Method for manufacturing high resistivity tellurium-zincium-cadmium crystal

A high resistivity, cadmium zinc telluride technology, applied in crystal growth, chemical instruments and methods, single crystal growth and other directions, can solve the problems of poor repeatability and difficult to master, achieve small changes in resistivity, improve uniformity and utilization rate , the effect of good resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

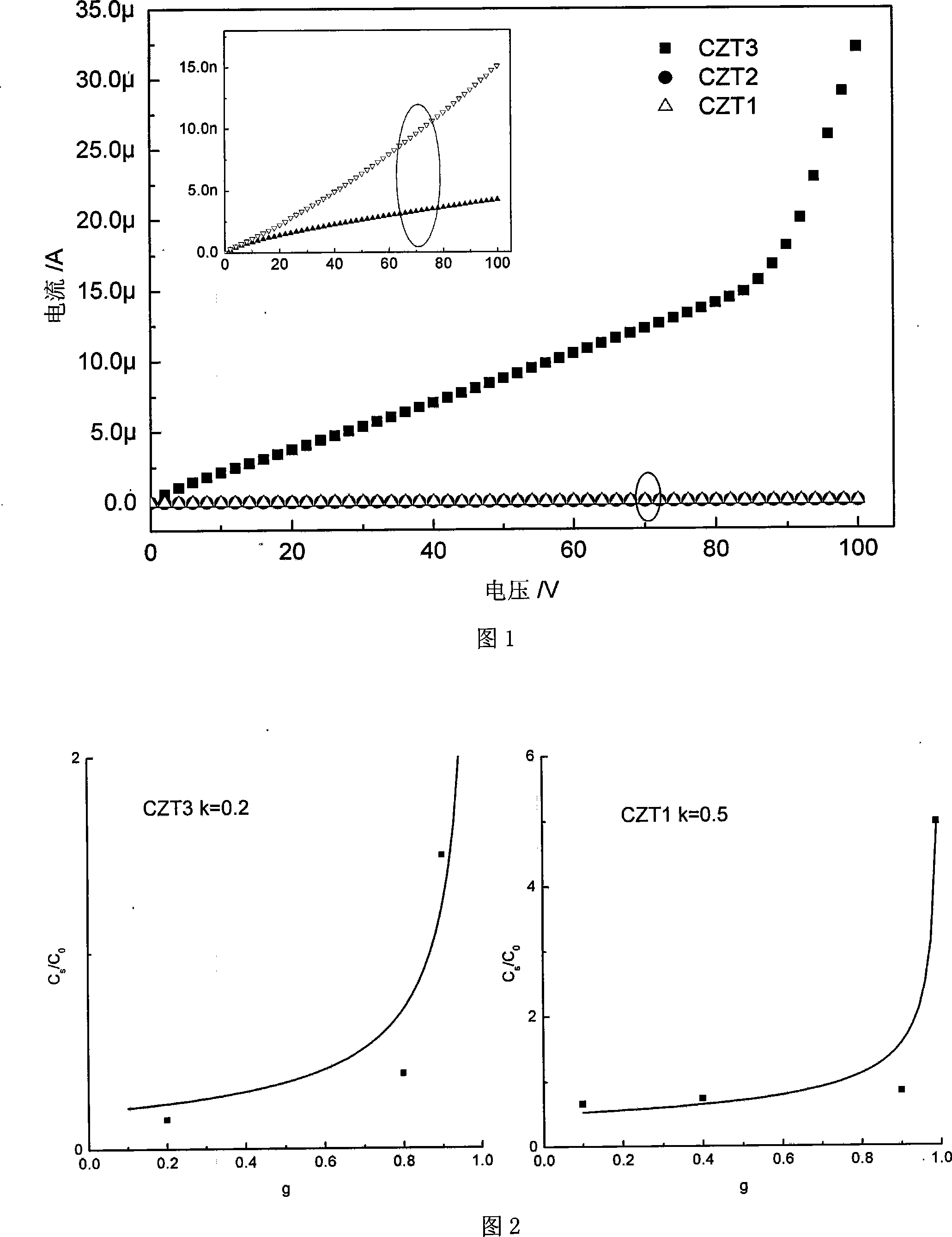

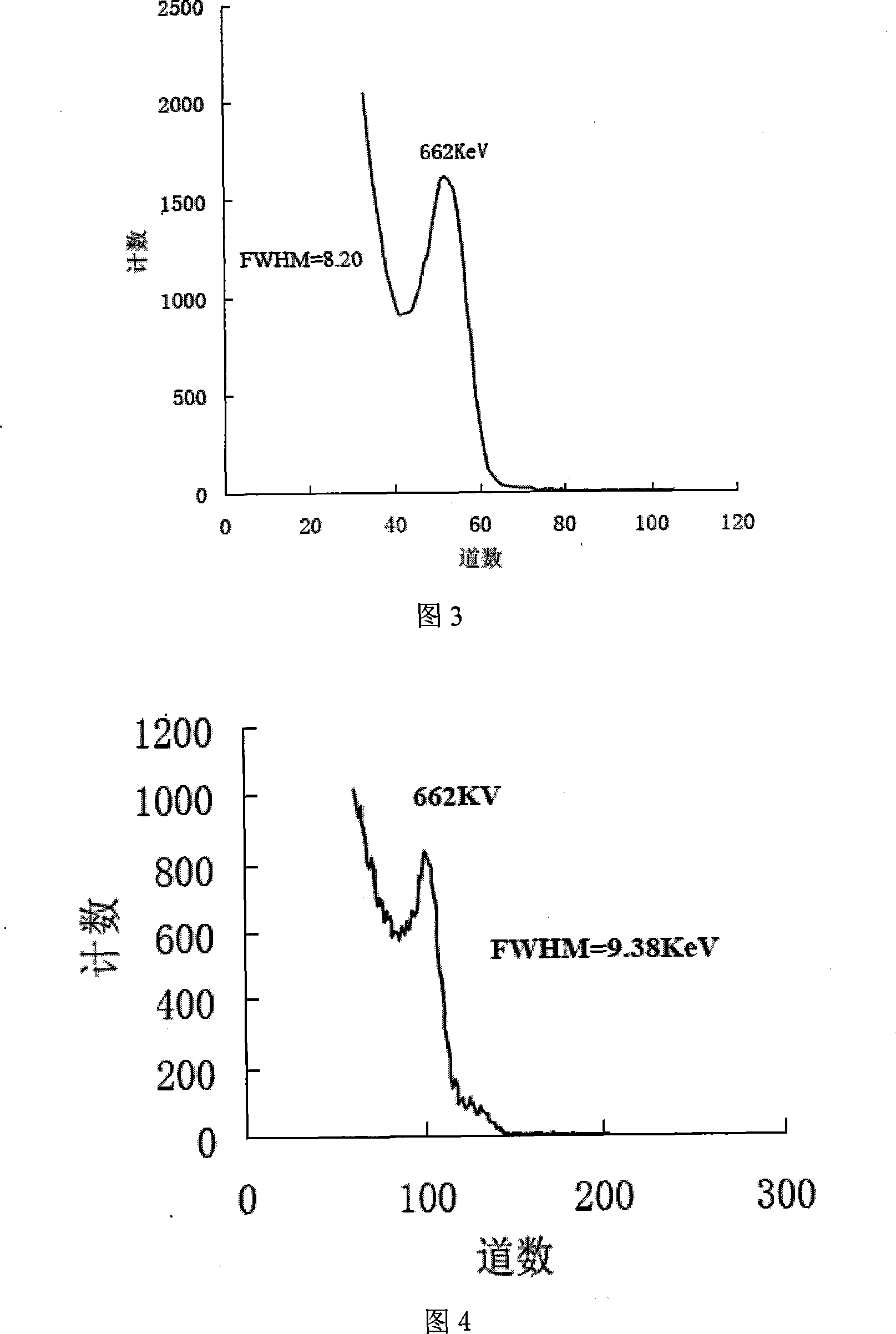

Embodiment 1

[0020] Embodiment 1: adopt component to be Cd 0.9 Zn 0.1 Te crystal, the mass percentage of excess Te is 2%, and the In doping concentration is 1×10 18 cm -3 .

[0021] First, the stoichiometric ratio will satisfy the Cd 0.9 Zn 0.1 The purity of Te is that 350g of the raw material of 7 9s is packed into the high-purity quartz crucible, and on this basis, adding mass percent is 2% excess Te7g, and the volume concentration is 1×10 18 cm -3 In0.0105g.

[0022] In the second step, a molecular pump is used to evacuate the inside of the quartz crucible. When the vacuum degree reaches 5×10 -5 At Pa, seal the quartz crucible.

[0023] The third step is to put the crucible into a swingable synthesis furnace to synthesize the raw materials, so that they can undergo a chemical reaction and mix them evenly. The time is 210 hours.

[0024] In the fourth step, the crucible is placed in a five-stage crystal growth furnace for crystal growth. The growth method is descending vertica...

Embodiment 2

[0028] Embodiment 2: adopt component to be Cd 0.9 Zn 0.1 Te crystal, the mass percentage of excess Te is 0.5%, and the In doping concentration is 6×10 18 cm -3 .

