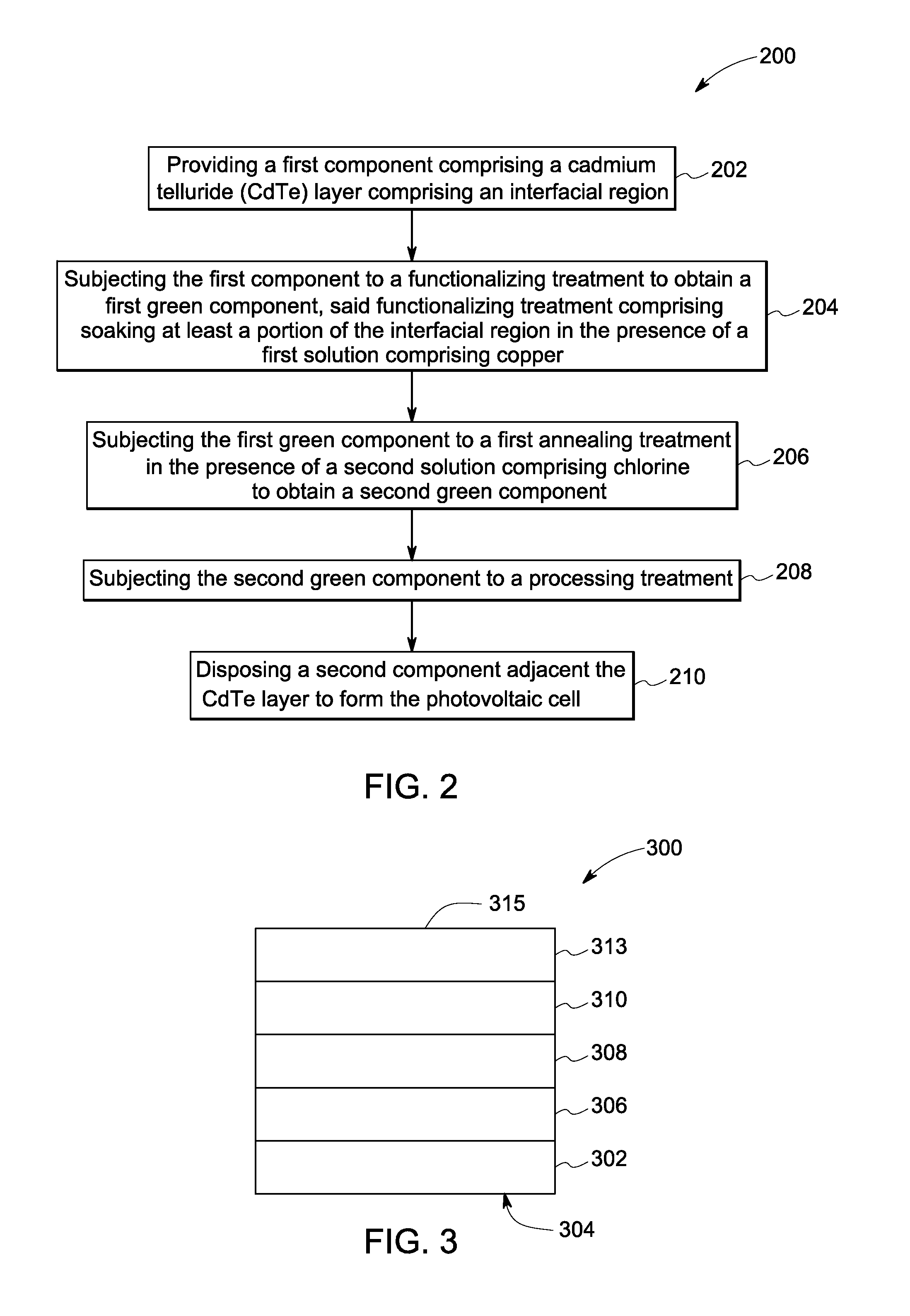

Method of p-type doping of cadmium telluride

InactiveUS8748214B2Final product manufactureSemiconductor/solid-state device manufacturingDopantHalogen

A method of p-type doping cadmium telluride (CdTe) is disclosed. The method comprising the steps of, (a) providing a first component comprising cadmium telluride (CdTe) comprising an interfacial region, and (b) subjecting the CdTe to a functionalizing treatment to obtain p-type doped CdTe, said functionalizing treatment comprising a thermal treatment of at least a portion of the interfacial region in the presence of a first material comprising a p-type dopant, and of a second material comprising a halogen. A method of making a photovoltaic cell is also disclosed.

