Patents

Literature

79 results about "Cdte solar cell" patented technology

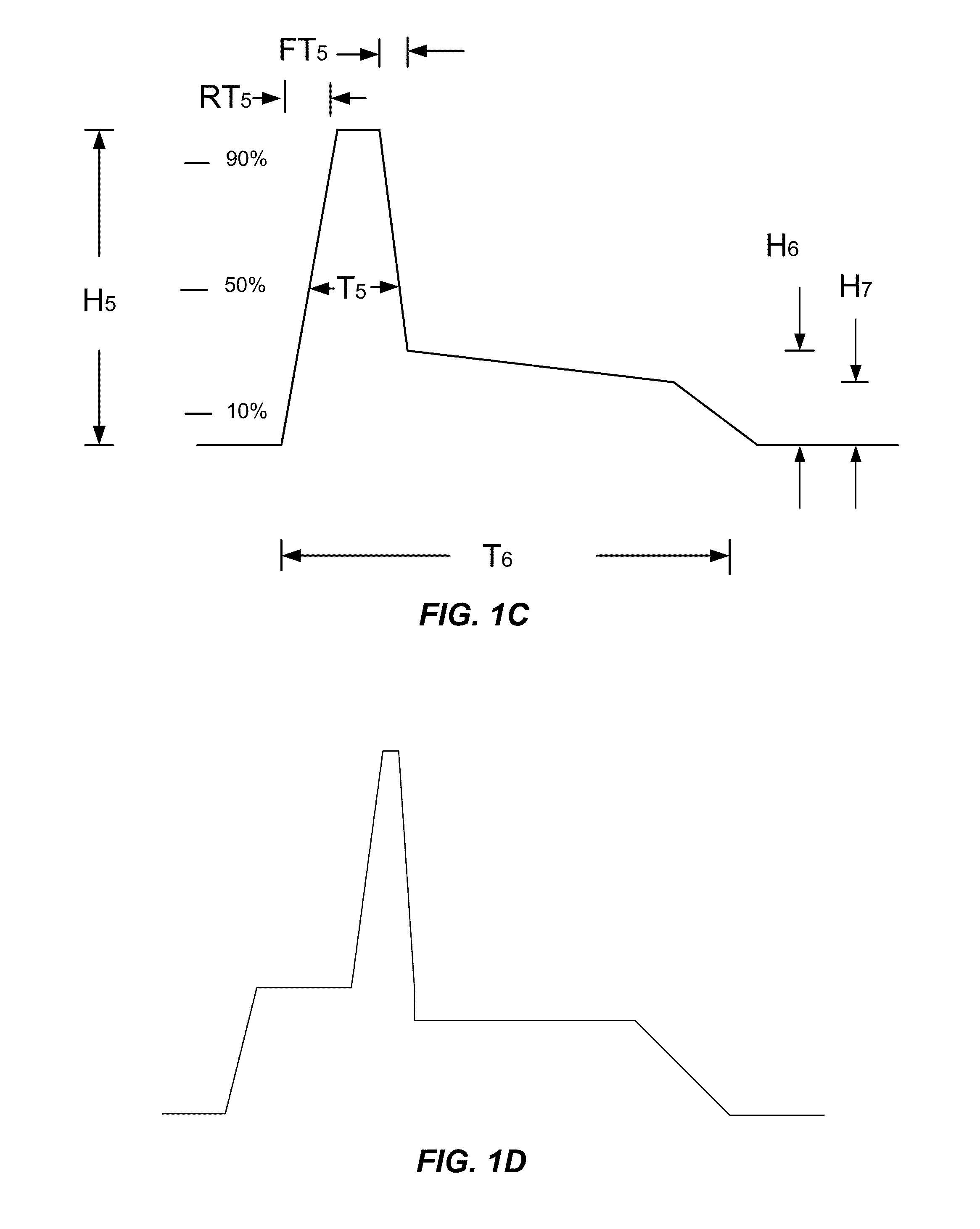

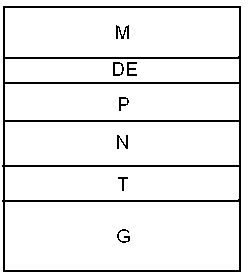

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

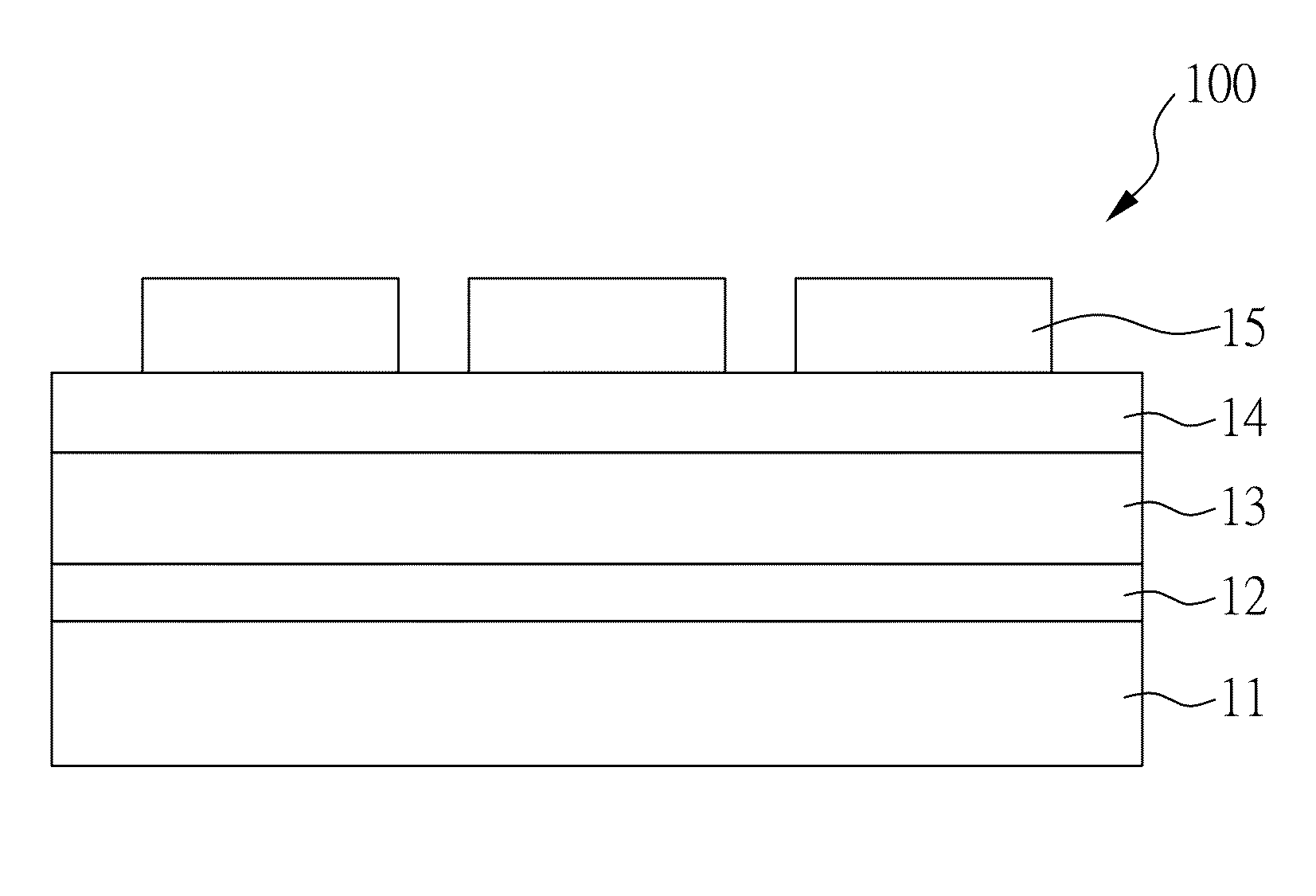

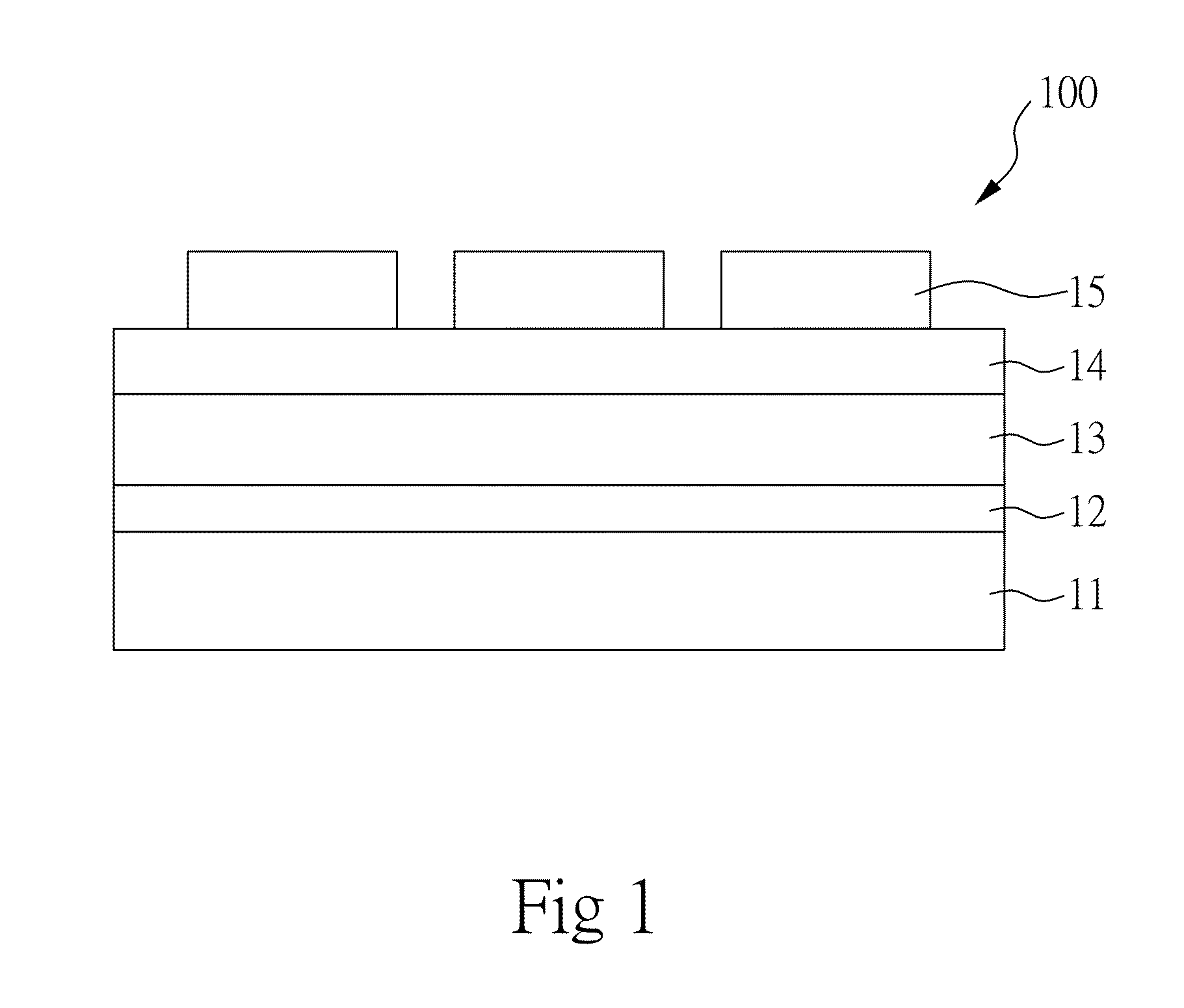

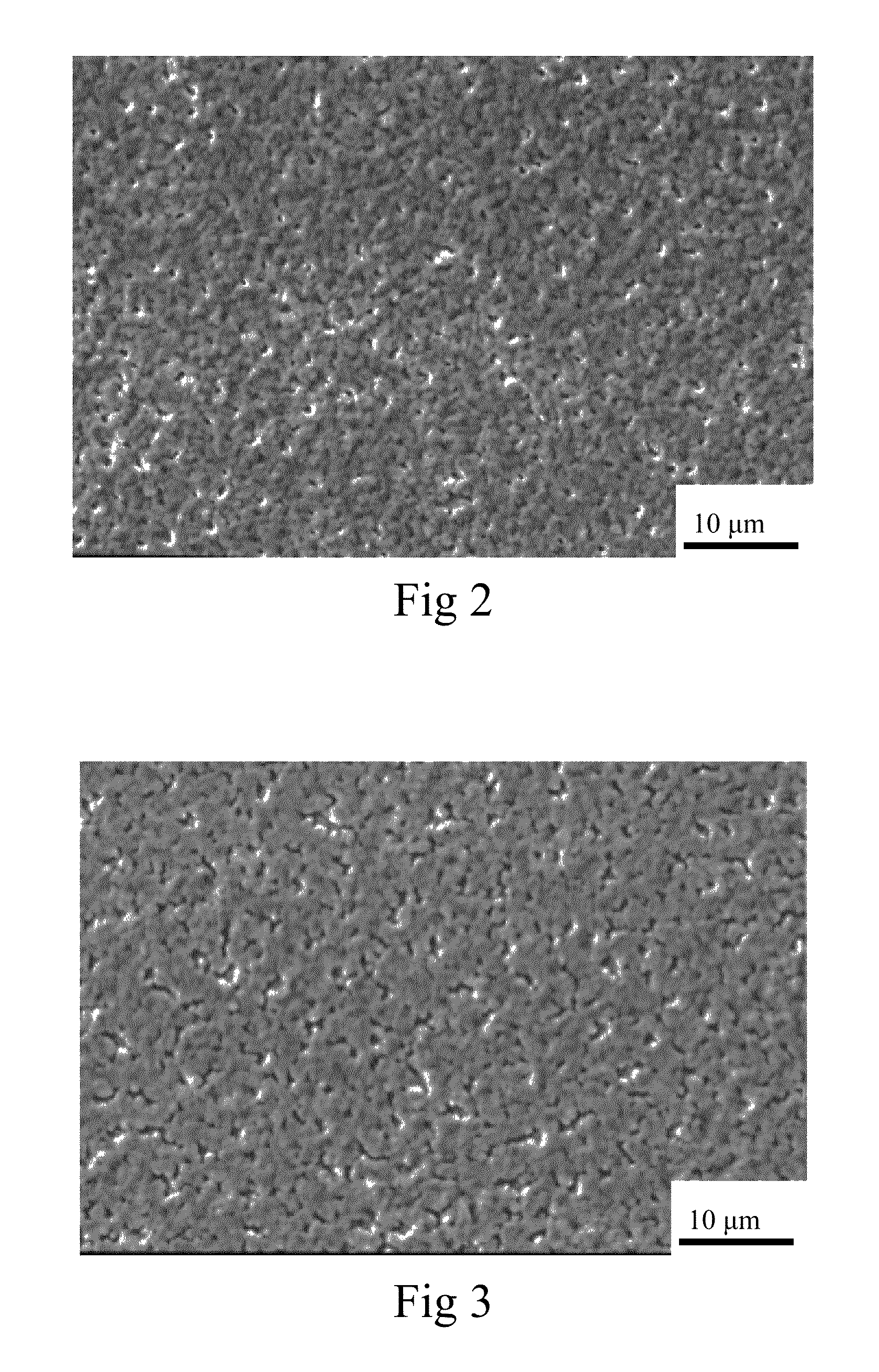

Perovskite solar cell

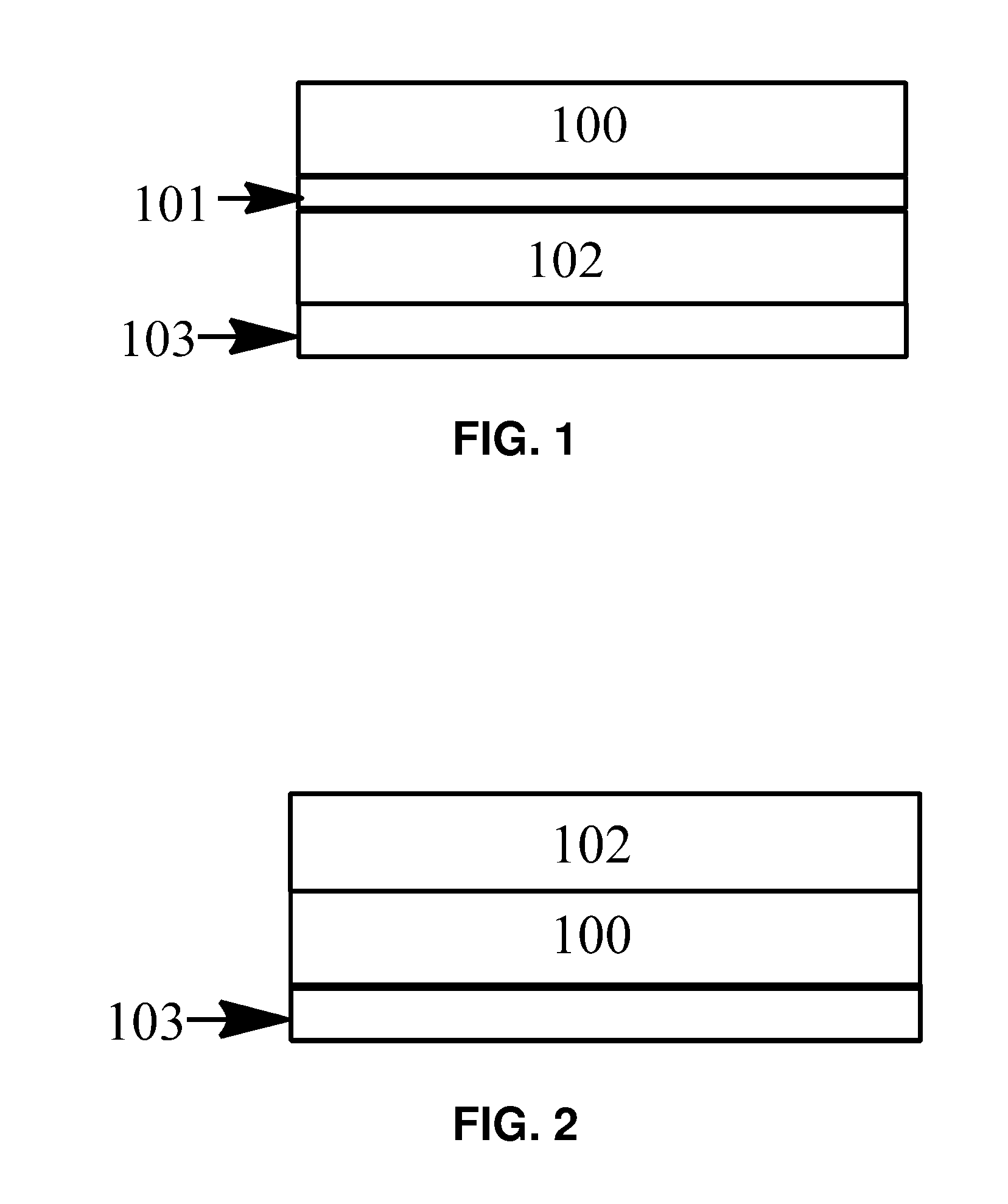

InactiveUS20160079552A1Expand coverageReduce roughnessSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectron transport layer

The present invention relates to a perovskite solar cell, which comprises a first electrode substrate; a perovskite material layer comprising a perovskite organic-inorganic material and a polymer additive, wherein the perovskite material layer is disposed above the first electrode substrate; and a second electrode, which is disposed above the perovskite material layer and corresponds to the first electrode substrate. The coverage of the perovskite material layer on the electrode or an electron-transport layer is significantly improved, and the roughness thereof is also decreased, thereby increasing the photoelectric conversion efficiency of the perovskite solar cell.

Owner:NAT TAIWAN UNIV

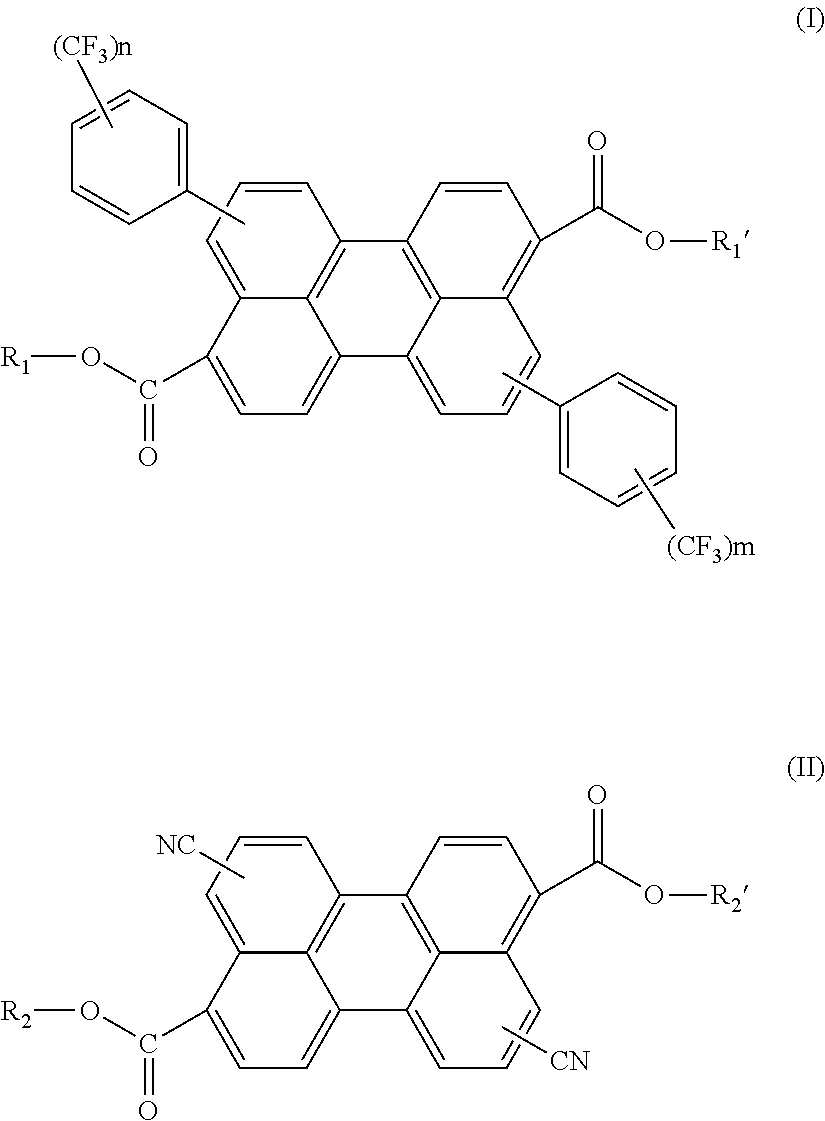

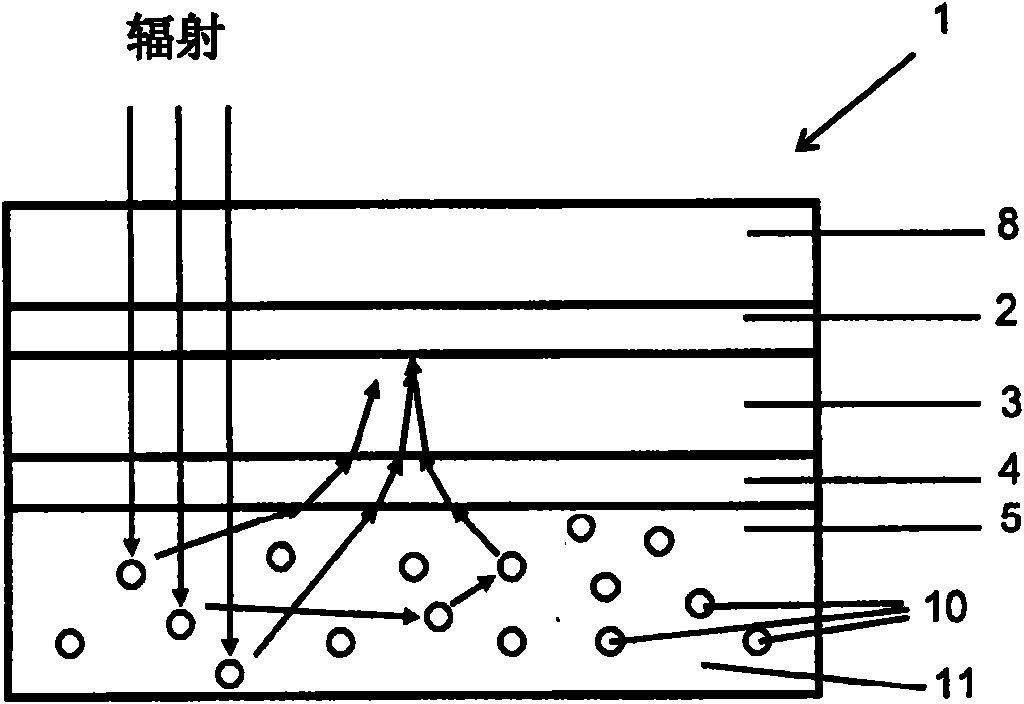

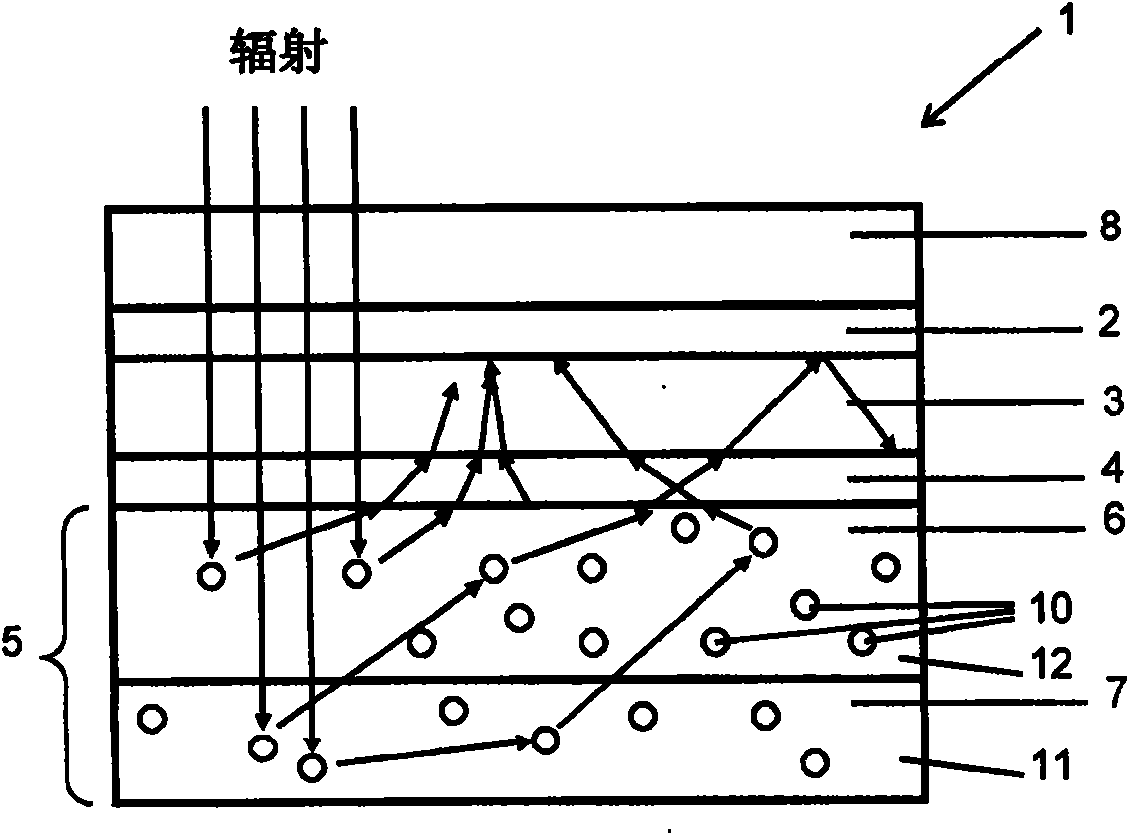

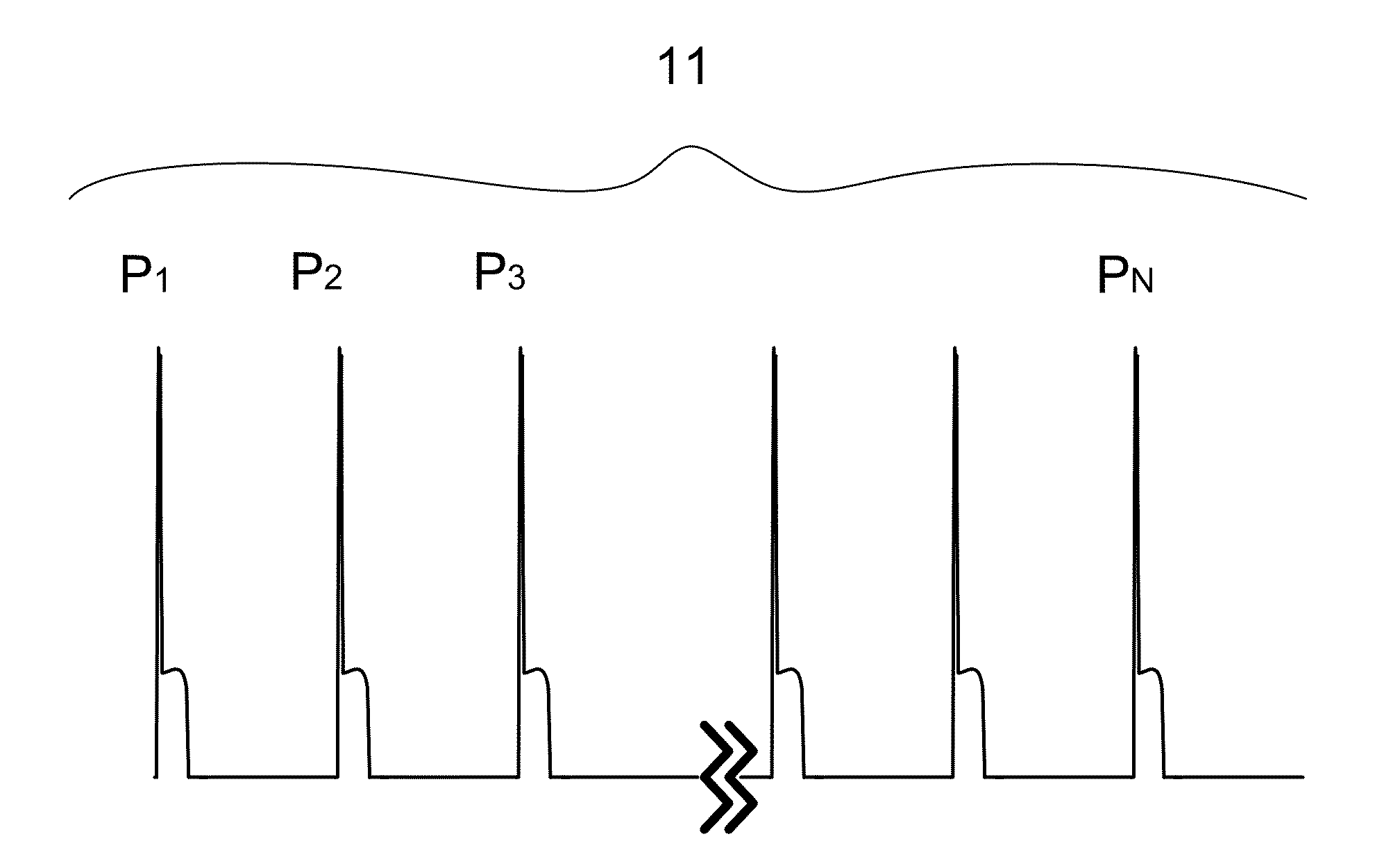

Wavelength conversion perylene diester chromophores and luminescent films

ActiveUS20130284265A1Improve photoelectric conversion efficiencyGood light fastnessOrganic chemistrySolid-state devicesCollection systemPerylene

This invention is related to novel perylene diester derivatives represented by the general formula (I) or general formula (II) as described herein. The derivatives are useful in various applications, such as luminescent dyes for optical light collection systems, fluorescence-based solar collectors, fluorescence-activated displays, and / or single-molecule spectroscopy. The invention also relates to a luminescent medium, such as a luminescent film, that can significantly enhance the solar harvesting efficiency of thin film CdS / CdTe or CIGS solar cells. The luminescent medium comprises an optically transparent polymer matrix and at least one luminescent dye that comprises a perylene diester derivative. Over 16% of an efficiency enhancement to a CdS / CdTe solar cell and over 12% of an efficiency enhancement to a CIGS solar cell can be achieved.

