Patents

Literature

360results about How to "Strong chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

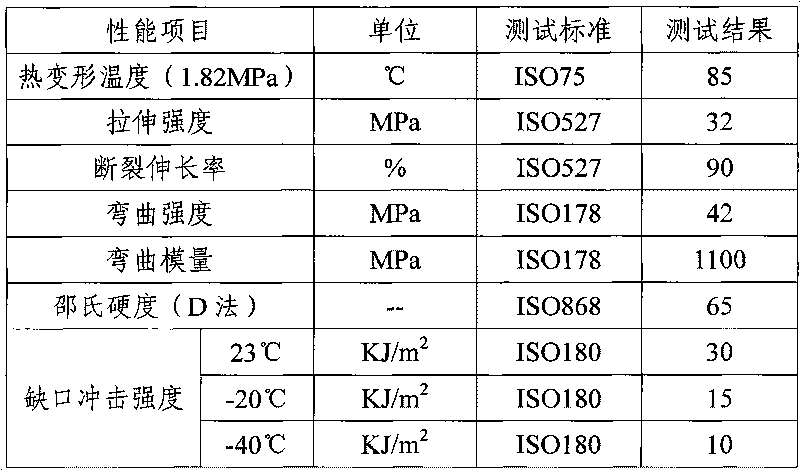

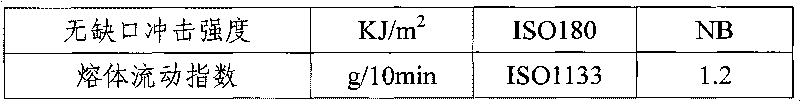

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

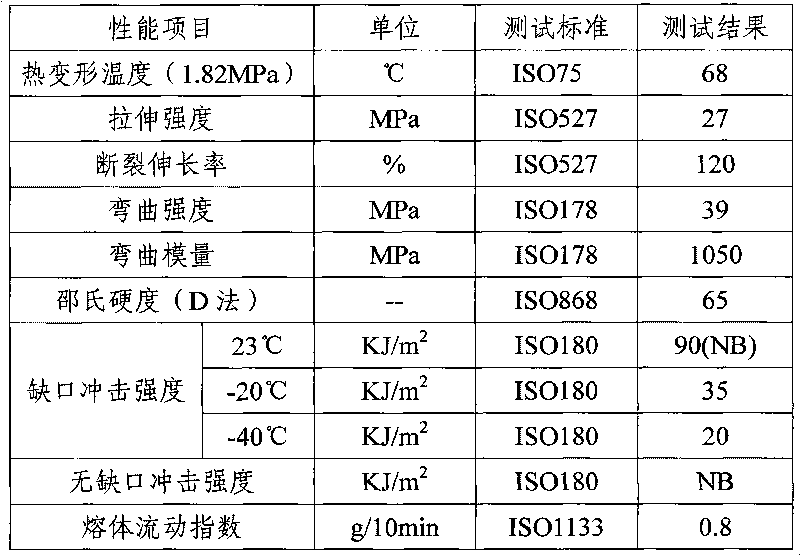

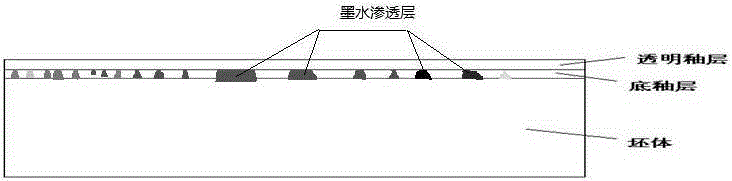

One-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and manufacturing method thereof

The invention relates to one-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and a manufacturing method thereof. According to the manufacturing method, a bottom green brick layer, a priming glaze slurry, a semitransparent glaze slurry, and a transparent glaze slurry are prepared respectively; the bottom green brick layer is subjected to following treatment respectively: a priming glaze layer is formed via priming glaze slurry pouring, jet printing of decorative patterns is carried out, a semitransparent glaze layer is formed via semitransparent glaze slurry pouring, and drying is carried out; obtained green bricks are printed with decorative patterns with ink-jet of penetrating ink and jet printing of a permeation promoter, and are allowed to stand for more than 5min; the obtained green bricks are printed with isolation glaze with water isolating performance via silk-screen printing, and are dried and cooled; the green bricks are coated with the transparent glaze slurry via pouring; the green bricks are subjected to one time sintering so as to obtain one-time sintered ink-jet penetrating porcelain tile semi-finished products with three-dimensional decorative effects; the semi-finished products are subjected to polishing via inelastic module technology so as to obtain the one-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects.

Owner:MONALISA GRP CO LTD

High strong adhesive and method for preparing same

The powerful adhesive includes neoprene, grafting monomer, thickener, dispersant, adhesion promoter, catalyst, antioxidant, solvent, stuffing, etc. The present invention also discloses the preparation process of the adhesive, and the preparation includes introducing grafting monomer to neoprene molecule chain to raise the adhesion strength, selecting proper adhesion promoting resin to increase the initial adhesion force, and adopting mixed solvent to form high adhering performance. The adhesive has high solid content and excellent environment protecting performance, and has also excellent antiageing performance, high resistance to heat, oil, chemical and corrosion, high weather resistance, good mildew-proof performance, antibiotic performance, etc. and may be used for adhering timber, concrete, rubber, metal, gypsum board, brick and other building material.

Owner:GUANGZHOU GLORYSTAR CHEM

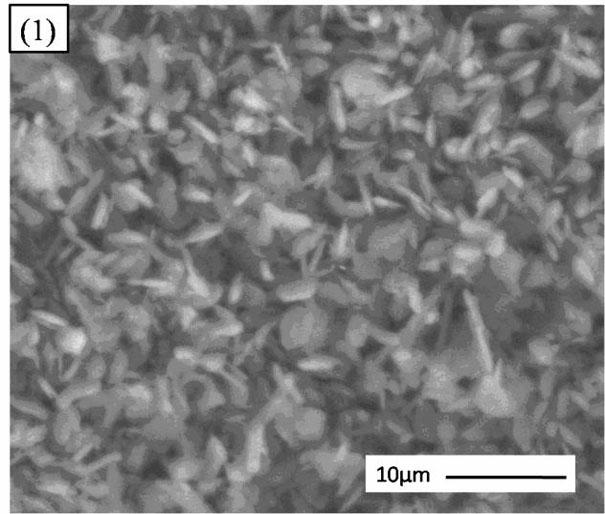

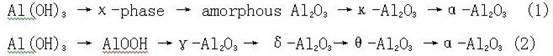

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Ultrahigh-molecular weight polyethylene composite material and preparation method thereof

The invention discloses an ultrahigh-molecular weight polyethylene composite material and a preparation method thereof. The ultrahigh-molecular weight polyethylene composite material comprises the following component in parts by weight: 100 parts of ultrahigh-molecular weight polyethylene, 0.1-10 parts of a lubricating agent, 10-60 parts of a filling material, 5-40 parts of reinforcing fiber and 0.1-10 parts of nanometer inorganic filler. The ultrahigh-molecular weight polyethylene composite material overcomes the difficulty that the ultrahigh-molecular weight polyethylene is very high in melt viscosity and is difficult to prepare; the ultrahigh-molecular weight polyethylene composite material can be prepared into different products through extrusion moulding of an extruder; the modified ultrahigh-molecular weight polyethylene composite material not only has high strength, impact resistance, wear resistance, high rigidity, high surface hardness, chemical corrosion resistance and other performance, but also has good self lubrication and dimensional stability.

Owner:GUANGDONG TAUGHNESS CONVEYOR BELTING

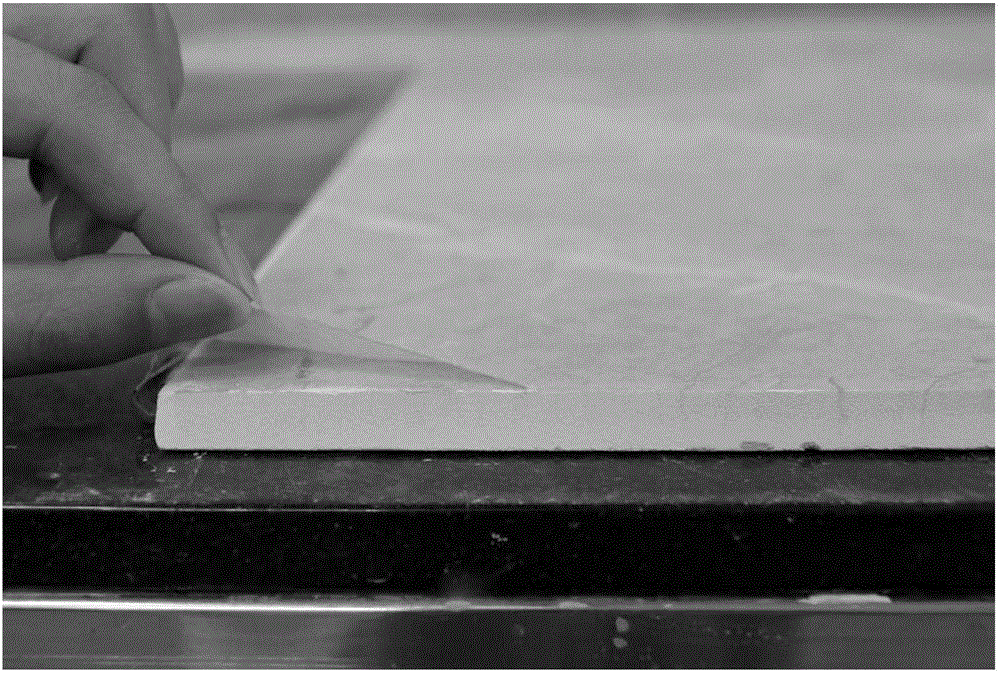

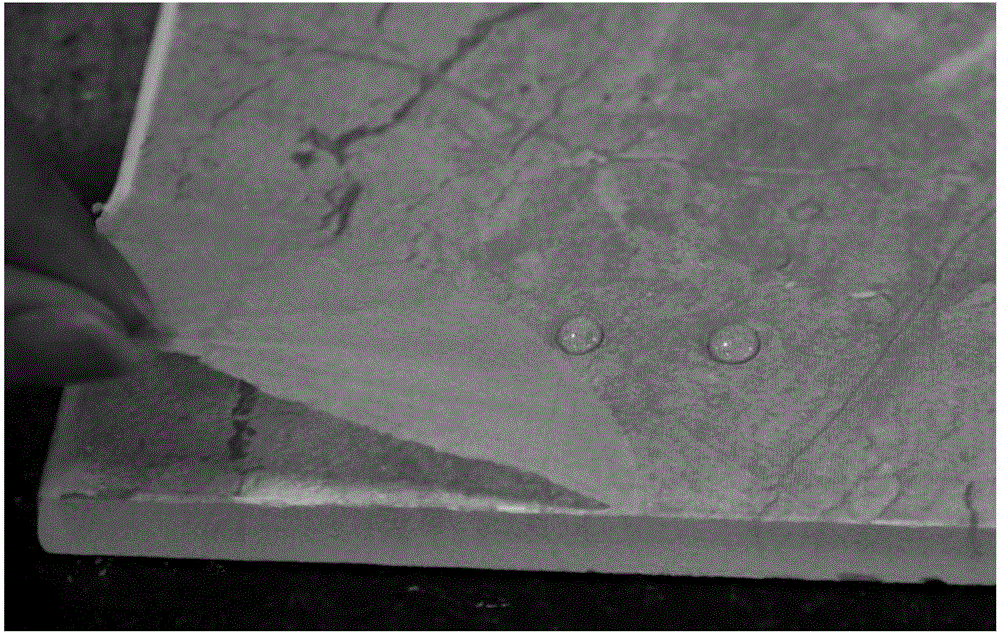

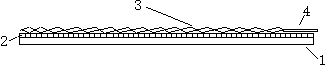

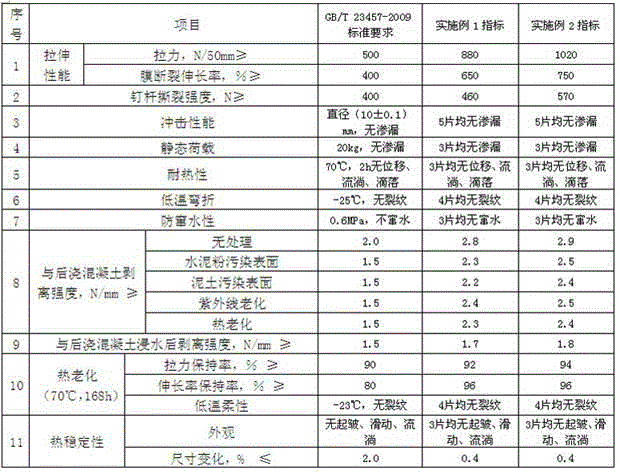

Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

ActiveCN104057686ACost efficientObvious cost advantageSynthetic resin layered productsLaminationWet bondingMineral particles

The invention relates to a preparation method of a pre-laid waterproof coiled material for concrete mortar bonding construction. According to the technical scheme, the preparation method comprises the following steps: fully applying an SIS hot-melt pressure-sensitive adhesive to a modified polyethylene plastic waterproof main body layer by virtue of a hot-melt pressure sensitive adhesive coating machine, so as to form an SIS hot-melt pressure-sensitive self-sticking layer, and then coating the hot-melt pressure-sensitive self-sticking layer with a weather resistant mineral grain functional layer with cement reactivity and an anti-sticking isolation membrane positioned on one side of the coiled material. The preparation method has the beneficial effects that (1) a novel wet bonding technique is provided, the coiled material and structural concrete are permanently and organically combined, no water channeling hazards exist between the coiled material and the structural concrete, and the reliability of a waterproof layer is improved; (2) the impact resistant performance and the puncture resistant performance are excellent, and the construction load which directly acts on the pre-laid waterproof coiled material and the impact of a steel skeleton can be born; (3) strong chemical resistance is provided; (4) the construction is convenient, and a leveling blanket is not needed; (5) the waterproof coiled material and a basic layer are in border adhibiting without influence of sedimentation deformation of the basic layer.

Owner:胜利油田大明新型建筑防水材料有限责任公司

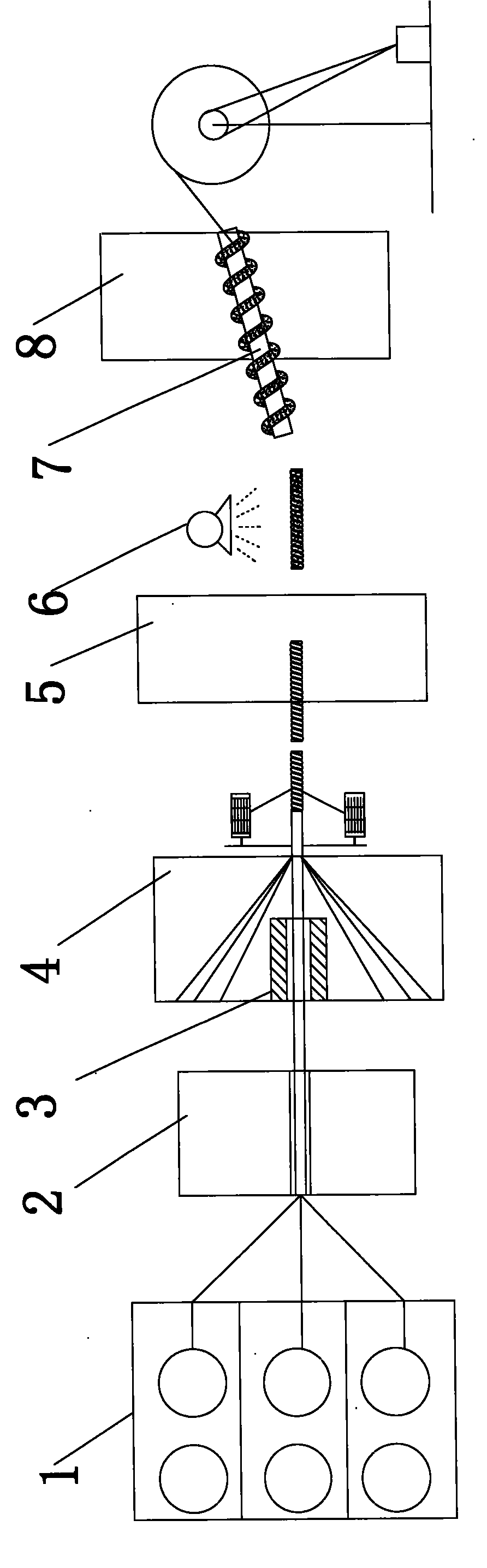

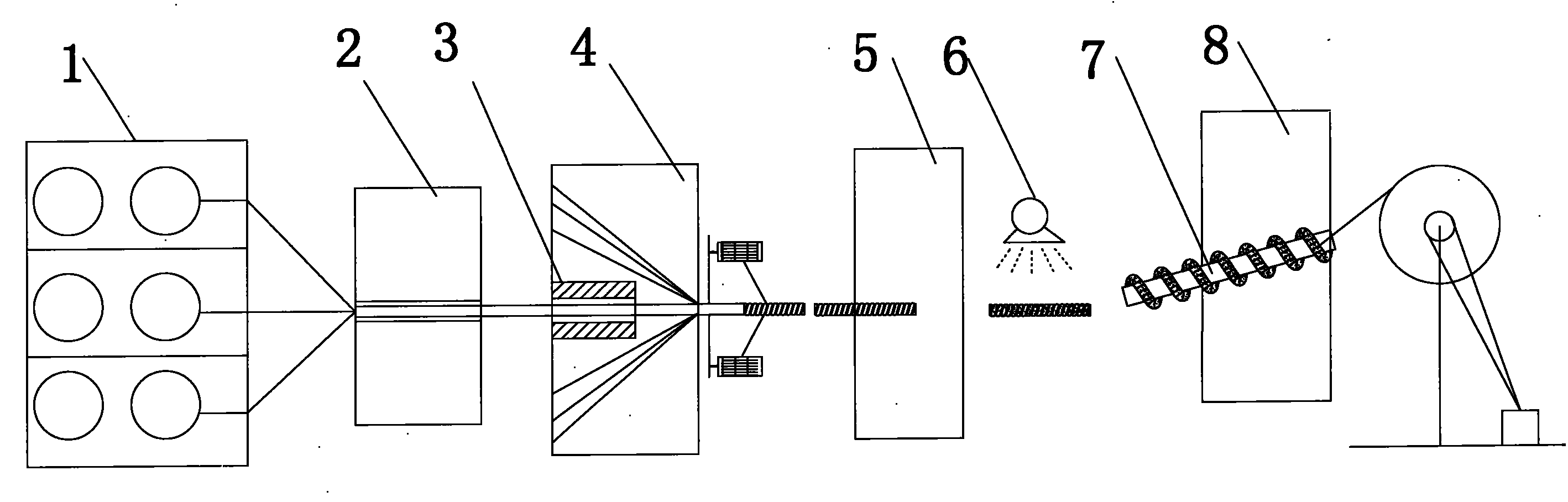

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

Colourful environmental-friendly synthesized polymer waterproof paint

InactiveCN102108234AWith comprehensive performanceImprove physical performance indicatorsPolyurea/polyurethane coatingsMulticolor effect coatingsUltravioletSynthetic Polymeric Macromolecules

The invention relates to a colourful environmental-friendly synthesized polymer waterproof paint which comprises the following components in parts by weight: 3-7 parts of petroleum resin, 5-15 parts of styrene-ethylene-butylene-styrene (SEBS), 5-15 parts of styrene-butylene-styrene (SBS), 5-10 parts of thermoplastic polyurethane elastomer, 4-8 parts of terpene resin, 4-8 parts of poly-alpha-methyl styrene, 2-5 parts of tung oil, 10-15 parts of mica powder, 0.2-0.5 part of antiager D, 0.2-0.5 part of antioxidant 264, 0.2-0.5 part of defoaming agent, 0.3-0.5 part of ultraviolet absorber, 35-45 parts of 120 # solvent, 5-15 parts of butyl acetate and 1-3 parts of color paste. The paint has the characteristics of unique waterproof property, acid-base resistance, ultraviolet irradiation resistance, heat insulation, anti-aging property, high adhesion strength, water repellent, good leakage-resisting effect, heat resistance, frost resistance and good elongation; and the paint also has the advantages of wide application range, moderate price, environmental friendliness, durability and the like, and is convenient to use, thereby meeting the demand of people in a real life.

