Anti-corrosion and anti-creep pump valve seal gasket

A sealing gasket and anti-creep technology, applied in the field of pump valve gaskets, can solve problems such as pump valves not working properly, and achieve the effects of improving corrosion resistance and creep resistance, excellent comprehensive performance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

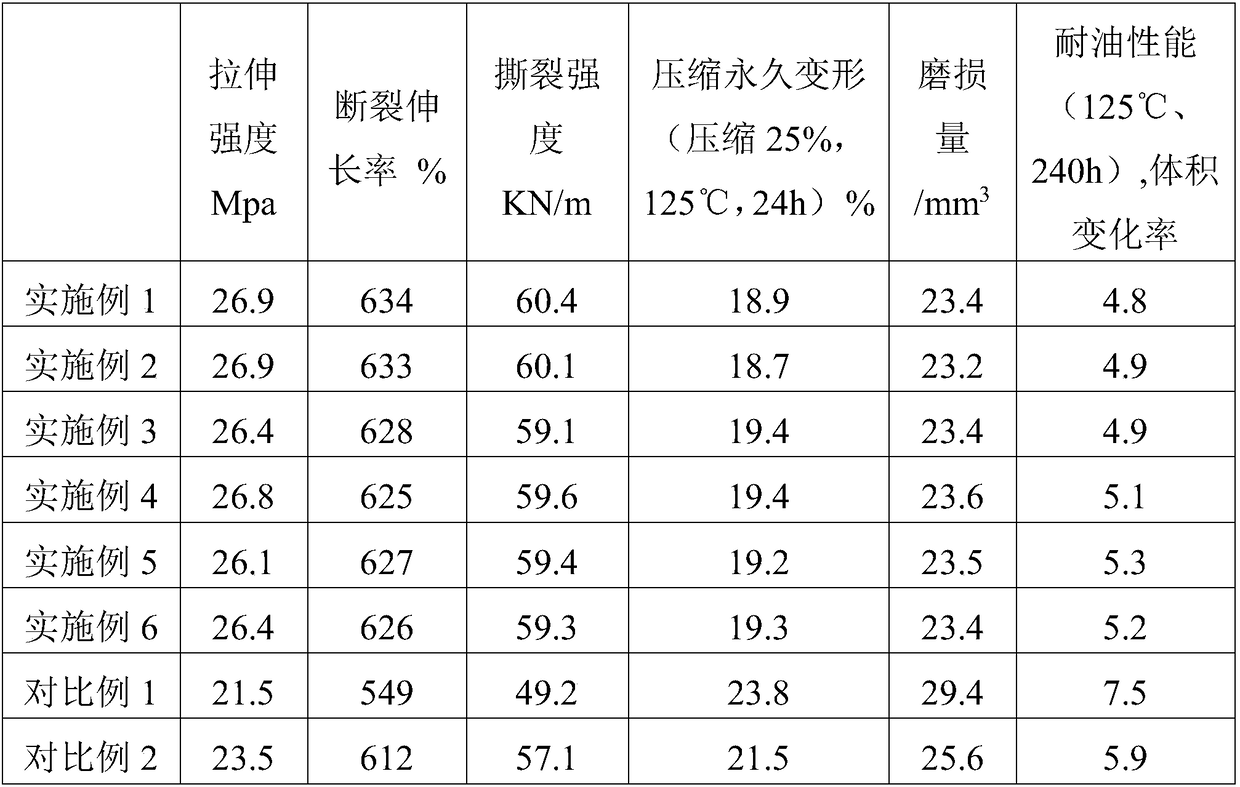

Examples

Embodiment 1

[0028] A pump valve sealing gasket, which comprises the following raw materials: 16 kg of fluorinated rubber, 7 kg of chloroether rubber, 5 kg of hydrogenated nitrile rubber, 2 kg of precipitated white carbon black, 0.3 kg of dimorphine disulfide, and 1.2 kg of modified attapulgite kg, 2,2,4-trimethyl-1,2-dihydroquinoline 1kg, 2,2'-dithiodibenzothiazole 0.15kg.

[0029] The preparation method of the modified attapulgite is as follows: add a surfactant and a coupling agent to the attapulgite, stir and mix and then transfer it to a heating kneader, the stirring speed is 50r / min, and the temperature is raised to 70°C while stirring. ℃, then stir at constant temperature for 2 hours, when the temperature of the material drops to 40 ℃, add PEG-2000, control the stirring speed to 30r / min, and discharge after stirring for 20 minutes;

[0030] Use a vibrating disc dryer to control the drying temperature to 45°C. When the moisture content of the material is less than 1%, transfer the ma...

Embodiment 2

[0035] The formula of the pump valve gasket in this embodiment is basically the same as that in Example 1, the difference is that tetramethylthiuram disulfide is selected as the vulcanizing agent, and the rest remain unchanged to prepare the pump valve gasket.

Embodiment 3

[0037] A pump valve sealing gasket, which is prepared from the following raw materials: 15kg of fluorinated rubber, 3kg of chloroether rubber, 3kg of hydrogenated nitrile rubber, 1.2kg of precipitated white carbon black, 0.2kg of dimorphine disulfide, and modified attapulgite 1.0kg, 0.8kg of 2,2,4-trimethyl-1,2-dihydroquinoline, and 0.1kg of 2,2'-dithiodibenzothiazole.

[0038] The preparation method of the modified attapulgite is as follows: add a surfactant and a coupling agent to the attapulgite, stir and mix and then transfer it to a heating kneader, the stirring speed is 50r / min, and the temperature is raised to 70°C while stirring. ℃, then stir at constant temperature for 1 hour, when the material temperature drops to 40 ℃, add PEG-2000, control the stirring speed to 30r / min, and discharge after stirring for 10 minutes;

[0039] Use a vibrating disc dryer to control the drying temperature to 45°C. When the moisture content of the material is less than 1%, transfer the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com