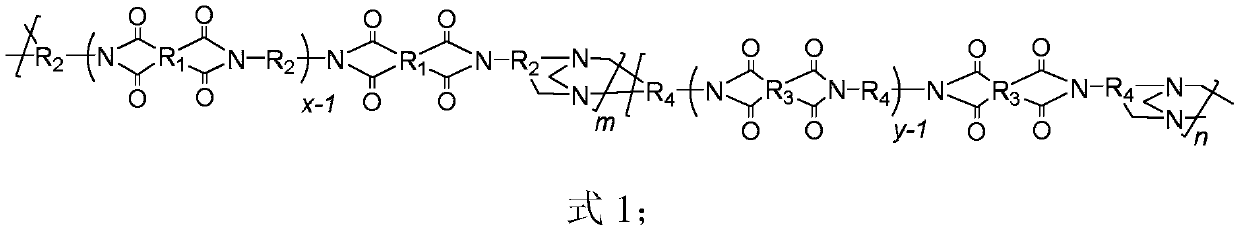

Semi-aromatic polyimide, preparation method and application thereof, and gas separation membrane containing the semi-aromatic polyimide

A gas separation membrane, polyimide technology, applied in its preparation method, semi-aromatic polyimide material, use and the field of gas separation membrane containing the same, can solve the problems of low permeability and selection, and achieve The effect of improving gas permeability, reducing the degree of orderly stacking, and increasing stacking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

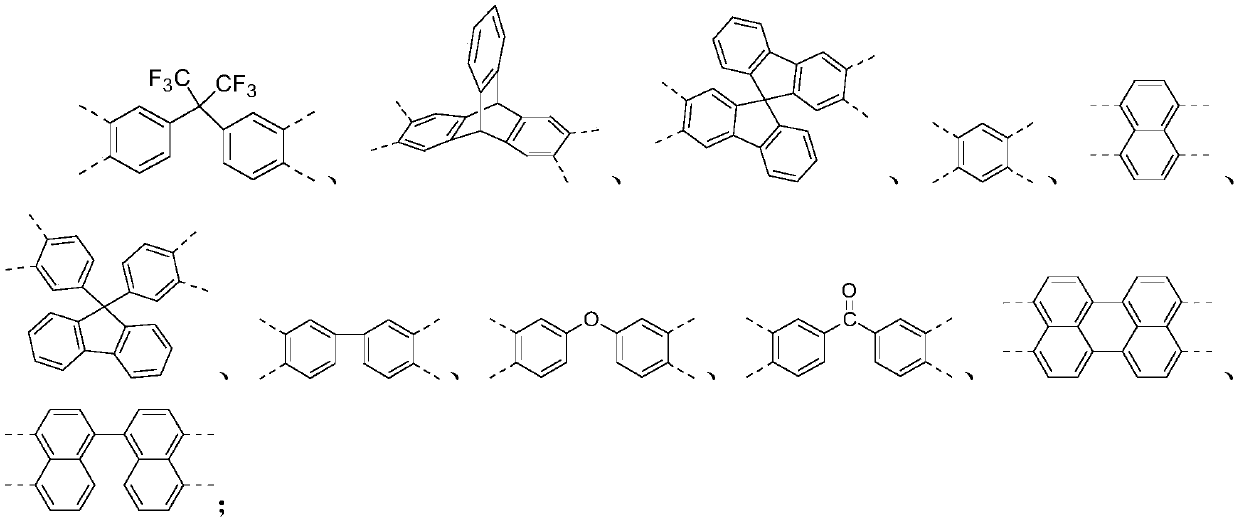

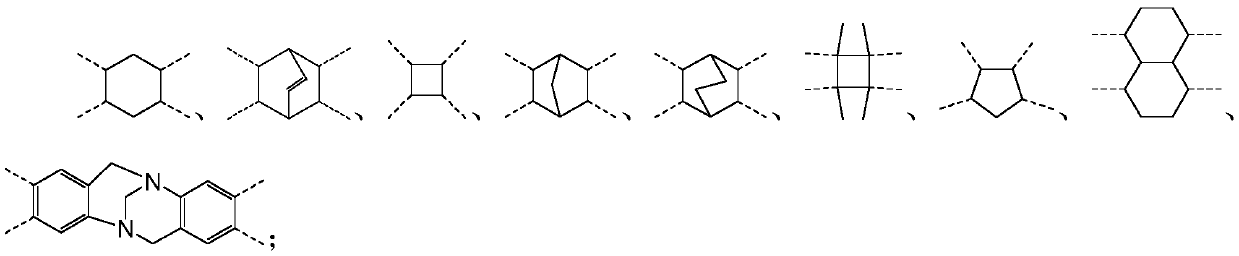

Method used

Image

Examples

Embodiment 1

[0064] The present embodiment provides a kind of semi-aromatic polyimide, and its structural formula is as follows:

[0065]

[0066] The specific preparation method is as follows:

[0067] (1) Preparation of diamine monomer I containing imide chain link

[0068]Add the aromatic diamine DPD (8.1720g, 60mmol) into a 500mL three-neck flask under nitrogen protection, then add 150mL of NMP, and after the DPD is completely dissolved, add the aromatic dianhydride 6FDA (8.8848g, 20mmol), at room temperature Stir and react at low temperature for 12 hours. After the reaction is over, add 50 mL of water-carrying agent toluene, and stir and reflux at 180°C for 9 hours to obtain a solution of diamine monomer I containing imide chain segments. After the toluene is completely distilled off, stop Heating, after naturally cooling to normal temperature, the reaction solution was poured into a mixture of high-speed stirring methanol and water (2L, V 甲醇 :V 水 = 1:1), a precipitate was preci...

Embodiment 2

[0078] The present embodiment provides a kind of semi-aromatic polyimide, and its structural formula is as follows:

[0079]

[0080] The specific preparation method is as follows:

[0081] (1) Preparation of diamine monomer I containing imide chain link

[0082] Add the aromatic diamine DPD (8.1720g, 60mmol) into a 500mL three-necked flask under nitrogen protection, and then add 140mL of NMP. After the DPD is completely dissolved, add the aromatic dianhydride NTCDA (5.3636g, 20mmol), Stir and react for 9 hours. After the reaction is over, add 45 mL of water-carrying agent toluene, and stir and reflux for 10 hours at 180 ° C to obtain a solution of diamine monomer I containing imide chain segments. After the toluene is completely distilled, stop Heating, after naturally cooling to normal temperature, the reaction solution is poured into the mixture (3L, V 甲醇 :V 水 = 1:1), a precipitate was precipitated, and the obtained precipitate was dissolved in DMAc, then precipitated...

Embodiment 3

[0091] The present embodiment provides a kind of semi-aromatic polyimide, and its structural formula is as follows:

[0092]

[0093] The specific preparation method is as follows:

[0094] (1) Preparation of diamine monomer I containing imide chain link

[0095] Add the aromatic diamine o-Tolidine (12.738g, 60mmol) into a 500mL three-necked flask under nitrogen protection, and then add 150mL of NMP. After the o-Tolidine is completely dissolved, add the aromatic dianhydride BPDA (5.8844g, 20mmol ), stirred and reacted at 0°C for 24 hours, after the reaction was over, added 50 mL of water-carrying agent ortho-xylene, stirred and refluxed at 200°C for 2 hours, and obtained a solution of diamine monomer I containing imide chain segments, and waited After the o-xylene was completely distilled off, stop heating, and after naturally cooling to normal temperature, the reaction solution was poured into a mixture of methanol and water (2L, V 甲醇 :V 水 = 1:1), a precipitate was prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com