Owner:白铁林

Copper-plated carbon nanotube reinforced pantograph pan material and preparation method thereof

InactiveCN102031439ACompact structureImprove performancePower current collectorsCopper platingHydrogen

The invention provides a copper-plated carbon nanotube reinforced pantograph pan material and a preparation method thereof. The material comprises the following raw materials: Cu, CNTs, Ti3SiC2 and TiB2 in a volume ratio of (65-90):(1-20):(2-30):(1-20). The preparation method comprises the following steps of: uniformly mixing the four raw materials and glycerol, baking the mixture, loading the mixture into a steel mould, cold molding, placing the mixture in a high-temperature furnace under the protection of hydrogen, raising the temperature to 700 to 900 DEG C, preserving heat for 5 to 30 minutes, taking out the sample, cold molding again, sintering the sample at the temperature of between 800 and 900 DEG C for the second time and preserving heat for 30 to 60 minutes. The method has a simple process; the performance of the pantograph pan material can be greatly improved by the traditional equipment; and the prepared pantograph pan material has the advantage of relatively low cost.

Owner:WUHAN UNIV OF TECH

Polyurethane resin combination and preparation method and using method thereof

The invention provides a polyurethane resin composition, its preparation method, and using method of the same used as filling material of railway plate type dreg-free track convex block. The polyurethane resin composition is mainly used as filling material of railway plate type dreg-free track convex block, and mainly includes: polyether or polyester polyol, isocyanate or prepolymer of the same, pigment, filling and other auxiliary agent. Advantages of the prepared polyurethane resin are: construction manufacturability is better, bonding to cement of cured resin is good; the polyurethane resin is resistant of ultraviolet ray irradiation, moisture, heat, ageing and fatigue, and owns appropriate elasticity and integrated mechanical capability.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Inkjet infiltrating glazed porcelain tile and preparation method thereof

The invention relates to an inkjet infiltrating glazed porcelain tile and a preparation method thereof. The preparation method comprises the following steps: 1) preparing ground glaze slurry and transparent glaze slurry; 2) spraying the ground glaze slurry onto a blank, performing drying, coating a ground glaze layer with infiltrating ink and an infiltrating aid, and standing for more than 5 minutes to guarantee an infiltrating effect; 3) performing biscuit firing on the blank prepared in the step 2) at the temperature of 800 to 950 DEG C; 4) spraying the transparent glaze slurry onto the biscuit-fired blank in the step 3); 5) firing the blank, onto which the transparent glaze slurry is sprayed, prepared in the step 4) at the temperature of 1,150 to 1,230 DEG C, and then performing polishing to obtain the inkjet infiltrating glazed porcelain tile. Due to the fact that the ink infiltrates into the ground glaze layer after firing, the whole layer of transparent glaze is polished by a non-elastic module and then is polished to a ground glaze upper middle layer, so that local exposure can be avoided.

Owner:MONALISA GRP CO LTD

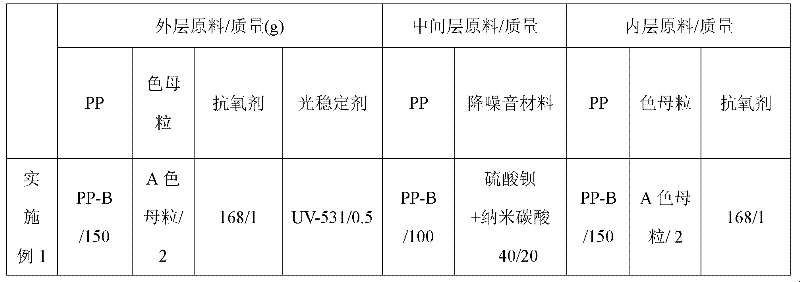

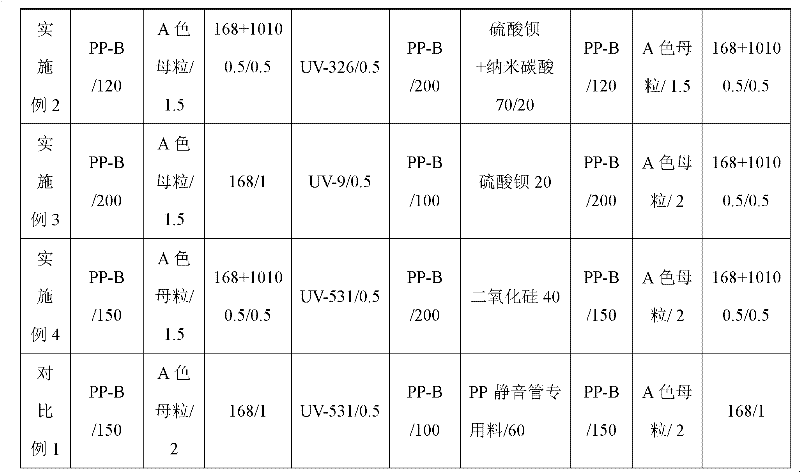

Mute water discharging pipe

ActiveCN102345312AGood noise reductionGood mechanical propertiesDomestic plumbingPolypropyleneCalcium carbonate

The invention discloses a mute water discharging pipe, belonging to the field of pipe materials. The mute water discharging pipe not only has a good noise reducing effect, but also has good mechanical performance, and has a three-layer structure, wherein the inner layer and the outer layer are polypropylene felts, and the middle layer is a sound-absorbing core layer; and the sound-absorbing core layer comprises the raw materials in parts by weight: 100-200 parts of polypropylene resin and 20-100 parts of noise-absorbing material, wherein the polypropylene resin is made of block copolymerized polypropylene, homopolymerized polypropylene or random copolymerized polypropylene; and the noise-absorbing material is selected from at least one of wollastonite, calcium carbonate, talcum powder, barium sulfate and silicon dioxide. The mute water discharging pipe disclosed by the invention has the advantages of excellent muting effect, superstrong chemical corrosion resistance, excellent high temperature resistance, good impact resistance, long service life and the like.

Owner:KANGTAI PLASTIC SCI & TECH GRP

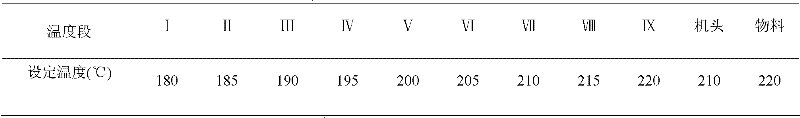

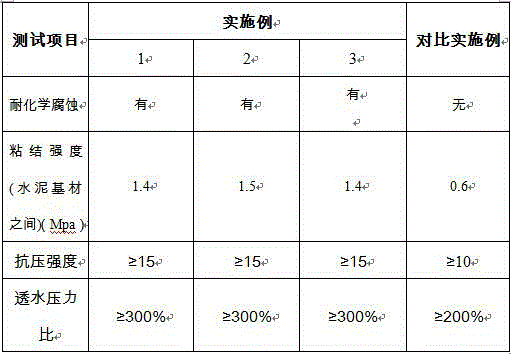

Geopolymer chemically-bonded ceramic tile and preparation method thereof

ActiveCN105236933ALow costSuperior performanceCeramic materials productionClaywaresBuilding materialCeramic tiles

The invention relates to a geopolymer chemically-bonded ceramic tile and a preparation method thereof. The geopolymer chemically-bonded ceramic tile is prepared from solid wastes like fly ash, filtered steel and copper slag, and industrial-grade chemical raw materials. The unburned ceramic tile is prepared from, by mass, 60 to 75% of the solid wastes, 19 to 38% of a liquid activator, 1 to 3% of a base-material additive and 1 to 3% of a compound liquid additive by procedures like mixing, sieving and granulating. Due to implementation of a firing-free process, energy conversation and consumption reduction can be realized; pollution is reduced; meanwhile, performances of the geopolymer chemically-bonded ceramic tile can reach national standards of fired ceramic tiles. The geopolymer ceramic tile does not need to introduce calcined kaolin, and after 12 to 48 hours of easy and practicable special maintenance, a ceramic bonded three-dimensional network body is rapidly formed, so the ceramic tile reaches and is superior in a part of performances to the 60-day-age level of similar geopolymer materials; limited mineral resources are not consumed; and energy consumption of calcination is avoided. The geopolymer chemically-bonded ceramic tile provided by the invention can change wastes into treasures, significantly saves energy and reduces consumption, can be used as a novel building material and has extensive application prospects.

Owner:JINGDEZHEN CERAMIC INSTITUTE

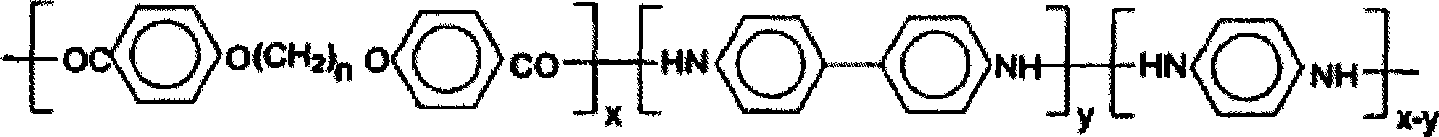

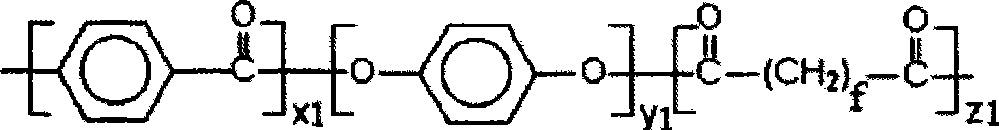

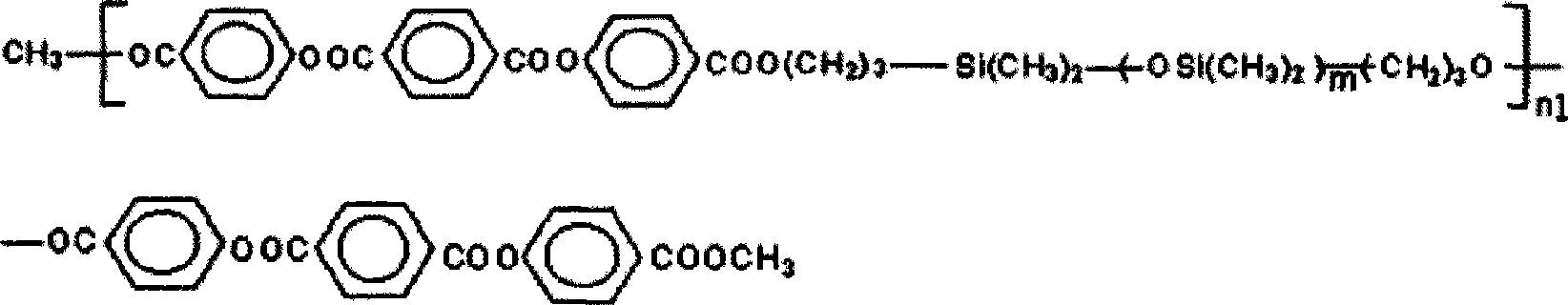

Polyphenyl thioether / thermotropic liquid crystal complex fiber and preparation thereof

InactiveCN101440536AImprove performanceImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentArtifical filament manufactureWater bathsDry heat

The invention discloses a polyphenylene sulfide / thermotropic liquid crystal composite fiber and a method for preparing the same. The polyphenylene sulfide / thermotropic liquid crystal composite fiber comprises 100 portions of polyphenylene sulfide slice or powder material and 0.5 to 5 portions of thermotropic liquid crystal. The method for preparing the polyphenylene sulfide / thermotropic liquid crystal composite fiber comprises the following steps: drying the polyphenylene sulfide slice or the powder material and the thermotropic liquid crystal through a vacuum rotary drum dryer respectively, and mixing the materials evenly; performing melt spinning on the obtained mixture in a screw spinning device to obtain a fused body which is spouted out from a spinneret plate, passes through a annealing device, and then is cooled naturally and solidified into a fiber; and coiling the cooled fiber after the fiber is oiled and clustered, and performing hot water bath first-stage stretching, dry heat second-stage stretching and a one-step heat-setting treatment on the coiled fiber so as to obtain the polyphenylene sulfide / thermotropic liquid crystal composite fiber. The polyphenylene sulfide / thermotropic liquid crystal composite fiber has the advantages that the mechanical property and the processing performance of the polyphenylene sulfide fiber can be improved, the equipment is simple, and the operation is easy.

Owner:DONGHUA UNIV

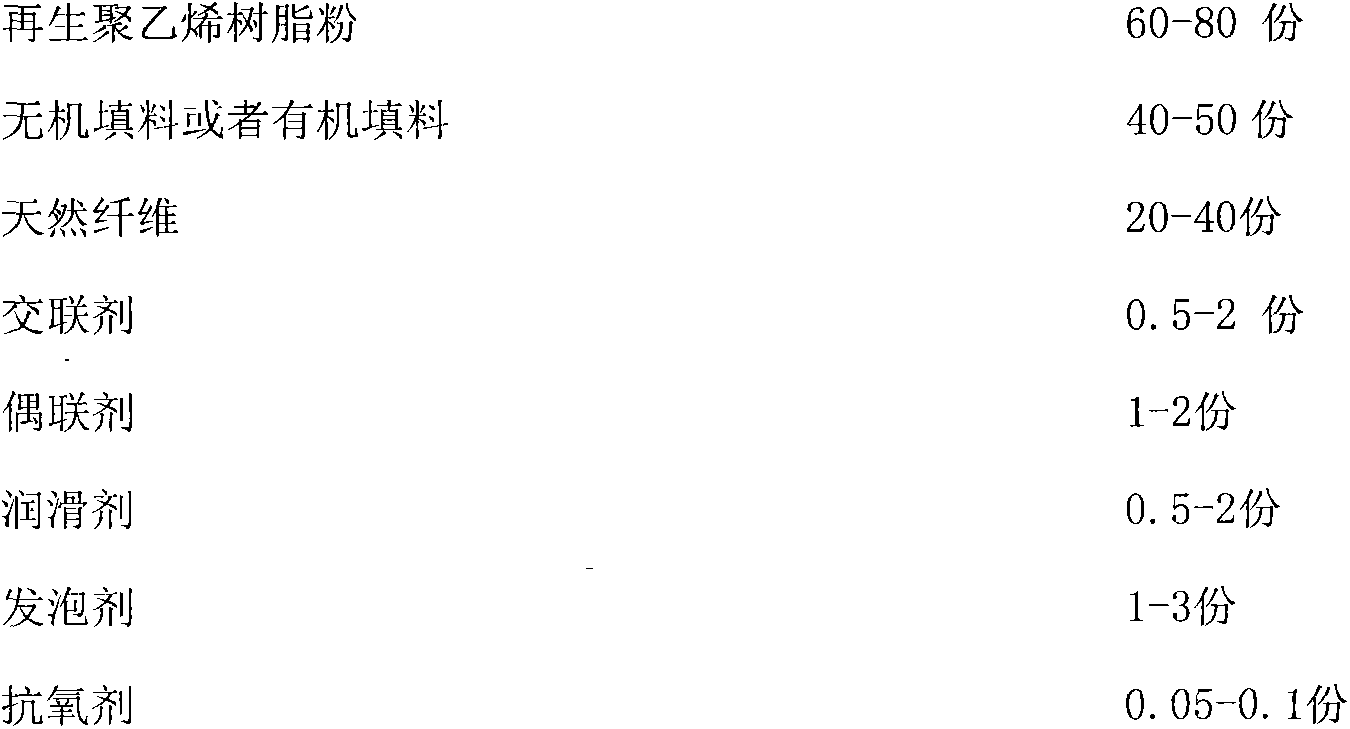

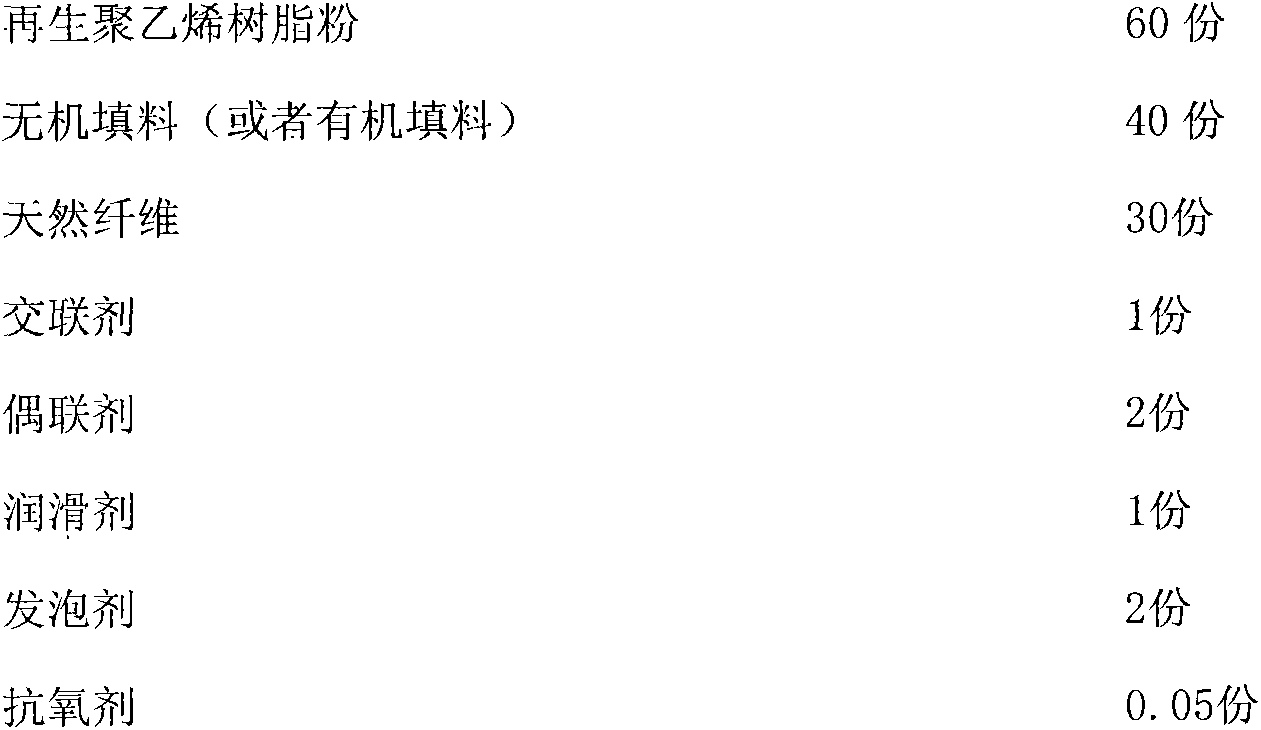

Superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe and manufacturing method thereof

The invention belongs to the field of pipes, relates to an enhanced drainage pipe and mainly relates to a superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe which is suitable for wastewater discharging, engineering transforming projects and home decoration of villa communities, high-rise residential communities, high-grade residential apartment communities and the like and industrial building fields like water discharging, sewage discharging, waste discharging and the like of industrial enterprises. The superstrong-muting PE composite drainage pipe is a multilayer composite body formed by a high-density polyethylene resin inner layer, a middle PE micro-foamed layer and a high-density polyethylene resin outer layer, the thickness ratio of the inner layer, the middle layer and the outer layer is 1:4:1, and the PE micro-foamed layer is composed of regenerated polyethylene resin powder, inorganic filler or organic filler, natural fibers, a cross-linking agent, a coupling agent, a lubricating agent, a foaming agent and an antioxidant. The superstrong-muting PE core layer micro-foamed drainage pipe has excellent denoising and muting performance, superstrong resistance to chemical corrosion and good impact resistance.

