Patents

Literature

79results about How to "Strong creep resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

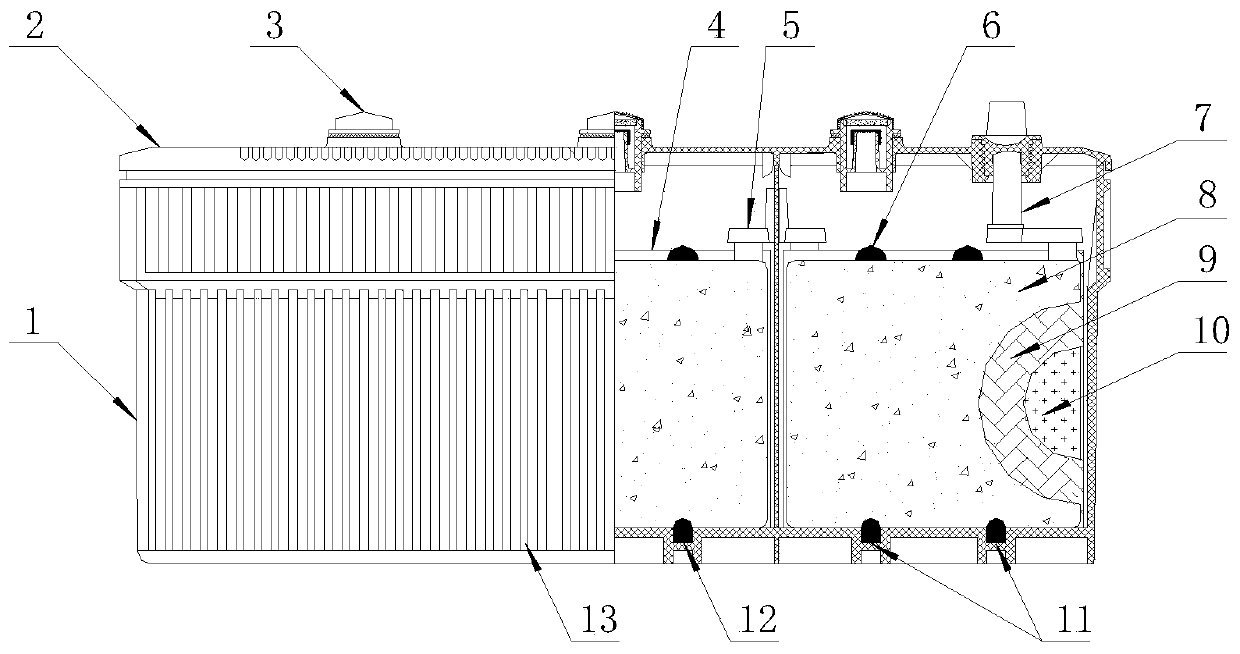

Cement-based grouting material and preparation method thereof

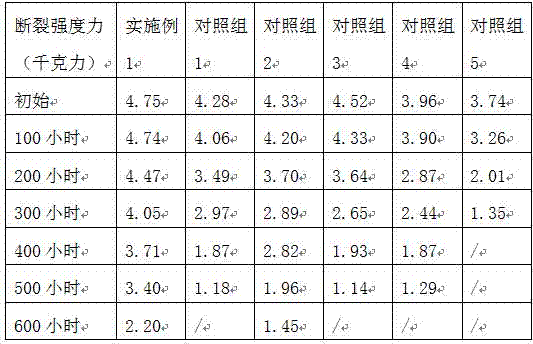

The invention relates to a cement-based grouting material and a preparation method thereof. The cement-based grouting material comprises a component A, a component B and a component C, wherein the component A comprises the following components by weight part: 80 to 90 parts of epoxy resin, 1 to 10 parts of diluents, 0 to 1 part of defoaming agent and 1 to 5 parts of coupling agent; the component B comprises a water-soluble amine curing agent with an emulsification function; the component C comprises the following components by weight part: 30 to 50 parts of cement, 2 to 4 parts of ultrafine mineral powder, 0 to 1 part of silica micropowder, 2 to 4 parts of expanding agent, 0 to 1 part of water-reducing agent and 40 to 60 parts of river sand; and the weight ratio among the component A, the component B and the component C is (60 to 100) : (90 to 150) : (400 to 800). Mechanical indexes, such as compressive strength, breaking strength and the like, of the cement-based water-soluble epoxy resin grouting material are far more excellent than those of the common cement grouting material.

Owner:天津天盈新型建材有限公司

Negative electrode of lithium ion battery and preparation method thereof

InactiveCN103985841AImprove convenienceImprove adhesionCell electrodesSecondary cellsAdhesivePhysical chemistry

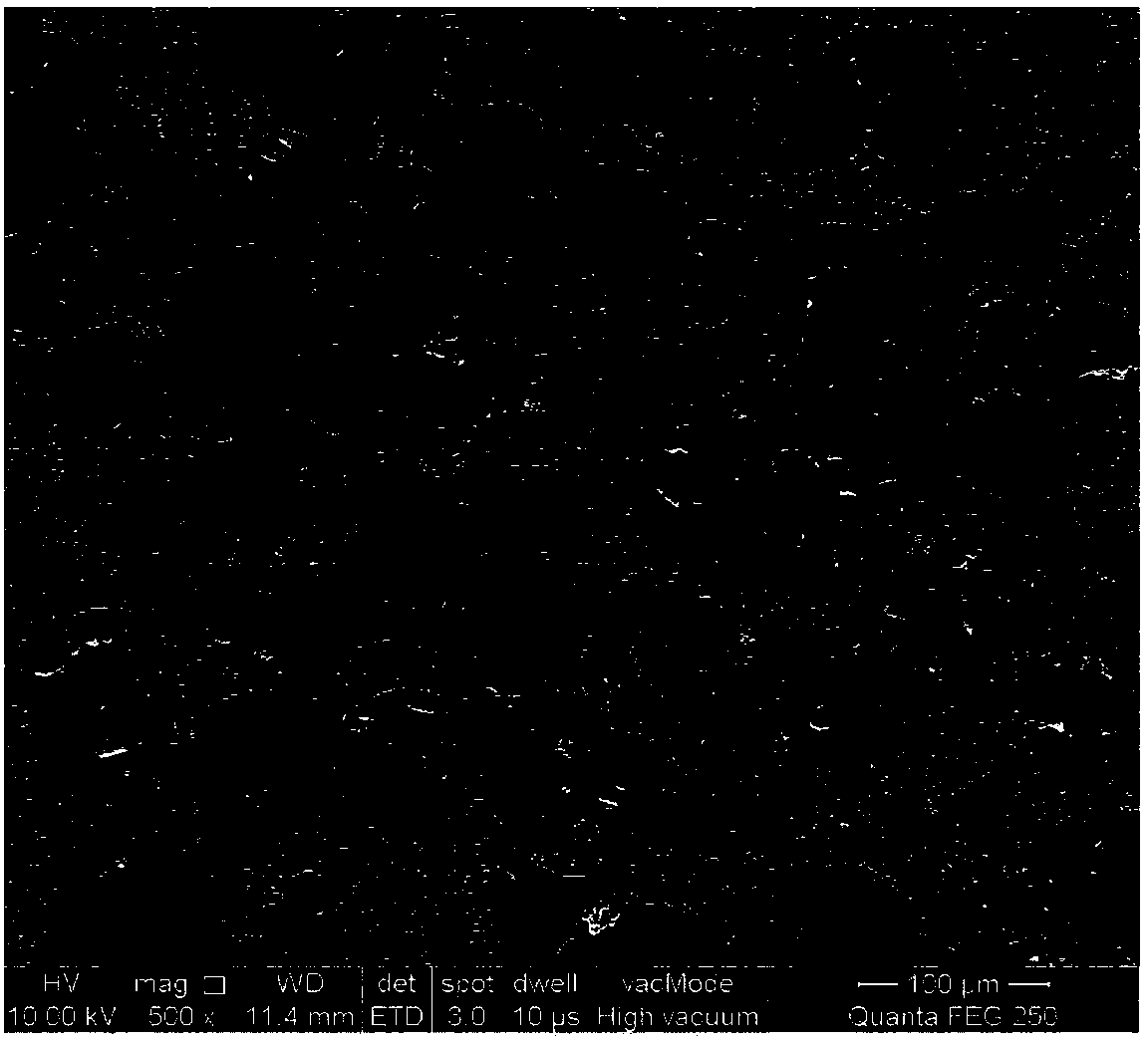

The invention belongs to the field of materials of lithium ion batteries, and particularly relates to a negative electrode of the lithium ion battery and a preparation method thereof. The negative electrode of the lithium ion battery comprises a current collector and negative electrode paste for coating the current collector, wherein the negative electrode paste comprises the following dry ingredients by weight percent: 92-99% of active material and 1-8% of an adhesive; the active material is graphite or graphite alloy; the adhesive is waterborne multi-component copolymerization emulsion. The waterborne multi-component copolymerization emulsion is used for replacing conventional butadiene styrene rubber and serves as the adhesive for the lithium ion battery, so that the more excellent adhesive performance is realized in comparison with the adhesive performance of a conventional adhesive, and meanwhile, the prepared battery has prominently excellent performances such as good low temperature characteristics, low circulation expansion rate, good long cycling performance and relatively excellent processing characteristics; the negative electrode prepared by using the method has relatively small impedance and relatively good dynamic performance and is capable of effectively solving the problem of risk of separation of lithium in the lithium ion battery at low temperature; the prepared battery has the characteristics of safety, reliability and long cycle life.

Owner:MCNAIR TECH +1

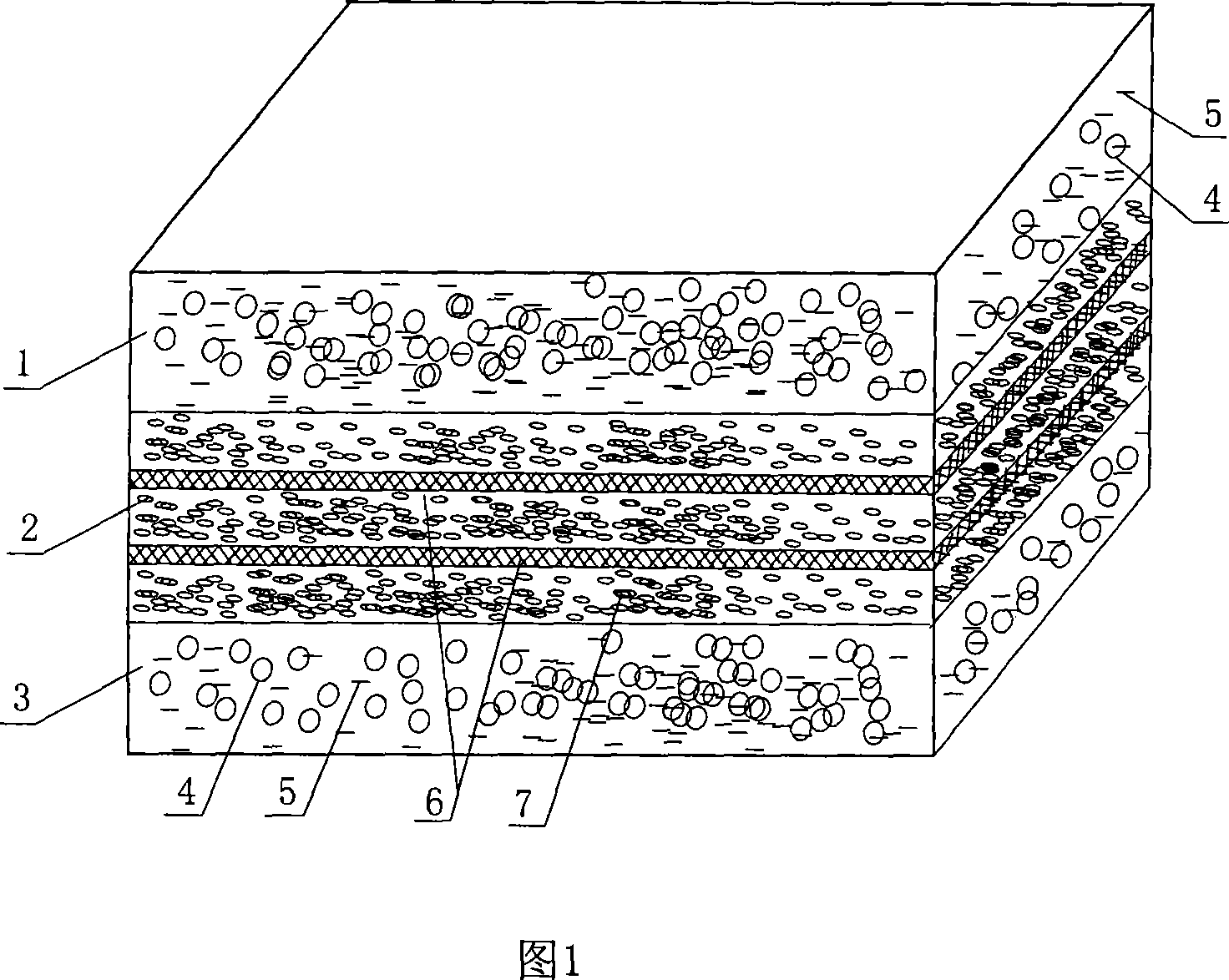

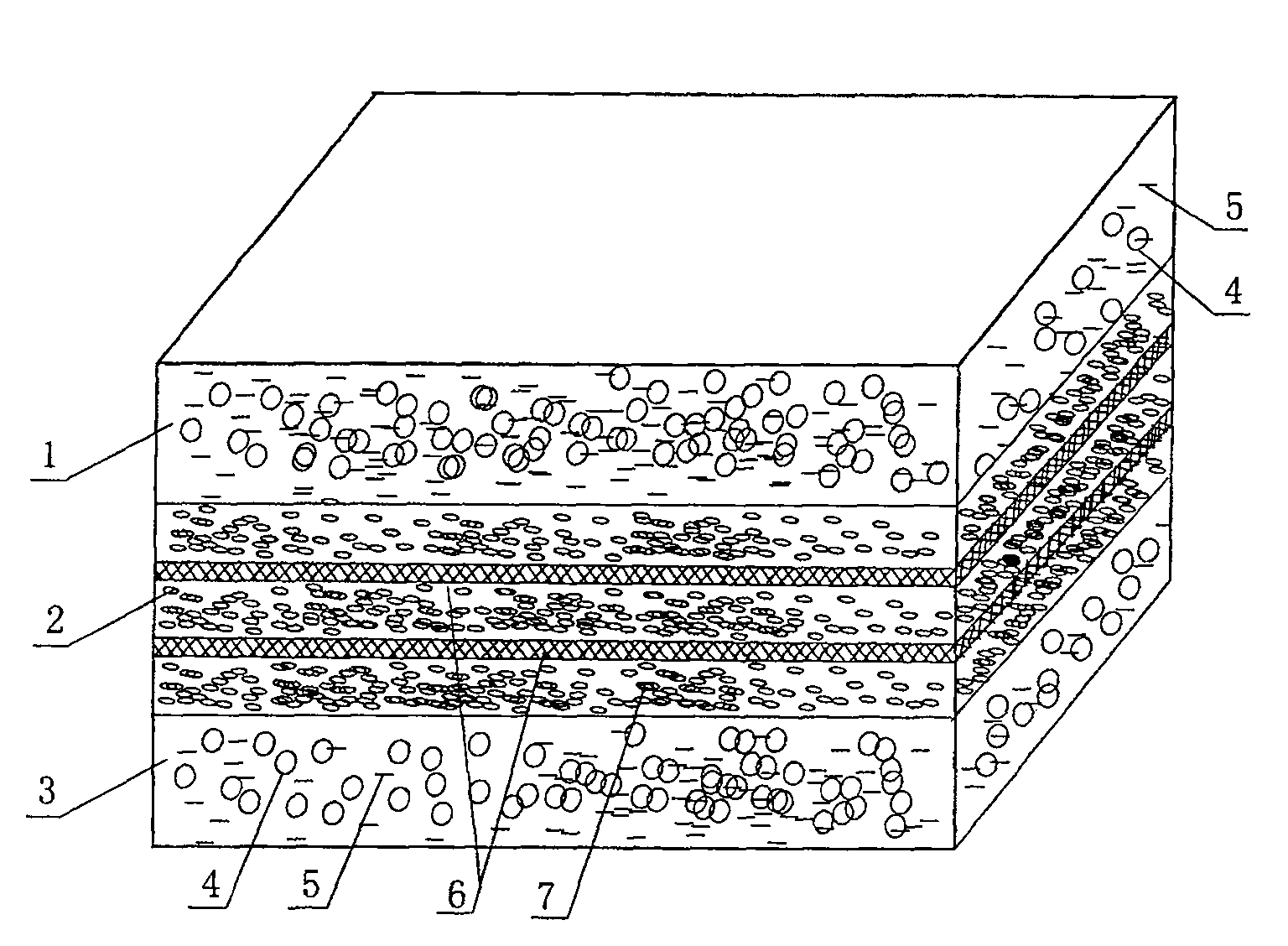

Jute and plastic compound material plank stuff and manufacturing method thereof

InactiveCN101229700AReasonable designSimple structureSynthetic resin layered productsCellulosic plastic layered productsFiberEngineering

The invention relates to a linen-plastic compound material plate and a preparation method thereof, in particular to a compound material and an environment-friendly material and a preparation method thereof. The material is preferably used for manufacturing goods shelf plates, door panels, etc. of vehicles such as cars, planes, etc. in traffic field, manufacturing decorative boards, palisades, rails, etc. in architecture field as well as manufacturing trays, goods shelves, etc. in packaging field. The linen-plastic compound material plates consist of two layers of linen fiber modification plastic layers and a linen fiber cloth enhancement plastic layer; the linen fiber cloth enhancement plastic layer is molded and pressed between the two layers of linen fiber modification plastic layers; modification plastic particles, linen fiber and interface compatilizer are mixed and calendered to form the linen fiber modification plastic layers; the plastic particle and a plurality of layers of fiber linen cloth processed by silane coupling agent are molded and pressed to form the linen fiber cloth enhancement plastic layer.

Owner:NANJING FORESTRY UNIV

Dispersion strengthening platinum/rhodium30-platinum/rhodium6 thermocouple wires and production method thereof

ActiveCN101561323AAchieve tissue fibrosisStrong creep resistanceThermometers using electric/magnetic elementsUsing electrical meansChemistryYttrium

The invention discloses dispersion strengthening platinum / rhodium30-platinum / rhodium6 thermocouple wires, comprising a cathode and an anode; the thermocouple wires are characterized in that the anode contains ingredients according to the following weight percentage: 30% of rhodium; the excess is platinum; the cathode contains ingredients according to the following weight percentage: 5.94-6% of rhodium; 0-0.5% of zirconium; 0-0.5% of yttrium; 0-0.5% of calcium; 0-0.5% of lanthanum; 0-0.5% of titanium; the excess is platinum. The production method of dispersion strengthening platinum / rhodium30-platinum / rhodium6 thermocouple wires comprise mixing ingredients, vacuum melting, placing and rolling, oxidizing, combined machining and drawing forming. The dispersion strengthening platinum / rhodium30-platinum / rhodium6 thermocouple wires of the invention enjoy long service life, high adaptive temperature, strong contamination resistance and low use cost.

