Poly(4-methyl-1-pentene) hollow fiber membrane with gradient pore structure and preparation method thereof

A gradient pore and pentene technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of continuous and stable production of high-performance poly hollow fiber membranes, affecting the safety of fiber membranes, and phase separation Difficulty in controlling crystallization behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

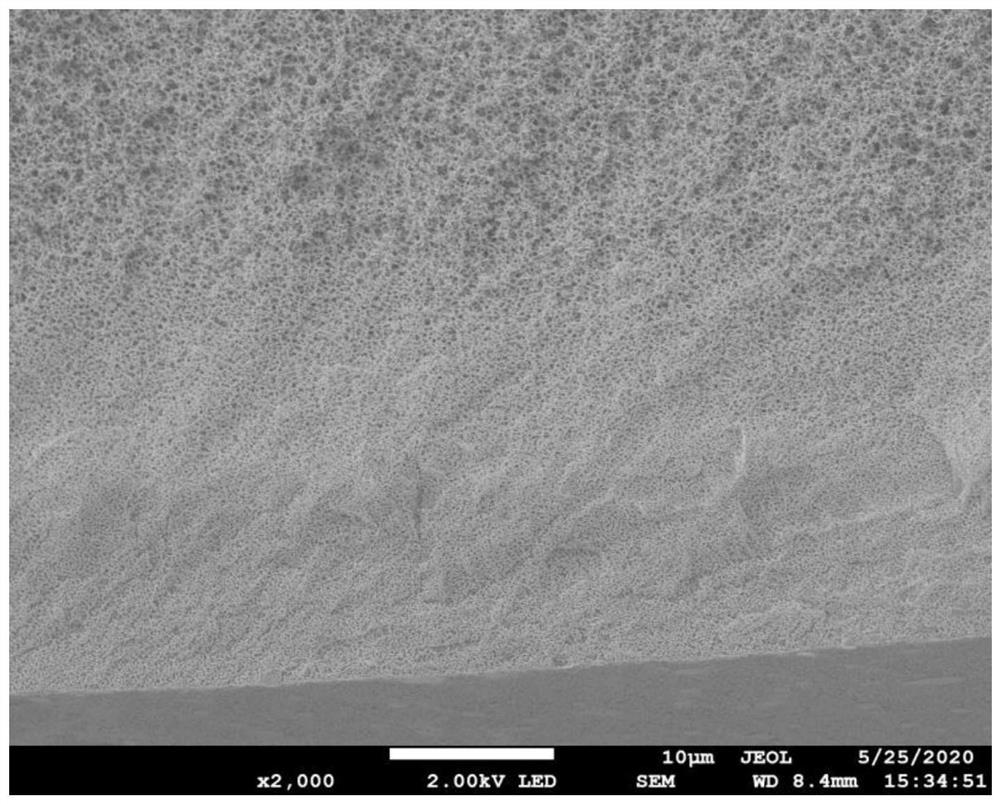

[0035] The preparation method of poly(4-methyl-1-pentene) hollow fiber gradient pore membrane is carried out through the following steps:

[0036] 1) Preparation of casting solution: mix poly(4-methyl-1-pentene) with a mass fraction of 25%, dibutyl adipate with a mass fraction of 70%, and propylene glycol with a mass fraction of 5% as Casting solution;

[0037] 2) Extrusion molding: Extrude the casting solution described in step 1) into a hollow fiber shape through a twin-screw extruder at 250°C at a speed of 80m / min;