Owner:LINYI DONGLI PLASTIC BUILDING MATERIAL CO LTD

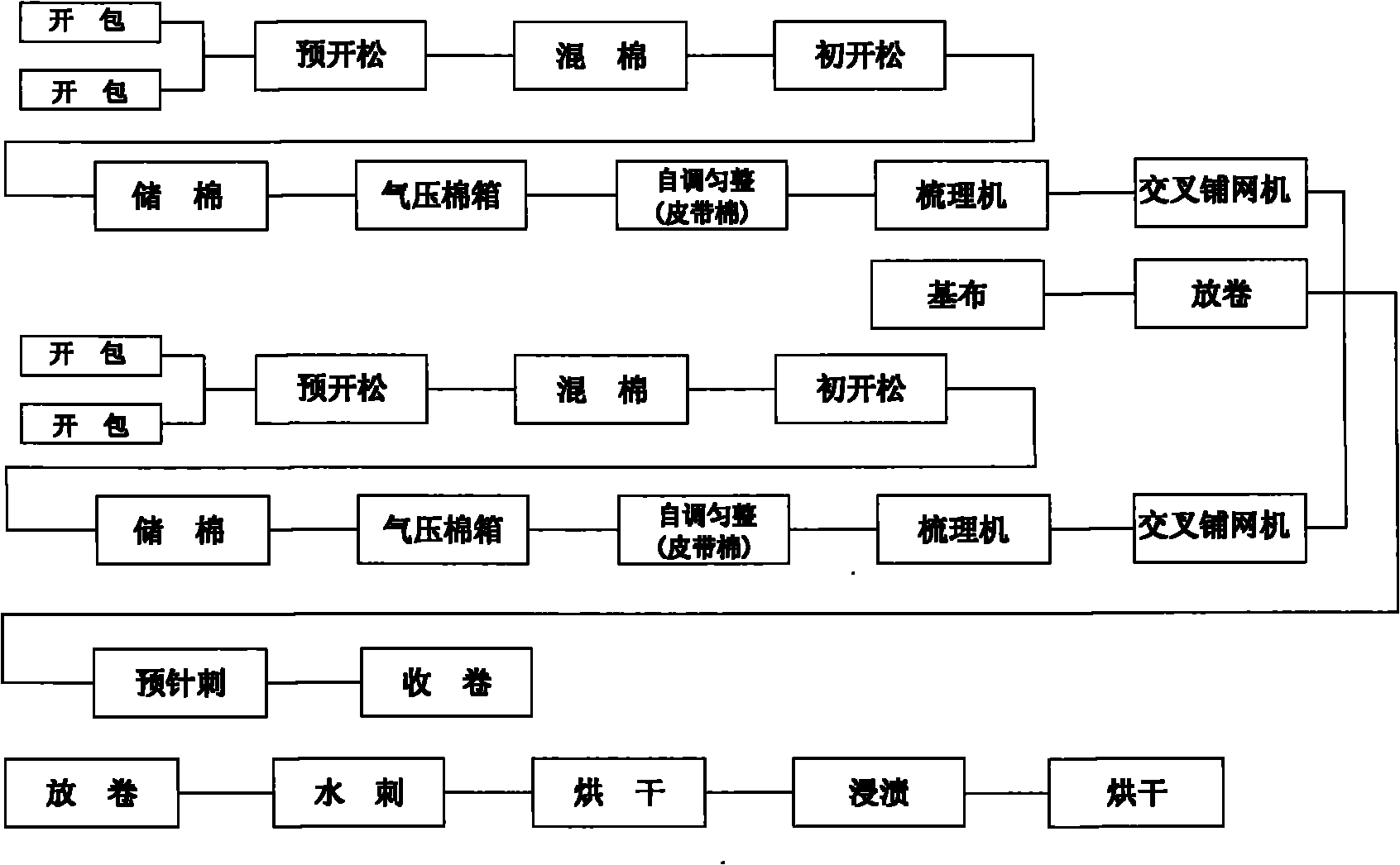

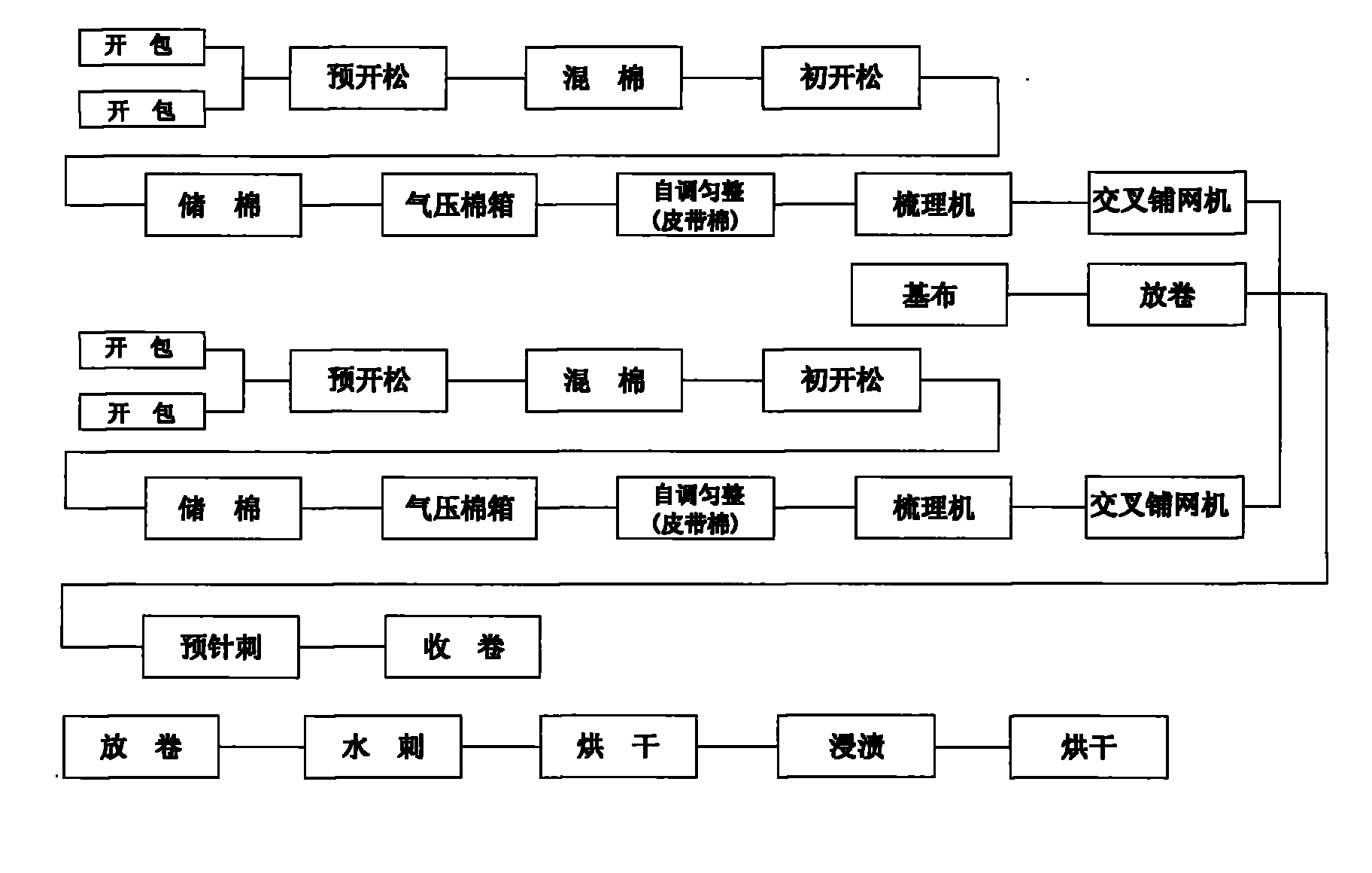

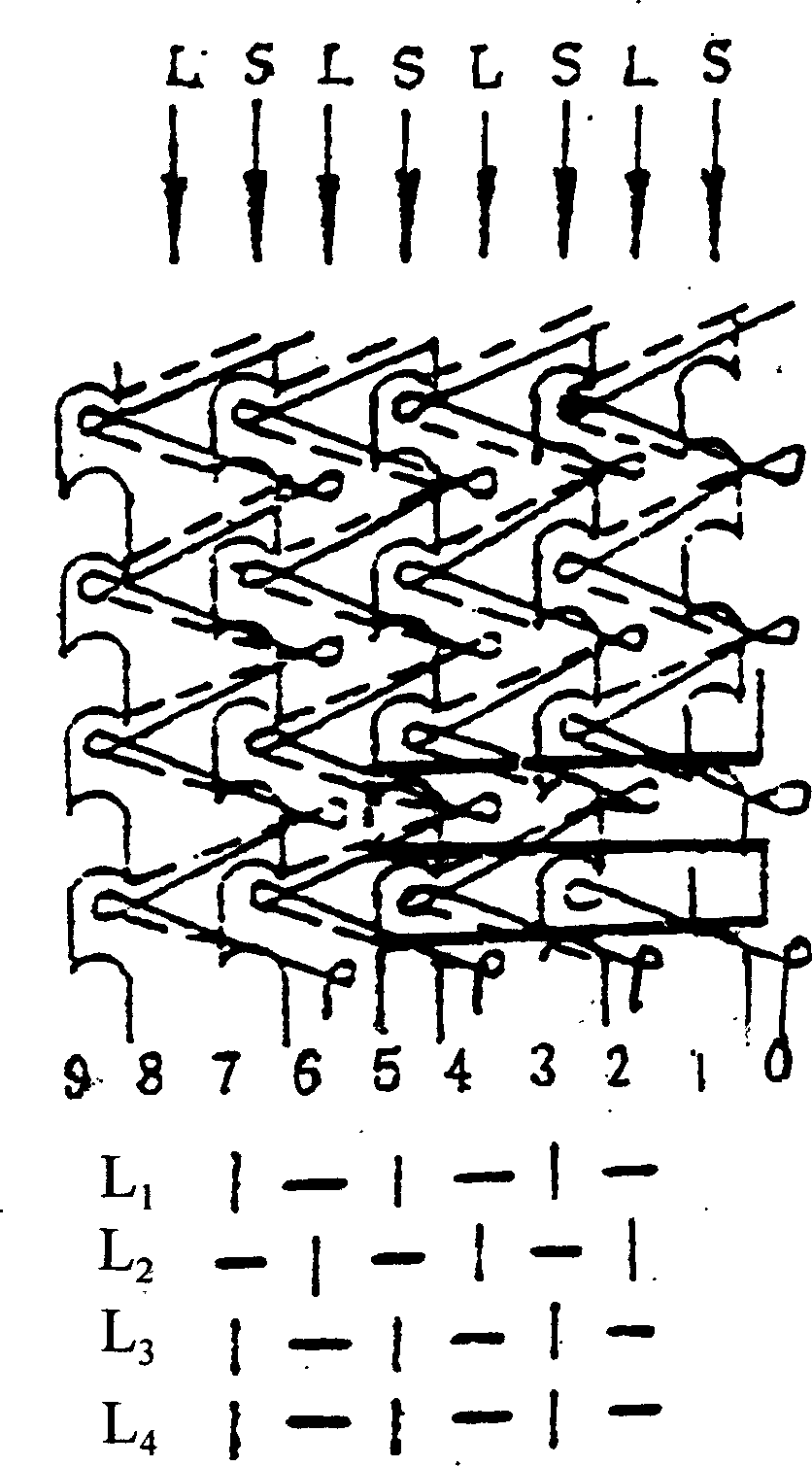

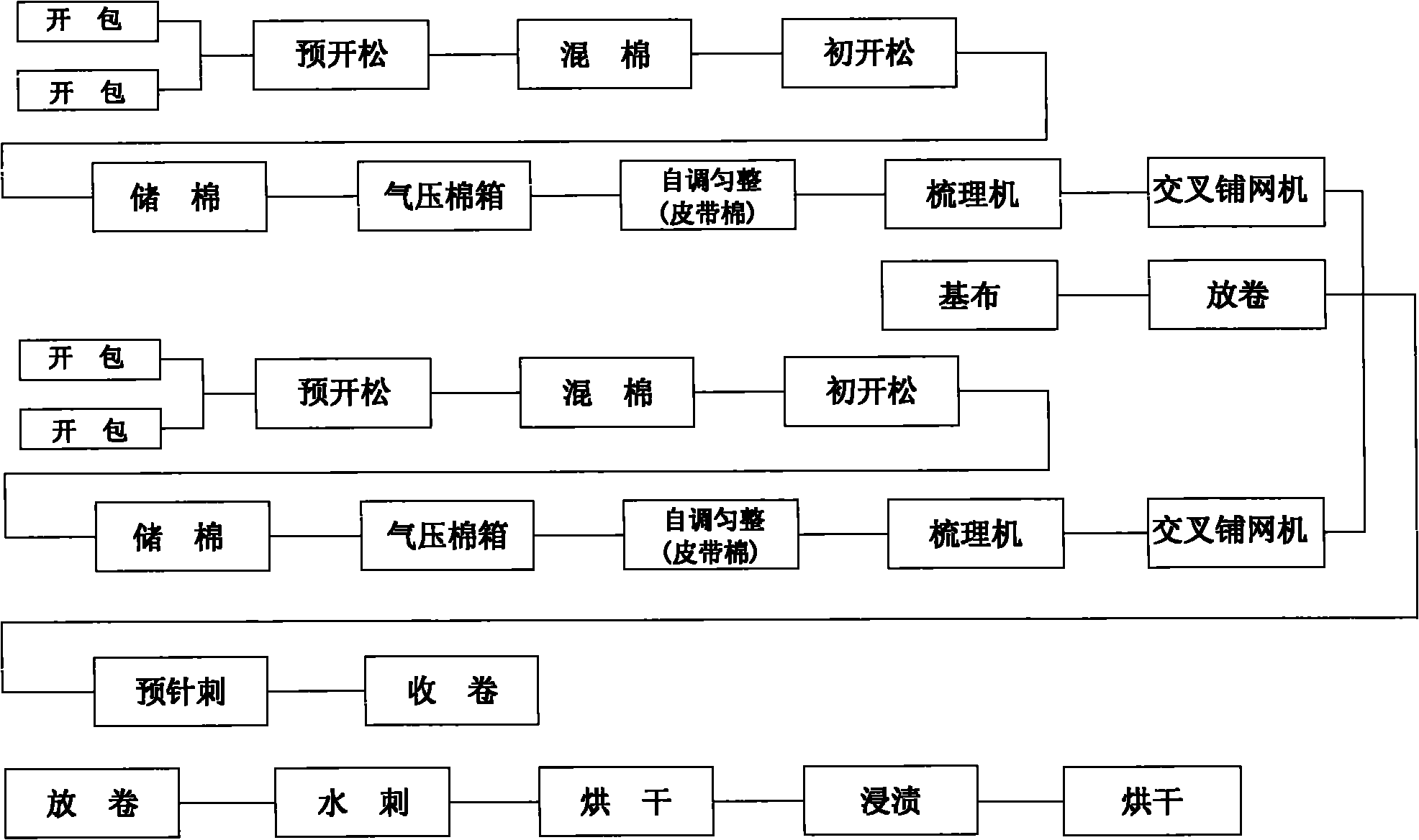

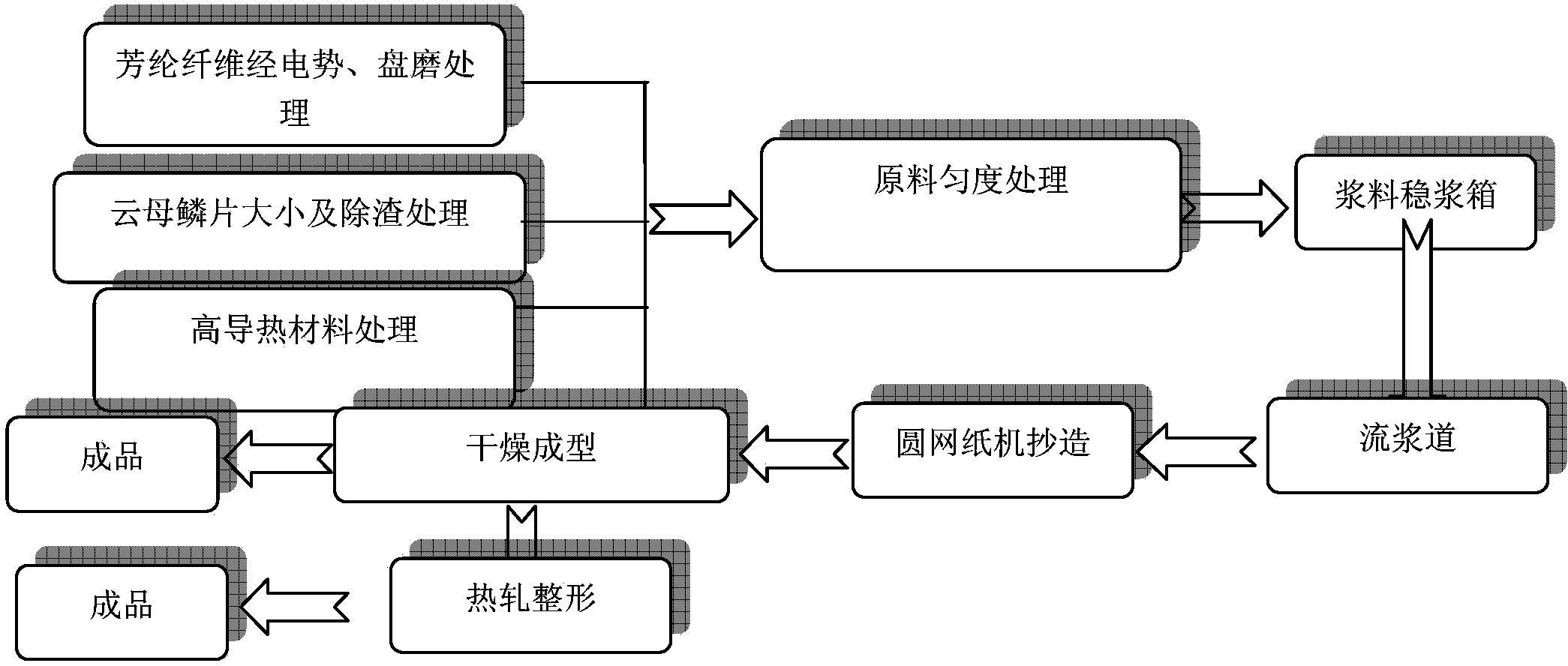

Preparation method of specific composite filter material for coal-fired power plant electric bag integration project