Owner:CHOSHU IND

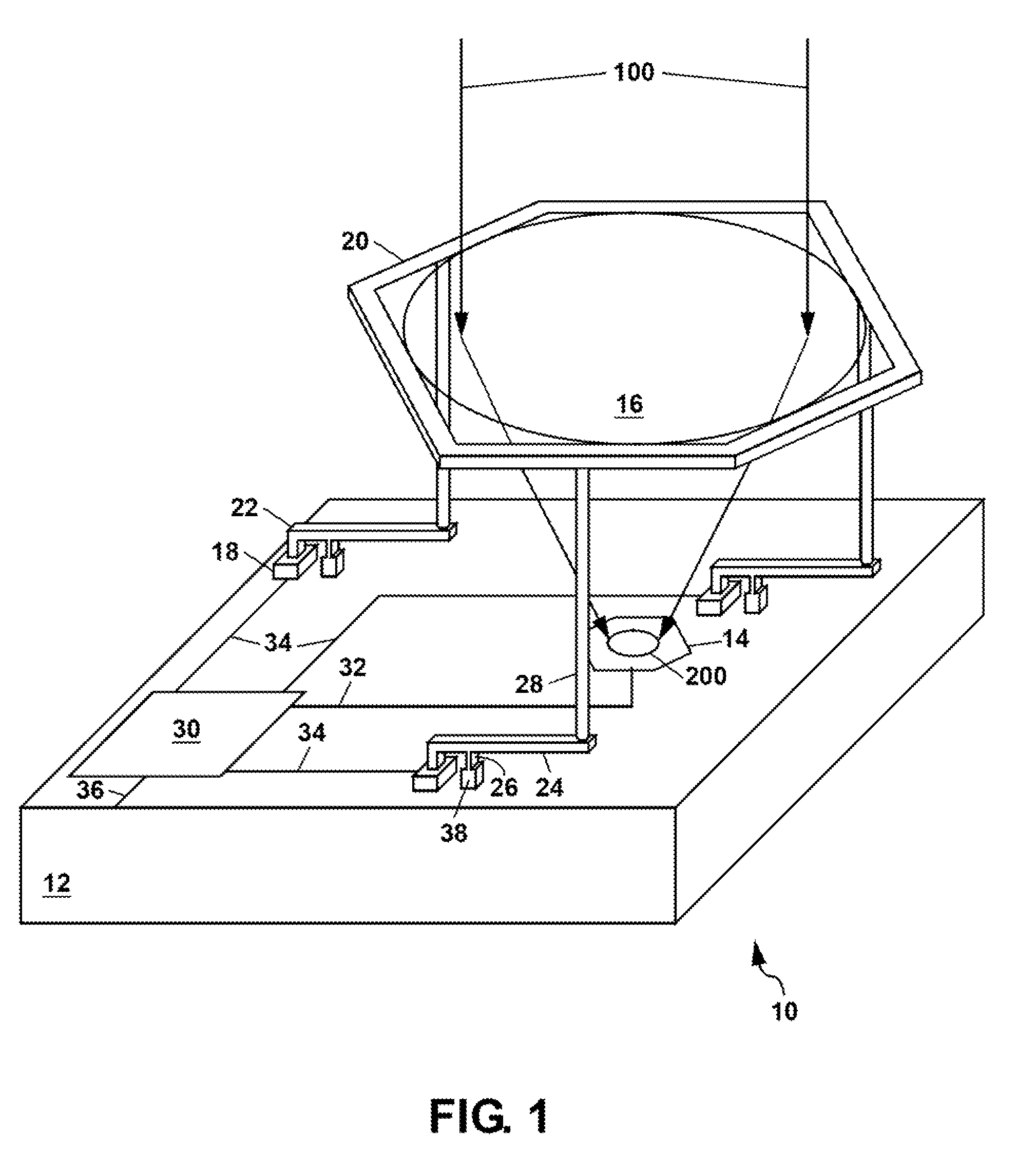

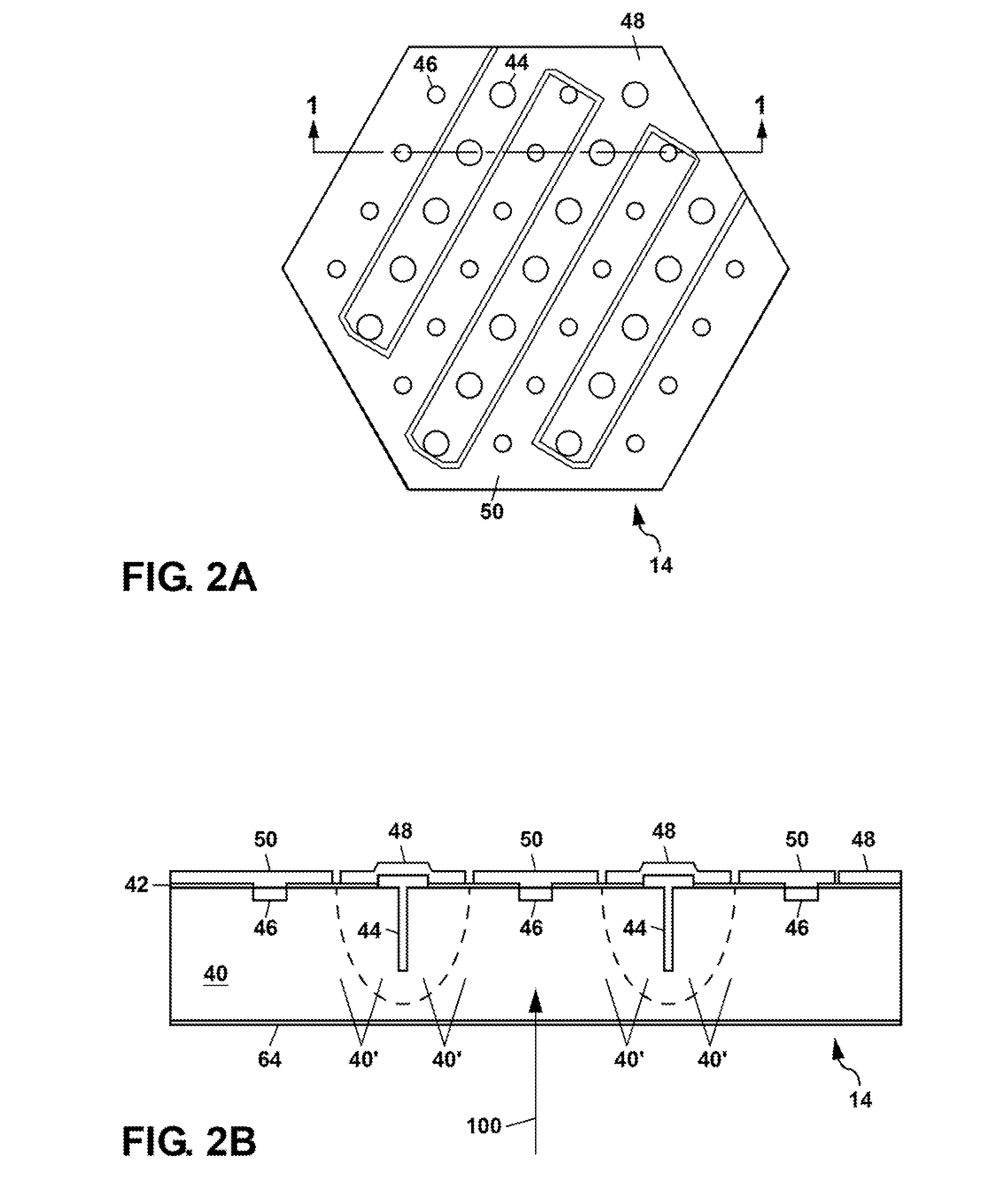

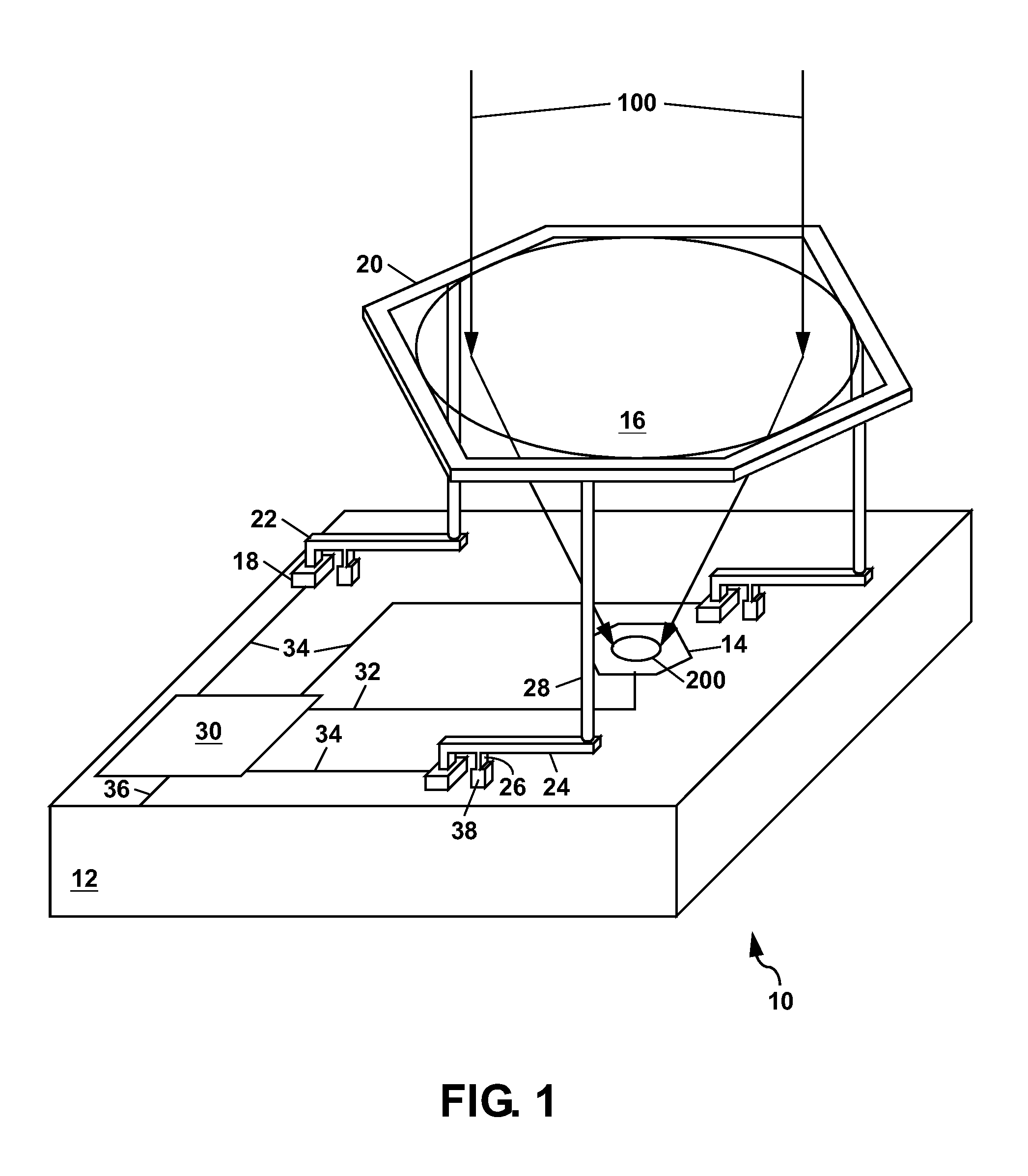

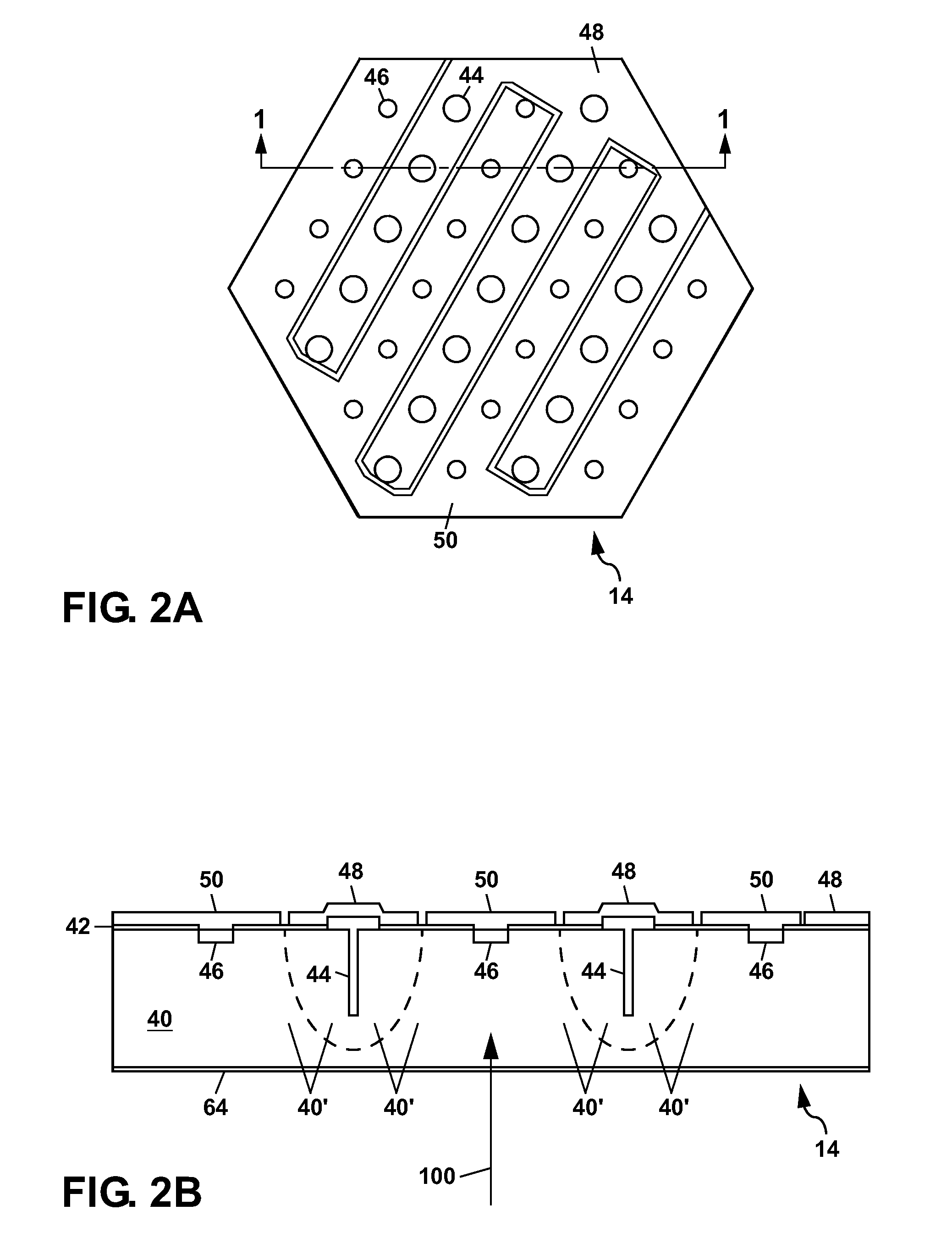

Photovoltaic solar concentrator

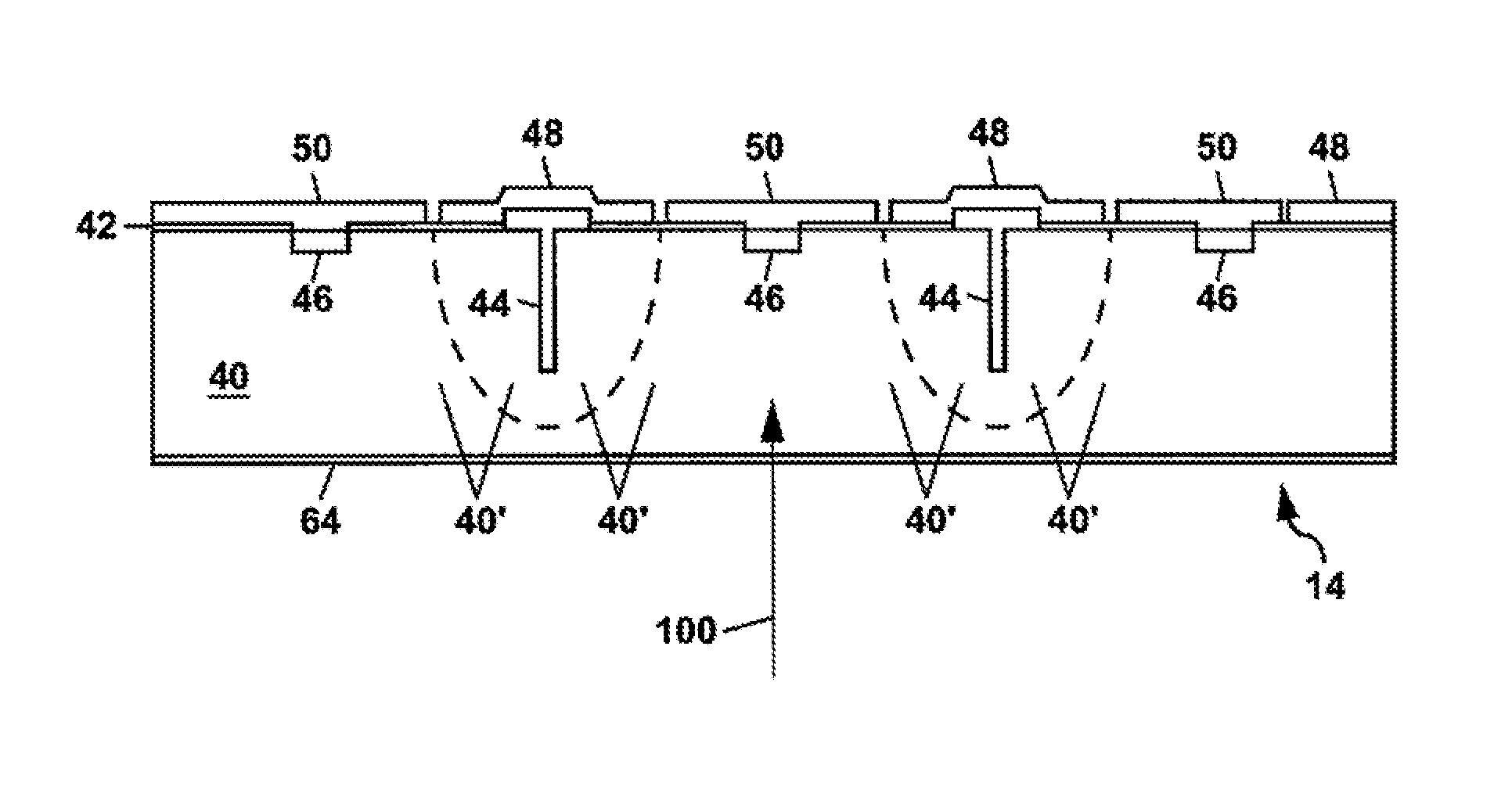

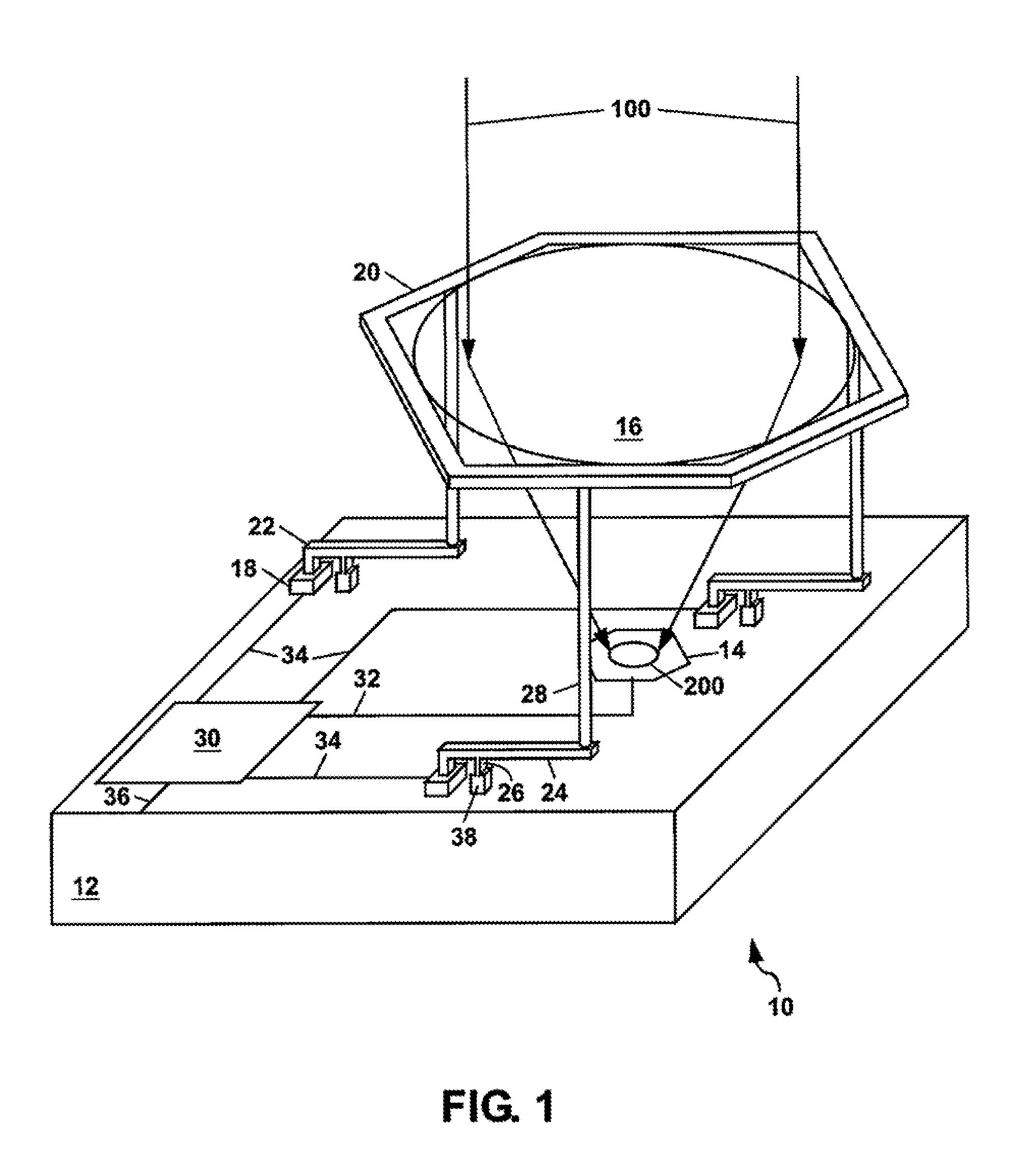

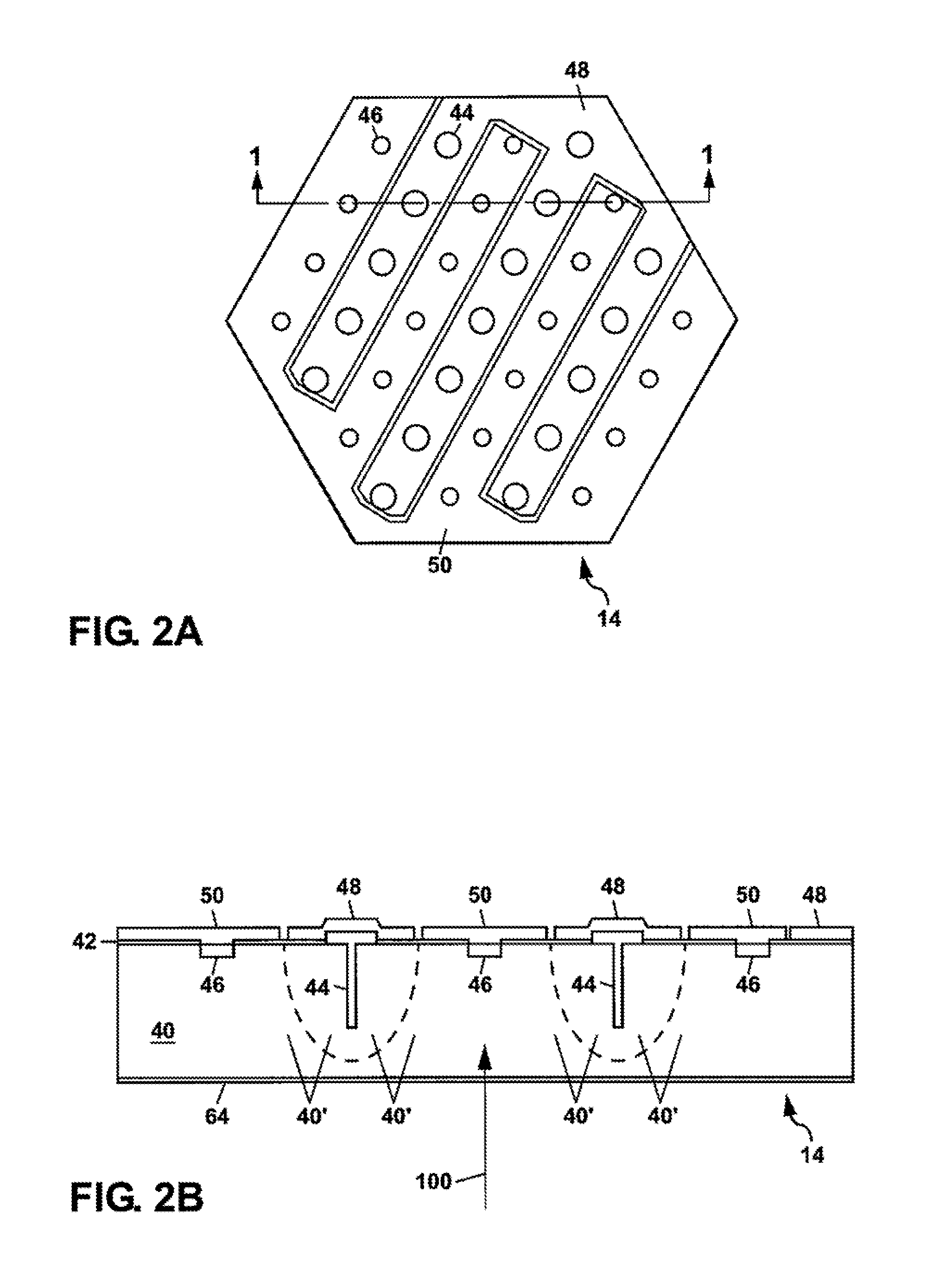

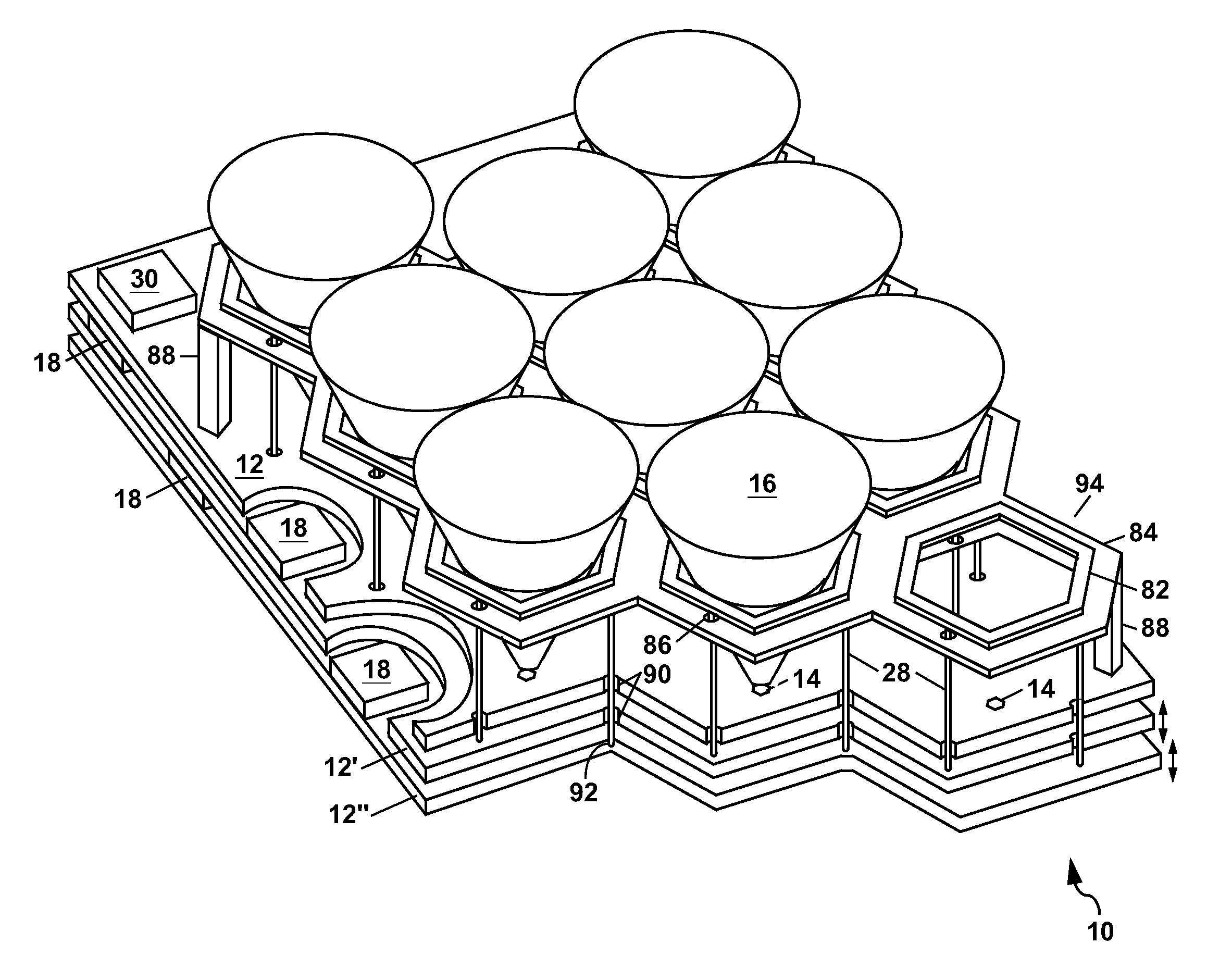

ActiveUS8329503B1Increase displacementStay focusedPhotovoltaic supportsSemiconductor/solid-state device manufacturingEngineeringPiezoelectric generator

A photovoltaic solar concentrator is disclosed with one or more transverse-junction solar cells (also termed point contact solar cells) and a lens located above each solar cell to concentrate sunlight onto the solar cell to generate electricity. Piezoelectric actuators tilt or translate each lens to track the sun using a feedback-control circuit which senses the electricity generated by one or more of the solar cells. The piezoelectric actuators can be coupled through a displacement-multiplier linkage to provide an increased range of movement of each lens. Each lens in the solar concentrator can be supported on a frame (also termed a tilt plate) having three legs, with the movement of the legs being controlled by the piezoelectric actuators.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

CdTe solar cell manufacturing method capable of reducing defect density

InactiveCN106252432AReduce defect densityImprove performanceFinal product manufacturePhotovoltaic energy generationCadmium zinc tellurideThermal treatment

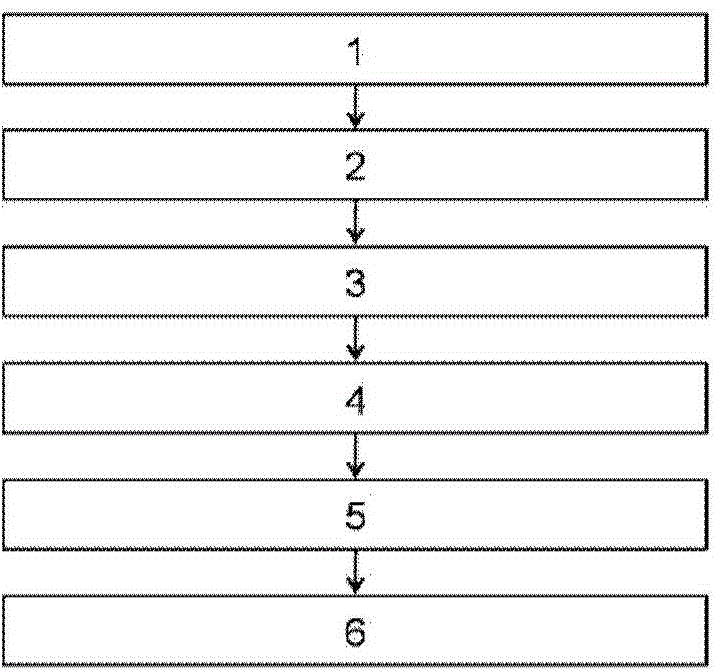

The invention discloses a CdTe solar cell manufacturing method capable of reducing defect density. The method comprises the following steps: (A) a substrate is provided; (B) a transparent conductive oxide thin film is deposited on the substrate; (C) a window layer CdS thin film is deposited; (D) an absorption layer CdTe thin film is deposited on the CdS thin film; (E) a CdCl2 solution is sprayed on the surface of the CdTe thin film, and then thermal treatment is carried out; (F) a solution containing nitric acid is used for etching the CdTe thin film after thermal treatment; and (G) PECVD plasma treatment is carried out on the etched CdTe thin film to passivate defects. According to the method of the invention, during the CdTe solar cell manufacturing process, plasma treatment is introduced to passivate the defects, the defect density of the CdTe thin film is effectively reduced, the material performance is improved, the photoelectric conversion efficiency of the CdTe thin film solar cell is further improved, and the cell performance is improved.

Owner:ZHONGSHAN RUIKE NEW ENERGY CO LTD

CdTe solar cell by using V-Se film as back contact layer

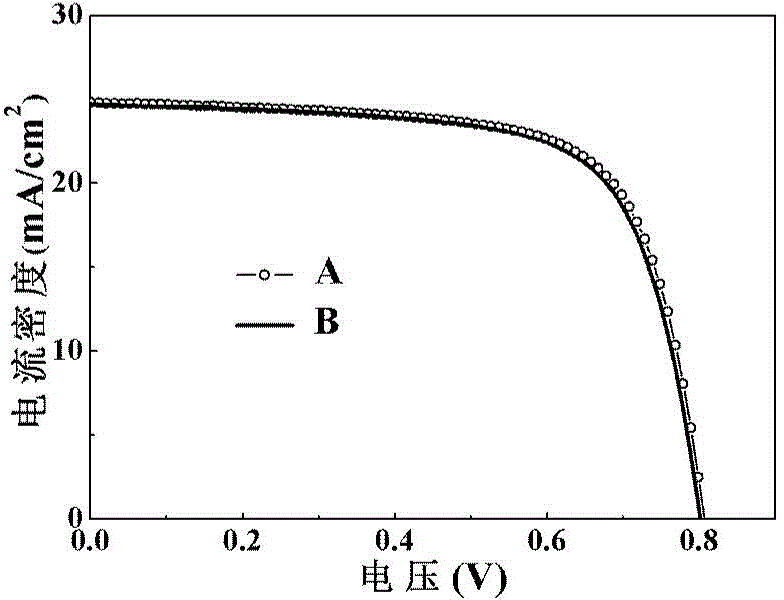

