Cadmium telluride thin-film battery and manufacturing method thereof

A thin-film battery and cadmium telluride technology, which is applied in the manufacture of circuits, electrical components, and final products, etc., to achieve the effects of reducing optical distance, improving light absorption capacity, and good light trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

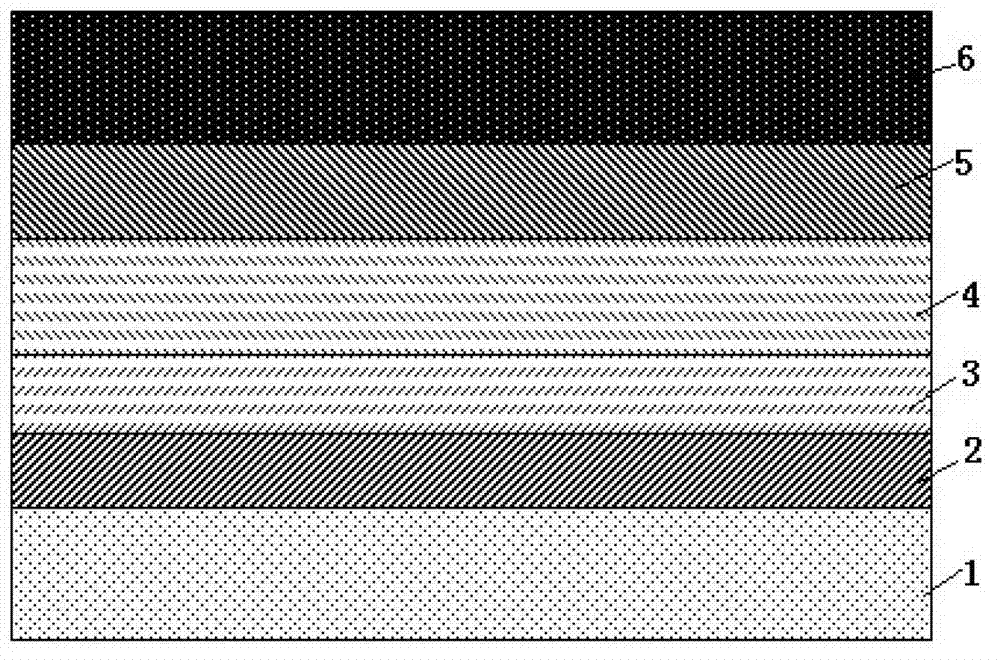

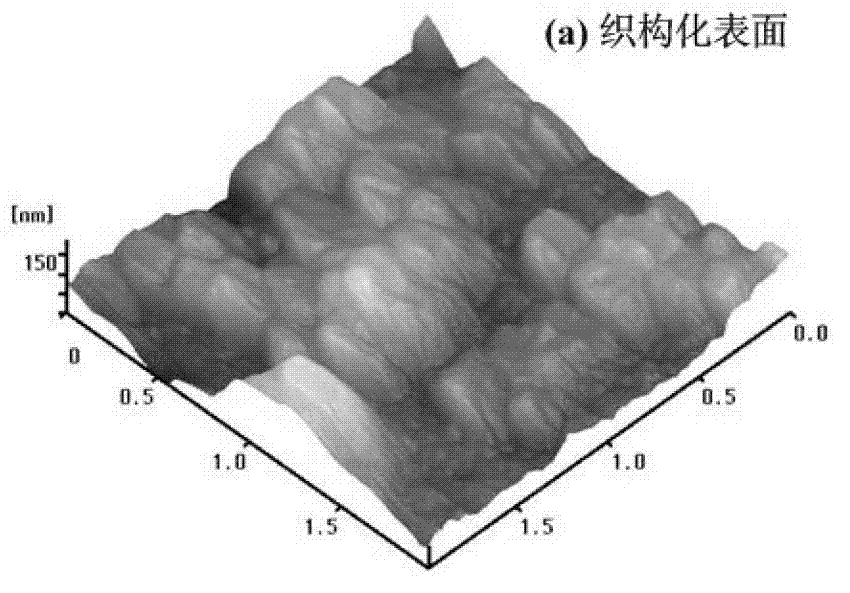

[0034] Such as figure 1 As shown, a cadmium telluride thin film battery includes: a substrate 1 and an epitaxial stack grown on the substrate 1 . The epitaxial stack is sequentially composed of a conductive layer 2 , a window layer 3 , a light absorbing layer 4 , a back barrier layer 5 and a back electrode 6 from bottom to top. The window layer 3 is a textured cadmium sulfide thin film layer, the light absorbing layer 4 is a cadmium telluride thin film layer, and the back barrier layer 5 is zinc telluride, copper-doped zinc telluride composite layer, mercury telluride and / or copper-doped mercury telluride Composite film layer. The back electrode 6 is one or more of graphite slurry or graphene slurry thin film layer or copper thin film layer, nickel thin film layer, copper-nickel alloy thin film layer, molybdenum thin film layer. A barrier layer can be selected between the substrate 1 and the conductive layer 2, the barrier layer is an indium oxide, aluminum oxide, tin oxide...