InactiveCN101804272AStrong chemical resistancePower does not decayDispersed particle filtrationLayered productsSolventCompound (substance)

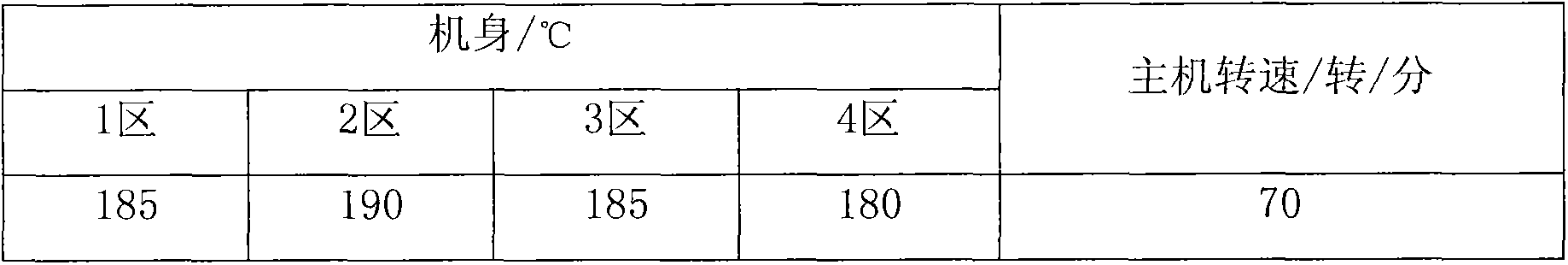

The invention discloses a preparation method of a specific composite filter material for a coal-fired power plant electric bag integration project; in the preparation method, a dust facing surface is mixedly blended from PTFE fibers and PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent; base cloth is interwoven from 100 percent PTFE long filaments in longitude and latitude directions; a bottom layer is mixedly blended from the PTFE fibers and the PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent; and a plain blanket is formed through an acupuncture and spunlace composite process, and is soaked in chemical solvent, to prepare the specific composite filter material for the coal-fired power plant electric bag integration project. The preparation method overcomes the defects of the traditional electric bag integration project that the oxidizability and the acid corrosion of the flue gas are strong so the 100 percent PPS loses effectiveness because of oxidation and chemical corrosion, improves the oxidation resistance, prolongs the service life, improves the permeability, the tensile strength and the filtration precision of filter material, and reduces the operation resistance of the equipment.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP

Surface-ornamental styrene-acrylic bromine-carbon latex fire-proof paint and preparation thereof

InactiveCN101255302AImprove the decorative effectGood chemical resistanceFireproof paintsWax coatingsAntimony trioxidePhenol

The invention provides a decorative type styrene-acrylic bromine carbon latex fire-retardant coatings and preparation method thereof. The induction of flameretardant element bromine and synthesis of intrinsic flamertardant polymer resin can increase ageing effect and flame retardant property of fire-retardant coatings, and conquer the defects of fireretardant system of addition type fire-retardant coatings such as effusion, movement and volatilization. The phenol is used as raw material to produce tribromo phenol in the present of sodium bromate and sodium bromide, furthermore the tribromo phenol reacts with acryloyl chloride to obtain acrylic 2,4,6-tribromo phenyl ester. The styrene-acrylic bromine carbon latex is produced through polymerizing the acrylic 2,4,6-tribromo phenyl ester with butyl acrylate, methyl methacrylate, styrene and acrylic acid by free radical. Finally the decorative type styrene-acrylic bromine carbon latex fire-retardant coatings can be produced by using styrene-acrylic bromine carbon latex as base material and mixing the ammonium polyphosphate, melamine, dipentaerythritol, molybdenum hemitrioxide, antimony oxide, zinc borate, boron-moisten soil and titanium white powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

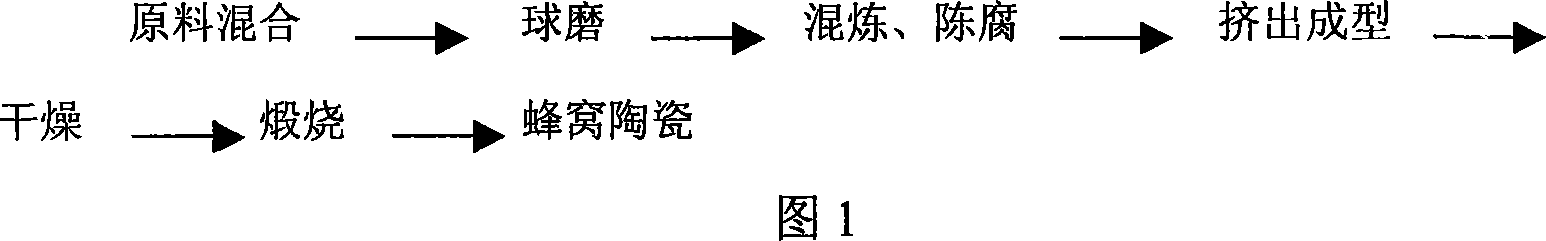

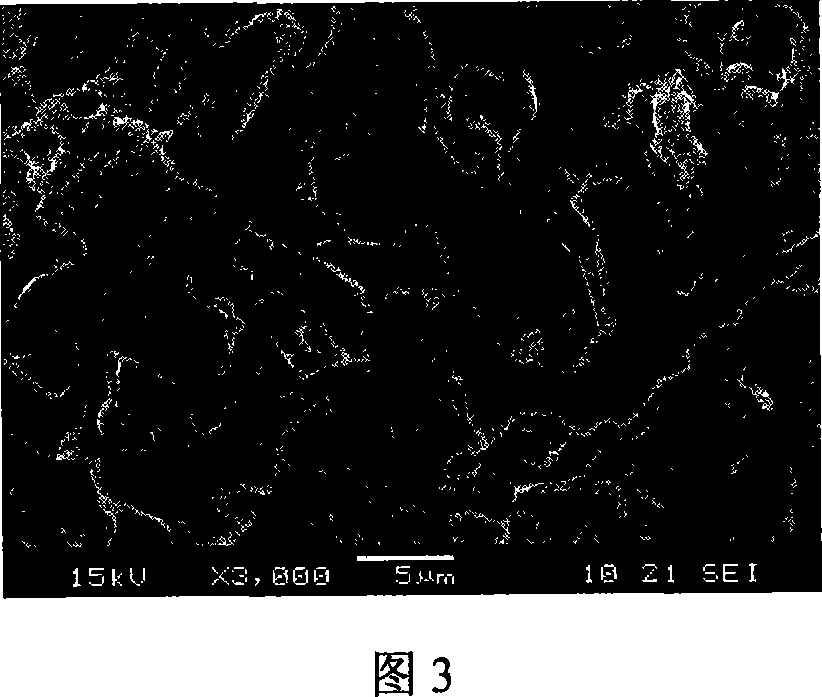

Multi-phase functional ceramic honeycomb support and preparation method thereof

ActiveCN101062868AThe preparation method is simple and controllableLow costCatalyst carriersCeramicwareRare earthSilicon dioxide

The invention discloses a preparing method of polyphase functionality honeycomb ceramic supporting body, which comprises the following steps: choosing titanium white, silica dioxide and aluminum oxide as main raw material; doping rare earth; adding right amount magnesium oxide accelerating burnt agent and additive; mixed-refining; squeezing; forming; drying; calcining for 2-3 h under 1200-1500 deg. c; generating the product with aluminium titanate and red schorl as principal crystalline phase. This product possesses shockproof, corrosion resistant, high intensity and good association with coated carrier, which can be used to the carrier of car exhaust gas cleansing activator and carrier reactor of photocatalyzer.

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

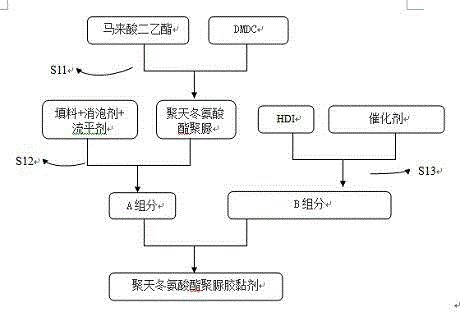

Polyaspartate polyurea adhesive and preparation method thereof

InactiveCN104559899AMethod stableLow VOC contentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceMeth-

The invention discloses a polyaspartate polyurea adhesive and a preparation method thereof. The polyaspartate polyurea adhesive comprises a component A and a component B spaced from each other before being used, wherein the component A and the component B are mixed at a weight ratio of 4 to (1-1.05) when being used; the component A comprises the following components in parts by weight: 4.0-5.0 parts of polyaspartate polyurea, 4.0-4.50 parts of fillers, 0.005-0.01 parts of a defoamer and 0.005-0.01 parts of a leveling agent; the component B is hexamethylene diisocyanate trimer. According to the polyaspartate polyurea adhesive, the component A and the component B are mixed, so that the bonding strength in a bonding process is high and especially the bonding strength between the adhesive and a cement matrix is high; moreover, the adhesive has excellent performances of chemical corrosion resistance, water resistance, weather resistance, temperature resistance, low VOC (volatile organic compounds), environmental protection and the like.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Method for manufacturing nylon/polyester compound ultra-fine fibre cleaning cloth

ActiveCN1736318AHas a hydrophilic oil baseStrong dust absorptionCarpet cleanersFloor cleanersChemical cleaningCleaning agent

A method for making composite polyester brocade superfine fiber cleaning towel, using polyester brocade composite fiber as raw material, braiding to knit cloth with braiding art work, and the braided knit cloth is cut and sewn into cleaning towel after spotting, fiber-extracting, coloration, drying, finishing. It is characterized by the following: in the procedure deoil art work and fiber-extracting art work, put the knit cloth in water which bath ratio is 1:8-15 and contains scouring agent C-320 or scouring agent DN or scouring agent C-24, caustic soda, chelate dispersing agent 25DX or chelate dispersing agent PC680, elevating temperature in operation, thermal insulation, cooling, tapping, water scrubbing, tapping; the fiber number is no more than 0.13dtex after the composite fiber is extracted. The cleaning towel can easily removal the greasy dirt, stain using water alone and no chemical cleaning agent as cleaning agent, and no washmarking retained. All greasy dirt left in the cleaning towel can be clean in clean water easily. The cleaning towel has long lifetime.

Owner:HEBEI YIKANG FUNCTIONAL MATERIALS CO LTD

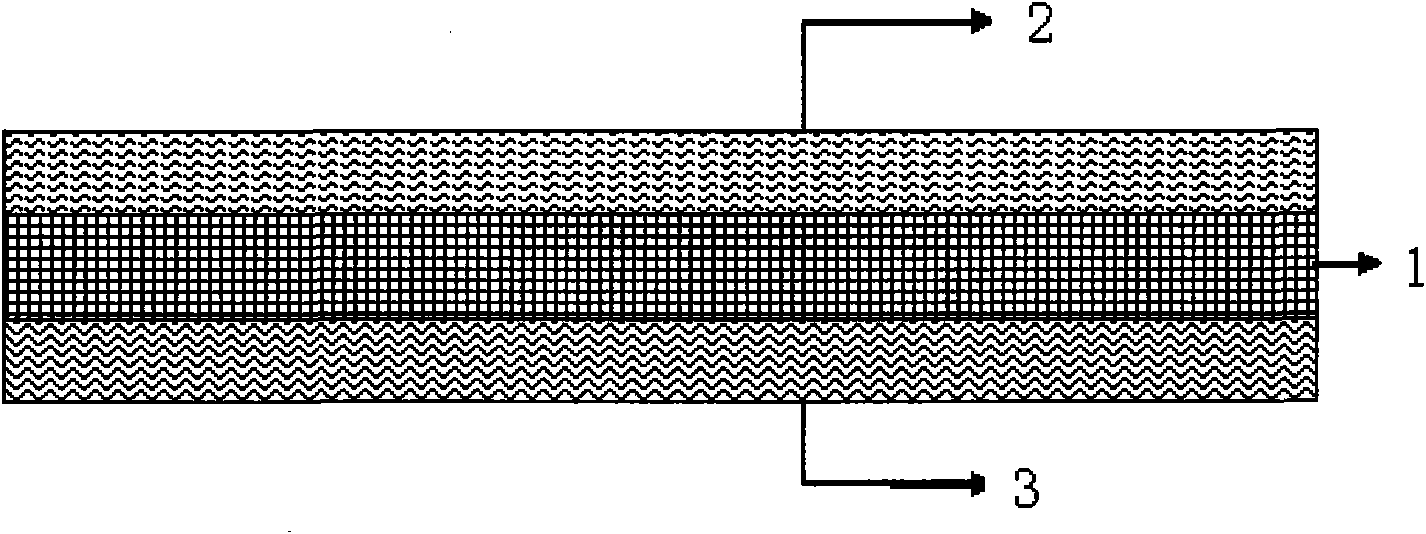

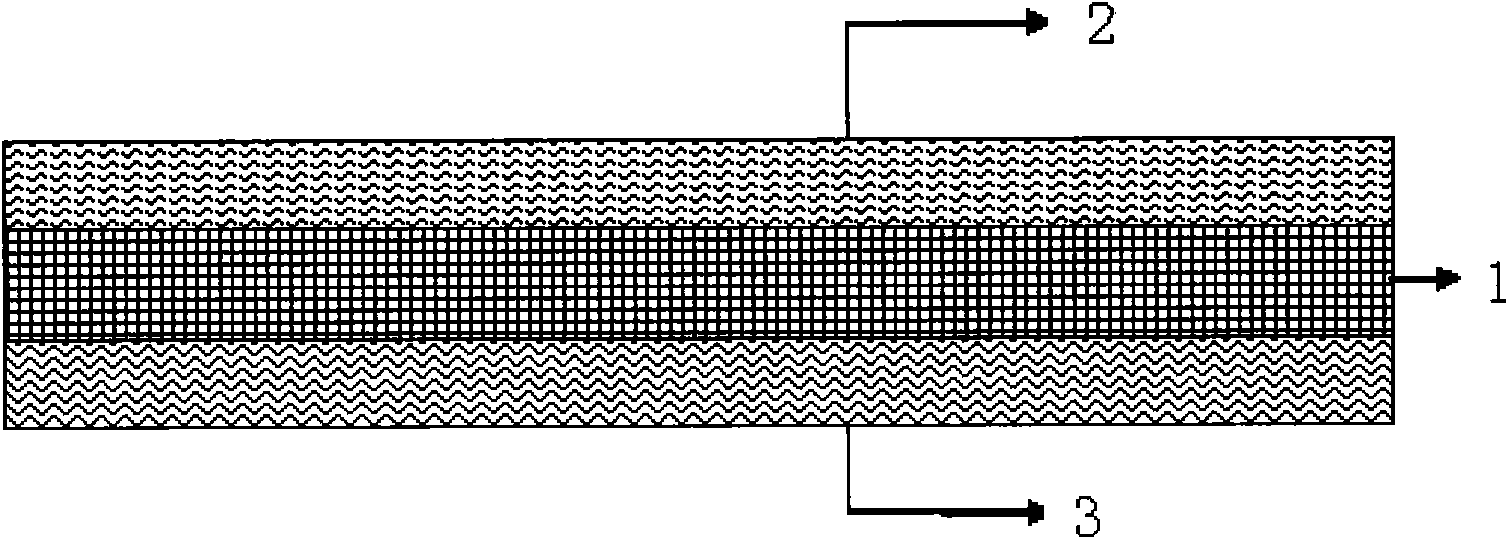

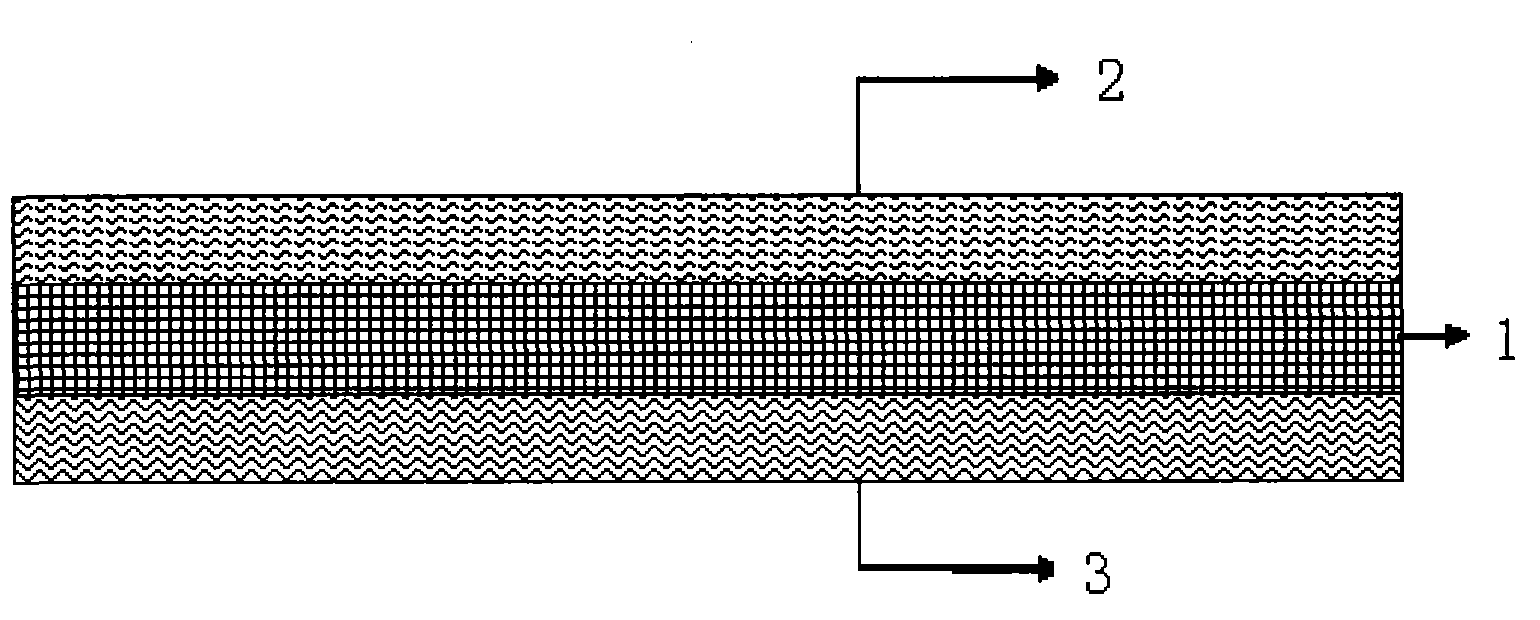

Specific composite filter material for coal-fired power plant electric bag integration project