Owner:FIRST SOLAR INC (US)

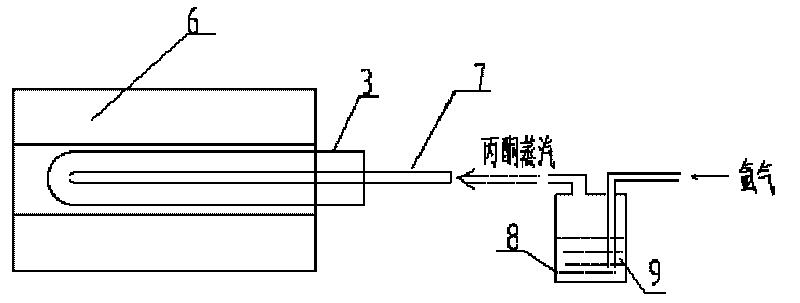

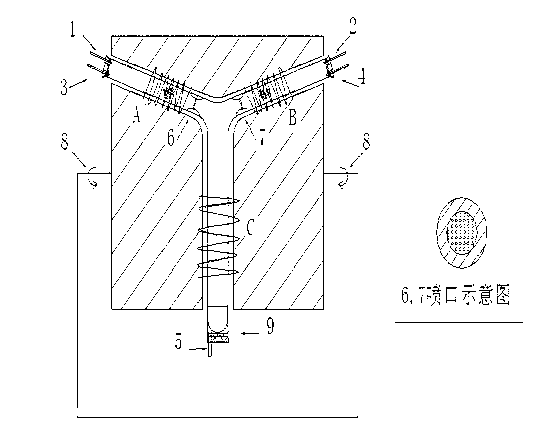

High-temperature liquid-phase synthesis method of cadmium telluride powder

ActiveCN102849693ASafe workmanshipEfficient process methodBinary selenium/tellurium compoundsBreatherSynthesis methods

The invention discloses a high-temperature liquid-phase synthesis method of cadmium telluride powder, which comprises the following steps: respectively containing cadmium blocks and tellurium blocks in the end A and the end B of a Y-shaped tube according to a mol ratio of 1:1; horizontally placing the Y-shaped quartz tube in an open / close type Y-shaped furnace chamber performing three-section heating; then vacuumizing the quartz tube to 1*10<-3>-1*10<-4> Pa; respectively heating the section A, the section B and the section C of the Y-shaped quartz tube to 350-400 DEG C, 480-600 DEG C and 600-1100 DEG C, and keeping the temperature until the test is finished; when the tellurium and the cadmium are molten into liquids, vertically arranging the open / close type furnace performing three-section heating through a bracket 8; then closing vacuum valves 1 and 2, opening breather valves 3 and 4 and a bleed valve 5, and introducing Ar gas of 0.01-1 MPa, so that the tellurium and cadmium liquids are respectively sprayed out from nozzles 6 and 7 and atomized, the high-purity cadmium telluride powder can be synthesized through the contact of the atomized tellurium and cadmium liquid drops, and the cadmium telluride powder scatters on the bottom of the end C of the Y-shaped quartz tube; and after the atomization process is finished, stopping heating, cooling to room temperature, opening an end cover 9 at the end C, and collecting the high-purity cadmium telluride powder.