Owner:英特派铂业股份有限公司

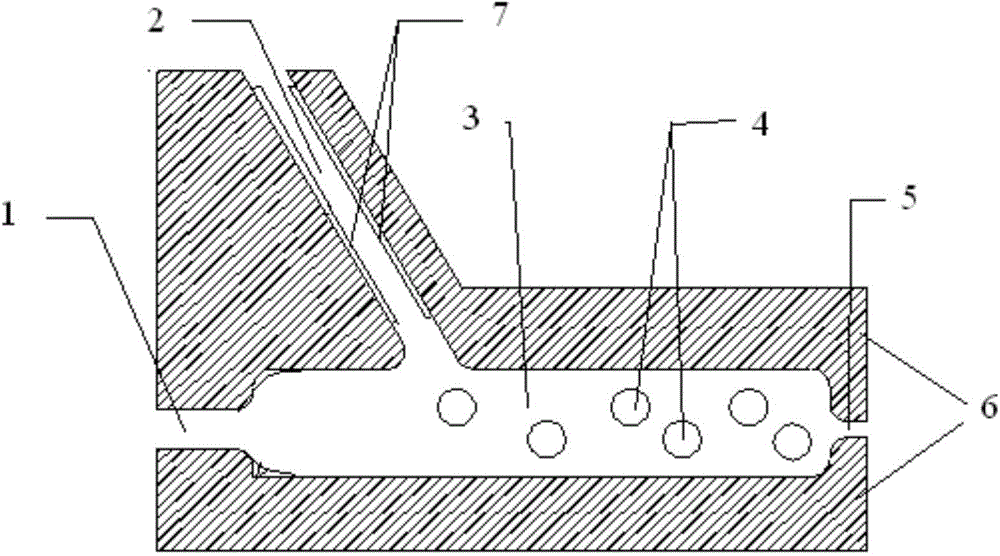

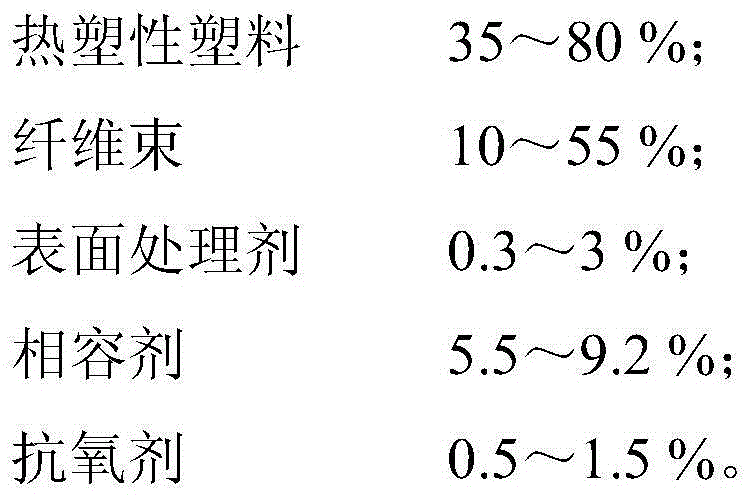

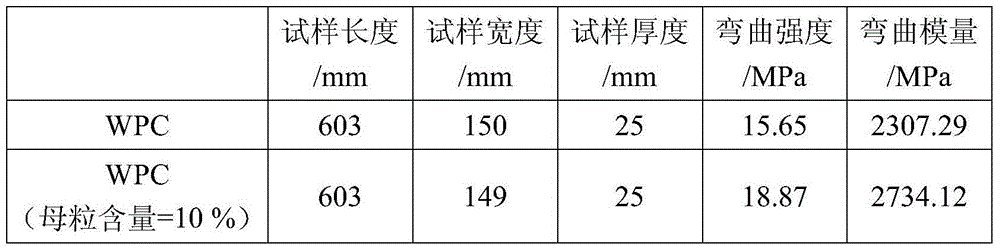

High-rigidity creep-resistant long-fiber-reinforced master batch for wood plastic products, and preparation and mold thereof

ActiveCN104356511AImprove appearance and performanceStrong rigidity and creep resistanceThermoplasticSurface finishing

The invention belongs to the technical field of preparation of long-fiber-reinforced master batches, and particularly relates to a high-rigidity creep-resistant long-fiber-reinforced master batch for wood plastic products and a preparation method thereof, and an impregnation mold for the preparation method. The master batch comprises the following components in percentage by mass: 35-80% of thermoplastic, 10-55% of fiber bundle, 0.3-3% of surface treating agent, 5.5-9.2% of compatilizer and 0.5-1.5% of antioxidant. By adopting the specific thermoplastic, compatilizer and other materials and utilizing the specific impregnation mold, the long fiber bundle is sufficiently impregnated in the master batch so as to lower the porosity and provide impregnation effect, and thus, the master batch has higher rigidity and creep resistance. After being added into the wood plastic profile product, the master batch enhances the bending modulus, strength and creep resistance, and can perform the function of reducing deformation in the profile use process, so that the application performance and long-term usage stability of the obtained WPC profile are improved.

Owner:GUANGZHOU ZAISEN NEW MATERIAL TECH CO LTD

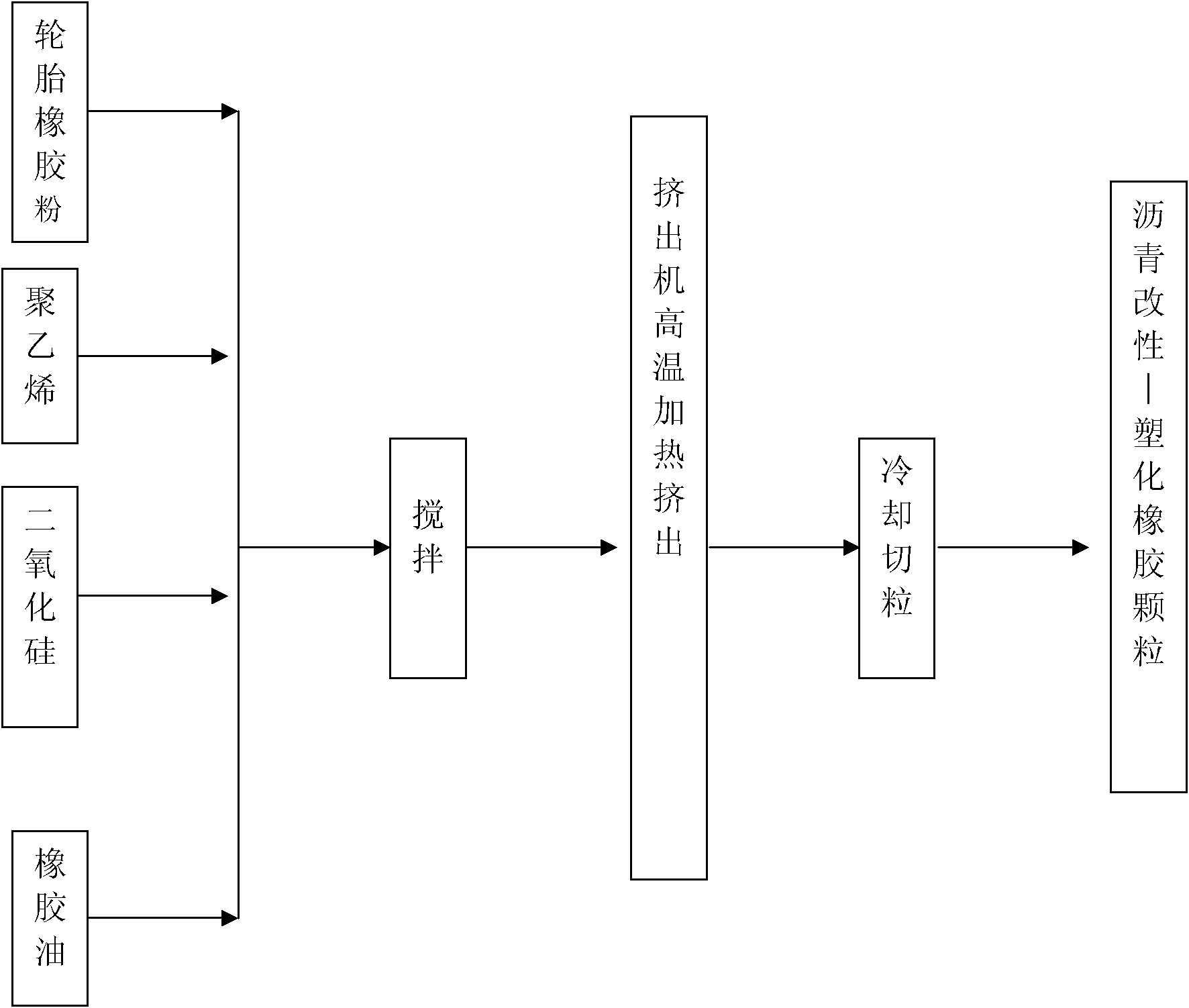

Asphalt modifier and preparation method thereof

InactiveCN101979440AGood compatibilityGood dispersionIn situ pavingsBuilding insulationsPolymer scienceSilicon dioxide

The invention aims to provide an asphalt modifier and a preparation method thereof, which overcome the disadvantages of nonuniform modification, serious pollution and hidden danger caused by adding rubber powder into asphalt and solve the technical problem of the modification and prefabrication of the rubber powder. The invention provides the asphalt modifier. The asphalt modifier is characterized by comprising the following components of: tire rubber powder, polyethylene, silicon dioxide and rubber oil, wherein the components are stirred, heated, extruded, cooled and cut to obtain plasticized rubber sticky particles, namely the asphalt modifier. The plasticized rubber sticky particle product of the invention greatly reduce high-temperature processing and pollution of rubber asphalt; the produced rubber asphalt sticky particles are a directly thrown type novel internal modification material and can be directly thrown into the asphalt and stones for mixing; and the asphalt modifier is odorless, can reduce secondary pollution, and has better meltability than that of rubber powder modified asphalt. The rubber asphalt particles are black sticky particles and are easy to package and transport.

Owner:无锡市同义路面新材料有限公司 +1

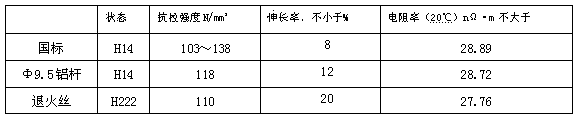

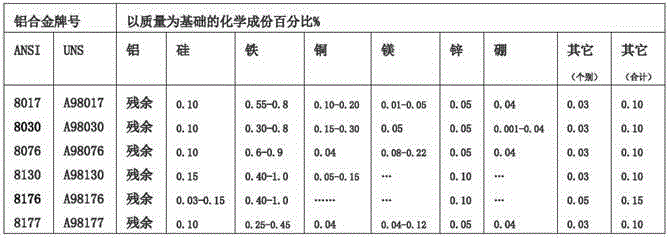

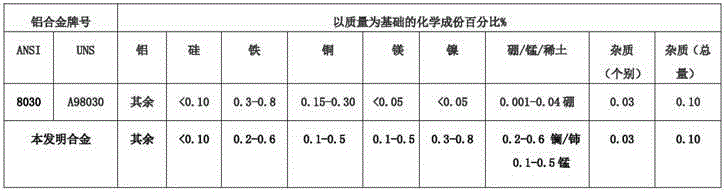

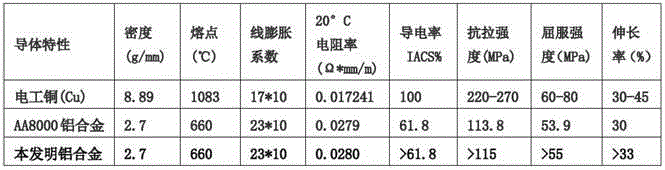

Aluminum alloy cable core and method for preparing same

InactiveCN103469019ASafe and reliableStrong creep resistanceFlexible cablesMetal/alloy conductorsRare-earth elementChemical industry

The invention discloses an aluminum alloy cable core and a method for preparing the aluminum alloy cable core. The cable core is composed of 0.06wt% of Si, 0.40-1.2wt% of Fe, 0.05wt% of Cu, 0.01-0.05wt% of Mg, 0.01-0.3wt% of RE, 0.05wt% of Zn, 0.04wt% of B and the rest of Al. According to the aluminum alloy cable core and the method for preparing the aluminum alloy cable core, rare earth resources in China are utilized; after rare earth elements are added to conductor materials, aluminum alloy conductors which are extremely competitive in conductivity, flexibility, bending property, tensile property, creep resistance and connecting stability and excellent in resistance to corrosion are prepared through the smelting process, the rod drawing process, the wire drawing process, the compressing process and the stranding process and special annealing treatment; after being detected and verified by authorities at home and abroad, the compensative performance of the aluminum alloy cable core is far beyond current industry standards at home and abroad; high-tech aluminum alloy cable products can be widely applied to fields like electric power, automobiles, traffics, mineral products, ships, chemical industries and military, and the advantages of the high-tech aluminum alloy cable products are more obvious when the high-tech aluminum alloy cable products are used in complex and severe engineering environments.

Owner:SICHUAN AOSHENDA GENERAL CABLE

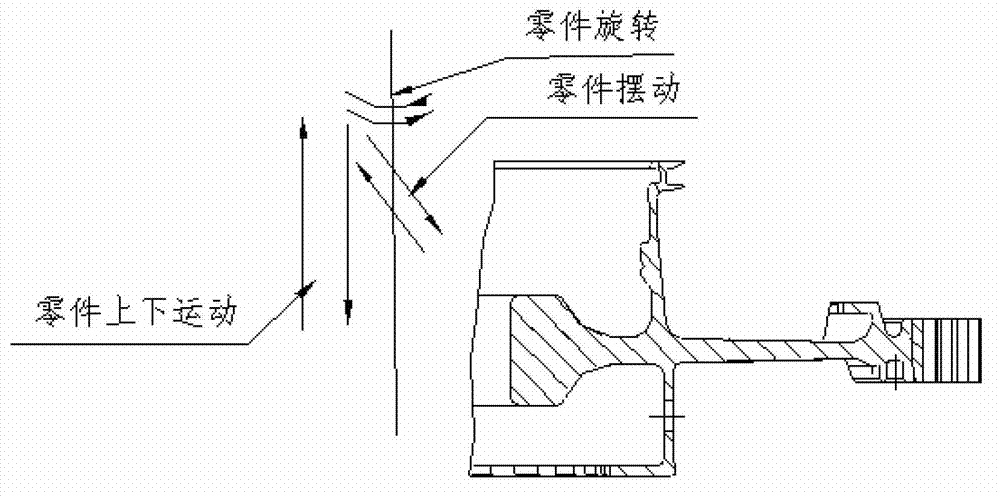

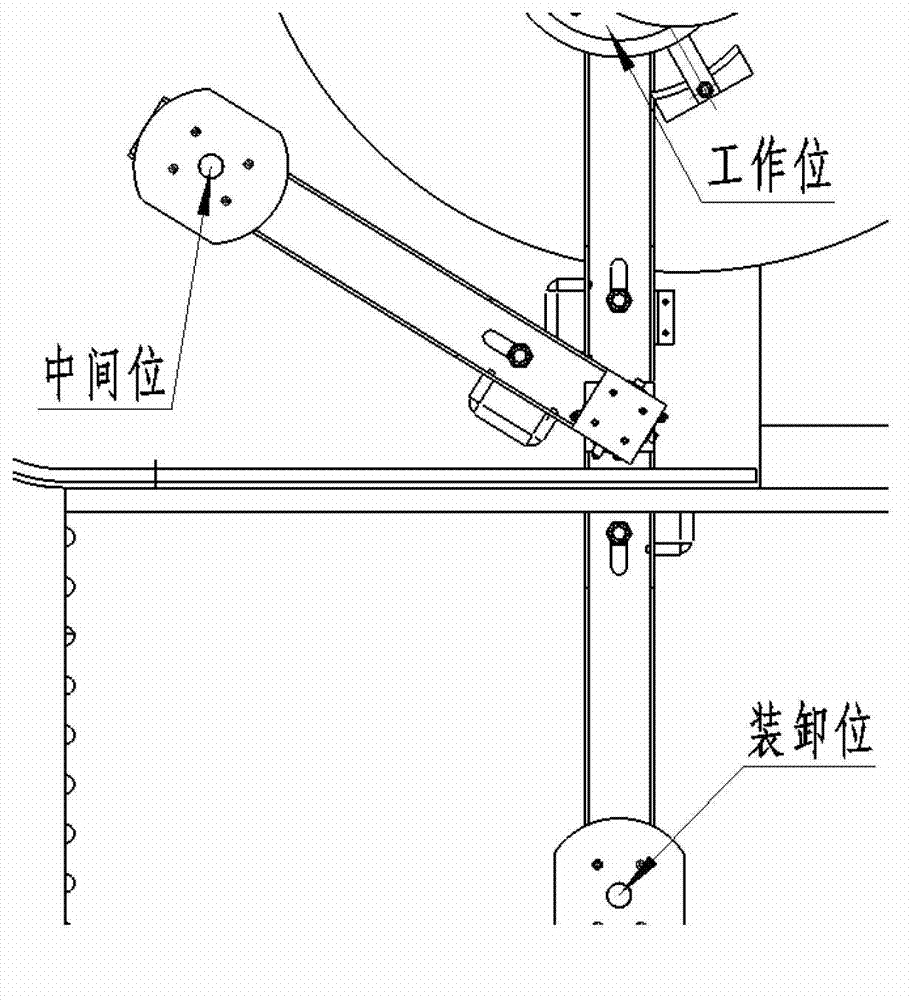

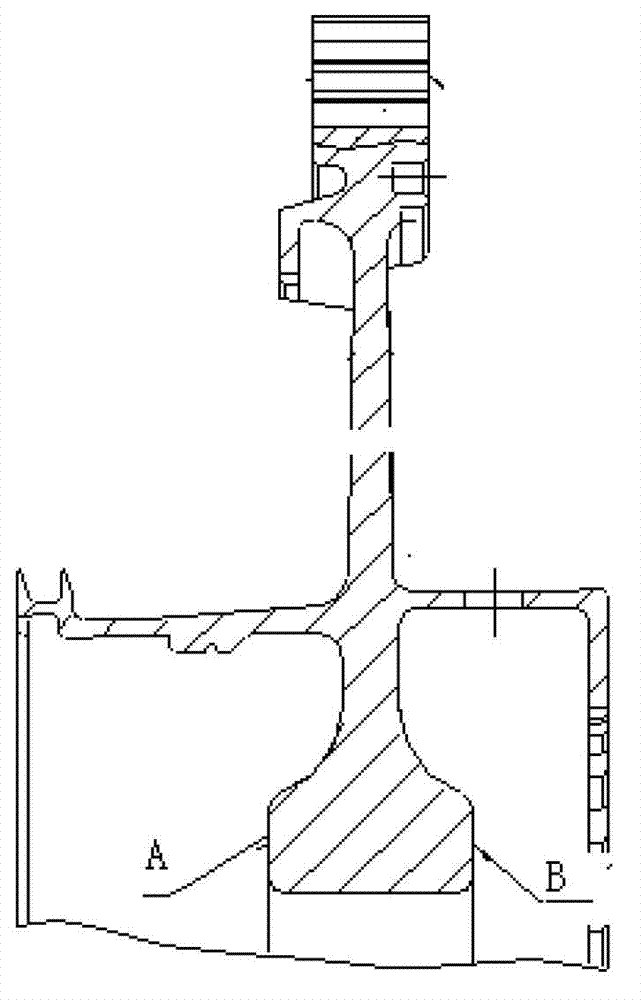

Efficient automatic polishing processing method for molding surface of closed inner chamber, and dedicated equipment adopting method

