Molybdenum sputtering targets

a molybdenum sputtering target and molybdenum technology, applied in the field of molybdenum sputtering target, can solve the problems of non-uniform film deposited on substrates and devices, non-uniform molybdenum microstructure, and wrought microstructure, and achieve the effect of improving performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Other than in the operating examples or where otherwise indicated, all numbers or expressions referring to quantities of ingredients, reaction conditions, etc., used in the specification and claims are to be understood as modified in all instances by the term “about.” Various numerical ranges are disclosed in this patent application. Because these ranges are continuous, they include every value between the minimum and maximum values. Unless expressly indicated otherwise, the various numerical ranges specified in this application are approximations.

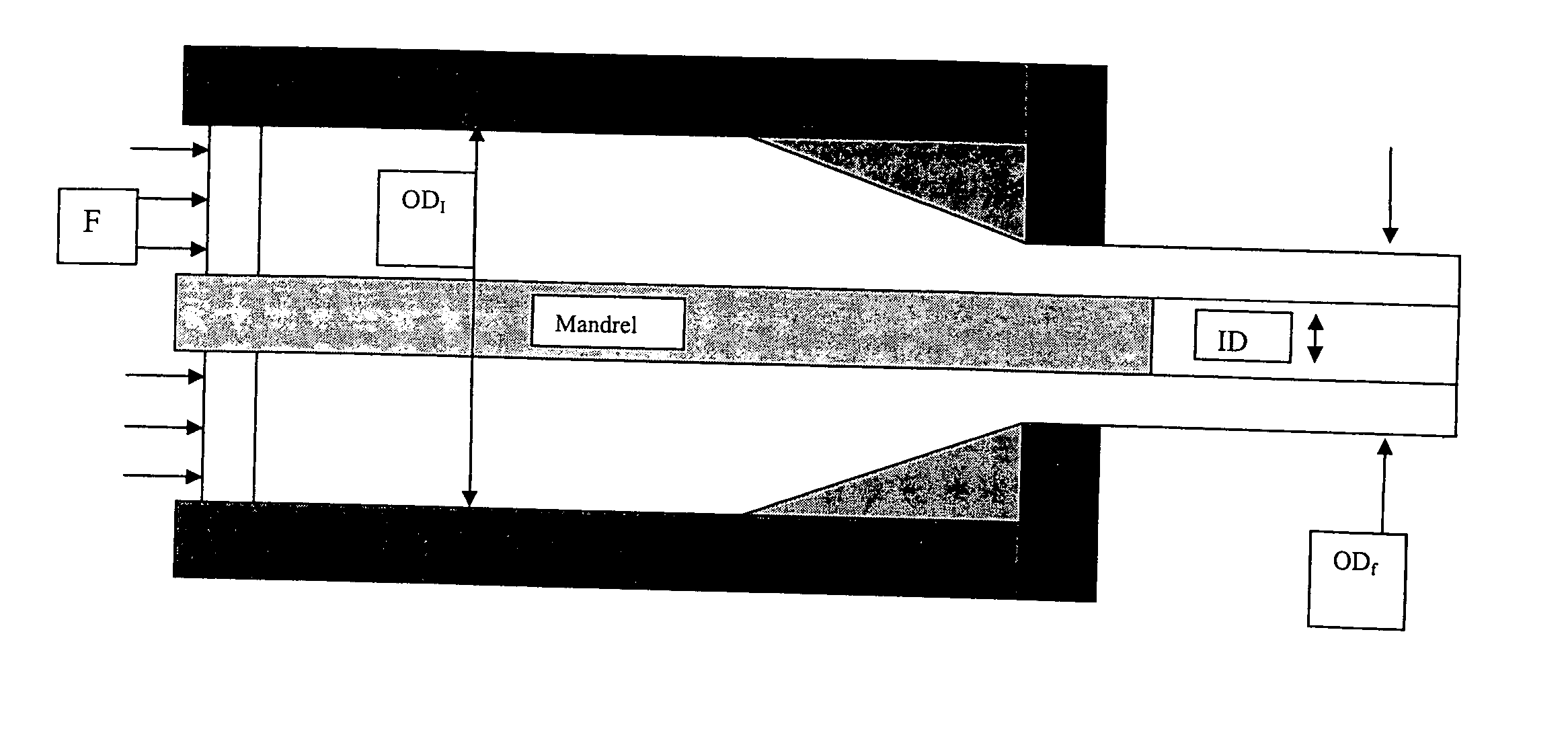

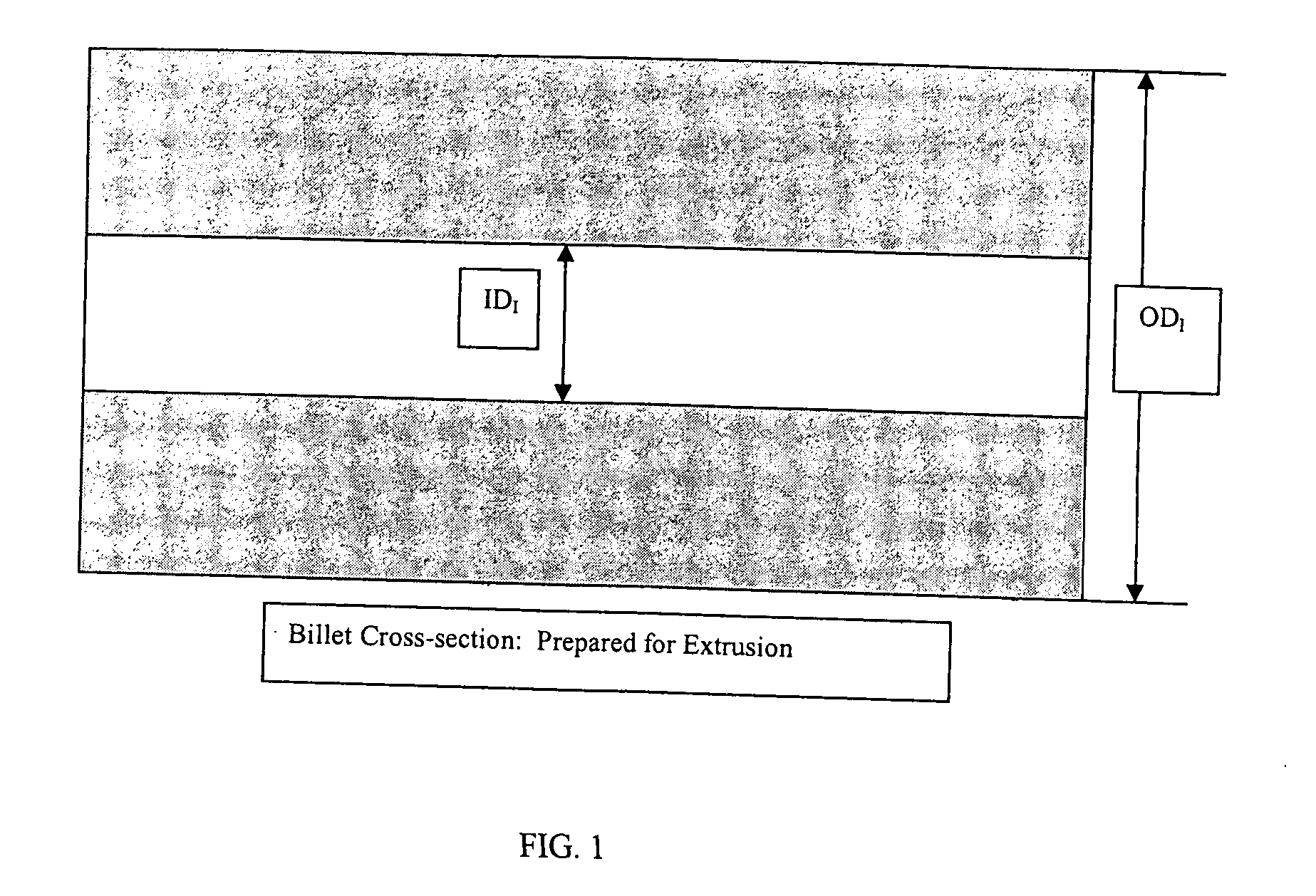

