Composite transparent conductive film of cadmium telluride (CdTe) solar battery and preparation method of composite transparent conductive film

A technology for transparent conductive films and solar cells, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems that the film layer is not easy to form a continuous film, destroy the pn junction characteristics of the battery, and the film quality is not easy to control, etc., to solve the problem of thickness control. , the effect of improving quantum efficiency and increasing short-circuit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The glass substrate was cleaned and dried with nitrogen, and placed on the substrate stage of the magnetron sputtering chamber. The ZnO:Al target (Al 2 o 3 Doping dose ratio is 2wt%) and Zn 2 SnO 4 The targets are installed on the respective target guns, and the sputtering chamber is vacuumed to 2×10 -4 Pa, and then use radio frequency magnetron sputtering technology to grow ZnO:Al film on the glass substrate first, and then grow Zn 2 SnO 4 film.

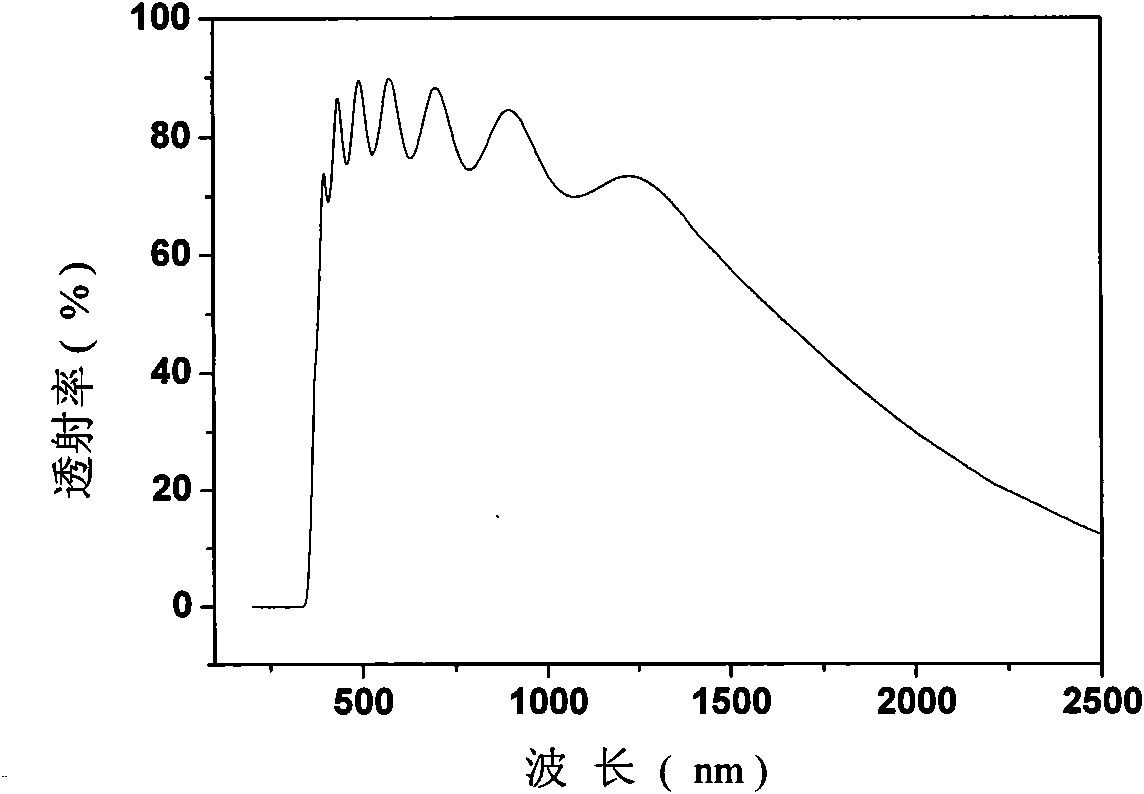

[0025] Magnetron sputtering parameter range setting of ZnO:Al film layer: sputtering power is 200W, sputtering gas is high-purity Ar, sputtering gas pressure is 0.15Pa, substrate temperature is room temperature, deposition time is 1.5 hours, and the film thickness obtained is 683nm.

