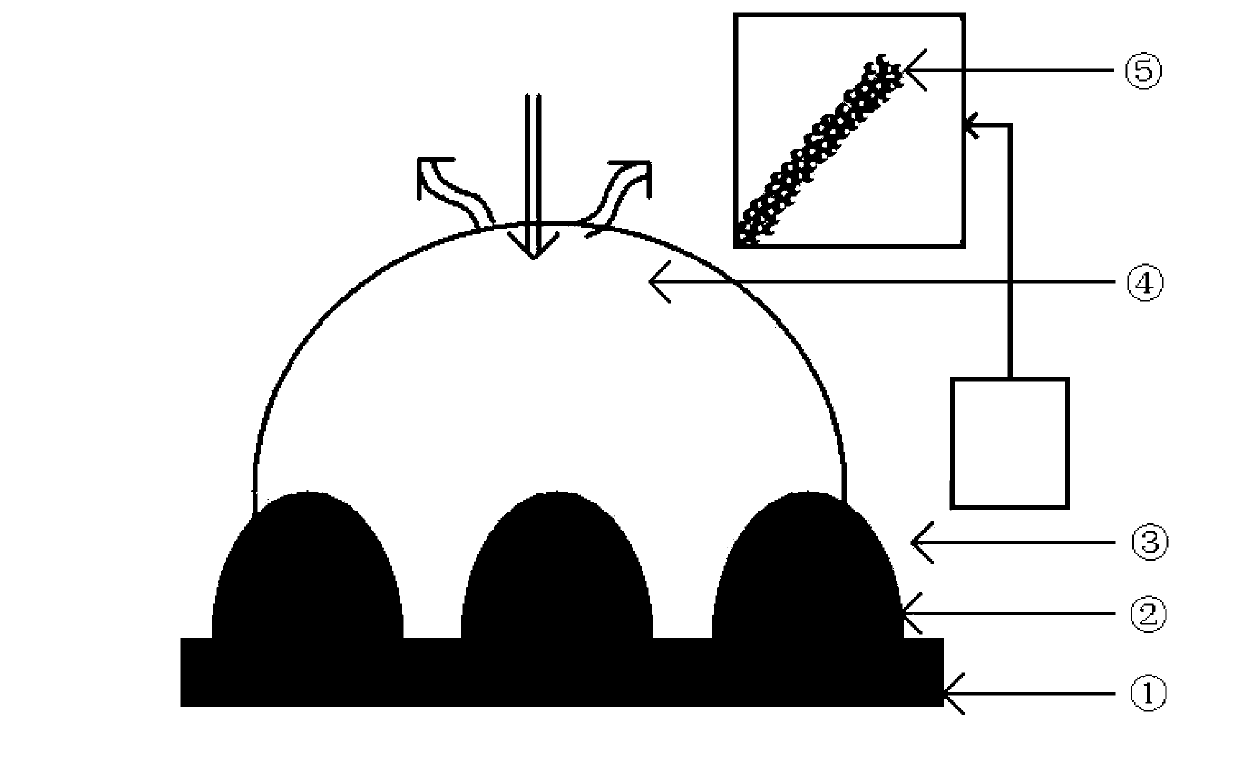

Preparation method of active radical with surface-enhanced Raman scattering (SERS) effect

A surface-enhanced Raman and active substrate technology, applied in Raman scattering, material excitation analysis, etc., can solve problems such as affecting substrate application, poor experimental repeatability and spectral reproducibility, and inability to obtain metal particles with surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Add 40mL of 0.5mol / L hydrofluoric acid into a 50mL autoclave, weigh 0.162g ferric nitrate and mix hydrofluoric acid to make an etching solution, and polish the p-type (111) silicon with a resistivity of 0.01-0.09 Ωcm on one side The slices were cut into square slices with a size of 2 cm × 2 cm, put into an autoclave, and etched at 170° C. for 5 minutes to obtain nano-silicon.

[0027] 2. Put 0.2g of zinc powder into the tubular heating furnace, use a gas flow meter to feed 20 sccm oxygen as a reaction gas, and 80 sccm nitrogen as a protective gas, and use a vacuum pump to control the pressure of the reaction chamber at about 5 Torr. The obtained nano-silicon was placed downstream of the zinc source gas flow, and reacted at 400° C. for 60 minutes to obtain a zinc oxide nanowire array.

[0028] 3. Prepare a mixed solution of 0.1mM chloroauric acid and 0.1mM methanol, soak the nanowire structure substrate prepared by steps 1 and 2 in the solution, and react at 100°C for...

Embodiment 2

[0032] 1. Add 80mL of 7mol / L hydrofluoric acid solution into a 100ml autoclave, weigh 3.23g of ferric nitrate and dissolve it in the hydrofluoric acid solution. Cut single-sided polished n-type (100), resistivity 30-50Ωcm monocrystalline silicon wafer into 2cm×2cm size, and fix it in etching solution. Corrosion at 70° C. for 100 minutes to obtain a silicon nanoporous pillar array.

[0033] 2. Add 0.5g of titanium dioxide powder to the hydrothermal reaction kettle, and add 40mL of 0.1M sodium hydroxide solution. The nano-silicon substrate prepared by the above method is placed in the solution, and the reaction kettle is heated to 140° C. in a vacuum drying oven and kept for 20 minutes. After cooling to room temperature, the substrate was taken out, washed with deionized water and alcohol, and dried to obtain a silicon-based titania nanowire array.

[0034] 3. Prepare 0.01M silver nitrate solution and 0.01M sodium borohydride ethanol solution, soak the substrate prepared under...

Embodiment 3

[0038] 1. Add 40ml of saturated hydrofluoric acid solution and 40ml of absolute ethanol into a 100ml beaker as the electrolyte. Single-sided polished n-type (111) single-crystal silicon wafers with a resistivity of 5-10 Ω cm were cut into a size of 2 cm × 2 cm, cleaned and fixed in an etching solution. A carbon rod is used as a cathode, and a current of 300 mA is passed through, and the silicon nanoporous column array is obtained by etching for 10 min.

[0039] 2. Put 0.5g zinc powder into the tubular heating furnace, utilize gas flowmeter to feed 20sccm oxygen as reaction gas, 600sccm nitrogen as protective gas, utilize vacuum pump to control reaction chamber pressure at about 50 Torr, the obtained in step 1 Nano-silicon is placed near the upstream of the zinc source gas flow, and reacted at 900° C. for 10 minutes to obtain a zinc oxide nanowire array.

[0040] 3. Prepare 0.1M silver nitrate solution and 0.1M sodium borohydride ethanol solution, soak the substrate prepared u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com