InactiveCN101804273AImprove Oxygen LimitationStrong chemical resistanceCombination devicesLayered productsCompound (substance)Engineering

The invention discloses a specific composite filter material for a coal-fired power plant electric bag integration project; the composite filter material comprises base cloth, a dust facing surface and a bottom layer; the dust facing surface is arranged on the upper surface of the base cloth; the bottom layer is arranged on the lower surface of the base cloth; the dust facing surface is mixedly blended from PTFE fibers and PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent; the base cloth is interwoven from 100 percent PTFE long filaments in the longitudinal and latitude directions; and the bottom layer is mixedly blended from the PTFE fibers and the PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent. The fibers tangle through an acupuncture and spunlace composite process to form a plain blanket which is soaked into chemical solvent, so as to further improve the corrosion resistance and chemical performance resistance. The specific composite filter material for the coal-fired power plant electric bag integration project has smooth surface, improves the dust removing capability, reduces the operation resistance of equipment, prolongs the service life, can ensure the use for 35000h in the electric bag integration project, and is applicable to the coal-fired power plant electric bag integration project.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP

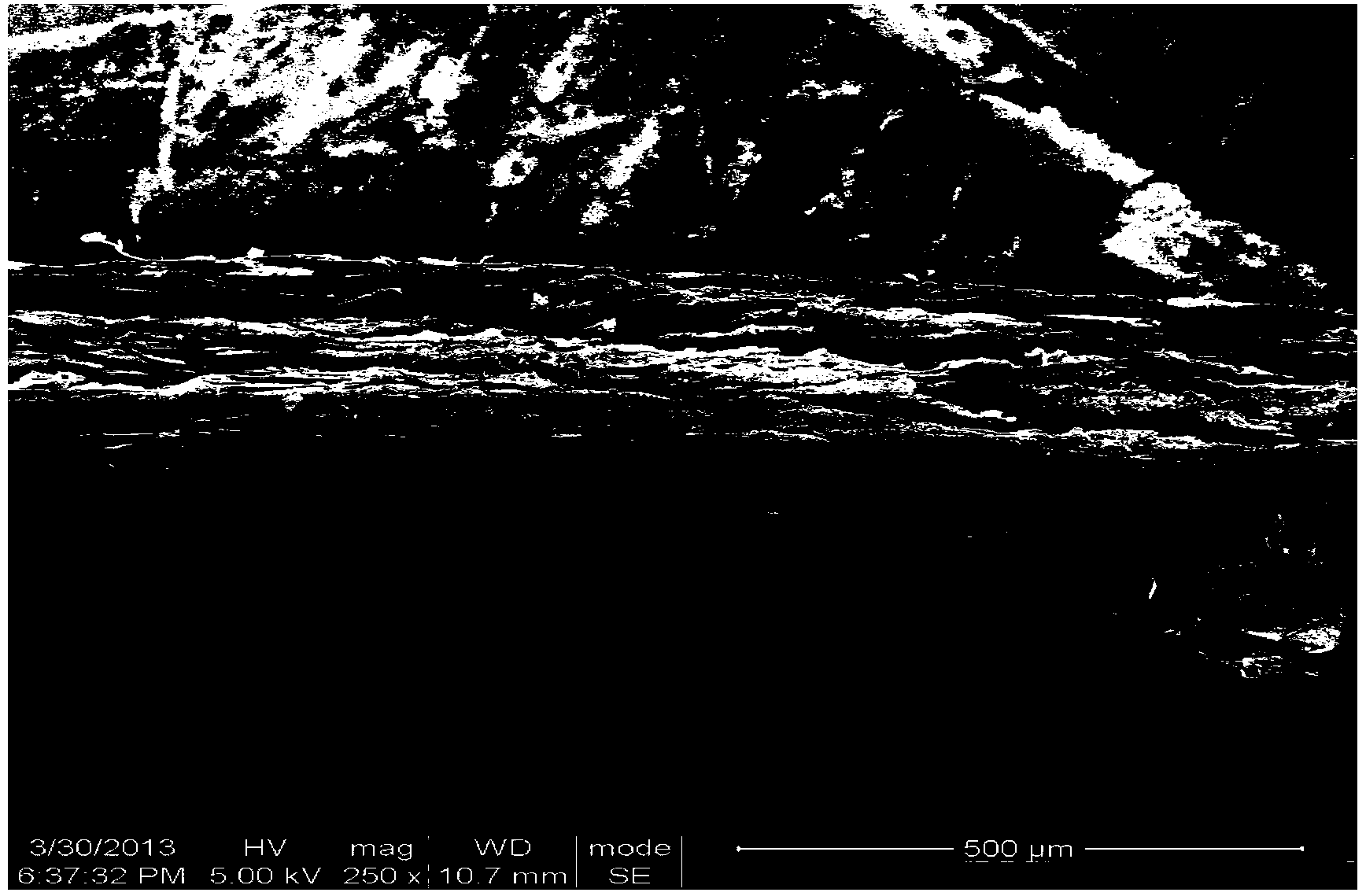

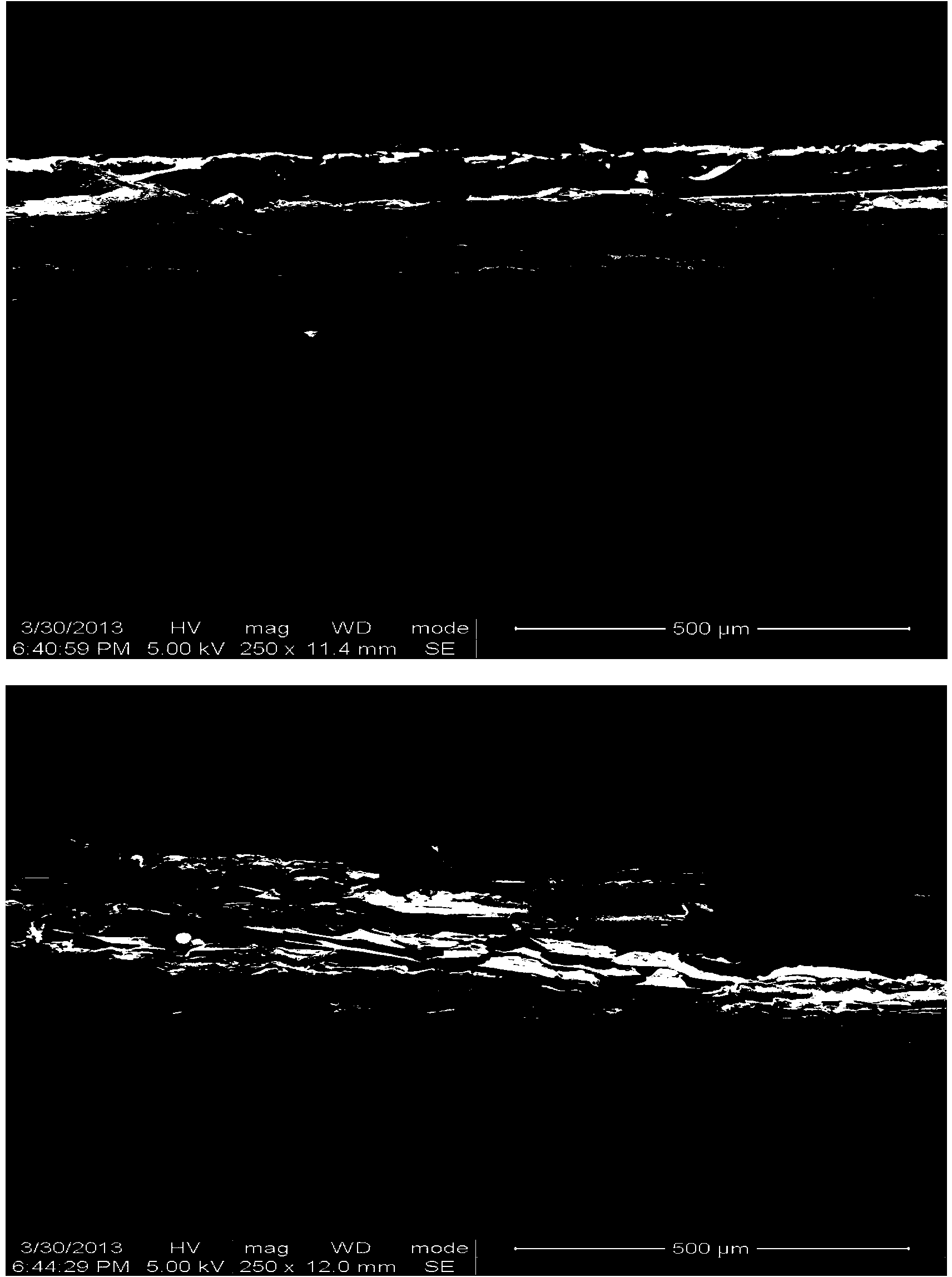

High-heat-conductive boron nitride insulation material and preparation method thereof

ActiveCN104072988AImprove thermal conductivityImprove insulation performanceHeat-exchange elementsThermal fatigueBoron nitride

The invention discloses a high-heat-conductive boron nitride insulation material as well as a preparation method and an application thereof. The insulation material provided by the invention comprises aramid fibers, fibrids, mica, and granular boron nitride which is treated by polyphenylene sulfide. The insulation material has the characteristics of high heat conductivity, high insulativity, high strength, strong machinability, high physical property, high chemical resistance and the like, and is excellent in compact resistance, chemical corrosion resistance and heat fatigue resistance. Thus, the insulation material provided by the invention can be applied to high-end composite insulation materials.

Owner:LONGPONT

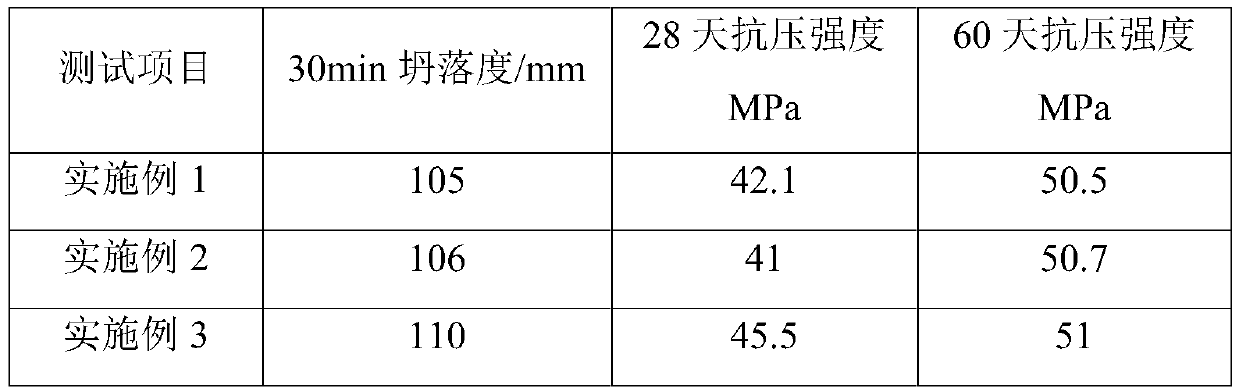

High-compressive-strength recycled concrete and preparation process thereof

The invention discloses high-compressive-strength recycled concrete and a preparation process thereof. The high-compressive-strength recycled concrete comprises the following components in parts by weight: 300-420 parts of reinforced recycled aggregate, 25-35 parts of recycled micro powder, 100-200 parts of natural coarse aggregate, 120-200 parts of natural fine sand, 120-170 parts of cement, 50-130 parts of fly ash, 50-120 parts of mineral powder, 6-12 parts of a waterproof agent, 0.8-2.2 parts of an air entraining agent, 120-160 parts of water and 20-35 parts of polypropylene mixed filler. The preparation process comprises the following steps: S1, weighing corresponding amounts of cement and natural fine sand, putting the cement and the natural fine sand into a stirrer, and stirring for40-60 seconds; S2, weighing the regenerated micro-powder, the fly ash, the mineral powder and the polypropylene mixed filler according to corresponding proportions, adding the weighed materials into the stirrer in the step S1, continuing to stir and mix for 30-40 seconds, adding half of the water according to the proportion, continuing to stir for 30-40 seconds, and mixing to obtain mortar with uniform color; and S3, adding the rest half of the water, the reinforced recycled aggregate, the natural coarse aggregate, the air entraining agent and the waterproof agent according to the proportion in the step S2, and continuously stirring for 60-80 seconds until the mixture is uniform.