InactiveCN102873629AImproves machined surface integrityEnsure consistencyEdge grinding machinesPolishing machinesPolishingEngineering

The invention aims to provide an efficient automatic polishing processing method for a molding surface of a closed inner chamber, and dedicated equipment adopting the method. According to the method, a part is processed by adopting a vibrating polishing machine; and the method adopts the technological processes of clamping the part, adding grinding material into a work bin, and carrying out vibrating and polishing. The method is characterized in that the molding surface of the closed inner chamber is polished and processed automatically by adopting the dedicated vibrating polishing machine; the processing process comprises a roughing step and a finishing step; rough grinding material used in the roughing step is required to have sharp edges; fine grinding material used in the finishing step is required to have round corners; during clamping, the effective vertical lifting height of the part is guaranteed to be larger than twice the thickness of the part, and the vertical deflection of the part is not smaller than 30 degrees; and the vibration frequency of the work bin is 1,000 to 1,450 per minute, the vibration and swing frequency of a machine head is 15 to 30 per minute, and the lifting speed of the part is 1.5 to 2 m per minute.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

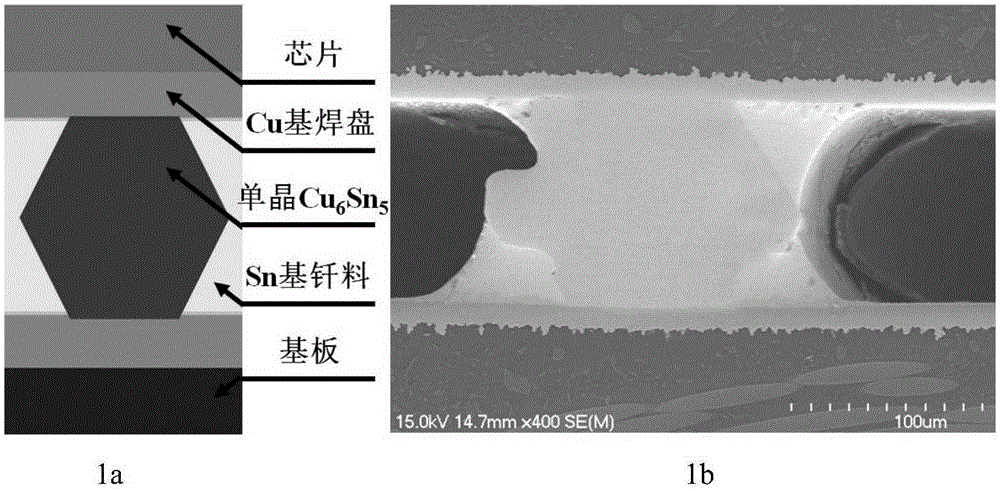

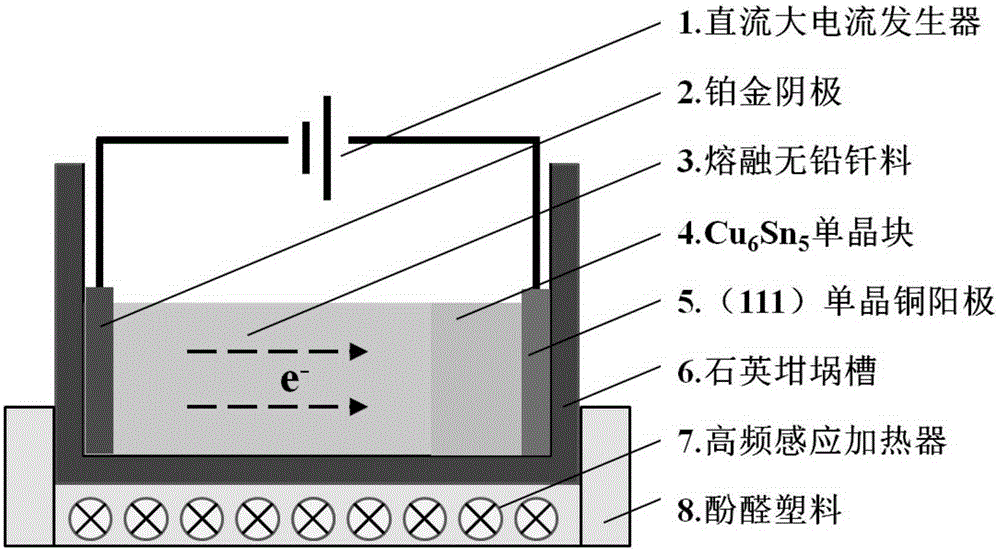

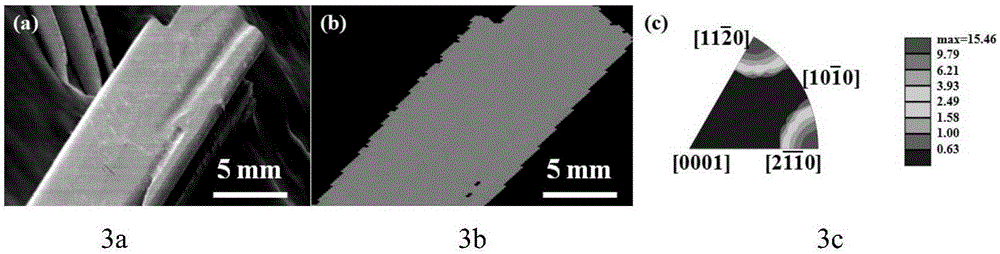

Directional interconnection method for Cu6Sn5-base single-crystal lead-free solder joints for high-temperature packaging

InactiveCN105171168ALow costStrong creep resistanceSolid-state devicesSemiconductor/solid-state device manufacturingInterconnectionFiller metal

The invention belongs to the technical field of materials, and provides a directional interconnection method for Cu6Sn5-base single-crystal lead-free solder joints for high-temperature packaging. The method comprises the steps of firstly, preparation of a Cu6Sn5-base single-crystal block body, secondly, cutting of the Cu6Sn5-base single-crystal block body, thirdly, surface pretreatment of a Cu-base welding disc, and fourthly, interconnection of Cu6Sn5-base single-crystal welding blocks. The elasticity modulus of the Cu6Sn5-base single-crystal lead-free interconnected solder joints prepared with the method is 235% of that of common Sn-base brazing filler metal, the conductivity of the Cu6Sn5-base single-crystal lead-free interconnected solder joints is 52.4% that of the Sn-base brazing filler metal, and the heat conductivity of the Cu6Sn5-base single-crystal lead-free interconnected solder joints is 57.8% that of the Sn-base brazing filler metal. The method has the beneficial effects of being low in cost, resistant to high temperature, high in reliability of interconnection of the solder joints and a Cu-base welding disc, high in creep-resistance, and capable of being used for a long time under the severe condition. The method has the beneficial effects of being simple in working principle, low in cost, rapid in single-crystal preparation and high in quality.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