The invention aims to eliminate the defects of copper or back contact layer materials containing copper in a CdTe cell and avoid the negative influence of copper diffusion on the performance of the CdTe solar cell. A copper-free V-S material is added between an absorbing layer and a metal back electrode in the basic structure of the CdTe solar cell and is taken as a back contact layer of the CdTe solar cell, thus an ohmic contact of the CdTe solar cell can be realized, the depletion region of the solar cell can be widened, the interface recombination can be reduced, the bypass resistance can be increased, the filling factor can be increased and the conversion efficiency can be improved. Since an acceptor doping agent, such as copper, is not used in the invention, the cell does not have attenuation after being used or stored for a long term, and the device has good stability.

Owner:SICHUAN UNIV

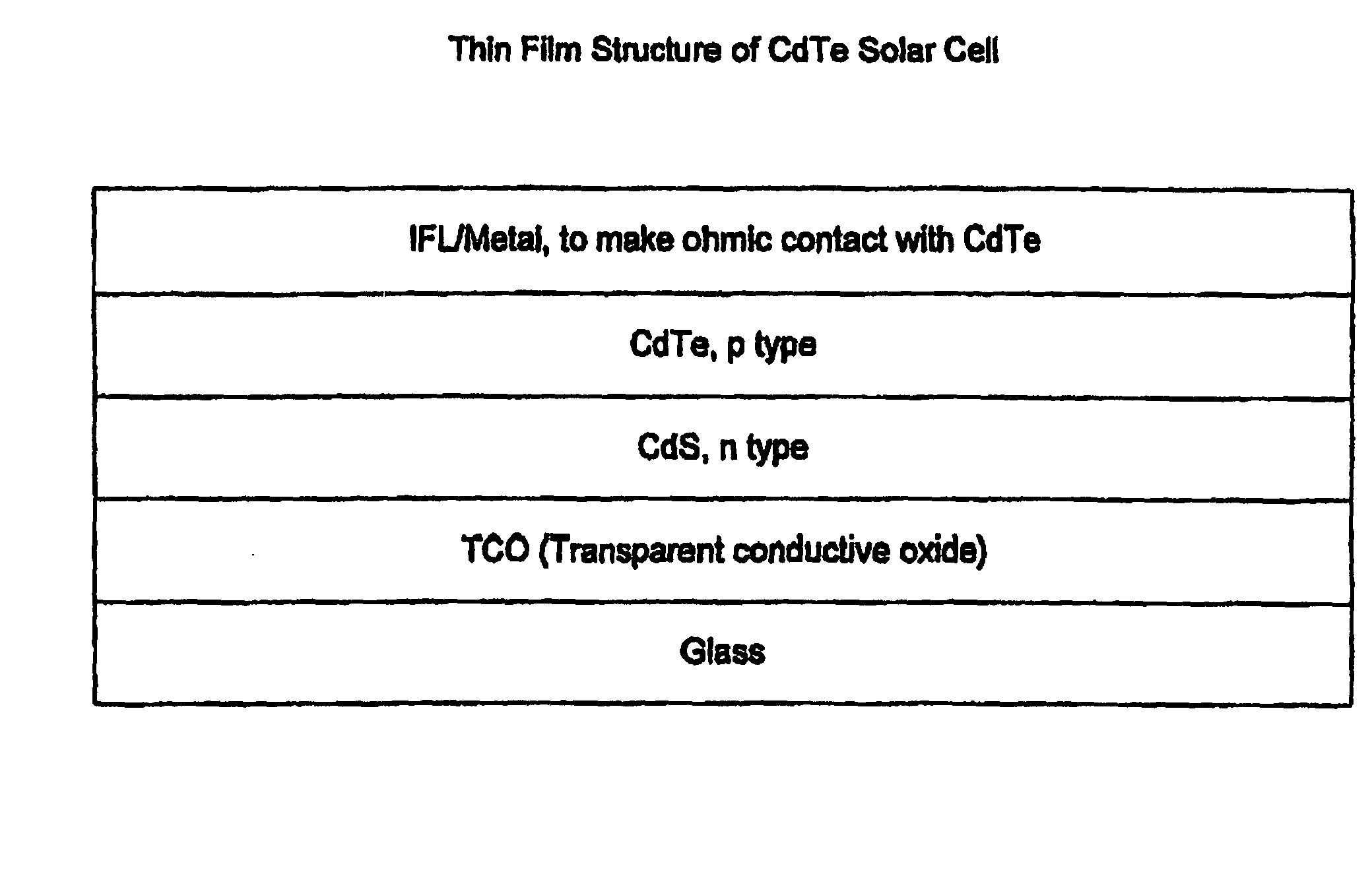

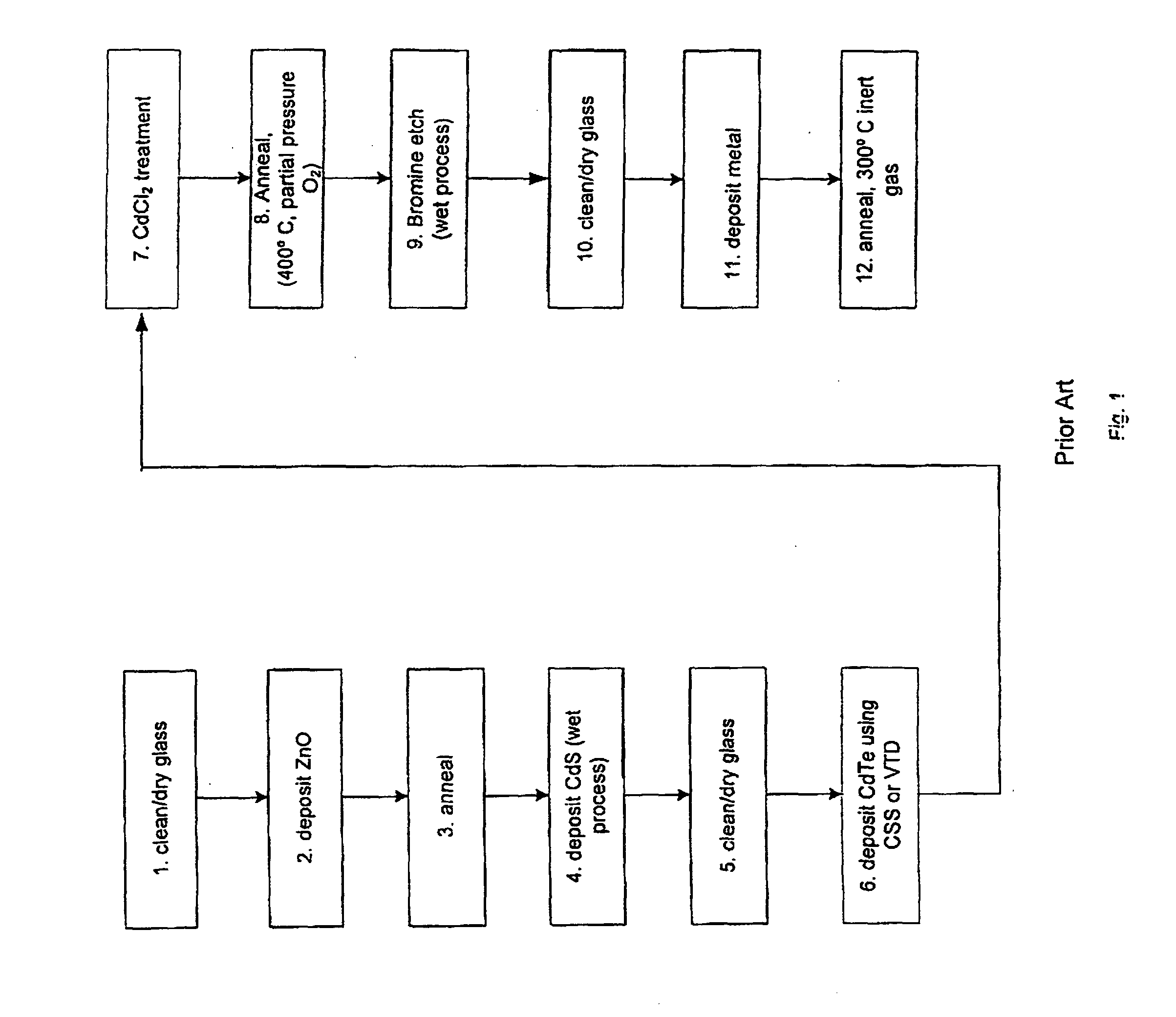

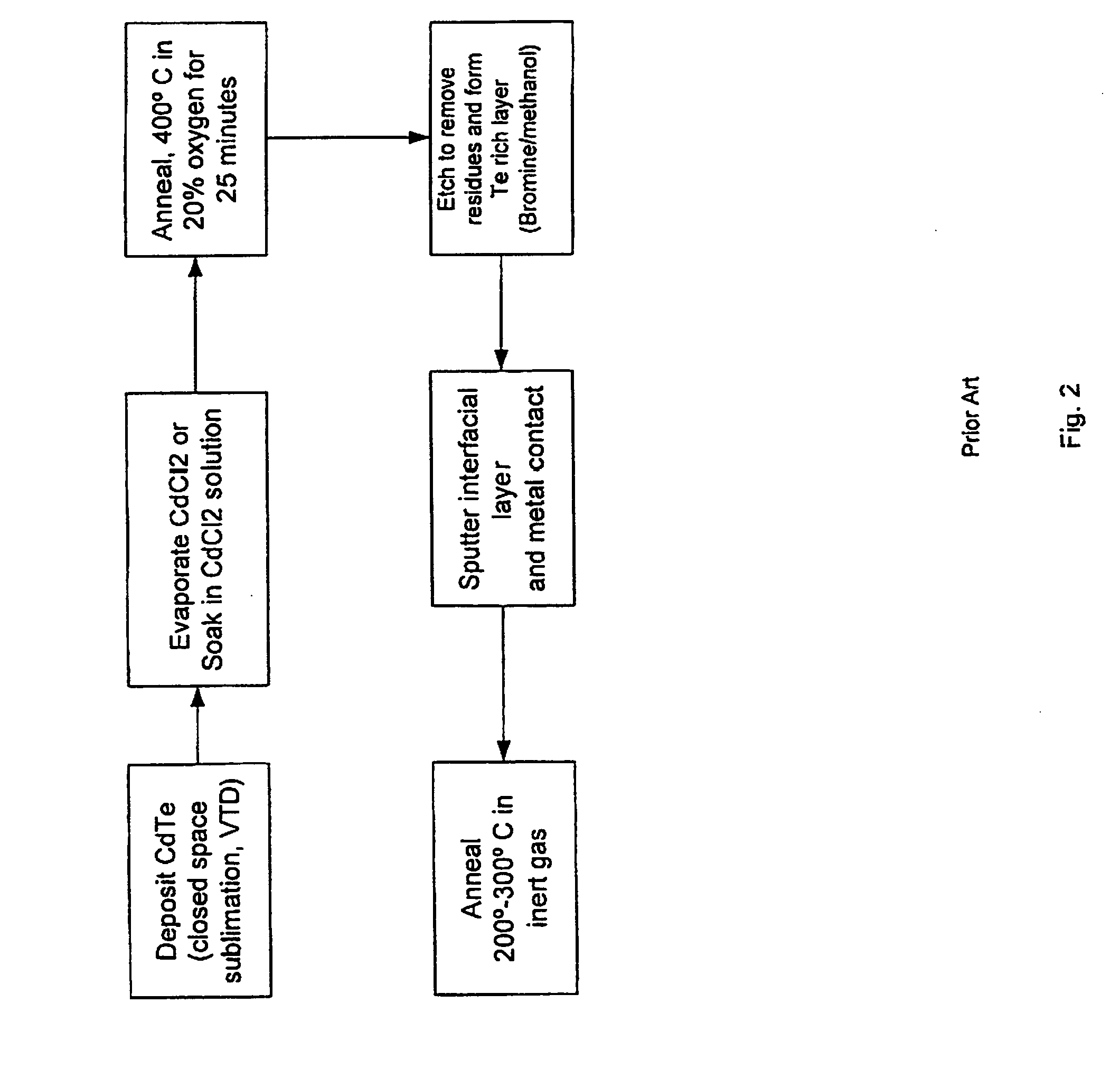

CdTe deposition process for solar cells

InactiveUS20100126580A1Avoid expensesAvoid complexitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationSputteringToxic gas

An inexpensive system is provided for manufacturing a CdTe solar cell in a single pass using sputtering without the need for a wet process and without the need for high temperature gas diffusion. Thus, toxic gases and wet chemical baths are advantageously eliminated. A halogen gas, such as chlorine, and oxygen are added during the sputtering of a CdTe film, so that a wet process is eliminated and the deposited CdTe film can be annealed rapidly, such as by a rapid thermal anneal process (RTA).

Owner:SURYA POWER

Cadmium-Te solar battery with ultra-thin graphite slice as underlay

The invention relates to a CdTe solar cell which has a substrate of ultra-thin flake graphite,belonging to the field of new energy material and device. The invention uses flexible ultra-thin flake graphite as the substrate material, and sputters a layer of copper on the flake graphite, then carries heat treatment. The copper diffuses into graphite forming copper-doped flake graphite. The invention deposits a layer of tellurium on the copper-doped fake graphite, then deposits the CdTe and carries annealing treatment. In the process of deposition and annealing treatment of CdTe, heavily doped CuxTe layer is formed between flake graphite and CdTe, thus realizing ohmic contact between flexible ultra-thin graphite substrate and CdTe. And the invention deposits CdS, transparent conductive film and grid pattern aluminum electrode in turn to obtain flexible CdTe film solar cell. The invention solves the contradiction which is between high processing temperature required by preparing high efficient flexible CdTe and low tolerance temperature of conventional flexible substrate.

Owner:SICHUAN UNIV

Back contact layer structure and CdTe solar battery comprising back contact layer structure

The invention discloses a back contact layer structure and a CdTe solar battery comprising the back contact layer structure. The quantity of Cu elements required by implementation of ohm back contact is greatly decreased by introducing a high-work function transitional metal oxide layer between a CdTe thin film and a metal back electrode; meanwhile, the transitional metal oxide layer achieves an effect of preventing metal atoms in the metal back electrode from being dispersed to a CdTe and CdS / CdTe p-n node; therefore, the stability of the back contact electrode is improved, and high-conversion efficiency of the battery and the long-term stability of the battery in a use process are guaranteed.