Owner:西安百固源混凝土有限公司

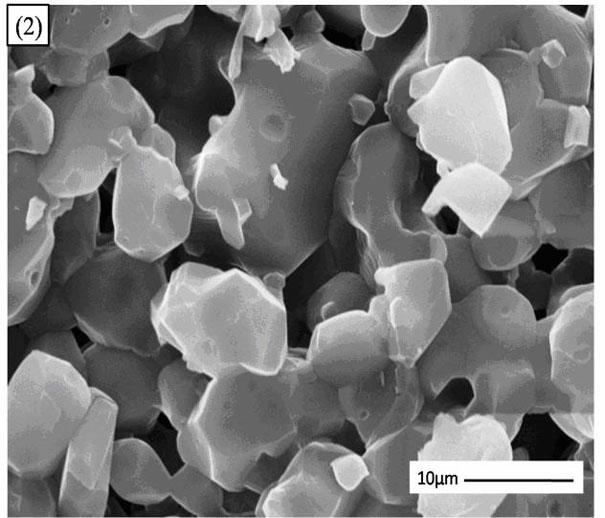

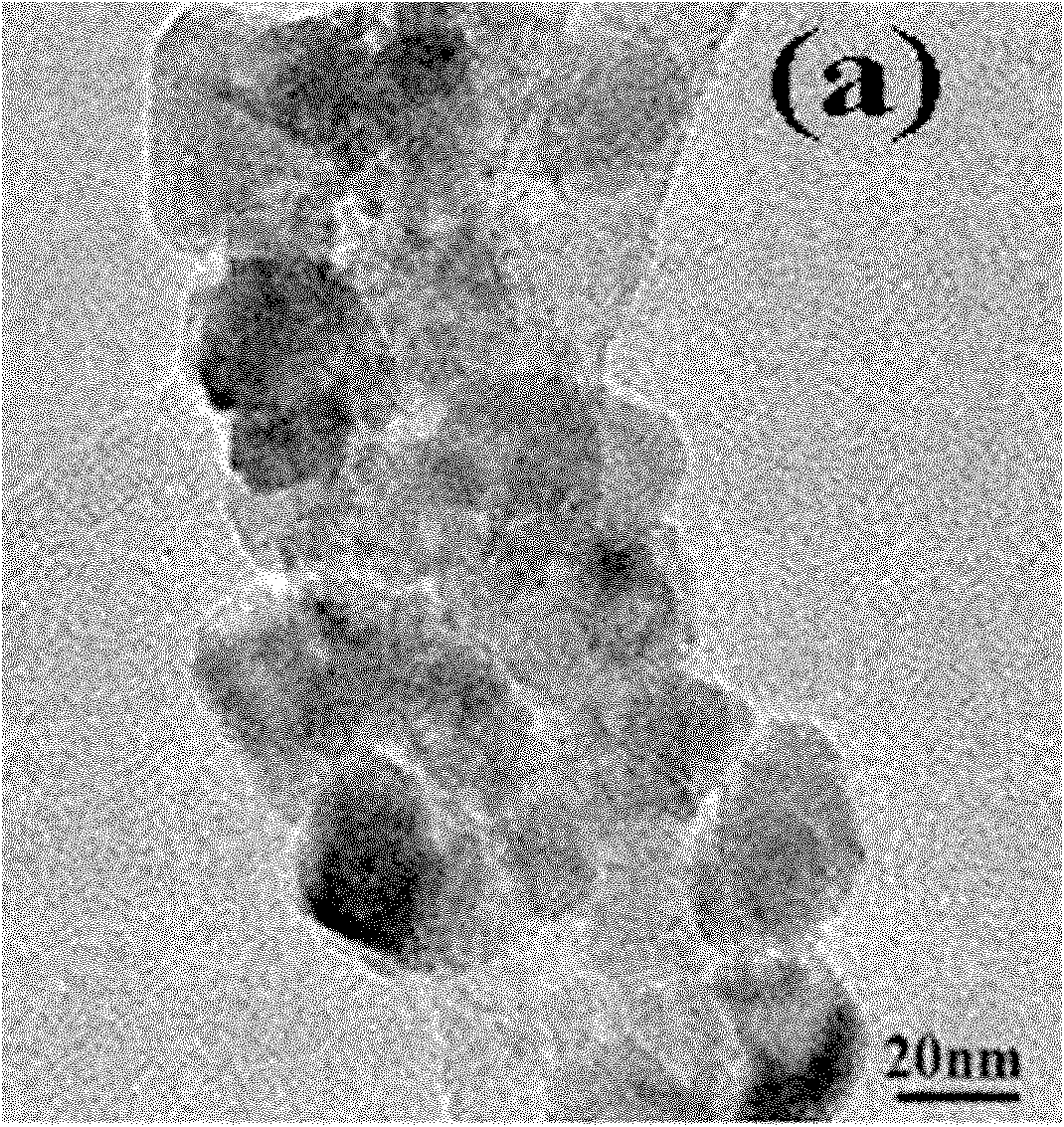

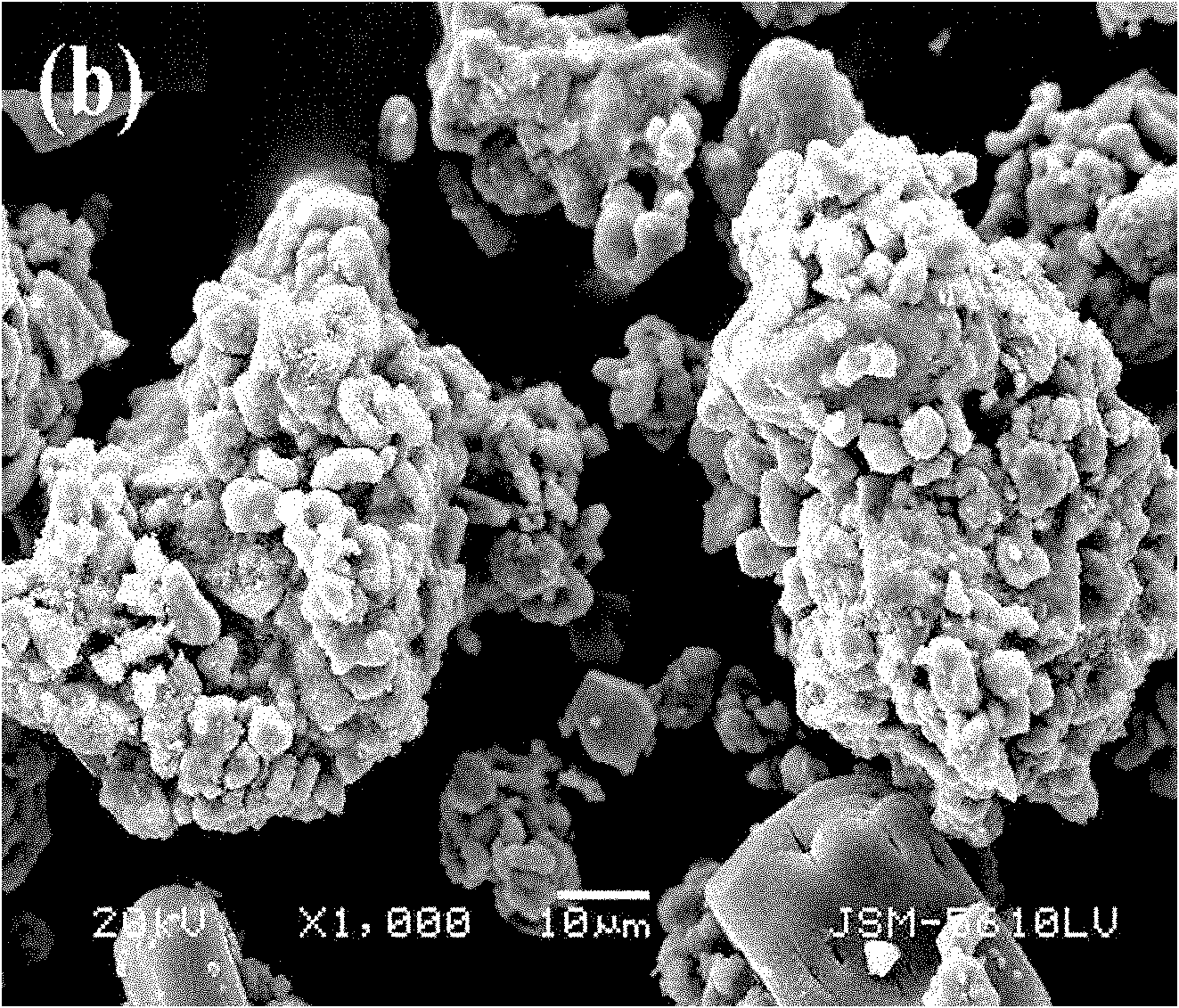

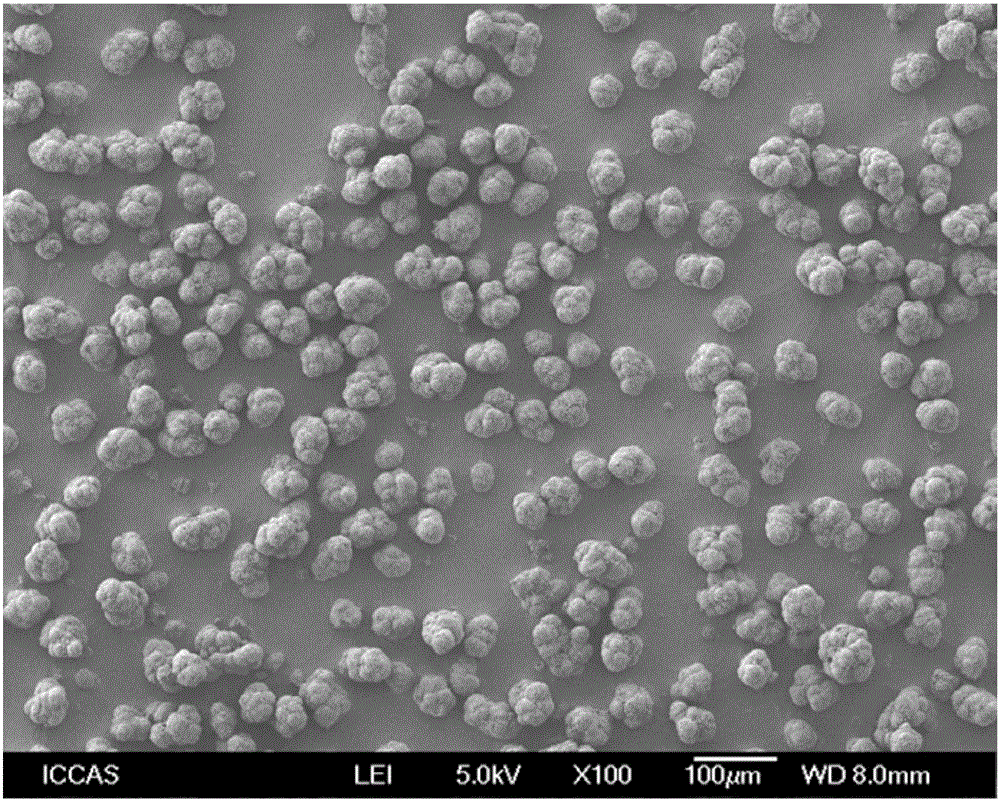

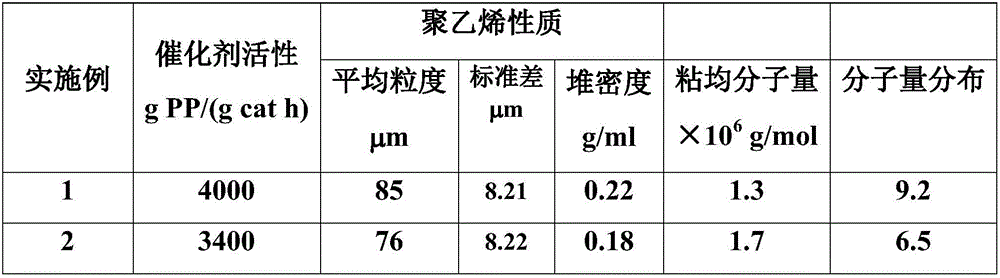

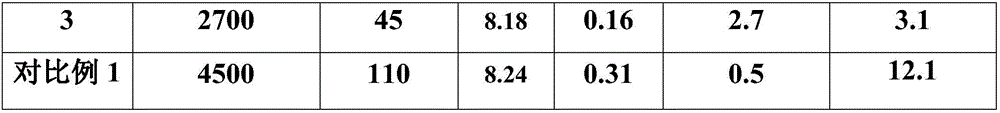

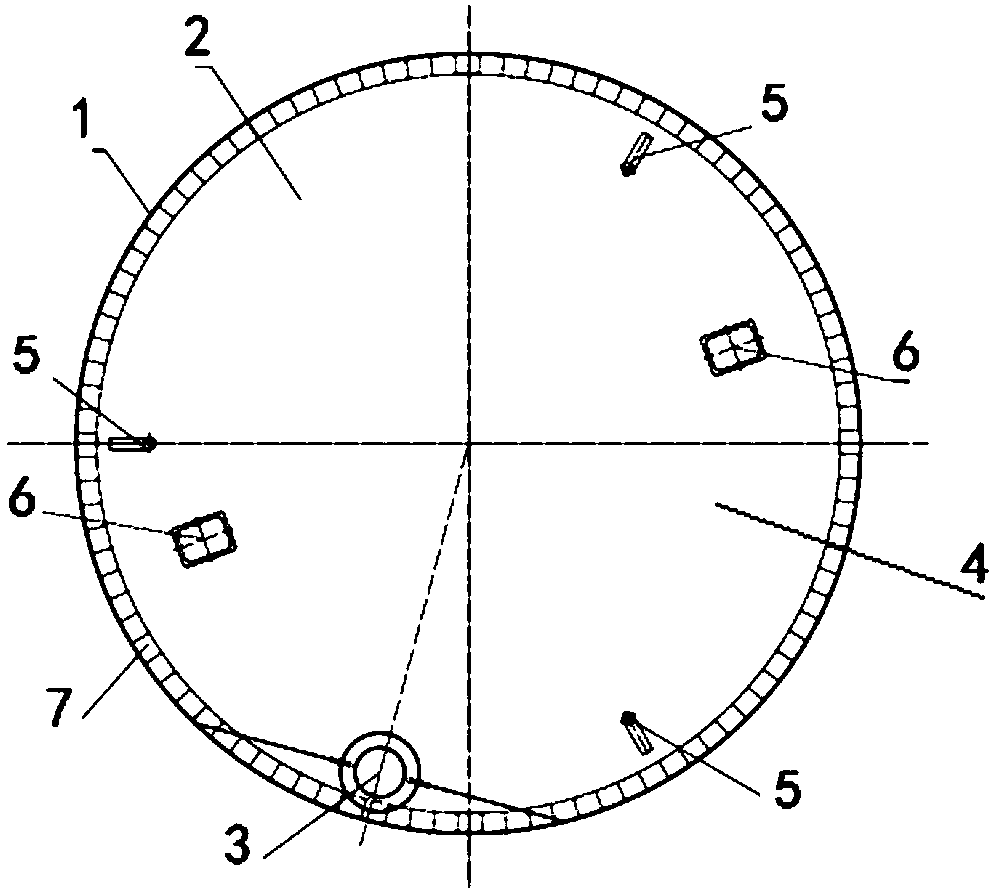

Ultrahigh molecular weight superfine polyethylene powder and preparation method thereof

The invention relates to ultrahigh molecular weight superfine polyethylene powder and a preparation method thereof. Polyethylene is greater than 1*106 in viscosity average molecular weight (Mv), and the polyethylene powder is spherical or sphere-like granules, having an average particle size of 10-100 Mum, a standard deviation of 2-15 Mum and a bulk density of 0.1-0.3 g / mL. The preparation method has simple steps, is easy to control and high in repeatability, and is suitable for industrialization. The powder of the invention has both ultrahigh molecular weight and superfine particle size range, is suitable particularly for processing and application, and is easy to graft-modify, and the applicable range of the ultrahigh molecular weight polyethylene materials is greatly widened.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Sandwich-structure fiber glass reinforced plastic inner floating plate for oil storage tank and manufacturing method of sandwich-structure fiber glass reinforced plastic inner floating plate

PendingCN108584182AEasy to operateImprove construction safetySynthetic resin layered productsLarge containersUltimate tensile strengthChemical corrosion

The invention discloses a sandwich-structure fiber glass reinforced plastic inner floating plate for an oil storage tank and a manufacturing method of the sandwich-structure fiber glass reinforced plastic inner floating plate. The sandwich-structure fiber glass reinforced plastic inner floating plate comprises a sandwich-structure fiber glass reinforced plastic inner floating plate body. The sandwich-structure fiber glass reinforced plastic inner floating plate body comprises a floating plate and sealing devices surrounding the inner wall of the oil storage tank, and the sealing devices are installed between the floating plate and the inner wall of the oil storage tank. Each sealing device comprises a two-layer stainless steel part and Teflon sealing adhesive tape which are stacked together, wherein the Teflon sealing adhesive tape is tightly attached to the inner wall of the oil storage tank, one end of the two-layer stainless steel part and one end of the Teflon sealing adhesive tapeare downward, and the other end of the two-layer stainless steel part and the other end of the Teflon sealing adhesive tape are connected with an edge baffle through a stainless steel bolt with a stainless steel pressing part. The edge portion of the floating plate is connected with the corresponding sealing devices through the edge baffle surrounding the floating plate. The sandwich-structure fiber glass reinforced plastic inner floating plate for the oil storage tank is simple and unified in structure, low in weight, high in strength and rigidity, low in heat conductivity and good in chemical corrosion resistance, and has broad market prospects.

Owner:广州市双时复合材料有限公司

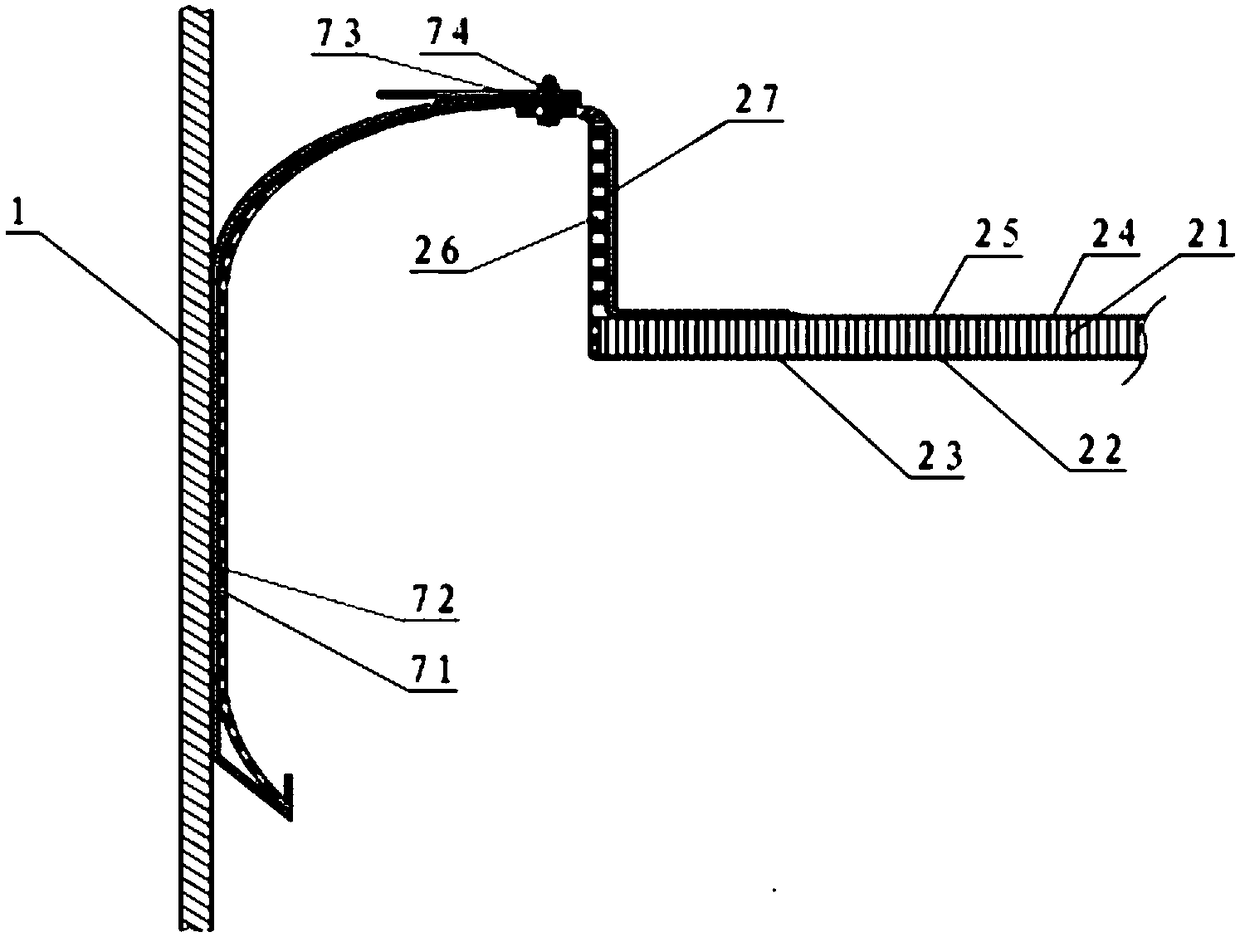

Low-surface-energy polyurethane photocureable coating and preparation method thereof

ActiveCN104804496AImprove water resistanceGood acid and alkali resistanceCoatingsUltravioletEnergy conservation

The invention belongs to the technical field of polyurethane coatings and discloses a low-surface-energy polyurethane photocureable coating and a preparation method thereof. The coating comprises the following components in parts by weight: 100 parts of a low-surface-energy polyurethane prepolymer, 0.01-50 parts of an active diluent, 0.5-10 parts of a photoinitiator and 0.5-10 parts of an assistant. A fluorinated acrylate modified polyurethane polymer is synthesized with a chemical method, and high-fluorine-content polyurethane with relatively uniform phase distribution is obtained, unlikely to be separated, unlikely to be separated out and crystallize and made into the photocureable coating. The coating has the characteristics of a fluorinated compound and polyurethane, has excellent performances such as water resistance, oil resistance, acid and base resistance, chemical corrosion resistance and the like as well as good adhesion, can be quickly cured through ultraviolet irradiation and is improved in cohesion. With the adoption of ultraviolet curing, the preparation method has the characteristics of low energy consumption, environmental protection, energy conservation and high efficiency.

