Preparation method of CdTe solar cells under magnetic field

A technology of solar cells and thin-film solar cells, which is applied in the manufacture of circuits, electrical components, and final products, and can solve the problems of understanding, scattered CdTe solar cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

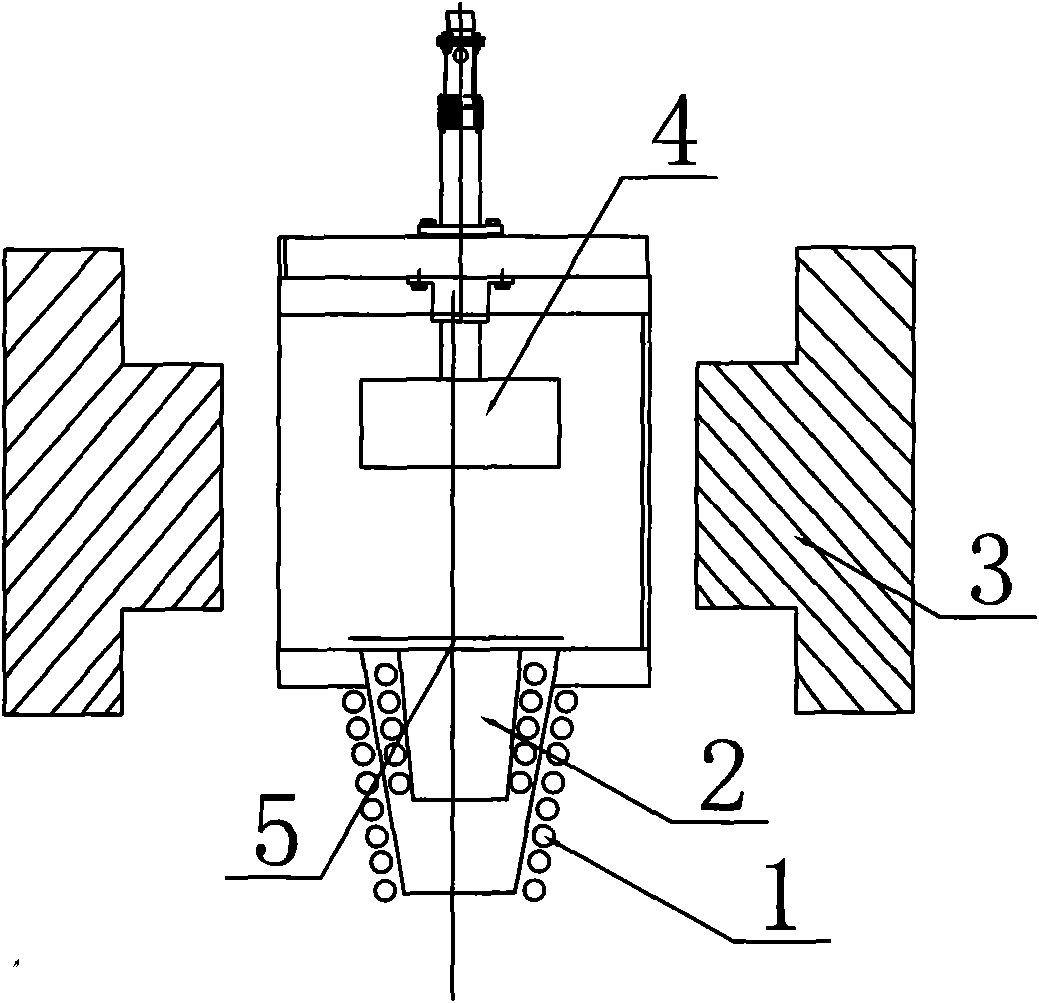

Image

Examples

Embodiment

[0030] (1) First pre-treat the transparent glass substrate: use 1713 transparent glass as the deposition substrate, use acetone ultrasonic cleaning to remove the grease on the glass surface, then deionized water ultrasonic cleaning to remove impurities on the glass surface; finally dry the glass Put it into the pretreatment chamber and use plasma to clean the glass substrate.

[0031] (2) Preparation of In 2 o 3 :F transparent conductive film: the transparent glass substrate is automatically transferred to the sample stage of the magnetron sputtering instrument by the robot arm in a vacuum environment, and the sputtering target is high-purity In 2 o 3 , first use a vacuum pump to evacuate the sputtering chamber, then use a molecular pump to evacuate the reaction chamber, feed Ar gas and 5% CHF3, adjust the flow rate; adjust the reaction pressure and sputtering power, and sputter for a certain period of time.

[0032] (3) Growth of CdS thin film: The substrate of the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com