Method for preparing Te-Zn-Cd monocrystal in large volume

A cadmium zinc telluride, large-volume technology, applied in the field of preparing large-volume cadmium zinc telluride single crystals, can solve the problems of small CZT single crystal volume, achieve small lattice mismatch, simple and easy operation, and low dislocation density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

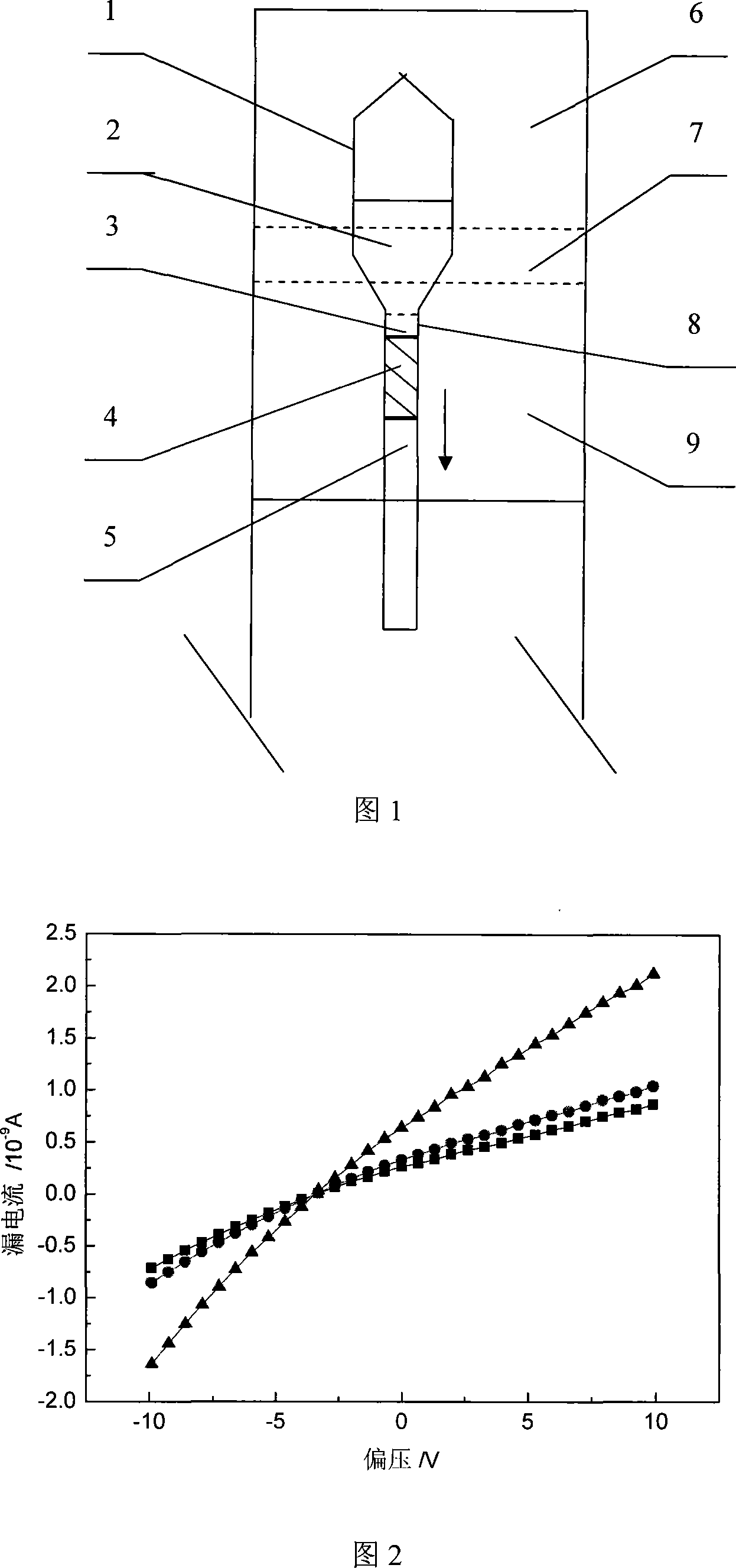

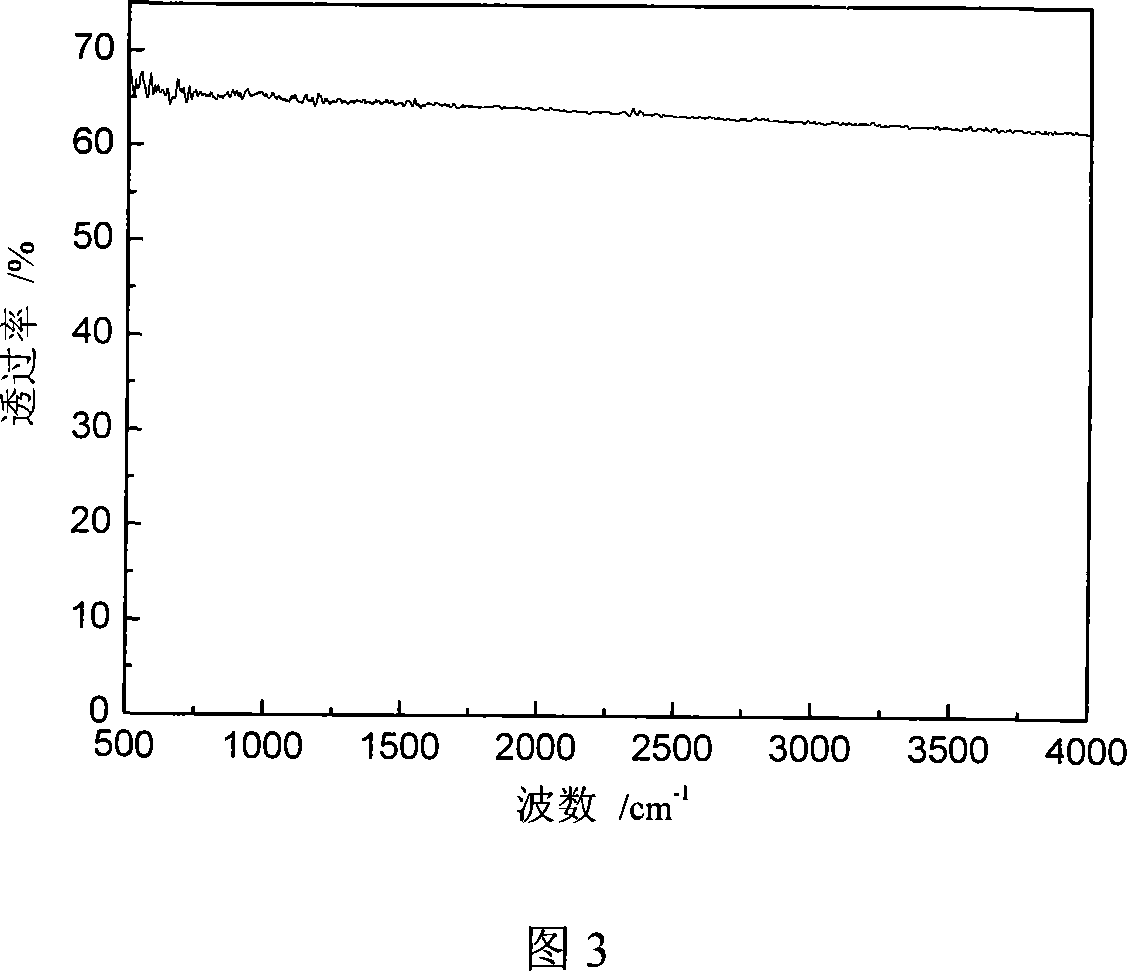

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: adopt component to be Cd 0.8 Zn 0.2 The crystal of Te is oriented to the seed crystal, and the growth surface of the seed crystal is the B face, and the seed crystal growth is performed.

[0019] First, select Cd 0.8 Zn 0.2 After directional cutting and mechanical polishing of Te single crystal, a crystal orientation seed crystal with a diameter of 10 mm and a length of 35 mm is processed, with a crystal orientation deviation of 40'. Using HNO 3 / HF=3:1 volume ratio of the prepared solution was etched for 3 seconds, the A and B surfaces of the seed crystal were determined, and the B surface was chamfered for marking, and the seeding growth surface was selected as the B surface. Then use 50 ml of bromine-methanol solution with a volume fraction of 2% of bromine to etch the seed crystal for 5 minutes to remove surface mechanical damage and dirt, and rinse the seed crystal with methanol after etching. Finally, use absolute ethanol to ultrasonically cle...

Embodiment 2

[0024] Embodiment 2: adopt component to be Cd 0.9 Zn 0.1The crystal of Te is oriented to the seed crystal, and the growth surface of the seed crystal is the B face, and the seed crystal growth is performed.

[0025] First, select Cd 0.9 Zn 0.1 After directional cutting and mechanical polishing, the Te single crystal is processed into a seed crystal with a diameter of 10mm and a length of 30mm in the crystal orientation, with a crystal orientation deviation of 30'. Using HNO 3 / HF=2:1 volume ratio of the prepared solution was etched for 4 seconds to determine the A and B surfaces of the seed crystal, and chamfered the B surface for marking, and the seeding growth surface was selected as the B surface. Then use 50ml of bromine-methanol solution with a volume fraction of 4% to corrode the seed crystal for 3 minutes to remove mechanical damage and dirt on the surface, rinse the seed crystal with methanol after etching, and finally use absolute ethanol to ultrasonically clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com