Owner:国科广化(南雄)新材料研究院有限公司 +1

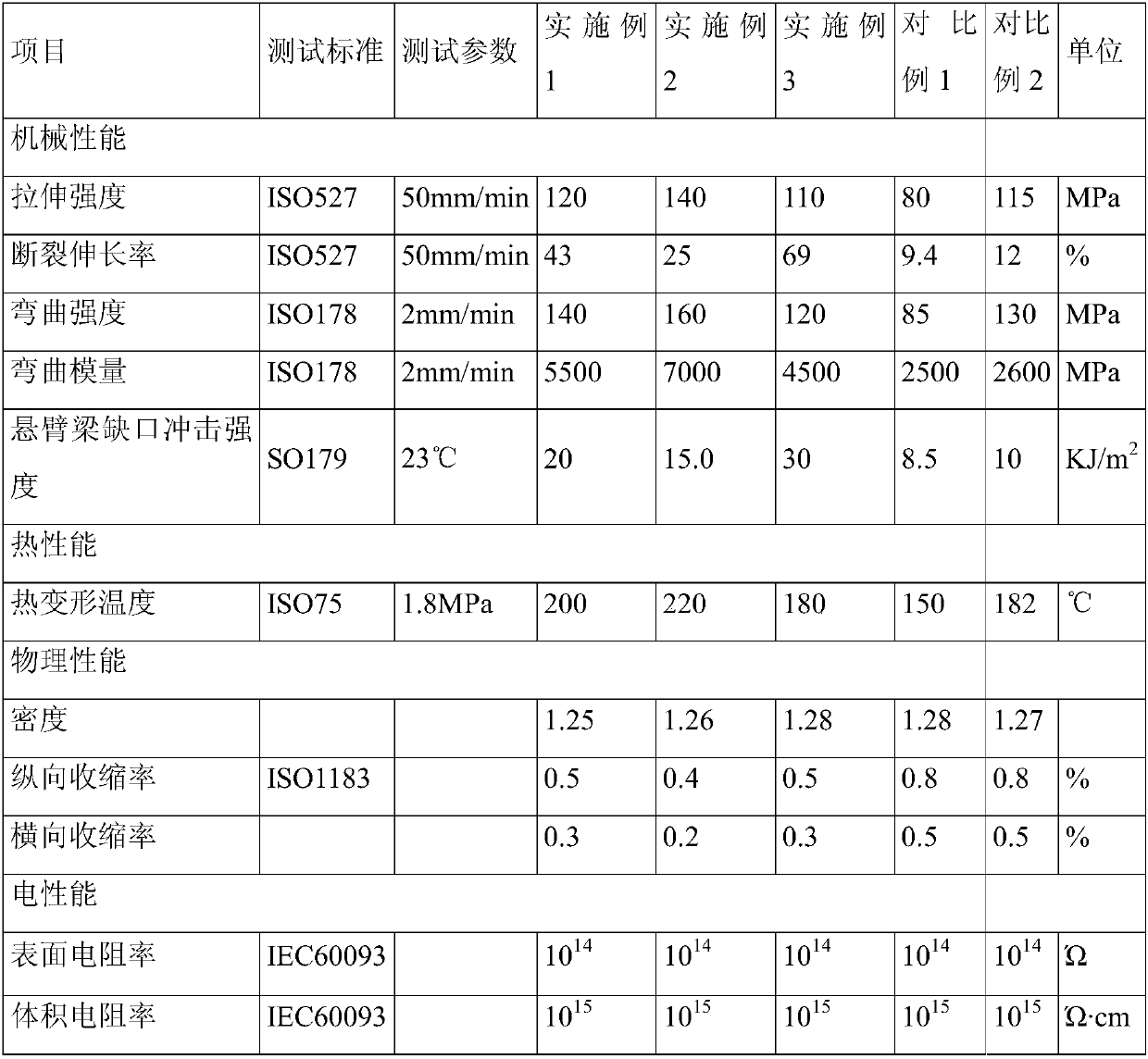

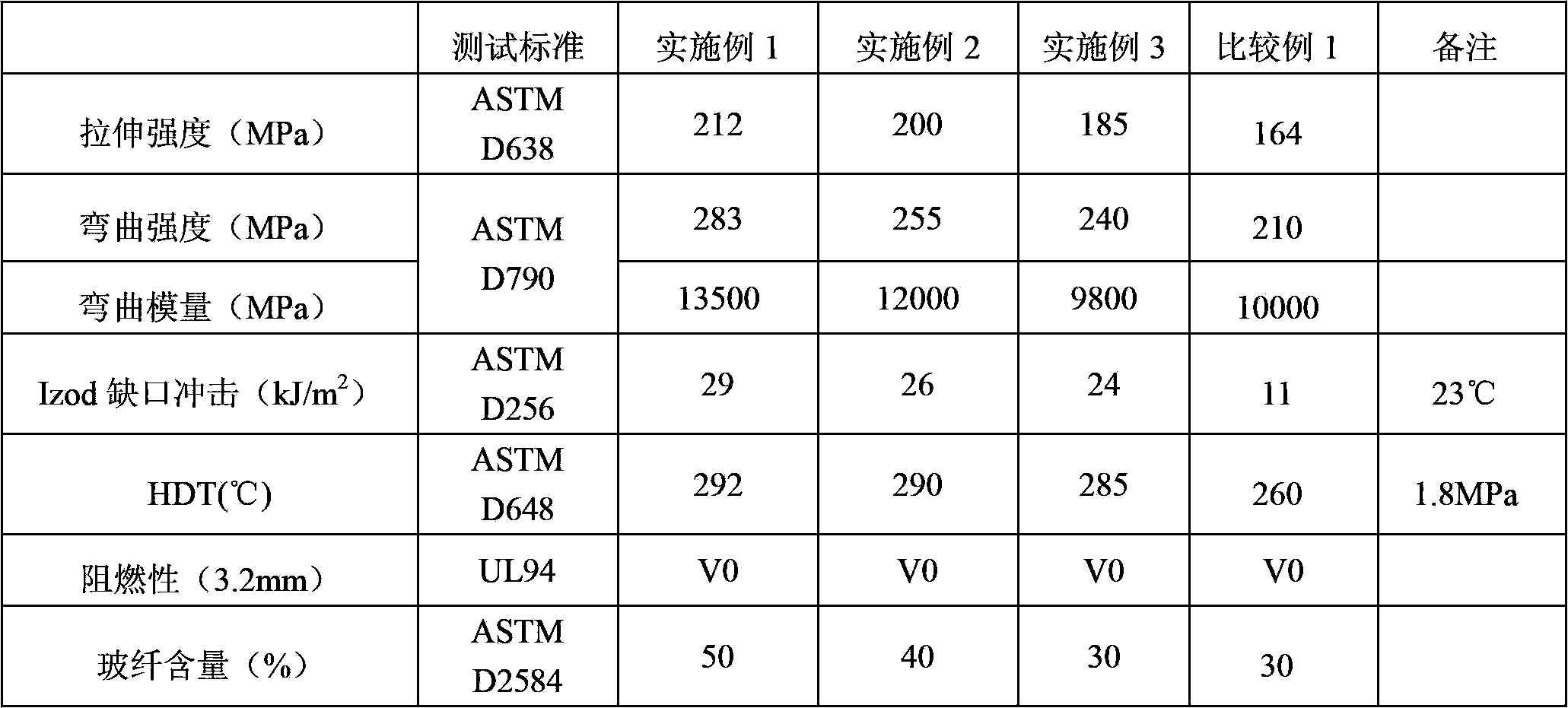

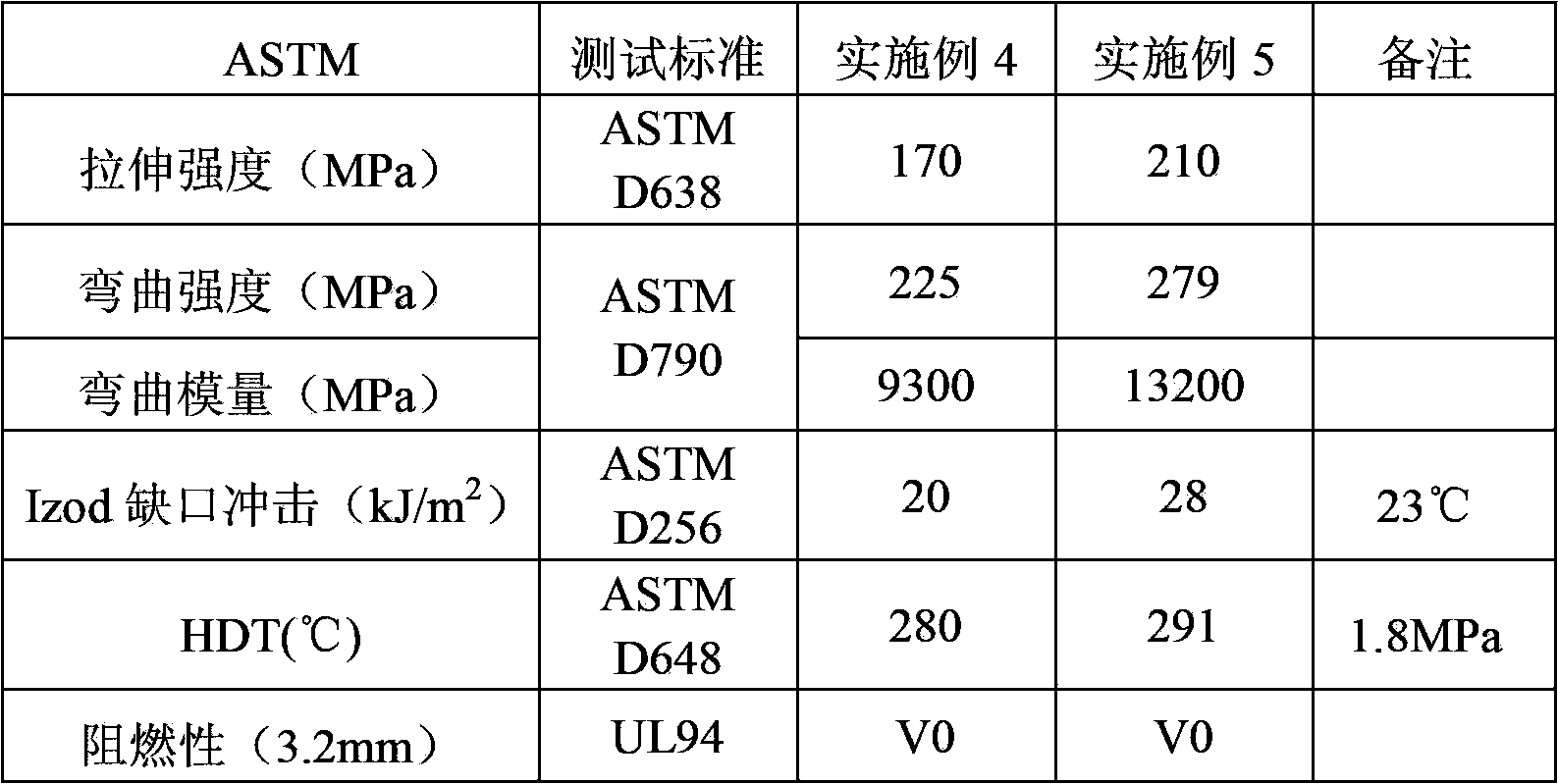

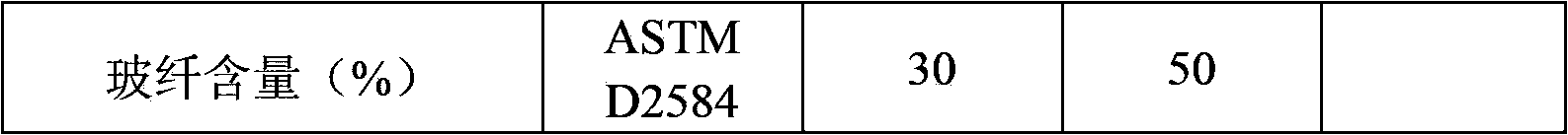

Environment-friendly polycarbonate/polyester composite material and preparation method and application thereof

ActiveCN109777065AImprove notched impact strengthImprove interface compatibilityGlass fiberAging resistance

The invention provides an environment-friendly polycarbonate / polyester composite material and a preparation method and application thereof. The environment-friendly polycarbonate / polyester composite material is prepared from the following components in parts by weight: 30-80 parts of polyester, 20-60 parts of polycarbonate, 5-30 parts of glass fibers, 1-5 parts of an ester exchange inhibitor, 1-5parts of a flexibilizer, 0.5-10 parts of a compatilizer, 1-20 parts of a flame retardant, 0.1-1 part of an antioxidant, 0.1-1 part of an anti-UL agent, 0.1-1 part of a lubricating agent and 0.1-0.5 part of a coupling agent. The environment-friendly polycarbonate / polyester composite material provided by the invention has excellent mechanical properties, flame retardance and ageing resistance, the preparation method of the environment-friendly polycarbonate / polyester composite material is simple in process, and the production cost of the environment-friendly polycarbonate / polyester composite material is lowered.

