Three-dimensional ordered monodisperse macroporous material, and its preparing method and functionizing method

A three-dimensional ordered, macroporous material technology, applied in the field of polymer materials, can solve the problems of non-uniform pore size, non-uniform pore size of porous materials, and inability to precisely control the pore size, achieving fast crystallization rate, easy functionalization, and thermal dimensional stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

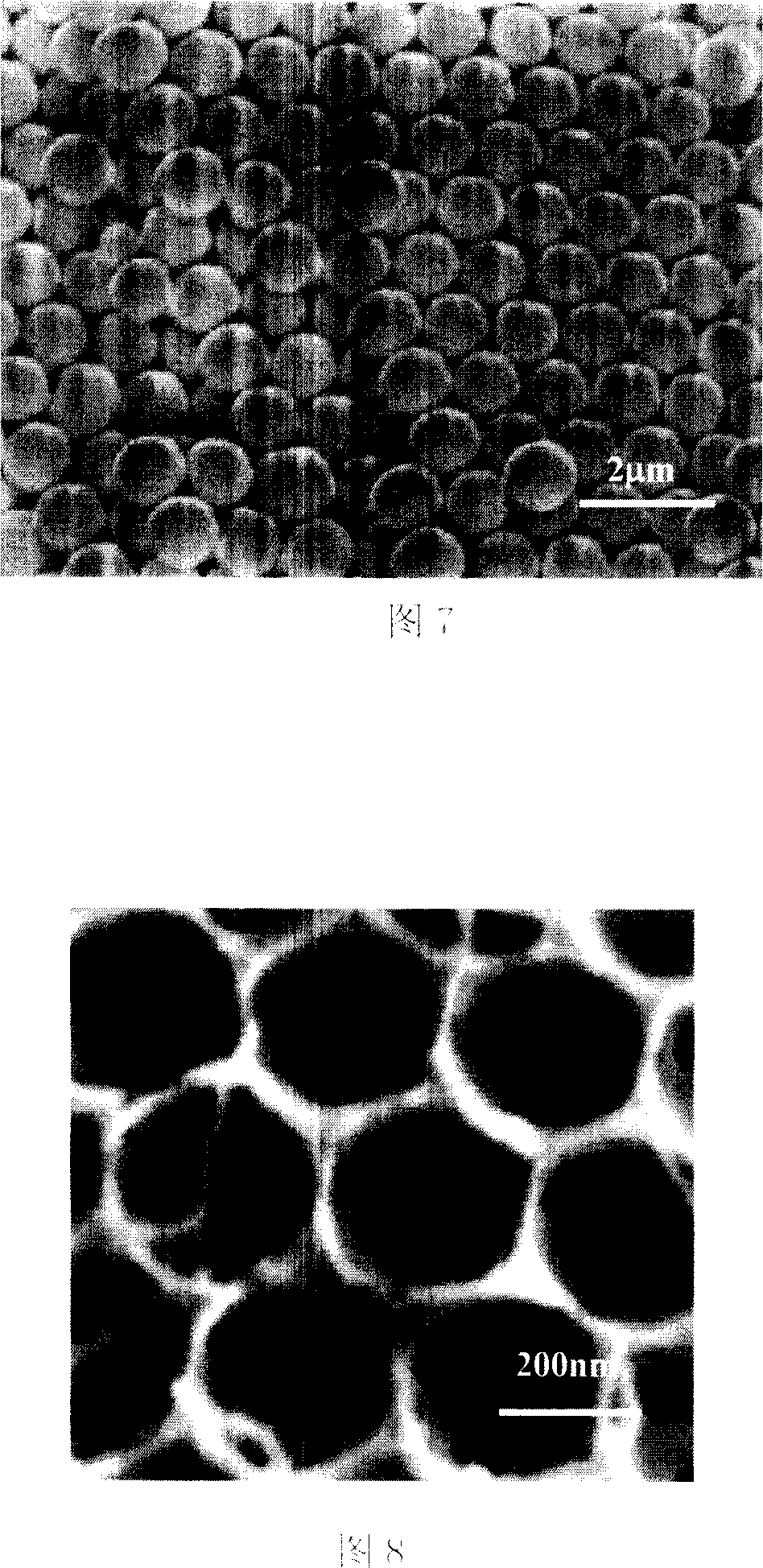

[0054] Preparation of 3DOM syndiotactic polystyrene (3DOM sPS) with an average pore diameter of 80 nm.

[0055] (1) Preparation of colloidal crystal template with an average particle size of 120nm

[0056] At room temperature, in a 500ml three-necked bottle equipped with an electric stirring device, add successively 10g, 72g, 6.5g, and 3.2g of ammonia water, absolute ethanol, distilled water, and ethyl orthosilicate at a percentage concentration of 25%. Stirring, the solution becomes turbid, indicating that the hydrolysis of ethyl orthosilicate produces silicon dioxide microspheres, until the solution becomes turbid and no longer changes, that is, the hydrolysis reaction is completed, then the resulting suspension is transferred to a 250ml beaker, and naturally Stand still until the solvent evaporates completely, and a three-dimensional ordered silica colloidal crystal template with an average particle size of 120nm is obtained. The prepared silica colloidal crystal template i...