Owner:UNIV OF SCI & TECH OF CHINA

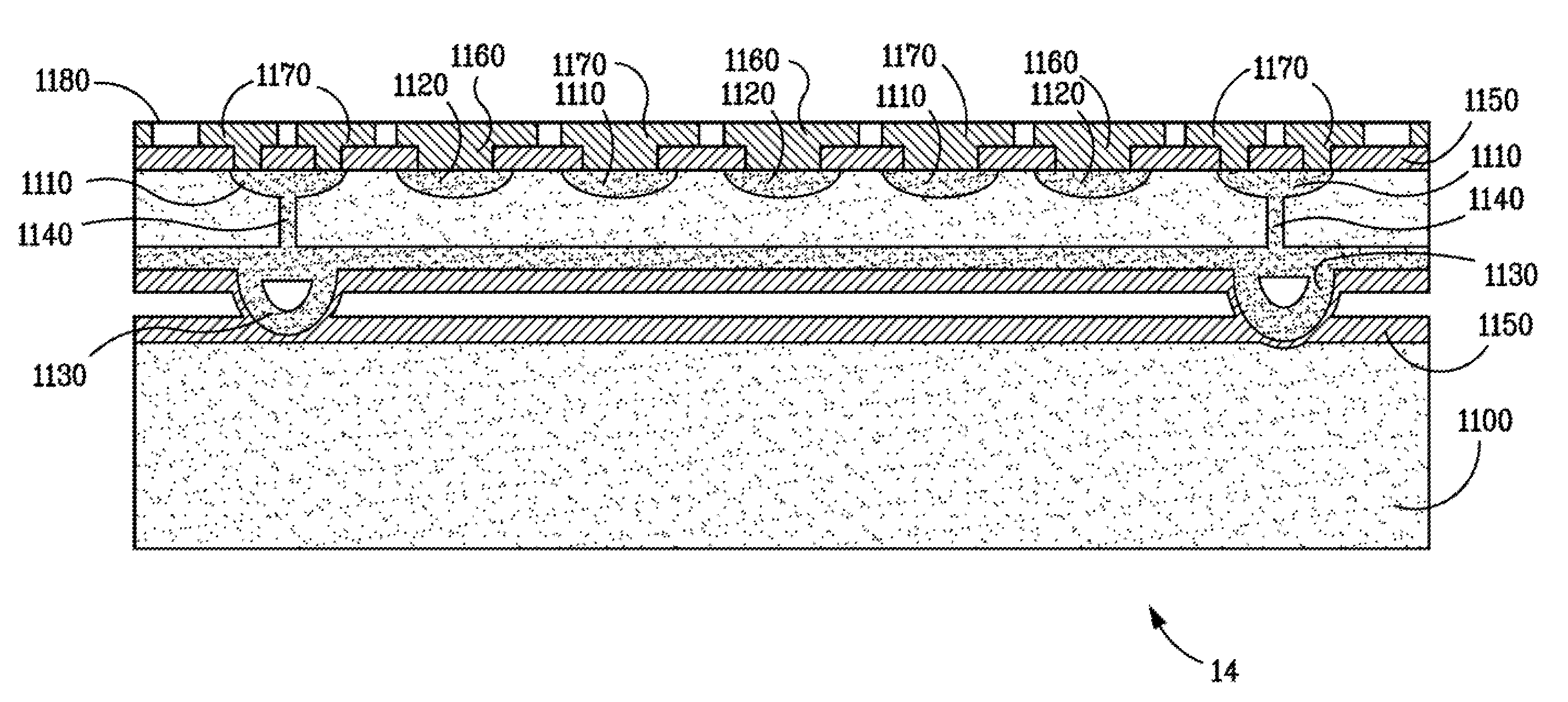

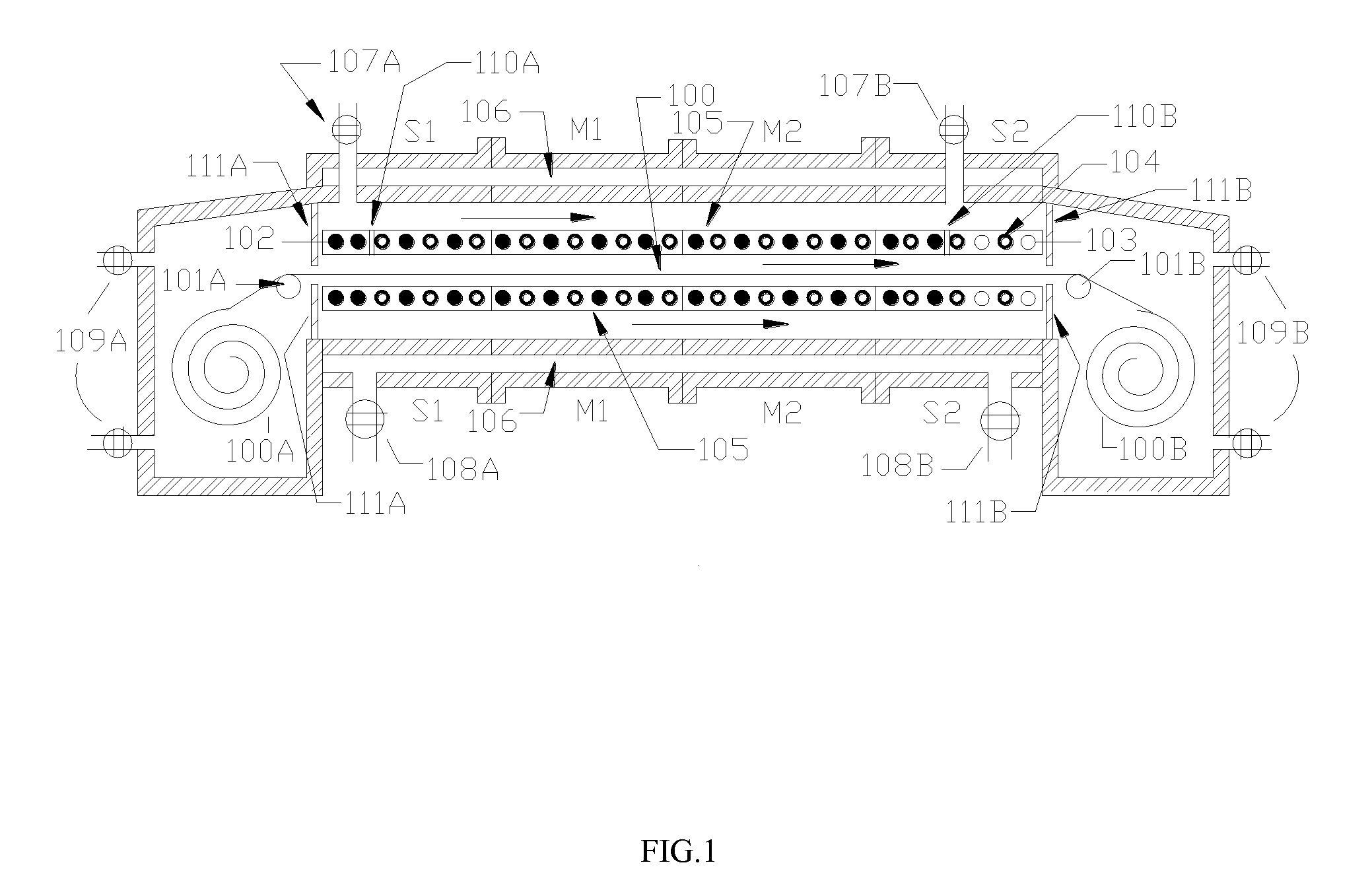

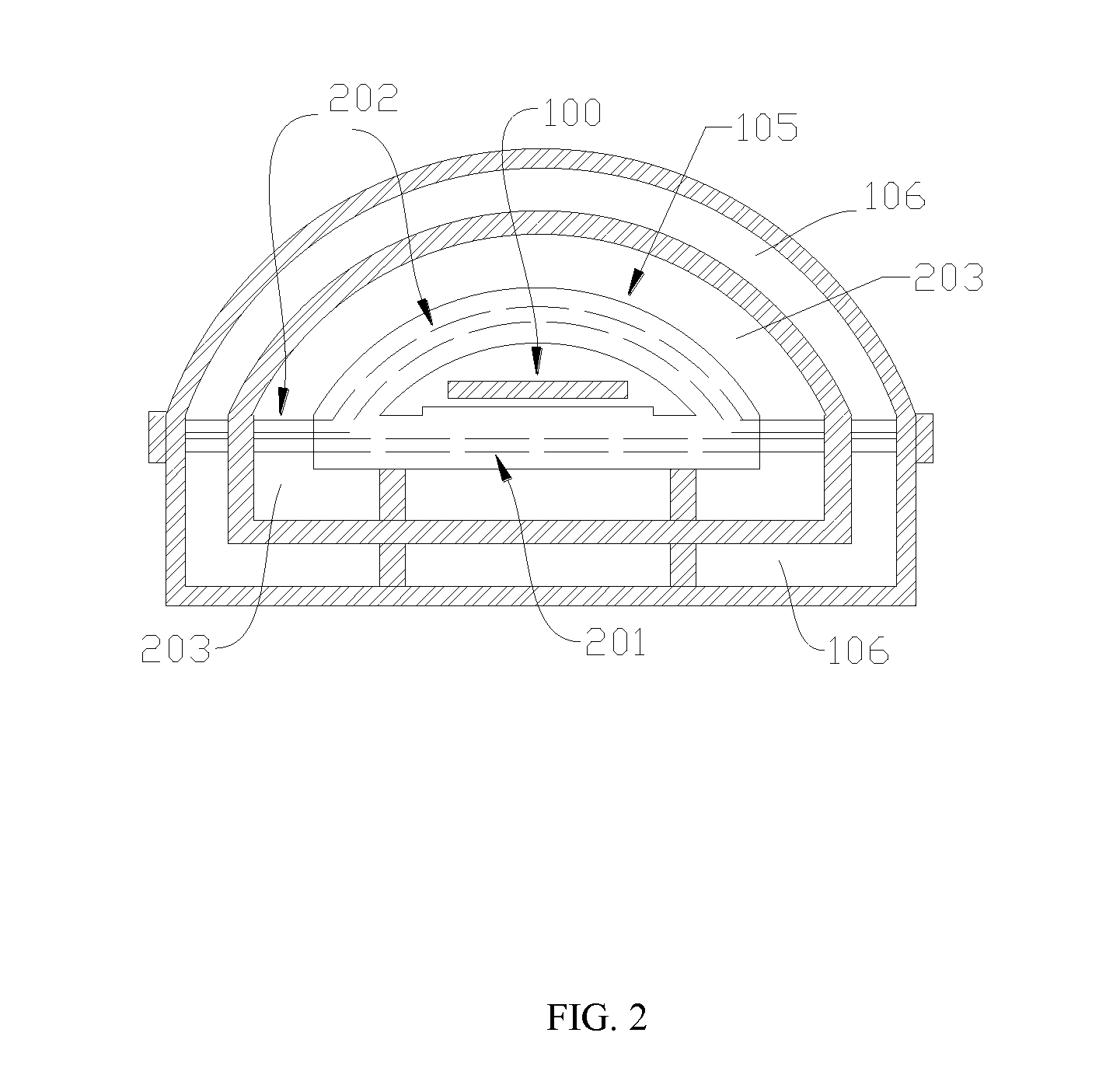

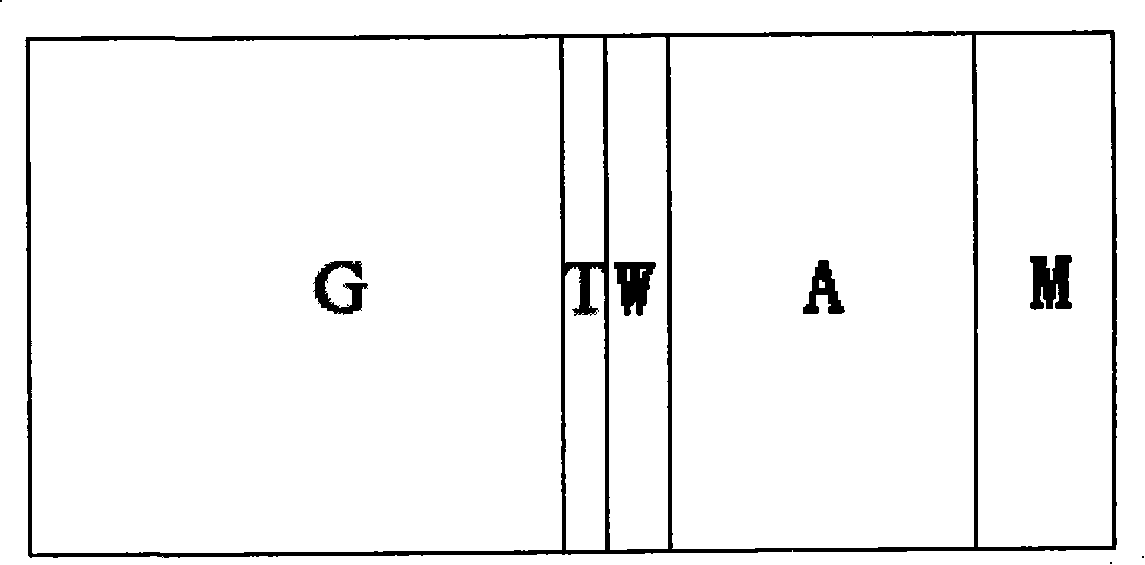

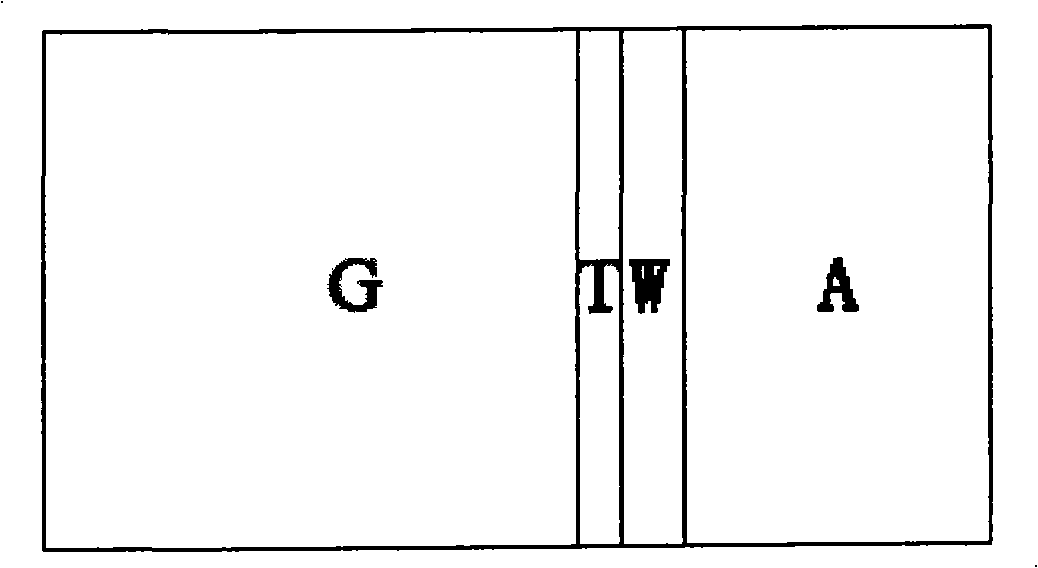

Assembled Reactor for Fabrications of Thin Film Solar Cell Absorbers through Roll-to-Roll Processes

InactiveUS20120264075A1Precise temperature controlSemiconductor/solid-state device manufacturingFurnace typesReactive gasComputer module

A roll-to-roll or reel-to-reel reactor, which is assembled with a heating section, a cooling section, plus a series of modular buffer sections between them, is provided. The length of this apparatus is controlled by adding or reducing numbers of the modular buffer sections on the basis of required reaction time and the delivery speed of a continuous flexible workpiece. The whole reactor contains a heating oven, included inside a main vacuum chamber, which is assembled with a series of modular thermal control components. One or more vacuum chambers can be put outside the main vacuum chamber for the purposes of heat insulation and gas leaking protection. A thermal control component has a segment cross-section shape with some heating elements, thermocouples and cooling elements installed inside. The reactor can also be designed for annealing and / or reaction of a precursor at a surface facing down position. A modular thermal control component is fabricated with a top and a bottom piece to form a rectangle cross-section shape. Some heating modules are arranged on the top and underneath of this thermal control component. The present reactor can be used for annealing and reaction of various precursor films on a flexible substrate under vacuum and in an inert or reactive gas ambient at a temperature ranging from a room temperature to a thousand of Celsius degrees. This reactor is particularly useful in manufacturing Group IB-IIIA-VIA and Group IIB-VIA thin film solar cells such as CIGS and CdTe solar cells on flexible substrates through a continuous roll-to-roll process.

Owner:WANG JIAXIONG

Surface corrosion of CdTe film and CdTe solar cell preparing by the process

InactiveCN101335310AImprove performanceLower barrier heightFinal product manufactureSemiconductor/solid-state device manufacturingSchottky barrierTe element

The invention relates to a method for surface corrosion of a CdTe film and preparation of a CdTe solar cell by adopting the method, pertaining to the processing field of semiconductor devices. An mixed liquid of nitric acid, glacial acetic acid, NaAc and deionized water is served as corrosive liquid, wherein, the NaAc is served as a buffering agent to keep the pH value of the intermixture unchanged and lead the reaction to be more stable; CdTe and the nitric acid react to generate a layer rich in tellurium; after washing and blow-drying, a back contact layer containing Cu or without Cu is sedimented; finally, a back electrode is sedimented for preparing the CdTe solar cell. Sedimentation of back contact material can increase carrier concentration near a pn junction, reduce the height of Schottky potential barrier and avoid direct sedimentation of Cu from forming a comparatively complex CuxTe structure. By adopting the method for corrosion and the preparation of the CdTe solar cell, the performance of the solar cell can be obviously improved and the stability and the repeatability of the device can be ensured.

Owner:SICHUAN UNIV

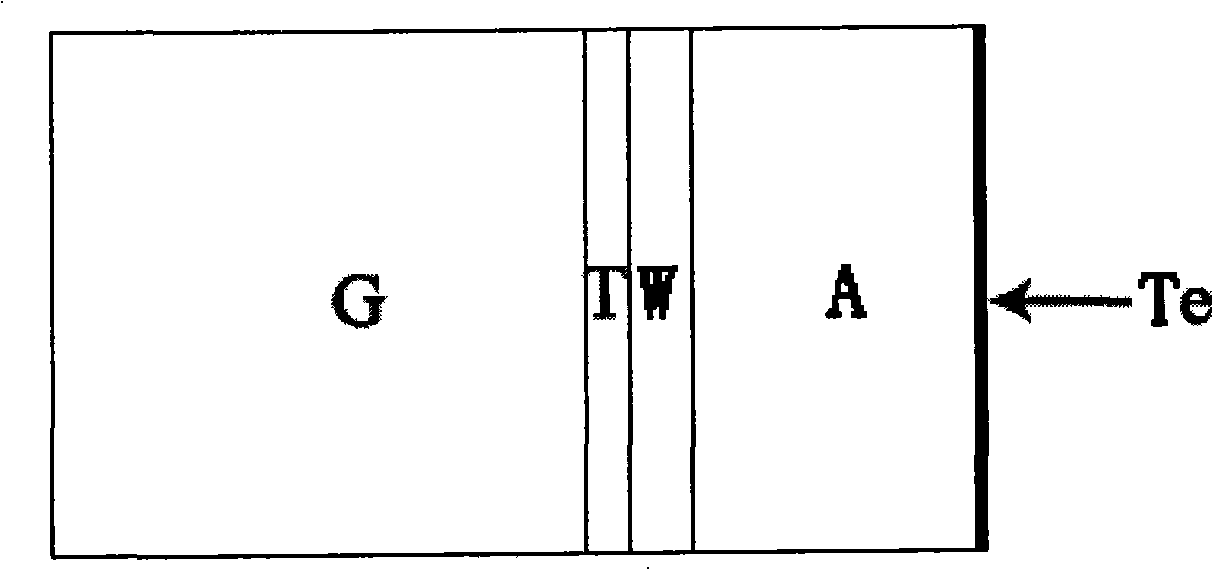

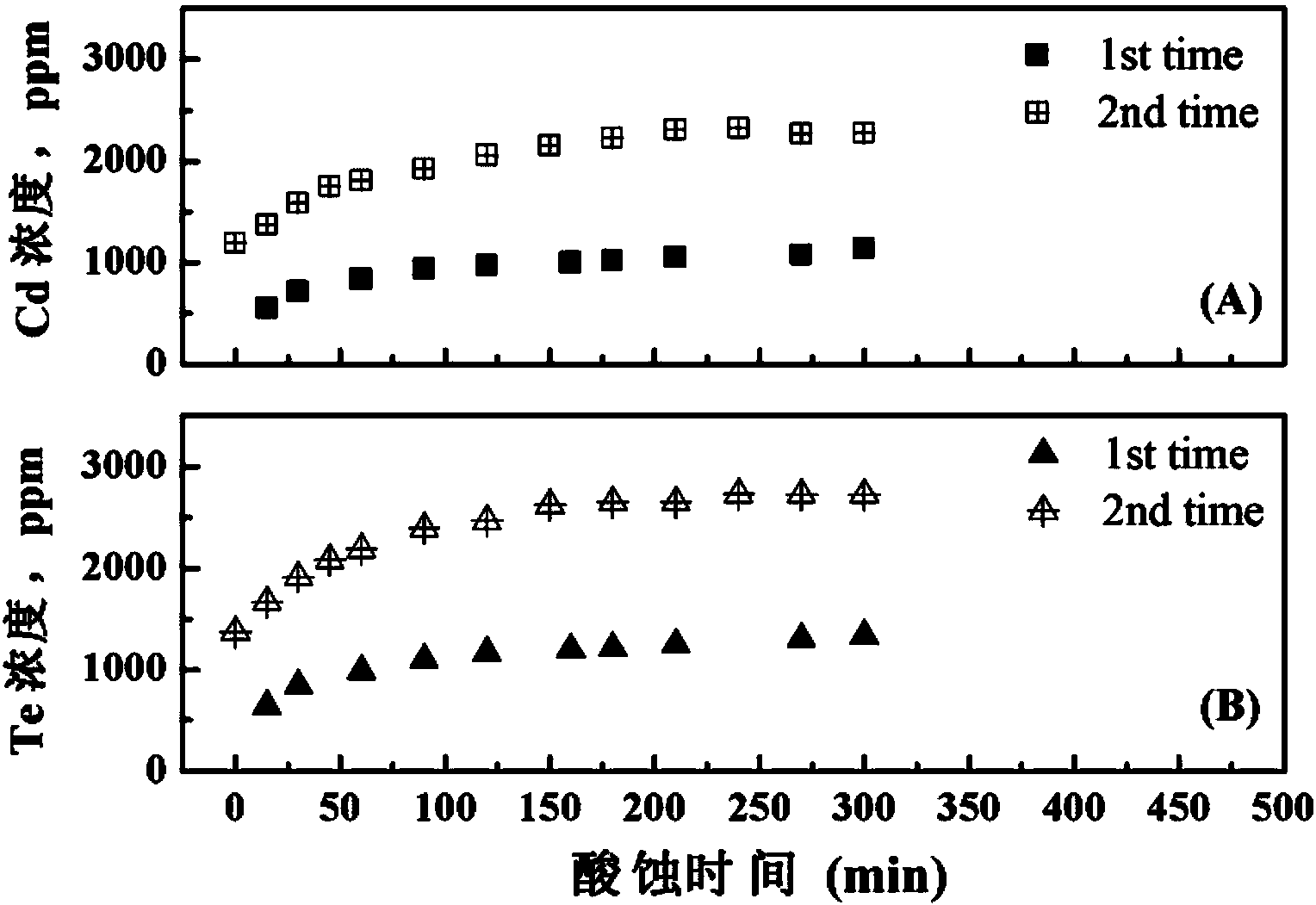

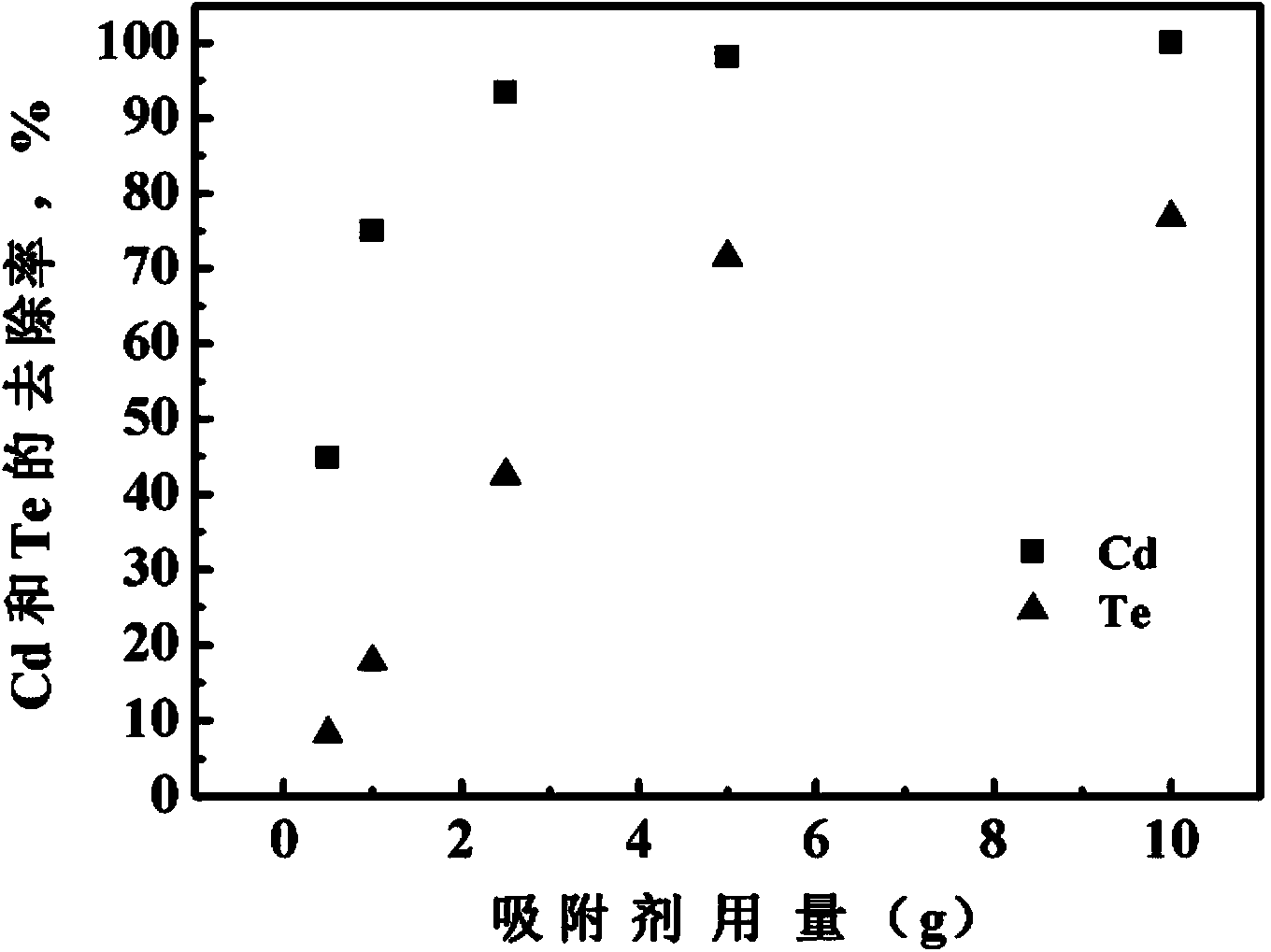

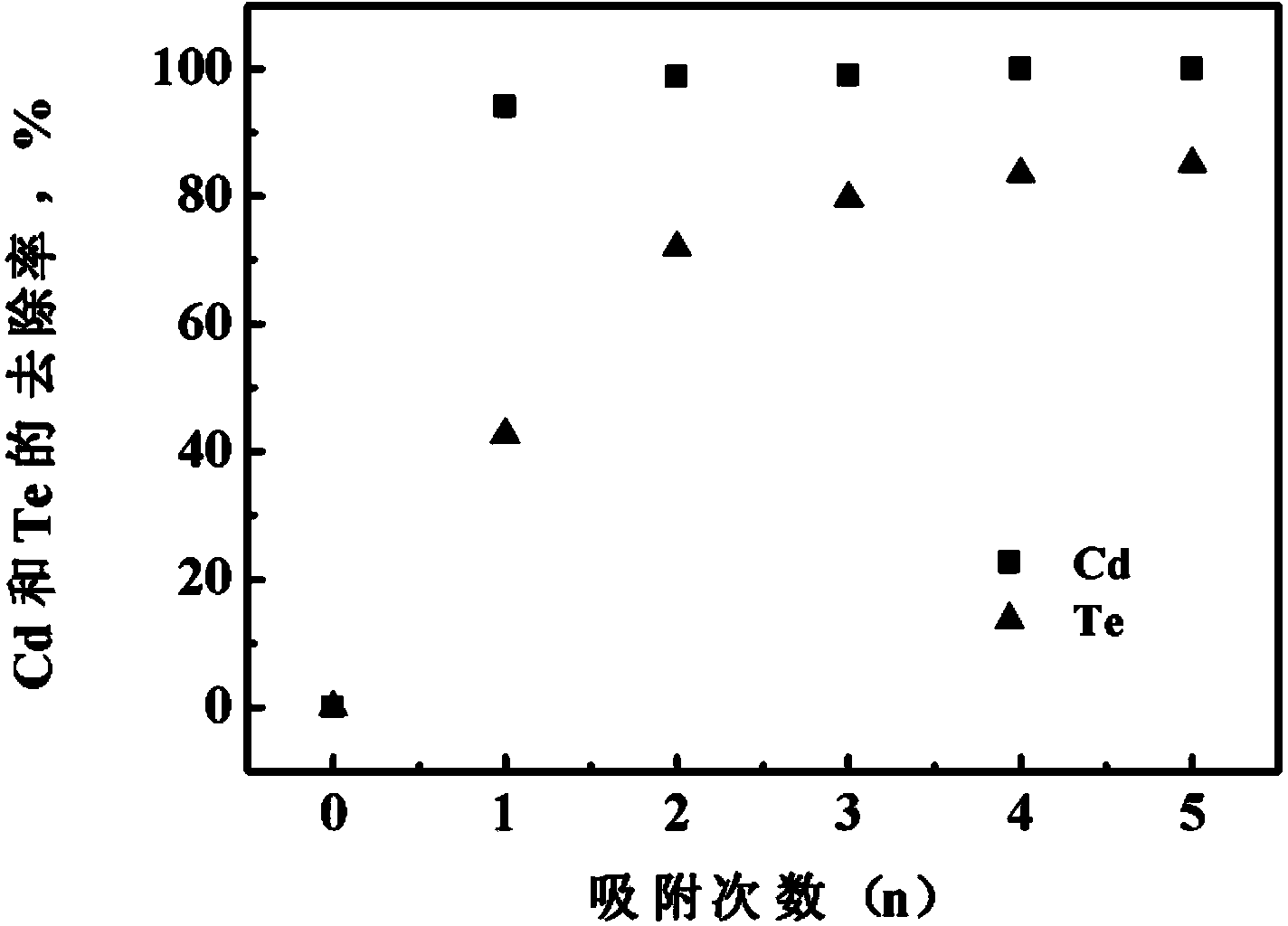

Recycling method of CdTe solar cell module

InactiveCN103866129AAvoid difficult pH controlAvoid the disadvantage of large amount of acid and alkaliSelenium/tellurium compundsProcess efficiency improvementAcid etchingHigh concentration

The invention discloses a recycling method of a CdTe solar cell module. The recycling method is characterized in that the CdTe solar cell glass module of which EVA encapsulation adhesive is removed is dipped in a sulfuric acid / hydrogen peroxide solution to be subjected to adequate acid etching, Cd and Te elements are directly and quickly gathered from an acid etching solution of CdTe by using magnetic polymer microspheres, and obtained high-concentration Cd and Te acid etching solution can be further used for an electrolytic process. The recycling process has the characteristics of high gathering separation efficiency, simple technical process and easy amplification, and the magnetic polymer microspheres can be recycled.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

