Life buoy and preparation method thereof

A lifebuoy and floating ring technology, applied in water lifesaving, ship safety, ships and other directions, can solve the problems affecting the safety performance and service life of the lifebuoy, poor thermal stability, environmental stress sensitivity, etc., and achieve high resistance to seawater immersion. , Good thermal stability, good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

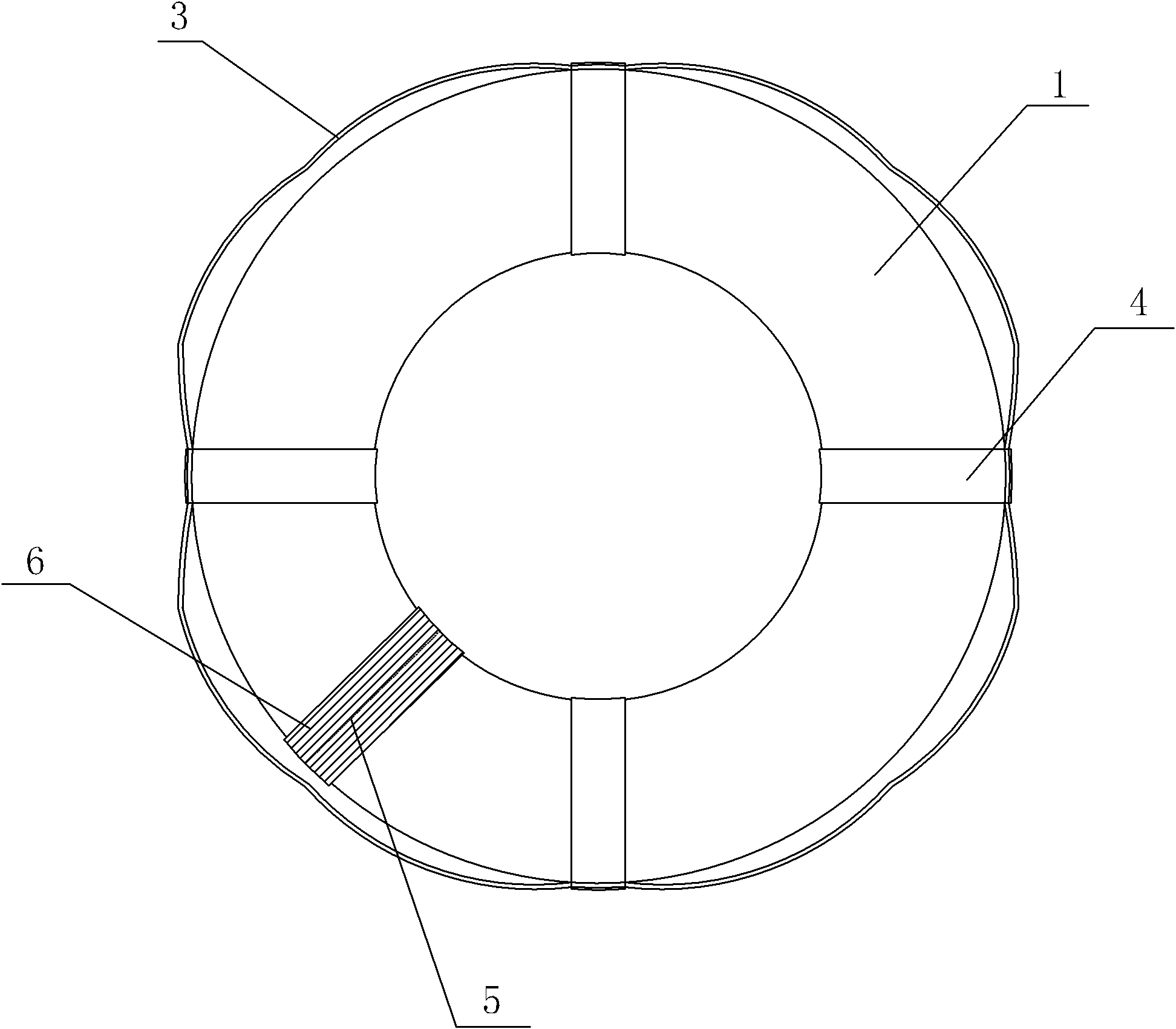

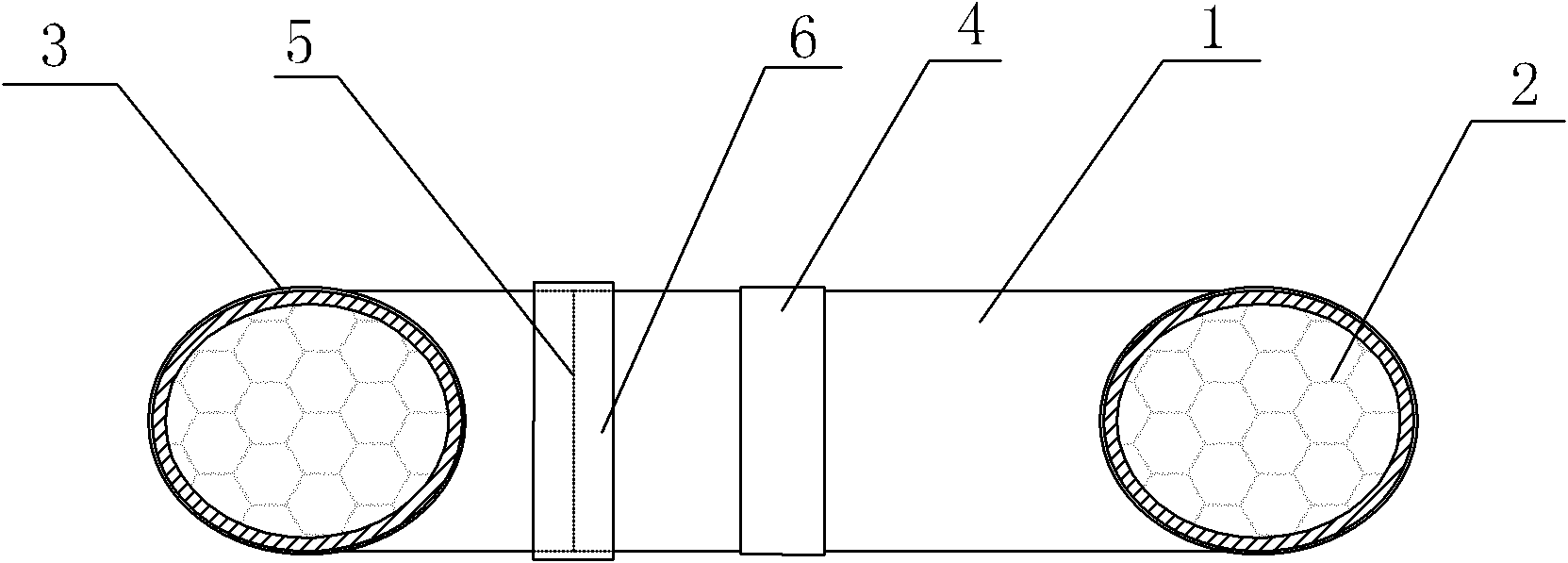

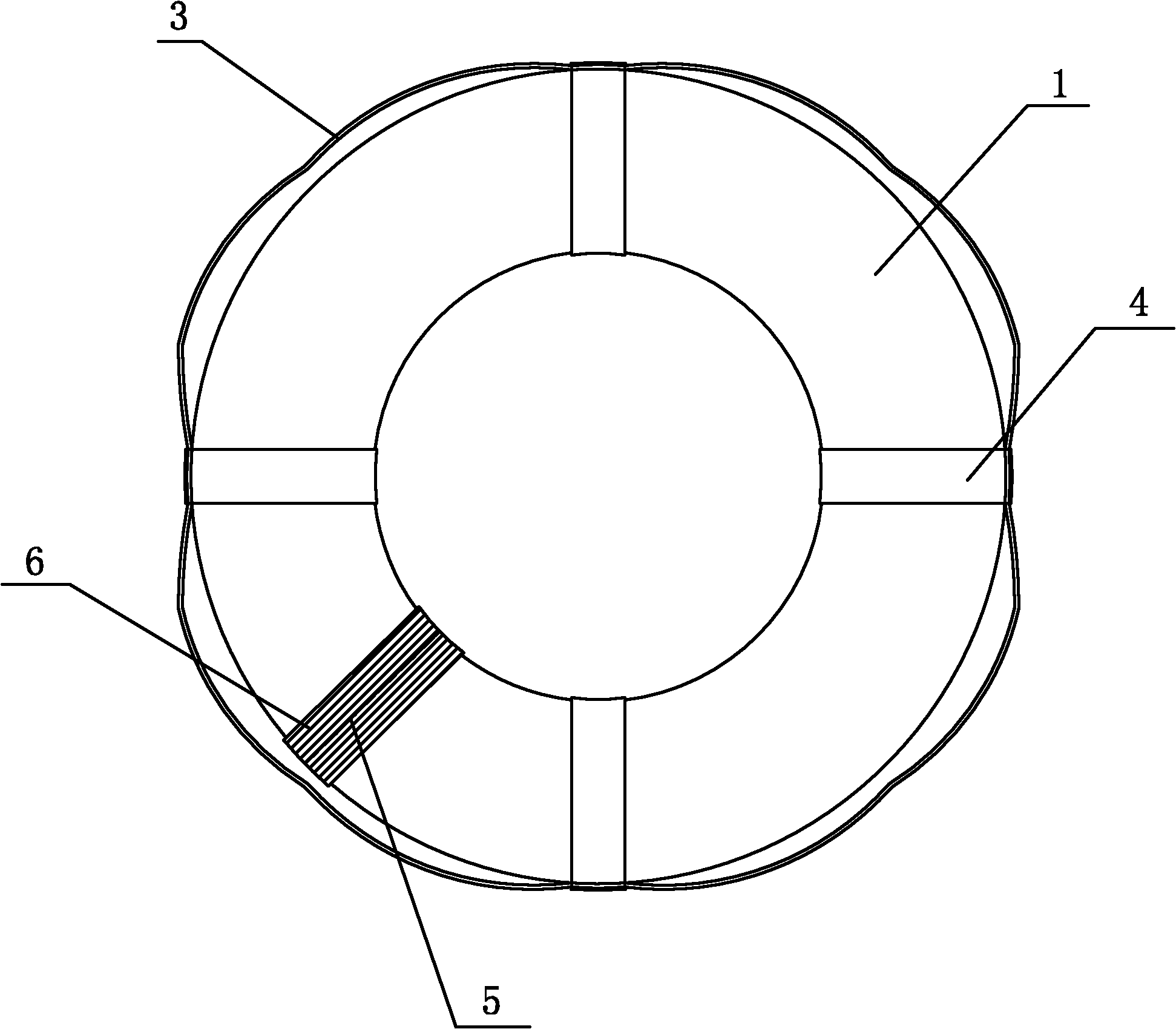

[0036] As shown in the figure, a lifebuoy includes a buoyant ring body 1 and a polyurethane foam 2 filled in the buoyant ring body 1, wherein the buoyant ring body 1 is a ring body made of sisal wood-plastic composite material, This sisal wood-plastic composite material is mainly composed of the following raw materials, which are prepared and mixed according to the ratio of parts by mass:

[0037] High Density Polyethylene (HDPE) 100 Sisal powder 20

[0038] Glass fiber 4 Foaming agent 2 Coupling agent 1 Plasticizer 3.5 Flame retardant 1.5

[0039] Antifungal agent 0.3 Antioxidant 0.3 Light stabilizer 0.4,

[0040] The buoyant ring body 1 of the lifebuoy of the present invention is made of sisal wood-plastic composite material, and the wood-plastic composite material is a new type of environmental protection material. After adding sisal powder into the high-density polyethylene plastic, the sisal wood-plastic composite material The creep resistance, flexural strength, and fl...

Embodiment 2

[0047] The structure of this embodiment is basically the same as that of Embodiment 1, and the only difference is that the mass and fraction ratios of the raw materials of the sisal wood-plastic composite material used in the buoyant ring body 1 of the lifebuoy of this embodiment are as follows:

[0048] High Density Polyethylene (HDPE) 95 Sisal powder 24

[0049] Glass fiber 3 Foaming agent 2.5 Coupling agent 2 Plasticizer 2 Flame retardant 2

[0050] Antifungal agent 0.1 Antioxidant 0.5 Light stabilizer 0.6.

Embodiment 3

[0052] The structure of this embodiment is basically the same as that of Embodiment 1 and Embodiment 2, and the only difference is that the mass and number ratios of the raw materials of the sisal wood-plastic composite material used in the buoyant ring body 1 of the lifebuoy of the present embodiment are as follows:

[0053] High Density Polyethylene (HDPE) 105 Sisal powder 16

[0054] Glass fiber 5 Foaming agent 3 Coupling agent 1.5 Plasticizer 4 Flame retardant 2.5

[0055]Antifungal agent 0.5 Antioxidant 0.8 Light stabilizer 1.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com