Owner:SICHUAN UNIV

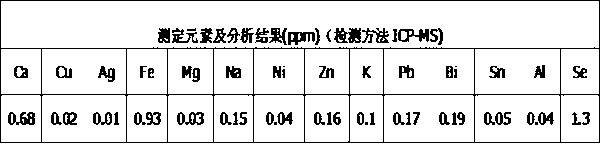

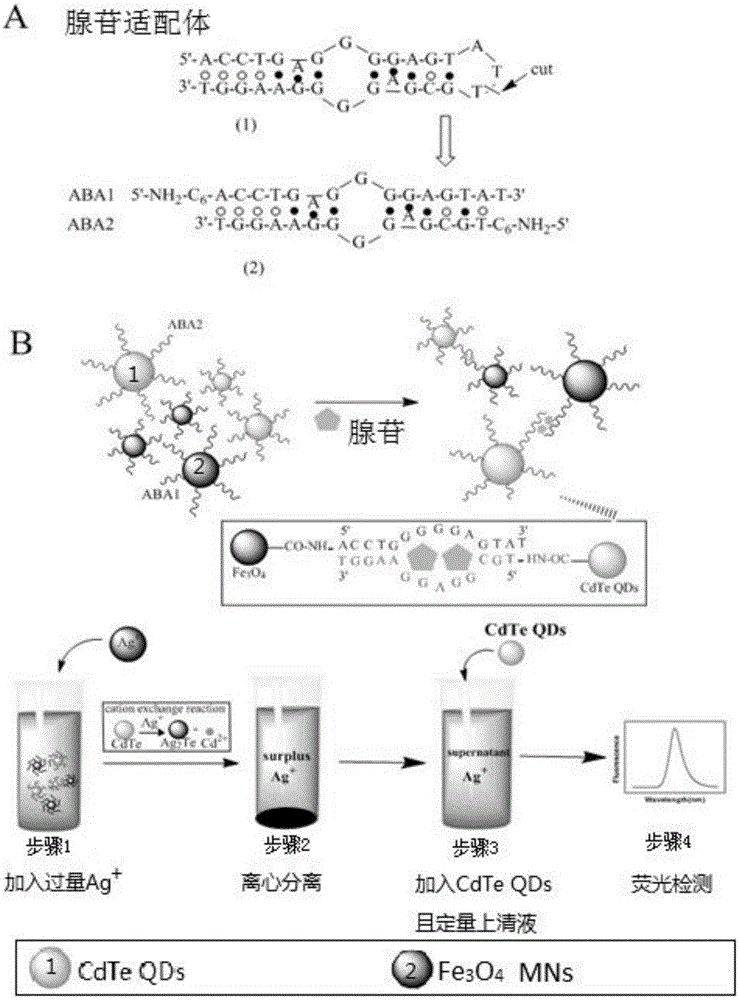

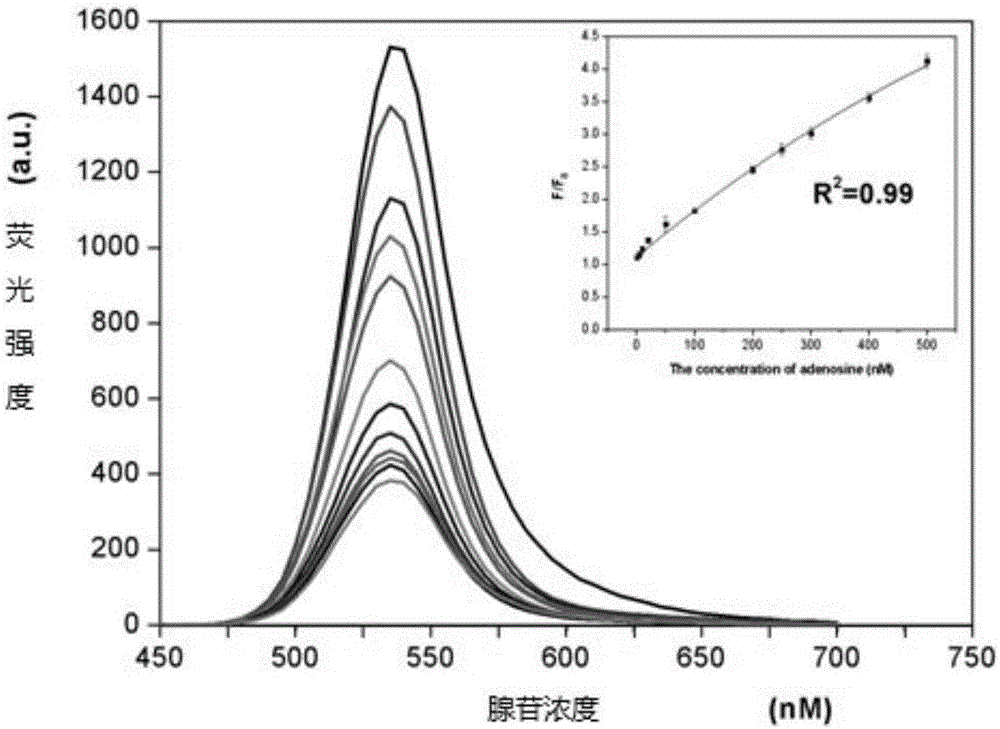

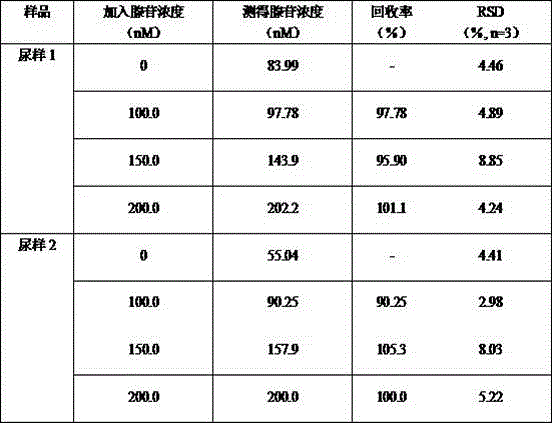

Detection method for content of adenosine in biological sample

InactiveCN105866082AWide linear rangeBiological testingFluorescence/phosphorescenceAdenosineIon exchange

The invention relates to a detection method for the content of adenosine in a biological sample. An adenosine probe is formed by mixing ferriferrous oxide magnetic nano-particles with surfaces modified by an adenosine aptamer segment 1 and cadmium telluride quantum dots with surfaces modified with an adenosine aptamer segment 2; the adenosine probe and the adenosine are paired by an alkali group to form an adenosine sandwiched structure, and the adenosine sandwiched structure is separated from the biological sample; the content of the adenosine is quantified by applying ion exchange effect of silver ions and cadmium ions in the cadmium telluride quantum dots in the adenosine sandwiched structure; the method has the characteristics of very high sensitivity, accuracy and precision.