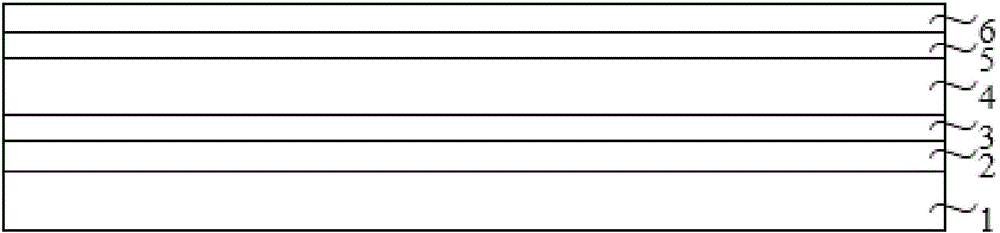

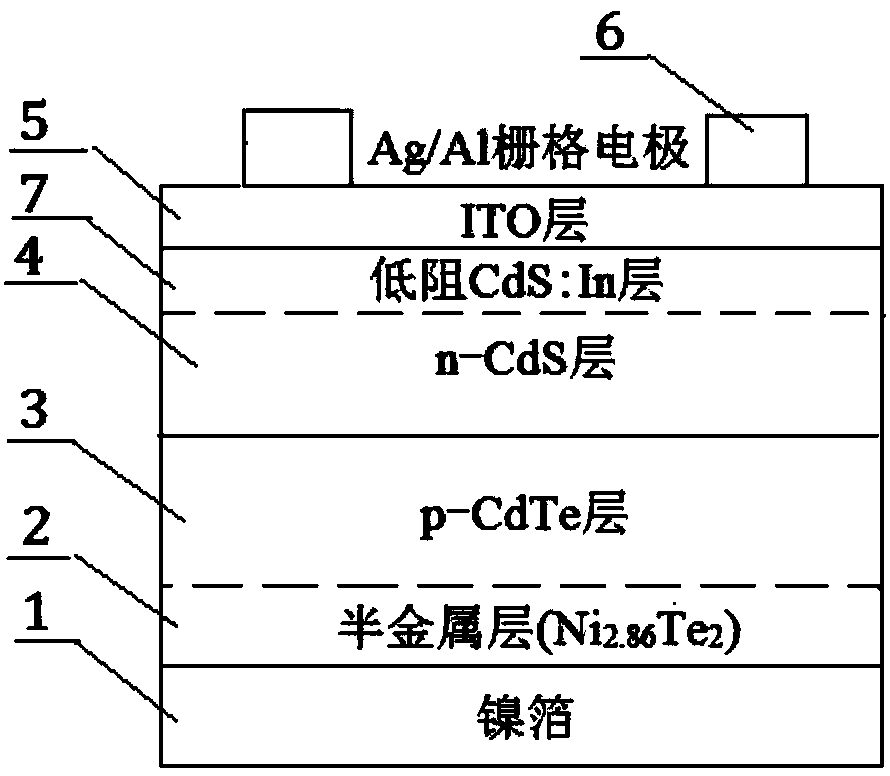

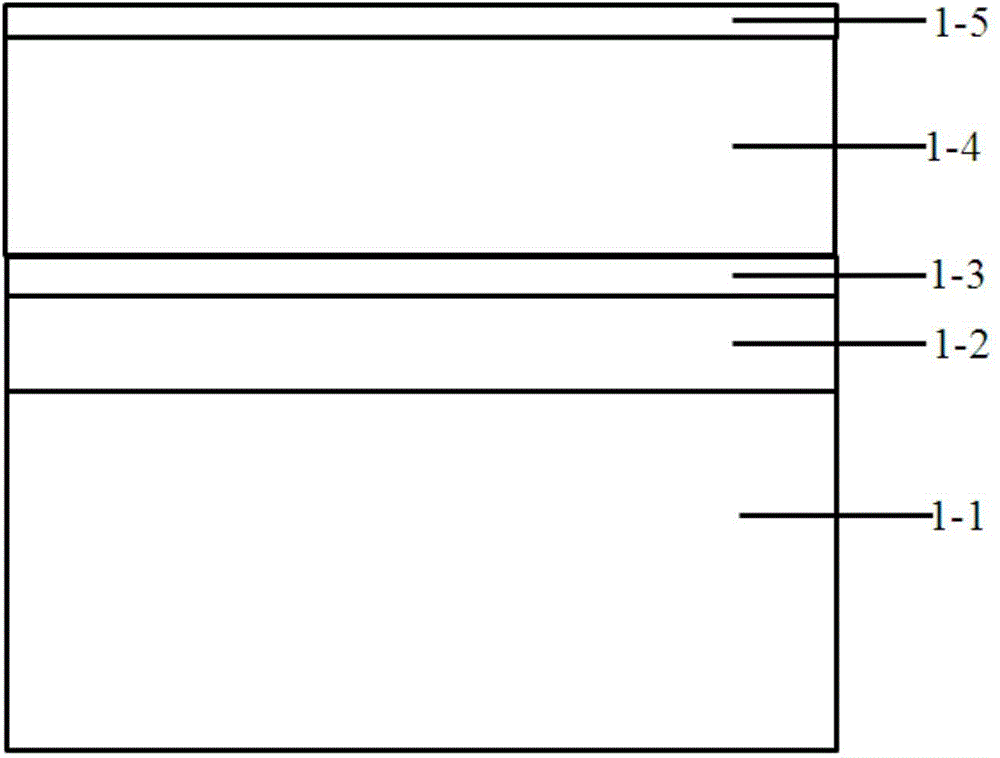

Flexible CdTe (Cadmium Telluride) film solar battery and preparation method thereof

InactiveCN103811579AUniform film thicknessRaw materials are easy to getFinal product manufacturePhotovoltaic energy generationIndiumEvaporation

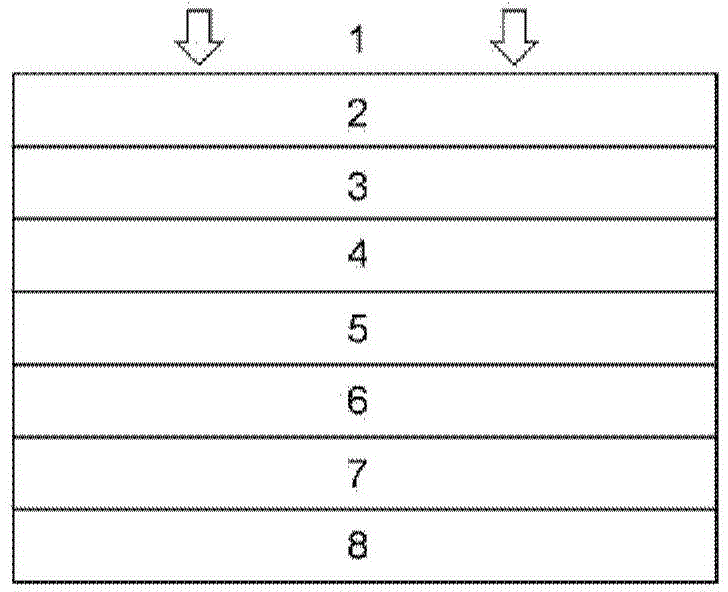

The invention discloses a flexible CdTe (Cadmium Telluride) film solar battery and a preparation method thereof, belonging to the field of a solar battery technology. The structural sequence of the battery is a metal back electrode (1), a semimetal layer (2), a p type CdTe layer (3), a n type CdS (Cadmium Sulfide) layer (4), a transparent electric film (5), a metal grid electrode (6) and a low resistance CdS: In (Indium) layer (7). The CdTe film solar battery is prepared by electrochemical deposition, the transparent electric film is deposited by selecting a deposition potential and subsequent thermal evaporation, the semimetal layer, the p type CdTe layer gradiently rich in tellurium, the n type CdS layer and an indium doped stannic oxide transparent conductive layer are respectively prepared on a nickel foil substrate, and the metal grid electrode is prepared on the surface of the transparent conductive layer by using an ion sputtering method. The film solar battery is likely to obtain raw materials, easy to operate, simple in technology, short in elapsed time and high in the stable photoelectric conversion efficiency of a battery module, thereby being applicable to manufacturing CdTe film solar batteries with large areas.

Owner:JILIN UNIV

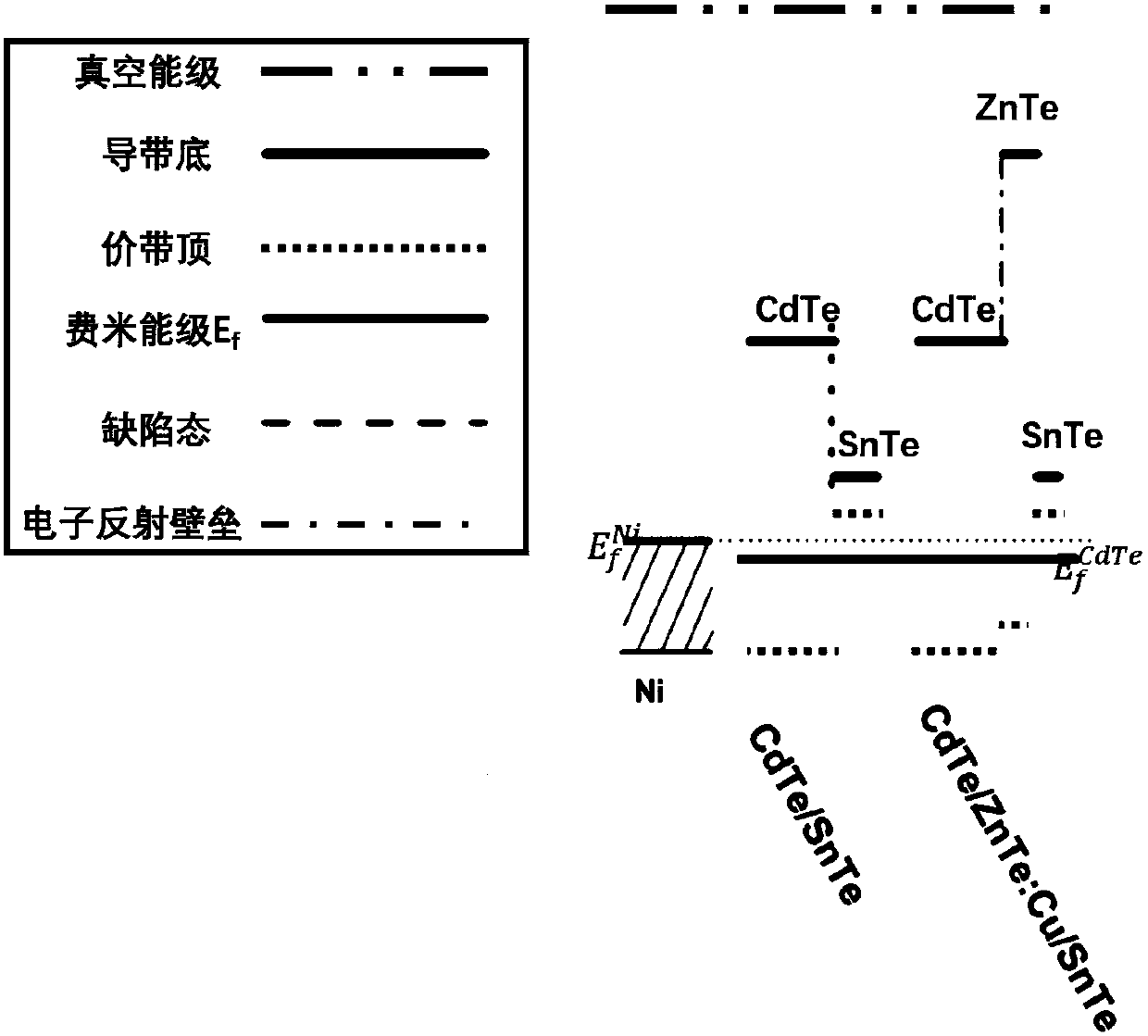

CdTe thin film solar battery taking SnTe as back electrode buffer layer, and preparation method of thin film solar battery

ActiveCN107946393AIncrease the carrier concentrationHigh hole mobilityFinal product manufacturePhotovoltaic energy generationHeterojunctionCharge carrier

The invention discloses a CdTe thin film solar battery taking SnTe as a back electrode buffer layer, and a preparation method of the thin film solar battery. According to the CdTe thin film solar battery taking SnTe as the back electrode buffer layer, a battery is arranged in the back electrode position of the CdTe thin film solar battery, and a layer of SnTe buffer layer or a composite buffer layer which is formed by ZnTe:Cu and SnTe is grown between CdTe and a metal back electrode, wherein the SnTe thin film is P+ type. The SnTe thin film has quite high carrier concentration, high hole mobility and extremely low resistivity; and a heterojunction energy band structure formed by the SnTe thin film and CdTe highly facilitates hole transport, thereby lowering potential barrier in the back electrode position of the CdTe thin film solar battery.

Owner:ZHEJIANG UNIV +1

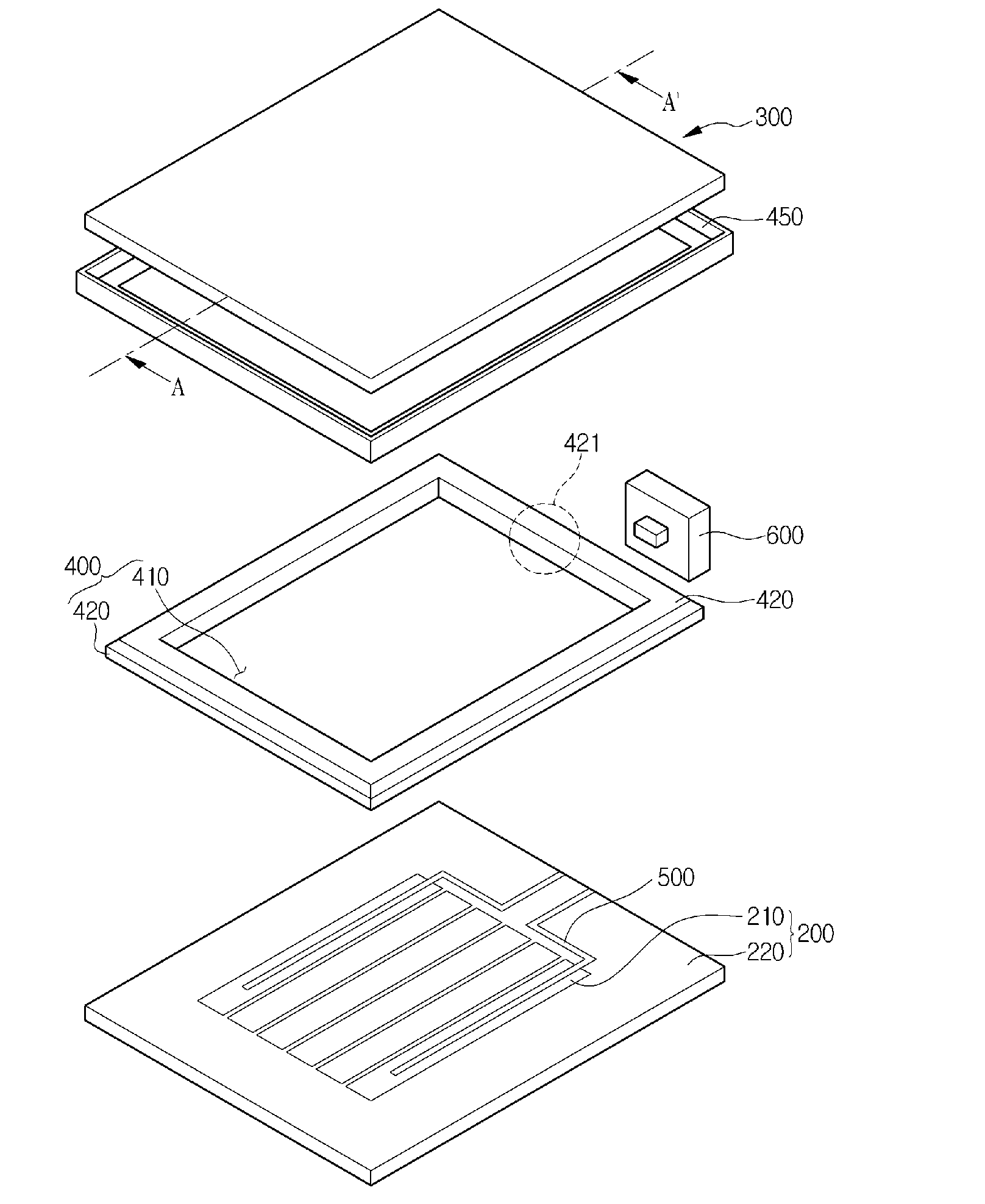

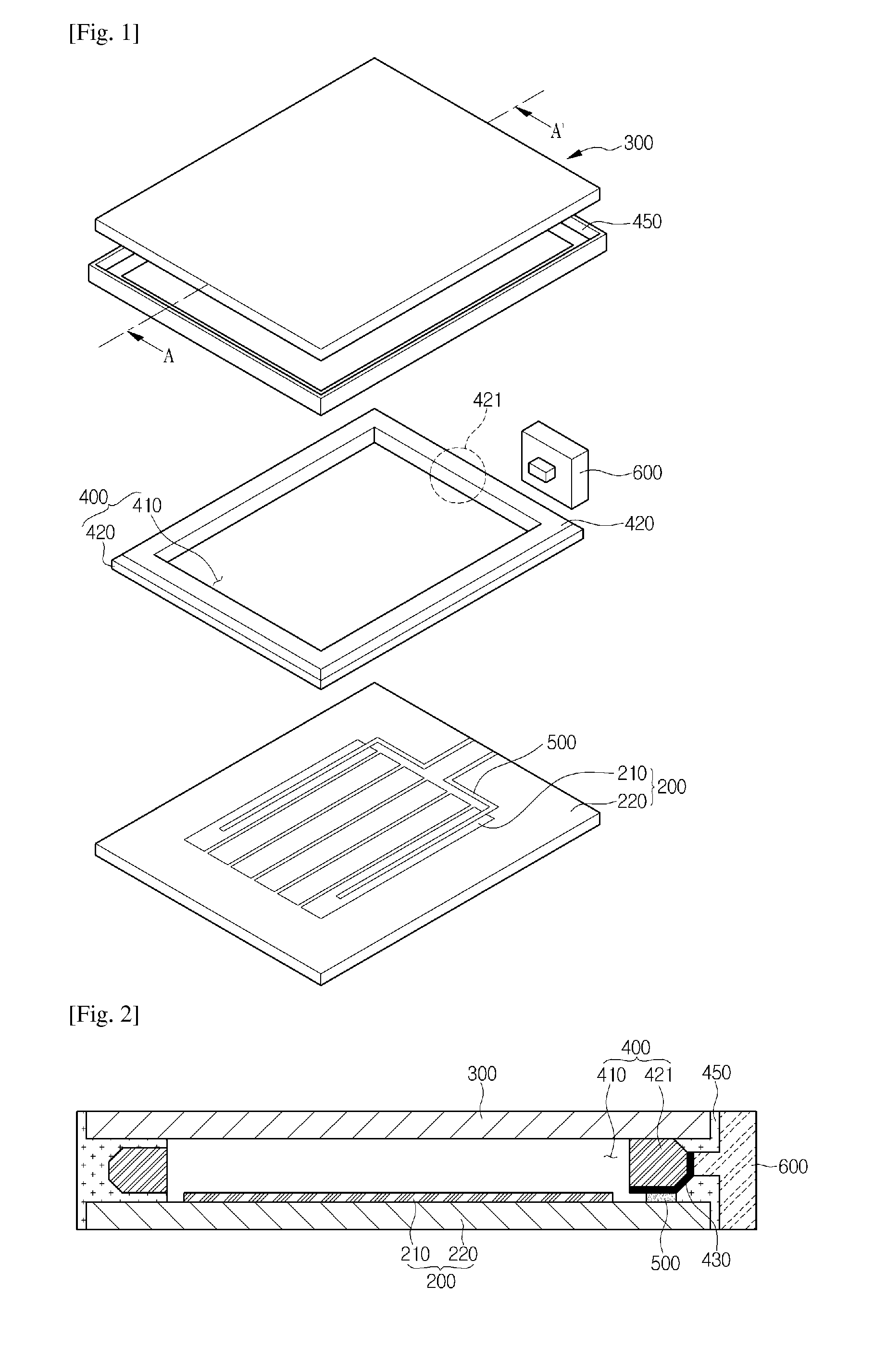

Solar cell module

InactiveUS20150020872A1Improve insulation performanceImprove insulation effectPV power plantsPhotovoltaic energy generationEngineeringAir layer

A solar cell module includes a solar cell panel including a plurality of solar cells and a bus bar connected to the solar cells, a protective substrate on the solar cell panel, and a spacer part between the solar cell panel and the protective substrate. The spacer part includes an air layer and a spacer surrounding the air layer.

Owner:LG INNOTEK CO LTD

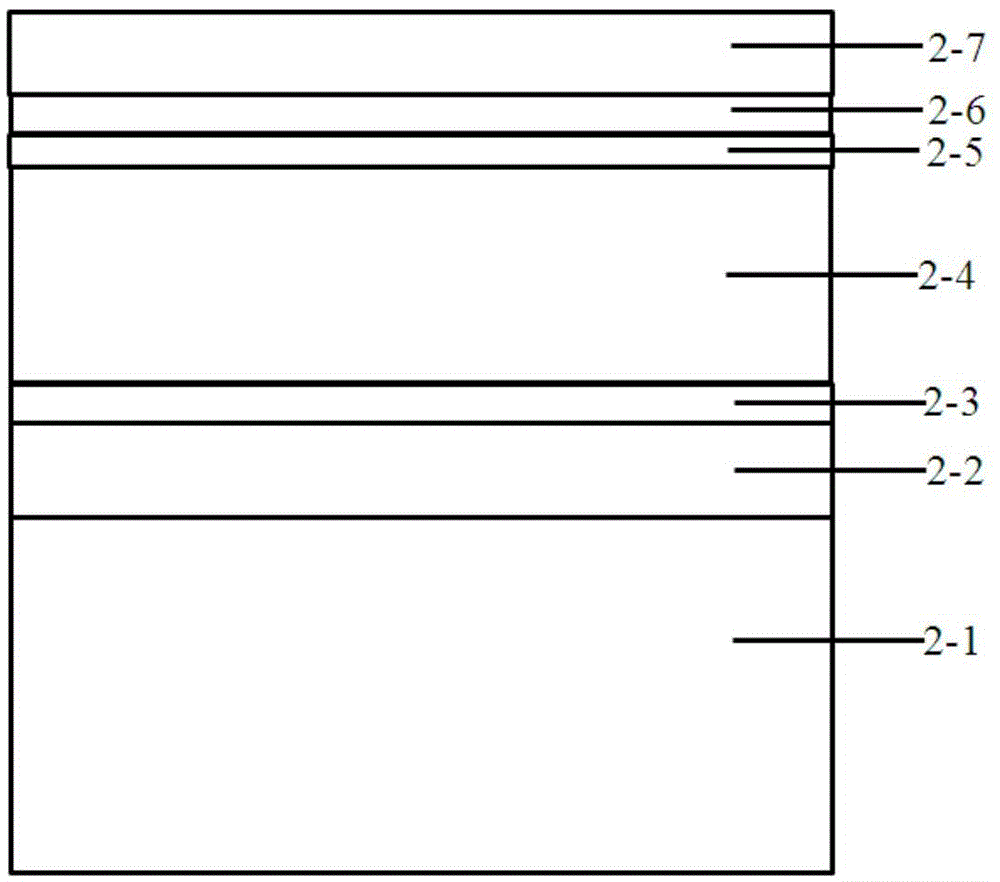

CdTe cell with p-i-n structure and preparation method thereof

InactiveCN104064618AReduce usageGuaranteed micro-flatnessFinal product manufacturePhotovoltaic energy generationSputteringMetal electrodes

The invention discloses a CdTe solar cell with a p-i-n structure. The CdTe solar cell comprises a substrate, a transparent conductive electrode layer, a CdS n-type semiconductor layer, a CdTe intrinsic light absorption layer, a broad-band gap ternary II-VI group semiconductor p<+> layer, a ZnO:Al or In2O3:Sn n<+> layer and a metal electrode layer sequentially from the bottom up. The CdTe solar cell with the p-i-n structure is prepared by low-temperature magnetron sputtering.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Photovoltaic solar cell

ActiveUS9130092B1Increase displacementStay focusedPhotovoltaic supportsFinal product manufactureElectrical batteryEngineering

A photovoltaic solar concentrator is disclosed with one or more transverse-junction solar cells (also termed point contact solar cells) and a lens located above each solar cell to concentrate sunlight onto the solar cell to generate electricity. Piezoelectric actuators tilt or translate each lens to track the sun using a feedback-control circuit which senses the electricity generated by one or more of the solar cells. The piezoelectric actuators can be coupled through a displacement-multiplier linkage to provide an increased range of movement of each lens. Each lens in the solar concentrator can be supported on a frame (also termed a tilt plate) having three legs, with the movement of the legs being controlled by the piezoelectric actuators.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Photovoltaic solar concentrator

ActiveUS9287430B1Increase displacementStay focusedPhotovoltaic supportsFinal product manufacturePiezoelectric generatorEngineering

A photovoltaic solar concentrator is disclosed with one or more transverse-junction solar cells (also termed point contact solar cells) and a lens located above each solar cell to concentrate sunlight onto the solar cell to generate electricity. Piezoelectric actuators tilt or translate each lens to track the sun using a feedback-control circuit which senses the electricity generated by one or more of the solar cells. The piezoelectric actuators can be coupled through a displacement-multiplier linkage to provide an increased range of movement of each lens. Each lens in the solar concentrator can be supported on a frame (also termed a tilt plate) having three legs, with the movement of the legs being controlled by the piezoelectric actuators.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