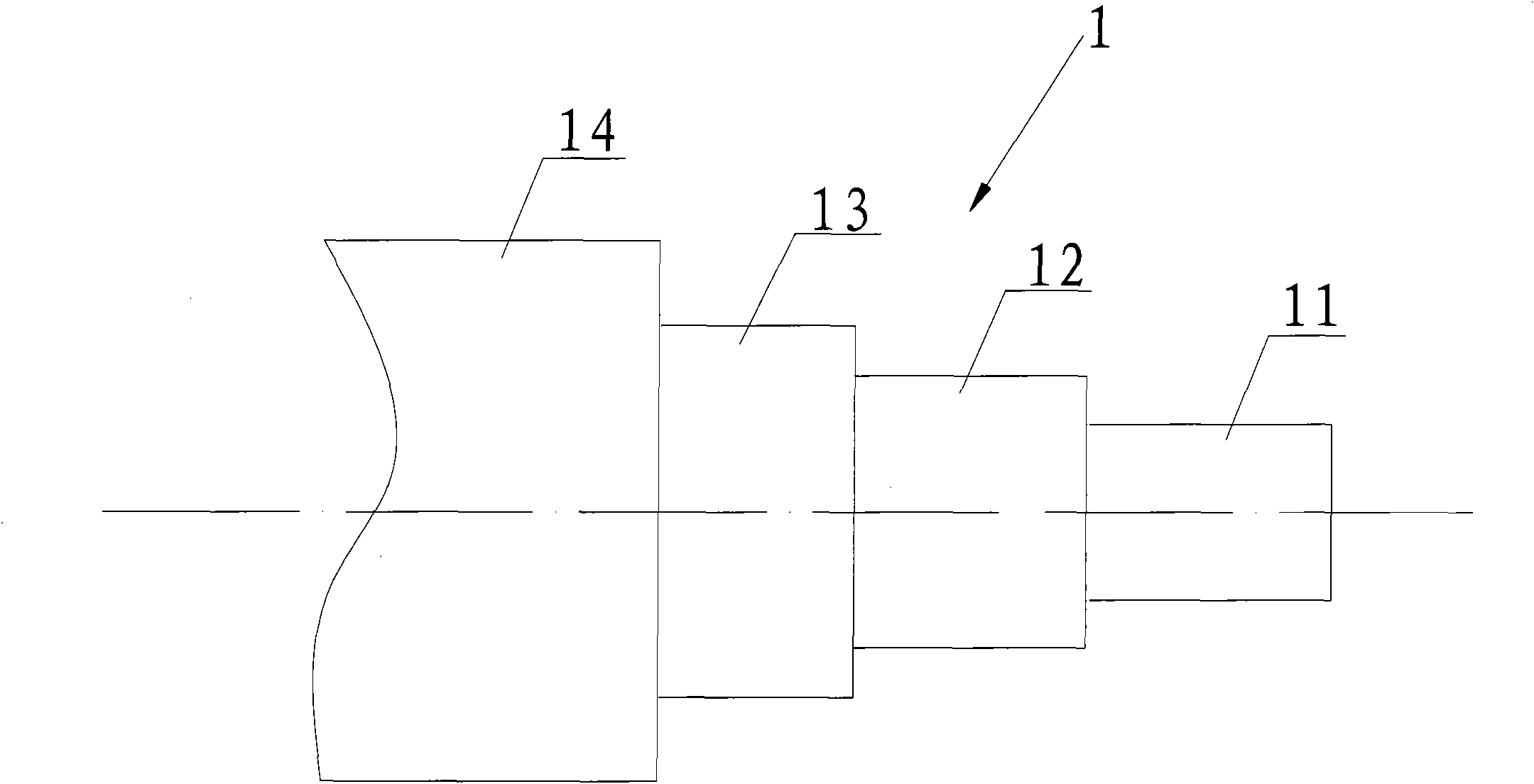

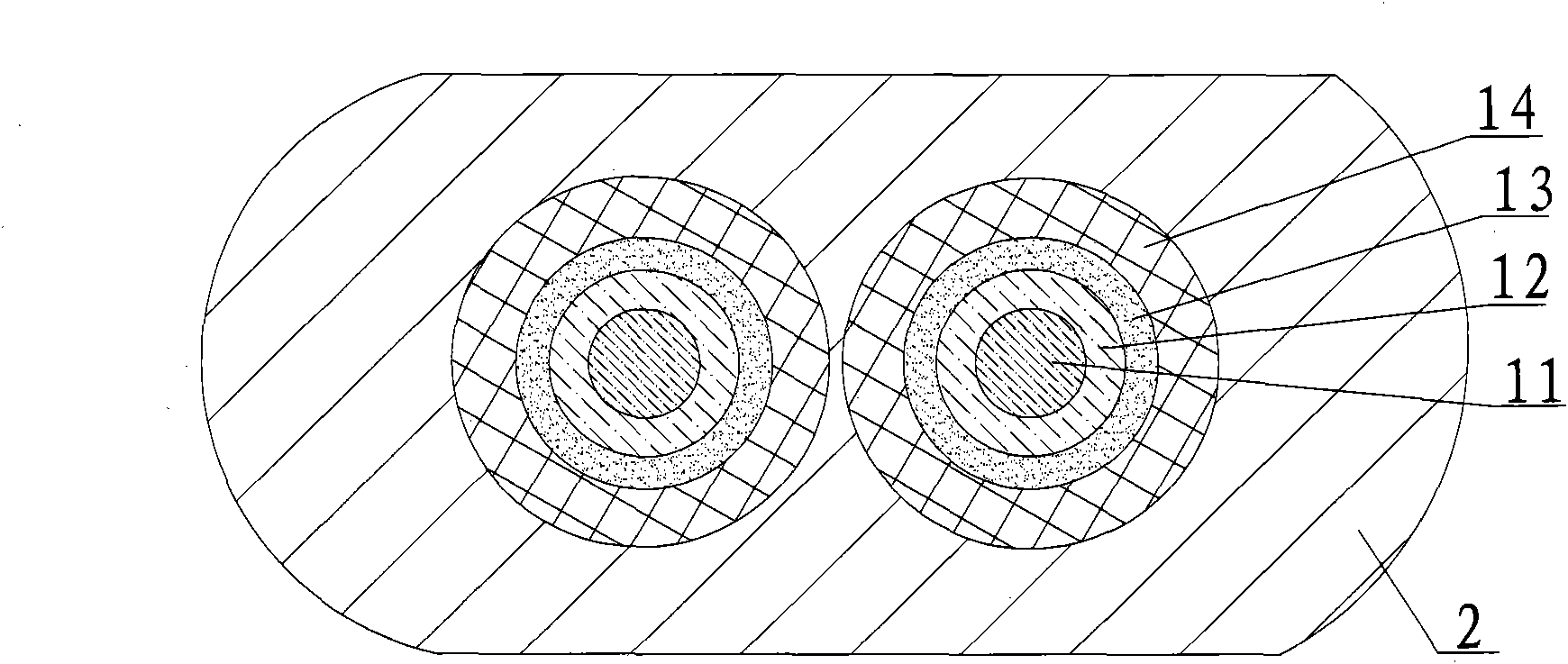

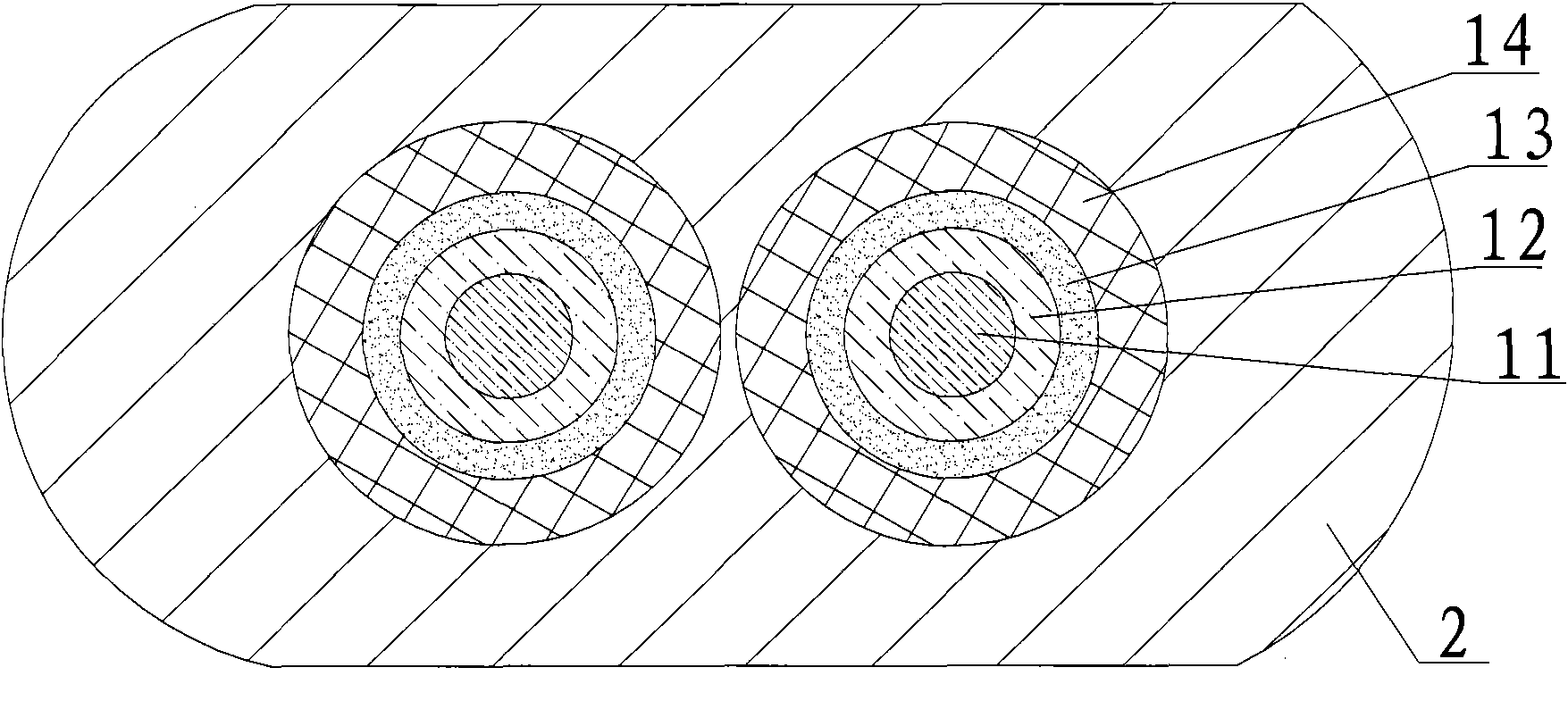

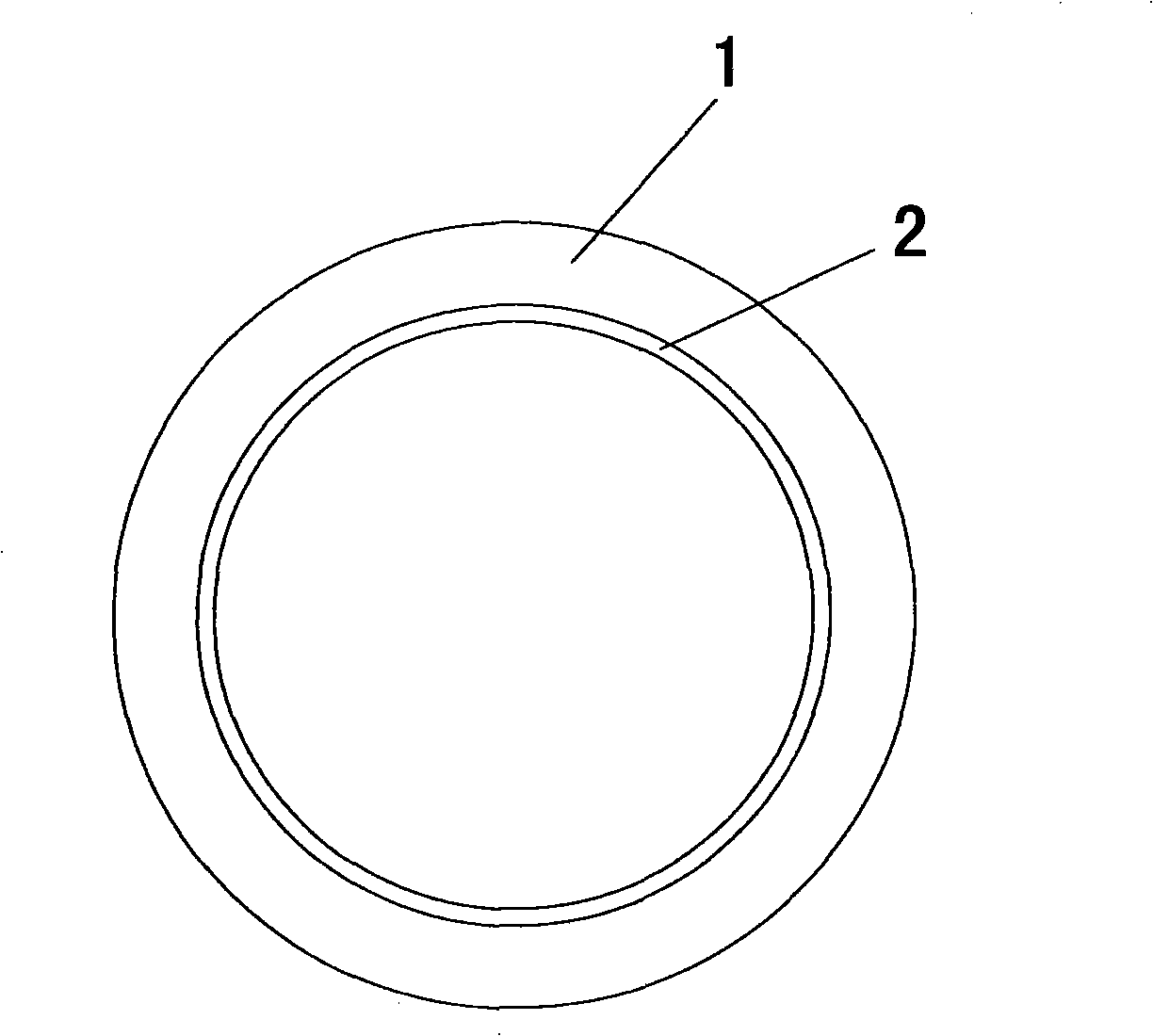

Tightly packaged fiber, and dual-core indoor cable and processing method thereof

InactiveCN101957484AStrong chemical resistanceStrong creep resistanceFibre mechanical structuresDistribution frameFiber

The invention relates to a tightly packaged fiber, and a dual-core cable using the tightly packaged fiber and a processing method thereof. The tightly packaged fiber consists of a single-mode or multi-mode fiber core, a cladding layer clad on the circumference of the fiber core, a primary coating layer coated on the circumference of the cladding layer and a secondary coated layer tightly sleeved on the circumference of the primary coating layer, wherein the secondary coated layer is a polyvinyl fluoride protection layer. By taking polyvinyl fluoride which has relatively high chemical corrosion resistance, creep resistance and compressive strength and relatively wide bearable temperature range as the secondary coated layer of the tightly packaged fiber, the tightly packaged fiber can have enough mechanical and environmental protection capability and can be independently used. The dual-core cable using the tightly packaged fiber, which is processed by the method has the advantages of small volume, light weight, stable performance and low cost, is suitable for indoor comprehensive wiring and can be used as internal connection wires of various optical devices, optical modules and optical distribution frames.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

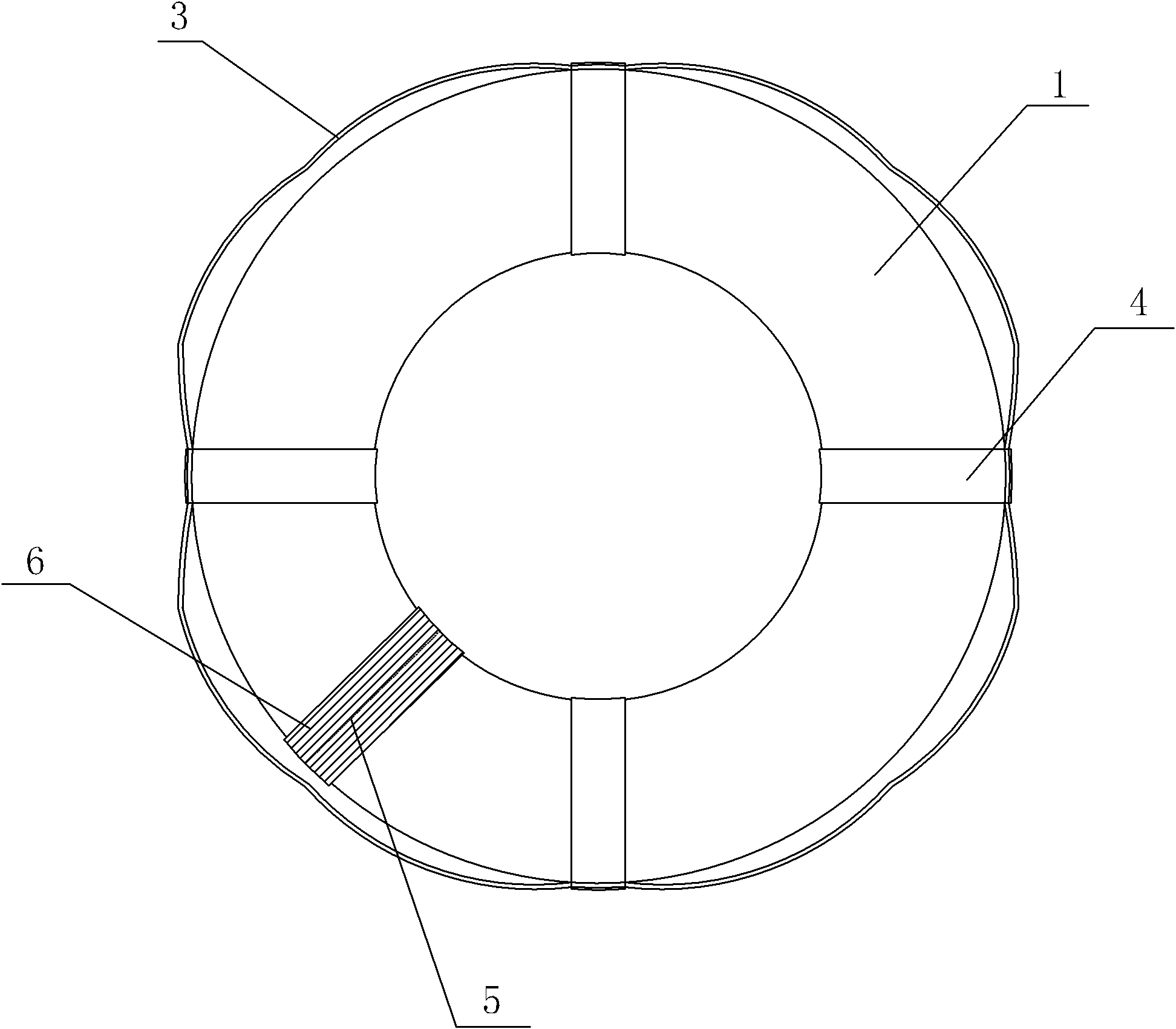

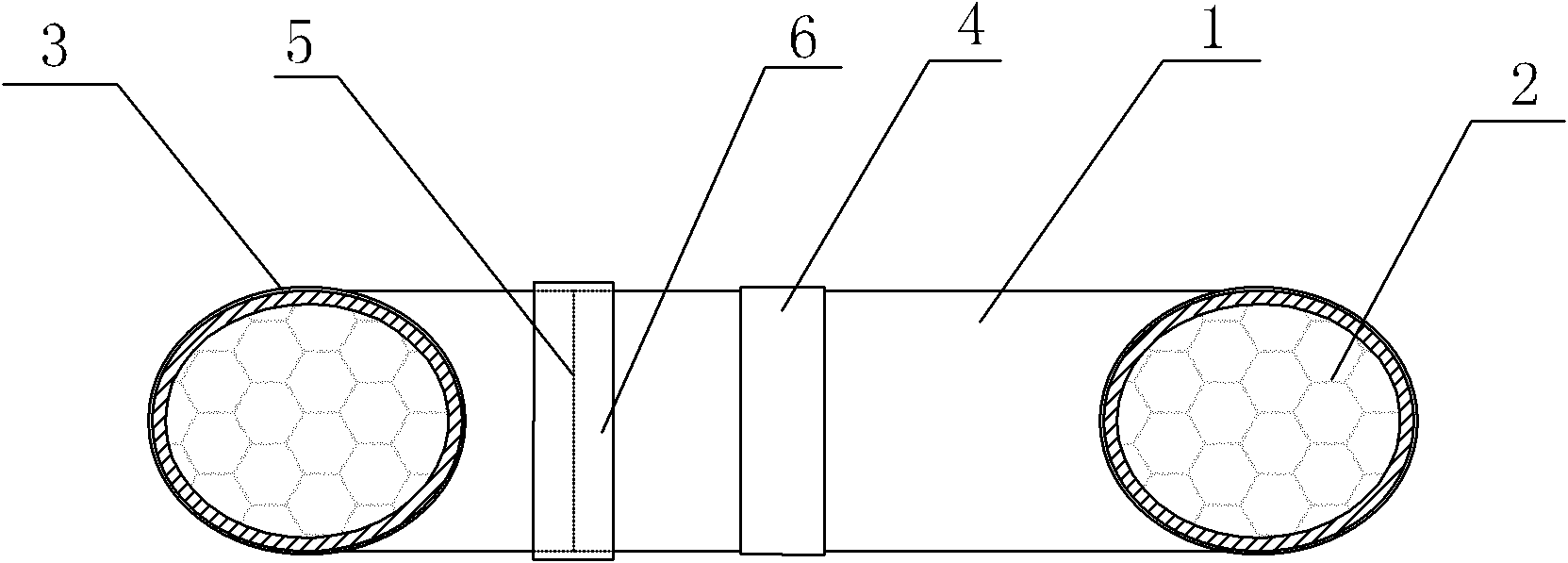

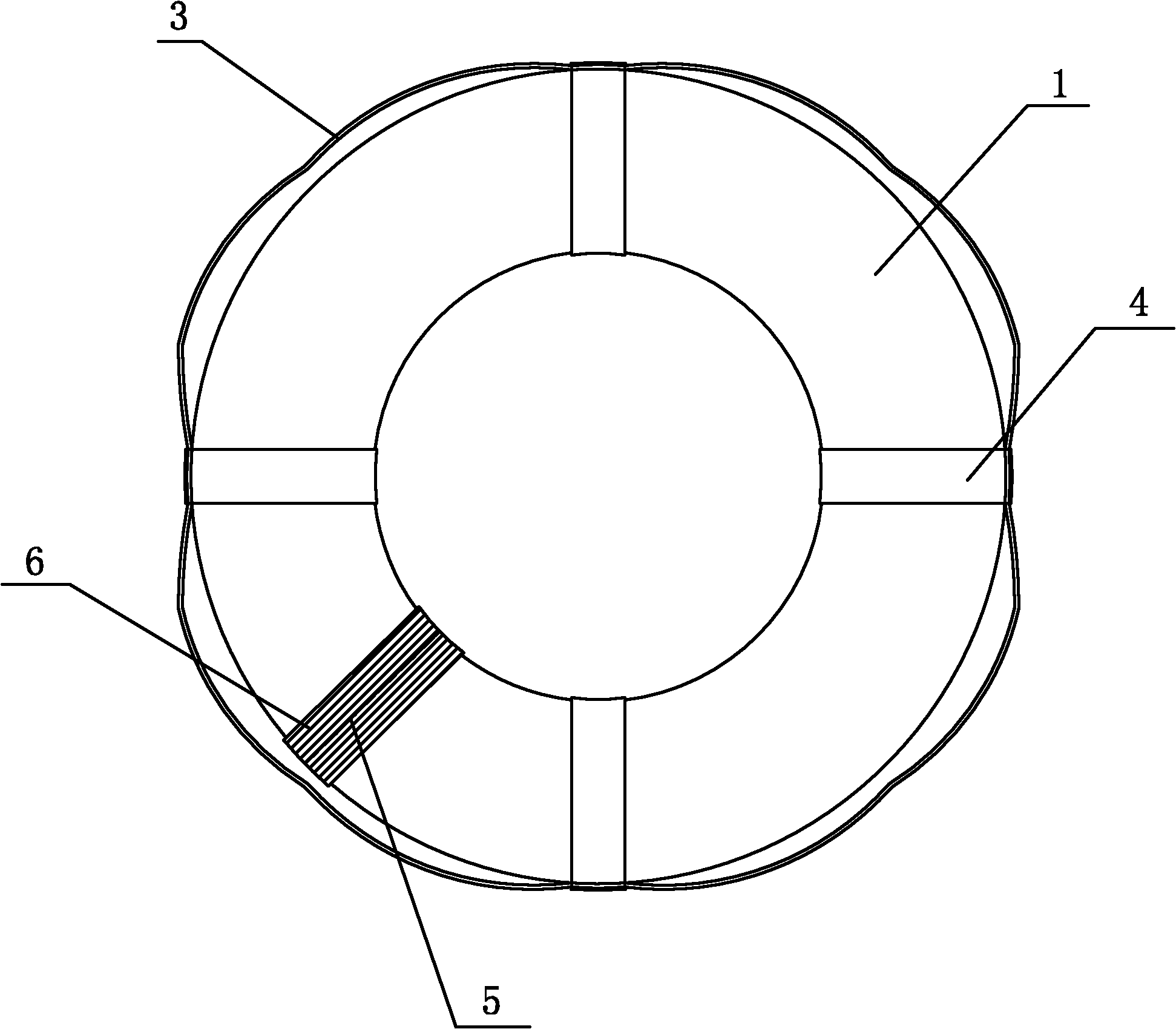

Life buoy and preparation method thereof

The invention discloses a life buoy and a preparation method thereof. The life buoy comprises a buoyant ring body, wherein the buoyant ring body is made of a sisal wood plastic composite material; the life buoy has the advantages that the buoyant ring body is made of the sisal wood plastic composite material; due to the combination of the sisal and glass fiber, the life buoy has extremely high seawater immersion resistance; the life buoy has high thermal stability, aging resistance and bending strength; therefore, the prepared life buoy has high thermal stability, aging resistance, bending strength, creep resistance, bending elastic modulus and the like, the safety performance of the life buoy is greatly reduced and the service life of the life buoy is prolonged simultaneously.

Owner:宁波维卡绿建科技有限公司 +1

Titanium alloy gear and preparation method thereof

ActiveCN107893228AImprove power densityReduce power densityAdditive manufacturing apparatusPortable liftingHardnessTitanium alloy

The invention provides a preparation method for a titanium alloy gear. The preparation method includes the steps that a titanium alloy gear substrate is prepared through a 3D printing method; the titanium alloy gear substrate is subjected to hot isostatic pressing treatment, and a titanium alloy gear blank is obtained; a hardened layer is formed on the surface of the titanium alloy gear blank through a fusion covering method, and the titanium alloy gear is obtained; and the thickness of the hardened layer is 1-2 mm. According to the preparation method for the titanium alloy gear, the mechanical properties of the gear substrate are improved through hot isostatic pressing treatment, and the thick hardened layer can be formed on the surface of the gear substrate through the fusion covering method. The titanium alloy gear prepared through the process is high in surface hardness, low in friction coefficient, resistant to abrasion, high in impact resistance and fatigue performance, and suitable for gear transmission equipment in the aerospace industry, automobile industry and the like.