Owner:定州旭邦新材料科技有限公司

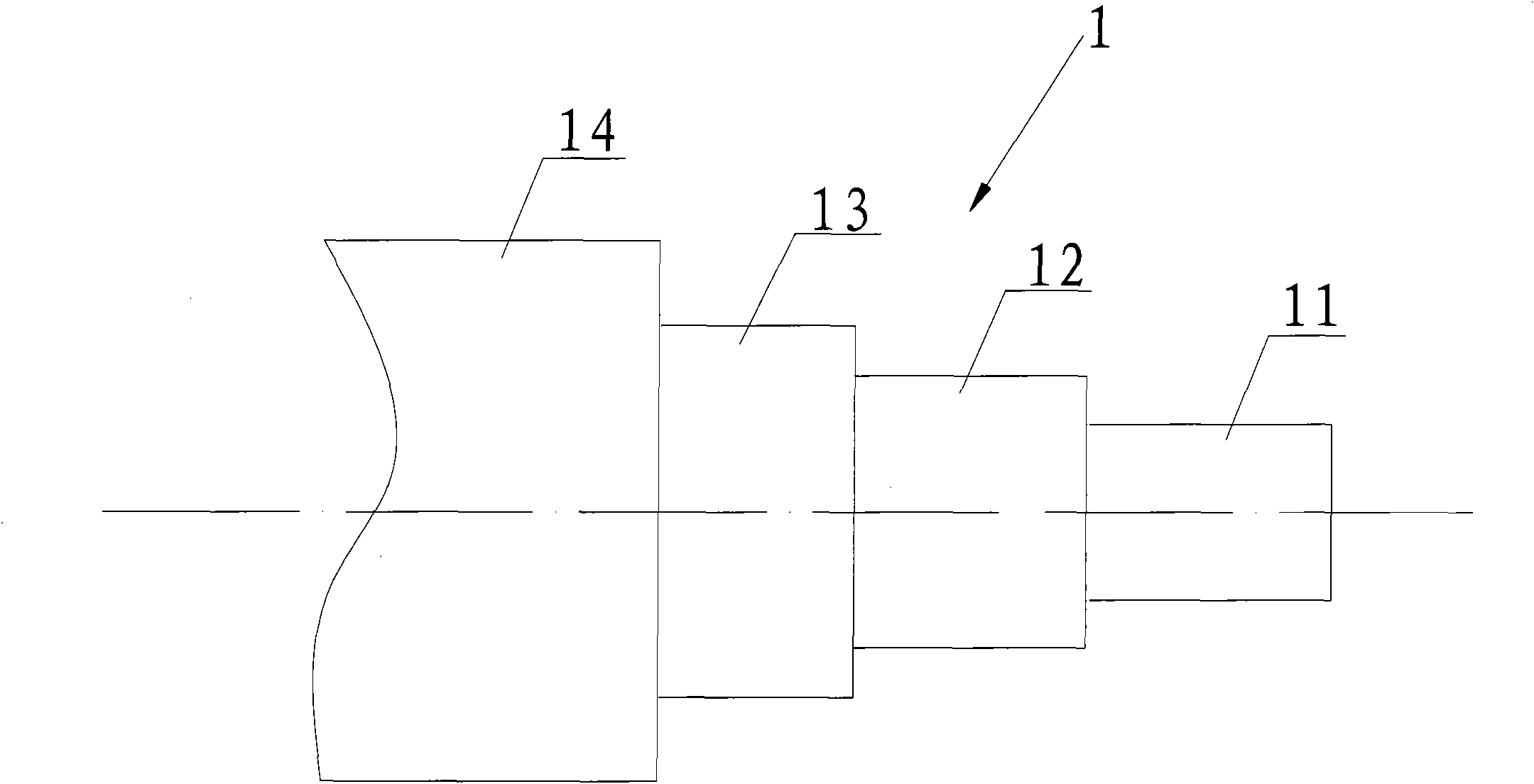

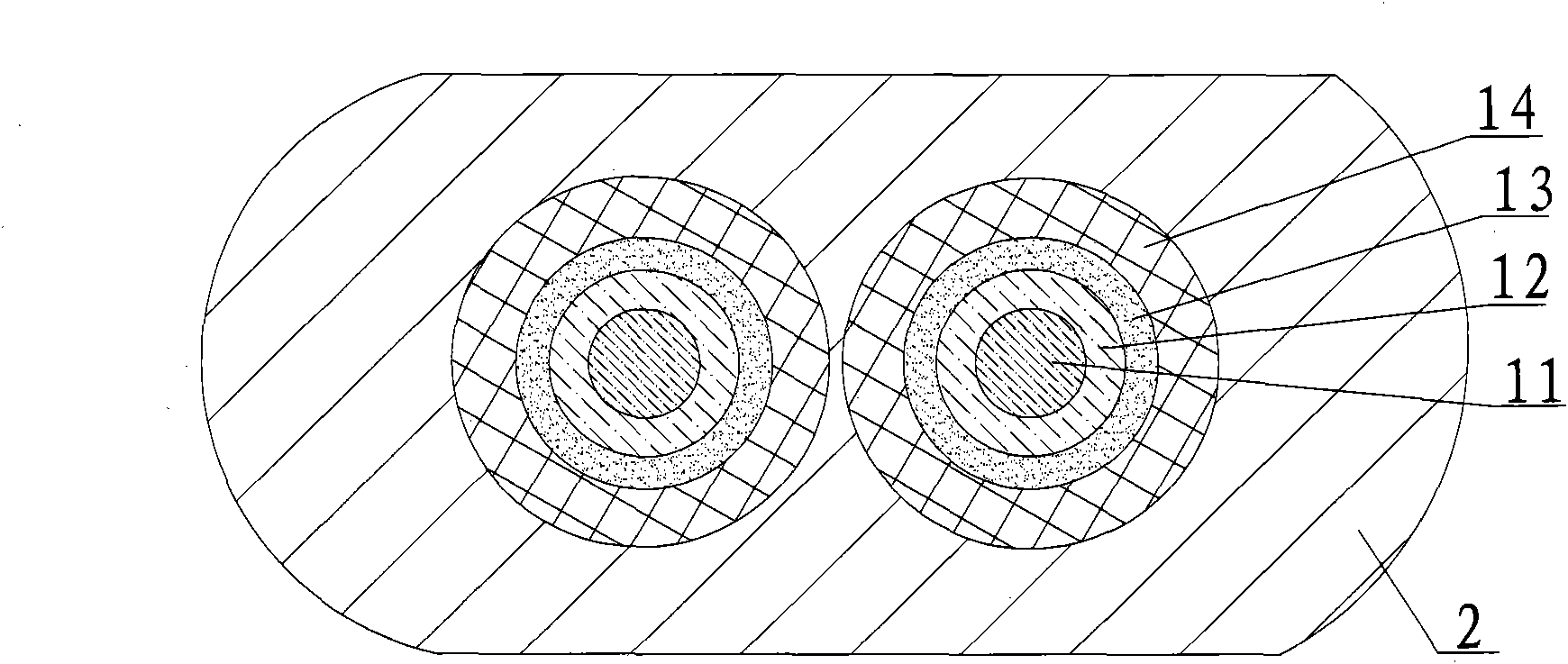

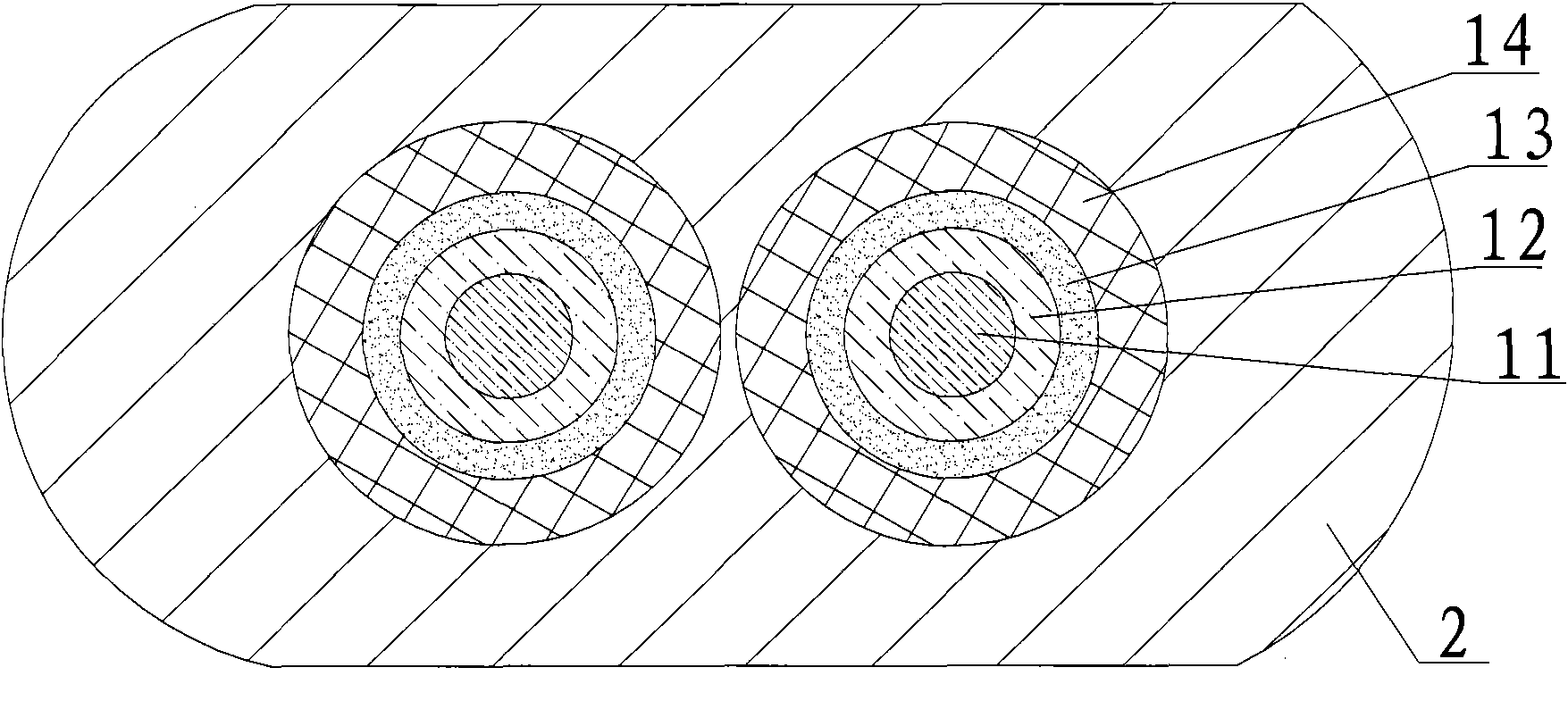

Tightly packaged fiber, and dual-core indoor cable and processing method thereof

InactiveCN101957484AStrong chemical resistanceStrong creep resistanceFibre mechanical structuresDistribution frameFiber

The invention relates to a tightly packaged fiber, and a dual-core cable using the tightly packaged fiber and a processing method thereof. The tightly packaged fiber consists of a single-mode or multi-mode fiber core, a cladding layer clad on the circumference of the fiber core, a primary coating layer coated on the circumference of the cladding layer and a secondary coated layer tightly sleeved on the circumference of the primary coating layer, wherein the secondary coated layer is a polyvinyl fluoride protection layer. By taking polyvinyl fluoride which has relatively high chemical corrosion resistance, creep resistance and compressive strength and relatively wide bearable temperature range as the secondary coated layer of the tightly packaged fiber, the tightly packaged fiber can have enough mechanical and environmental protection capability and can be independently used. The dual-core cable using the tightly packaged fiber, which is processed by the method has the advantages of small volume, light weight, stable performance and low cost, is suitable for indoor comprehensive wiring and can be used as internal connection wires of various optical devices, optical modules and optical distribution frames.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

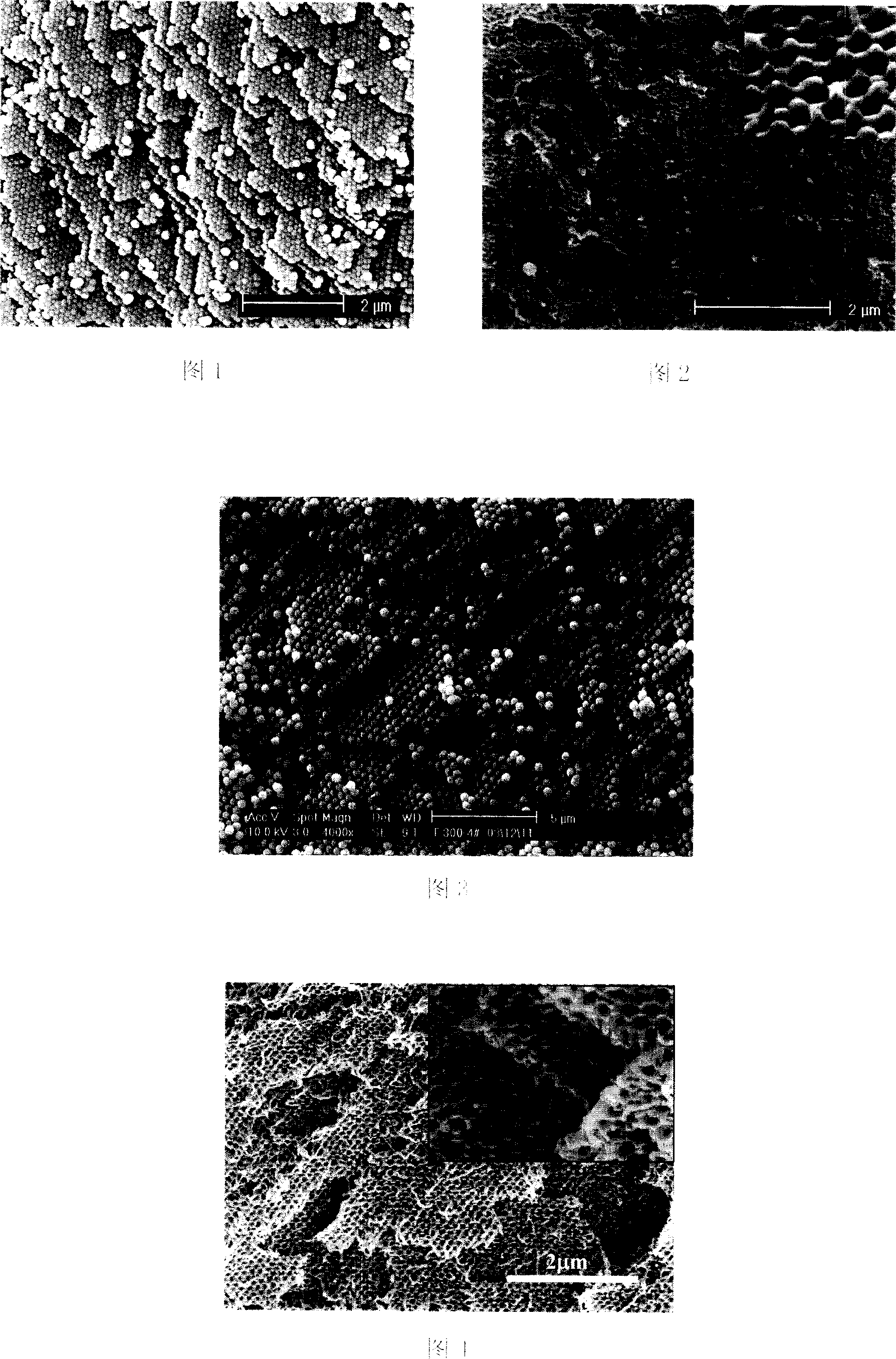

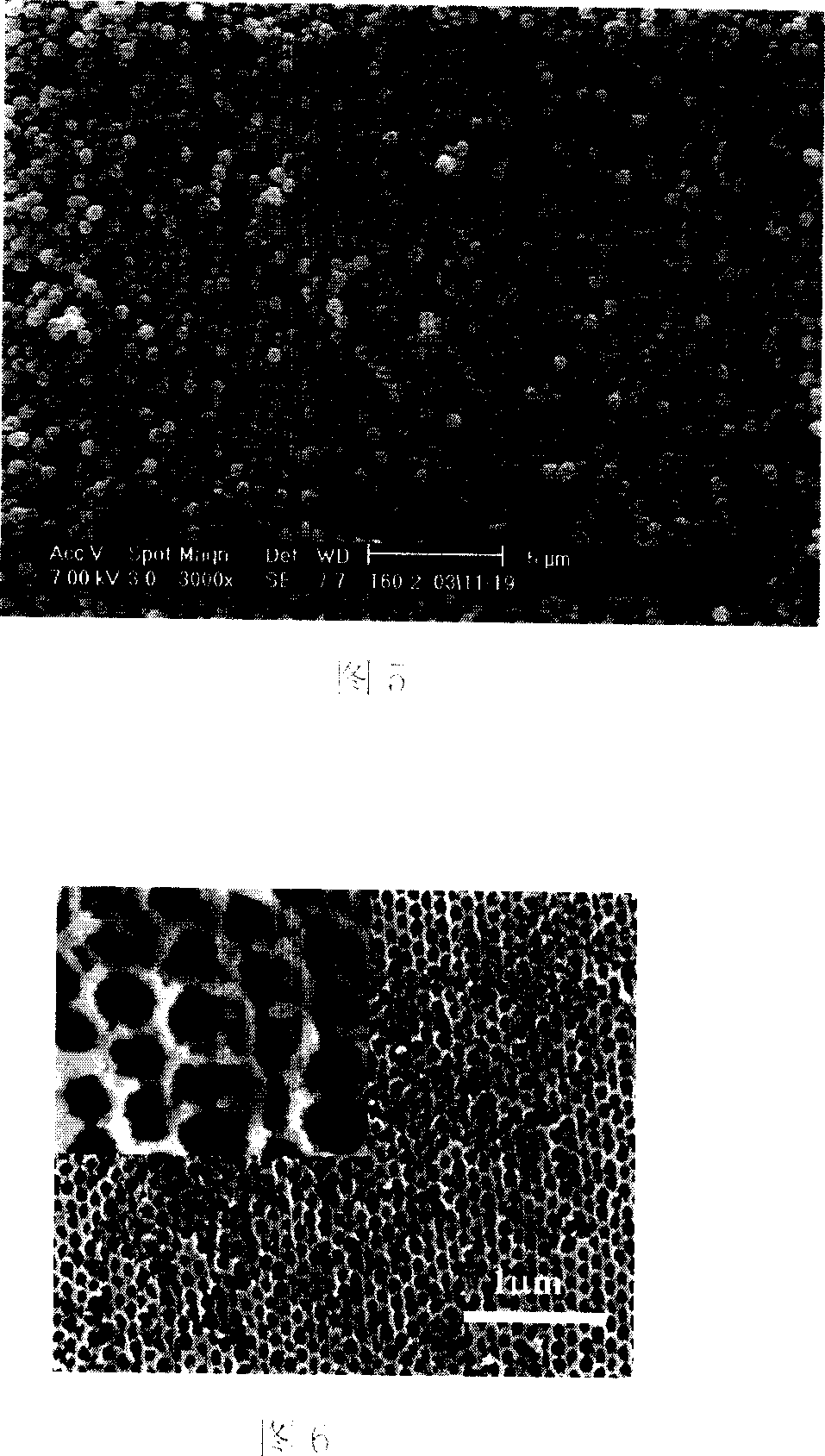

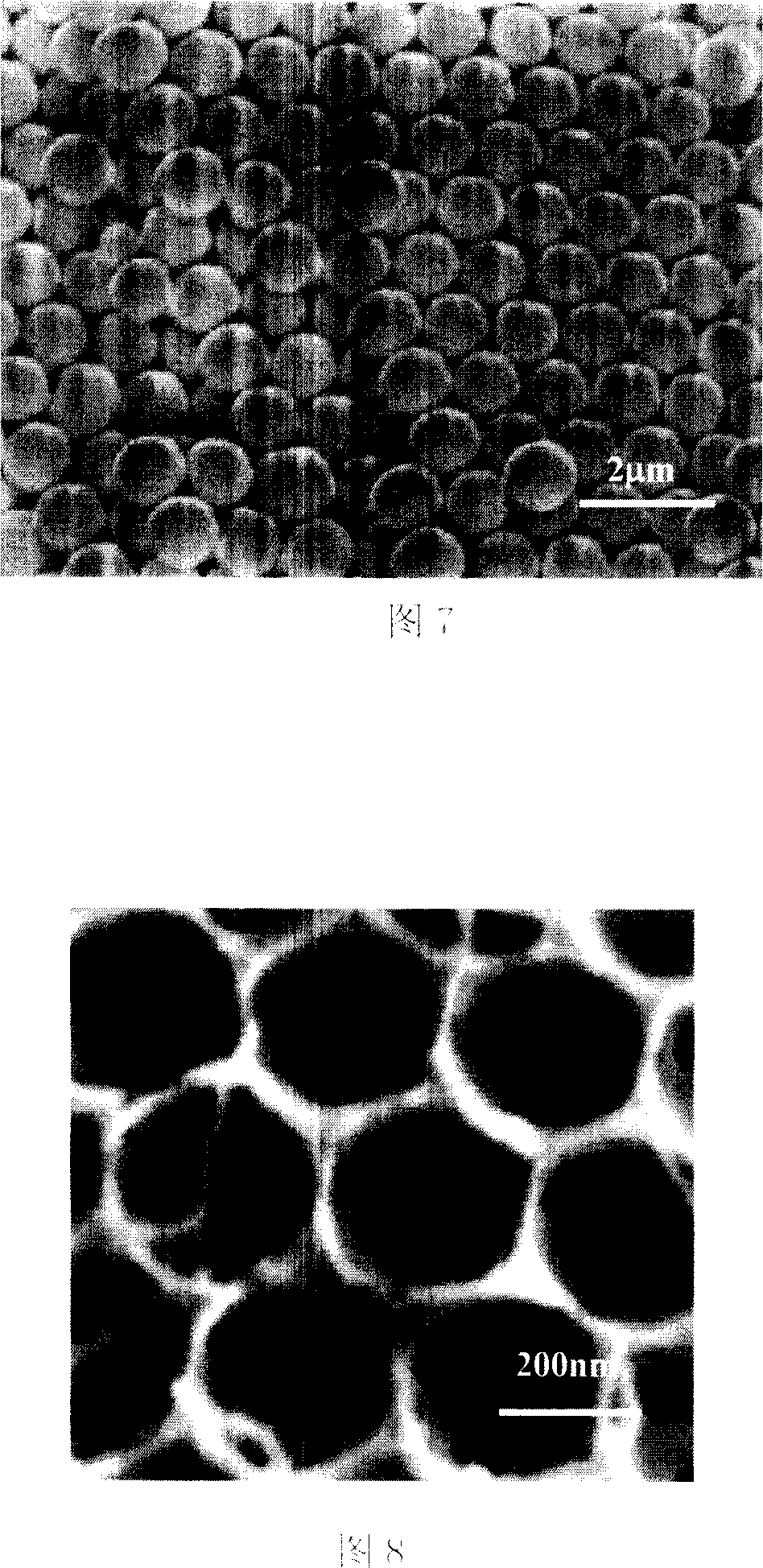

Three-dimensional ordered monodisperse macroporous material, and its preparing method and functionizing method

InactiveCN1935857AHigh melting pointFast crystallization ratePolyvinyl alcoholCoordination polymerization

The invention relates to three-dimensional order mono-disperse macropore material and its preparation method and functionalizing method. The three-dimensional order mono-disperse macropore material has 91%-98% syndiotactic polyvinyl alcohol arene, 80 nm-1000 nm average aperture. Its preparation method includes the following steps: using colloid crystal mold board method to make three-dimensional order mono-disperse macropore polyvinyl alcohol without water and oxygen by coordination polymerization; using copolymerization or chloromethylation to functionalize. It has the advantages of high melting point, quick crystallization rate, strong chemical resistance, good size stability, processing surface chemical modification, and wide application prospect in sensor, photon chip, photon band gap material preparation etc.

Owner:HEBEI UNIV OF TECH

Continuous long fiber reinforced PPS composite material and preparation method thereof

The invention relates to the field of polymer materials, and relates to a continuous long fiber reinforced PPS composite material and a preparation method thereof. The composite material comprises the following components by weight: 450-650 parts of polyphenylene sulfide, 300-500 parts of a continuous fiber reinforced agent, 5-10 parts of a coupling agent, 10-30 parts of an antioxidant and 10-20 parts of a lubricant. Compared with the prior art, an engine cooling water pump impeller made from the material through injection moulding has characteristics of light weight, good dimensional stability, stable working dynamic balancing performance, strong resistance to chemical corrosion and high strength; an automobile water pump using the continuous long fiber reinforce PPS impeller has smooth working performance, high efficiency and long service life, and can work normally at the temperature of -40 DEG C to -140 DEG C.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com