[0029] First, the stoichiometric ratio will satisfy the Cd 0.9 Zn 0.1 The purity of Te is that the raw material of 7 9 is loaded into the interior of high-purity quartz crucible, and on this basis, adding mass percent is 0.5% excess Te1.75g, and volume concentration is 6×1018 cm -3 In0.063g.

[0030] In the second step, a molecular pump is used to evacuate the inside of the quartz crucible. When the vacuum degree reaches 5×10 -5 At Pa, seal the quartz crucible.

[0031] The third step is to put the crucible into a swingable synthesis furnace to synthesize the raw materials, so that they can undergo a chemical reaction and mix them evenly. The time is 200 hours.

[0032] In the fourth step, the crucible is placed in a five-stage crystal growth furnace for crystal growth. The growth method is descending vert...

Embodiment 3

[0035] Embodiment 3: adopt component to be Cd 0.9 Zn 0.1 Te crystal, the mass percentage of excess Te is 1%, and the In doping concentration is 4.5×10 18 cm -3 .

[0036] First, the stoichiometric ratio will satisfy the Cd 0.9 Zn 0.1 The purity of Te is that the raw material of 7 9 is loaded into the high-purity quartz crucible inside, and on this basis, adding mass percent is 1% excess Te3g, and volume concentration is 4.5 * 10 18 cm -3 In 0.0473g.

[0037] In the second step, a molecular pump is used to evacuate the inside of the quartz crucible. When the vacuum degree reaches 5×10 -5 At Pa, seal the quartz crucible.

[0038] The third step is to put the crucible into a swingable synthesis furnace to synthesize the raw materials, so that they can undergo a chemical reaction and mix them evenly. The time is 190 hours.

[0039] In the fourth step, the crucible is placed in a five-stage crystal growth furnace for crystal growth. The growth method is descending vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com