Owner:SEED TECH CORP LTD

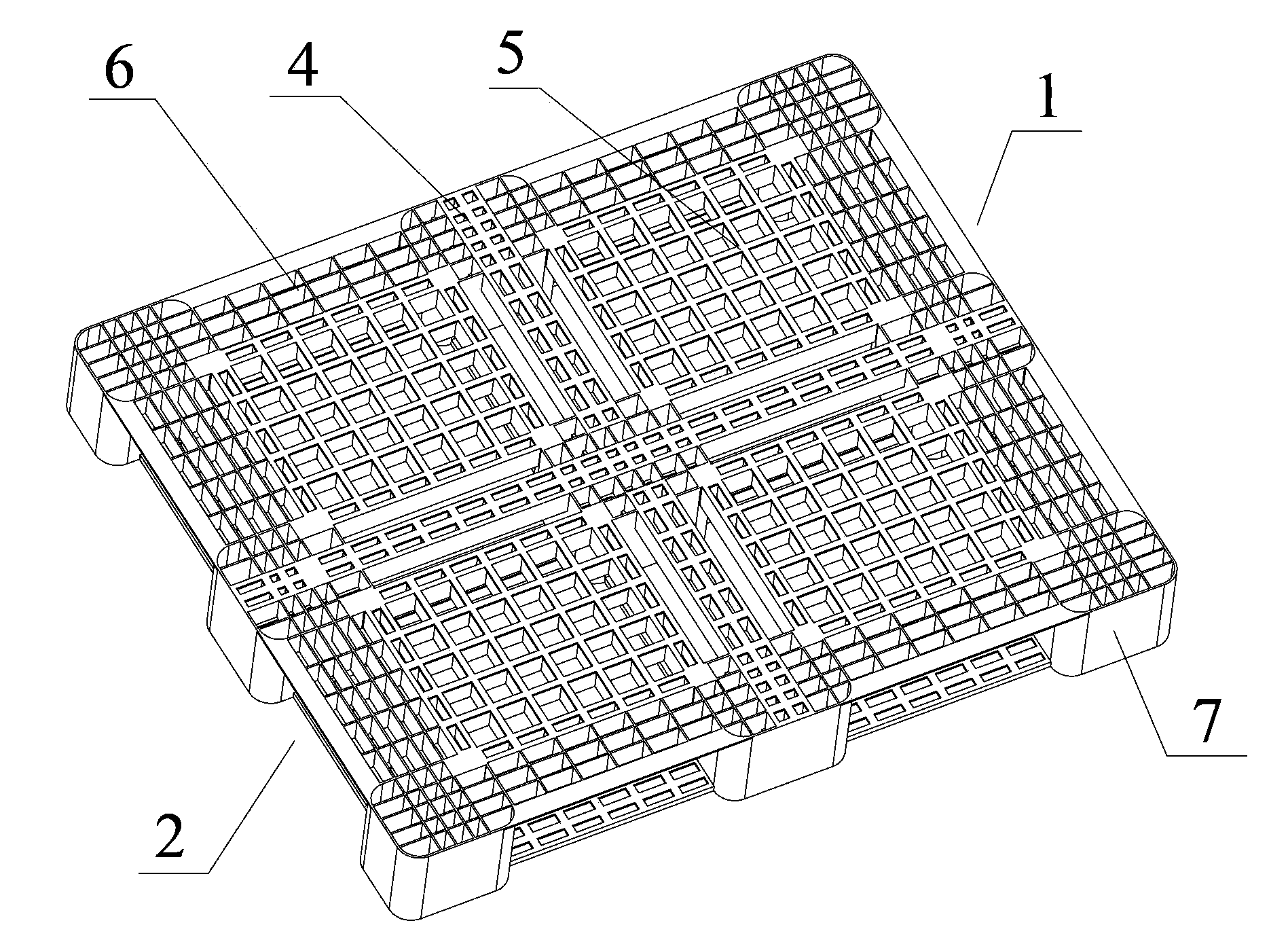

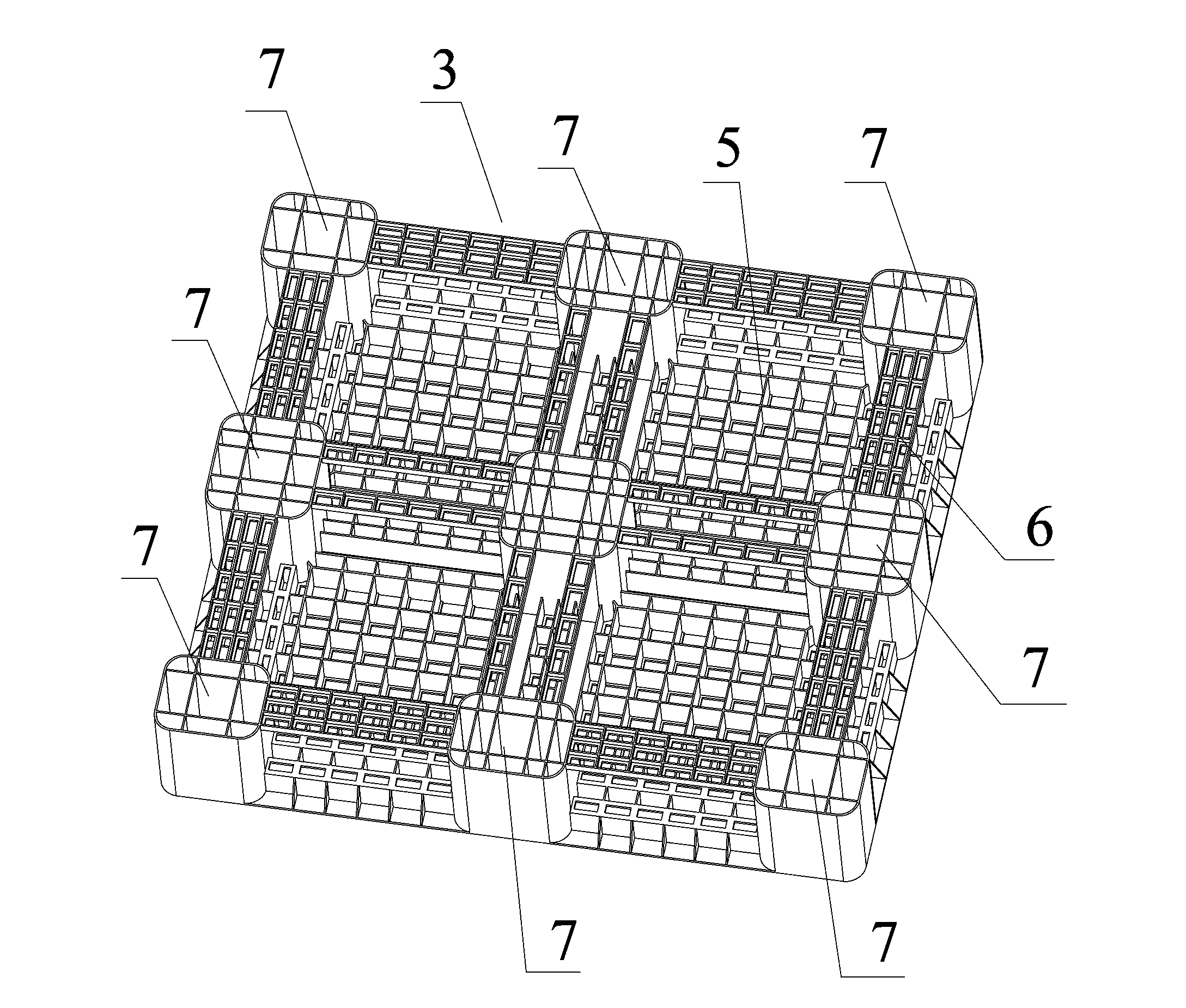

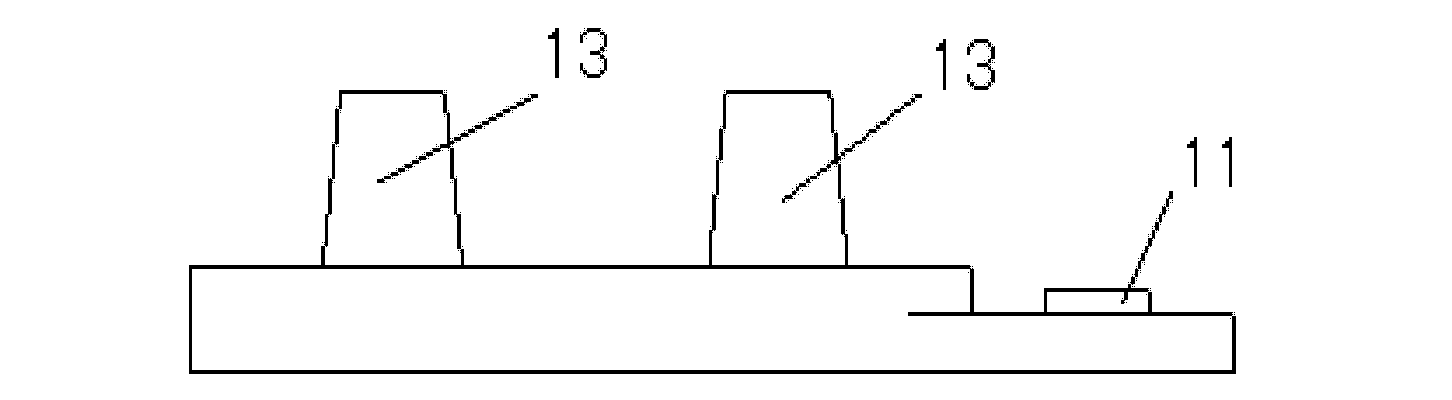

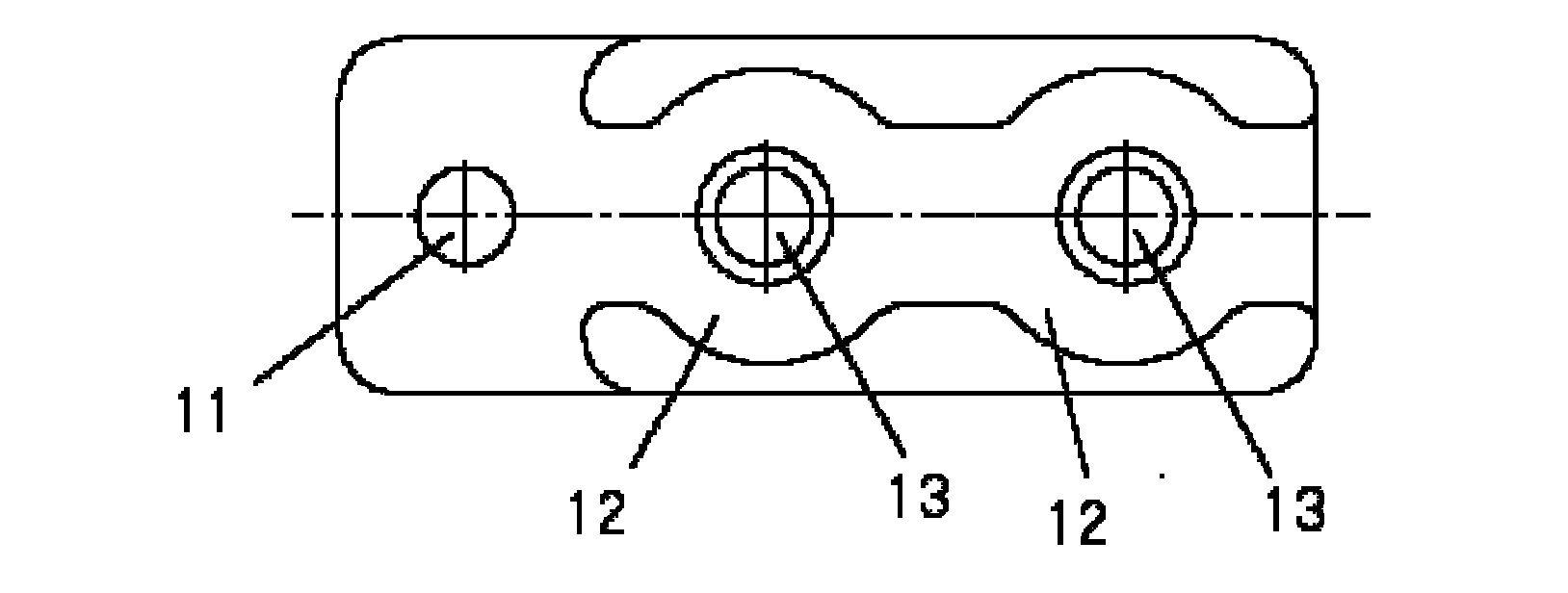

High-strength ultralight tray and preparation method thereof

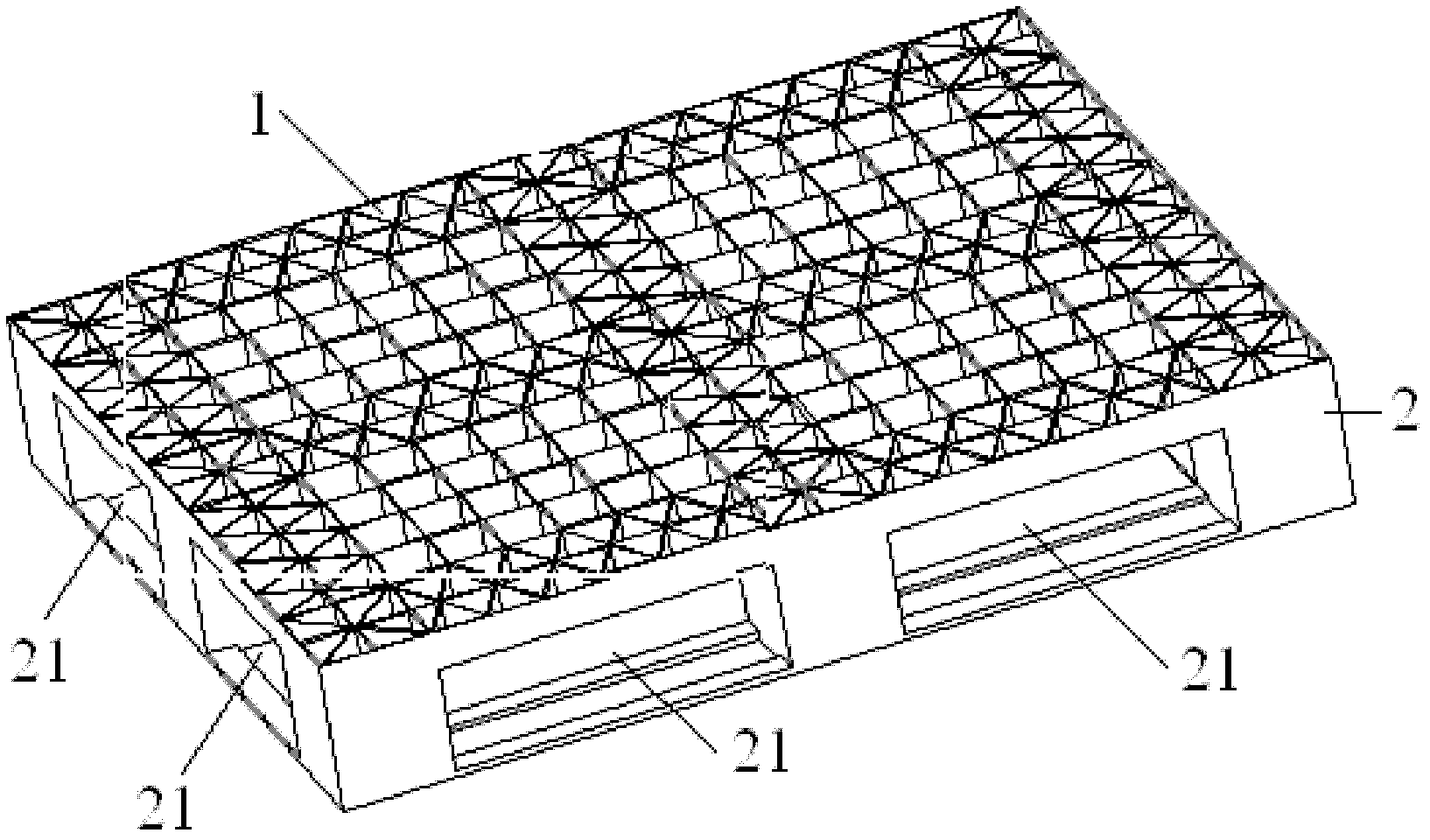

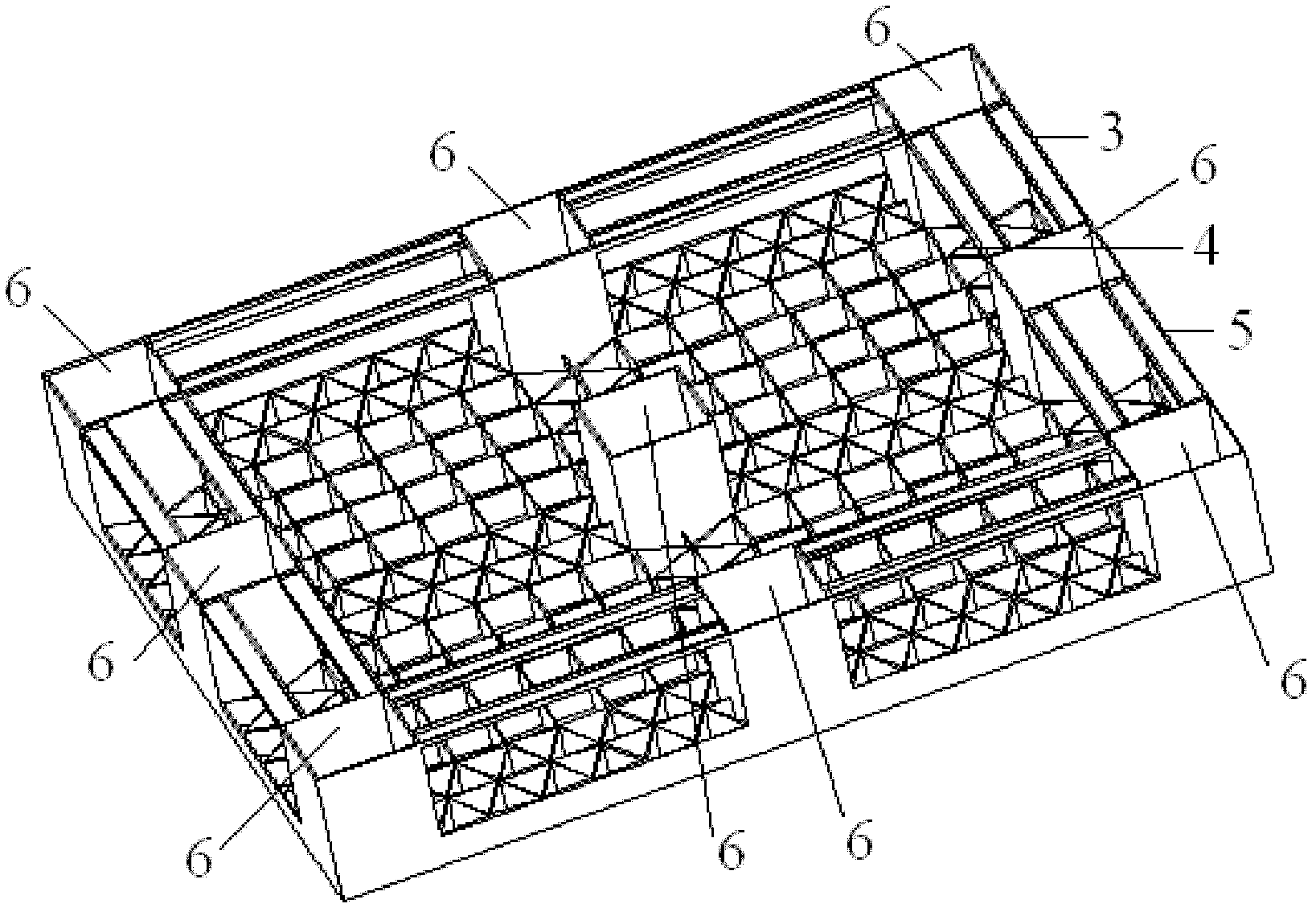

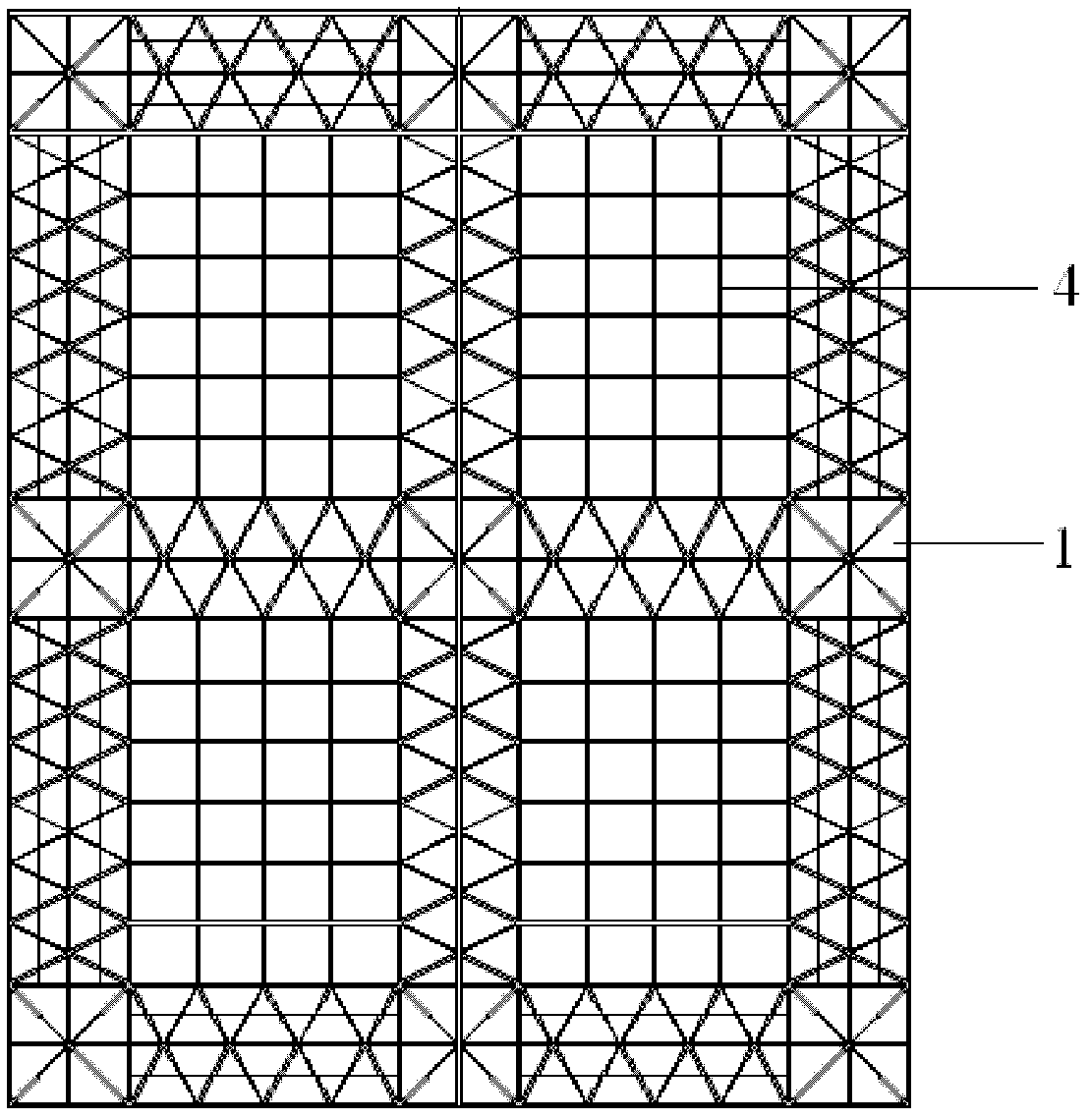

ActiveCN103183168AHigh mechanical strengthIncreased load-bearing capacityRigid containersPolyolefinHigh intensity

The invention relates to a high-strength ultralight tray and a preparation method thereof. The high-strength ultralight tray is subjected to injection molding by thermoplastic composite material; the upper surface of the high-strength ultralight tray is a plane in a hollow structure; cross-shaped grid ribs are arranged in the hollow structure; the side surface and the upper surface of the high-strength ultralight tray are in 90-degree connection; the junction is in fillet transition; the side surface is provided with an opening used for a forklift; the side surfaces are connected at an angle of 90 degrees; the junction is in the fillet transition; the bottom surface is provided with nine footings; one footing is arranged on the center position; and the rest eight footings are evenly distributed around the bottom surface and are connected by connection ribs. The preparation method comprises the following steps of firstly, preparing polyolefin reinforcing material, and then carrying out injection molding to obtain the high-strength ultralight tray. Compared with the prior art, the invention has the advantages of short injection molding period time, high production efficiency and low production cost, and the obtained product has the advantages of light weight, big bearing and relatively long service life.

Owner:HEFEI GENIUS NEW MATERIALS

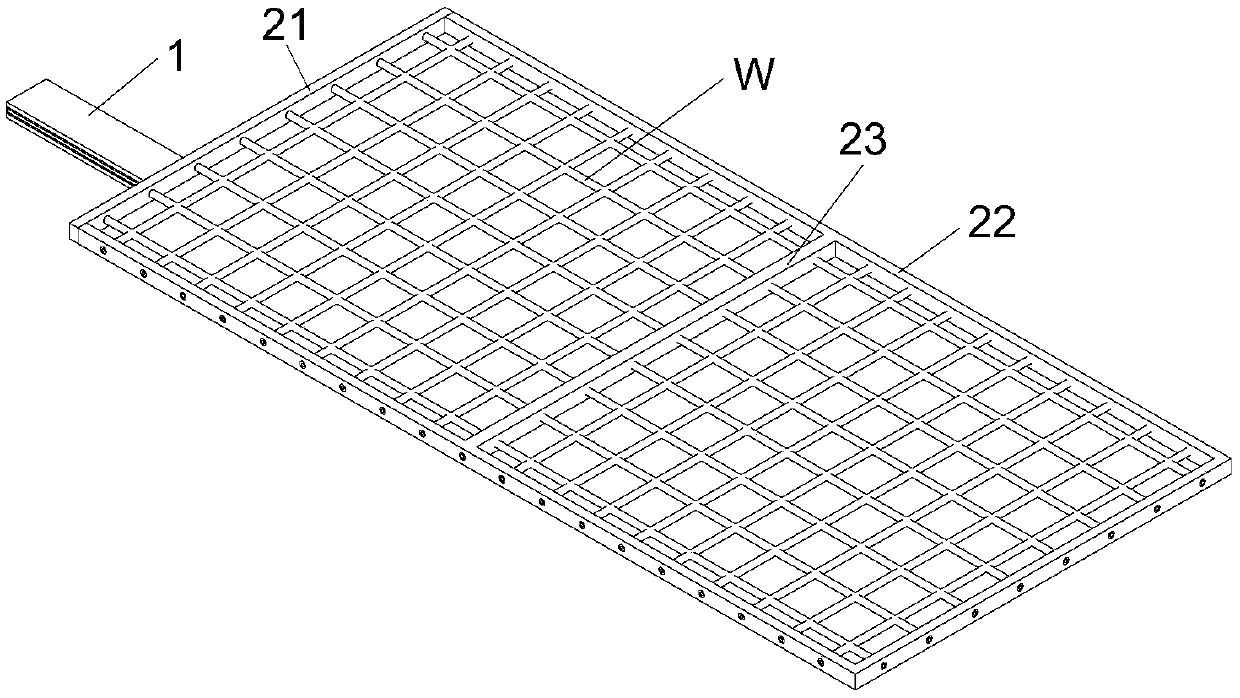

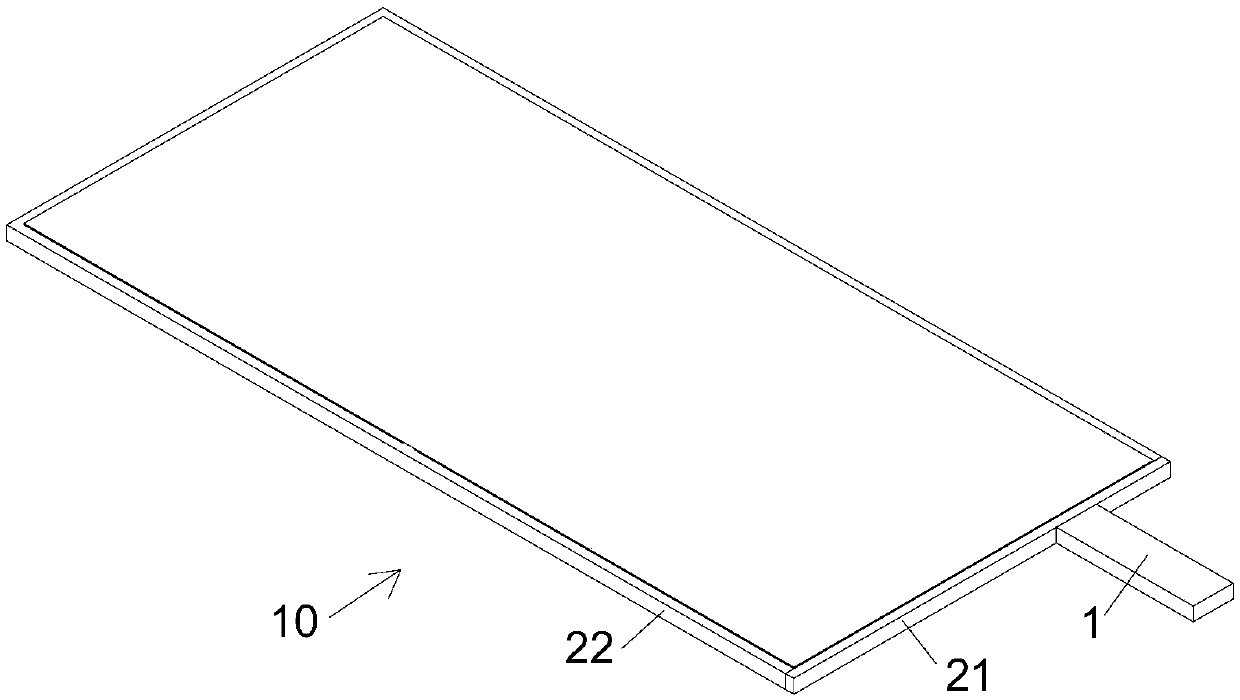

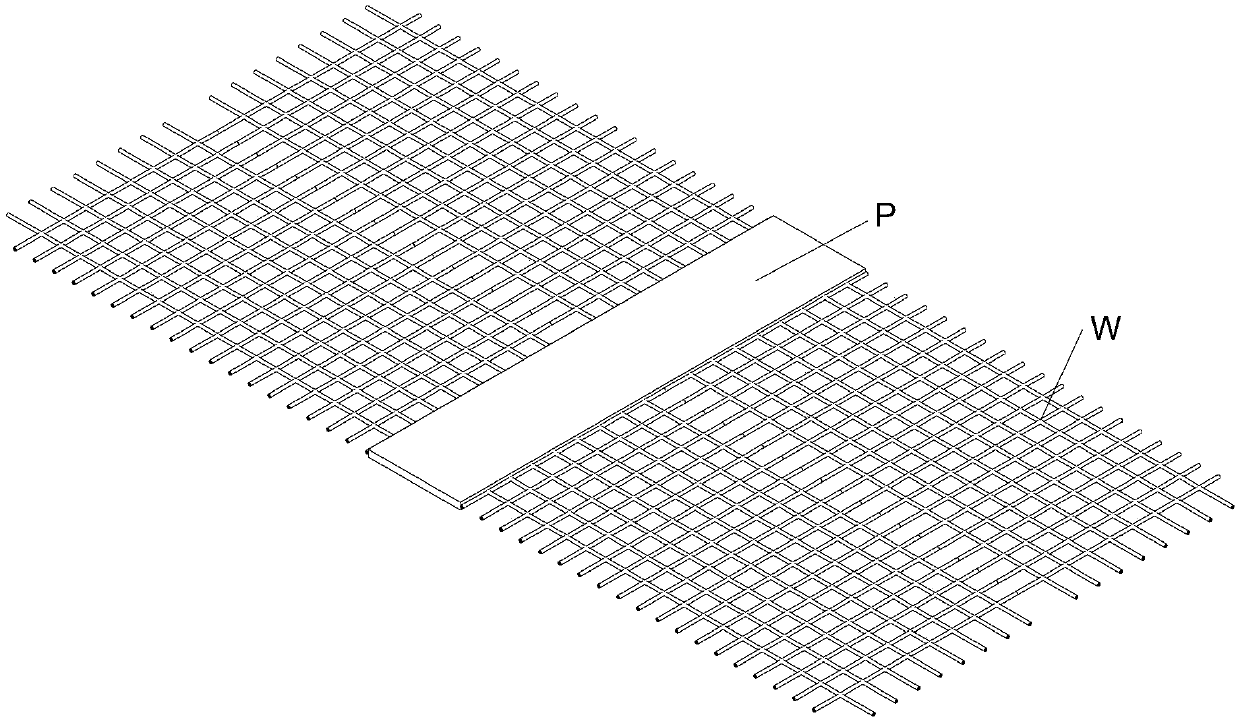

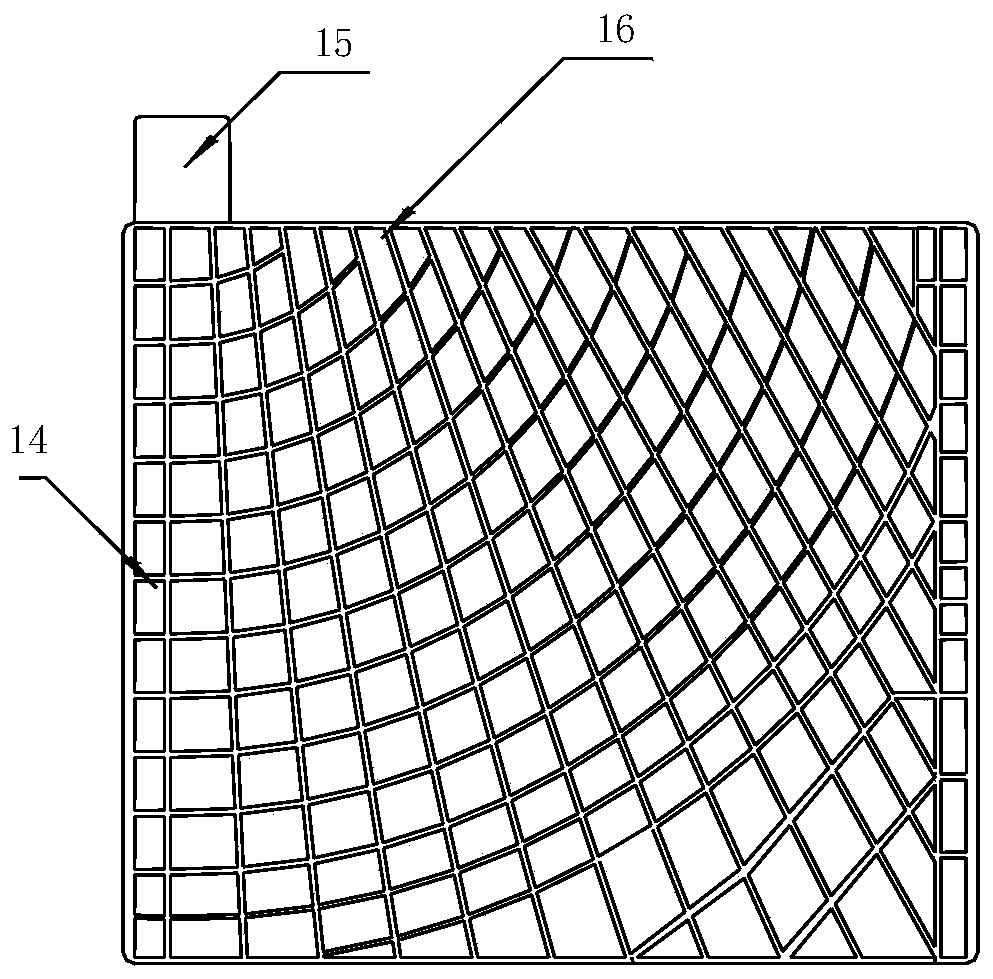

Grid, manufacturing method thereof, pole plate and lead-acid storage battery

ActiveCN109524673AImprove structural strengthStrong creep resistanceFinal product manufactureElectrode carriers/collectorsPlastic materialsAlloy