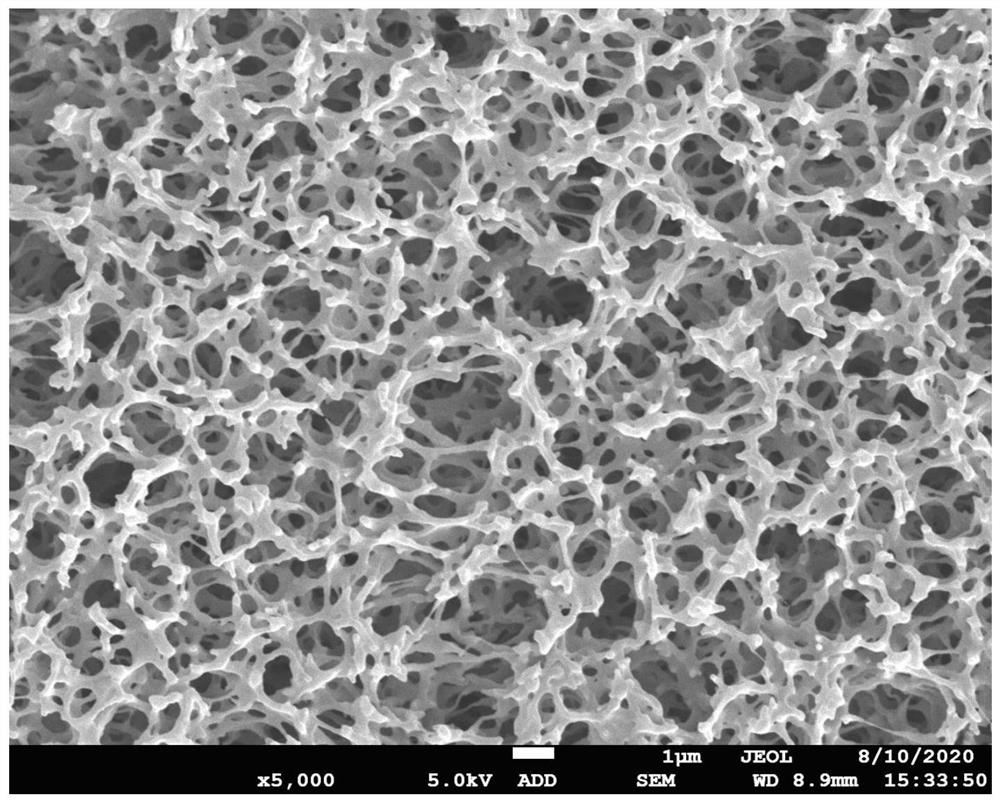

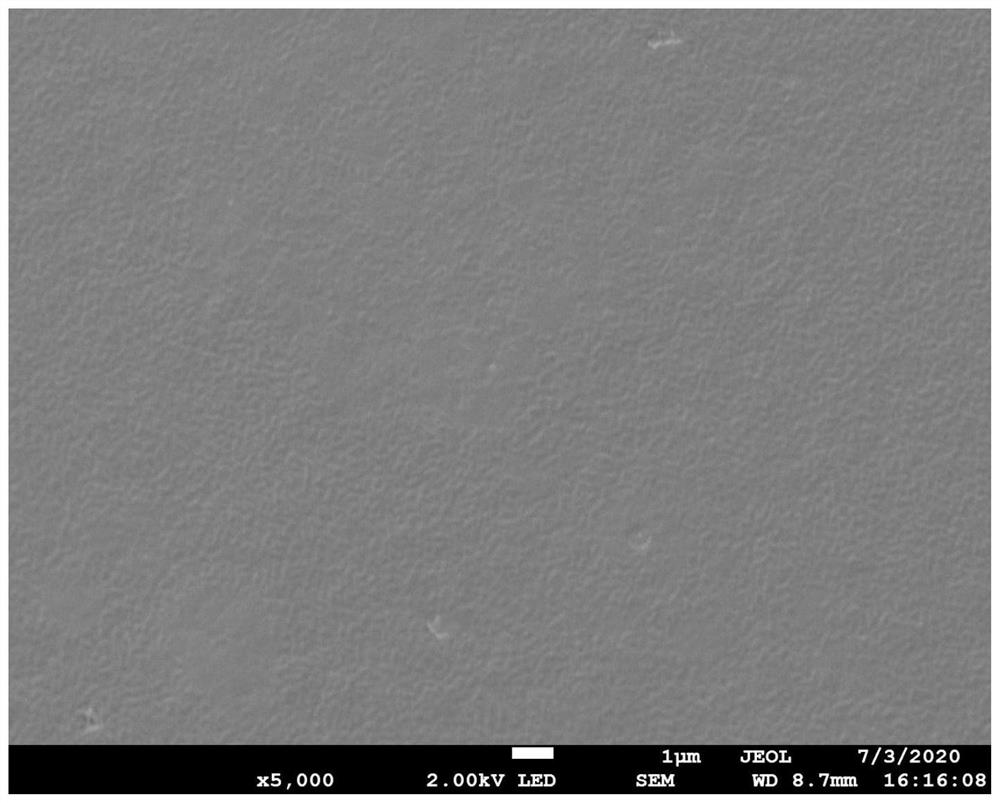

[0038] 3) Phase separation and solidification: the hollow fiber described in step 2) is cooled in a water bath at a temperature of 30°C for 2 seconds after passing through an air section at 25°C for 10 ms, poly(4-methyl-1-pentene) / diluted The solvent system undergoes thermal-induced phase separation and non-solvent-induced phase separation at the same time, and then solidifies to form a film;

[0039] 4) extracting and removing the diluent: immersing the memb...

Embodiment 2

[0042] The mass fraction of poly(4-methyl-1-pentene) in the preparation of the casting solution in step 1) of Example 1 is increased to 30%, and the mass fractions of dibutyl adipate and propylene glycol are respectively reduced to 65.3% and 4.7% , with other conditions unchanged.

Embodiment 3

[0044] In step 1) of Example 1, dibutyl adipate was replaced by tributyl phosphate in the preparation of the casting solution, the mass fraction was reduced to 45%, the mass fraction of propylene glycol was increased to 30%, and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com