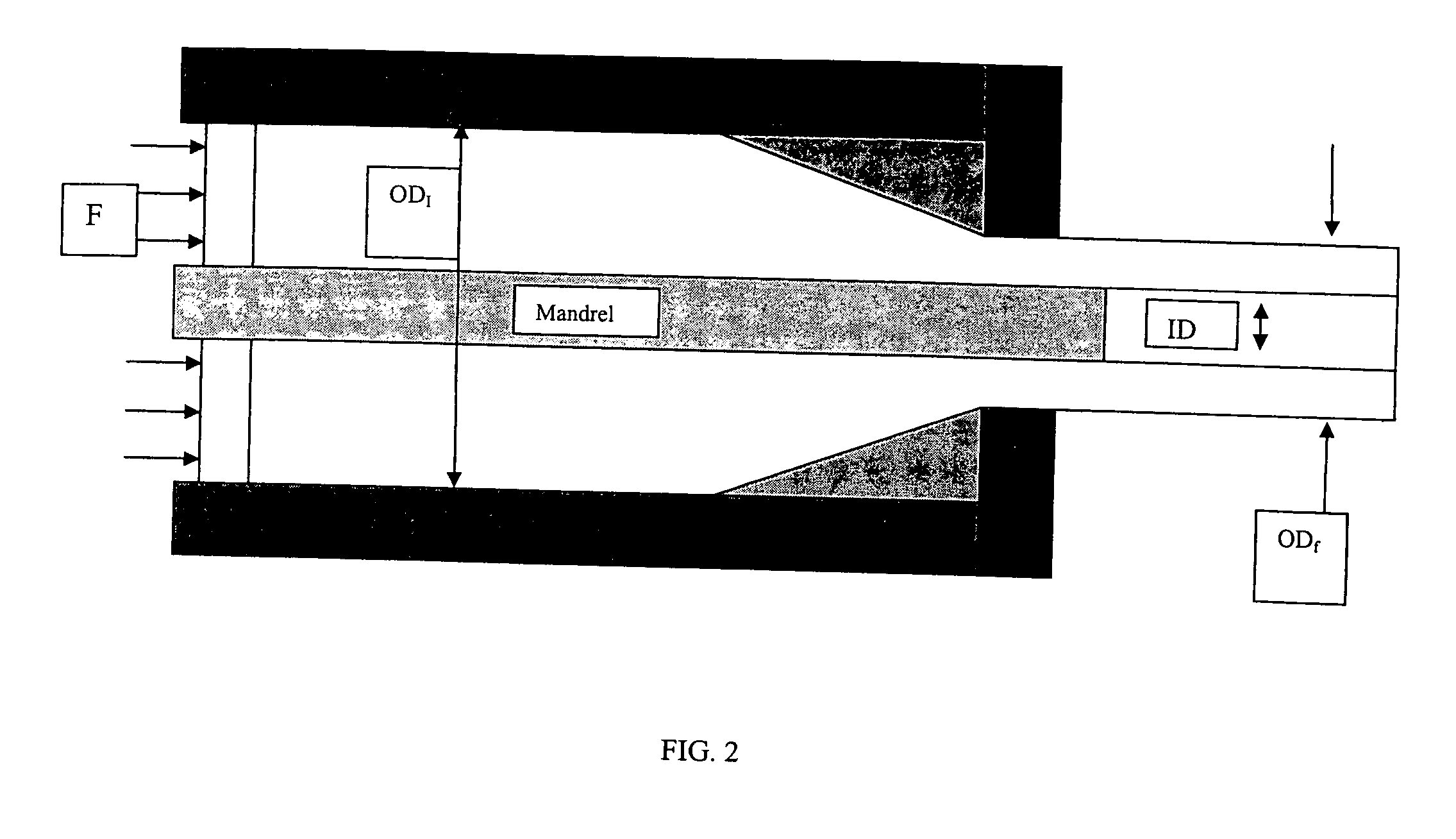

[0055] As used herein, the term “banding” refers to non-uniformities in the grain or texture, the grain size, or grain orientation that occur in a strip or pattern along the surface of the sputtering target. As used herein, the term “through thickness gradient” refers to changes in grain or texture, grain size, or grain orientation moving from the edge of the target to the center of the target.

[0056] The forms of molybdenum, sputt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com