The invention relates to the field of storage batteries, and discloses a grid, a manufacturing method thereof, a pole plate and a lead-acid storage battery. The grid comprises a tab, a frame and a plurality of conductive ribs staggered in the frame to form a mesh structure; the frame is higher than the mesh structure in the thickness direction of the mesh structure, so that lead paste can fill theframe with the mesh structure as a support; the frame comprises an upper beam and side frames, wherein the upper beam is arranged along one side edge of the mesh structure and is made of a lead alloymaterial; the side frames are connected with two ends of the upper beam and are made of a plastic material; the side frames and the upper beam jointly form the frame surrounding the mesh structure; and the tab is connected with the upper beam. According to the grid, the manufacturing method thereof, the pole plate and the lead-acid storage battery, the grid has high strength and high creep resistance and is not easy to deform, and the active lead paste filling the frame is not prone to falling and being contaminated; and meanwhile, the weight and size are small, so that the cost is favorablyreduced and the usage performance of the product is favorably improved.

Owner:CHAOWEI POWER CO LTD

Aluminum alloy power cable

InactiveCN105355257AImprove performanceImprove conductivityMetal/alloy conductorsPower cableEconomic benefits

The invention discloses an aluminum alloy power cable. The chemical constituents of the aluminum alloy power cable include by mass: 0.01-0.30% of Si, 0.5-1.3% of Fe, 0.01-0.05% of Mn, 0.03-0.05% of Cu, 0.01-0.5% of Mg, 0.01-0.09% of Zn, 0.005-0.20% of (V+Ti+Cr+Ni+Co+Zr), 0.01-0.06% of E and the balance being Al and inevitable impurities, wherein the element E is one or two of B and Be. The aluminum alloy power cable has the advantages that aluminum alloy has relatively high comprehensive performance due to the addition of elements Fe, Mg and the like, particularly the proportions of specific contents; meanwhile, the aluminum alloy power cable has obvious advantages of a light weight; when the aluminum alloy power cable disclosed by the invention substitutes a copper cable, the cable weight can be reduced, the installation cost, the abrasion of the device and the cable and the operation cost are reduced, energy is saved, the environment is protected, and the economic benefit is improved.

