CdTe solar cell by using V-Se film as back contact layer

A technology for solar cells and vanadium selenide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex composition and structure of tellurium-copper phase, battery performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

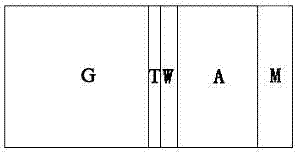

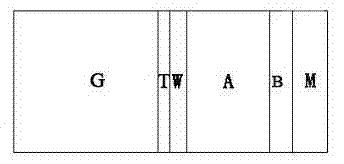

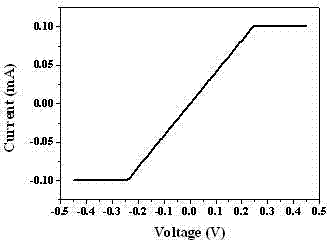

Image

Examples

Embodiment 1

[0018] (1) Preparation of V-Se thin film

[0019] Put the sample into the vacuum chamber with a vacuum of 10 -4 pa, the sample temperature is room temperature, and the electron beam evaporation method is used to alternately evaporate vanadium and selenium, wherein the purity of vanadium is 99.999%, and the purity of selenium is 99.97%. The thickness of deposited vanadium is 1~10 nm, the thickness ratio of vanadium and selenium is 0.26, and the total thickness of V-Se film is 80 nm;

[0020] (2) Post-treatment V-Se thin film

[0021] Take out the sample deposited with V-Se thin film, put it into a vacuum annealing furnace protected by nitrogen or inert gas, and carry out post-treatment at a temperature of 250 0 C~300 0 C, the time is 10~60 minutes, and then naturally cooled to room temperature, that is, to obtain VSe 2-x (x=0) Sample of thin film.

Embodiment 2

[0023] (1) Preparation of V-Se thin film

[0024] Put the sample into the vacuum chamber with a vacuum of 10 -4 pa, the sample temperature is 300 0 C, using the electron beam evaporation method to alternately evaporate vanadium and selenium, wherein the purity of vanadium is 99.999%, and the purity of selenium is 99.97%. The thickness of deposited vanadium is 1~10 nm, the thickness ratio of vanadium and selenium is 0.26, and the total thickness of V-Se film is 100 nm;

[0025] (2) Post-treatment V-Se thin film

[0026] In a vacuum chamber, keep the sample warm for 10-60 minutes, and then naturally cool to room temperature, that is, to obtain 2-x (x=0) Sample of thin film.

Embodiment 3

[0028] (1) Install the target and sample

[0029] Fix the vanadium target (purity 99.99% and above) and the selenium target (purity 99.99% and above) on the two target positions corresponding to the sputtering device, fix the sample on the substrate position, and adjust the target and substrate. The distance is 6~9 cm;

[0030] (2) Preparation of V-Se thin film

[0031] In-situ growth of V-Se thin film, that is, first heating the sample temperature to 300 0 C, followed by co-sputtering vanadium and selenium to obtain V-Se thin films, in which the background vacuum ~10 -4 Pa, the working gas is argon, the working pressure is 0.1~3.5 Pa, the sputtering power of vanadium target is 30~300 W, the sputtering power of selenium target is 30~100 W, the sputtering rate V / Se is 0.26~0.27, and the sputtering thickness is 70 nm;

[0032] (3) Post-treatment V-Se thin film

[0033] After the sputtering is completed, keep the pressure in the sputtering chamber for 10-60 minutes under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com