Embodiment 2

[0043] This embodiment is the same as Embodiment 1 except for the following features: the preparation process of the cadmium telluride thin film battery is as follows:

[0044] 1) Preparation of transparent conductive layer : Low-pressure chemical vapor deposition (LPCVD) is used to deposit fluorine-doped tin oxide (FTO) conductive glass. Among them, the substrate temperature is 400 o C, the reaction pressure is 3kPa, the reaction precursor is Tetramethyltin (TMT), Bromotrifluoromethane (CBrF 3 ) gas provides the source of F, and at the same time feeds oxygen (O 2 ) and nitrogen (N2), wherein nitrogen (N2) is used as a carrier gas; conductive layer The deposition thickness is about 500nm.

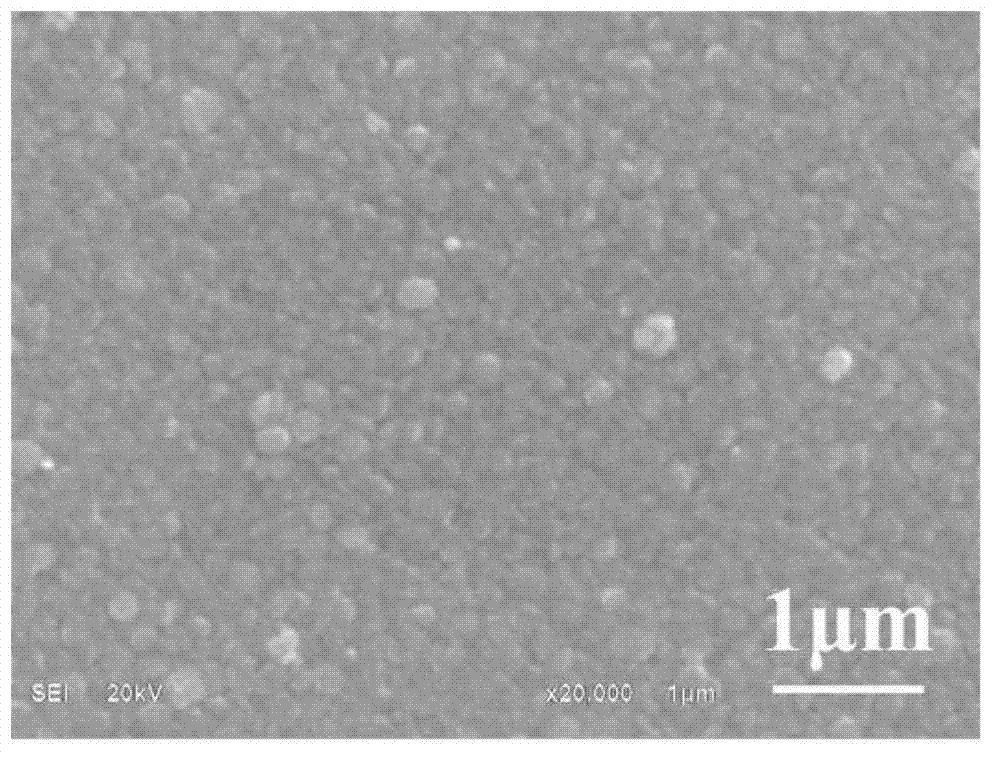

[0045] ) window layer preparation: Adopt chemical water bath method to prepare cadmium sulfide (CdS) layer, reactant is ammonium acetate, cadmium acetate, ammoniacal liquor and thiourea; Add deionized water in the airtight container again, heat to 80 o C, add cadmium acetate, ammon...

Embodiment 3

[0051] This embodiment is the same as Embodiment 1 except for the following features: the preparation process of the cadmium telluride thin film battery is as follows:

[0052] 1) Preparation of transparent conductive layer : Low-pressure chemical vapor deposition (LPCVD) is used to deposit fluorine-doped tin oxide (FTO); the substrate temperature is 400 o C, the reaction pressure is 3kPa, the reaction precursor is Tetramethyltin (TMT), Bromotrifluoromethane (CBrF 3 ) gas provides the source of F, and at the same time feeds oxygen (O 2 ) and nitrogen (N2), wherein nitrogen (N2) is used as a carrier gas; conductive layer The deposition thickness is about 500nm.

[0053] ) window layer preparation: Adopt chemical water bath method to prepare cadmium sulfide (CdS) layer, reactant is ammonium acetate, cadmium acetate, ammoniacal liquor and thiourea; Add deionized water in the airtight container again, heat to 80 o C, add cadmium acetate, ammonium acetate, and ammonia water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com