Owner:沈阳沈缆四环电缆制造有限公司

Lead alloy anode material and smelting method for electrodeposition zinc

ActiveCN103160704AImprove corrosion resistanceImprove mechanical propertiesPhotography auxillary processesProcess efficiency improvementRare earthAlloy

The invention discloses lead alloy anode material and a smelting method for electrodeposition zinc and belongs to the technical field of preparation of lead alloy anode material and a smelting method for the electrodeposition zinc. The anode material comprises the following components by percent by weight: 0.1-0.3% of silver, 0.05-0.15% of calcium, 0.02-0.06% of strontium, 0.005-0.03% of aluminum, 0-0.1% of rare earth meal, and lead of allowance. The melting process includes that after lead is melted, aluminum powder / silver piece / silver ingot is added by proportion, an aluminum plate is added by proportion after the silver is melted, after the aluminum is partly melted, the lead calcium, the lead strontium alloy and the rare earth metal are added by proportion and stands after mixed, scum is removed, and blank alloy pig is cast. The anode material has good mechanical performance and anti-corrosion resistance performance, can obviously prolong service life of an anode in the process of wet process electrodeposition zinc process, and reduces bath voltage and energy consumption of the process of electrodeposition.

Owner:GRIMAT ENG INST CO LTD

Strong-strength load bearing pallet

The invention relates to a strong-strength load bearing pallet. The pallet is formed by injection-molding a composite thermoplastic material, and consists of an upper surface, lateral surfaces and a lower surface, wherein the upper surface consists of four horizontal squared structures; hollow structures consisting of grating ribs are arranged between the squared structures; cross-shaped reinforcing ribs are arranged in the squared structures; the lateral surfaces are connected with the upper surface at 90 degrees, and rounded corners are adopted for transition at joints; positions for a forklift truck are arranged on the lateral surfaces; every two lateral surfaces are connected at 90 degrees, and rounded corners are adopted for transition at joints; and the lower surface is provided with nine footings, one footing is arranged at a central position, and the other eight footings are uniformly distributed on the periphery of the lower surface, and are connected through connecting ribs. Compared with the prior art, the invention has the advantages that the pallet has the advantages of light weight, high load bearing capacity and longer service life; and during logistics transfer and production transportation, the pallet has remarkable advantages, and the cost can be remarkably reduced.

Owner:HEFEI GENIUS NEW MATERIALS

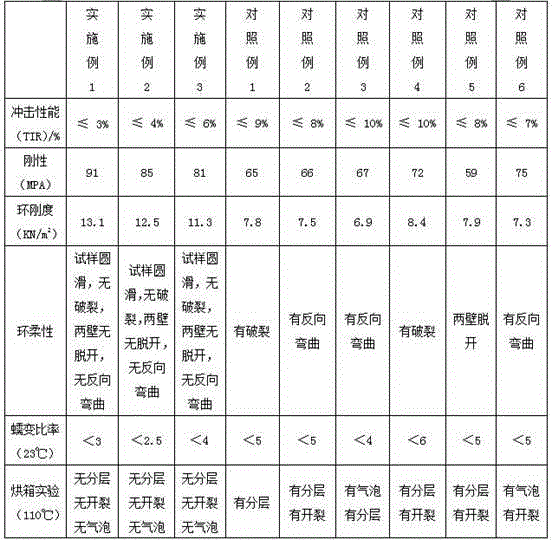

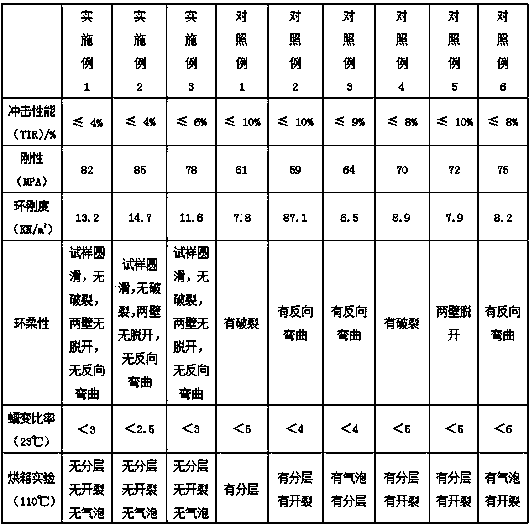

Enhanced HDPE (High-Density Polyethylene) double-wall corrugated pipe and preparation method thereof

ActiveCN104448466AImprove rigidityIncreased ring stiffnessRigid pipesPolymer scienceButadiene Dioxide

The invention relates to an enhanced HDPE (High-Density Polyethylene) double-wall corrugated pipe and a preparation method thereof. The formula of the enhanced HDPE double-wall corrugated pipe is prepared from the following raw materials in parts by weight: 100 parts of HDPE, 40-60 parts of wood flour, 1-3 parts of a titanate coupling agent and 7-9 parts of styrene-butadiene-styrene block copolymer, wherein the mesh of the wood flour is 80-110, and the ratio of styrene to butadiene in the styrene-butadiene-styrene block copolymer is (50: 50) to (60: 40). The enhanced HDPE double-wall corrugated pipe prepared by the preparation method has relatively good low-temperature impact toughness, good rigidity, high ring stiffness and excellent creep resistance and meanwhile has relatively low cost, thereby having broad application prospects.

Owner:HESHAN LESSO IND DEV

Enhanced HDPE double-wall corrugated pipe and preparation method thereof

ActiveCN104371167AImprove rigidityIncreased ring stiffnessPolymer scienceEthylene-propylene-diene-monomer

The invention relates to an enhanced HDPE double-wall corrugated pipe and a preparation method thereof. According to a formula, the enhanced HDPE double-wall corrugated pipe is composed of the following raw materials in parts by weight: 100 parts of HDPE, 40-60 parts of wood meal, 1-3 parts of titanate coupling agent and 7-9 parts of ethylene-propylene-diene rubber, wherein the particle size of the wood meal is 80-110 meshes; the Mooney point of the ethylene-propylene-diene rubber is 70-90; and the ratio of ethylene to propylene is (55:45)-(65:35). The enhanced HDPE double-wall corrugated pipe prepared by using the preparation method disclosed by the invention is relatively good in low-temperature impact toughness, good in rigidity, high in ring stiffness, excellent in creep resistance, relatively low in cost and wide in application prospect.

Owner:HENAN LIANSU IND

SiSiC cushion block for walking beam furnace and preparation method thereof

The invention relates to a preparation method of a SiSiC cushion block for a walking beam furnace. The preparation method comprises the following steps of: grinding 90-99 parts of SiC powder, 1-10 parts of carbon powder, 0.5-1.5 parts of an additive and 16-20 parts of water into slurry; molding by casting; drying a wet blank; sintering through a siliconizing reaction; machining and the like. The preparation method disclosed by the invention has the advantages of simple process, low cost, and capability of realizing direct baking without sintering through a nitriding reaction. The prepared SiSiC cushion block has the advantages of high temperature resistance, very high strength, high creeping resistance, low heat conductivity coefficient, high thermal shock resistance and capability of replacing a heat-resistant alloy steel cushion block.

Owner:湖北红花高温材料股份有限公司

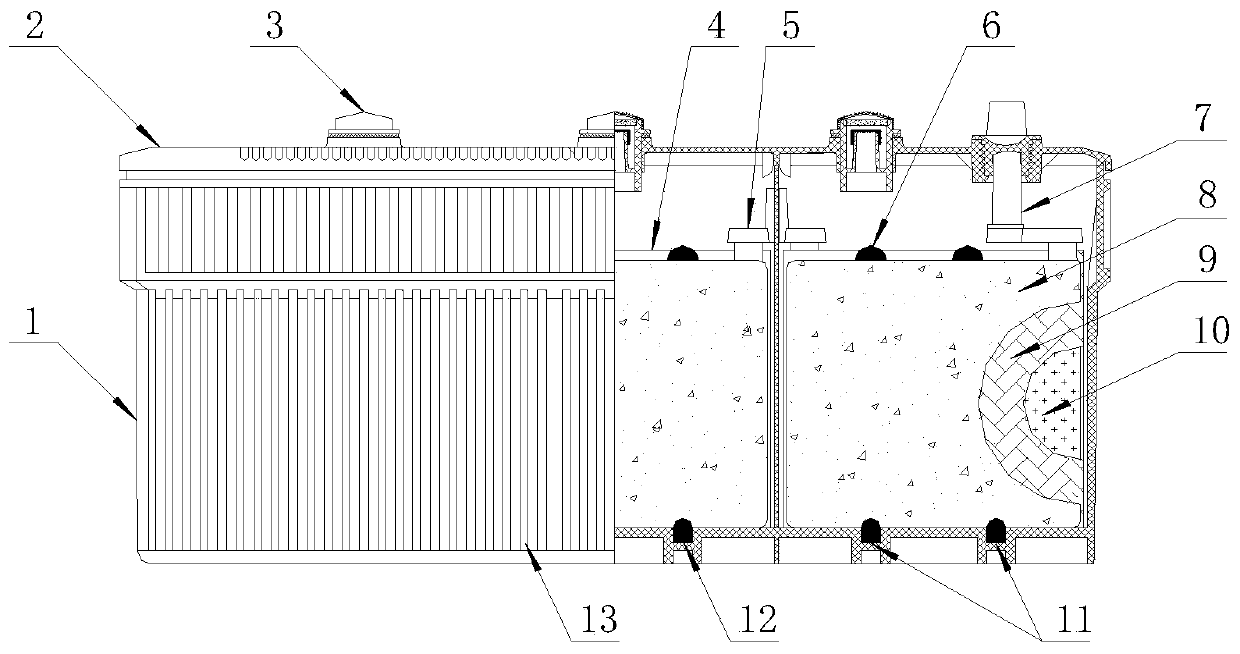

Novel commercial vehicle lead-acid storage battery with long service life

ActiveCN111129613AImprove vibration resistanceAvoid destructionFinal product manufactureSmall-sized cells cases/jacketsElectrolytic agentBusbar

The invention discloses a novel commercial vehicle lead-acid storage battery with a long service life. The storage battery comprises a storage battery groove, a storage battery cover, a safety valve,pole groups and an electrolyte. Two glue remaining grooves are arranged in a bottom of an inner cavity of each grid of the storage battery groove. When the storage battery is assembled, a first hot melt glue is injected into the glue remaining grooves firstly, then the pole groups are installed, and each pole group is fixed to the bottom of the storage battery groove through the first hot melt glue; each pole group comprises a negative plate, an AGM partition plate, a positive plate, a busbar and a pole column; assembly pressure of each pole group is 35-45 kPa, two second hot melt glues are added to an upper part of each pole group; and the negative plate, the AGM partition plate and the positive plate are fixed by the second hot melt glues, and the electrolyte is adsorbed in the negativeplate, the AGM partition plate and the positive plate. The hot melt glue is used for bonding each pole group in the storage battery groove, and the hot melt glue added at the upper part of each pole group is used for fixing the positive plate, the negative plate and the AGM partition plate so that up-and-down movement between pole plates in a vibration process of the storage battery is prevented,and vibration resistance of the storage battery is enhanced.

Owner:陕西凌云蓄电池有限公司

High-conductivity and high-heat conductivity aluminum-iron-nickel-rare earth alloy

InactiveCN104658630AImprove conductivityGood correlationMetal/alloy conductorsRare-earth elementImpurity

The invention relates to the technical field of aluminum alloys and specifically provides an ultrahigh-conductivity and high-heat conductivity aluminum alloy. The ultrahigh-conductivity and high-heat conductivity aluminum alloy is characterized by comprising 0.2-0.6% by mass of Fe, 0.3-0.8% by mass of Ni and 0.2-0.6% by mass of rare earth element Ce or La or mixture of Ce and La; meanwhile, one or two or three in an additive A is additionally added, the additive A is Mg, Cu, Mn or the mixture thereof, the mass content of each is 0.1-0.5%, and the content of the total additive is controlled within 0.9%; meanwhile, other impurities are controlled as follows: the individual content is less than 0.03% and the total content is less than 0.1%; the balance is Al and inevitable impurities. The aluminum alloy has high conductivity of above 61.8% IACS, excellent heat conductivity and a heat conduction coefficient of 225W / m.k or above, thereby being an excellent aluminum alloy cable material and high-performance heat conduction material.

Owner:朱岳群

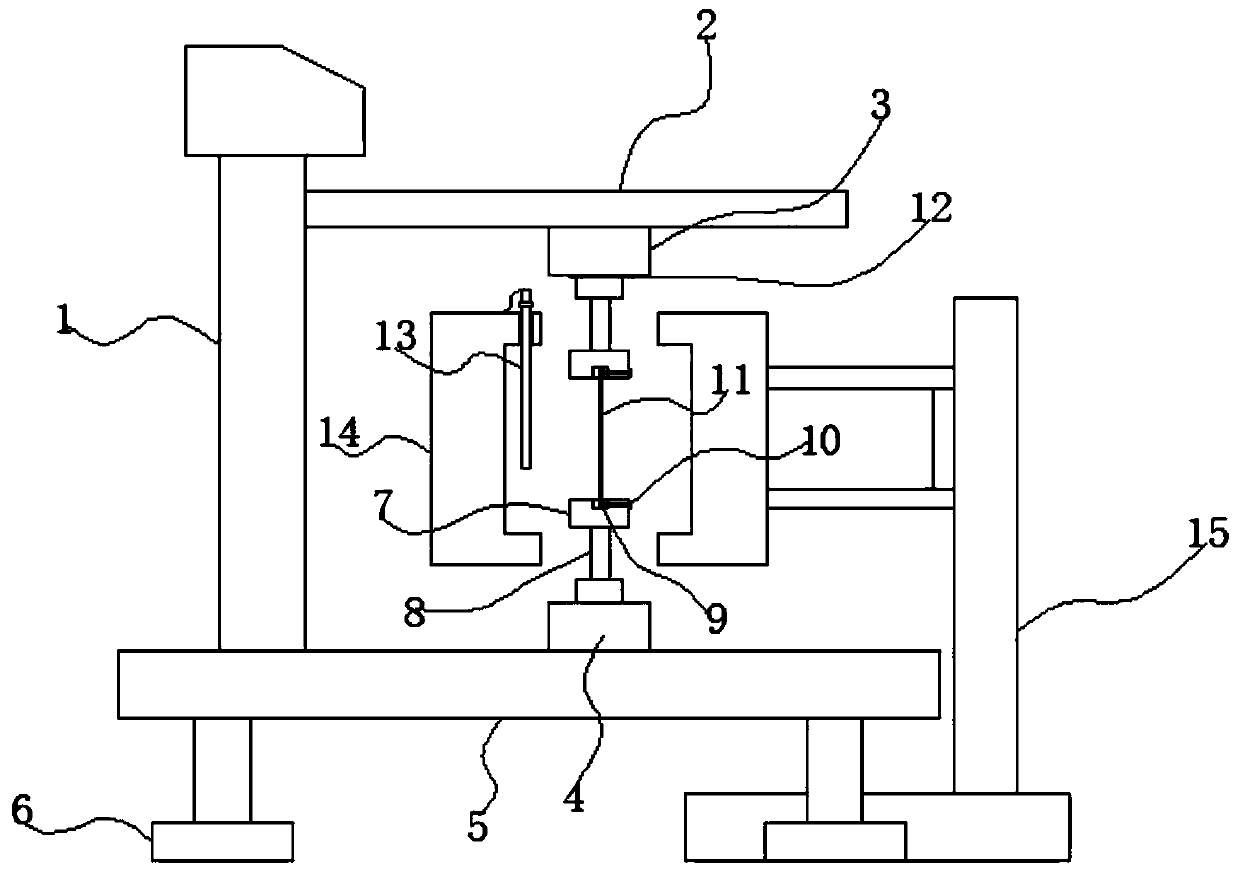

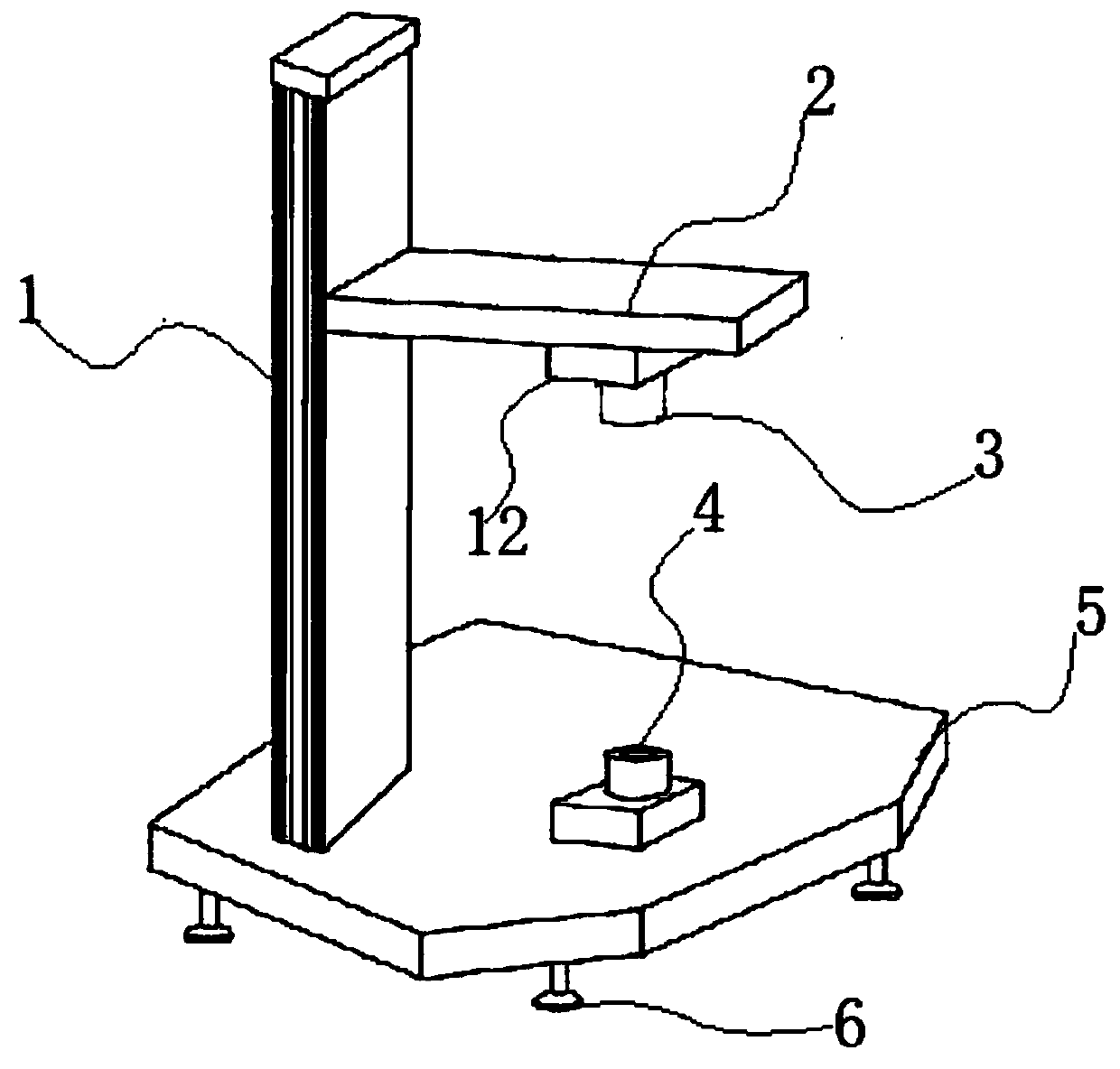

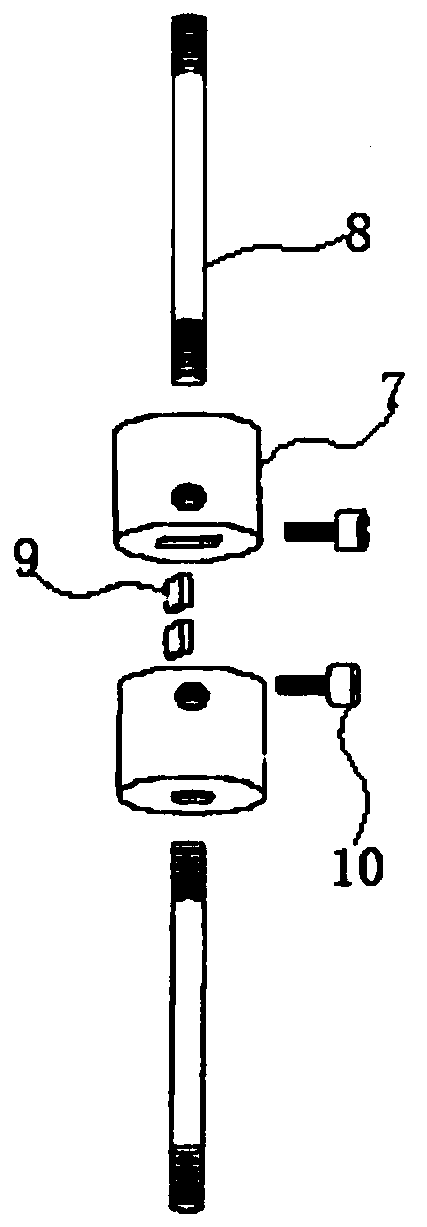

Novel small sample micro-tensile test device and test method thereof

InactiveCN110954411AReduce the temperatureReduce the numberMaterial strength using tensile/compressive forcesSmall sampleTest sample