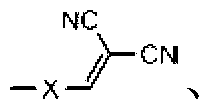

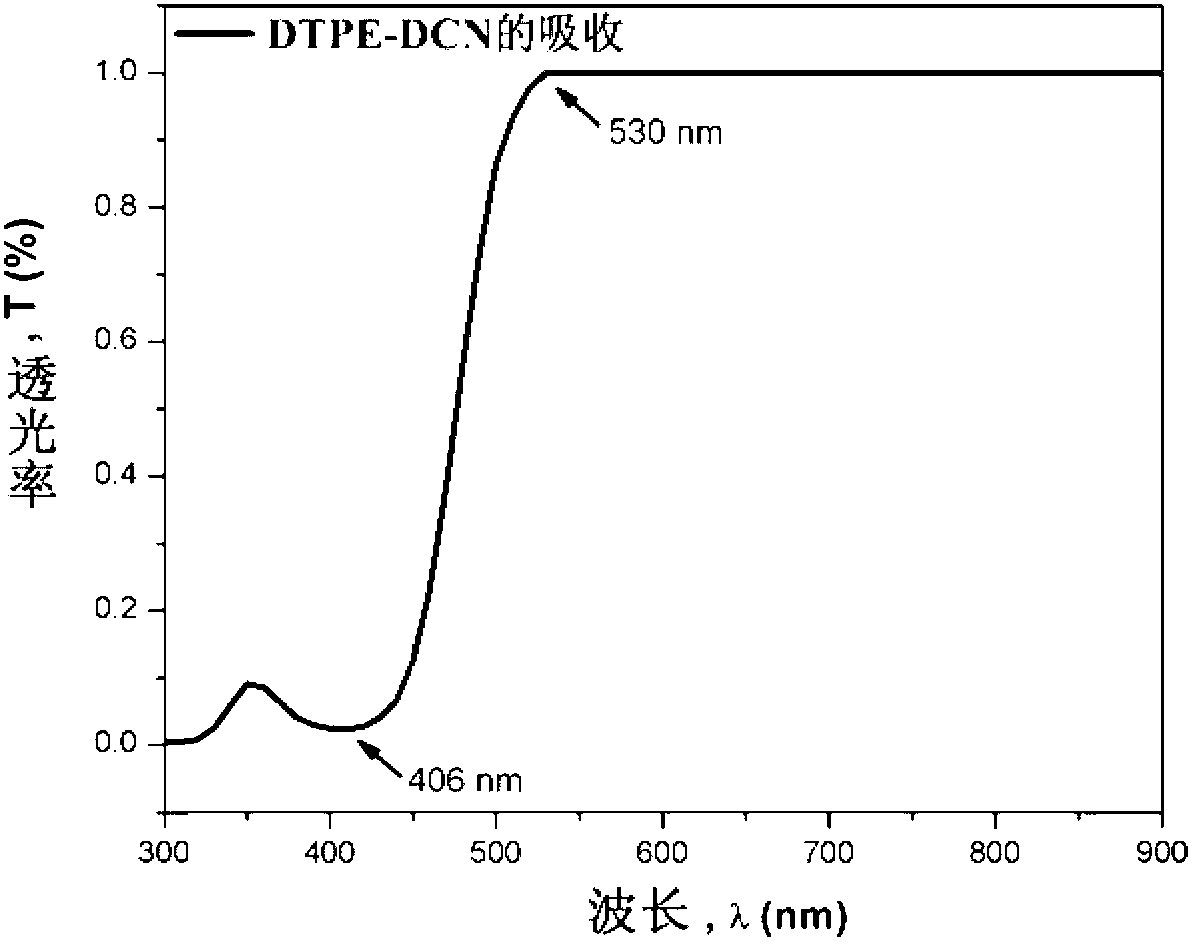

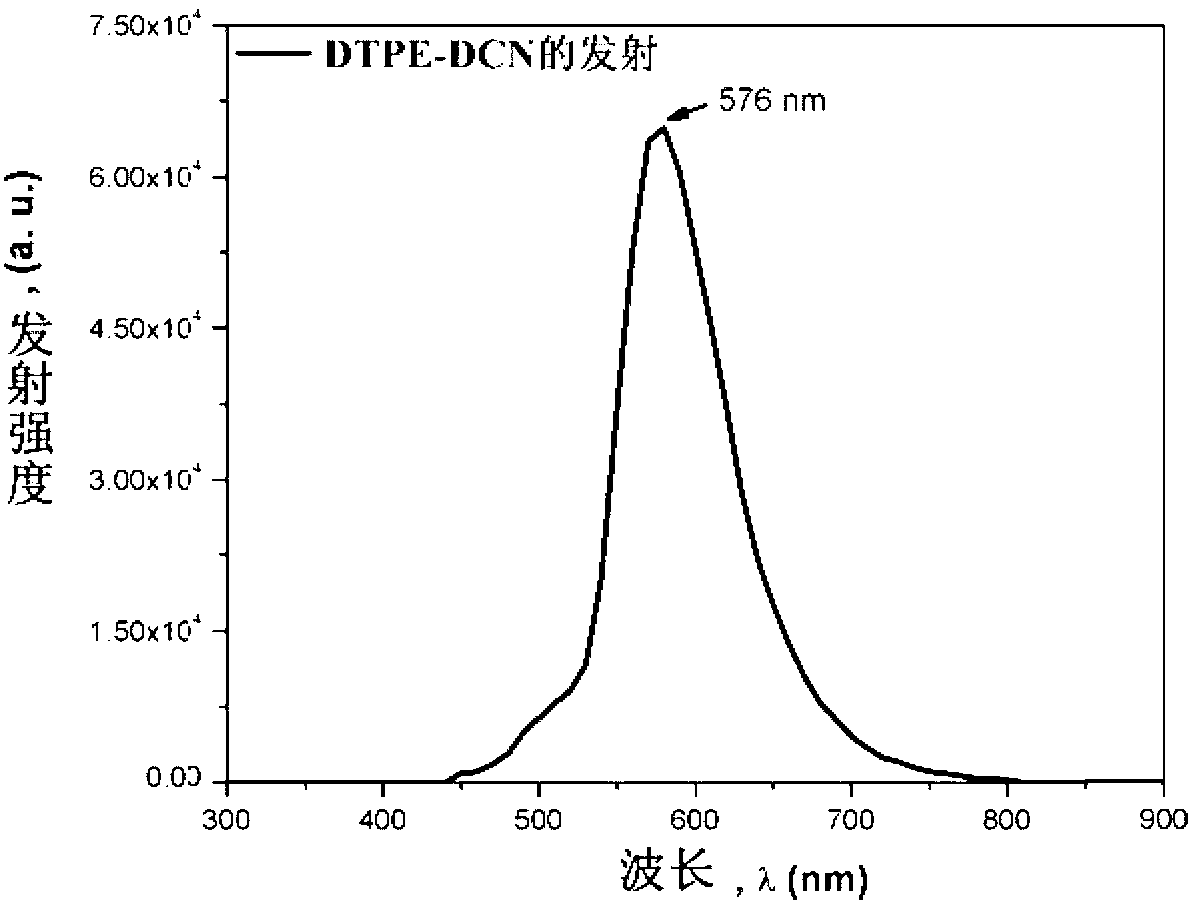

Under-wavelength transfer material as well as preparation method and application thereof

ActiveCN103274965AHas aggregated state fluorescence enhancement propertiesWide absorption rangeCarboxylic acid nitrile preparationOrganic compound preparationSolar batteryStructural formula

The invention provides an under-wavelength transfer material as well as a preparation method and an application thereof. The structural formula of the under-wavelength transfer material is as shown in (I) or (II). According to the preparation method, the under-wavelength transfer material is prepared by reacting a tetraphenyl ethylene midbody with functional groups and groups with electron-deficient property through Suzuki, Stille and Knoevenagel. The application mode of the under-wavelength transfer material is as follows: mixing the under-wavelength transfer material in a polymer in proportion to prepare a synergism film, directly coating the surface of a CdS / CdTe solar battery with the synergism film, and filling space between interfaces with a refractive index matching liquid. The prepared synergism film can be used for expanding the absorption of the CdS / CdTe solar battery on photons with the wavelength of 500nm, so that the efficiency of the CdS / CdTe solar battery is improved by 6%-11%, and the CdS / CdTe solar battery has a good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Solar cell

InactiveCN102034885APhotovoltaic energy generationSemiconductor devicesRefractive indexDielectric layer

The invention relates to a solar cell having a pigmented dielectric reflector which has two dielectric layers with different refractive indexes and a pigment embedded in the layer, so that the high efficiency of the solar cell is obtained under the condition of having a smaller reflector thickness. The invention also relates to a material system applicable to manufacturing the dielectric reflector.

Owner:SCHOTT SOLAR AG (DE)

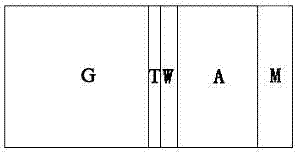

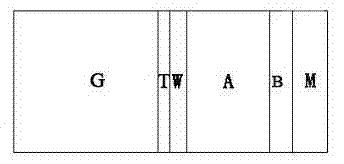

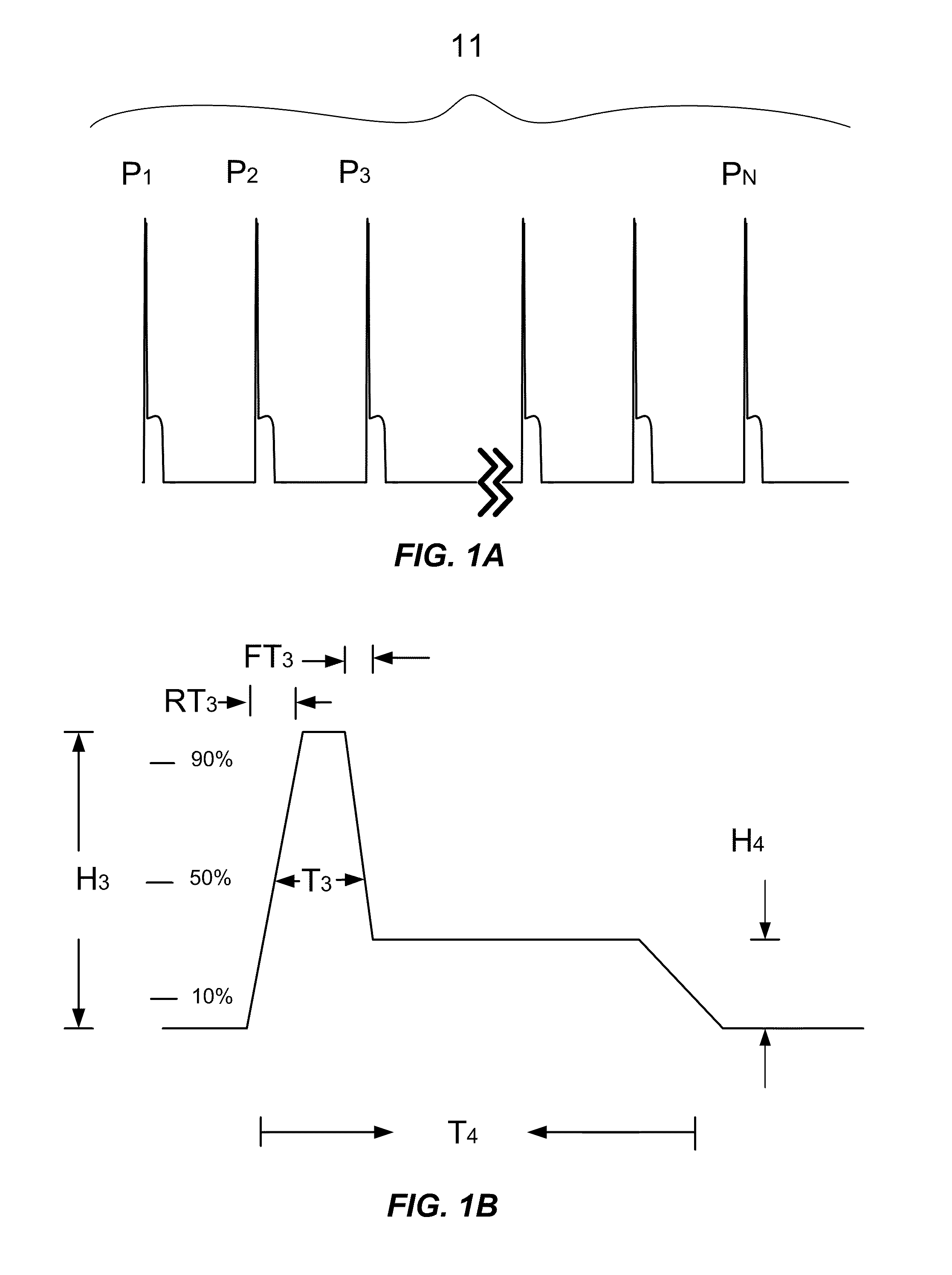

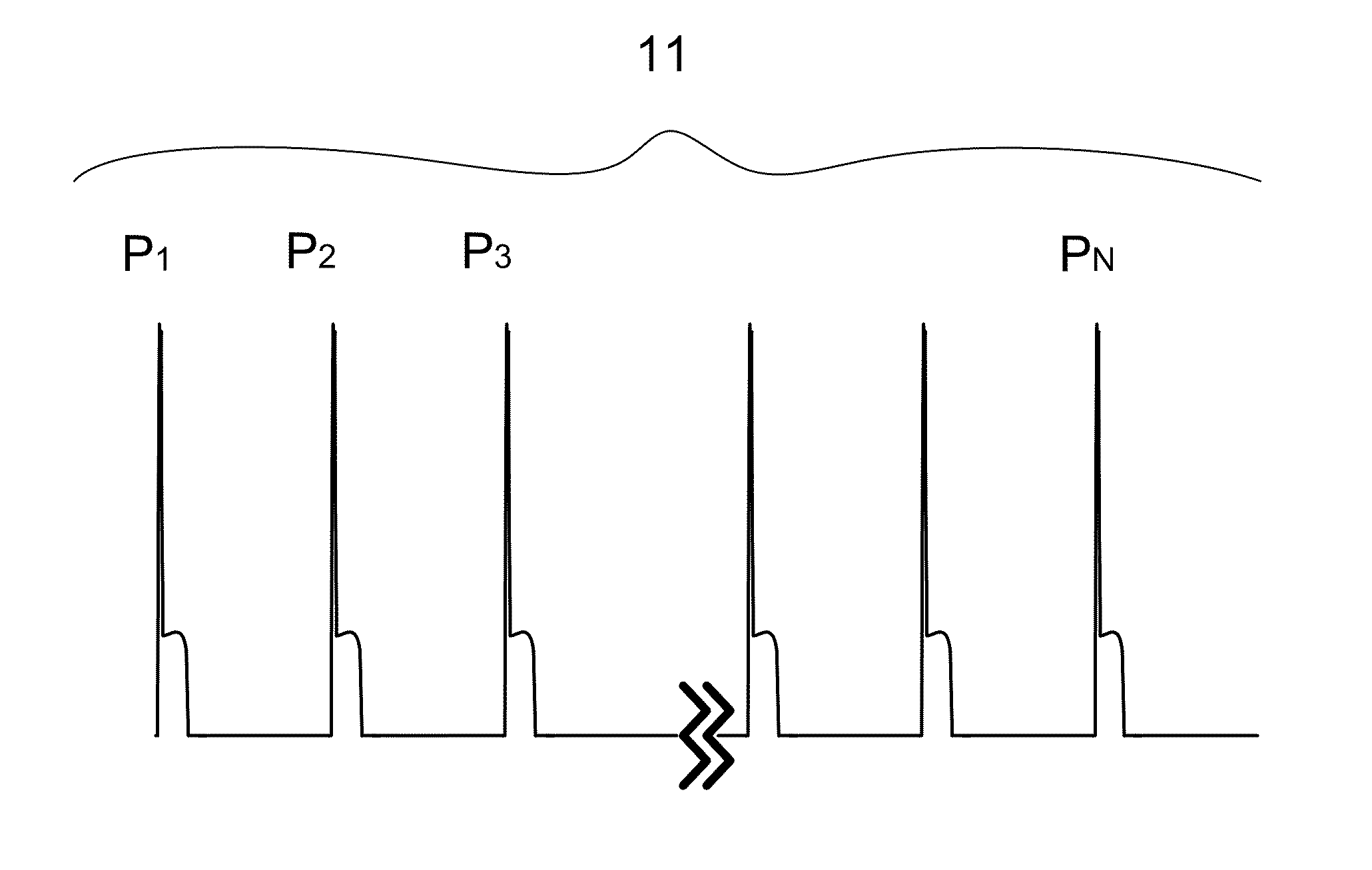

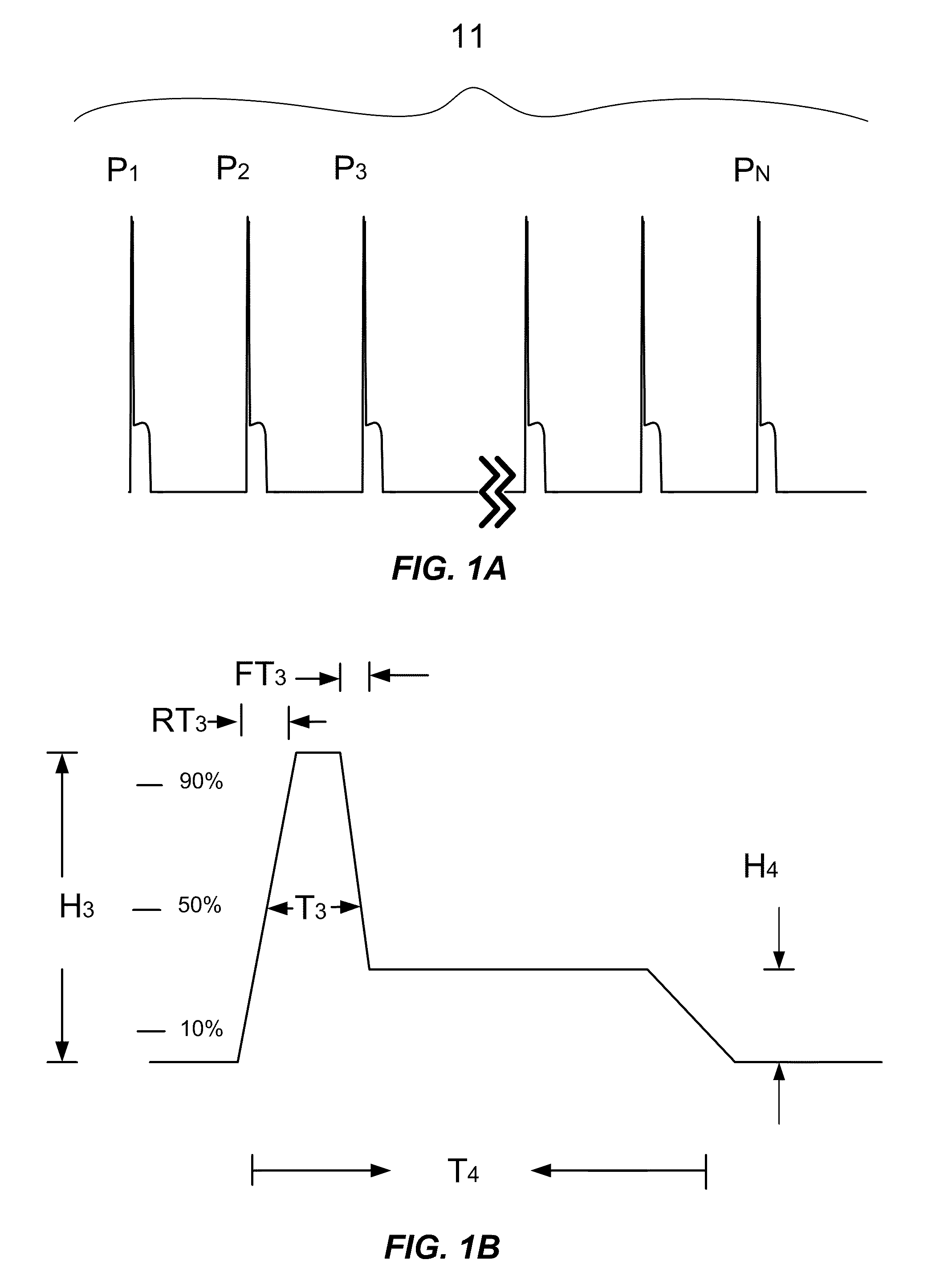

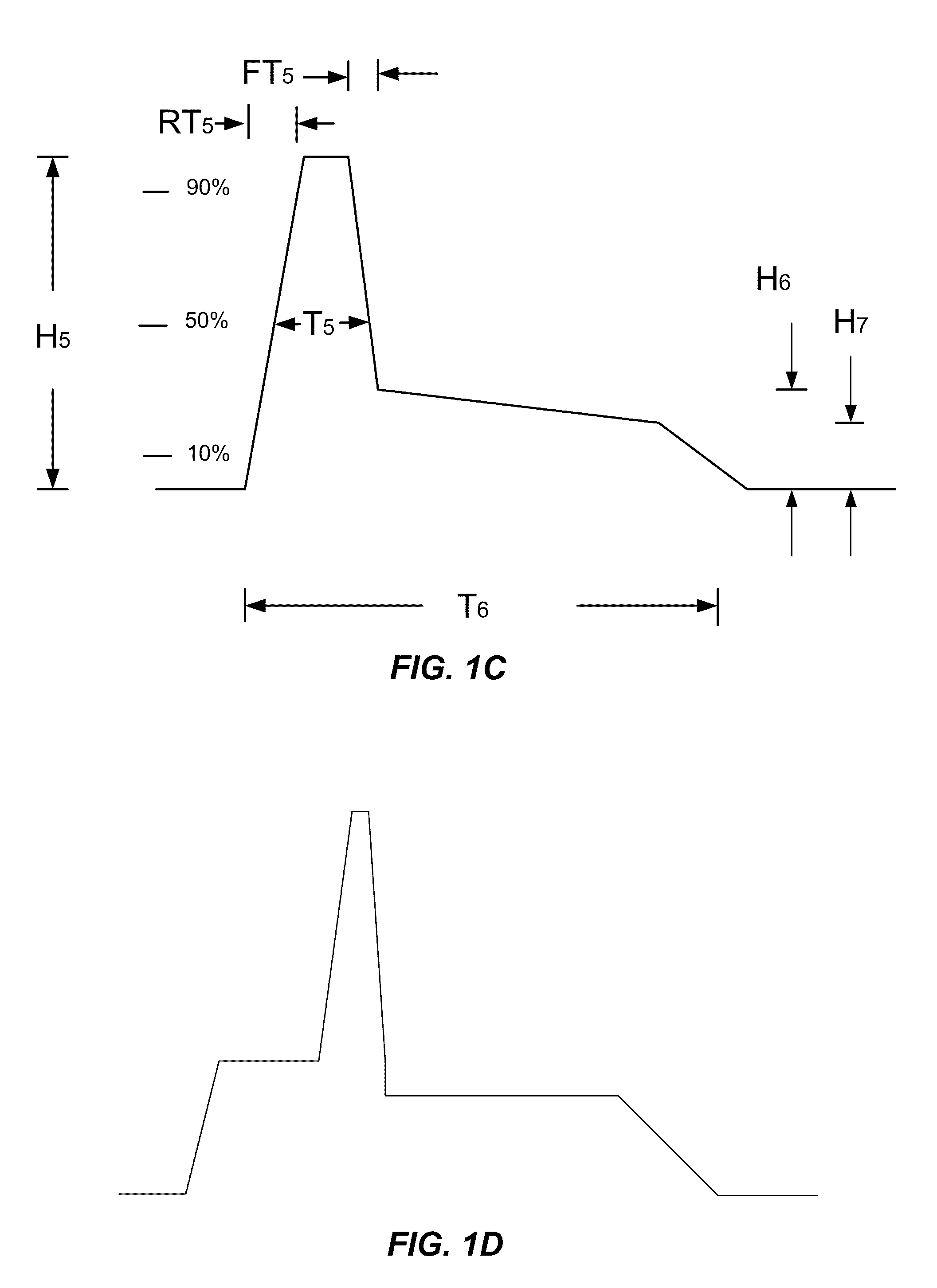

Method and apparatus to scribe thin film layers of cadmium telluride solar cells

InactiveUS20110240614A1Quality improvementHigh yieldWelding/soldering/cutting articlesLaser beam welding apparatusControl layerLaser scribing

A method of laser scribing a CdTe solar cell structure includes providing a laser operable to produce an optical pulse. The optical pulse is characterized by a temporal profile having a first power level during a first portion of the optical pulse and a second power level less than the first power level during a second portion of the optical pulse. The method also includes directing the optical pulse to impinge on the CdTe solar cell structure. The CdTe solar cell structure includes a substrate, a transmission spectrum control layer adjacent the substrate; a barrier layer adjacent the transmission spectrum control layer, and a conductive layer adjacent the barrier layer. The method further includes initiating a removal process for the conductive layer and terminating the removal process prior to removing the insulating layer.

Owner:ELECTRO SCI IND INC

CdTe solar cell and method for manufacturing same

ActiveCN102723384AAvoid absorptionIncrease profitFinal product manufacturePhotovoltaic energy generationPhysical chemistryEngineering

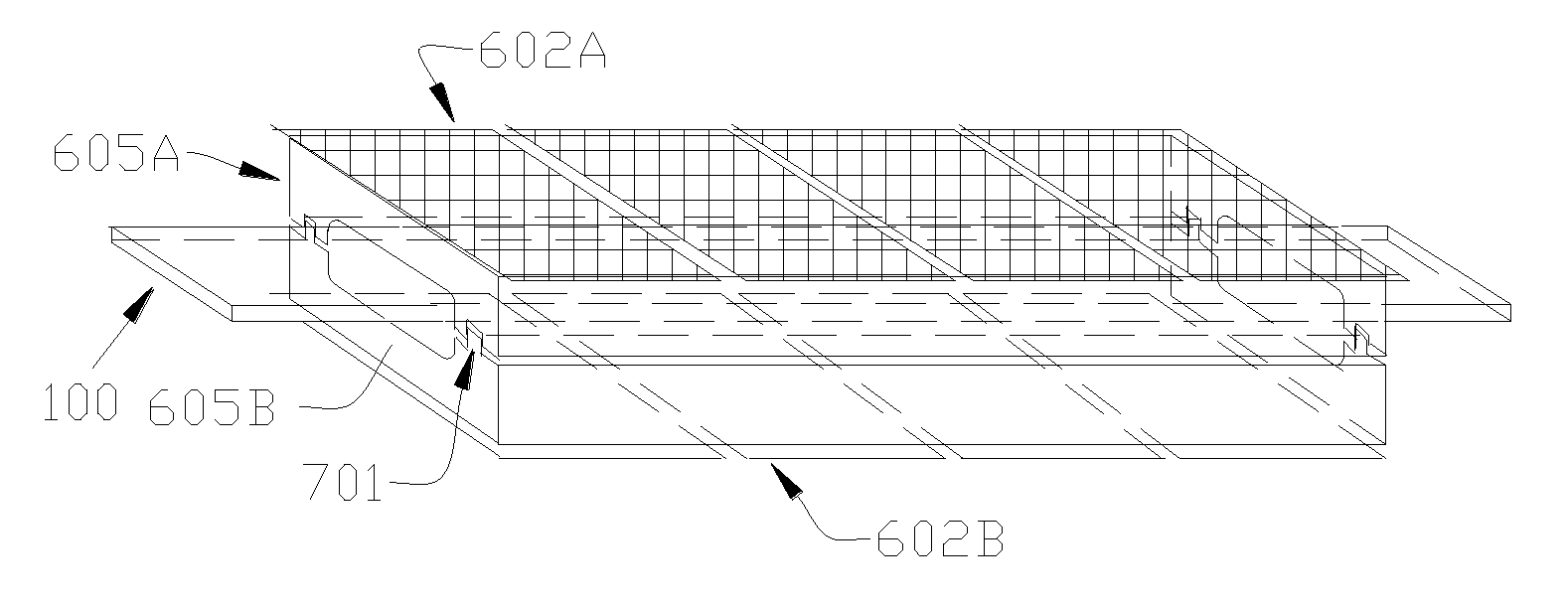

The invention provides a CdTe solar cell, comprising a glass substrate, a light absorption layer, a first electrode area, and a second electrode area. The light absorption layer is laminated on the glass substrate, and the upper surface of the light absorption layer is provided with the first electrode area and the second electrode area; the first electrode area comprises a corroded light absorption layer, a back contact transition layer and a positive electrode layer laminated in sequence; the second electrode area comprises an N-type layer and a P-type layer laminated in sequence; the corroded light absorption layer is in contact with the upper surface of the light absorption layer; the N-type layer is in contact with the upper surface of the light absorption layer; and the first electrode area and the second electrode area are insulated from each other. The solar cell is of a novel structure, which reduces the technical process and the manufacturing cost, significantly improves the photoelectric conversion efficiency of the CdTe solar cell, and is beneficial to mass production.

