High-performance non-linear non-ether group doped mixed-matrix film

A mixed matrix membrane and non-linear technology, applied in membrane technology, semi-permeable membrane separation, climate sustainability, etc., can solve the problems of low free volume and poor permeability of materials, and achieve the effect of improving gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Weigh a certain mass of Pebax particles and add them to ethanol / water (70wt% / 30wt%), stir at ~80°C for 4 hours to obtain a uniform and transparent 5wt% Pebax solution, then cast it on a PTFE plate, and evaporate the solvent at room temperature , take it off after the film is formed, put it in a vacuum oven at 40°C for at least 48 hours, remove the residual solvent, and obtain a pure Pebax film, whose gas permeability is shown in Table 1.

Embodiment 2

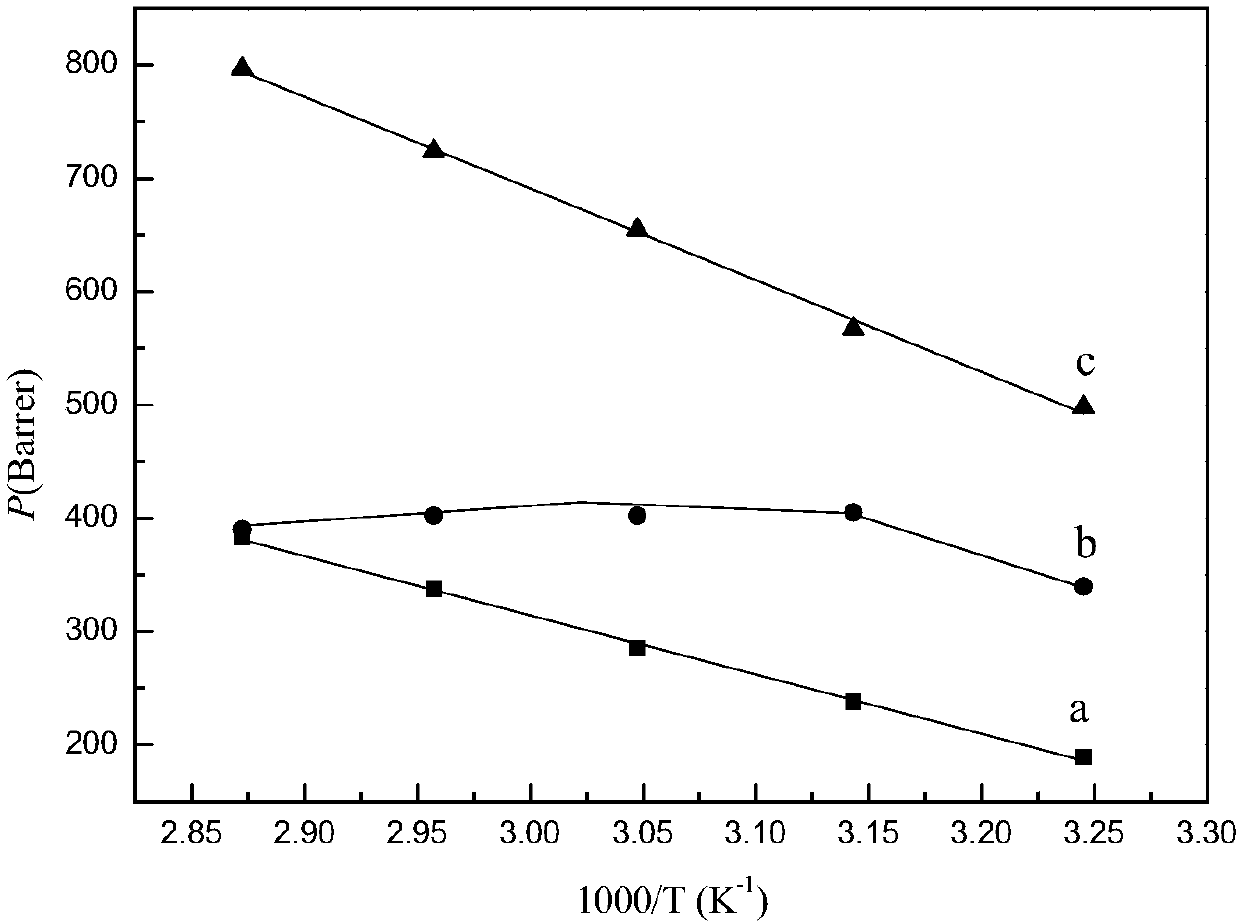

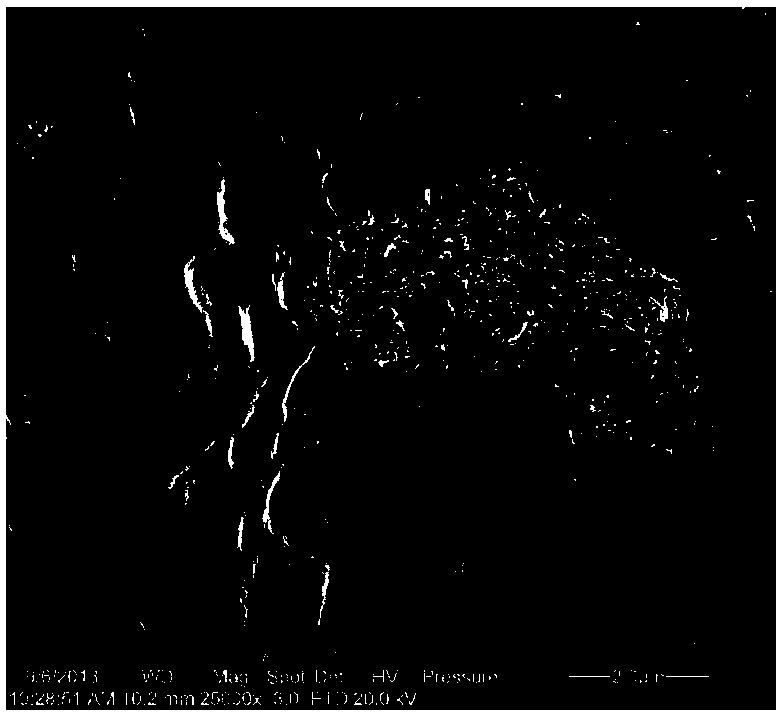

[0082] First prepare the ethanol / water (70 / 30wt%) solution of 5wt% Pebax, then the aminated multi-walled carbon nanotubes (MWNTs-NH 2 ) was added, and then sonicated for at least 2h to improve the MWNTs-NH 2 After ultrasonication, stir the solution at room temperature for 4 hours, then cast it on a PTFE plate, evaporate the solvent at room temperature, remove it after the film is formed, put it in a vacuum oven at 40°C for at least 48 hours, remove the residual solvent, and obtain a mass ratio of 10:1 Pebax / MWNTs-NH 2 Mixed matrix membrane, Pebax and MWNTs-NH 2 The mass fractions are 91wt% and 9wt%, respectively, and their gas permeability properties are shown in Table 1 and figure 1 , the cross-sectional scanning electron microscope sees figure 2 .

Embodiment 3

[0084] First prepare the ethanol / water (70 / 30wt%) solution of 5wt% Pebax, then the aminated multi-walled carbon nanotubes (MWNTs-NH 2 ) was added, and then sonicated for at least 2h to improve the MWNTs-NH 2 After ultrasonication, stir the solution at room temperature for 4 hours, then cast it on a PTFE plate, evaporate the solvent at room temperature, remove it after the film is formed, put it in a vacuum oven at 40°C for at least 48 hours, remove the residual solvent, and obtain a mass ratio of 10:5 Pebax / MWNTs-NH 2 Mixed matrix membrane, Pebax and MWNTs-NH 2 The mass fractions are 67wt% and 33wt%, respectively, and the gas permeability properties at 35°C and 0.7MPa are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com