Embodiment 2

[0060] Preparation of 3DOM Syndiotactic Poly-p-Methylstyrene (sPPMS) with Average Pore Size of 180nm

[0061] (1) Preparation of colloidal crystal template with an average particle size of 340nm

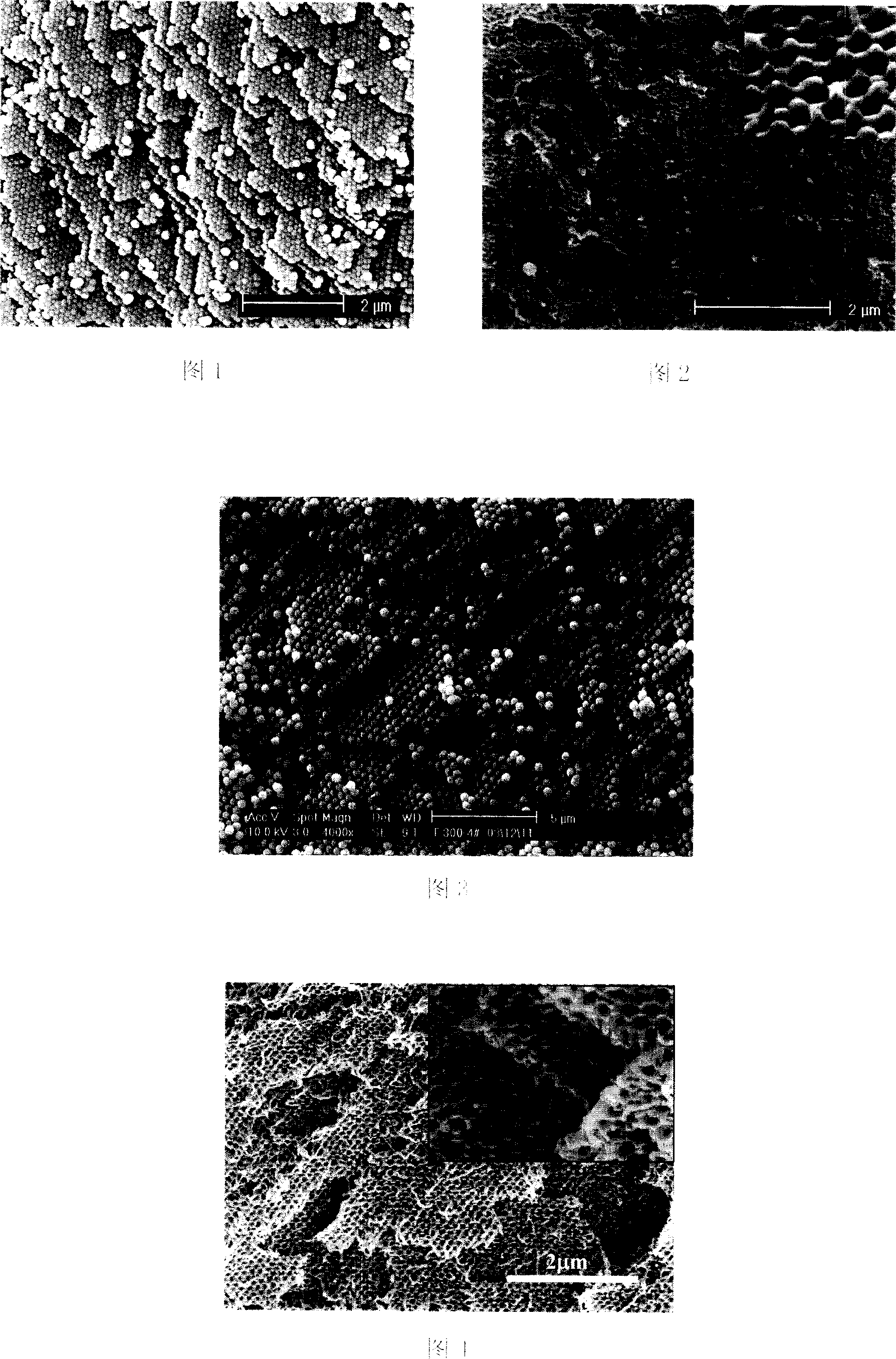

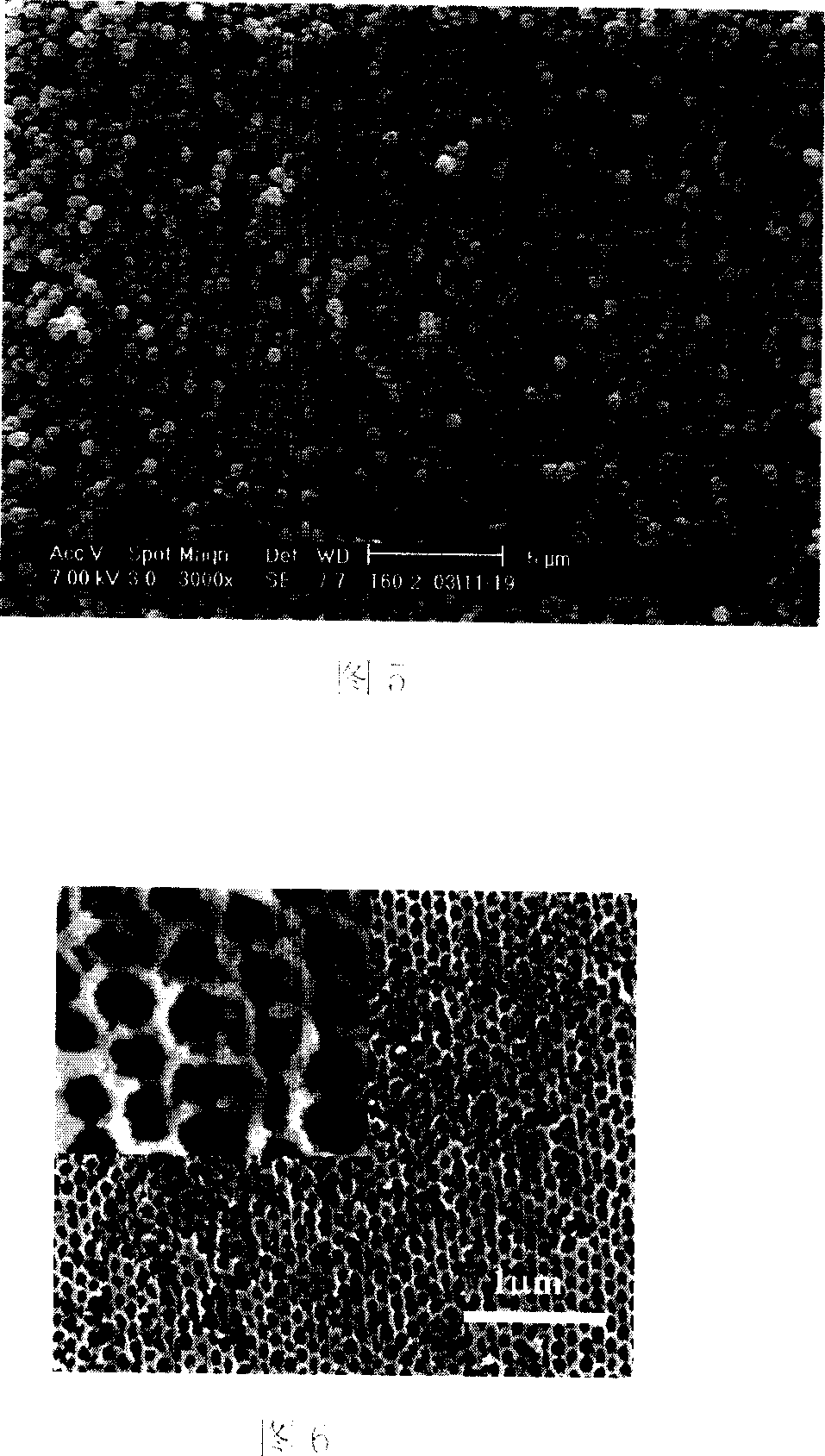

[0062] The other steps of the preparation method of silica colloidal template are the same as in Example 1 (1), except that the quality of ammoniacal liquor, dehydrated alcohol, distilled water, and tetraethyl orthosilicate that the percentage concentration is 25% is respectively 10g, 58g, 7.8g. , and 4.1g, to obtain the colloidal crystal template of 340nm by the average particle diameter, see accompanying drawing 3, as seen from Fig. 3, the average particle diameter is the cohesive and uniform ordered silica microspheres of the 340nm colloidal crystal template.

[0063] (2) Preparation of 3DOM syndiotactic poly-p-methylstyrene (sPPMS) with an average pore size of 180 nm

[0064] All operations are carried out under anhydrous and oxygen-free conditions. Add the silica colloidal cry...

Embodiment 3

[0066] Syndiotactic Copolymer of 3DOM Styrene and p-Methylstyrene (sPMS) with Average Pore Diameter of 460nm Prepared by Direct Functionalization

[0067] (1) Preparation of colloidal crystal template with an average particle size of 548nm

[0068] Other steps of the preparation method of silica colloidal crystal template are the same as embodiment 1 (1), and just adjustment percentage concentration is 25% ammoniacal liquor, dehydrated alcohol, distilled water and tetraethyl orthosilicate quality are respectively 10g, 46g, 6.2g, And 7.8g, promptly obtain the colloidal crystal template that the silica microspheres of 548nm are adhered to each other with an average particle diameter, see accompanying drawing 5, as seen from Fig. sequenced silica microspheres.

[0069] (2) Preparation of a syndiotactic copolymer (sPMS) of 3DOM styrene and p-methylstyrene with an average pore size of 460 nm

[0070] All operations are carried out under anhydrous and oxygen-free conditions. Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com