Owner:BYD CO LTD

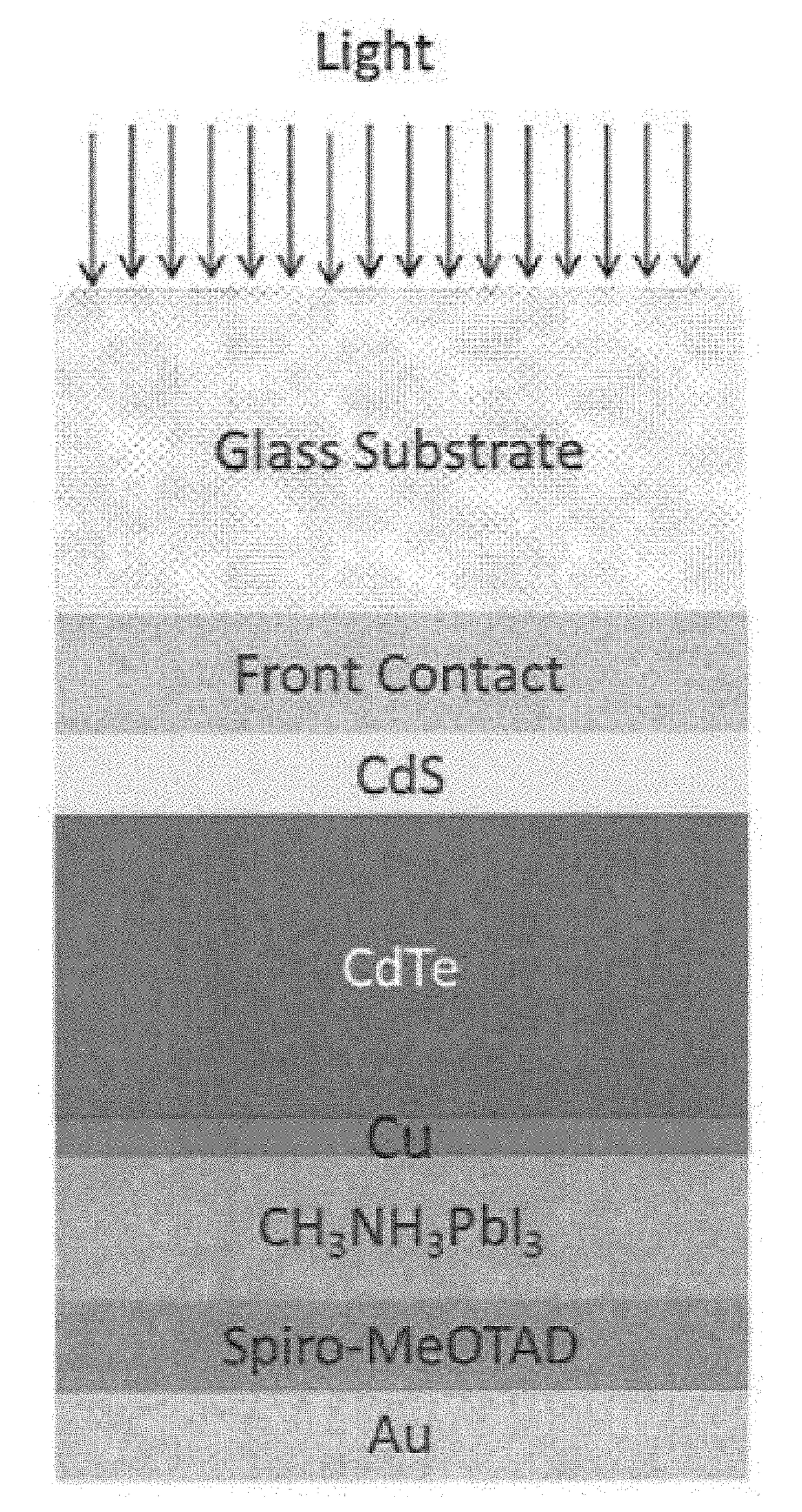

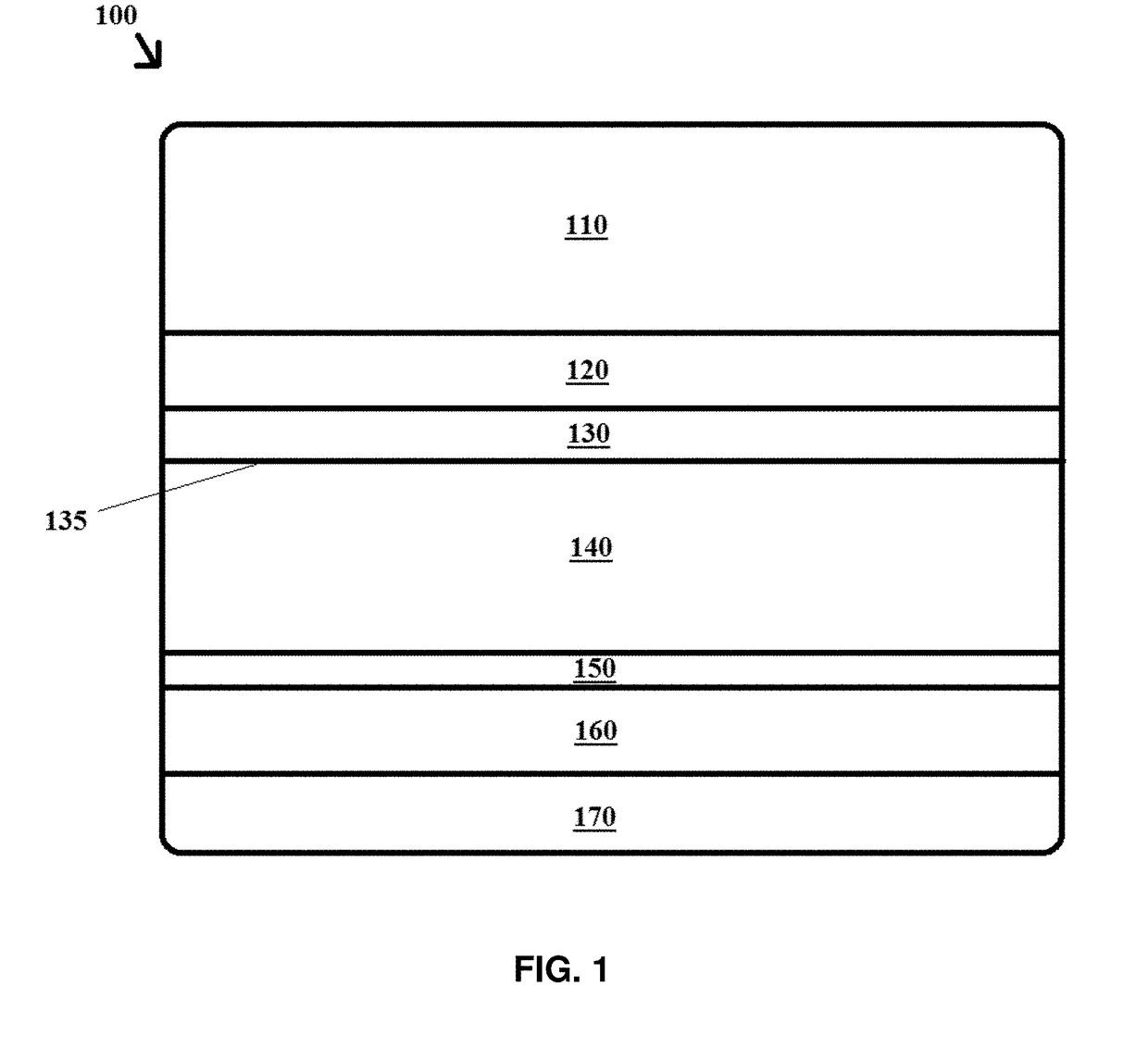

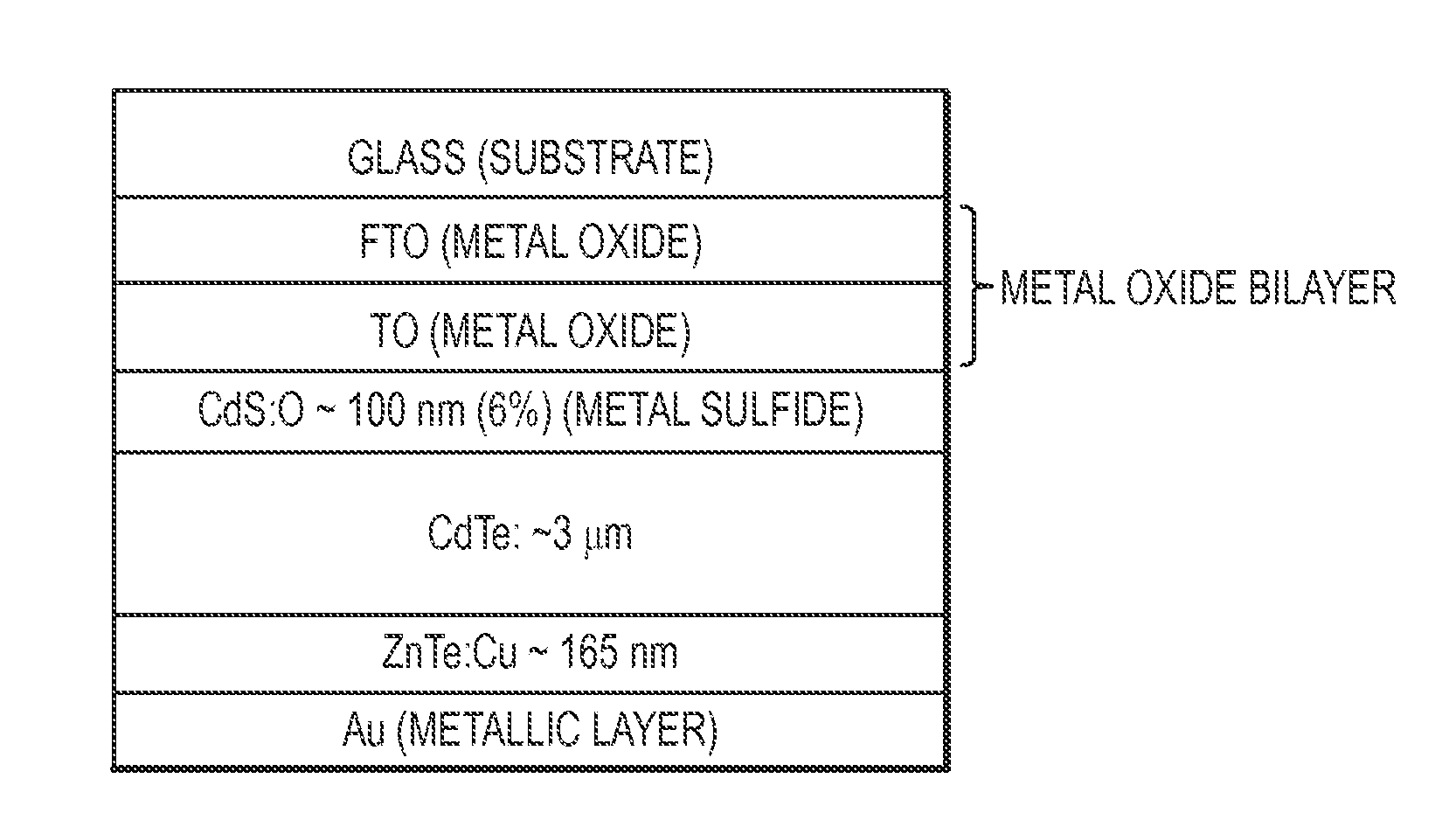

Inexpensive, Earth-Abundant, Tunable Hole Transport Material For CdTe Solar Cells

ActiveUS20180219166A1Solid-state devicesSemiconductor/solid-state device manufacturingHole transport layerElectron transport layer

Hole transport layers, electron transport layers, layer stacks, and optoelectronic devices involving perovskite materials and materials used as precursors, and methods of making the same, are described.

Owner:UNIVERSITY OF TOLEDO

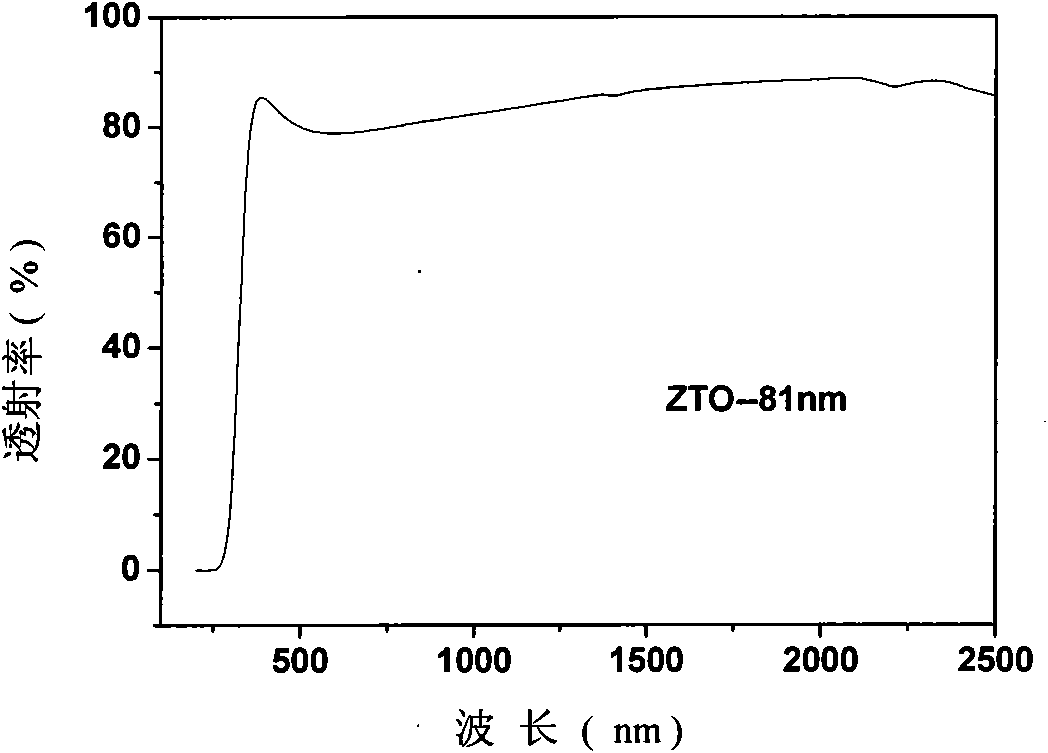

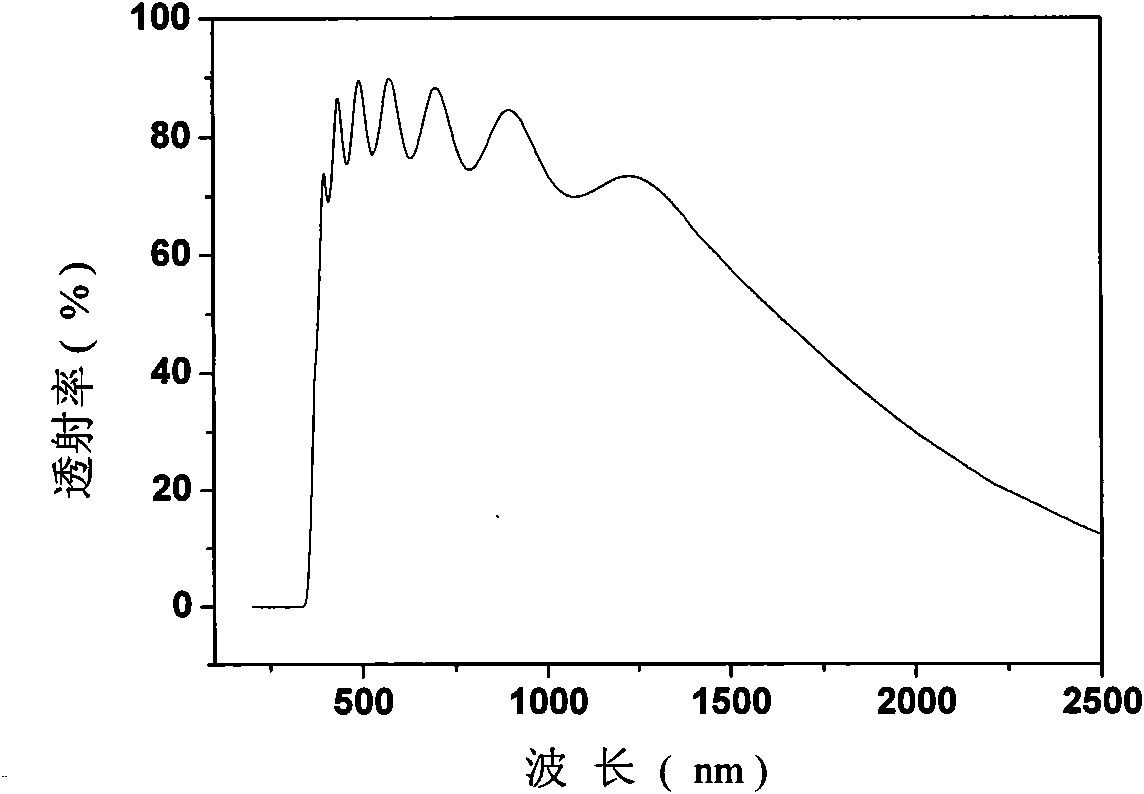

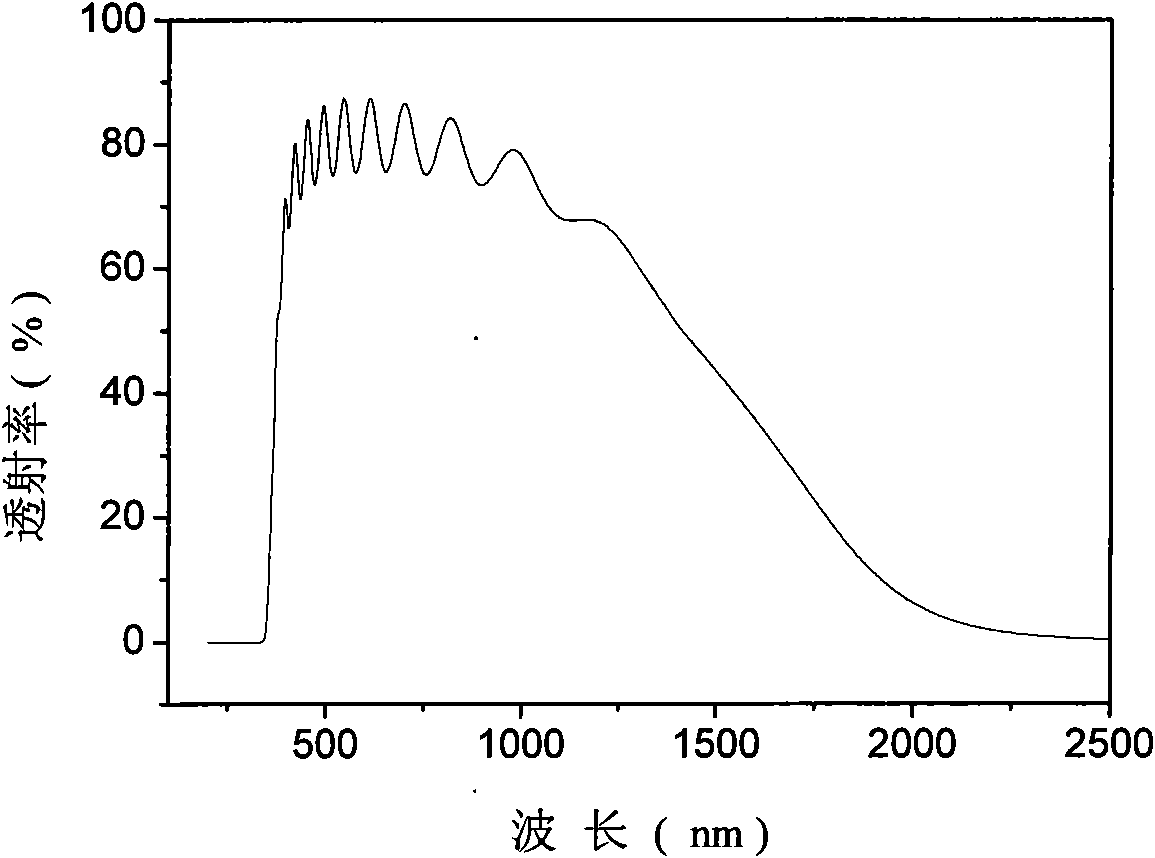

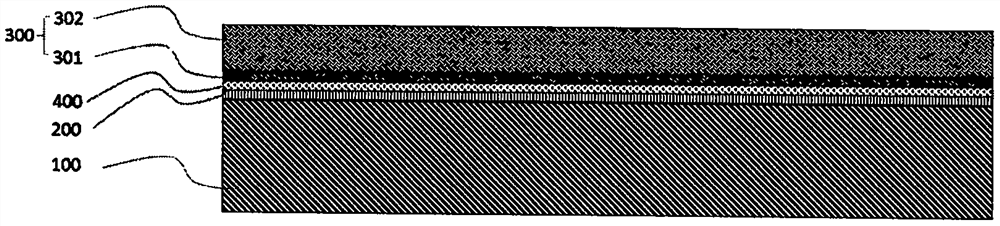

Composite transparent conductive film of cadmium telluride (CdTe) solar battery and preparation method of composite transparent conductive film

InactiveCN102169908APromote growthReduce stressFinal product manufactureVacuum evaporation coatingComposite filmSolar battery

The invention discloses a composite transparent conductive film of a cadmium telluride (CdTe) solar battery and a preparation method of the composite transparent conductive film. The composite transparent conductive film consists of zinc oxide: aluminium (ZnO:Al) and zinc 2 stannic oxide 4 (Zn2SnO4) which are environment-friendly. The method comprises a step of forming the composite transparent conductive film by magnetron sputtering growth and high-temperature quick annealing treatment. The invention has the advantages that: a film material is non-toxic, rich in resources and low in cost; a Zn2SnO4 film can solve the problem of poor adhesion between an active layer and a transparent conductive film layer of the battery, can solve the problem of a too-narrow band gap of cadmium sulphide (CdS), can reduce influence of the thickness of the CdS on the performance of the battery, and can improve the quantum efficiency of the CdTe battery in a whole effective wave band; and the composite film with ZnO:Al and Zn2SnO4 structures has low resistivity and high transmissivity, and is a novel transparent conductive film applied to the CdTe solar battery.

Owner:上海太阳能电池研究与发展中心

Method and apparatus to scribe thin film layers of cadmium telluride solar cells

InactiveUS8890025B2Quality improvementHigh yieldWelding/soldering/cutting articlesLaser beam welding apparatusControl layerLaser scribing

A method of laser scribing a CdTe solar cell structure includes providing a laser operable to produce an optical pulse. The optical pulse is characterized by a temporal profile having a first power level during a first portion of the optical pulse and a second power level less than the first power level during a second portion of the optical pulse. The method also includes directing the optical pulse to impinge on the CdTe solar cell structure. The CdTe solar cell structure includes a substrate, a transmission spectrum control layer adjacent the substrate; a barrier layer adjacent the transmission spectrum control layer, and a conductive layer adjacent the barrier layer. The method further includes initiating a removal process for the conductive layer and terminating the removal process prior to removing the barrier layer.

Owner:ELECTRO SCI IND INC

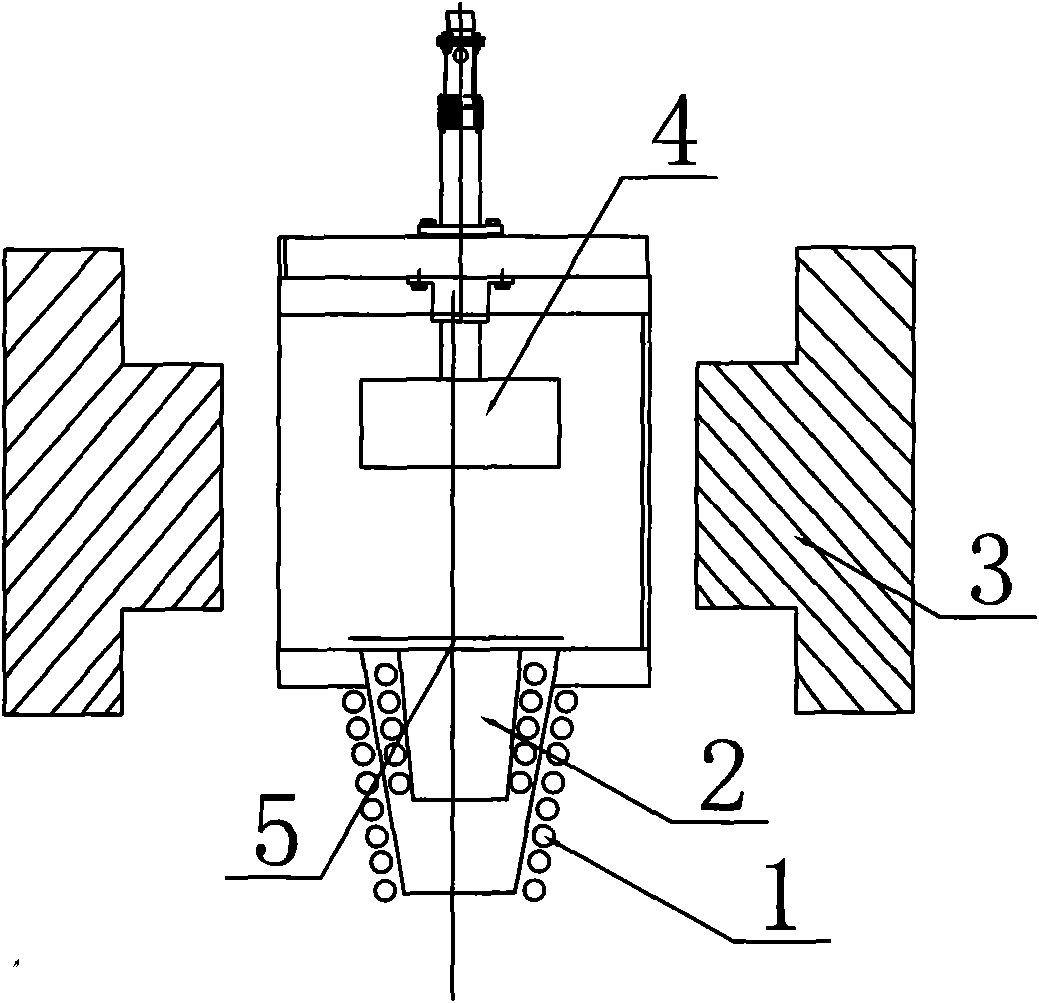

Preparation method of CdTe solar cells under magnetic field

The invention discloses a preparation method of CdTe solar cells under a magnetic field, which comprises the following steps: pretreating a transparent glass substrate; preparing an In2O3:F transparent conductive film on the transparent glass substrate; putting the glass substrate in a near space subliming furnace, and growing a Cds buffer layer on the glass substrate; growing a CdTe film on the prepared CdS film by using a near space sublimation method, and applying a magnetic field of 1-15T by using a superconducting magnet coil on the substrate to grow a CdTe absorption layer; spattering ametal back electrode on the CdTe surface to form an ohmic contact; and obtaining the high-efficiency CdTe film solar cell. Since the CdTe solar cell is prepared by using the near space sublimation method under the intense magnetic field, the surface smoothness and the compactness of the CdTe film are obviously improved, and the conversion efficiency of the CdTe film solar cell is enhanced.

Owner:上海联孚新能源科技集团有限公司

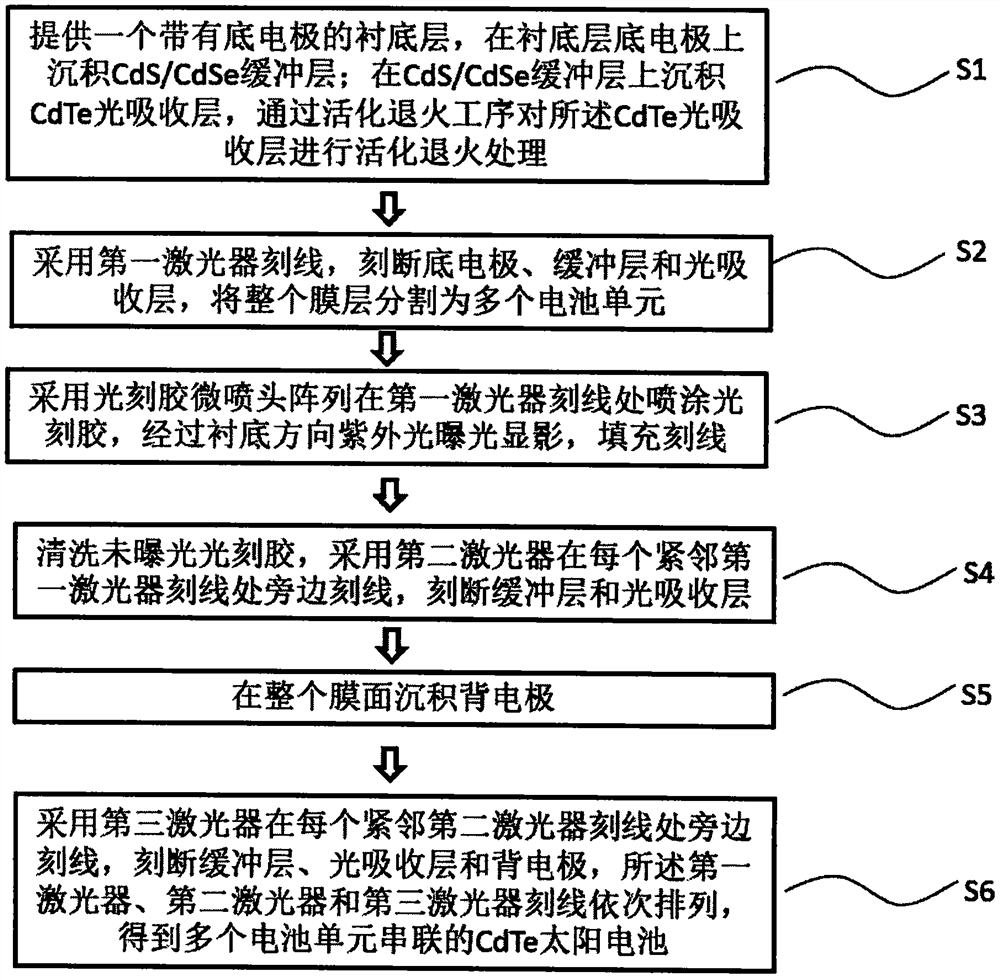

Manufacturing process of CdTe solar cell

InactiveCN112768556AReduce wasteReduce pressure on environmental protectionFinal product manufacturePhotovoltaic energy generationUltraviolet lightsPhysical chemistry

The invention provides a manufacturing process of a CdTe solar cell, which is characterized by comprising the steps of providing a substrate layer with a bottom electrode, and depositing a buffer layer and a light absorption layer on the bottom electrode; activating and annealing the light absorption layer; etching the bottom electrode, the buffer layer and the light absorption layer by using a first laser; spraying photoresist at the etching line of the first laser by adopting a photoresist micro-nozzle array, exposing and developing by ultraviolet light in the direction of the substrate, and filling the etching line; cleaning the unexposed photoresist, and etching the buffer layer and the light absorption layer beside each etching line adjacent to the first laser by using a second laser; depositing a back electrode on the whole film surface; and etching the buffer layer, the light absorption layer and the back electrode beside each etching line adjacent to the second laser by adopting a third laser to obtain the CdTe solar cell with a plurality of cell units connected in series. According to the invention, the laser grooving area is accurately filled with the photoresist through the micro nozzle array, so that the photoresist waste and the environmental protection pressure are reduced, the cost is obviously reduced in the technological process, and the yield is improved.