The invention relates to the technical field of small sample micro-tensile tests, and discloses a novel small sample micro-tensile test device and a test method thereof. The novel small sample micro-tensile test device comprises a base, a single arm is connected to the top of the base, and a cross beam is connected to the side wall of the single arm. An upper chuck is installed at the bottom of the cross beam, a lower chuck is installed at the top of the base, and two connecting rods are arranged between the upper chuck and the lower chuck. The device can normally operate at the high temperature of 1000 DEG C or above, the number of parts of the device is small, the disassembly is flexible and convenient, the test sample can be easily taken out after experiment, the floor area is small, the cost is lower, and the production process is simple. The materials used by the device are high in corrosion resistance and creep resistance, and the ceramic materials are long in service life and low in maintenance cost, so that the requirement of a high-temperature experiment can be met. The device can conveniently locate the position of a sample, it is guaranteed that the sample and the forceare coaxial, and the unnecessary errors are avoided. The device is convenient to operate, only a screw needs to be rotated to provide thrust in the clamping process, and the force is larger.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

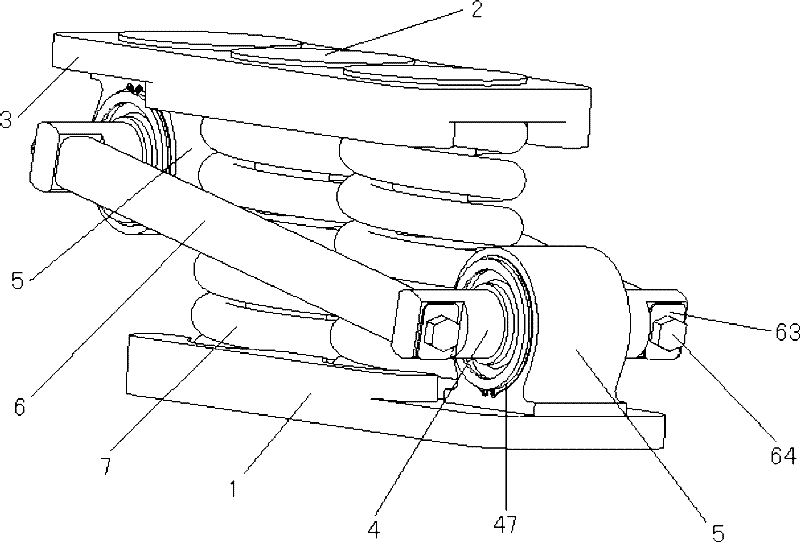

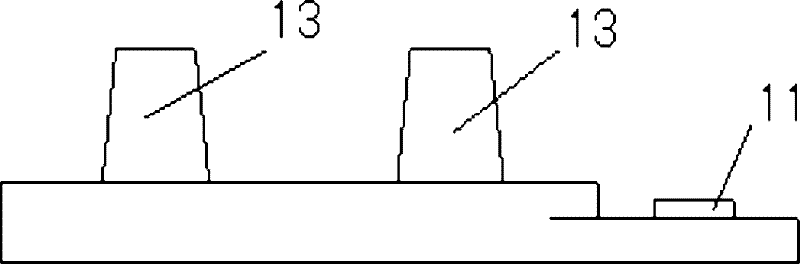

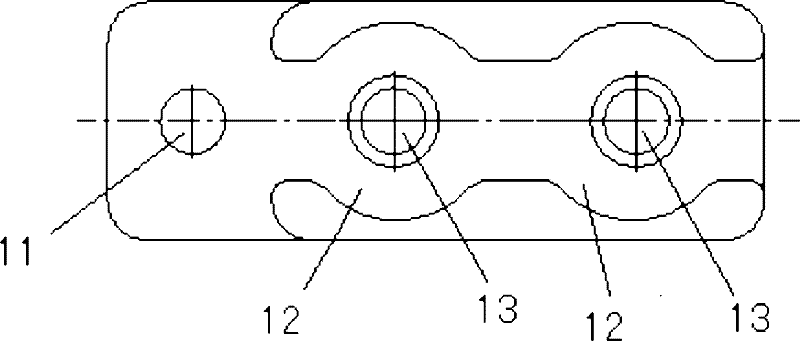

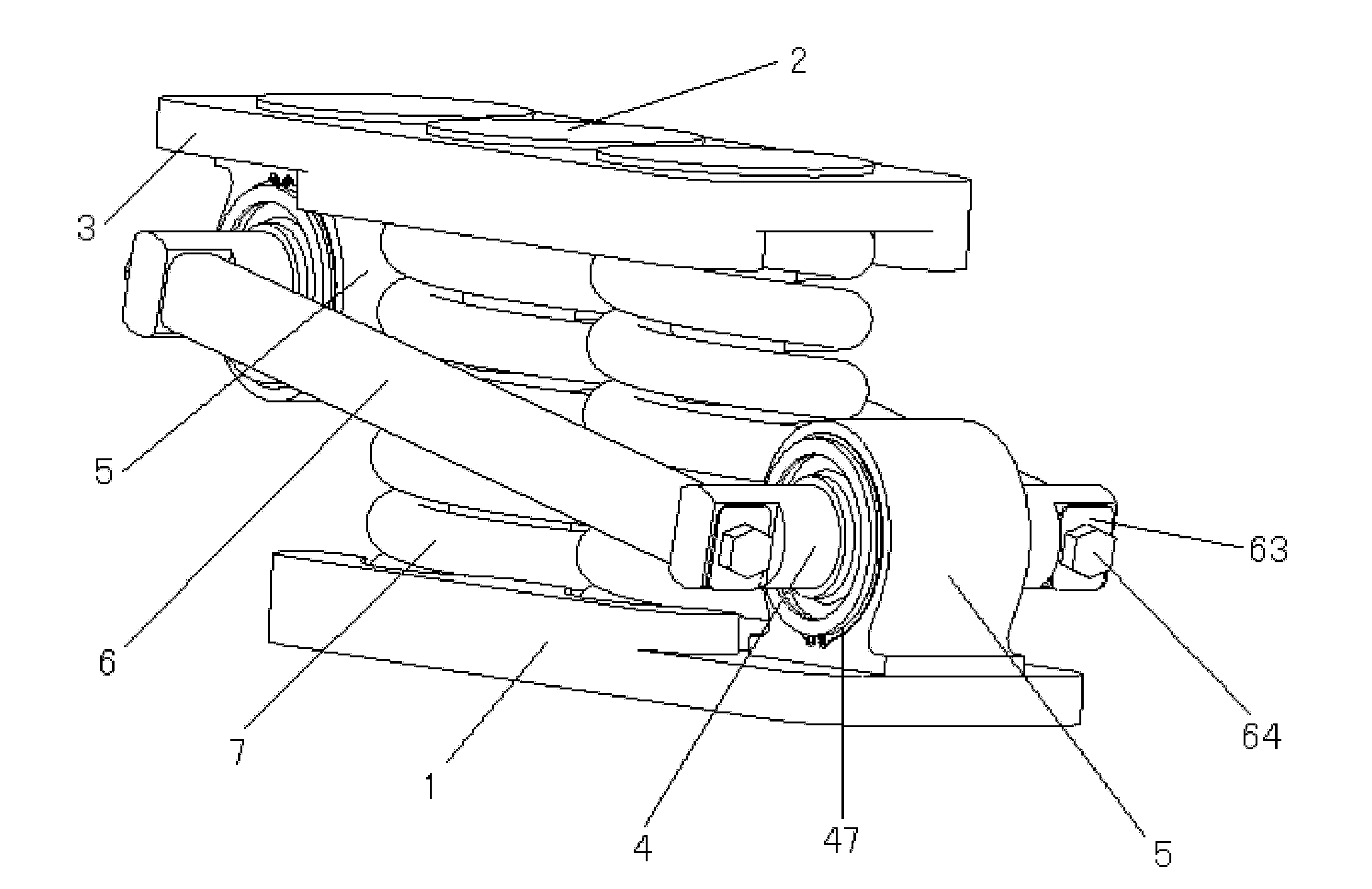

Elastic side bearing

ActiveCN102180180BAchieve longitudinal elastic positioningStrong roll resistanceBogie-underframe connectionsBogieEngineering

The invention relates to an elastic side bearing, comprising a side bearing base, wearing plates, a wearing plate installing seat, elastic joints, elastic joint installing seats, a connecting guide rod and side bearing springs, wherein a locating boss, a circular groove and a locating frustum are arranged on the side bearing base; a locating boss, a circular groove and a locating frustum are also arranged on the wearing plate installing seat; concave holes are arranged on the other side of the wearing plate installing seat at intervals and the wearing plates are pressed in the concave holes; one elastic joint installing seat is arranged on the side bearing base and the other elastic joint installing seat is arranged on the wearing plate installing seat; the elastic joints are arranged in the elastic joint installing seats; the side bearing base and the wearing plate installing seat which are respectively provided with the elastic joints are arranged oppositely; the side bearing springs are respectively sleeved on the two locating frustums; and the connecting guide rod is fixed in through holes of the elastic joints. According to the elastic side bearing provided by the invention, the problems of creep deformation and axial clearance of the elastic side bearing can be solved, therefore, the operation security of vehicles is guaranteed; and the elastic side bearing can be widely applied between the bogie swing bolster and the car body of a rail wagon.

Owner:北京隆轩橡塑有限公司

High wear-resistant fishing net suitable for complex seabed fishing environment

InactiveCN107082932AImprove toughnessReduced porosityConjugated synthetic polymer artificial filamentsArtifical filament manufactureLow-density polyethyleneWear resistant

The invention belongs to the technical field of fishing net processing, and particularly relates to a high wear-resistant fishing net suitable for a complicated seabed fishing environment. The fishing net is prepared by modifying high density polyethylene by modified nanosilicon dioxide with a surface hydroxy number not higher than 0.4 / nm<2>; the use amount of the high density polyethylene is 74 to 78 percent of the total amount of raw materials of the finishing net. Compared with the prior art, the high wear-resistant fishing net has the following advantages: the high density polyethylene is modified by using the modified nanosilicon dioxide, an interval multipore structure is reduced, processability and mechanical properties are obviously improved, the prepared finishing net is high in strength, good in toughness and strong in impact resistance, and has stronger creep resistance and weather fastness in the complicated seabed environment and environment with strong wind and big waves, and the service life is greatly prolonged in the complicated seabed environment, and is more remarkably prolonged in a simple environment.

Owner:CHAOHU LOTUS FISHING NET

Elastic side bearing

ActiveCN102180180AAchieve longitudinal elastic positioningStrong roll resistanceBogie-underframe connectionsBogieEngineering

The invention relates to an elastic side bearing which is characterized by comprising a side bearing base, wearing plates, a wearing plate installing seat, elastic joints, elastic joint installing seats, a connecting guide rod and side bearing springs, wherein a locating boss, a circular groove and a locating frustum are arranged on the side bearing base; a locating boss, a circular groove and a locating frustum are also arranged on the wearing plate installing seat; concave holes are arranged on the other side of the wearing plate installing seat at intervals and the wearing plates are pressed in the concave holes; one elastic joint installing seat is arranged on the side bearing base and the other elastic joint installing seat is arranged on the wearing plate installing seat; the elastic joints are arranged in the elastic joint installing seats; the side bearing base and the wearing plate installing seat which are respectively provided with the elastic joints are arranged oppositely; the side bearing springs are respectively sleeved on the two locating frustums; and the connecting guide rod is fixed in through holes of the elastic joints. According to the elastic side bearing provided by the invention, the problems of creep deformation and axial clearance of the elastic side bearing can be solved, therefore, the operation security of vehicles is guaranteed; and the elastic side bearing can be widely applied between the bogie swing bolster and the car body of a rail wagon.

Owner:北京隆轩橡塑有限公司

Anti-corrosion and anti-creep pump valve seal gasket

The invention belongs to the technical field of pump valve seal gaskets and particularly relates to an anti-corrosion and anti-creep pump valve seal gasket. The seal gasket is prepared from 12-20 parts by weight of fluorinated rubber, 1-10 parts by weight of chloroether rubber, 1-9 parts by weight of hydrogenated nitrile rubber, 0.5-3 parts by weight of precipitated white carbon black, 0.1-0.5 parts by weight of a vulcanizing agent, 0.8-1.6 parts by weight of modified attapulgite, 0.6-1.3 parts by weight of an anti-aging agent and 0.05-0.35 parts by weight of an accelerator. Through mixing offluorinated rubber, chloroether rubber and hydrogenated nitrile rubber and use of modified attapulgite and precipitated white carbon black as fillers, the corrosion resistance and creep resistance ofthe seal gasket are improved. The modified attapulgite can effectively improve the mechanical strength and wear resistance of the seal gasket, thereby improving the service life of the pump valve sealgasket.

Owner:ANHUI SANHUAN PUMP

Jute and plastic compound material plank stuff and manufacturing method thereof

InactiveCN100564023CReasonable designSimple structureSynthetic resin layered productsCellulosic plastic layered productsHemp fibrePlastic compound

The present invention relates to a hemp-plastic composite material board and its preparation method, which relate to a composite material, an environmentally friendly material and its preparation method, and are suitable for making shelf boards, door inner boards, etc. of transportation vehicles such as automobiles and airplanes. Decorative panels, fences, railings, etc. in the construction field, pallets, shelves, etc. in the packaging field. The hemp-plastic composite material board is composed of two layers of hemp fiber modified plastic layer and hemp fiber cloth reinforced plastic layer, and a hemp fiber cloth reinforced plastic layer is molded between the two layers of hemp fiber modified plastic layer; the hemp fiber modified plastic layer is composed of Modified plastic particles, hemp fibers and interfacial compatibilizer are mixed and calendered; the reinforced plastic layer of hemp fiber cloth is formed by molding plastic particles and several layers of hemp fiber cloth treated with silane coupling agent.

Owner:NANJING FORESTRY UNIV

Novel antimicrobial PE tube

InactiveCN101270833AGood heat preservation and energy saving effectImprove toughnessRigid pipesThermal coefficientEngineering

A novel antibacterial PE pipe relates to construction pipes. The outer layer is PE pipe. The invention is characterized in that the inner wall of the PE pipe is provided with a layer of inorganic antibacterial layer by co-extrusion. In the invention, the thickness of the pipe wall of the PE pipe is between 2mm and 10mm. The thickness of the inorganic antibacterial layer is between 0.3mm and 1.0mm. The invention has the beneficial effect that the novel antibacterial PE pipe integrates antibacterial property, energy saving, sanitation and self-cleaning, which can be directly applied to the transportation system of purified water. The invention is a novel green and environmentally-friendly construction material. The thermal coefficient is only 2 percent of the metal pipe and the hot-water pipe has excellent heat insulating and energy saving effects. Adopting the consubstantial hot melt connection, the tubes and the pipes have the advantages of no leakiness, high toughness and strong heat resistance and creep resistance. When used under normal pressure and temperature, the service life of the tubes and the pipes can be 50 years.

Owner:SHANGHAI RUIHE ENTERPRISE GRP

Dispersion strengthening platinum/rhodium10-platinum thermocouple wires and production method thereof

ActiveCN101561321BAchieve tissue fibrosisAchieve fibrosisThermometers using electric/magnetic elementsUsing electrical meansPolymer scienceThermocouple Wire

The invention discloses dispersion strengthening platinum / rhodium10-platinum thermocouple wires, comprising a cathode and an anode; the thermocouple wires are characterized in that the anode contains ingredients according to the following weight percentage: 9.9-10% of rhodium; 0-0.5% of zirconium; 0-0.5% of yttrium; 0-0.5% of calcium; 0-0.5% of lanthanum; 0-0.5% of titanium; the excess is platinum; the cathode contains ingredients according to the following weight percentage: 0-0.5% of zirconium; 0-0.5% of yttrium; 0-0.5% of calcium; 0-0.5% of lanthanum; 0-0.5% of titanium; the excess is platinum. The production method of dispersion strengthening platinum / rhodium10-platinum thermocouple wires comprises mixing ingredients, vacuum melting, placing and rolling, oxidizing, combined machining and drawing forming. The dispersion strengthening platinum / rhodium10-platinum thermocouple wires of the invention enjoy long service life, high adaptive temperature, strong contamination resistance andlow use cost.

Owner:英特派铂业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com