High-heat-conductive boron nitride insulation material and preparation method thereof

An insulating material, boron nitride technology, applied in the field of boron nitride high thermal conductivity insulating material and its preparation, can solve the problems of distribution and arrangement that cannot be achieved by the production process, and achieve high strength, high thermal conductivity, and high insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

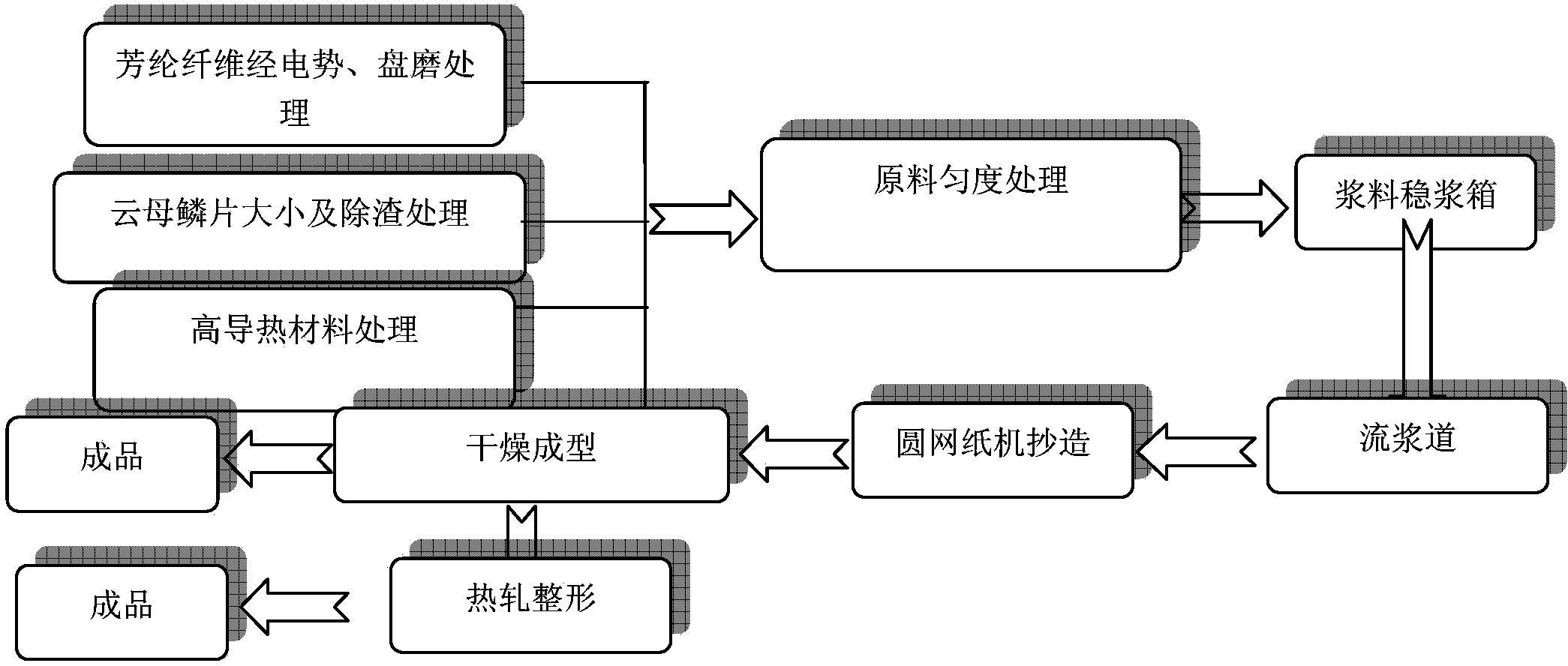

Method used

Image

Examples

Embodiment 1

[0041] 1) Pretreatment of boron nitride:

[0042] Make 25 parts by weight of pure boron nitride into a whisker shape with a large specific surface area, and then blend boron nitride with a biphenyl solution of 2% PPS at a mass ratio of 1:1 for 5 minutes , filtered, and dried at a high temperature to obtain granular boron nitride with a thermal conductivity of 10W / m·K and a particle size of 5-80 μm;

[0043] 2) After beating 5 parts by weight of aramid fiber 1313 in a water crushing equipment, and then performing a broom treatment with a metal disc mill, to obtain aramid fiber with a beating degree of 50oSR;

[0044] 3) 10 parts by weight of 1313 fibrids are subjected to beating treatment in water crushing equipment, and then broomized with a high-speed rotating metal disc mill for 5 minutes to obtain fibrous fibrids that are divided into brooms, and the degree of beating is 60oSR;

[0045] Table 1. Zeta potential comparison table after aramid fiber treatment

[0046]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com