Owner:CHINA TRIUMPH INT ENG

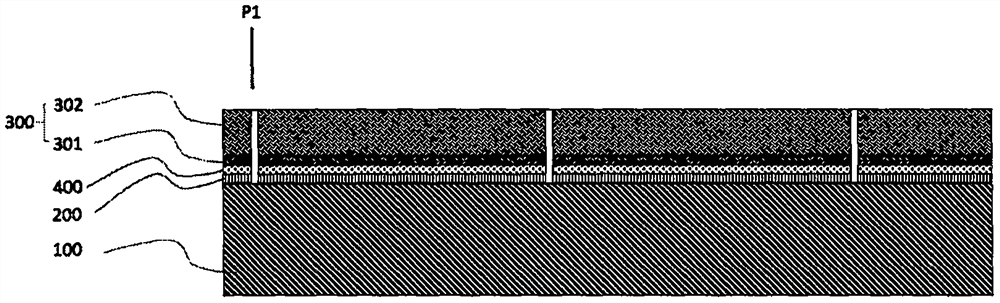

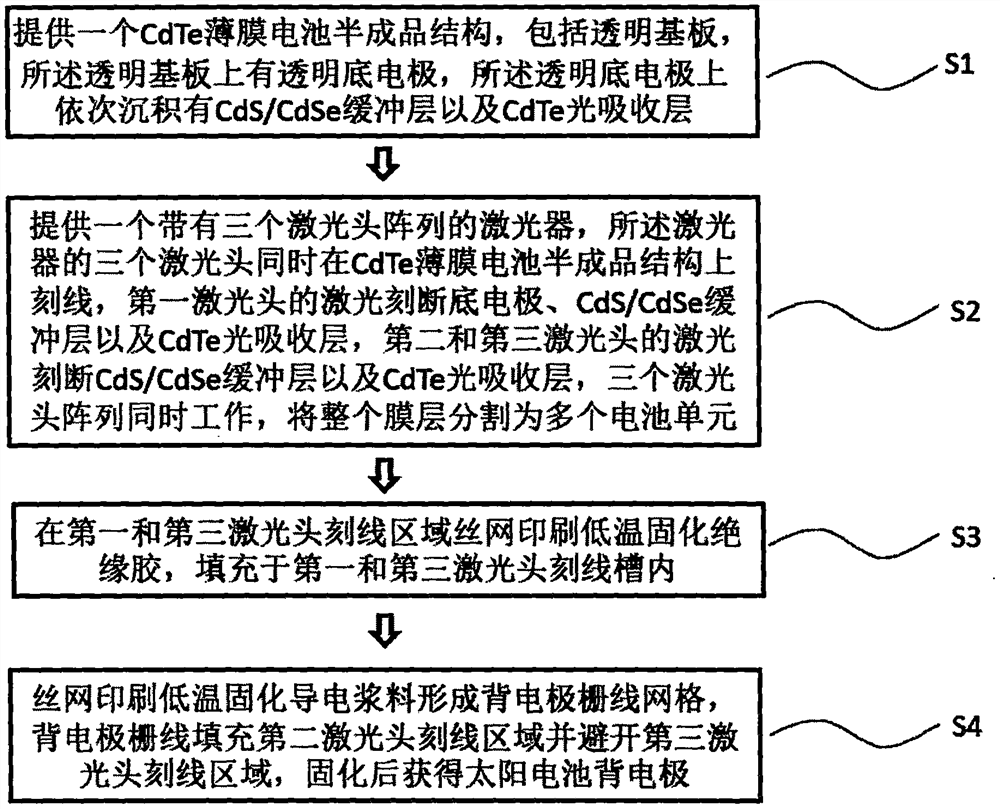

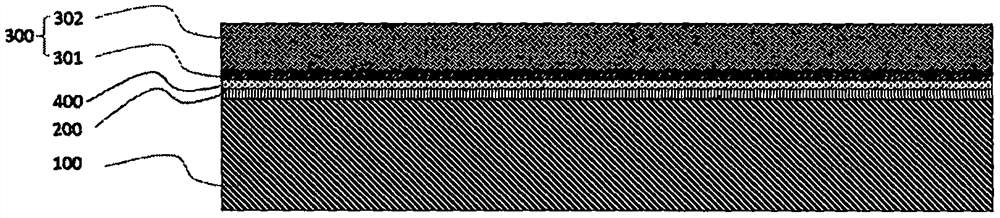

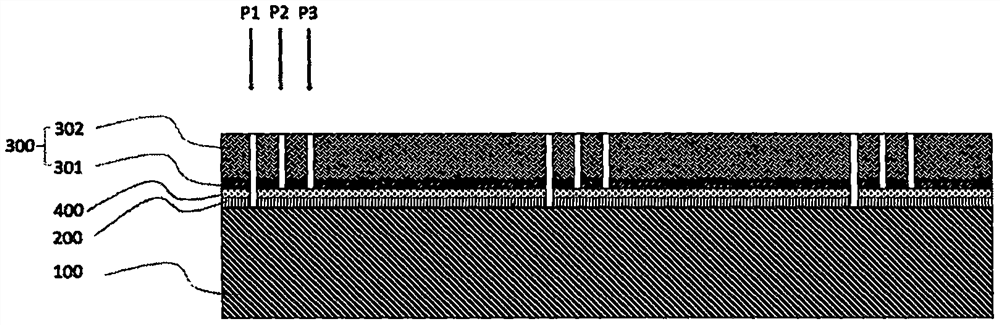

Method for manufacturing back electrode of CdTe solar cell

PendingCN113270506AReduce wasteReduce pressure on environmental protectionPhotovoltaic energy generationSemiconductor devicesScreen printingEngineering

The invention provides a method for manufacturing a back electrode of a CdTe solar cell, and the method is characterized in that a laser with three laser head arrays is used for simultaneously etching lines on a CdTe light absorption layer of a CdTe thin film cell semi-finished product structure; a bottom electrode, a buffer layer and the light absorption layer are etched by the laser of a first laser head, and the buffer layer and the light absorption layer are etched by the laser of a second laser head and a third laser head; the three laser head arrays work at the same time, and the whole film layer is divided into a plurality of battery units; silk-screen printing is performed on low-temperature curing insulation paste in the first and third laser head scribing areas, and the low-temperature curing insulation paste is put in the first and third laser head scribing grooves; silk-screen printing is performed on the low-temperature curing conductive slurry to form a back electrode grid line grid, back electrode grid lines are kept away from a third laser head scribing area, and curing is performed to obtain the back electrode of the solar cell. The method simplifies the technological process, reduces the environmental protection pressure, remarkably reduces the cost in the technological process, and improves the yield.

Owner:CHINA TRIUMPH INT ENG

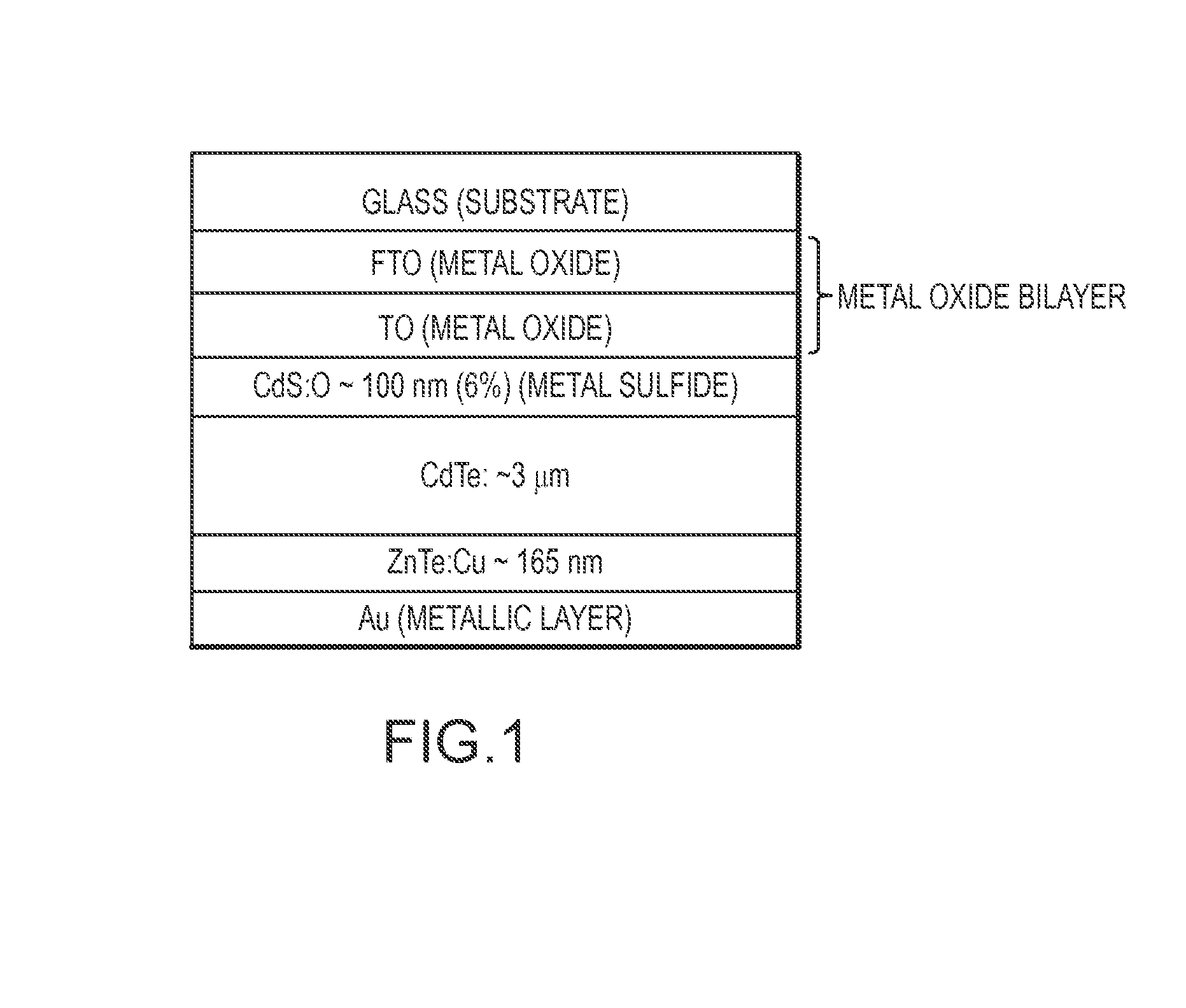

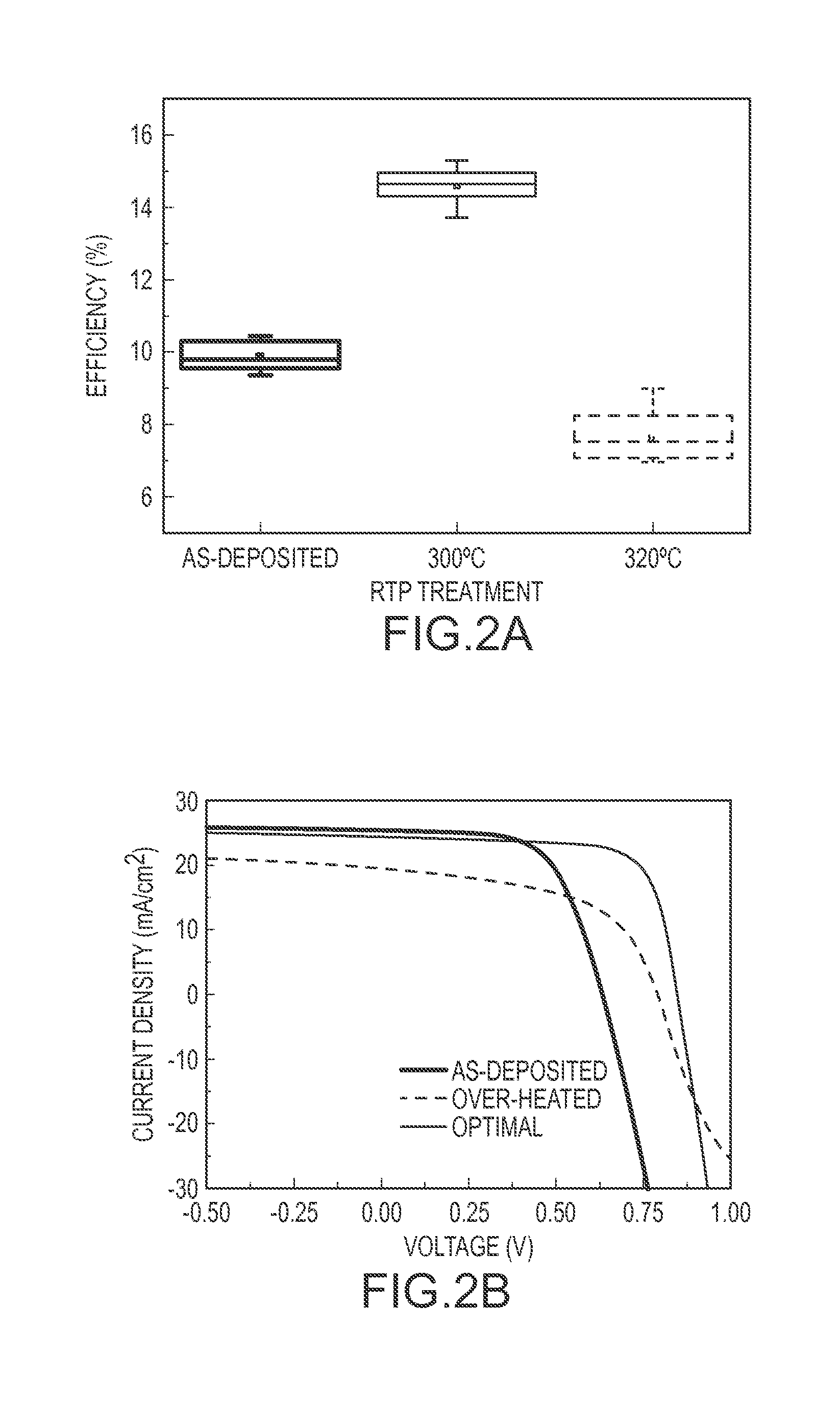

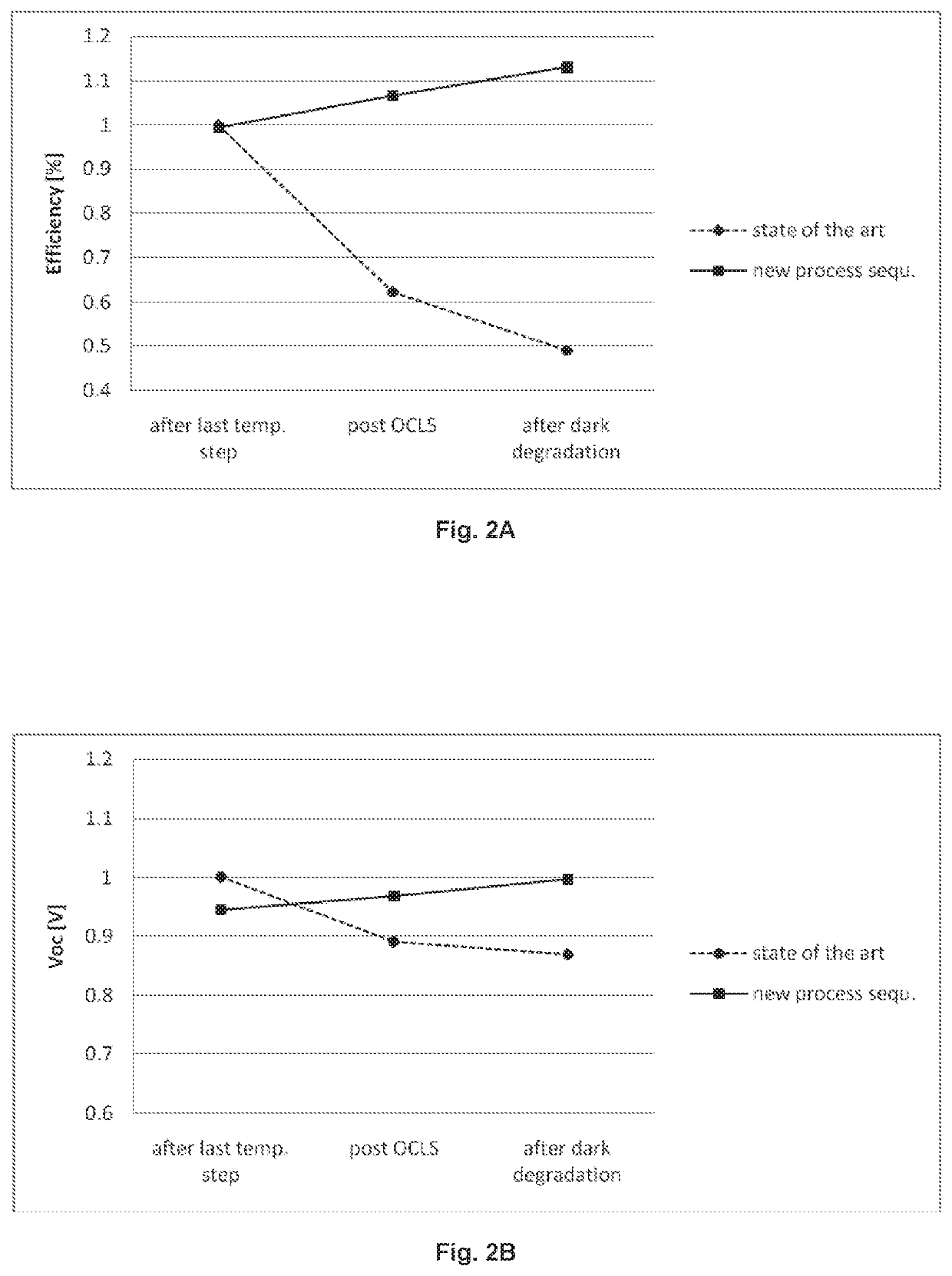

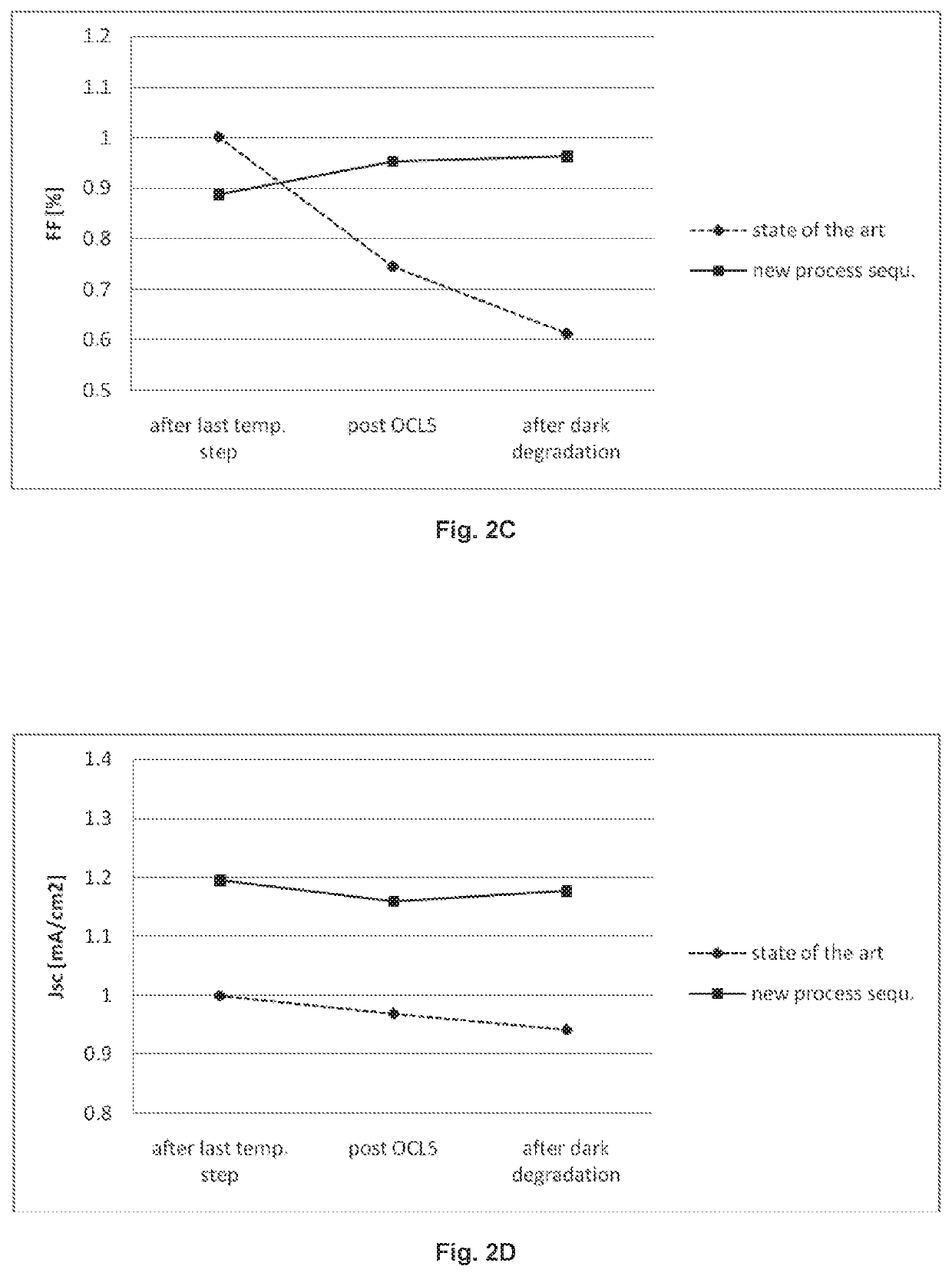

Rapid thermal processing of back contacts for cdte solar cells

InactiveUS20150325718A1Improve throughputReducing back contact barrierFinal product manufactureSemiconductor/solid-state device manufacturingHeat treatedRapid thermal processing

The present invention relates to a back contact and methods of making the same. In the present invention, rapid thermal processing is highly effective to activate ZnTe:Cu-based back contacts, and provides significant improvements in VOC, FF, and efficiency.

Owner:COLORADO SCHOOL OF MINES

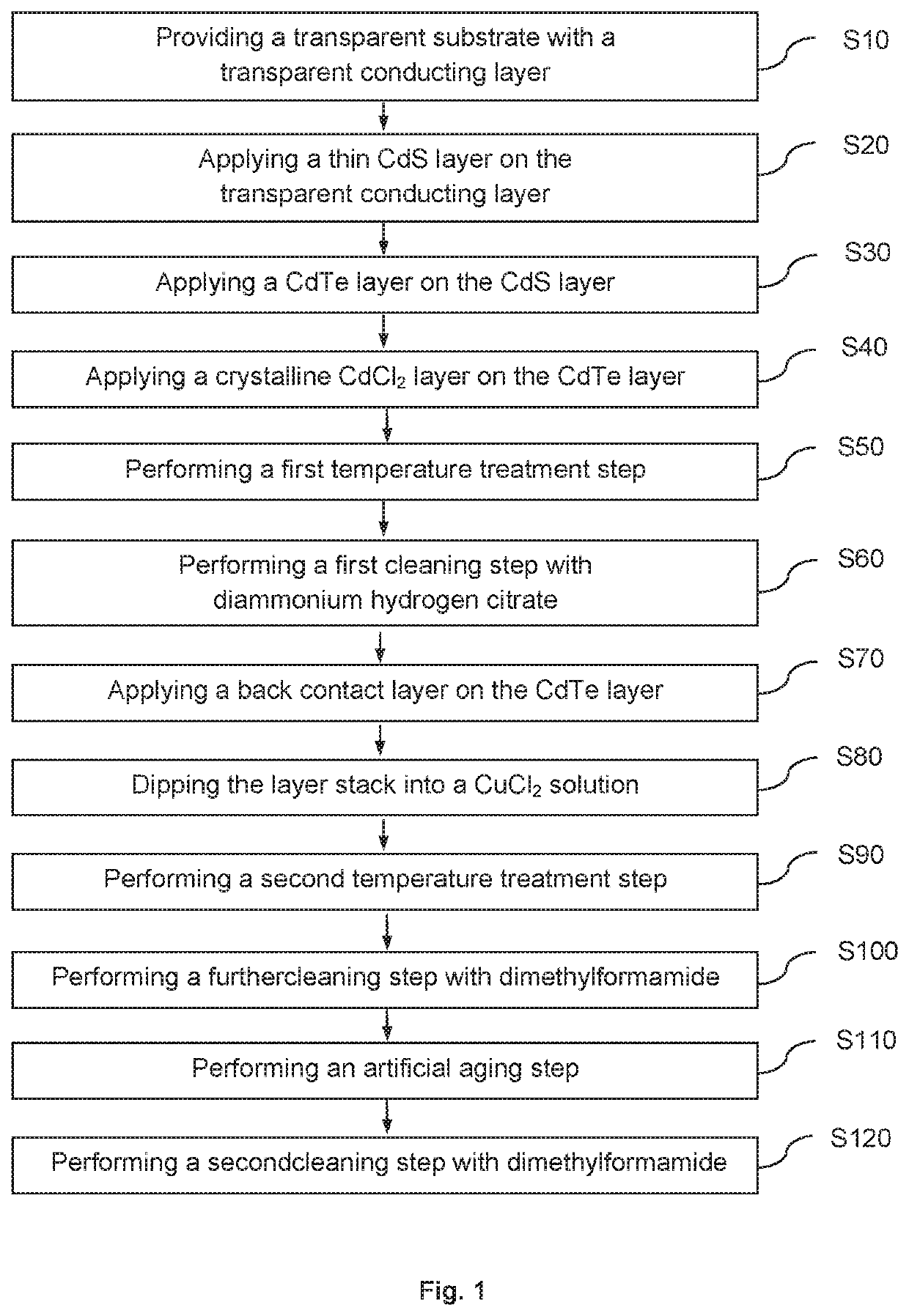

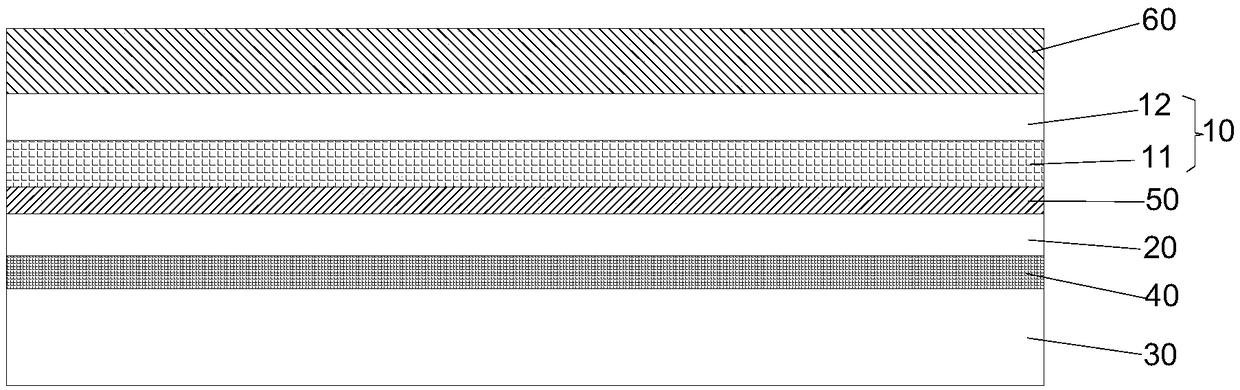

METHOD FOR PRODUCING A CdTe THIN-FILM SOLAR CELL

ActiveUS20210210650A1Excellent electrical propertiesIncrease illuminationSemiconductor devicesPhysical chemistrySolar battery

The present invention describes a method for producing CdTe thin-film solar cells, in which special parameters of different processing steps and a special sequence of processing steps result in improved characteristics of the produced CdTe solar cells.

Owner:CHINA TRIUMPH INT ENG +1

Solar cell lamination method and solar cell

InactiveCN108831957ALow costFinal product manufacturePhotovoltaic energy generationPhotoelectric conversionEngineering

The invention provides a solar cell lamination method and a solar cell. The solar cell lamination method comprises the step of laying a glue film layer on at least one electrode layer so that light can be reflected onto a photoelectric conversion layer of the solar cell by the glue film layer, wherein the glue film layer comprises a white glue film and an auxiliary glue film. By the solar cell lamination method, the problem of relatively high cost of the solar cell lamination method in the prior art is solved.

Owner:山东彼岸时代科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com