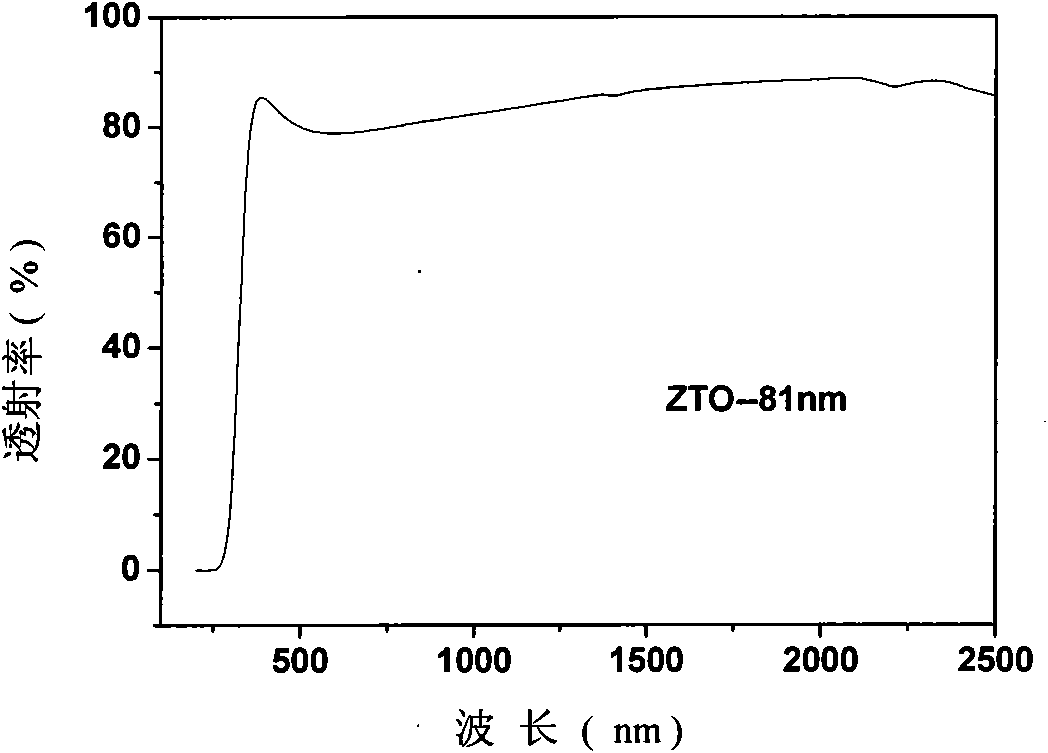

[0026] Zn 2 SnO 4 Magnetron sputtering parameter range setting of the film layer: the sputtering power is 100W, and the sputtering gas is high-purity O 2, the sputtering pressure is 0.33Pa, the substrate temperature is room temperature...

Embodiment 2

[0029] The glass substrate was cleaned and dried with nitrogen, and placed on the substrate stage of the magnetron sputtering chamber. The ZnO:Al target (Al 2 o 3 Doping dose ratio is 2wt%) and Zn 2 SnO 4 The targets are installed on the respective target guns, and the sputtering chamber is vacuumed to 2×10 -4 Pa, and then use radio frequency magnetron sputtering technology to grow ZnO:Al film on the glass substrate first, and then grow Zn 2 SnO 4 film.

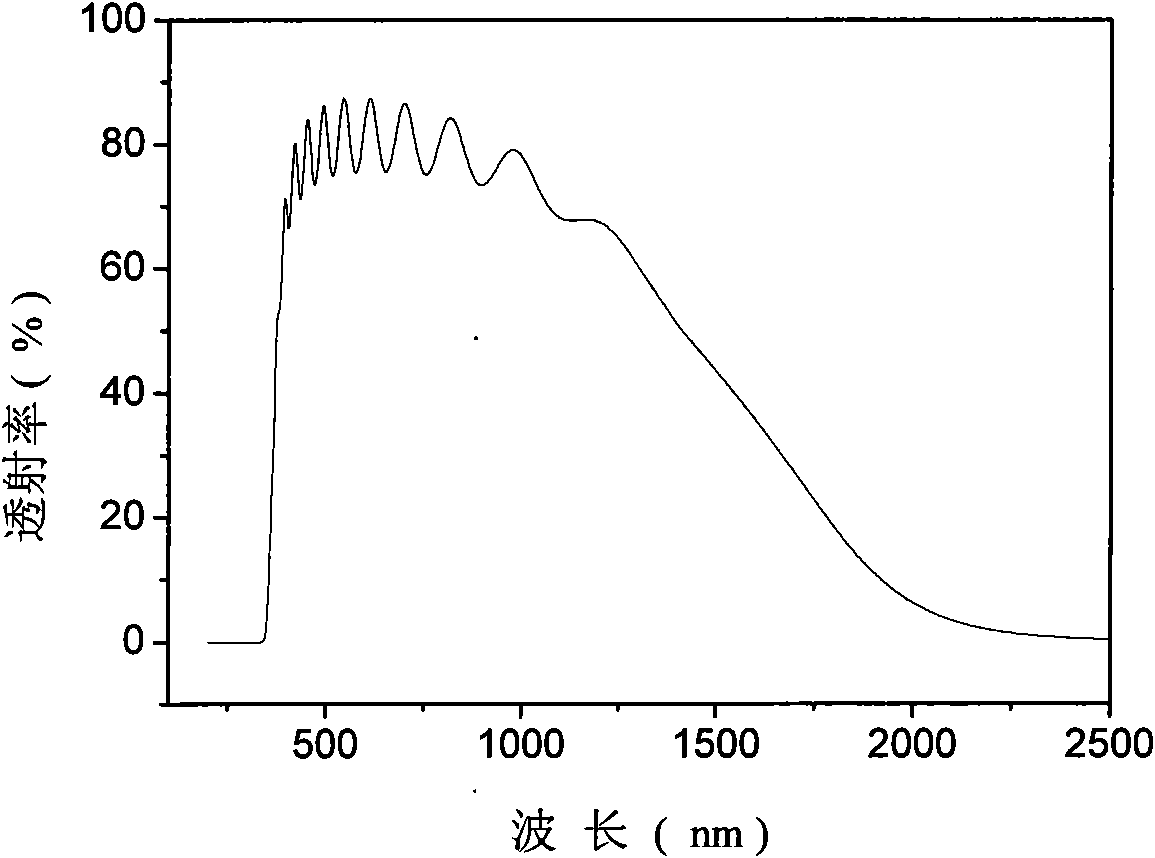

[0030] Magnetron sputtering parameter range setting of ZnO:Al film layer: sputtering power is 250W, sputtering gas is high-purity Ar, sputtering pressure is 0.15Pa, substrate temperature is room temperature, deposition time is 2 hours, and the film thickness obtained is 1006nm.

[0031] Zn 2 SnO 4 Magnetron sputtering parameter range setting of the film layer: the sputtering power is 100W, and the sputtering gas is high-purity O 2 , the sputtering pressure is 0.33Pa, the substrate temperature is room temperature, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com