Method for preparing ion exchange SAPO-34 molecular sieve membrane

A SAPO-34, ion exchange technology, applied in the direction of molecular sieve and alkali exchange phosphate, chemical instruments and methods, membrane technology, etc., can solve the problems of decreased permeability, reduce synthesis cost, simplify the preparation process, and improve separation performance and reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

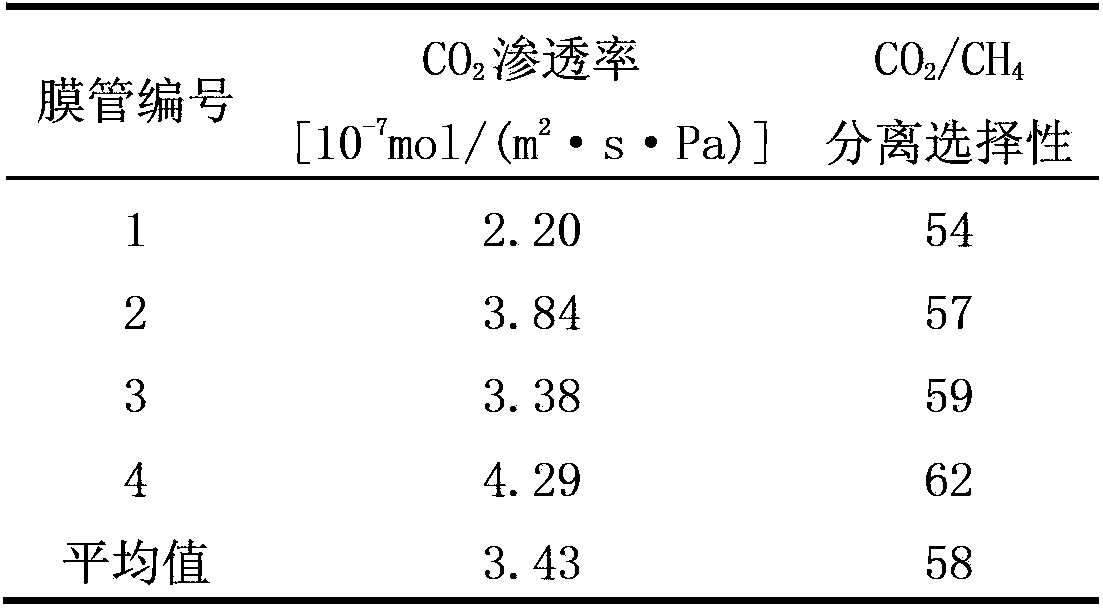

[0025] Embodiment 1 does not pass through ion exchange, roasts under vacuum condition and prepares SAPO-34 molecular sieve membrane

[0026] Step 1: Add 2.46g of deionized water to 31.13g of tetraethylammonium hydroxide solution (TEAOH, 35%), then weigh 7.56g of aluminum isopropoxide into the aforementioned solution, and stir at room temperature for 2-3 hours; then Add 1.665g of silica sol (40%) dropwise and stir for 1 hour; finally slowly add 8.53g of phosphoric acid solution (H 3 PO 4 , 85%), stirred overnight. Microwave heating was used for crystallization at 180°C for 7 hours. After the product is taken out, it is centrifuged, washed, and dried to obtain SAPO-34 molecular sieve seed crystals.

[0027] Step 2: Select a porous ceramic tube with a pore size of 100nm as the carrier, seal both ends of the carrier with glaze, wash and dry, seal the outer surface with PTFE tape, and brush the SAPO-34 molecular sieve seed crystal to the inner surface of the ceramic tube.

[00...

Embodiment 2

[0037] Embodiment 2 Soak with 1% sodium nitrate solution, prepare Na-SAPO-34 molecular sieve membrane by vacuum roasting

[0038] The difference from Example 1 is that after step 3 is completed and before step 4 is performed, the molecular sieve membrane tube prepared in step 3 is soaked in 1% sodium nitrate solution for 10 minutes, and then put into an oven for drying. All the other steps are the same as in Example 1.

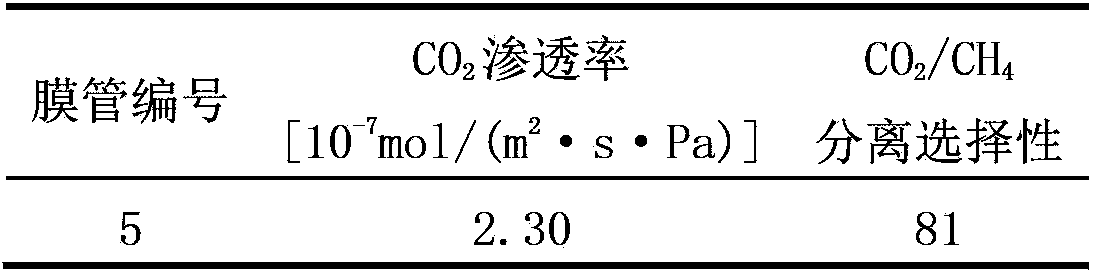

[0039] CO 2 / CH 4 The gas separation test method is the same as in Example 1, and the test results are shown in Table 3. CO 2 / CH 4 The separation selectivity of the mixed gas is 81, which is 40% higher than that of the SAPO-34 molecular sieve membrane without ion exchange in Example 1.

[0040] Table 3 CO of Example 2 2 / CH 4 Gas Separation Test Results

[0041]

[0042] Note: The pressure difference between the feed side and the permeate side of the membrane tube is 3.99MPa

Embodiment 3

[0043] Example 3 Soak with 1% potassium nitrate solution, prepare K-SAPO-34 molecular sieve membrane by vacuum roasting

[0044] The difference from Example 1 is that after step 3 is completed and before step 4 is carried out, the molecular sieve membrane tube prepared in step 3 is soaked in 1% potassium nitrate solution for 3 minutes, and then put into an oven for drying. All the other steps are the same as in Example 1.

[0045] CO 2 / CH 4 The gas separation test method is the same as in Example 1, and the test results are shown in Table 4. CO 2 / CH 4 The separation selectivity of the mixed gas is 73, which is 26% higher than that of the SAPO-34 molecular sieve membrane without ion exchange in Example 1.

[0046] Table 4 CO of Example 3 2 / CH 4 Gas Separation Test Results

[0047]

[0048] Note: The pressure difference between the feed side and the permeate side of the membrane tube is 3.99MPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com