Owner:NANJING MEDICAL UNIV

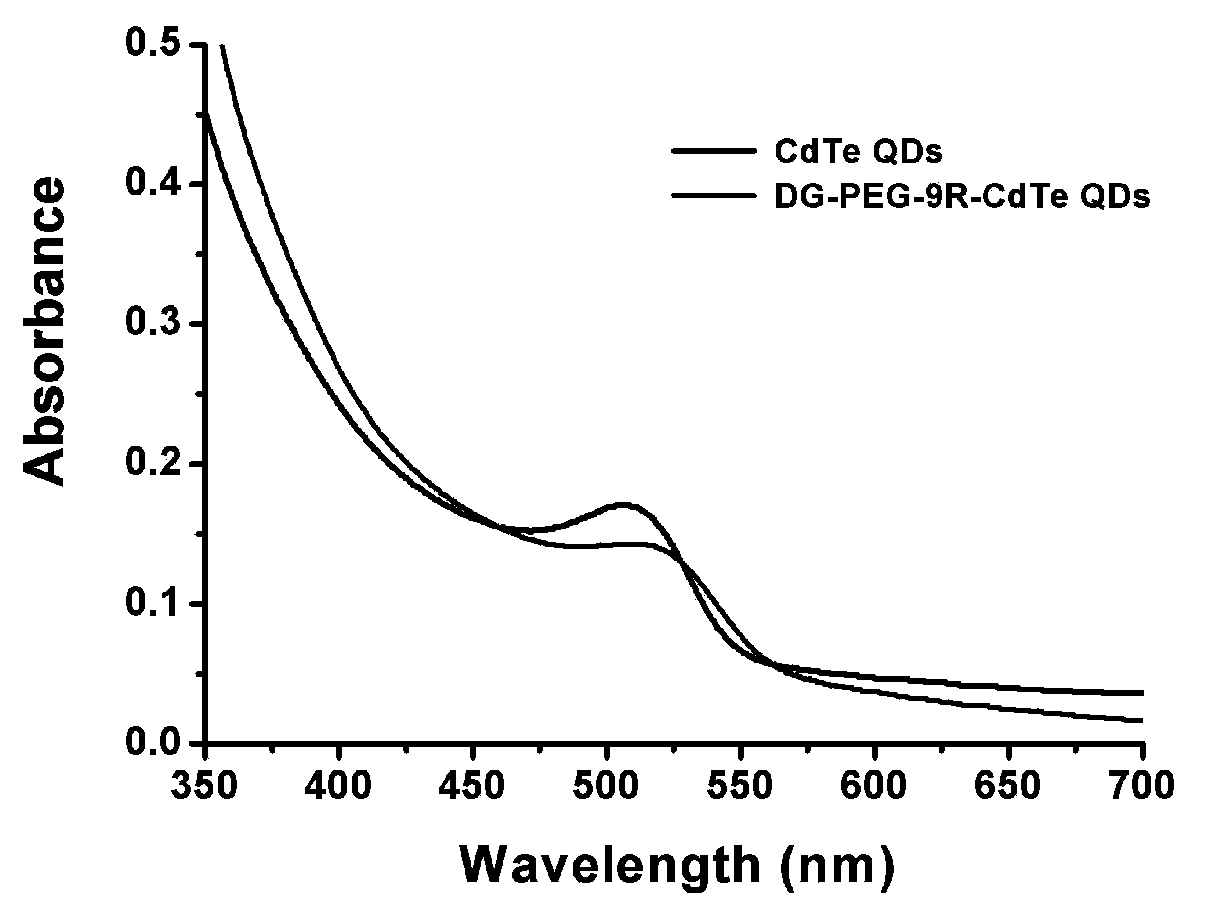

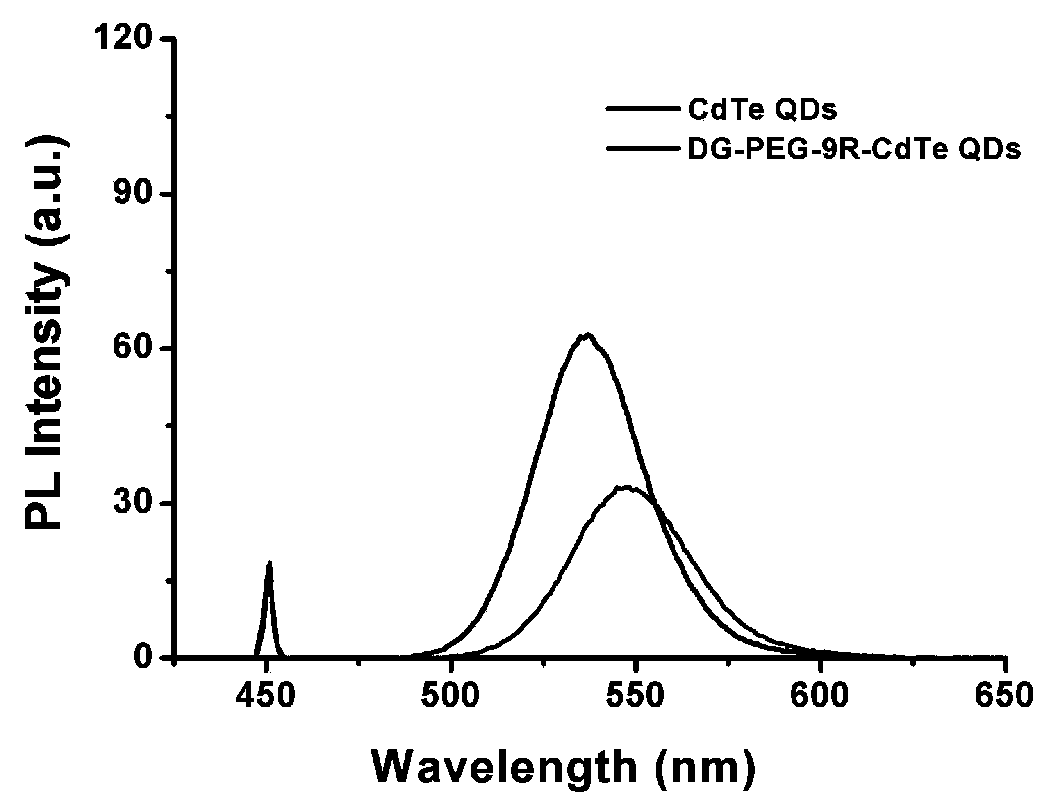

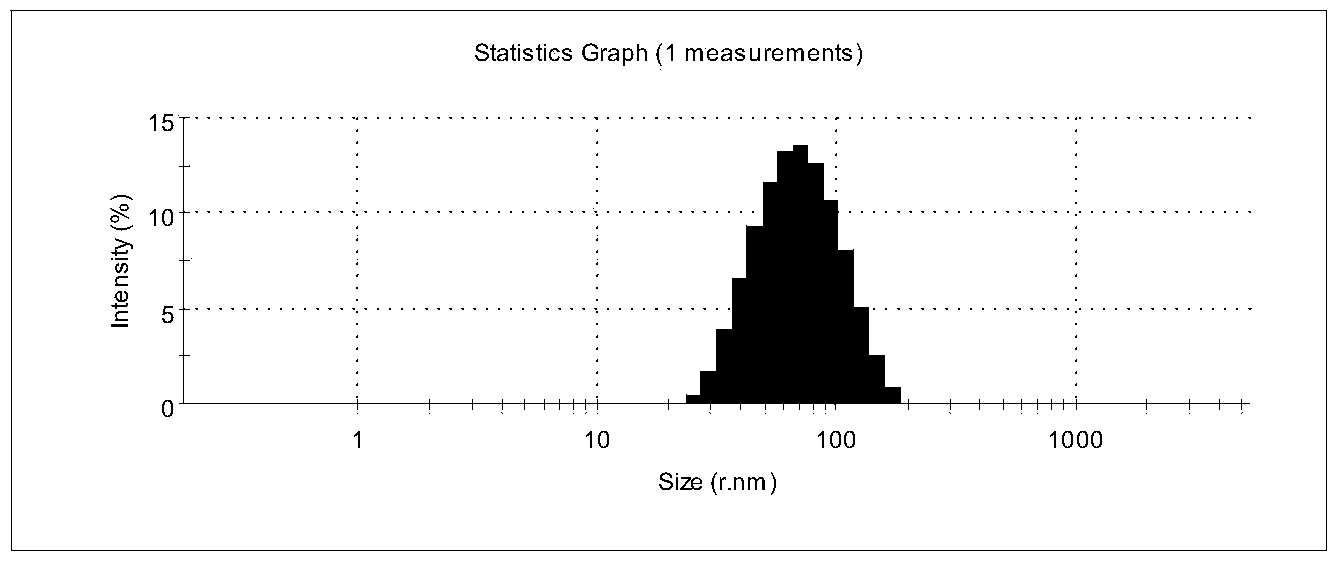

Preparation and application of quantum dot-based multifunctional nano siRNA (Small Interfering Ribonucleic Acid) carrier system

ActiveCN103830745ATargetedGood biocompatibilityGenetic material ingredientsPharmaceutical non-active ingredientsTumor targetQuantum yield

The invention relates to a preparation method and application of a multifunctional nano siRNA (Small Interfering Ribonucleic Acid) carrier system which integrates tumor targeting, pH sensitivity, visualization and the like. The core of the siRNA nano carrier system consists of cadmium telluride quantum dots. A nano carrier shell consists of a tumor targeted gene, a 9 poly-l-arginine peptide chain and PEG (Polyethylene Glycol). The siRNA nano carrier is good in biocompatibility, strong in tumor targeting and high in cell transfection efficiency, and has the characteristics of high quantum yield, strong optical stability, lossless in-position real-time monitoring and the like, so that the system is suitable for being used as a nano transmission system for in vivo gene therapy of tumors.

Owner:澎立生物医药技术(上海)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com